Thermal Performance Evaluation of Phase Change Material-Integrated Triple-Glazed Windows Under Korean Climatic Conditions

Abstract

1. Introduction

2. Methodology

2.1. Field Measurement Setup

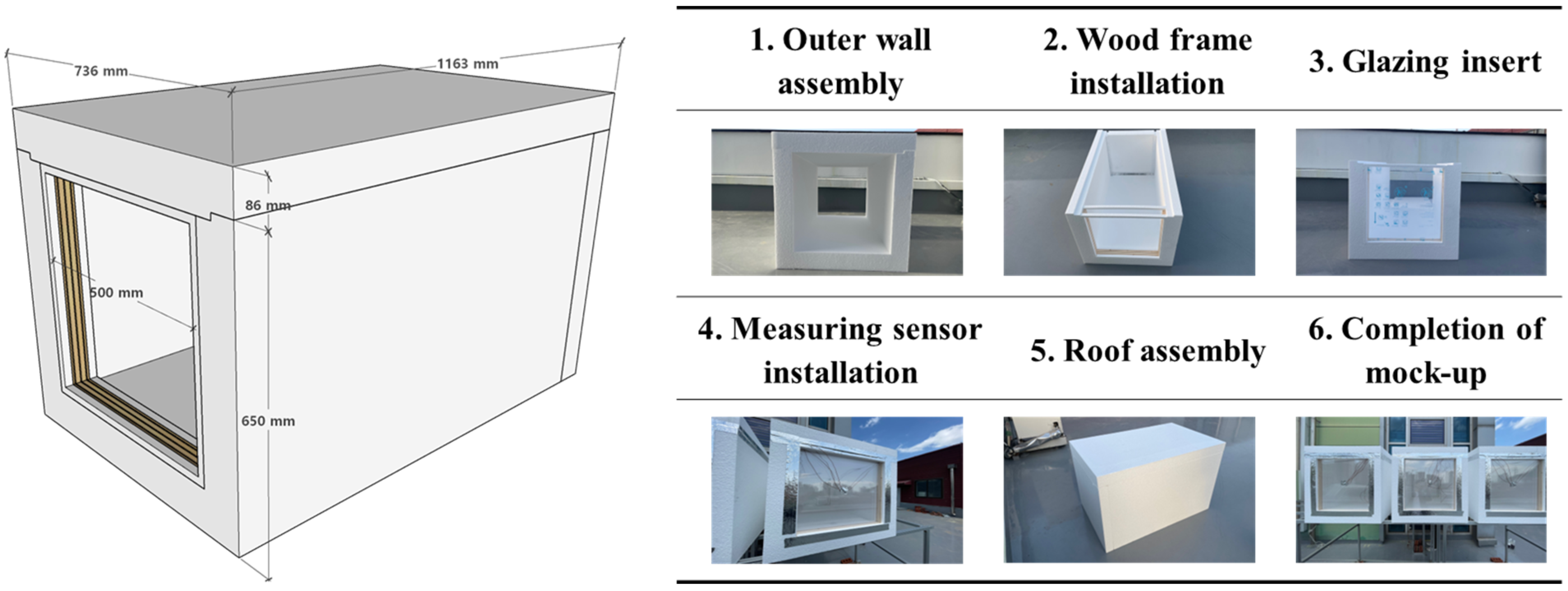

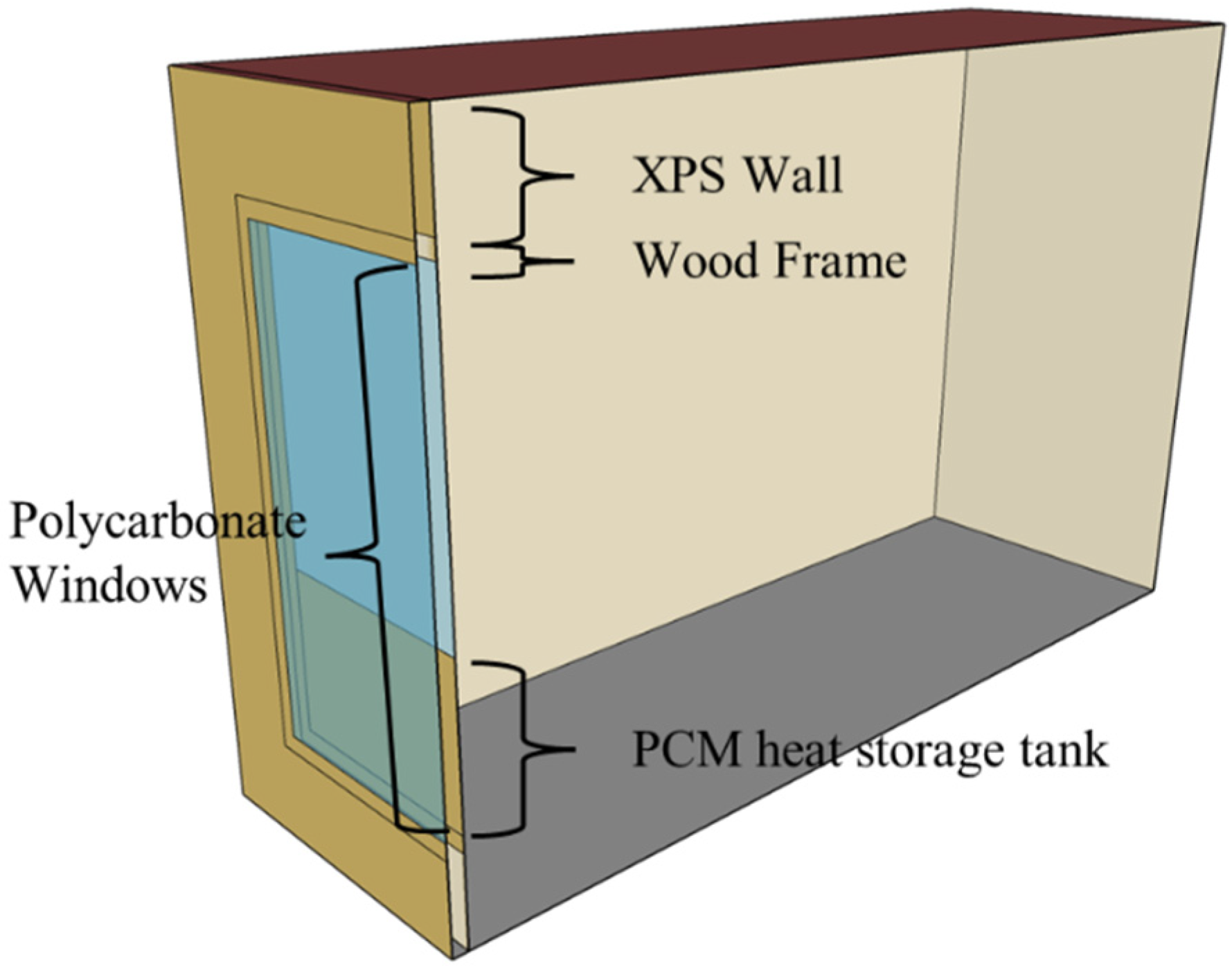

2.1.1. Description of Mock-Up Test

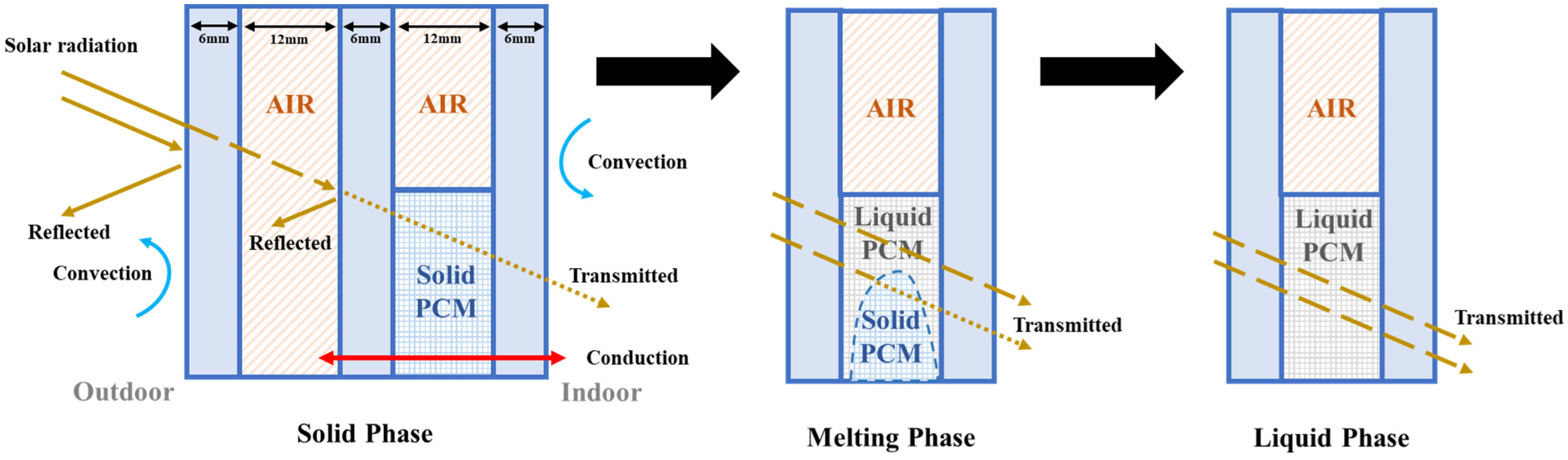

2.1.2. PCM-Integrated Window Design

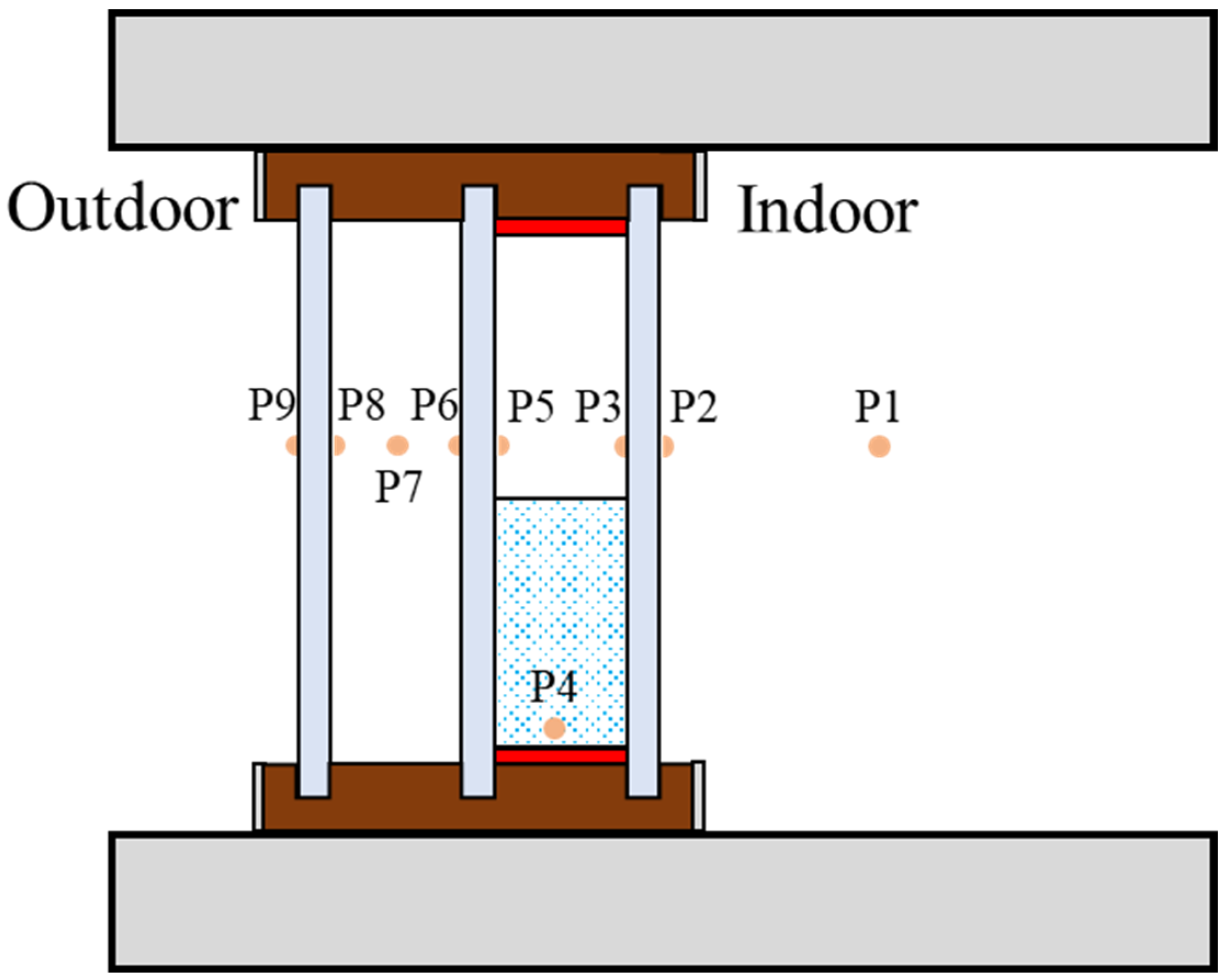

2.1.3. Data Collection and Analysis Process

2.2. Simulation Setup

2.2.1. Simulation Model Development

2.2.2. Calculation Method for the PCM-Integrated Window

3. Results and Discussion

3.1. Field Test-Based Results

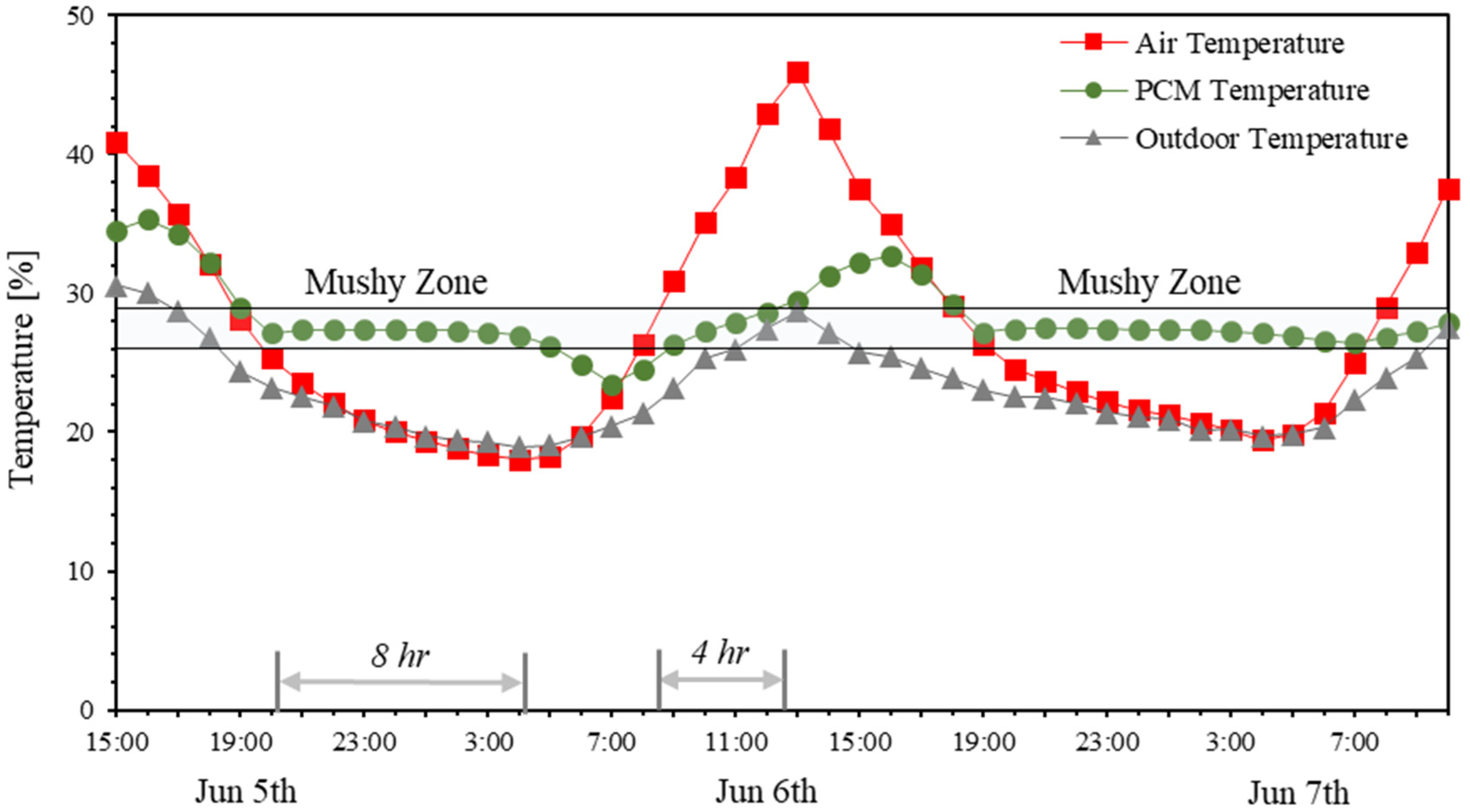

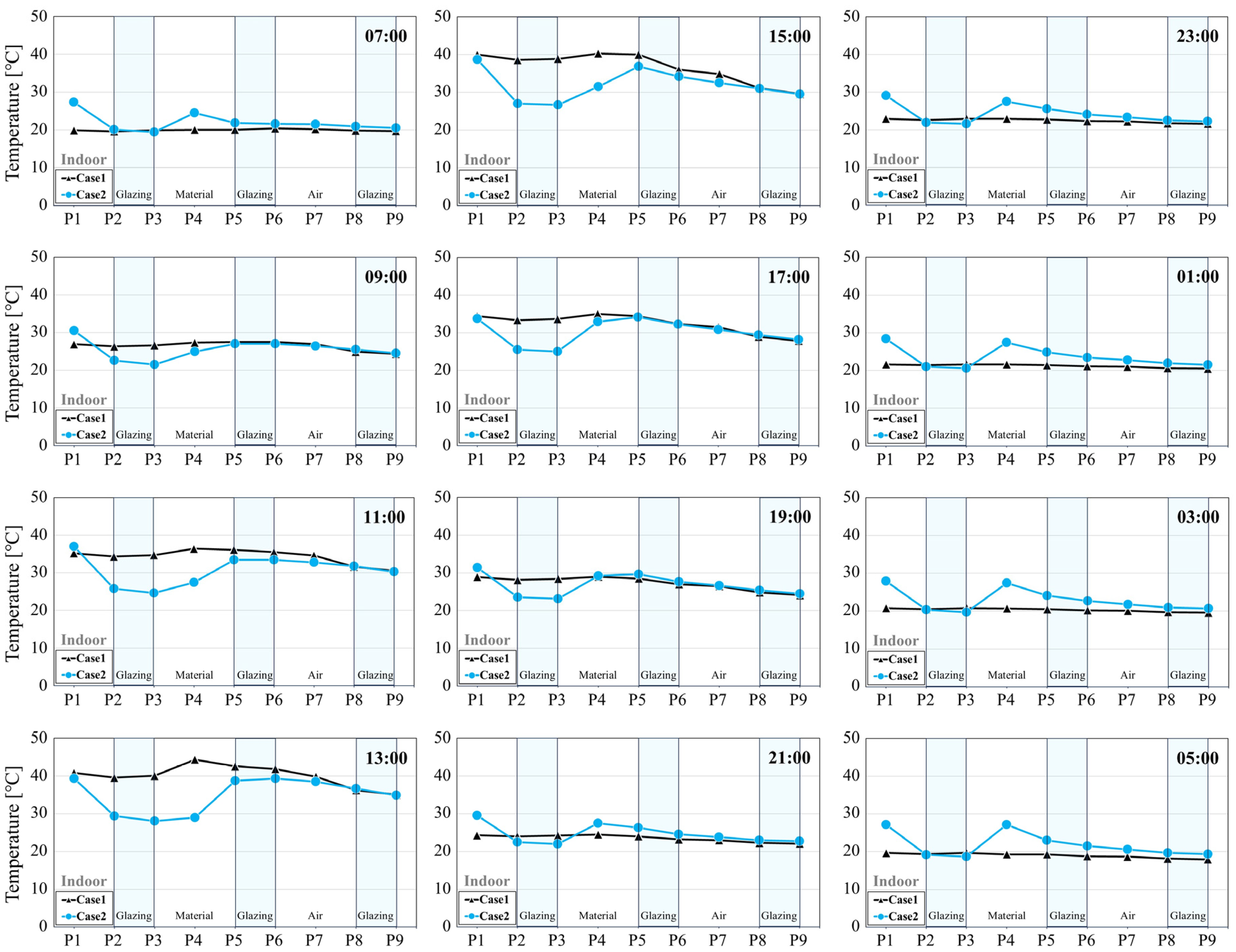

3.1.1. Thermal Behavior and Phase Change Cycle of the PCM

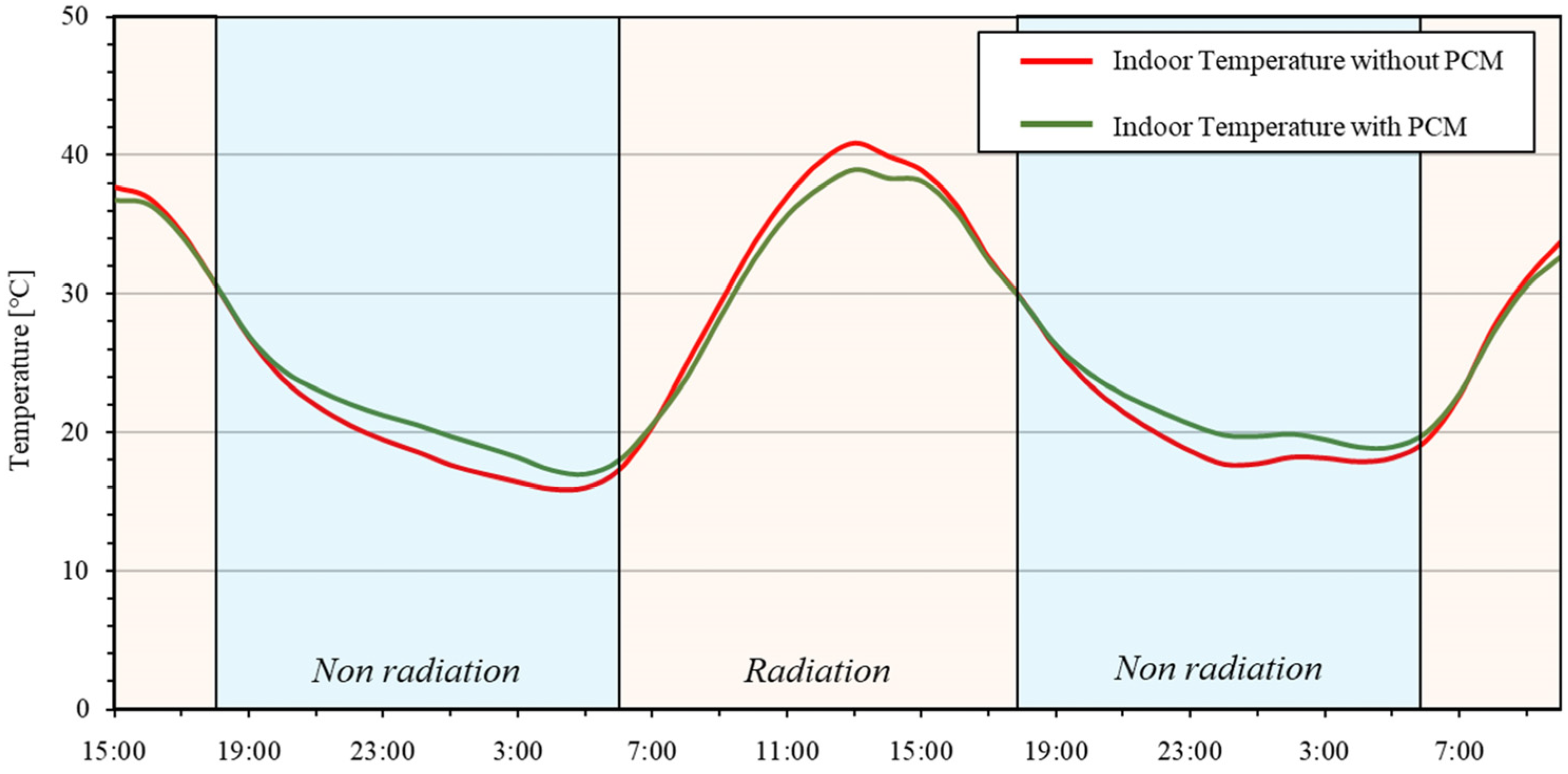

3.1.2. Indoor Thermal Performance of the PCM-Integrated Mock-Up Window

3.2. Simulation-Based Results

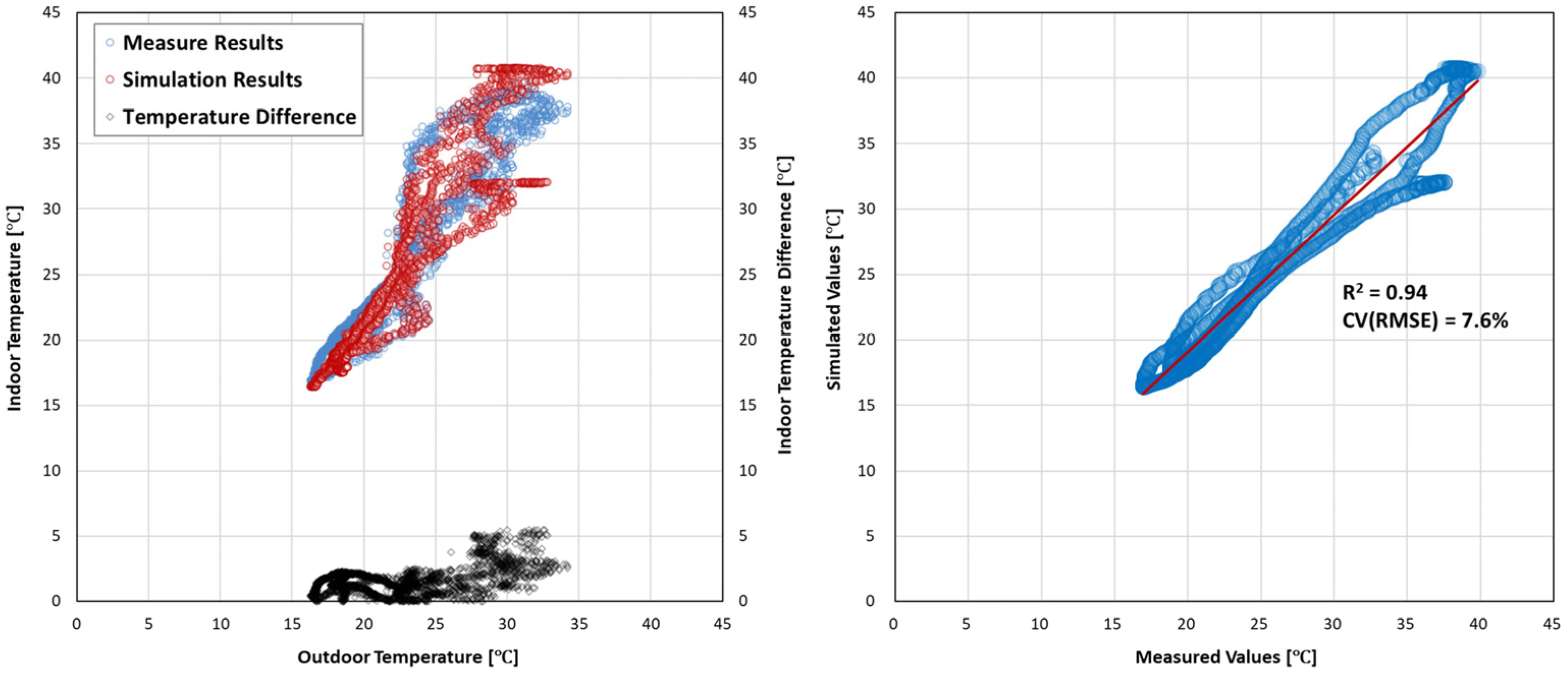

3.2.1. Validation Through Measurement Comparisons

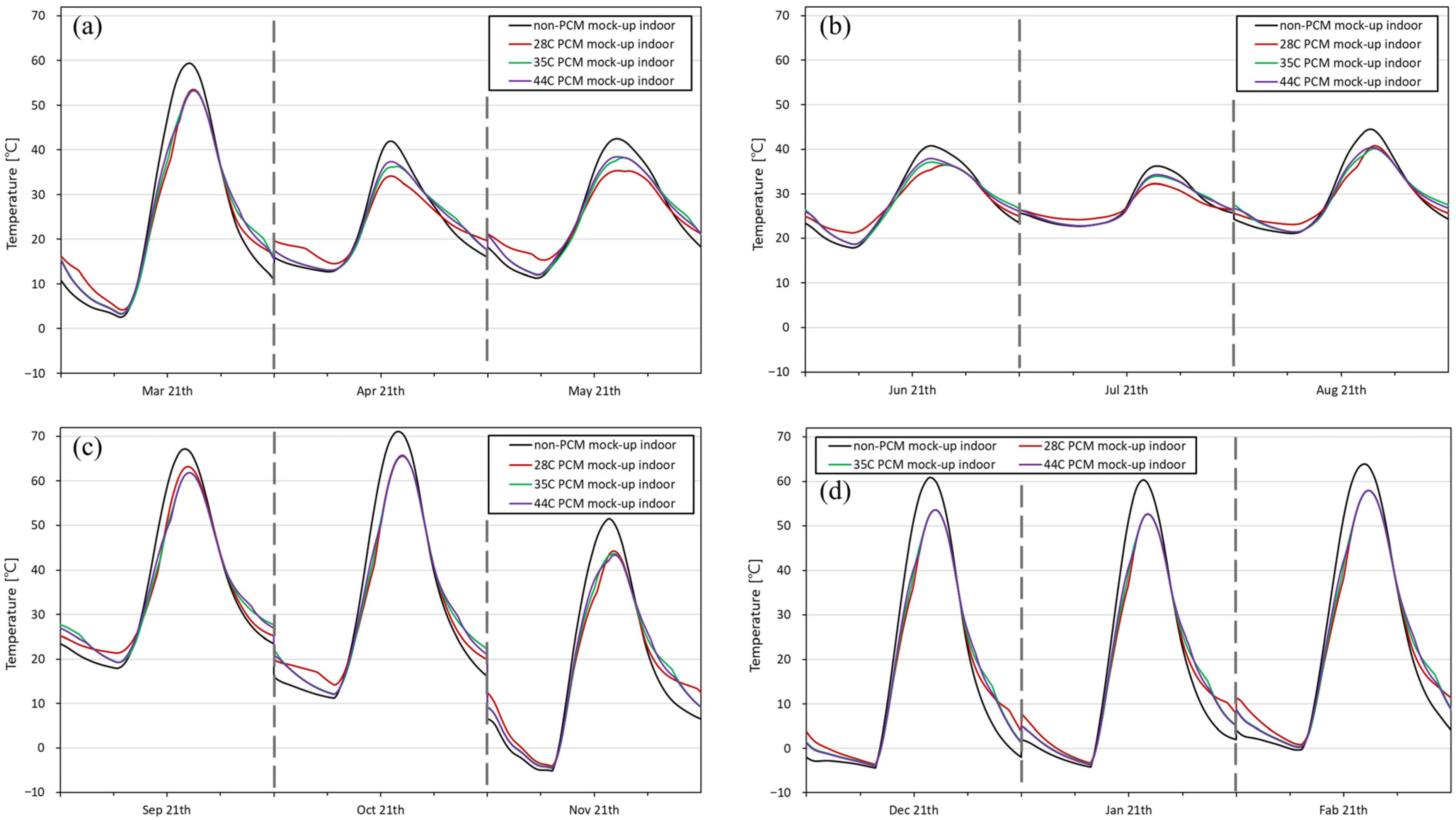

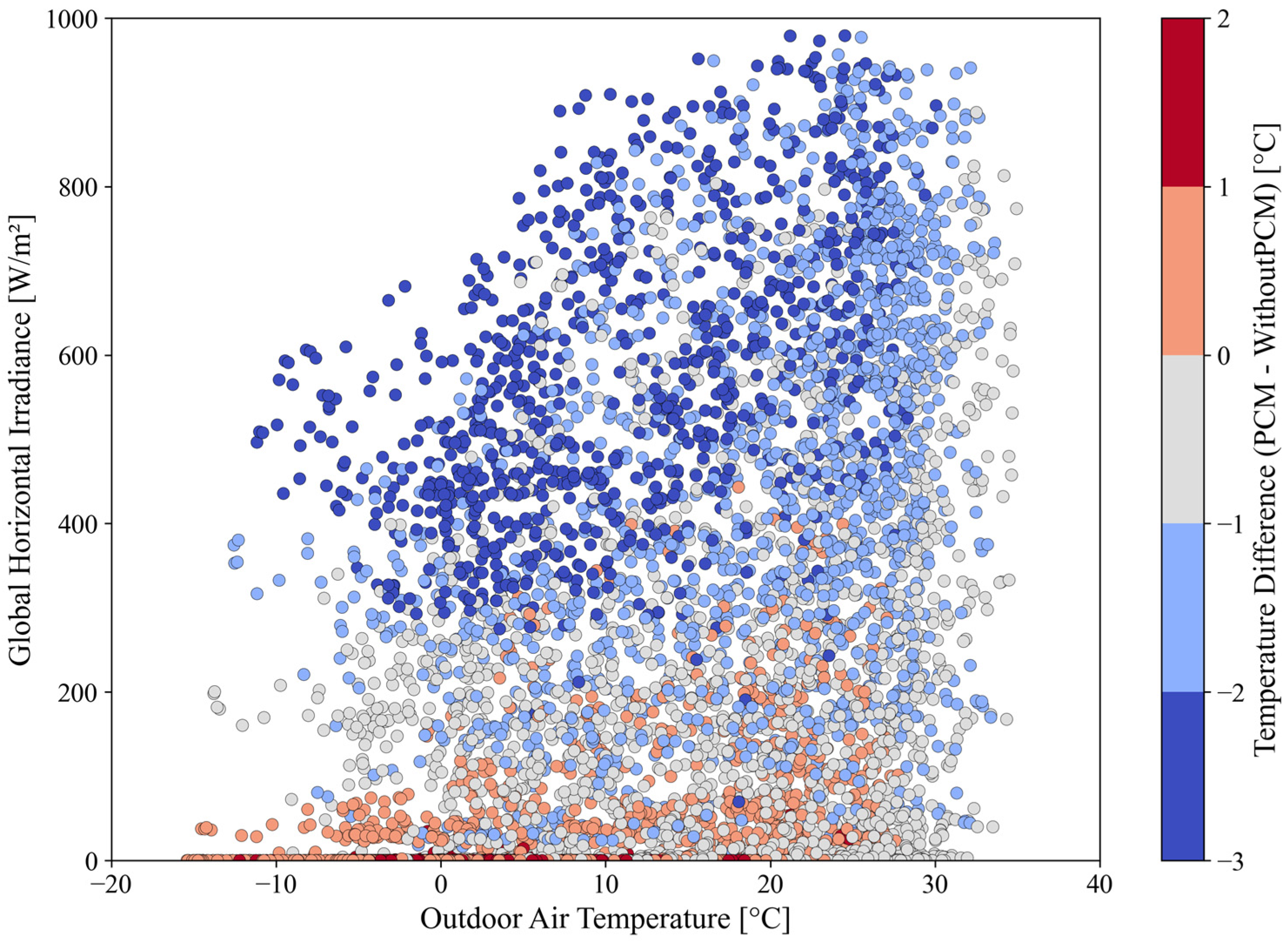

3.2.2. Annual Thermal Behavior from the Model-Based Analysis

4. Conclusions

- For the n-Octadecane-based solid PCM, the solid-to-liquid phase change cycle was four hours on average and the liquid-to-solid phase change cycle was eight hours or more based on May and June. In other words, the duration of heat release was approximately twice as long as the heat storage time. This confirms that PCM plays a crucial role in maintaining indoor temperature at night during intermediate seasons with large daily temperature fluctuations. These asymmetric charge–discharge cycles suggest that, over extended periods, PCM glazing can consistently mitigate daytime overheating while sustaining nighttime comfort, thereby reducing cooling and heating energy demand in real building operation.

- The indoor temperature control effect of the PCM window model showed the following seasonal tendencies. In summer, the rise in indoor temperature during daytime was inhibited under all melting temperature conditions. In particular, the 28 °C PCM exhibited the highest overheating inhibition effect during daytime. During winter and intermediate seasons, daytime indoor temperatures showed similar levels due to the limited phase change of the PCM caused by low outdoor air temperatures, while the 28 °C PCM exhibited the highest nighttime heat release effect followed by the 35 °C PCM and 44 °C PCM. This confirms that PCM inhibits overheating in summer and exhibits the nighttime heat release effect in winter.

- During the experiment, however, the temperature of the PCM inside the triple-glazed window increased to a maximum of 32.7 °C after phase change. Consequently, the indoor temperature also increased to 40.9 °C. This appears to be due to the high airtightness of the mock-up and the insufficient installation capacity of the PCM. Therefore, it is necessary to properly design the melting temperature and installation capacity of PCM according to indoor airtightness and solar radiation conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| XPS | Extruded poly styrene |

| PCM | Phase change material |

| TES | Thermal energy storage |

| LHTES | Latent heat thermal energy storage |

| PCH | Phase change hysteresis |

| SC | Supercooling |

References

- IPCC. IPCC Report Global Warming of 1.5 °C; Global Warm, 1 °C. An IPCC Special Report on the Impacts of Global Warming of 1.5 °C Above Pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the Threat of Climate Change; IPCC: Geneva, Switzerland, 2018; Volume 2. [Google Scholar]

- Cho, J. Understanding the impact of decadal climate change on building cooling design in Seoul amidst soaring summer temperatures. J. Archit. Inst. Korea 2023, 39, 187–197. [Google Scholar]

- Young-Sun, J.; Suhyun, C.; Sun-Hye, M.; Changyoon, J. Scenario to Reduce Greenhouse Gas Emissions in Building Sector towards the goal of Carbon Neutrality by 2050. J. Archit. Inst. Korea 2021, 37, 189–197. [Google Scholar] [CrossRef]

- Korea Energy Agency. 2023 Energy Consumption Statistics; Korea Energy Agency: Seoul, Republic of Korea, 2024; Available online: https://www.kea.or.kr (accessed on 29 August 2024).

- Ryu, Y.-J.; Kim, D.-N.; Sohn, S.-H. An Analysis of Factors, Influencing Carbon Emissions to Realize a Low-carbon Green City—A Case Study based on the Carbon Emissions of Gyeonggi-do Province. J. Urban Des. Inst. Korea Urban Des. 2013, 14, 149–159. [Google Scholar]

- Dong-Ik, H.; Seong-Hwan, Y. An analysis of energy saving effect of deteriorated detached house through green remodeling—Focusing on Nam-gu, Busan, Korea. J. Archit. Inst. Korea 2021, 37, 145–154. [Google Scholar] [CrossRef]

- Cho, Y.-B.; Lee, K.-I. An Experimental Study on Thermal Insulation, Air Tightness and Thermal Mass of Green Remodeling. Archit. Inst. Korea 2017, 37, 628–631. [Google Scholar]

- Kim, D.H.; Kim, E.S.; Song, D.S. Analysis of the energy saving effects according to differences in interests between experts and building users when establishing a green remodeling plan for old buildings. Korean J. Air-Cond. Refrig. Eng. 2022, 34, 399–409. [Google Scholar] [CrossRef]

- Reddy, V.J.; Ghazali, M.F.; Kumarasamy, S. Advancements in phase change materials for energy-efficient building construction: A comprehensive review. J. Energy Storage 2024, 81, 110494. [Google Scholar] [CrossRef]

- King, M.F.L.; Rao, P.N.; Sivakumar, A.; Mamidi, V.K.; Richard, S.; Vijayakumar, M.; Arunprasath, K.; Kumar, P.M. Thermal performance of a double-glazed window integrated with a phase change material (PCM). Mater. Today Proc. 2022, 50, 1516–1521. [Google Scholar] [CrossRef]

- Li, S.; Sun, G.; Zou, K.; Zhang, X. Experimental research on the dynamic thermal performance of a novel triple-pane building window filled with PCM. Sustain. Cities Soc. 2016, 27, 15–22. [Google Scholar] [CrossRef]

- Ravasio, L.; Calay, R.K.; Riise, R. Simplified thermal performance evaluation of a PCM-filled triple-glazed window under arctic climate conditions. Energies 2021, 14, 8068. [Google Scholar] [CrossRef]

- Uribe, D.; Vera, S. Assessment of the effect of phase change material (PCM) glazing on the energy consumption and indoor comfort of an office in a semiarid climate. Appl. Sci. 2021, 11, 9597. [Google Scholar] [CrossRef]

- Liu, L.; Hammami, N.; Trovalet, L.; Bigot, D.; Habas, J.-P.; Malet-Damour, B. Description of phase change materials (PCMs) used in buildings under various climates: A review. J. Energy Storage 2022, 56, 105760. [Google Scholar] [CrossRef]

- Gowreesunker, B.L.; Stankovic, S.B.; Tassou, S.A.; Kyriacou, P.A. Experimental and numerical investigations of the optical and thermal aspects of a PCM-glazed unit. Energy Build. 2013, 61, 239–249. [Google Scholar] [CrossRef]

- Zhang, S.; Hu, W.; Li, D.; Zhang, C.; Arıcı, M.; Yıldız, Ç.; Zhang, X.; Ma, Y. Energy efficiency optimization of PCM and aerogel-filled multiple glazing windows. Energy 2021, 222, 119916. [Google Scholar] [CrossRef]

- Tabares-Velasco, P.C.; Christensen, C.; Bianchi, M. Verification and validation of EnergyPlus phase change material model for opaque wall assemblies. Build. Environ. 2012, 54, 186–196. [Google Scholar] [CrossRef]

- Wang, G.; Li, X.; Chang, C.; Ju, H. Multi-objective passive design and climate effects for office buildings integrating phase change material (PCM) in a cold region of China. J. Energy Storage 2024, 82, 110502. [Google Scholar] [CrossRef]

- Goia, F.; Perino, M.; Serra, V. Improving thermal comfort conditions by means of PCM glazing systems. Energy Build. 2013, 60, 442–452. [Google Scholar] [CrossRef]

- Bharathiraja, R.; Ramkumar, T.; Selvakumar, M.; Radhika, N. Thermal characteristics enhancement of paraffin wax phase change material (PCM) for thermal storage applications. Renew. Energy 2024, 222, 119986. [Google Scholar] [CrossRef]

- Wei, L.; Li, G.; Ruan, S.-T.; Qi, H. Dynamic coupled heat transfer and energy conservation performance of multilayer glazing window filled with phase change material in summer day. J. Energy Storage 2022, 49, 104183. [Google Scholar] [CrossRef]

- Crawley, D.B.; Lawrie, L.K.; Winkelmann, F.C.; Buhl, W.F.; Huang, Y.J.; Pedersen, C.O.; Strand, R.K.; Liesen, R.J.; Fisher, D.E.; Witte, M.J.; et al. EnergyPlus: Creating a new-generation building energy simulation program. Energy Build. 2001, 33, 319–331. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, X.; Xu, X.; Zhao, Y.; Zhang, S. The research progress on phase change hysteresis affecting the thermal characteristics of PCMs: A review. J. Mol. Liq. 2020, 317, 113760. [Google Scholar] [CrossRef]

- Feng, F.; Fu, Y.; Yang, Z.; O’Neill, Z. Enhancement of phase change material hysteresis model: A case study of modeling building envelope in EnergyPlus. Energy Build. 2022, 276, 112511. [Google Scholar] [CrossRef]

- US Department of Energy; Lawrence Berkeley National Laboratory. EnergyPlusTM; Version 22.1.0; Engineering reference; US Department of Energy: Washington, DC, USA; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2023; p. 1774. [Google Scholar]

- Al-Janabi, A.; Kavgic, M. Application and sensitivity analysis of the phase change material hysteresis method in EnergyPlus: A case study. Appl. Therm. Eng. 2019, 162, 114222. [Google Scholar] [CrossRef]

- ASHRAE. ASHRAE Industrial Advertising Policy on Standards; American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2014; Available online: http://www.ashrae.org/technology (accessed on 20 January 2024).

- Arasteh, H.; Maref, W.; Saber, H.H. Energy and Thermal Performance Analysis of PCM-Incorporated Glazing Units Combined with Passive and Active Techniques: A Review Study. Energies 2023, 16, 1058. [Google Scholar] [CrossRef]

- Tan, Q.; Siroux, M. Evaluation and Optimization of PCM-Integrated Walls: Energy, Exergy, Environmental, and Economic Perspectives. Renew. Sustain. Energy Rev. 2025, 222, 115922. [Google Scholar] [CrossRef]

| Type | Details | ||

|---|---|---|---|

| Mock-up Size | Indoor | Width | 536 mm |

| Depth | 980 mm | ||

| Height | 536 mm | ||

| Material | Triple Glazing (Polycarbonate) | Thickness | 33 mm (3PC + 12A + 3PC + 12A + 3PC) |

| Visible Light | Transmittance (91%) | ||

| Reflectance (7%) | |||

| Type | Details | |

|---|---|---|

| PCM | Formula | C18H38 |

| Melting point | 28 °C | |

| Heat of fusion | 241 kJ/kg | |

| Flash point | 165 °C | |

| Specific heat capacity | 2 kJ/kg °C | |

| Volume expansion | 12.5% | |

| Measure Points | |

|---|---|

| P1 | Indoor Air |

| P2 | Indoor Glazing Inner Surface |

| P3 | Indoor Glazing Outer Surface |

| P4 | Phase Change Materials |

| P5 | Middle Glazing Inner Surface |

| P6 | Middle Glazing Outer Surface |

| P7 | Window Air Layer |

| P8 | Outdoor Glazing Inner Surface |

| P9 | Outdoor Glazing Outer Surface |

| Type | Details | |||

|---|---|---|---|---|

| PCM | Formula | C18H38 | C20H42 | C22H46 |

| Melting point | 28 °C | 35 °C | 44 °C | |

| Heat of fusion | 241 kJ/kg | 208 kJ/kg | 230 kJ/kg | |

| Flash point | 165 °C | 177 °C | 186 °C | |

| Specific heat capacity | 2 kJ/kg °C | 2 kJ/kg °C | 2 kJ/kg °C | |

| Volume expansion | 12.5% | 12.0% | 12.5% | |

| Thermal Conductivity | 0.2 W/mK | 0.2 W/mK | 0.2 W/mK | |

| Solid State Density (Liquid State Density) | 880 kg/m3 (770 kg/m3) | 880 kg/m3 (770 kg/m3) | 880 kg/m3 (760 kg/m3) | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, K.; Lee, R.; Kim, D.; Yoon, J.; Shin, D. Thermal Performance Evaluation of Phase Change Material-Integrated Triple-Glazed Windows Under Korean Climatic Conditions. Energies 2025, 18, 5754. https://doi.org/10.3390/en18215754

Song K, Lee R, Kim D, Yoon J, Shin D. Thermal Performance Evaluation of Phase Change Material-Integrated Triple-Glazed Windows Under Korean Climatic Conditions. Energies. 2025; 18(21):5754. https://doi.org/10.3390/en18215754

Chicago/Turabian StyleSong, Kwanghyun, Ruda Lee, Dongsu Kim, Jongho Yoon, and Dongho Shin. 2025. "Thermal Performance Evaluation of Phase Change Material-Integrated Triple-Glazed Windows Under Korean Climatic Conditions" Energies 18, no. 21: 5754. https://doi.org/10.3390/en18215754

APA StyleSong, K., Lee, R., Kim, D., Yoon, J., & Shin, D. (2025). Thermal Performance Evaluation of Phase Change Material-Integrated Triple-Glazed Windows Under Korean Climatic Conditions. Energies, 18(21), 5754. https://doi.org/10.3390/en18215754