Managing Market Competition and Battery Disassembly Design in an Echelon Utilization Supply Chain: The Case of China Electric Vehicle Industry

Abstract

1. Introduction

- If a battery manufacturer opts for a disassembly design, should they join the battery recycling echelon utilization industry, and what impact will this choice have on their profits before and after joining?

- How will the intensity of market competition in the battery recycling sector and the profit from the echelon utilization of unit waste batteries influence the decision-making processes of battery manufacturers and new energy vehicle producers?

- What distinctions exist between the battery manufacturing and recycling decisions made by new energy vehicle manufacturers, and how do these choices affect the volume of batteries recycled in each scenario?

2. Literature Review

2.1. Battery Recycling and Echelon Utilization

2.2. Battery Disassembly Design

2.3. Research on Market Competition Intensity

3. Model Description and Construction

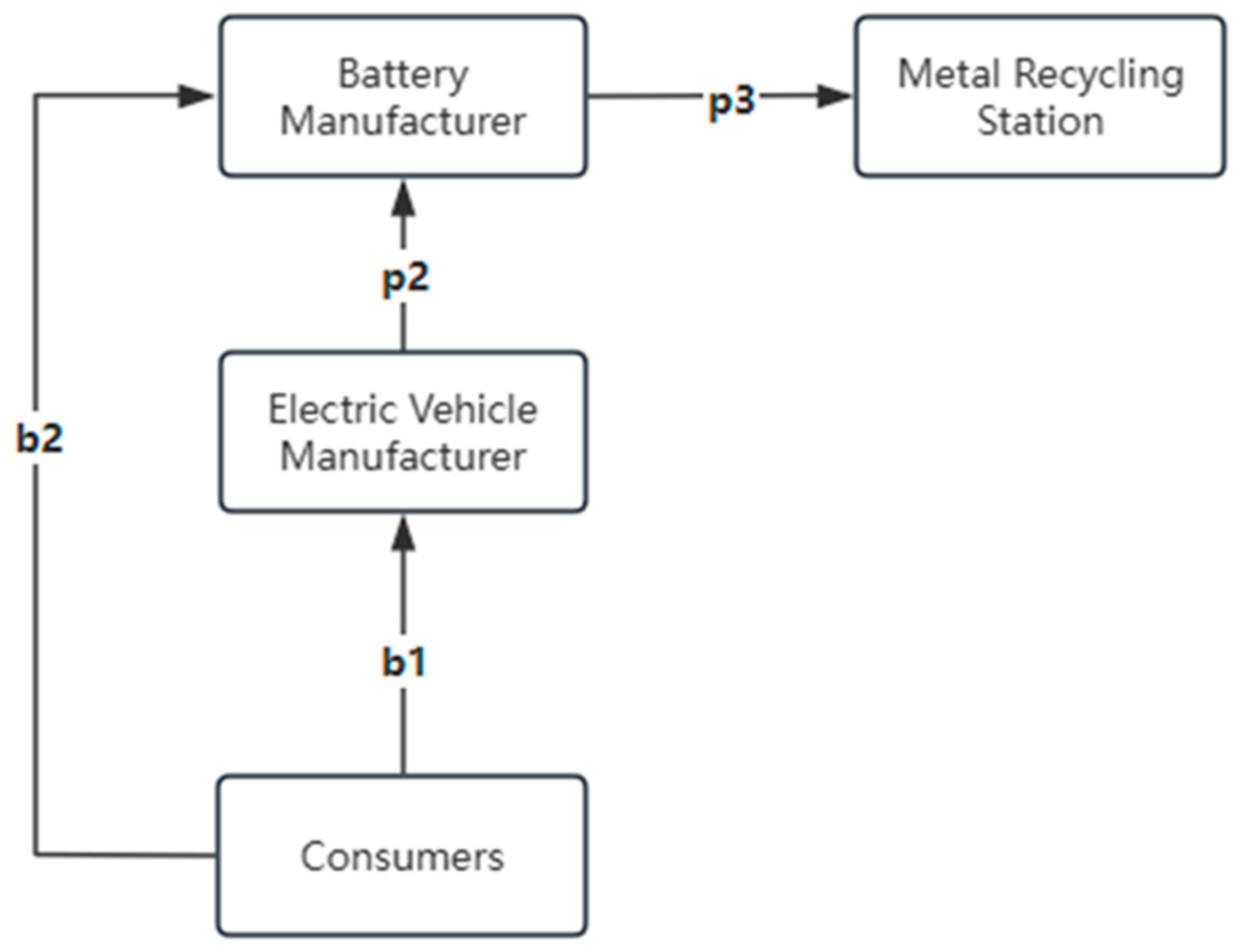

3.1. Problem Description

3.2. Modeling

3.3. Model Results and Analysis

3.3.1. The Equilibriums When Battery Manufacturers Do Not Participate in Battery Recycling

3.3.2. The Equilibria When Battery Manufacturers Participate in Battery Recycling

4. Numerical Experiments

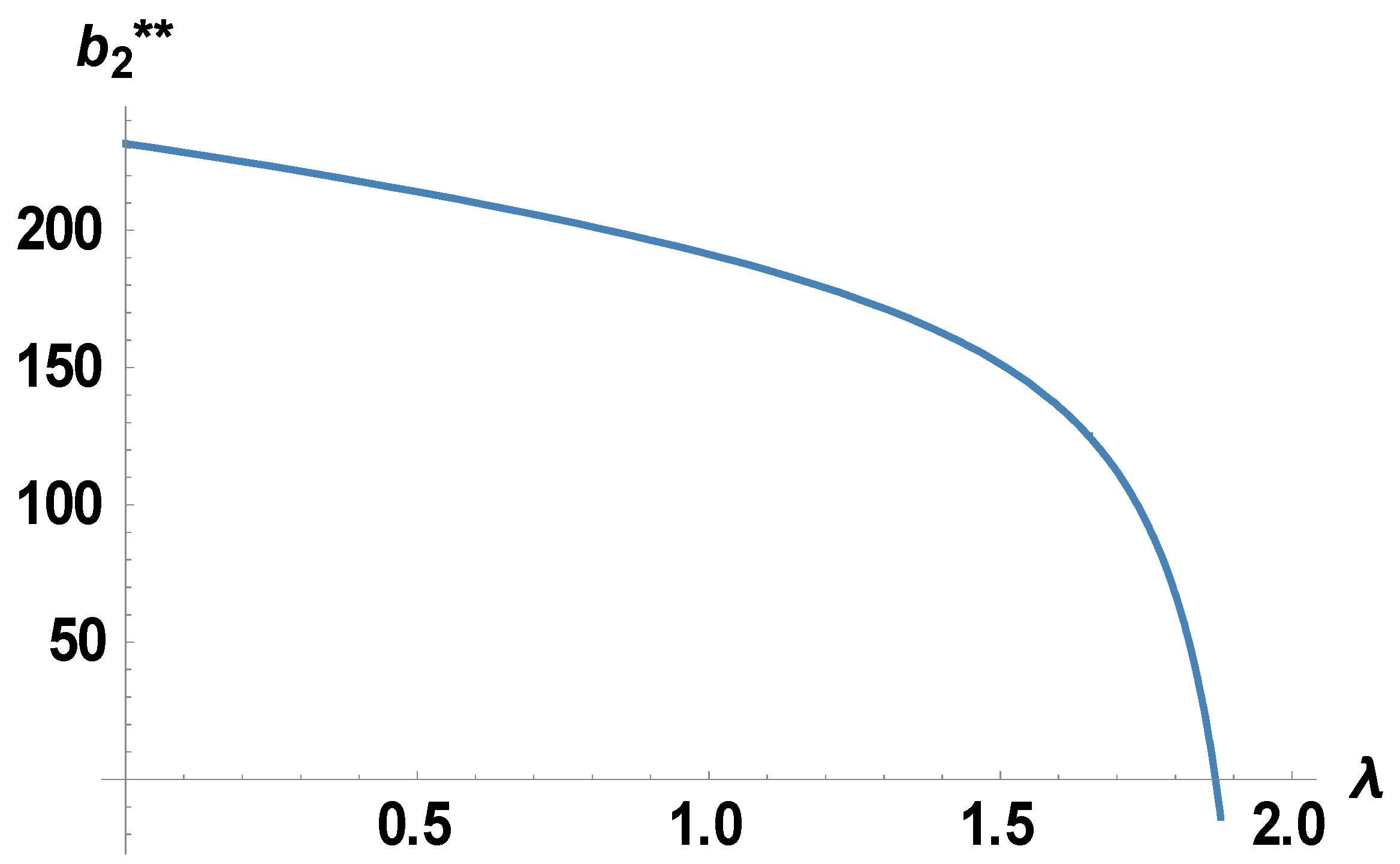

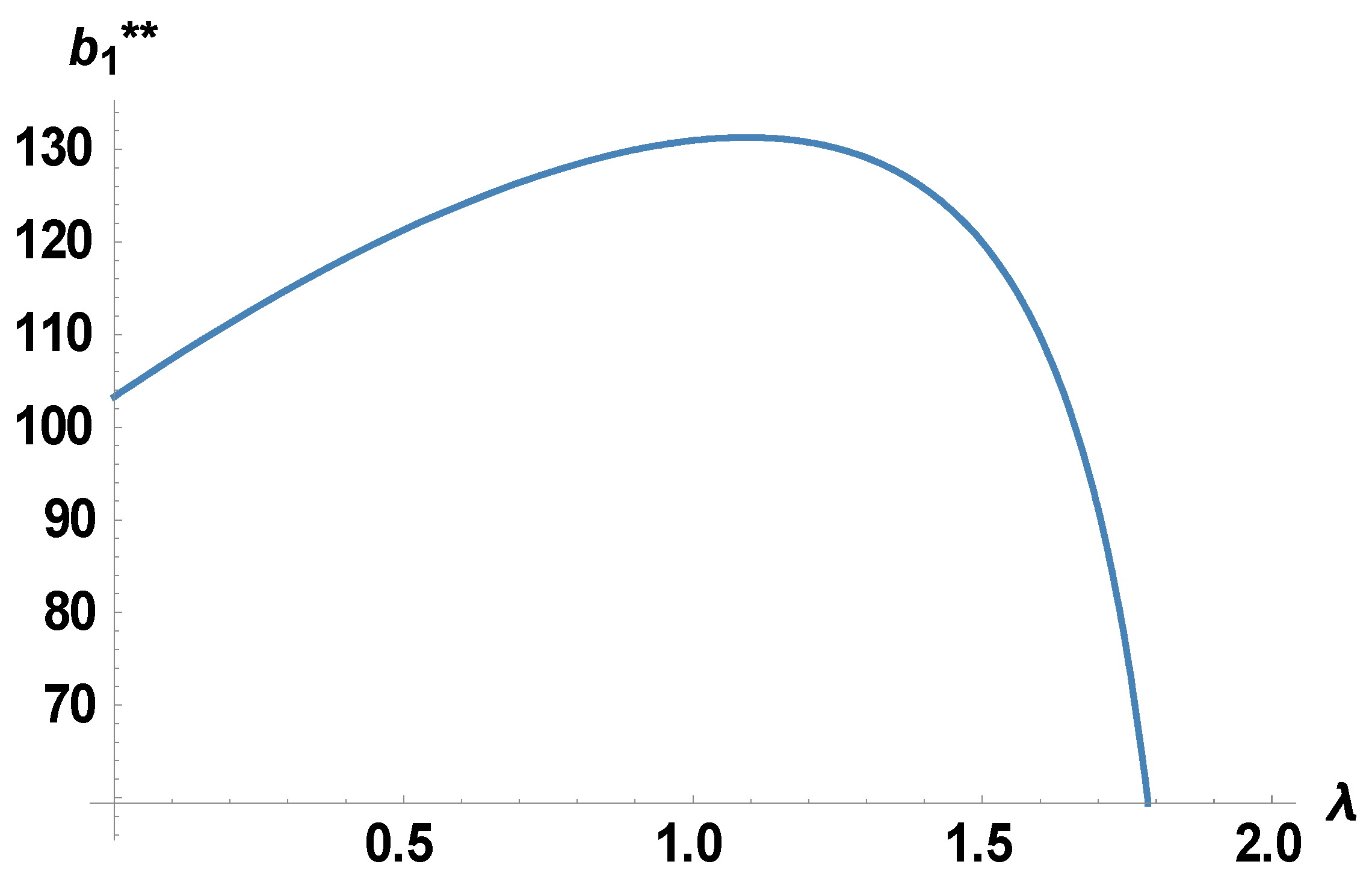

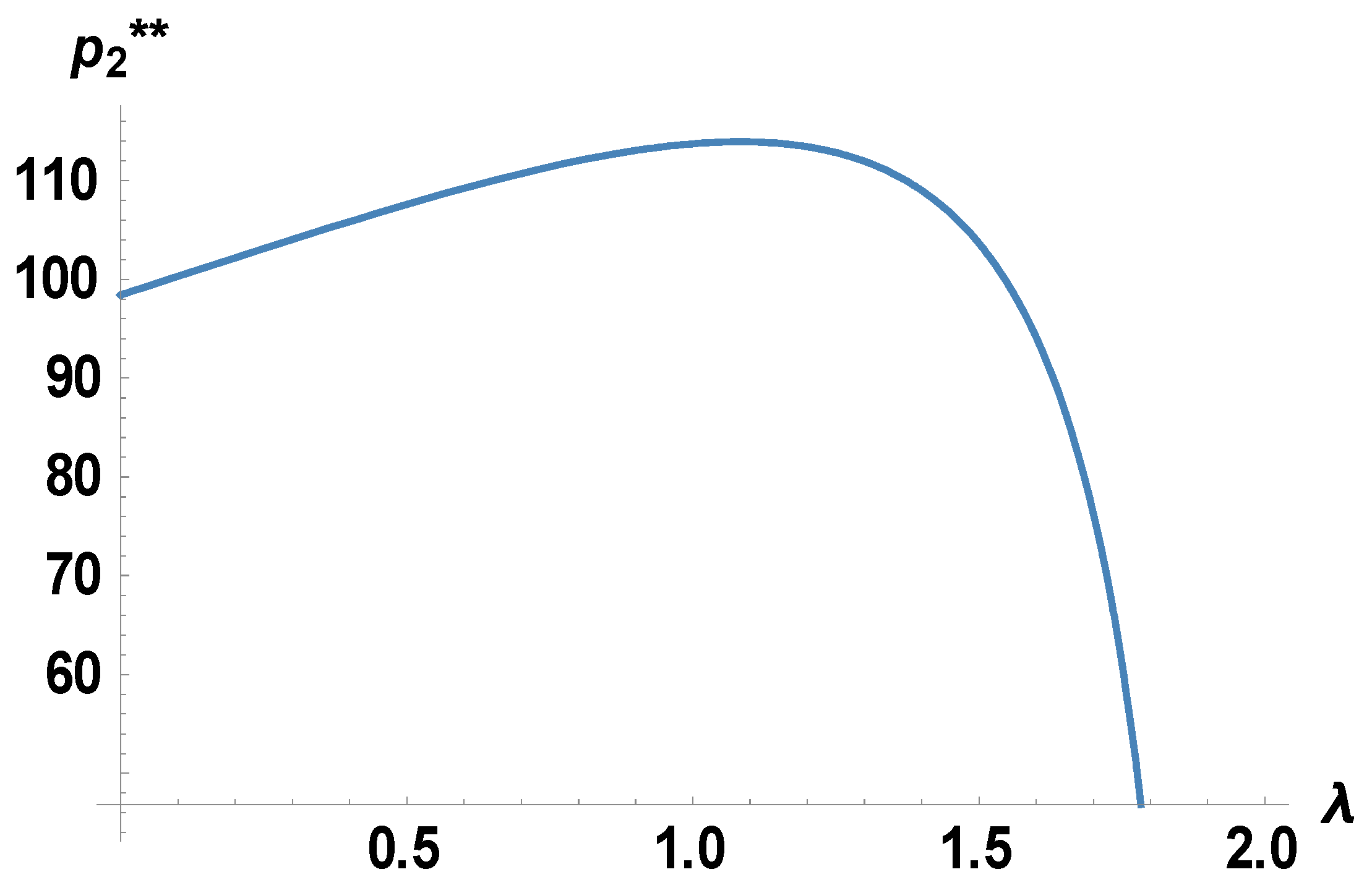

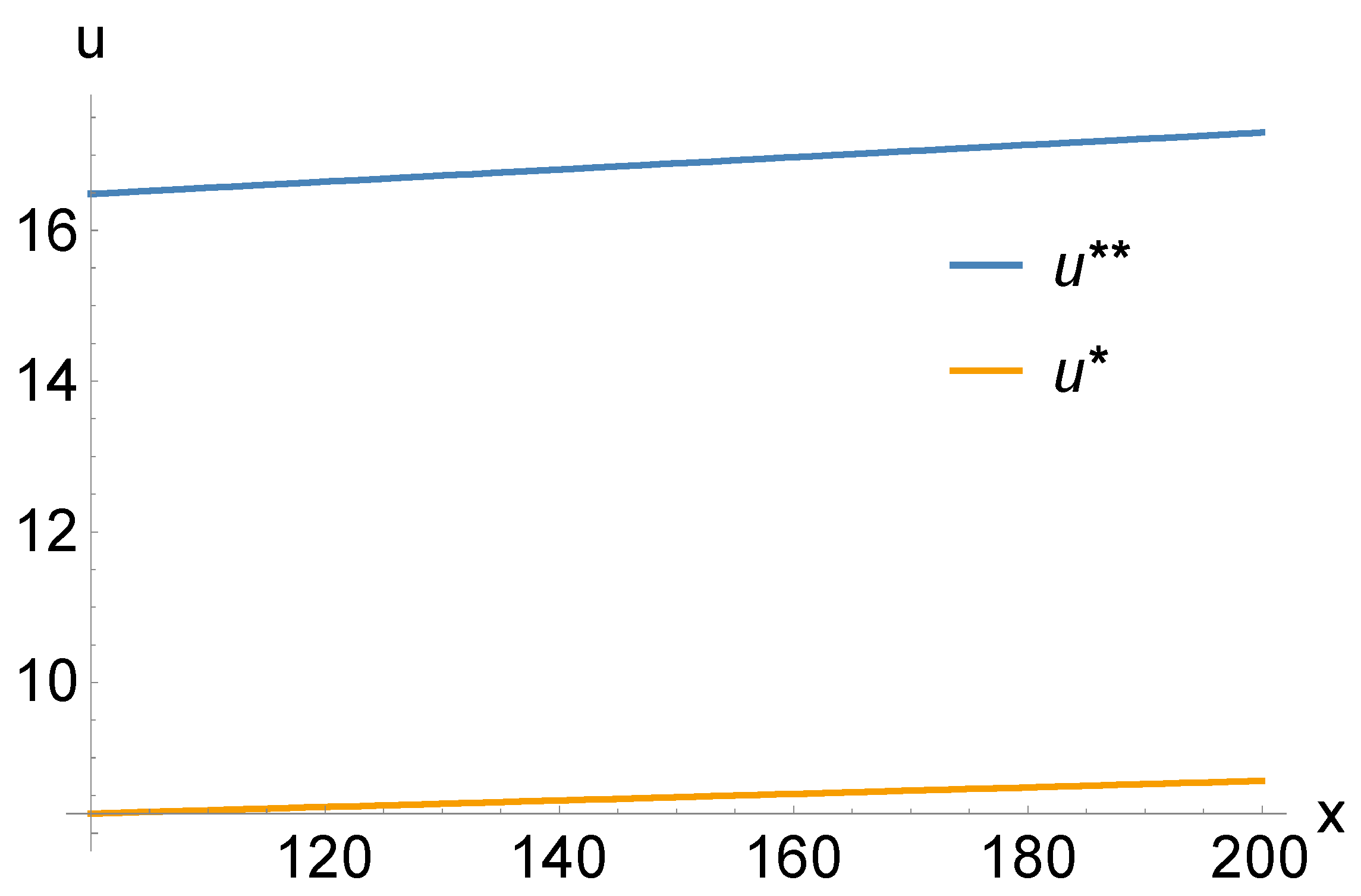

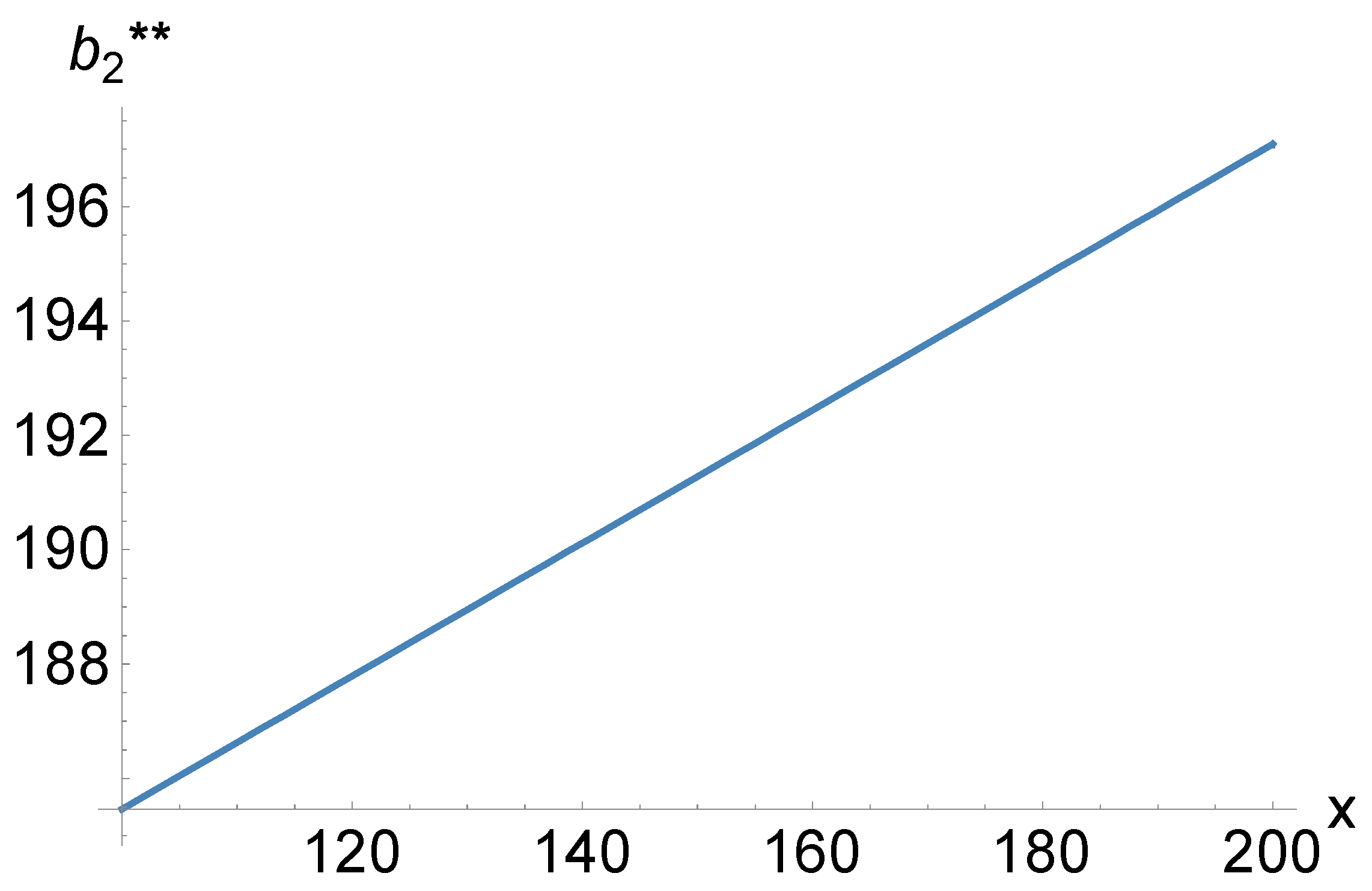

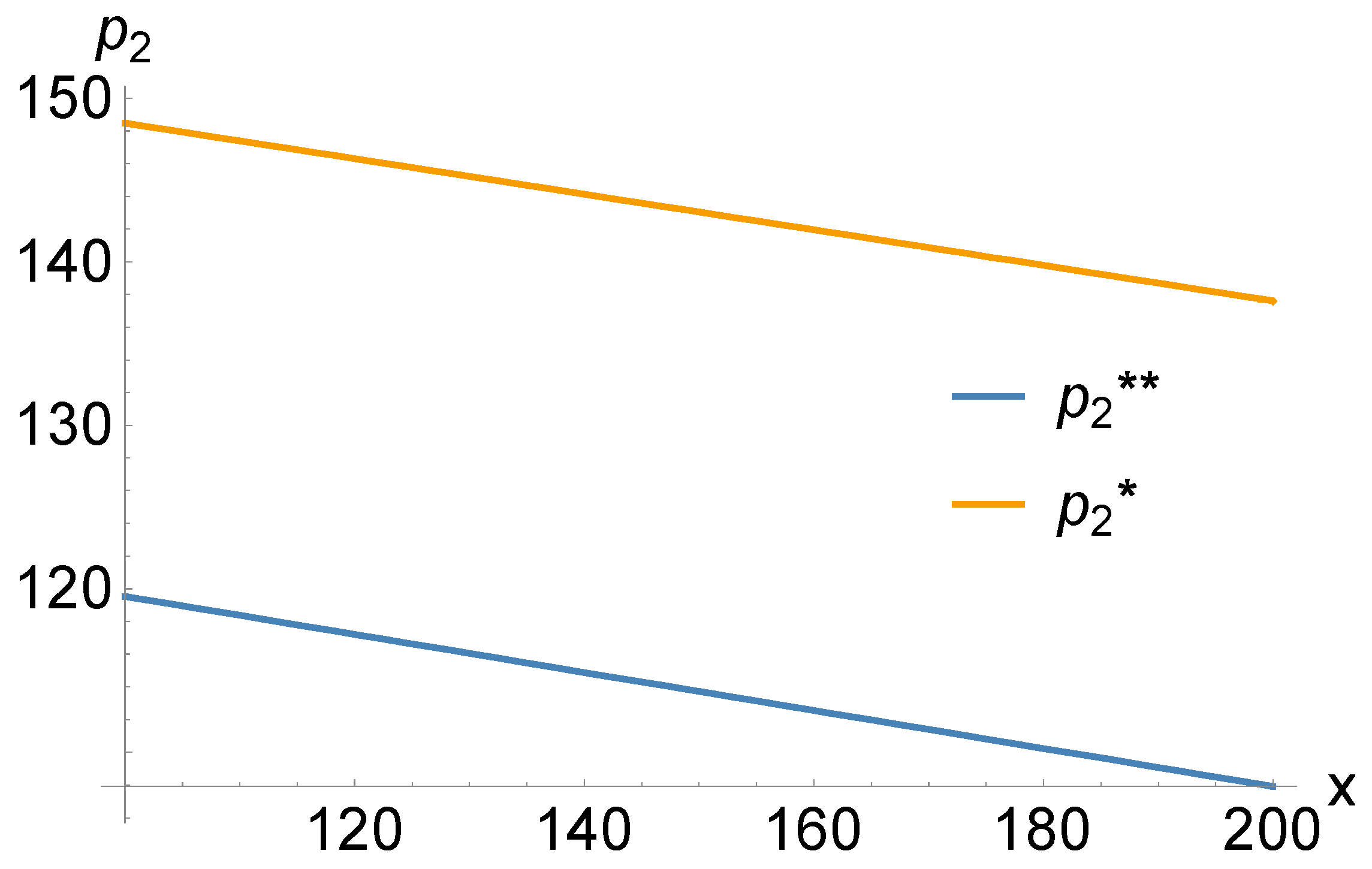

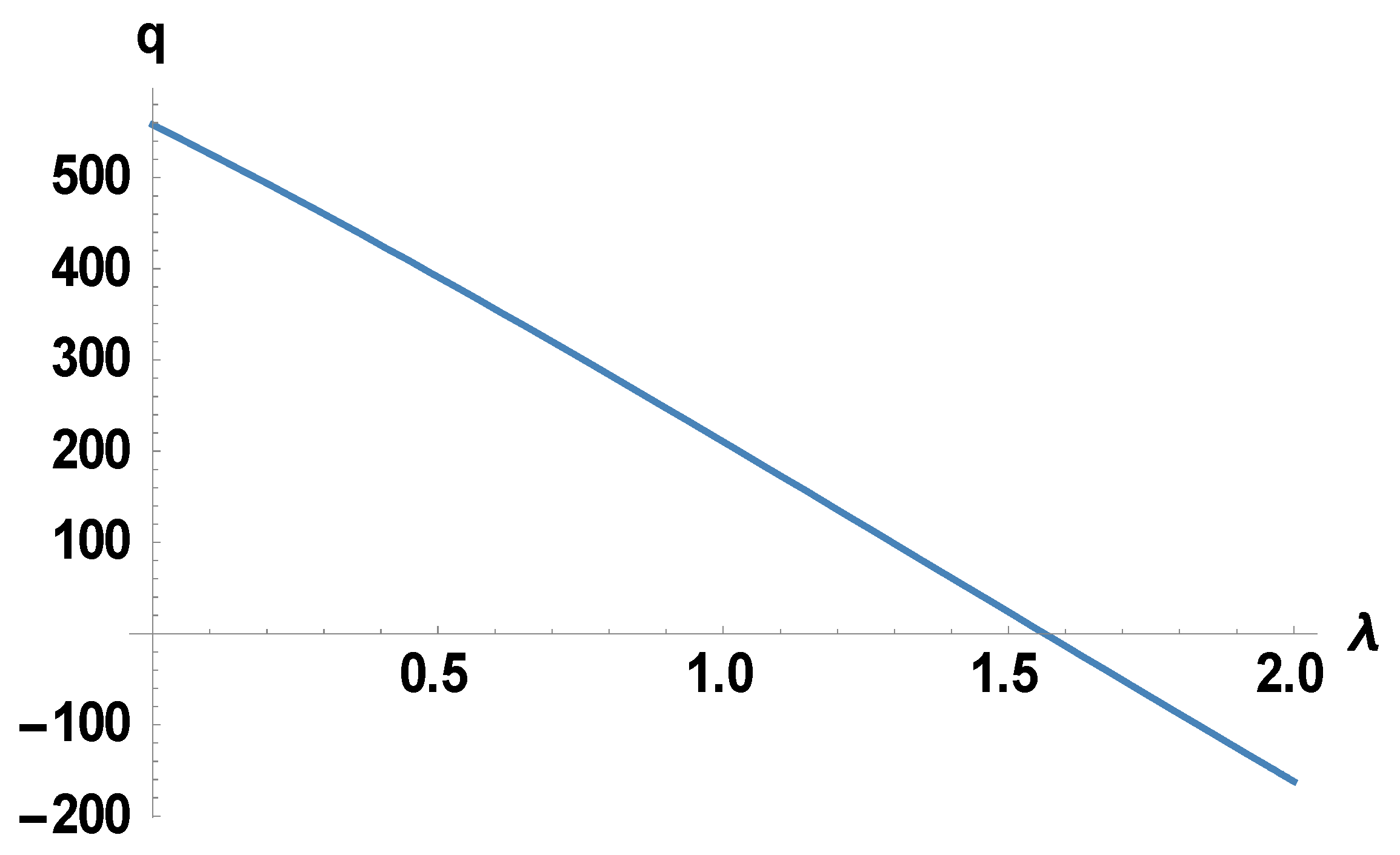

4.1. Numerical Analysis of Equilibrium Decision

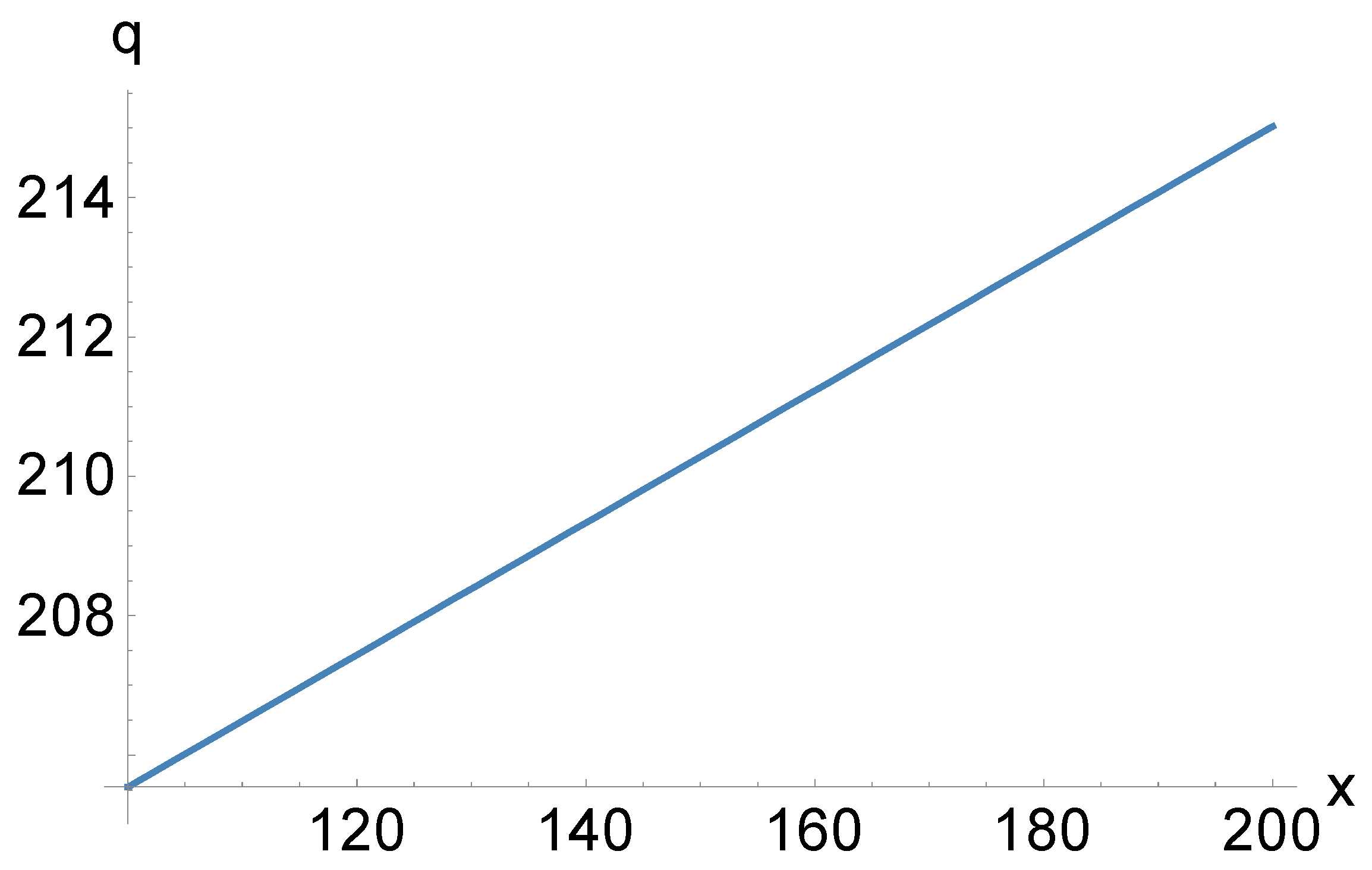

4.2. Numerical Analysis of the Number of Battery Recycling

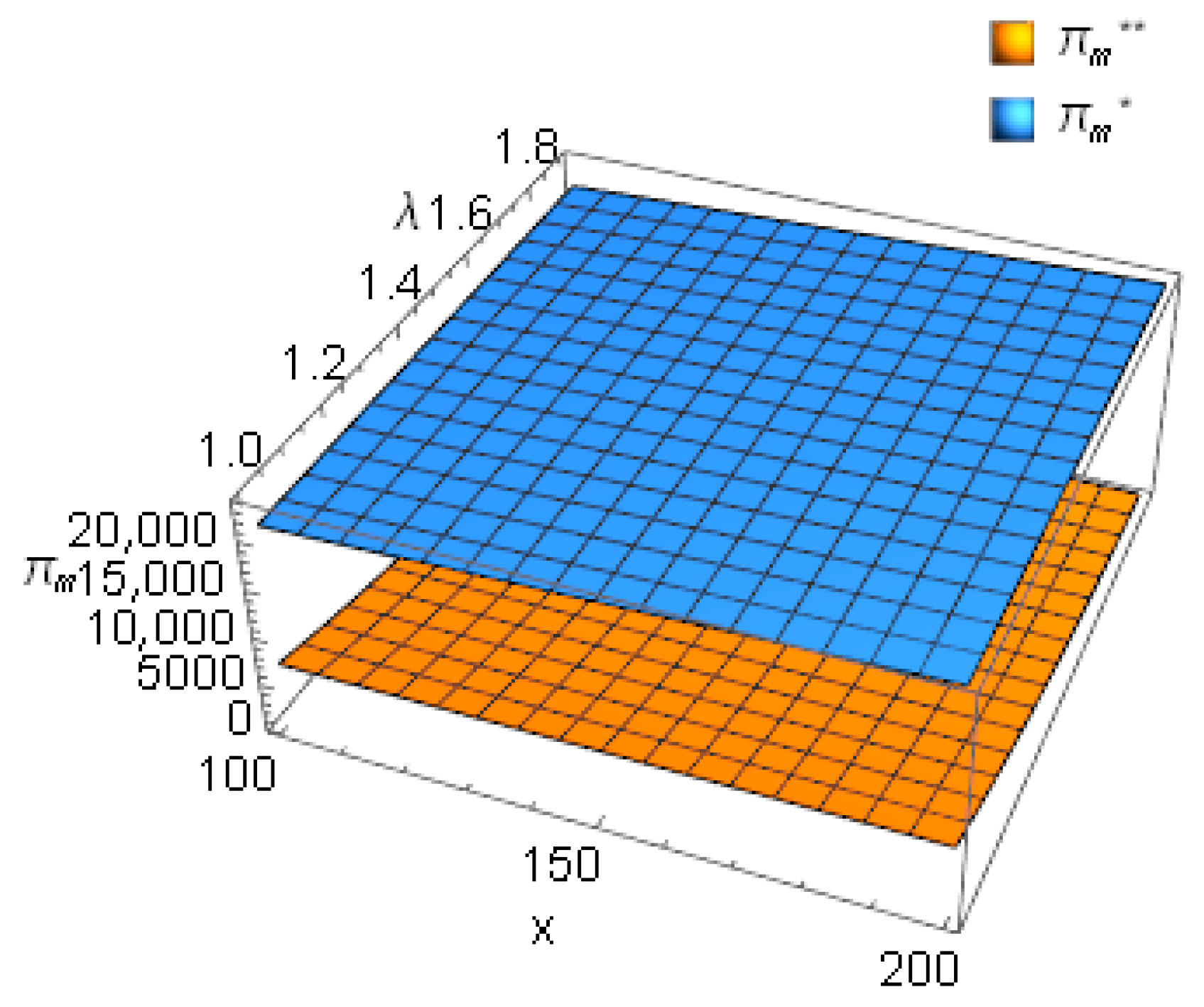

4.3. Numerical Analysis of Profit

5. Conclusions

5.1. Research Conclusions

5.2. Management Suggestions

5.3. Research Prospect

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

- Proof of Proposition 1

- Proof of Corollary 1

- Proof of Corollary 2

- Proof of Proposition 2

- Proof of Corollary 3

- Proof of Corollary 4

- Proof of Corollary 5

- Proof of Corollary 6

- Proof of Corollary 7

References

- Wang, Y.; Sun, J. A Study on the High-Quality Development of China’s Power Battery Recycling Industry for New Energy Vehicles. Sino-Glob. Energy 2025, 30, 7–13. [Google Scholar] [CrossRef]

- Chen, X. Research on the Current Situation and Strategy of New Energy Vehicle Power Battery Recycling. Auto Time 2023, 101–103. [Google Scholar] [CrossRef]

- Zhang, C.; Tian, Y.-X.; Cui, M. Selection of Hybrid Channel Recycling Modes and Carbon Emission Reduction Decisions for the Electric Vehicle Battery Manufacturer. Chin. J. Manag. Sci. 2024, 32, 184–195. [Google Scholar] [CrossRef]

- Xu, Y.; Ma, N.; Feng, Y.; Gao, M.; Chen, L.; Wang, G. Analysis of waste power battery problems based on EPR system. China Storage Transp. 2023, 199–200. [Google Scholar] [CrossRef]

- Feng, J. Analysis of power battery reverse logistics problems based on the development of new energy vehicles. China Storage Transp. 2023, 74–75. [Google Scholar] [CrossRef]

- Heydari, J.; Govindan, K.; Basiri, Z. Balancing price and green quality in presence of consumer environmental awareness: A green supply chain coordination approach. Int. J. Prod. Res. 2021, 59, 1957–1975. [Google Scholar] [CrossRef]

- Zhang, H.; Huang, J.; Hu, R.; Zhou, D.; Khan, H.u.R.; Ma, C. Echelon utilization of waste power batteries in new energy vehicles: Review of Chinese policies. Energy 2020, 206, 118178. [Google Scholar] [CrossRef]

- Xu, X.; Mi, J.; Fan, M.; Yang, K.; Wang, H.; Liu, J.; Yan, H. Study on the performance evaluation and echelon utilization of retired LiFePO4 power battery for smart grid. J. Clean. Prod. 2019, 213, 1080–1086. [Google Scholar] [CrossRef]

- Zhang, C.; Tian, Y.-X.; Han, M.-H. Recycling mode selection and carbon emission reduction decisions for a multi-channel closed-loop supply chain of electric vehicle power battery under cap-and-trade policy. J. Clean. Prod. 2022, 375, 134060. [Google Scholar] [CrossRef]

- Xiao, J.; Jiang, C.; Wang, B. A Review on Dynamic Recycling of Electric Vehicle Battery: Disassembly and Echelon Utilization. Batteries 2023, 9, 57. [Google Scholar] [CrossRef]

- Jiang, Y.; Jiang, J.; Zhang, C.; Zhang, W.; Gao, Y.; Li, N. State of health estimation of second-life LiFePO4 batteries for energy storage applications. J. Clean. Prod. 2018, 205, 754–762. [Google Scholar] [CrossRef]

- Lai, X.; Deng, C.; Li, J.; Zhu, Z.; Han, X.; Zheng, Y. Rapid sorting and regrouping of retired lithium-ion battery modules for echelon utilization based on partial charging curves. IEEE Trans. Veh. Technol. 2021, 70, 1246–1254. [Google Scholar] [CrossRef]

- Lai, X.; Huang, Y.; Deng, C.; Gu, H.; Han, X.; Zheng, Y.; Ouyang, M. Sorting, regrouping, and echelon utilization of the large-scale retired lithium batteries: A critical review. Renew. Sustain. Energy Rev. 2021, 146, 111162. [Google Scholar] [CrossRef]

- Gu, X.; Zhou, L.; Huang, H.; Shi, X.; Ieromonachou, P. Electric vehicle battery secondary use under government subsidy: A closed-loop supply chain perspective. Int. J. Prod. Econ. 2021, 234, 108035. [Google Scholar] [CrossRef]

- Yu, S.; Hou, Q. A closed-loop power battery supply chain differential game model considering echelon utilization under a cost subsidy. Kybernetes 2022, 52, 2826–2846. [Google Scholar] [CrossRef]

- Zhao, S.; Ma, C. Research on the coordination of the power battery echelon utilization supply chain considering recycling outsourcing. J. Clean. Prod. 2022, 358, 131922. [Google Scholar] [CrossRef]

- Lander, L.; Tagnon, C.; Nguyen-Tien, V.; Kendrick, E.; Elliott, R.J.; Abbott, A.P.; Edge, J.S.; Offer, G.J. Breaking it down: A techno-economic assessment of the impact of battery pack design on disassembly costs. Appl. Energy 2023, 331, 120437. [Google Scholar] [CrossRef]

- Chung, C.-J.; Wee, H.-M. Green-component life-cycle value on design and reverse manufacturing in semi-closed supply chain. Int. J. Prod. Econ. 2008, 113, 528–545. [Google Scholar] [CrossRef]

- Thompson, D.L.; Hartley, J.M.; Lambert, S.M.; Shiref, M.; Harper, G.D.; Kendrick, E.; Anderson, P.; Ryder, K.S.; Gaines, L.; Abbott, A.P. The importance of design in lithium ion battery recycling—A critical review. Green Chem. 2020, 22, 7585–7603. [Google Scholar] [CrossRef]

- Rosenberg, S.; Huster, S.; Baazouzi, S.; Glöser-Chahoud, S.; Al Assadi, A.; Schultmann, F. Field Study and Multimethod Analysis of an EV Battery System Disassembly. Energies 2022, 15, 5324. [Google Scholar] [CrossRef]

- Meng, K.; Xu, G.; Peng, X.; Youcef-Toumi, K.; Li, J. Intelligent disassembly of electric-vehicle batteries: A forward-looking overview. Resour. Conserv. Recycl. 2022, 182, 106207. [Google Scholar] [CrossRef]

- Talens Peiró, L.; Ardente, F.; Mathieux, F. Design for disassembly criteria in EU product policies for a more circular economy: A method for analyzing battery packs in PC-tablets and subnotebooks. J. Ind. Ecol. 2017, 21, 731–741. [Google Scholar] [CrossRef]

- da Silva, E.R.; Lohmer, J.; Rohla, M.; Angelis, J. Unleashing the circular economy in the electric vehicle battery supply chain: A case study on data sharing and blockchain potential. Resour. Conserv. Recycl. 2023, 193, 106969. [Google Scholar] [CrossRef]

- He, Z.; Ni, S.; Jiang, X.; Feng, C. The Influence of Demand Fluctuation and Competition Intensity on Advantages of Supply Chain Dominance. Mathematics 2023, 11, 4931. [Google Scholar] [CrossRef]

- Deng, W.; Feng, L.; Zhao, X.; Lou, Y. Effects of supply chain competition on firms’ product sustainability strategy. J. Clean. Prod. 2020, 275, 124061. [Google Scholar] [CrossRef]

- Liu, L. Top management characteristics, green supply chain management and corporate performance—Moderating effects of competition intensity. J. Hum. Resour. Sustain. Stud. 2019, 7, 55. [Google Scholar] [CrossRef][Green Version]

- Adida, E.; DeMiguel, V. Supply Chain Competition with Multiple Manufacturers and Retailers. Oper. Res. 2011, 59, 156–172. [Google Scholar] [CrossRef]

- Mahapatra, S.K.; Das, A.; Narasimhan, R. A contingent theory of supplier management initiatives: Effects of competitive intensity and product life cycle. J. Oper. Manag. 2012, 30, 406–422. [Google Scholar] [CrossRef]

- Anderson, E.J.; Bao, Y. Price competition with integrated and decentralized supply chains. Eur. J. Oper. Res. 2010, 200, 227–234. [Google Scholar] [CrossRef]

- Bian, W.; Shang, J.; Zhang, J. Two-way information sharing under supply chain competition. Int. J. Prod. Econ. 2016, 178, 82–94. [Google Scholar] [CrossRef]

- Chu, H.; Zhang, W.; Zhu, L. The impact of government policies on the coordination of power battery closed-loop supply chain. J. Clean. Prod. 2025, 519, 145961. [Google Scholar] [CrossRef]

- Zhao, S.; Han, Y.; Zhou, Q.; Xia, X. Collaborative management of battery manufacturer responsibility in electric vehicle production with ESG due diligence. J. Clean. Prod. 2025, 486, 144591. [Google Scholar] [CrossRef]

- Saxena, V. Enhancing EV battery lifecycle management: Robotic disassembly, design for disassembly, and sustainable solutions. J. Energy Storage 2025, 119, 116368. [Google Scholar] [CrossRef]

- Wu, W. Electric vehicle battery recycling strategy considering channel leadership under the carbon trading mechanism: Cooperation, competition, or monopoly? Energy 2025, 335, 138262. [Google Scholar] [CrossRef]

- Wu, C.-H. OEM product design in a price competition with remanufactured product. Omega 2013, 41, 287–298. [Google Scholar] [CrossRef]

| Author | Battery Recycling | Echelon Utilization | Battery Disassembly Design | Market Competition Intensity |

|---|---|---|---|---|

| Chu et al. [31] | √ | |||

| Zhao et al. [32] | √ | √ | ||

| Lander et al. [17] | √ | √ | ||

| Thompson et al. [19] | √ | √ | ||

| Saxena [33] | √ | |||

| He et al. [24] | √ | |||

| Wu et al. [34] | √ | √ | ||

| Zhang et al. [9] | √ | √ | √ | |

| This paper | √ | √ | √ | √ |

| Symbols | Definition |

|---|---|

| Recycling amount of waste batteries by new energy vehicle manufacturers | |

| Recycling amount of waste batteries by battery manufacturers | |

| Minimum number of used batteries recycled on the market | |

| Consumer sensitivity to battery recycling prices | |

| Battery recycling market competition intensity | |

| Proportion of waste batteries meeting echelon usage standards | |

| Waste batteries that meet the standard of echelon use can obtain unit value | |

| Cost of dismantling and inspection of waste batteries | |

| Unit cost of battery manufacturers to deal with waste batteries | |

| Investment cost coefficient for dismantling design | |

| Influence factors of disassembly design on disassembly cost | |

| Unit retail price of the third type of old battery | |

| New energy vehicle manufacturer profit | |

| Battery manufacturer profits | |

| Overall profit of supply chain members | |

| Unit price of waste battery recycling of new energy vehicle manufacturers | |

| Battery manufacturer waste battery recycling unit price | |

| Battery manufacturer repurchase price | |

| Battery disassembly level design |

| Scenario | Battery Manufacturers Do Not Participate in Battery Recycling | Proportion of Waste Batteries Meeting Echelon Usage Standards |

|---|---|---|

| / | ||

| / | ||

| / | ||

| Symbols | Value | Source |

|---|---|---|

| 50 | Zhao et al. [16] | |

| 0.25 | Wang et al. [1], “Management Measures for Echelon Utilization of New Energy Vehicle Power Battery” | |

| 20 | Lander et al. [17] | |

| 5 | “2023 Annual Report of CATL” | |

| 500 | “Chinese new energy battery recycling industry development report” | |

| 1 | Zhao et al. [16] | |

| 50 | Wu [35] | |

| 360 | Metal Recycling Market Data | |

| 4 | Lander et al. [17] | |

| 2 | Zhao et al. [16] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, S.; Wang, X.; Liu, H. Managing Market Competition and Battery Disassembly Design in an Echelon Utilization Supply Chain: The Case of China Electric Vehicle Industry. Energies 2025, 18, 5820. https://doi.org/10.3390/en18215820

Zhao S, Wang X, Liu H. Managing Market Competition and Battery Disassembly Design in an Echelon Utilization Supply Chain: The Case of China Electric Vehicle Industry. Energies. 2025; 18(21):5820. https://doi.org/10.3390/en18215820

Chicago/Turabian StyleZhao, Senlin, Xinkang Wang, and Hongchen Liu. 2025. "Managing Market Competition and Battery Disassembly Design in an Echelon Utilization Supply Chain: The Case of China Electric Vehicle Industry" Energies 18, no. 21: 5820. https://doi.org/10.3390/en18215820

APA StyleZhao, S., Wang, X., & Liu, H. (2025). Managing Market Competition and Battery Disassembly Design in an Echelon Utilization Supply Chain: The Case of China Electric Vehicle Industry. Energies, 18(21), 5820. https://doi.org/10.3390/en18215820