Machine Learning Improves Performance Prediction and Interpretation of Efficiency Influencing Factors of a Novel Basalt-Fiber-Bundle Thermal Flow-Reversal Reactor for Methane Recovery

Abstract

1. Introduction

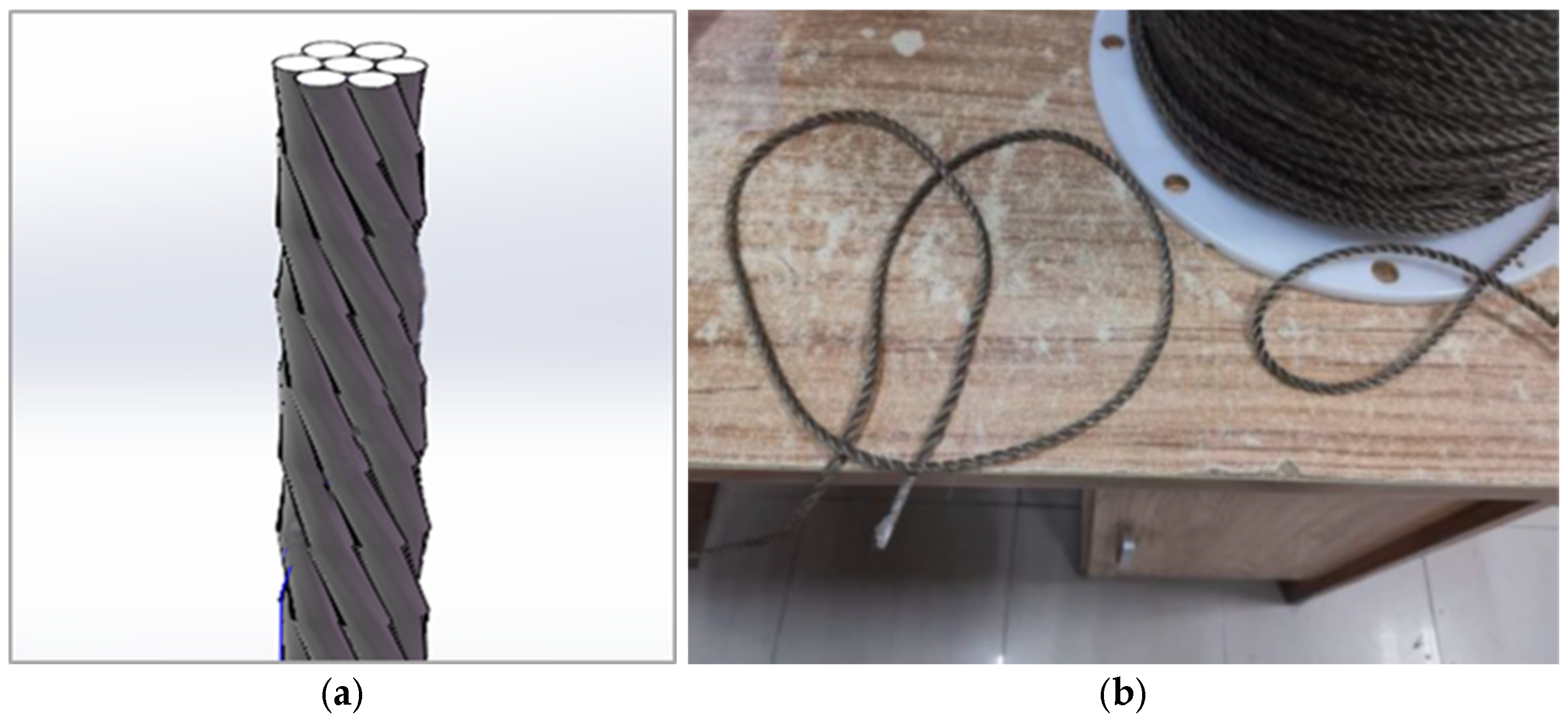

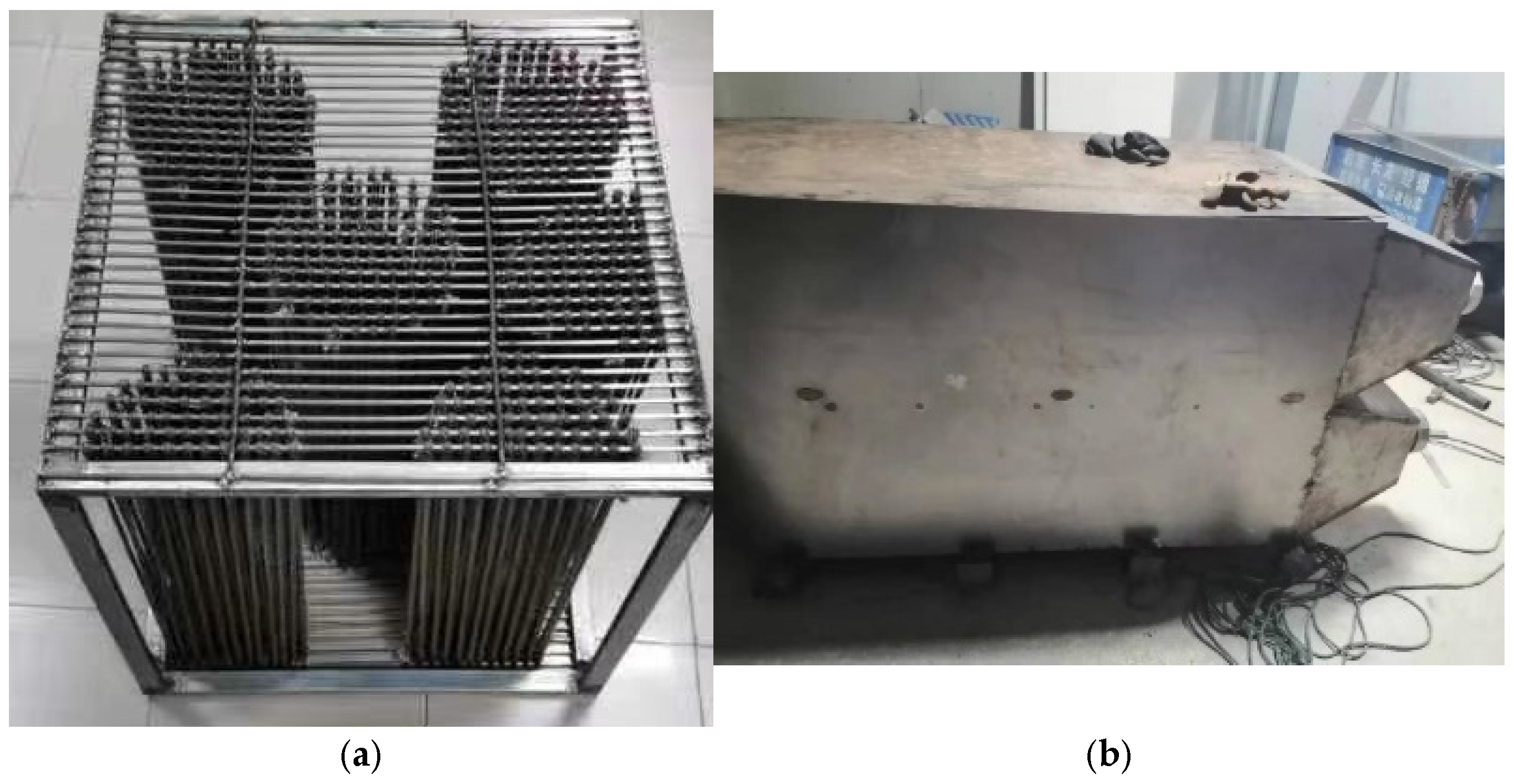

2. Basalt-Fiber-Bundle Thermal Flow-Reversal Reactor System

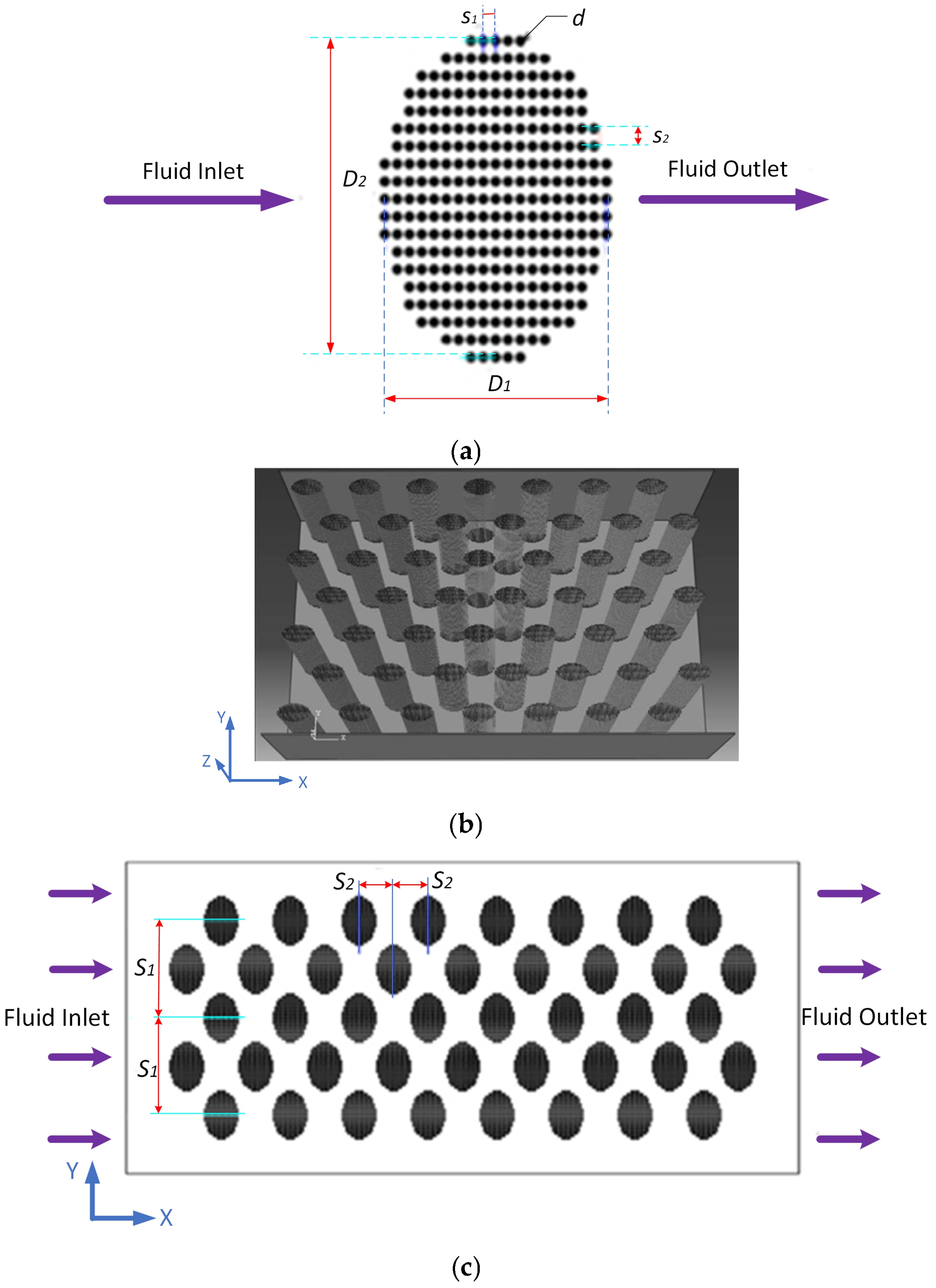

3. Modeling of the Reactor

3.1. Computational Fluid Dynamics (CFD)

- Regardless of thermal expansion and cold contraction of the basalt fiber bundle with temperature, it is assumed that the volume of the material will not change, i.e., the density is constant. This was also confirmed by actual material measurements;

- Radiation heat transfer in the channel is ignored, and convection heat transfer only is considered;

- It is assumed that the gas is an incompressible ideal gas.

3.2. Multiple Linear Regression (MLR) Model

3.3. Back Propagation (BP) Model

4. Data Analysis

4.1. Thermal Efficiency

4.2. Normalization

4.3. Statistical Indicators

5. Results

- Based on certain potential rules (e.g., Equation (17)), a set of hyperparameters is initially assumed for the model, such as the number of neurons in the hidden layers of a neural network.

- The training dataset is divided into a training subset and a validation subset. Cross-validation is then employed to train the model on the training subset and optimize the hyperparameters using the validation subset. The detailed steps are as follows:2.1. The original dataset is randomly partitioned into k subsets without replacement.2.2. In each iteration, one subset is selected as the validation set, while the remaining k − 1 subsets are used as the training set.2.3. Step 2.2 is repeated k times, so that each subset is used once as a validation set and k − 1 times as part of a training set.2.4. The model is trained on each training set.2.5. The trained model is evaluated on the corresponding validation set; the performance metrics are calculated and stored.2.6. The average of the k evaluation results is taken as an estimate of accuracy serving as the performance metric of the model under k-fold cross-validation.

- 3.

- The model hyperparameters are modified and Step 2 is repeated until all possible hyperparameter combinations have been tested and evaluated.

- 4.

- Through cross-validation, the model with the minimum error is selected and retrained using the entire training dataset.

- 5.

- Finally, the validated model is tested on the independent test dataset to assess its generalization capability.

5.1. Multiple Linear Regression (MLR)

5.2. Back Propagation (BP)

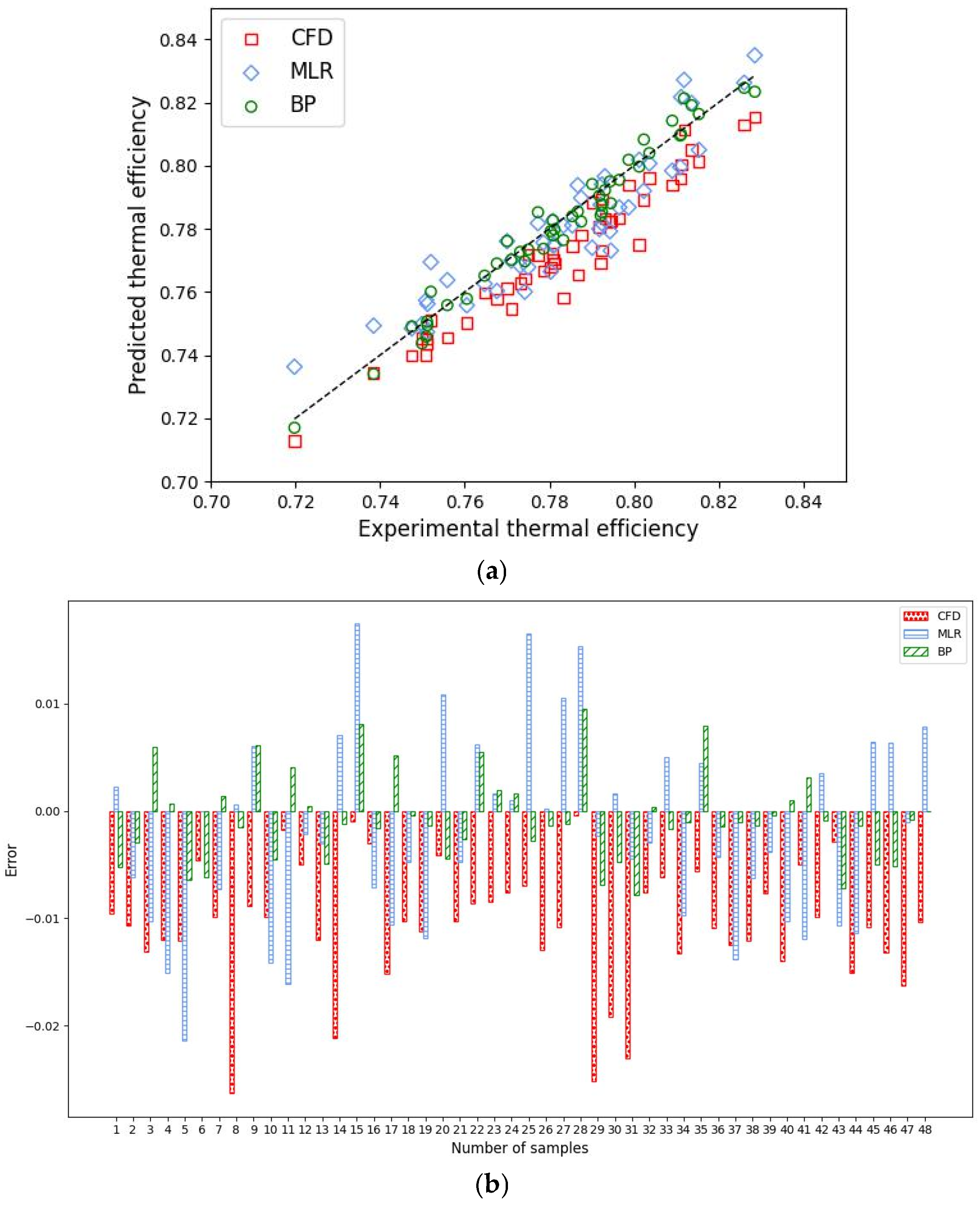

5.3. Comparison of Prediction Performance of Different Models

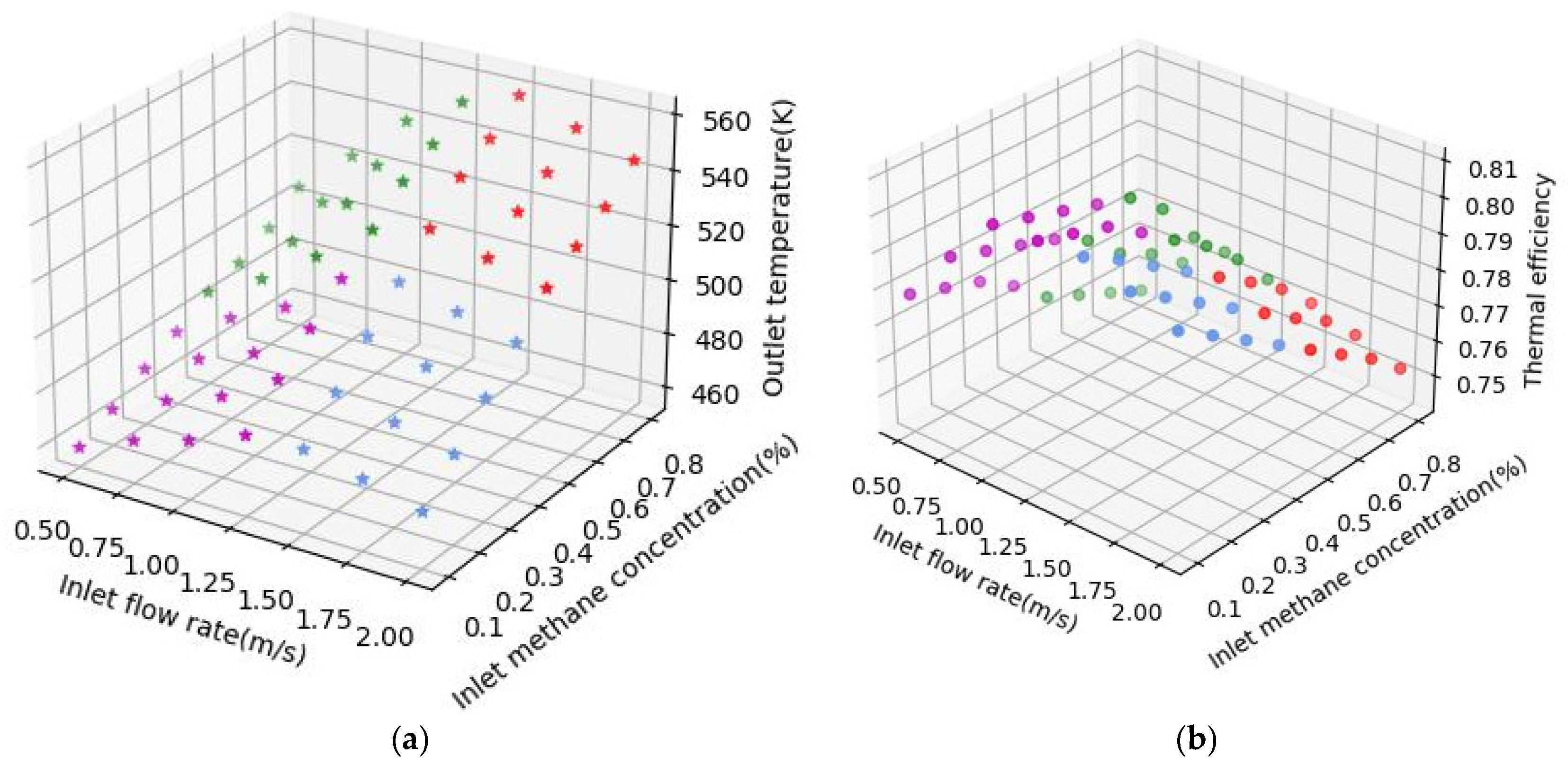

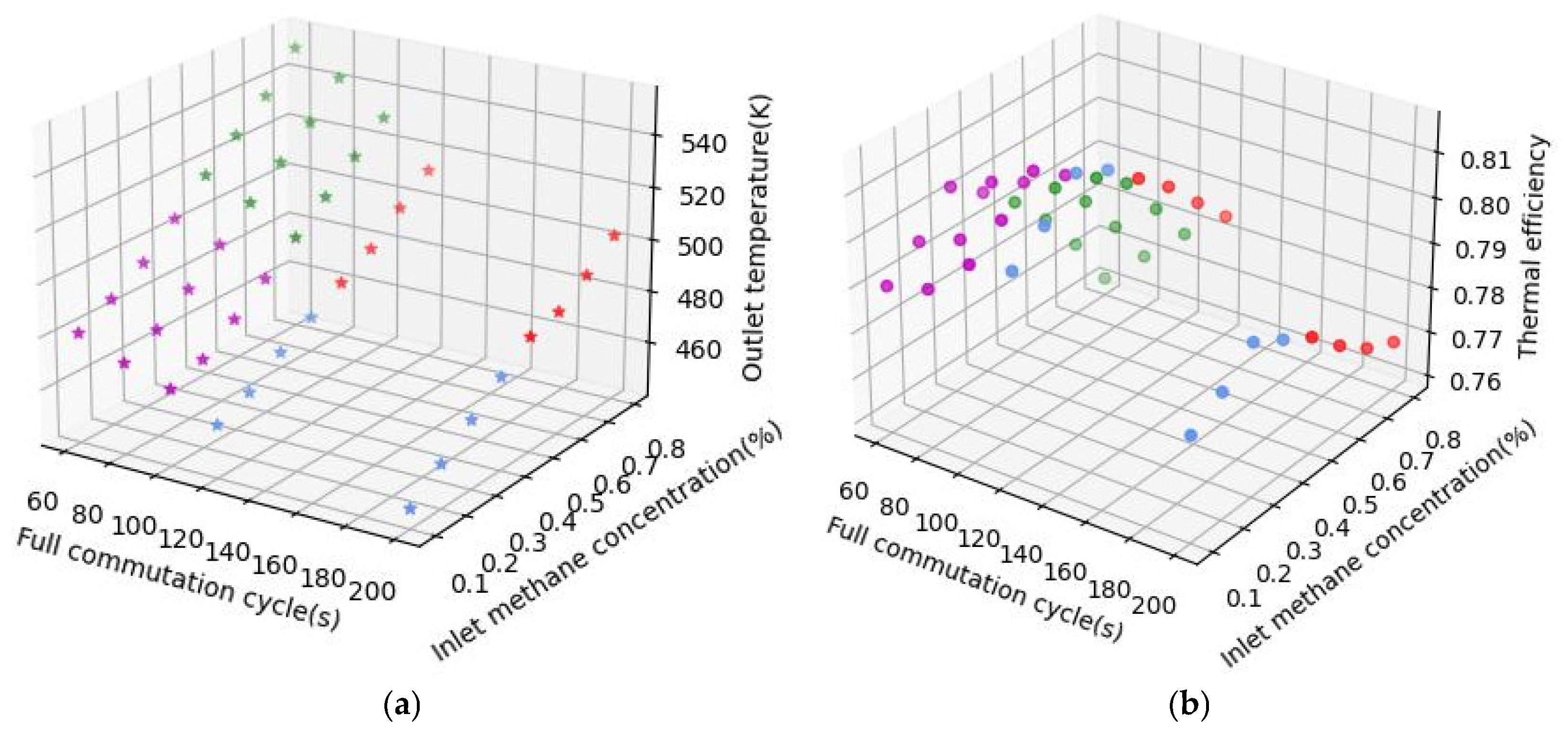

6. Effect of Gas Inlet Flow Rate, Commutation Cycle, and Gas Inlet Concentration on Thermal Efficiency

6.1. Gas Inlet Flow Rate

6.2. Commutation Cycle

6.3. Inlet Methane Concentration

6.4. Analysis of Relative Importance

7. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| A | pre-exponential factor |

| BP | back propagation |

| CFD | computational fluid dynamics |

| d | fiber bundle diameter (mm) |

| specific heat of air () | |

| specific heat of basalt bundle () | |

| short axis of elliptical fiber bundles (mm) | |

| long axis of elliptical fiber bundles (mm) | |

| E | activation energy |

| heat transfer coefficient between gas and solid | |

| +1 | |

| −1 | |

| reactor inlet temperature (K) | |

| reactor outlet temperature (K) | |

| mean absolute error | |

| multiple linear regression | |

| R | universal gas constant |

| coefficient of determination | |

| root mean square error | |

| fiber bundle arrangement horizontal spacing (mm) | |

| fiber bundle arrangement vertical spacing (mm) | |

| full commutation cycle (s) | |

| T | the average temperature of the high temperature section in the reactor (K) |

| temperature of the basalt fiber (K) | |

| temperature of gas (K) | |

| gas inlet temperature (K) | |

| gas outlet temperature (K) | |

| flow rate of gas | |

| volume of basalt fiber | |

| volume of gas | |

| methane consumption rate | |

| actual value | |

| predicted value | |

| mass fraction of gas component i | |

| Greek letters | |

| density of the basalt fiber | |

| density of gas | |

| thermal conductivity of the basalt fiber | |

| η | thermal efficiency |

References

- Forster, P.; Ramaswamy, V.; Artaxo, P.; Berntsen, T.; Betts, R.; Fahey, D.W.; Haywood, J.; Lean, J.; Lowe, D.C.; Myhre, G.; et al. Changes in Atmospheric Constituents and in Radiative Forcing. In Climate Change 2007: The Physical Science Basis. Contribution of Working Group I to the 4th Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2007. [Google Scholar]

- Su, S.; Beath, A.; Guo, H.; Mallett, C. An assessment of mine methane mitigation and utilization technologies. Prog. Energy Combust. Sci. 2005, 31, 123–170. [Google Scholar] [CrossRef]

- Su, S.; Agnew, J. Catalytic combustion of coal mine ventilation air methane. Fuel 2006, 85, 1201–1210. [Google Scholar] [CrossRef]

- Cheng, Y.P.; Wang, L.; Zhang, X.L. Environmental impact of coal mine methane emissions and responding strategies in China. Int. J. Greenh. Gas Control 2011, 5, 157–166. [Google Scholar] [CrossRef]

- Karakurt, I.; Aydin, G.; Aydiner, K. Mine ventilation air methane as a sustainable energy source. Renew. Sustain. Energy Rev. 2011, 15, 1042–1049. [Google Scholar] [CrossRef]

- Gosiewski, K.; Pawlaczyk, A. Catalytic or thermal reversed flow combustion of coal mine ventilation air methane: What is better choice and when? Chem. Eng. J. 2014, 238, 78–85. [Google Scholar] [CrossRef]

- Gosiewski, K.; Pawlazyk, A.; Jaschik, M. Energy recovery from ventilation air methane via reverse-flow reactor. Energy 2015, 92, 13–23. [Google Scholar] [CrossRef]

- Zhang, B.; Liu, Y.; Liu, R.; Meng, J.; Mao, M. Experimental investigation of flow resistance in a coal mine ventilation air methane preheated catalytic oxidation reactor. J. Chem. 2015, 2015, 375789. [Google Scholar] [CrossRef]

- Yuan, F.; Wang, H.; Zhou, P.; Xu, A.; He, D. Heat transfer performances of honeycomb regenerator with square or hexagon cell opening. Appl. Therm. Eng. 2017, 125, 790–798. [Google Scholar] [CrossRef]

- Li, Q.; Bai, F.; Yang, B.; Wang, Y.; Xu, L.; Chang, Z.; Wang, Z.; EI Hefni, B.; Yang, Z.; Kubo, S.; et al. Dynamic simulatioons of a honeycomb ceramic thermal energy storage in a solar thermal power plant using air as the heat transfer fluid. Appl. Therm. Eng. 2018, 129, 636–645. [Google Scholar] [CrossRef]

- Huang, J.S.; Chiang, M.S. Effects of microstructure, specimen and loading geometries on KIC of brittle honeycombs. Eng. Fract. Mech. 1996, 54, 813–821. [Google Scholar] [CrossRef]

- Kakroudi, M.G.; Vafa, N.P.; Asl, M.S.; Shokouhimehr, M. Effects of SiC content on thermal shock behavior and elastic modulus of cordierite-mullite composites. Ceram. Int. 2020, 46, 23780–23784. [Google Scholar] [CrossRef]

- Dhand, V.; Mittal, G.; Rhee, K.Y.; Park, S.-J.; Hui, D. A short review on basalt fiber reinforced polymer composites. Compos. Part B-Eng. 2015, 73, 166–180. [Google Scholar] [CrossRef]

- Liu, J.; Chang, Z.; Wang, L. Exploration of Basalt Glasses as High-Temperature Sensible Heat Storage Material. ACS Omega 2020, 5, 19236–19246. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Yang, J.; Chen, M.; Lei, L.; Wu, Z. Effects of SiO2, Al2O3 on heat resistance of basalt fiber. Thermochim. Acta 2018, 660, 56–60. [Google Scholar] [CrossRef]

- Slepterev, A.A.; Tsyrul’nikov, P.G.; Sal’nikov, V.S.; Zagoruiko, A.N. A study of the Homogeneous Oxidation of Low-Concentration Methane-containing Gases at High Temperature. Russ. J. Appl. Chem. 2012, 85, 1570–1576. [Google Scholar] [CrossRef]

- Glarborg, P.; Lilleheie, N.I.; Byggstoyl, S.; Magnussen, B.F.; Kilpinen, P.; Hupa, M. A reduced mechanism for nitrogen chemistry in methane combustion. Symp. Combust. 1992, 24, 889–898. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Y.; Qi, C. Homogeneous Combustion of Fuel Ultra-Lean Methane-Air Mixtures: Experimental Study and Simplified Reaction Mechanism. Energy Fuels 2011, 25, 3437–3445. [Google Scholar] [CrossRef]

- Gosiewski, K.; Matros, Y.S.; Warmuzinski, K. Homogenerous vs. catalytic combustion of lean methane-air mixtures in reverse-flow reactors. Chem. Eng. Sci. 2008, 63, 5010–5019. [Google Scholar] [CrossRef]

- Litto, R.; Hayes, R.E.; Sapoundjiev, H. Optimization of a flow reversal reactor for the catalytic combustion of lean methane mixture. Catal. Today 2006, 117, 536–542. [Google Scholar] [CrossRef]

- Xie, M.Z.; Shi, J.R.; Deng, Y.B.; Liu, H.; Zhou, L.; Xu, Y.-N. Experimental and numerical investigation on performance of a porous medium burner with reciprocating flow. Fuel 2009, 88, 206–213. [Google Scholar] [CrossRef]

- Gosiewski, K.; Pawlaczyk-Kure, K.A. Aerodynamic CFD simulations of experimental and industrial thermal flow reversal reactors. Chem. Eng. J. 2019, 373, 1367–1379. [Google Scholar] [CrossRef]

- Zhang, G.; Li, Q.; Liu, X.; Lin, B.; Li, D. Investigations on the mitigation of ventilation air methane and energy recovery in site trial thermal flow-reversal reactor. Chem. Eng. Process. Process Intensif. 2022, 170, 108703. [Google Scholar] [CrossRef]

- Lan, B.; Lia, Y.-R. Numerical study on thermal oxidation of lean coal mine methane in a thermal flow-reversal reactor. Chem. Eng. J. 2018, 351, 922–929. [Google Scholar] [CrossRef]

- You, Y.; Huang, H.; Shao, G. A three-dimensional numerical model of unsteady flow and heat transfer in ceramic honeycomb regenerator. Appl. Therm. Eng. 2016, 108, 1243–1250. [Google Scholar] [CrossRef]

- Gosiewski, K.; Pawlaczyk, A.; Warmuzinski, K.; Jaschik, M. A study of thermal combustion of lean methane-air mixtures: Simplified reaction mechanism and kinetic equations. Chem. Eng. J. 2009, 154, 9–16. [Google Scholar] [CrossRef]

- Fierro, M.; Arriagada, A.; Araneda, H.; Rosas, J.; Subiabre, G. Experimental investigation of steam and carbon dioxide influence on methane filtration combustion in a reversal flow porous media reactor. Int. J. Hydrogen Energy 2024, 82, 134–142. [Google Scholar] [CrossRef]

- Mao, M.; Liu, Y.; Shi, J.; Li, C.; Zhang, Q. Experimental study on control of flame inclination in a thermal flow reversal reactor with extra lean premixed methane/air intake. Fuel 2022, 318, 123722. [Google Scholar] [CrossRef]

- Kuang, R.; Liu, Y.; An, T.; Shen, Y. Numerical analysis of oxidation performance of basalt fiber bundle thermal flow-reversal reactor. Appl. Therm. Eng. 2022, 215, 118886. [Google Scholar] [CrossRef]

- Li, Q.; Chen, G.; Zhu, Y.; Li, X.; Yao, Y. Resonance response in the catalytic combustion of methane and propane binary mixture in reverse-flow reactor. Chem. Eng. J. 2018, 345, 375–388. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Sharshir, S.W.; Elaziz, M.A.; Kabeel, A.E.; Wang, G.L.; Zhang, H. Modeling of solar energy systems using artificial neural network: A comprehensive review. Sol. Energy 2019, 180, 622–639. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Development of an analytical model for the daily performance of solar thermal systems with experimental validation. Sustain. Energy Technol. Assess. 2018, 28, 22–29. [Google Scholar] [CrossRef]

- Ghritlahre, H.K.; Prasad, R.K. Application of ANN technique to predict the performance of solar collector systems—A Review. Renew. Sustain. Energy Rev. 2018, 84, 75–88. [Google Scholar] [CrossRef]

- Amelio, M.; Morrone, P. Numerical evaluation of the energetic performances of structured and random packed beds in regenerative thermal oxidizers. Appl. Therm. Eng. 2007, 27, 762–770. [Google Scholar] [CrossRef]

- Filipovic, P.; Dovic, D.; Ranilovic, B.; Horvat, I. Numerical and experimental approach for evaluation of thermal performance of a polymer solar collector. Renew. Sustain. Energy Rev. 2019, 112, 127–139. [Google Scholar] [CrossRef]

- Tagliafico, L.A.; Scarpa, F.; De Rosa, M. Dynamic thermal models and CFD analysis for flat-plate thermal solar collectors-A review. Renew. Sustain. Energy Rev. 2014, 30, 526–537. [Google Scholar] [CrossRef]

- Alfaro-Ayala, J.A.; Martinez-Rodriguez, G.; Picon-Nunez, M.; Uribe-Ramirez, A.R.; Gallegos-Munoz, A. Numerical study of a low temperature water-in-glass evacuated tube solar collector. Energy Convers. Manag. 2015, 94, 472–481. [Google Scholar] [CrossRef]

- Gosiewski, K. Effective approach to cyclic steady state in the catalytic reverse-flow combustion of methane. Chem. Eng. Sci 2004, 59, 4095–4101. [Google Scholar] [CrossRef]

- Sahin, M.; Kaya, Y.; Uyar, M. Comparison of ANN and MLR models for estimating solar radiation in Turkey using NOAA/AVHRR data. Adv. Space Res. 2013, 51, 891–904. [Google Scholar] [CrossRef]

- Kalogirou Soteris, A. Application of artificial neural-networks for energy systems. Appl. Energy 2000, 67, 17–35. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, F.; Su, S. Solar irradiance short-term prediction model based on BP neural network. Energy Procedia 2011, 12, 488–494. [Google Scholar] [CrossRef]

- Liu, L.; Liu, D.; Sun, Q.; Li, H.; Wennersten, R. Forecasting power output of photovoltaic system using a BP network method. Energy Procedia 2017, 142, 780–786. [Google Scholar] [CrossRef]

- Sadeghi, G.; Nazari, S.; Ameri, M.; Shama, F. Energy and exergy evaluation of the evacuated tube solar collector using Cu2O water nanofluid utilizing ANN methods. Sustain. Energy Technol. Assess. 2020, 37, 100578. [Google Scholar] [CrossRef]

- Ghritlahre, H.K.; Prasad, R.K. Investigation of thermal performance of unidirectional flow porous bed solar air heater using MLP, GRNN, and RBF models of ANN technique. Therm. Sci. Eng. Prog. 2018, 6, 226–235. [Google Scholar] [CrossRef]

- Sozem, A.; Menlikm, T.; Unvar, S. Determination of efficiency of flat-plate solar collectors using neural network approach. Expert Syst. Appl. 2008, 35, 1533–1539. [Google Scholar] [CrossRef]

- Hu, Q.; Zhang, R.; Zhou, Y. Transfer learning for short-term wind speed prediction with deep neural networks. Renew. Energy 2016, 85, 83–95. [Google Scholar] [CrossRef]

- Qureshi, A.S.; Khan, A.; Zameer, A.; Usman, A. Wind power prediction using deep neural network based meta regression and transfer learning. Appl. Soft Comput. 2017, 58, 742–755. [Google Scholar] [CrossRef]

- Khatib, T.; Mohamd, A.; Sopian, K. A review of solar energy modeling techniques. Renew. Sustain. Energy Rev. 2012, 16, 2864–2869. [Google Scholar] [CrossRef]

- Alvarez, M.E.; Hernandez, J.A.; Bourouis, M. Modelling the performance parameters of a horizontal falling film absorber with aqueous (lithium, potassium, sodium) nitrate solution using artificial neural networks. Energy 2016, 102, 313–323. [Google Scholar] [CrossRef]

| Model | R2 | RMSE | MAE | |||

|---|---|---|---|---|---|---|

| Gas outlet temperature | Thermal efficiency | Gas outlet temperature | Thermal efficiency | Gas outlet temperature | Thermal efficiency | |

| CFD | 0.7037 | 0.6819 | 16.7076 | 0.0120 | 15.7739 | 0.0106 |

| MLR | 0.8943 | 0.8647 | 9.8488 | 0.0086 | 7.8679 | 0.0070 |

| BP | 0.9742 | 0.9665 | 4.8649 | 0.0043 | 3.7567 | 0.0033 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuang, R.; Du, B.; Lund, P.D.; Wang, J.; Liu, Y. Machine Learning Improves Performance Prediction and Interpretation of Efficiency Influencing Factors of a Novel Basalt-Fiber-Bundle Thermal Flow-Reversal Reactor for Methane Recovery. Energies 2025, 18, 5730. https://doi.org/10.3390/en18215730

Kuang R, Du B, Lund PD, Wang J, Liu Y. Machine Learning Improves Performance Prediction and Interpretation of Efficiency Influencing Factors of a Novel Basalt-Fiber-Bundle Thermal Flow-Reversal Reactor for Methane Recovery. Energies. 2025; 18(21):5730. https://doi.org/10.3390/en18215730

Chicago/Turabian StyleKuang, Rao, Bin Du, Peter D. Lund, Jun Wang, and Yanying Liu. 2025. "Machine Learning Improves Performance Prediction and Interpretation of Efficiency Influencing Factors of a Novel Basalt-Fiber-Bundle Thermal Flow-Reversal Reactor for Methane Recovery" Energies 18, no. 21: 5730. https://doi.org/10.3390/en18215730

APA StyleKuang, R., Du, B., Lund, P. D., Wang, J., & Liu, Y. (2025). Machine Learning Improves Performance Prediction and Interpretation of Efficiency Influencing Factors of a Novel Basalt-Fiber-Bundle Thermal Flow-Reversal Reactor for Methane Recovery. Energies, 18(21), 5730. https://doi.org/10.3390/en18215730