Biogas Upgrading into Renewable Natural Gas: Part II—An Assessment of Emerging Technologies

Abstract

1. Introduction

- Review emerging technologies;

- Review developing technologies;

- Discuss case studies and process design.

2. Emerging Technologies for Biogas Treatment and Upgrading

2.1. Cryogenic Separation

- Removal of trace contaminants, mainly in the context of landfill gas;

- Extraction of major components such as CO2 (gas upgrading);

- Condensation of upgraded RNG for conversion into bio-based liquified natural gas (LNG) (i.e., liquidized biogas (LBG)).

2.2. In Situ Methane Enrichment

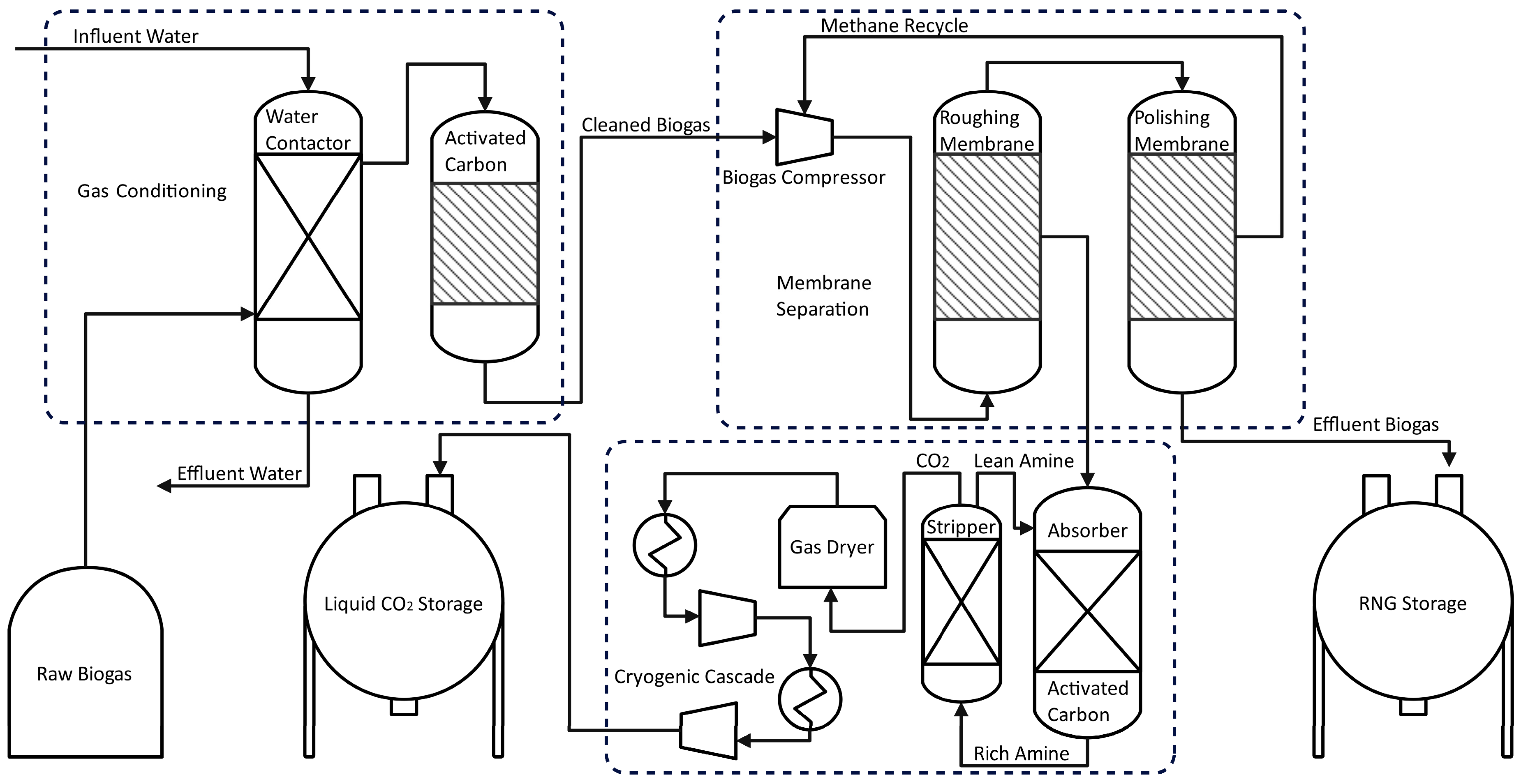

2.3. Hybrid Technologies

3. Developing Technologies for Biogas Treatment and Upgrading

3.1. Industrial Lung

3.2. Supersonic Separation

3.3. Chemical Hydrogenation Process

3.4. Hydrate Formation

3.5. Biological Technologies

- Chemo-autotrophic methods using in situ microbial communities;

- Photo-autotrophic methods;

- Biogas upgrading through fermentation processes;

- Biogas upgrading through microbial electrochemical methods.

3.5.1. Chemo-Autotroph Methods

- Ensures the stability of the conventional biogas process;

- No degradation of the organic substrates (hydrolysis and acidogenesis are avoided);

- Independent culture isolated from the biogas process;

- Can use another external source of CO2 (e.g., synthesis gas) to make the process more flexible.

- Archaea hydrogenotrophic methanogens facilitate the conversion of CO2 to CH4 via external H2 as an electron donor, effective at a 7 pH [89].

- The Wood-Ljungdahl mechanism, outlined in Equation (4), provides an indirect pathway, driven by homoacetogenic bacteria, relies on the exergonic transformation of CO2 into acetate.

3.5.2. Photo-Autotrophic Method

3.5.3. Fermentation-Based Biogas Upgrading

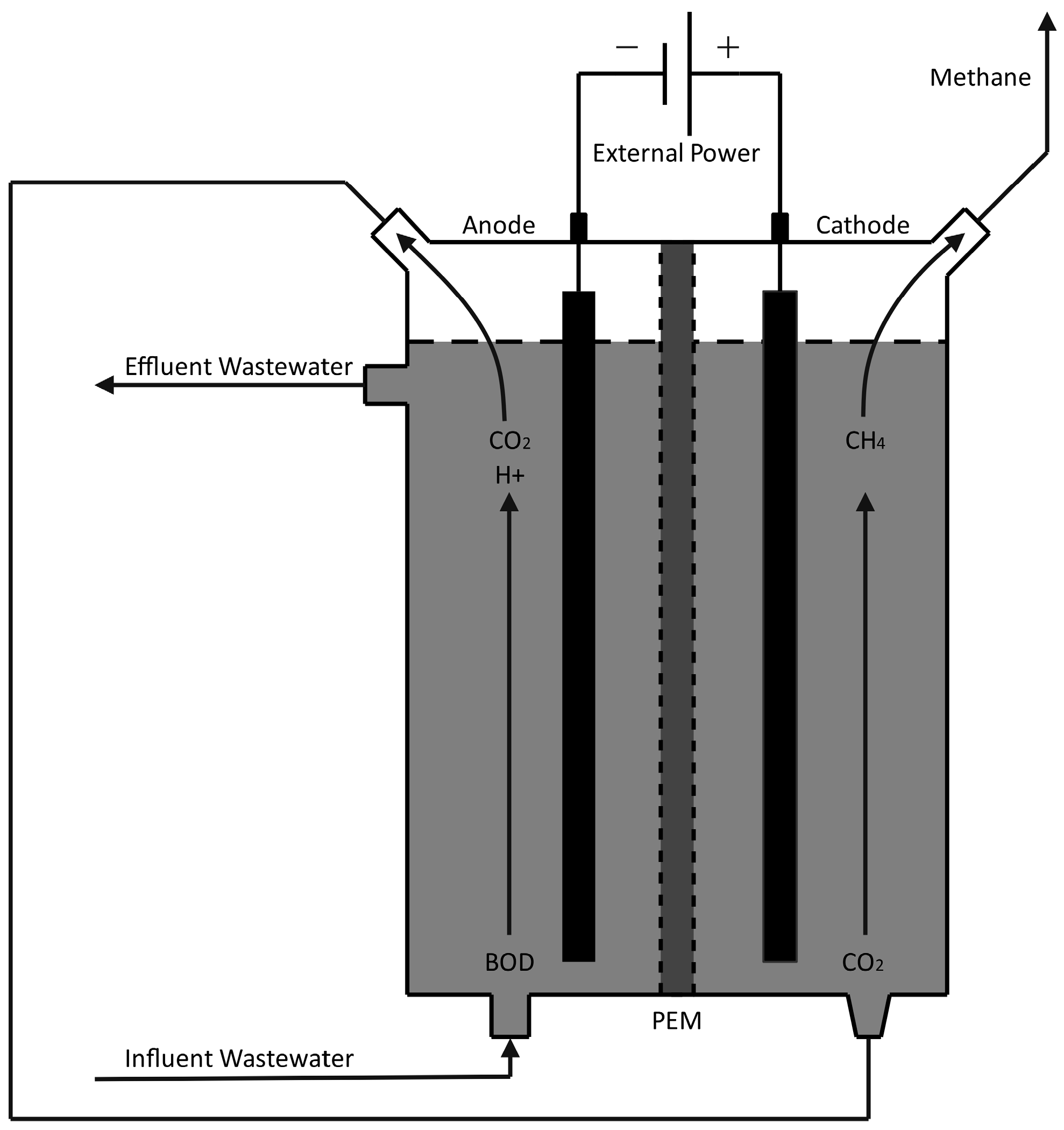

3.5.4. Microbial Electrochemical Methods

- Development of high surface area electrode materials with good catalytic properties for water oxidation and suitable properties for the development of biofilms in CO2 reduction by catalysis.

- Directing the flow through a porous electrode can effectively use the surface area and decrease the mass transfer losses.

- Decreasing the distances between the membrane and electrodes further minimizes loss by mass transfer.

- A membrane which is less permeable to CO2 and CH4 should be used to increase coulombic efficiency and the methane content of the gas.

4. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hagos, K.; Zong, J.; Li, D.; Liu, C.; Lu, X. Anaerobic co-digestion process for biogas production: Progress, challenges and perspectives. Renew. Sustain. Energy Rev. 2017, 76, 1485–1496. [Google Scholar] [CrossRef]

- Zirkler, D.; Peters, A.; Kaupenjohann, M. Elemental composition of biogas residues: Variability and alteration during anaerobic digestion. Biomass Bioenergy 2014, 67, 89–98. [Google Scholar] [CrossRef]

- Shrestha, B.; Foret, B.; Sharp, W.; Gang, D.; Hernandez, R.; Revellame, E.; Fortela, D.L.B.; Holmes, W.E.; Zappi, M.E. An Overview of the Potential for Municipal Wastewater Treatment Plants to Be Integrated into Urban Biorefineries for the Production of Sustainable Bio-Based Fuels and Other Chemicals. Curr. Pollut. Rep. 2024, 10, 548–564. [Google Scholar] [CrossRef]

- Jaffe, A.; Dominguez-Faus, R.; Parker, N.; Scheitrum, D.; Wilcock, J.; Miller, M. The Feasibility of Renewable Natural Gas as a Large-Scale, Low Carbon Substitute. 2016. Available online: https://ww2.arb.ca.gov/sites/default/files/classic/research/apr/past/13-307.pdf (accessed on 19 May 2023).

- Gaida, D.; Wolf, C.; Bongards, M. Feed control of anaerobic digestion processes for renewable energy production: A review. Renew. Sustain. Energy Rev. 2017, 68, 869–875. [Google Scholar] [CrossRef]

- Nguyen, D.; Gadhamshetty, V.; Nitayavardhana, S.; Khanal, S.K. Automatic process control in anaerobic digestion technology: A critical review. Bioresour. Technol. 2015, 193, 513–522. [Google Scholar] [CrossRef]

- Rasapoor, M.; Young, B.; Brar, R.; Sarmah, A.; Zhuang, W.Q.; Baroutian, S. Recognizing the challenges of anaerobic digestion: Critical steps toward improving biogas generation. Fuel 2020, 261, 116497. [Google Scholar] [CrossRef]

- Kunatsa, T.; Xia, X. A review on anaerobic digestion with focus on the role of biomass co-digestion, modelling and optimisation on biogas production and enhancement. Bioresour. Technol. 2022, 344, 126311. [Google Scholar] [CrossRef]

- Fortela, D.L.B.; Sharp, W.W.; Revellame, E.D.; Hernandez, R.; Gang, D.; Zappi, M.E. Computational evaluation for effects of feedstock variations on the sensitivities of biochemical mechanism parameters in anaerobic digestion kinetic models. Biochem. Eng. J. 2019, 143, 212–223. [Google Scholar] [CrossRef]

- Maqsood, K.; Mullick, A.; Ali, A.; Kargupta, K.; Ganguly, S. Cryogenic carbon dioxide separation from natural gas: A review based on conventional and novel emerging technologies. Rev. Chem. Eng. 2014, 30, 453–477. [Google Scholar] [CrossRef]

- Rufford, T.E.; Smart, S.; Watson, G.C.Y.; Graham, B.F.; Boxall, J.; Diniz da Costa, J.C.; May, E.F. The removal of CO2 and N2 from natural gas: A review of conventional and emerging process technologies. J. Pet. Sci. Eng. 2012, 94-95, 123–154. [Google Scholar] [CrossRef]

- Sarker, S.; Lamb, J.J.; Hjelme, D.R.; Lien, K.M. Overview of recent progress towards in-situ biogas upgradation techniques. Fuel 2018, 226, 686–697. [Google Scholar] [CrossRef]

- Kotagodahett, R.; Hewage, K.; Sadiq, R. Decarbonized Natural Gas Supply Chain with Low-Carbon Gaseous Fuels: A Life Cycle Environmental and Economic Assessment. Lect. Notes Civ. Eng. 2024, 367, 999–1014. [Google Scholar] [CrossRef]

- Yentekakis, I.V.; Goula, G. Biogas management: Advanced utilization for production of renewable energy and added-value chemicals. Front. Environ. Sci. 2017, 5, 237755. [Google Scholar] [CrossRef]

- Cyrs, T.; Feldmann, J.; Gasper, R. Renewable Natural Gas as a Climate Strategy: Guidance for State Policymakers. World Resources Institute. 2020. Available online: https://www.wri.org/research/renewable-natural-gas-climate-strategy-guidance-state-policymakers (accessed on 6 September 2024).

- SkyQuest. Renewable Natural Gas Market Size & Share—Industry Growth | 2031. 2024. Available online: https://www.skyquestt.com/report/renewable-natural-gas-market (accessed on 6 September 2024).

- Faransso, R. Jumpstarting the Clean Hydrogen Economy—The Final Rule for 45v. Available online: https://esgreview.net/2025/01/15/jumpstarting-the-clean-hydrogen-economy-the-final-rule-for-45v (accessed on 9 March 2025).

- USDOE; North Wind Inc. 2022 Annual Site Environmental Report. 2023. Available online: https://www.energy.gov/sites/default/files/2024-06/2022%20Site%20Environmental%20Report%2C%20Department%20of%20Energy%2C%20ETEC%20-%20Area%20IV%20Santa%20Susana%20Field%20Laboratory%2C%20October%202023.pdf (accessed on 7 November 2024).

- Service, I.R. Credit for Production of Clean Hydrogen and Energy Credit. 2023. Available online: https://www.federalregister.gov/documents/2023/12/26/2023-28359/section-45v-credit-for-production-of-clean-hydrogen-section-48a15-election-to-treat-clean-hydrogen (accessed on 18 June 2023).

- Lewis, E.; McNaul, S.; Jamieson, M.; Henriksen, M.S.; Matthews, H.S.; Walsh, L.; Grove, J.; Shultz, T.; Skone, T.J.; Stevens, R. Comparison of Commercial, State-of-the-Art, Fossil-Based Hydrogen Production Technologies; National Energy Technology Laboratory (NETL): Pittsburgh, PA, USA; Morgantown, WV, USA, 2022. [Google Scholar]

- Navarrete, A. Final regulations for the Inflation Reduction Act’s Section 45V Clean Hydrogen Production Tax Credit. POLICY. 2025. Available online: https://theicct.org/wp-content/uploads/2025/04/ID-337-%E2%80%93-Hydrogen-credit_policy-update_final.pdf (accessed on 24 September 2025).

- Sahota, S.; Shah, G.; Ghosh, P.; Kapoor, R.; Sengupta, S.; Singh, P.; Vijay, V.; Sahay, A.; Vijay, V.K.; Thakur, I.S. Review of trends in biogas upgradation technologies and future perspectives. Bioresour. Technol. Rep. 2018, 1, 79–88. [Google Scholar] [CrossRef]

- Angelidaki, I.; Treu, L.; Tsapekos, P.; Luo, G.; Campanaro, S.; Wenzel, H.; Kougias, P. Biogas upgrading and utilization: Current status and perspectives. Biotechnol. Adv. 2018, 36, 452–466. [Google Scholar] [CrossRef] [PubMed]

- Awe, O.W.; Zhao, Y.; Nzihou, A.; Minh, D.P.; Lyczko, N. A Review of Biogas Utilisation, Purification and Upgrading Technologies. Waste Biomass Valorization 2017, 8, 267–283. [Google Scholar] [CrossRef]

- Bauer, F.; Hulteberg, C.; Persson, T.; Tamm, D. Biogas Upgrading—Review of Commercial Technologies (Biogasuppgradering-Granskning av Kommersiella Tekniker) SGC Rapport 2013:270 “Catalyzing Energygas Development for Sustainable Solutions”. Available online: https://portal.research.lu.se/sv/publications/biogas-upgrading-technology-overview-comparison-and-perspectives-/ (accessed on 6 June 2022).

- Grande, C.A.; Blom, R. Cryogenic Adsorption of Methane and Carbon Dioxide on Zeolites 4A and 13X. Energy Fuels 2014, 28, 6688–6693. [Google Scholar] [CrossRef]

- Miltner, M.; Makaruk, A.; Harasek, M. Review on available biogas upgrading technologies and innovations towards advanced solutions. J. Clean. Prod. 2017, 161, 1329–1337. [Google Scholar] [CrossRef]

- Muñoz, R.; Meier, L.; Diaz, I.; Jeison, D. A review on the state-of-the-art of physical/chemical and biological technologies for biogas upgrading. Rev. Environ. Sci. Bio/Technol. 2015, 14, 727–759. [Google Scholar] [CrossRef]

- Ryckebosch, E.; Drouillon, M.; Vervaeren, H. Techniques for transformation of biogas to biomethane. Biomass Bioenergy 2011, 35, 1633–1645. [Google Scholar] [CrossRef]

- Ullah Khan, I.; Hafiz Dzarfan Othman, M.; Hashim, H.; Matsuura, T.; Ismail, A.F.; Rezaei-DashtArzhandi, M.; Wan Azelee, I. Biogas as a renewable energy fuel—A review of biogas upgrading, utilisation and storage. Energy Convers. Manag. 2017, 150, 277–294. [Google Scholar] [CrossRef]

- Hosseini, S.E.; Wahid, M.A. Biogas utilization: Experimental investigation on biogas flameless combustion in lab-scale furnace. Energy Convers. Manag. 2013, 74, 426–432. [Google Scholar] [CrossRef]

- Allegue, L.B.; Hinge, J. Biogas and bio-syngas upgrading. Dan. Technol. Inst. 2012, 5, 97. [Google Scholar]

- Sun, Q.; Li, H.; Yan, J.; Liu, L.; Yu, Z.; Yu, X. Selection of appropriate biogas upgrading technology-a review of biogas cleaning, upgrading and utilisation. Renew. Sustain. Energy Rev. 2015, 51, 521–532. [Google Scholar] [CrossRef]

- Yousef, A.M.; El-Maghlany, W.M.; Eldrainy, Y.A.; Attia, A. New approach for biogas purification using cryogenic separation and distillation process for CO2 capture. Energy 2018, 156, 328–351. [Google Scholar] [CrossRef]

- Kadam, R.; Panwar, N.L. Recent advancement in biogas enrichment and its applications. Renew. Sustain. Energy Rev. 2017, 73, 892–903. [Google Scholar] [CrossRef]

- Petersson, A.; Wellinger, A. Biogas Upgrading Technologies—Developments and Innovations. IEA Bioenergy Task 37-Energy from Biogas Landfill Gas. 2009. Available online: https://www.ieabioenergy.com/wp-content/uploads/2009/10/upgrading_rz_low_final.pdf (accessed on 21 September 2023).

- Hansson, M.; Yu, Z.; Nordberg, Å.; Rasmuson, Å. In-Situ Methane Enrichment in Anaerobic Digestion of Sewage Sludge—Stage 2. 2009. Available online: http://sgc.camero.se/ckfinder/userfiles/files/SGC280.pdf (accessed on 21 September 2023).

- Boontawee, S.; Koonaphapdeelert, S. In-Situ Biomethane Enrichment by Recirculation of Biogas Channel Digester Effluent Using Gas Stripping Column. Energy Procedia 2016, 89, 78–84. [Google Scholar] [CrossRef][Green Version]

- Belaissaoui, B.; Willson, D.; Favre, E. Membrane gas separations and post-combustion carbon dioxide capture: Parametric sensitivity and process integration strategies. Chem. Eng. J. 2012, 211–212, 122–132. [Google Scholar] [CrossRef]

- Freeman, B.; Hao, P.; Baker, R.; Kniep, J.; Chen, E.; Ding, J.; Zhang, Y.; Rochelle, G.T. Hybrid Membrane-absorption CO2 Capture Process. Energy Procedia 2014, 63, 605–613. [Google Scholar] [CrossRef]

- Song, C.; Liu, Q.; Ji, N.; Deng, S.; Zhao, J.; Li, Y.; Kitamura, Y. Reducing the energy consumption of membrane-cryogenic hybrid CO2 capture by process optimization. Energy 2017, 124, 29–39. [Google Scholar] [CrossRef]

- Surovtseva, D.; Amin, R.; Barifcani, A. Design and operation of pilot plant for CO2 capture from IGCC flue gases by combined cryogenic and hydrate method. Chem. Eng. Res. Des. 2011, 89, 1752–1757. [Google Scholar] [CrossRef]

- Budzianowski, W.M. A review of potential innovations for production, conditioning and utilization of biogas with multiple-criteria assessment. Renew. Sustain. Energy Rev. 2016, 54, 1148–1171. [Google Scholar] [CrossRef]

- Scholz, M.; Melin, T.; Wessling, M. Transforming biogas into biomethane using membrane technology. Renew. Sustain. Energy Rev. 2013, 17, 199–212. [Google Scholar] [CrossRef]

- Struk, M.; Kushkevych, I.; Vítězová, M. Biogas upgrading methods: Recent advancements and emerging technologies. Rev. Environ. Sci. Bio/Technol. 2020, 19, 651–671. [Google Scholar] [CrossRef]

- Pentair. Haffmans Biomethane & Green CO2 Biogas Upgrading Using Membrane & Cryogenic Technology. 2016. Available online: https://task37.ieabioenergy.com/wp-content/uploads/sites/32/2022/03/5T37Holland170406denHeijer.pdf (accessed on 20 October 2023).

- Soni Castro, P.; Martinez Zuniga, G.; Holmes, W.; Buchireddy, P.R.; Gang, D.D.; Revellame, E.; Zappi, M.; Hernandez, R. Review of the adsorbents/catalysts for the removal of sulfur compounds from natural gas. Gas Sci. Eng. 2023, 115, 205004. [Google Scholar] [CrossRef]

- Sosa, J.A.; Laines, J.R.; García, D.S.; Hernández, R.; Zappi, M.; Espinosa de los Monteros, A.E. Activated Carbon: A Review of Residual Precursors, Synthesis Processes, Characterization Techniques, and Applications in the Improvement of Biogas. Environ. Eng. Res. 2023, 28, 220100. [Google Scholar] [CrossRef]

- Andlar, M.; Belskaya, H.; Morzak, G.; Ivančić Šantek, M.; Rezić, T.; Petravić Tominac, V.; Šantek, B. Biogas Production Systems and Upgrading Technologies: A Review. Food Technol. Biotechnol. 2021, 59, 387–412. [Google Scholar] [CrossRef]

- Parent, C.; Dutil, F. Carbonic Anhydrase Bioreactor and Process. U.S. Patent 8329460B2, 11 December 2012. Available online: https://patents.google.com/patent/US8329460B2/en (accessed on 24 September 2025).

- Bian, J.; Cao, X.; Yang, W.; Song, X.; Xiang, C.; Gao, S. Condensation characteristics of natural gas in the supersonic liquefaction process. Energy 2019, 168, 99–110. [Google Scholar] [CrossRef]

- Ong, M.D.; Williams, R.B.; Kaffka, S.R. Comparative Assessment of Technology Options for Biogas Clean-Up. 2014. Available online: https://ucdavis.app.box.com/s/iaog2diybkvoe5xxdjud97xsrx3ypwmq (accessed on 16 June 2022).

- Altam, R.A.; Lemma, T.A.; Jufar, S.R. Trends in Supersonic Separator design development. MATEC Web Conf. 2017, 131, 03006. [Google Scholar] [CrossRef][Green Version]

- Jürgensen, L.; Ehimen, E.A.; Born, J.; Holm-Nielsen, J.B. Dynamic biogas upgrading based on the Sabatier process: Thermodynamic and dynamic process simulation. Bioresour. Technol. 2015, 178, 323–329. [Google Scholar] [CrossRef]

- Xia, A.; Cheng, J.; Murphy, J.D. Innovation in biological production and upgrading of methane and hydrogen for use as gaseous transport biofuel. Biotechnol. Adv. 2016, 34, 451–472. [Google Scholar] [CrossRef]

- Dalla Betta, R.A.; Piken, A.G.; Shelef, M. Heterogeneous methanation: Steady-state rate of CO hydrogenation on supported ruthenium, nickel and rhenium. J. Catal. 1975, 40, 173–183. [Google Scholar] [CrossRef]

- Jürgensen, L.; Ehimen, E.; Born, J.; Holm-Nielsen, J.; Rooney, D. Influence of trace substances on methanation catalysts used in dynamic biogas upgrading. Bioresour. Technol. 2014, 178, 319–322. [Google Scholar] [CrossRef] [PubMed]

- Witte, J.; Settino, J.; Biollaz, S.M.A.; Schildhauer, T.J. Direct catalytic methanation of biogas—Part I: New insights into biomethane production using rate-based modelling and detailed process analysis. Energy Convers. Manag. 2018, 171, 750–768. [Google Scholar] [CrossRef]

- Yoon, J.-H.; Lee, H. Clathrate phase equilibria for the water–phenol–carbon dioxide system. AIChE J. 1997, 43, 1884–1893. [Google Scholar] [CrossRef]

- Kang, S.-P.; Seo, Y.; Jang, W.; Seo, Y. Gas Hydrate Process for Recovery of CO2 from Fuel Gas. Chem. Eng. Trans. 2009, 17, 1449–1454. [Google Scholar] [CrossRef]

- Tajima, H.; Yamasaki, A.; Kiyono, F. Energy consumption estimation for greenhouse gas separation processes by clathrate hydrate formation. Energy 2004, 29, 1713–1729. [Google Scholar] [CrossRef]

- Wang, X.; Chen, G.; Yang, L.; Zhang, L. Study on the recovery of hydrogen from refinery (hydrogen + methane) gas mixtures using hydrate technology. Sci. China Ser. B Chem. 2008, 51, 171–178. [Google Scholar] [CrossRef]

- Jansen, M.; Heijne, A.; Buisman, C.; Hamelers, H.V.M. Microbial electrolysis cells for production of methane from CO2: Long-term performance and perspectives: A methane-producing MEC to increase land use efficiency. Int. J. Energy Res. 2012, 36, 809–819. [Google Scholar] [CrossRef]

- Horii, S.; Ohmura, R. Continuous separation of CO2 from a H2 + CO2 gas mixture using clathrate hydrate. Appl. Energy 2018, 225, 78–84. [Google Scholar] [CrossRef]

- Kougias, P.; Campanaro, S.; Treu, L.; Zhu, X.; Angelidaki, I. A novel archaeal species belonging to Methanoculleus genus identified via de-novo assembly and metagenomic binning process in biogas reactors. Anaerobe 2017, 46, 23–32. [Google Scholar] [CrossRef]

- Luo, G.; Johansson, S.; Boe, K.; Xie, L.; Zhou, Q.; Angelidaki, I. Simultaneous hydrogen utilization and in situ biogas upgrading in an anaerobic reactor. Biotechnol. Bioeng. 2012, 109, 1088–1094. [Google Scholar] [CrossRef] [PubMed]

- Luo, G.; Angelidaki, I. Co-digestion of manure and whey for in situ biogas upgrading by the addition of H2: Process performance and microbial insights. Appl. Microbiol. Biotechnol. 2013, 97, 1373–1381. [Google Scholar] [CrossRef] [PubMed]

- Luo, G.; Angelidaki, I. Hollow fiber membrane based H2 diffusion for efficient in situ biogas upgrading in an anaerobic reactor. Appl. Microbiol. Biotechnol. 2013, 97, 3739–3744. [Google Scholar] [CrossRef] [PubMed]

- Bassani, I.; Kougias, P.G.; Angelidaki, I. In-Situ biogas upgrading in thermophilic granular UASB reactor: Key factors affecting the hydrogen mass transfer rate. Bioresour. Technol. 2016, 221, 485–491. [Google Scholar] [CrossRef]

- Mulat, D.G.; Mosbæk, F.; Ward, A.J.; Polag, D.; Greule, M.; Keppler, F.; Nielsen, J.L.; Feilberg, A. Exogenous addition of H2 for an in situ biogas upgrading through biological reduction of carbon dioxide into methane. Waste Manag. 2017, 68, 146–156. [Google Scholar] [CrossRef]

- Agneessens, L.M.; Ottosen, L.D.M.; Voigt, N.V.; Nielsen, J.L.; de Jonge, N.; Fischer, C.H.; Kofoed, M.V.W. In-Situ biogas upgrading with pulse H2 additions: The relevance of methanogen adaption and inorganic carbon level. Bioresour. Technol. 2017, 233, 256–263. [Google Scholar] [CrossRef]

- Batstone, D.; Keller, J.; Angelidaki, I.; Kalyuzhnyi, S.; Pavlostathis, S.; Rozzi, A.; Sanders, W.; Siegrist, H.; Vavilin, V. Anaerobic digestion model No 1 (ADM1). Water Sci. Technol. J. Int. Assoc. Water Pollut. Res. 2002, 45, 65–73. [Google Scholar] [CrossRef]

- Caruso, M.C.; Braghieri, A.; Capece, A.; Napolitano, F.; Romano, P.; Galgano, F.; Altieri, G.; Genovese, F. Recent Updates on the Use of Agro-Food Waste for Biogas Production. Appl. Sci. 2019, 9, 1217. [Google Scholar] [CrossRef]

- Liu, Y.; Whitman, W.B. Metabolic, Phylogenetic, and Ecological Diversity of the Methanogenic Archaea. Ann. N. Y. Acad. Sci. 2008, 1125, 171–189. [Google Scholar] [CrossRef]

- Reeve, J.N.; Morgan, R.M.; Nölling, J. Environmental and molecular regulation of methanogenesis. Water Sci. Technol. 1997, 36, 1–6. [Google Scholar] [CrossRef][Green Version]

- Tirunehe, G.; Norddahl, B. The influence of polymeric membrane gas spargers on hydrodynamics and mass transfer in bubble column bioreactors. Bioprocess Biosyst. Eng. 2016, 39, 613–626. [Google Scholar] [CrossRef] [PubMed]

- Luo, G.; Wang, W.; Angelidaki, I. A new degassing membrane coupled upflow anaerobic sludge blanket (UASB) reactor to achieve in-situ biogas upgrading and recovery of dissolved CH4 from the anaerobic effluent. Appl. Energy 2014, 132, 536–542. [Google Scholar] [CrossRef]

- Alitalo, A.; Niskanen, M.; Aura, E. Biocatalytic methanation of hydrogen and carbon dioxide in a fixed bed bioreactor. Bioresour. Technol. 2015, 196, 600–605. [Google Scholar] [CrossRef]

- Bassani, I.; Kougias, P.G.; Treu, L.; Angelidaki, I. Biogas Upgrading via Hydrogenotrophic Methanogenesis in Two-Stage Continuous Stirred Tank Reactors at Mesophilic and Thermophilic Conditions. Environ. Sci. Technol. 2015, 49, 12585–12593. [Google Scholar] [CrossRef]

- Bassani, I.; Kougias, P.G.; Treu, L.; Porté, H.; Campanaro, S.; Angelidaki, I. Optimization of hydrogen dispersion in thermophilic up-flow reactors for ex situ biogas upgrading. Bioresour. Technol. 2017, 234, 310–319. [Google Scholar] [CrossRef]

- Burkhardt, M.; Koschack, T.; Busch, G. Biocatalytic methanation of hydrogen and carbon dioxide in an anaerobic three-phase system. Bioresour. Technol. 2015, 178, 330–333. [Google Scholar] [CrossRef]

- Burkhardt, M.; Busch, G. Methanation of hydrogen and carbon dioxide. Appl. Energy 2013, 111, 74–79. [Google Scholar] [CrossRef]

- Guneratnam, A.J.; Ahern, E.; FitzGerald, J.A.; Jackson, S.A.; Xia, A.; Dobson, A.D.W.; Murphy, J.D. Study of the performance of a thermophilic biological methanation system. Bioresour. Technol. 2017, 225, 308–315. [Google Scholar] [CrossRef]

- Kim, S.; Choi, K.; Chung, J. Reduction in carbon dioxide and production of methane by biological reaction in the electronics industry. Int. J. Hydrogen Energy 2013, 38, 3488–3496. [Google Scholar] [CrossRef]

- Lee, J.; Kim, J.; Chang, W.; Pak, D. Biological conversion of CO2 to CH4 using hydrogenotrophic methanogen in a fixed bed reactor. J. Chem. Technol. Biotechnol. 2012, 87, 844–847. [Google Scholar] [CrossRef]

- Luo, G.; Angelidaki, I. Integrated biogas upgrading and hydrogen utilization in an anaerobic reactor containing enriched hydrogenotrophic methanogenic culture. Biotechnol. Bioeng. 2012, 109, 2729–2736. [Google Scholar] [CrossRef] [PubMed]

- Martin, M.R.; Fornero, J.J.; Stark, R.; Mets, L.; Angenent, L.T. A single-culture bioprocess of Methanothermobacter thermautotrophicus to upgrade digester biogas by CO2-to-CH4 conversion with H2. Archaea 2013, 2013, 157529. [Google Scholar] [CrossRef] [PubMed]

- Rachbauer, L.; Voitl, G.; Bochmann, G.; Fuchs, W. Biological biogas upgrading capacity of a hydrogenotrophic community in a trickle-bed reactor. Appl. Energy 2016, 180, 483–490. [Google Scholar] [CrossRef]

- Stams, A.J.M.; Plugge, C.M. Electron transfer in syntrophic communities of anaerobic bacteria and archaea. Nat. Rev. Microbiol. 2009, 7, 568–577. [Google Scholar] [CrossRef]

- Schuchmann, K.; Müller, V. Autotrophy at the thermodynamic limit of life: A model for energy conservation in acetogenic bacteria. Nat. Rev. Microbiol. 2014, 12, 809–821. [Google Scholar] [CrossRef]

- Demirel, B.; Scherer, P. The roles of acetotrophic and hydrogenotrophic methanogens during anaerobic conversion of biomass to methane: A review. Rev. Environ. Sci. Bio/Technol. 2008, 7, 173–190. [Google Scholar] [CrossRef]

- Kougias, P.G.; Treu, L.; Benavente, D.P.; Boe, K.; Campanaro, S.; Angelidaki, I. Ex-Situ biogas upgrading and enhancement in different reactor systems. Bioresour. Technol. 2017, 225, 429–437. [Google Scholar] [CrossRef]

- Díaz, I.; Pérez, C.; Alfaro, N.; Fdz-Polanco, F. A feasibility study on the bioconversion of CO2 and H2 to biomethane by gas sparging through polymeric membranes. Bioresour. Technol. 2015, 185, 246–253. [Google Scholar] [CrossRef]

- Bremges, A.; Maus, I.; Belmann, P.; Eikmeyer, F.; Winkler, A.; Albersmeier, A.; Pühler, A.; Schlüter, A.; Sczyrba, A. Deeply sequenced metagenome and metatranscriptome of a biogas-producing microbial community from an agricultural production-scale biogas plant. GigaScience 2015, 4, 33. [Google Scholar] [CrossRef]

- Treu, L.; Campanaro, S.; Kougias, P.G.; Zhu, X.; Angelidaki, I. Untangling the Effect of Fatty Acid Addition at Species Level Revealed Different Transcriptional Responses of the Biogas Microbial Community Members. Environ. Sci. Technol. 2016, 50, 6079–6090. [Google Scholar] [CrossRef] [PubMed]

- Franco-Morgado, M.; Alcántara, C.; Noyola, A.; Muñoz, R.; González-Sánchez, A. A study of photosynthetic biogas upgrading based on a high rate algal pond under alkaline conditions: Influence of the illumination regime. Sci. Total Environ. 2017, 592, 419–425. [Google Scholar] [CrossRef]

- Meier, L.; Pérez, R.; Azócar, L.; Rivas, M.; Jeison, D. Photosynthetic CO2 uptake by microalgae: An attractive tool for biogas upgrading. Biomass Bioenergy 2015, 73, 102–109. [Google Scholar] [CrossRef]

- Meier, L.; Barros, P.; Torres, A.; Vilchez, C.; Jeison, D. Photosynthetic biogas upgrading using microalgae: Effect of light/dark photoperiod. Renew. Energy 2017, 106, 17–23. [Google Scholar] [CrossRef]

- Posadas, E.; Serejo, M.L.; Blanco, S.; Pérez, R.; García-Encina, P.A.; Muñoz, R. Minimization of biomethane oxygen concentration during biogas upgrading in algal–bacterial photobioreactors. Algal Res. 2015, 12, 221–229. [Google Scholar] [CrossRef]

- Posadas, E.; Marín, D.; Blanco, S.; Lebrero, R.; Muñoz, R. Simultaneous biogas upgrading and centrate treatment in an outdoors pilot scale high rate algal pond. Bioresour. Technol. 2017, 232, 133–141. [Google Scholar] [CrossRef]

- Prandini, J.M.; da Silva, M.L.B.; Mezzari, M.P.; Pirolli, M.; Michelon, W.; Soares, H.M. Enhancement of nutrient removal from swine wastewater digestate coupled to biogas purification by microalgae Scenedesmus spp. Bioresour. Technol. 2016, 202, 67–75. [Google Scholar] [CrossRef]

- Serejo, M.L.; Posadas, E.; Boncz, M.A.; Blanco, S.; García-Encina, P.; Muñoz, R. Influence of Biogas Flow Rate on Biomass Composition During the Optimization of Biogas Upgrading in Microalgal-Bacterial Processes. Environ. Sci. Technol. 2015, 49, 3228–3236. [Google Scholar] [CrossRef]

- Toledo-Cervantes, A.; Serejo, M.L.; Blanco, S.; Pérez, R.; Lebrero, R.; Muñoz, R. Photosynthetic biogas upgrading to bio-methane: Boosting nutrient recovery via biomass productivity control. Algal Res. 2016, 17, 46–52. [Google Scholar] [CrossRef]

- Toledo-Cervantes, A.; Madrid-Chirinos, C.; Cantera, S.; Lebrero, R.; Muñoz, R. Influence of the gas-liquid flow configuration in the absorption column on photosynthetic biogas upgrading in algal-bacterial photobioreactors. Bioresour. Technol. 2017, 225, 336–342. [Google Scholar] [CrossRef]

- Zhao, Y.; Sun, S.; Hu, C.; Zhang, H.; Xu, J.; Ping, L. Performance of three microalgal strains in biogas slurry purification and biogas upgrade in response to various mixed light-emitting diode light wavelengths. Bioresour. Technol. 2015, 187, 338–345. [Google Scholar] [CrossRef]

- Muñoz, R.; Guieysse, B. Algal–bacterial processes for the treatment of hazardous contaminants: A review. Water Res. 2006, 40, 2799–2815. [Google Scholar] [CrossRef]

- Yan, C.; Muñoz, R.; Zhu, L.; Wang, Y. The effects of various LED (light emitting diode) lighting strategies on simultaneous biogas upgrading and biogas slurry nutrient reduction by using of microalgae Chlorella sp. Energy 2016, 106, 554–561. [Google Scholar] [CrossRef]

- Guedes, A.C.; Amaro, H.M.; Malcata, F.X. Microalgae as sources of high added-value compounds-a brief review of recent work. Biotechnol. Prog. 2011, 27, 597–613. [Google Scholar] [CrossRef] [PubMed]

- Mussgnug, J.H.; Klassen, V.; Schlüter, A.; Kruse, O. Microalgae as substrates for fermentative biogas production in a combined biorefinery concept. J. Biotechnol. 2010, 150, 51–56. [Google Scholar] [CrossRef] [PubMed]

- Angenent, L.T.; Karim, K.; Al-Dahhan, M.H.; Wrenn, B.A.; Domíguez-Espinosa, R. Production of bioenergy and biochemicals from industrial and agricultural wastewater. Trends Biotechnol. 2004, 22, 477–485. [Google Scholar] [CrossRef]

- Agler, M.T.; Wrenn, B.A.; Zinder, S.H.; Angenent, L.T. Waste to bioproduct conversion with undefined mixed cultures: The carboxylate platform. Trends Biotechnol. 2011, 29, 70–78. [Google Scholar] [CrossRef]

- Kennes, D.; Abubackar, H.N.; Diaz, M.; Veiga, M.C.; Kennes, C. Bioethanol production from biomass: Carbohydrate vs syngas fermentation. J. Chem. Technol. Biotechnol. 2016, 91, 304–317. [Google Scholar] [CrossRef]

- Martin, M.E.; Richter, H.; Saha, S.; Angenent, L.T. Traits of selected Clostridium strains for syngas fermentation to ethanol. Biotechnol. Bioeng. 2016, 113, 531–539. [Google Scholar] [CrossRef]

- Zhang, F.; Ding, J.; Zhang, Y.; Chen, M.; Ding, Z.-W.; van Loosdrecht, M.C.M.; Zeng, R.J. Fatty acids production from hydrogen and carbon dioxide by mixed culture in the membrane biofilm reactor. Water Res. 2013, 47, 6122–6129. [Google Scholar] [CrossRef]

- Schiel-Bengelsdorf, B.; Dürre, P. Pathway engineering and synthetic biology using acetogens. FEBS Lett. 2012, 586, 2191–2198. [Google Scholar] [CrossRef]

- Latif, H.; Zeidan, A.A.; Nielsen, A.T.; Zengler, K. Trash to treasure: Production of biofuels and commodity chemicals via syngas fermenting microorganisms. Curr. Opin. Biotechnol. 2014, 27, 79–87. [Google Scholar] [CrossRef]

- Liu, C.; Li, J.; Zhang, Y.; Philip, A.; Shi, E.; Chi, X.; Meng, J. Influence of glucose fermentation on CO2 assimilation to acetate in homoacetogen Blautia coccoides GA-1. J. Ind. Microbiol. Biotechnol. 2015, 42, 1217–1224. [Google Scholar] [CrossRef] [PubMed]

- Devarapalli, M.; Atiyeh, H.K.; Phillips, J.R.; Lewis, R.S.; Huhnke, R.L. Ethanol production during semi-continuous syngas fermentation in a trickle bed reactor using Clostridium ragsdalei. Bioresour. Technol. 2016, 209, 56–65. [Google Scholar] [CrossRef] [PubMed]

- Nie, Y.; Liu, H.; Du, G.; Chen, J. Enhancement of acetate production by a novel coupled syntrophic acetogenesis with homoacetogenesis process. Process Biochem. 2007, 42, 599–605. [Google Scholar] [CrossRef]

- Nie, Y.; Liu, H.; Du, G.; Chen, J. Acetate yield increased by gas circulation and fed-batch fermentation in a novel syntrophic acetogenesis and homoacetogenesis coupling system. Bioresour. Technol. 2008, 99, 2989–2995. [Google Scholar] [CrossRef]

- Agler, M.T.; Spirito, C.M.; Usack, J.G.; Werner, J.J.; Angenent, L.T. Chain elongation with reactor microbiomes: Upgrading dilute ethanol to medium-chain carboxylates. Energy Environ. Sci. 2012, 5, 8189. [Google Scholar] [CrossRef]

- Kucek, L.A.; Spirito, C.M.; Angenent, L.T. High n-caprylate productivities and specificities from dilute ethanol and acetate: Chain elongation with microbiomes to upgrade products from syngas fermentation. Energy Environ. Sci. 2016, 9, 3482–3494. [Google Scholar] [CrossRef]

- Kozłowski, D.; Ignatowicz, K. Effect of Dosing PIX 113 Coagulant to the Batch on Mesophilic Fermentation Process and Reducing Hydrogen Sulfide Content in Biogas. J. Ecol. Eng. 2022, 23, 286–293. [Google Scholar] [CrossRef]

- Cukalovic, A.; Stevens, C.V. Feasibility of production methods for succinic acid derivatives: A marriage of renewable resources and chemical technology. Biofuels Bioprod. Biorefining 2008, 2, 505–529. [Google Scholar] [CrossRef]

- Guettler, M.V.; Rumler, D.; Jain, M.K. Actinobacillus succinogenes sp. nov., a novel succinic-acid-producing strain from the bovine rumen. Int. J. Syst. Evol. Microbiol. 1999, 49, 207–216. [Google Scholar] [CrossRef]

- Zeikus, J.G.; Jain, M.K.; Elankovan, P. Biotechnology of succinic acid production and markets for derived industrial products. Appl. Microbiol. Biotechnol. 1999, 51, 545–552. [Google Scholar] [CrossRef]

- Gunnarsson, I.B.; Alvarado-Morales, M.; Angelidaki, I. Utilization of CO2 Fixating Bacterium Actinobacillus succinogenes 130Z for Simultaneous Biogas Upgrading and Biosuccinic Acid Production. Environ. Sci. Technol. 2014, 48, 12464–12468. [Google Scholar] [CrossRef] [PubMed]

- van Heerden, C.D.; Nicol, W. Continuous succinic acid fermentation by Actinobacillus succinogenes. Biochem. Eng. J. 2013, 73, 5–11. [Google Scholar] [CrossRef]

- Yan, D.; Wang, C.; Zhou, J.; Liu, Y.; Yang, M.; Xing, J. Construction of reductive pathway in Saccharomyces cerevisiae for effective succinic acid fermentation at low pH value. Bioresour. Technol. 2014, 156, 232–239. [Google Scholar] [CrossRef]

- Cheng, S.; Xing, D.; Call, D.F.; Logan, B.E. Direct Biological Conversion of Electrical Current into Methane by Electromethanogenesis. Environ. Sci. Technol. 2009, 43, 3953–3958. [Google Scholar] [CrossRef]

- Lovley, D.R.; Nevin, K.P. Electrobiocommodities: Powering microbial production of fuels and commodity chemicals from carbon dioxide with electricity. Curr. Opin. Biotechnol. 2013, 24, 385–390. [Google Scholar] [CrossRef]

- Lu, L.; Ren, Z.J. Microbial electrolysis cells for waste biorefinery: A state of the art review. Bioresour. Technol. 2016, 215, 254–264. [Google Scholar] [CrossRef]

- Xu, H.; Wang, K.; Holmes, D.E. Bioelectrochemical removal of carbon dioxide (CO2): An innovative method for biogas upgrading. Bioresour. Technol. 2014, 173, 392–398. [Google Scholar] [CrossRef]

- Villano, M.; Aulenta, F.; Ciucci, C.; Ferri, T.; Giuliano, A.; Majone, M. Bioelectrochemical reduction of CO2 to CH4 via direct and indirect extracellular electron transfer by a hydrogenophilic methanogenic culture. Bioresour. Technol. 2010, 101, 3085–3090. [Google Scholar] [CrossRef]

- Chaudhuri, S.K.; Lovley, D.R. Electricity generation by direct oxidation of glucose in mediatorless microbial fuel cells. Nat. Biotechnol. 2003, 21, 1229–1232. [Google Scholar] [CrossRef]

- Logan, B.E.; Hamelers, B.; Rozendal, R.; Schröder, U.; Keller, J.; Freguia, S.; Aelterman, P.; Verstraete, W.; Rabaey, K. Microbial Fuel Cells: Methodology and Technology. Environ. Sci. Technol. 2006, 40, 5181–5192. [Google Scholar] [CrossRef]

- Sleutels, T.H.J.A.; Lodder, R.; Hamelers, H.V.M.; Buisman, C.J.N. Improved performance of porous bio-anodes in microbial electrolysis cells by enhancing mass and charge transport. Int. J. Hydrogen Energy 2009, 34, 9655–9661. [Google Scholar] [CrossRef]

- ter Heijne, A.; Hamelers, H.V.M.; Saakes, M.; Buisman, C.J.N. Performance of non-porous graphite and titanium-based anodes in microbial fuel cells. Electrochim. Acta 2008, 53, 5697–5703. [Google Scholar] [CrossRef]

- Zhang, Y.; Angelidaki, I. Microbial electrolysis cells turning to be versatile technology: Recent advances and future challenges. Water Res. 2014, 56, 11–25. [Google Scholar] [CrossRef] [PubMed]

- Zeppilli, M.; Lai, A.; Villano, M.; Majone, M. Anion vs cation exchange membrane strongly affect mechanisms and yield of CO2 fixation in a microbial electrolysis cell. Chem. Eng. J. 2016, 304, 10–19. [Google Scholar] [CrossRef]

- Zhou, H.; Xing, D.; Xu, M.; Su, Y.; Zhang, Y. Biogas upgrading and energy storage via electromethanogenesis using intact anaerobic granular sludge as biocathode. Appl. Energy 2020, 269, 115101. [Google Scholar] [CrossRef]

- Escapa, A.; Mateos, R.; Martínez, E.J.; Blanes, J. Microbial electrolysis cells: An emerging technology for wastewater treatment and energy recovery. From laboratory to pilot plant and beyond. Renew. Sustain. Energy Rev. 2016, 55, 942–956. [Google Scholar] [CrossRef]

| Emerging Technologies | Objective |

|---|---|

| Cryogenic Separation | CO2, H2O, & Trace Removal |

| Methane Enrichment in situ | CO2 Removal |

| Hybrid Technologies | CO2, H2O, & Trace Removal |

| Sludge Samples | TS [%] | VS [%] | NH4 [mg/L] | TKN [mg/L] | pH | Soluble CO2 [mg/L] | |

|---|---|---|---|---|---|---|---|

| Sludge 1 | Pre-aeration | 3.0 | 1.9 | 1023 | 2258 | 7.3 | 540 |

| Sludge 1 | Post-aeration | - | - | 1054 | 2167 | 7.8 | 195 |

| Sludge 2 | Pre-aeration | 3.2 | 1.9 | 995 | 2119 | 7.3 | 700 |

| Sludge 2 | Post-aeration | - | - | 1020 | 2176 | 7.8 | 150 |

| Development Path | Objective |

|---|---|

| Industrial Lung | CO2 Removal |

| Supersonic Separation | CO2 H2O, & Heavy Hydrocarbon Removal |

| Chemical Hydrogenation | CO2 Removal |

| Hydrate Formation | CO2 & Heavy Hydrocarbon Removal |

| Biological Technologies | CO2 Removal and Additional CH4 Production |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Foret, B.; Laines Canepa, J.R.; Núñez-Nogueira, G.; Dufreche, S.; Hernandez, R.; Gang, D.; Sharp, W.; Revellame, E.; Fortela, D.L.B.; Simoneaux, S.; et al. Biogas Upgrading into Renewable Natural Gas: Part II—An Assessment of Emerging Technologies. Energies 2025, 18, 5760. https://doi.org/10.3390/en18215760

Foret B, Laines Canepa JR, Núñez-Nogueira G, Dufreche S, Hernandez R, Gang D, Sharp W, Revellame E, Fortela DLB, Simoneaux S, et al. Biogas Upgrading into Renewable Natural Gas: Part II—An Assessment of Emerging Technologies. Energies. 2025; 18(21):5760. https://doi.org/10.3390/en18215760

Chicago/Turabian StyleForet, Blake, José Ramón Laines Canepa, Gabriel Núñez-Nogueira, Stephen Dufreche, Rafael Hernandez, Daniel Gang, Wayne Sharp, Emmanuel Revellame, Dhan Lord B. Fortela, Sarah Simoneaux, and et al. 2025. "Biogas Upgrading into Renewable Natural Gas: Part II—An Assessment of Emerging Technologies" Energies 18, no. 21: 5760. https://doi.org/10.3390/en18215760

APA StyleForet, B., Laines Canepa, J. R., Núñez-Nogueira, G., Dufreche, S., Hernandez, R., Gang, D., Sharp, W., Revellame, E., Fortela, D. L. B., Simoneaux, S., Hulin, H., Holmes, W. E., & Zappi, M. E. (2025). Biogas Upgrading into Renewable Natural Gas: Part II—An Assessment of Emerging Technologies. Energies, 18(21), 5760. https://doi.org/10.3390/en18215760