Adaptive Microprocessor-Based Interval Type-2 Fuzzy Logic Controller Design for DC Micro-Motor Control Considering Hardware Limitations

Abstract

1. Introduction

- Present refined hardware-in-the-loop approach, integrating real-time PSO directly on STM32 microcontroller, with comprehensive hardware–software co-design analysis highlighting constraints and trade-offs.

- Develop novel optimized hybrid FT2-PID controller tailored for embedded platforms.

- Validate the proposed FT2-PID controller against PI, PID, and PIDF controllers, showing significantly faster settling times and reduced overshoot at higher reference speeds.

- Address critical hardware limitations, including processing time, memory constraints, and real-time execution challenges, being overlooked in theoretical studies.

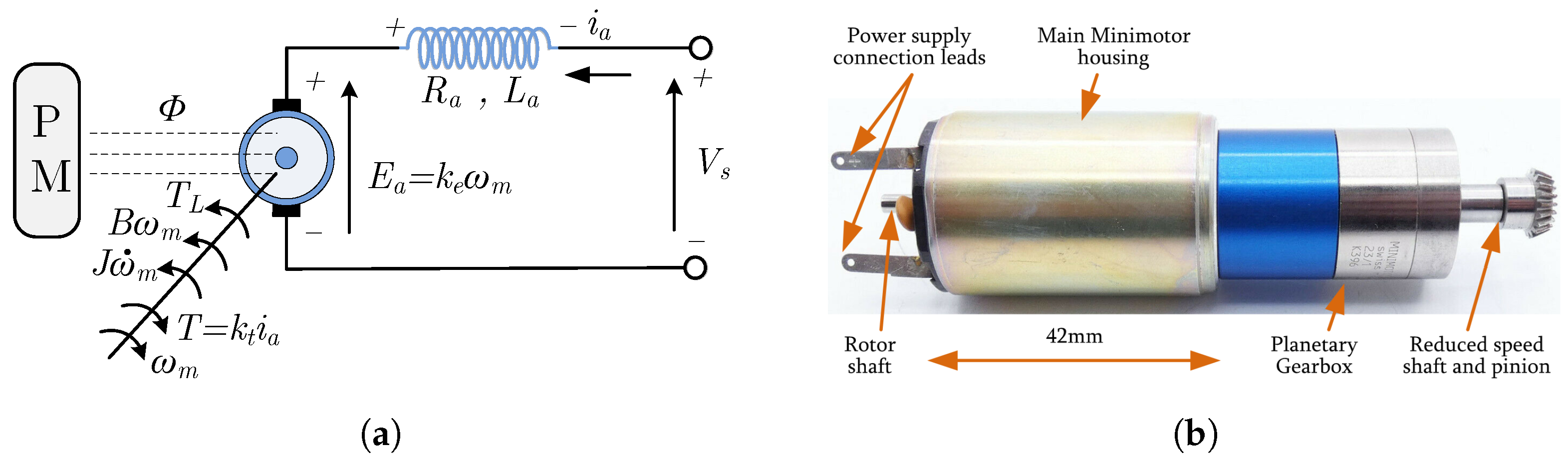

2. Brief DC Micro-Motor Theory Overview

3. Control Strategies

3.1. Closed-Loop Control for Micro-Motor Speed Regulation

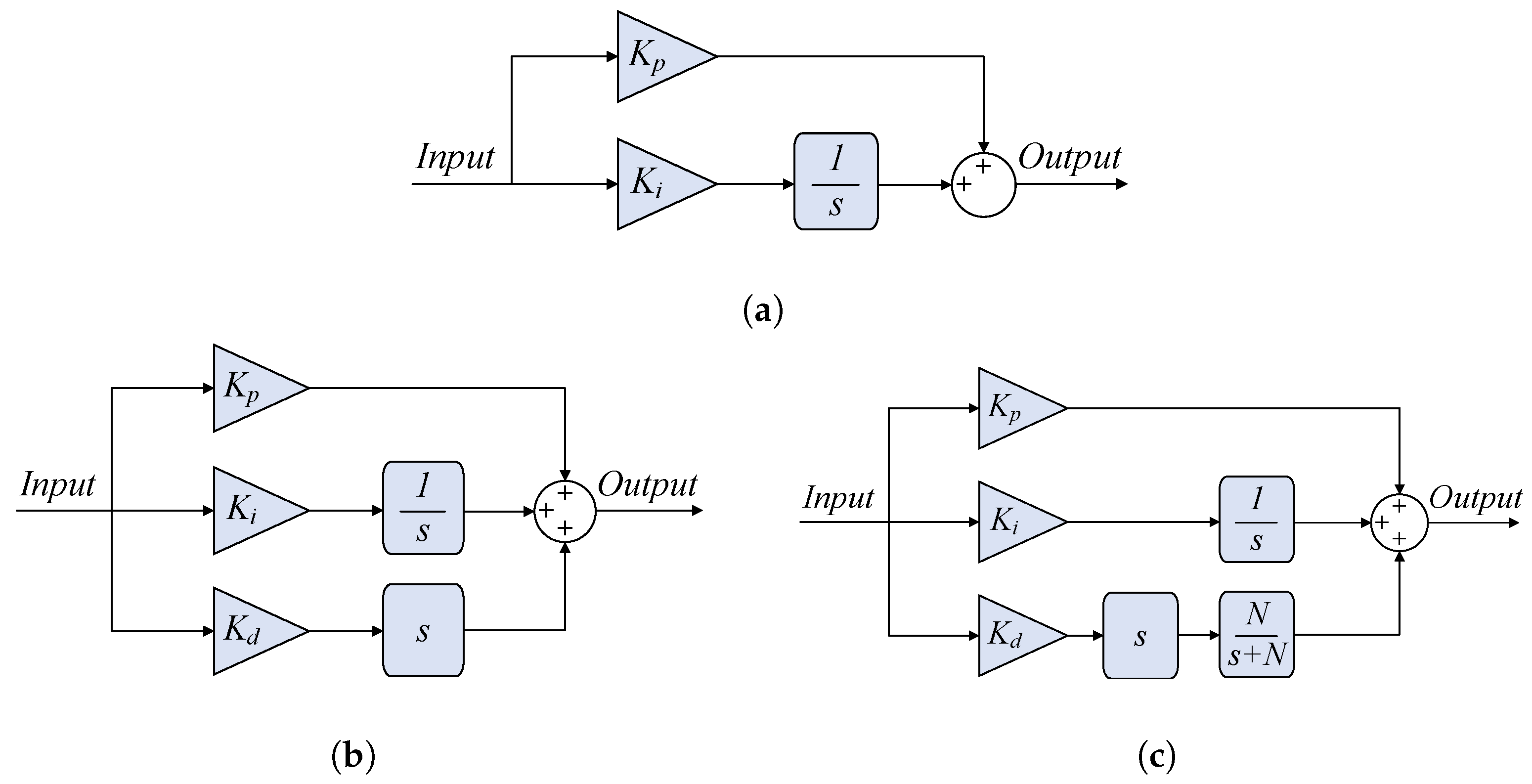

3.2. PI, PID, and PIDF Controllers

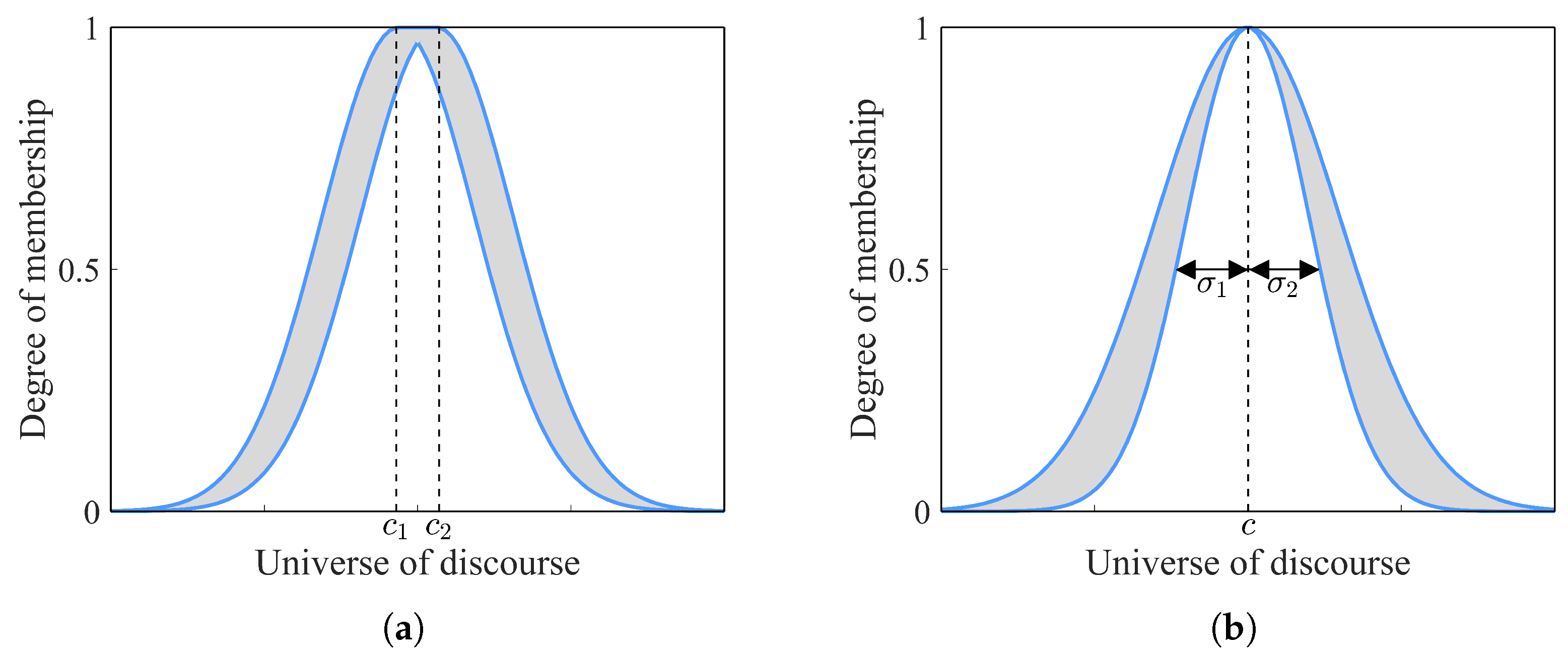

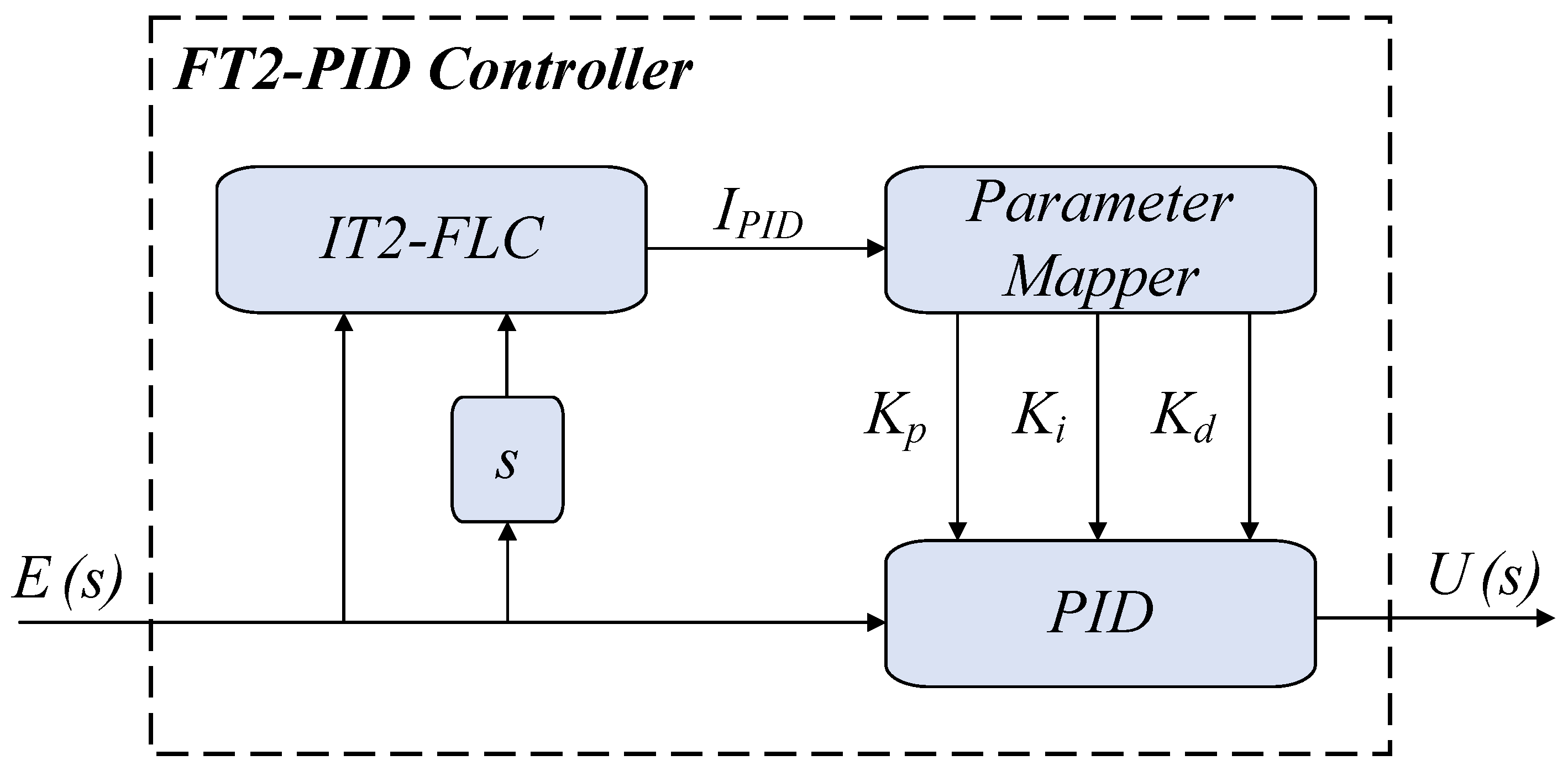

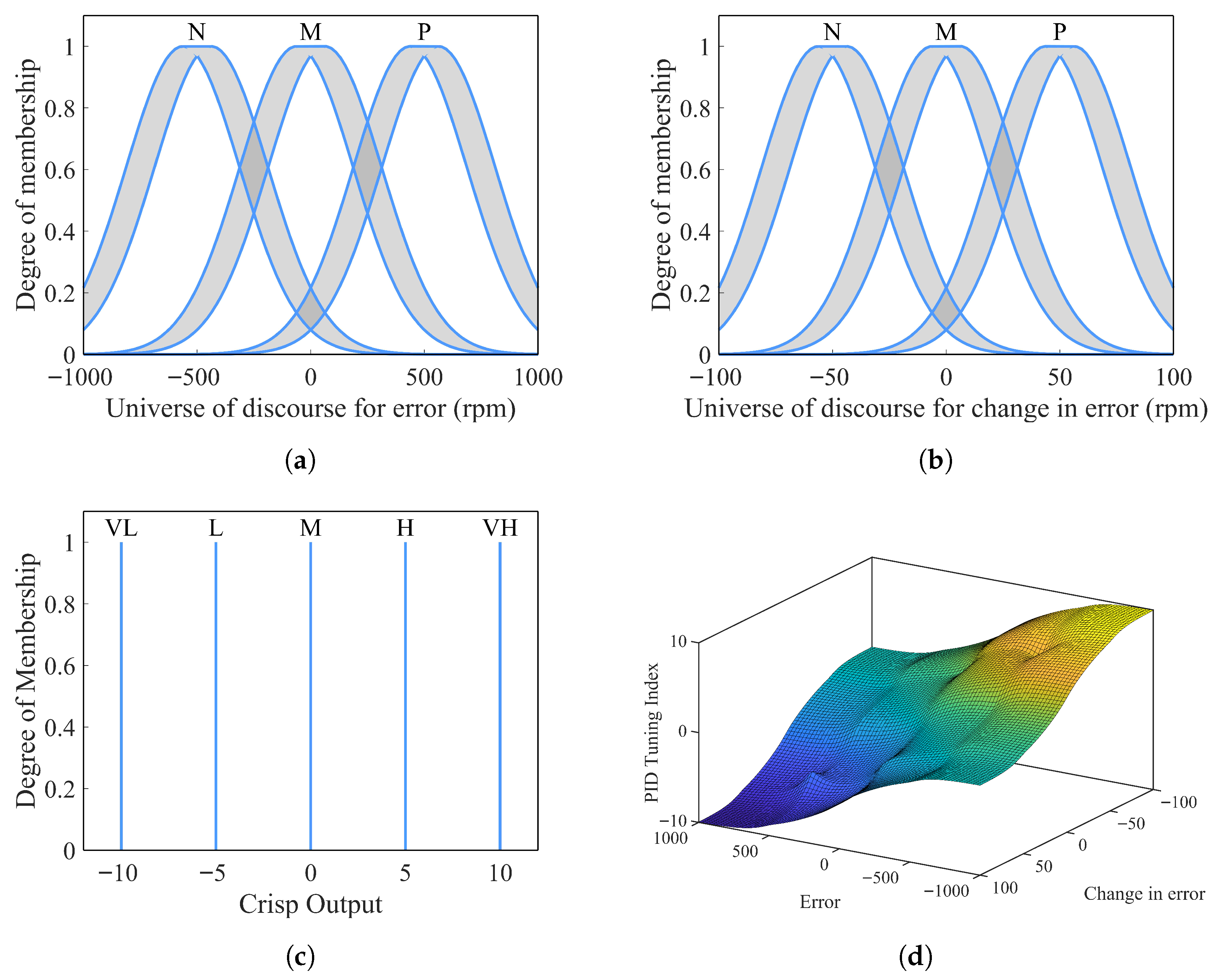

3.3. FT2-PID Controller

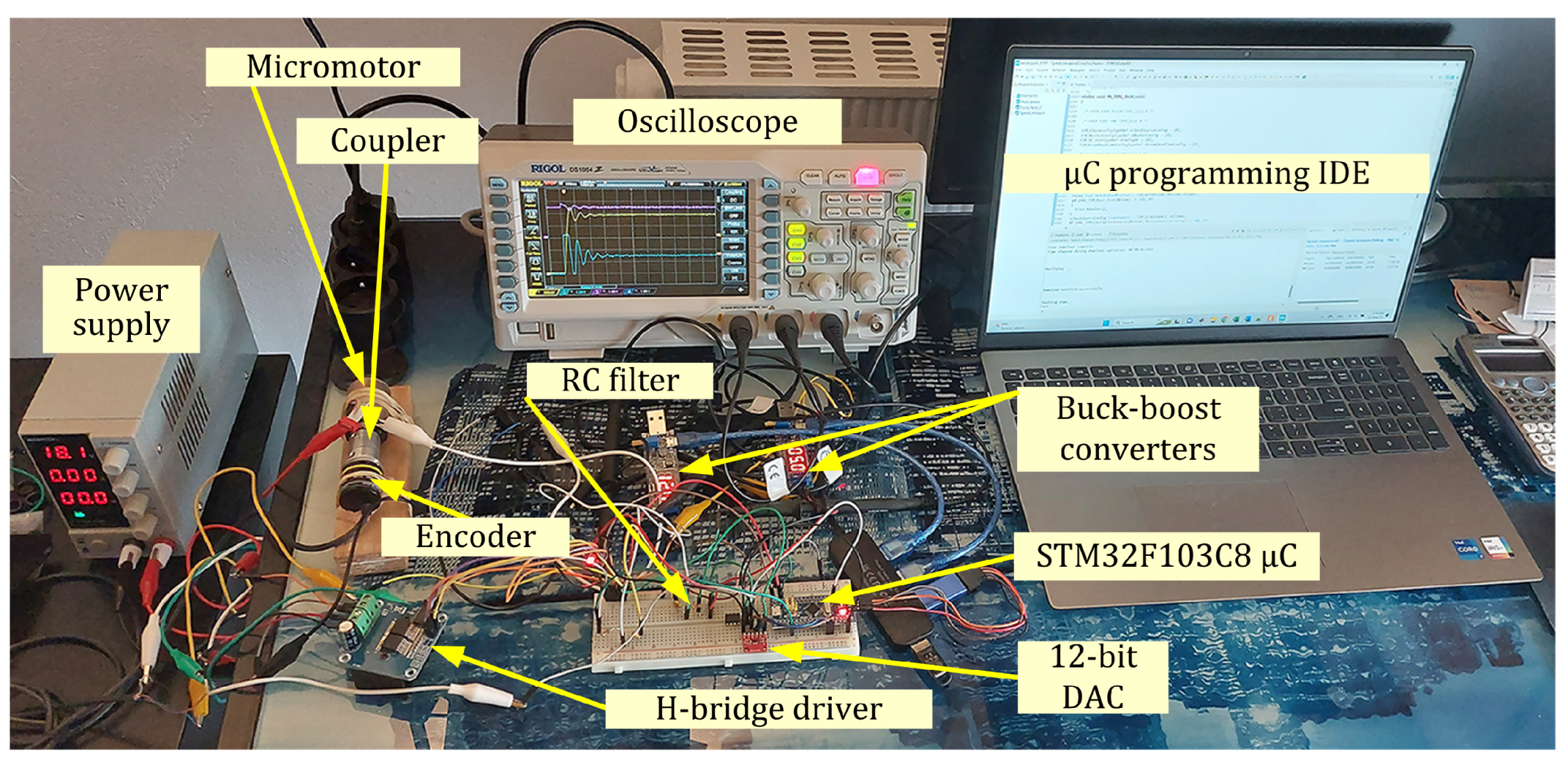

4. Prototype Design and Development

4.1. Microcontroller

4.2. Power Supply

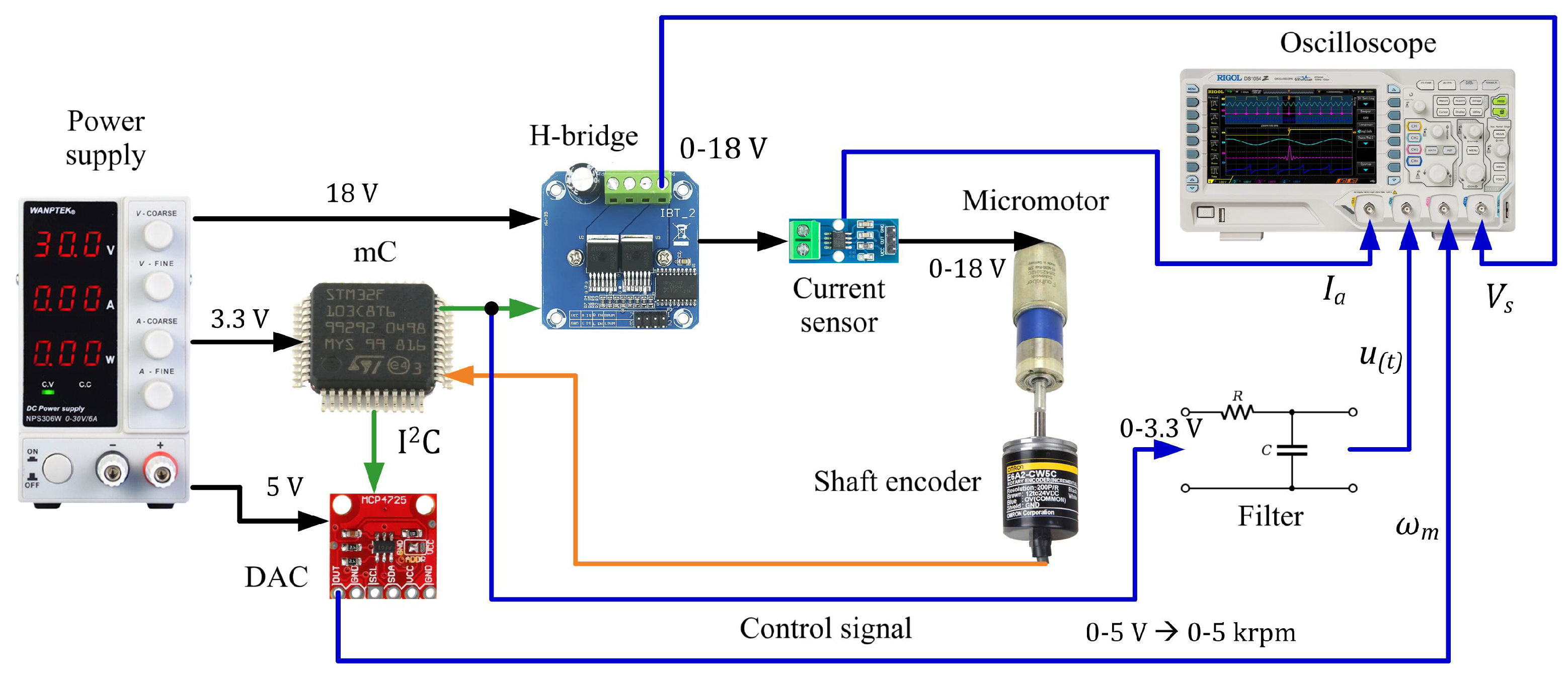

4.3. Driver, Sensors, and Peripherals

5. Software Development Considering Hardware Limitations

5.1. Software Development Philosophy

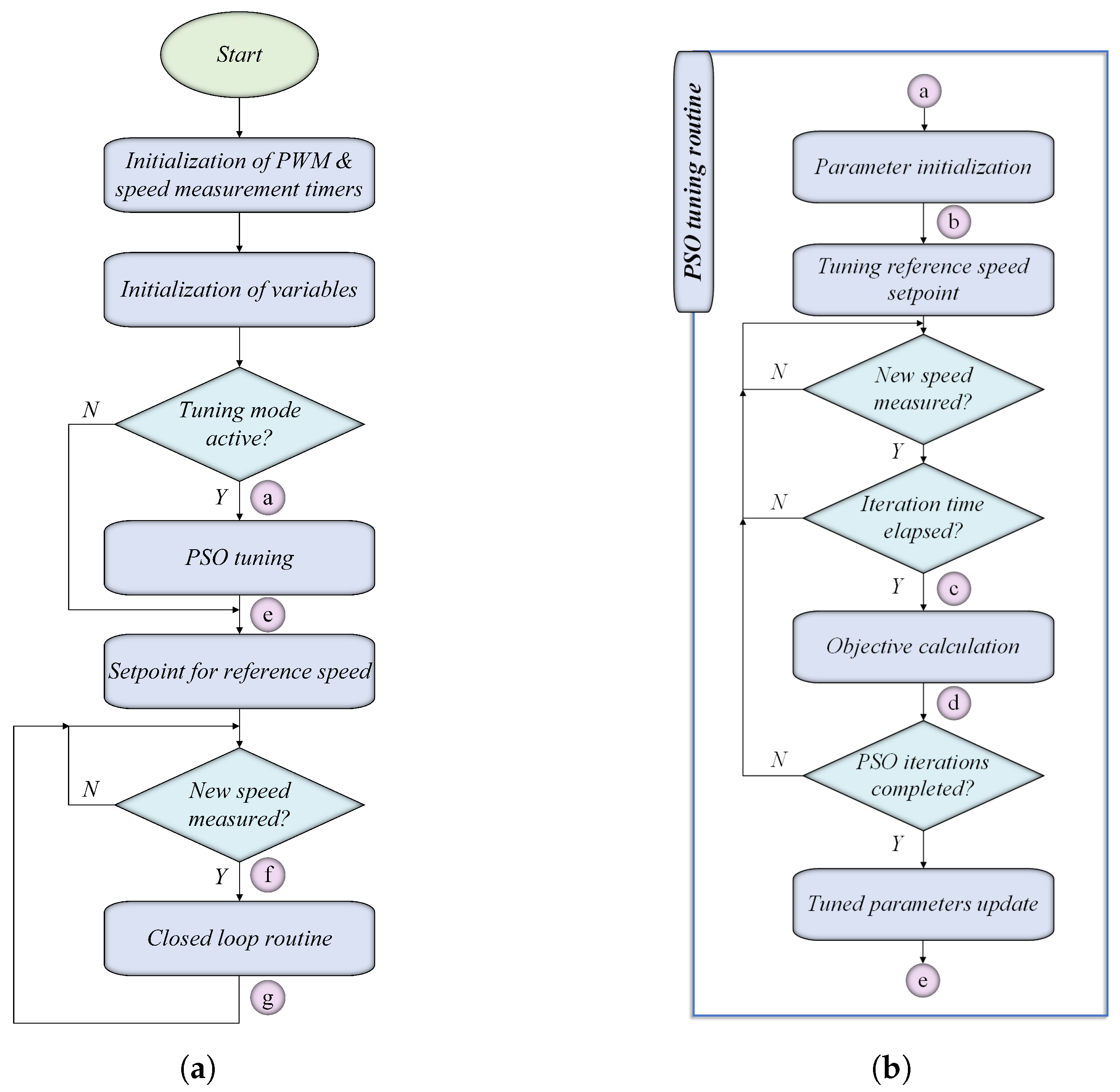

5.2. Main Flowchart

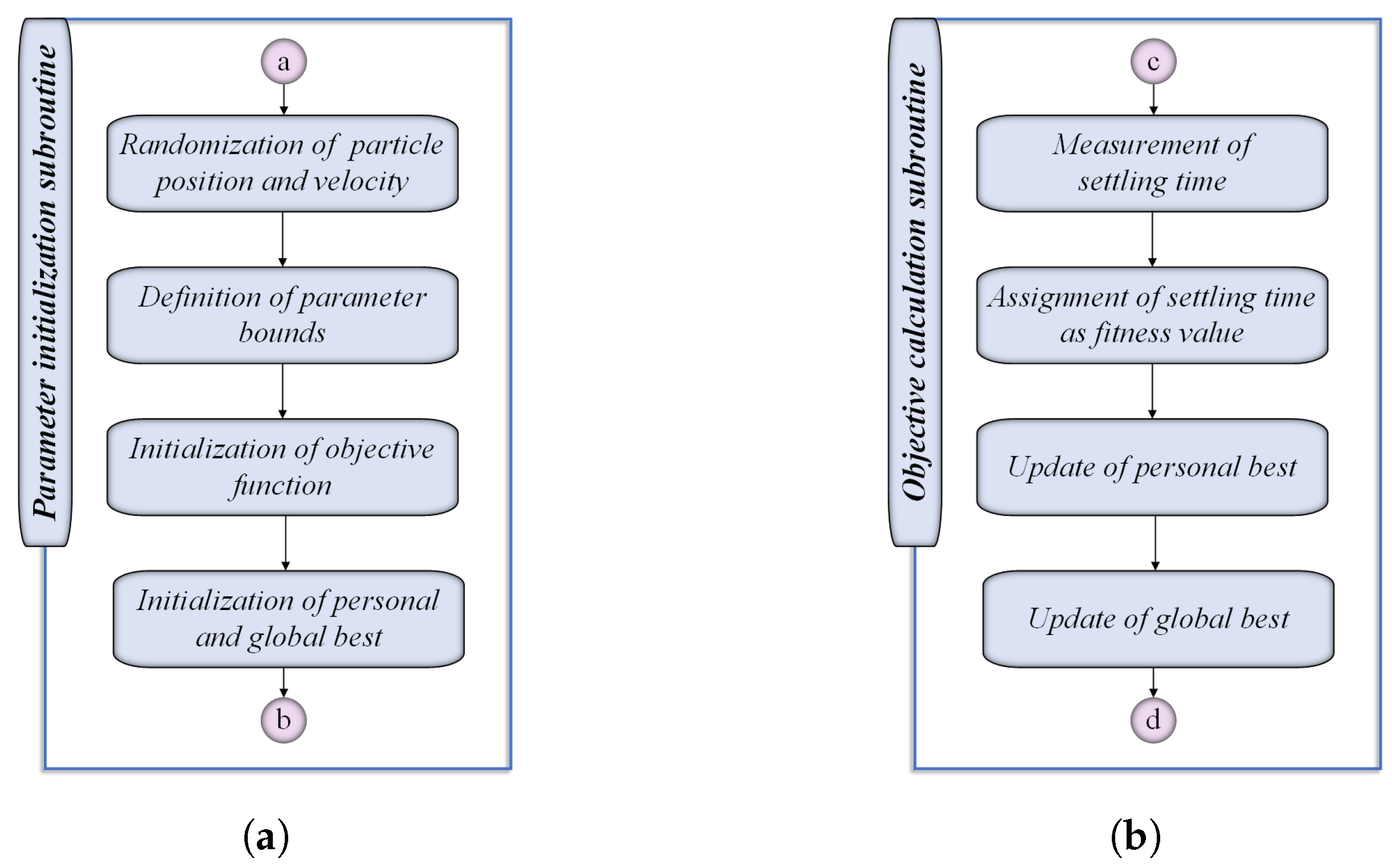

5.3. PSO Tuning Routine

- denotes the position of the i-th particle at time t;

- represents the velocity of the i-th particle at time t;

- w is the inertia weight, which adjusts the influence of the particle’s prior velocity;

- and are the cognitive and social coefficients, which determine the weight given to the personal best and global best positions in influencing the particle’s movement, respectively;

- and have random values, uniformly distributed between 0 and 1, adding stochastic behavior to the algorithm;

- refers to the best position found by the i-th particle during its search;

- represents the best position found by the entire swarm.

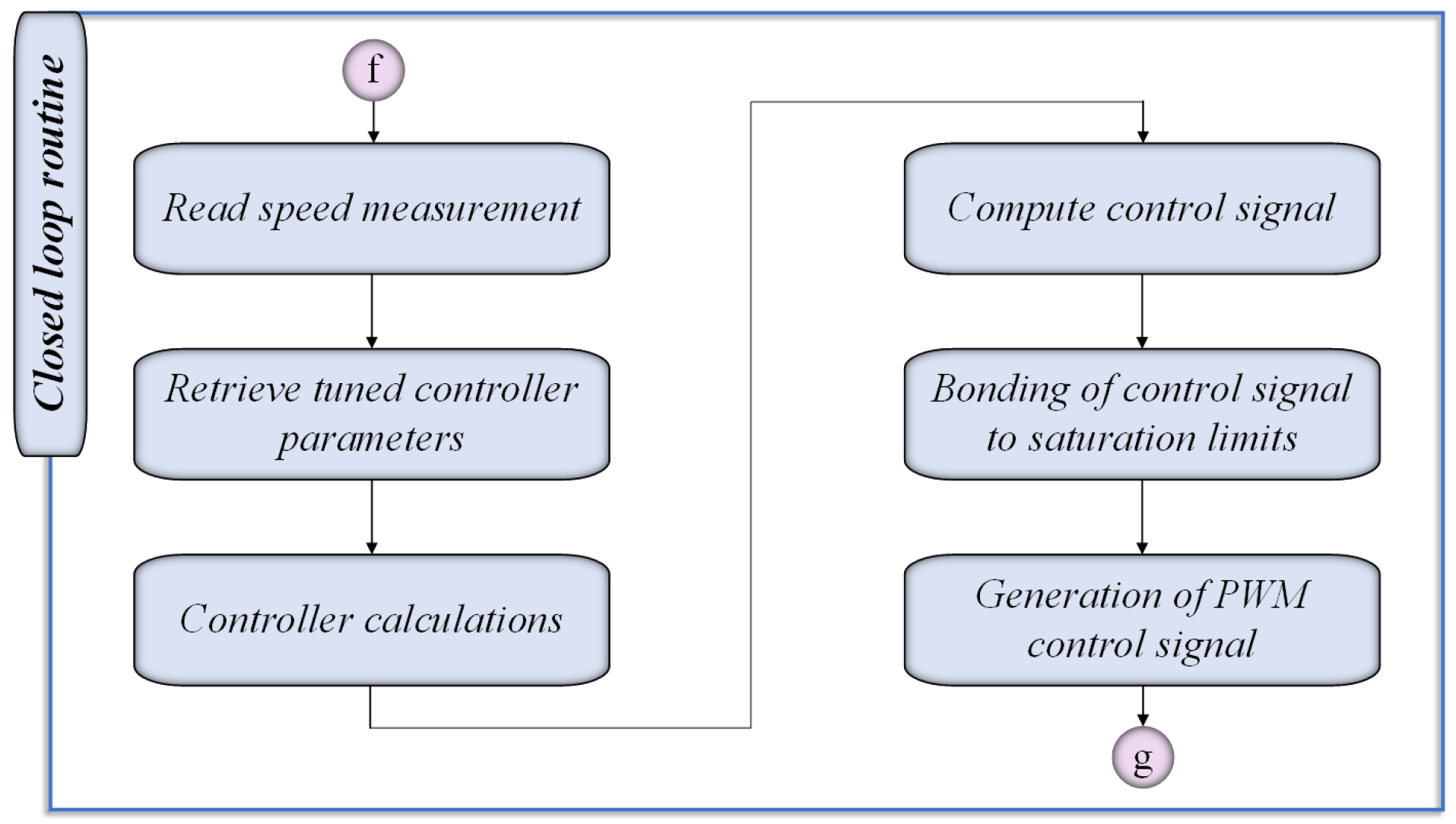

5.4. Closed-Loop Routine

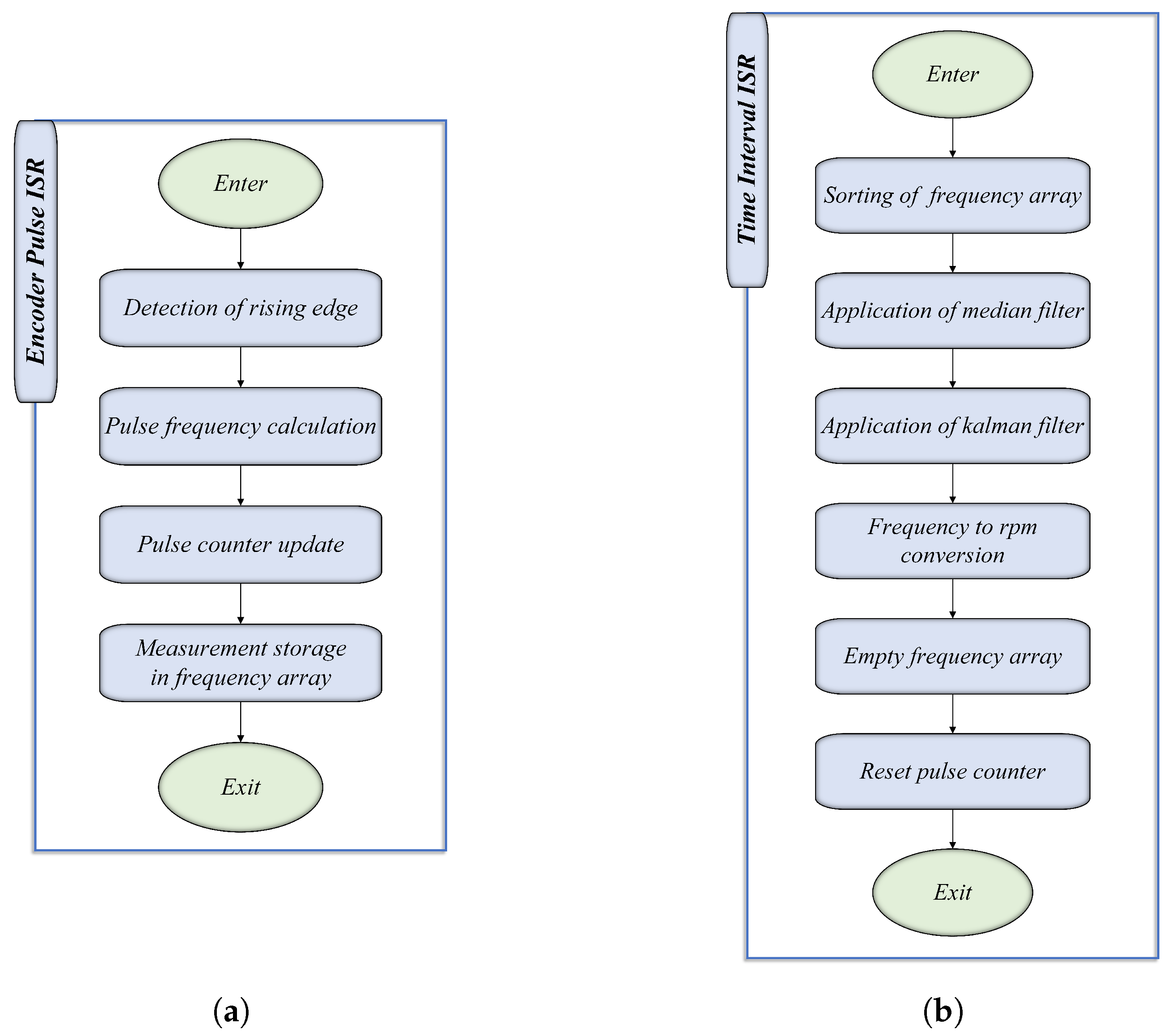

5.5. Interrupt Services Routines

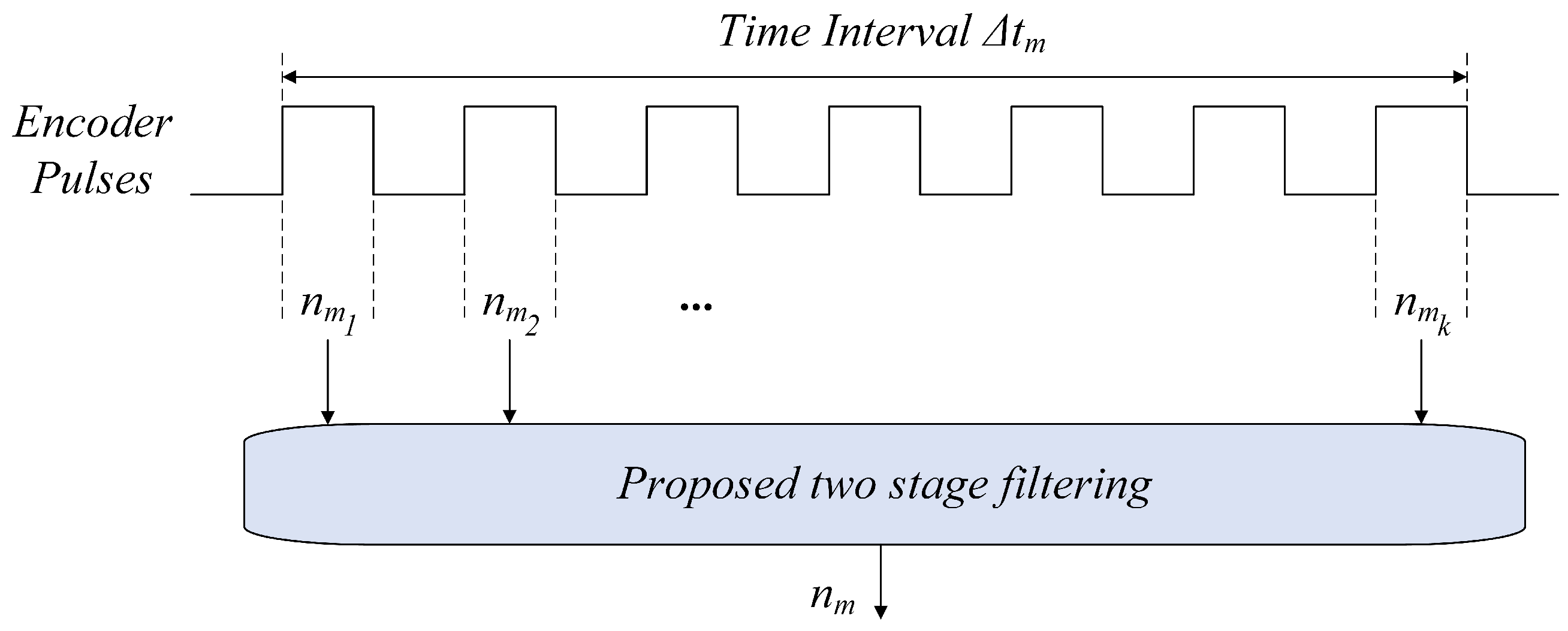

5.5.1. Speed Measurement Methodology

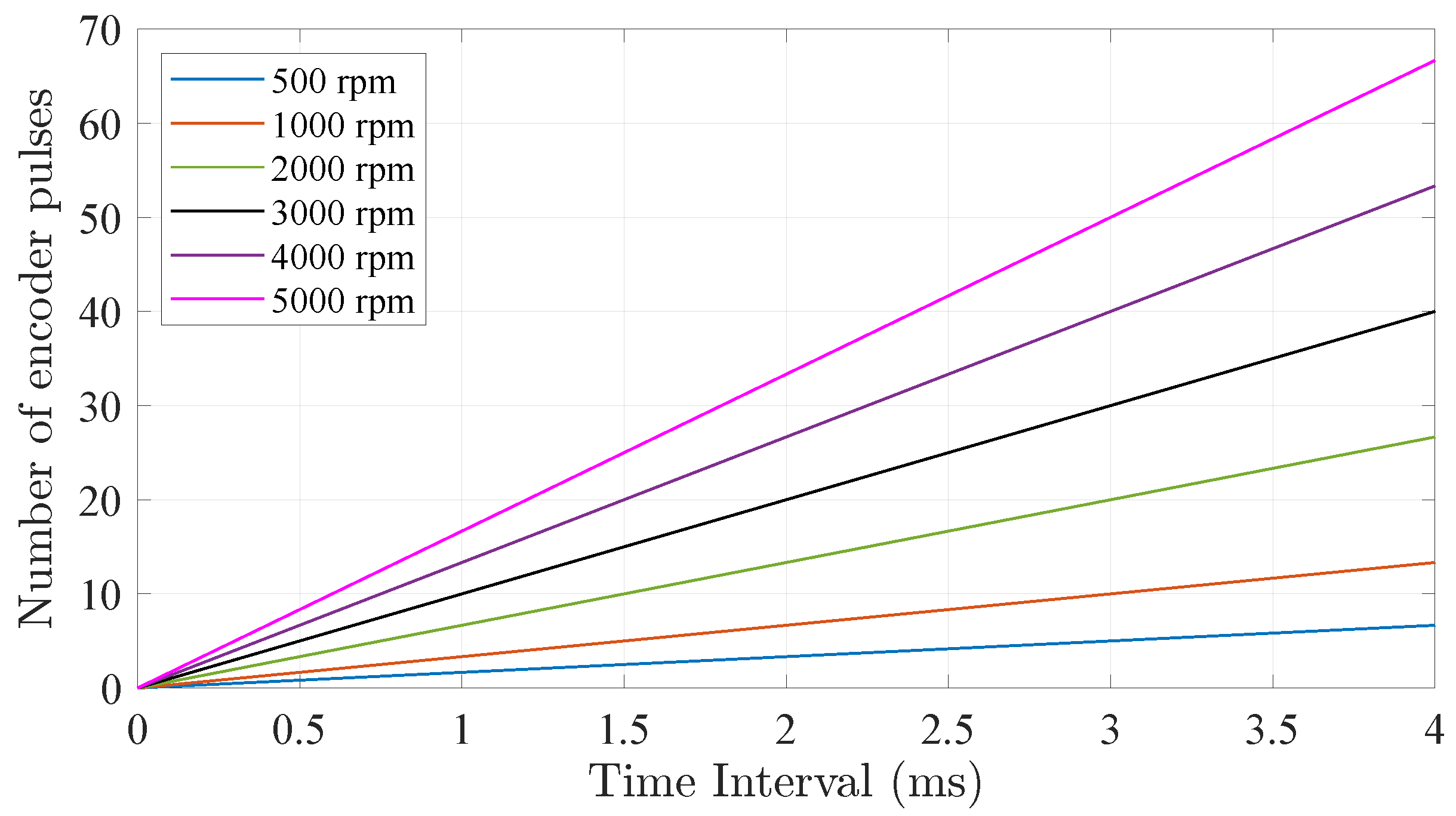

5.5.2. Time Interval

5.5.3. Proposed Two-Stage Filtering Method

- K: Kalman gain, determining the weight of the new measurement;

- P: Estimate error covariance;

- Q: Process noise covariance;

- R: Measurement noise covariance;

- : Estimated speed at the current time step k;

- : Measured speed after the median filter at time step k.

6. Results and Discussion

6.1. Real-Time PSO Tuning

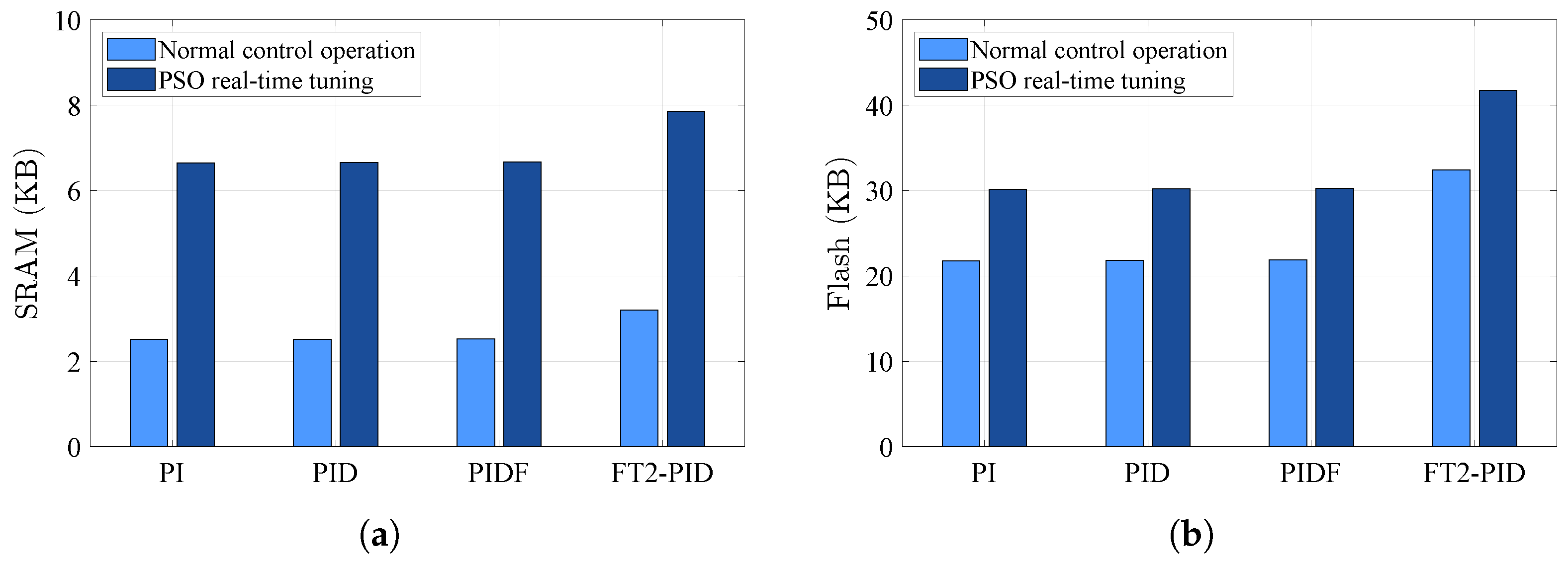

6.2. Memory Usage and Analysis

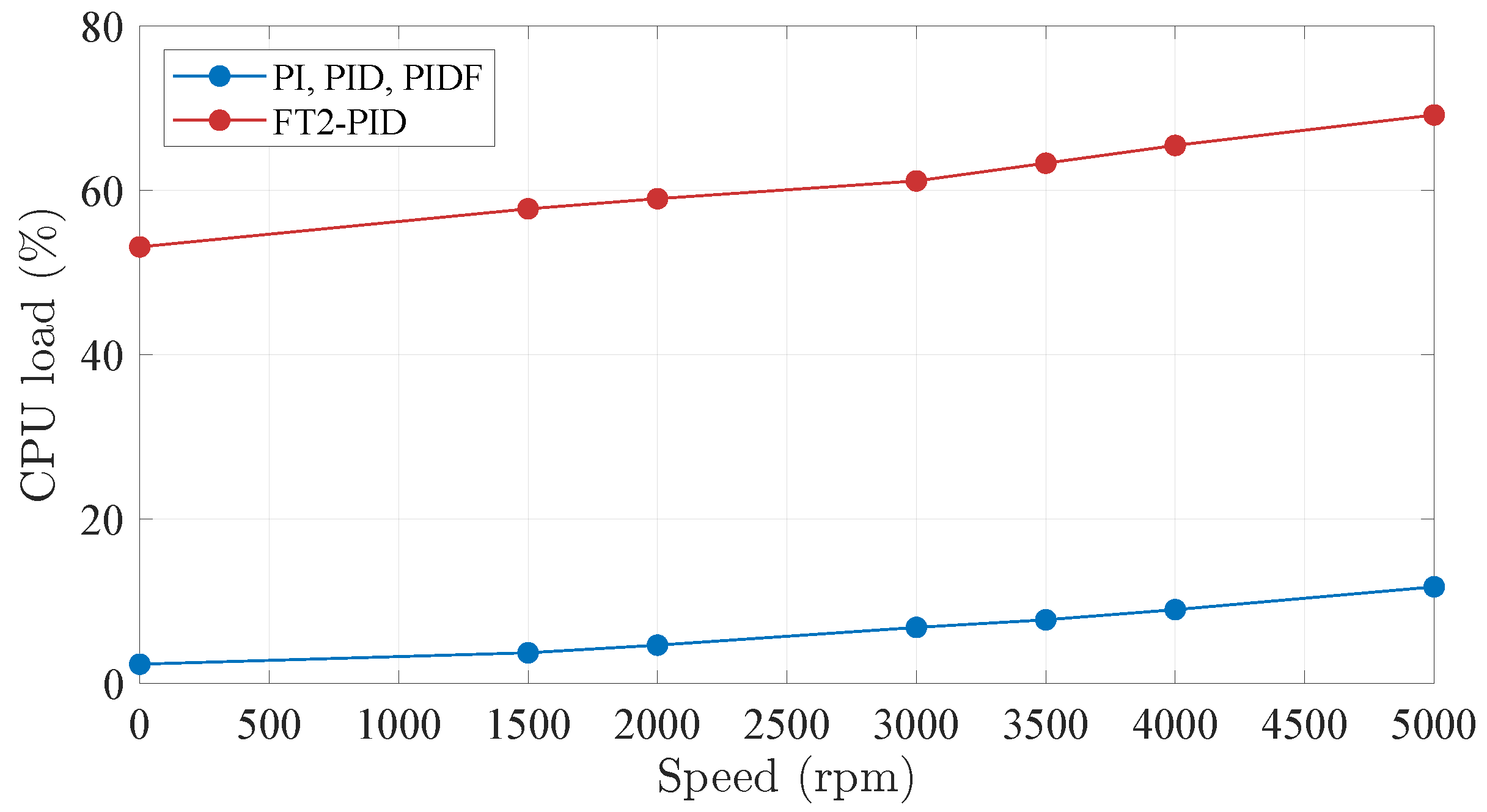

6.3. CPU Load Analysis

6.4. Controller Performance Evaluation

6.4.1. Experimental Cases

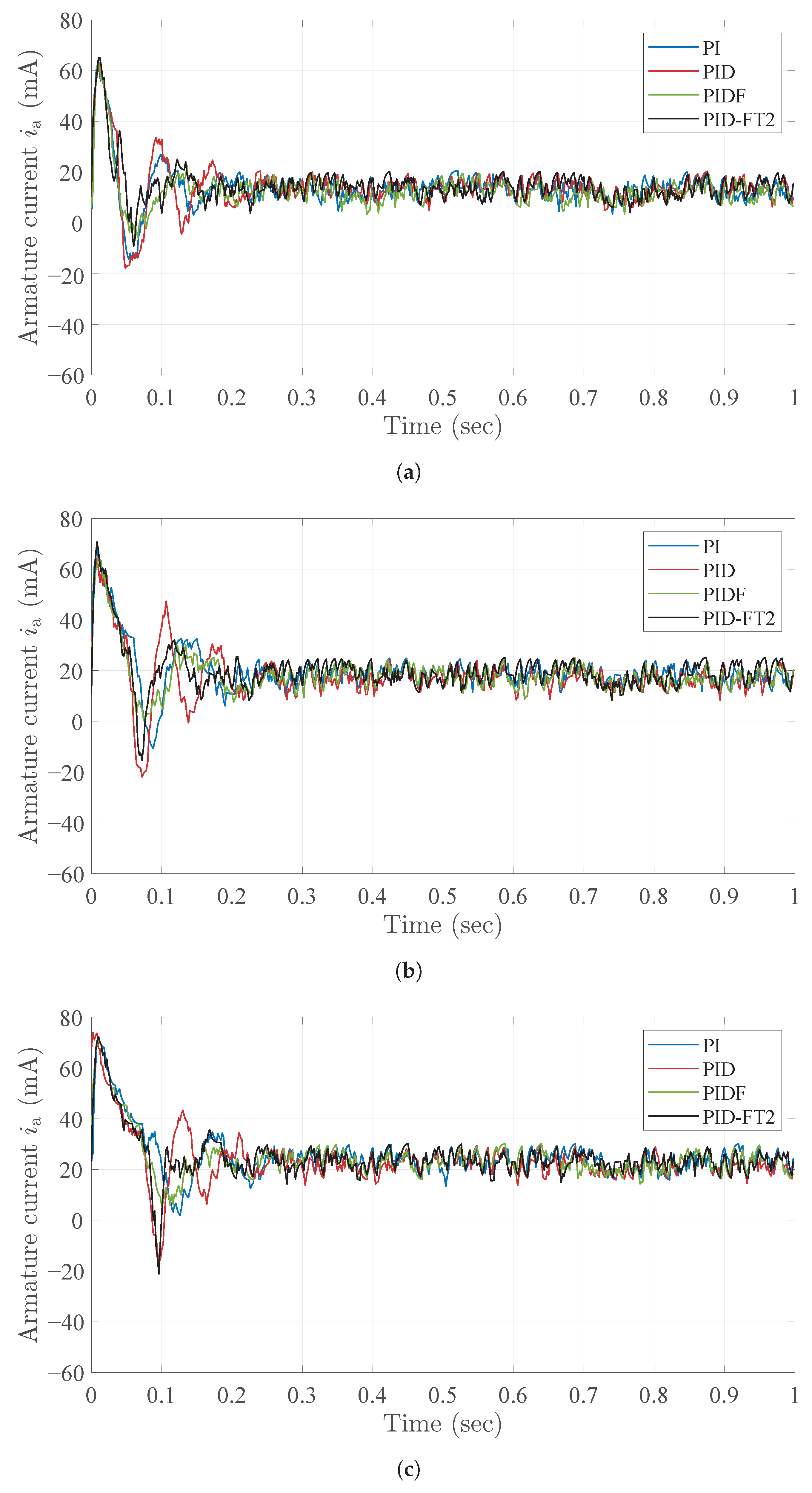

6.4.2. Experimental Results: Current, Voltage, and Speed

6.4.3. Controller Performance Metrics

6.4.4. Rise Time

6.4.5. Overshoot

6.4.6. Settling Time

6.4.7. Summary

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Quantity | Symbol | Value | Unit |

|---|---|---|---|

| Rated power | 6.19 | W | |

| Efficiency | 74 | % | |

| Nominal voltage | 18 | V | |

| Terminal resistance | 12.5 | ||

| Rotor inductance | 1300 | H | |

| Back-EMF constant | 3.52 | mV/rpm | |

| Torque constant | 0.03 | ||

| Rotor inertia | J | 14 | g·cm2 |

| Mechanical time constant | 15 | ms | |

| No-load current | 33 | mA | |

| Current constant | 0.03 | ||

| Friction torque | 0.156 | oz·in | |

| Stall torque | 7.193 | oz·in | |

| No-load speed | 5000 | rpm | |

| Rated speed | 2500 | rpm | |

| Speed constant | 284 | rpm/V | |

| Slope of n-T curve | 106 | rpm/mNm | |

| Angular acceleration | rad/s2 |

References

- Cheng, M.; Sun, L.; Buja, G.; Song, L. Advanced electrical machines and machine-based systems for electric and hybrid vehicles. Energies 2015, 8, 9541–9564. [Google Scholar] [CrossRef]

- Praveen, R.; Ravichandran, M.; Achari, V.S.; Raj, V.J.; Madhu, G.; Bindu, G. A novel slotless Halbach-array permanent-magnet brushless DC motor for spacecraft applications. IEEE Trans. Ind. Electron. 2011, 59, 3553–3560. [Google Scholar] [CrossRef]

- Wang, T.; Du, W.; Zeng, L.; Su, L.; Zhao, Y.; Gu, F.; Liu, L.; Chi, Q. Design and Testing of an End-Effector for Tomato Picking. Agronomy 2023, 13, 947. [Google Scholar] [CrossRef]

- Lee, D.H. Combined sensor–sensorless control of PMDC motor for HD camera of unmanned monitoring system. J. Electr. Eng. Technol. 2020, 15, 27–35. [Google Scholar] [CrossRef]

- Tajdari, F.; Ebrahimi Toulkani, N. Implementation and intelligent gain tuning feedback–based optimal torque control of a rotary parallel robot. J. Vib. Control 2022, 28, 2678–2695. [Google Scholar] [CrossRef]

- Karnavas, Y.L.; Topalidis, A.S.; Drakaki, M. Development of a low cost brushless DC motor sensorless controller using dsPIC30F4011. In Proceedings of the 2018 7th International Conference on Modern Circuits and Systems Technologies (MOCAST), Thessaloniki, Greece, 7–9 May 2018; pp. 1–4. [Google Scholar]

- Sun, L. A new method for sensorless control of brushless DC motor. Clust. Comput. 2019, 22, 2793–2800. [Google Scholar] [CrossRef]

- Lee, D.H. Balanced parallel instantaneous position control of PMDC motors with low-cost position sensors. J. Power Electron. 2020, 20, 834–843. [Google Scholar] [CrossRef]

- Ghder Soliman, W.; Rama Koti Reddy, D. Microprocessor based prototype design of a PMDC motor with its system identification and PI controller design. SN Appl. Sci. 2019, 1, 1–8. [Google Scholar] [CrossRef]

- Sankardoss, V.; Geethanjali, P. Parameter estimation and speed control of a PMDC motor used in wheelchair. Energy Procedia 2017, 117, 345–352. [Google Scholar] [CrossRef]

- Bao, D.; Shen, H.; Ding, W.; Yuan, H.; Guo, Y.; Song, Z.; Gong, T. Research on the High Stability of an Adaptive Controller Based on a Neural Network for an Electrolysis-Free-Capacitor Motor Drive System. Energies 2025, 18, 2076. [Google Scholar] [CrossRef]

- Kecskés, I.; Burkus, E.; Király, Z.; Odry, Á.; Odry, P. Competition of motor controllers using a simplified robot leg: Pid vs fuzzy logic. In Proceedings of the 2017 Fourth International Conference on Mathematics and Computers in Sciences and in Industry (MCSI), Corfu, Greece, 24–27 August 2017; pp. 37–43. [Google Scholar]

- Sankardoss, V.; Geethanjali, P. Design and low-cost implementation of an electric wheelchair control. IETE J. Res. 2021, 67, 657–666. [Google Scholar] [CrossRef]

- Yang, S.K. A new anti-windup strategy for PID controllers with derivative filters. Asian J. Control 2012, 14, 564–571. [Google Scholar] [CrossRef]

- Huba, M.; Vrančič, D. Comparing filtered PI, PID and PIDD control for the FOTD plants. IFAC-PapersOnLine 2018, 51, 954–959. [Google Scholar] [CrossRef]

- Vrančić, D.; Huba, M. High-order filtered PID controller tuning based on magnitude optimum. Mathematics 2021, 9, 1340. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, Z. Improvements of direct current motor control and motion trajectory algorithm development for automated guided vehicle. Adv. Mech. Eng. 2019, 11, 1687814018824937. [Google Scholar] [CrossRef]

- Xue, J.; Chen, J.; Stancu, A.; Wang, X.; Li, J. Spatial Trajectory Tracking of Wall-Climbing Robot on Cylindrical Tank Surface Using Backstepping Sliding-Mode Control. Micromachines 2023, 14, 548. [Google Scholar] [CrossRef] [PubMed]

- Chu, H.; Gao, B.; Gu, W.; Chen, H. Low-speed control for permanent-magnet DC torque motor using observer-based nonlinear triple-step controller. IEEE Trans. Ind. Electron. 2016, 64, 3286–3296. [Google Scholar] [CrossRef]

- Humaidi, A.J.; Kasim Ibraheem, I. Speed control of permanent magnet DC motor with friction and measurement noise using novel nonlinear extended state observer-based anti-disturbance control. Energies 2019, 12, 1651. [Google Scholar] [CrossRef]

- Ahmad, N.S. Robust H∞-fuzzy logic control for enhanced tracking performance of a wheeled mobile robot in the presence of uncertain nonlinear perturbations. Sensors 2020, 20, 3673. [Google Scholar] [CrossRef]

- Ganzaroli, C.A.; de Carvalho, D.F.; Coimbra, A.P.; do Couto, L.A.; Calixto, W.P. Comparative Analysis of the Optimization and Implementation of Adjustment Parameters for Advanced Control Techniques. Energies 2022, 15, 4139. [Google Scholar] [CrossRef]

- Tuna, M.; Fidan, C.B.; Kocabey, S.; Gorgulu, S. Effective and reliable speed control of permanent magnet DC (PMDC) motor under variable loads. J. Electr. Eng. Technol. 2015, 10, 2170–2178. [Google Scholar] [CrossRef][Green Version]

- Murugananth, G.R.; Vijayan, S. Development of fuzzy controlled chopper drive for permanent magnet DC motor. J. Vib. Control 2015, 21, 555–562. [Google Scholar] [CrossRef]

- Çorapsiz, M.R. Performance analysis of speed control of PMDC motor using fuzzy logic controller. East. Anatol. J. Sci. 2017, 3, 16–29. [Google Scholar]

- Velagic, J.; Galijasevic, A. Design of fuzzy logic control of permanent magnet DC motor under real constraints and disturbances. In Proceedings of the 2009 IEEE Control Applications,(CCA) & Intelligent Control, (ISIC), St. Petersburg, Russia, 8–10 July 2009; pp. 461–466. [Google Scholar]

- Odry, Á.; Fullér, R.; Rudas, I.J.; Odry, P. Fuzzy control of self-balancing robots: A control laboratory project. Comput. Appl. Eng. Educ. 2020, 28, 512–535. [Google Scholar] [CrossRef]

- Kumar, N.S.; Sadasivam, V.; Asan Sukriya, H. A comparative study of PI, fuzzy, and ANN controllers for chopper-fed DC drive with embedded systems approach. Electr. Power Components Syst. 2008, 36, 680–695. [Google Scholar] [CrossRef]

- Guan, X.; Lou, S.; Li, H.; Tang, T. Intelligent control of quad-rotor aircrafts with a STM32 microcontroller using deep neural networks. Ind. Robot Int. J. Robot. Res. Appl. 2021, 48, 700–709. [Google Scholar] [CrossRef]

- Prakash, R.; Vasanthi, R. Speed control of DC-DC converter fed DC motor using robust adaptive intelligent controller. J. Vib. Control 2015, 21, 3107–3120. [Google Scholar] [CrossRef]

- Öztürk, N.; Celik, E. Speed control of permanent magnet synchronous motors using fuzzy controller based on genetic algorithms. Int. J. Electr. Power Energy Syst. 2012, 43, 889–898. [Google Scholar] [CrossRef]

- Nizami, T.K.; Chakravarty, A.; Mahanta, C. Design and implementation of a neuro-adaptive backstepping controller for buck converter fed PMDC-motor. Control Eng. Pract. 2017, 58, 78–87. [Google Scholar] [CrossRef]

- Elmas, C.; Ustun, O. A hybrid controller for the speed control of a permanent magnet synchronous motor drive. Control Eng. Pract. 2008, 16, 260–270. [Google Scholar] [CrossRef]

- Erenturk, K. MATLAB-based GUIs for fuzzy logic controller design and applications to PMDC motor and AVR control. Comput. Appl. Eng. Educ. 2005, 13, 10–25. [Google Scholar] [CrossRef]

- Li, D.; Ranjitkar, P. A fuzzy logic-based variable speed limit controller. J. Adv. Transp. 2015, 49, 913–927. [Google Scholar] [CrossRef]

- Hagras, H.A. A hierarchical type-2 fuzzy logic control architecture for autonomous mobile robots. IEEE Trans. Fuzzy Syst. 2004, 12, 524–539. [Google Scholar] [CrossRef]

- Mendel, J.M. Uncertain rule-based fuzzy systems. In Introduction and New Directions; Springer: Cham, Switzerland, 2017; Volume 684. [Google Scholar]

- Karnavas, Y.L.; Chatzipapas, N.V. Interval Type-2 Fuzzy Logic Controller Development for Coreless DC Micromotor Speed Control Applications. In Proceedings of the Fourth International Conference on Communication, Computing and Electronics Systems, Coimbatore, India, 15–16 September 2022; Springer: Singapore, 2023; pp. 755–767. [Google Scholar]

- Hassani, H.; Zarei, J. Interval Type-2 fuzzy logic controller design for the speed control of DC motors. Syst. Sci. Control Eng. 2015, 3, 266–273. [Google Scholar] [CrossRef]

- Buyukyildiz, C.; Saritas, I. Sensorless brushless DC motor control using type-2 fuzzy logic. Int. J. Intell. Syst. Appl. Eng. 2020, 8, 184–190. [Google Scholar] [CrossRef]

- Shi, Q.; Lam, H.K.; Xiao, B.; Tsai, S.H. Adaptive PID controller based on Q-learning algorithm. CAAI Trans. Intell. Technol. 2018, 3, 235–244. [Google Scholar] [CrossRef]

- Mahmud, M.; Motakabber, S.; Alam, A.Z.; Nordin, A.N. Adaptive PID controller using for speed control of the BLDC motor. In Proceedings of the 2020 IEEE International Conference on Semiconductor Electronics (ICSE), Kuala Lumpur, Malaysia, 28–29 July 2020; pp. 168–171. [Google Scholar]

- Shokouhandeh, H.; Jazaeri, M. An enhanced and auto-tuned power system stabilizer based on optimized interval type-2 fuzzy PID scheme. Int. Trans. Electr. Energy Syst. 2018, 28, e2469. [Google Scholar] [CrossRef]

- Chiu, C.H. Adaptive fuzzy control strategy for a single-wheel transportation vehicle. IEEE Access 2019, 7, 113272–113283. [Google Scholar] [CrossRef]

- Rigatos, G.G. Adaptive fuzzy control of DC motors using state and output feedback. Electr. Power Syst. Res. 2009, 79, 1579–1592. [Google Scholar] [CrossRef]

- Dhinakaran, P.; Manamalli, D. Novel strategies in the Model-based Optimization and Control of Permanent Magnet DC motors. Comput. Electr. Eng. 2015, 44, 34–41. [Google Scholar] [CrossRef]

- Ahmed, S.; Amin, A.A.; Wajid, Z.; Ahmad, F. Reliable speed control of a permanent magnet DC motor using fault-tolerant H-bridge. Adv. Mech. Eng. 2020, 12, 1687814020970311. [Google Scholar] [CrossRef]

- Shen, Y.; Yao, X.; Liu, S. Research on the drive control of the Disk Coreless BLDC motor based on the soft switching inverter. In Proceedings of the 2020 5th International Conference on Mechanical, Control and Computer Engineering (ICMCCE), Harbin, China, 25–27 December 2020; pp. 1019–1022. [Google Scholar]

- Alset, U.; Apte, A.; Mehta, H. Implementation of Fuzzy Logic based High Performance Speed Control System for PMDC motor using ATMEGA-328P-PU Micro-controller. In Proceedings of the 2020 IEEE International Conference on Electronics, Computing and Communication Technologies (CONECCT), Bangalore, India, 2–4 July 2020; pp. 1–5. [Google Scholar]

- Soliman, W.G.; Rama Koti Reddy, D.; Reddy, D.A. Microprocessor-based performance indices analysis of individual systems distributed motion control strategies. SN Appl. Sci. 2020, 2, 26. [Google Scholar] [CrossRef]

- Mishra, P.; Banerjee, A.; Ghosh, M. FPGA-based real-time implementation of quadral-duty digital-PWM-controlled permanent magnet BLDC drive. IEEE/ASME Trans. Mechatronics 2020, 25, 1456–1467. [Google Scholar] [CrossRef]

- Chaber, P.; Ławryńczuk, M. Fast analytical model predictive controllers and their implementation for STM32 ARM microcontroller. IEEE Trans. Ind. Inform. 2019, 15, 4580–4590. [Google Scholar] [CrossRef]

- Shan, X.; Li, M.; Yan, H.; Wang, Q.; Lan, Z. Design and implementation of the electrically powered wheelchair controller based on STM32. In Proceedings of the 2015 IEEE International Conference on Mechatronics and Automation (ICMA), Beijing, China, 2–5 August 2015; pp. 1484–1488. [Google Scholar]

- Rhouma, A.; Hafsi, S.; Bouani, F. Global optimization in robust fractional control of uncertain fractional order systems: A thermal application using the stm32 microcontroller. Electronics 2022, 11, 268. [Google Scholar] [CrossRef]

- Sharaf, A.M.; Elgammal, A.A. Novel AI-based soft computing applications in motor drives. In Power Electronics Handbook; Elsevier: Amsterdam, The Netherlands, 2018; pp. 1261–1302. [Google Scholar]

- Mostafa, J.; Serdar, E.; Davut, I.; Mohit, B.; Ievgen, Z. Efficient DC motor speed control using a novel multi-stage FOPD(1 + PI) controller optimized by the Pelican optimization algorithm. Sci. Rep. 2024, 14, 22442. [Google Scholar]

| N | Advantages | Disadvantages |

|---|---|---|

| Small | ✓ Fast response to rapid error changes. ✓ Better adaptation to dynamic error changes. ✓ Improved tracking of small error variations. | ✗ Limited noise suppression. ✗ Increased sensitivity to noise. ✗ Potential instability due to noise amplification. |

| Large | ✓ Enhanced noise filtering capabilities. ✓ Reduced controller impact of high-frequency noise. ✓ Improved stability by attenuating unwanted oscillations. | ✗ Slower response to fast error dynamics. ✗ Reduced system responsiveness to fast error changes. ✗ Possible increased overshoot and longer settling time. |

| Error | ||||

|---|---|---|---|---|

| N | M | P | ||

| N | VH | H | M | |

| Change in Error | M | H | M | L |

| P | M | L | VL |

| Corresponding PID Parameters | |

|---|---|

| [0, 1] | |

| (1, 2] | |

| (2, 3] | |

| (3, 4] | |

| (4, 5] | |

| (5, 6] | |

| (6, 7] | |

| (7, 8] | |

| (8, 9] | |

| (9, 10] |

| Parameter | Details |

|---|---|

| Microcontroller | STM32F103C8 |

| Core Architecture | 32-bit ARM Cortex M3 |

| Clock Speed | 72 MHz |

| Operating Voltage | 3.3 V |

| Flash Memory | 64 KB |

| SRAM | 20 KB |

| Data Bus Width | 32 b |

| Cost | 5 € |

| Hardware | Part Number |

|---|---|

| Micro-motor | Faulhaber 2842S018C |

| Microcontroller | STM32F103C8 |

| Power supply | NPS306W |

| Oscilloscope | Rigol DS1054Z |

| Motor driver | BTS7960 |

| Speed sensor | OMRON E6A2-CW5C |

| Current Sensor | ACS712 |

| DAC | MCP4725 |

| Buck-boost | DR-YM-288 |

| Parameter | Value | Description |

|---|---|---|

| Population Size (N) | 6 | Particle population of the swarm. |

| Maximum Iterations () | 100 | Number of iterations. |

| Inertia Weight (w) | Varies between 0.2 and 0.9 | Exploration-exploitation balance. |

| Cognitive Coefficient () | 2 | Weight for the best personal position. |

| Social Coefficient () | 2 | Weight for the best global position. |

| Bounds for | [0, 10] | Proportional gain parameter range. |

| Bounds for | [0, 1] | Integral gain parameter range. |

| Bounds for | [0, 1] | Derivative gain parameter range. |

| Bounds for N | [0, 100] | Filter coefficient range. |

| Reference Speed Setpoint | 2750 rpm | Tuning micro-motor speed. |

| Bit Resolution | PWM Frequency (Hz) |

|---|---|

| 10 | 70,314 |

| 11 | 35,156 |

| 12 | 17,578 |

| 13 | 8789 |

| 14 | 4394 |

| Advantages | Disadvantages | |

|---|---|---|

| Small | ✓ Enables faster control updates, improving response to dynamic changes. ✓ Facilitates frequent speed measurements, enhancing the precision of real-time control. ✓ Enhances the system’s capability to adapt to fast changes in speed. | ✗ Lower accuracy in speed estimation due to fewer encoder pulses within the interval. ✗ Increased sensitivity to signal noise, potentially introducing control instability. ✗ Limited low speed resolution, due to the small number of pulses produced within the time interval. |

| Large | ✓ Improves measurement accuracy by averaging over more encoder pulses. ✓ Provides smoother speed calculations with reduced sensitivity to noise. ✓ Increased resolution at low speeds since a higher number of pulses generated within the time interval. | ✗ Slower system response to dynamic changes, leading to potential prolonged error correction. ✗ Delays in control actions, potentially affecting performance in fast-changing scenarios. ✗ Increased likelihood of missing short-duration speed events. |

| Parameter | Value |

|---|---|

| Process Noise Covariance (Q) | 0.0005 |

| Measurement Noise Covariance (R) | 0.1 |

| Initial Estimate Error Covariance (P) | 1 |

| Initial Speed Estimate () | 0 |

| Initial Kalman Gain (K) | 1 |

| Controller | N | |||

|---|---|---|---|---|

| PI | 4 | 0.12 | - | - |

| PID | 7.8 | 0.059 | 0.41 | - |

| PIDF | 2.72 | 0.0069 | 0.61 | 57.4 |

| [0, 1] | |||

| (1, 2] | |||

| (2, 3] | |||

| (3, 4] | |||

| (4, 5] | |||

| (5, 6] | |||

| (6, 7] | |||

| (7, 8] | |||

| (8, 9] | |||

| (9, 10] |

| Memory | Total Size | PI | PID | PIDF | FT2-PID |

|---|---|---|---|---|---|

| SRAM | 20 KB | 2.51 KB | 2.52 KB | 2.53 KB | 3.20 KB |

| Flash | 64 KB | 21.78 KB | 21.84 KB | 21.88 KB | 32.39 KB |

| Memory | Total Size | PI | PID | PIDF | FT2-PID |

|---|---|---|---|---|---|

| SRAM | 20 KB | 6.64 KB | 6.66 KB | 6.67 KB | 7.86 KB |

| Flash | 64 KB | 30.14 KB | 30.22 KB | 30.28 KB | 41.69 KB |

| Speed (rpm) | CPU Load (%—PI, PID, PIDF) | CPU Load (%—FT2-PID) |

|---|---|---|

| 0 | 2.31 | 53.09 |

| 1500 | 3.70 | 57.72 |

| 2000 | 4.63 | 58.95 |

| 3000 | 6.79 | 61.11 |

| 3500 | 7.72 | 63.27 |

| 4000 | 8.95 | 65.43 |

| 5000 | 11.73 | 69.14 |

| Case | Target Speed (rpm) | Controllers Evaluated | Objective |

|---|---|---|---|

| Case 1 | 2000 | PI, PID, PIDF, FT2-PID | Low-Speed Performance |

| Case 2 | 2750 | PI, PID, PIDF, FT2-PID | Mid-Speed Performance |

| Case 3 | 3500 | PI, PID, PIDF, FT2-PID | High-Speed Performance |

| Case | Reference Speed | PI | PID | PIDF | FT2-PID |

|---|---|---|---|---|---|

| 1 | 2000 rpm | 22.7 ms | 24.3 ms | 26.1 ms | 29.7 ms |

| 2 | 2750 rpm | 34.5 ms | 37.8 ms | 35.9 ms | 37.7 ms |

| 3 | 3500 rpm | 50.7 ms | 49.9 ms | 52.3 ms | 53.5 ms |

| Case | Reference Speed | PI | PID | PIDF | FT2-PID |

|---|---|---|---|---|---|

| 1 | 2000 rpm | 19.00% | 14.00% | 9.00% | 12.00% |

| 2 | 2750 rpm | 21.00% | 11.00% | 11.00% | 12.30% |

| 3 | 3500 rpm | 25.00% | 8.00% | 16.00% | 12.50% |

| Case | Reference Speed | PI | PID | PIDF | FT2-PID |

|---|---|---|---|---|---|

| 1 | 2000 rpm | 240 ms | 230 ms | 145 ms | 104 ms |

| 2 | 2750 rpm | 250 ms | 203 ms | 149 ms | 123 ms |

| 3 | 3500 rpm | 313 ms | 245 ms | 225 ms | 167 ms |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chatzipapas, N.V.; Karnavas, Y.L. Adaptive Microprocessor-Based Interval Type-2 Fuzzy Logic Controller Design for DC Micro-Motor Control Considering Hardware Limitations. Energies 2025, 18, 5781. https://doi.org/10.3390/en18215781

Chatzipapas NV, Karnavas YL. Adaptive Microprocessor-Based Interval Type-2 Fuzzy Logic Controller Design for DC Micro-Motor Control Considering Hardware Limitations. Energies. 2025; 18(21):5781. https://doi.org/10.3390/en18215781

Chicago/Turabian StyleChatzipapas, Nikolaos V., and Yannis L. Karnavas. 2025. "Adaptive Microprocessor-Based Interval Type-2 Fuzzy Logic Controller Design for DC Micro-Motor Control Considering Hardware Limitations" Energies 18, no. 21: 5781. https://doi.org/10.3390/en18215781

APA StyleChatzipapas, N. V., & Karnavas, Y. L. (2025). Adaptive Microprocessor-Based Interval Type-2 Fuzzy Logic Controller Design for DC Micro-Motor Control Considering Hardware Limitations. Energies, 18(21), 5781. https://doi.org/10.3390/en18215781