1. Introduction

The escalating global energy demand and the environmental impact of fossil fuel consumption have intensified the transition toward clean and renewable energy sources [

1,

2]. Among them, solar energy has emerged as a promising alternative due to its abundance, sustainability, and potential to significantly reduce carbon emissions. In this context, solar thermal technologies have attracted growing attention for their ability to efficiently convert solar radiation into useful thermal energy. Among the various solar technologies, parabolic trough collectors (PTCs) represent the most mature and widely deployed system for concentrated solar power generation [

3]. Their ability to effectively convert solar radiation into thermal energy makes them a key component in sustainable energy production and industrial heat applications [

4]. To enhance the thermal performance of PTC systems, researchers have proposed various enhancement strategies over the past decades [

5,

6,

7]. These approaches are generally classified into three categories: active, passive, and compound methods. Passive techniques, such as the use of fins, twisted tapes, and dimple turbulators [

8,

9,

10,

11,

12], are often preferred due to their simplicity and reliability, although they can induce a higher pressure drop that limits their efficiency.

Recent studies have examined the impact of these modifications on the absorber tube of PTCs. For instance, Shaker et al. [

13] conducted CFD simulations on a parabolic trough absorber tube equipped with helical twisted-tape inserts, reporting a 60% increase in the Nusselt number compared to a smooth tube, while the friction factor rose by about 40%. Similarly, Ahmed et al. [

14] numerically investigated toroidal ring-type turbulators and found that the periodic rings significantly enhanced local mixing, leading to improved convective heat transfer and better thermal uniformity along the absorber tube. Vicente et al. [

15] experimentally investigated the thermo-hydraulic behavior of helically dimpled tubes using water and ethylene glycol as working fluids for Reynolds numbers between 2000 and 100,000. Their results showed that dimples enhanced heat transfer by 150–350% while the friction factor increased by up to 250% compared with smooth tubes. The study concluded that deeper dimples and optimized pitch-to-diameter ratios yield superior thermal performance at the cost of higher pumping power. Kaood et al. [

16] numerically analyzed the entropy generation in turbulent flow through conical tubes with dimples using the realizable

k–

ε model within ANSYS Fluent. The study covered Reynolds numbers from 3 × 10

3 to 4 × 10

4 and revealed that convergent dimpled tubes with diameter ratios between 1.5 and 3 achieved the best thermal performance. The results showed up to 50.5% and 3.6% reductions in the normalized entropy generation number compared with smooth configurations, confirming that optimized dimple geometry enhances both heat transfer and thermodynamic efficiency. Khetib et al. [

17] numerically examined the effect of spherical grooves on the thermal–hydraulic and exergy performance of a parabolic trough solar collector using a hybrid MWCNT–Al

2O

3/water nanofluid. Simulations were performed for groove heights of 1.5–3.5 mm, Reynolds numbers between 5000 and 20,000, and nanoparticle volume fractions up to 3%. The optimal case at

Re = 20,000 and φ = 3% achieved up to 88.42% improvement in heat transfer and 149.01% enhancement in exergy efficiency compared with the smooth configuration, confirming the strong potential of grooved surfaces for hybrid nanofluid-based PTCs. Mwesigye et al. [

18] developed a multi-objective and thermodynamic optimization of a parabolic trough receiver equipped with perforated plate inserts, combining CFD, RSM, and the NSGA-II algorithm. The study optimized the plate orientation angle, spacing, and diameter across Re = 1.02 × 10

4–1.36 × 10

6 to minimize entropy generation while enhancing heat transfer. Results indicated an entropy reduction of 53% and a notable improvement in heat transfer performance, confirming that perforated plates can effectively balance thermal efficiency and fluid dynamic losses in PTC receivers. Esmaeili et al. [

19] conducted a numerical investigation on a modified parabolic trough collector equipped with conical turbulators and hybrid nanofluids to assess their combined influence on heat transfer and entropy generation. The results demonstrated that the insertion of the conical turbulators enhanced the heat transfer coefficient by nearly 57%, while the total entropy generation decreased by approximately 33%. The authors emphasized that this hybrid enhancement technique significantly improved the thermodynamic performance of the PTC system under turbulent flow conditions. Song et al. [

20] conducted a numerical investigation on photovoltaic thermal solar air heaters equipped with rectangular hole plates and baffles. Their results showed that the optimized configuration (Type III) achieved a reduction in pressure losses by 7.8–20.3% compared with the baseline design, while the thermal efficiency increased by 12.9–20% and the exergy efficiency improved by 5.6–8.9%. These findings confirm that geometric modifications of internal structures can markedly enhance the thermohydraulic performance of solar thermal systems. Bellos et al. [

21] investigated the thermal enhancement of parabolic trough collectors (PTCs) by combining nanofluids with a converging–diverging absorber tube. Their results revealed that the use of Al

2O

3 nanoparticles dispersed in thermal oil improved the mean collector efficiency by 4.25%, while the application of a wavy (converging–diverging) absorber geometry increased it by 4.55% compared with the conventional smooth tube. Mahmoudi et al. [

22] numerically analyzed the thermo-hydraulic performance of nanofluid-based linear solar receiver tubes equipped with forward perforated ring steps with a triangular cross-section. Their results indicated that the use of CuO–water nanofluid achieved the highest performance, with the thermal efficiency reaching 76.5% at a Reynolds number of 200,000 when the ring step diameter equaled the tube diameter (

D =

d). Increasing the nanoparticle concentration from 1% to 4% enhanced the thermal efficiency by approximately 3%, while reducing the step spacing significantly increased both the Nusselt number and friction factor. Otmani et al. [

23] experimentally analyzed the optical and thermal behavior of a parabolic trough collector prototype tested under North African climatic conditions. Five receiver configurations were compared, revealing that the three-tube receiver with a central black-coated tube achieved the highest thermal efficiency of about 85%, owing to improved solar ray focusing and uniform temperature distribution. The study highlighted the importance of receiver design in enhancing optical capture and overall PTC performance.

According to the aforementioned investigations, enhancing the thermal and hydraulic performance of parabolic trough collectors (PTCs) remains a crucial challenge for improving their overall energy efficiency and economic feasibility. However, to the authors’ knowledge, there is a lack of numerical studies addressing the effect of periodically segmented ring-type inserts within the absorber tube. Therefore, the present study introduces a novel geometric concept termed the Angularly-Segmented Ring Turbulator (ASRT) to intensify convective heat transfer while maintaining acceptable pressure losses. The main objective of this work is to examine the influence of the ASRT configuration on the hydrothermal performance of a PTC absorber under turbulent flow conditions with Reynolds numbers of 3300, 5500, 7500, and 11,000. The analysis considers a non-uniform heat flux distribution applied along the absorber wall to replicate realistic solar concentration effects. In this study, the hydrothermal characteristics are evaluated in terms of velocity and temperature contours, Nusselt number, friction factor, and overall thermal enhancement.

3. Solution Method

This study is performed using a Computational Fluid Dynamics (CFD) approach implemented in ANSYS Fluent 19.2. The software solves the governing equations based on the finite volume method (FVM) to simulate the fluid flow and heat transfer characteristics within the absorber tube. The governing equations are solved under steady-state conditions and can be expressed as follows [

24]:

Momentum conservation equation:

Energy conservation equation:

where

ρ is the fluid density,

u is the fluid velocity,

p is the static pressure,

µ is the dynamic viscosity,

Cp is the specific heat capacity,

k is the thermal conductivity, and

T is the temperature. RNG turbulence model is adopted for all cases. The RNG transport equation for kinetic energy

K and ε turbulence dissipation [

25]:

where

µeff represents the effective viscosity. The terms

Gk and

Gb represents the production of turbulent kinetic energy resulting from the mean velocity gradients and buoyancy effects, respectively. The parameter

Ym accounts for the effects of the fluctuating dilatation in compressible turbulence on the overall dissipation rate. The coefficients

αk and

αε correspond to the inverse effective Prandtl numbers for

k and

ε, respectively.

Sk and

Sε are user-defined source terms included in the model formulation.

And

where η represents the dimensionless strain parameter and

S denotes the mean rate strain magnitude. The constants used in the turbulence model are given as below:

The Semi-Implicit Method for Pressure-Linked Equations (SIMPLE) algorithm was employed to establish the coupling between pressure and velocity fields, thereby ensuring mass and momentum conservation throughout the computational domain [

26,

27]. The Quadratic Upstream Interpolation for Convective Kinematics (QUICK) scheme was adopted for the discretization of convection terms, while a second-order central difference was used for the diffusion terms to maintain both accuracy and numerical stability. The convergence criteria for the continuity, momentum, energy and turbulence (

k and

ε) equations were set to 1 × 10

−6, ensuring reliable and stable solutions for all simulated cases.

3.1. Boundary Conditions

The numerical simulation was configured by applying a non-uniform wall heat flux on the outer surface of the absorber tube. This heat flux was implemented through a User Defined Function (UDF) generated from the Monte Carlo Ray Tracing (MCRT) analysis. The MCRT computation accounted for the optical behavior of the collector system, including mirror reflectivity, glass transmissivity, and absorber absorptivity, to determine the realistic circumferential distribution of absorbed solar energy [

19,

28]. The resulting flux profile was imposed as a boundary condition in ANSYS Fluent to accurately reproduce the solar irradiation pattern experienced by the outer absorber wall.

In the present model, both the solid wall and the fluid domains were explicitly solved using a Conjugate Heat Transfer (CHT) approach. The non-uniform solar heat flux derived from the MCRT analysis was applied to the outer surface of the absorber wall, while heat conduction through the solid wall and convective heat transfer within the fluid were simultaneously computed to capture the temperature coupling at the wall–fluid interface.

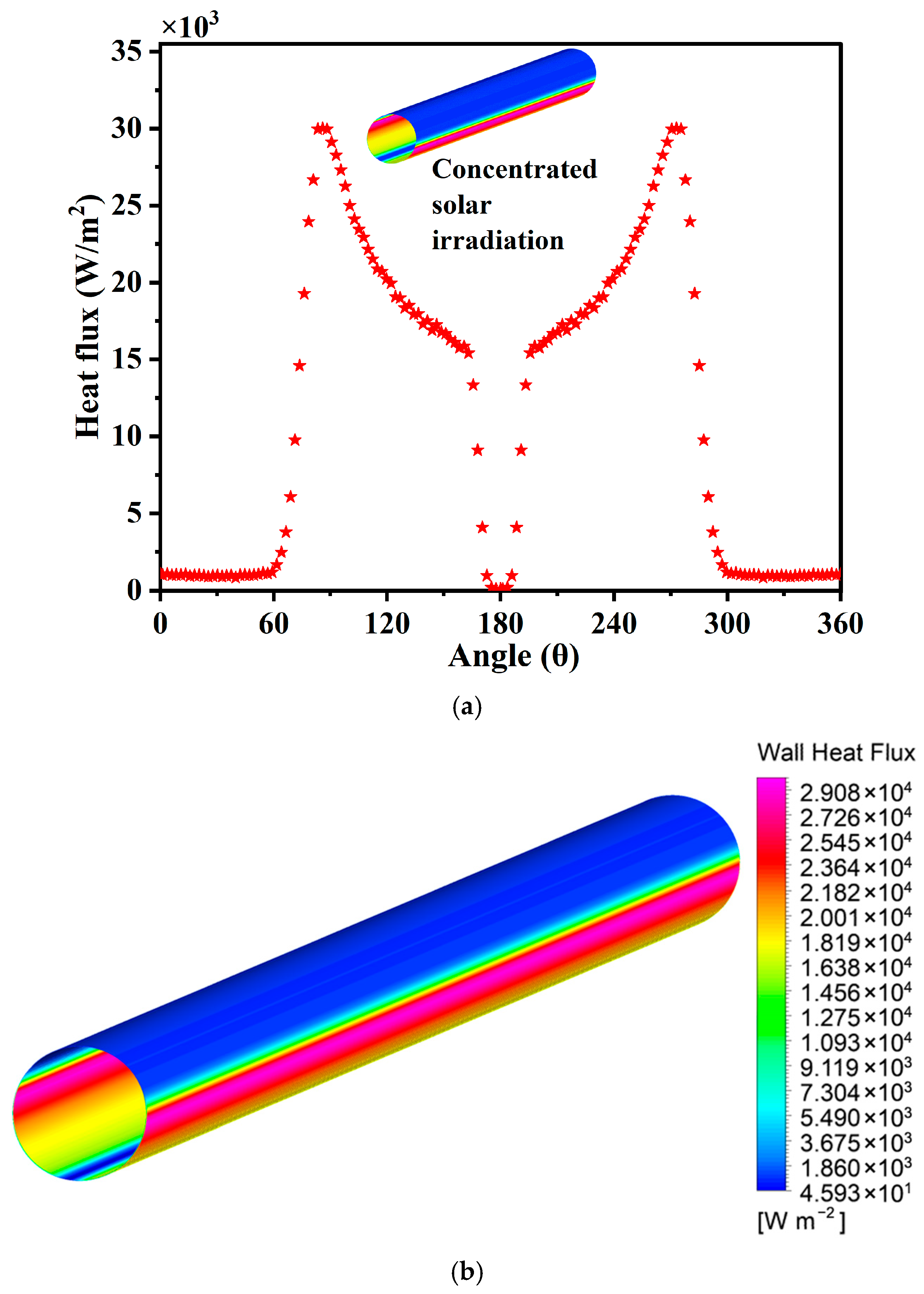

The circumferential heat-flux distribution applied to the absorber wall is illustrated in

Figure 3, showing both the angular variation of absorbed solar flux (

Figure 3a) and the corresponding three-dimensional wall heat flux distribution (

Figure 3b). The MCRT model reveals a highly non-uniform profile, with the maximum heat flux reaching approximately 3 × 10

4 W/m

2 in the illuminated zone (

θ = 80–110°). The flux intensity progressively decreases toward the shaded region near

θ = 180°, where the value drops below 5 × 10

3 W/m

2. This spatially varying heat-flux pattern clearly illustrates the circumferential thermal gradient induced by optical concentration, which governs the non-uniform heating behavior of the absorber surface. The non-uniform solar heat-flux profile obtained from the MCRT computation is consistent with the general distribution trends reported in the literature for parabolic trough receivers. As observed by Esmaeili et al. [

19] and Al-aloosi et al. [

28], the flux exhibits a pronounced asymmetry, with the highest intensity concentrated on the upper illuminated region of the absorber and a gradual decrease toward the lower shaded side. This behavior reflects the intrinsic optical characteristics of parabolic trough concentrators and ensures the physical relevance of the imposed boundary condition.

At the inlet, water was introduced as the working fluid with uniform velocity values of 0.15, 0.25, 0.35 and 0.5 m/s corresponding respectively to Reynolds numbers of 3300, 5500, 7500, and 11,000. The inlet temperature was fixed at 300 K. At the outlet, a pressure outlet boundary condition with a fixed static pressure of 0 Pa gauche.

3.2. Parameter Definitions

This section presents the fundamental parameters and dimensionless quantities used to characterize the thermohydraulic performance of the present study.

The Reynolds number of fluid flow is defined as:

To calculate the Nusselt number

The friction factor is calculated as [

29]:

where Δ

P refers to the pressure drop along the tube.

It is worth highlighting that, for all absorber configurations equipped with toroidal rings, the overall thermohydraulic performance was assessed through the Performance Evaluation Criterion (

PEC) [

14]. This dimensionless parameter provides an integrated measure of heat transfer improvement while accounting for the associated hydraulic penalty, under identical pumping power conditions. A higher

PEC value indicates that the modified configuration offers a more favorable balance between thermal enhancement and frictional losses compared to the smooth reference tube. The

PEC at constant pumping power is expressed as [

30,

31]:

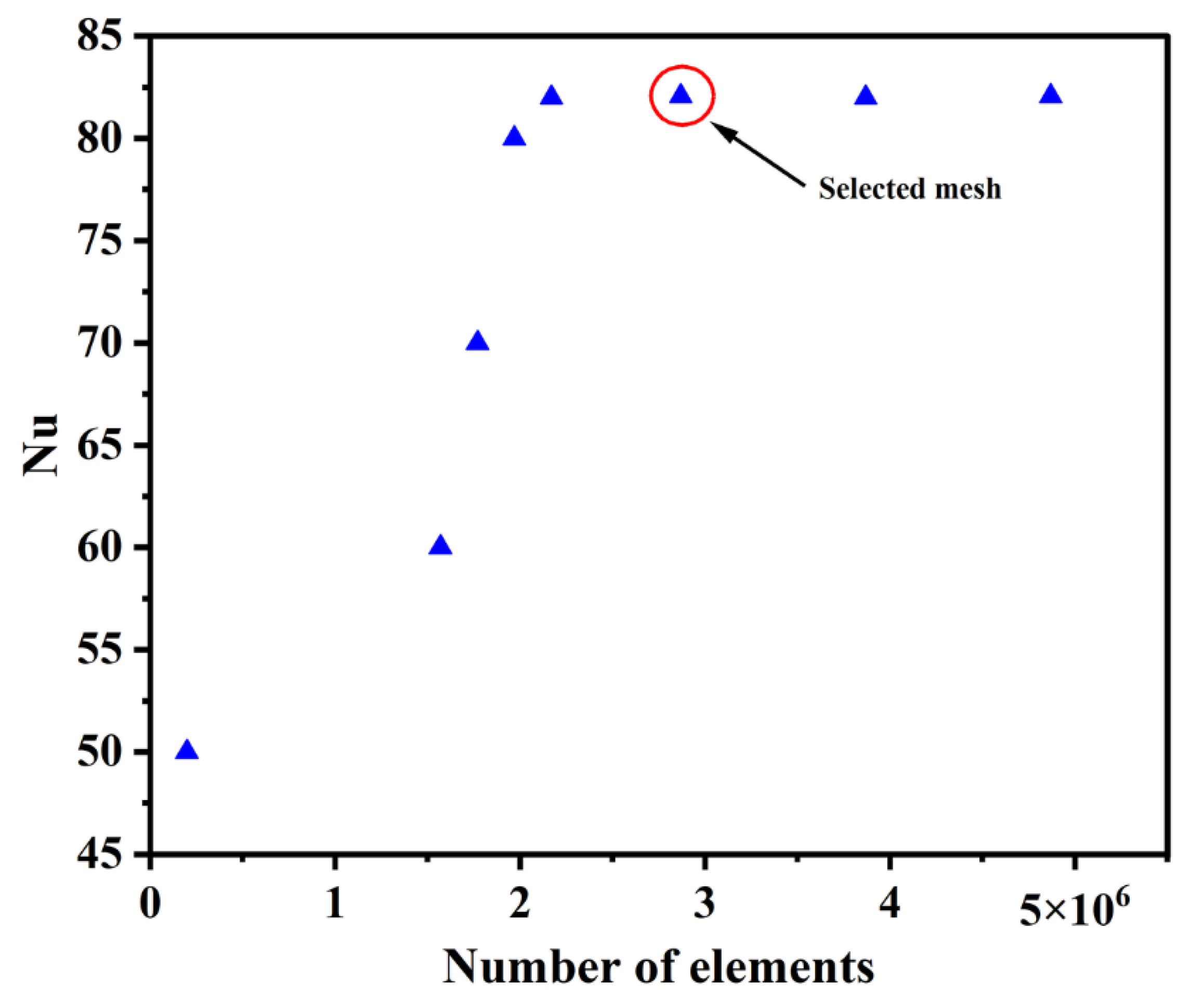

3.3. Grid Independence Study

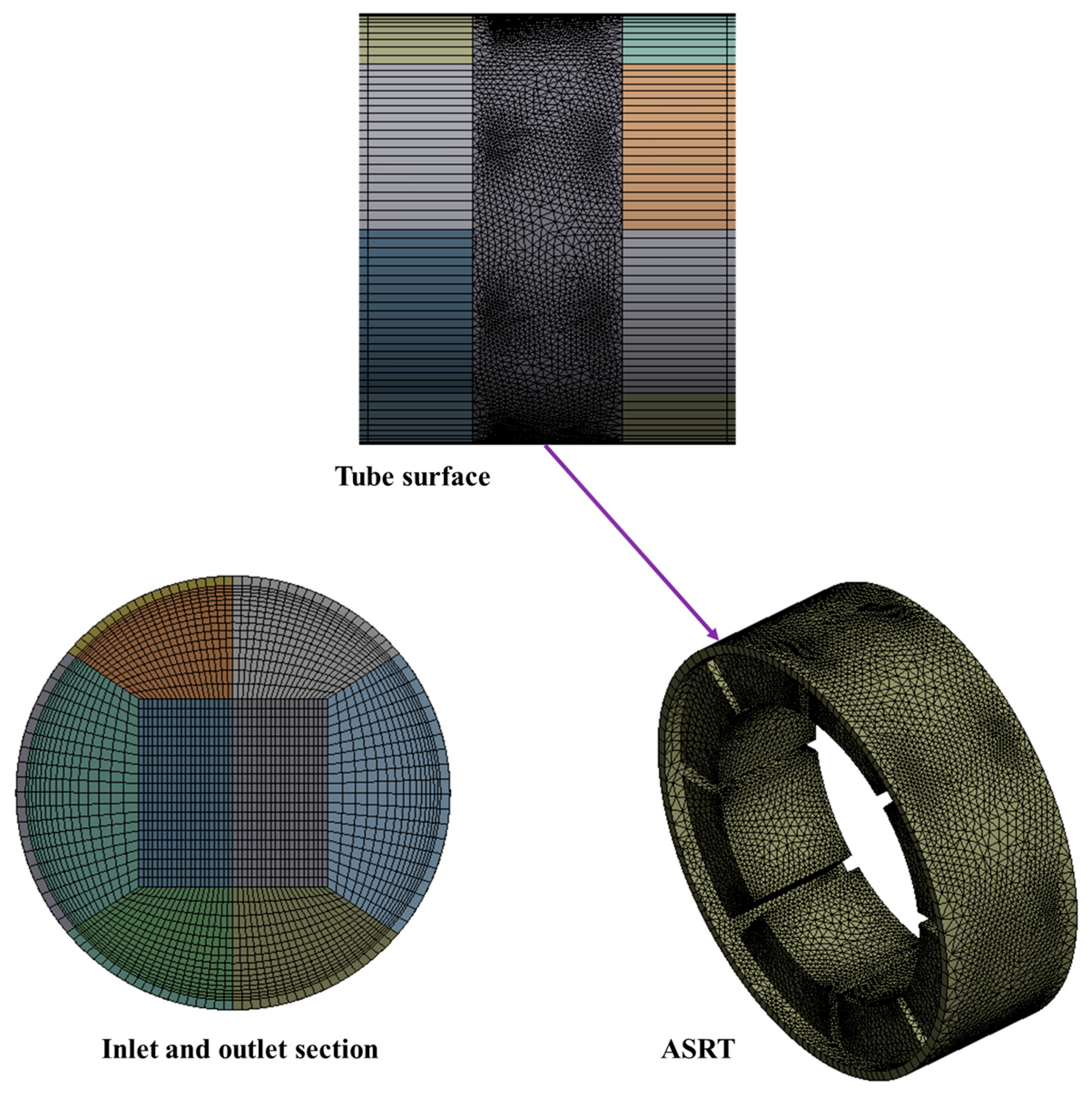

The computational domain was discretized using ANSYS Meshing 2019, with a refined mesh near the absorber wall and the segmented annular rings to accurately capture strong gradients in temperature and velocity, while coarser elements were applied in the core flow region to reduce computational time (

Figure 4). To verify grid independence, several mesh densities were tested, ranging from 5 × 10

5 to 5 × 10

6 elements. As shown in

Figure 5, the Nusselt number (

Nu) increases significantly with mesh refinement up to around 2.8 × 10

6 elements, after which the variation becomes negligible. This indicates that the numerical solution is independent of further grid refinement. Therefore, the mesh containing approximately 2.0 × 10

6 elements was selected for all subsequent simulations, providing a suitable compromise between accuracy and computational cost.

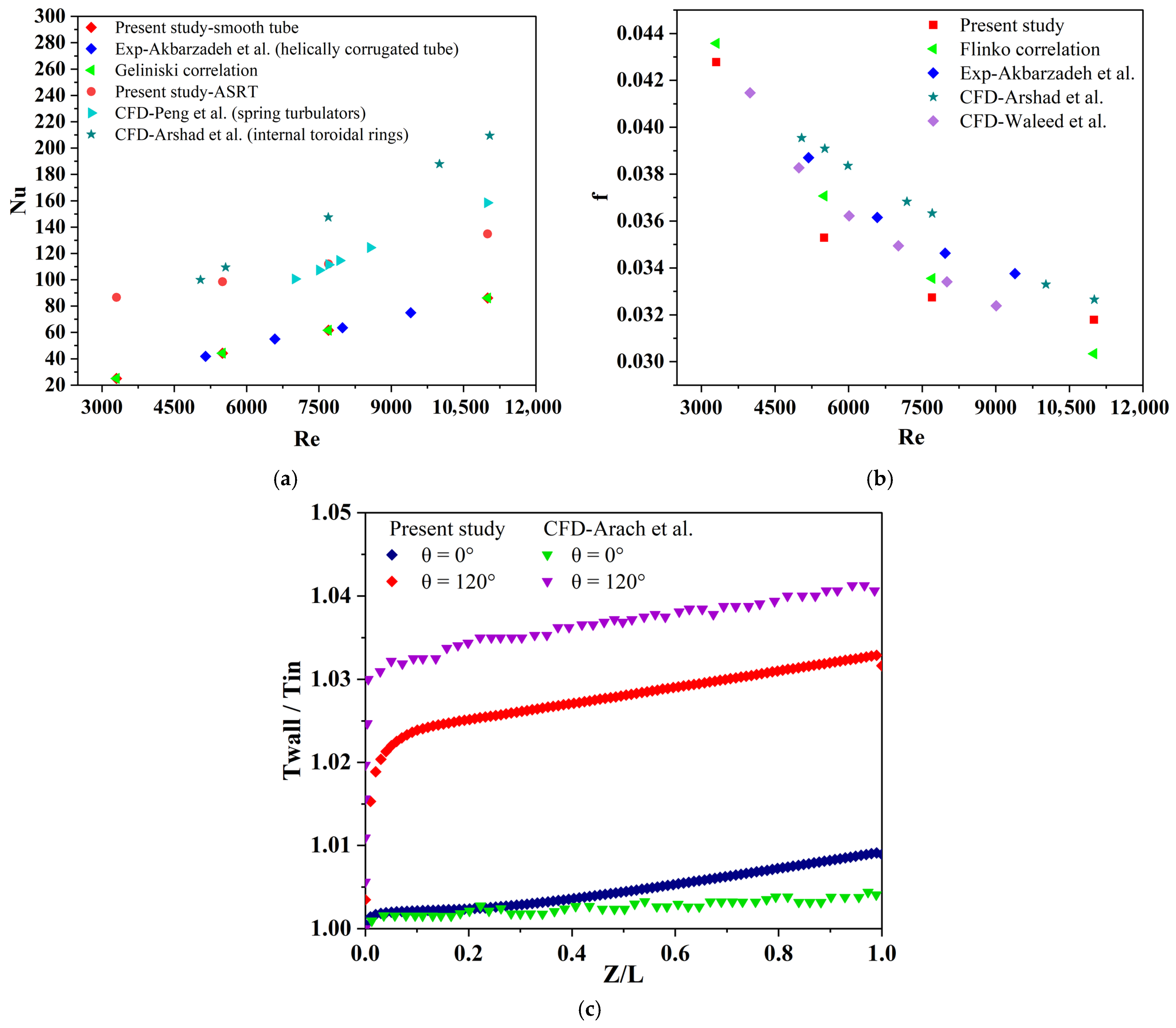

3.4. Model Validation

To ensure the reliability of the numerical model, the predicted results were compared with well-established empirical correlations for turbulent flow in smooth circular tubes. The average convective heat transfer was validated using the Gnielinski correlation for the Nusselt number, while the pressure loss was compared with the Filonenko correlation for the friction factor.

where the friction factor

f′ is given by

The Filonenko relation for the friction factor is given by

The reliability of the numerical model was assessed by comparing the predicted results with the Gnielinski and Filonenko correlations, which are commonly applied to fully developed turbulent flow in smooth circular tubes. This reference case was used to evaluate the overall consistency of the thermal–hydraulic predictions of the present model.

To ensure the model’s applicability under non-uniform wall heat-flux conditions, additional comparisons were performed using available experimental and numerical results from [

14,

28,

32,

33] involving tubes equipped with various internal inserts such as helically corrugated surfaces, spring turbulators, and toroidal rings. These studies demonstrate similar thermofluidic behaviors under circumferentially varying heat flux, supporting the consistency and reliability of the present CFD model. As illustrated in

Figure 6a, the Nusselt numbers predicted for the smooth tube agree well with the Gnielinski correlation, whereas the ASRT configuration exhibits a noticeable increase in convective heat-transfer performance.

Figure 6b shows that the predicted friction-factor values are consistent with both the Filonenko relation and published data, with deviations remaining below 6%, confirming the numerical stability and accuracy of the adopted mesh.

The wall temperature ratio

presented in

Figure 6c exhibits the same trend as the results of Arach et al. [

10] for

θ = 0° and

θ = 120°. Slight differences are attributed to geometric variations between the models, but the overall temperature evolution remains consistent under similar flow conditions. The results demonstrate that the developed CFD model accurately captures both the thermal and hydrodynamic characteristics under non-uniform wall heating, ensuring its reliability for the subsequent analysis of the ASRT absorber.

4. Results and Discussion

In this section, the numerical findings derived from the CFD simulations are analyzed and discussed. The analysis investigates how variations in the Nr and the α influence the thermo-hydraulic behavior of the absorber tube equipped with the ASRT. The discussion encompasses the evolution of the internal flow field, turbulence intensity, and temperature distribution, followed by the assessment of key performance indicators, including the Nu, f, and PEC.

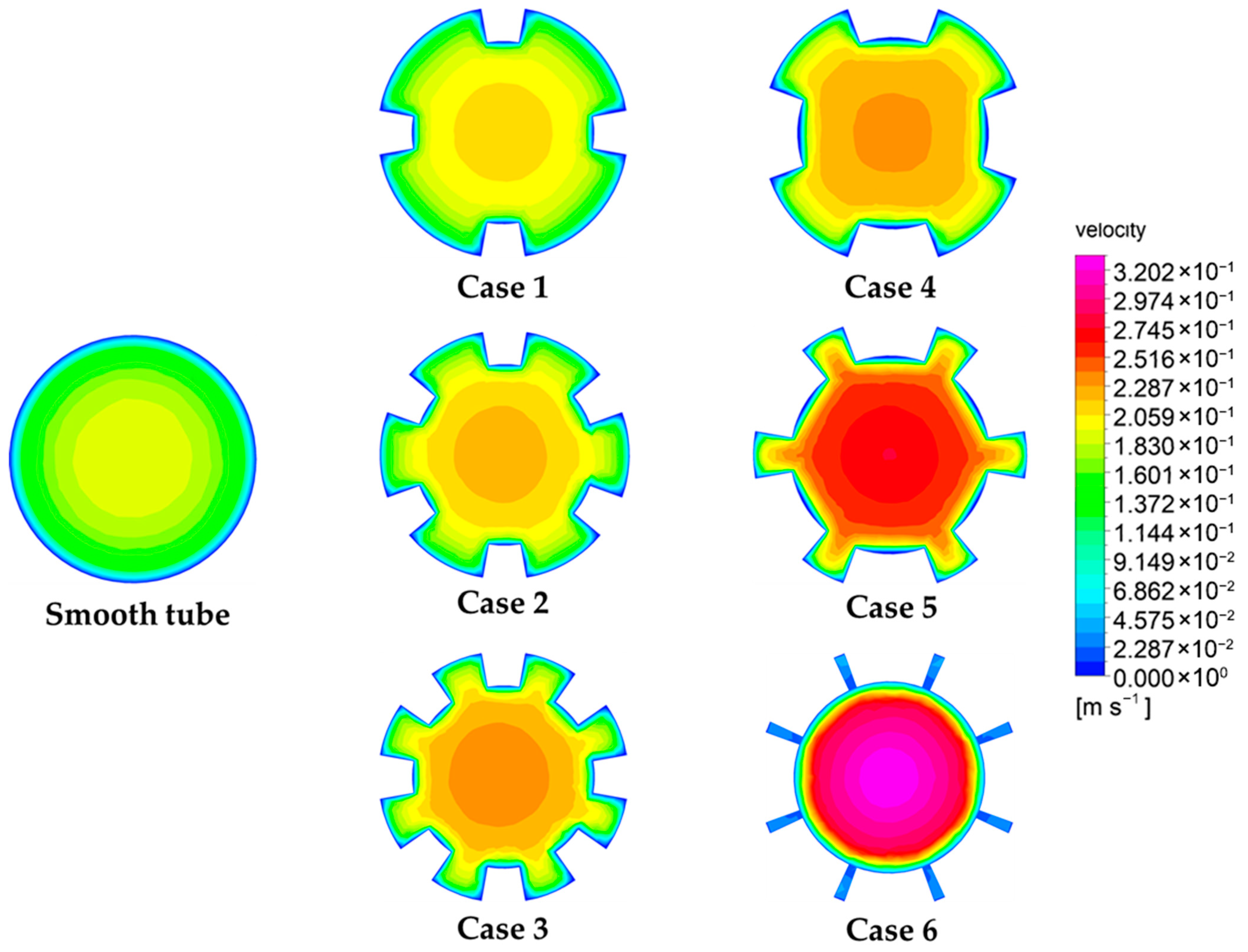

Figure 7 illustrates the velocity contours at the mid-section (700 mm) for the smooth tube and the ASRT configurations (Cases 1–6). The numerical analysis was conducted at a Re of 3300, corresponding to an inlet velocity of 0.15 m/s. In the smooth tube, the flow exhibits a classical parabolic velocity distribution, where the maximum velocity reaches approximately 0.26 m/s in the core region and progressively decreases toward the wall because of viscous effects. This uniform and symmetric pattern reflects a fully developed laminar to turbulent transition typical of low-Reynolds internal flows. When the ASRT inserts are introduced, the internal flow field becomes noticeably more complex. The segmented annular rings interrupt the boundary layer symmetry and generate localized recirculation zones downstream of each segment, enhancing axial momentum redistribution and promoting convective mixing. A comparison between Case 1 and Case 2, which isolates the effect of the Nr, shows that adding additional segments increases the number of small secondary vortices, yet their influence on the overall flow structure remains moderate. In contrast, comparing Case 1 and Case 4, which examines the influence of the α, reveals a substantial modification of the velocity field. Enlarging α widens the high velocity core region and intensifies the acceleration of fluid between adjacent ring gaps, leading to stronger shear layers and improved near-wall mixing. These results confirm that the combined increase in α promotes a more vigorous axial transport and better mixing between the core and near-wall regions, leading to a more uniform velocity distribution along the tube [

34].

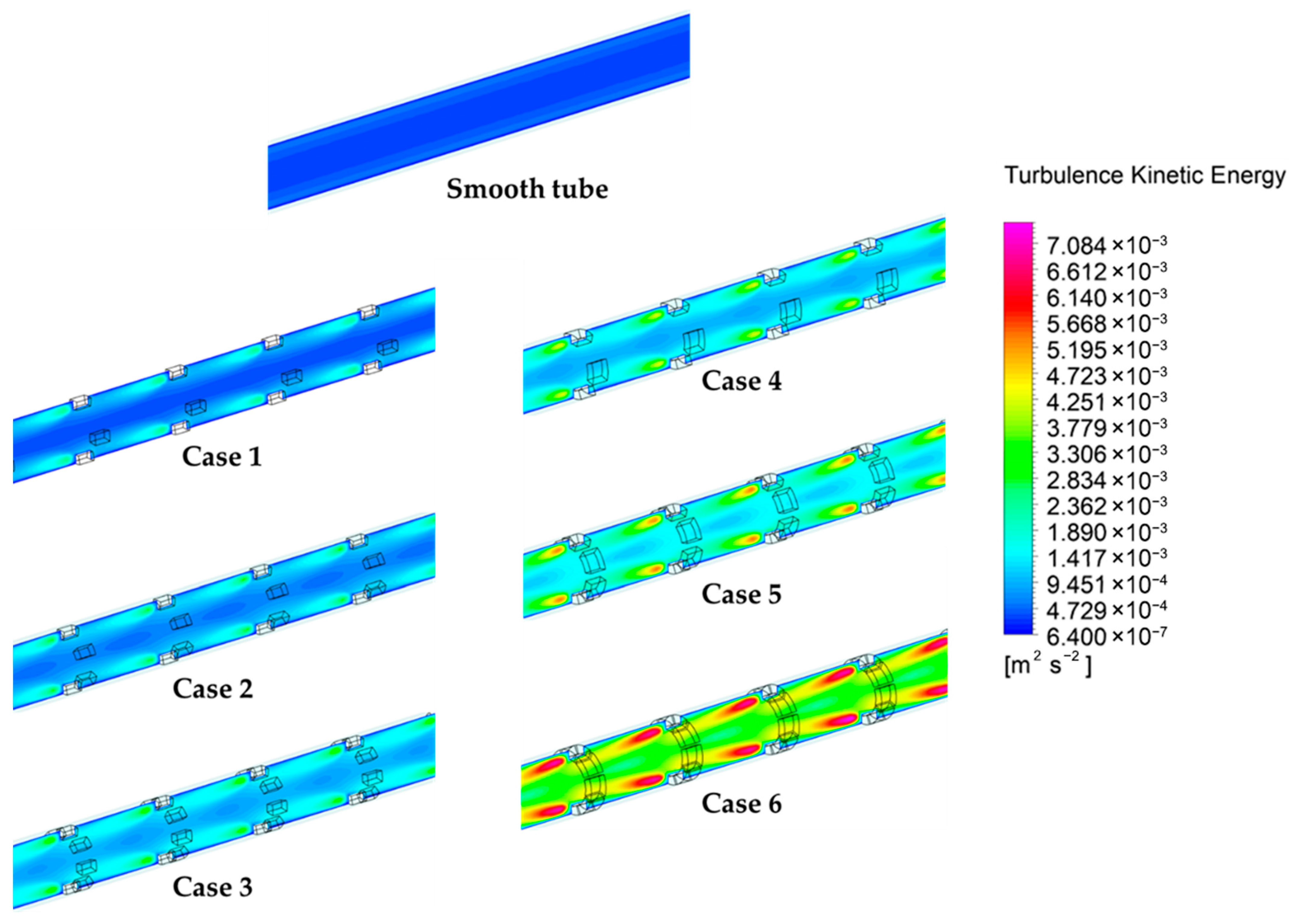

Figure 8 presents the turbulent kinetic energy (

TKE) contours along the absorber tube for the smooth configuration and the six ASRT geometries (Cases 1–6). For the smooth tube, the turbulence intensity remains very low (around 6.4 × 10

−7–9.4 × 10

−4 m

2/s

2) and nearly uniform throughout the core, reflecting a laminar-like velocity field with negligible fluctuations. In Case 1, the introduction of four angularly segmented rings slightly enhances local turbulence downstream of each segment, forming small recirculating zones with limited interaction. As the number of rings increases (Cases 2 and 3), the

TKE peaks rise to the order of 2.3 × 10

−3–3.8 × 10

−3 m

2/s

2, indicating the generation of stronger shear layers and enhanced energy dissipation near the ring edges. The influence of angular spacing becomes more evident in Cases 4 to 6, where larger angular offsets between successive rings promote a stronger periodic disturbance along the tube. In particular, Case 6 exhibits the most pronounced turbulent activity, with

TKE values reaching approximately 7.0 × 10

−3 m

2/s

2. This is attributed to the combined effects of increased angular spacing and multiple interacting vortices that intensify mixing and momentum exchange between the core and near-wall regions [

35]. Overall, the ASRT configurations demonstrate a progressive amplification of turbulent energy with both the number of rings and angular spacing, confirming the geometry’s effectiveness in enhancing internal flow agitation and, consequently, convective heat transfer.

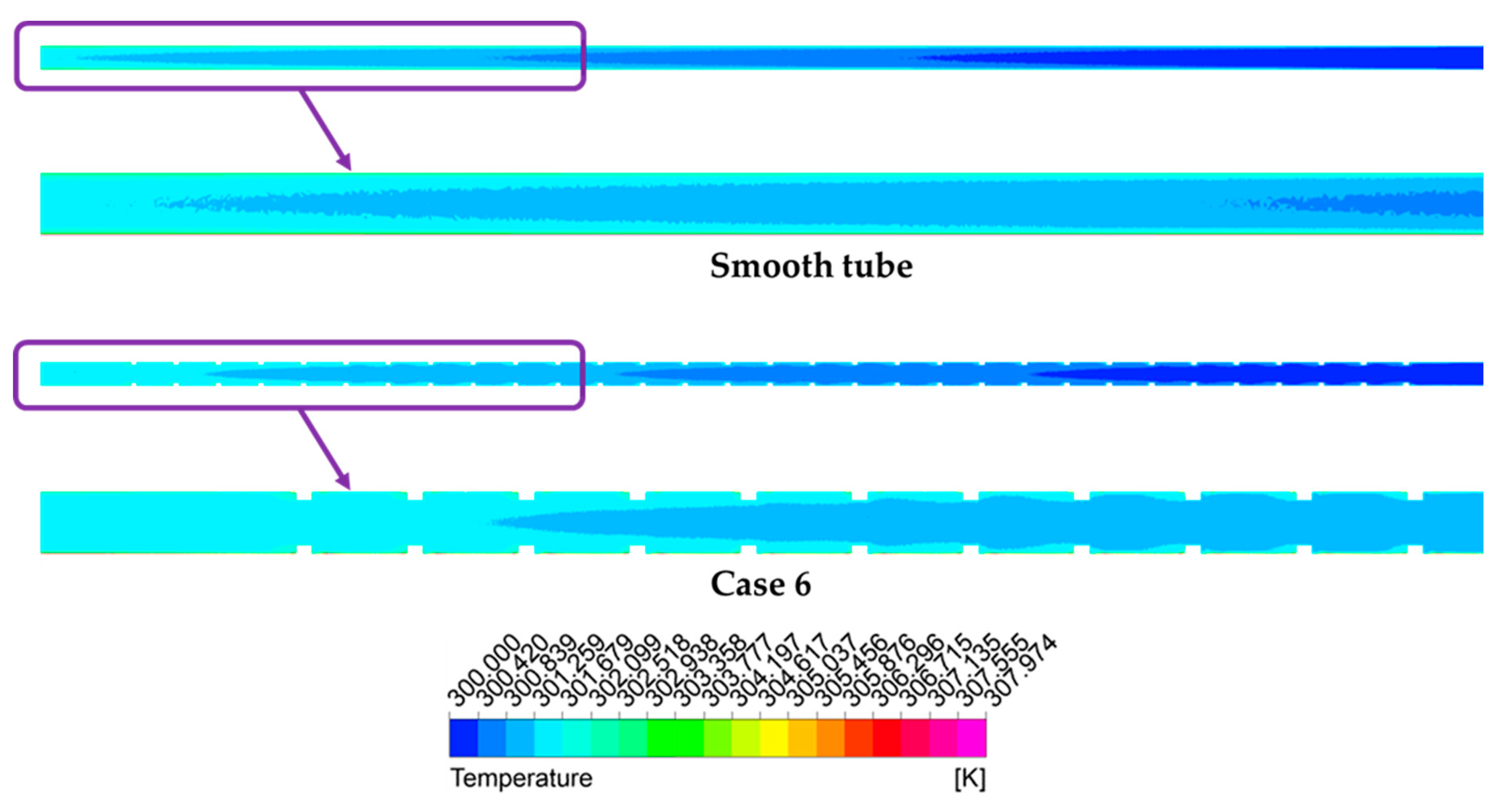

Figure 9 depicts the temperature contours of the working fluid along the entire absorber tube for both the smooth configuration and the ASRT geometry (Case 6). The temperature scale ranges from 300 K to 307.9 K, illustrating the gradual thermal evolution of the fluid from the inlet to the outlet due to continuous heat absorption through the heated wall. In the smooth tube, the temperature field remains nearly uniform along the axis, with a limited rise of approximately 6–7 K, indicating weak convective mixing and a thick, undeveloped thermal boundary layer. In contrast, the ASRT configuration exhibits a more distinct temperature gradient, with higher wall temperatures and localized hot streaks forming behind each ring segment. These alternating hot and cold regions reveal the influence of flow separation and recirculation zones generated by the angularly segmented rings. The stronger near-wall convection and intensified axial mixing result in an overall temperature increase of nearly 8 K along the tube length, confirming the enhanced convective heat exchange. The zoomed view near the outlet clearly highlights this effect: the smooth tube preserves a relatively laminar thermal pattern, whereas the ASRT case shows periodic fluctuations in the temperature field due to the interaction between successive vortical structures. This periodic alternation of warm and cool streaks demonstrates the direct coupling between turbulence generation and heat transfer enhancement within the absorber.

To facilitate comparison, the numerical results are expressed in dimensionless form using the normalized Nusselt number and the friction factor with respect to the smooth reference tube. The following discussion analyzes the influence of the geometric parameters, the Nr and the α, on flow resistance, heat transfer characteristics, and the PEC.

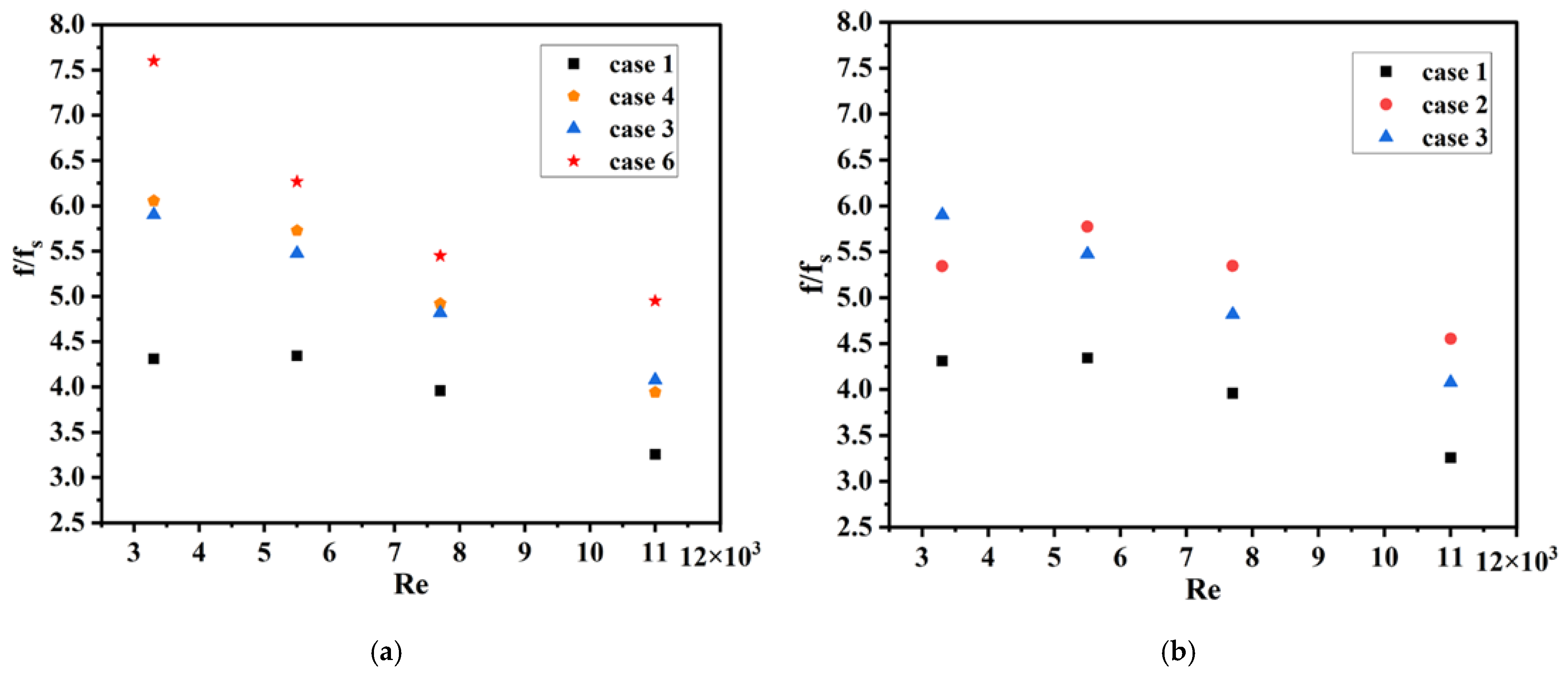

Figure 10 illustrates the variation of the

with Re for the different ASRT configurations. In all cases, the friction ratio decreases steadily with increasing

Re, which is consistent with the attenuation of viscous effects and the progressive stabilization of the turbulent boundary layer at higher flow rates. In the first group of cases (

Figure 10b), where the α is kept constant at α = 10° and the

Nr varies from 4 to 8,

drops from approximately 6.0 → 4.0 for Case 3 and from 5.2 → 3.9 for Case 2 as Re increases from 3300 to 11,000. The increase in

Nr enhances flow disturbance and generates additional wall shear, leading to a rise in

between Case 1 (smooth) and Case 3 (8 rings). The second group (

Figure 10a) highlights the influence of α while maintaining the same number of segments. When α increases from 10° to 20°, the friction factor rises noticeably due to stronger flow acceleration near the ring openings. At Re = 3300,

reaches 7.5 for Case 6 (

α = 20°,

Nr = 8) compared to 5.8 for Case 3 (

α = 10°,

Nr = 10). A similar trend is observed for smaller Nr, where

increases from 5.9 (Case 4) to 7.4 (Case 6) at low

Re.

Figure 11 displays the evolution of the

as a function of the Re for all ASRT configurations. As expected, the heat transfer ratio tends to decline gradually with increasing Re, since the contribution of the geometric disturbances becomes less dominant once inertial transport strengthens. At lower Reynolds numbers, the flow is more responsive to the presence of the segmented rings, leading to a pronounced rise in the local turbulence intensity and stronger convective exchange between the wall and the core flow.

In the configurations with a fixed inclination of

α = 10° (

Figure 11b), increasing the number of rings from 4 to 8 results in a modest improvement of the heat transfer performance. At

Re = 3300, the ratio

rises from 2.9 (Case 1) to 3.1 (Case 3). This trend suggests that beyond a certain number of rings, the additional disturbances overlap, creating periodic recirculation with limited incremental benefit. In contrast, when the inclination angle is doubled from 10° to 20° (

Figure 11a), the enhancement becomes much more evident. The Nusselt ratio rises from approximately 3.1 (Case 3) to 3.6–3.7 (Case 6) at

Re = 3300. The sharper inclination promotes fluid redirection toward the wall regions, strengthens the impingement effect behind the rings, and enhances the mixing intensity of the secondary vortices.

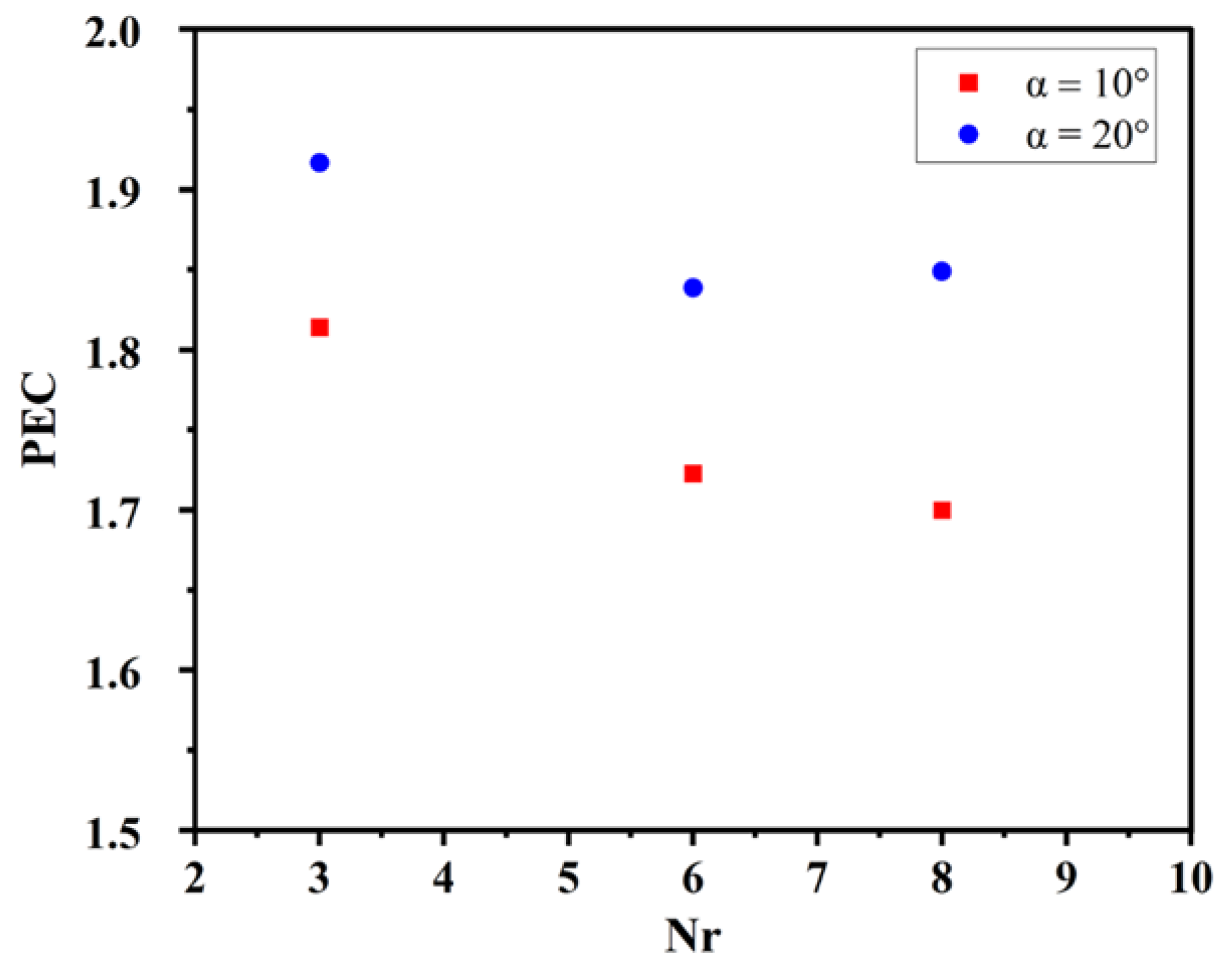

Figure 12 presents the variation of the

PEC as a function of the

Nr for two angles (

α = 10° and 20°). The

PEC reflects the combined effect of convective enhancement and frictional losses, providing a global indicator of thermal–hydraulic efficiency. As shown, all configurations equipped with ASRTs yield

PEC values higher than unity, confirming that the heat transfer improvement outweighs the associated pressure-drop penalty. For

α = 10°,

PEC decreases slightly with increasing

Nr, from about 1.82 for

Nr = 4 to 1.70 for

Nr = 8, indicating that adding more rings increases flow resistance more than it enhances turbulence. This suggests a threshold beyond which further segmentation provides diminishing returns in overall performance. Conversely, at

α = 20°, PEC values remain consistently higher around 1.9–1.85 and show less sensitivity to

Nr. The stronger α promotes vigorous secondary motion and efficient wall core mixing, leading to superior heat transfer efficiency despite the added shear losses. Compared to the lower angle cases, the gain in

PEC reaches approximately 6–10%, highlighting the dominant role of

α in optimizing the thermal hydraulic balance of the ASRT configuration. Overall, these results demonstrate that while increasing

Nr alone does not guarantee improved global efficiency, an adequate combination of moderate segmentation and enhanced angular inclination yields the best trade-off between heat-transfer augmentation and pumping power.