Abstract

In the context of increasing demands for the reliability and efficiency of electrical complexes and systems, the problem of assessing and monitoring the technical condition (TC) of electrical equipment is becoming particularly relevant. This review is devoted to a comprehensive analysis of the factors affecting the performance of electrical equipment and modern methods for diagnosing its TC. The review article examines in detail the impact of various operational factors, including climatic conditions (temperature fluctuations, humidity, contamination) and electrical equipment operating modes. Special attention is paid to modern methods of technical diagnostics, such as thermographic diagnostics, vibration diagnostics, and chromatographic analysis of dissolved gases, which make it possible to identify defects and predict failures at early stages of their development. A significant part of the review is devoted to modern approaches to predicting the durability indicators of electrical equipment using mathematical modeling and neural networks. The advantages of a condition-based maintenance (CBM) and repair strategy, based on assessing the actual TC of the equipment, are analyzed in detail and compared with the strategy of scheduled preventive maintenance. This review particularly emphasizes the importance of integrating digital technologies, including the internet of things (IoT), digital twins (DT), and intelligent diagnostic monitoring systems, to create effective systems for predicting and managing TC. The review demonstrates that a comprehensive consideration of the actual TC of electrical equipment and its operating conditions can significantly increase the reliability of power systems, optimize maintenance and repair costs, and extend the service life of electrical equipment under various intensities of impacting operational factors.

1. Introduction

In the context of the global energy transition, requirements for the efficiency and sustainability of energy systems are increasing. The growing demand for electricity and the limitations of traditional sources, such as coal, gas, and oil, necessitate an active shift towards renewable energy sources [1]. To achieve sustainable development goals, it is crucial to ensure the high reliability of electrical equipment involved in the processes of generation, transmission, and distribution of electricity. This is particularly relevant for hybrid energy complexes based on hydrogen technologies and renewable energy sources, where underestimating the probability of electrical equipment failure can lead to accidents and significant economic consequences [2]. Thus, ensuring the high reliability of electrical equipment becomes an integral task for the operation of electric power facilities.

One of the most significant factors affecting the reliability of electrical equipment is power quality, which depends on actual operating conditions. For instance, in networks with frequency converters, typical for the mining industry, higher harmonics arise, leading to additional heating and accelerated equipment wear [3]. Accurately determining the harmonic impedance of an electrical network in the mining industry allows for minimizing voltage distortions, reducing the risk of damage to electrical equipment [4]. Under such conditions, enterprises implement demand-side management to stabilize power grid parameters and improve power supply reliability [5]. Furthermore, the application of energy efficiency technologies in the mining industry reduces the load on electrical equipment, promoting its reliability during mineral resource extraction [6]. Distributed generation also creates challenges in maintaining voltage within permissible limits and ensuring power quality [7], especially in hybrid power supply systems where harmonics, voltage sags, and other distortions occur, negatively affecting the operation of electrical equipment [8,9]. Consequently, actual operating conditions significantly influence the technical condition (TC) of equipment, which must be considered when assessing reliability indicators.

The reliability of electrical equipment is particularly critical in high-tech industries reliant on automated control systems. In sectors such as oil and gas production, the failure of electrical equipment can lead to the shutdown of key technological processes [10]. Failures of electric drives, sensors, controllers, and power supplies in distributed gas production control systems can disrupt reservoir pressure management and reduce field operation efficiency [11]. The use of energy storage systems in the gas industry helps improve power quality indicators, reducing the risk of electrical equipment failures [12]. Moreover, oil production facilities are sensitive to power quality—a voltage sag lasting 0.15 s can stop electric motors, requiring up to 30 min to restore the technological process [13]. These examples demonstrate that the reliability of electrical equipment is a key condition for the sustainable functioning of industrial enterprises.

To ensure the required level of reliability, monitoring and diagnostic methods focused on assessing the actual TC of electrical equipment are becoming increasingly relevant. This approach not only allows for the timely detection of potential defects but also enables the formation of economically sound maintenance and repair strategies, which is particularly important for electric power facilities. For example, monitoring systems for aluminum electrolyzers, which track current, voltage, and temperature parameters, contribute to increased equipment reliability through early detection of deviations and failure prevention [14]. Similarly, monitoring deformations of fastener bolts in hydro turbines allows for the detection of hidden defects, thereby increasing the reliability of hydro turbines [15]. Collectively, such diagnostic methods and TC assessments form the basis for transitioning from scheduled preventive maintenance to CBM strategies for electrical equipment. This underscores the necessity of a comprehensive approach to technical diagnostics as a key element in improving the reliability indicators of electrical equipment.

Thus, in modern conditions, ensuring a high level of reliability for electrical equipment requires a systematic consideration of operating conditions, diagnostic methods, and TC assessment tools. This review is devoted to the analysis of factors affecting the TC of electrical equipment, modern methods for diagnostics and reliability assessment, and the formation of effective maintenance strategies. Particular attention is paid to the role of digital technologies in enhancing the resilience and economic efficiency of energy systems amidst digitalization and the energy transition.

The ongoing energy transition brings not only opportunities for cleaner generation but also new operational challenges for diagnostic and maintenance strategies of electrical equipment. The integration of renewable and distributed energy sources has increased variability in power flows, voltage fluctuations, and bidirectional load conditions, which accelerate thermal, electrical, and mechanical stress on components. As a result, conventional time-based maintenance approaches are becoming less effective under dynamic operating regimes. To ensure system reliability, diagnostic and maintenance frameworks must adapt to these changing conditions by incorporating real-time monitoring, predictive analytics, and condition-based maintenance (CBM) strategies. Strengthening this link between energy transition and evolving maintenance practices highlights the growing importance of adaptive, data-driven reliability management.

This review aims to provide a comprehensive study of factors influencing the reliability of electrical equipment, modern diagnostic methods, and maintenance strategies. The main objectives of the review are to analyze:

- -

- The influence of operating conditions and regimes on the TC of electrical equipment;

- -

- Methods and means of technical diagnostics for assessing the TC of electrical equipment;

- -

- Methods and approaches for the quantitative assessment of electrical equipment reliability indicators, considering its TC;

- -

- The use of diagnostic results for assessing the durability indicators of electrical equipment;

- -

- The formation of maintenance and repair strategies for electrical equipment based on its TC;

- -

- Methods and approaches for automating the processes of reliability calculation, TC assessment, repair planning, and maintenance management.

The review emphasizes the role of digital technologies in enhancing the reliability and economic efficiency of electric power systems in the context of digitalization.

This review provides an integrative framework that, for the first time, combines the analysis of operating conditions, diagnostic methods, quantitative reliability assessment, and maintenance strategies into a unified system for electrical equipment. The proposed classification structure systematically links climatic and operational factors, diagnostic technologies, and digital solutions, allowing for a holistic evaluation of the TC of electrical equipment. Unlike previous reviews that focused on individual aspects, this study develops a structured approach that connects reliability modeling with real operational data and maintenance decision-making. The review also proposes a transition framework from time-based and preventive maintenance to CBM, enhancing both reliability and economic efficiency. Furthermore, the paper outlines future research directions, including the integration of explainable artificial intelligence (XAI), digital twins (DT), and reliability modeling under varying climatic and operational conditions.

2. Methodology

The research methodology is based on a systematic analysis of scientific literature, technological solutions, and engineering approaches for assessing the reliability of electrical equipment, considering its TC. The study is conducted in several stages, ensuring a comprehensive review and structuring of information.

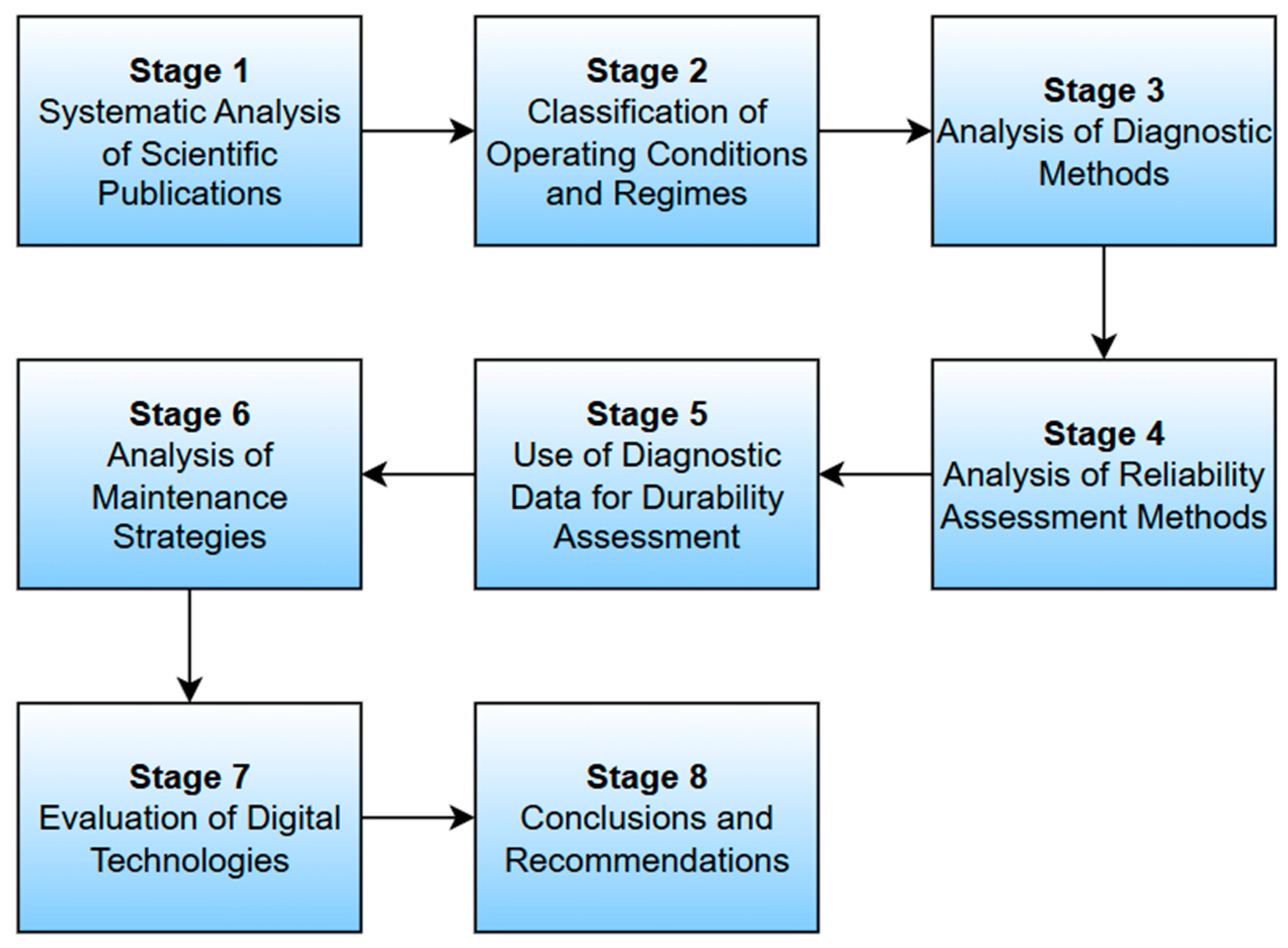

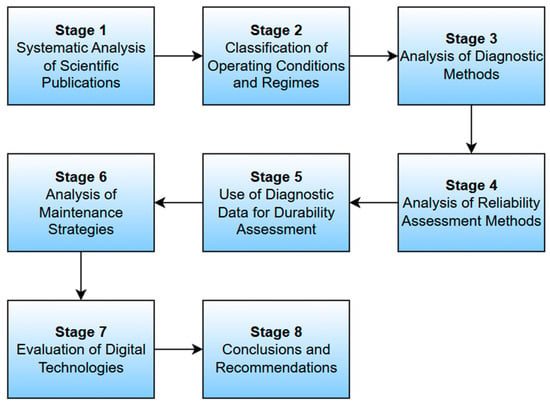

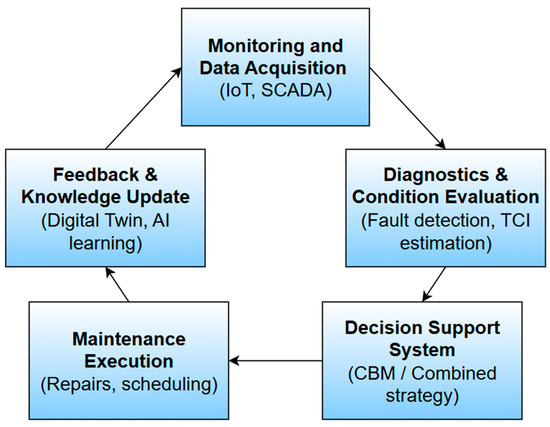

The methodological workflow of the review is shown in Figure 1.

Figure 1.

Workflow of the review.

The subsequent description outlines each stage of the review in detail, starting with the systematic analysis of relevant scientific publications:

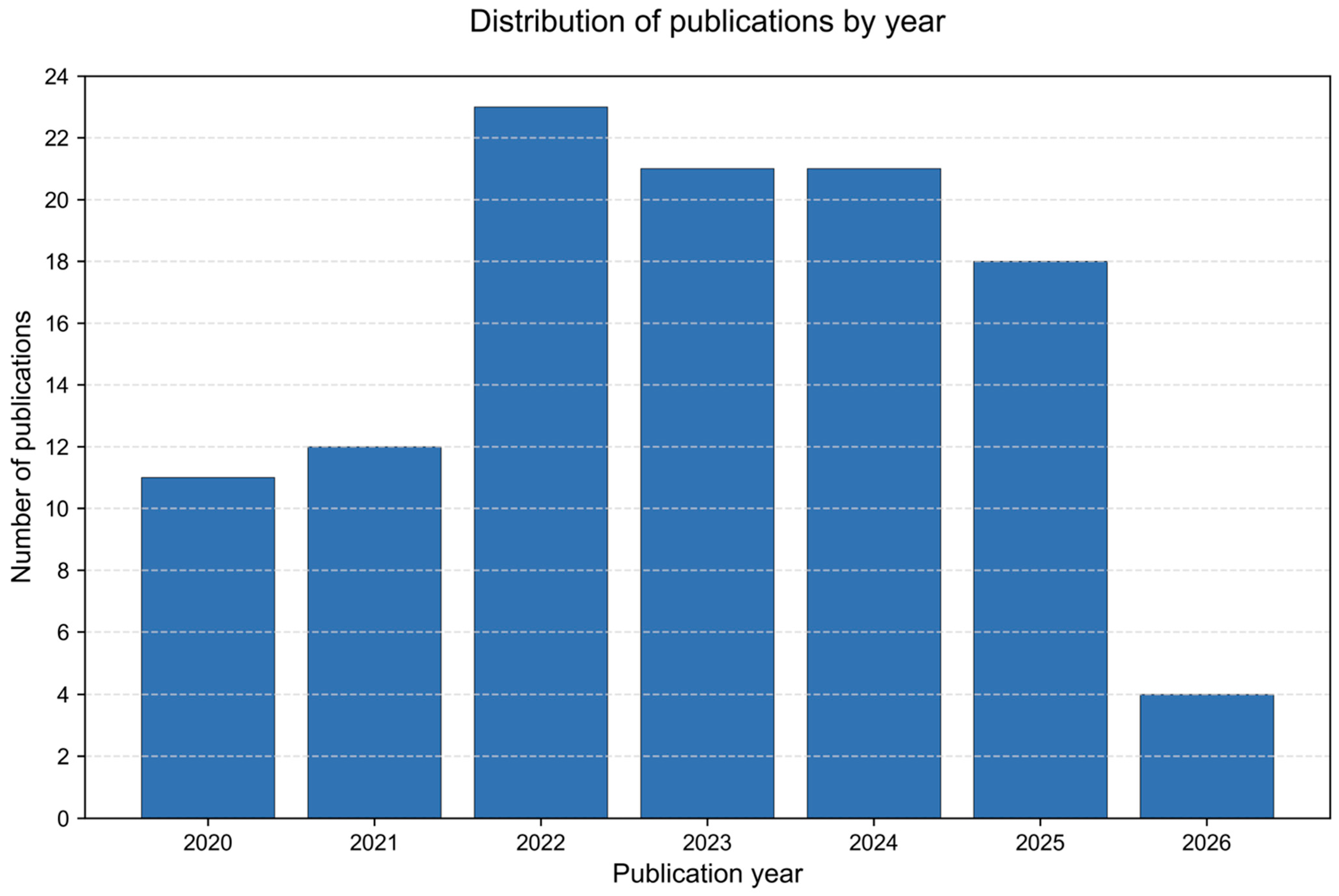

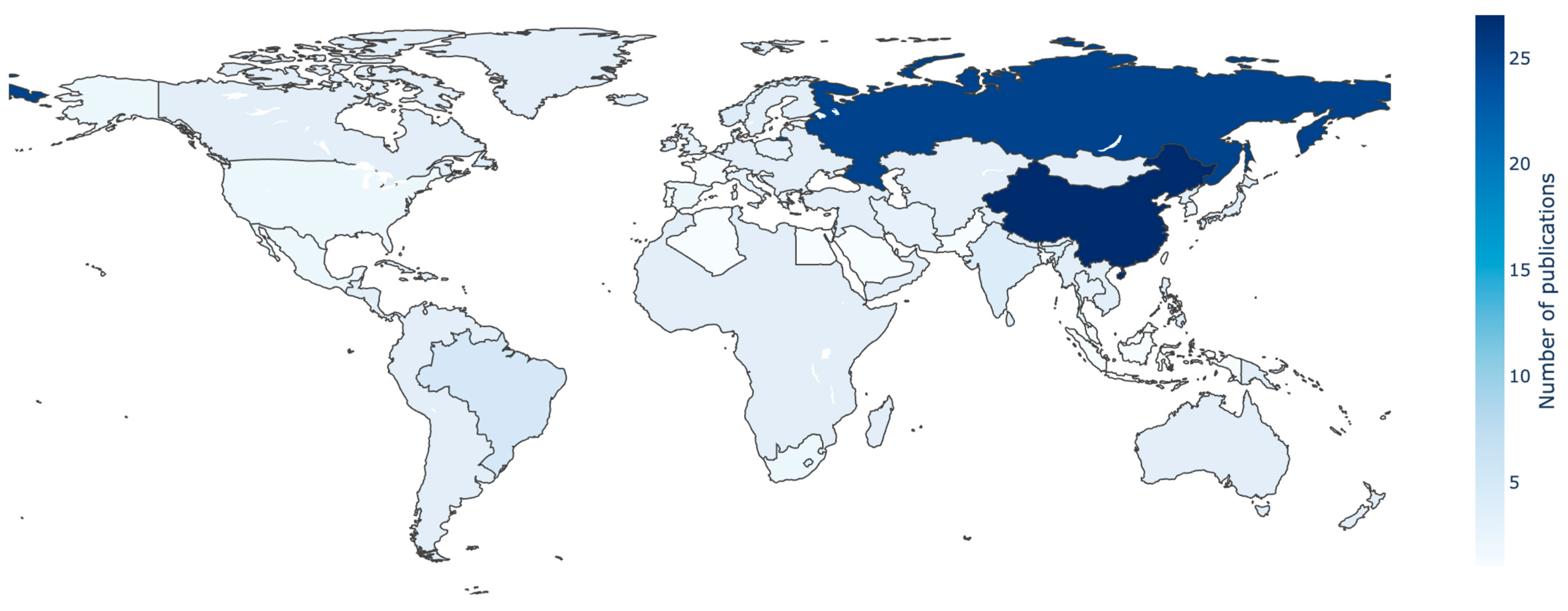

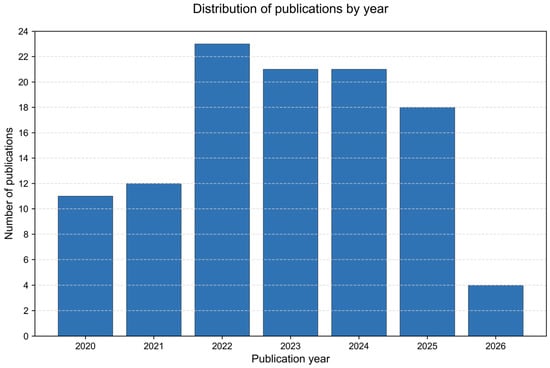

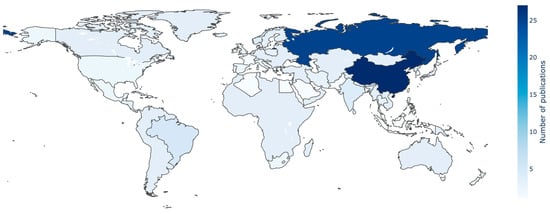

- Systematic Analysis of Scientific Publications. The first stage involves the collection and analysis of publications dedicated to assessing reliability indicators, diagnostics, monitoring, and maintenance of electrical equipment, considering its TC. Databases such as Scopus, Web of Science, and Google Scholar are used for gathering publications. The criteria for selecting sources include relevance (publications from the last 5 years), scientific significance, and applicability in the operational context of industrial enterprises.

- Classification of Operating Conditions and Regimes for Electrical Equipment. Based on the collected information, a systematization of factors affecting the TC of electrical equipment is conducted. This includes climatic factors (humidity, temperature, contaminants, wind, solar radiation) and operational factors (operating mode).

- Analysis of Methods and Means of Technical Diagnostics. Diagnostic methods, such as frequency response analysis (FRA), current signature analysis (CSA), Thermographic Diagnostics, and others, are classified based on their application, accuracy, and specific usage features. Particular attention is paid to combined technical diagnostic methods.

- Review of Quantitative Reliability Assessment Methods. Mathematical models used for assessing the reliability indicators of electrical equipment are examined, including statistical methods, fuzzy logic, Weibull distribution, and Markov processes. Their applicability for assessing reliability indicators, considering the TC of the equipment, is analyzed.

- Analysis of Using Diagnostic Results for Durability Assessment. This stage studies approaches to using diagnostic results for assessing the durability indicators of electrical equipment, such as remaining useful life (RUL). Parameters obtained through diagnostics (e.g., insulation polymerization degree, dissolved gas concentration, dielectric loss tangent) and their relationship with aging and wear processes are considered. Methods for calculating the RUL, considering actual operating conditions, are analyzed.

- Analysis of Maintenance Strategies. Approaches to forming maintenance strategies are studied, including time-based, preventive, and CBM. A comparative analysis of their effectiveness in terms of cost, reliability, and adaptability to operating conditions is conducted. Combined strategies and their role in improving the accuracy and optimization of maintenance are examined.

- Evaluation of Digital Technologies. Modern digital solutions, such as neural networks, supervisory control and data acquisition (SCADA), the internet of things (IoT), DT, and virtual reality (VR), are analyzed in terms of their contribution to automating diagnostics, monitoring, and maintenance planning. The accuracy and effectiveness of these digital solutions are assessed.

- Formulation of Conclusions and Recommendations. At the final stage, the analysis results are synthesized to identify key trends and development prospects. Recommendations are developed for optimizing diagnostics, reliability assessment, and maintenance strategies, considering the actual condition of the electrical equipment and modern digital technologies.

The described research methodology ensures a comprehensive approach to studying the topic, combining theoretical analysis with practical aspects. The obtained results allow for the formulation of scientifically grounded conclusions and recommendations for enhancing the reliability and efficiency of electrical equipment operation, considering its actual TC.

3. The Influence of Operating Conditions and Regimes on the Technical Condition of Electrical Equipment

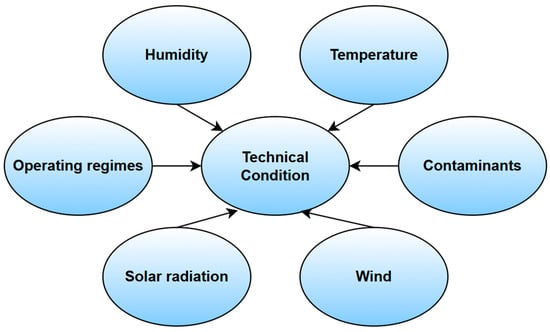

The TC of electrical equipment is influenced by various operating conditions. Based on their origin, these conditions can be divided into climatic factors and those related to the equipment’s operating regime.

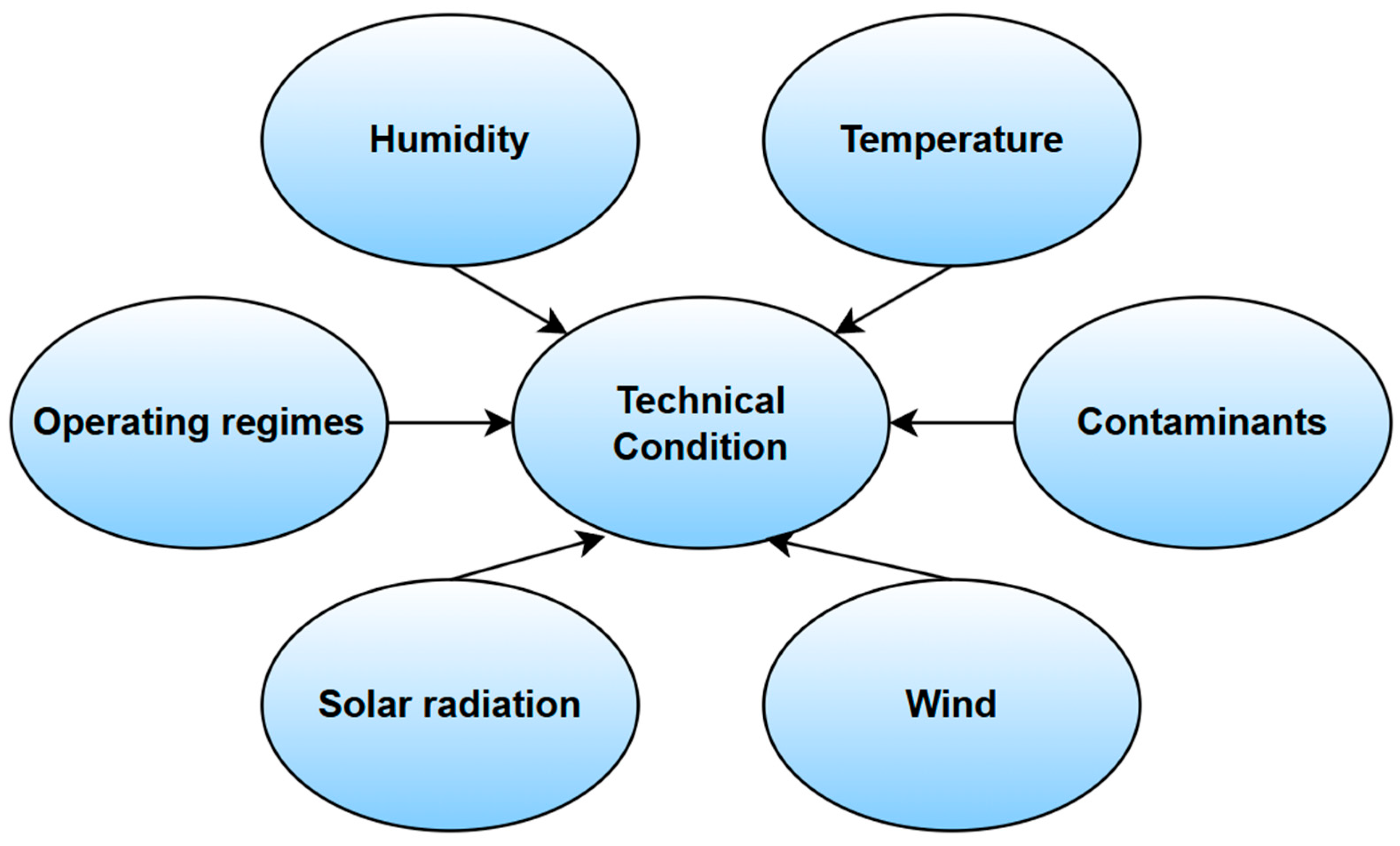

The relationship between climatic and operational factors affecting the TC of electrical equipment is illustrated in Figure 2.

Figure 2.

Climatic and operational factors influencing the technical condition of electrical equipment.

Climatic factors affecting the TC include humidity, ambient temperature, and airborne contaminants. Factors related to the operating regimes include the increase in equipment temperature due to changes in transmitted power.

3.1. Influence of Humidity on the Technical Condition of Electrical Equipment

High air humidity leads to corrosion, accelerated wear, and a reduced service life of electrical equipment. In mountainous and coastal areas, the technical condition index (TCI) can differ by up to 20% [16]. High humidity can rapidly degrade TC; for example, it can increase contact resistance by more than 10% over 2 years [17].

3.2. Influence of Temperature on the Technical Condition of Electrical Equipment

Ambient temperature affects reliability indicators, such as the failure rate. During a year-long observation of electrical equipment, the highest failure rate was recorded at the lowest observed temperature of −25 °C, while the longest failure durations occurred at the highest temperature of 35 °C [18]. In summer, the failure rate for feeders exceeds the minimum value by more than 4 times, and for overhead lines and transformers by more than 5 times [19].

3.3. Influence of Contaminants on the Technical Condition of Electrical Equipment

Airborne contaminants such as SO2, Cl−, and dust significantly impact the corrosion of carbon steel. When the SO2 concentration exceeds 0.5%, corrosion intensifies markedly [20]. In agricultural regions, the presence of (NH4)2SO4 leads to an increase in metal resistivity and a 21% drop in equipment performance due to surface corrosion [21].

3.4. Influence of Wind on the Technical Condition of Electrical Equipment

Wind affects the TC of electrical equipment. Its influence is particularly evident in the analysis of overhead power lines (OHPL). At low wind speeds, damage to insulators and hardware occurs. At wind speeds between 6 m/s and 25 m/s, conductor galloping is observed. Vibrations from galloping can lead to conductors clashing and being damaged. At wind speeds exceeding 12 m/s, the damage intensity to OHPL increases sharply. Wind load, resulting from wind acting on OHPL, causes 18–20% of failures on 110 kV lines. The probability of failure for a 110 kV OHPL ranges from 53.51 × 10−4 to 62.36 × 10−4 per 100 km of line length [22].

3.5. Influence of Solar Radiation on the Technical Condition of Electrical Equipment

Solar radiation flux affects the temperature of electrical equipment. When assessing the operating temperature of substation equipment, it was found that for every 50 W/m2 increase in solar radiation flux, the operating temperature rises by 0.5 °C [23]. This increase can lead to accelerated wear of functional components, such as insulation, resulting in a reduced service life and increased maintenance frequency.

3.6. Influence of Operating Regimes on the Technical Condition of Electrical Equipment

The TC of electrical equipment depends on its operating regime. Frequent overloads and power fluctuations lead to increased electrical losses and wear of functional components [24]. To simulate heavy-duty regimes, accelerated thermal aging tests of insulation can be conducted. These tests established that an increase of 14 °C in the hottest-spot temperature compared to normal operating conditions reduces the insulation service life by more than half [25].

Climatic conditions and operating regimes significantly influence the TC and reliability indicators of electrical equipment. Climatic factors such as high humidity, temperature, contaminants, wind, and solar radiation contribute to accelerated aging, corrosion, and failures of functional components. For instance, wind can be responsible for up to 20% of failures on 110 kV OHPL, and high summer temperatures increase feeder failure rates by more than 4 times. Operating regimes involving frequent overloads and power fluctuations lead to additional thermal and electrical stress, reducing insulation service life by half or more. These data confirm the necessity of considering actual operating conditions when assessing TC and planning maintenance activities. This approach enhances diagnostic accuracy, enables timely failure prevention, and ensures the reliable and cost-effective operation of electrical equipment based on its actual operating environment.

The main factors influencing the TC of electrical equipment are presented in Table 1. The check mark (✓) in Table 1 indicates the presence of a specific operating factor considered in the corresponding publication related to the influence of operating conditions on the technical condition of electrical equipment.

Table 1.

The Influence of Operating Conditions on the Technical Condition of Electrical Equipment.

4. Application of Methods and Means of Technical Diagnostics for Assessing the Technical Condition of Electrical Equipment

The efficient operation of electrical equipment directly depends on the accuracy and timeliness of assessing its TC. The application of methods and means of technical diagnostics allows for the identification of defects at early stages, prevents emergency situations, and reduces maintenance and repair costs. Modern diagnostic technologies, based on monitoring operational parameters and assessing the TC of electrical equipment, are becoming an integral part of strategies for ensuring the reliable and safe operation of energy facilities.

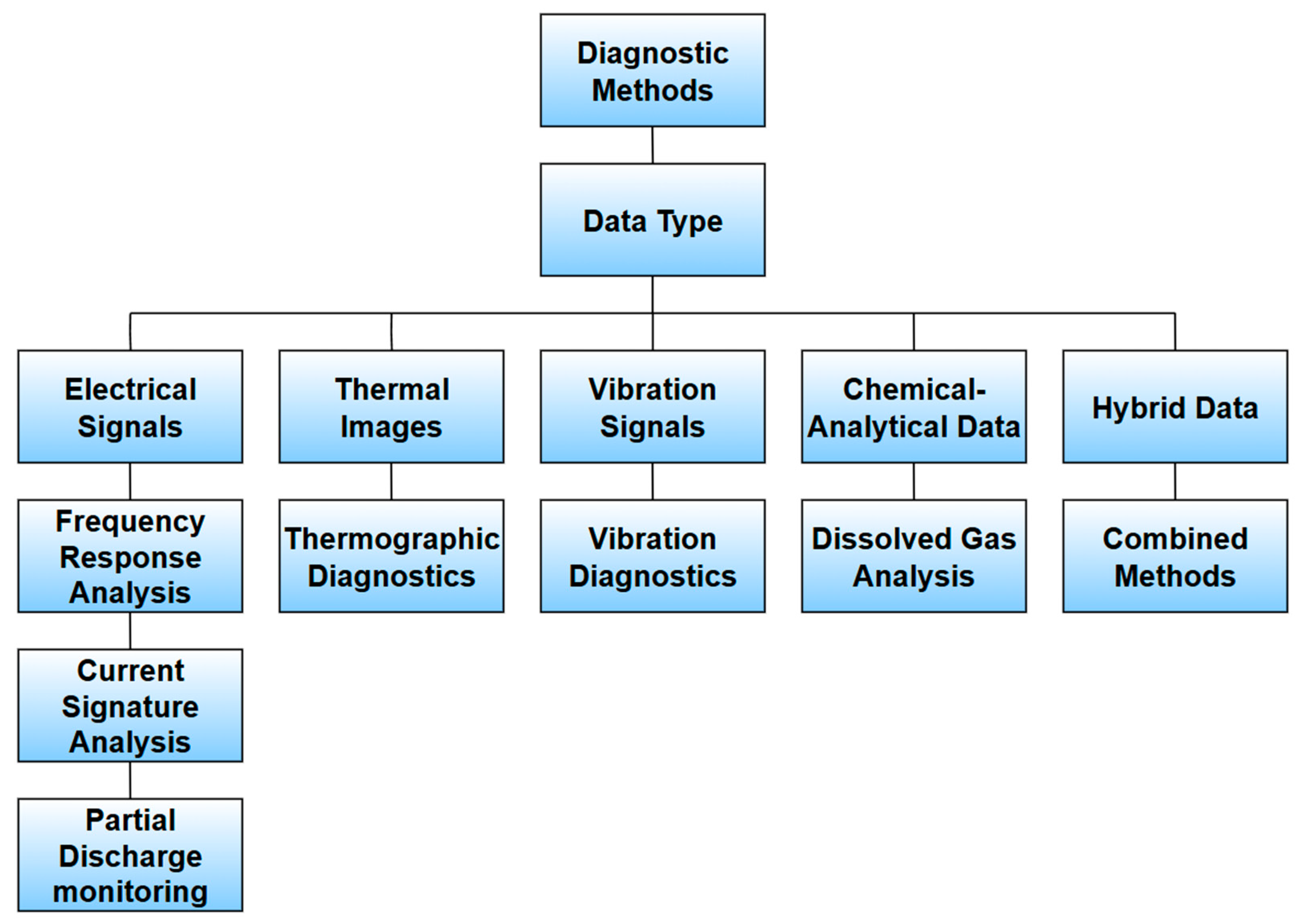

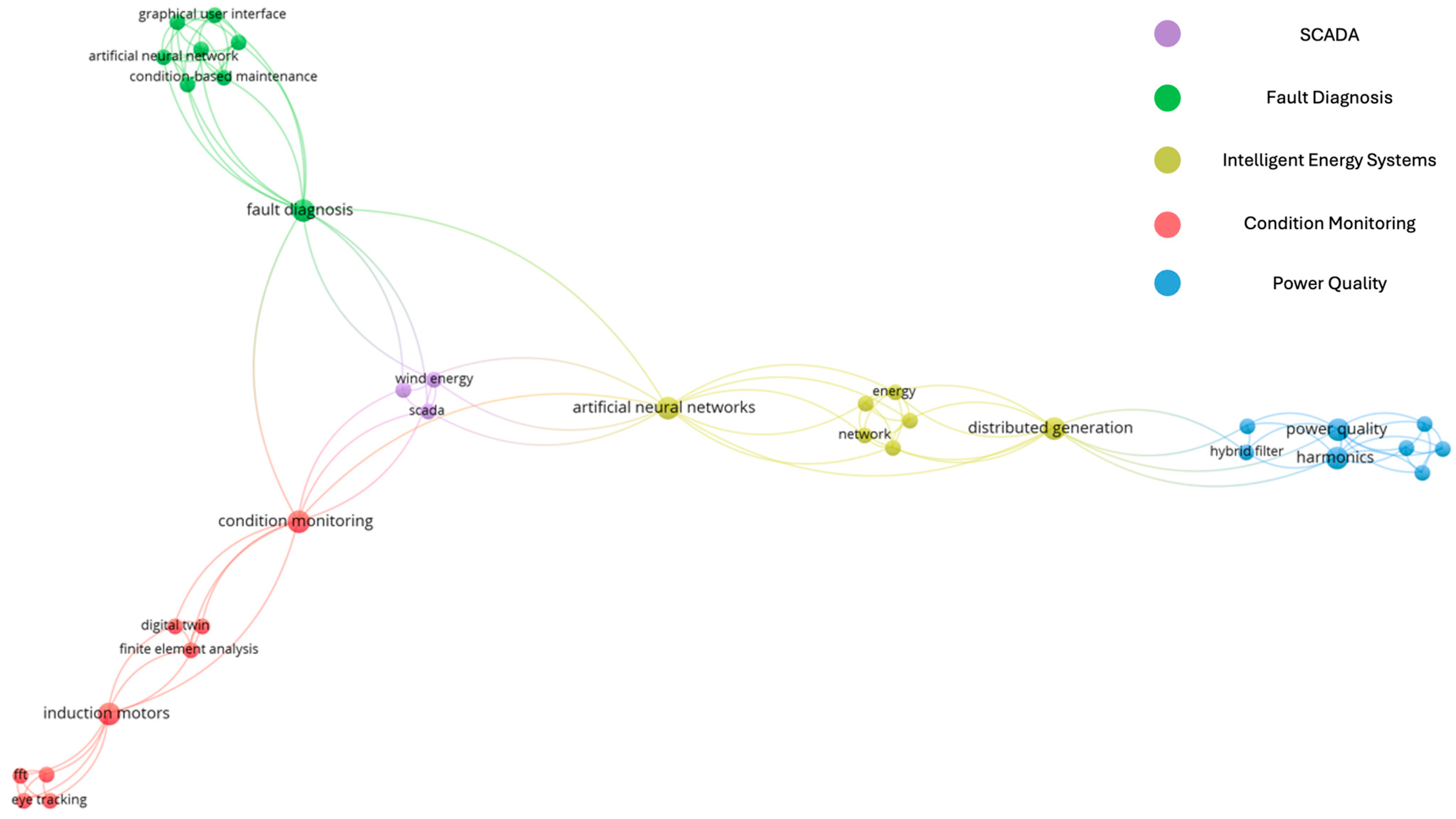

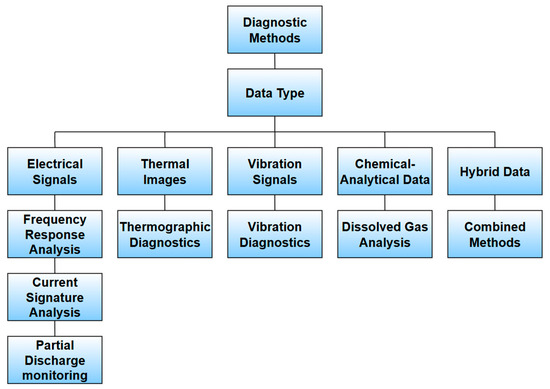

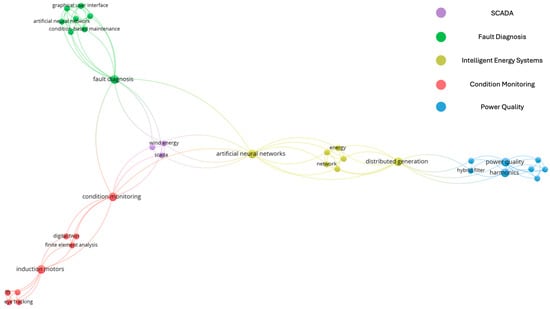

The diagnostic methods can be classified according to the type of data and the processing approach. This classification reflects the physical nature of the measured information, the corresponding analytical techniques, and the level of integration within digital diagnostic systems. The overall structure of the classification is shown in Figure 3.

Figure 3.

Classification of diagnostic methods by data type and processing approach.

4.1. Frequency Response Analysis

Methods based on non-destructive testing can be used to assess the TC of electrical equipment. One such method is FRA. In [26], the authors use this method to identify mechanical changes in the functional components of a power transformer. A key feature of this assessment method is the ability to detect a defect before disassembling the equipment, for example, axial deformation of the high-voltage winding in the frequency range above 400 kHz. The accuracy of fault classification using FRA can range from 80% to 100% [27].

4.2. Current Signature Analysis

Over 40% of asynchronous motor faults are caused by bearing failures. To assess the early occurrence of bearing defects in asynchronous motors, the authors in [28] use stator CSA. The approach considered by the authors helps avoid increased energy losses due to the deteriorating TC of the motor bearing. CSA can detect faults in asynchronous machines under both steady-state and transient conditions [29]. The accuracy of the CSA method can reach 100% when diagnosing broken rotor bars in asynchronous motors [30].

4.3. Partial Discharge Monitoring

Partial Discharge (PD) monitoring is used to assess the condition of electrical equipment insulation. The occurrence of PDs leads to insulation degradation, which in the long term can cause equipment failure. The output is an indicator of insulation condition, based on which it is possible to determine the location of a defect in the equipment as it transitions from a normal to a pre-fault state. Based on the results of online monitoring of the apparent charge, it is possible to assess and manage the TC of the insulation [31,32]. The accuracy of fault diagnosis using PD monitoring can reach 98.6% [33].

4.4. Thermographic Diagnostics

Thermographic diagnostics is a method for diagnosing electrical equipment based on the measurement and analysis of infrared radiation. This method allows for the detection of hidden defects, such as heat leaks, insulation problems, and faults in electrical systems. The primary tool for thermographic diagnostics is the infrared camera. Infrared cameras create thermal images used to classify faults during equipment operation. Using infrared cameras, it is possible to identify 11 types of faults in an asynchronous motor with an accuracy of 98.94% [34]. The sensitivity of thermal diagnostics is very high, capable of reaching 65 warnings per monitored section. This value indicates high accuracy in locating damage caused by thermal effects [35]. The absolute temperature measurement error during thermographic diagnostics is very small and can be 0.15 °C. Consequently, thermographic diagnostics can be used to determine temperature from infrared images and obtain highly accurate temperature values [36].

4.5. Vibration Diagnostics

Vibration diagnostics is a method for diagnosing electrical equipment that allows for the identification of faults and assessment of TC based on vibration analysis results. Vibration diagnostics also enables the detection of defects at early stages due to changes in frequency characteristics and can track their emergence in real time with up to 100% accuracy [37]. Based on the vibration spectrum, it is possible to determine and classify the type of fault. This is because each fault has a characteristic amplitude and frequency signature [38]. For example, vibration diagnostics can study the relationship between the occurrence of a fault in an asynchronous motor and the vibration frequency. At a vibration frequency of 23.5 Hz, damage to the bearing outer race is observed, and at 27.1 Hz, damage to the inner race. Vibration diagnostics can diagnose bearing faults with up to 95% accuracy [39].

4.6. Dissolved Gas Analysis

Dissolved Gas Analysis (DGA) is a technical diagnostic method based on the extraction and analysis of the composition of gases dissolved in oil. It allows for the identification of equipment defects based on the characteristic gas composition formed during overheating of current-carrying connections, defects in solid insulation, and electrical discharges in the oil. This diagnostic method is effective for monitoring the condition of oil-filled equipment and can be used both for early defect detection and for assessing the overall TC. A gas chromatograph is used as the diagnostic tool. The accuracy of fault diagnosis using chromatographic analysis of dissolved gases can reach 93.7% [40].

A quantitative indicator calculated based on the concentrations of dissolved gases can be used to assess the TC of an oil-filled transformer. This quantitative indicator is the dissolved gas analysis factor (DGAF). Each gas is assigned a score (1–6) depending on its concentration. The scores are multiplied by weighting coefficients. The DGAF value is calculated as the sum of the weighted scores. The DGAF value becomes a parameter in assessing the health index (HI) of the electrical equipment [41].

The Mahalanobis distance (MD) can be used to eliminate subjectivity in choosing weighting coefficients in dissolved gas chromatography data analysis for transformer condition assessment. The HI of the equipment can be calculated using the formula:

where is the Mahalanobis Distance for the current TC based on data collected from chromatographic analysis of dissolved gases; α is a correction coefficient.

In turn, the correction coefficient α can be determined by the formula:

where is the confidence probability, is the average value of MD for a set of healthy TCs.

Equations (1) and (2) establish the relationship between the MD and the HI, providing a quantitative basis for evaluating the deviation of current diagnostic data from the reference state. A lower MD value corresponds to a healthier TC, while higher MD values indicate increasing deviation and deterioration. The correction coefficient α ensures the normalization of HI values within the range (0, 1), enabling consistent comparison of equipment units under different operating conditions.

The method for assessing the TC of a transformer described in [42] allows for the elimination of redundant factors in chromatographic gas analysis and improves the accuracy of the transformer’s TC assessment.

4.7. Combined Methods

Combined diagnostic methods for electrical equipment improve accuracy, allow for distinguishing between faults with overlapping diagnostic features, and enable the simultaneous detection of several fault types. For example, vibration diagnostics and CSA can be used together to monitor the TC of an asynchronous motor. The described approach allows for effective diagnosis of multiple and combined faults. Multiple faults refer to several separate defects occurring simultaneously but in different functional components. Each fault has its own diagnostic features and they are independent of each other. Combined defects refer to situations where one functional component of the equipment is subjected to several interrelated influences simultaneously; they often affect each other or amplify the manifestation of the fault. The proposed method uses 465 statistical features, 45 of which are extracted from the time domain and 420 from the frequency domain. The proposed methodology allows for the classification of multiple and combined faults with an accuracy of 98.25% [43].

For comparison, Table 2 presents the application, accuracy, and key features of methods for diagnosing the TC of electrical equipment. The check mark (✓) in Table 2 indicates that the corresponding publication considers the specified diagnostic method in assessing the technical condition of electrical equipment.

Table 2.

Comparison of Methods for Diagnosing the Technical Condition of Electrical Equipment.

Although combined diagnostic approaches significantly improve the accuracy and reliability of fault detection, they also differ from single-method diagnostics in terms of implementation cost, complexity, and practical application. Table 3 summarizes the comparative characteristics of single and combined diagnostic methods.

Table 3.

Comparative Analysis of Single and Combined Diagnostic Methods.

In addition to electrical and chemical diagnostic techniques, optical and infrared (IR) spectroscopy has demonstrated strong potential for evaluating the quality and degradation of insulating and lubricating oils. Ultrasonic-assisted IR analysis of highly viscous oils improves spectral clarity and enables accurate detection of composition changes and impurities, which are directly linked to the reliability and thermal performance of electrical equipment [44].

The integration of FRA and DGA provides a more comprehensive understanding of transformer faults by combining mechanical and chemical diagnostics. FRA detects mechanical deformations in windings and core structures, while DGA identifies thermal and electrical degradation in insulating materials. When applied together, these methods enable the detection of coupled electro-mechanical defects—such as winding displacement accompanied by insulation overheating—that may remain unnoticed when using each method individually. The complementary nature of FRA and DGA thus enhances diagnostic accuracy and supports more reliable decision-making for CBM.

The methods and means of technical diagnostics presented in this section demonstrate high effectiveness in assessing the TC of electrical equipment. They enable the identification of a wide range of faults at early stages of development. The application of approaches such as FRA, CSA, thermographic diagnostics, vibration diagnostics, PD monitoring, and chromatographic analysis of dissolved gases provides comprehensive monitoring of various functional components. The high accuracy of these methods, ranging from 80% to 100%, confirms their practical value and applicability under various operating conditions. Particularly significant are combined methods that integrate signals from various diagnostic parameters, enabling the identification of multiple and interconnected faults with an accuracy of up to 98.25%. Thus, modern methods and means of technical diagnostics are becoming an integral part of electrical equipment reliability management systems, forming the basis for implementing CBM strategies utilizing various digital technologies.

5. Quantitative Assessment of Electrical Equipment Reliability Indicators Considering Technical Condition

Quantitative assessment of reliability indicators and the TC of electrical equipment is a key stage in forming an effective maintenance strategy and ensuring the failure-free operation of electrical complexes and systems. Under modern operating conditions characterized by high load, complex climatic influences, and an increasing degree of network intellectualization, there is a growing need to utilize various mathematical models. This chapter examines modern approaches to the quantitative assessment of electrical equipment reliability indicators, considering its TC, including statistical methods, fuzzy logic, the Weibull distribution, Markov processes, and mathematical models accounting for climatic influences. Special attention is paid to the use of TC indices for functional components, which enhances the accuracy and flexibility of equipment assessment considering operational factors.

5.1. Statistical Methods

Transformer reliability is assessed by aggregating various parameters (winding capacitance, magnetizing current, insulation resistance, etc.) using Dempster–Shafer theory, which accounts for incomplete or inaccurate data. Each parameter is assigned a weight, and its assessments are converted into qualitative ones, such as “excellent” or “good.” The transformer’s TC is analyzed by functional components (windings, insulation, cooling) based on online monitoring data and direct diagnostic results. The mathematical framework of Dempster–Shafer theory allows assessing the TC through a confidence factor and an estimate of the result uncertainty [45].

The authors in [46] define diagnostic conditions depending on reliability indicators by type of electrical equipment. These indicators include the probability of failure-free operation , the probability of failure , failure rate , the density distribution of time to failure, and Mean Time Between Failures (MTBF). When determining the failure rate and MTBF of an electrical system, failure statistics were collected by equipment type. Based on the obtained quantitative assessment of reliability indicators considering the TC, the calculation of optimal inter-diagnostic periods for the equipment was performed.

The failure rate of electrical equipment based on retrospective failure data of its functional components within a group can be determined by the formula [47]:

where is the number of intervals for which data are collected; is the number of functional components; is the number of failures; is the number of electrical equipment units within the group; is the observation duration for the group of electrical equipment, = hours.

5.2. Fuzzy Logic

The mathematical framework of fuzzy logic is based on the use of fuzzy or distorted input variables defined not quantitatively but qualitatively. This means that linguistic variables are used instead of precise numerical values. Each such qualitative description is formalized using membership functions that determine the degree to which a given value belongs to a particular fuzzy set. This approach allows describing systems whose behavior is difficult or impossible to express strictly mathematically. Fuzzy logic provides high flexibility when working with incomplete or distorted information. From the perspective of assessing the TCI, the fuzzy logic mathematical framework allows determining this indicator with an accuracy of 91% [48]. The application of fuzzy indices allows assessing reliability indicators considering the TC of the equipment. These include the failure rate , Expected Energy Not Supplied (EENS), the difference in EENS before and after maintenance (ΔEENS), and the reduction in EENS considering maintenance costs for the electrical equipment [49].

5.3. Weibull Distribution

The Weibull distribution can be used for the quantitative assessment of reliability indicators for various types of electrical equipment. The properties of a random variable according to the Weibull law [50]:

where is the operating time of the object, [] = hours; is the shape parameter; is the scale parameter, [] = hours.

Probability of failure-free operation:

Failure rate:

Here, is the shape parameter defining the failure behavior (—early failures, —random failures, —wear-out failures), and is the scale parameter (characteristic life corresponding to 63.2% of failures). The variable denotes the operating time. The failure rate represents the instantaneous probability of failure per unit time, and is the reliability function. The model parameters are typically estimated using the Maximum Likelihood Estimation (MLE) method based on historical failure data.

This distribution is widely used due to its ability to describe various types of failures, such as fatigue, sudden, or gradual failures. Using this distribution allows for estimating the failure rate , probability of failure-free operation , and failure frequency [51,52,53].

5.4. Markov Processes

In [54], the authors conducted a quantitative assessment of reliability indicators for turbogenerators of a station auxiliary power system using semi-Markov processes. Based on this approach, the failure rate , probability of failure-free operation , and turbogenerator recovery time were numerically assessed. As a result, system reliability indicators were obtained, including mean time to system failure and repair rate .

For the quantitative determination of the probability of electrical equipment being in a certain state, a mathematical apparatus based on Kolmogorov–Chapman equations can be used. These equations are used to describe Markov processes. Based on these equations, a graph is constructed whose edges have parameters. The first parameter characterizes the transition intensity of the system from one state to another, and is the recovery intensity, which characterizes the return from the latter state to the previous one [55].

A more comprehensive comparison of quantitative reliability models can be achieved through performance-based evaluation and validation examples. The Weibull distribution demonstrates high statistical accuracy (R2 > 0.95) in modeling aging-related failures of power transformers, particularly when extended to bivariate or multivariate forms that incorporate correlations between failure and repair times [56]. Markov models achieve prediction accuracies exceeding 90% in multi-state and repairable systems when properly calibrated, supporting effective modeling of state transitions and system redundancy optimization [57]. Fuzzy logic-based approaches have shown practical effectiveness under conditions of diagnostic uncertainty by integrating expert knowledge into failure prediction and reliability allocation [58]. Hybrid and data-driven techniques also demonstrate enhanced predictive performance and adaptability. For example, a sustainable fast-charging strategy for lithium-ion batteries has been proposed based on a random forest-enhanced electro-thermal degradation model, enabling accurate capacity estimation under variable thermal and operational conditions [59].

5.5. Quantitative Assessment of Reliability Indicators Considering Climatic Influences

Considering the combined impact of climatic factors (wind speed, air temperature, and precipitation), it is possible to quantitatively assess their influence on the reliability indicators of electrical equipment. The assessment of climatic factor impact is performed using econometric models. Econometric models are statistical models that quantitatively describe the relationship between the reliability indicators of electrical equipment and climatic factors. The average failure rate and average recovery time of electrical equipment can be determined by the following econometric functional dependencies:

where is air temperature, [] = °C; is wind speed, [] = m/s; is daily precipitation, [] = mm.

For each type of electrical equipment, the econometric models for the functions of the average failure rate and average recovery time are different, so the form of the above functions will differ c.

The econometric relationships describing the influence of environmental factors (temperature, wind speed, and precipitation) on failure rate and restoration time are region-dependent. The general functional form of these models remains valid across different climatic zones, while the coefficients require calibration using local meteorological and reliability data. Calibration can be performed through multiple regression analysis based on regional failure statistics, ensuring that the model accurately reflects the influence of specific climatic conditions on equipment reliability [55].

Indicators adjusted for the impact of climatic factors can be used for quantitative reliability assessment. These indicators include the failure rate and recovery rate based on forecasting changes in weather conditions over time, as well as the effective failure rate and recovery rate . Effective reliability indicators are based on a joint assessment of retrospective failure data and forecasting changes in weather conditions. When accounting for weather factors, the annual downtime of electrical equipment can increase from 8.47% to 11.52%. This indicates that classical quantitative assessment methods may underestimate risks arising from climatic influences [60].

5.6. Technical Condition Index of Functional Components

A method based on determining the TC of its functional components can be used for the quantitative assessment of the TC of electrical equipment. The TCI of the -th functional component in percentage can be determined according to the equation:

where is the worst assessment based on the results of the -th technical diagnostic; is the maximum assessment based on technical diagnostic results; is the weight coefficient of the -th technical diagnostic; is the number of technical diagnostics.

The TCI of the electrical equipment in percentage can be determined by the following formula:

where is the weight coefficient of the -th functional component; is the number of functional components.

The weighting coefficients are determined through expert evaluation of the relative importance of each functional component in ensuring the reliable operation of the equipment. Experts assign importance scores based on operational experience, failure statistics, and the functional role of each component within the system. The obtained scores are then normalized so that the total contribution of all components equals 100%, which ensures the comparability of results and the consistency of the overall TCI calculation.

A conditional factor is used to adjust the TCI value considering operating conditions and retrospective failure data, which can be calculated by the formula:

where is the assessment of the -th impact factor; is the maximum assessment for each impact factor; is the weight coefficient of the c-th impact factor; is the number of factors.

Based on the obtained data, considering the operational factor, the overall TCI in percentage is quantitatively assessed:

Equations (9)–(12) together describe a hierarchical assessment framework that links diagnostic parameters to the overall TC of electrical equipment. Equation (9) quantifies the condition of each functional component based on diagnostic results, while Equation (10) aggregates these values into an integral %HI using weighting coefficients that reflect the relative importance of each component. Equation (11) introduces a CF that adjusts the TCI according to real operating conditions and retrospective failure data. Finally, Equation (12) provides the %OHI, representing the total TC of the equipment, where values close to 100% indicate excellent condition and lower values correspond to progressive degradation.

In practical applications, the %OHI values can be interpreted as follows: 90–100%—good condition, 60–89%—moderate condition, and below 60%—poor condition.

The described quantitative assessment method allows for determining and classifying electrical equipment based on the TC of its functional components [61].

Thus, modern methods for the quantitative assessment of reliability and TC of electrical equipment provide a comprehensive approach to monitoring, diagnostics, and lifecycle management of equipment. The use of statistical models, fuzzy logic, and Markov processes allows for the consideration of both retrospective data and current indicators obtained from diagnostics. The application of econometric models and accounting for climatic factors enhances calculation accuracy and allows adjusting maintenance strategies according to actual operating conditions. The use of TC indices for functional components is particularly significant, enabling the formation of an integral assessment of the equipment’s TC based on its structural model. The presented methods make it possible to objectively assess the probabilities of failures, determine maintenance priorities, and implement CBM approaches. These methods serve as the basis for improving the reliability, safety, and economic efficiency of electrical equipment operation within electrical complexes and systems.

6. Using Diagnostic Results to Assess the Durability Indicators of Electrical Equipment

The reliability of electrical equipment includes a property characterizing its durability. Durability is the ability to maintain operational capability until transitioning to a limiting state. From a durability perspective, electrical equipment must be operated with interruptions for maintenance and repair. One quantitative indicator of durability is the service life.

Service life is understood as the calendar period from the start of equipment operation or its resumption after repair until its transition to a limiting state. Service life is divided into normative, actual, and residual.

Depending on operating conditions, these quantitative indicators can change. Under severe or light operating conditions, the service life may differ from the normative one. Therefore, to assess the service life considering actual operating conditions and technical state, it is necessary to use various diagnostic results.

6.1. Assessment of Residual Service Life of Electrical Equipment

If the TCI is determined through diagnostics, the residual service life of the electrical equipment can be calculated. The residual service life can be defined as the difference between the expected service life and the service life calculated based on the TCI assessment [62].

To determine the residual service life of rotating machines, it is necessary to use diagnostic results. Based on these, indicators of the TC of functional components are determined, on which the residual service life of the equipment depends, considering actual operating conditions [63].

6.2. Diagnostic Parameters for Power Transformers

Based on diagnostic data on insulation condition, moisture content, and equipment operating regimes, it is possible to determine the residual service life of a transformer [64].

One diagnostic result for a transformer is the Degree of Polymerization (DP) of the insulation. The DP values of transformer cellulose insulation are classified as follows: 700 ≤ DP < 1200 corresponds to a healthy state, 450 ≤ DP < 700 indicates moderate degradation, 250 ≤ DP < 450 indicates severe degradation, and DP < 250 is an end-of-life criterion.

Based on the Degree of Polymerization (DP), the residual service life of a transformer can be estimated using the following equation:

Poor paper integrity leads to early insulation deterioration, potentially contributing to transformer failure after a winding short circuit.

The ranges of the transformer’s TCI and their corresponding service life spans are: 85–100%—very good (>15 years), 70–85%—good (>10 years), 50–70%—satisfactory (<10 years), 30–50%—unsatisfactory (<3 years), 0–30%—critical (TCI corresponds to end of service life) [65].

When determining the TCI for transformers up to 132 kV, the highest weight coefficient corresponds to results obtained from chromatographic analysis of dissolved gases. Gas concentrations in transformer oil are classified as follows: a normal level is 0–1920 mg/m3, and an elevated level is from 1920 mg/m3 and above. High gas concentration values lead to accelerated wear of functional components and a reduction in the transformer’s residual service life [66].

Information about the nature of arc discharges (duration, energy, power, current strength) can also be used as diagnostic results [67]. Data on the number of equipment switching cycles can also be used, as for some types, such as furnace transformers, the number of grid connections can be up to 100 times per day [68].

6.3. Diagnostic Parameters for Asynchronous Motors

When assessing the residual service life of asynchronous motors, parameters such as torque signals, stator current, and rotational speed can be used as diagnostic inputs [69].

6.4. Diagnostic Parameters for Cable Lines

The dielectric loss tangent () can be used to assess the service life of cable lines. It reflects the overall aging of the insulation. An increase in indicates a rise in dielectric losses due to moisture, thermal or electrical aging of the insulation caused by mechanical or thermal stresses. Subsequently, an increase in leads to a reduction in the service life of cable lines [70].

Thus, technical diagnostic results play a key role in assessing the durability indicators of electrical equipment and allow for an objective determination of the residual service life considering actual operating conditions. The use of diagnostic parameters such as insulation polymerization degree, dissolved gas concentrations, , current signals, vibration, rotational speed, and torque ensures high accuracy in predicting the residual service life of electrical equipment. Unlike the normative service life, the approach based on diagnostic results allows for refining service life estimates for each piece of equipment, accounting for actual operating conditions and the degree of wear of functional components. Calculating the residual service life of transformers, asynchronous motors, and cable lines using indicators like the TCI enables a transition from scheduled maintenance to CBM. This approach not only helps extend the service life of electrical equipment but also reduces the likelihood of failures, enhances the reliability of electrical complexes and systems, and lowers operational costs.

7. Formation of a Maintenance Strategy for Electrical Equipment Considering Its Technical Condition

Maintenance represents a set of measures to maintain the operational state of electrical equipment.

A maintenance strategy is a systemic management model. The maintenance strategy defines the principles for planning activities to achieve set goals, considering the capabilities and constraints of resource allocation at the enterprise where the electrical equipment is operated.

Main Maintenance Strategies:

- -

- Periodic (Time-Based) Maintenance;

- -

- Preventive Maintenance;

- -

- CBM.

In periodic maintenance, activities are carried out at fixed time intervals or operating hours according to the schedules established in the technical documentation.

In preventive maintenance, activities are performed at set intervals to maintain operational readiness, enable early fault detection, and reduce the probability of failures.

In CBM, equipment monitoring is performed with a specified periodicity according to established documentation. However, the timing and scope of maintenance activities are determined by the current condition of the equipment, allowing for more accurate maintenance cost planning and preventing premature interventions.

Depending on the operating conditions and resources of the enterprises performing the maintenance, various methods can be used to assess the effectiveness of a proposed strategy.

7.1. Approaches to Forming a Maintenance Strategy

A method based on classifying the TC of equipment through logical conditions can be used to form a maintenance strategy. The TC is determined by comparing monitored parameters with allowable values. Risk assessment is conducted as a function of failure probability and potential consequences, allowing for a quantitative determination of the hazard level. The core set of possible decisions includes a closed set of options: the possibility and feasibility of continued operation; the necessity for a repair shutdown; the advisability of decommissioning and planning for replacement. Decision optimization is performed considering the acceptable risk level and costs, with the ultimate goal being the selection of a decision with minimal total costs, ensuring a balance between economic efficiency and equipment reliability [71].

When determining the most effective maintenance strategy, decision vectors representing different maintenance strategies can be used. Criteria for the effectiveness of a maintenance strategy are defined, and the best possible values are selected from them. Based on these best values, an optimal decision vector is constructed. Each strategy is represented as a vector in a multidimensional space. The proximity of a proposed strategy to this optimal decision vector is then assessed. Among scheduled repair, targeted repair based on diagnostics, and continuous condition monitoring and tracking, the latter shows the greatest proximity to the optimal decision vector—0.9963 [72].

7.2. Condition-Based Maintenance

CBM offers several advantages over other maintenance strategies. The advantage of CBM lies in the precise tracking of the equipment’s TC. The application of CBM can significantly reduce expenses compared to periodic maintenance, increasing savings by up to 32.5% [73].

Compared to preventive maintenance, a CBM strategy can lead to a 40% reduction in the average long-term cost rate [74].

Using CBM allows for accounting for heterogeneous failure dependencies across different inspection intervals, where the wear of one functional component leads to the wear of another. Short intervals between inspections improve reliability indicators but increase the cost of conducting them. Long intervals between inspections reduce maintenance costs but increase failure probabilities. CBM allows for determining the optimal time between inspections to minimize maintenance costs while maintaining high reliability indicators and accounting for failure heterogeneity [75].

Under certain conditions, accelerated wear can occur between the moments of TC assessment. Depending on the equipment’s TCI, the CBM cycle can be adjusted using the following formula:

where and are the time points corresponding to lower and higher TCI values, respectively, [] = [] = hours [76]. Equation (14) defines the adjustment interval () between two successive maintenance actions, depending on the degradation rate reflected by the TCI variation. A larger indicates slower degradation, while a smaller corresponds to accelerated wear and requires a shorter inspection interval.

To determine the maintenance order considering TC, an index characterizing the Maintenance Priority (MP) can be used. This coefficient can take values from 0 to 1. The closer the MP value is to 1, the higher its maintenance priority. If the MP value is greater than 0.5, the equipment is considered a priority compared to others. When determining the maintenance sequence between two identical types of equipment, the priority is determined by the following formula:

where is the number of parameters determining the TC of the equipment; represents the evaluation of equipment X’s current condition relative to its previous state, and characterizes the comparative condition of equipment X and Y based on diagnostic parameters [77]. Equation (15) thus provides a practical basis for prioritizing maintenance activities among similar units, supporting balanced resource allocation and improved reliability management.

In turn, CBM has disadvantages. One drawback is the randomness of maintenance timing. From this perspective, scheduled maintenance has an advantage as it allows for activity planning. At the same time, scheduled maintenance can lead to over-maintenance or under-maintenance.

7.3. Combined Maintenance Strategies

Due to the advantages and disadvantages of each strategy, combined maintenance strategies can be used. The joint use of different strategies combines and minimizes the shortcomings of various approaches, allowing for cost reduction. For example, a strategy based on both periodic maintenance and CBM can be used. For instance, periodic maintenance is conducted at intervals set in the documentation (time or operating hours), but adjusted based on data about the actual TC of the equipment [78].

Based on data about the actual TC, the failure probability function is determined. This allows for finding the optimal wear level M for performing preventive maintenance. Accounting for the actual TC allows finding the wear level M at which the total costs and failure probability are minimal. Compared to preventive maintenance, the cost coefficient in CBM approaches the optimal value much faster [79].

A maintenance strategy considering the TC can be adjusted through a penalty system consisting of three components: a penalty for separate maintenance of functional components (economic costs), a penalty for premature replacement of serviceable functional components (incomplete resource utilization), and a penalty for the impact of failed functional components on serviceable ones (increased load). Accounting for TC through continuous monitoring of equipment parameters allows assessing the condition of functional components and calculating total penalties. The optimal maintenance strategy is chosen by minimizing the total penalty. This ensures a reduction in the economic costs of maintenance [80].

Most information about failures and events during power system operation is stored in textual form as diagnostic reports. A knowledge graph can be used to form a maintenance strategy. This graph is a model consisting of nodes (dates, events, equipment types) and edges (relationships between objects and properties). Through monitoring TC parameters, the graph is dynamically updated. This allows for the automatic selection of a maintenance strategy considering TC, cost minimization, and a high level of reliability. A combined f-measure metric is used to assess the accuracy of the knowledge graph. It evaluates how well the system simultaneously avoids missing events and making errors in their interpretation. The proposed knowledge graph-based system can achieve an f-measure of up to 94.2% for event detection and 83.5% for event extraction [81].

Compared to periodic maintenance, CBM can reduce average costs by 27% and increase the MTBF by 2.5 times [82].

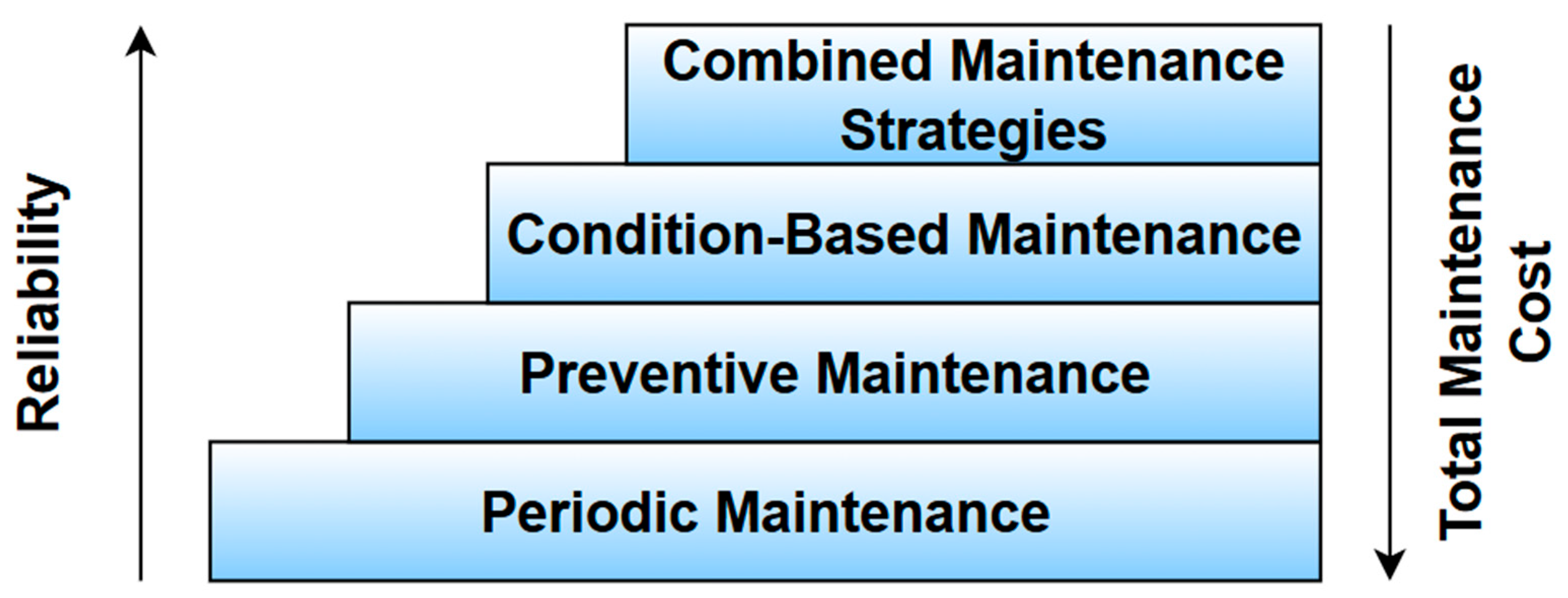

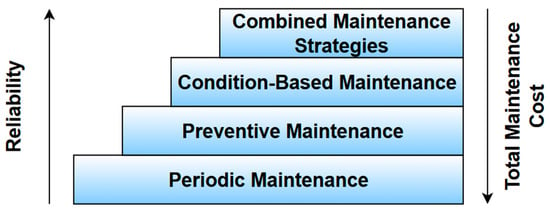

The comparative analysis of maintenance strategies demonstrates that reliability and economic efficiency can be significantly improved when transitioning from reactive and preventive approaches to condition-based and combined maintenance strategies. The development of maintenance strategies can thus be represented as an evolutionary sequence, where each stage reflects a higher level of TC awareness and decision-making maturity.

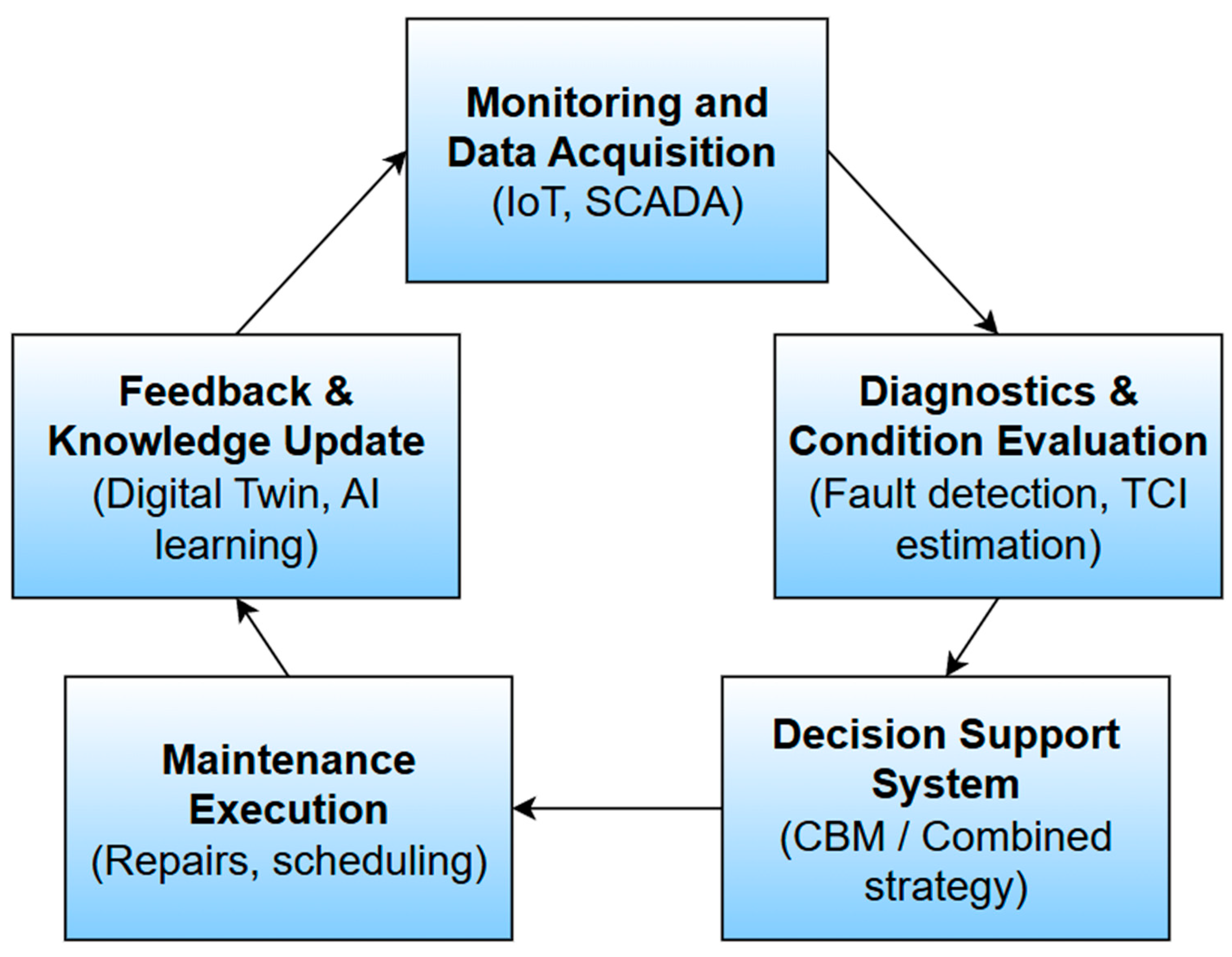

Figure 4 illustrates the evolution of maintenance strategies for electrical equipment. As reliability increases, total maintenance expenditures decrease due to optimized scheduling, early defect detection, and reduced downtime.

Figure 4.

Evolution of maintenance strategies based on technical condition.

7.4. Challenges of Condition-Based Maintenance Implementation

Despite its proven advantages, implementing CBM in real industrial environments faces several practical challenges that influence cost, data reliability, and personnel competence:

- Data quality and availability. Effective CBM depends on continuous data acquisition from sensors and monitoring systems. Incomplete, noisy, or biased data can distort diagnostic results and lead to incorrect maintenance decisions. Establishing standardized data formats, calibration procedures, and validation routines is essential to ensure the reliability of the TC assessment.

- Initial investment and infrastructure. Transitioning from scheduled maintenance to CBM requires the installation of sensors, data-acquisition modules, and analytics software. The initial capital investment typically ranges from 3% to 8% of total equipment value. However, long-term cost savings—reduced downtime and optimized repair frequency—can compensate for these investments within 2–3 years.

- Personnel competence and organizational readiness. CBM implementation requires staff with both electrical engineering and data analytics skills. Maintenance personnel must be trained to interpret diagnostic results and to operate digital systems (SCADA, IoT, AI-based analytics). Introducing interdisciplinary training programs and cooperation with equipment manufacturers helps overcome this barrier.

- Integration and cybersecurity. Integrating CBM data flows with existing SCADA or enterprise asset-management systems can create compatibility and cybersecurity issues. Data-access policies, network segmentation, and encryption protocols are necessary to protect sensitive operational data.

- Addressing these challenges through structured investment planning, personnel training, and standardization of data quality procedures will accelerate the transition to fully digitalized CBM strategies.

Comparative analysis of different maintenance strategies demonstrates that the transition from periodic and preventive approaches to condition-based and combined strategies significantly improves both reliability and cost efficiency. Industrial experience confirms that digitalization and diagnostic integration enhance maintenance planning, reduce downtime, and optimize resource utilization. This comparison, as shown in Table 4, highlights the evolution of maintenance concepts from schedule-driven to data-driven approaches, reflecting the increasing role of diagnostics, real-time monitoring, and predictive modeling in modern power systems.

Table 4.

Comparison of Maintenance Strategies for Electrical Equipment.

These results demonstrate the gradual shift in modern maintenance systems toward intelligent, predictive, and risk-oriented management frameworks, serving as a foundation for the digital technologies discussed in the next section.

Thus, forming a maintenance strategy for electrical equipment considering its TC is an important direction for improving the reliability and economic efficiency of electrical complexes and systems. Unlike periodic and preventive maintenance, CBM allows for decisions based on the actual wear level of the equipment, leading to cost reductions of up to 32.5% and an increase in MTBF by up to 2.5 times. The use of TC indices, failure probability functions, maintenance priorities, and knowledge graphs ensures accurate planning of maintenance activities and optimization of maintenance intervals. Combined strategies, integrating the advantages of different approaches, allow for considering both normative and actual operating conditions. Additionally, accounting for failure heterogeneity, penalty systems for inefficient maintenance, and the application of intelligent decision-support systems provide flexibility in adapting maintenance strategies under various conditions. Collectively, strategies focused on TC contribute to reducing the probability of failures, enhancing the resilience of electrical complexes and systems, and the rational allocation of resources within the maintenance management strategy.

8. Automation of Reliability Calculation, Technical Condition Assessment, Repair Planning, and Maintenance Management Processes

Nowadays, the automation of processes for calculating reliability, assessing TC, planning repairs, and managing maintenance is highly relevant. Automation is driven by the need to improve the operational efficiency of electrical equipment and reduce maintenance costs. Automating these processes enhances the accuracy of calculations and predictions of the TCI, thereby contributing to an extended service life of electrical equipment. The implementation of such systems is particularly in demand in the context of industrial digitalization.

These automation processes are built upon the diagnostic and reliability assessment frameworks presented in Section 4 and Section 5. Digital technologies such as AI, IoT, SCADA, and VR form the technological basis for implementing these frameworks in practice. They provide continuous acquisition, processing, and integration of diagnostic data obtained from FRA, CSA, DGA, and PD monitoring. By linking these diagnostic methods with quantitative reliability models (Weibull, Markov, and fuzzy logic), digital technologies enable real-time reliability evaluation and automated decision-making for adaptive maintenance strategies.

8.1. Neural Networks

AI refers to a system capable of making decisions and performing actions similar to a human, based on large datasets. A field within AI is machine learning (ML). ML deals with algorithms that can learn from datasets. ML automatically learns and improves from experience without being explicitly programmed. A subset of ML is Neural Networks. A neural network is a computer algorithm capable of processing large volumes of data, mimicking the activity of the human brain. A neural network learns new subjects, draws conclusions, and subsequently uses the acquired information to form inferences.

In the electric power industry, neural networks allow for data analysis to accurately predict the reliability of electrical equipment, as well as recognize and classify faults based on their origin. The main causes of faults include: arc formation, corona discharge, mechanical impacts, and tracking (the process of gradual formation of conductive carbon tracks on the surface of external insulation in high-voltage installations due to the combined effect of electrical voltage, humidity, and contaminants). The minimum accuracy of fault recognition in switchgear by a neural network can be 83.33%, and the maximum—100% [83]. In turn, the accuracy of detecting faults in power lines by analyzing images using neural networks can reach 96.5% [84,85].

Based on the continuous collection of data from sensors, the TCI can be automatically determined, the residual service life calculated, and the maintenance schedule for electrical equipment optimized. The accuracy of a model using a neural network can be 99.6% [86].

For classifying the operation of electrical equipment under various operating conditions, a neural network with pattern recognition can be used. Such a neural network is applied to classify input data according to predefined target values. For example, classifying the operating state of a power transformer as normal based on the concentration of combustible gases inside it. The accuracy of the neural network during the training and testing phases can reach 98% [87].

To reduce the costs associated with tuning neural network parameters, an adaptive algorithm for optimizing the structure of a multilayer neural network can be used. The described algorithm automatically determines the optimal number of neurons and layers. This is because too many neurons in the hidden layers can slow down the neural network’s learning process. The best prediction accuracy for faults when assessing the TC of transformers can be 86.6% with two hidden layers containing 5 neurons each [88].

For determining the TC of electrical equipment, an automatic artificial neural network with an expanded hidden layer can be used. This neural network can classify the TC using 18 different parameters obtained from sensors (pressure, temperature, vibration). Based on these values, the neural network determines the condition of the functional components. The average classification accuracy across all functional components for this type of neural network can reach 99% [89].

8.2. Continual Learning Approaches for Intelligent Diagnostics

One of the most promising trends in the development of intelligent diagnostic systems is the application of continual learning (CL). This concept represents a new paradigm in AI, in which models are capable of continuous self-improvement and adaptation to changing operating conditions, aging processes, and new fault types without losing previously acquired knowledge. Unlike traditional retraining-based approaches that require complete model reinitialization when new data becomes available, continual learning ensures stable incremental adaptation of diagnostic algorithms, maintaining both accuracy and memory of previously learned patterns.

In the context of electrical equipment diagnostics, CL enables neural networks to incrementally learn from streaming data collected during long-term operation. Such models can expand their diagnostic capabilities by identifying additional fault categories or new degradation modes as they appear in field data, while avoiding catastrophic forgetting. This is particularly relevant for rotating electrical machines and transformers, where the spectrum of mechanical and electrical faults gradually evolves with equipment wear, changing load cycles, and environmental influences. Continual learning allows diagnostic algorithms to remain up to date throughout the entire life cycle of equipment, providing stable accuracy even under non-stationary conditions [90].

Recent CL-based frameworks introduce adaptive mechanisms for dynamically adjusting network architecture during training. These mechanisms include elastic or expandable neural structures that automatically add or prune branches depending on the complexity of new diagnostic tasks. This flexibility prevents overfitting and reduces computational cost while preserving the knowledge of previously learned fault classes. In addition, multiscale feature extraction and multiobjective optimization are employed to enhance the robustness of representation learning, ensuring that diagnostic features remain discriminative under various working conditions and signal noise levels [91].

Another important advantage of continual learning is its capacity to integrate condition data collected from multiple sensors—vibration, temperature, current harmonics, or PD signals—without requiring model retraining for each new sensor configuration. By continuously updating embeddings and latent representations, the model gradually refines its understanding of normal and faulty behavior. This allows maintenance systems to adapt to both gradual parameter drifts (e.g., insulation aging) and abrupt operational changes (e.g., switching regimes or overloads) in real time.

From a maintenance management perspective, continual learning contributes to forming self-evolving diagnostic systems capable of autonomous improvement as new data arrives. Integrating CL into DT and IoT-based monitoring frameworks enables automated updates of diagnostic models directly within maintenance platforms, reducing the need for manual recalibration. As a result, reliability assessment becomes more dynamic, reflecting the real TC of equipment in continuously changing environments.

Therefore, continual learning constitutes a crucial step toward next-generation maintenance systems that combine adaptability, scalability, and sustainability of diagnostic knowledge. Such systems can automatically expand their fault classification range, account for non-stationary operational regimes, and improve long-term forecasting of degradation trends, ensuring a high level of reliability and economic efficiency of electrical equipment operations.

8.3. Supervisory Control and Data Acquisition

SCADA is a comprehensive software and hardware solution that provides real-time collection of telemetric data from industrial facilities, its processing, visualization, and long-term archiving. In the electric power industry, SCADA is used to collect and analyze data on the current state of the power system and equipment condition. Parameters monitored for electrical equipment operation include voltage, frequency, current, and power.

SCADA systems enable real-time data collection and visualization, providing continuous assessment of the TC of wind turbines. By analyzing SCADA signals related to turbine operation—such as generator temperature rise, nacelle vibration levels, rotor speed fluctuations, or pitch control responses—it becomes possible to identify developing faults and optimize maintenance planning. Real-time monitoring of these parameters allows timely detection of abnormal operating patterns, prevention of unplanned shutdowns, and improvement of overall turbine reliability and performance [92].

SCADA allows for the collection of data with a large number of parameters over extended periods. When analyzing generator set operation, the initial dataset can contain 45 parameters. SCADA can collect data on cylinder, phase, and ambient temperatures; cylinder pressure; and active power magnitude. Data collection can occur at five-minute intervals over 16 months of generator set operation [93].

For continuous monitoring of TC, fault detection, and diagnostics, an integrated online system can be used. This system is based on collecting data from torque and vibration sensors, processing signal data, detecting deviations from normal operation, and assessing TC. The assessment is based on a fault detection index. This index can range from 0 to 100%. Based on this index, histograms are built that display the frequency of specific index values in the data sample. Under normal operating conditions, the fault detection index value should be close to zero or uniformly distributed. The described method allows for distinguishing between normal and abnormal operating modes, various fault types, and assessing the TC of electrical equipment [94].

8.4. Virtual Reality

VR refers to a computer-generated immersive environment that enables users to interact with simulated objects and scenarios through multiple sensory channels. This technology provides a unique opportunity to study equipment behavior, visualize internal processes, and simulate abnormal or emergency conditions without physical intervention or risk to personnel.

Recent studies confirm that the integration of VR into fault diagnosis and maintenance training offers significant performance benefits. For example, a VR-based fault diagnosis system for electrical equipment allows users to interactively simulate electrical circuits, locate faults, and perform maintenance in a virtual environment. Experiments have shown that VR-assisted diagnosis reduces fault detection time to under 30 s, compared to 30–52 s with manual methods, and increases diagnostic accuracy from 75% to over 90%, proving that virtual simulation substantially improves both efficiency and safety [95].

In addition to diagnostic improvement, VR also provides an effective training environment. Immersive simulations allow maintenance personnel to practice identifying complex electrical faults—such as bearing wear, insulation failure, or circuit imbalance—under safe and repeatable conditions. This capability supports accelerated learning and long-term knowledge retention by enabling direct interaction with 3D models of electrical systems. DT–based virtual environments enable engineers to conduct training, monitoring, and fault prediction interactively, transforming operation and maintenance from experience-driven to data-driven paradigms [96].

Furthermore, VR enhances visual data analysis and decision-making by integrating diagnostic signals (e.g., temperature, vibration, current harmonics) into a 3D space. Combining VR with data-driven risk analysis supports intuitive visualization of equipment states and facilitates operator collaboration by mapping complex sensor data into spatially coherent, immersive scenes that improve fault localization and response accuracy [97].

In practical applications, VR can be coupled with DT architectures to form hybrid systems where virtual replicas of real equipment are continuously updated with live sensor data. This approach enables real-time fault prediction, visualization of equipment degradation, and virtual rehearsal of corrective actions before physical intervention [96]. In the electric power industry, VR has already been applied to assess the TC of functional components of electrical equipment. The software complex developed in [98] enables real-time study of asynchronous motor operation, fault simulation, and CSA, allowing users to detect typical mechanical and electrical failures such as rotor breakage, imbalance, or misalignment.

Thus, VR is not merely a visualization tool but an integral component of intelligent diagnostic and training ecosystems. By merging immersive simulation, human–machine interaction, and data-driven analysis, VR improves diagnostic precision, reduces human error, and enhances operational safety. Its integration with DT and risk analytics represents a promising direction for next-generation CBM systems.

8.5. Internet of Things

The IoT is a network of interconnected devices that exchange data and commands without the need for human intervention. The main goal of IoT is to increase device efficiency, expand their functionality, and simplify automation processes.

A DT is an IoT technology representing a virtual copy of a real object. The purpose of using a DT is to analyze, monitor, and optimize the operation of the real object.

To assess the TC of an electric motor without affecting the operation of an asynchronous motor, the authors in [99] propose using a DT and the industrial internet of things (IIoT). For this, a motor monitoring and analysis system was created, which tracks current and temperature from the motor housing using sensors and a data acquisition module. The proposed approach provides high accuracy in measuring phase current and motor temperature—the relative error between commercial sensors and the proposed system is less than 10%. Thus, the system serves as a tool that can contribute to predicting the condition of asynchronous motors, as it provides stable results in steady-state operation.

For monitoring the TC of a transformer, an intelligent monitoring system was used in [100]. The system includes creating a DT of the transformer to detect abnormal operating conditions. IoT is used to collect real-time data on the transformer, namely temperature, oil quality, and power factor. Based on the collected data, the equipment’s TCI is quantitatively determined.

For automated real-time diagnostics of the TC of distribution transformers, the principal component analysis (PCA) method and the k-nearest neighbors (k-NN) method are used. To assess the TCI, 11 parameters measured in real-time are collected: voltages, currents, power factor, total harmonic distortion, and temperature. The PCA method allows transforming the 11 parameters into 2, preserving, on average, more than 86% of the available information. The k-NN method allows placing the transformer on an operational map that characterizes the TCI. This map is updated in real-time and allows determining how close the equipment’s TC is to a critical value [101].