Hydrodynamic Characteristic Around the Riprap Protection of Monopile Wind Power Foundation with Scour Pit During Scour

Abstract

1. Introduction

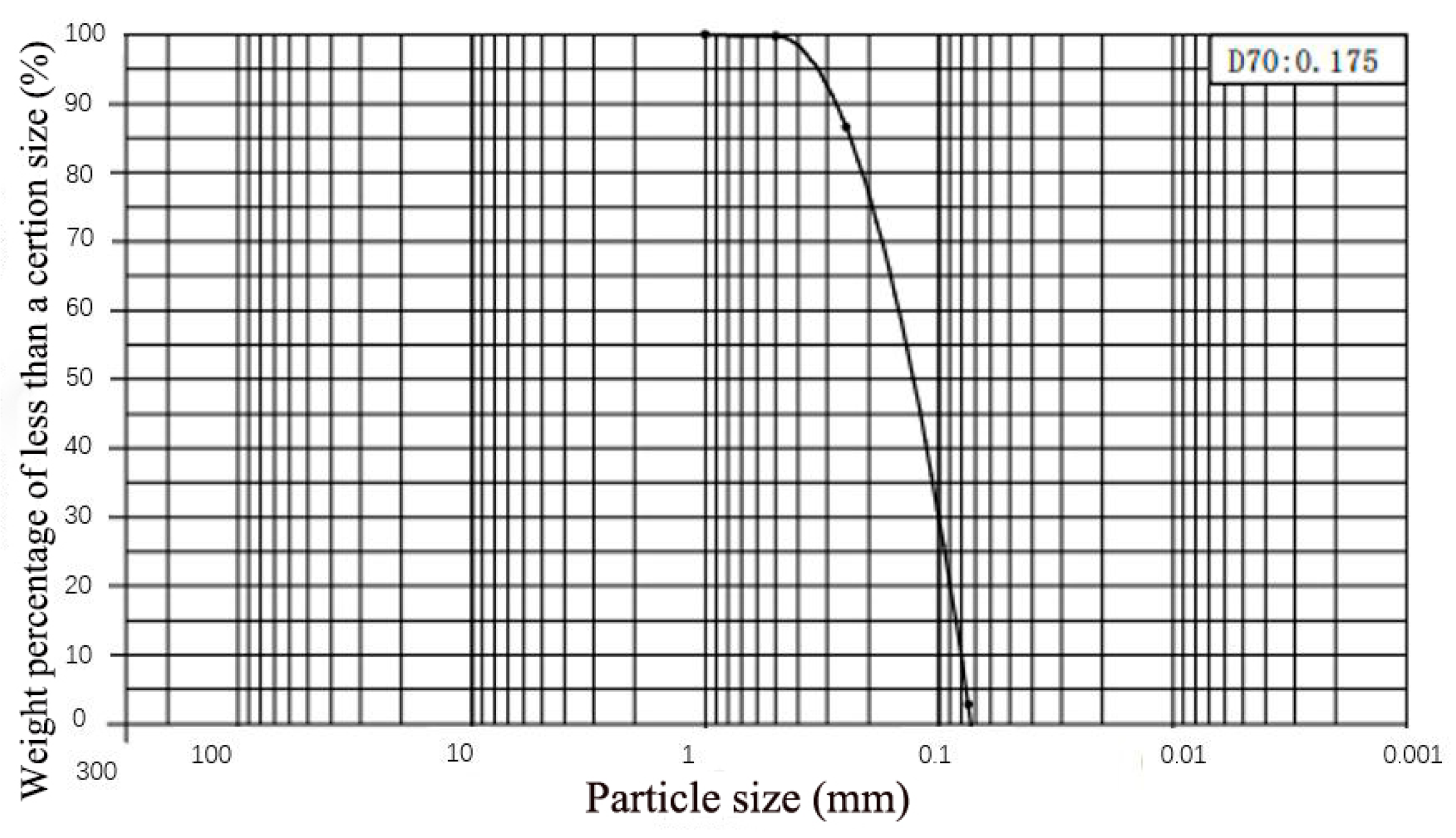

2. Physical Modeling Experiment

2.1. Experimental Setup

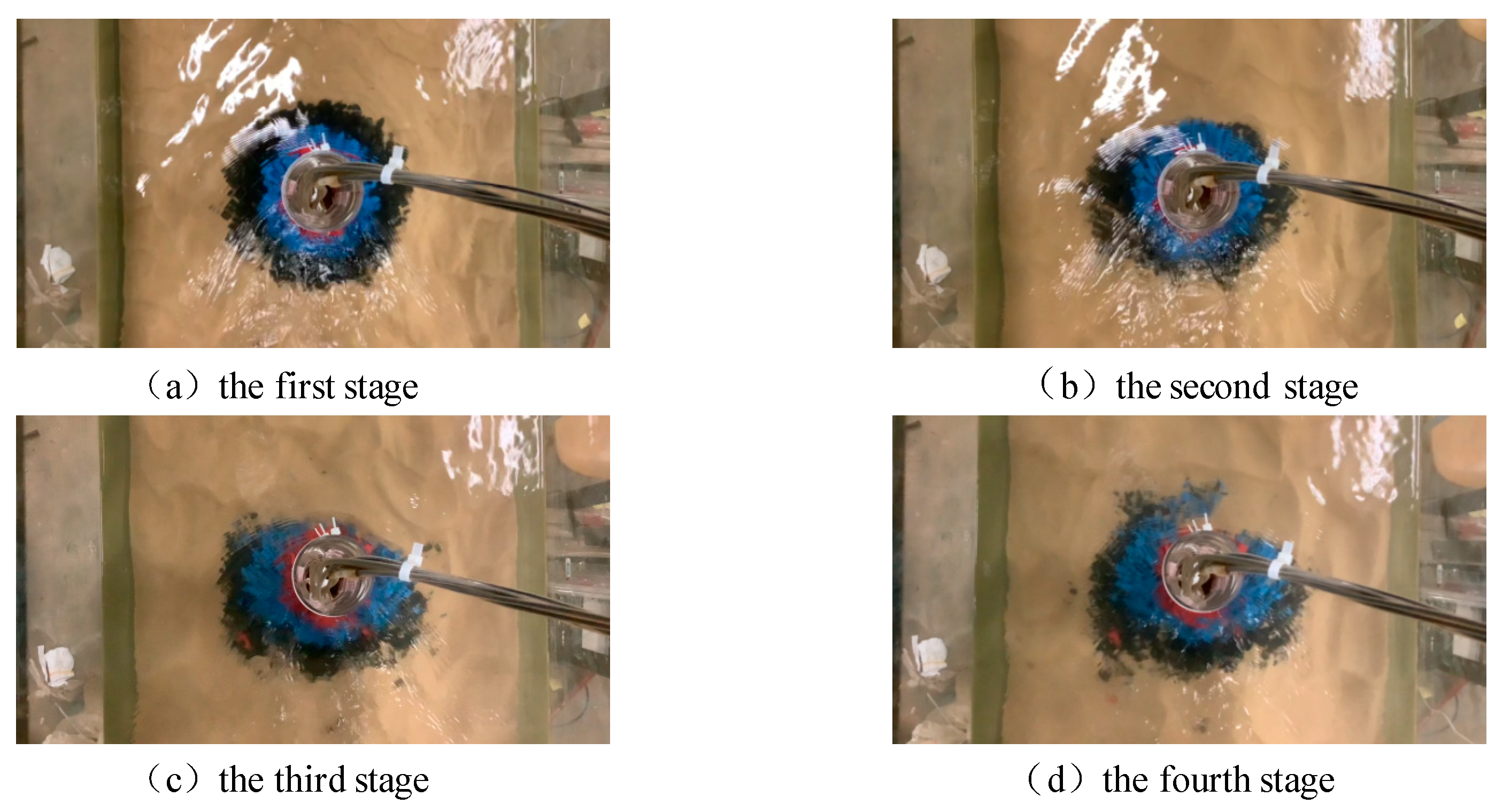

2.2. Test Procedure

2.3. Division of Scour Stage

3. The Hydrodynamics Numerical Model of Current-Pile-Riprap-Seabed Interaction

3.1. Numerical Method

3.1.1. Governing Equations

3.1.2. The Turbulence Model

3.1.3. Boundary Conditions and the Initial Conditions

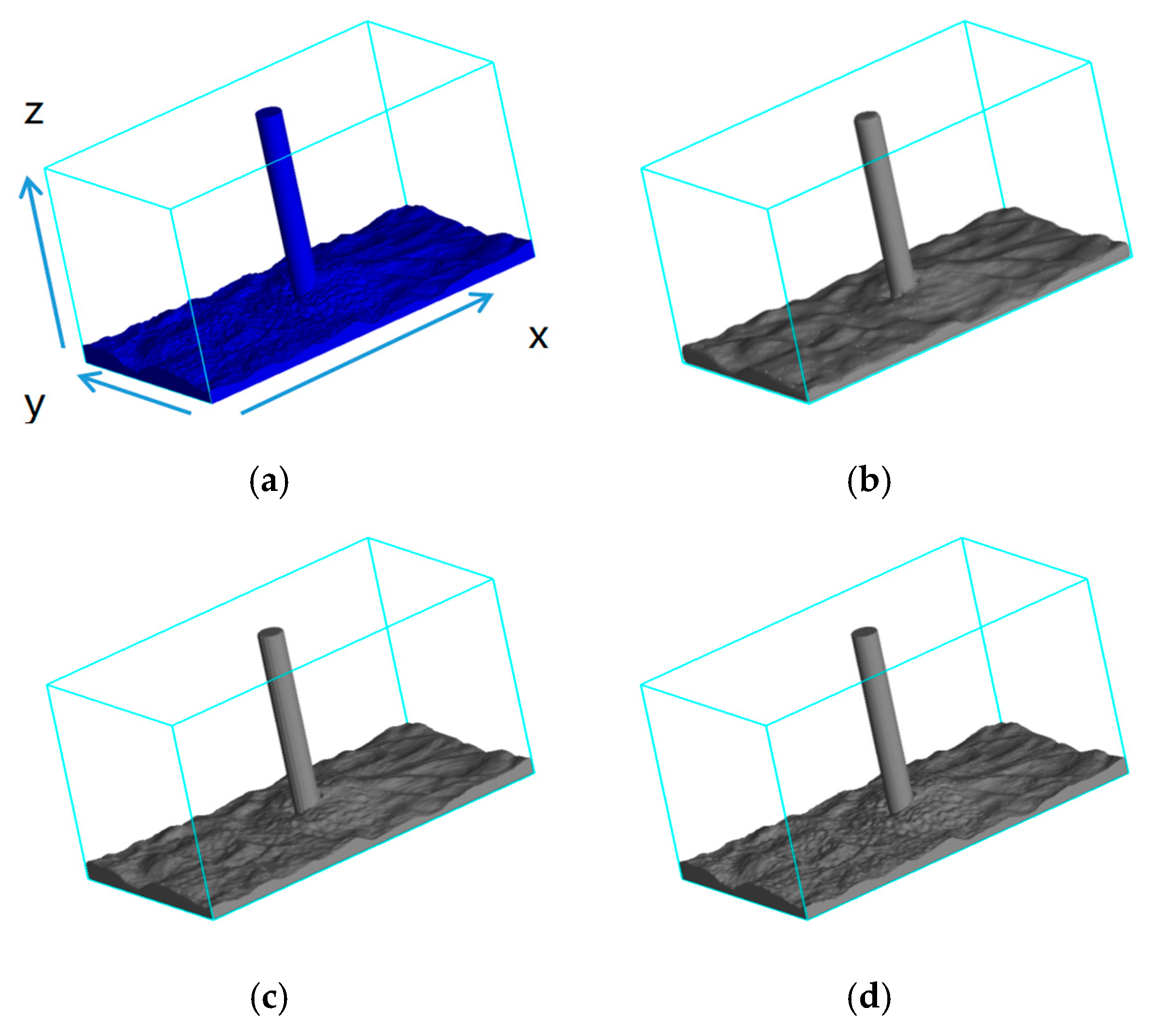

3.2. Establishment and Verification of the Numerical Model

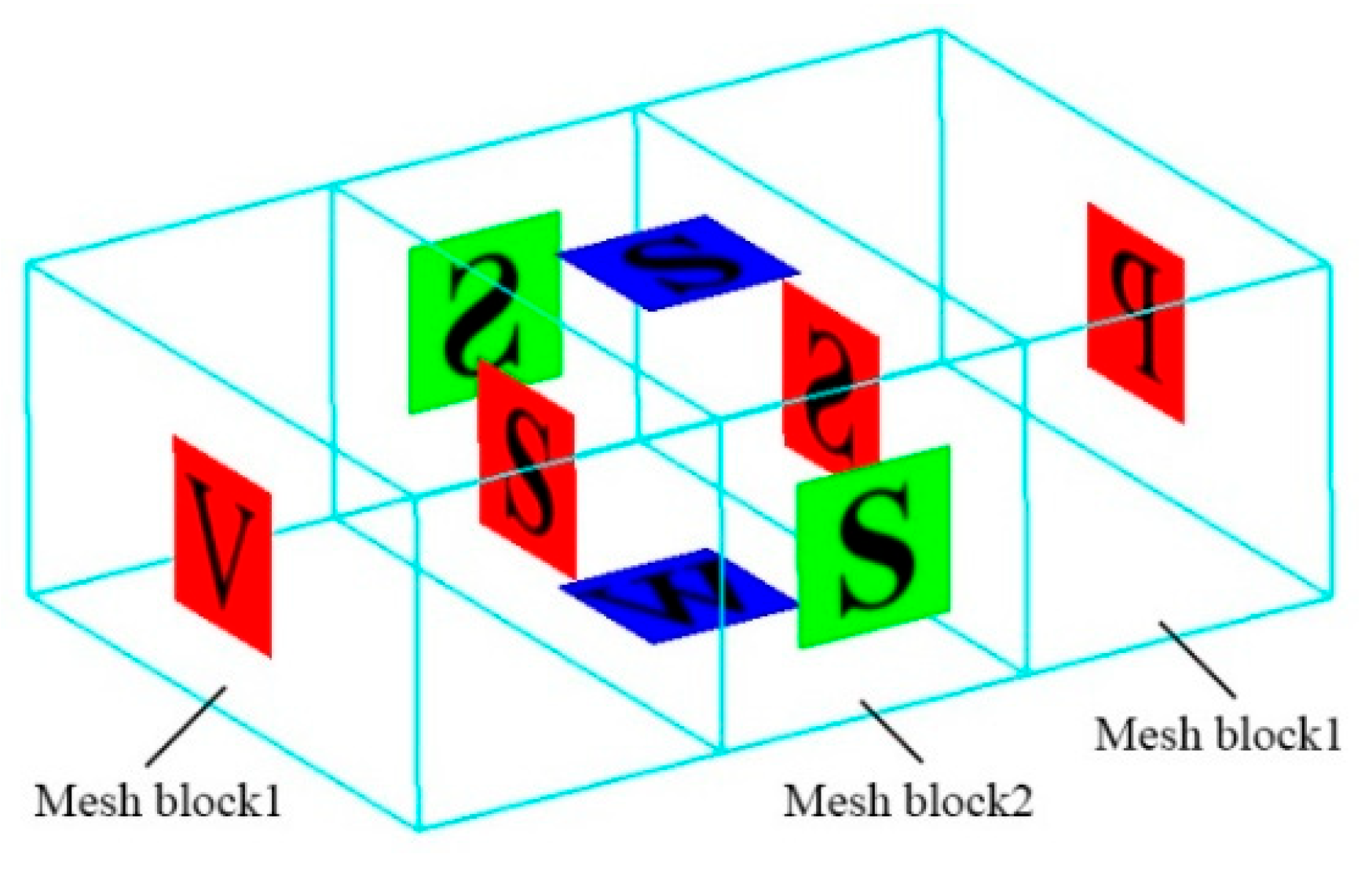

3.2.1. Establishment of Numerical Model

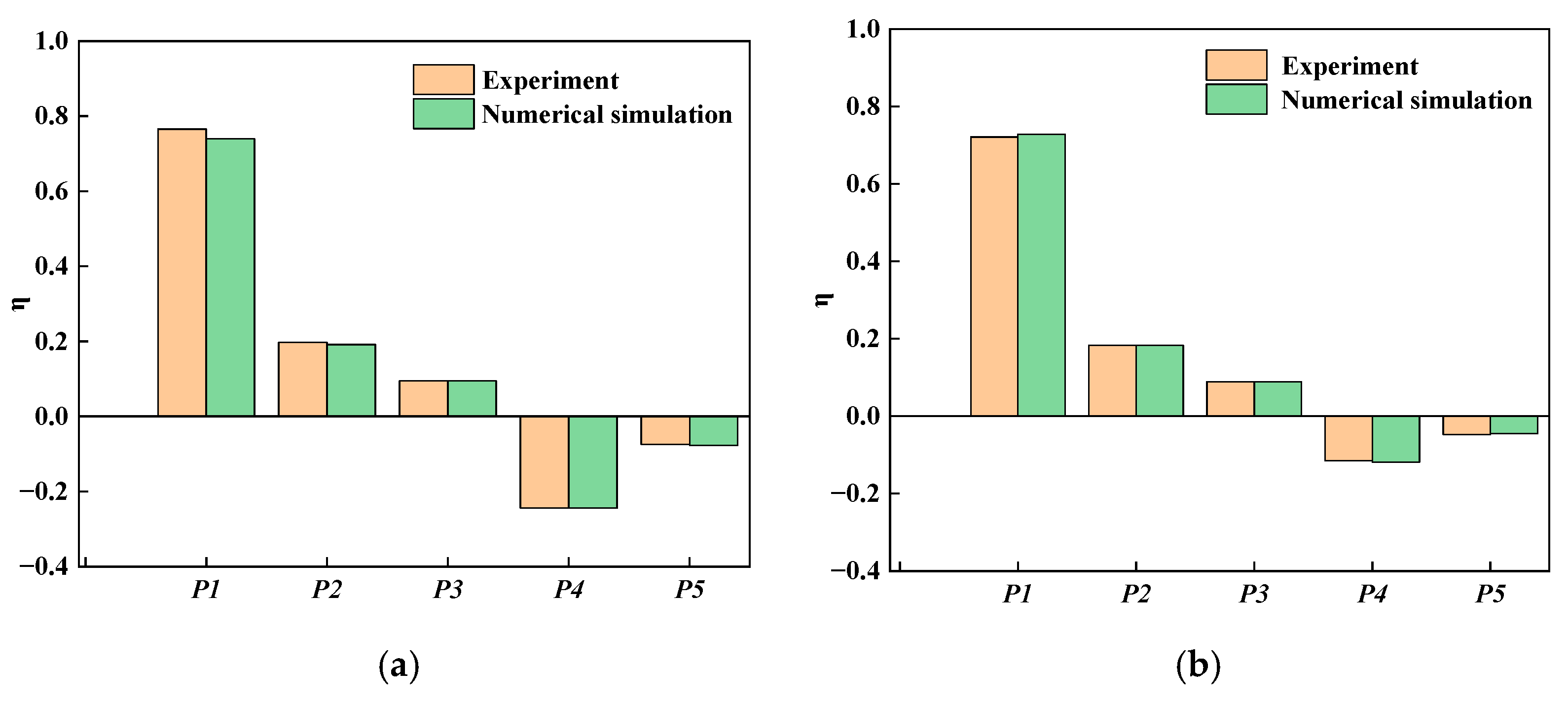

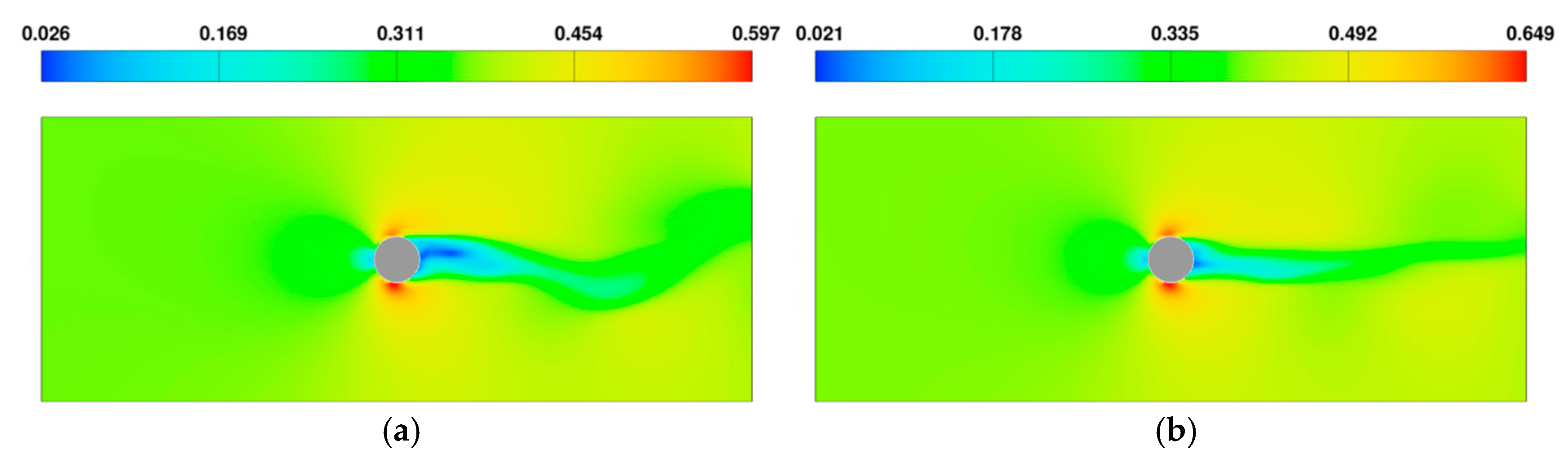

3.2.2. Verification of Numerical Model

4. Hydrodynamic Characteristics Around the Pile Foundation

4.1. Characteristics of the Flow Field Around the Pile Foundation

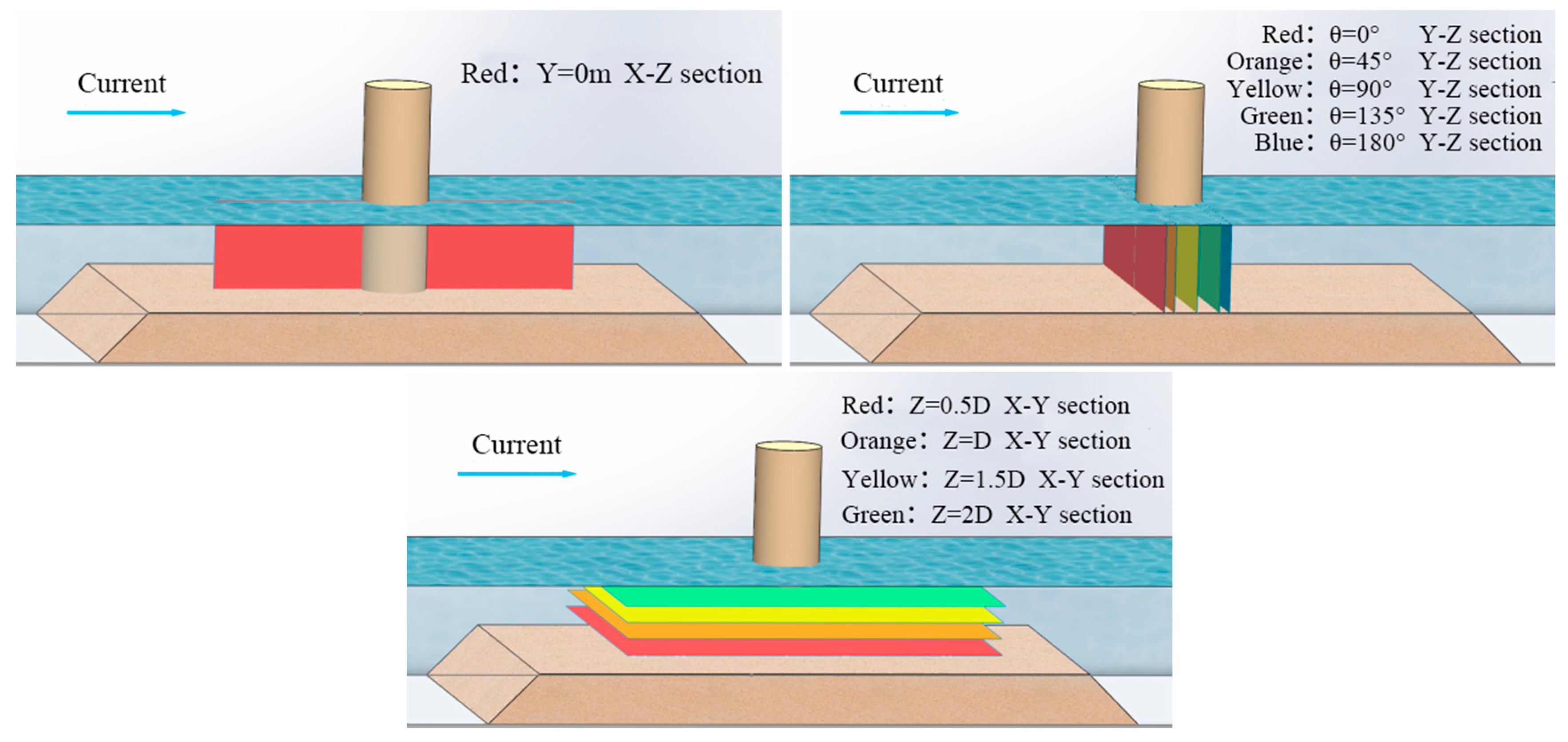

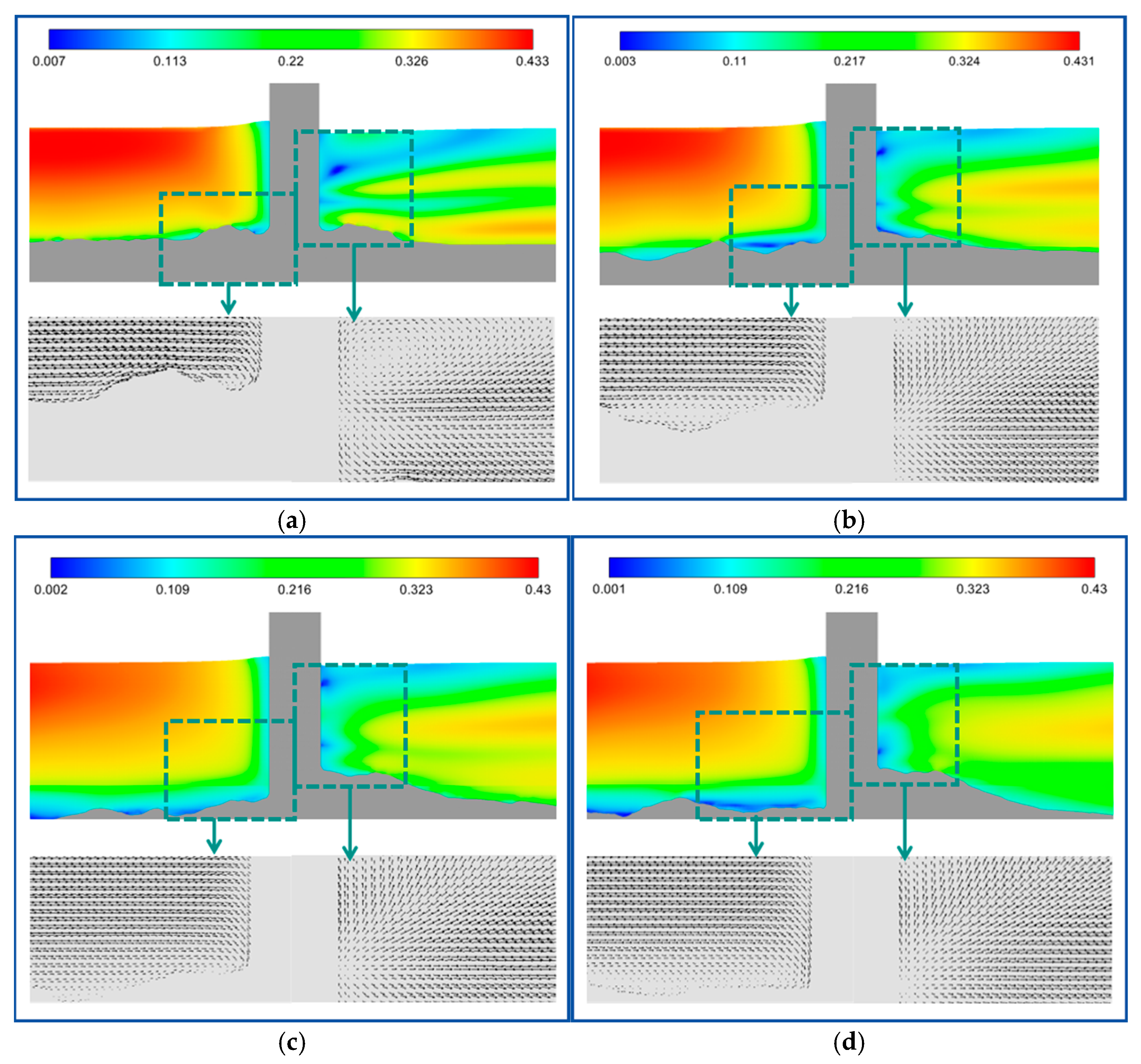

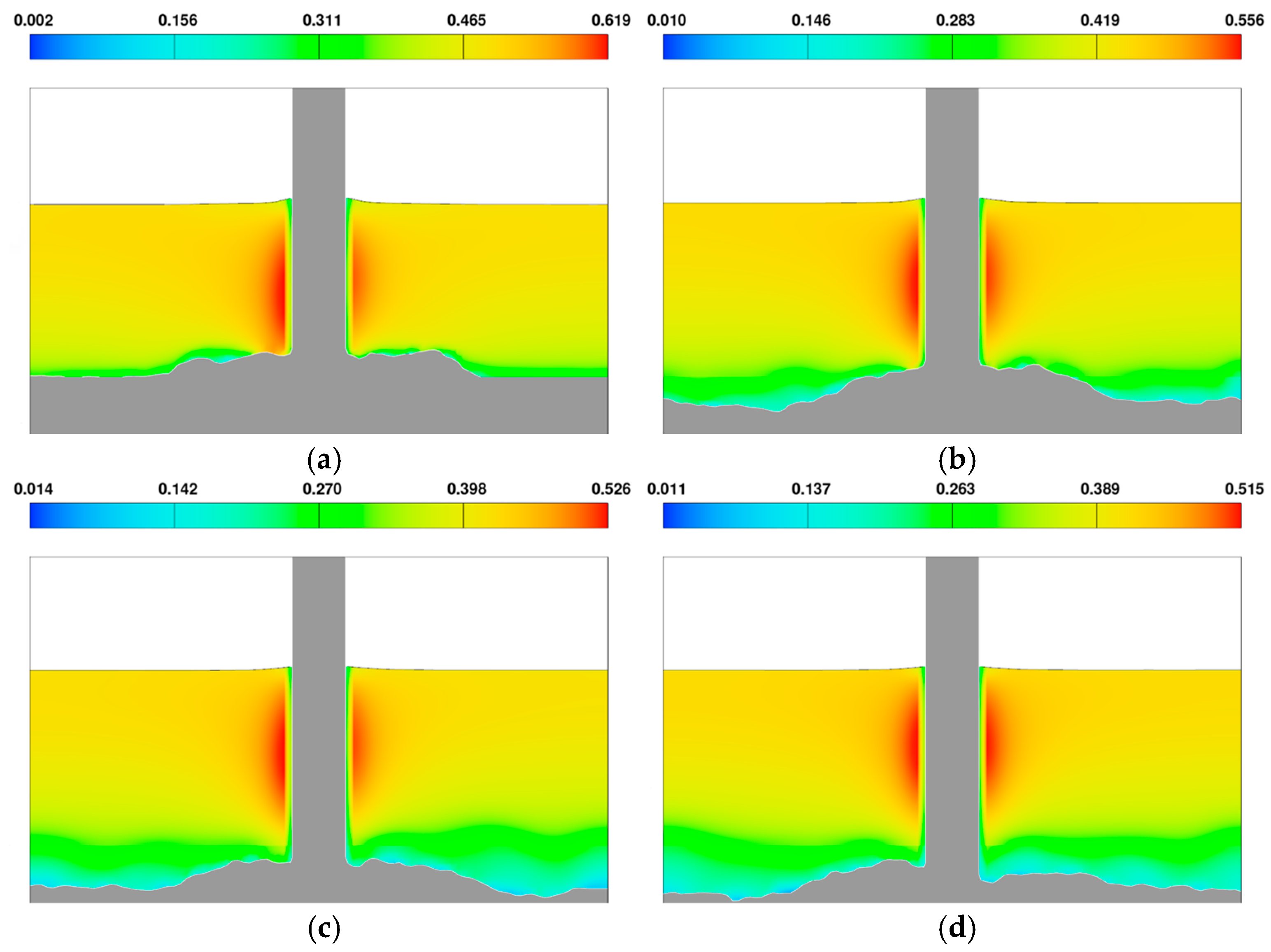

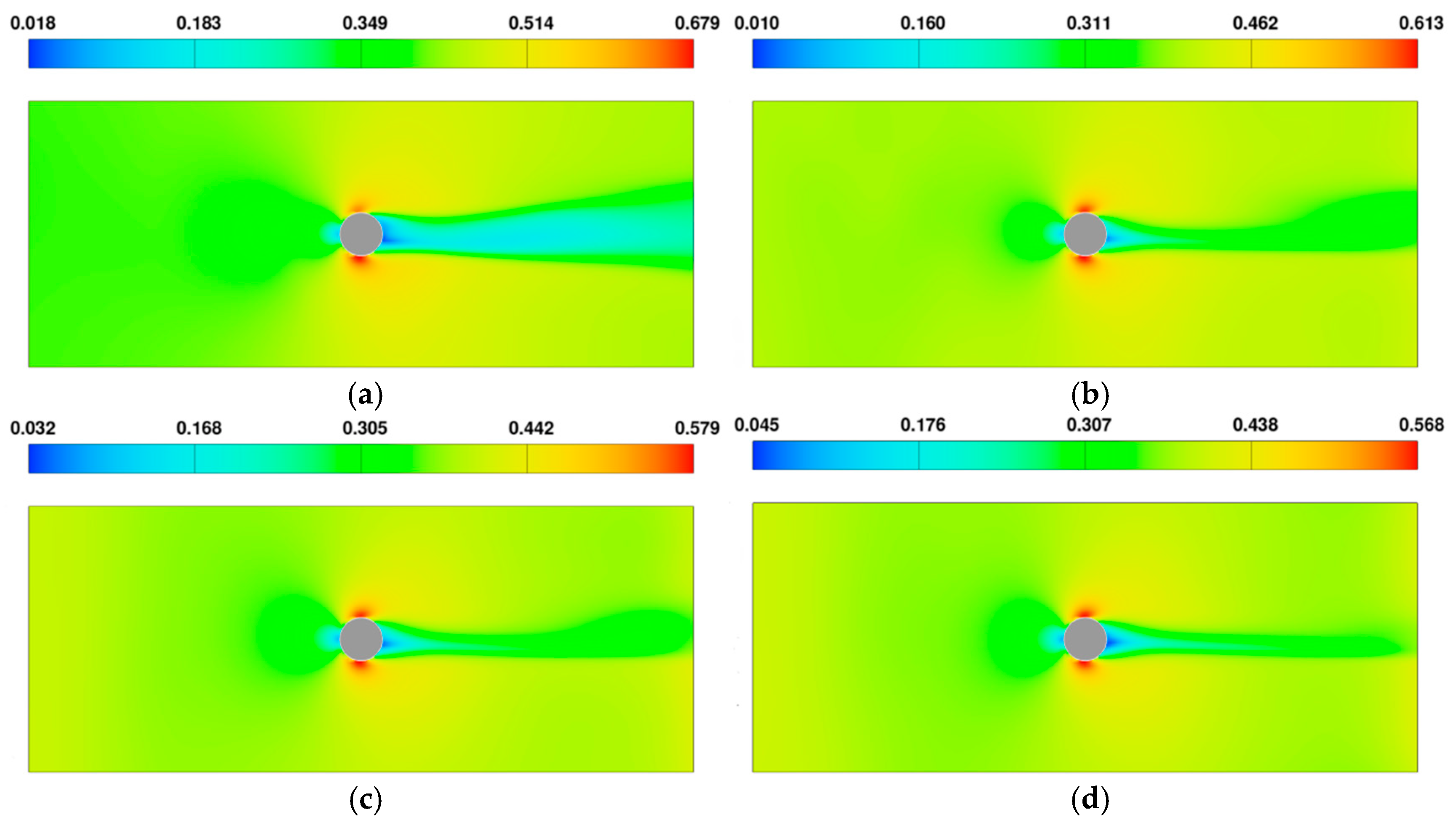

4.1.1. Velocity of X-Z Section

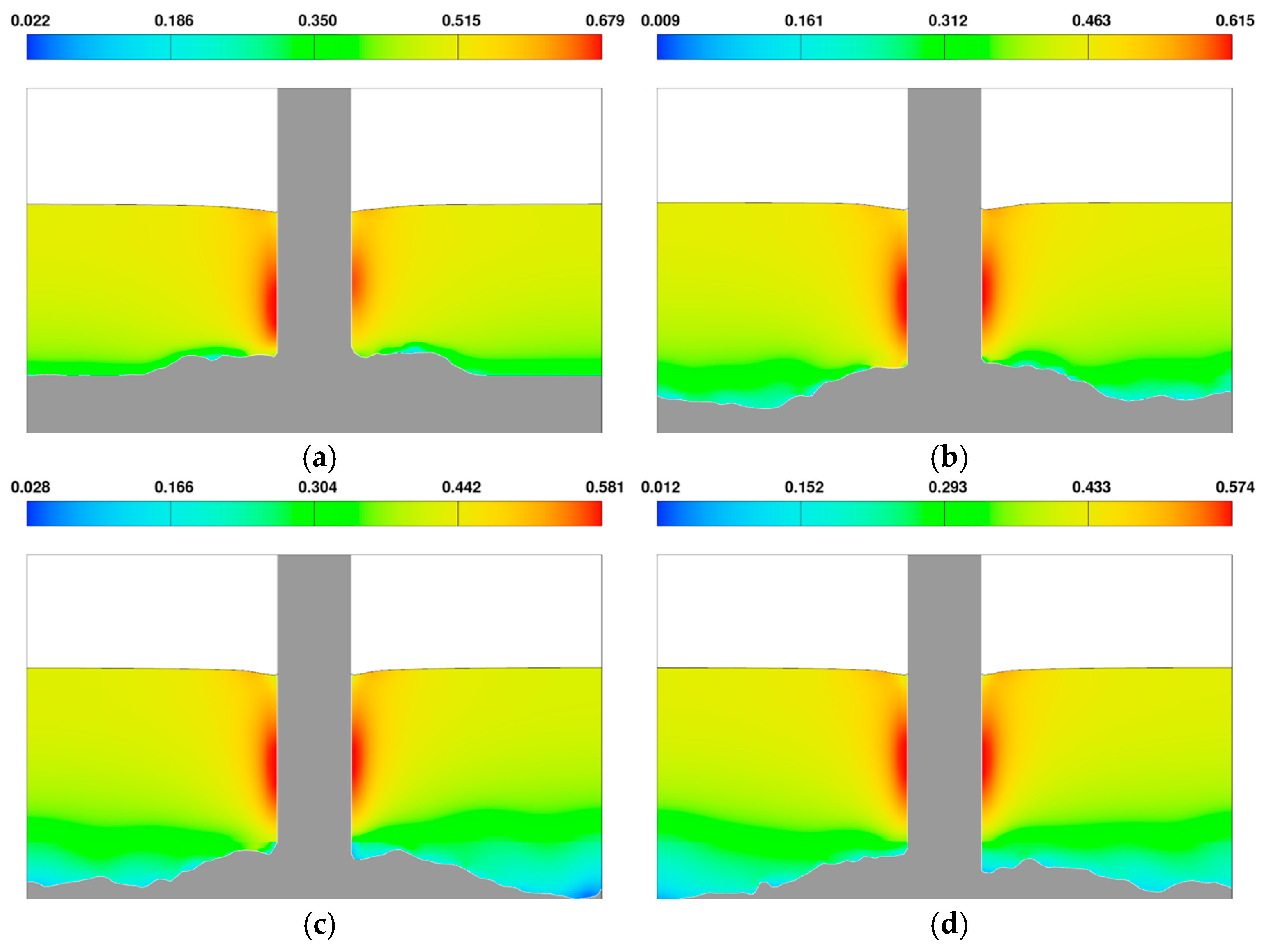

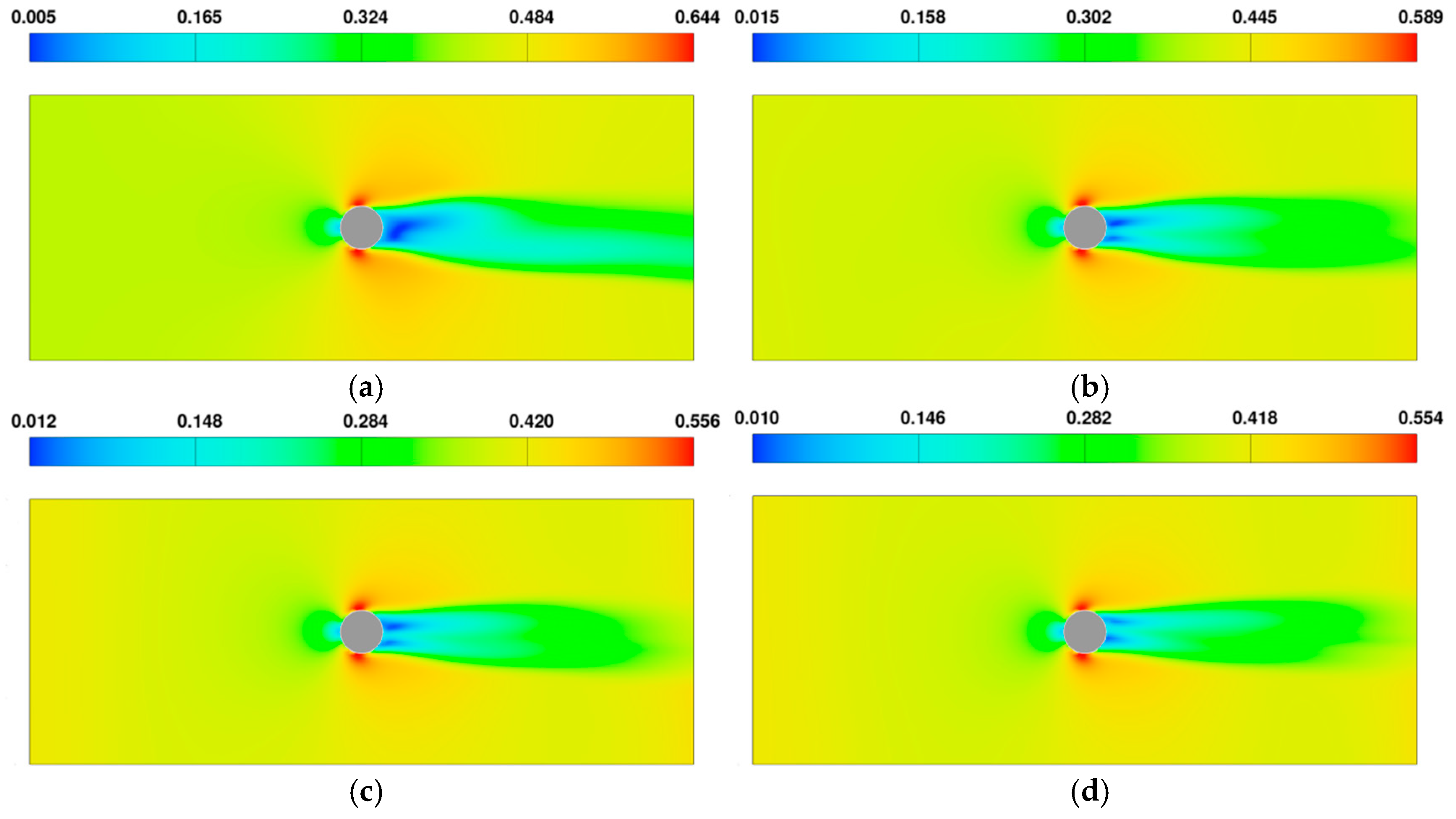

4.1.2. Velocity of Y-Z Section

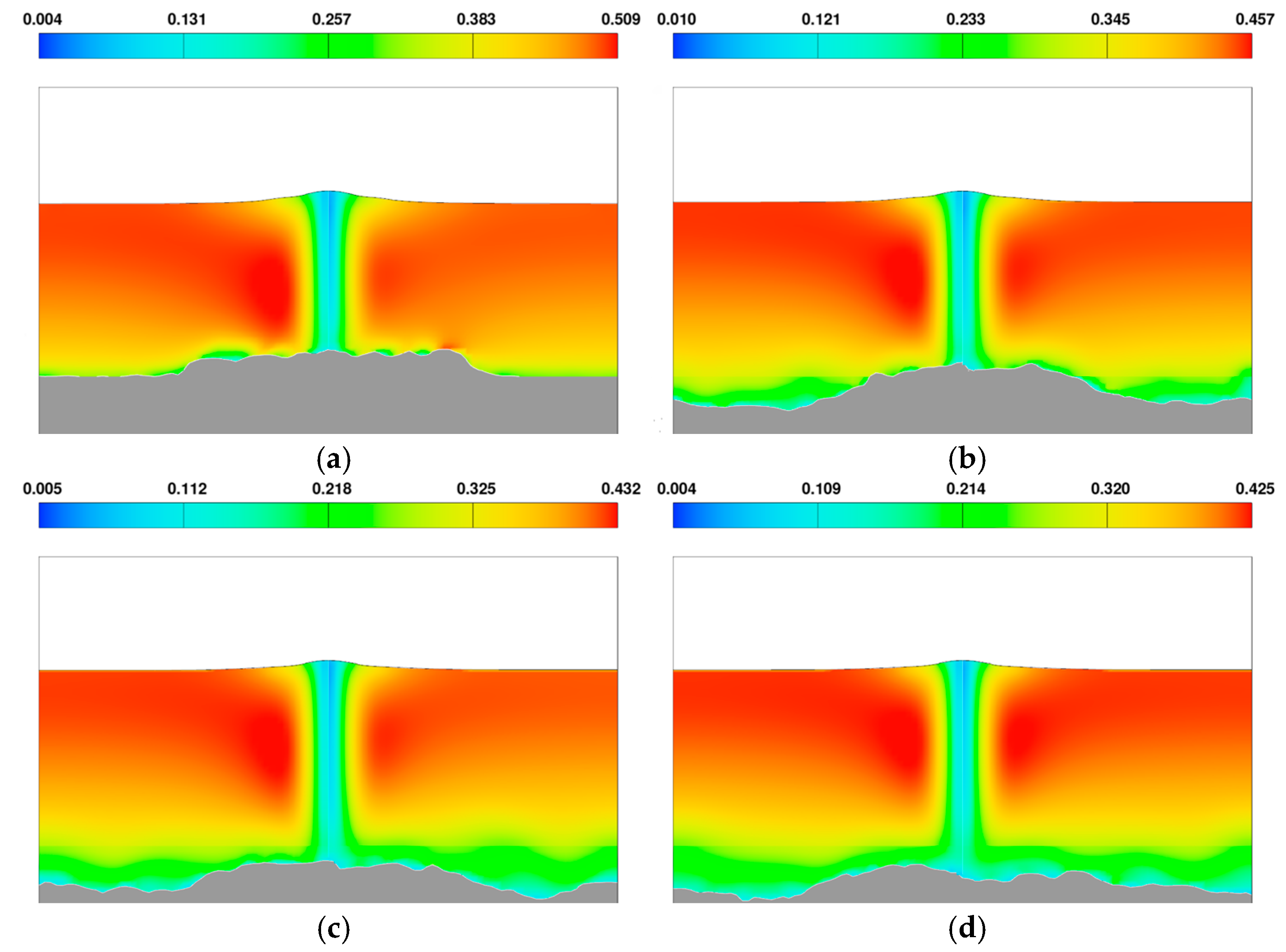

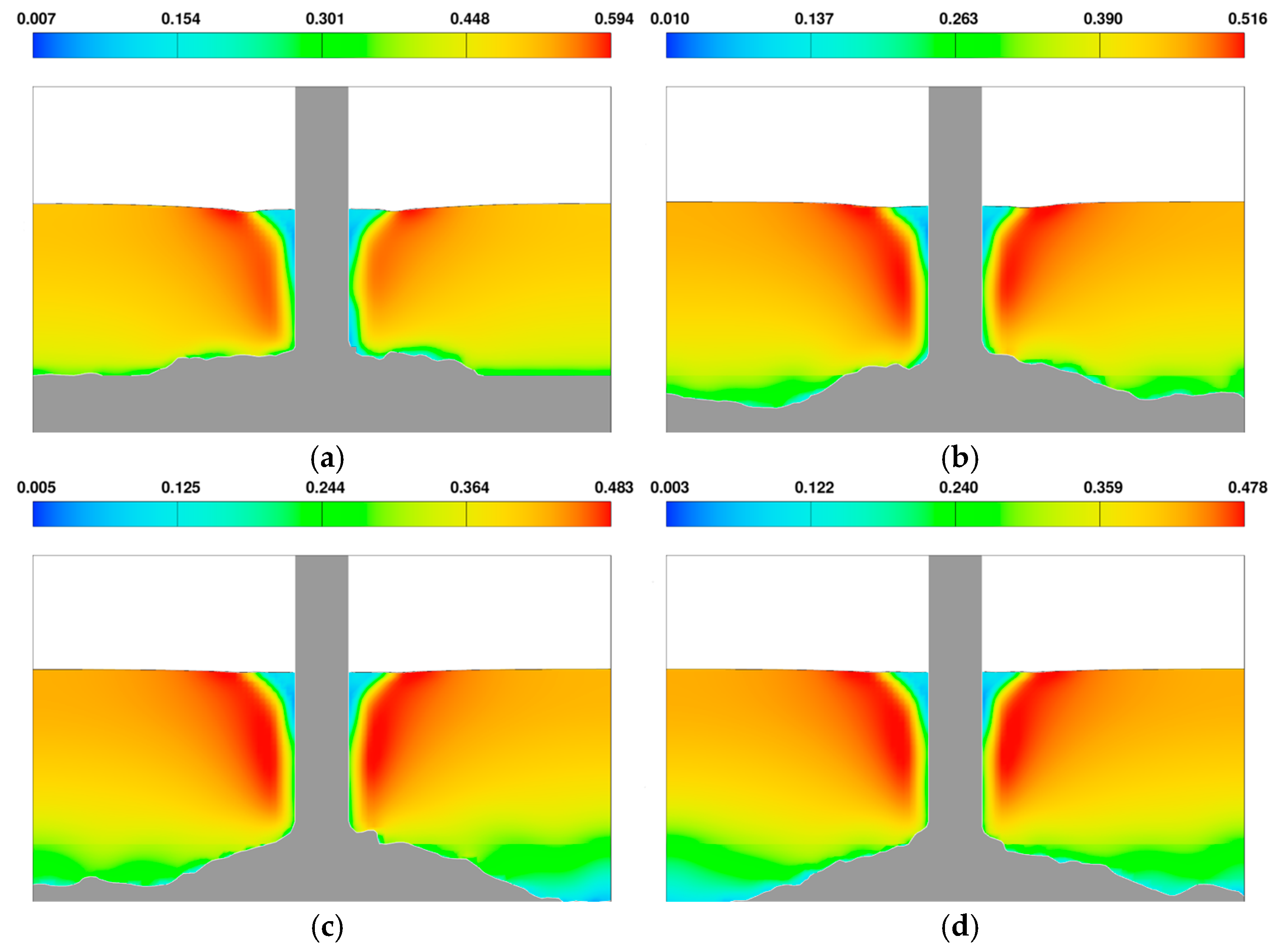

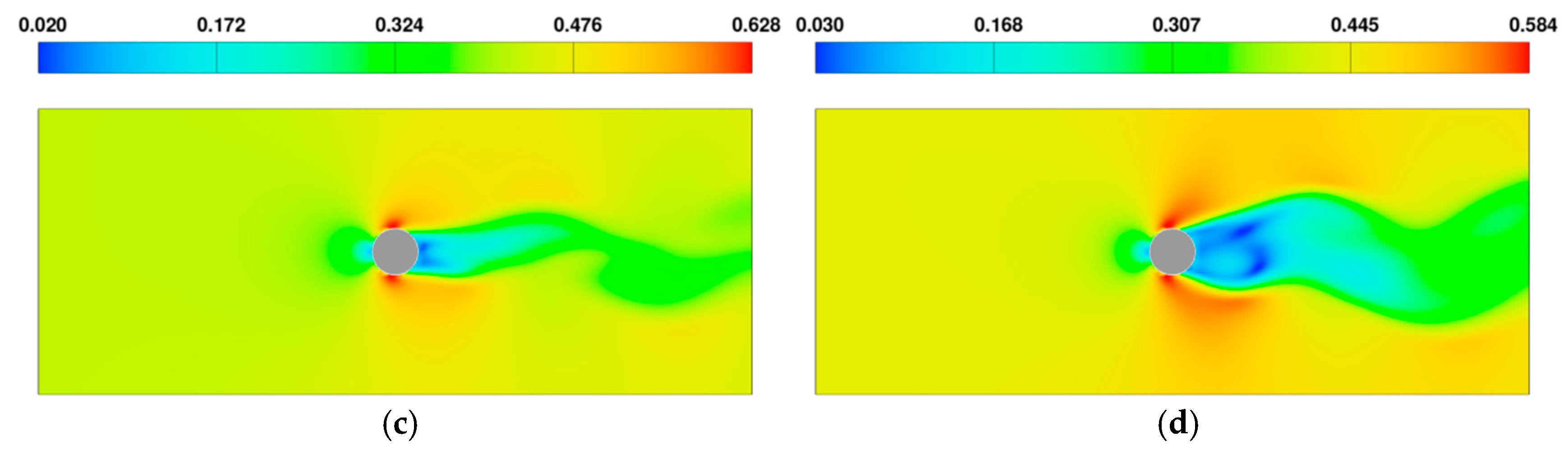

4.1.3. Velocity of X-Y Section

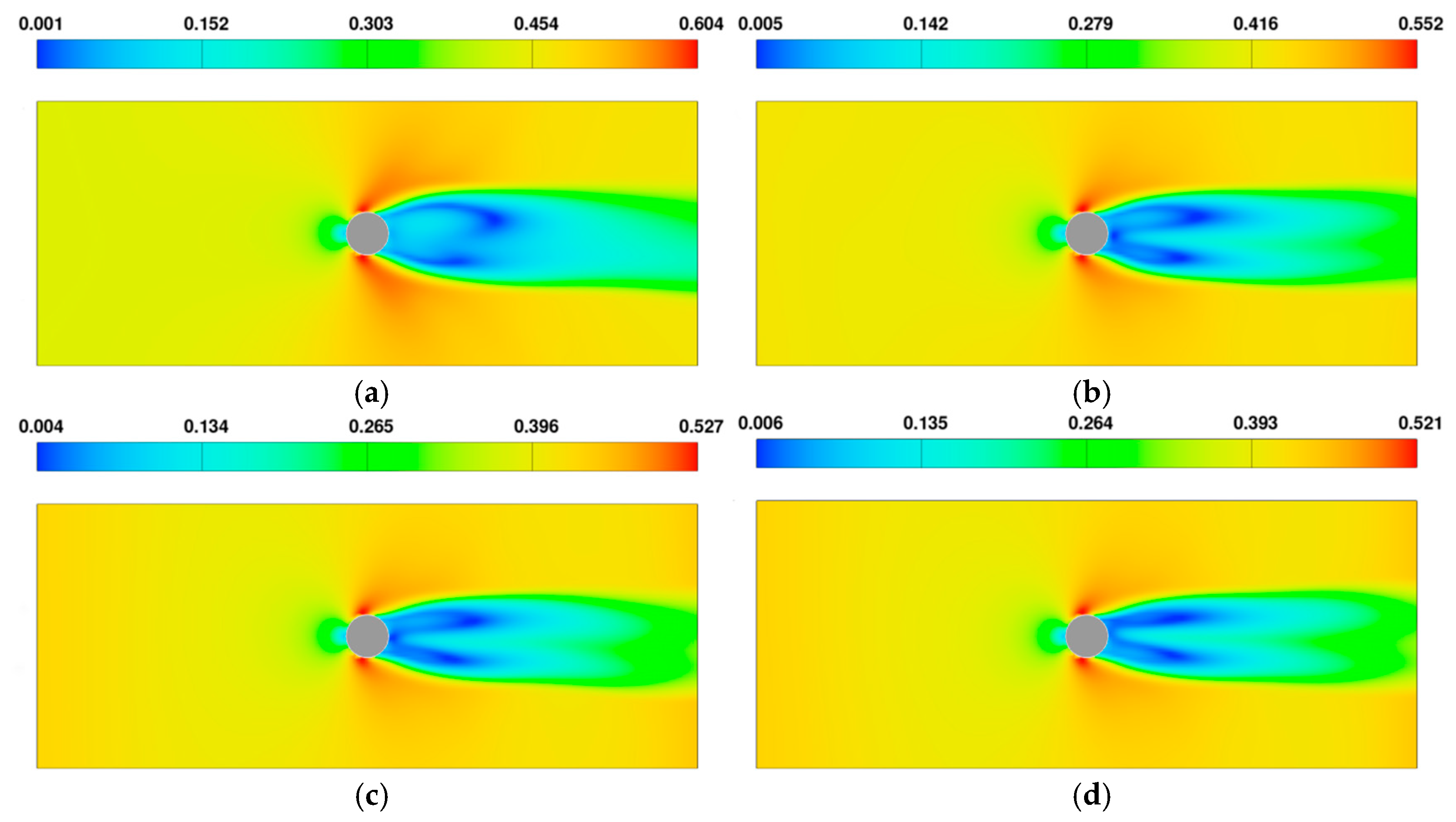

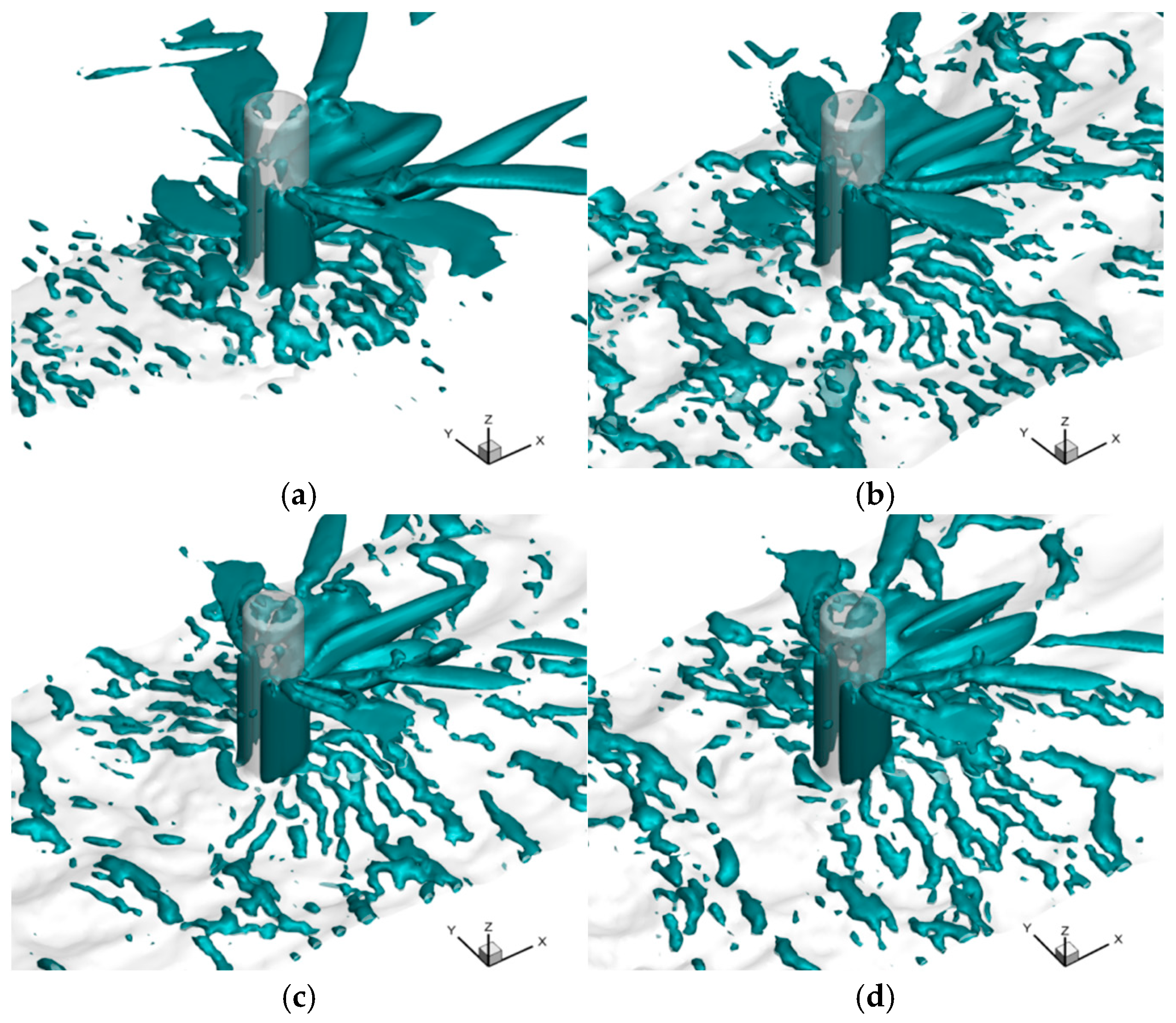

4.2. Horseshoe Vortex

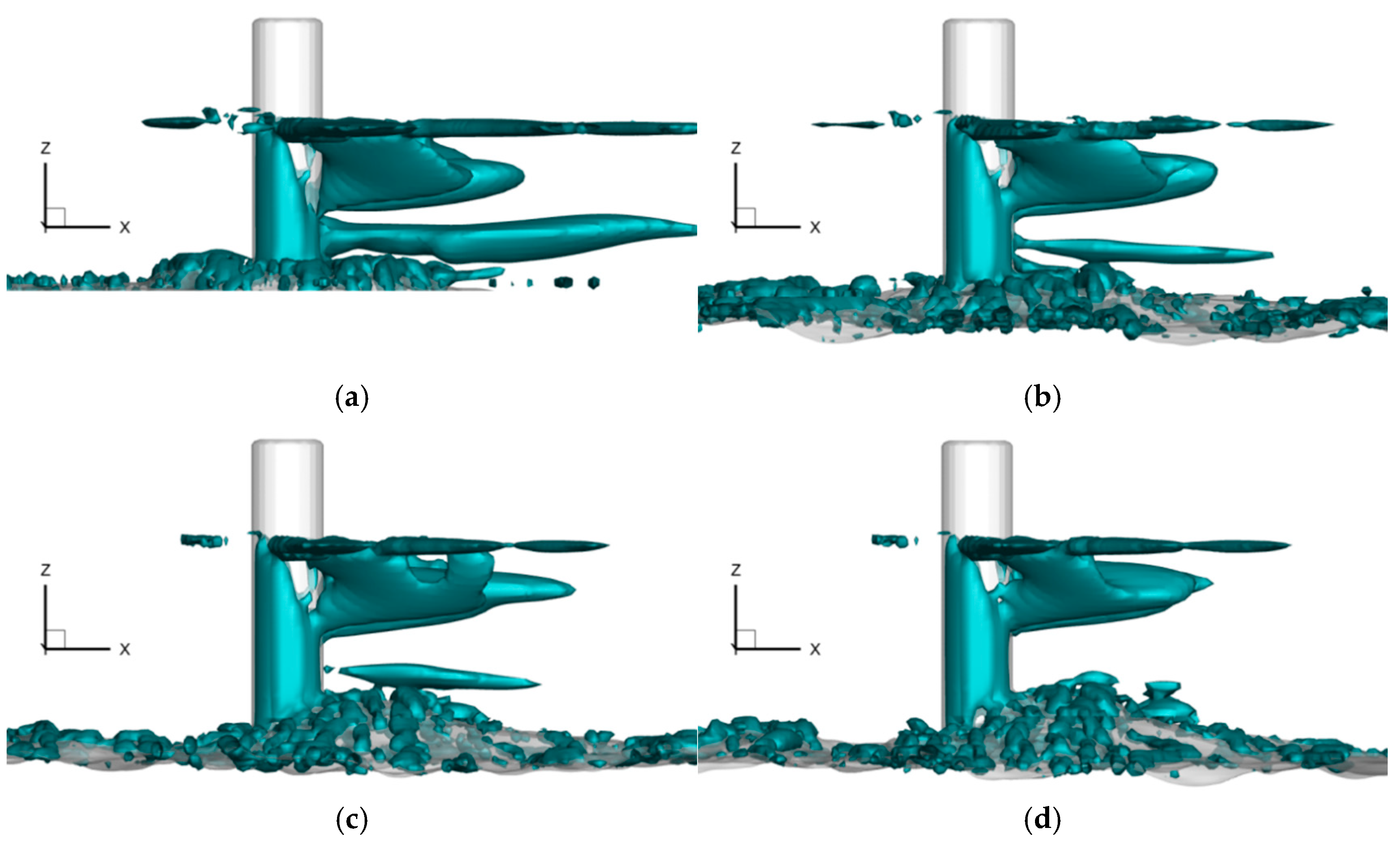

4.3. Wake Vortex

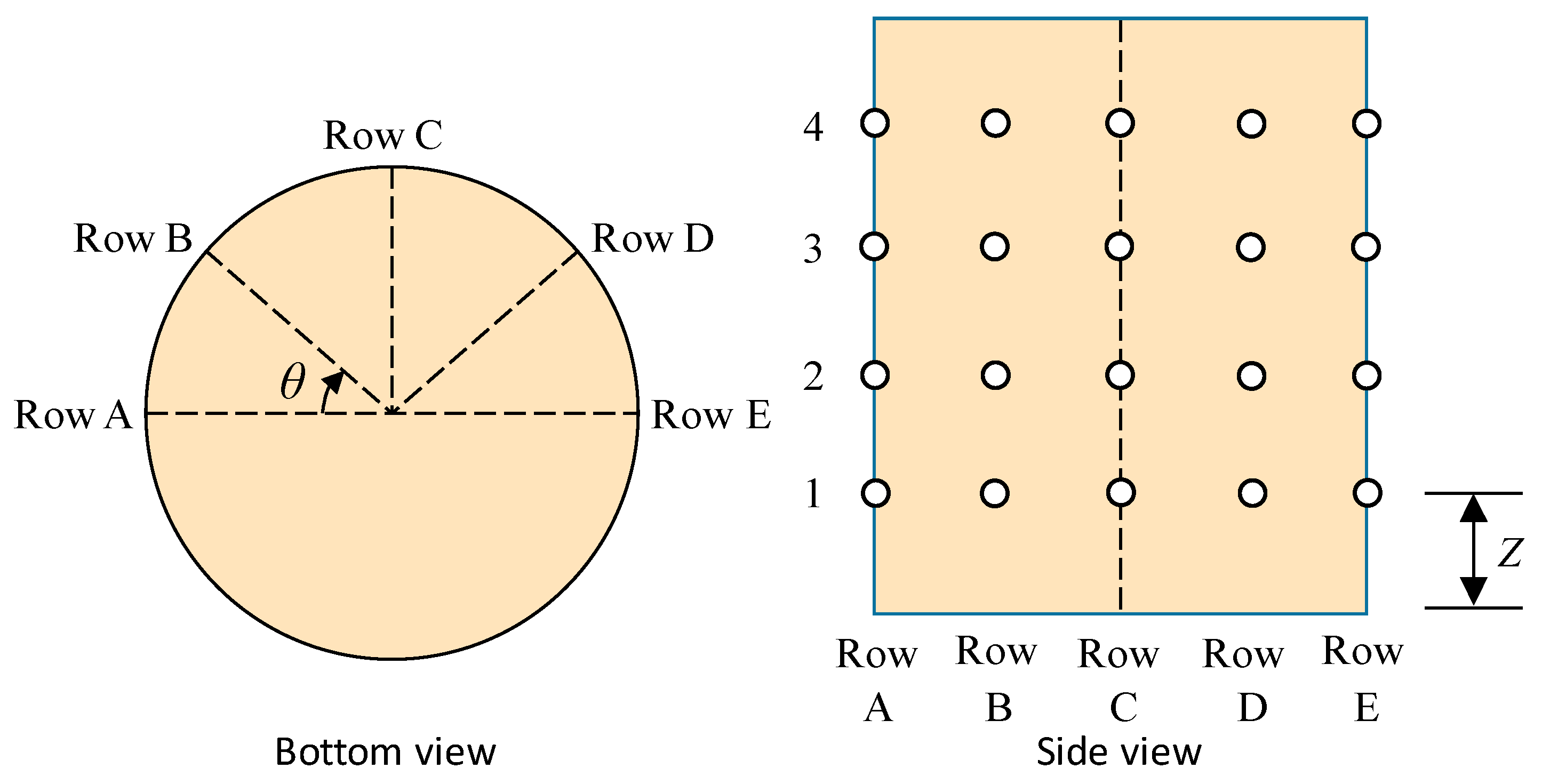

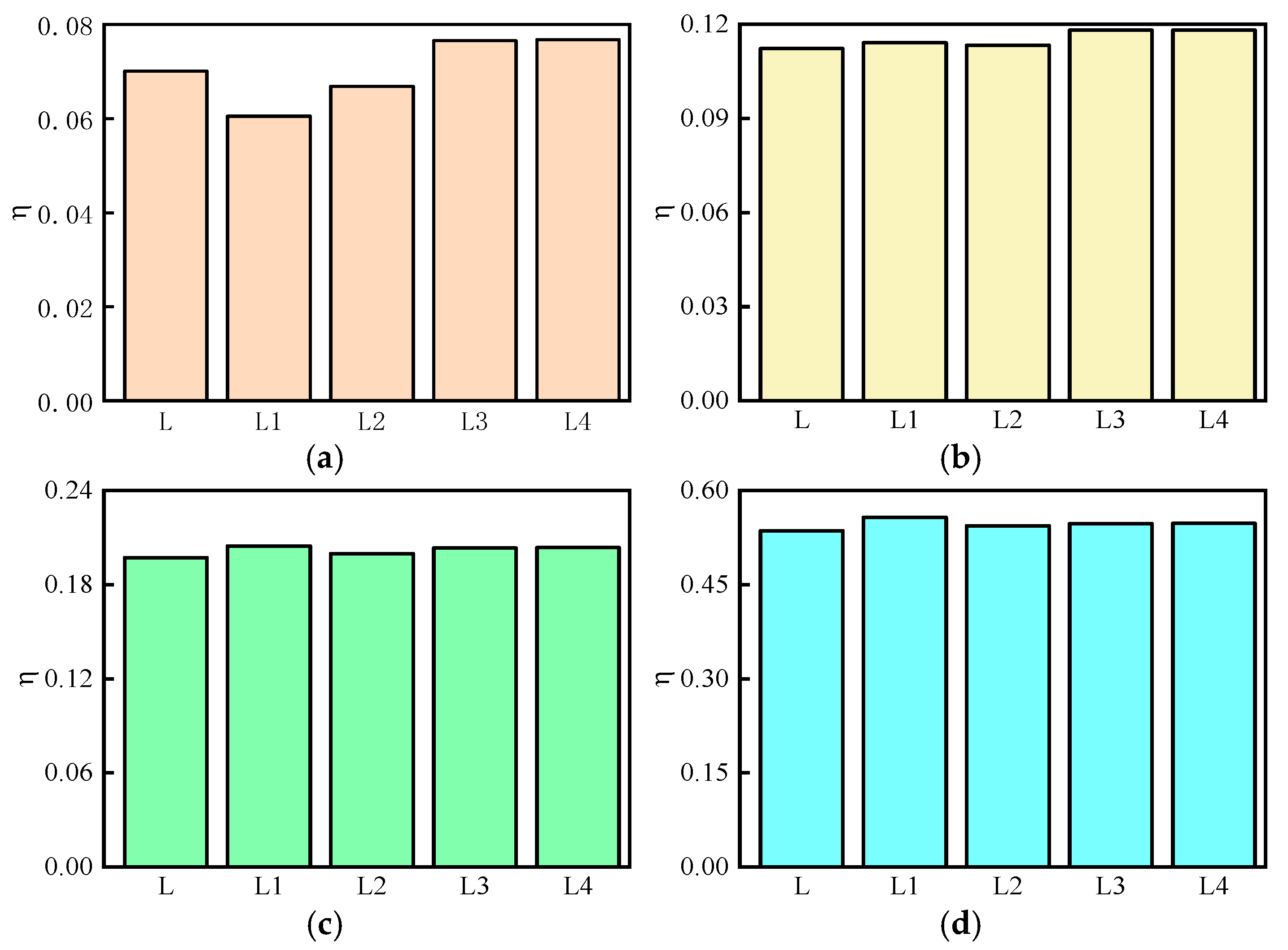

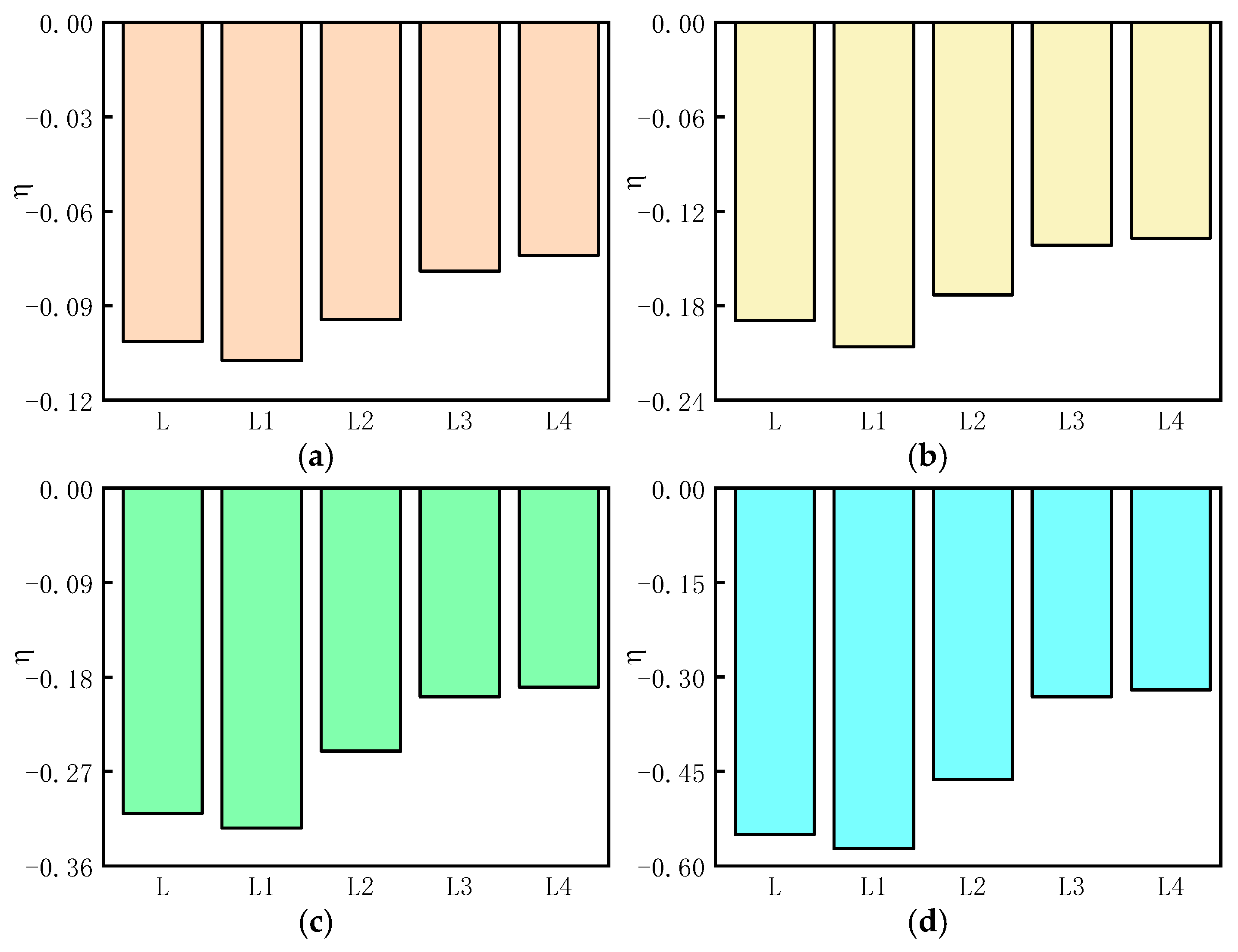

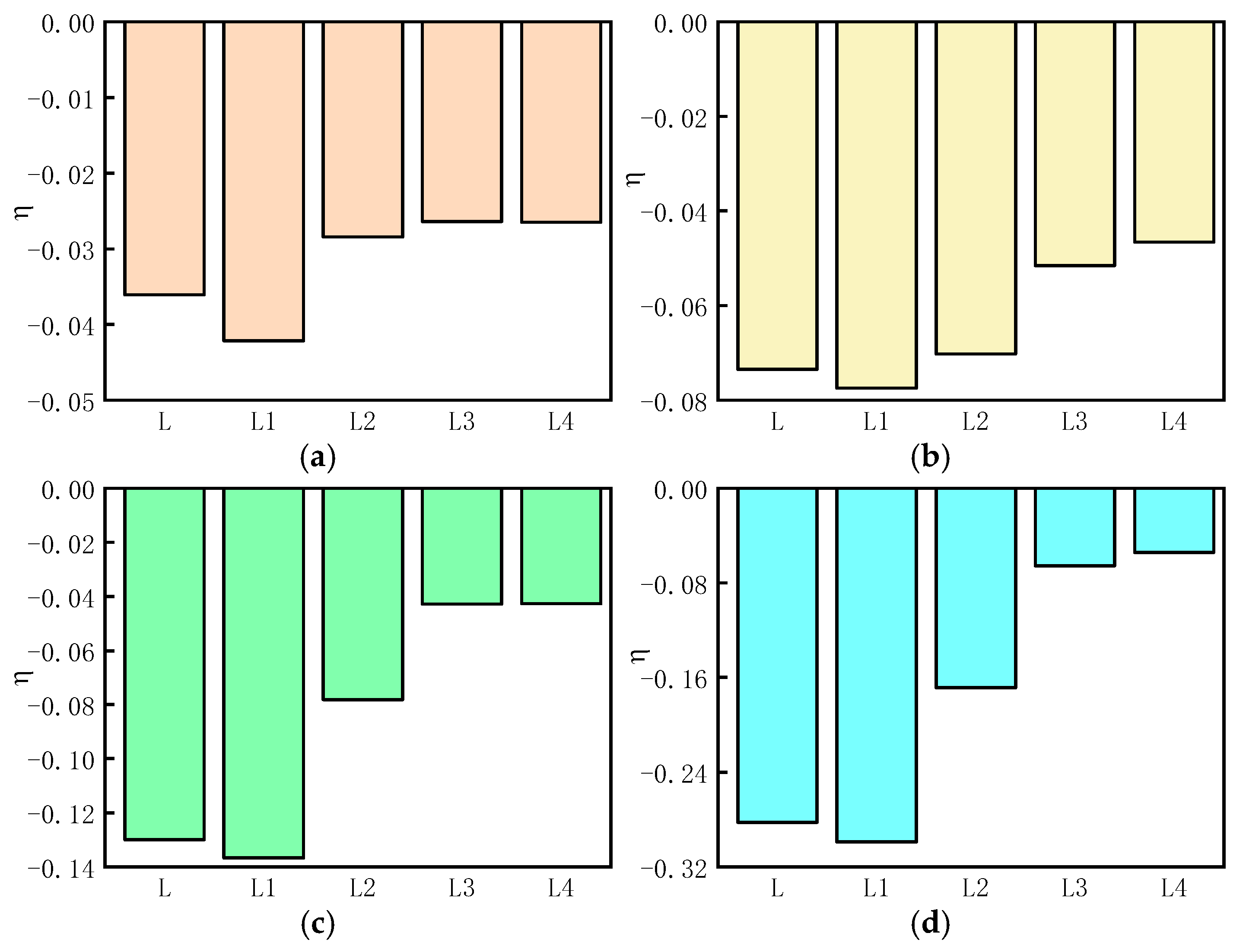

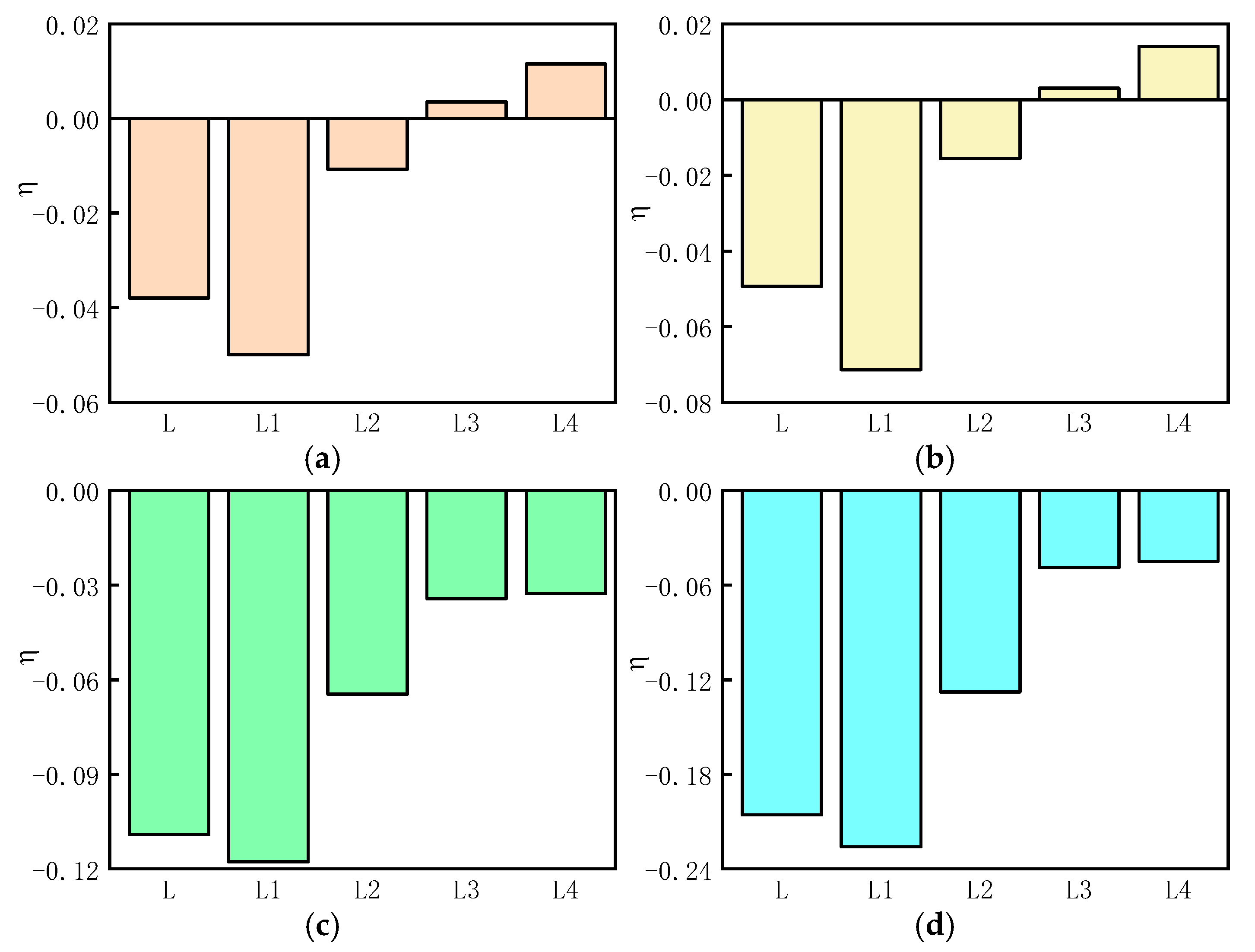

4.4. Pressure Distribution Around the Pile Foundation

5. Conclusions

- (1)

- In the horizontal direction along the water flow direction, the maximum flow velocity around the piles continues to decrease during the riprap failure. After the stabilization of scour, the maximum flow velocities around the piles decrease to varying degrees, ranging from 9.32% to 17.05%.

- (2)

- Compared with the unprotected monopile, the range of the horseshoe vortex in front of the pile with riprap protection increases obviously, and then decreases continuously during the failure of riprap. The wake vortex behind the pile maintains a relatively constant shape and size near the water surface during the failure of riprap, while the wake vortex near the riprap protection gradually becomes thinner and shorter, eventually disappearing.

- (3)

- The pressure in front of the monopile is the largest, and the pressure values in front of the pile remain almost unchanged during the failure of riprap, while the pressure values at other positions show an increasing trend with varying magnitudes. When the scour is stable, the maximum pressure increase can reach 338% compared to the unprotected pile foundation.

- (4)

- During the scour process, the wake vortex is the main change in the hydrodynamic characteristics between the riprap—protected monopile and the unprotected monopile, and the pressure changes on the pile should not be overlooked.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Blanco, M.I. The economics of wind energy. Renew. Sustain. Energy Rev. 2008, 13, 1372–1382. [Google Scholar] [CrossRef]

- Sunday, K.; Brennan, F. A review of offshore wind monopiles structural design achievements and challenges. Ocean Eng. 2021, 235, 109409. [Google Scholar] [CrossRef]

- Chambel, J.; Fazeres-Ferradosa, T.; Miranda, F.; Bento, A.; Taveira-Pinto, F.; Lomonaco, P. A comprehensive review on scour and scour protections for complex bottom-fixed offshore and marine renewable energy foundations. Ocean Eng. 2024, 304, 117829. [Google Scholar] [CrossRef]

- Majumder, M.; Chakraborty, D. Effects of scour-hole depth on the bearing and uplift capacities of under-reamed pile in clay. Ocean Eng. 2021, 240, 109927. [Google Scholar] [CrossRef]

- Li, J.; Guo, Y.; Lian, J.; Wang, H. Mechanisms, assessments, countermeasures, and prospects for offshore wind turbine foundation scour research. Ocean Eng. 2023, 281, 114893. [Google Scholar] [CrossRef]

- Grimaldi, C.; Gaudio, R.; Calomino, F.; Cardoso, A.H. Countermeasures against local scouring at bridge piers: Slot and combined system of slot and bed sill. J. Hydraul. Eng. 2009, 135, 425–431. [Google Scholar] [CrossRef]

- Lian, J.; Li, J.; Guo, Y.; Wang, H.; Yang, X. Numerical study on local scour characteristics of multi-bucket jacket foundation considering exposed height. Appl. Ocean Res. 2022, 121, 103092. [Google Scholar] [CrossRef]

- Zhang, F.; Chen, X.; Yan, J.; Gao, X. Countermeasures for local scour around offshore wind turbine monopile foundations: A review. Appl. Ocean Res. 2023, 141, 103764. [Google Scholar] [CrossRef]

- Parola, A.C. Stability of Riprap at Bridge Piers. J. Hydraul. Eng. 1993, 119, 1080–1093. [Google Scholar] [CrossRef]

- Chiew, Y.M. Mechanics of Riprap Failure at Bridge Piers. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1996, 33, 177. [Google Scholar] [CrossRef]

- Chiew, Y.-M.; Lim, F.-H. Failure Behavior of Riprap Layer at Bridge Piers under Live-Bed Conditions. J. Hydraul. Eng. 2000, 126, 43–55. [Google Scholar] [CrossRef]

- Lauchlan, C.S.; Melville, B.W. Riprap protection at bridge piers. J. Hydraul. Eng. 2001, 127, 412–418. [Google Scholar] [CrossRef]

- Lim, F.-H.; Chiew, Y.-M. Parametric study of riprap failure around bridge piers. Hydraul. Res. 2001, 39, 61–72. [Google Scholar] [CrossRef]

- Nielsen, A.W.; Probst, T.; Petersen, T.U.; Sumer, B.M. Sinking of armour layer around a vertical cylinder exposed to waves and current. Coast. Eng. 2015, 100, 58–66. [Google Scholar] [CrossRef]

- Nielsen, A.W.; Sumer, B.M.; Fredsøe, J.; Christensen, E.D. Sinking of armour layer around a cylinder exposed to a current. Proc. Inst. Civ. Eng. Marit. Eng. 2011, 164, 159–172. [Google Scholar] [CrossRef]

- Petersen, T.U.; Sumer, B.M.; Fredsøe, J.; Raaijmakers, T.C.; Schouten, J.-J. Edge scour at scour protections around piles in the marine environment —laboratory and field investigation. Coast. Eng. 2015, 106, 42–72. [Google Scholar] [CrossRef]

- Nielsen, A.W.; Petersen, T.U. Stability of cover stones around a vertical cylinder under the influence of waves and current. Coast. Eng. 2019, 154, 103563. [Google Scholar] [CrossRef]

- Whitehouse, R.J.S.; Harris, J.M.; Sutherland, J.; Rees, J. The nature of scour development and scour protection at offshore windfarm foundations. Mar. Pollut. Bull. 2011, 62, 73–88. [Google Scholar] [CrossRef]

- de Almeida, G.A.M.; Martín-Vide, J.P. Riprap stability: Transverse and longitudinal versus continuous protections. J. Hydraul. Eng. 2009, 135, 447–456. [Google Scholar] [CrossRef][Green Version]

- Tang, Z.; Melville, B.; Shamseldin, A.Y.; Singhal, N.; Guan, D.; Stolte, A. Performance of riprap armour at vibrating offshore wind turbine monopile foundations. Coast. Eng. 2023, 186, 104392. [Google Scholar] [CrossRef]

- De Vos, L.; De Rouck, J.; Troch, P.; Frigaard, P. Empirical design of scour protections around monopile foundations. Part 1: Static approach. Coast. Eng. 2011, 58, 540–553. [Google Scholar] [CrossRef]

- De Vos, L.; De Rouck, J.; Troch, P.; Frigaard, P. Empirical design of scour protections around monopile foundations. Part 2: Dynamic approach. Coast. Eng. 2012, 60, 286–298. [Google Scholar] [CrossRef]

- Richardson, E.V.; Davis, S.R. Evaluating Scour at Bridges; Federal Highway Administration: Washington, DC, USA, 2001. [Google Scholar]

- Lagasse, P.F.; Clopper, P.E.; Zevenbergen, L.W.; Girar, L.G. Countermeasures to Protect Bridge Piers from Scour; Transportation Research Board; Ayres Associates Inc.: Fort Collins, CO, USA, 2007. [Google Scholar]

- Wei, K.; Zhou, C.; Zhang, M.; Ti, Z.; Qin, S. Review of the hydrodynamic challenges in the design of elevated pile cap foundations for sea-crossing bridges. Adv. Bridg. Eng. 2020, 1, 21. [Google Scholar] [CrossRef]

- Liu, M.; Zeng, L.; Wu, L.; Chen, G.; Shen, L.; Abi, E. In-Situ Test Method for Hydrodynamic Characteristics of Water Flowing Around Piles. Front. Environ. Sci. 2022, 10, 855334. [Google Scholar] [CrossRef]

- Melville, B.W.; Coleman, S.E. Bridge Scour; Water Resources Publications: Littleton, CO, USA, 2000. [Google Scholar]

- Kirkgoz, M.S.; Mehmet, A. Velocity profiles of developing and developed open channel flow. J. Hydraul. Eng. 1997, 123, 1099–1105. [Google Scholar] [CrossRef]

- Roulund, A.; Sumer, B.M.; Fredsøe, J.; Michelsen, J. Numerical and experimental investigation of flow and scour around a circular pile. J. Fluid Mech. 2005, 534, 351–401. [Google Scholar] [CrossRef]

- Hunt, J.; Wray, A.; Moin, P. Eddies, Stream, and Convergence Zones in Turbulent Flows; Center for Turbulence Research: Stanford, CA, USA, 1988; pp. 193–208. [Google Scholar]

- Muzzammil, M.; Gangadhariah, T. The mean characteristics of horseshoe vortex at a cylindrical pier. J. Hydraul. Res. 2003, 41, 285–297. [Google Scholar] [CrossRef]

| Type | Length Scale Ratio | Time Scale Ratio | Force Scale Ratio |

|---|---|---|---|

| Value | 60 | 7.74 | 216,000 |

| Position | Point | Y (m) |

|---|---|---|

| Front of pile | P1 | 0.015 |

| P2 | 0.055 | |

| P3 | 0.095 | |

| Back of pile | P4 | 0.015 |

| P5 | 0.075 |

| Mesh Size (m) | Mesh Quantity (Million) | ∆x (m) | ∆y (m) | ∆z (m) | Computational Times (min) |

|---|---|---|---|---|---|

| 0.01 | 0.3 | 0.01 | 0.01 | 0.01 | 240 |

| 0.005 | 2.4 | 0.005 | 0.005 | 0.005 | 480 |

| 0.0025 | 19.2 | 0.0025 | 0.0025 | 0.0025 | 1260 |

| ) | Mesh Size (m) | Mesh Quantity (Million) | |

|---|---|---|---|

| Mesh block1 | 15 × 0.6 × 0.25 | 0.01 | 2.25 |

| Mesh block2 | 2 × 0.6 × 0.25 | 0.005 | 2.4 |

| Z/D | Row A | Row B | Row C | Row D | Row E |

|---|---|---|---|---|---|

| 0.5 | A1 | B1 | C1 | D1 | E1 |

| 1 | A2 | B2 | C2 | D2 | E2 |

| 1.5 | A3 | B3 | C3 | D3 | E3 |

| 2 | A4 | B4 | C4 | D4 | E4 |

| θ (°) | Observation Point |

|---|---|

| 0 | A1–A4 |

| 45 | B1–B4 |

| 90 | C1–C4 |

| 135 | D1–D4 |

| 180 | E1–E4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, T.; Wang, L.; Mei, C.; Dong, X. Hydrodynamic Characteristic Around the Riprap Protection of Monopile Wind Power Foundation with Scour Pit During Scour. Energies 2025, 18, 5792. https://doi.org/10.3390/en18215792

Yu T, Wang L, Mei C, Dong X. Hydrodynamic Characteristic Around the Riprap Protection of Monopile Wind Power Foundation with Scour Pit During Scour. Energies. 2025; 18(21):5792. https://doi.org/10.3390/en18215792

Chicago/Turabian StyleYu, Tongshun, Li Wang, Congbao Mei, and Xiaofeng Dong. 2025. "Hydrodynamic Characteristic Around the Riprap Protection of Monopile Wind Power Foundation with Scour Pit During Scour" Energies 18, no. 21: 5792. https://doi.org/10.3390/en18215792

APA StyleYu, T., Wang, L., Mei, C., & Dong, X. (2025). Hydrodynamic Characteristic Around the Riprap Protection of Monopile Wind Power Foundation with Scour Pit During Scour. Energies, 18(21), 5792. https://doi.org/10.3390/en18215792