Study on Energy-Saving Potential Based on Heat and Moisture Transfer Characteristics During Fresh Air Introduction in Deep Underground Engineering

Abstract

1. Introduction

2. Mathematical–Physical Model

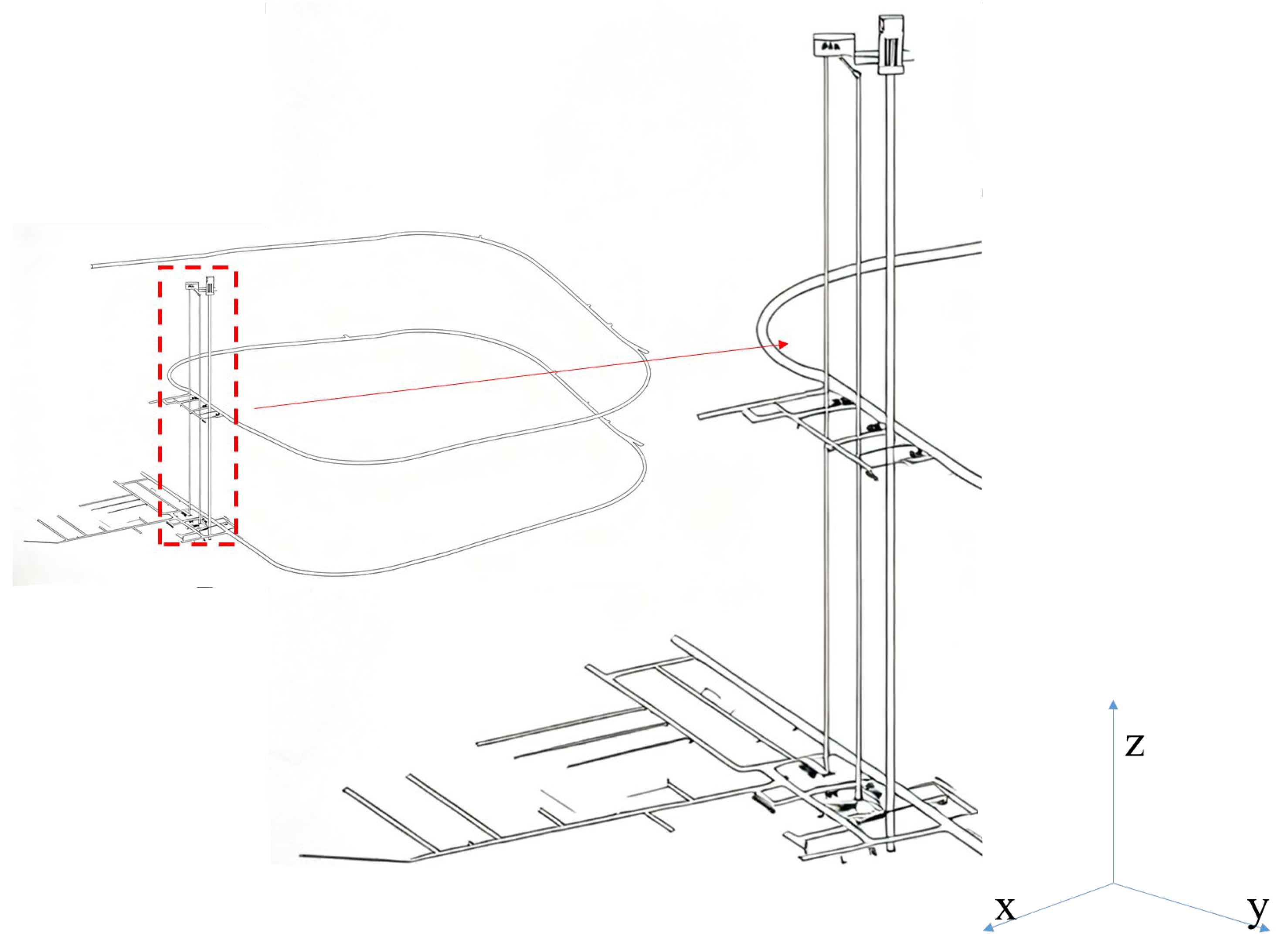

2.1. Physical Model

2.2. Mathematic Model

- (1)

- The surrounding rock medium is assumed to be uniform, continuous, and isotropic, with its physical properties (e.g., thermal conductivity, permeability) remaining consistent across all spatial positions and directions;

- (2)

- Moisture within the surrounding rock is restricted to two phases: gas (water vapor) and liquid (liquid water), with moisture freezing in low-temperature environments neglected for the present;

- (3)

- Water vapor is treated as an ideal gas, with its state changes adhering to the ideal gas law. Intermolecular forces and molecular volume of real gases are neglected;

- (4)

- Any micro-region (i.e., local point) within the surrounding rock is assumed to satisfy heat and moisture balance conditions, without instantaneous drastic fluctuations in temperature or humidity parameters;

- (5)

- Given the regular shape of the surrounding rock, its heat–moisture transfer is assumed to occur solely along its thickness direction (exhibiting one-dimensional transfer), with heat and moisture exchange in other directions neglected;

- (6)

- Under isothermal conditions, capillary hysteresis during moisture adsorption–desorption in the surrounding rock is neglected to simplify the computational complexity of moisture migration;

- (7)

- The surrounding rock is assumed to lie within the underground constant temperature zone, where seasonal atmospheric temperature fluctuations do not affect its initial temperature, ensuring stable initial temperature conditions for the model.

2.3. Material Properties

3. Model Implementation and Validation

3.1. The Implementation of the Numerical Model

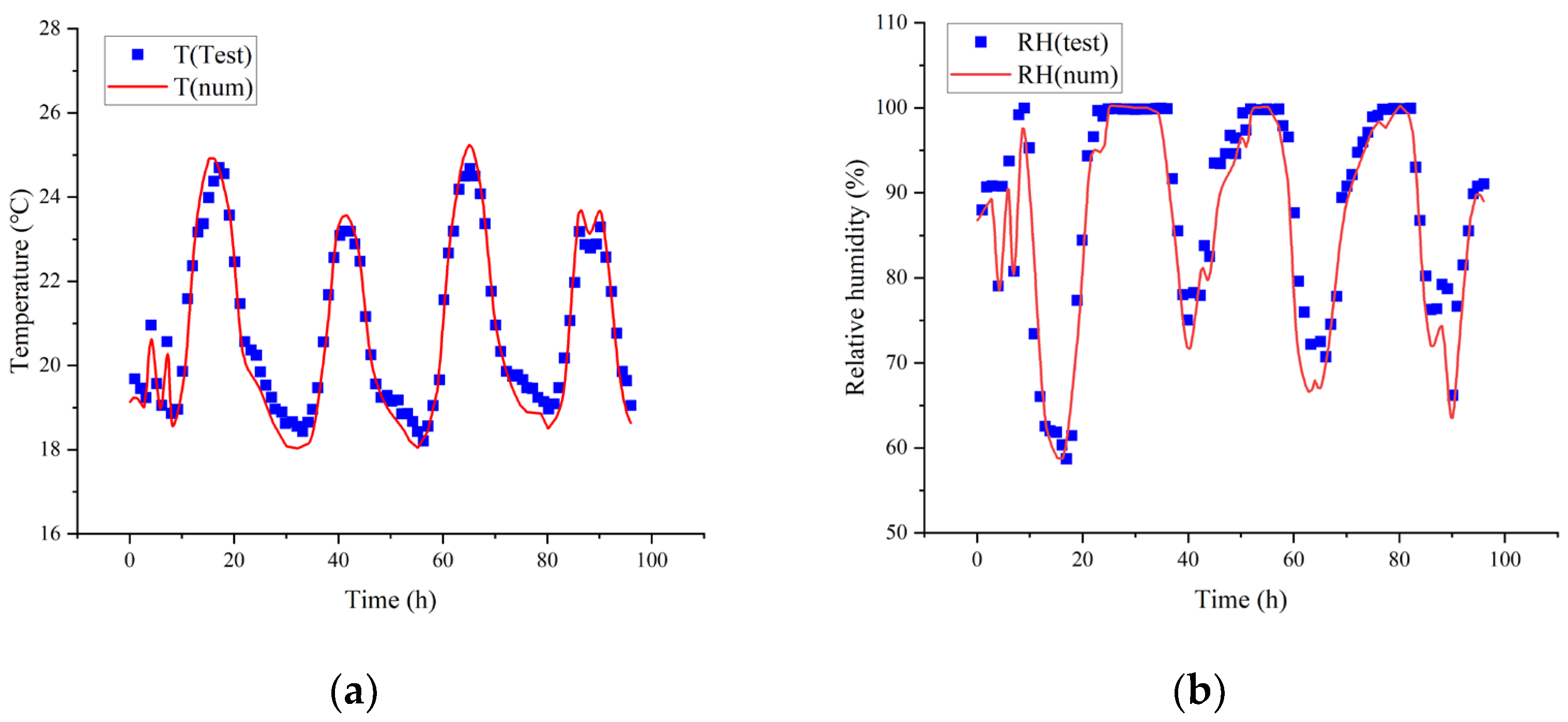

3.2. The Validation of the Numerical Model

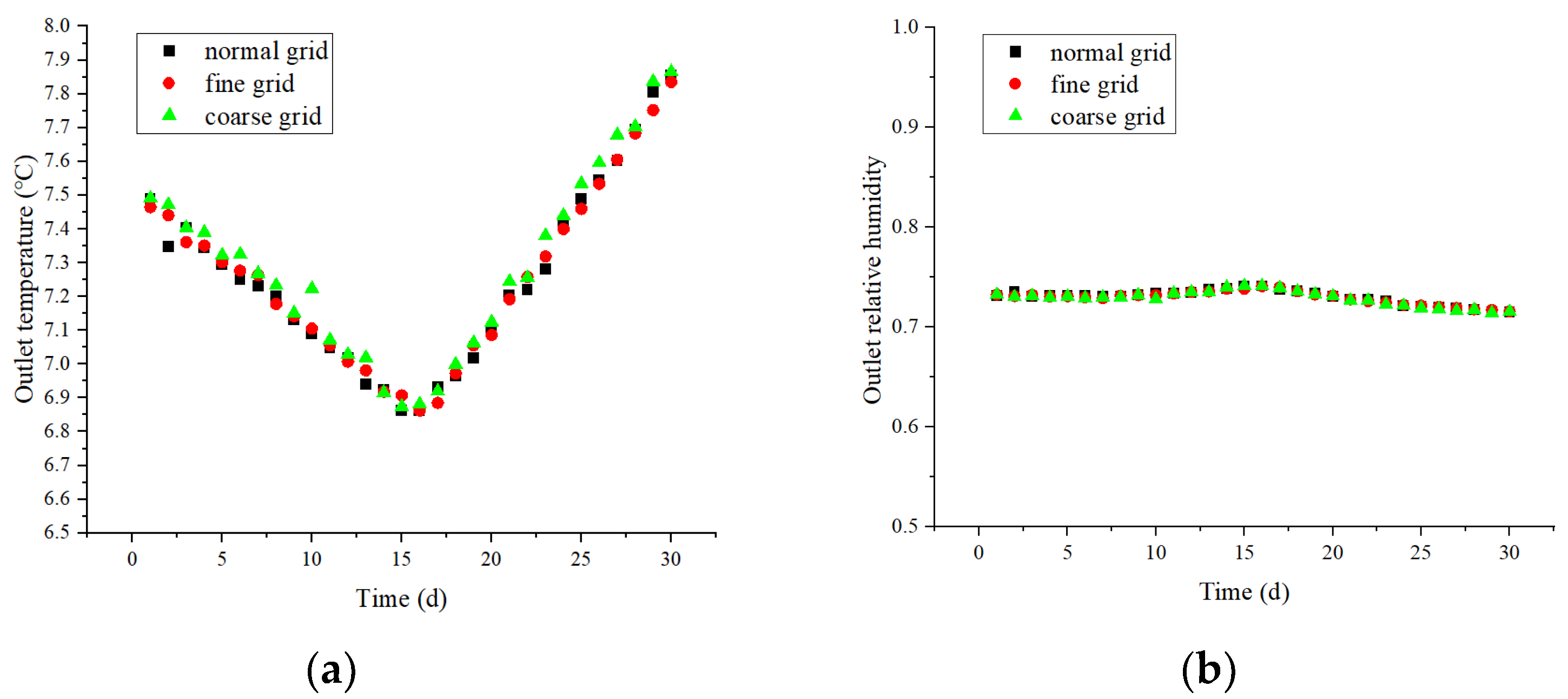

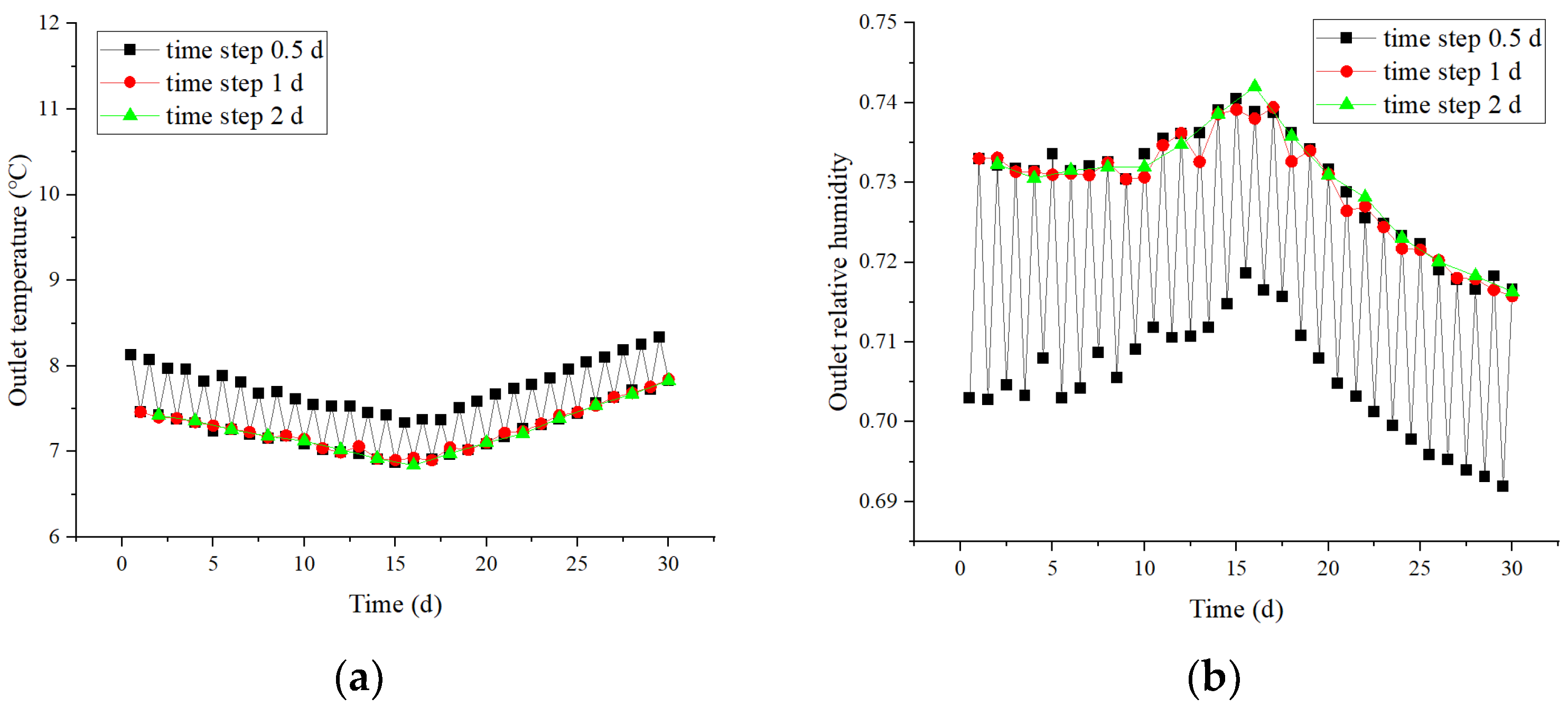

3.3. The Validation of the Grid and Time Step Independence

4. Results and Discussion

4.1. Heat–Moisture Coupled Transfer Characteristics of Underground Air Tunnels

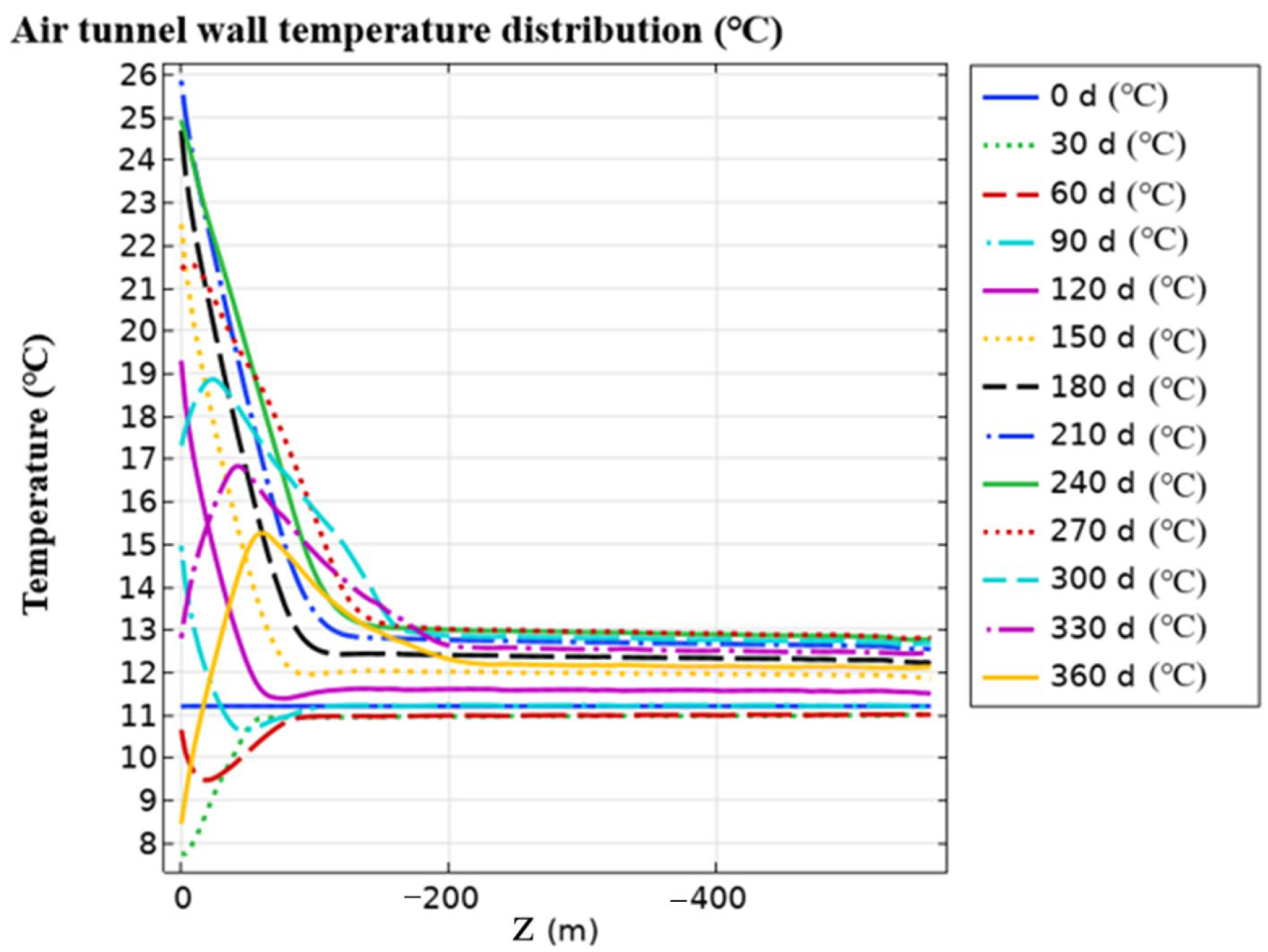

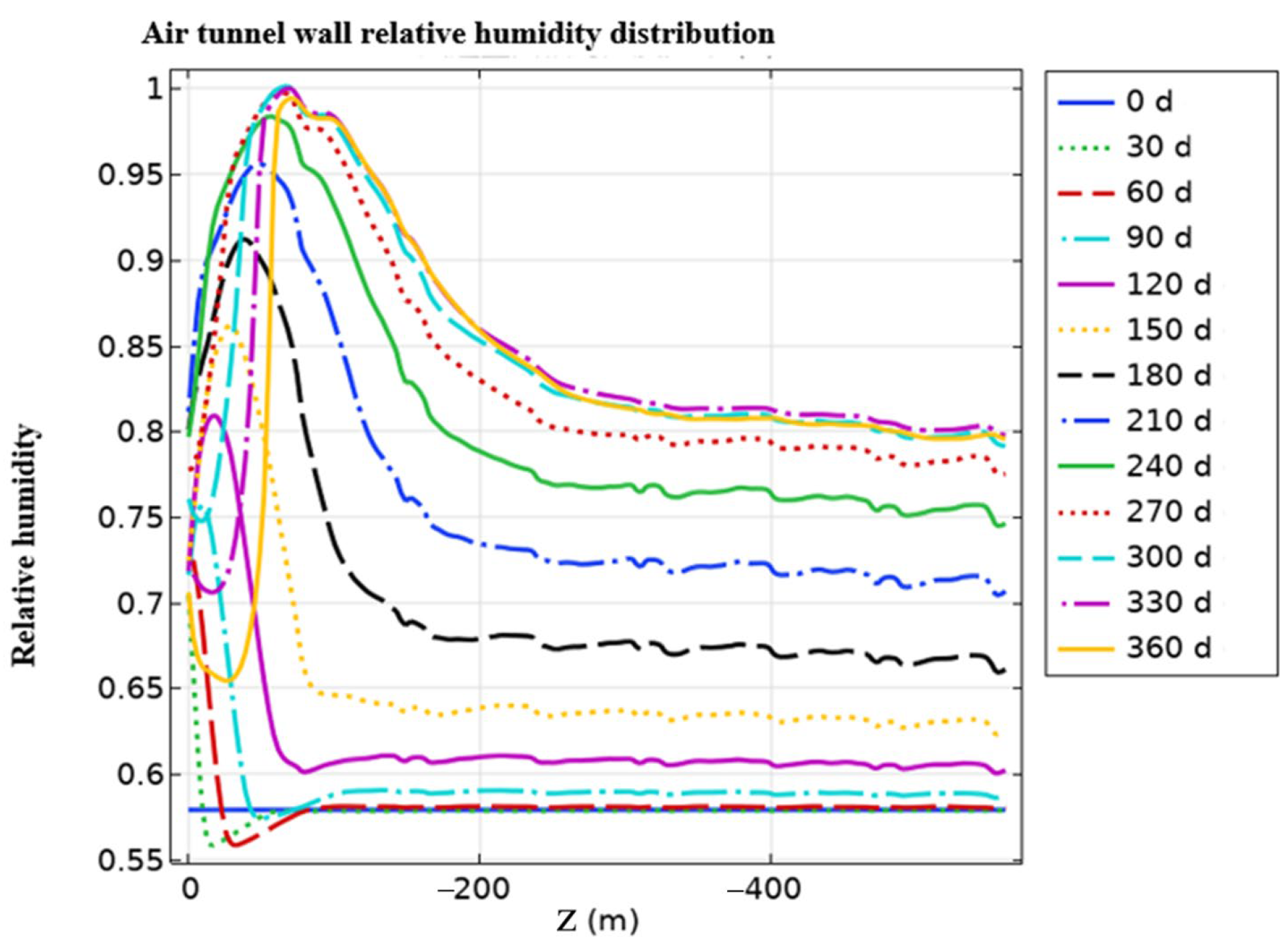

4.1.1. Variation in Heat and Humid Characteristics of the Tunnel Surface

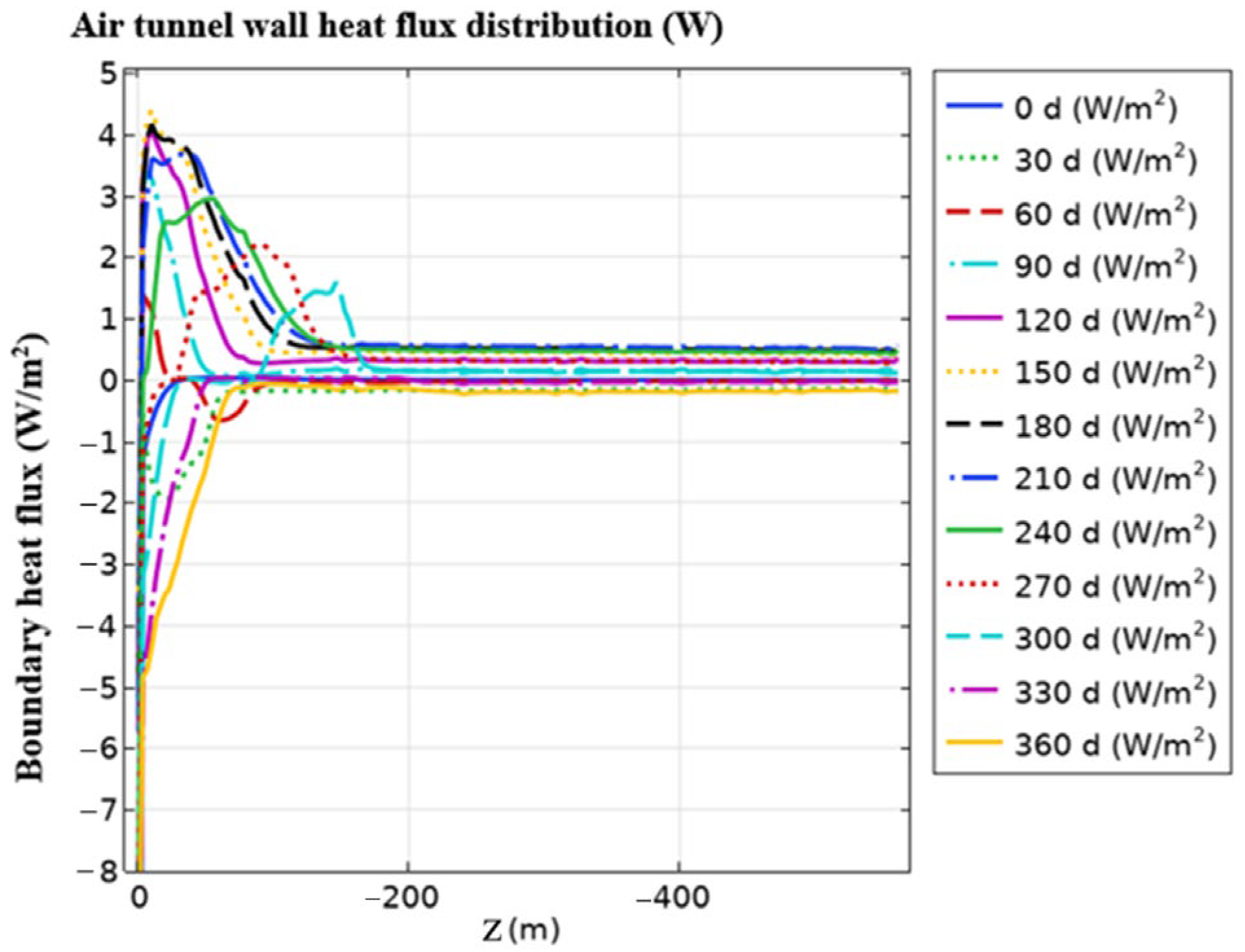

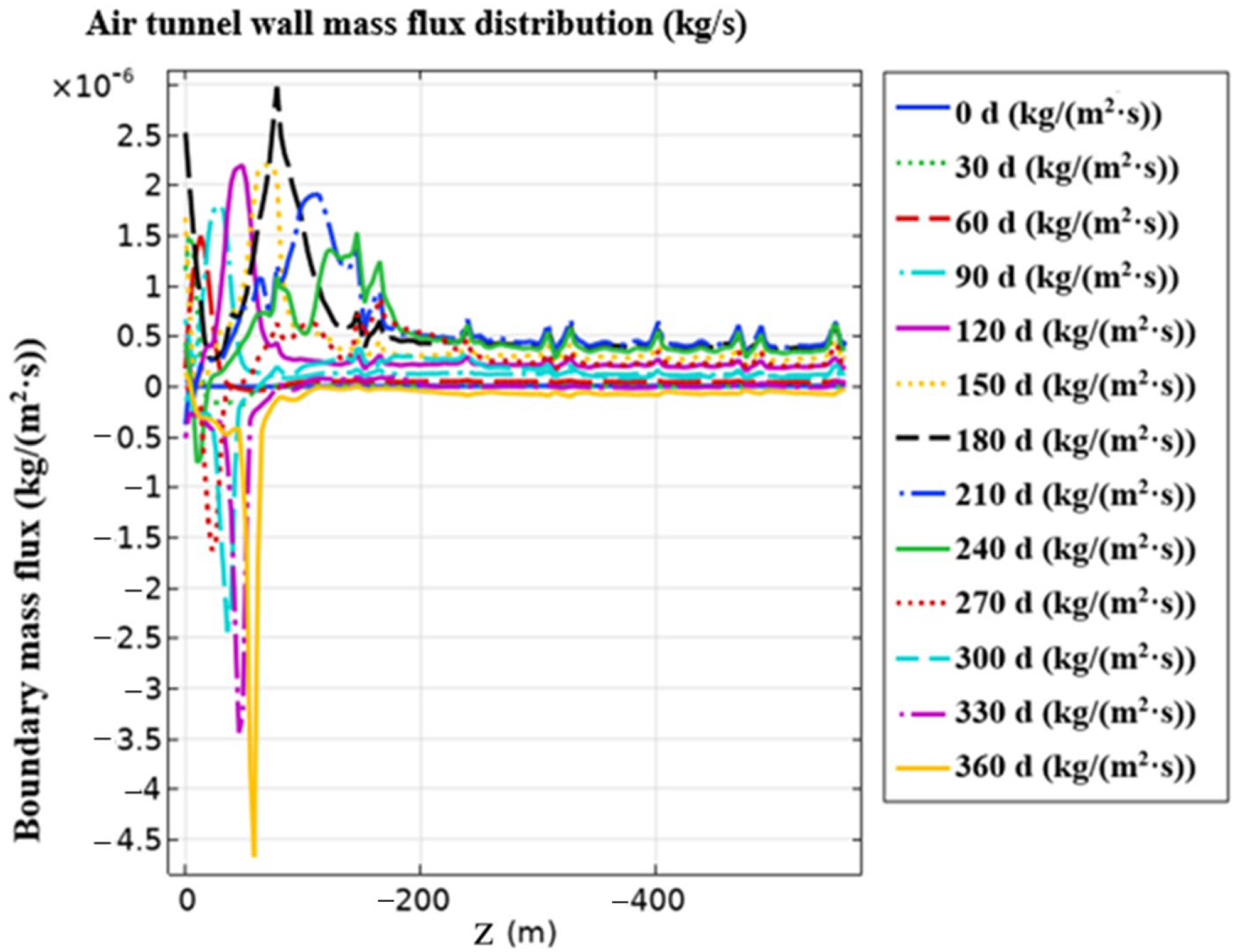

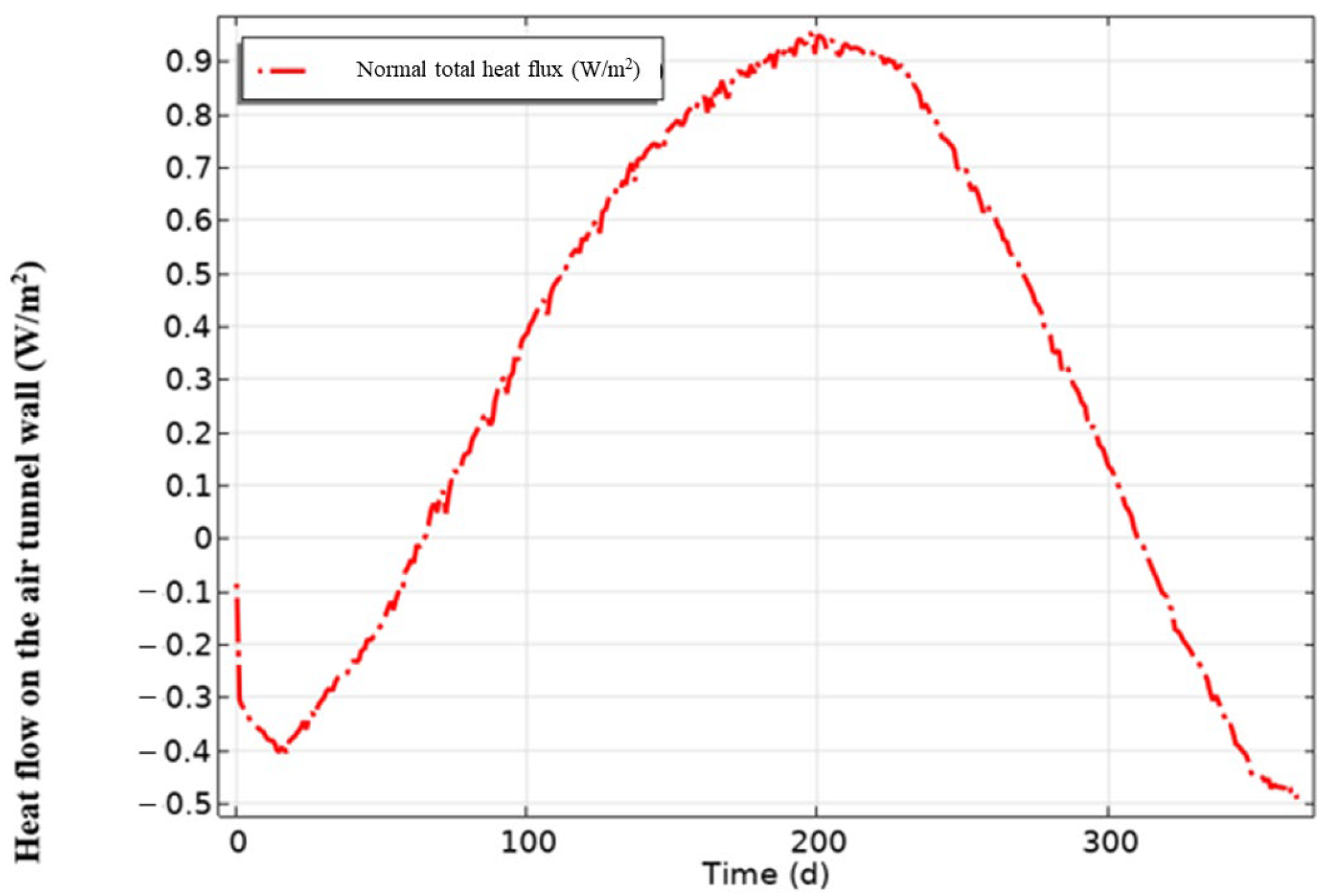

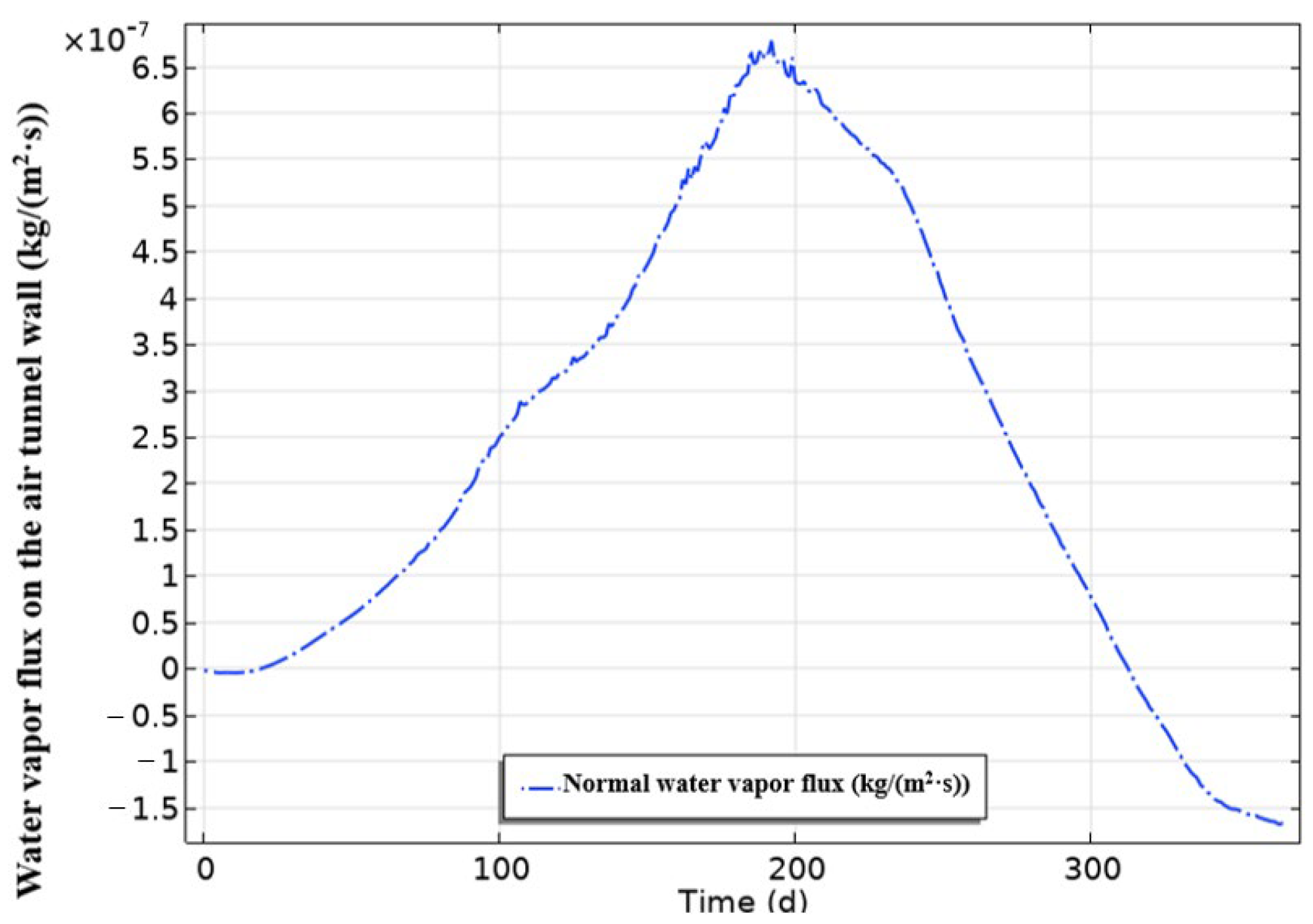

4.1.2. Variation in Heat and Moisture Flux of the Tunnel Wall Surface

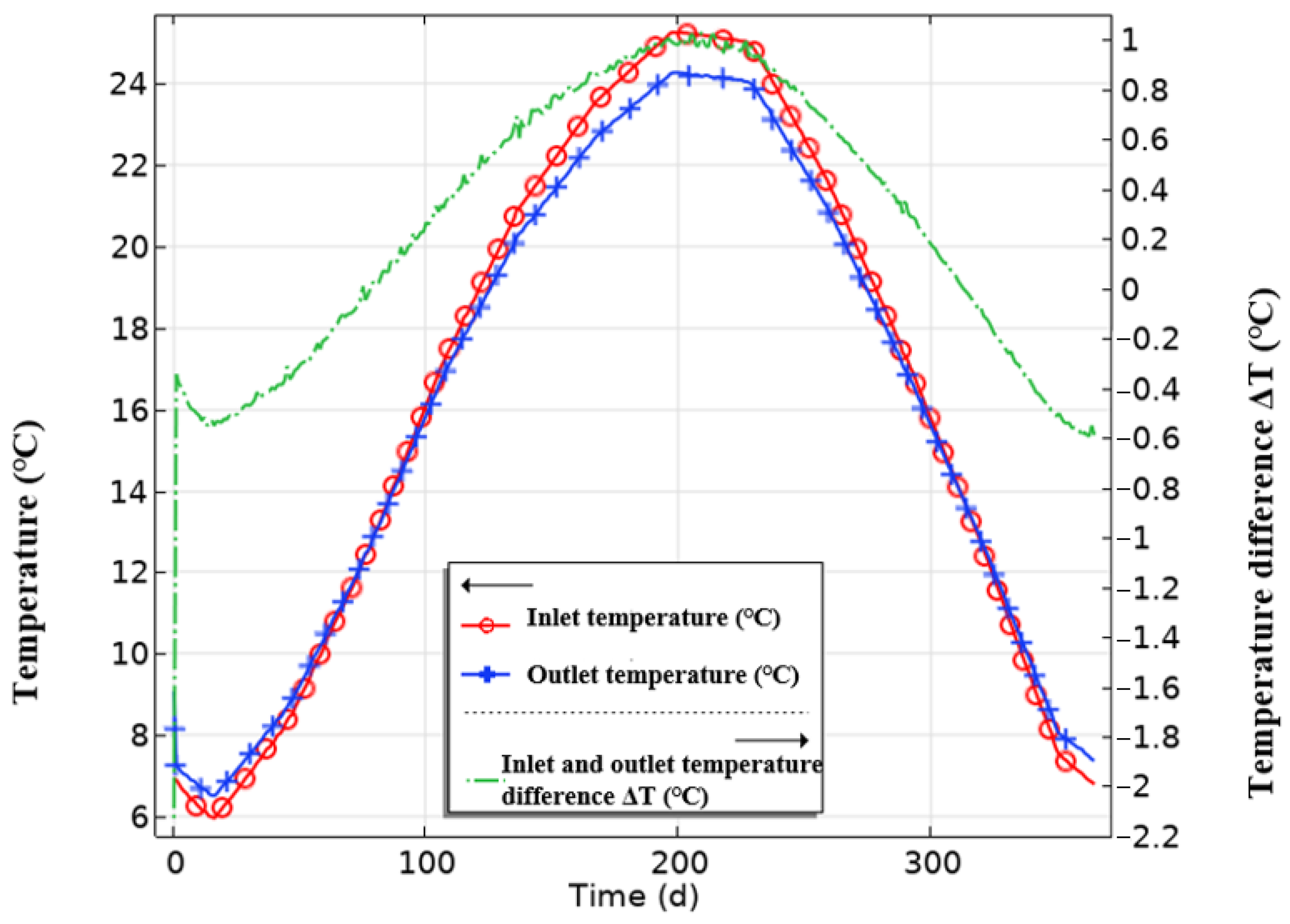

4.1.3. Heat–Moisture Coupled Transfer Characteristics of Airflow

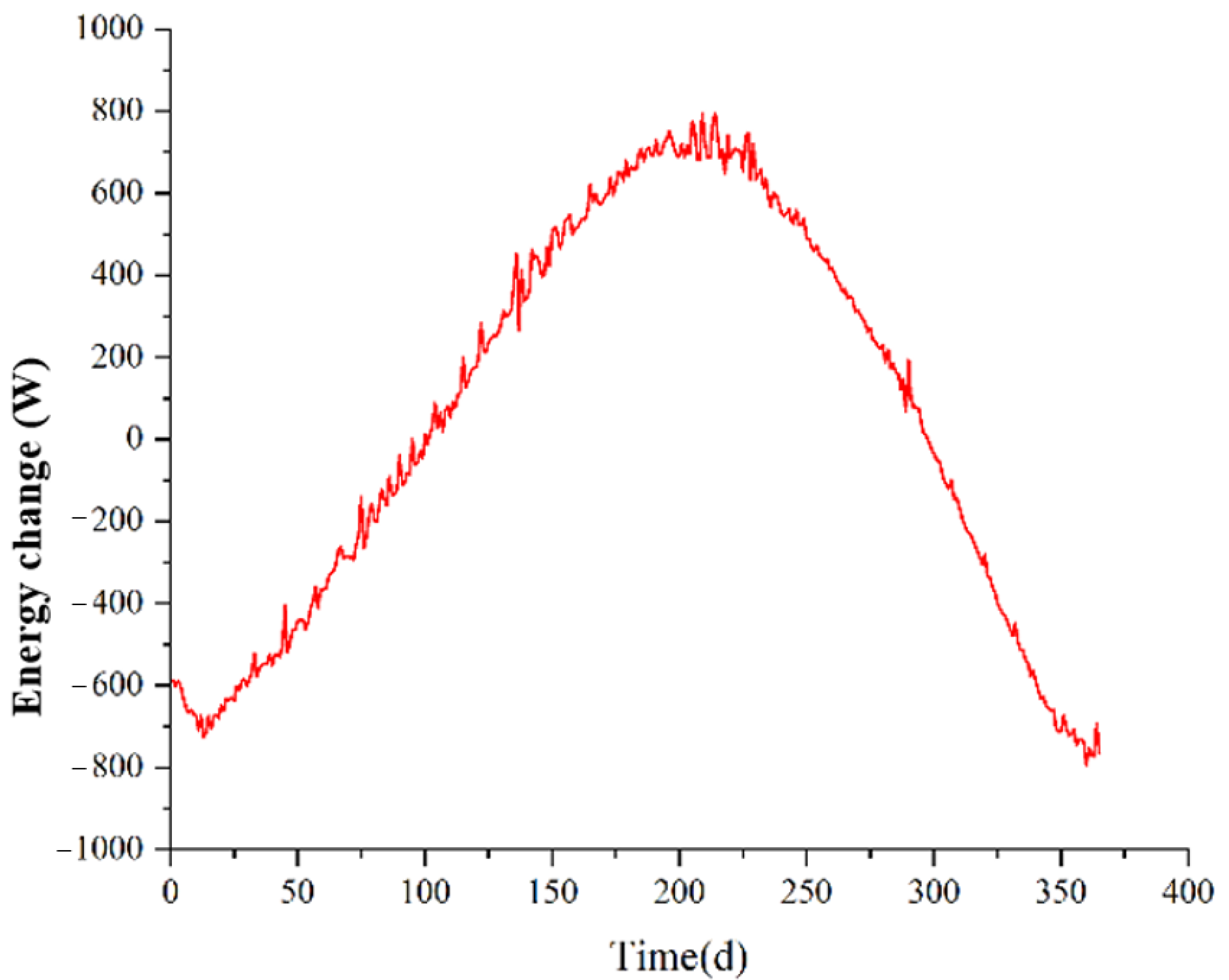

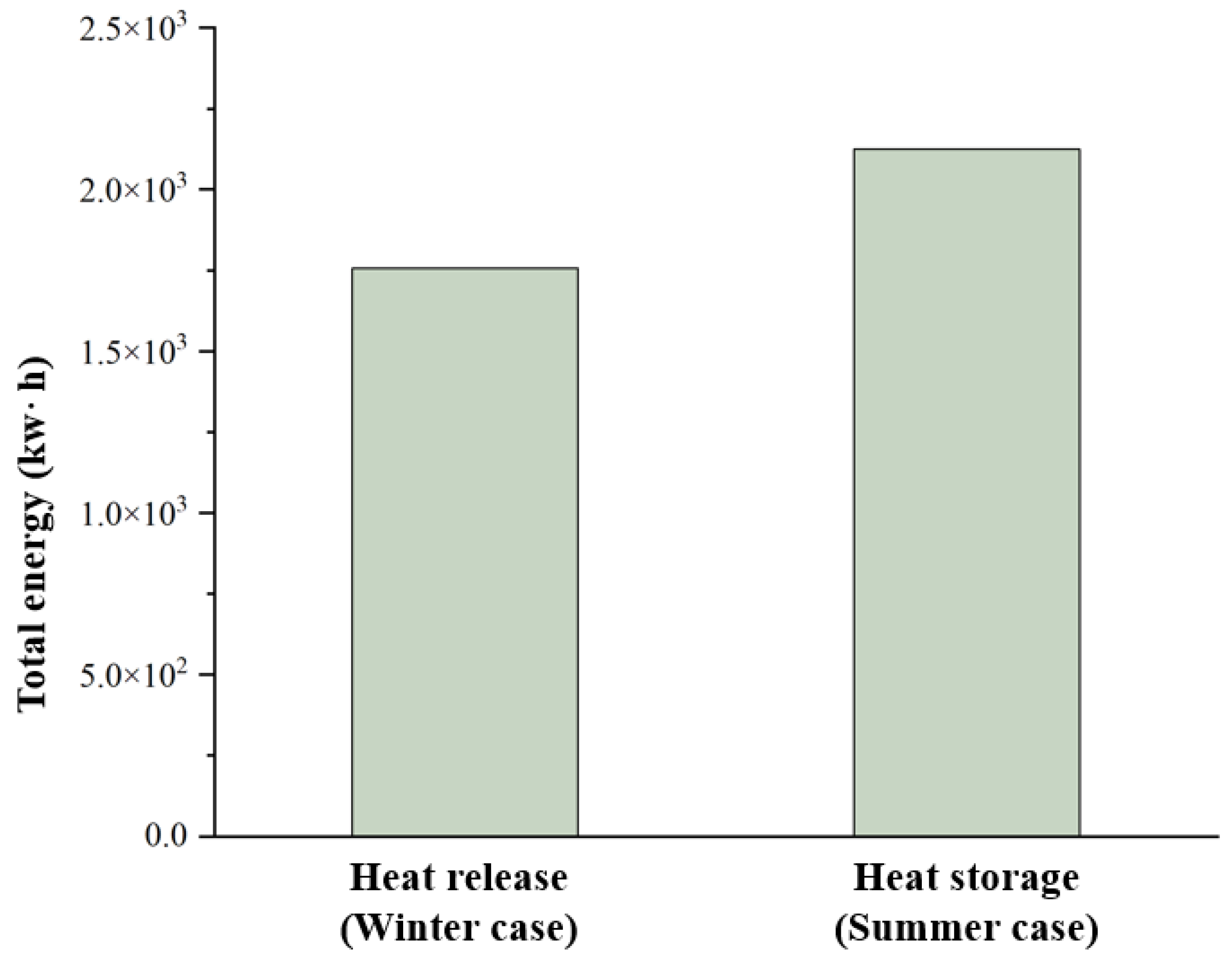

4.1.4. Energy Storage of the Air Tunnel Surroundings

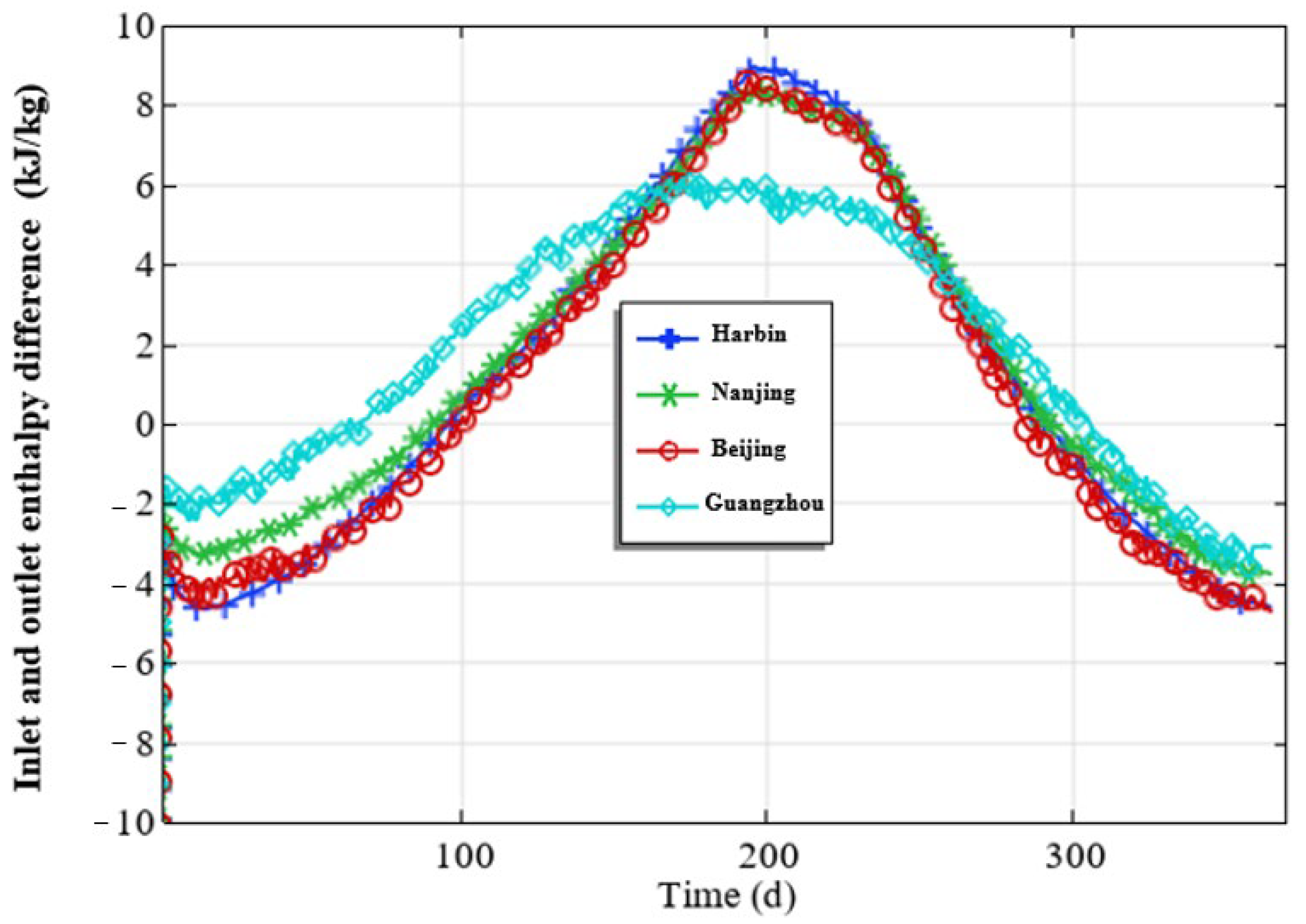

4.2. The Ventilation Characteristics of Underground Air Tunnels in Cities of Different Climate Zones of China

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| The specific heat capacity of water vapor, | |

| The specific heat capacity of liquid water, | |

| The specific heat capacity of solid materials, | |

| The concentration of water vapor in the airflow, | |

| The diffusion coefficient, | |

| The diffusion coefficient of liquid water, | |

| The mass transfer coefficient caused by the relative humidity gradient, | |

| The mass transfer coefficient caused by temperature gradient, | |

| The moisture source, | |

| The convective heat transfer coefficient, | |

| The liquid water transfer, | |

| The water vapor transfer, | |

| The permeability of liquid water, | |

| The latent heat of evaporation, | |

| The relative molecular mass, | |

| The saturation vapor pressure, | |

| The vapor pressure, | |

| The heat flow, | |

| The heat source, | |

| The diameter, | |

| Gas constant of water vapor, | |

| The capillary pressure, | |

| The temperature, | |

| The wall temperature, | |

| The density of surrounding rock, | |

| The density of liquid water, | |

| The relative humidity | |

| The water vapor permeability coefficient, | |

| The effective thermal conductivity, | |

| Airflow velocity, | |

| Moisture content, | |

| Time, |

References

- Underground Space Branch of the Chinese Society of Rock Mechanics and Engineering. White Paper on the Development of Urban Underground Space in China (2014); Tongji University Press: Shanghai, China, 2015. (In Chinese) [Google Scholar]

- Ghosal, M.K.; Tiwari, G.N.; Srivastava, N.S.L. Thermal modeling of a greenhouse with an integrated earth to air heat exchanger: An experimental validation. Energy Build. 2004, 36, 219–227. [Google Scholar] [CrossRef]

- Ozgener, O.; Ozgener, L. Determining the optimal design of a closed loop earth to air heat exchanger for greenhouse heating by using exergoeconomics. Energy Build. 2011, 43, 960–965. [Google Scholar] [CrossRef]

- Yu, J.; Kang, Y.; Zhai, Z. Advances in research for underground buildings: Energy, thermal comfort and indoor air quality. Energy Build. 2020, 215, 109916. [Google Scholar] [CrossRef]

- Gao, X.; Qu, Y.; Xiao, Y. A numerical method for cooling and dehumidifying process of air flowing through a deeply buried underground tunnel with unsaturated condensation model. Appl. Therm. Eng. 2019, 159, 113891. [Google Scholar] [CrossRef]

- Gao, X.; Zhang, Z.; Xiao, Y. Modelling and thermo-hygrometric performance study of an underground chamber with a long vertical earth-air heat exchanger system. Appl. Therm. Eng. 2020, 180, 115773. [Google Scholar] [CrossRef]

- Al-Ajmi, F.; Loveday, D.; Hanby, V. The cooling potential of earth-air heat exchangers for domestic buildings in a desert climate. Build. Environ. 2006, 41, 235–244. [Google Scholar] [CrossRef]

- Liu, Z.; Yu, Z.; Yang, T.; Roccamena, L.; Sun, P.; Li, S.; Zhang, G.; El Mankibi, M. Numerical modeling and parametric study of a vertical earth-to-air heat exchanger system. Energy 2019, 172, 220–231. [Google Scholar] [CrossRef]

- De la Rocha Camba, E.; Petrakopoulou, F. Earth-Cooling Air Tunnels for Thermal Power Plants: Initial Design by CFD Modelling. Energies 2020, 13, 797. [Google Scholar] [CrossRef]

- Wang, Y.; Tian, Y.; Zhao, Z.; Wang, D.; Liu, Y.; Liu, J. Effect of Moisture Transfer on Heat Transfer through Exterior Corners of Cooled Buildings in Hot and Humid Areas. J. Build. Eng. 2021, 43, 103160. [Google Scholar] [CrossRef]

- Tariku, F.; Kumaran, K.; Fazio, P. Transient Model for Coupled Heat, Air and Moisture Transfer through Multilayered Porous Media. Int. J. Heat Mass Transf. 2010, 53, 3035–3044. [Google Scholar] [CrossRef]

- Liu, Y. Research on the Heat Sink of Subway Tunnel—Heat Sink Effects Caused by the Periodic Change of the Ambient Temperature. J. Railway Eng. Soc. 2018, 35, 92–96. (In Chinese) [Google Scholar]

- Qin, Y.; Wang, H.; Guo, K.; Xue, P.; Wang, J.; Wu, J. Simulation of finite volume method and experimental analysis for temperature field of roadway surrounding rock. J. China Coal Soc. 2017, 42, 3166–3175. (In Chinese) [Google Scholar]

- Qin, Y.; Song, H.; Wu, J.; Dong, Z.Y. Numerical analysis of temperature field of surrounding rock under periodic boundary using Finite Volume Method. J. China Coal Soc. 2015, 40, 1541–1549. (In Chinese) [Google Scholar]

- Wang, L.; Zou, X.; Tao, H.; Song, J.; Zheng, Y. Experimental Study on Evolution Characteristics of the Heat Storage of Surrounding Soil in Subway Tunnels. Procedia Eng. 2017, 205, 2728–2735. [Google Scholar] [CrossRef]

- Liu, X.; Xiao, Y.; Inthavong, K.; Tu, J. A Fast and Simple Numerical Model for a Deeply Buried Underground Tunnel in Heating and Cooling Applications. Appl. Therm. Eng. 2014, 62, 545–552. [Google Scholar] [CrossRef]

- Liu, X.C. Formation Mechanism of Heat and Moisture Environment in Underground Hydropower Station and Its Energy-Saving Control Strategy. Ph.D. Thesis, Chongqing University, Chongqing, China, 2014. (In Chinese). [Google Scholar]

- Zhang, H.L. Study on the Thermal and Humid Environment in Hydroelectric Station Underground Plants. Ph.D. Thesis, Chongqing University, Chongqing, China, 2007. (In Chinese). [Google Scholar]

- Xiang, N. The Study of Measuring Method for Moisture Absorption and Discharge of Concrete Structures in Underground Hydropower Station. Ph.D. Thesis, Chongqing University, Chongqing, China, 2013. (In Chinese). [Google Scholar]

- Liu, Y.; Xiao, Y.; Chen, J.; Augenbroe, G.; Zhou, T. A network model for natural ventilation simulation in deep buried underground structures. Build. Environ. 2019, 153, 288–301. [Google Scholar] [CrossRef]

- Zeng, C. Research on the Performance of Water-Phase Change Material Tank Auxiliary Ground Source Heat Pump System in Underground Shelter. Ph.D. Thesis, Southwest Jiaotong University, Chengdu, China, 2021. (In Chinese). [Google Scholar]

| Volumetric Moisture Content (kg/m3) | Thermal Conductivity (W/(m·K)) | Water Vapor Permeability Coefficient (kg/(m·s·Pa)) | Liquid Water Transfer Coefficient (kg/(m·s·Pa)) |

|---|---|---|---|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, J.; Zhou, X.; Huang, L.; Deng, B.; He, L.; Cao, X.; Qiu, S. Study on Energy-Saving Potential Based on Heat and Moisture Transfer Characteristics During Fresh Air Introduction in Deep Underground Engineering. Energies 2025, 18, 5684. https://doi.org/10.3390/en18215684

Ma J, Zhou X, Huang L, Deng B, He L, Cao X, Qiu S. Study on Energy-Saving Potential Based on Heat and Moisture Transfer Characteristics During Fresh Air Introduction in Deep Underground Engineering. Energies. 2025; 18(21):5684. https://doi.org/10.3390/en18215684

Chicago/Turabian StyleMa, Jiangyan, Xu Zhou, Lin Huang, Baoshun Deng, Lei He, Xiaoling Cao, and Shuang Qiu. 2025. "Study on Energy-Saving Potential Based on Heat and Moisture Transfer Characteristics During Fresh Air Introduction in Deep Underground Engineering" Energies 18, no. 21: 5684. https://doi.org/10.3390/en18215684

APA StyleMa, J., Zhou, X., Huang, L., Deng, B., He, L., Cao, X., & Qiu, S. (2025). Study on Energy-Saving Potential Based on Heat and Moisture Transfer Characteristics During Fresh Air Introduction in Deep Underground Engineering. Energies, 18(21), 5684. https://doi.org/10.3390/en18215684