Abstract

Coal constitutes China’s most significant resource endowment at present. Utilizing coal resources for hydrogen production represents an early-stage pathway for China’s hydrogen production industry. The analysis of energy quality and carbon emissions in coal gasification-based hydrogen production holds practical significance. This paper integrates the exergy analysis methodology into the traditional LCA framework to evaluate the exergy and carbon emission scales of coal gasification-based hydrogen production in China, considering the technical conditions of CCUS. This paper found that the life cycle exergic efficiency of the whole chain of gasification-based hydrogen production in China is accounted to be 38.8%. By analyzing the causes of exergic loss and energy varieties, it was found that the temperature difference between the reaction of coal gasification and CO conversion unit and the pressure difference due to the compressor driven by the electricity consumption of the compression process in the variable pressure adsorption unit are the main causes of exergic loss. Corresponding countermeasures were suggested. Regarding decarbonization strategies, the CCUS process can reduce CO2 emissions across the life cycle of coal gasification-based hydrogen production by 48%. This study provides an academic basis for medium-to-long-term forecasting and roadmap design of China’s hydrogen production structure.

1. Introduction

As a clean energy carrier, hydrogen energy serves as a crucial pathway for China’s carbon emission reduction strategy. Globally, fossil fuel-based hydrogen production remains the predominant method, with only 0.74% of hydrogen derived from renewable energy sources [1]. Coal hydrogen production is the dominant large-scale centralized hydrogen production method in China due to its relatively abundant coal resources. Approximately 63.6% of China’s hydrogen supply originates from coal [2]. For China’s gasification-based hydrogen production process, this paper conducts a life cycle assessment based on the energy flow scale and proposes an energy analysis research methodology. This is of great practical significance for identifying energy losses in the hydrogen production chain and making energy conservation recommendations. This study can also assist government decision-making departments and industry in formulating strategies, and it lays a foundation of data and methodology for future scenario studies of China’s hydrogen energy industry.

In recent years, the following research findings have emerged in the field of LCA of the hydrogen production technology chain. Zheng et al. (2022) established a foundational database for hydrogen production pathways using China’s domestic data [3]. They conducted energy efficiency, carbon emissions, and economic assessments for pathways including fossil fuel-based hydrogen production and renewable electricity-based hydrogen production. Kristjan V (2023) conducted a techno-economic assessment of Iceland’s PEM hydrogen production method using a full life cycle approach [4]. The study found that increasing the proportion of renewable electricity in regional power grids can reduce greenhouse gas emissions in the hydrogen production process, thereby enabling deep decarbonization. Dana (2024) employed LCA methodology to evaluate 18 blue hydrogen production methods, finding that blue hydrogen production can leverage existing natural gas infrastructure for hydrogen supply and significantly reduce carbon emissions compared to gray hydrogen production [5]. Chen (2025) conducted a review analysis of life cycle assessment studies on hydrogen production pathways, finding that energy sources and feedstocks play a crucial role in the environmental impacts of hydrogen production methods [6]. To enhance the comparability of LCA conclusions, standardizing functional units is essential. Tara (2024) conducted a life cycle assessment study on coal gasification hydrogen production technology in Australia [7]. The findings revealed that incorporating CCS technology could reduce carbon emissions from coal gasification hydrogen production by over 90%. This discovery provides a decision-making basis for low-carbon strategies relying on fossil fuel-based hydrogen production. This study found that coal gasification hydrogen production (including CCS) technology can reduce hydrogen production carbon emissions to levels between 0.1 and 1.1 kg, demonstrating significant carbon reduction effects. This is close to the carbon emissions of wind power hydrogen production in China. However, the LCA technology chain does not fully account for all aspects (excluding raw material acquisition and transportation stages). Li (2020) employed process simulation to compare the LCA energy consumption and carbon emissions of coal-based hydrogen production versus biomass-based hydrogen production [8]. Findings indicate that biomass-based hydrogen production achieves approximately 75% lower energy efficiency and approximately 90% lower carbon emissions compared to coal-based methods. The significance of developing coal-based hydrogen production lies in alleviating the shortage of hydrogen applications. Research indicates that maximum energy efficiency in coal gasification hydrogen production is achieved within the 1400–1500 °C temperature range. However, this study did not account for factors such as pressure systems and catalysts when evaluating methods to enhance coal gasification energy efficiency. Liu (2024) employed LCA methodology to compare the energy consumption and carbon emissions of underground coal gasification hydrogen production with surface coal gasification hydrogen production [9]. Findings indicate that underground coal gasification hydrogen production can achieve a relative reduction in energy consumption of 64%, significantly lowering energy use. Under scenarios incorporating carbon capture, the carbon emissions from both coal gasification hydrogen production methods are comparable. Lozynskyi (2023) reviewed underground coal gasification technology, finding that despite progress beyond the laboratory stage, its application remains limited due to factors such as technological complexity and environmental concerns [10]. The researcher proposed that gas yield could be enhanced through methods including increasing reaction channel temperatures, oxygen-enriched operation, and pressure swing operation.

Exergic analysis focuses on the “irreversibility” in energy conversion and is crucial for identifying changes in energy quality within hydrogen production pathways. Key achievements in exergic analysis for hydrogen production include the following. Ozbilen (2012) combined LCA methodology with uranium loss analysis to examine thermochemical hydrolysis hydrogen production using nuclear energy [11]. The analysis revealed that uranium processing represents the stage with the highest uranium loss. Li (2025) evaluated the energy, environmental disturbance, and cost viability of photovoltaic and wind-based hydrogen production, concluding that solar radiation and wind speed are key factors influencing hydrogen production efficiency [12]. Masresha (2025) conducted an energy and exergy analysis of methanol steam reforming for hydrogen production, finding that increasing the proportion of water and methanol in the feedstock effectively reduces CO selectivity while enhancing H2 production rates [13]. Lidia (2024) conducted an energy and exergy study on a biomass co-production system for electricity and hydrogen, finding that biomass fluid mass exhibits a negative correlation with mass and energy efficiency and exergy, but a positive correlation with electricity generation and hydrogen production [14]. Zheng et al. (2025) proposed a life cycle exergy analysis method based on the “energy quality factor” [15]. They conducted a technical assessment of three hydrogen production methods in China and provided corresponding process optimization recommendations to reduce exergy losses.

Based on the aforementioned research findings, studies addressing energy quality and carbon emissions in the life cycle assessment (LCA) of coal gasification-based hydrogen production remain relatively scarce. Furthermore, research on the energy and carbon emission impacts of coal gasification for hydrogen production combined with carbon capture, utilization, and storage (CCUS) technology remains insufficient. This paper integrates exergy analysis methods into LCA, proposing a methodology for assessing the exergy efficiency and exergy losses in hydrogen production technologies through LCA. This paper analyzes the exergy efficiency of coal gasification-based hydrogen production throughout its entire life cycle, identifies irreversibilities within the technology chain, and proposes corresponding technical optimization recommendations. These findings provide a reference basis for scenario analysis and design in hydrogen energy development roadmaps.

2. Methodology

2.1. Research Methodology and Accounting Boundaries

2.1.1. Exergy Analysis Methods

The analysis of exergy mainly involves the following important concepts and elements:

Exergic efficiency [11]:

Exergic losses [11]:

where is the exergy consumed during this process step, is the exergy remaining after this process step.

Thermal exergy [16,17]:

where Q represents the heat transferred during the chemical reaction, Ti denotes the temperature required for the reaction, and T0 indicates the ambient temperature.

Energy quality factor [18,19]

where E denotes the energy contained within that energy source.

The relationship between the energy quality factor and exergy efficiency is as follows:

where is the energy quality factor of the inflowing energy, and is the energy quality factor of the outflowing energy. represents the energy contained in the inflowing energy, and represents the energy contained in the outflowing energy.

The energy quality factors for different energy species are shown in Table 1.

Table 1.

Energy quality factors for Different Energy Species [15].

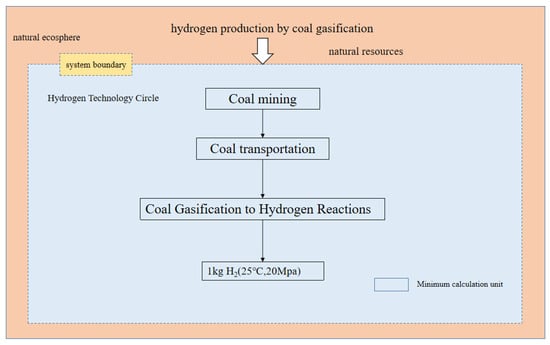

2.1.2. Life Cycle Exergic Analysis Accounting Boundary

The maximum change that can occur when a system or flow state is out of equilibrium with a reference environment is called “exergy” [11]. Based on Table 1, 1 kg of H2 (25 °C and 20 MPa) contains 118.2 MJ of exergy. In this study, the accounting boundary, as shown in Figure 1, will be established for the coal gasification hydrogen production route in China according to the life cycle evaluation method.

Figure 1.

Boundary of the Life Cycle Analysis System for Hydrogen Production via Coal Gasification.

Conventional exergy calculations are based on thermodynamic models, such as pressure and temperature differences at a certain stage. In this paper, the exergy calculation based on the “energy quality factor” takes each link in the LCA chain as an “inflow-outflow” system. This can greatly simplify the calculation process and improve the accuracy of the calculation.

3. Data Collection and Exergy Calculation

Gasification-based hydrogen production includes three stages: coal mining, coal transportation and coal gasification to hydrogen reactions. Among them, in the hydrogen production reaction process, coal will undergo reforming conversion reaction with water vapor and CO, and then through the variable pressure adsorption process and compression process, the hydrogen will be obtained [3]. The main chemical reactions involved in gasification-based hydrogen production are:

The energy and material inputs and emissions data for the entire life cycle of hydrogen production via coal gasification are shown in Table 2.

Table 2.

List of Life Cycle Data of gasification-based hydrogen production (1 kg H2 (20 MPa, 25 °C)).

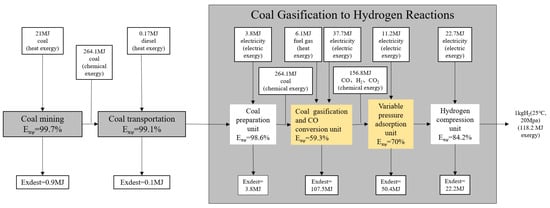

To extract 118.2 MJ of exergy from 1 kg of hydrogen (20 MPa, 25 °C), a coal mining plant in China is required to mine and process coal from the coal mine. In which coal containing 0.9 MJ exergy needs to be burned in order to maintain the temperature of the wellbore [20]. In order to drive the electric-hydraulic shovel, crusher, and belt conveyor in the coal mining area, electricity containing 0.0004 MJ exergy is required. Coal trucks inside the mining area need to consume diesel fuel containing 0.001 MJ exergy [21] and get raw coal containing 261.4 MJ of chemical exergy. Exergic efficiency and exergic loss are, respectively, 99.66% and 0.9 MJ.

The collected feedstock coal is delivered to the coal gasification hydrogen plant 200 km away by means of railroad transportation [21], this process consumes diesel fuel containing 0.087 MJ exergy. Exergic efficiency and exergic loss are, respectively, 99.97% and 0.09 MJ.

Coal feedstock is required to undergo compression to prepare for the coal gasification chemical reaction process, during which 3.8 MJ of electrical exergy is consumed [3]. Exergic efficiency and exergic loss are, respectively, 98.57% and 3.8 MJ.

Next, a gasification reaction [22] occurred at 1200 °C [26], and a conversion reaction was made by mixing CO with water, consuming coal containing 261.4 MJ exergy [25], fuel gas containing 6.1 MJ exergy [23], and electricity containing 37.7 MJ exergy. Exergic efficiency and exergic loss are, respectively, 59.3% and 107.5 MJ.

The acid gases (CO2, SO2, H2S) in the hydrogen were separated using methanol containing 0.06 MJ of exergy, and power containing 11.2 MJ of exergy was consumed to improve the purity of the hydrogen by using the pressure-variable adsorption (PSA) technique, which resulted in an exergic efficiency of 70% at this stage, with exergic loss of 50.4 MJ.

Finally a reciprocating compressor was started to compress the hydrogen to 20 Mpa using electricity containing 22.7 MJ exergy to obtain 1 kg H2 (20 MPa, 25 °C) containing 118.2 MJ exergy. Exergic efficiency and exergic loss are, respectively, 84.2% and 22.2 MJ.

Exergic analytical accounting process for the whole life cycle of gasification-based hydrogen production is shown in Table 3.

Table 3.

Exergic Analysis Process for Hydrogen from Coal Gasification Analysis.

4. Discussion

4.1. Analysis of Exergic Efficiency and Exergic Loss

From an LCA perspective, the exergy flow and consumption processes across each stage of China’s coal gasification hydrogen production are illustrated in Figure 2. By compiling exergy flow data from all stages, the exergic efficiency of coal gasification hydrogen production in the LCA is determined to be 38.8%. The calculated results are consistent with the conclusions (35–49%) regarding the exergy efficiency of coal gasification-based hydrogen production LCA as measured in [16,17].

Figure 2.

Flow Process of Exergy in the Life Cycle of gasification-based hydrogen production (1 kg H2 (20 MPa, 25 °C),118.2 MJ exergy).

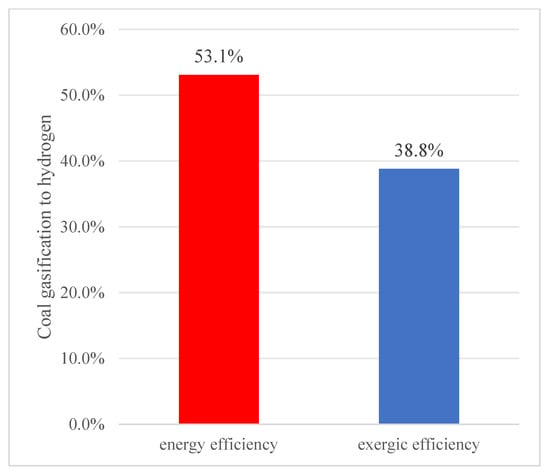

The completion result of energy efficiency and exergy efficiency throughout the entire life cycle of coal gasification-based hydrogen production is shown in Figure 3. It is evident that significant irreversibility in energy conversion exists during the coal-to-hydrogen reaction process, necessitating optimization through process innovation.

Figure 3.

Completion Result of Energy Efficiency and Exergic Efficiency in Gasification-based Hydrogen production (1 kg H2 (20 MPa, 25 °C)).

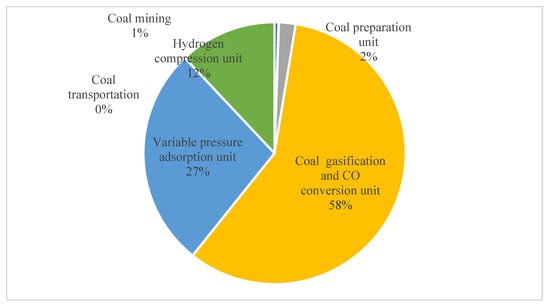

Exergic losses at different stages of gasification-based hydrogen production are shown in Figure 4.

Figure 4.

Exergic Losses at Different Stages of Gasification-based Hydrogen Production (1 kg H2 (20 MPa, 25 °C),118.2 MJ exergy).

As shown in Figure 4, in the coal gasification hydrogen production process, the stage with the greatest exergy loss is the coal gasification and carbon monoxide conversion unit. This stage accounts for 58% of the total thermal energy loss, indicating the highest degree of irreversibility in this process. The irreversibility of temperature differences and chemical reactions themselves, along with gas–solid interactions, are the primary causes of exergic losses during this stage. Therefore, it is necessary to optimize the reaction temperature control system. When using catalysts such as K2CO3 [27], chemical reactions can occur at lower temperatures. By implementing measures such as oxygen enrichment and pressure swing operations to enhance control over the reaction gas flow [10], more efficient chemical reaction conditions can be created to improve exergy efficiency.

The second is the exergic loss in the compression process of the VAS unit, which occupies 27% of the overall exergic loss, the main reason for the exergic loss is the larger shaft power of the piston compressor used in the VAS system compared to the hydrogen compressor (the former is about 4–5 times larger than the latter). Furthermore, the technical limitations of the compressor’s own energy efficiency (currently around 80% [23]) lead to higher electrical power consumption, with the hydrogen compression unit accounting for 12% of the overall exergic losses. In the pressure swing adsorption process, factors such as employing variable frequency drive air compressors and installing high-efficiency oil removal, dust removal, and drying equipment should be considered [28]. In addition to the compressor’s own energy efficiency limitations, the hydrogen compressor is less powerful than the PSA compressor and consumes less electrical power to process the same flow rate of gas, resulting in relatively low exergic losses.

It can be seen that for gasification-based hydrogen production, in order to reduce the exergic losses in the hydrogen production process, it is necessary to improve the chemical reaction process in the coal gasification and CO conversion unit, use catalysts (e.g., K2CO3) [27] that can improve the efficiency of the chemical reaction, and increase the supply of steam as well as the supply of oxygen for the chemical reaction to reduce the carbon buildup of the catalyst. The irreversibility of the heating process due to the heat transfer process is reduced by means of system management such as preheating and reheating [24]. From the power point of view, in order to reduce the input of exergy, the PSA technology as well as the hydrogen compressor technology need to be improved to increase the efficiency of the compressor itself and reduce the power of the PSA technology.

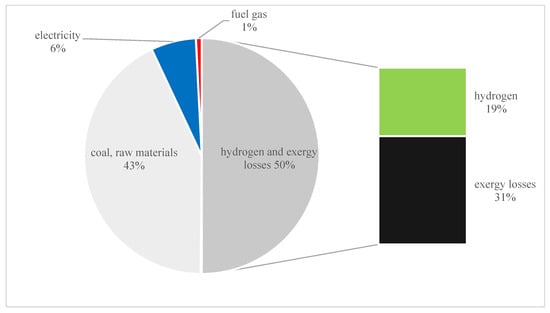

The exergy input and output structure of gasification-based hydrogen production by species is shown in Figure 5. It can be seen that coal as the feedstock is the type of energy variety with the most exergy inputs, followed by inputs of electricity for starting up the PSA equipment as well as the hydrogen compressor and other equipment. Fuel gas is mainly used to provide temperature to the coal gasification hydrogen process, and this energy variety contains the least exergy inputs from the LCA perspective, which is negligible. In terms of exergy output, the effective energy (hydrogen) accounts for 38.8% of the total output.

Figure 5.

Structure of Inputs and Outputs of Gasification-based Hydrogen Production by Exergic Species (100% = 610 MJ) (1 kg H2 (20 MPa, 25 °C), 118.2 MJ exergy).

4.2. Sensitivity Analyses

According to the above analysis, it was found that the pressure difference caused by the temperature difference in the chemical reaction in the “coal gasification and CO conversion unit” process and the efficiency of the compressor is the main cause of the fire loss during the whole life cycle of coal gasification hydrogen production. Therefore, the two options of “improving thermal efficiency” and “improving compressor efficiency” were selected for sensitivity analysis. The sensitivity analysis for “improving thermal efficiency” is shown in Table 4.

Table 4.

Sensitivity analysis of the “improve thermal efficiency” solution.

The sensitivity analysis of “improving compressor efficiency” is shown in Table 5.

Table 5.

Sensitivity analysis of the “improve compressor efficiency” solution.

4.3. Discussion of CO2 Emissions

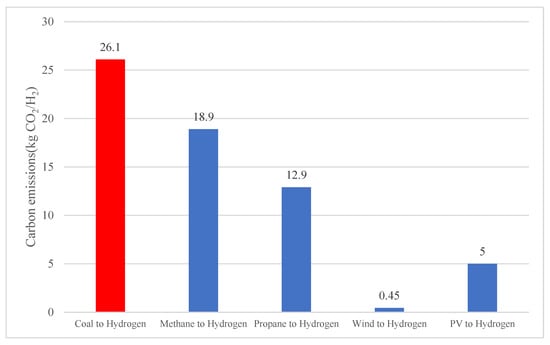

Figure 6 shows a comparison of the life cycle carbon emissions for China’s primary hydrogen production methods (gasification-based hydrogen production, natural gas, propane dehydrogenation, wind power, and photovoltaic systems). It is evident that gasification-based hydrogen production, classified as a “gray” hydrogen production method, has the highest carbon emissions. As a country rich in coal resources, China faces the practical challenge of relying on coal for hydrogen supply during the early stages of hydrogen energy development. It is of significant importance to study the impact of Carbon Capture, Utilization, and Storage (CCUS) on carbon emissions from coal gasification-based hydrogen production.

Figure 6.

Comparison of Life Cycle Carbon Emissions of Major Hydrogen Production Methods in China.

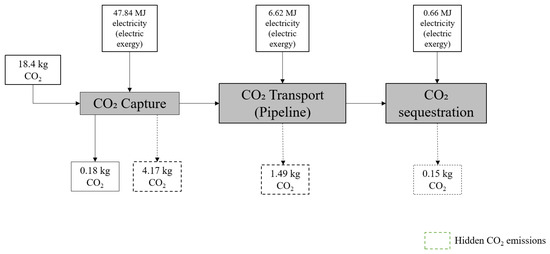

A life cycle assessment (LCA) was conducted on the CCUS process (including CO2 capture, CO2 transport (pipeline), and CO2 sequestration), revealing the exergy flow distribution of coal gasification-based hydrogen production within the CCUS segment, as shown in Figure 7. Research has demonstrated that CCUS technology can directly capture 90% of emissions during hydrogen production from coal [26]. The CO2 capture stage consumed 47.84 MJ [29] of electrical energy to process 18.4 kg of CO2 directly emitted during the coal gasification hydrogen production reaction stage. This resulted in 0.18 kg of direct CO2 emissions and 4.17 kg of indirect CO2 emissions (using the China Southern Power Grid’s marginal power emission factor of 0.808 tCO2e/MWh [3]). During the CO2 Transport (Pipeline) phase, assuming a transport distance of 100 km, 6.62 MJ of electricity is consumed [30], resulting in 1.49 kg of indirect CO2 emissions. The CO2 sequestration phase utilizes 0.66 MJ of electricity for CO2 storage and results in 0.15 kg of indirect CO2 emissions.

Figure 7.

LCA exergy and CO2 flow in gasification-based hydrogen production within the CCUS Process.

Overall, the CCUS process can reduce CO2 emissions across the life cycle of coal gasification-based hydrogen production by 48%. The life cycle energy efficiency of coal gasification for hydrogen production, considering CCUS processes, is 44.1%, with a life cycle exergy efficiency of 32.7%.

We compared coal gasification hydrogen production technology with coal-fired power generation hydrogen production technology. Taking a 660 MW coal-fired unit as an example, when paired with an alkaline electrolyzer, producing 1 kg of H2 requires consuming 55 kWh of electricity. Without CCUS, this would result in emissions of 45.53 kg of CO2. Using CCUS can reduce CO2 emissions by 20% to 50%. Estimated at a 50% carbon reduction rate, CO2 emissions from coal-fired power generation for hydrogen production amount to 22.77 kg, which is 68% higher than those from coal gasification for hydrogen production (including CCUS).

5. Conclusions

China is rich in coal resources, and gasification-based hydrogen production is the most important method of hydrogen production in China. This paper applies the LCA method to technically assess the exergic efficiency and exergic loss of gasification-based hydrogen production in China and accounts for the whole life cycle exergic efficiency of the whole chain of gasification-based hydrogen production in China to be 38.8%. The paper analyzes the causes of exergic losses and gives corresponding countermeasure suggestions.

The main conclusions of this paper are as follows:

First, from the perspective of exergy efficiency over the entire life cycle, the coal gasification and carbon monoxide conversion units, along with the variable pressure adsorption unit, contributed 58% and 27% of the exergy losses, respectively. The factors causing exergy losses in the former are temperature differences, the inherent irreversibility of chemical reactions, and gas–solid interactions. The factors leading to exergy losses in the latter are the pressure differentials present during the pressure swing adsorption process.

Next, to enhance the exergy efficiency throughout the entire life cycle of coal gasification-based hydrogen production, measures can be implemented during coal gasification and carbon monoxide conversion to optimize reaction temperature control systems (such as adopting reheating and preheating systems). When using catalysts like K2CO3, chemical reactions can occur at lower temperatures. By employing oxygen-enriched operation and pressure swing processes, enhanced control over reaction gas flows can be achieved, thereby creating more efficient chemical reaction conditions. For the pressure swing adsorption (PSA) stage, factors such as employing variable frequency drive (VFD)-controlled air compressors and installing high-efficiency oil removal, dust removal, and drying equipment should be considered.

Finally, to further investigate the impact of CCUS processes on the energy efficiency, exergy efficiency, and carbon reduction potential throughout the entire life cycle of coal gasification-based hydrogen production, this study calculates that CCUS can reduce LCA carbon emissions from coal gasification hydrogen production by 48%, approaching the LCA carbon emission level of propane dehydrogenation (12.9 kg CO2). This makes CCUS a viable consideration for the coal gasification hydrogen production process. The overall energy efficiency and exergy efficiency after CCUS implementation are 44.1% and 32.7%, respectively. This is primarily due to the consumption of 47.84 MJ/kg H2 of electrical exergy during the CO2 adsorption process.

The limitation of this paper is that the amount of energy input involved in the mining and transportation of coal is used as an estimated value, and in the actual production process, there will be some changes in the mode and distance of transportation. In addition, the technical indicators quoted in this study are the current technical level in China, and with the development of coal gasification hydrogen production technology, the thermal efficiency of coal gasification hydrogen production will be further improved.

Author Contributions

L.Z.: Conceptualization, Methodology, Data curation, Writing—original draft, Writing—review & editing, Project administration. X.J.: Methodology, Data curation, Writing—original draft, Investigation, Software. S.W.: Writing—review & editing, Investigation. J.H.: Writing—review & editing, Investigation. Y.W.: Writing—review & editing. L.H.: Writing—review & editing. K.X.: Conceptualization, Supervision, Writing—original draft, Writing—review & editing, Formal analysis. P.W.: Writing—review & editing, Formal analysis, Project administration. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Chinese Academy of Sciences, grant number XDA29010500.

Data Availability Statement

All data that support the findings of this study are included within the article. Other related data associated with this study could be available if the readers raise such a request.

Conflicts of Interest

Authors Lixing Zheng, Xuhui Jiang, Song Wang, Jiajun He, Yuhao Wang and Linbin Hu were employed by the company PowerChina Chongqing Engineering Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Japan: International Energy Agency. Report prepared by the IEA for the G20. In The Future of Hydrogen: Seizing Today’s Opportunities; IEA: Tokyo, Japan, 2019. [Google Scholar]

- National Development and Reform Commission. Medium and Long-Term Plan for the Development of Hydrogen Energy Industry (2021–2035). 23 March 2022. Available online: https://zfxxgk.nea.gov.cn/1310525630_16479984022991n.pdf (accessed on 20 April 2025).

- Zheng, L.; Zhao, D.; Qi, X.; Chen, Y. Research on Energy Efficiency, Carbon Emission and Economy of Hydrogen Production Routes in China Based on Life Cycle Assessment Method. J. Eng. Thermophys. 2022, 43, 2306–2317. [Google Scholar]

- Vilbergsson, K.V.; Dillman, K.; Emami, N.; Ásbjörnsson, E.J.; Heinonen, J.; Finger, D.C. Can remote green hydrogen production play a key role in decarbonizing Europe in the future? A cradle-to-gate LCA of hydrogen production in Austria, Belgium, and Iceland. Int. J. Hydrogen Energy 2023, 48, 17711–17728. [Google Scholar] [CrossRef]

- Alghool, D.; Haouari, M.; Trucco, P. It is not the same blue: A comparative LCA study of blue hydrogen supply network pathways. Int. J. Hydrogen Energy 2024, 81, 214–224. [Google Scholar] [CrossRef]

- Chen, Y.; Guo, W.; Ngo, H.H.; Chen, Z.; Wei, C.; Bui, X.T.; Van Tung, T.; Zhang, H. Ways to assess hydrogen production via life cycle analysis. Sci. Total Environ. 2025, 977, 179355. [Google Scholar] [CrossRef]

- Hosseini, T.; Tabatabaei-Zavareh, M.; Smart, S.; Ashman, P.J. Low-emission hydrogen production from gasification of Australian coals—Process simulation and technoeconomic assessment. Int. J. Hydrogen Energy 2024, 86, 245–260. [Google Scholar] [CrossRef]

- Li, G.; Cui, P.; Wang, Y.; Liu, Z.; Zhu, Z.; Yang, S. Life cycle energy consumption and GHG emissions of biomass-to-hydrogen process in comparison with coal-to-hydrogen process. Energy 2020, 191, 116588. [Google Scholar] [CrossRef]

- Liu, H.; Liu, S. Life cycle energy consumption and GHG emissions of hydrogen production from underground coal gasification in comparison with surface coal gasification. Int. J. Hydrogen Energy 2021, 46, 9630–9643. [Google Scholar] [CrossRef]

- Lozynskyi, V. Critical review of methods for intensifying the gas generation process in the reaction channel during underground coal gasification (UCG). Min. Miner. Depos. 2023, 17, 67–85. [Google Scholar] [CrossRef]

- Ozbilen, A.; Dincer, I.; Rosen, M.A. Exergetic life cycle assessment of a hydrogen production process. Int. J. Hydrogen Energy 2012, 37, 5665–5675. [Google Scholar] [CrossRef]

- Li, C.; Gao, Y.; Liu, H.; Zhai, R. Energy, exergy, environmental, and economic analysis of a novel hydrogen production system integrating concentrated photovoltaic thermal collectors and wind turbines. Energy 2025, 322, 135670. [Google Scholar] [CrossRef]

- Achomo, M.A.; Muthukumar, P.; Peela, N.R. Thermodynamic, energy and exergy analysis of steam reforming of methanol for hydrogen production. Int. J. Hydrogen Energy 2025, 149, 150040. [Google Scholar] [CrossRef]

- Budovich, L.S. Energy, exergy analysis in a hybrid power and hydrogen production system using biomass and organic Rankine cycle. Int. J. Thermofluids 2024, 21, 100584. [Google Scholar] [CrossRef]

- Zheng, L.; Jiang, X.; Zhang, X.; Wang, S.; Wang, R.; Hu, L.; Xie, K.; Wang, P. A Study of the Life Cycle Exergic Efficiency of Hydrogen Production Routes in China. Sustainability 2025, 17, 1413. [Google Scholar] [CrossRef]

- Rosen, M.A. Thermodynamic comparison of hydrogen production processes. Int. J. Hydrogen Energy 1996, 21, 349–365. [Google Scholar] [CrossRef]

- Granovskii, M.; Dincer, I.; Rosen, M.A. Exergetic life cycle assessment of hydrogen production from renewables. J. Power Sources 2007, 167, 461–471. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, P.; Liang, S.; Liu, B.; Shuai, Y.; Li, B. Exergy analysis of hydrogen production from steam gasification of biomass: A review. Int. J. Hydrogen Energy 2019, 44, 14290–14302. [Google Scholar] [CrossRef]

- Xue, Z.; Liu, X.; Fu, L. One new assessment method for the energy utilization manner. J. Sol. Energy 2006, 27, 349. [Google Scholar]

- Cui, Y.; Sun, R.; Zhao, Y. Carbon emission accounting study on entire life circle of coal-made gas. Resour. Ind. 2018, 20, 52. [Google Scholar]

- Zhang, X. Carbon emission measurement method and comparative study of green building structure system. Harbin Inst. Technol. 2014, 92–115. [Google Scholar] [CrossRef]

- Xie, J.; Li, W.; Chen, Y. Exploration of new technology of gasification-based hydrogen production. Mod. Chem. Ind. 2007, 335–336. [Google Scholar] [CrossRef]

- Lan, H.; Tian, J.; Ma, G. Analysis of the effect of multivariate index on compressor energy efficiency. Chem. Manag. 2021, 35, 3. [Google Scholar]

- Chen, W.H.; Chiu, T.W.; Hung, C.I. Enhancement effect of heat recovery on hydrogen production from catalytic partial oxidation of methane. Int. J. Hydrogen Energy 2010, 35, 7427–7440. [Google Scholar] [CrossRef]

- Han, D.; Liu, Y.; Sun, X. Discussion on the techno-economics of the coal-to-hydrogen process route. Henan Chem. Ind. 2017, 02, 41–42. [Google Scholar]

- Jiang, N.; Shen, Y.; Liu, B.; Zhang, D.; Tang, Z.; Li, G.; Fu, B. CO2 capture from dry flue gas by means of VPSA, TSA and TVSA. J. CO2 Util. 2020, 35, 153–168. [Google Scholar] [CrossRef]

- Dai, F.; Zhang, S.; Luo, Y.; Wang, K.; Liu, Y.; Ji, X. Recent Progress on Hydrogen-Rich Syngas Production from Coal Gasification. Processes 2023, 11, 1765. [Google Scholar] [CrossRef]

- Liemberger, W.; Groß, M.; Miltner, M.; Harasek, M. Experimental analysis of membrane and pressure swing adsorption (PSA) for the hydrogen separation from natural gas. J. Clean. Prod. 2017, 167, 896–907. [Google Scholar] [CrossRef]

- Centre for Energy and Environmental Policy Research, Beijing Institute. Technology Frontiers and Trend Forecasts in Carbon Capture Technology Development; Centre for Energy and Environmental Policy Research, Beijing Institute: Beijing, China, 2025; Available online: https://ceep.bit.edu.cn/docs/2025-01/d31601f5da4c4bebaf9dea01246655d5.pdf (accessed on 20 April 2025).

- Dahowski, R.T.; Davidson, C.L.; Li, X.C.; Wei, N. Examining CCS Deployment Potential in China Via Application of an Integrated CCS Cost Curve. Energy Procedia 2013, 37, 2487–2494. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).