An Experimental Study on the Effects of Pre-Chamber Geometry on the Combustion Characteristics of Ammonia/Air Mixtures Using Turbulent Jet-Post Spark Ignition Strategy

Abstract

1. Introduction

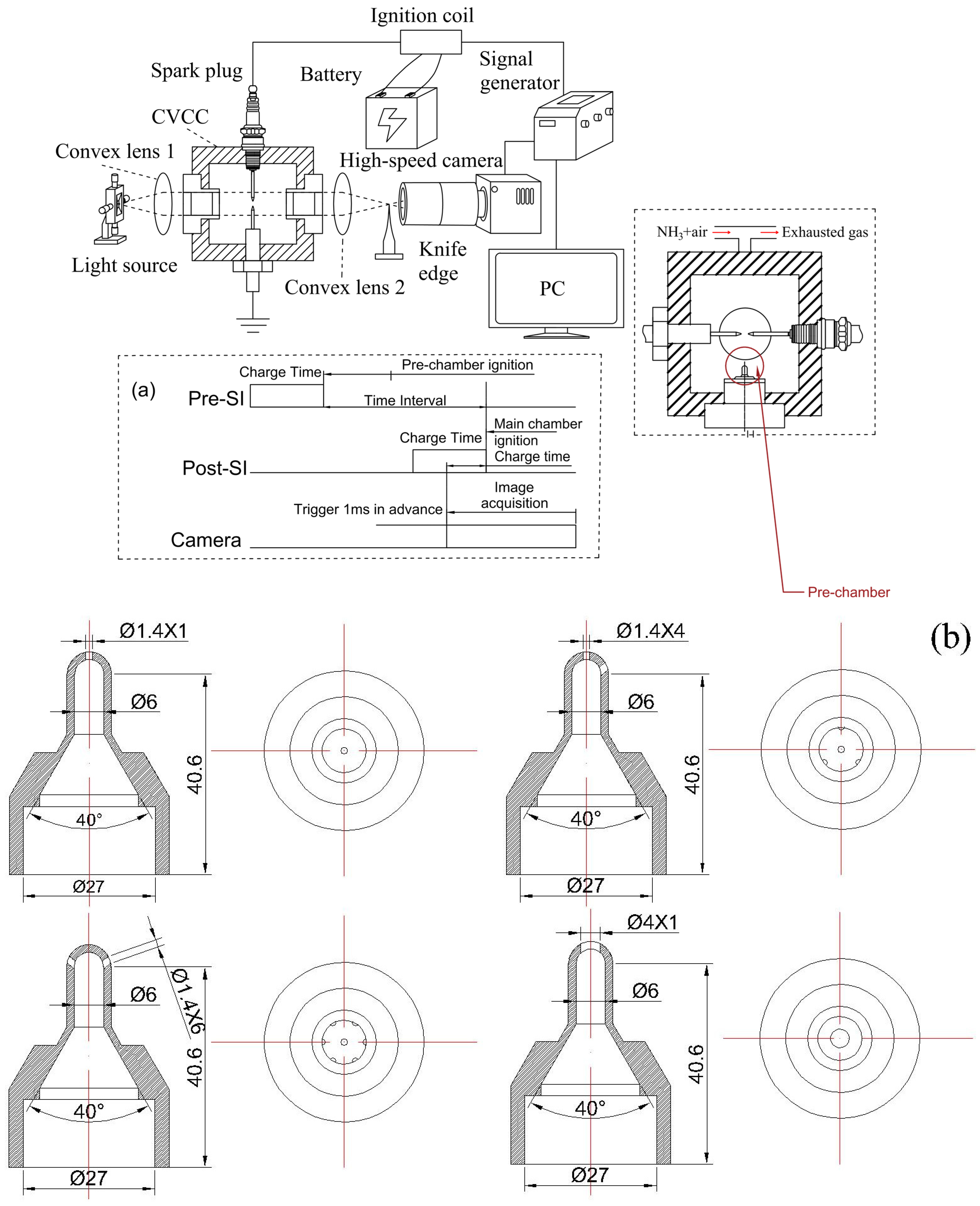

2. Experimental Setup

3. Heat Release Calculation

4. Results and Discussions

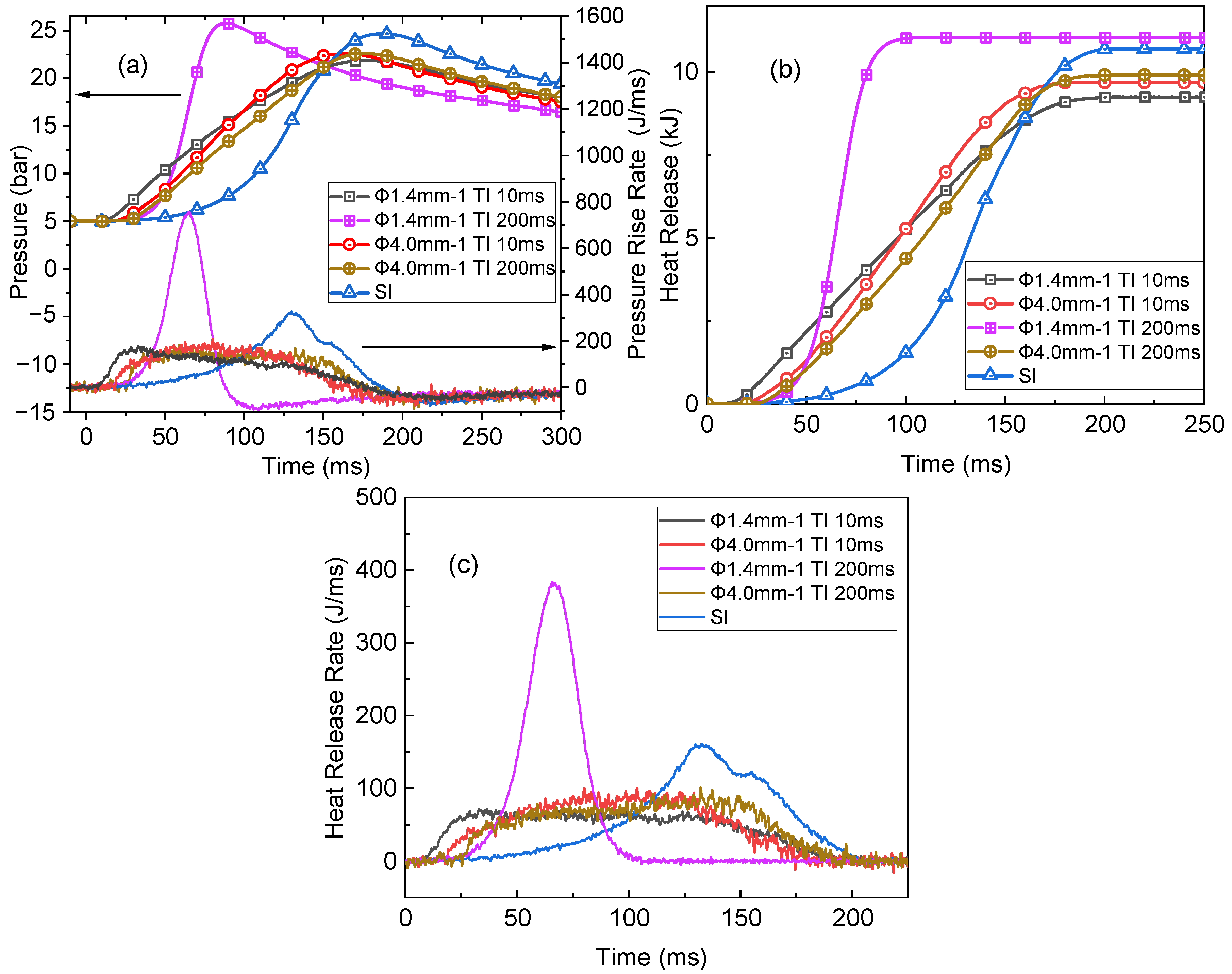

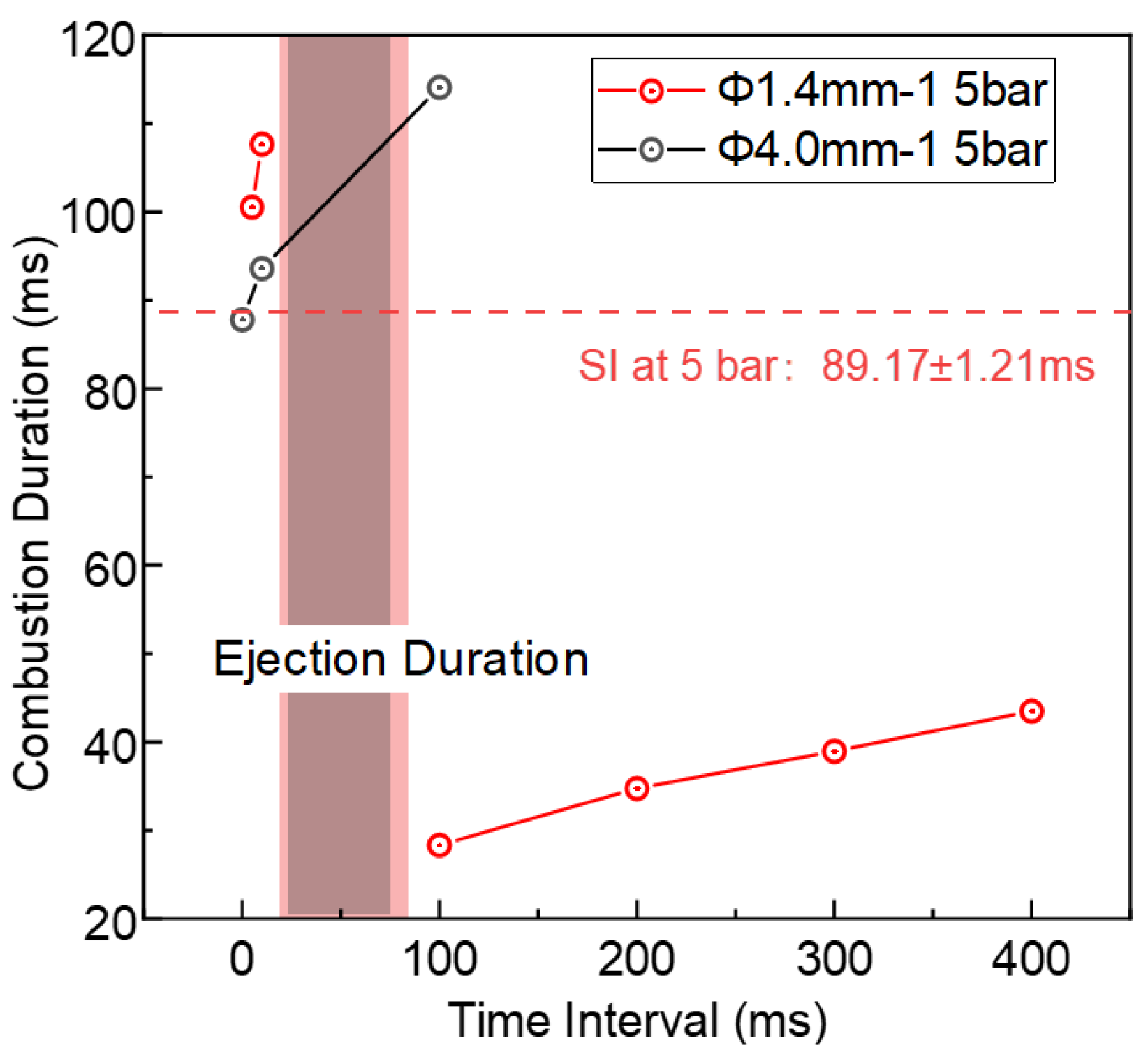

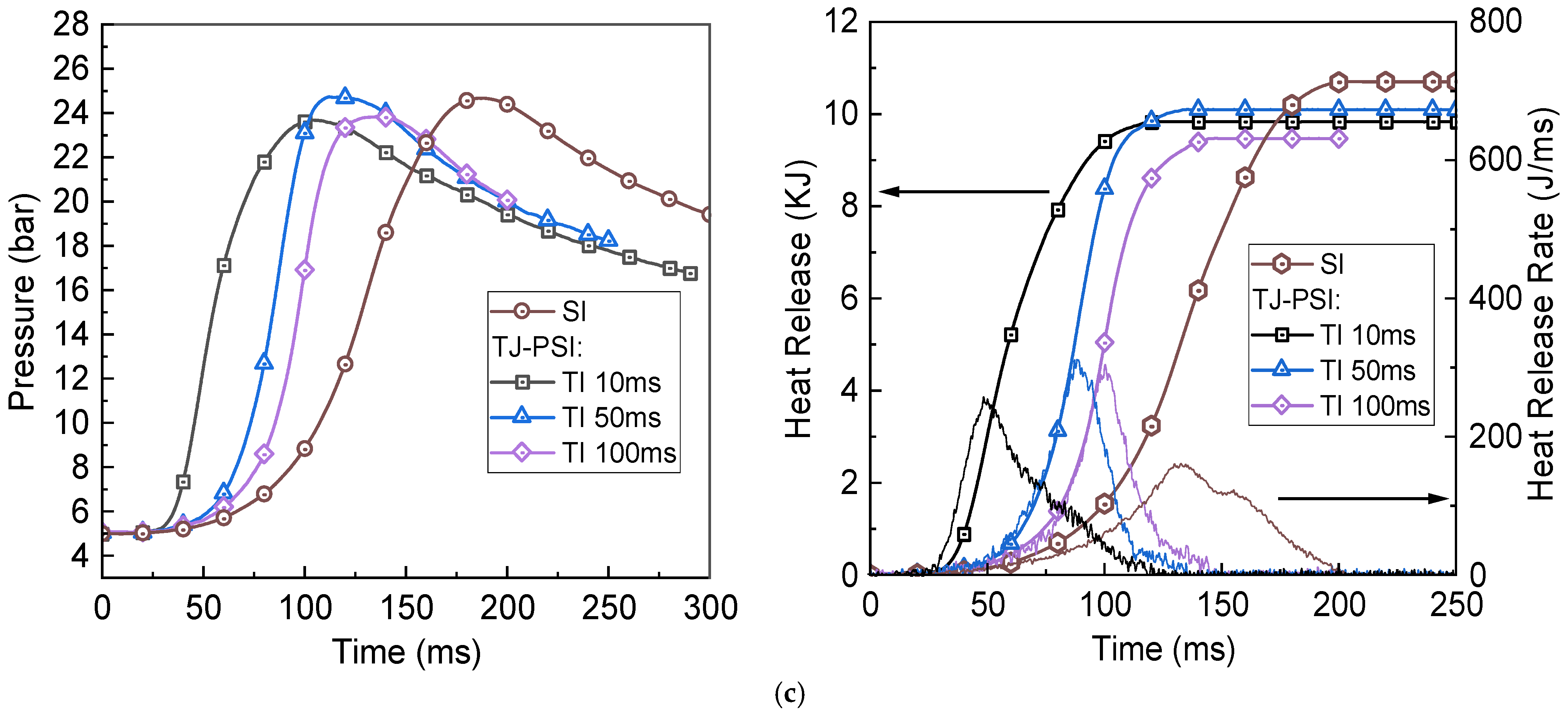

4.1. The Influence of Pre-Chamber Orifice Diameter on the Combustion Characteristics of TJ-PSI Strategy

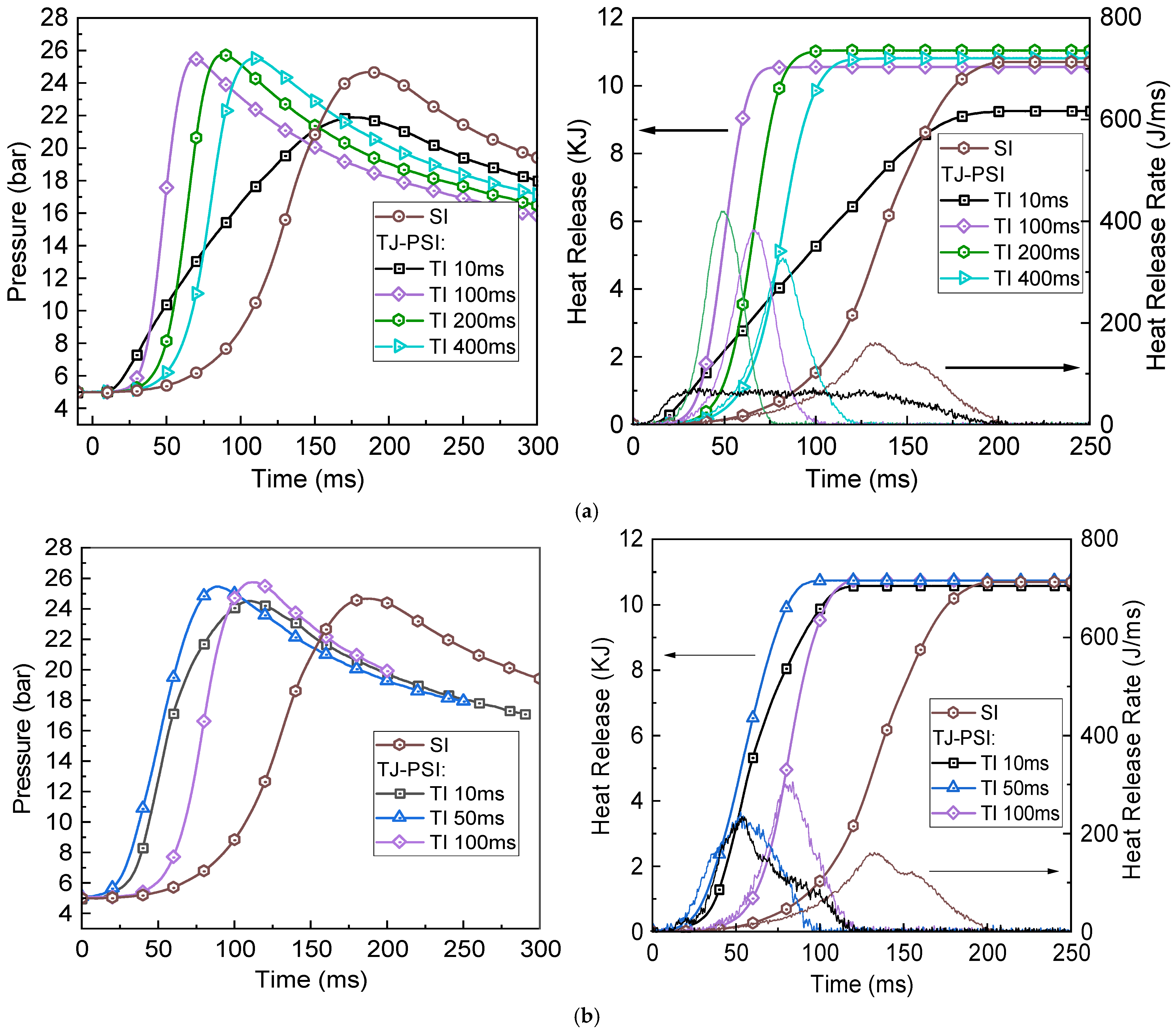

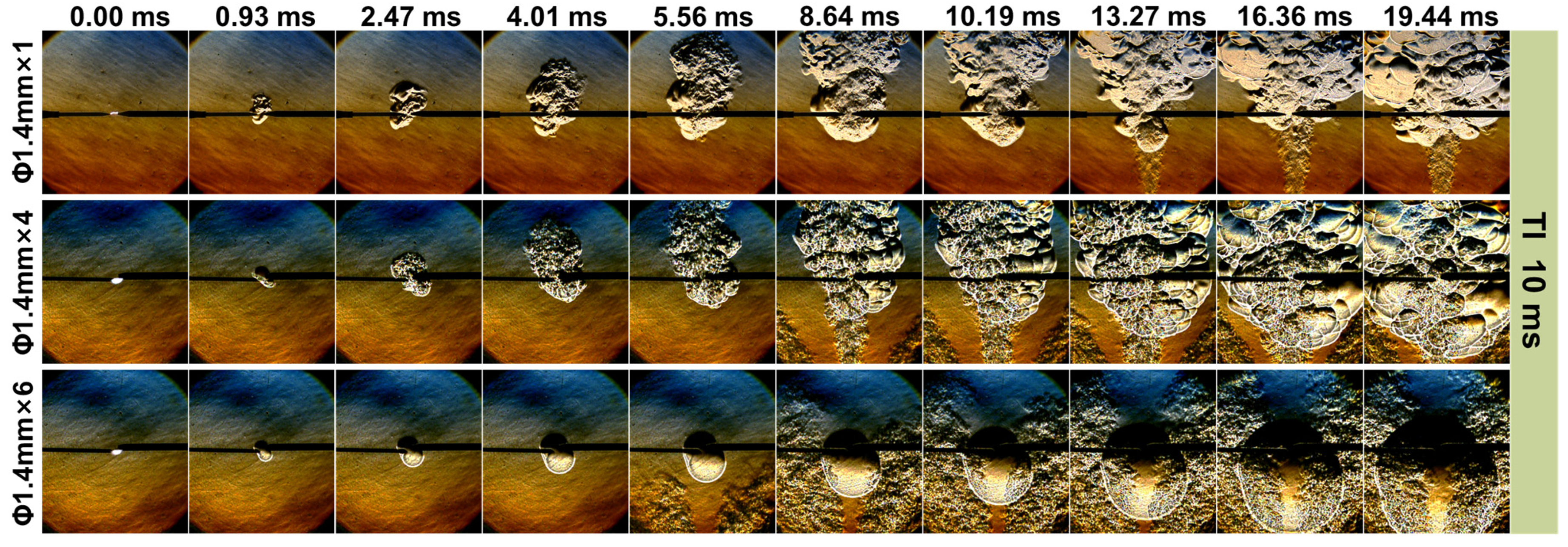

4.2. The Influence of Pre-Chamber Orifice Number on the Combustion Characteristics of TJ-PSI Strategy

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| TJ-PSI | Turbulent Jet-post Spark Ignition |

| TI | Time Interval |

| TJI | Turbulent Jet Ignition |

| SI | Spark Ignition |

| CVV | Constant Volume Vessel |

| dQ | heat release rate |

| φ | Pre-mixed gas fuel-air equivalence ratio |

| T0 | Initial temperature |

| P0 | Initial pressure |

References

- Valera-Medina, A.; Amer-Hatem, F.; Azad, A.K.; Dedoussi, I.C.; De Joannon, M.; Fernandes, R.X.; Glarborg, P.; Hashemi, H.; He, X.; Mashruk, S.; et al. Review on Ammonia as a Potential Fuel: From Synthesis to Economics. Energy Fuels 2021, 35, 6964–7029. [Google Scholar] [CrossRef]

- Kumar, P.; Meyer, T.R. Experimental and Modeling Study of Chemical-Kinetics Mechanisms for H2-NH3-Air Mixtures in Laminar Premixed Jet Flames. Fuel 2013, 108, 166–176. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, T.; Chen, R.; Wang, N.; Wei, Y.; Wu, D. Injection Characteristics and Fuel-Air Mixing Process of Ammonia Jets in a Constant Volume Vessel. Fuel 2021, 304, 121408. [Google Scholar] [CrossRef]

- Ryu, K.; Zacharakis-Jutz, G.E.; Kong, S.C. Effects of Gaseous Ammonia Direct Injection on Performance Characteristics of a Spark-Ignition Engine. Appl. Energy 2014, 116, 206–215. [Google Scholar] [CrossRef]

- Dimitriou, P.; Javaid, R. A Review of Ammonia as a Compression Ignition Engine Fuel. Int. J. Hydrogen Energy 2020, 45, 7098–7118. [Google Scholar] [CrossRef]

- Berwal, P.; Kumar, S.; Khandelwal, B. A Comprehensive Review on Synthesis, Chemical Kinetics, and Practical Application of Ammonia as Future Fuel for Combustion. J. Energy Inst. 2021, 99, 273–298. [Google Scholar] [CrossRef]

- Kurien, C.; Mittal, M. Review on the Production and Utilization of Green Ammonia as an Alternate Fuel in Dual-Fuel Compression Ignition Engines. Energy Convers. Manag. 2022, 251, 114990. [Google Scholar] [CrossRef]

- Ma, F.; Guo, L.; Li, Z.; Zeng, X.; Zheng, Z.; Li, W.; Zhao, F.; Yu, W. A Review of Current Advances in Ammonia Combustion from the Fundamentals to Applications in Internal Combustion Engines. Energies 2023, 16, 6304. [Google Scholar] [CrossRef]

- Tornatore, C.; Marchitto, L.; Sabia, P.; De Joannon, M. Ammonia as Green Fuel in Internal Combustion Engines: State-of-the-Art and Future Perspectives. Front. Mech. Eng. 2022, 8, 944201. [Google Scholar] [CrossRef]

- Zhao, Z.; Qi, Y.; Cai, K. Research on the combustion mechanism of plasma-induced ammonia-hydrogen jet ignition engine. Int. J. Hydrogen Energy 2024, 65, 398–409. [Google Scholar] [CrossRef]

- D’Antuono, G.; Lanni, D.; Galloni, E.; Fontana, G. Numerical Analysis of the Combustion Process in a Pre-Chamber Marine Engine Fueled with Ammonia-Hydrogen Mixtures. In Proceedings of the 17th International Conference on Engines and Vehicles, Capri, Italy, 14–17 September 2025; SAE Technical Paper, No. 2025-24-0021. SAE: Warrendale, PA, USA, 2025. [Google Scholar] [CrossRef]

- Yang, X.; Li, G.; Wang, P.; Cheng, Y.; Zhao, Y. Numerical Investigation of the Operating Characteristics of the Passive and Active Prechamber Jet Ignition in a Natural Gas Engine. ACS Omega 2024, 9, 31933–31945. [Google Scholar] [CrossRef]

- Rajasegar, R.; Niki, Y.; García-Oliver, J.M.; Li, Z.; Musculus, M.P.B. Fundamental Insights on Ignition and Combustion of Natural Gas in an Active Fueled Pre-Chamber Spark-Ignition System. Combust. Flame 2021, 232, 111561. [Google Scholar] [CrossRef]

- Qiang, Y.; Jin, K.; Zhao, S.; Cai, J.; Su, F.; Wang, S.; Ji, C. Optimization of Power Performance and Combustion Stability of Ultra-Lean Combustion in Hydrogen Fuel Engines through Combined Turbulent Jet Ignition and Variable Valve Timing. Fuel 2025, 381, 133493. [Google Scholar] [CrossRef]

- Zhu, S.; Akehurst, S.; Lewis, A.; Yuan, H. A Review of the Pre-Chamber Ignition System Applied on Future Low-Carbon Spark Ignition Engines. Renew. Sustain. Energy Rev. 2022, 154, 111872. [Google Scholar] [CrossRef]

- Biswas, S.; Tanvir, S.; Wang, H.; Qiao, L. On Ignition Mechanisms of Premixed CH4/Air and H2/Air Using a Hot Turbulent Jet Generated by Pre-Chamber Combustion. Appl. Therm. Eng. 2016, 106, 925–937. [Google Scholar] [CrossRef]

- Wu, H.; Li, R.; Dong, S.; Deman, Z.; Xu, J.; Wang, Z. Enhancing Ammonia Combustion Using Pre-Chamber Turbulent Jet Combined with Post Spark Ignition Strategy. Fuel 2024, 371, 131979. [Google Scholar] [CrossRef]

- Yan, B.; Waters, B.; Haines, A.; McGhee, M.; Hu, T.; Deng, W.; Pu, Y.; Ma, T. Experimental Study for Effect of Multi-Site Spark Ignition on Dedicated Hybrid Engine Performance under High Dilution Condition. J. Therm. Sci. 2024, 34, 254–267. [Google Scholar] [CrossRef]

- Feng, Z.; Zhou, L.; Liu, P.; Gao, Q.; Li, K.; Wei, H. Effect of Turbulent Jet Ignition Based on Different Pre-Chamber Structures on the Combustion Characteristics of Methane Fuel. Chin. Intern. Combust. Engine Eng. 2021, 42, 23–28, 35. [Google Scholar]

- Hua, J.; Zhou, L.; Gao, Q.; Feng, Z.; Wei, H. Influence of Pre-Chamber Structure and Injection Parameters on Engine Performance and Combustion Characteristics in a Turbulent Jet Ignition (TJI) Engine. Fuel 2021, 283, 119236. [Google Scholar] [CrossRef]

- Cui, Z.; Tian, J.; Zhang, X.; Yin, S.; Long, W.; Song, H. Experimental Study of the Effects of Pre-Chamber Geometry on the Combustion Characteristics of an Ammonia/Air Pre-Mixture Ignited by a Jet Flame. Processes 2022, 10, 2102. [Google Scholar] [CrossRef]

- Tang, Q.; Sampath, R.; Sharma, P.; Echeverri, M.; Cenker, E.; Magnotti, G. Study on the Effects of Narrow-Throat Pre-Chamber Geometry on the Pre-Chamber Jet Velocity Using Dual Formaldehyde PLIF Imaging. Combust. Flame 2022, 240, 111987. [Google Scholar] [CrossRef]

- Huang, L.; Tang, Q.; Sun, J.; Yao, M. Study on the Effects of Nozzle Layouts of the Passive Pre-Chamber on Jet and Combustion Characteristics. J. Eng. Thermophys. 2024, 45, 2531–2539. [Google Scholar]

- Wang, B.; Xie, F.; Hong, W.; Du, J.; Chen, H.; Su, Y. The Effect of Structural Parameters of Pre-Chamber with Turbulent Jet Ignition System on Combustion Characteristics of Methanol-Air Pre-Mixture. Energy Convers. Manag. 2022, 274, 116473. [Google Scholar] [CrossRef]

- Yang, J.; Xie, F.; Jiang, B.; Li, X.; Su, Y.; Zhang, H. Influence of Structure Parameters of Pre-Chamber on Lean Combustion of Active Pre-Chamber Jet Ignition Engine. Energy 2024, 304, 132053. [Google Scholar] [CrossRef]

- Xie, F.; Wang, J.; Dou, H.; Li, J.; Wang, B.; Hong, W. Influence of Structural Parameters of Pre-Combustion Chamber on the Development Characteristics of Gasoline Hot Jet. Automot. Eng. 2022, 44, 1716–1724. [Google Scholar] [CrossRef]

- Tomić, R.; Sjerić, M.; Krajnović, J.; Ugrinić, S. Influence of Pre-Chamber Volume, Orifice Diameter and Orifice Number on Performance of Pre-Chamber SI Engine—An Experimental and Numerical Study. Energies 2023, 16, 2884. [Google Scholar] [CrossRef]

- Li, F.; Zhao, Z.; Wang, Z.; Wang, B. Experimental and numerical study of a methane-fueled pre-chamber system in rapid compression machine. Combust. Sci. Technol. 2021, 193, 1463–1494. [Google Scholar] [CrossRef]

- Lapuerta, M.; Sanz-Argent, J.; Raine, R. Heat Release Determination in a Constant Volume Combustion Chamber from the Instantaneous Cylinder Pressure. Appl. Therm. Eng. 2014, 63, 520–527. [Google Scholar] [CrossRef]

- Woschni, G. A Universally Applicable Equation for the Instantaneous Heat Transfer Coefficient in the Internal Combustion Engine. SAE Trans. 1968, 76, 3065–3083. [Google Scholar] [CrossRef]

- Zhou, L.; Song, Y.; Hua, J.; Liu, F.; Liu, Z.; Wei, H. Effects of Different Hole Structures of Pre-Chamber with Turbulent Jet Ignition on the Flame Propagation and Lean Combustion Performance of a Single-Cylinder Engine. Fuel 2022, 308, 121902. [Google Scholar] [CrossRef]

- Wei, F.; Lu, M.; Long, W.; Dong, D.; Dong, P.; Xiao, G.; Tian, J.; Tian, H.; Wang, P. Optical Experiment Study on Ammonia/Methanol Mixture Combustion Performance Induced by Methanol Jet Ignition in a Constant Volume Combustion Bomb. Fuel 2023, 352, 129090. [Google Scholar] [CrossRef]

- Mueller, C.; Driscoll, J.; Reuss, D.; Drake, M. Effects of unsteady stretch on the strength of a freely-propagating flame wrinkled by a vortex. Symp. Int. Combust. 1996, 26, 347–355. [Google Scholar] [CrossRef]

- Sayama, S.; Kinoshita, M.; Mandokoro, Y.; Fuyuto, T. Spark ignition and early flame development of lean mixtures under high-velocity flow conditions: An experimental study. Int. J. Engine Res. 2019, 20, 236–246. [Google Scholar] [CrossRef]

- Mathpatii, C.S.; Tabib, M.V.; Deshpande, S.S.; Joshi, J.B. Dynamics of Flow Structures and Transport Phenomena, 2. Relationship with Design Objectives and Design Optimization. Ind. Eng. Chem. Res. 2009, 48, 8285–8311. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Y.; Zhang, X.; Cao, Y.; Zhang, J.; Li, R.; Wu, H.; Dong, S.; Wang, Z. An Experimental Study on the Effects of Pre-Chamber Geometry on the Combustion Characteristics of Ammonia/Air Mixtures Using Turbulent Jet-Post Spark Ignition Strategy. Energies 2025, 18, 5659. https://doi.org/10.3390/en18215659

Gao Y, Zhang X, Cao Y, Zhang J, Li R, Wu H, Dong S, Wang Z. An Experimental Study on the Effects of Pre-Chamber Geometry on the Combustion Characteristics of Ammonia/Air Mixtures Using Turbulent Jet-Post Spark Ignition Strategy. Energies. 2025; 18(21):5659. https://doi.org/10.3390/en18215659

Chicago/Turabian StyleGao, Yichen, Xipu Zhang, Yang Cao, Jiashen Zhang, Rongjie Li, Huimin Wu, Shijun Dong, and Zhaowen Wang. 2025. "An Experimental Study on the Effects of Pre-Chamber Geometry on the Combustion Characteristics of Ammonia/Air Mixtures Using Turbulent Jet-Post Spark Ignition Strategy" Energies 18, no. 21: 5659. https://doi.org/10.3390/en18215659

APA StyleGao, Y., Zhang, X., Cao, Y., Zhang, J., Li, R., Wu, H., Dong, S., & Wang, Z. (2025). An Experimental Study on the Effects of Pre-Chamber Geometry on the Combustion Characteristics of Ammonia/Air Mixtures Using Turbulent Jet-Post Spark Ignition Strategy. Energies, 18(21), 5659. https://doi.org/10.3390/en18215659