Photovoltaic-Thermal (PVT) Solar Collector and System Overview

Abstract

1. Introduction

2. Fundamentals of PVT Systems

3. Performance and Cooling Mechanisms

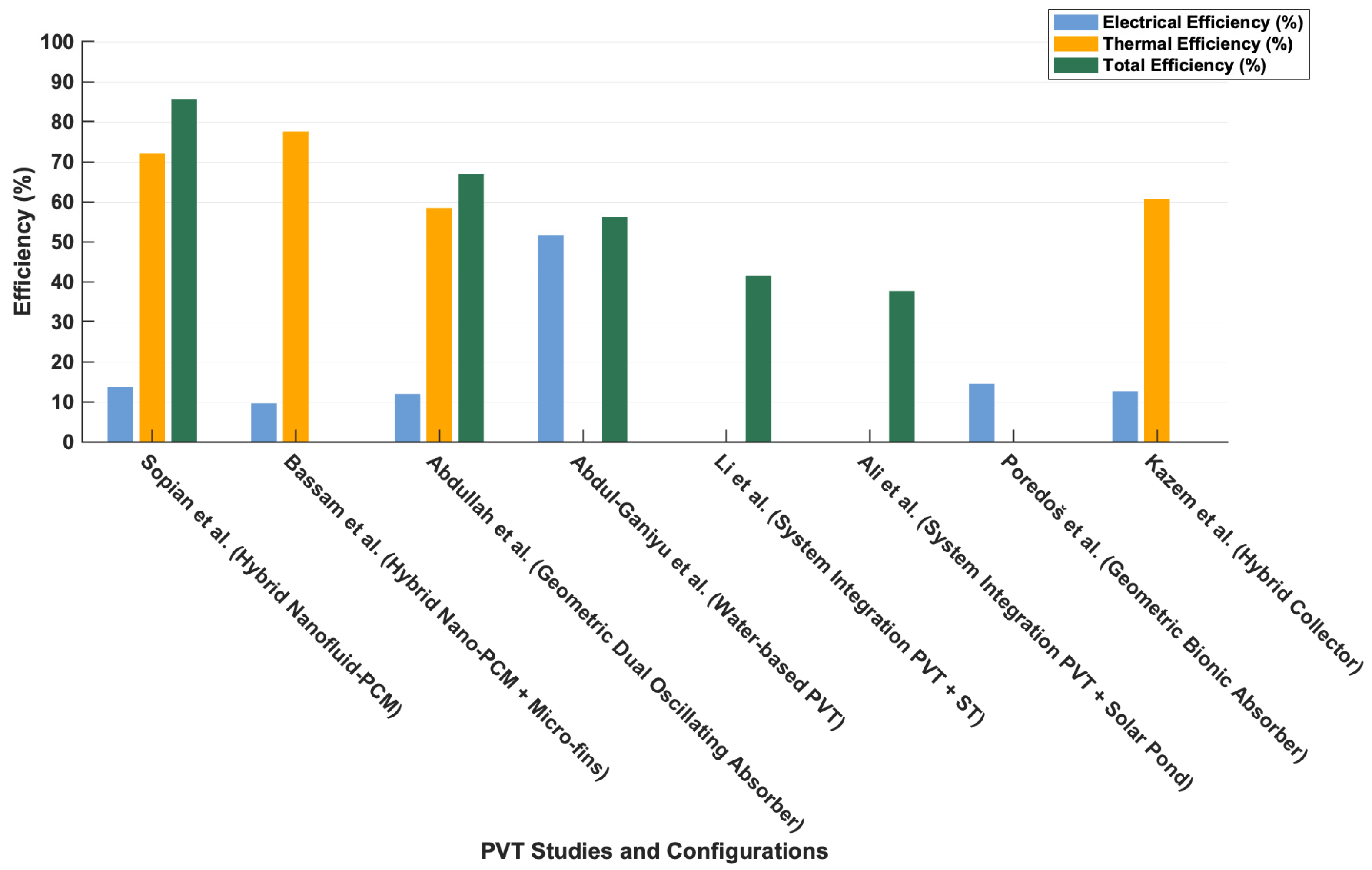

3.1. Collector-Level Advancements

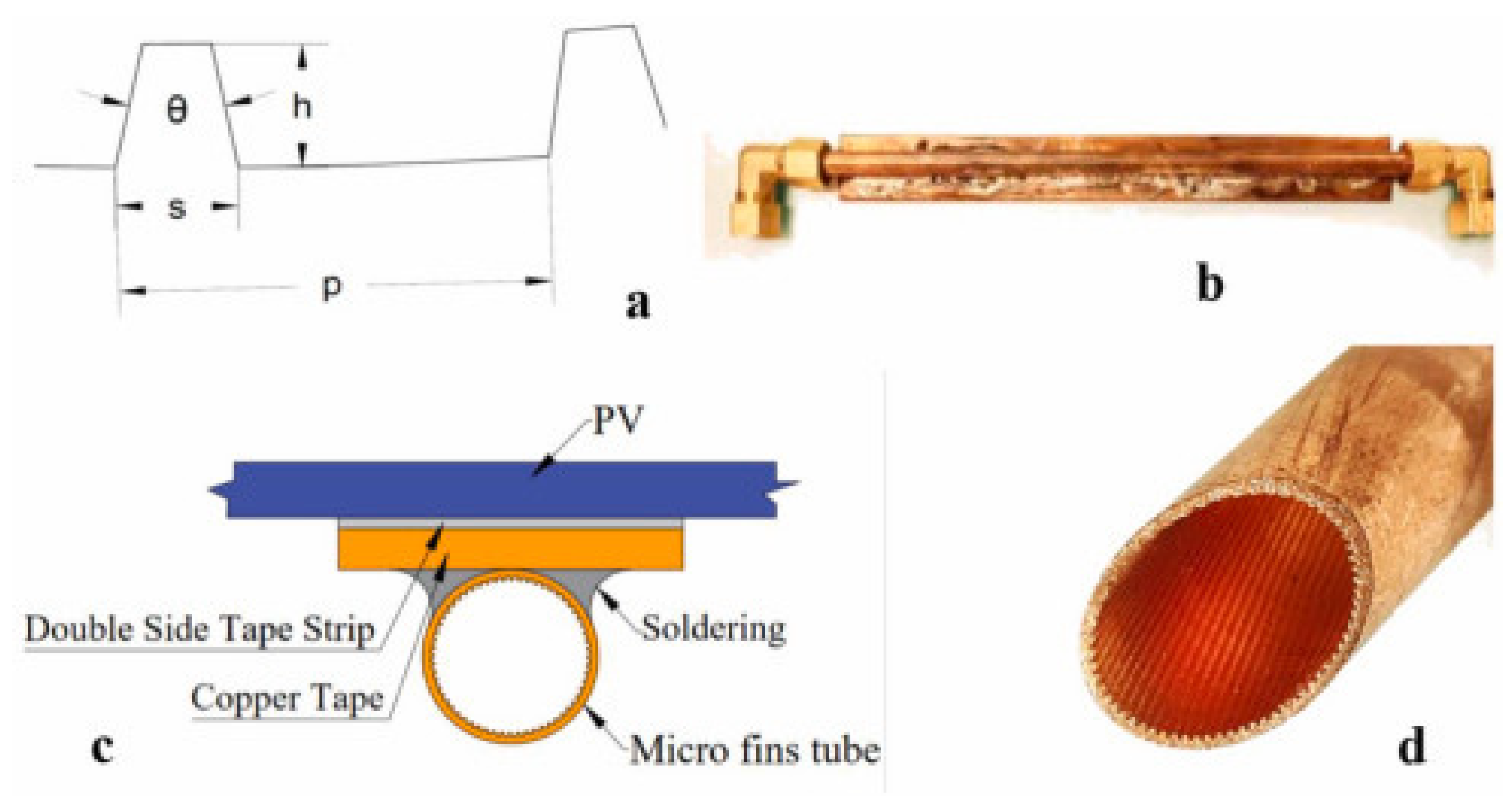

3.1.1. Cooling Mechanisms, Absorber Designs, and Working Fluids

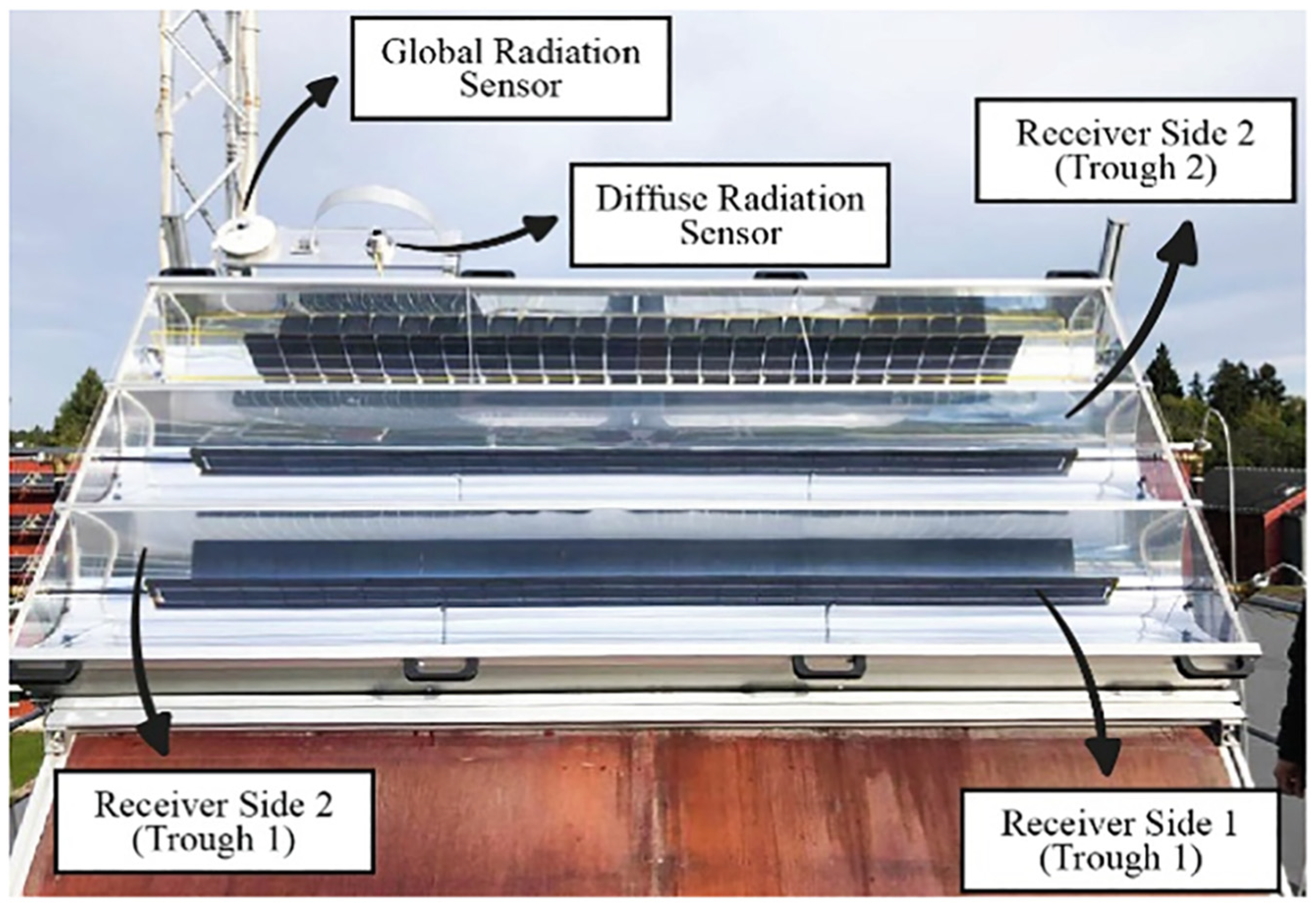

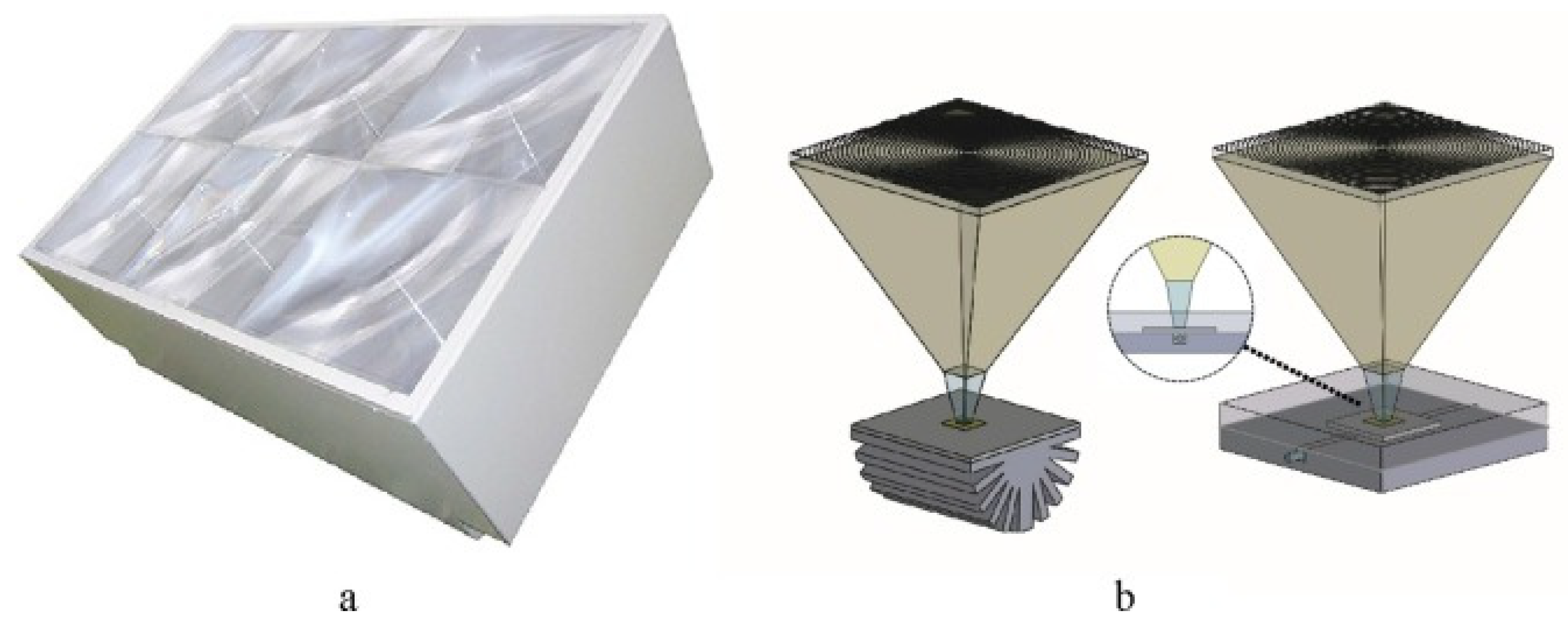

3.1.2. High-Concentration and Asymmetric PVT Collectors

3.1.3. Modelling Approaches for Performance Prediction

3.2. System-Level Integration

3.2.1. Hybrid System and Integration with Other Technologies

3.2.2. Evaluating PVT System Efficiency Across Different Climates

4. Applications and Market Trends

4.1. PVT in Buildings and Industry

4.1.1. PVT in Buildings

4.1.2. PVT in Industry

4.2. Environmental and Policy Considerations

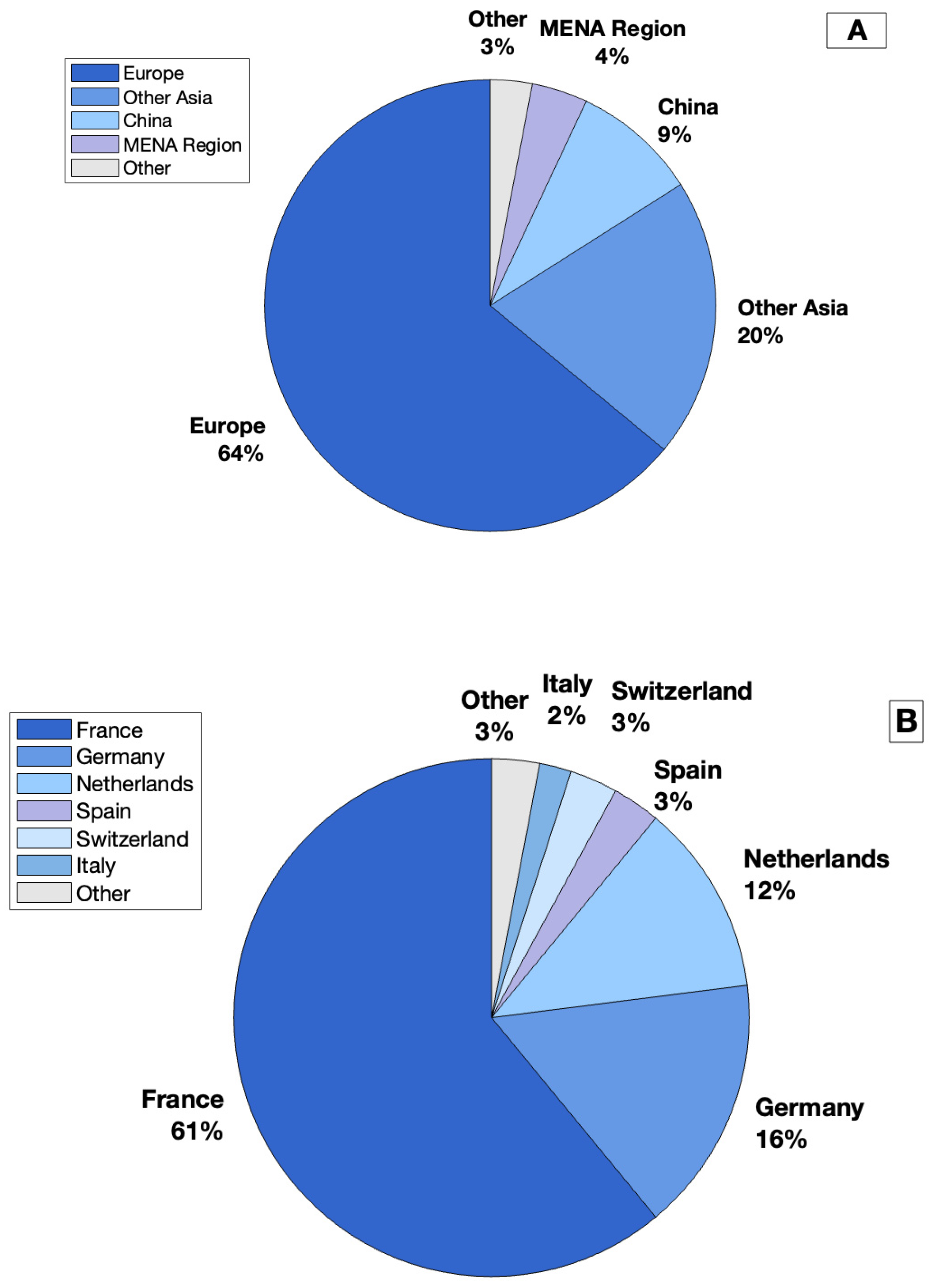

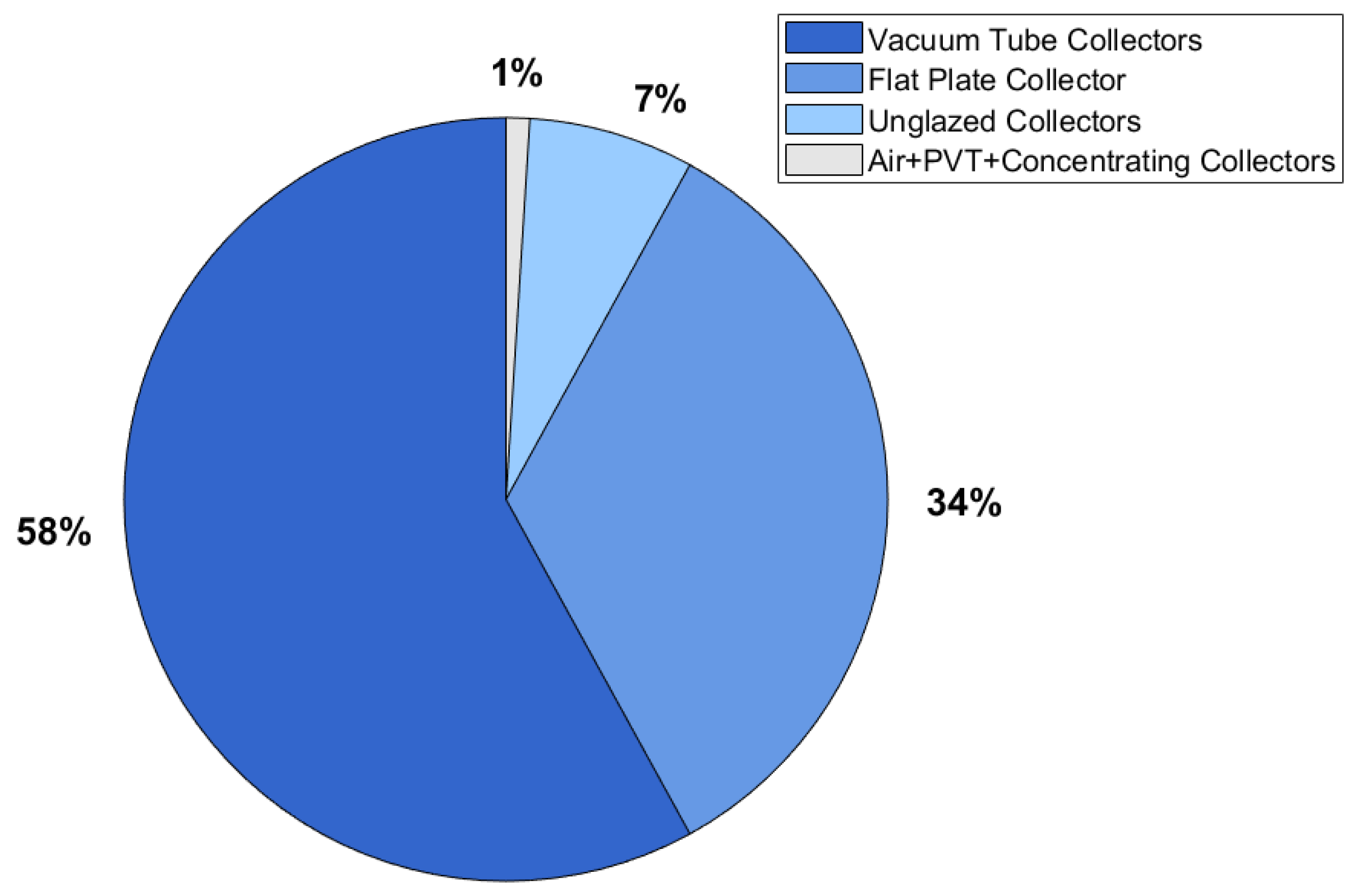

4.3. PVT Market Overview

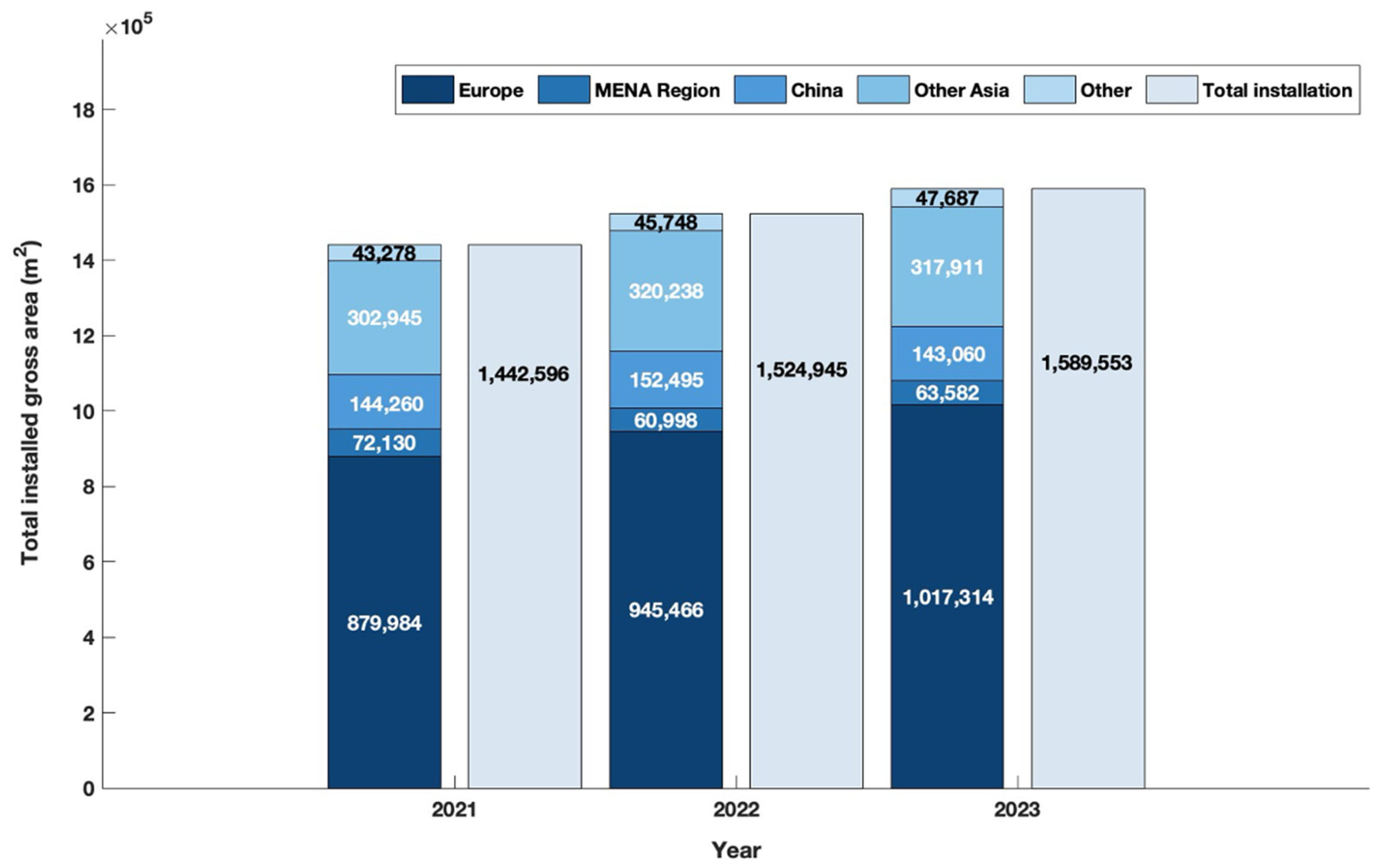

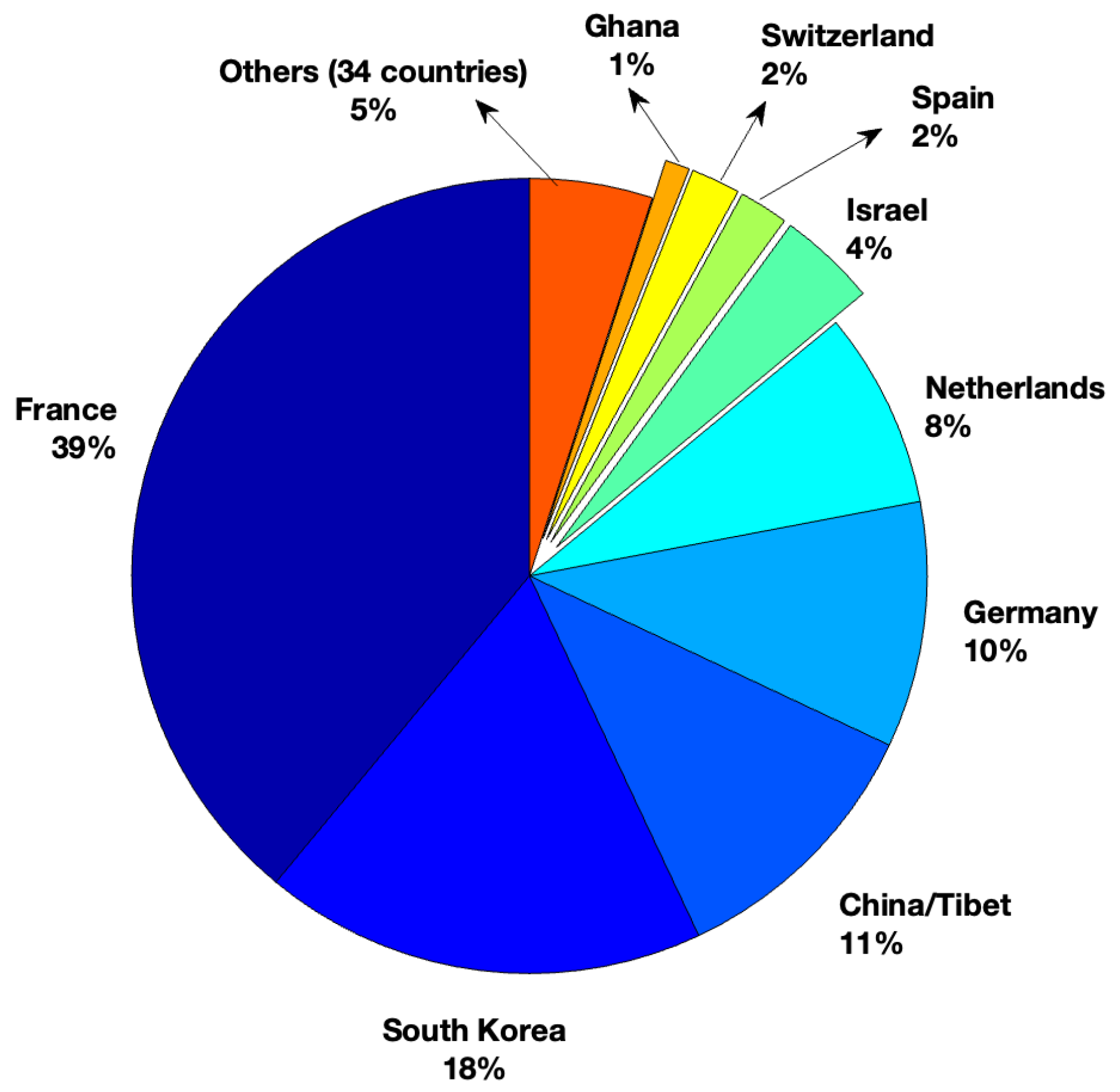

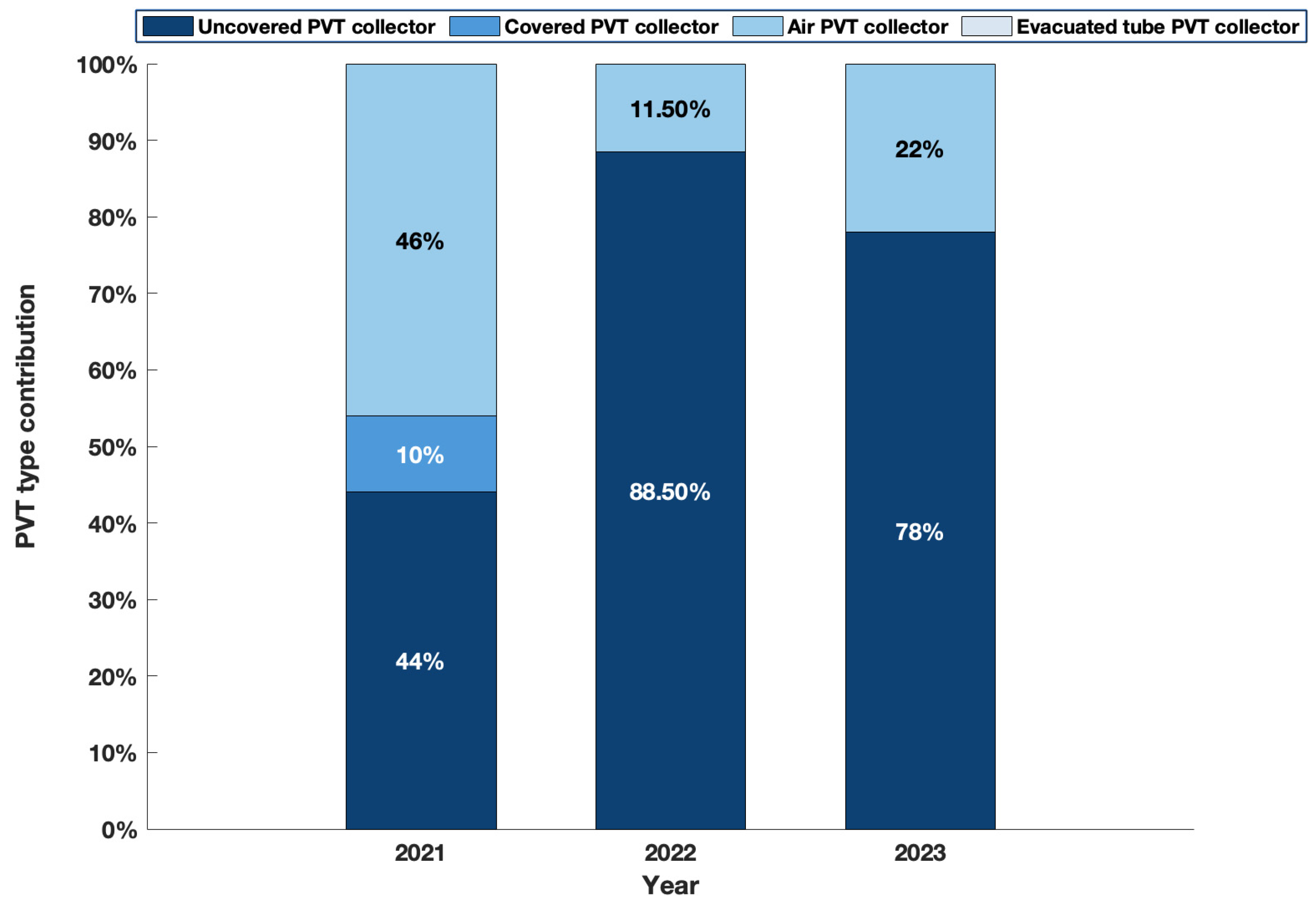

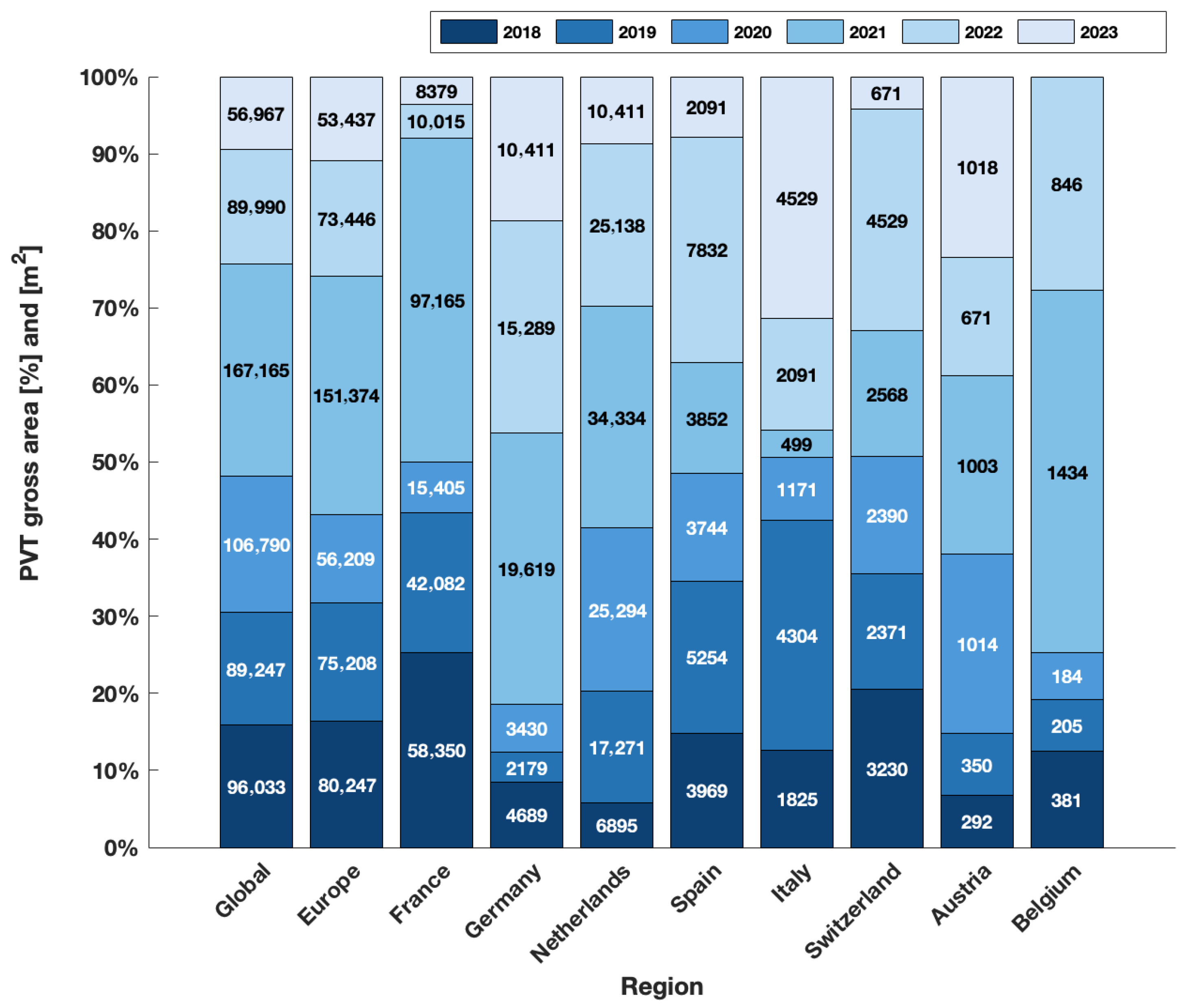

4.3.1. Global PVT Market Statistics and Trends

4.3.2. PVT Market Growth

4.4. Large-Scale PVT Projects

4.4.1. Sunmaxx PVT-Germany

4.4.2. Abora Solar-Spain

| Project | Sector | Location/Installation Year | Usage | Number of Panels | Total Savings of Emissions | Electrical Production | Thermal Production |

|---|---|---|---|---|---|---|---|

| Swimming Club—Barcelona | Sports centre | Spain/2023 | Swimming pool and DHW heating | 1041 | 774,809 kgCO2/year | 543,438 kWh | 1,641,095 kWh |

| Kungsbacka | Rest Home | Sweden/2023 | DHW + Heating + Electricity | 126 | 55,640 kgCO2/year | 42,716 kWh | 120,054 kWh |

| Babylon Hotel | Hotel | The Netherlands/2023 | DHW + Electricity | 31 +104 PV | 18,368 kgCO2/year | 47,310 kWh | 27,919 kWh |

| Ruigrok | Hotel | The Netherlands/2023 | Hot water + electricity | 44 | 14,723 kgCO2/year | 14,546 kWh | 39,676 kWh |

| Hospital La Maz | Hospital | Zaragoza/2023 | DHW + Electricity | 90 | 66,684 kgCO2/year | 51,881 kWh/year | 137,320 kWh/year |

| Hotel Iberostar Albufera Park | Hotel | Spain/2023 | DHW + Pool | 180 | 174,693 kgCO2/year | 70,988 kWh/year | 274,068 kWh/year |

4.4.3. DualSun-France

5. Technological Challenges and Future Opportunities

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ACH | Absorption Chiller |

| ADS | Adsorption Desalination System |

| AHU | Air Handling Unit |

| ANFIS | Adaptive Neuro-Fuzzy Inference Systems |

| ANN | Artificial Neural Networks |

| ASHP | Air Source Heat Pump |

| BIPVT | Building-Integrated PVT |

| CCHP | Combined Cooling, Heating, and Power |

| CHP | Combined Heating and Power |

| COP | Coefficient of Performance |

| CPC | Compound Parabolic Concentrator |

| CPVT | Concentrated Photovoltaic-Thermal |

| DHW | Domestic Hot Water |

| DM-CPVT | Double MaReCo (Solar Collector) |

| DX-SAHP | Direct Expansion Solar-Assisted Heat Pump |

| ETC | Evacuated Tube Collectors |

| GNP | Graphene Nanoplatelet |

| HCPVT | High-Concentration Photovoltaic-Thermal |

| HP | Heat Pump |

| HRS | Heat Recovery System |

| IHT | Inter-seasonal Heat Transfer |

| LSSVM | Least Squares Support Vector Machines |

| MCDM | Multi-Criteria Decision-Making |

| MED | Multi-Effect Distillation |

| MENA Region | Middle East and North Africa Region |

| NEPCM | Nano-enhanced Phase Change Material |

| PBT | Payback Time |

| PCM | Phase Change Materials |

| PEM | Proton Exchange Membrane |

| PTES | Pit Thermal Energy Storage |

| PTSC | Parabolic Trough Solar Collector |

| PV | Photovoltaic |

| PVT | Photovoltaic-Thermal |

| RES | Renewable Energy Source |

| RES-E | Renewable Energy Source for Electricity |

| RES-H | Renewable Energy Source for Heating |

| RHI | Renewable Heat Incentive |

| RO | Reverse Osmosis |

| SBS | Spectral Beam Splitting |

| SC | Solar Central |

| ST | Solar Thermal |

| TEG | Thermoelectric Generators |

| VMD | Vacuum Membrane Distillation |

References

- Lämmle, M.; Oliva, A.; Hermann, M.; Kramer, K.; Kramer, W. PVT Collector Technologies in Solar Thermal Systems: A Systematic Assessment of Electrical and Thermal Yields with the Novel Characteristic Temperature Approach. Sol. Energy 2017, 155, 867–879. [Google Scholar] [CrossRef]

- Rukman, N.S.B.; Fudholi, A.; Razali, N.F.M.; Ruslan, M.H.; Sopian, K. Investigation of TiO2 and MWCNT Nanofluids-Based Photovoltaic-Thermal (PV/T) System. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Kuala Lumpur, Malaysia, 11–14 December 2018; IOP Publishing: Bristol, UK, 2019; Volume 268, p. 12076. [Google Scholar]

- Dubey, S.; Sarvaiya, J.N.; Seshadri, B. Temperature Dependent Photovoltaic (PV) Efficiency and Its Effect on PV Production in the World—A Review. Energy Procedia 2013, 33, 311–321. [Google Scholar] [CrossRef]

- Ahmed, M.F.; Kabir, M.H.; Islam, M.R. Photovoltaic Thermal (PVT) Systems: Coupling Solar Cells with Heat Harvesting for Increased Overall Efficiency. J. Knowl. Learn. Sci. Technol. 2024, 4, 98–103. [Google Scholar]

- Hosouli, S.; Cabral, D.; Gomes, J.; Kosmadakis, G.; Mathioulakis, E.; Mohammadi, H.; Loris, A.; Naidoo, A. Performance Assessment of Concentrated Photovoltaic Thermal (CPVT) Solar Collector at Different Locations. In Proceedings of the ISES SWC 2021 Solar World Congress, Virtual Conference, 25–29 October 2021; ISES: Freiburg, Germany, 2021. [Google Scholar]

- ISO 9806:2017; Solar Energy—Solar Thermal Collectors—Test Methods. International Organization for Standardization: London, UK, 2017.

- Ul-Abdin, Z.; Zeman, M.; Isabella, O.; Santbergen, R. Investigating the Annual Performance of Air-Based Collectors and Novel Bi-Fluid Based PV-Thermal System. Sol. Energy 2024, 276, 112687. [Google Scholar] [CrossRef]

- Kiran, S.; Devadiga, U. Performance Analysis of Hybrid PV/Thermal Systems. Int. J. Emerg. Technol. Adv. Eng. 2014, 4, 80–86. [Google Scholar]

- El Manssouri, O.; Hajji, B.; Tina, G.M.; Gagliano, A.; Aneli, S. Electrical and Thermal Performances of Bi-Fluid PV/Thermal Collectors. Energies 2021, 14, 1633. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Khalili, Z. Solar Photovoltaic-Thermal System with Novel Design of Tube Containing Eco-Friendly Nanofluid. Renew. Energy 2024, 222, 119862. [Google Scholar] [CrossRef]

- Widyolar, B.; Jiang, L.; Brinkley, J.; Hota, S.K.; Ferry, J.; Diaz, G.; Winston, R. Experimental Performance of an Ultra-Low-Cost Solar Photovoltaic-Thermal (PVT) Collector Using Aluminum Minichannels and Nonimaging Optics. Appl. Energy 2020, 268, 114894. [Google Scholar] [CrossRef]

- Samykano, M. Hybrid Photovoltaic Thermal Systems: Present and Future Feasibilities for Industrial and Building Applications. Buildings 2023, 13, 1950. [Google Scholar] [CrossRef]

- Acosta-Pazmiño, I.; Rivera-Solorio, C.; Gijón-Rivera, M. Energetic and Economic Analyses of an LCPV/T Solar Hybrid Plant for a Sports Center Building in Mexico. Energies 2020, 13, 5681. [Google Scholar] [CrossRef]

- International Energy Agency Market and Technology Trends in the Global PVT Sector. Available online: https://task73.iea-shc.org/article?NewsID=515 (accessed on 23 June 2025).

- Herez, A.; El Hage, H.; Lemenand, T.; Ramadan, M.; Khaled, M. Review on Photovoltaic/Thermal Hybrid Solar Collectors: Classifications, Applications and New Systems. Sol. Energy 2020, 207, 1321–1347. [Google Scholar] [CrossRef]

- Weiss, W.; Spörk-Dür, M. Solar Heat Worldwide: Edition 2024—Global Market Development and Trends 2023, Detailed Market Figures 2022; AEE—Institute for Sustainable Technologies: Gleisdorf, Austria, 2024. [Google Scholar]

- Poredoš, P.; Tomc, U.; Petelin, N.; Vidrih, B.; Flisar, U.; Kitanovski, A. Numerical and Experimental Investigation of the Energy and Exergy Performance of Solar Thermal, Photovoltaic and Photovoltaic-Thermal Modules Based on Roll-Bond Heat Exchangers. Energy Convers. Manag. 2020, 210, 112674. [Google Scholar] [CrossRef]

- Hermann, M.; Lunz, K.; Hillerns, F.B. Development of A Bionic Solar Collector with Aluminium Roll-Bond Absorber; Fraunhofer Institute for Solar Energy Systems ISE: Freiburg, Germany, 2011. [Google Scholar]

- Abdullah, A.L.; Misha, S.; Tamaldin, N.; Rosli, M.A.M.; Sachit, F.A. Theoretical Study and Indoor Experimental Validation of Performance of the New Photovoltaic Thermal Solar Collector (PVT) Based Water System. Case Stud. Therm. Eng. 2020, 18, 100595. [Google Scholar] [CrossRef]

- Tyagi, P.K.; Arora, G.; Kumar, R.; Ali, H.M.; Pushpendra; Singh, R.K. Recent Advances in the Shape and Configuration of Photovoltaic Thermal Absorbers. Energy Sources Part. A Recovery Util. Environ. Eff. 2023, 45, 4211–4241. [Google Scholar] [CrossRef]

- Zhang, L.; Chang, R.; Zhang, C.; Yu, C. Improving Thermal Performance and Energy Production of Photo-Voltaic Thermal Collector by Bifurcating Tree-like Cooling Channels. Therm. Sci. 2025, 21. [Google Scholar] [CrossRef]

- Gomes, J. Assessment of the Impact of Stagnation Temperatures in Receiver Prototypes of C-PVT Collectors. Energies 2019, 12, 2967. [Google Scholar] [CrossRef]

- Ramdani, H.; Ould-Lahoucine, C. Study on the Overall Energy and Exergy Performances of a Novel Water-Based Hybrid Photovoltaic-Thermal Solar Collector. Energy Convers. Manag. 2020, 222, 113238. [Google Scholar] [CrossRef]

- Cabral, D.; Gomes, J.; Hayati, A.; Karlsson, B. Experimental Investigation of a CPVT Collector Coupled with a Wedge PVT Receiver. Sol. Energy 2021, 215, 335–345. [Google Scholar] [CrossRef]

- Rahaei, A.; Rafee, R.; Zargarabadi, M.R. A Photovoltaic Thermal System with a Complete Contact between Water and PV Modules Suitable for District Heating and Electric Power Generation. Sustain. Energy Technol. Assess. 2021, 47, 101325. [Google Scholar] [CrossRef]

- Chaouch, A.; BRAHIM, T.; Abdelati, R.; JEMNI, A. Energy and Exergy Analysis of a Long-Term Nonlinear Dynamic Roll Bond PVT Solar Collector Model under Tunisian (North Africa) Climatic Conditions. Therm. Sci. Eng. Progress. 2024, 53, 102727. [Google Scholar] [CrossRef]

- Hissouf, M.; Feddaoui, M.; Najim, M.; Charef, A. Performance of a Photovoltaic-Thermal Solar Collector Using Two Types of Working Fluids at Different Fluid Channels Geometry. Renew. Energy 2020, 162, 1723–1734. [Google Scholar] [CrossRef]

- Sopian, K.; Al-Waeli, A.H.A.; Kazem, H.A. Energy, Exergy and Efficiency of Four Photovoltaic Thermal Collectors with Different Energy Storage Material. J. Energy Storage 2020, 29, 101245. [Google Scholar] [CrossRef]

- Yazdanifard, F.; Ameri, M.; Taylor, R. Parametric Investigation of a Nanofluid-NEPCM Based Spectral Splitting Photovoltaic/Thermal System. Energy Convers. Manag. 2021, 240, 114232. [Google Scholar] [CrossRef]

- Tembhare, S.P.; Barai, D.P.; Bhanvase, B.A. Performance Evaluation of Nanofluids in Solar Thermal and Solar Photovoltaic Systems: A Comprehensive Review. Renew. Sustain. Energy Rev. 2022, 153, 111738. [Google Scholar] [CrossRef]

- Bassam, A.M.; Sopian, K.; Ibrahim, A.; Fauzan, M.F.; Al-Aasam, A.B.; Abusaibaa, G.Y. Experimental Analysis for the Photovoltaic Thermal Collector (PVT) with Nano PCM and Micro-Fins Tube Nanofluid. Case Stud. Therm. Eng. 2023, 41, 102579. [Google Scholar] [CrossRef]

- Moreno, A.; Chemisana, D.; Fernández, E.F. Hybrid High-Concentration Photovoltaic-Thermal Solar Systems for Building Applications. Appl. Energy 2021, 304, 117647. [Google Scholar] [CrossRef]

- Ahmadi, A.; Ehyaei, M.A.; Doustgani, A.; El Haj Assad, M.; Hmida, A.; Jamali, D.H.; Kumar, R.; Li, Z.X.; Razmjoo, A. Recent Residential Applications of Low-Temperature Solar Collector. J. Clean. Prod. 2021, 279, 123549. [Google Scholar] [CrossRef]

- Croitoru, C.; Bode, F.; Calotă, R.; Berville, C.; Georgescu, M. Harnessing Nanomaterials for Enhanced Energy Efficiency in Transpired Solar Collectors: A Review of Their Integration in Phase-Change Materials. Energies 2024, 17, 1239. [Google Scholar] [CrossRef]

- Hossain, M.D.S.; Kumar, L.; Arshad, A.; Selvaraj, J.; Pandey, A.K.; Rahim, N.A. A Comparative Investigation on Solar PVT-and PVT-PCM-Based Collector Constancy Performance. Energies 2023, 16, 2224. [Google Scholar] [CrossRef]

- Ma, T.; Li, M.; Kazemian, A. Photovoltaic Thermal Module and Solar Thermal Collector Connected in Series to Produce Electricity and High-Grade Heat Simultaneously. Appl. Energy 2020, 261, 114380. [Google Scholar] [CrossRef]

- Kazemian, A.; Khatibi, M.; Ma, T.; Peng, J.; Hongxing, Y. A Thermal Performance-Enhancing Strategy of Photovoltaic Thermal Systems by Applying Surface Area Partially Covered by Solar Cells. Appl. Energy 2023, 329, 120209. [Google Scholar] [CrossRef]

- Kazemian, A.; Khatibi, M.; Entezari, S.; Ma, T.; Yang, H. Efficient Energy Generation and Thermal Storage in a Photovoltaic Thermal System Partially Covered by Solar Cells and Integrated with Organic Phase Change Materials. Renew. Sustain. Energy Rev. 2023, 188, 113705. [Google Scholar] [CrossRef]

- Li, M.; Zhong, D.; Ma, T.; Kazemian, A.; Gu, W. Photovoltaic Thermal Module and Solar Thermal Collector Connected in Series: Energy and Exergy Analysis. Energy Convers. Manag. 2020, 206, 112479. [Google Scholar] [CrossRef]

- Ghazy, M.; Ibrahim, E.M.M.; Mohamed, A.S.A.; Askalany, A.A. Cooling Technologies for Enhancing Photovoltaic–Thermal (PVT) Performance: A State of the Art. Int. J. Energy Environ. Eng. 2022, 13, 1205–1235. [Google Scholar] [CrossRef]

- Ali, M.M.; Ahmed, O.K.; Abbas, E.F. Performance of Solar Pond Integrated with Photovoltaic/Thermal Collectors. Energy Rep. 2020, 6, 3200–3211. [Google Scholar] [CrossRef]

- Emmi, G.; Bordignon, S.; Zarrella, A.; De Carli, M. A Dynamic Analysis of a SAGSHP System Coupled to Solar Thermal Collectors and Photovoltaic-Thermal Panels under Different Climate Conditions. Energy Convers. Manag. 2020, 213, 112851. [Google Scholar] [CrossRef]

- Wang, X.; Xia, L.; Bales, C.; Zhang, X.; Copertaro, B.; Pan, S.; Wu, J. A Systematic Review of Recent Air Source Heat Pump (ASHP) Systems Assisted by Solar Thermal, Photovoltaic and Photovoltaic/Thermal Sources. Renew. Energy 2020, 146, 2472–2487. [Google Scholar] [CrossRef]

- Wen, X.; Ji, J.; Li, Z.; Song, Z. Performance Analysis of a Concentrated System with Series Photovoltaic/Thermal Module and Solar Thermal Collector Integrated with PCM and TEG. Energy 2022, 249, 123777. [Google Scholar] [CrossRef]

- Madurai Elavarasan, R.; Mudgal, V.; Selvamanohar, L.; Wang, K.; Huang, G.; Shafiullah, G.M.; Markides, C.N.; Reddy, K.S.; Nadarajah, M. Pathways toward High-Efficiency Solar Photovoltaic Thermal Management for Electrical, Thermal and Combined Generation Applications: A Critical Review. Energy Convers. Manag. 2022, 255, 115278. [Google Scholar] [CrossRef]

- Zeng, R.; Zhang, X.; Deng, Y.; Li, H.; Zhang, G. Optimization and Performance Comparison of Combined Cooling, Heating and Power/Ground Source Heat Pump/Photovoltaic/Solar Thermal System under Different Load Ratio for Two Operation Strategies. Energy Convers. Manag. 2020, 208, 112579. [Google Scholar] [CrossRef]

- Monjezi, A.A.; Chen, Y.; Vepa, R.; Kashyout, A.E.H.B.; Hassan, G.; Fath, H.E.B.; Kassem, A.E.W.; Shaheed, M.H. Development of an Off-Grid Solar Energy Powered Reverse Osmosis Desalination System for Continuous Production of Freshwater with Integrated Photovoltaic Thermal (PVT) Cooling. Desalination 2020, 495, 114679. [Google Scholar] [CrossRef]

- Kuefouet Alexis, L.; Julius Kewir, T.; Kanouo Boris Merlain, D.; Segning Harry Bertholt, S. Experimental Study on the Electrical and Thermal Characteristics of a Hybrid Photovoltaic/Thermal Water Solar Collector Model Using Photovoltaic Solar Modules of Different Brands. Energy Convers. Manag. X 2022, 14, 100198. [Google Scholar] [CrossRef]

- Abdul-Ganiyu, S.; Quansah, D.A.; Ramde, E.W.; Seidu, R.; Adaramola, M.S. Investigation of Solar Photovoltaic-Thermal (PVT) and Solar Photovoltaic (PV) Performance: A Case Study in Ghana. Energies 2020, 13, 2701. [Google Scholar] [CrossRef]

- Kazem, H.A.; Chaichan, M.T.; Al-Waeli, A.H.A.; Sopian, K. Comparison and Evaluation of Solar Photovoltaic Thermal System with Hybrid Collector: An Experimental Study. Therm. Sci. Eng. Progress. 2021, 22, 100845. [Google Scholar] [CrossRef]

- Joo, H.J.; An, Y.S.; Kim, M.H.; Kong, M. Long-Term Performance Evaluation of Liquid-Based Photovoltaic Thermal (PVT) Modules with Overheating-Prevention Technique. Energy Convers. Manag. 2023, 296, 117682. [Google Scholar] [CrossRef]

- Behzadi, A.; Arabkoohsar, A.; Yang, Y. Optimization and Dynamic Techno-Economic Analysis of a Novel PVT-Based Smart Building Energy System. Appl. Therm. Eng. 2020, 181, 115926. [Google Scholar] [CrossRef]

- Braun, R.; Haag, M.; Stave, J.; Abdelnour, N.; Eicker, U. System Design and Feasibility of Trigeneration Systems with Hybrid Photovoltaic-Thermal (PVT) Collectors for Zero Energy Office Buildings in Different Climates. Sol. Energy 2020, 196, 39–48. [Google Scholar] [CrossRef]

- Polito, F.; Huang, G.; Markides, C.N. A Building-Integrated Hybrid Photovoltaic-Thermal (PV-T) Window for Synergistic Light Management, Electricity and Heat Generation. Adv. Sci. 2025, 12, 2408057. [Google Scholar] [CrossRef]

- Elaouzy, Y.; El Fadar, A. Investigation of Building-Integrated Photovoltaic, Photovoltaic Thermal, Ground Source Heat Pump and Green Roof Systems. Energy Convers. Manag. 2023, 283, 116926. [Google Scholar] [CrossRef]

- Herrando, M.; Pantaleo, A.M.; Wang, K.; Markides, C.N. Solar Combined Cooling, Heating and Power Systems Based on Hybrid PVT, PV or Solar-Thermal Collectors for Building Applications. Renew. Energy 2019, 143, 637–647. [Google Scholar] [CrossRef]

- Ranjbar Golafshani, S.; Houshfar, E. Integrated Ejector Cooling, PVT, and MGT System for Smart Building Applications: An Exergy and Technoeconomic Optimization Study. Case Stud. Therm. Eng. 2025, 66, 105752. [Google Scholar] [CrossRef]

- Bacha, H.B.; Abdullah, A.S.; Alqasir, U.; Salama, R.S.; Abdelgaied, M.; Kabeel, A.E. Performance Analysis and Techno-Economic Assessment of a Developed Cooling/Preheating Small PVT-RO Desalination Plant. Front. Energy Res. 2023, 11, 1287743. [Google Scholar] [CrossRef]

- Acosta-Pazmiño, I.P.; Rivera-Solorio, C.I.; Gijón-Rivera, M. Hybridization of a Parabolic Trough-Based Thermal Plant for Industrial Heat and Power Generation. Renew. Energy 2022, 191, 961–973. [Google Scholar] [CrossRef]

- Gorjian, S.; Calise, F.; Kant, K.; Ahamed, M.S.; Copertaro, B.; Najafi, G.; Zhang, X.; Aghaei, M.; Shamshiri, R.R. A Review on Opportunities for Implementation of Solar Energy Technologies in Agricultural Greenhouses. J. Clean. Prod. 2021, 285, 124807. [Google Scholar] [CrossRef]

- Herrando, M.; Simón, R.; Guedea, I.; Fueyo, N. The Challenges of Solar Hybrid PVT Systems in the Food Processing Industry. Appl. Therm. Eng. 2021, 184, 116235. [Google Scholar] [CrossRef]

- Gu, X.; Taylor, R.A.; Morrison, G.; Rosengarten, G. Theoretical Analysis of a Novel, Portable, CPC-Based Solar Thermal Collector for Methanol Reforming. Appl. Energy 2014, 119, 467–475. [Google Scholar] [CrossRef]

- Murali, D.; Acosta-Pazmiño, I.P.; Loris, A.; García, A.C.; Benni, S.; Tinti, F.; Gomes, J. Experimental Assessment of a Solar Photovoltaic-Thermal System in a Livestock Farm in Italy. Sol. Energy Adv. 2024, 4, 100051. [Google Scholar] [CrossRef]

- Hosouli, S.; Gomes, J.; Loris, A.; Pazmiño, I.A.; Naidoo, A.; Lennermo, G.; Mohammadi, H. Evaluation of a Solar Photovoltaic Thermal (PVT) System in a Dairy Farm in Germany. Sol. Energy Adv. 2023, 3, 100035. [Google Scholar] [CrossRef]

- Santana, J.P.; Rivera-Solorio, C.I.; Chew, J.W.; Tan, Y.Z.; Gijón-Rivera, M.; Acosta-Pazmiño, I. Performance Assessment of Coupled Concentrated Photovoltaic-Thermal and Vacuum Membrane Distillation (CPVT-VMD) System for Water Desalination. Energies 2023, 16, 1541. [Google Scholar] [CrossRef]

- Calise, F.; Dentice d’Accadia, M.; Piacentino, A. A Novel Solar Trigeneration System Integrating PVT (Photovoltaic/Thermal Collectors) and SW (Seawater) Desalination: Dynamic Simulation and Economic Assessment. Energy 2014, 67, 129–148. [Google Scholar] [CrossRef]

- Chen, J.; Chen, K.; Zhang, W.; Su, J.M.; Zhao, B.; Hu, M.; Pei, G. Numerical Study of a Solar District Heating System with Photovoltaic-Thermal Collectors and Pit Thermal Energy Storage. Energy 2025, 317, 134705. [Google Scholar] [CrossRef]

- Atiz, A. Evaluation of Energy, Exergy, Economic, and Carbon Savings Analyses, along with Green Hydrogen Production of PVs and PVTs under Daily Solar Radiation for Various Tilt Angles and Mass Flow Ratios. Int. J. Hydrogen Energy 2025, 98, 657–672. [Google Scholar] [CrossRef]

- Barthwal, M.; Rakshit, D. A Solar Spectral Splitting-Based PVT Collector with Packed Transparent Tube Receiver for Co-Generation of Heat and Electricity. Appl. Energy 2023, 352, 121926. [Google Scholar] [CrossRef]

- Anand, B.; Shankar, R.; Murugavelh, S.; Rivera, W.; Midhun Prasad, K.; Nagarajan, R. A Review on Solar Photovoltaic Thermal Integrated Desalination Technologies. Renew. Sustain. Energy Rev. 2021, 141, 110787. [Google Scholar] [CrossRef]

- Abdelgaied, M.; Kabeel, A.E.; Abdullah, A. Performance Optimization of the Hybrid HDH-RO Desalination System Powered by Photovoltaic-thermal Modules Using Solar Dish Concentrators. Int. J. Energy Res. 2022, 46, 14946–14963. [Google Scholar] [CrossRef]

- Wang, K.; Pantaleo, A.M.; Herrando, M.; Faccia, M.; Pesmazoglou, I.; Franchetti, B.M.; Markides, C.N. Spectral-Splitting Hybrid PV-Thermal (PVT) Systems for Combined Heat and Power Provision to Dairy Farms. Renew. Energy 2020, 159, 1047–1065. [Google Scholar] [CrossRef]

- Gomes, M.; Coelho, P.; Yıldızhan, H.; Bozkurt, A.; Hayati, A.; Cabral, D.; Furbo, S.; Perers, B.; Dragsted, J.; Hosouli, S.; et al. Highlights of Legal Face of PVT Systems in European Countries. In Proceedings of the 10th European Conference on Renewable Energy Systems, Istanbul, Turkey, 7–9 May 2022. [Google Scholar]

- Acosta-Pazmiño, I.P.; Rivera-Solorio, C.I.; Gijón-Rivera, M. Scaling-up the Installation of Hybrid Solar Collectors to Reduce CO2 Emissions in a Mexican Industrial Sector from Now to 2030. Appl. Energy 2021, 298, 117202. [Google Scholar] [CrossRef]

- Weiss, W.; Spörk-Dür, M. Solar Heat Worldwide: Edition 2023—Global Market Development and Trends 2022, Detailed Market Figures 2021; AEE—Institute for Sustainable Technologies: Gleisdorf, Austria, 2023. [Google Scholar]

- Weiss, W.; Spörk-Dür, M. Solar Heat Worldwide: Edition 2022—Global Market Development and Trends 2021, Detailed Market Figures 2020; AEE—Institute for Sustainable Technologies: Gleisdorf, Austria, 2022. [Google Scholar]

- Biermayr, P.; Eberl, M.; Enigl, M.; Fechner, H.; Kristöfel, C.; Leonhartsberger, K.; Maringer, F.; Moidl, S.; Strasser, C.; Weiss, W. Innovative Energietechnologien in Österreich Marktentwicklung 2021. Biomasse, Photovoltaik, Solarthermie, Wärmepumpen und Windkraft. 2015. Available online: https://pvaustria.at/wp-content/uploads/Marktstatistik_2021.pdf (accessed on 31 July 2025).

- Sunmaxx PVT. World’s Largest PVT Module Production. Available online: https://sunmaxx-pvt.com/sunmaxx-has-started-the-buildout-of-the-worlds-largest-pvt-module-production-in-saxony/ (accessed on 23 June 2025).

- Sunmaxx PVT. About Us. Available online: https://sunmaxx-pvt.com/about/ (accessed on 23 June 2025).

- Abora Solar The Most Cost-Effective Solar Panel. Available online: https://abora-solar.com/en/ (accessed on 22 June 2025).

- Solarthermalworld. Growing Production Capacities of PVT Collectors in Europe. Available online: https://solarthermalworld.org/news/growing-production-capacities-of-pvt-collectors-in-europe/ (accessed on 22 June 2025).

- Abora Solar. Discover All Our Installations|Hybrid Solar Panel. Available online: https://abora-solar.com/en/installations/ (accessed on 23 June 2025).

- DualSun. DualSun Installations Around the World. Available online: https://dualsun.com/en/installations/ (accessed on 22 June 2025).

- Hosouli, S.; Gaikwad, N.; Qamar, S.H.; Gomes, J. Optimizing Photovoltaic Thermal (PVT) Collector Selection: A Multi-Criteria Decision-Making (MCDM) Approach for Renewable Energy Systems. Heliyon 2024, 10, e27605. [Google Scholar] [CrossRef]

- Chandrasekar, M.; Senthilkumar, T. Five Decades of Evolution of Solar Photovoltaic Thermal (PVT) Technology—A Critical Insight on Review Articles. J. Clean. Prod. 2021, 322, 128997. [Google Scholar] [CrossRef]

- Kazem, H.A.; Chaichan, M.T.; Al-Waeli, A.H.A.; Sopian, K. A Systematic Review of Photovoltaic/Thermal Applications in Heat Pumps Systems. Sol. Energy 2024, 269, 112299. [Google Scholar] [CrossRef]

- Kumar, S.; Thakur, R.; Singhy, A.; Tripathi, R.K.; Sethi, M. A Review of Heat Removal Mechanism in Concentrated PVT Systems Using Beam Splitter. Mater. Today Proc. 2022, 50, 952–961. [Google Scholar] [CrossRef]

| PVT System Type | Electrical Efficiency (%) | Thermal Efficiency (%) | Total Efficiency (%) | Reference |

|---|---|---|---|---|

| Hybrid Nanofluid-PCM | 13.7 | 72 | 85.7 | [28] |

| Hybrid Nano-PCM + Micro-fins | 9.6 | 77.5 | N/R 1 | [31] |

| Geometric Dual Oscillating Absorber (Water-based PVT) | 11.97 | 58.43 | 66.87 | [19] |

| Traditional PV (Ghana) | N/R | N/R | 56.1 (Combined Efficiency) | [49] |

| System Integration PVT + ST | N/R | N/R | 41.51 (Energy Efficiency); 17.63 (Exergy Efficiency) | [39] |

| System Integration PVT + Solar Pond | N/R | N/R | 37.67 | [41] |

| Geometric Bionic Absorber (PVT) | 14.5 | Lower than ST module | N/R | [17] |

| Hybrid Collector (Oman) | 12.7 | 60.7 | N/R | [50] |

| Application/Temperature | Place of Study/Type | Type of Collector | Findings |

|---|---|---|---|

| Residential heating/cooling 50–70 °C | South Korea/Experimental + Field Testing (1 Year) | Flat Plate (Glazed with Transparent Film, Glass, and Unglazed) | - Three flat PVT module types evaluated: Type A (glazed with transparent film), Type B (glazed with glass), and Type C (unglazed with glass). - For laboratory tests, the maximum overall efficiencies for Type A, B, and C PVT modules were 71.1%, 68.1%, and 61.1%, respectively. - For field tests, thirteen PVT modules (Type B) installed in the residential building were field-tested for one year and they produced 8187.1 kWh heat and 4430.1 kWh electricity with an average thermal and electrical efficiency of 17.7% and 9.7%, respectively. - Performance reduced by shading, glazing-induced transmittance losses, and overheating actuator. - Overheating-prevention system effectively prevented thermal failure [51]. |

| Smart Energy System (40–60 °C) | Denmark (Esbjerg)/Simulation (TRNSYS) | Flat Plate PVT (uninsulated, no battery) | - System provides real-time electricity and covers 123.4 m3 of domestic hot water demand while exporting 402.8 m3 to the district heating grid. - Achieved total annual electricity generation of 3647.4 kWh, with 3200.1 kWh used directly. - Optimisation reduced total product cost to 13.26 €/MWh and achieved exergy efficiency of 49.07%. - PVT panel and tank were main sources of exergy destruction. - System outperformed traditional setups economically (e.g., electricity: 16.9 €/MWh vs. 30 €/MWh grid) [52]. |

| Zero-energy office, multi-climate | Simulation study across 3 climate zones (e.g., Stuttgart, Moscow, Dubai) | Hybrid PVT (coupled with reversible heat pump) | - PVT collectors function as both heat source and sink for a reversible heat pump, enabling trigeneration (electricity, heat, and cooling). - Optimised systems were evaluated for different climates and building standards. - In climates like Germany with feed-in tariffs, up to 100 m2 PVT area is feasible, offering economic and CO2 benefits. - In regions like Russia or UAE, only small-scale systems (~10 m2) are viable due to lack of renewable energy incentives. - System lowers primary energy use and increases self-consumption. - Annual costs are comparable to conventional solar cooling systems [53]. |

| Urban glass-based spaces (~34 °C) | London/Experimental | Hybrid PVT Window (semi-transparent PV + liquid thermal absorber) | - A PVT window (PVTW) combining semi-transparent PV and liquid-based thermal absorber achieved 3.6% electrical and 10.7% thermal efficiency at 30° tilt under peak solar irradiance (~1100 W/m2). - At a vertical (90°) tilt, water temperature dropped (7 °C), but thermal efficiency increased to 17.6%. - Outperformed standalone solar thermal windows (10 °C higher water temp and 10% higher thermal efficiency). - Suitable for glass-based urban buildings where roof space is limited. - Total unit weight ≈ 30 kg/m2, similar to medium-thickness double-glazed windows. - Can work thermosiphonically, reducing need for pumps. - Future optimisation involves spectral-splitting PV and advanced light management [54]. |

| Residential energy optimisatio/Multi-climate evaluation | Morocco—6 climatic zones/Simulation | Flat-plate, liquid-based PVT | - PVT systems showed the best performance among all technologies (PV, GSHP, GR) across all climates in terms of energy, environmental, and economic indicators. - Achieved a carbon payback period of 0.59–0.84 years, better than all other systems. - Levelized Cost of Energy (LCOE) ranged between 0.027 and 0.039 $/kWh. - Performance was highest in desert climate, and lowest in Mediterranean. - With a carbon tax of $75/tCO2e, the Savings-to-Investment Ratio (SIR) of PVT improved by ~61.42%. - Study confirms the feasibility of flat-plate PVT in hot climates and its superiority over other systems for Moroccan residential sectors [55]. |

| Residential buildings/Electricity + High-grade heat (~50 °C+) | Shanghai/Simulation+ Experimentation | Unglazed Flat Plate Liquid-Based PVT Collector | - PVT-ST system combines a PVT module and a solar thermal (ST) collector in series to overcome low output temperature limitations of standalone PVT systems. - Validated 2D steady-state model with RMSD of ~1.12–1.39%. - Achieved 0.82 kWh/day electricity and 5.75 kWh/day heat output on average. - Annual PES efficiency of 83.48%; annual electrical and thermal efficiencies were 12.78% and 49.85%, respectively. - Electrical efficiency slightly lower than standalone PV or unglazed PVT but higher thermal and overall PES efficiency. - Solar radiation and flow rate positively affect performance; high inlet water temperature negatively impacts it [36]. |

| HVAC/80 °C | Bari, Italy/Theoretical | Flat-plate PVT | - A 1.68-MWp PVT-based S-CCHP system covered 55.1% cooling, 20.9% heating, and 16.3% electricity demands of a university campus. - PVT system displaced 911 tons CO2/year and saved ~5460 MWh of primary energy. - Payback time (PBT) was 16.7 years–2.7× higher than PV but 2.3× lower than ETC. - Space availability limits system scaling. - Economic performance is highly sensitive to utility prices (e.g., PBT drops to 10.2 years under Danish prices). - ETC systems lacked electricity output, reducing profitability [56]. |

| Smart Energy system | Tehran, Iran/Theoretical (TRNSYS) | Flat-plate PVT | - A novel system combining PVT, micro-gas turbine (MGT), ejector cooling, and HRSG without battery use. - Annual exergy efficiency: 11.31% (operation), improved to 19.2% (optimised). - Product cost reduced from $25.78/MWh to $17.71/MWh via optimisation. - Annual outputs: 1911.87 kWh from PVT, 22,381 kWh from MGT, 296 kWh cooling. - PVT was the major exergy destruction point (8827 kWh/year). - Grid interaction allows flexible energy management (12,591 kWh sold, 12,695 kWh bought). - System optimised using TRNOPT; performance affected by TIT, PVT length, pressure ratio, etc. [57]. |

| Application/Temperature | Place of Study/Type | Type of Collector | Findings |

|---|---|---|---|

| Water Desalination/<50 °C (inferred) | MENA Region (Middle East and North Africa)/Theoretical | Not Mentioned | - An average reduction of 0.135 kWh/m3 in particular electricity usage. - an average increase of 8% in electricity generation output. - It reduced the cost of freshwater by 49.5% compared to results from Anand [70] and by 24.5% compared to Monjezi et al. and Abdelgaied et al. [47,71]. |

| Boiler water pre-heating/<80 °C | Mexico (Chihuahua, Jalisco, Quintana Roo)/Theoretical | Concentrating (CPVT) (Parabolic Trough) | - Specific energy yield of LCPVT up to 92% higher than ST plant, superior yield-to-area utilisation ratio. - CO2 emissions reductions highest in fuel oil displacement scenario. - PBT less than 5 years is achievable. - Non-intuitive economic behaviour due to location-dependent factors [59]. |

| Agriculture (Dairy Farm)/40 °C | Bari, Southern Italy | CPVT collectors &Semi-transparent PVT | A novel spectral-splitting PVT system for dairy farms simultaneously provides electricity (14%), hot water (40%), and steam (52%). It is economically viable if the spectrum splitter cost is reduced, offering significant decarbonization potential (890 tCO2/year) [72]. |

| Food Processing (Vegetable and Fruit Canning Plant) | Zaragoza, Spain | Evacuated tube collectors | - Covered PVT systems deliver 45.4% of hot water demand and 38.4% with uncovered PVT. - ETC systems cover 58.6% of hot water demand and achieve a 5x higher cooling demand than covered PVTs [61]. |

| Chemical Production | N/A | CPVT (CPC) | - Proposed a novel CPC-based solar thermal collector integrated with vacuum insulation and selective coatings. - Achieved efficiency of 65–71% with a concentration ratio of 1.75. - Demonstrated capability to drive methanol reforming for portable power applications. - System suitable for portable clean power supply using fuel cells [62]. |

| Swine Farm | Mirandola, Italy (Golinelli Swine Farm)/Experimental | FP (uninsulated) | - Deployment of standardised solar central (SC). - Ambient temperature influences BTES performance by affecting soil temperature. Potential for further BTES capacity expansion for larger PVT systems [63]. |

| Agriculture (Dairy Farm)/FP: <45 °C, CPVT: <65 °C. | LVAT-ATB, Germany | CPVT | - FP-PVT produced higher electricity output, but CPVT reached higher temperatures, making them more suitable for the farm’s heat requirements. - CPVT collectors met 16% of the farm’s annual hot water demand and up to 38% during the summer months. - Payback period for the PVT system is less than 6 years [64]. |

| Desalination Hybrid CPVT-VMD/<55 °C | Acapulco (MX), La Paz (MX), Nadi (FJ), Singapore (SG) | CPVT (Parabolic Trough) | - CPVT collector with a triangular receiver generates more electricity with a smaller PV surface and hybridises with parabolic thermal collectors. - Specific permeate production ranged from 170.365 m3/m2 VMD in Singapore to 218.410 m3/m2 VMD in Acapulco. - Profitability for Acapulco achieved in 7 years [65]. |

| Polygeneration (Heating, cooling and water) | European Mediterranean countries | CPVT | The system includes CPVT collectors, MED for seawater desalination, and a single-stage LiBr-H2O ACH. Optimal solar field-to-ACH capacity ratio: 5.9 m2/kW; storage volume: 15 L/m2 solar field. 5. MED performance improves with 14 effects [66]. |

| District Heating/9 °C to 66 °C | Lhasa, China | FP (glazed) | The proposed system integrates PVT collectors, PTES, and a water-to-water heat pump for district heating during winter. Solar thermal and electrical fractions of 77.4% and 236.8%, respectively. Increasing collector area or storage volume improves solar fractions but decreases utilisation ratios and PTES efficiency [67]. |

| Hydrogen Production | Adana, Turkey/Comparative | FP (PVT-PEM) | PVT-PEM systems consistently surpassed PV-PEM under different tilt angles and cooling rates. PVT-PEM yielded higher electricity, hydrogen, energy/exergy (49.85% and 9.723%, respectively) efficiencies, carbon savings (76.96 kg), and economic contributions ($49.53), demonstrating benefits of cooling [68]. |

| Combined heating and power (CHP) systems | Delhi, India | CPVT (CPC) | The novel PVT system’s spectral splitting achieves heat transfer fluid temperatures exceeding PV cells (ratio > 1.6), yielding over 100 °C thermal rise and 18.77% electrical efficiency while effectively controlling cell temperature [69]. |

| Country | Water Collectors [m2] | Air Collectors [m2] | Concentrators [m2] | Total [m2] | ||

|---|---|---|---|---|---|---|

| Uncovered | Covered | Evacuated Tube | ||||

| France | 67,024 | 1952 | 0 | 547,575 | 0 | 616,551 |

| Korea, South | 280,814 | 0 | 0 | 0 | 0 | 280,814 |

| China | 177,721 | 1034 | 0 | 0 | 171 | 178,926 |

| Germany | 154,900 | 6939 | 3 | 512 | 195 | 162,549 |

| Netherlands | 113,654 | 11,794 | 33 | 0 | 1822 | 127,303 |

| Israel | 70,054 | 0 | 0 | 0 | 0 | 70,054 |

| Spain | 1552 | 32,640 | 0 | 0 | 0 | 34,192 |

| Switzerland | 22,257 | 128 | 0 | 3530 | 0 | 25,915 |

| Ghana | 22,000 | 0 | 0 | 0 | 22,000 | |

| Italy | 18,091 | 2696 | 0 | 0 | 0 | 20,787 |

| United States | 10,676 | 20 | 7 | 0 | 0 | 10,702 |

| Austria | 1929 | 2710 | 4639 | |||

| Belgium | 4177 | 32 | 290 | 15 | 4515 | |

| United Kingdom | 1440 | 1539 | 640 | 348 | 135 | 4102 |

| Country | Water Collectors | Air Collectors | Concentrators | Total | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Uncovered | Covered | Evacuated Tube | ||||||||||

| [kWth] | [kWpeak] | [kWth] | [kWpeak] | [kWth] | [kWpeak] | [kWth] | [kWpeak] | [kWth] | [kWpeak] | [kWth] | [kWpeak] | |

| France | 34,701 | 14,083 | 1029 | 330 | 0 | 271,352 | 88,288 | 307,081 | 102,701 | |||

| Korea, South | 137,599 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 137,599 | 47,828 | |

| China | 89,866 | 32,207 | 452 | 180 | 0 | 0 | 98 | 20 | 90,416 | 32,407 | ||

| Germany | 77,048 | 30,124 | 3562 | 1189 | 1 | 0 | 263 | 87 | 109 | 22 | 80,983 | 31,423 |

| Netherlands | 58,827 | 24,160 | 5441 | 2031 | 14 | 4 | 0 | 0 | 1046 | 213 | 65,328 | 26,407 |

| Israel | 34,566 | 12,368 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 34,566 | 12,368 | |

| Spain | 775 | 284 | 16,714 | 5630 | 0 | 0 | 0 | 0 | 0 | 0 | 17,489 | 5914 |

| Switzerland | 11,264 | 5054 | 63 | 21 | 0 | 0 | 1806 | 576 | 0 | 0 | 13,134 | 5651 |

| Ghana | 11,958 | 4140 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 11,958 | 4140 |

| Italy | 9009 | 3618 | 1280 | 501 | 0 | 0 | 0 | 0 | 0 | 0 | 10,289 | 4119 |

| Austria | 968 | 416 | 1372 | 469 | 0 | 0 | 0 | 0 | 0 | 0 | 2340 | 885 |

| United States | 5449 | 2160 | 11 | 3 | 3 | 1 | 0 | 0 | 0 | 0 | 5462 | 2164 |

| Belgium | 2115 | 948 | 0 | 0 | 16 | 4 | 141 | 46 | 9 | 2 | 2281 | 1000 |

| United Kingdom | 722 | 307 | 819 | 268 | 273 | 72 | 170 | 55 | 66 | 15 | 2050 | 717 |

| Project | Sector | Location/ Installation Year | Usage | Number of Panels | Electrical Production | Thermal Production | Thermal Feature |

|---|---|---|---|---|---|---|---|

| Karlskrona | Residential Building | Sweden/2023 | DHW + Heating + Electricity | 84 PVT+ 130 PV | 76.5 MWh | 422 kWh/sqm | 4023 m2 |

| Sion | Residential Building | Switzerland/2017 | Heating + Electricity | 41 PVT | 11.48 kWc | 15.33 kWth | 2000 L solar storage tank, backed up by an Oertli geothermal heat pump (45 m probe in the ground water) |

| Sancoins | Commercial Complex | France/2017 | DHW + Heating + Electricity | 18 PVT + 8000 PV | 2.3 MWp | 6.73 kWth | 600 L storage tank, electrical back-up for the restaurant’s heating needs |

| Saint | Residential Building | Switzerland/2016 | Heating + Electricity | 8 PVT | 2 kWp | 6.37 kWth | 200 L balloon for pool shower, underfloor heating integrated into pool slab |

| Geneva | Residential Building | Switzerland/2016 | 18 PVT | 4.5 kWp | 6.73 kWth | 2800 L solar tanks (Cipag), Air-water heat pump as booster (Elco) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hosouli, S.; Aliakbari, M.; Raeisi, F.; Jahangir, M.T.; Gomes, J.; Murali, D.; Acosta Pazmiño, I.P. Photovoltaic-Thermal (PVT) Solar Collector and System Overview. Energies 2025, 18, 5643. https://doi.org/10.3390/en18215643

Hosouli S, Aliakbari M, Raeisi F, Jahangir MT, Gomes J, Murali D, Acosta Pazmiño IP. Photovoltaic-Thermal (PVT) Solar Collector and System Overview. Energies. 2025; 18(21):5643. https://doi.org/10.3390/en18215643

Chicago/Turabian StyleHosouli, Sahand, Mansoureh Aliakbari, Forough Raeisi, Muhammad Talha Jahangir, João Gomes, Damu Murali, and Iván P. Acosta Pazmiño. 2025. "Photovoltaic-Thermal (PVT) Solar Collector and System Overview" Energies 18, no. 21: 5643. https://doi.org/10.3390/en18215643

APA StyleHosouli, S., Aliakbari, M., Raeisi, F., Jahangir, M. T., Gomes, J., Murali, D., & Acosta Pazmiño, I. P. (2025). Photovoltaic-Thermal (PVT) Solar Collector and System Overview. Energies, 18(21), 5643. https://doi.org/10.3390/en18215643