Numerical Analysis of Thermal Performance of PCM-Containing Honeycomb Wallboard for Building Energy Harvesting

Abstract

1. Introduction

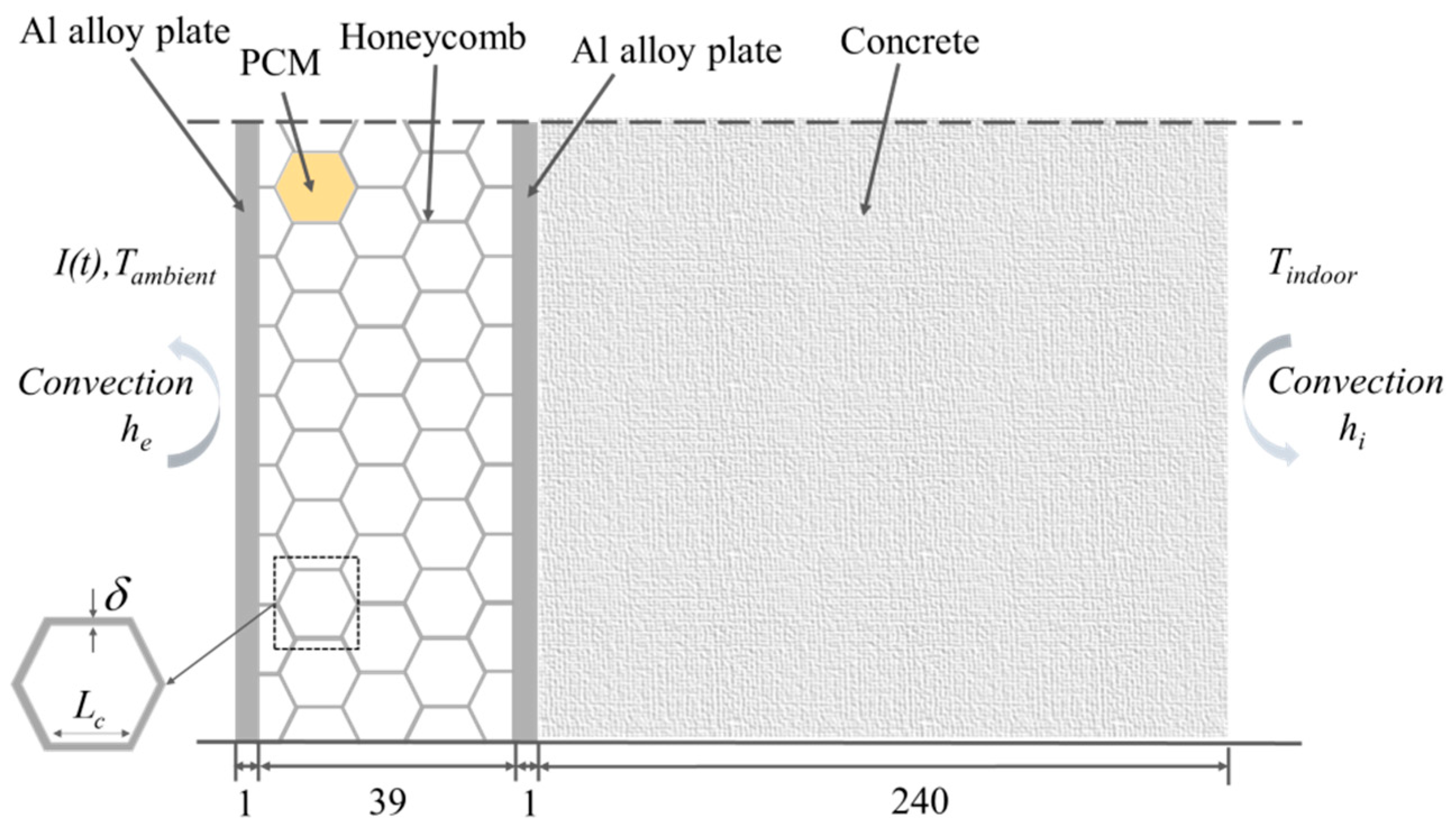

2. Computational Model

- (i)

- The thermal physical properties of solid domains (aluminum alloy and concrete walls) remain independent of temperature;

- (ii)

- The melted PCM flow is Newtonian incompressible laminar, with negligible three-dimensional convection, thermal radiation, and viscous dissipations.

- (iii)

- The PCM is homogeneous and isotropic.

- (iv)

- The influence of natural convection within the fluid region is calculated using the Boussinesq approximation.

3. Mathematical Formulations

3.1. Front and Back Surfaces

3.2. Inside the Concrete and Honeycomb Fins

3.3. Inside the PCM

3.3.1. Energy Equation

3.3.2. Momentum Equation

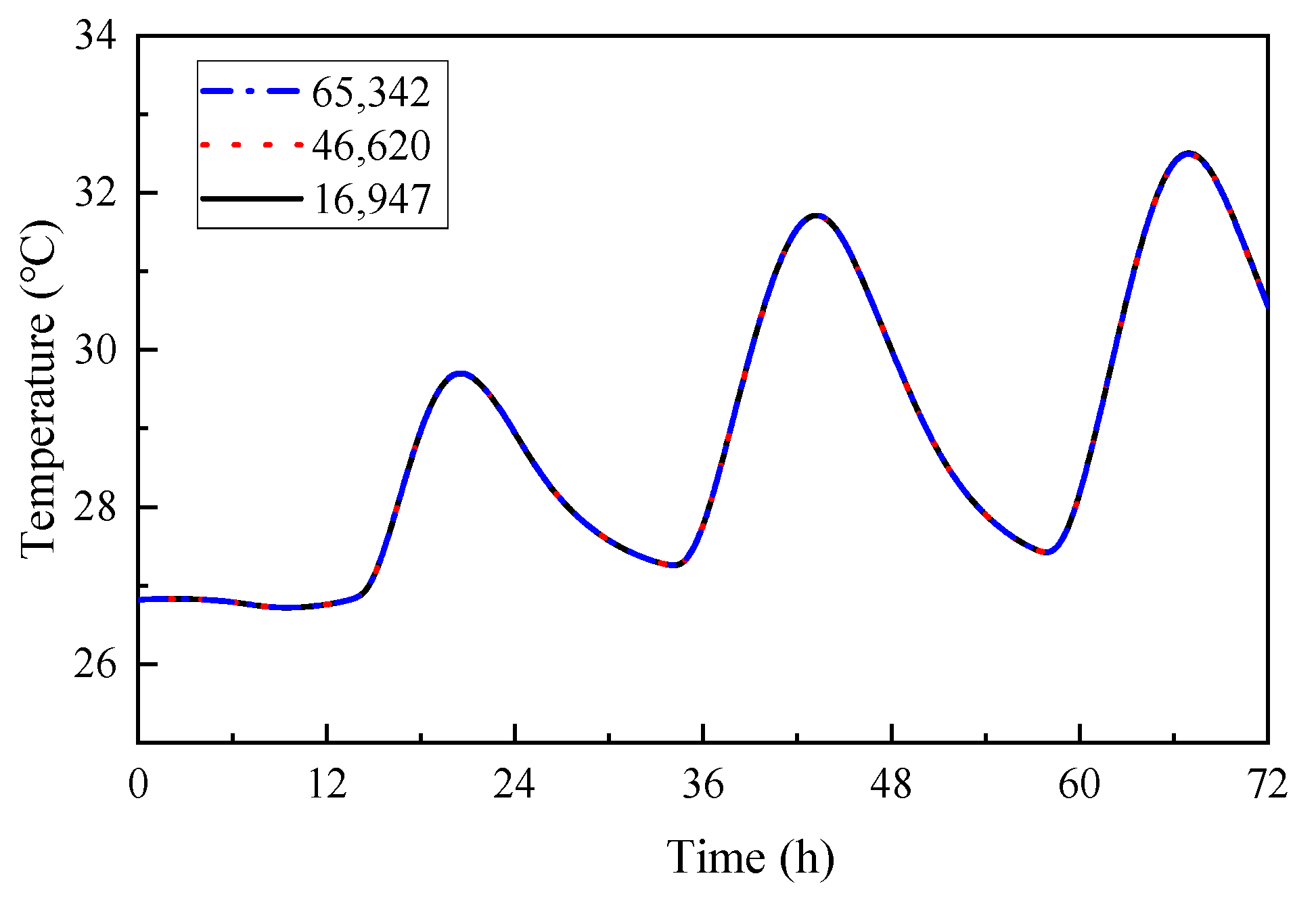

4. Numerical Method and Model Verification

4.1. Method and Mesh Dependency

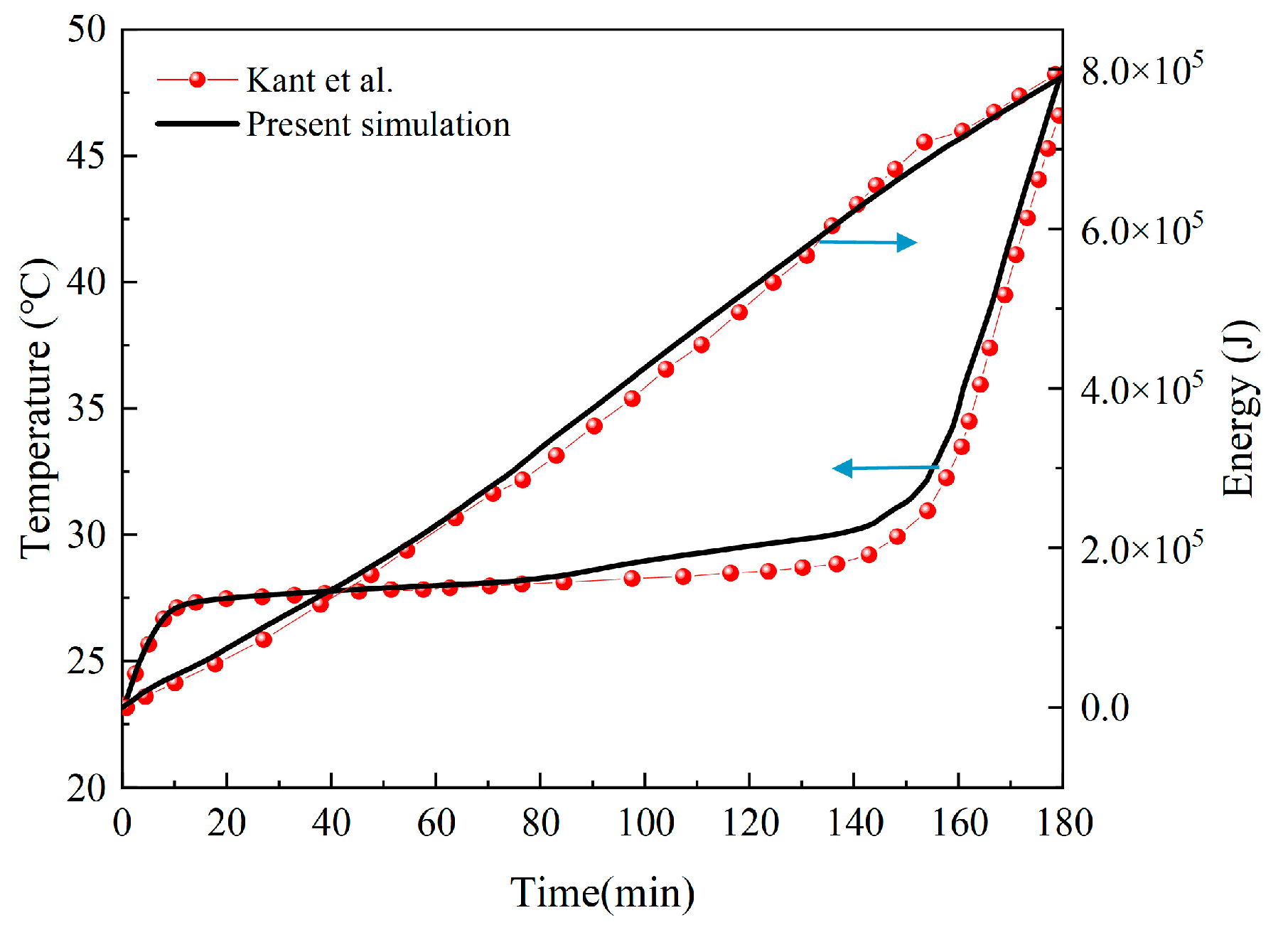

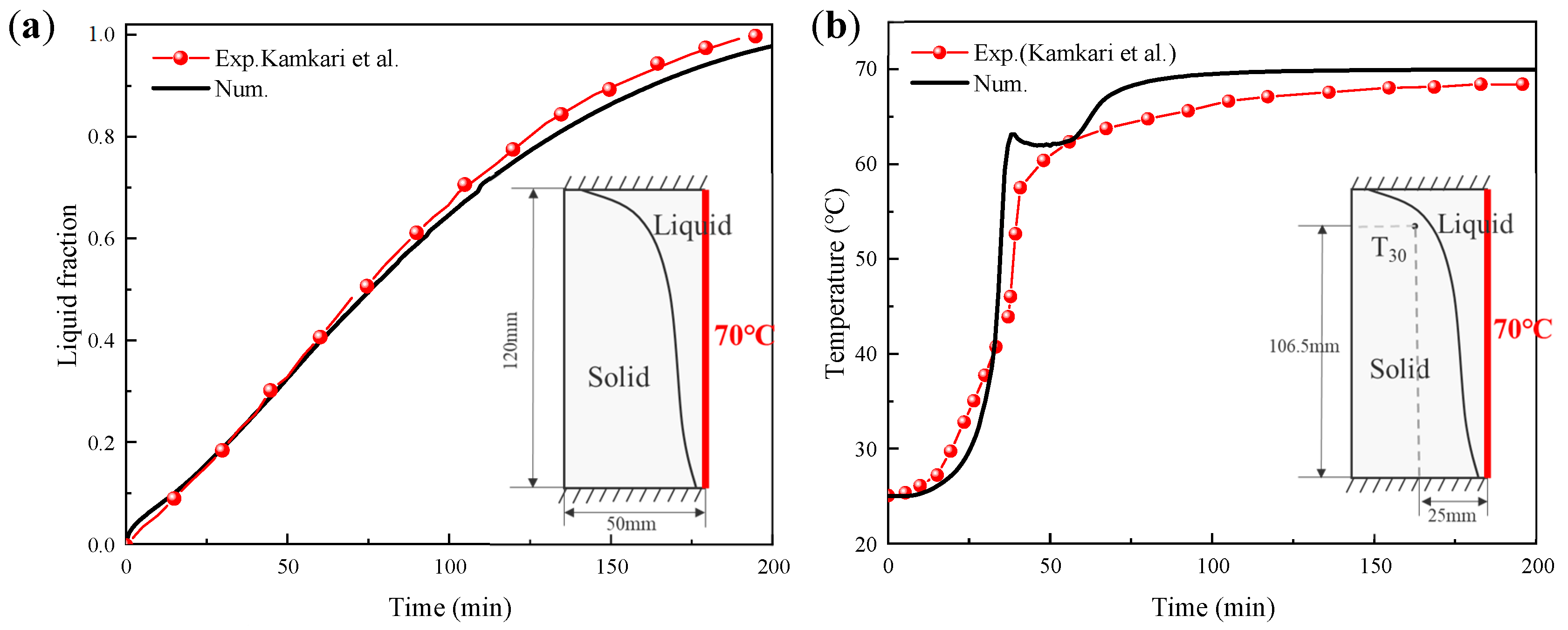

4.2. Model Validation

5. Results and Discussion

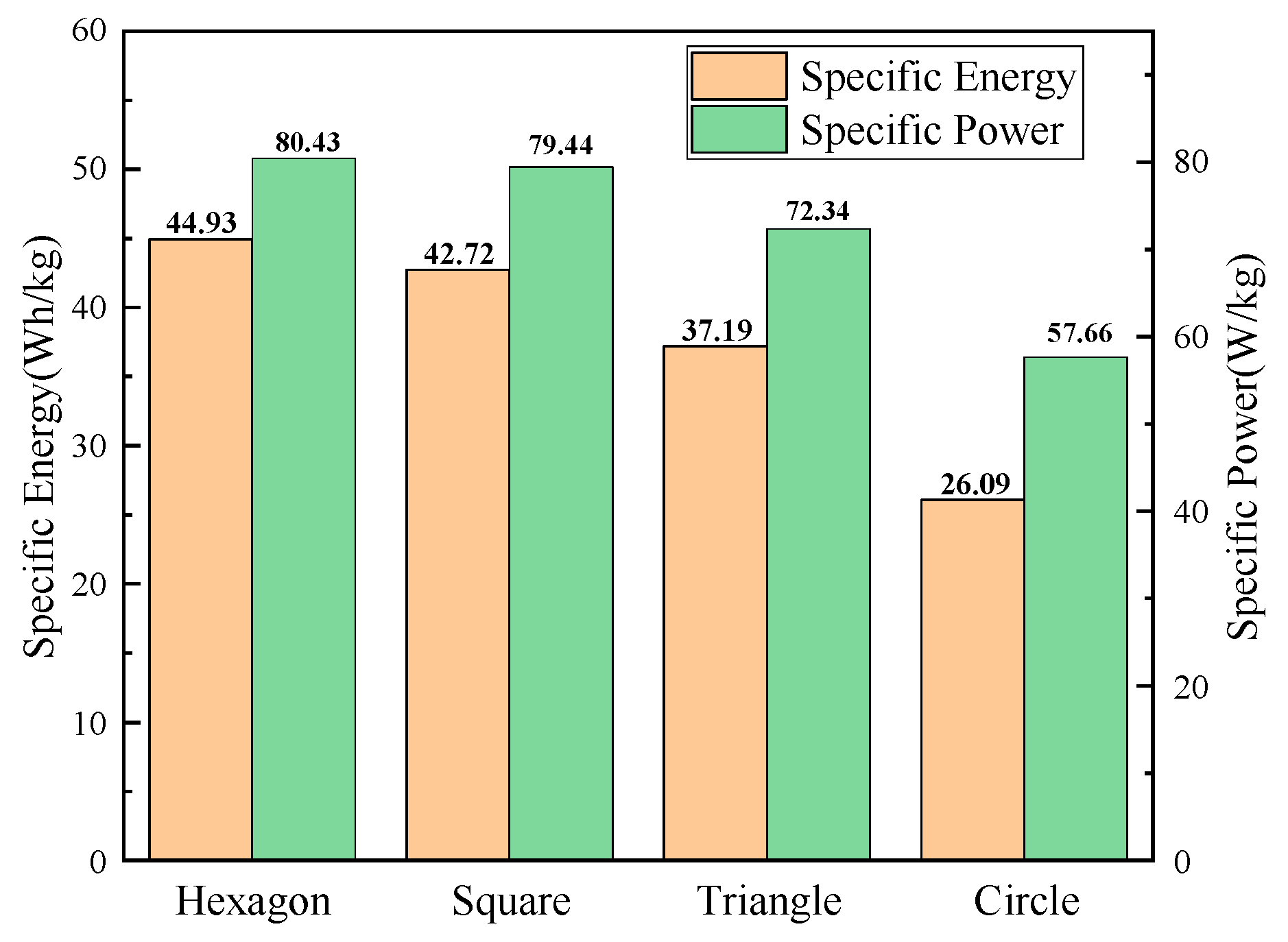

5.1. Evaluation of Energy Storage Efficiency Among Diverse Structures

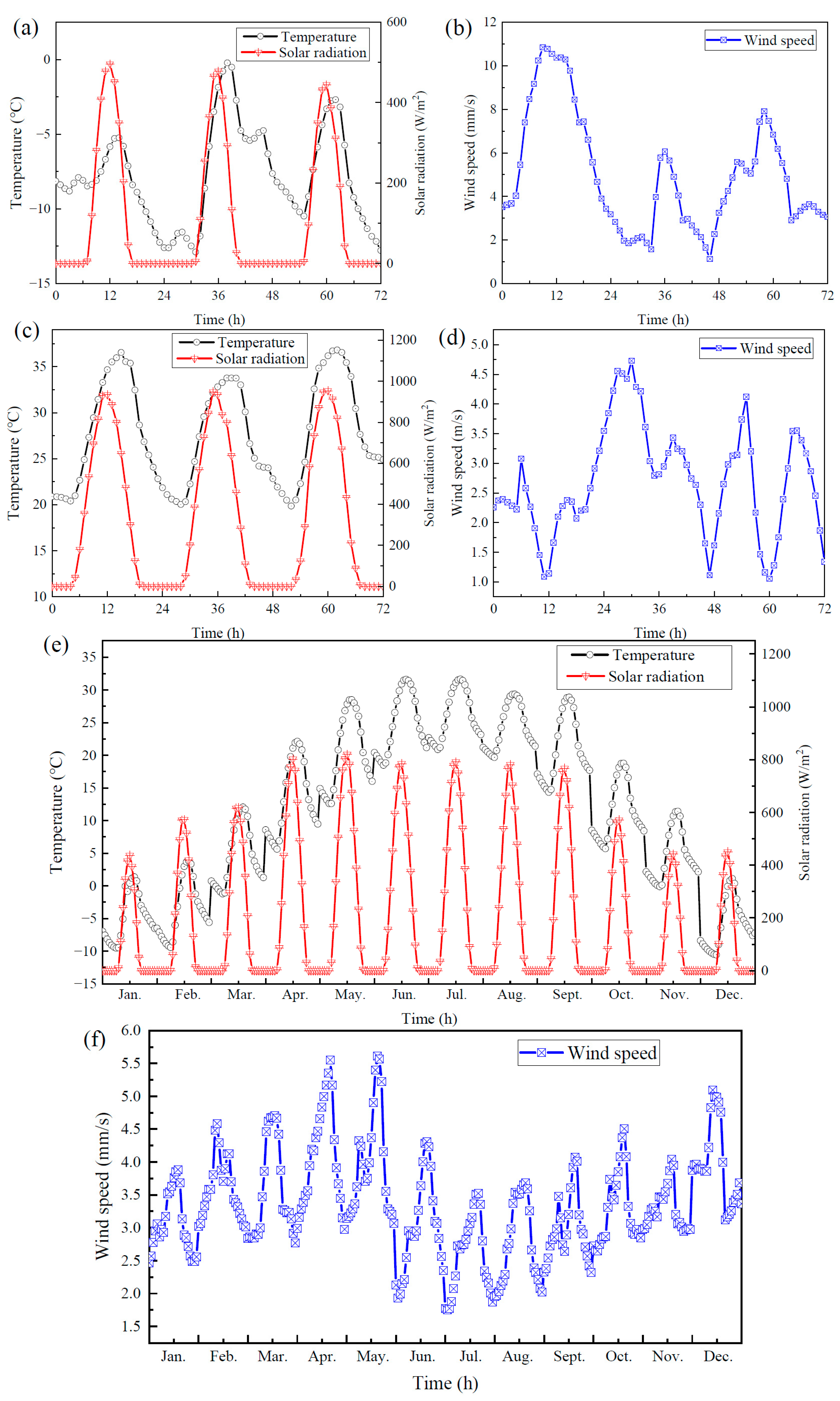

5.2. Energy Prediction of Honeycomb-like Wallboard Under Different Climates

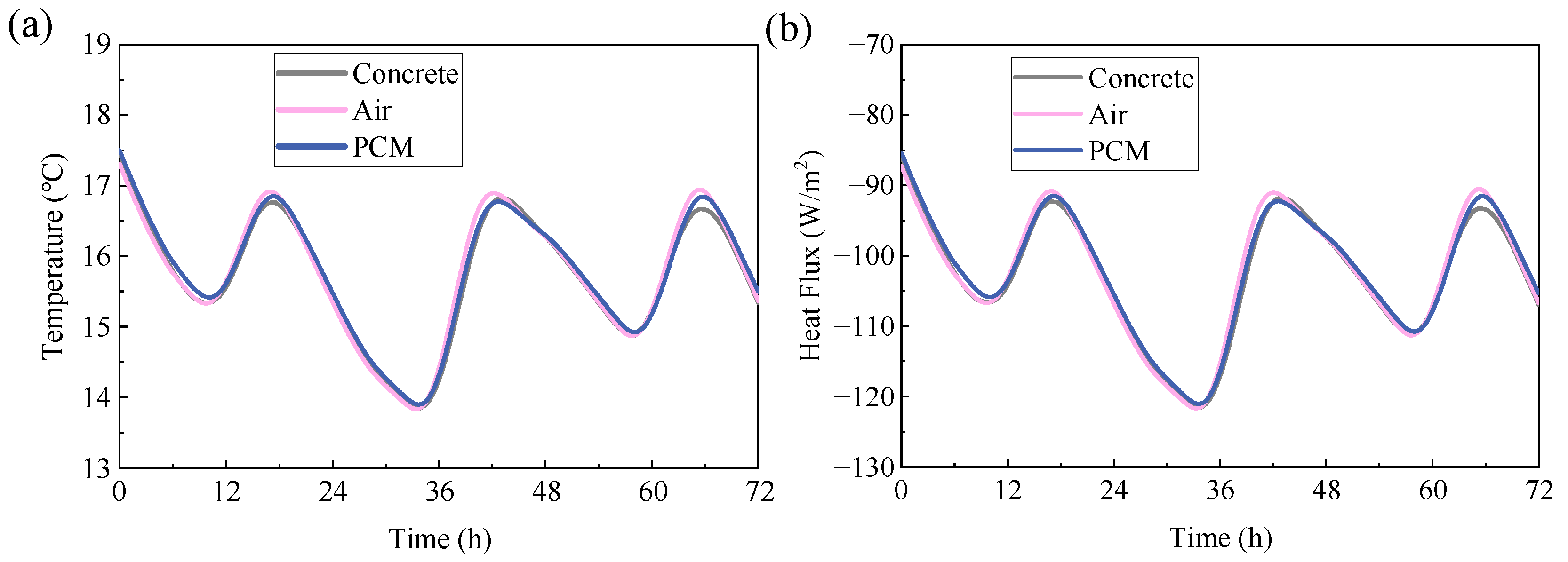

5.2.1. Three Days Results in Winter

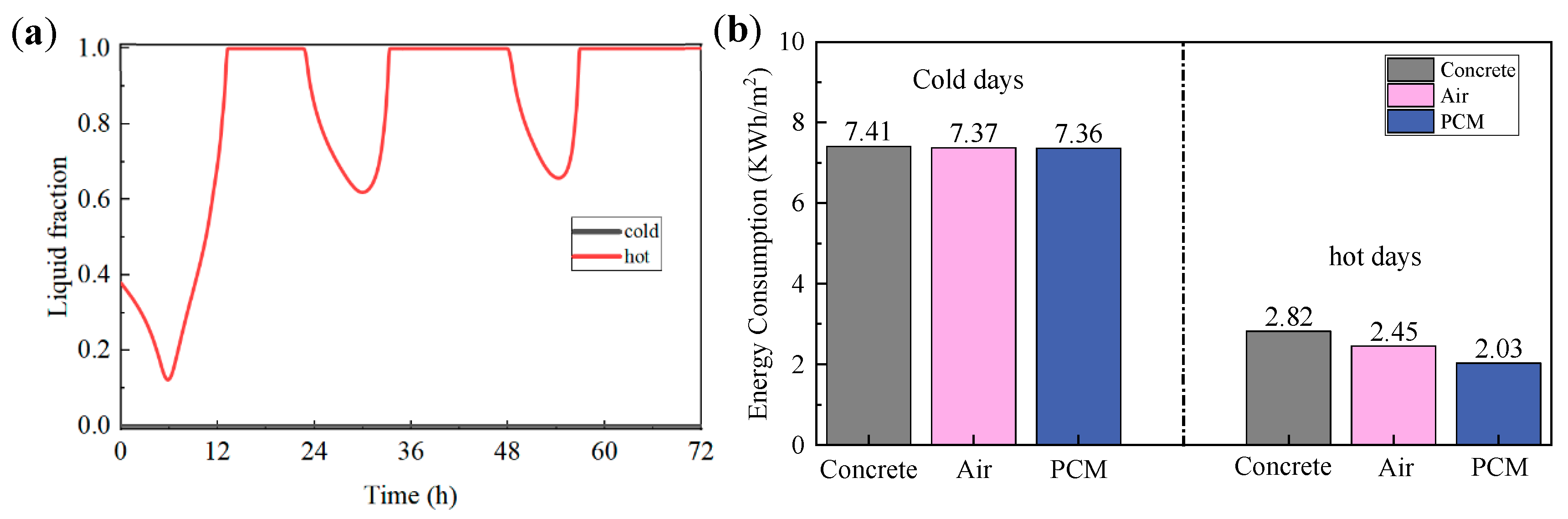

5.2.2. Three Days Results in Summer

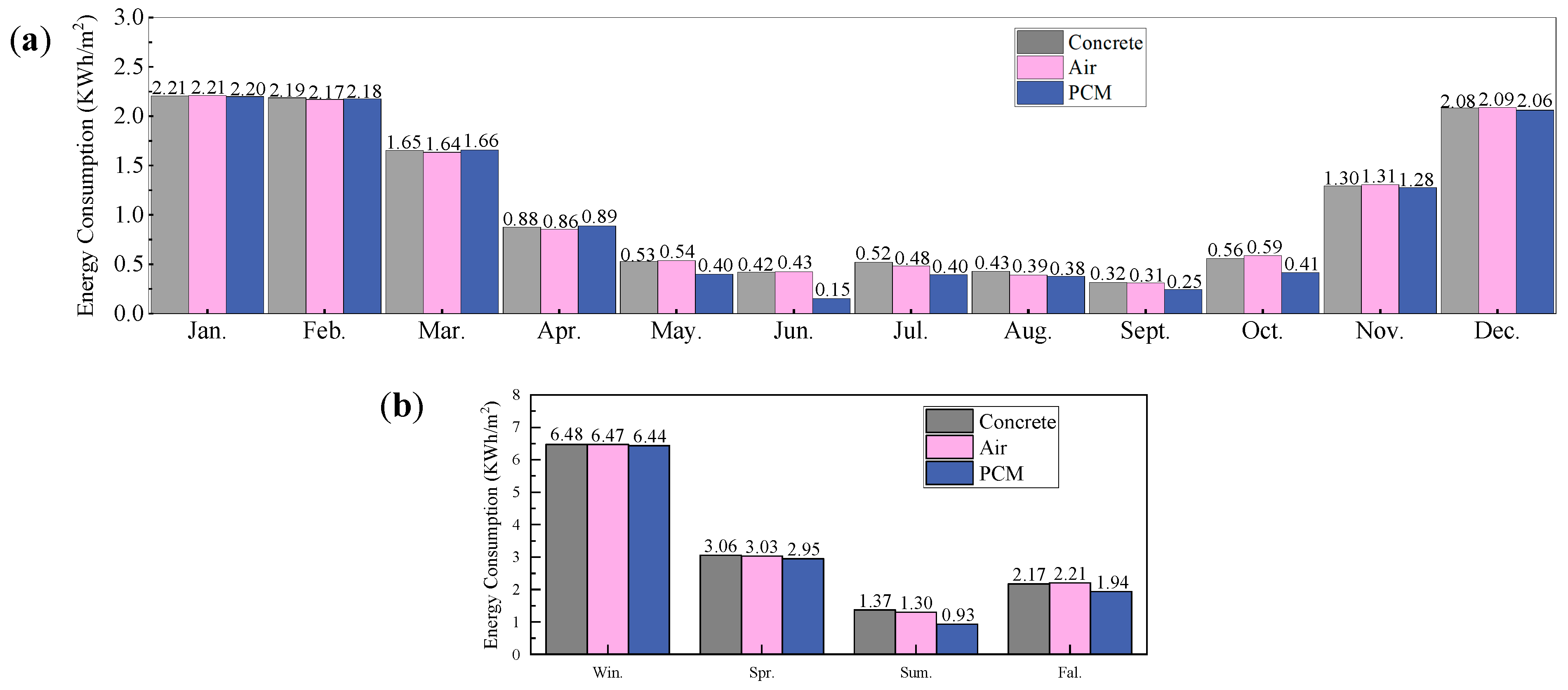

5.2.3. Energy Prediction of a Whole Year

- (i)

- The temperature and heat flux are notably lower than that of air and concrete;

- (ii)

- The presence of phase change lags in PCM hinders the transfer of heat flow;

- (iii)

- The risk of thermal cracking can be reduced due to the small temperature difference within the PCM.

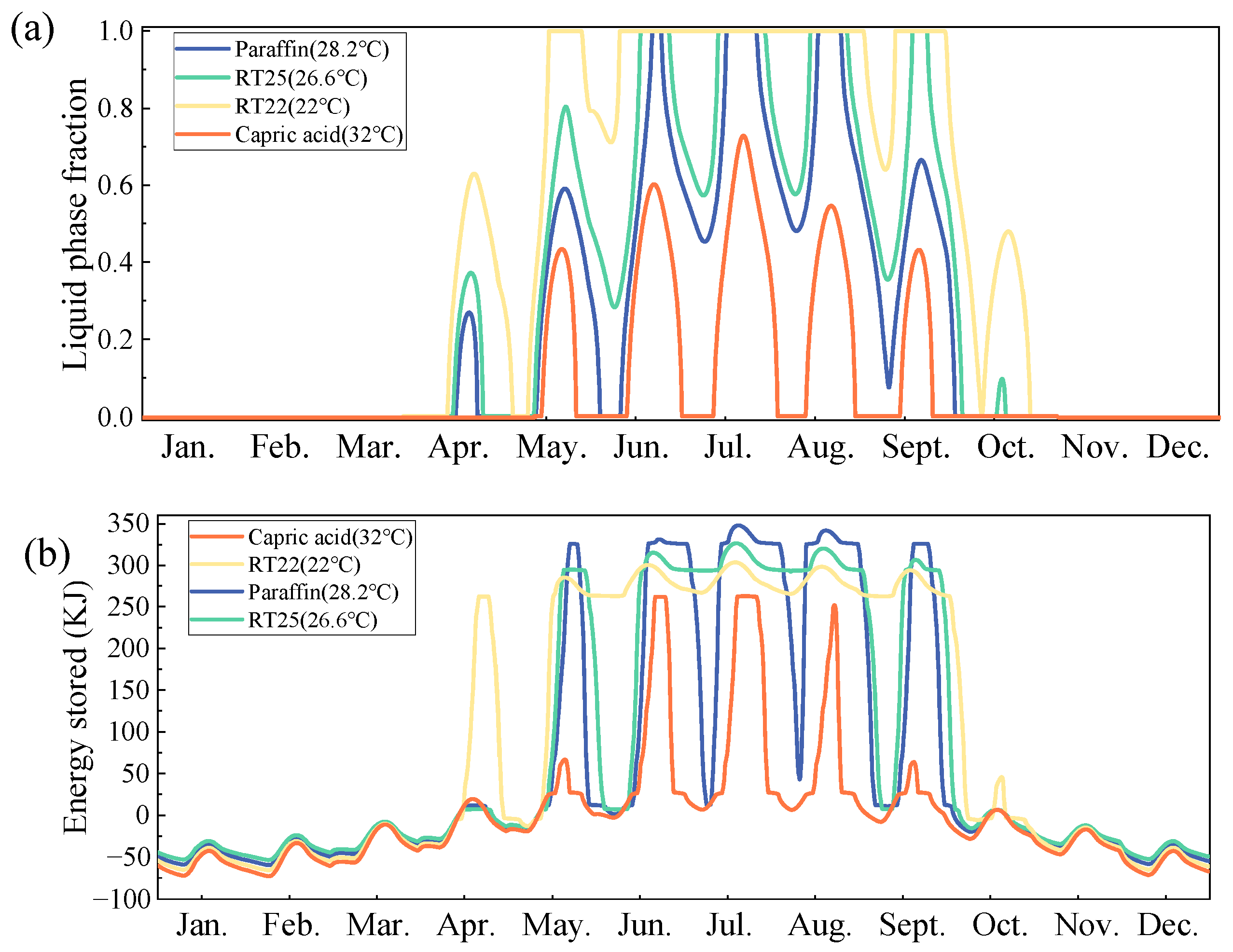

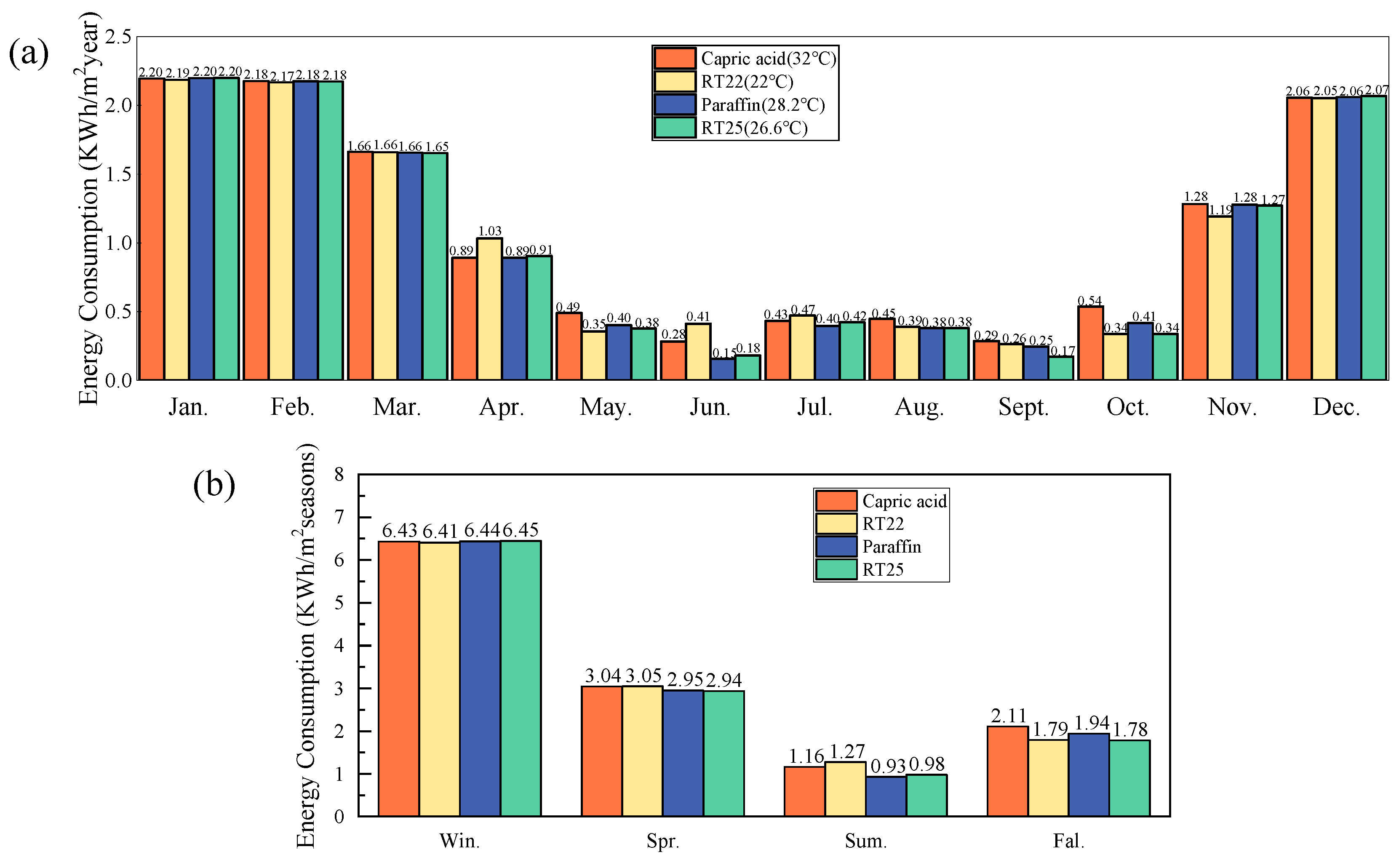

5.3. Effect on Energy Prediction of Different PCMs

6. Conclusions

- (i)

- Annual energy consumption projections reveal a significant reduction of 5.76% and 6.27% when utilizing PCM-infused systems compared to air-filled and concrete-based building envelopes, respectively.

- (ii)

- The system exhibits strong climate-adaptive performance. While its effect is limited in cold seasons, it manifests a noteworthy potential for energy savings during scorching summers, reducing consumption by 28.46% and 32.12% compared to its air-filled counterpart and plain concrete, respectively.

- (iii)

- PCM performance is highly dependent on phase transition temperature. RT25 (26.6 °C) shows optimal annual performance due to its proximity to the comfort range. Seasonally, PCMs with lower phase transition temperatures could utilize latent heat storage effectively in winter, while capric acid (32 °C) proves most effective in summer by suppressing peak heat flow and blocking heat ingress. Thus, PCM selection must be tailored to specific climatic conditions for optimal energy efficiency.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Abbreviation | ||

| velocity vector | [m/s] | |

| T | temperature | °C |

| t | time | [s] |

| p | pressure | [Pa] |

| m | mass | [kg] |

| C | mushy zone constant | [kg/(m3·s)] |

| ρ | density | [kg/m3] |

| k | thermal conductivity | [W/m·k)] |

| Cp | specific heat capacity | [J/(kg·K)] |

| g | gravitational acceleration | [m/s2] |

| Tm | melting temperature | [°C] |

| Lf | latent heat of fusion | [kJ/kg] |

| Tini | initial temperature | [°C] |

| Lc | length of honeycomb cell | [mm] |

| h | convective heat transfer coefficient | [W/(m2·K)] |

| B(T) | liquid phase fraction | |

| E | total energy stored | [J] |

| Tamb | outdoor ambient temperature | |

| I(t) | solar radiation. | |

| ΔT | transition temperature | [°C] |

| v | wind velocity | [m/s] |

| SE | specific energy | [Wh/kg] |

| SP | specific power | [W/kg] |

| Greek symbol | ||

| thermal expansion coefficient | [1/K] | |

| solar absorptivity | ||

| thickness of honeycomb cell | [mm] | |

| dynamic viscosity | [Pa·s] | |

| Subscript | ||

| s | solid phase of PCM | |

| l | liquid phase of PCM | |

| e | external surface | |

| i | inner surface | |

| amb | ambient | |

| plate | aluminum alloy plate | |

| concrete | concrete |

References

- Cao, Z.; Zhang, G.; Shi, Y.; Xu, C.; Sun, Y. Thermal behavior of phase change plates using tunnel lining GHEs for cool storage: Effect of pipe design parameters and PCM latent heat. Energy Build. 2023, 301, 113737. [Google Scholar] [CrossRef]

- Han, X.X.; Tian, Y.; Zhao, C.Y. An effectiveness study of enhanced heat transfer in phase change materials (PCMs). Int. J. Heat Mass Transf. 2013, 60, 459–468. [Google Scholar] [CrossRef]

- Liu, L.; Wang, Y.; Wang, Z.; Li, S.; Li, J.; He, G.; Li, Y.; Liu, Y.; Piao, S.; Gao, Z.; et al. Potential contributions of wind and solar power to China’s carbon neutrality. Resour. Conserv. Recycl. 2022, 180, 106155. [Google Scholar] [CrossRef]

- Jayathunga, D.S.; Karunathilake, H.P.; Narayana, M.; Witharana, S. Phase change material (PCM) candidates for latent heat thermal energy storage (LHTES) in concentrated solar power (CSP) based thermal applications—A review. Renew. Sustain. Energy Rev. 2024, 189, 113904. [Google Scholar] [CrossRef]

- Abdulateef, A.M.; Jaszczur, M.; Hassan, Q.; Anish, R.; Niyas, H.; Sopian, K.; Abdulateef, J. Enhancing the melting of phase change material using a fins–nanoparticle combination in a triplex tube heat exchanger. J. Energy Storage 2021, 35, 102227. [Google Scholar] [CrossRef]

- Pielichowska, K.; Szatkowska, M.; Pielichowski, K. Thermal Energy Storage in Bio-Inspired PCM-Based Systems. Energies 2025, 18, 3548. [Google Scholar] [CrossRef]

- Ni, S.; Zhu, N.; Hou, Y.; Zhang, Z. Research on indoor thermal comfort and energy consumption of zero energy wooden structure buildings in severe cold zone. J. Build. Eng. 2023, 67, 105965. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, L.; Zhang, L.; Wu, X. Optimizing energy efficiency and thermal comfort in building green retrofit. Energy 2021, 237, 121509. [Google Scholar] [CrossRef]

- Lin, Q.; Chen, Y.-C.; Chen, F.; DeGanyar, T.; Yin, H. Design and experiments of a thermoelectric-powered wireless sensor network platform for smart building envelope. Appl. Energy 2022, 305, 117791. [Google Scholar] [CrossRef]

- Lin, Q.; Zhang, Y.; Van Mieghem, A.; Chen, Y.C.; Yu, N.; Yang, Y.; Yin, H. Design and experiment of a sun-powered smart building envelope with automatic control. Energy Build. 2020, 223, 110173. [Google Scholar] [CrossRef]

- Lin, Q.; Chen, F.; Yin, H. Experimental and theoretical investigation of the thermo-mechanical deformation of a functionally graded panel. Eng. Struct. 2017, 138, 17–26. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, Y.; Wang, T.; Zhang, L.; Gao, Y. Thermoelastic behavior analysis of finite composites embedded in ellipsoidal inhomogeneities with inclusion-based boundary element method. Int. J. Solids Struct. 2025, 309, 113172. [Google Scholar] [CrossRef]

- Bayram, M.; Ustaoglu, A.; Kursuncu, B.; Hekimoglu, G.; Sari, A.; Ugur, L.O.; Subasi, S.; Gencel, O.; Ozbakkaloglu, T. 3D-printed polylactic acid-microencapsulated phase change material composites for building thermal management. Renew. Sustain. Energy Rev. 2024, 191, 114150. [Google Scholar] [CrossRef]

- Alshammari, T.O.; Ahmad, S.F.; Houran, M.A.; Agrawal, M.K.; Pulla, S.F.; Nutakki, T.U.K.; Albani, A.; Youshanlouei, H.M. Thermal energy simulation of the building with heating tube embedded in the wall in the presence of different PCM materials. J. Energy Storage 2023, 73, 109134. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, M.; Qin, H. The energy storage characteristic analysis and optimization of latent heat energy storage component with finned tubes in building envelope. Case Stud. Therm. Eng. 2022, 33, 101946. [Google Scholar] [CrossRef]

- Krasoń, J.; Miąsik, P.; Starakiewicz, A.; Lichołai, L. Thermal Energy Storage Possibilities in the Composite Trombe Wall Modified with a Phase Change Material. Energies 2025, 18, 1433. [Google Scholar] [CrossRef]

- Anter, A.G.; Sultan, A.A.; Hegazi, A.A.; El Bouz, M.A. Thermal performance and energy saving using phase change materials (PCM) integrated in building walls. J. Energy Storage 2023, 67, 107568. [Google Scholar] [CrossRef]

- Alawadhi, E.M. Thermal analysis of a building brick containing phase change material. Energy Build. 2008, 40, 351–357. [Google Scholar] [CrossRef]

- Kant, K.; Shukla, A.; Sharma, A. Heat transfer studies of building brick containing phase change materials. Sol. Energy 2017, 155, 1233–1242. [Google Scholar] [CrossRef]

- Silva, T.; Vicente, R.; Soares, N.; Ferreira, V. Experimental testing and numerical modelling of masonry wall solution with PCM incorporation: A passive construction solution. Energy Build. 2012, 49, 235–245. [Google Scholar] [CrossRef]

- Wang, Q.; Wu, R.; Wu, Y.; Zhao, C.Y. Parametric analysis of using PCM walls for heating loads reduction. Energy Build. 2018, 172, 328–336. [Google Scholar] [CrossRef]

- Fateh, A.; Borelli, D.; Devia, F.; Weinläder, H. Summer thermal performances of PCM-integrated insulation layers for light-weight building walls: Effect of orientation and melting point temperature. Therm. Sci. Eng. Prog. 2018, 6, 361–369. [Google Scholar] [CrossRef]

- Hosseinzadeh Kh Montazer, E.; Shafii, M.B.; Ganji, A.R.D. Solidification enhancement in triplex thermal energy storage system via triplets fins configuration and hybrid nanoparticles. J. Energy Storage 2021, 34, 102177. [Google Scholar] [CrossRef]

- Sathyamurthy, R. Silver (Ag) based nanoparticles in paraffin wax as thermal energy storage for stepped solar still—An experimental approach. Sol. Energy 2023, 262, 111808. [Google Scholar] [CrossRef]

- Kant, K.; Shukla, A.; Sharma, A.; Biwole, P.H. Heat transfer study of phase change materials with graphene nano particle for thermal energy storage. Sol. Energy 2017, 146, 453–463. [Google Scholar] [CrossRef]

- Deng, Z.; Liu, X.; Zhang, C.; Huang, Y.; Chen, Y. Melting behaviors of PCM in porous metal foam characterized by fractal geometry. Int. J. Heat Mass Transf. 2017, 113, 1031–1042. [Google Scholar] [CrossRef]

- Chen, Z.; Gao, D.; Shi, J. Experimental and numerical study on melting of phase change materials in metal foams at pore scale. Int. J. Heat Mass Transf. 2014, 72, 646–655. [Google Scholar] [CrossRef]

- Ji, C.; Qin, Z.; Dubey, S.; Choo, F.H.; Duan, F. Simulation on PCM melting enhancement with double-fin length arrangements in a rectangular enclosure induced by natural convection. Int. J. Heat Mass Transf. 2018, 127, 255–265. [Google Scholar] [CrossRef]

- Biwole, P.H.; Groulx, D.; Souayfane, F.; Chiu, T. Influence of fin size and distribution on solid-liquid phase change in a rectangular enclosure. Int. J. Therm. Sci. 2018, 124, 433–446. [Google Scholar] [CrossRef]

- Mortazavi, A.; Morciano, M.; Asinari, P.; Chiavazzo, E. Topology-Optimized Latent Heat Battery: Benchmarking Against a High-Performance Geometry. Energies 2025, 18, 4054. [Google Scholar] [CrossRef]

- Liu, F.; Wang, J.; Liu, Y.; Wang, F.; Yang, N.; Liu, X.; Liu, H.; Li, W.; Liu, H.; Huang, B. Performance analysis of phase change material in battery thermal management with biomimetic honeycomb fin. Appl. Therm. Eng. 2021, 196, 117296. [Google Scholar] [CrossRef]

- Corgnale, C.; Hardy, B.; Chahine, R.; Cossement, D. Hydrogen desorption using honeycomb finned heat exchangers integrated in adsorbent storage systems. Appl. Energy 2018, 213, 426–434. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, L.; Lei, G.; Gao, Y. Estimation of heat transfer and thermal conductivity of particle-reinforced hollow cylinder composites. Mech. Adv. Mater. Struct. 2024, 31, 13195–13209. [Google Scholar] [CrossRef]

- Lai, C.; Hokoi, S. Thermal performance of an aluminum honeycomb wallboard incorporating microencapsulated PCM. Energy Build. 2014, 73, 37–47. [Google Scholar] [CrossRef]

- Wang, S.-M.; Matiašovský, P.; Mihálka, P.; Lai, C.-M. Experimental investigation of the daily thermal performance of a mPCM honeycomb wallboard. Energy Build. 2018, 159, 419–425. [Google Scholar] [CrossRef]

- Hasse, C.; Grenet, M.; Bontemps, A.; Dendievel, R.; Sallée, H. Realization, test and modelling of honeycomb wallboards containing a Phase Change Material. Energy Build. 2011, 43, 232–238. [Google Scholar] [CrossRef]

- Kočí, J.; Fořt, J.; Černý, R. Energy efficiency of latent heat storage systems in residential buildings: Coupled effects of wall assembly and climatic conditions. Renew. Sustain. Energy Rev. 2020, 132, 110097. [Google Scholar] [CrossRef]

- Thiele, A.M.; Sant, G.; Pilon, L. Diurnal thermal analysis of microencapsulated PCM-concrete composite walls. Energy Convers. Manag. 2015, 93, 215–227. [Google Scholar] [CrossRef]

- Liu, C.; Zhou, Y.; Li, D.; Meng, F.; Zheng, Y.; Liu, X. Numerical analysis on thermal performance of a PCM-filled double glazing roof. Energy Build. 2016, 125, 267–275. [Google Scholar] [CrossRef]

- Xihe Energy Big Data Platform. Available online: http://xihe-energy.com (accessed on 4 June 2023).

- Groulx, D.; Biwole, P.H.; Bhouri, M. Phase change heat transfer in a rectangular enclosure as a function of inclination and fin placement. Int. J. Therm. Sci. 2020, 151, 106260. [Google Scholar] [CrossRef]

- Zhao, D.; Tan, G. Numerical analysis of a shell-and-tube latent heat storage unit with fins for air-conditioning application. Appl. Energy 2015, 138, 381–392. [Google Scholar] [CrossRef]

- Liu, H.; Chen, Z.; Han, Q.; Chen, B.; Bu, Y. Study on the thermal behavior of aluminum reticulated shell structures considering solar radiation. Thin-Walled Struct. 2014, 85, 15–24. [Google Scholar] [CrossRef]

- Jennings, B. Environmental Engineering; International Textbook Company: Scranton, PA, USA, 1970. [Google Scholar]

- Test, F.L.; Lessmann, R.C.; Johary, A. Heat Transfer During Wind Flow over Rectangular Bodies in the Natural Environment. J. Heat Transf. 1981, 103, 262–267. [Google Scholar] [CrossRef]

- Kant, K.; Shukla, A.; Sharma, A.; Biwole, P.H. Melting and solidification behaviour of phase change materials with cyclic heating and cooling. J. Energy Storage 2018, 15, 274–282. [Google Scholar] [CrossRef]

- Karami, R.; Kamkari, B. Investigation of the effect of inclination angle on the melting enhancement of phase change material in finned latent heat thermal storage units. Appl. Therm. Eng. 2019, 146, 45–60. [Google Scholar] [CrossRef]

- Voller, V.R.; Prakash, C. A fixed grid numerical modelling methodology for convection-diffusion mushy region phase-change problems. Int. J. Heat Mass Transf. 1987, 30, 1709–1719. [Google Scholar] [CrossRef]

- Moench, S.; Dittrich, R. Influence of Natural Convection and Volume Change on Numerical Simulation of Phase Change Materials for Latent Heat Storage. Energies 2022, 15, 2746. [Google Scholar] [CrossRef]

- Kant, K.; Biwole, P.H.; Shukla, A.; Sharma, A.; Gorjian, S. Heat transfer and energy storage performances of phase change materials encapsulated in honeycomb cells. J. Energy Storage 2021, 38, 102507. [Google Scholar] [CrossRef]

- Kamkari, B.; Shokouhmand, H. Experimental investigation of phase change material melting in rectangular enclosures with horizontal partial fins. Int. J. Heat Mass Transf. 2014, 78, 839–851. [Google Scholar] [CrossRef]

- Zhao, W.; Yu, G.; Li, S.; Liu, Z.; Wu, L. Rate capability and Ragone plots for thermal management multifunctional structure designing. Int. J. Mech. Sci. 2023, 252, 108367. [Google Scholar] [CrossRef]

| Properties | Paraffin [19] | RT25 [41] | RT22 [42] | Capric Acid [25] | Aluminum Alloy | Concrete |

|---|---|---|---|---|---|---|

| Specific [J/(kg·K)] | 1934 (s) | 1800 (s) | 2000 | 1900 (s) | 900 | 880 |

| 2196 (l) | 2400 (l) | 2400 (l) | ||||

| Density [kg/m3] | 814 (s) | 785 (s) | 880 (s) | 1018 (s) | 2700 | 2300 |

| 775 (l) | 749 (l) | 770 (l) | 888 (l) | |||

| Thermal conductivity [W/(m·K)] | 0.350 (s) | 0.19 (s) | 0.2 | 0.372 (s) | 201 | 1.8 |

| 0.149 (l) | 0.18 (l) | 0.153 (l) | ||||

| Melting temperature [°C] | 28.2 | 26.6 | 22 | 32 | NA | NA |

| Latent heat [kJ/kg] | 245 | 232 | 200 | 152.7 | NA | NA |

| Thermal expansion coefficient [1/K] | 9.1 × 10−4 | 10−3 | 10−3 | 10−3 | NA | NA |

| Kinematic viscosity [m2/s] | 5 × 10−6 | NA | NA | 3 × 10−6 | NA | NA |

| Dynamic Viscosity [Pa·s] | NA | 1.798 × 10−3 | 3.2 × 10−3 | NA | NA | NA |

| Seasons | Concrete | Air | PCM | |

|---|---|---|---|---|

| Win. | 6.48 | 6.47 | 6.44 | Energy Consumption (KWh/m2) |

| 0.62 | 0.15 | 0.46 | Reduction (%) | |

| Spr. | 3.06 | 3.03 | 2.95 | Energy Consumption (KWh/m2) |

| 3.59 | 0.98 | 2.64 | Reduction (%) | |

| Sum. | 1.37 | 1.30 | 0.93 | Energy Consumption (KWh/m2) |

| 32.12 | 5.11 | 28.46 | Reduction (%) | |

| Fal. | 2.17 | 2.21 | 1.94 | Energy Consumption (KWh/m2) |

| 10.60 | −1.84 | 12.22 | Reduction (%) | |

| — | Covered by honeycomb wallboard containing PCMs VS Concrete | Covered by honeycomb wallboard VS Concrete | Covered by honeycomb wallboard containing PCMs VS Covered by honeycomb wallboard |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Yang, Y.; Zhou, L.; Lei, G.; Wei, Z.; Zhang, L. Numerical Analysis of Thermal Performance of PCM-Containing Honeycomb Wallboard for Building Energy Harvesting. Energies 2025, 18, 5720. https://doi.org/10.3390/en18215720

Zhang Y, Yang Y, Zhou L, Lei G, Wei Z, Zhang L. Numerical Analysis of Thermal Performance of PCM-Containing Honeycomb Wallboard for Building Energy Harvesting. Energies. 2025; 18(21):5720. https://doi.org/10.3390/en18215720

Chicago/Turabian StyleZhang, Yifan, Yusheng Yang, Lei Zhou, Gang Lei, Zhenhua Wei, and Liangliang Zhang. 2025. "Numerical Analysis of Thermal Performance of PCM-Containing Honeycomb Wallboard for Building Energy Harvesting" Energies 18, no. 21: 5720. https://doi.org/10.3390/en18215720

APA StyleZhang, Y., Yang, Y., Zhou, L., Lei, G., Wei, Z., & Zhang, L. (2025). Numerical Analysis of Thermal Performance of PCM-Containing Honeycomb Wallboard for Building Energy Harvesting. Energies, 18(21), 5720. https://doi.org/10.3390/en18215720