An Accurate Method for Designing Piezoelectric Energy Harvesters Based on Two-Dimensional Green Functions Under a Tangential Line Force

Abstract

1. Introduction

2. General Solutions to Orthotropic Piezoelectric and Elastic Materials

2.1. General Solutions to Orthotropic Piezoelectric Materials

2.2. General Solution for Orthotropic Elastic Material

3. Green Function for the Tangential Line Force onto Orthotropic Piezoelectric-Coated Structure Surface

4. Numerical Results

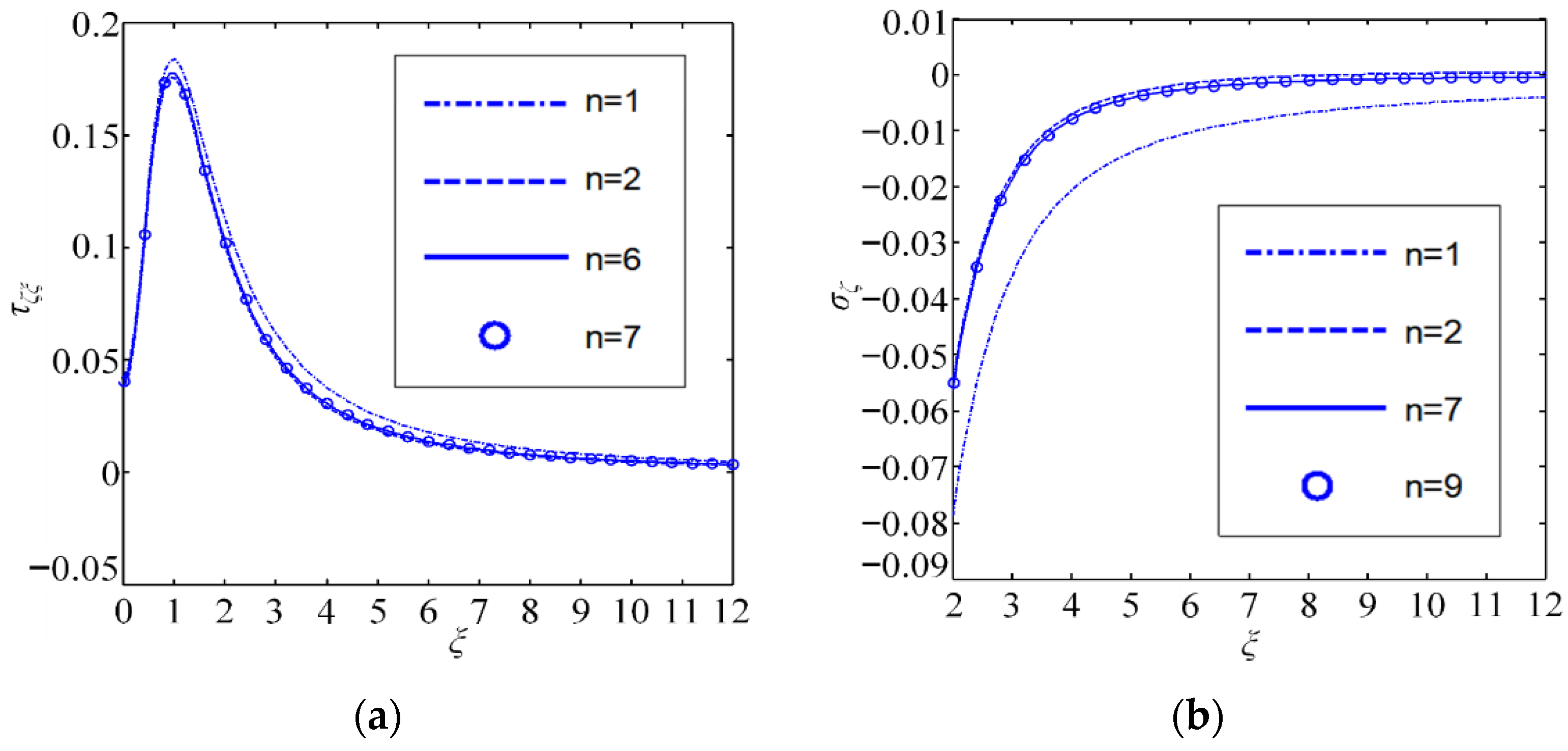

4.1. Computational Accuracy

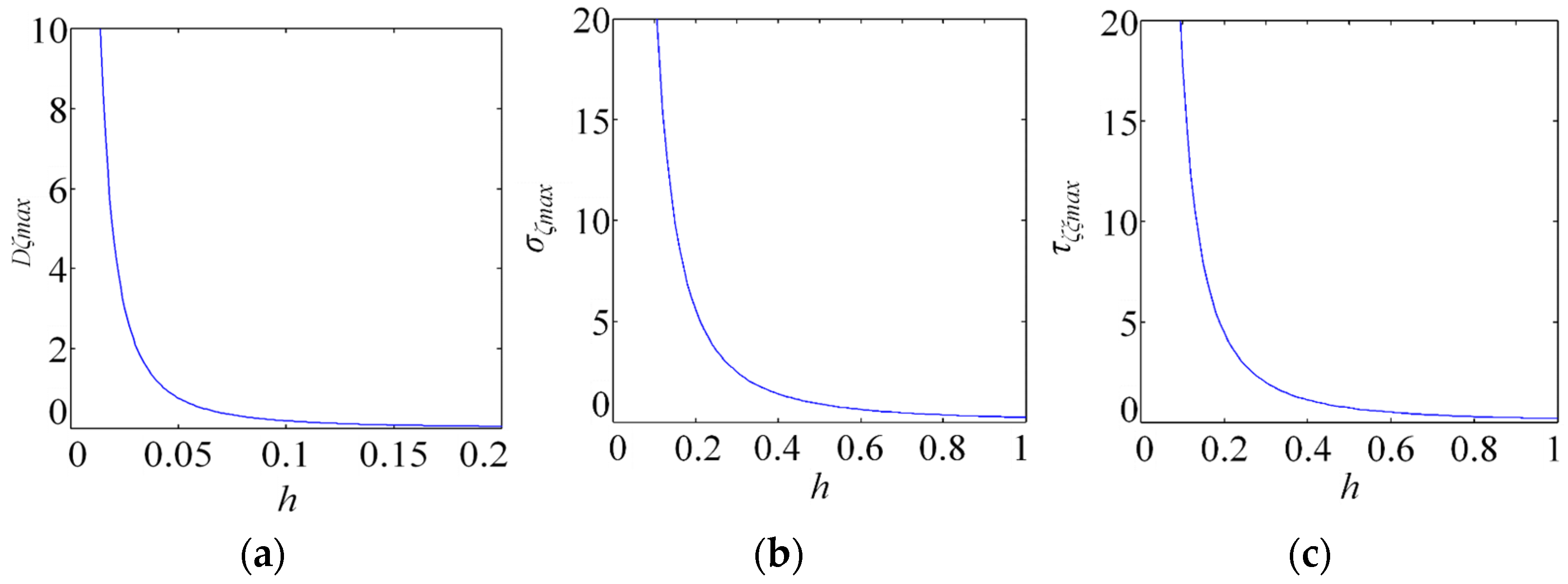

4.2. Impact Induced by Coating Thickness Against Maximal Interfacial Stresses as Well as Electric Displacement

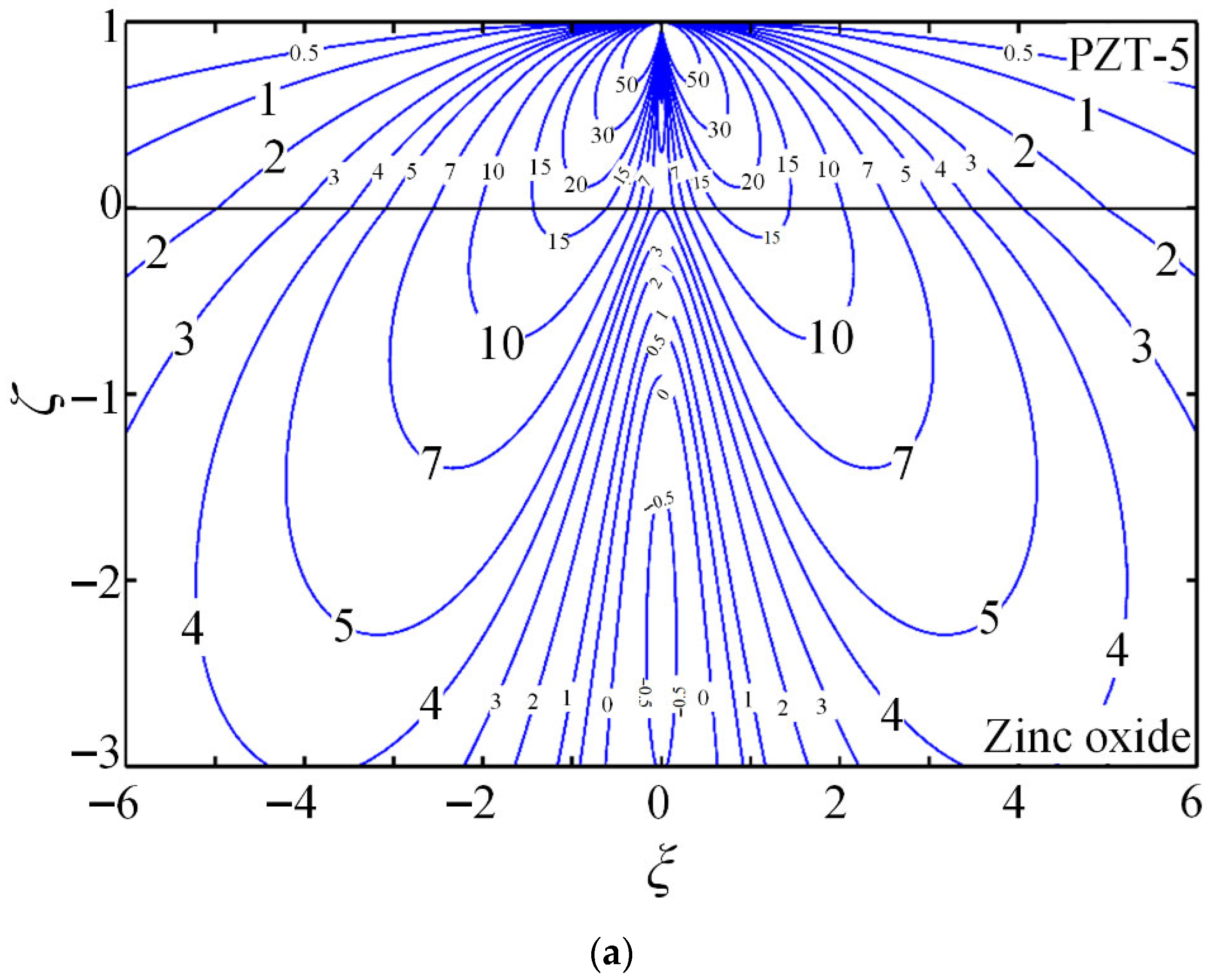

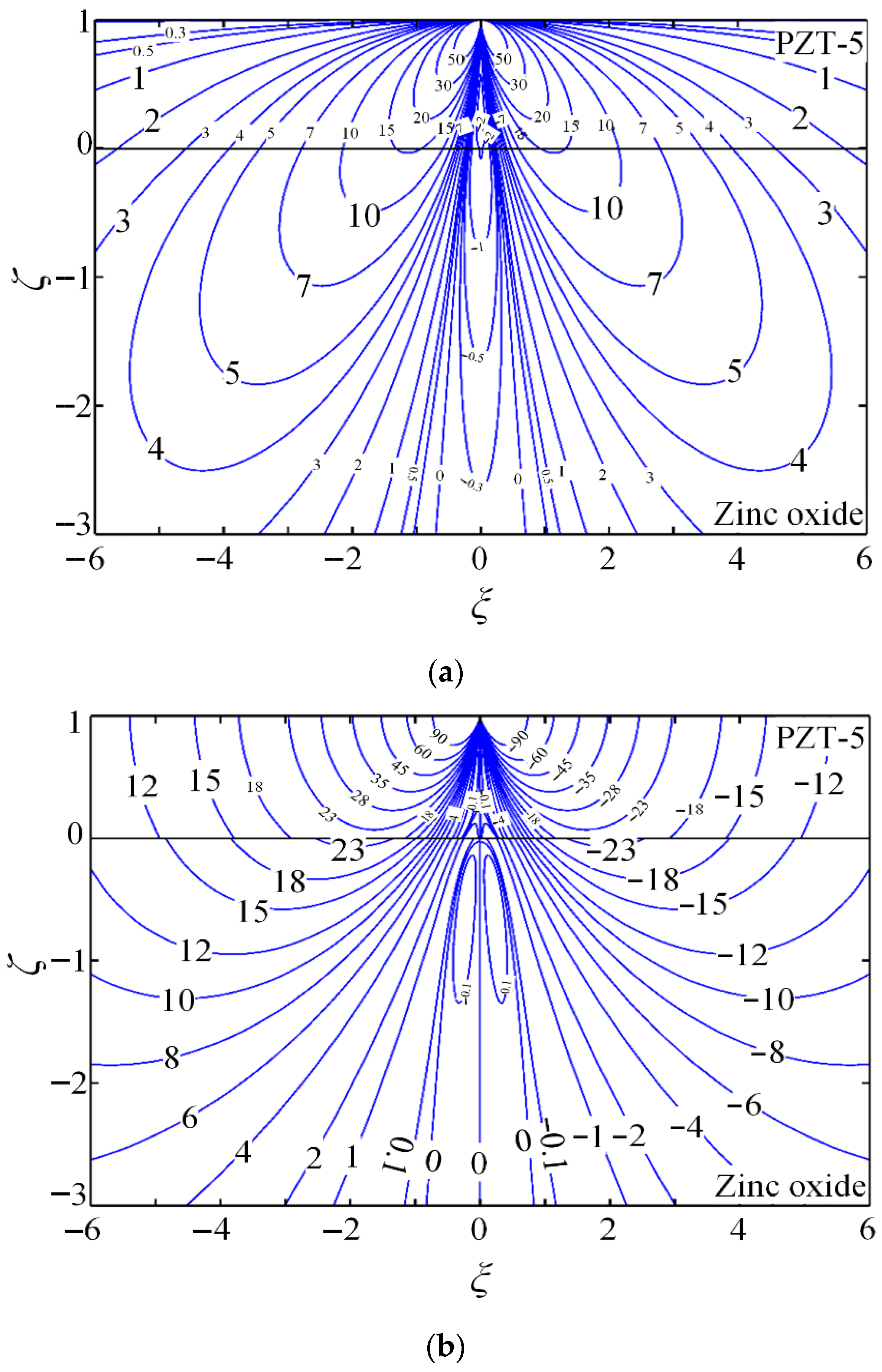

4.3. Stress Component and Electric Displacement Contours with the Tangential Line Force

- (1)

- For a piezoelectric coupling field, the distribution can be quite complicated, especially within the coating. Owing to the piezoelectric coupling effect, large gradients and high field values are obtained; these features must be considered for the reliable design of piezoelectric energy harvesters under optimal conditions. Numerical approaches such as FEM require extremely fine meshes to simulate the coupled fields, often leading to ill-conditioned systems and inaccurate results. Consequently, it becomes difficult to obtain accurate and stable solutions for piezoelectric coating structures with conventional numerical platforms.

- (2)

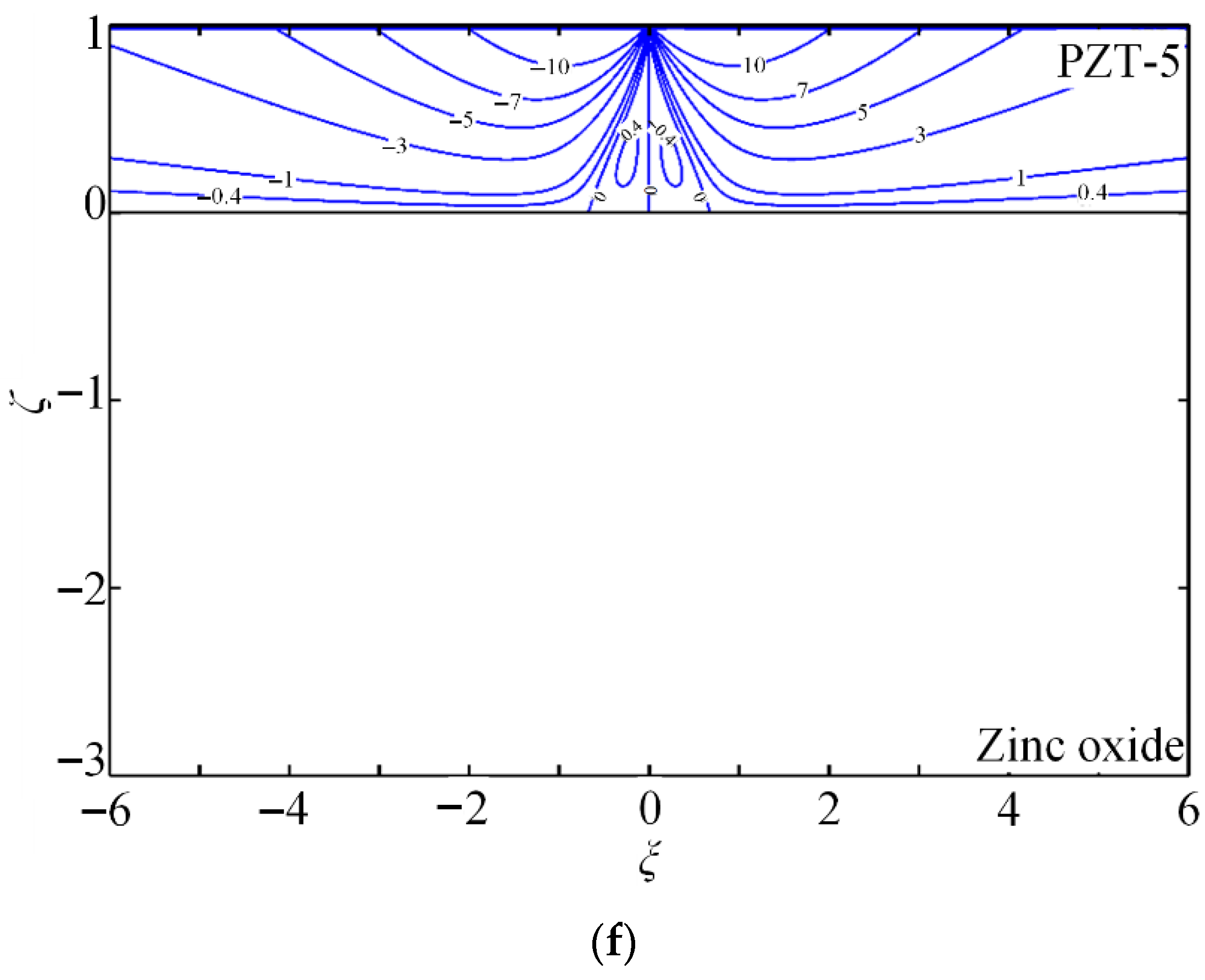

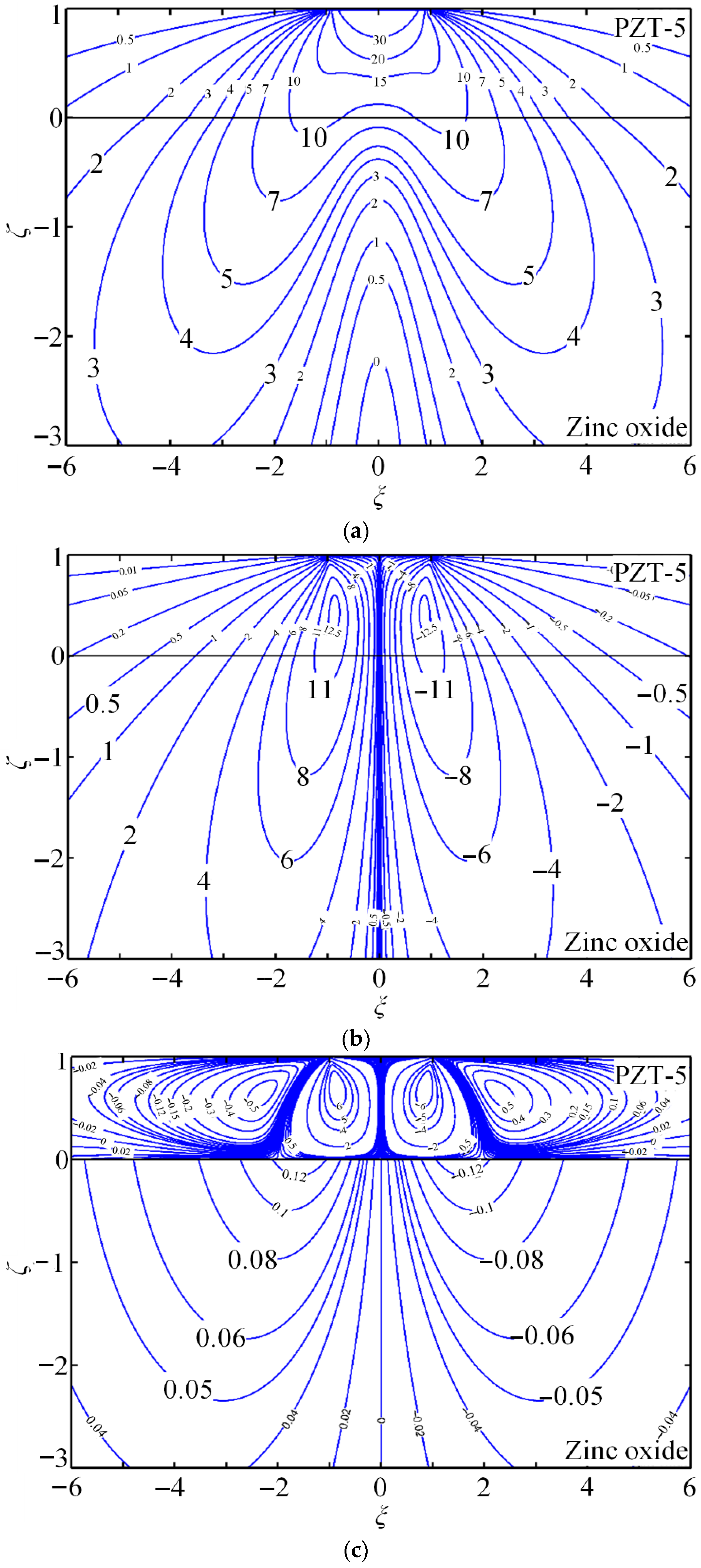

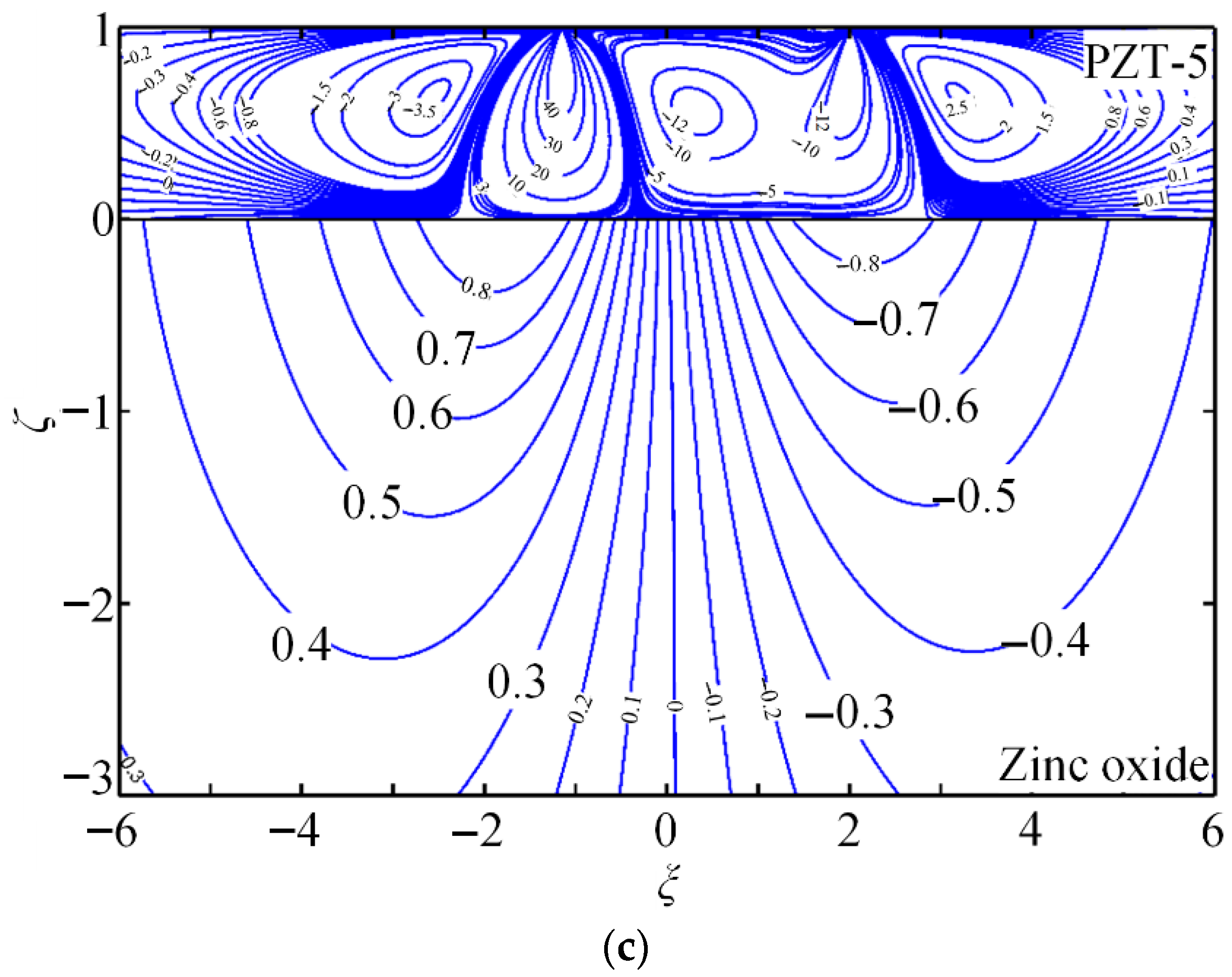

- Shear stresses are shown in Figure 4a and Figure 5a, normal stresses are shown in Figure 4c and Figure 5c, electrical displacements are shown in Figure 4e, and potentials are shown in Figure 4f, which show interfacial continuity, conforming to interfacial continuity Equation (20). However, the gradient of the above components shows interfacial discontinuity; as a result, contours are angled during interface crossing. This can be attributed to interfacial effect resulting from various coating–substrate material characteristics, which can be even apparent within contours for electrical displacements . Normal stresses from Figure 4b and Figure 5b and electrical displacements from Figure 4d are identical owing to interfacial discontinuity. In addition, a hexagonal zinc substrate serves as the electrical conductor with interfacial distribution of free charge because of the polarization effect. This substrate is the equipotential body ( from Figure 5f) without electric displacement components ( from Figure 5d, from Figure 5e).

- (1)

- Stress contours reveal substantially larger stress components within the coating than in the substrate. When a tangential line force is applied, most of the mechanical energy is confined to the coating, enhancing its electromechanical response.

- (2)

- A steep stress gradient appears around the zero-stress contour; as the stress field varies, energy release can interact with micro-cracks, potentially driving crack propagation and eventual device failure.

- (3)

- Figure 4a–c and Figure 5a–c are the dielectrics of the substrate. The stress component profiles in Figure 4a–c and Figure 5a–c are very complicated, without any universal rules to follow. It can be ascribed to the coupling effect induced by the piezoelectric coupling field. When designing piezoelectric energy harvesters, it is necessary to conduct comprehensive analysis and optimization based on precise computation.

- (4)

- Positive interfacial normal stress and shear stress can initiate tension and shear delamination, leading to failure. Figure 4a shows that is positive under the tangential line force; Figure 4c and Figure 5c indicate that the peak occurs near the loading point. Similarly, Figure 5b shows positive interfacial shear stress with its maximum close to the origin.

- (5)

- (1)

- (2)

- Three peak values of electric displacement appear at the interface midpoint and on both sides along the -coordinate (Figure 4d and Figure 5d): a negative value at the midpoint and positive values on the two sides. Two opposite peak values of occur at the interface on both sides (Figure 4e and Figure 5e). For the dielectric substrate, Figure 5a shows two negative interfacial peaks of potential on both sides; for the electrically conducting substrate, Figure 5f shows that the interfacial potential is zero throughout.

- (3)

- When electrodes are technologically embedded beneath the piezoelectric coating or substrate at any arbitrary position, higher-performance piezoelectric energy harvesters can be fabricated. Based on the electric field contours in Figure 4d and Figure 5d, the optimal pre-embedded electrode location is determined.

- (4)

- Performance is assessed by comparing multi-point output measurements of several electric field peak values. Subsequently, piezoelectric energy harvesters with superior efficacy are realized through the synergistic use of multi-point electric field energy.

4.4. Stress Component and Electric Displacement Contours in the Arbitrary Distributed Force

5. Conclusions

- (1)

- Harmonic functions (four sets) in the form of elementary functions are formulated, enabling the determination of the electromechanical coupling fields in piezoelectric energy harvesters. An orthotropic piezoelectric layer is combined with an orthotropic elastic substrate through a systematic permutation of material constants within a general solution framework.

- (2)

- By combining linear superposition theory with Gaussian quadrature, the coupled fields can be efficiently computed. Numerical studies shed important light on device behavior: coating fracture and interfacial delamination are the predominant failure modes that must be prioritized in reliability assessments. To optimize performance, energy conversion efficiency can be enhanced by adjusting the material and structural parameters.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, W.; Thompson, D.J.; Yurchenko, D. Energy harvesting technologies on high-speed railway infrastructure: Review and comparative analysis of the potential and practicality. Sustain. Energy Technol. Assess. 2025, 74, 104187. [Google Scholar] [CrossRef]

- Bhatt, K.; Kumar, S.; Kumar, S. A review on energy harvesting technologies: Comparison between non-conventional and conceptual approaches. Energy Rep. 2024, 12, 4717–4740. [Google Scholar] [CrossRef]

- Jiao, W.; Ma, R.; Gao, Y. Research advances in electrochemical human motion energy harvesting technologies. J. Electroanal. Chem. 2024, 967, 118474. [Google Scholar] [CrossRef]

- Cao, D.; Qin, W.; Zhou, Z. Enhancing wind energy harvesting through two V-shaped attachments and monostable characteristics in the galloping piezoelectric harvester. Energy Convers. Manag. 2024, 318, 118871. [Google Scholar] [CrossRef]

- Zhou, Z.; Cao, D.; Huang, H.; Qin, W. Biomimetic swallowtail V-shaped attachments for enhanced low-speed wind energy harvesting by a galloping piezoelectric energy harvester. Energy 2024, 304, 132063. [Google Scholar] [CrossRef]

- Cook-Chennault, K.A.; Thambi, N.; Sastry, A.M. Powering MEMS portable devices—A review of non-regenerative and regenerative power supply systems with special emphasis on piezoelectric energy harvesting systems. Smart Mater. Struct. 2008, 17, 043001. [Google Scholar] [CrossRef]

- Verma, A.K.; Rahman, M.A.; Vashishtha, P.; Guo, X.Y.; Sehrawat, M.; Mitra, R.; Giridhar, S.P.; Waqar, M.; Bhoriya, A.; Murdoch, B.J.; et al. Oxygen-Passivated Sulfur Vacancies in Monolayer MoS2 for Enhanced Piezoelectricity. ACS Nano 2025, 19, 3478–3489. [Google Scholar] [CrossRef]

- Dai, K.; Huo, Z.Y.; Miao, X.Y. Self-powered triboelectric functional devices and microsystems in health-care applications: An energy perspective. EnergyChem 2023, 5, 100109. [Google Scholar] [CrossRef]

- Chen, W.; Mo, J.; Zhao, J.; Ouyang, H. A two-degree-of-freedom pendulum-based piezoelectric-triboelectric hybrid energy harvester with vibro-impact and bistable mechanism. Energy 2024, 304, 132143. [Google Scholar] [CrossRef]

- Wang, J.; Kan, J.W.; Gu, Y.Q.; He, C.Y. Design, performance evaluation and calibration of an indirectly-excited piezoelectric wind energy harvester via a double-bluffbody exciter. Energy Convers. Manag. 2023, 284, 116969. [Google Scholar] [CrossRef]

- Kan, J.W.; Wu, Y.Q.; Li, S.J.; Wang, S.Y. A tunable rotational energy harvester exploiting a flexible-clamping piezoelectric beam by deploying magnetic repulsive force. Sens. Actuators A Phys. 2023, 353, 114198. [Google Scholar] [CrossRef]

- Wong, V.K.; Ho, J.H.; Chai, A.B. Performance of a piezoelectric energy harvester in actual rain. Energy 2017, 124, 364–371. [Google Scholar] [CrossRef]

- Wang, W.; Cao, J.; Bowen, C.R.; Zhou, S. Optimum resistance analysis and experimental verification of nonlinear piezoelectric energy harvesting from human motions. Energy 2017, 118, 221–230. [Google Scholar] [CrossRef]

- Huang, H.H.; Chen, K.S. Design, analysis, and experimental studies of a novel PVDF-based piezoelectric energy harvester with beating mechanisms. Sens. Actuators A Phys. 2016, 238, 317–328. [Google Scholar] [CrossRef]

- Wang, H.; Yi, M.; Zhang, Z.; Zhang, H. A wind-solar energy harvester based on airflow enhancement mechanism for rail-side devices. Energy 2023, 283, 129116. [Google Scholar] [CrossRef]

- Poulin-Vittrant, G.; Oshman, C.; Opoku, C.; Dahiya, A.S. Fabrication and characterization of ZnO nanowire-based piezoelectric nanogenerators for low frequency mechanical energy harvesting. Phys. Procedia 2015, 70, 909–913. [Google Scholar] [CrossRef]

- Zhao, F.; Wang, Z.; Bai, H.; Tang, H. Energy harvesting based on flow-induced vibration of a wavy cylinder coupled with tuned mass damper. Energy 2023, 282, 128584. [Google Scholar] [CrossRef]

- Guo, Y.; Maalla, A.; Habibi, M.; Moradi, Z. Electroelastic wave dispersion in the rotary piezoelectric NEMS sensors/actuators via nonlocal strain gradient theory. Mech. Syst. Signal Process. 2024, 216, 111453. [Google Scholar] [CrossRef]

- Fan, K.; Tan, Q.; Liu, H.; Cai, M. Harvesting energy from twisting vibration of a rotor suspended by a piece of string. Smart Mater. Struct. 2019, 28, 07LT01. [Google Scholar] [CrossRef]

- Lin, S.; Kan, J.; He, C.; Yu, Y. A direction-parallel piezoelectric wind-induced vibration energy harvester with the transducer movement oriented toward wind direction for pipeline energy harvesting. Energy 2025, 319, 135028. [Google Scholar] [CrossRef]

- Zhang, P.; Lin, W.; Xie, Z.; Cao, H. L-shaped cantilever beam piezoelectric energy harvester with frequency up-conversion for ultra-low-frequency rotating environments. Mech. Syst. Signal Process. 2025, 225, 112281. [Google Scholar] [CrossRef]

- Bagherzadeh, R.; Abrishami, S.; Shirali, A.; Rajabzadeh, A.R. Wearable and flexible electrodes in nanogenerators for energy harvesting, tactile sensors, and electronic textiles: Novel materi-als, recent advances, and future perspectives. Mater. Today Sustain. 2022, 20, 100233. [Google Scholar] [CrossRef]

- Zhang, X.F.; Di, H.S.; Tzou, H.S. Experimental study of a piezoelectric ring energy harvester. In Proceedings of the Symposium on Piezoelectricity, Acoustic Waves, and Device Applications (SPAWDA), Changsha, China, 25–27 October 2013; Zhejiang University Press: Hangzhou, China, 2013; pp. 26–32. [Google Scholar]

- Farhan, M.; Muthalif, A.G.A.; Ali, M.S.M. Innovative approaches to optimize vibration energy harvesting (VEH): A comprehensive review. Energy Rep. 2024, 12, 5194–5219. [Google Scholar] [CrossRef]

- Zhang, C.; Jiang, Z.; Sun, M. Nature-inspired helical piezoelectric hydrogels for energy harvesting and self-powered human-machine interfaces. Nano Energy 2025, 136, 110755. [Google Scholar] [CrossRef]

- Rasheed, A.; Ajmal, S.; Wang, P.; Lee, S.G. Energizing the future: Unveiling challenges and prospects in MXene-based piezoelectric and triboelectric nanogenerators for micro-and nanoscale energy harvesting applications. Appl. Mater. Today 2024, 39, 102270. [Google Scholar] [CrossRef]

- Huang, S.Q.; Tang, P.J.; Hou, P.F.; Zhang, W.H. A method of coating analysis based on cylindrical indenter loading on coated structure. Acta Mech. 2023, 234, 2223–2267. [Google Scholar] [CrossRef]

- Li, Y.; Tang, S.; Li, P.; Ren, J. Shear mode solutions to penny-shaped crack problems in two-dimensional hexagonal piezoelectric quasicrystal media. Theor. Appl. Fract. Mech. 2024, 134, 104762. [Google Scholar] [CrossRef]

- Huang, R.; Ding, S.; Chen, Q.; Lv, C.; Zhang, X. Sliding frictional contact of one dimensional hexagonal piezoelectric quasicrystals coating on piezoelectric substrate with imperfect interface. Int. J. Solids Struct. 2022, 239–240, 111423. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, K.; Xie, Y.; Long, G.; Zeng, X. Finite element analysis on properties evolution of slab track FLC under the coupling action of rainfall and fatigue load. Eng. Struct. 2022, 271, 114919. [Google Scholar] [CrossRef]

- Biswas, S.; Schwen, D.; Hales, J.D. Development of a finite element based strain periodicity implementation method. Finite. Elem. Anal. Des. 2020, 179, 103436. [Google Scholar] [CrossRef]

- Marchiori, G.; Lopomo, N.; Boi, M.; Berni, M.; Bianchi, M.; Gambardella, A. Optimizing thickness of ceramic coatings on plastic components for orthopedic applications: A finite element analysis. Mater. Sci. Eng. C 2016, 58, 381–388. [Google Scholar] [CrossRef]

- Moradi, A.; Ansari, R.; Hassanzadeh-Aghdam, M.K.; Jang, S.H. Thermomechanical behavior of carbon nanotube/graphene nanoplatelet-reinforced shape memory polymer nanocomposites: A micromechanics-based finite element approach. Eur. J. Mech. A Solids 2024, 107, 105360. [Google Scholar] [CrossRef]

- Tang, X.; Yang, W.; Yang, Q.; Liang, Y. Effects of interfacial imperfections on nanoscale adhesive contact for layered medium. Appl. Math. Model. 2025, 138, 115803. [Google Scholar] [CrossRef]

- Zhang, X.C.; Xu, B.S.; Wang, H.D.; Jiang, Y.; Wu, Y.X. Application of functionally graded interlayer on reducing the residual stress discontinuities at interfaces within a plasma-sprayed thermal barrier coating. Surf. Coat. Technol. 2007, 201, 5716–5719. [Google Scholar] [CrossRef]

- Shang, S.; Xiao, J.; Jiang, T.; Zhang, W.H. Analytical solution of multilayered structures with Green’s function. Int. J. Solids Struct. 2024, 290, 112636. [Google Scholar] [CrossRef]

- Li, Q.; Hou, P.F.; Shang, S.; Zhang, W. Thermal-stress assessment of double-layer thermoelastic coatings based on Green’s function. Int. J. Solids Struct. 2023, 260–261, 112041. [Google Scholar] [CrossRef]

- Tong, J.; Xu, Z.L.; Li, J.P.; Zhang, Y.; Hou, P.F. Green’s function for a line heat source acting on the surface of a coated isotropic thermoelastic material. J. Therm. Stresses. 2019, 42, 279–293. [Google Scholar] [CrossRef]

- Hou, P.F.; Zhang, Y. Study on the piezoelectric coated devices based on the 2D Green’s functions under a tangential line force. Z. Angew. Math. Phys. 2018, 69, 48. [Google Scholar] [CrossRef]

- Tong, J.; Li, J.; Su, J.; Liu, Y.J. Two-dimensional Green’s function for an isotropic equal-thickness double-layer structure. AIP Adv. 2025, 15, 015138. [Google Scholar] [CrossRef]

- Ding, H.J.; Wang, G.Q.; Chen, W.Q. A boundary integral formulation and 2D fundamental solutions for piezoelectric media. Comput. Methods Appl. Mech. Eng. 1998, 158, 65–80. [Google Scholar] [CrossRef]

- Hou, P.F.; Jiang, H.Y.; Li, J.R. A method for the orthotropic coating-substrate system: Green’s function for a normal line force on the surface. Int. J. Mech. Sci. 2015, 96–97, 172–181. [Google Scholar] [CrossRef]

| Material | Zinc Oxide | Hexagonal Zinc | PZT-5H | |

|---|---|---|---|---|

| Elastic constants (×109 N/m) | C11 | 209.7 | 162.8 | 126 |

| C13 | 105.1 | 36.2 | 53 | |

| C33 | 210.9 | 62.7 | 117 | |

| C44 | 42.5 | 38.5 | 35.3 | |

| Piezoelectric constant (C/m2) | e31 | / | / | −6.5 |

| e33 | / | / | 13 | |

| e15 | / | / | 17 | |

| Dielectric constant (×10−9 C/Vm) | ε11 | 0.17 | / | 15.1 |

| ε33 | 0.25 | / | 13 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tong, J.; Zhang, Y.; Hou, P.-F. An Accurate Method for Designing Piezoelectric Energy Harvesters Based on Two-Dimensional Green Functions Under a Tangential Line Force. Energies 2025, 18, 5564. https://doi.org/10.3390/en18215564

Tong J, Zhang Y, Hou P-F. An Accurate Method for Designing Piezoelectric Energy Harvesters Based on Two-Dimensional Green Functions Under a Tangential Line Force. Energies. 2025; 18(21):5564. https://doi.org/10.3390/en18215564

Chicago/Turabian StyleTong, Jie, Yang Zhang, and Peng-Fei Hou. 2025. "An Accurate Method for Designing Piezoelectric Energy Harvesters Based on Two-Dimensional Green Functions Under a Tangential Line Force" Energies 18, no. 21: 5564. https://doi.org/10.3390/en18215564

APA StyleTong, J., Zhang, Y., & Hou, P.-F. (2025). An Accurate Method for Designing Piezoelectric Energy Harvesters Based on Two-Dimensional Green Functions Under a Tangential Line Force. Energies, 18(21), 5564. https://doi.org/10.3390/en18215564