Abstract

To ensure the transition to electric transport in order to reduce CO2 emissions, a number of projects have been initiated to develop and introduce new types of locally produced vehicles. The Russian Federation market is quite conservative and has its own specifics and a special consumer model. In addition, the component base of localized components for electric vehicles is relatively small, which is justified by relatively low demand and market volumes. To create the concept of a Class C passenger vehicle with electric traction, marketing research was conducted in a group of people who are potentially ready to abandon traditional vehicles and choose electric vehicles or hybrids. The purpose of the study is to evaluate the opinion of consumers and to form the technical characteristics of a Class C hybrid car based on localized components. Methods: To obtain the results, various components of the power unit were modeled, and a balanced solution was found that meets the requirements of consumers in the region. Mathematical modeling was carried out and analytical studies of the power reserve of various configurations of power units within the WLTC cycle were carried out in the digital environment of Siemens Amesim. Analytical work on the study of the composition of cars for calculating the masses of modern components and aggregates was carried out using Autodatas. Consumer opinions were assessed through a survey using the Yandex. Forms service. The relevance of the study is confirmed by the lack of domestic models of sequential hybrids on the market and the lack of similar studies, based on the opinion of a potential consumer. The result is the technical parameters of the main components and assemblies, which should ensure the optimal cost of the final product and meet the requirements of the consumer. Conclusion: As a result of the study, a concept of a combined sequential-type power unit was developed based on available components, meeting the main consumer properties, and the technical characteristics of the components were presented.

1. Introduction

In connection with the identified problem of temperature changes on planet Earth, associated with increasing greenhouse gas emissions from various industries, a set of measures has been developed, referred to as the decarbonization of economies. This set of measures is aimed at reducing the volume of greenhouse gas emissions into the atmosphere resulting from the combustion of fossil fuels.

Decarbonization includes several methods [1,2], such as the transition to alternative energy sources, increasing energy efficiency in production processes, and the reuse of materials. Decarbonization has significantly affected the automotive industry, where Directive (EU) 2019/631 [3] set a target of 94 g of CO2 per 1 km traveled by 2025 at the manufacturer level. Thus, the reorientation of automakers toward vehicles with electric propulsion has become systemic. According to the report [4,5], not all automakers conform to the current standards, as indicated by the declared results for 2024.

The development of lithium-ion Rechargeable Electrical Energy Storage Systems (REESS) has made a significant contribution to the advancement of electric propulsion, but the cost of such a system is quite high when needing to provide a vehicle range comparable to that of internal combustion engine (ICE) vehicles. Thus, the rhetoric of “electric vehicle or ICE” should be supplemented with an intermediate option—a combined powertrain or “hybrid.”

At the same time, the ratio of the fuel tank to the volume of REESS varies greatly in different regions of the world, as does the power of the electric drive and the configuration of the combined powertrain. Most automakers started by producing relatively expensive electric vehicles in higher segments (D, E class is in accordance with the Classification of the European Economic Commission, which focuses on segmentation of the target market), which does not promote the popularization of energy-efficient transport among budget segment C car buyers, while in the Russian Federation this is the most common segment [6,7].

Thus, the task for the authors of the study is to analyze the consumer preferences of potential users in the region, conduct an analysis of hybrid powertrain configurations, and identify the most preferred option from a technological standpoint, then determine the technical characteristics of the hybrid powertrain for a Class C passenger vehicle (Class C (middle class)—length 4.0–4.5 m, engine capacity 1.6–2.0 L, according to the European Classification System of passenger vehicles) based on the primary requirements of the regional consumer. In Russia, the development of electric vehicles began with the launch of the Mitsubishi iMiEV in 2011. We can say that this event was timely and did not lead to a large lag behind global trends. But, the relatively high price, lack of infrastructure, and low consumer properties made the electric car an outsider in the market, and sales statistics varied by units. Currently, all the pros and cons of various concepts for reducing the carbon footprint in transport have been identified. There are user experience and infrastructure, and it is already possible to analyze and draw conclusions for the local production of electric vehicles, which will be relevant to the market and financially justified as a commercial project. Therefore, the urgency of developing a highly localized electric vehicle or hybrid and its components has reached its peak only this year. This research is conducted as part of the search for a market niche and the determination of primary consumer properties.

2. Research Issues

In Russia, research and development of electric vehicles was carried out, but it was associated with the demonstration of unmanned technologies, which was not widely used and had no marketing justification. The development of BEV and even hybrid vehicles in the Russian Federation began much later than the time when the trend of switching to electric drive was already formed. For the first time, they decided to think about the development and production of xEV when it was necessary to master the high-level ADAS system. To implement the basic Lada 1118 (Tolyatti, Russia) internal combustion engine vehicle, it was converted into a BEV with corresponding changes to the braking and steering systems. Thus, through increased autonomy, mechanical units began to be replaced by CAN-controlled ones from the general Vehicle Control Unit [8]. A separate problem was formulated in the work on the development of an actual temperature control system for REESS. On the territory of the Russian Federation, the temperature range can be from +50 to −90 degrees Celsius. Of course, the operating temperature of a vehicle is often limited to the range from −40 to +50 degrees Celsius, but nevertheless, the technology of the lithium-ion battery thermal stabilization system had not yet been developed at REESS at that time, and the concept of a thermal stabilization system based on Peltier elements was proposed. Such a system, although it showed some effectiveness in climate tests, was quite complex. The results were not implemented in production [9]. It is worth noting that several attempts were made to launch the production of a standard-sized range of components, and an analysis of the global market of vehicles and components for xEV was conducted, but it all ended with the creation of a financial model based on the results of an analytical review and lack of profitability. With the available technologies, BEV could not compete with cars with internal combustion engines, and hybrids were even more difficult and expensive [10]. Currently, with reduced competition in the domestic market due to restrictive sanctions, it has become possible to develop modern xEV that will be commercially successful both domestically and in the markets of the Eurasian Customs Union countries.

Requirements to reduce harmful emissions from equipment operation, in line with global trends, were established by an agreement ratified in 2019 by the President of the Russian Federation within the framework of the UN Framework Convention on Climate Change, which sets measures to reduce carbon dioxide content in the atmosphere starting from 2020 (the 2015 Paris Agreement). Thus, since 2020, a course has been set towards the electrification of the vehicle fleet.

In the Russian Federation, the spread of electric vehicles is progressing slowly, as the main limiting factors are the relative high cost of electric vehicles compared to conventional internal combustion engine (ICE) vehicles, underdeveloped charging infrastructure, and large distances between populated areas. The charging infrastructure can be illustrated by the example of Moscow and the Moscow region, the region most saturated with charging stations, where the ratio of electric vehicles (xEV) to charging infrastructure is 14 to 1. Research carried out [11] identifies an optimal ratio as a maximum of eight vehicles per one electric charging station (ECS).

The analysis of the xEV fleet in the Russian Federation [12] indicates that consumers show greater preference for series hybrids (07-2025—72 thousand units) than electric vehicles (07-2025: 65.2 thousand units).

This statistical information should make it clear that the xEV market in the Russian Federation has only now begun to grow at a pace at which it is possible to plan commercially successful production of highly localized xEVs.

The problem with the electric vehicle fleet also lies in the fact that 17.3 thousand units are imported used cars with right-hand drive. The average price of such a vehicle is about 5000 euros. Thus, the driver is not ecological but the low purchase cost and low operating cost, since electric vehicle owners have 100% parking privileges, are exempt from transport tax, and some charging networks offered free charging. Consequently, the cost of the electric vehicle and the cost of ownership significantly influence its spread.

The abandonment of the internal combustion engine (ICE) in the vehicle’s design and the switch to electric propulsion lead to all comfort functions reducing the driving range: heating and air conditioning, power supply, telematics, and multimedia. Many consumers are not ready to accept this state of affairs, and automakers have responded by increasing battery capacity [13].

Thus, vehicle models have appeared whose design defies rational explanation. For example, the Cadillac Escalade IQ (Detroit, MI, USA) has become significantly heavier compared to the analogous ICE model. A comparison of characteristics is given in Table 1 [14].

Table 1.

Comparison of technical characteristics of different generations Cadillac Escalade IQ (USA).

Excessive vehicle mass affects tire wear, which also negatively impacts environmental pollution. Additionally, it should be noted that the stated CO2 emission figures are given according to the WLTC cycle, which does not account for the use of climate control equipment.

An analysis of vehicles across different classes, according to the unofficial European classification, showed that mass has increased on average by 16.8% over the last 25 years, with electric vehicles being on average 16.5% heavier compared to analogous ICE models (Table 2).

Table 2.

Comparison of car weight values over the past 25 years.

A comparison of the masses of modern vehicles with internal combustion engines (ICE) and electric drive has shown a noticeable difference, which fundamentally influenced the introduction of Euro 7 standards with requirements to account for tire and brake pad wear, and is also expected to impact changes in passive safety requirements during certification (Table 3).

Table 3.

Comparison of car weight values over the past 25 years within the same model.

Thus, it can be stated that combating the excess weight of electric drivetrains is also one of the main conditions for the transition to electric propulsion and the fight not only against CO2 emissions but also against accompanying emissions such as brake dust and rubber crumb.

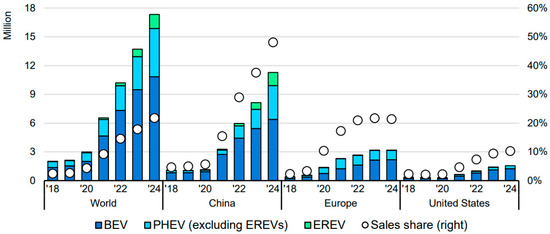

According to the report [16], the fleet of vehicles with electric propulsion is increasing, but at the same time, the shares of different types of powertrains are being redistributed. Global statistics show how the fleet of series hybrids has grown. Comparing their growth statistics in China and Europe, it can be concluded that the global fleet of series hybrids is represented mainly by vehicles of Chinese manufacture, indicating a new consumer preference in China (Figure 1).

Figure 1.

Electric car registrations and sales share in selected countries and regions, 2018–2024.

Since the fleet of series hybrids in the Russian Federation is larger than the fleet of electric vehicles, it can be concluded that consumer preference patterns are similar—valuing a long driving range due to the need to cover large distances daily, limited availability of charging stations during peak hours, and reduced dependence on charging time and the electrical grid. The next step in the study was to conduct a survey of opinions and preferences of potential consumers regarding the operational characteristics of an electric drive vehicle they would like to purchase when replacing their current car.

3. Analyzing the Opinion of a Potential Consumer

The assessment of consumer opinions was conducted through a survey using the Yandex.Forms (Moscow, Russia) service. Respondents were asked to choose one answer from four options for each question. The list of questions and answer choices is presented in Table 4. A total of 1168 people from various regions participated in the survey. The survey results are shown in Table 5.

Table 4.

Questions and answers for surveys.

Table 5.

Survey results.

The overall conclusions can be expressed as follows: the majority prefer a parallel-type hybrid powertrain with traction motor power ranging from 200 to 250 hp, front-wheel drive, acceleration dynamics of about 8 s to 100 km/h, maximum driving range, and the ability to replenish the electric energy supply from an external charging station.

4. Analysis of Electric Vehicle Power Plants

According to General Resolution No. 2 (GR.2) on the 1958 and 1998 agreements, which contains the definitions of vehicle powertrains [17], the following types are distinguished: full electric vehicle, ICE vehicle, and hybrid vehicle (parallel, series, and combined systems). In the Russian Federation, there is GOST R 59078-2020 “Electric vehicles and automobile vehicles with combined power plants. Classification”, which also introduces a classification of vehicles by powertrain type. This classification is then used both for calculating customs duties upon importation and for calculating the transport tax, which is charged annually based on the vehicle’s power simply for owning the vehicle.

This analysis is very important as it explains why most consumers avoid cars with maximum power exceeding 250 hp, which subsequently determines the type of powertrain developed for the vehicle. An example of tax payment calculations for various cars is provided in Table 6.

Table 6.

The cost of tax payments in Moscow depends on the capacity.

BEV—a vehicle with an electric traction drive. To provide a consumer-desired driving range of over 700 km according to the WLTP cycle, it is necessary to have a REESS capacity of more than 100 kWh, which will lead to an increase in vehicle mass and cost. Analysis of the most common electric vehicles worldwide has shown that a mass under 2000 kg with a REESS capacity of about 70 kWh is achievable, but only with technologies such as Gigacasting [18] or hot stamping of high-strength steels. The authors do not consider these technologies due to their absence in the automotive industry. Additionally, given the underdeveloped charging infrastructure, a larger REESS capacity will require more time to replenish energy to the required driving range.

The tax component is calculated based on the sum of the power of all traction electric motors, determined according to UN Regulation 85, i.e., the 30 min continuous power.

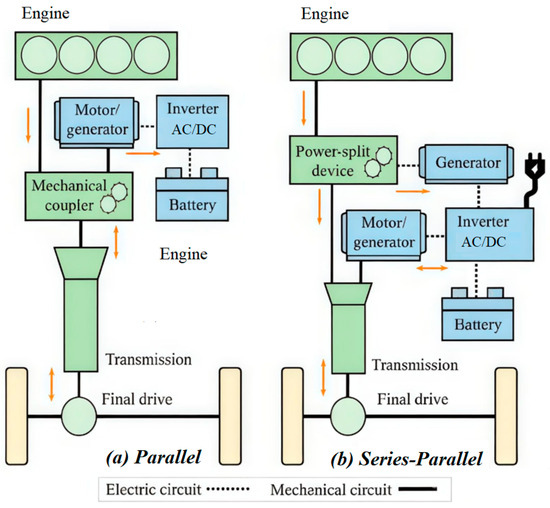

HEV, PHEV—parallel and series-parallel type designs (Figure 2) [19], both with and without the possibility of charging from an external charger, are widely used in the Russian Federation.

Figure 2.

Schematic representation of power plants HEV and PHEV with parallel and series-parallel system.

According to data from the National Agency of Industrial Information, in 2024 the fleet of HEV and PHEV vehicles amounted to 425,600 units. Typically, this type of vehicle has a REESS capacity of no more than 10 kWh, which provides movement at low speeds and supplies electricity for acceleration in parallel mode. Driving range without engaging the ICE based on the WLTP methodology is either impossible or very small (up to 50 km without accounting for the operation of comfort-related consumers). The authors consider this system structurally outdated and not relevant in modern conditions in terms of energy efficiency. The complexity and high manufacturing cost of the planetary gearbox and unified powertrain module also lead to abandoning consideration of such a system for a prospective vehicle.

The tax component for HEV and PHEV is calculated by summing the maximum power of the ICE and the 30 min continuous power of all electric motors intended for propulsion, which often exceeds the critical barrier of 250 hp, causing the tax payment to double.

EREV—a vehicle with a series-type powertrain, originally marketed as an extended-range electric vehicle. It is worth noting that the most clear example of a rational design is the BMW i3 Rex (Munich, Germany), where the gasoline generator unit was initially intended for brief replenishment of electric energy in rare cases. The primary operation was supposed to be as an electric vehicle. This theory is supported by the fuel tank volume of 8 L. The European model of vehicle use implies maximum driving range on REESS with episodic ICE activations. With the development of the automotive industry in the People’s Republic of China (PRC) and the withdrawal of European automakers from supplying vehicles to the Russian Federation, the EREV market has shifted towards vehicles from the PRC. These EREVs demonstrate a consumption model different from the European one: with a relatively small REESS (up to 40 kWh), they install an ICE with a displacement of 1500 cm3 and a fuel tank up to 70 L. According to the analysis of EREV brands and models on the market, the Chinese consumption model—where electric drive is used for short distances, and when charging is unavailable or for long trips, a gasoline generator can provide driving at speeds of 120–140 km/h—is most favorable for the Russian consumer. As design nuances, one can note the asymmetrical placement of the REESS due to the ICE exhaust system under the hood and the presence of an electric generator comparable in power to the traction electric motor.

The tax component for EREV is comparable to BEV, since the power delivered directly to the wheels does not depend on the ICE power, as there is no mechanical connection between the ICE and the transmission.

Based on the review of current electric vehicle powertrain schemes, the authors collectively believe that the most in-demand powertrain in the Russian Federation will be the series-type powertrain ideologically based on the Chinese vehicle consumption model, where the combined fuel tank volume and battery capacity provide a driving range of about 1000 km.

5. Materials and Methods

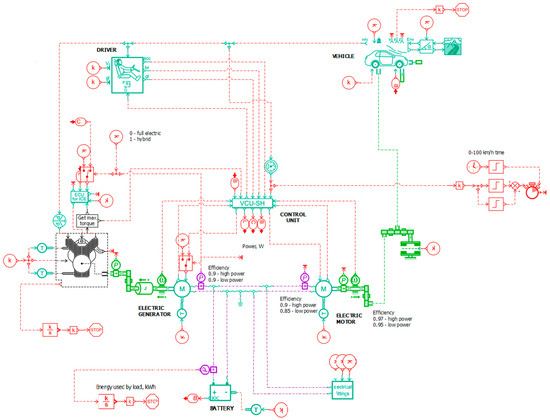

Modeling is carried out in the Siemens Amesim 2310 (Plano, TX, USA) environment using standard modules. This software shows good convergence of results and has been repeatedly used to model hybrid vehicles with a different type of layout: MHEV [20] and MSEH-HEV [21]. The general view of a vehicle system with a series hybrid powertrain is shown in Figure 3.

Figure 3.

General view of the calculation model.

Siemens Amesim 2310 software (USA) integrates various physical domains, enabling precise analysis of complex system interactions. This allows for effective performance analysis based on the different domains of the system and provides essential information during the design optimization process. The developed system model consists of an internal combustion engine module, an electric drive, an electric generator, a battery, a gearbox, a voltage converter, a VCU, the driver’s steering action and the car itself with its technical parameters. To perform the simulation, a sampling step of 0.1 s was used in the program settings.

It is worth noting that the previous phase of research on the development of the highly localized xEV concept included a global review of the market and production capabilities of all participants in the automotive and electronic components market. This is exactly what explains the components selected for modeling.

- ICE

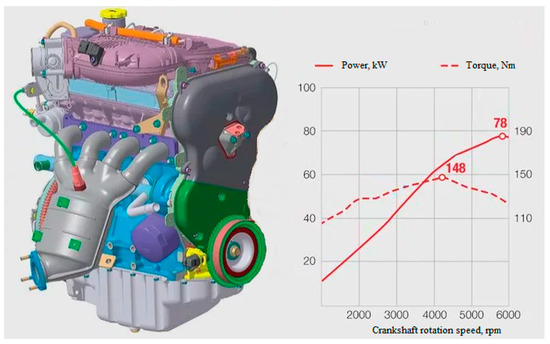

For the implementation of the calculation model and as a prospective powertrain, the ICE VAZ-21179 with a displacement of 1800 cm3 and the VAZ-21129 with a displacement of 1600 cm3 were selected (Figure 4).

Figure 4.

External speed characteristic of the ICE VAZ-21129 with a displacement of 1600 cm3.

The mass of the internal combustion engine used for calculation is 101.6 kg, according to the manufacturer’s specification and is taken into account in the total weight of the car. The total mass of the internal combustion engine is 109 kg, but since the gas generator set is powered by a reversible electric machine, we subtract the mass of the starter (3 kg) and generator (5.4 kg) from this mass. The weight of the electric car of the gasoline generator set is given in the electric car section. The characteristics of ICE are shown in Table 7.

Table 7.

ICE parameters.

- Vehicle

The vehicle characteristics used for the calculation are shown in Table 8. The mass characteristic of 2100 kg is obtained by analyzing the components included in the BOM and does not include the mass of the REESS. The BOM was determined based on an analysis of fifteen units of electric vehicles and successive hybrids in the Autodatas (PRC) system; the requirements for the models met the criteria indicated by the respondents during the survey. The Drag coefficient and Front area characteristics are calculated as the average value among the selected models.

Table 8.

Vehicle parameters.

- Electric Generator and Electric Motor

In Russia, the manufacturer of current electric drive systems for cars is TVEL (Moscow, Russia), whose product line contains an electric drive made according to the 3-in-1 principle, with the characteristics shown in Table 9. The mass of the TVEL electric drive is 90 kg; if it is used without a gearbox as an electric generator, the mass of the electric machine and the inverter will be 65 kg. This mass is taken into account in the mass of the gasoline generator set. Thus, the loaded mass of the vehicle, excluding the battery, adopted for the calculation, will be 2070 kg.

Table 9.

EM parameters.

- Battery

It consists of modules of VDA batteries with the chemical structure of NMC 811 from manufacturer Renera (Moscow, Russia). At the REESS level, the energy density is 162 Wh/kg, which gives the following characteristics for calculation (Table 10 and Table 11). The REESS model was developed using the Simcenter Amesim Battery Pre-Sizing Tool, based on three criteria: REESS voltage, capacity, and power. The results obtained inside the Amesim module were adjusted by a coefficient in accordance with the existing groundwork in the field of self-construction of mathematical models of REESS, which was built on real batteries with preliminary testing in climate chambers [22]. An example was considered as a model of thermal stabilization of REESS, which allowed a more accurate approach to modeling heat exchange processes in EREV, taking into account the exchange of thermal energy between a low-temperature and high-temperature circuit [23].

Table 10.

REESS parameters.

Table 11.

REESS and vehicle weight.

- Driver

The driver’s model is expressed by the control action on the car, which describes the movement of the car according to the WLTC cycle. The cycle movement occurs until the end of the gasoline in the fuel tank and the discharge of the REESS. Due to the fact that the energy supply on board runs out at different stages of the cycle, the amount of residual electricity in the REESS is different. For example, for dynamic acceleration in the high-speed zone of the cycle, there is not enough available energy in the battery; even if it is not fully discharged, the car stops. This explains the different percentage of remaining electricity in REESS (SOC).

6. Results

The simulation results showed that the optimal characteristics for a Class C sedan in the Russian Federation would be the following set of technical parameters, which are presented in Table 12.

Table 12.

Calculation results.

According to the calculation, 10 kWh of REESS can increase the range of a hybrid vehicle by 50 km, while 10 L of gasoline increase the driving range by an average of 200 km. CO2 emissions in grams per 1 km traveled are calculated according to formula (1), with a fuel–air mixture ratio of 14.4 and a fuel energy content of 42,700 kJ/kg.

m(CO2) = m(fuel) × 3.15/km

According to the goals of Directive (EU) 2019/631 [3], by 2030, the manufacturer-wide average CO2 emissions must not exceed 50 g/km. Currently, annual requirements have been replaced by three-year phases [24], within which the target is to reach 85 g/km by 2028 and 50 g/km by 2030.

7. Conclusions

According to the authors of this study, the best performance is achieved by a hybrid vehicle with the following energy storage characteristics: REESS of 40 kWh and a fuel tank of 20 L, with CO2 emissions of 70 g/km. As we can see, a REED with a capacity of less than 40 kWh is not able to provide the power of a traction electric drive, which significantly affects the dynamic characteristics.

To continue the research, it is obvious that ICEs with more relevant characteristics should be considered, such as smaller-displacement turbocharged engines or those operating on the Atkinson cycle.

Based on components currently available in the Russian domestic market and the abundance of natural resources, particularly natural gas, converting ICEs to run on natural gas is highly relevant, which should also reduce emissions directly from the vehicle.

In the subsequent stages of the work, when the bill of materials (BOM) and Vehicle Technical Specifications (VTS) are developed, the model should be refined considering updated component characteristics and the energy consumed for auxiliary needs. Additionally, in a separate case, the model should be adjusted to account for the climatic features of the region of operation and the energy required to ensure the comfort of the driver and passengers.

Author Contributions

Conceptualization—A.F.K.; methodology—A.F.K. and K.E.K.; validation—S.E.Z. and F.K.K.; Data curation management—S.E.Z. and F.K.K.; Formal analysis—A.F.K., P.I. and F.K.K.; writing—original draft preparation A.F.K. and K.E.K.; writing—review and editing—A.F.K. and K.E.K.; visualization, P.I.; project administration—K.E.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Ministry of Science and Higher Education of the Russian Federation within the framework of the project “Development of a hybrid power train for M1 (passenger car) based on domestic components”, code FZRR-2025-0009.

Data Availability Statement

The data presented in this study are available in [Advancements, challenges, and prospects of cost-effective electric vehicles] at [https://doi.org/10.1016/j.aej.2025.05.088], reference number [19], [Vehicle giga-casting Al alloys technologies, applications, and beyond] at [https://doi.org/10.1016/j.jallcom.2025.178552], reference number [18], [Analytical Study of the Power Parameters of Electric Traction Drive for Modern Vehicles] at [https://doi.org/10.1007/978-3-030-64719-3_23], reference number [10], [Features of Creation andOperation of Electric and Hybrid Vehicles in Countries with Difficult Climatic Conditions, for Example, in the Russian Federation] at [https://doi.org/10.1088/1757-899X/157/1/012014], reference number [9], [Coping with decarbonisation: An inventory of strategies from resistance to transformation] at [https://doi.org/10.1016/j.gloenvcha.2025.102968], reference number [2], [Decarbonization via Nature-Based Solutions: National Policy and International Practice] at [https://doi.org/10.1134/S2079970523701022], reference number [1].

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| WLTP | Worldwide Harmonised Light Vehicle Test Procedure |

| WLTC | Worldwide Harmonized Light Vehicles Test Cycle |

| BEV | Battery Electric Vehicle |

| HEV | Hybrid Electric Vehicle |

| MSEH-HEV | Master–Slave Electro-Hydraulic Hybrid Electric Vehicle |

| PHEV | Plug-in Hybrid Electric Vehicle |

| ICE | Internal Combustion Engine |

| xEV | Electric Traction Drive Vehicles of Various Designs |

| BOM | Bill of Materials |

References

- Ptichnikov, A.V.; Shvarts, E.A. Decarbonization via Nature-Based Solutions: National Policy and International Practice. Reg. Res. Russ. 2023, 13, 631–645. [Google Scholar] [CrossRef]

- Claire, B.M.; Cantoni, R. Coping with decarbonisation: An inventory of strategies from resistance to transformation. Glob. Environ. Chang. 2025, 90, 102968. [Google Scholar] [CrossRef]

- Regulation (EU) 2019/631 of the European Parliament and of the Council of 17 April 2019 Setting CO2 Emission Performance Standards for New Passenger Cars and for New Light Commercial Vehicles, and Repealing Regulations (EC) No 443/2009 and (EU) No 510/2011 (Recast) (Text with EEA Relevance.). Available online: https://eur-lex.europa.eu/eli/reg/2019/631/oj/eng (accessed on 30 June 2025).

- European Market Monitor Cars and Vans: January 2025. Available online: https://theicct.org/publication/european-market-monitor-cars-vans-jan-2025-feb25 (accessed on 15 July 2025).

- An Amendment to the CO2 Standards for New Passenger Cars and Vans in the European Union. Available online: https://theicct.org/wp-content/uploads/2025/06/ID-399-%E2%80%93-EU-car-standards_amend_update_final.pdf (accessed on 15 July 2025).

- The SUV C Segment Has Become a Leader in the Russian Car Market. Available online: https://www.autostat.ru/news/59458/ (accessed on 15 July 2025).

- The Most Common Models in Various Segments of the Russian Fleet Have Become Known. Available online: https://www.autostat.ru/news/57119/ (accessed on 15 July 2025).

- Saykin, A.M.; Buznikov, S.E.; Endachev, D.V.; Karpukhin, K.E.; Terenchenko, A.S. Development of Russian Driverless Electric Vehicle. Int. J. Mech. Eng. Technol. 2017, 8, 955–965. [Google Scholar] [CrossRef]

- Karpukhin, K.E.; Terenchenko, A.S. Features of Creation and Operation of Electric and Hybrid Vehicles in Countries with Difficult Climatic Conditions, for Example, in the Russian Federation. IOP Conf. Ser. Mater. Sci. Eng. 2016, 157, 012014. [Google Scholar] [CrossRef]

- Kolbasov, A.; Karpukhin, K.; Sheptunov, D.; Andrey, P.; Tuan, N.K.; Minh, N.K. Analytical Study of the Power Parameters of Electric Traction Drive for Modern Vehicles. Lect. Notes Netw. Syst. 2021, 178, 200–209. [Google Scholar] [CrossRef]

- Khairetdinova, A.R.; Kasatkin, I.I.; Kolbasov, A.F. Model for the Development of the Charging Infrastructure of Moscow. Mosc. Transport. Sci. Des. 2025, 1, 14–22. [Google Scholar]

- The Number of Electric Vehicles in Russia Has Reached 65,000 Units. Available online: https://rucars.ru/magazine/news/detail/kolichestvo-elektromobiley-v-rossii-dostiglo-65-tysyach-edinits/ (accessed on 25 August 2025).

- Carsized. Available online: https://www.carsized.com/ru/cars/compare/cadillac-escalade-iq-2024-suv-vs-cadillac-escalade-2024-suv-lwb/ (accessed on 30 August 2025).

- Dealer Web-Site. Available online: https://aecsv.com/cadillac-europe/cadillac-escalade-overview/ (accessed on 30 August 2025).

- Environmental Friendliness and Economic Efficiency of Refrigeration Systems on the CO2. Available online: https://www.nord-sm.ru/poleznaya-informaciya/stati/ekologichnost-i-ekonomicheskaya-effektivnost-holodilnyh-sistem-na-so2-v-magazinostroenii (accessed on 2 September 2025).

- Global EV Outlook 2025 Expanding Sales in Diverse Markets INTERNATIONAL ENERGY AGENCY. Available online: https://www.iea.org/data-and-statistics/data-tools/global-ev-data-explorer (accessed on 30 August 2025).

- Mutual Resolution No. 2 (M.R.2) of the 1958 and the 1998 Agreements Containing Vehicle Propulsion System Definitions, ECE/TRANS/WP.29/1121. Available online: https://unece.org/DAM/trans/main/wp29/wp29resolutions/ECE-TRANS-WP29-1121e.pdf (accessed on 15 July 2025).

- Yang, J.; Liu, B.; Shu, D.; Yang, Q.; Hu, T. Vehicle giga-casting Al alloys technologies, applications, and beyond. J. Alloys Compd. 2025, 1013, 178552. [Google Scholar] [CrossRef]

- Mojumder, M.R.H.; Nakib, T.H.; Hasanuzzaman, M.; Abdel-Khalik, A.S. Advancements, challenges, and prospects of cost-effective electric vehicles: A review. Alex. Eng. J. 2025, 128, 437–456. [Google Scholar] [CrossRef]

- Saragea, Ș.; Frățilă, G.; Badea, G. Fuel consumption and emission improvements obtained using a mild hybrid electrical system on a vehicle equipped with a manual gearbox. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1037, 012053. [Google Scholar] [CrossRef]

- Jia, Q.; Zhang, H.; Zhang, Y.; Yang, J.; Wu, J. Parameter Matching and Performance Analysis of a Master-Slave Electro-Hydraulic Hybrid Electric Vehicle. Processes 2022, 10, 1664. [Google Scholar] [CrossRef]

- Malyshev, A.N.; Debelov, V.V.; Endachev, D.V.; Anatolevich, G.E.; Sergeevichy, S.A. Mathematical and simulation model for testing the management system of high voltage batteries for hybrid and electric vehicles. AIP Conf. Proc. 2022, 2383, 020010. [Google Scholar] [CrossRef]

- Li, K.; Liu, Q.; Hu, Y.; Gao, J.; Chen, H. A Coupling Thermal Management Strategy Based on Fuzzy Control for a Range Extended Electric Vehicle Power System. IEEE Trans. Veh. Technol. 2022, 71, 2573–2586. [Google Scholar] [CrossRef]

- Dornof, J. CO2 Emission Standards for New Passenger Cars and Vans in the European Union. Available online: https://theicct.org/publication/eu-co2-standards-cars-vans-may23/ (accessed on 30 August 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).