Sustainable Aviation Fuels: A Review of Current Techno Economic Viability and Life Cycle Impacts

Abstract

1. Introduction

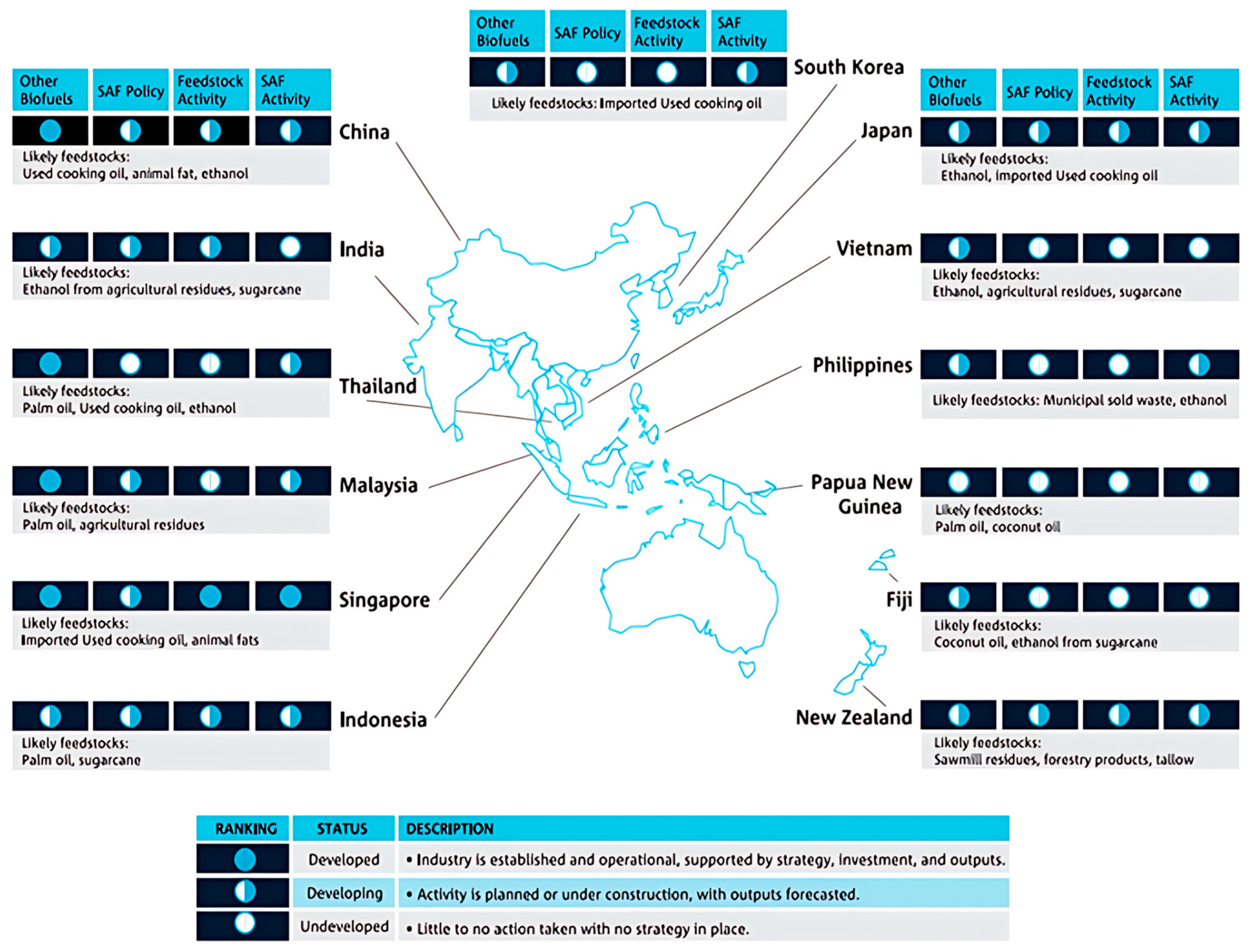

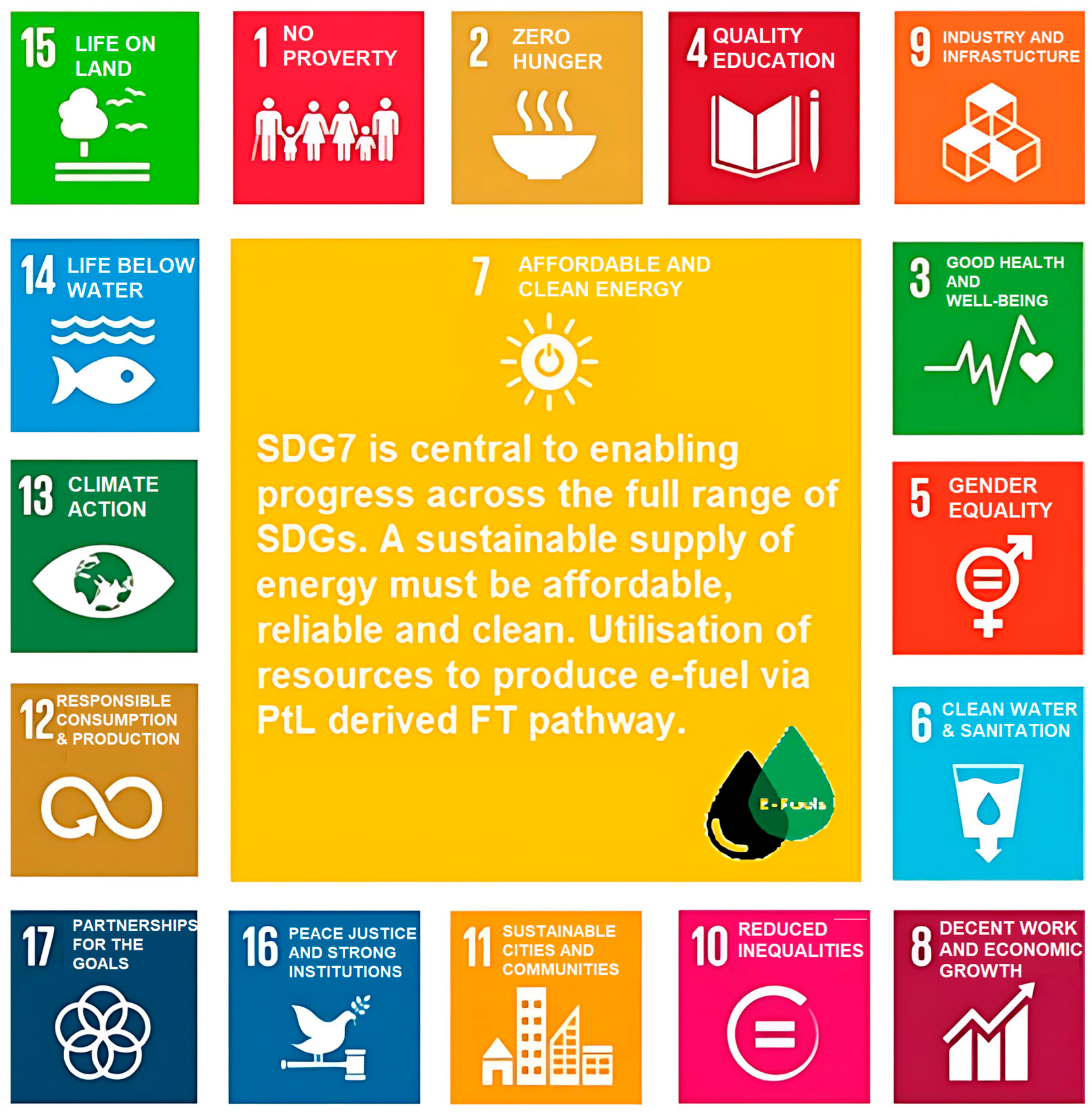

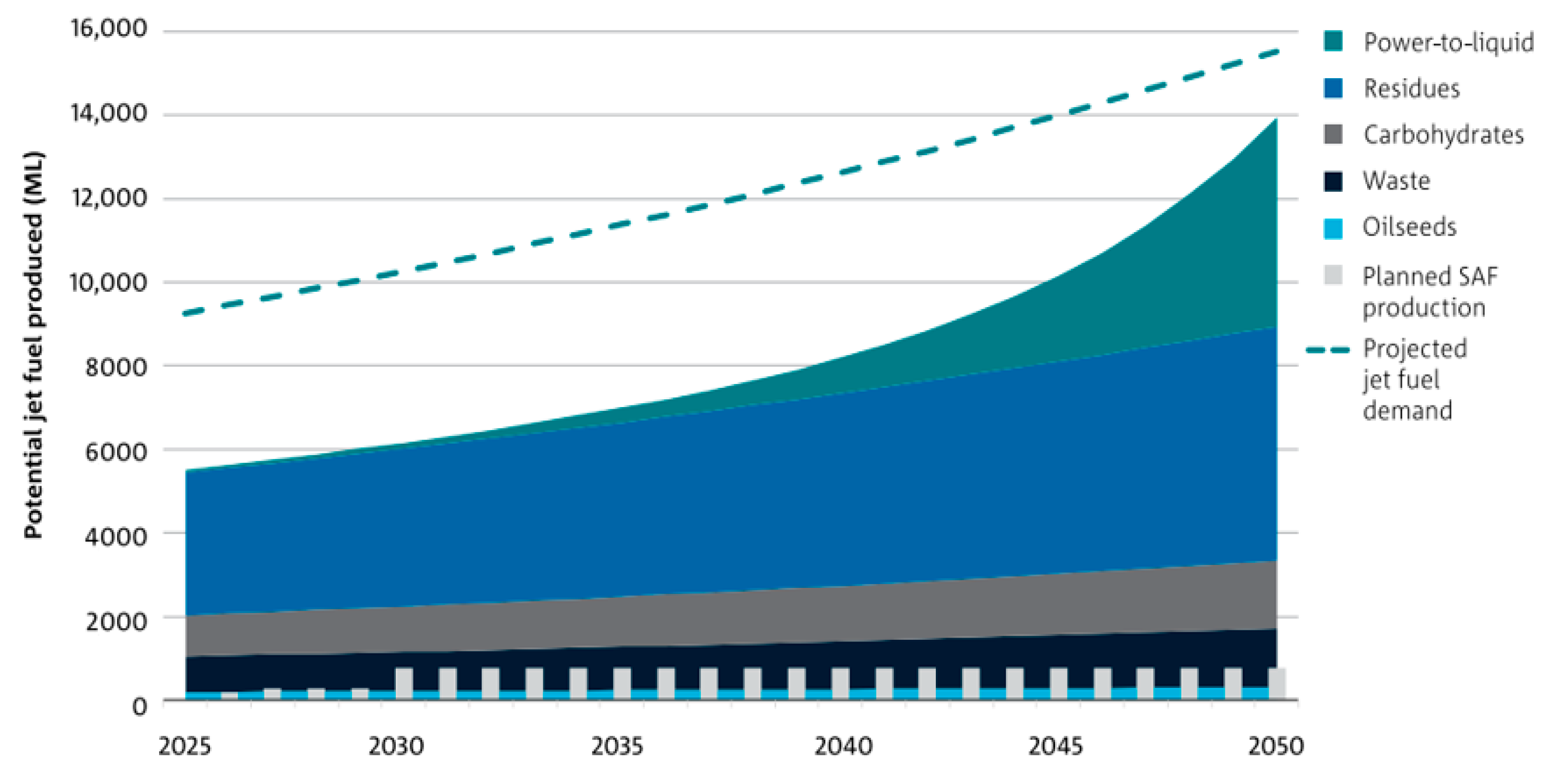

2. SAF Development in Australia

3. SAF Production Pathways

3.1. ASTM-Approved SAF Pathway

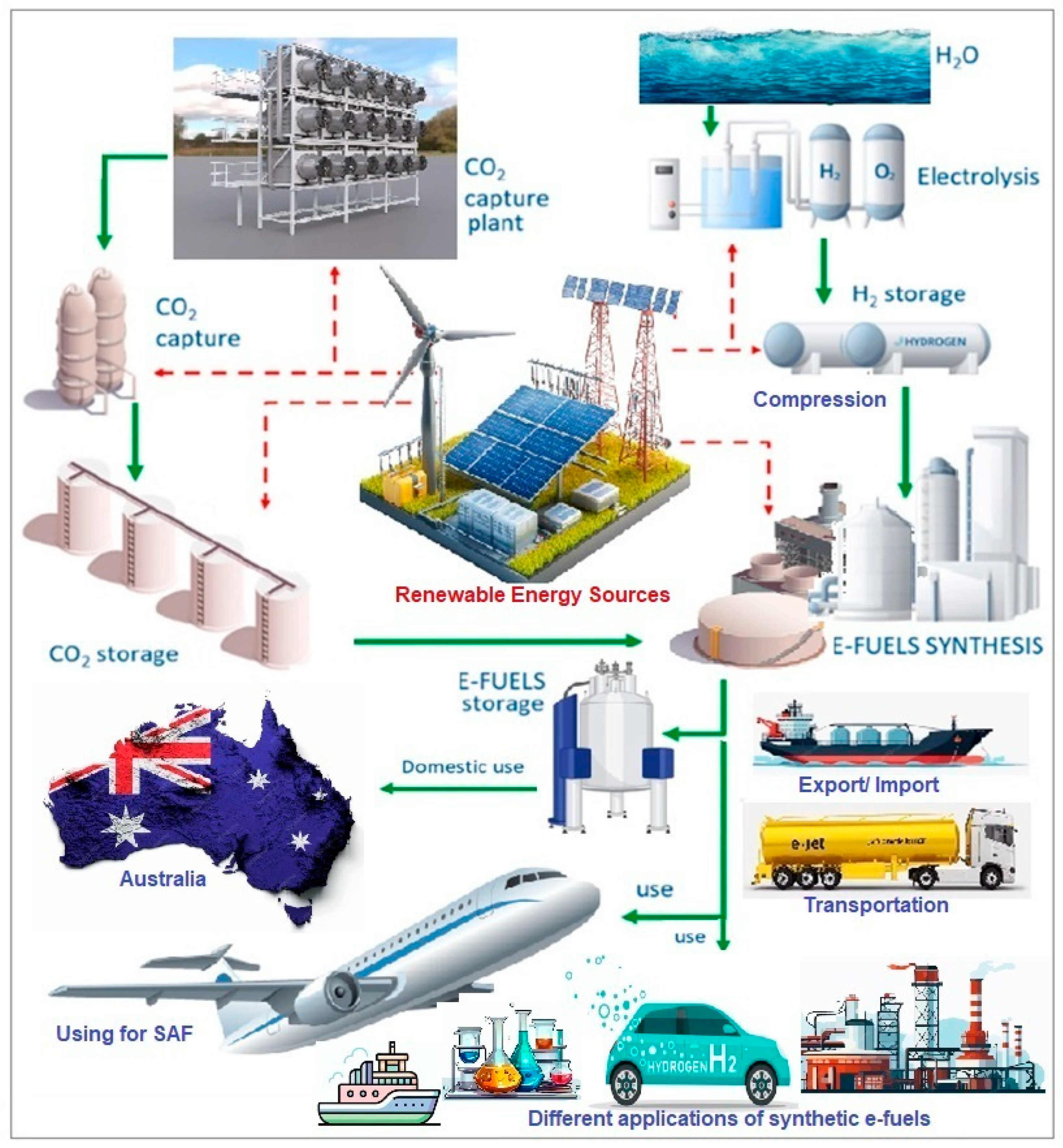

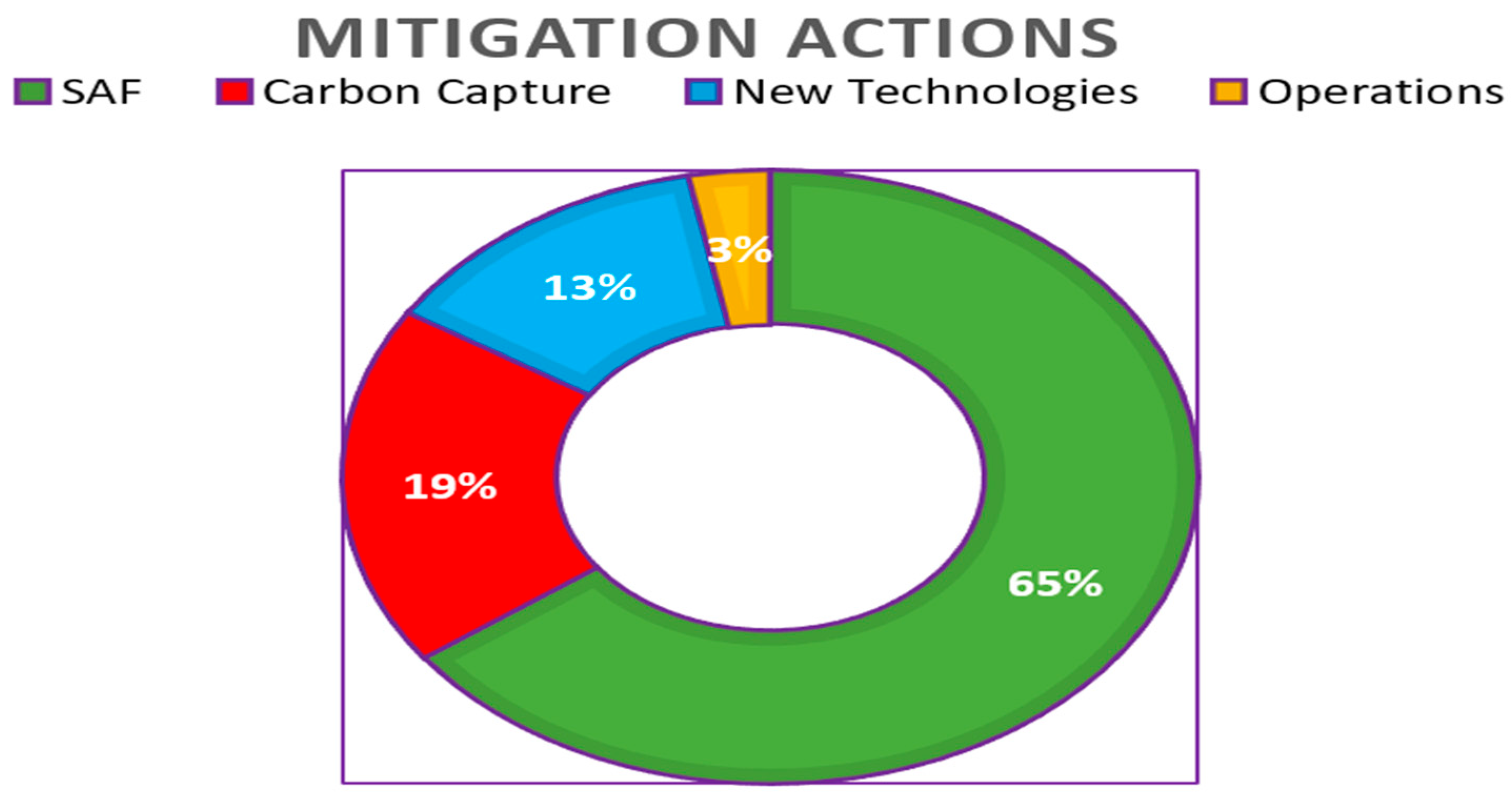

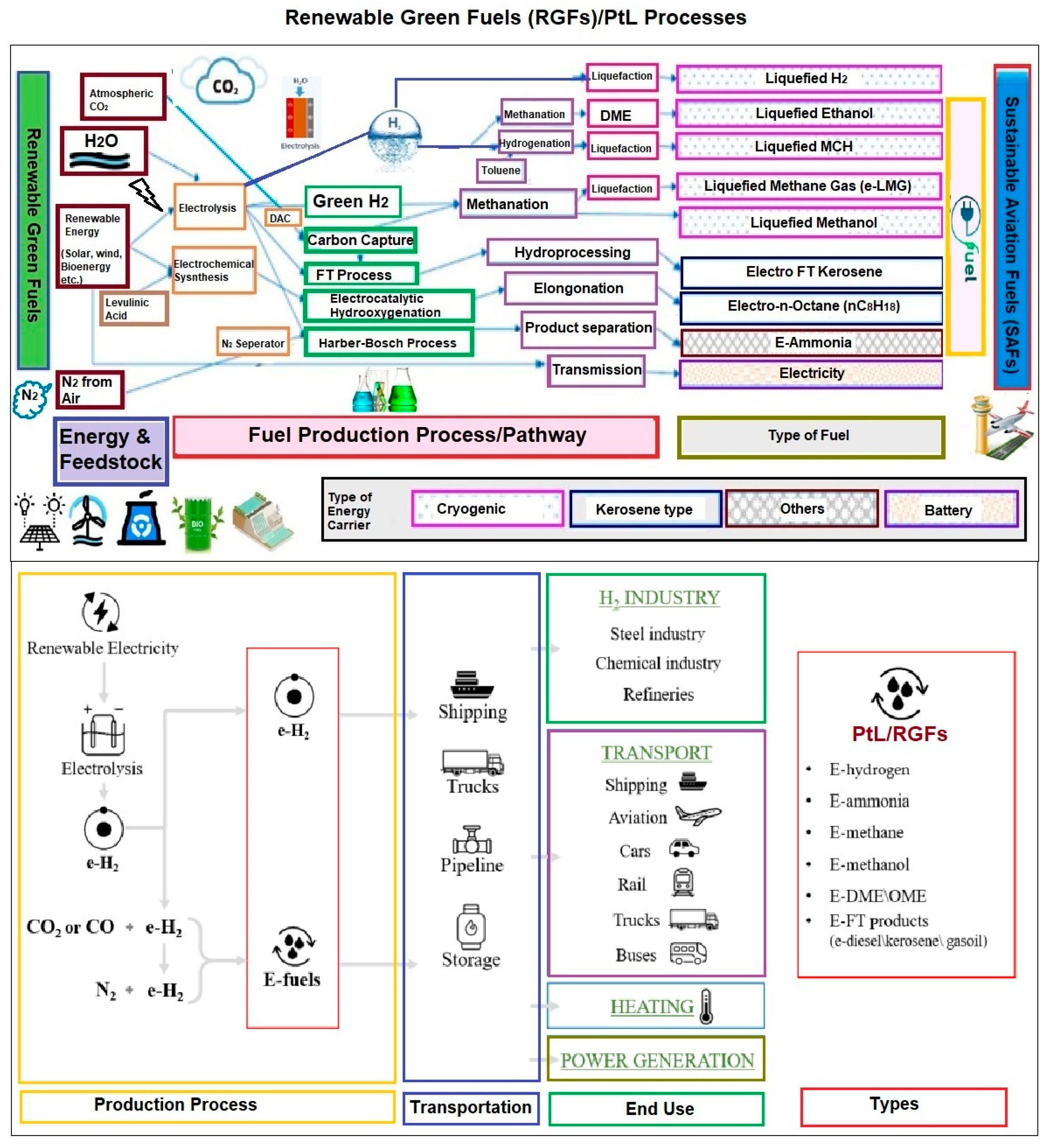

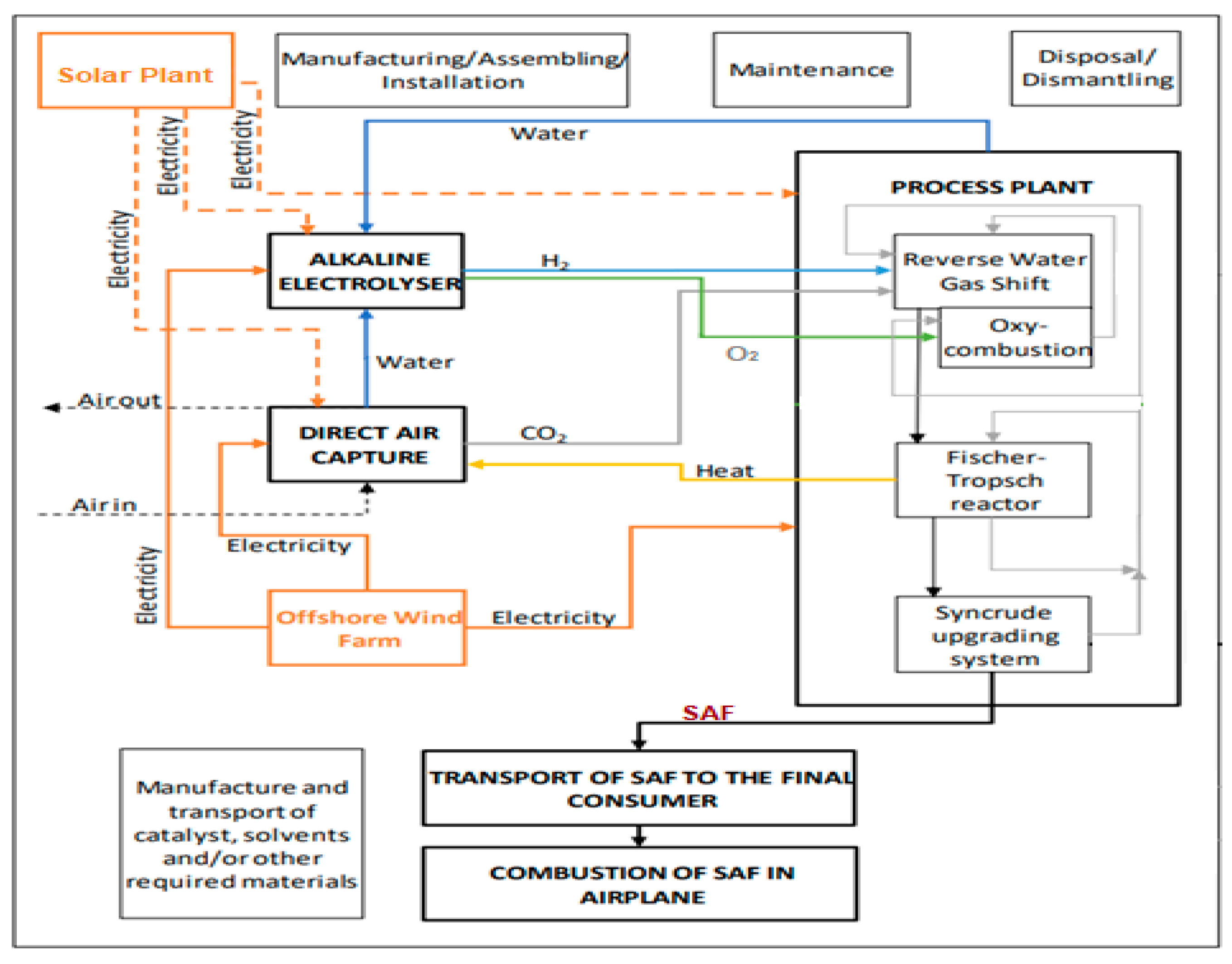

3.2. Power-to-Liquids (PtL)

3.3. Alcohol-to-Jet (AtJ)

3.4. Comparison of the SAF Pathways

| SAF Pathway | Technology Maturity | Scalability Potential | GHG Reduction Potential | Production Cost Trend | Key Advantages | Key Limitations |

|---|---|---|---|---|---|---|

| HEFA | High (commercial) | Moderate (feedstock-limited) | Medium (40–70%) | Medium | Commercially available; drop-in fuel | Feedstock competition; limited GHG gains if unsustainable sourcing |

| FT Synthetic Kerosene | Medium (some commercial plants) | High (with sustainable feedstocks) | High (up to 90% with biomass + CCUS) | High | Flexible feedstocks; high-quality fuel | High CAPEX/OPEX; energy-intensive |

| AtJ (EtJ, BtJ, MtJ) | Low–Medium (early scale-up) | Medium | Medium–High | High | Can use multiple alcohol sources; low particulate emissions | Feedstock competition; limited current capacity |

| BtL | Low (pilot/demo) | High (abundant biomass) | High (up to 90% with residues) | High | Uses lignocellulosic waste; low sulfur | Complex process; high energy input |

| Algal Biofuels | Low (R&D/pilot) | High (non-arable land use) | High | Very High | Minimal land competition; high yield | High production cost; cultivation challenges |

| PtL | Low (demo projects) | Very High (renewables + DAC) | Very High (>90%) | Very High | No biomass limits; true carbon-neutral potential | High energy demand; expensive |

4. Techno-Economic Evaluation (TEA) and Life Cycle Assessment (LCA)

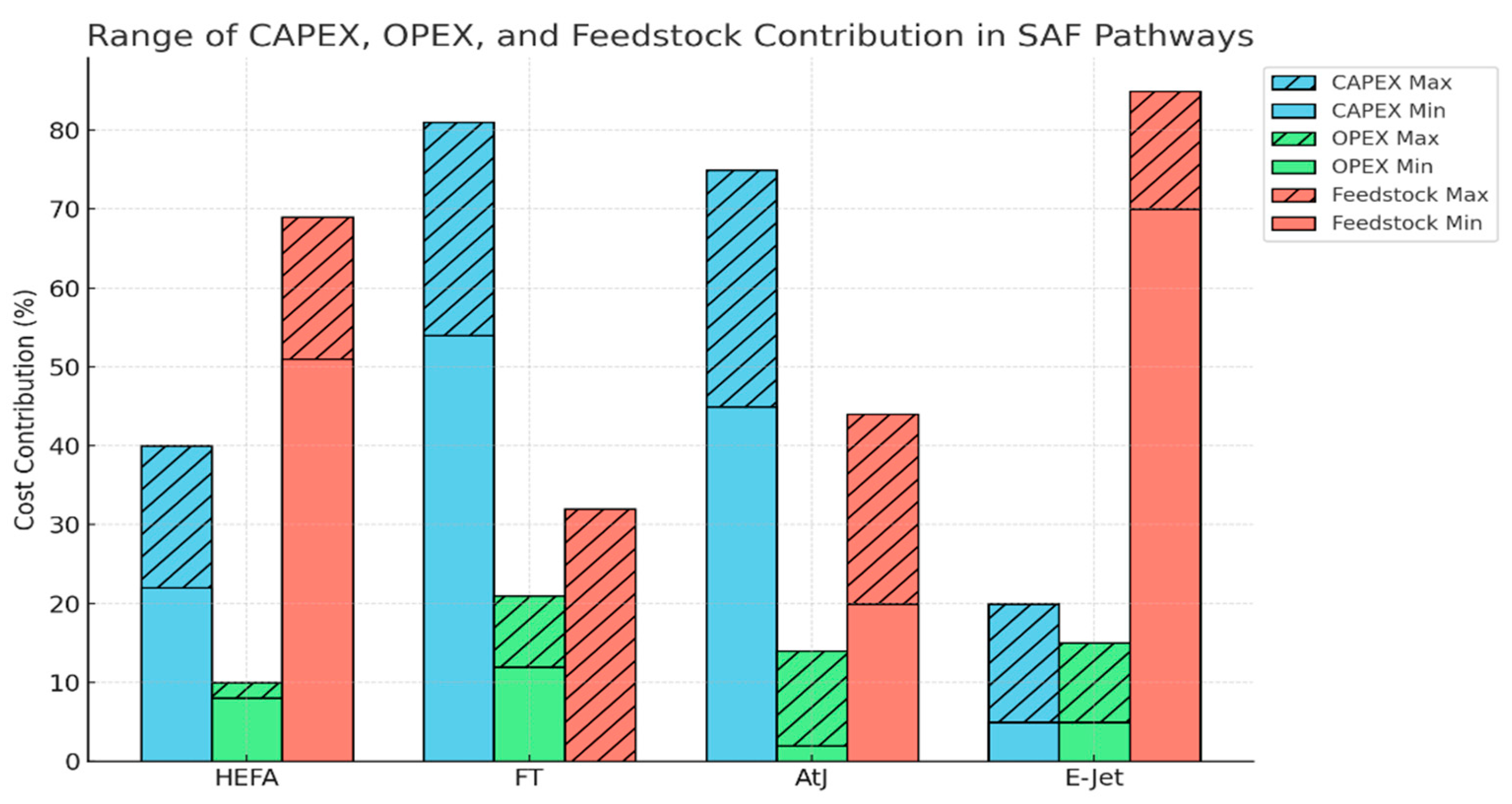

4.1. Techno-Economic Analysis (TEA)

4.2. Life Cycle Assessment (LCA)

4.3. The Power-to-Liquid (PtL) Method for Generating SAF

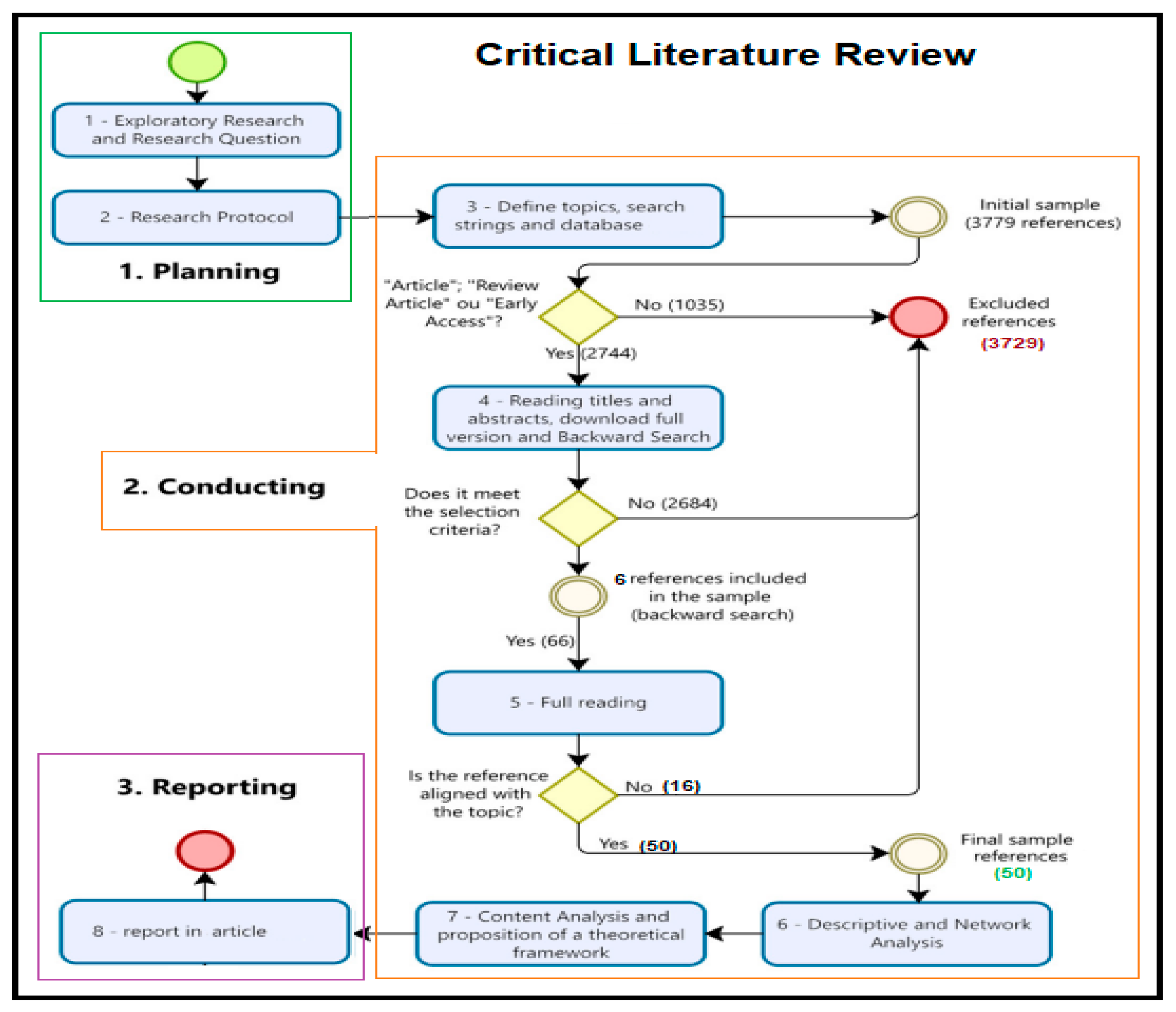

5. Methodologies

5.1. Search String

- Articles that specifically explored FT based e-fuel production for SAF utilizing green hydrogen and atmospheric CO2.

- Studies offering a techno-economic analysis or a life cycle assessment of the PtL derived synthetic e-fuel production process.

- Works that were published in English during the years January 2023 to June 2025.

- Articles that mainly focused on alternative aviation fuels without specifically addressing FT based e-fuels.

- Publications that were deficient in substantial data or lacked clarity in their methodology.

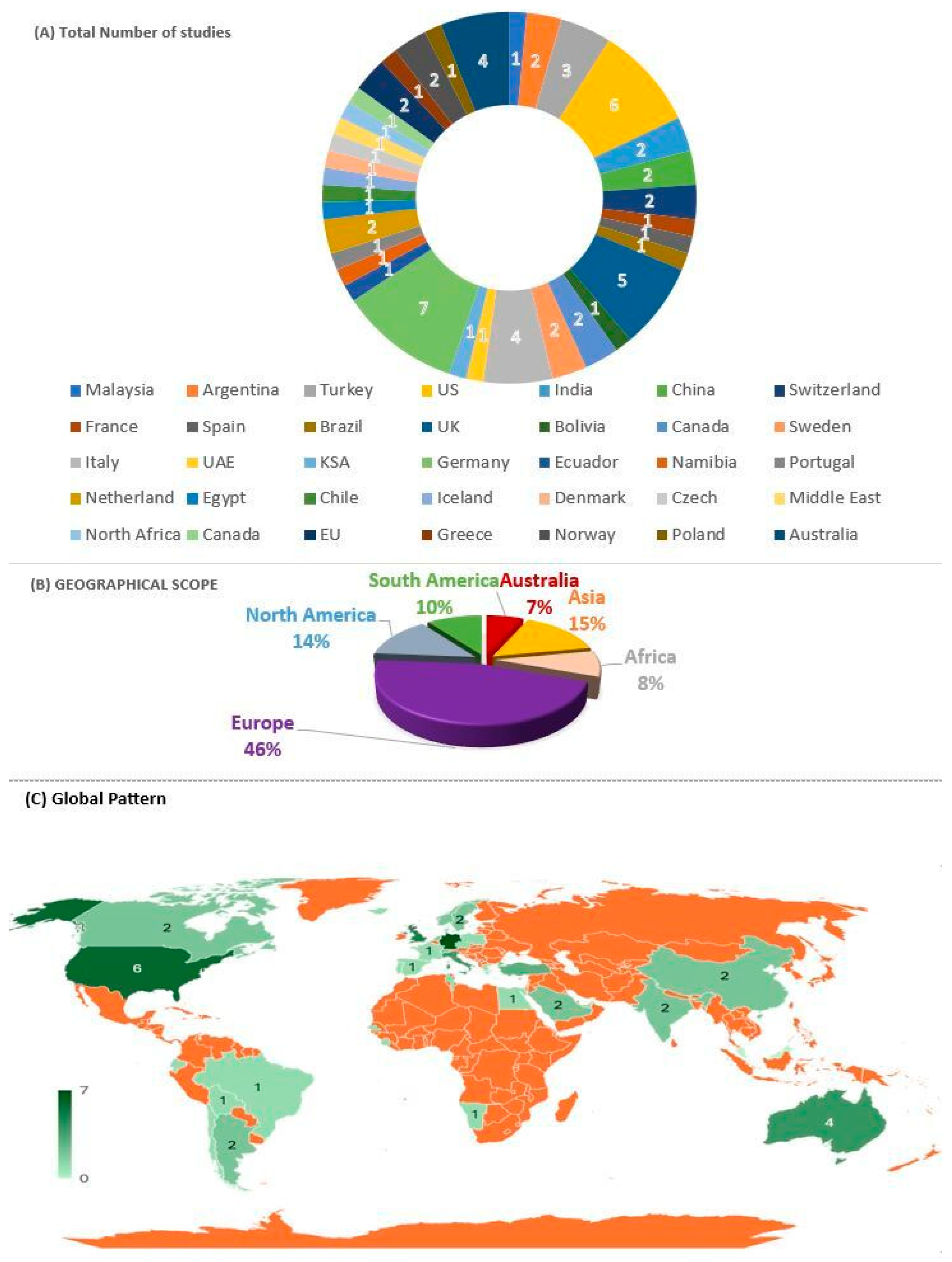

5.2. Data Analysis

5.3. Techno-Economic Viability and Life Cycle Impacts of SAF

- (i)

- (ii)

- (iii)

Critical Analysis

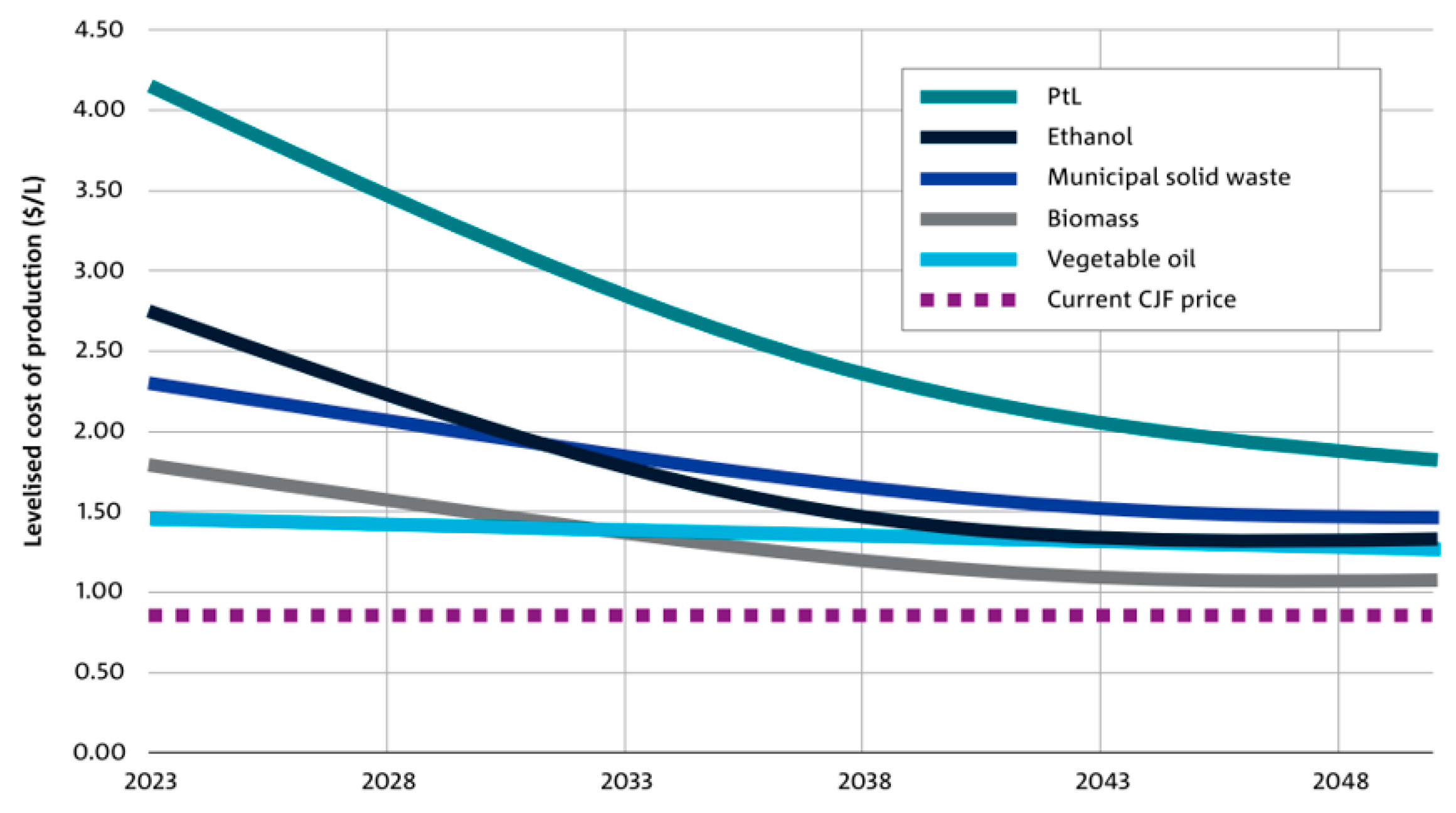

5.4. Cost of Production: Current Status and Future Projections

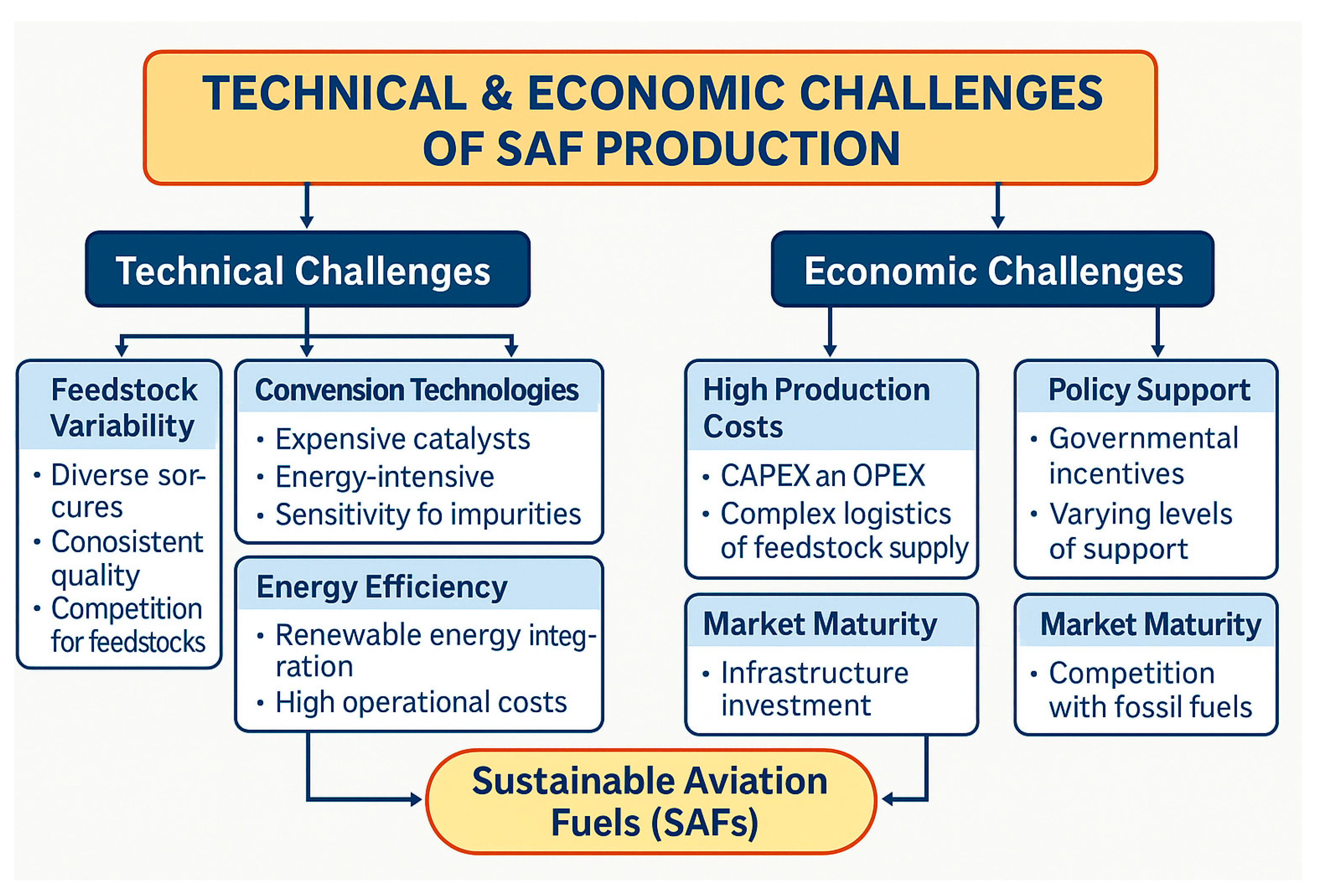

5.5. Economic Viability and Challenges

Commercialization and Collaborative Efforts of SAF

6. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Abbreviation | Full Term |

| A | Acidification |

| ARENA | Australian Renewable Energy Agency |

| C6H12O5 | CH3CH2OH |

| CE | CH3OH |

| CNG | Compressed natural gas |

| CO | Carbon monoxide |

| E | Eutrophication |

| EC | Ethyl cellulose |

| EJ | Exajoules |

| FT | Fischer Tropsc |

| GIE | Gas Infrastructure Europe |

| GWh | Gigawatt hours |

| H2 | Hydrogen |

| H2S | Hydrogen sulfide |

| HT | Human toxicity |

| IR | Industrial revolution |

| LCA | Life-cycle assessment |

| LCIA | Lifecycle inventory analysis |

| LNG | Liquified natural gas |

| Mbtu | Mega British thermal units |

| MW | Megawatt |

| N2 | Nitrogen |

| NH3 | Ammonia |

| O2 | Oxygen |

| MSW | Municipal solid waste |

| RGF | Renewable “Green” Fuels |

| WE | Waste Energy |

| TEA | Techno-economic analysis |

| TJ | Terajoule |

| TSA | Temperature swing adsorption |

| USA/US | United States of America |

| AbD | Abiotic depletion |

| OECD | Organization of Economic Co-operation and Development |

| C6H12O6 | Glucose |

| CH4 | Methane |

| CO2 | Carbon dioxide |

| DEA | Diethanol amine |

| EBA | European Biogas Association |

| EE | Electrical energy |

| EMD | Early modern development |

| GHG | Greenhouse gases |

| GJ | Gigajoule |

| GWP | Global warming potential |

| H2O | Water |

| HPWS | High pressure water scrubbing |

| IEA | International Energy Agency |

| IRR | Internal rate of return |

| LCC | Lifecycle costing |

| LLCA | Life-cycle cost analysis |

| MAET | Marine aquatic ecotoxicity |

| MDEA | Methyl diethanol amine |

| MWh | Megawatt hours |

| NCf | Net cash flow |

| NPV | Net present value |

| WWTP | Waste Water treatment plant |

| OLD | Ozone layer depletion |

| SO2 | Sulfur dioxide |

| STP | Standard temperature and pressure |

| TE | Thermal energy |

| TRL | Technological readiness level |

| TWh | Terawatt hours |

| PTL | Power to Liquid |

References

- Nunes, L.J. The rising threat of atmospheric CO2: A review on the causes, impacts, and mitigation strategies. Environments 2023, 10, 66. [Google Scholar] [CrossRef]

- Miao, Q.; Nduneseokwu, C. Global environmental leadership: Addressing the triple planetary crisis. In Environmental Leadership in a VUCA Era: An Interdisciplinary Handbook; Springer: Berlin/Heidelberg, Germany, 2025; pp. 37–119. [Google Scholar]

- Fu, B.; Li, J.; Gasser, T.; Ciais, P.; Piao, S.; Tao, S.; Shen, G.; Lai, Y.; Han, L.; Li, B. Climate warming mitigation from nationally determined contributions. Adv. Atmos. Sci. 2022, 39, 1217–1228. [Google Scholar] [CrossRef]

- Alghamdi, A.; Alharethi, M.; Leal-Arcas, R. COP30 in Brazil: A Critical Juncture for the Paris Agreement. In Queen Mary Law Research Paper No. 010/2025; Queen Mary University of London: London, UK, 2025; pp. 1–40. [Google Scholar] [CrossRef]

- Sulik-Górecka, A.; Strojek-Filus, M. CO2 Emission Reporting of maritime and air transport in the context of sustainable development. Prod. Eng. Arch. 2022, 28, 381–389. [Google Scholar] [CrossRef]

- Wang, L.K.; Balasubramanian, R.; He, J.; Wang, M.-H.S. Control and Management of Air Emissions from the Transportation Industry. In Control of Heavy Metals in the Environment; CRC Press: Boca Raton, FL, USA, 2025; pp. 396–420. [Google Scholar]

- Leal Filho, W.; Ng, A.W.; Sharifi, A.; Janová, J.; Özuyar, P.G.; Hemani, C.; Heyes, G.; Njau, D.; Rampasso, I. Global tourism, climate change and energy sustainability: Assessing carbon reduction mitigating measures from the aviation industry. Sustain. Sci. 2023, 18, 983–996. [Google Scholar] [CrossRef]

- Quaresma, G.; Magalhães, L.B.; Ferreira, A.F.; Silva, A. E-Kerosene Potential for Commercial Aviation Decarbonization. In Proceedings of the 34th Congress of the International Council of the Aeronautical Sciences (ICAS 2024), Florence, Italy, 9–13 September 2024; pp. 9–13. [Google Scholar]

- Etchebehere, V. Climate change and aviation. In Handbook of Business and Climate Change; Edward Elgar Publishing: Cheltenham, UK, 2023; pp. 187–207. [Google Scholar]

- Mustapha, C. The burden of a ton CO2! Emission trading systems and the air transport business. In The Air Transportation Industry; Elsevier: Amsterdam, The Netherlands, 2022; pp. 27–53. [Google Scholar]

- de la Hoz, J.; Martín, H.; Guerrero, J.M. Technologies and policies for decarbonisation of the industrial and transport sectors. Front. Media SA 2023, 11, 1200837. [Google Scholar] [CrossRef]

- Edgell, R.; Henao, F.; Durgin, W.W.; Olney, J.; Chappala, R. The Future of Sustainable Aviation: Navigating the Sociotechnical Matters of Concern. In Proceedings of the AIAA Aviation Forum and Ascend 2025, Las Vegas, NV, USA, 21–25 July 2025. [Google Scholar]

- Ismael, M.A.; El-Adawy, M.; Farooqi, A.S.; Hamdy, M.; Shahid, M.Z.; Elserfy, Z.; Nemitallah, M.A. Sustainable Aviation Fuel: Operational Challenges, Techno-Economics, and Life Cycle Analysis. Energy Fuels 2025, 39, 13848–13878. [Google Scholar] [CrossRef]

- Huete, J.; Nalianda, D.; Zaghari, B.; Pilidis, P. A Strategy to Decarbonize Civil Aviation: A phased innovation approach to hydrogen technologies. IEEE Electrif. Mag. 2022, 10, 27–33. [Google Scholar] [CrossRef]

- Belcher, A.; Workman, M.; Jefferson, A.; Ostrovnaya, A. Aviation sector decarbonisation as a case of deep uncertainty: The need for an integrative, exploratory, and interdisciplinary approach. Energy Res. Soc. Sci. 2025, 127, 104158. [Google Scholar] [CrossRef]

- Sethi, V.; Sun, X.; Nalianda, D.; Rolt, A.M.; Holborn, P.; Wijesinghe, C.; Xisto, C.; Jonsson, I.; Grönstedt, T.; Ingram, J. Enabling cryogenic hydrogen-based CO2-free air transport: Meeting the demands of zero carbon aviation. IEEE Electrif. Mag. 2022, 10, 69–81. [Google Scholar] [CrossRef]

- El-Adawy, M.; Dalha, I.B.; Ismael, M.A.; Al-Absi, Z.A.; Nemitallah, M.A. Review of sustainable hydrogen energy processes: Production, storage, transportation, and color-coded classifications. Energy Fuels 2024, 38, 22686–22718. [Google Scholar] [CrossRef]

- López Gómez, M. Value Chain for the Implementation in Use and Production of Sustainable Aviation Fuel (SAF) in Colombia. Ph.D. Thesis, University of the Andes, Bogotá, Colombia, 2024. [Google Scholar]

- Koščáková, M.; Korba, P.; Sekelová, I.; Koščák, P.; Pastír, D. Analysis of Sustainable Aviation Fuels Market. In Proceedings of the 2022 New Trends in Aviation Development (NTAD), Novy Smokovec, Slovakia, 24–25 November 2022; IEEE: New York, NY, USA, 2022. [Google Scholar]

- Meydani, A.; Shahinzadeh, H.; Gharehpetian, G.B.; Hayati, M.M.; Abapour, M. Power-to-X: Pioneering the Future of Sustainable Energy. In Power-to-X in Regional Energy Systems; CRC Press: Boca Raton, FL, USA, 2025; pp. 1–56. [Google Scholar]

- Ambraziejus, L. Towards Safe and Sustainable Aviation Decarbonization: The Case for Fewer Flights on Higher Quality SAF. Master’s Thesis, Utrecht University VET, Utrecht, The Netherlands, 2025. [Google Scholar]

- Klimczyk, W.; Jasiński, R.; Niklas, J.; Siedlecki, M.; Ziółkowski, A. Sustainable Aviation Fuels: A Comprehensive Review of Production Pathways, Environmental Impacts, Lifecycle Assessment, and Certification Frameworks. Energies 2025, 18, 3705. [Google Scholar] [CrossRef]

- Rahman, A. Battery and Fuel Cell Powertrains for Small Passenger Aircrafts. Bachelor’s Thesis, LUT University, Lappeenranta, Finland, 2025. [Google Scholar]

- Raj, C.A. Aerospace technologies and their impact on global climate change: The role of electrical systems in sustainable aviation and space travel. World J. Adv. Res. Rev. 2025, 26, 543–553. [Google Scholar] [CrossRef]

- Flüthmann, N.; Schunkert, T.; Gelhausen, M.; Leipold, A. Emission Reduction Potential of Hydrogen-Powered Aviation Between Airports in Proximity of Seaports. Aerospace 2025, 12, 661. [Google Scholar] [CrossRef]

- Cardi, D. Sustainable Future of Mobillity: Potential Alternatives to Traditional Fuels for Transportation. Master’s Thesis, University of Bologna, Bologna, Italy, 2025. Advanced Design Program [LM-DM270]. Available online: https://amslaurea.unibo.it/id/eprint/34988 (accessed on 15 August 2025).

- Zhang, S.; Lee, D.E.; Qiao, L. Assessing the drag implications of hydrogen fuel utilization in small aircraft: A preliminary numerical analysis. arXiv 2023, arXiv:2310.01265. [Google Scholar] [CrossRef]

- Adler, E. Hydrogen-Powered Aircraft Design Optimization. Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 2024. [Google Scholar]

- Diaz Tapia, I.V. Challenges of SAF Production Under the Requirements of the ReFuelEU Aviation Initiative. Master’s Thesis, Hasselt University, Hasselt, Belgium, 2024. [Google Scholar]

- Cazzola, P.; Murphy, C.; Kang, L.; Ro, J.W.; Wolff, C.; Teter, J. Comparative Assessment of the EU and US Policy Frameworks to Promote Low-Carbon Fuels in Aviation and Shipping; European Transport and Energy Research Centre: Paris, France, 2024. [Google Scholar]

- Höwelhans, C. A European Perspective on the Impact of Sustainable Aviation Fuels on Business Models Across the Air Cargo Industry Value Chain. Master’s Thesis, Technology, Policy and Management, Delft, The Netherlands, 2024. [Google Scholar]

- Ebrahimi, S.; Chen, J.; Bridgelall, R.; Szmerekovsky, J.; Motwani, J. Unlocking the Commercialization of SAF Through Integration of Industry 4.0: A Technological Perspective. Sustainability 2025, 17, 7325. [Google Scholar] [CrossRef]

- Arousell, L.S. Will Sustainable Aviation Fuel (SAF) Be Able to Meet Future Demand for Sustainable Air Travel, and If So, at What Cost? Master’s Thesis, University of Geneva, Geneva, Switzerland, 2025. Available online: https://archive-ouverte.unige.ch/unige:183059 (accessed on 15 August 2025).

- Brodzik, Ł.; Prokopowicz, W.; Ciupek, B.; Frąckowiak, A. Minimizing the Environmental Impact of Aircraft Engines with the Use of Sustainable Aviation Fuel (SAF) and Hydrogen. Energies 2025, 18, 472. [Google Scholar] [CrossRef]

- Uddin, M.; Wang, F. Fuelling a clean future: A systematic review of Techno-Economic and Life Cycle assessments in E-Fuel Development. Appl. Sci. 2024, 14, 7321. [Google Scholar] [CrossRef]

- Wang, M.; Yu, X. An Overview of the Sustainable Aviation Fuel: LCA, TEA, and the Sustainability Analysis. Eng. Proc. 2024, 80, 3. [Google Scholar]

- Havle, C.A.; İlhan, C. Analyzing the Requirements for Transitioning to Sustainable Aviation Fuels Using the Spherical Fuzzy AHP Method. In Proceedings of the International Conference on Intelligent and Fuzzy Systems, Istanbul, Turkiye, 29–31 July 2025; Springer: Berlin/Heidelberg, Germany, 2025. [Google Scholar]

- Barbosa, F.C. Sustainable Aviation Fuel—An Effective Tool for Complying with the Aviation’s Global Environmental Commitment; SAE Technical Paper; Society of Automotive Engineers (SAE): Warrendale, PA, USA, 2024. [Google Scholar]

- Szyc, R.; Lenort, R. Sustainable Aviation Fuels as the Path to Carbon Neutrality in Air Transport. Rocz. Ochr. Srodowiska 2024, 26, 707–715. [Google Scholar] [CrossRef]

- Jarin, J.-B.; Champion-Réaud, J.-L.; Sallinen, R.; Steenwinkel, E. Emissions Comparison of 100% SAF with Bio-Aromatics and Conventional (Fossil) Jet Fuel. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 2024. [Google Scholar]

- Köse, Y.; Polat, E.O. An Empirical Analysis on the Use of Sustainable Fuels in the Aviation Industry. Int. J. Aviat. Sci. Technol. 2024, 5, 90–100. [Google Scholar] [CrossRef]

- Escobar, N.; Seber, G.; Skalsky, R.; Wögerer, M.; Jung, M.; Malina, R. Spatially-explicit land use change emissions and carbon payback times of biofuels under the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA). Sci. Total Environ. 2024, 948, 174635. [Google Scholar] [CrossRef] [PubMed]

- Nanaki, E.A.; Kiartzis, S. Sustainability Assessment of Alternative Energy Fuels for Aircrafts—A Life Cycle Analysis Approach. Fuels 2024, 5, 825–838. [Google Scholar] [CrossRef]

- Chen, W.; Ai, Y. Research on the carbon emission prediction and reduction strategies for the civil aviation industry in China: A system dynamics approach. Sustainability 2024, 16, 8950. [Google Scholar] [CrossRef]

- Dischl, R.; Sauer, D.; Voigt, C.; Harlaß, T.; Sakellariou, F.; Märkl, R.; Schumann, U.; Scheibe, M.; Kaufmann, S.; Roiger, A. Measurements of particle emissions of an A350-941 burning 100% sustainable aviation fuels in cruise. Atmos. Chem. Phys. 2024, 24, 11255–11273. [Google Scholar] [CrossRef]

- Karpuk, S.; Freund, Y.; Hanke-Rauschenbach, R. Potential of Hydrogen Fuel Cell Aircraft for Commercial Applications with Advanced Airframe and Propulsion Technologies. Aerospace 2025, 12, 35. [Google Scholar] [CrossRef]

- Suárez, M.Z.; Moreno, F.P.; Jurado, R.D.-A.; Valdés, R.M.A.; Comendador, V.F.G. An overview of the possibilities, current status, and limitations of battery technologies to electrify aviation. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2024. [Google Scholar]

- Münch, M.; Teichmann, F. Australian e-SAF for the German Aviation Sector; Adelphi Consult GmbH: Berlin, Germany, 2025. [Google Scholar]

- Pattanayak, T.; Mavris, D. Battery technology for sustainable aviation: A review of current trends and future prospects. Appl. Energy 2025, 397, 126356. [Google Scholar] [CrossRef]

- Kurzawska-Pietrowicz, P.; Jasiński, R. A Review of Alternative Aviation Fuels. Energies 2024, 17, 3890. [Google Scholar] [CrossRef]

- Batteiger, V.; Ebner, K.; Moser, L.; Penke, C.; Portner, B.; Sizmann, A. Power-To-Liquid (PTL) Kerosene and Opportunities to Introduce Green Hydrogen in Aviation. In Powerfuels: Status and Prospects; Springer: Berlin/Heidelberg, Germany, 2024; pp. 849–878. [Google Scholar]

- Nyholm, F.; Toppinen, S.; Saxen, H. Holistic Evaluation Method for Concept-Level Study of Power-to-Liquids Technologies for e-Kerosene Production. Ind. Eng. Chem. Res. 2024, 63, 20264–20286. [Google Scholar] [CrossRef]

- Mukherjee, A.; Grahn, M.; Hansson, J.; Boter, T.; Junginger, M.; Rådberg, H.; Wallington, T.J.; de Jong, S.; De Kleine, R. PtL Fuels and Biofuels: A Dream Team? In Powerfuels. Green Energy and Technology; Bullerdiek, N., Neuling, U., Kaltschmitt, M., Eds.; Springer: Cham, Switzerland, 2025; pp. 1127–1156. [Google Scholar] [CrossRef]

- Langston, S.E. Sustainable Aviation Fuel. In Inaugural Issue: Energy Convers; Neste: Espoo, Finland, 2025; Volume 1, Available online: https://energyconversions.org/index.php/ecm/article/view/20 (accessed on 15 August 2025).

- Uddin, M.N.; Wang, F. Sustainable Aviation Fuels: Addressing Barriers to Global Adoption. Appl. Sci. 2025, 15, 10925. [Google Scholar] [CrossRef]

- Mobarezkhoo, H.; Barke, A.; Joormann, I.; Spengler, T.S. Potentials of electrofuels for decarbonizing long-haul flights: A holistic framework for evaluating the impacts of carbon capture strategies in electrofuel production. Procedia CIRP 2025, 135, 744–749. [Google Scholar] [CrossRef]

- Fagerström, A.; Abdelaziz, O.; Poulikidou, S.; Lewrén, A.; Hulteberg, C.; Wallberg, O.; Rydberg, T. Economic and environmental potential of large-scale renewable synthetic jet fuel production through integration into a biomass CHP Plant in Sweden. Energies 2022, 15, 1114. [Google Scholar] [CrossRef]

- Davoudi, S.; Khalili-Garakani, A.; Kashefi, K. Power-to-X for renewable-based hybrid energy systems. In Whole Energy Systems: Bridging the Gap via Vector-Coupling Technologies; Springer: Berlin/Heidelberg, Germany, 2022; pp. 23–40. [Google Scholar]

- Gavril, J. E-Fuels’ Worldwide Production Potential. Master’s Thesis, Technische Universität Wien, Vienna, Austria, 2023. [Google Scholar]

- Fasihi, M.; Efimova, O.; Breyer, C. Techno-economic assessment of CO2 direct air capture plants. J. Clean. Prod. 2019, 224, 957–980. [Google Scholar] [CrossRef]

- Nilsson, M. ADVANCING CARBON NEUTRALITY: Techno-Economic Analysis of Direct Air Capture at Commercial Scale. Master’s Thesis, Mälardalens University, Västerås, Sweden, 2024; p. 52. Available online: http://www.diva-portal.org/smash/record.jsf?pid=diva2%3A1879970 (accessed on 15 August 2025).

- Ueckerdt, F.; Bauer, C.; Dirnaichner, A.; Everall, J.; Sacchi, R.; Luderer, G. Potential and risks of hydrogen-based e-fuels in climate change mitigation. Nat. Clim. Change 2021, 11, 384–393. [Google Scholar] [CrossRef]

- Qasem, N.A.; Mourad, A.; Abderrahmane, A.; Said, Z.; Younis, O.; Guedri, K.; Kolsi, L. A recent review of aviation fuels and sustainable aviation fuels. J. Therm. Anal. Calorim. 2024, 149, 4287–4312. [Google Scholar] [CrossRef]

- Redda, Z.T.; Manyazewal, D.E.; Gizaw, D.G.; Laß-Seyoum, A.; Periyasamy, S. Biomass Conversion to Synthetic Aviation Fuels. In Agricultural Waste to Value-Added Products: Bioproducts and Its Applications; Springer: Berlin/Heidelberg, Germany, 2024; pp. 183–205. [Google Scholar]

- Barbosa, F.C. Power to Liquid (PtL) Synthetic Aviation Fuel—A Sustainable Pathway for Jet Fuel Production; SAE Technical Paper; Society of Automotive Engineers (SAE): Warrendale, PA, USA, 2022. [Google Scholar]

- Brynolf, S.; Taljegard, M.; Grahn, M.; Hansson, J. Electrofuels for the transport sector: A review of production costs. Renew. Sustain. Energy Rev. 2018, 81, 1887–1905. [Google Scholar] [CrossRef]

- Raj Shah, D.V.M. Recent Advances in the Development and Scalability of Sustainable Aviation Fuels. PIN MONTH/MONTH 2025, Pages 8–11. Available online: https://www.petro-online.com/article/analytical-instrumentation/11/koehler-instrument-company/recent-advances-in-the-development-and-scalability-of-sustainable-aviation-fuels/3593 (accessed on 15 August 2025).

- Kroef, A. Towards Neto-Zero Skies: Identifying and Overcoming Barriers to SAF Adoption in Dutch Military and Commercial Aviation; University of Twente: Enschede, The Netherlands, 2024. [Google Scholar]

- Rosales Calderon, O.; Tao, L.; Abdullah, Z.; Moriarty, K.; Smolinski, S.; Milbrandt, A.; Talmadge, M.; Bhatt, A.; Zhang, Y.; Ravi, V. Sustainable Aviation Fuel (SAF) State-of-Industry Report: State of SAF Production Process; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2024.

- Gan, K.E.; Taikan, O.; Gan, T.Y.; Weis, T.; Yamazaki, D.; Schüttrumpf, H. Enhancing renewable energy systems, contributing to Sustainable Development Goals of United Nation and building resilience against climate change impacts. Energy Technol. 2023, 11, 2300275. [Google Scholar] [CrossRef]

- Zschocke, A.; Quante, G.; Bullerdiek, N.; Pechstein, J. Blending of Aviation Powerfuels. In Powerfuels: Status and Prospects; Springer: Berlin/Heidelberg, Germany, 2024; pp. 791–818. [Google Scholar]

- Task, I.B. Progress in Commercialization of Biojet/Sustainable Aviation Fuels (SAF): Technologies and Policies; IEA Bioenergy: Paris, France, 2024. [Google Scholar]

- Yoo, E.; Lee, U.; Wang, M. Life-cycle greenhouse gas emissions of sustainable aviation fuel through a net-zero carbon biofuel plant design. ACS Sustain. Chem. Eng. 2022, 10, 8725–8732. [Google Scholar] [CrossRef]

- Kurzawska-Pietrowicz, P. Life cycle emission of selected sustainable aviation fuels—A review. Transp. Res. Procedia 2023, 75, 77–85. [Google Scholar] [CrossRef]

- Chen, S. Sustainable Aviation and Transportation Fuels. In Sustainable Oil and Gas Using Blockchain; Springer: Berlin/Heidelberg, Germany, 2023; pp. 203–219. [Google Scholar]

- Walker III, T.K.; Tatsutani, M.; Lewis, J. Decarbonizing Aviation: Enabling Technologies for a Net-Zero Future; Clean Air Task Force: Washington, DC, USA, 2024. [Google Scholar]

- Dieterich, V.; Buttler, A.; Hanel, A.; Spliethoff, H.; Fendt, S. Power-to-liquid via synthesis of methanol, DME or Fischer–Tropsch-fuels: A review. Energy Environ. Sci. 2020, 13, 3207–3252. [Google Scholar] [CrossRef]

- Dell’Aversano, S.; Villante, C.; Gallucci, K.; Vanga, G.; Di Giuliano, A. E-fuels: A comprehensive review of the most promising technological alternatives towards an energy transition. Energies 2024, 17, 3995. [Google Scholar] [CrossRef]

- Aigner, M. E-fuels for the Energy Transition in the Transport Sector–Properties and Application: Current State of Research. In Proceedings of the 13th International Colloquium Fuels: Conventional and Future Energy for Automobiles, Stuttgart, Germany, 15–16 September 2021. [Google Scholar]

- Asia-Pacific (APAC). Low Carbon Fuels and CCUS Summit White Paper. 2025. Available online: https://www.lcfccussummit.com/whitepaper-apac-low-carbon-solutions (accessed on 15 August 2025).

- Rony, M.A.; Rangon, M.T.; Uddin, M.N. A Review on the Production of Sustainable Aviation Fuels from Biomass and Wastes using Pyrolysis Technologies: Part I. Johns. Matthey Technol. Rev. 2025, 69, 536–545. [Google Scholar] [CrossRef]

- Seymour, K.; Held, M.; Stolz, B.; Georges, G.; Boulouchos, K. Future costs of power-to-liquid sustainable aviation fuels produced from hybrid solar PV-wind plants in Europe. Sustain. Energy Fuels 2024, 8, 811–825. [Google Scholar] [CrossRef]

- Arnold, M.M.; Taylor, T.G.; Becker, K.M.; Lant, C.L. Newspaper discourses shore up an unviable energy technology: Algae biofuels in the United States. Energy Res. Soc. Sci. 2024, 114, 103594. [Google Scholar] [CrossRef]

- Borrill, E.; Koh, S.L.; Yuan, R. Review of technological developments and LCA applications on biobased SAF conversion processes. Front. Fuels 2024, 2, 1397962. [Google Scholar] [CrossRef]

- Davis, C.D.; Sreekumar, S.; Altman, R.; Clarens, A.F.; Lambert, J.H.; Colosi, L.M. Geospatially explicit technoeconomic assessment of sustainable aviation fuel production: A regional case study in Virginia. Fuel Commun. 2024, 19, 100114. [Google Scholar] [CrossRef]

- Greene, J.M.; Quiroz, D.; Limb, B.J.; Quinn, J.C. Geographically-resolved techno-economic and life cycle assessment comparing microalgae-based renewable diesel and sustainable aviation fuel in the United States. Environ. Sci. Technol. 2025, 59, 3472–3483. [Google Scholar] [CrossRef]

- Limb, B.J.; Smith, J.P.; Simske, S.; Quinn, J.C. Addressing the Sustainable Aviation Fuel Grand Challenge: Economic and Environmental Insights from Feedstock Optimization. Environ. Sci. Technol. 2025, 59, 18628–18640. [Google Scholar] [CrossRef]

- Klenner, J.; Muri, H.; Strømman, A.H. Domestic and international aviation emission inventories for the UNFCCC parties. Environ. Res. Lett. 2024, 19, 054019. [Google Scholar] [CrossRef]

- Rodrigues, A.J.; Fernandes, T.; Gírio, F.; Vreugdenhil, B.; Watanabe, M.; Güell, B.M.; Janssen, R.; Christus, M. Systemic Constraints in the Entire Value Chains: GAP Analysis. International Cooperation for Sustainable Aviation Biofuels. Ref. Ares(2025)535980—23/01/2025. Available online: https://www.icarus-biojet.eu/events-news/project-spotlights (accessed on 15 August 2025).

- Xu, Y.; Zhang, Y.; Deng, X.; Lee, S.-Y.; Wang, K. Developing sustainable aviation fuel to deepen south Australia’s green economy: A BERTopic-enhanced SWOT analysis. Case Stud. Transp. Policy 2025, 21, 101562. [Google Scholar] [CrossRef]

- Dossow, M.; Shadravan, V.; Naim, W.; Fendt, S.; Harris, D.; Spliethoff, H. Potentials of Sustainable Aviation Fuel Production from Biomass and Waste: How Australia’s Sugar Industry Can Become a Successful Global Example. Biomass 2025, 5, 21. [Google Scholar] [CrossRef]

- Dissanayaka, M.; Ryley, T.; Spasojevic, B.; Caldera, S. Developing airport management practices towards net zero emissions: Experiences from the Australian aviation industry. Heliyon 2025, 11, e41201. [Google Scholar] [CrossRef]

- Rony, M.A.; Rangon, M.T.; Uddin, M.N. A Review on the Production of Sustainable Aviation Fuels from Biomass and Wastes using Pyrolysis Technologies: Part II. Johns. Matthey Technol. Rev. 2025, 69, 546–556. [Google Scholar] [CrossRef]

- O’Sullivan, C.; Mishra, A.; Mueller, S.; Nadeem, H.; Flentje, W. Opportunities and Priorities for a Low Carbon Liquid Fuel Industry in Australia; Australia’s National Science Agency: Canberra, Australia, 2025. [Google Scholar]

- Wang, F.; Swinbourn, R.; Li, C.e. Shipping Australian sunshine: Liquid renewable green fuel export. Int. J. Hydrogen Energy 2023, 48, 14763–14784. [Google Scholar] [CrossRef]

- Sanders, M.; O’Brien, G.; de Morton, S.; Byers, D. A roadmap for carbon capture and storage deployment in Australia: Key constraints and opportunities. Aust. Energy Prod. J. 2025, 65, EP24210. [Google Scholar] [CrossRef]

- HAMR Energy. 2025. Available online: https://www.hamrenergy.com/news/hamr-energy-announces-plans-for-australias-first-major-methanol-to-jet-fuel-production-facility (accessed on 28 July 2025).

- Hochman, G.; Appasamy, V. The case for carbon capture and storage technologies. Environments 2024, 11, 52. [Google Scholar] [CrossRef]

- Sen, R.; Mukherjee, S. Recent advances in microalgal carbon capture and utilization (bio-CCU) process vis-à-vis conventional carbon capture and storage (CCS) technologies. Crit. Rev. Environ. Sci. Technol. 2024, 54, 1777–1802. [Google Scholar] [CrossRef]

- Nyholm, F.; Toppinen, S.; Saxén, H. Sustainable power-to-liquids aviation fuels: Modelling and comparison of two Fischer-Tropsch upgrading process concepts. Energy Convers. Manag. 2025, 342, 120153. [Google Scholar] [CrossRef]

- Boehm, R.C.; Yang, Z.; Bell, D.C.; Faulhaber, C.; Mayhew, E.; Bauder, U.; Eckel, G.; Heyne, J.S. Perspective on Fuel Property Blending Rules for Design and Qualification of Aviation Fuels: A Review. Energy Fuels 2024, 38, 17128–17145. [Google Scholar] [CrossRef]

- Ranpati Dewage, A. Sustainable Approach for Future Aviation: Sustainable Aviation Fuel Partnerships and Fleet Modernization. Bachelor’s Thesis, LAB University of Applied Sciences, Lahti, Finland, 2025. [Google Scholar]

- Detsios, N.; Maragoudaki, L.; Rebecchi, S.; Quataert, K.; De Winter, K.; Stathopoulos, V.; Orfanoudakis, N.G.; Grammelis, P.; Atsonios, K. Techno-economic evaluation of jet fuel production via an alternative gasification-driven biomass-to-liquid pathway and benchmarking with the state-of-the-art Fischer–Tropsch and alcohol-to-Jet concepts. Energies 2024, 17, 1685. [Google Scholar] [CrossRef]

- Swinbourn, R.; Li, C.; Wang, F. A comprehensive review on biomethane production from biogas separation and its techno-economic assessments. ChemSusChem 2024, 17, e202400779. [Google Scholar] [CrossRef]

- Uddin, M.M.; Lee, U.; Xu, H.; Li, Y.; Kwon, H.; Zhang, Y.; Smolinski, S.; Cai, H.; Tao, L. Sustainable aviation fuel from ethanol: Techno-economic analysis and life cycle analysis. Appl. Energy 2025, 398, 126373. [Google Scholar] [CrossRef]

- Anderson, C.; Anderson, M.; Lackens, S. Assessing the Prospects for Minnesota-Produced Sustainable Aviation Fuel; Minnesota Department of Commerce: Saint Paul, MN, USA, 2025.

- Nasr, N.M.Y. Sustainable Design and Analysis for Gasoline Produced from GTL and MTG Processes: Process Simulation, Techno-Economic, and Environment Assessment; Qatar University Digital Hub: Doha, Qatar, 2023. [Google Scholar]

- Tony, Harrington. Surge in New Projects Announced by Asia-Pacific Airlines on SAF Production in the Region, 5 April 2023. Available online: https://www.greenairnews.com/?p=4178 (accessed on 15 August 2025).

- Rosales Calderon, O.; Tao, L.; Abdullah, Z.; Talmadge, M.; Milbrandt, A.; Smolinski, S.; Moriarty, K.; Bhatt, A.; Zhang, Y.; Ravi, V. Sustainable Aviation Fuel State-of-Industry Report: Hydroprocessed Esters and Fatty Acids Pathway; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2024.

- de Jong, S.; Antonissen, K.; Hoefnagels, R.; Lonza, L.; Wang, M.; Faaij, A.; Junginger, M. Life-cycle analysis of greenhouse gas emissions from renewable jet fuel production. Biotechnol. Biofuels 2017, 10, 64. [Google Scholar] [CrossRef] [PubMed]

- Han, G.B.; Jang, J.H.; Ahn, M.H.; Jung, B.H. Recent Application of Bio-Alcohol: Bio-Jet Fuel; IntechOpen: London, UK, 2019; Volume 1. [Google Scholar]

- Romero-Izquierdo, A.G.; Gómez-Castro, F.I.; Gutierrez-Antonio, C.; Hernández, S.; Errico, M. Intensification of the alcohol-to-jet process to produce renewable aviation fuel. Chem. Eng. Process. Process Intensif. 2021, 160, 108270. [Google Scholar] [CrossRef]

- Habermeyer, F.; Weyand, J.; Maier, S.; Kurkela, E.; Dietrich, R.-U. Power Biomass to Liquid—An option for Europe’s sustainable and independent aviation fuel production. Biomass Convers. Biorefinery 2024, 14, 16199–16217. [Google Scholar] [CrossRef]

- Neves, R.C.; Klein, B.C.; da Silva, R.J.; Rezende, M.C.A.F.; Funke, A.; Olivarez-Gómez, E.; Bonomi, A.; Maciel-Filho, R. A vision on biomass-to-liquids (BTL) thermochemical routes in integrated sugarcane biorefineries for biojet fuel production. Renew. Sustain. Energy Rev. 2020, 119, 109607. [Google Scholar] [CrossRef]

- Rojas-Michaga, M.F.; Michailos, S.; Cardozo, E.; Akram, M.; Hughes, K.J.; Ingham, D.; Pourkashanian, M. Sustainable aviation fuel (SAF) production through power-to-liquid (PtL): A combined techno-economic and life cycle assessment. Energy Convers. Manag. 2023, 292, 117427. [Google Scholar] [CrossRef]

- Tanzil, A.H.; Brandt, K.; Zhang, X.; Wolcott, M.; Stockle, C.; Garcia-Perez, M. Production of sustainable aviation fuels in petroleum refineries: Evaluation of new bio-refinery concepts. Front. Energy Res. 2021, 9, 735661. [Google Scholar] [CrossRef]

- Ali, S.A.; Bangash, I.A.; Sajjad, H.; Karim, M.A.; Ahmad, F.; Ahmad, M.; Habib, K.; Nasir Shah, S.; Sami, A.; Laghari, Z.A. Review on the Role of Electrofuels in Decarbonizing Hard-to-Abate Transportation Sectors: Advances, Challenges, and Future Directions. Energy Fuels 2025, 39, 5051–5098. [Google Scholar] [CrossRef]

- Izurieta, E.M.; Cañete, B.; Pedernera, M.N.; Lopez, E. Conceptual design, process simulation and economic evaluation for the production of synthetic fuels in Argentina. Chem. Eng. Res. Des. 2025, 214, 377–389. [Google Scholar] [CrossRef]

- Doğan, A.; Yüksel, G.; Uğur, A.; Boy, M.; Kayabaşı, E.; Demirsöz, R. Synthetic Fuels as a Cornerstone of Net-Zero Emissions: A Review of Production Methods and Future Prospects. DCE Doğa Bilim. Derg. DCE Doğa Bilim. Derg. 2025, 5, 113–131. [Google Scholar]

- Bardon, P.; Massol, O. Decarbonizing aviation with sustainable aviation fuels: Myths and realities of the roadmaps to net zero by 2050. Renew. Sustain. Energy Rev. 2025, 211, 115279. [Google Scholar] [CrossRef]

- Wandelt, S.; Zhang, Y.; Sun, X. Sustainable aviation fuels: A meta-review of surveys and key challenges. J. Air Transp. Res. Soc. 2025, 4, 100056. [Google Scholar] [CrossRef]

- İlhan, C.; Şahin, A.E. Evaluation of the EU Aviation Sector’s Progress Towards Net-Zero CO2 Emission by 2050. Süleyman Demirel Üniversitesi Vizyoner Derg. 2025, 16, 261–277. [Google Scholar] [CrossRef]

- Joshi, J.; Shen, Q.; Garg, S.; Bhatelia, T.; Sun, B. Techno-economic and Carbon Intensity Analysis of CO2-derived Sustainable Aviation Fuel. Res. Sq. 2024, preprint. [Google Scholar]

- Saad, D.M.; Terlouw, T.; Sacchi, R.; Bauer, C. Life cycle economic and environmental assessment of producing synthetic jet fuel using CO2/biomass feedstocks. Environ. Sci. Technol. 2024, 58, 9158–9174. [Google Scholar] [CrossRef]

- Prakash, R. The Role of Aviation in Economic in Developemnt. Ph.D. Thesis, Dublin Business School, Dublin, Ireland, 2024. [Google Scholar]

- Wang, F.; Rijal, D. Sustainable aviation fuels for clean skies: Exploring the potential and perspectives of strained hydrocarbons. Energy Fuels 2024, 38, 4904–4920. [Google Scholar] [CrossRef]

- Boilley, J.; Berrady, A.; Shahrel, H.B.; Gürbüz, E.; Gallucci, F. Energy analysis of a power-to-jet-fuel plant. Int. J. Hydrogen Energy 2024, 58, 1160–1176. [Google Scholar] [CrossRef]

- Almena, A.; Siu, R.; Chong, K.; Thornley, P.; Röder, M. Reducing the environmental impact of international aviation through sustainable aviation fuel with integrated carbon capture and storage. Energy Convers. Manag. 2024, 303, 118186. [Google Scholar] [CrossRef]

- Tian, G.; Zhang, C.; Wei, F. Fueling the future: Innovating the path to carbon-neutral skies with CO2-to-aviation fuel. Carbon Future 2024, 1, 9200010. [Google Scholar] [CrossRef]

- Watson, M.J.; Machado, P.G.; Da Silva, A.; Saltar, Y.; Ribeiro, C.; Nascimento, C.A.O.d.; Dowling, A.W. Sustainable aviation fuel technologies, costs, emissions, policies, and markets: A critical review. J. Clean. Prod. 2024, 449, 141472. [Google Scholar] [CrossRef]

- Ozkan, M.; Narappa, A.B.; Namboodiri, T.; Chai, Y.; Babu, M.; Jennings, J.S.; Gao, Y.; Tasneem, S.; Lam, J.; Talluri, K.R. Forging a sustainable sky: Unveiling the pillars of aviation e-fuel production for carbon emission circularity. IScience 2024, 27, 109154. [Google Scholar] [CrossRef]

- Olumoh, F.A. Converting Carbon Dioxide into Synthetic Aviation Fuels: A Techno-Economic Assessment; Carleton University: Ottawa, ON, Canada, 2024. [Google Scholar]

- Bernardi, A.; Casan, D.B.; Symes, A.; Chachuat, B. Enviro-economic assessment of sustainable aviation fuel production from direct CO2 hydrogenation. In Computer Aided Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2023; Volume 52, pp. 2345–2350. [Google Scholar]

- Habermeyer, F.; Papantoni, V.; Brand-Daniels, U.; Dietrich, R.-U. Sustainable aviation fuel from forestry residue and hydrogen–a techno-economic and environmental analysis for an immediate deployment of the PBtL process in Europe. Sustain. Energy Fuels 2023, 7, 4229–4246. [Google Scholar] [CrossRef]

- Sollai, S.; Porcu, A.; Tola, V.; Ferrara, F.; Pettinau, A. Renewable methanol production from green hydrogen and captured CO2: A techno-economic assessment. J. CO2 Util. 2023, 68, 102345. [Google Scholar] [CrossRef]

- Tregambi, C.; Bareschino, P.; Hanak, D.P.; Mancusi, E.; Montagnaro, F.; Pepe, F. Techno-economic assessment of a synthetic methane production process by hydrogenation of carbon dioxide from direct air capture. Int. J. Hydrogen Energy 2023, 48, 37594–37606. [Google Scholar] [CrossRef]

- Ravi, S.S.; Mazumder, J.; Sun, J.; Brace, C.; Turner, J.W. Techno-Economic assessment of synthetic E-Fuels derived from atmospheric CO2 and green hydrogen. Energy Convers. Manag. 2023, 291, 117271. [Google Scholar] [CrossRef]

- Delgado, H.E.; Cappello, V.; Zang, G.; Sun, P.; Ng, C.; Vyawahare, P.; Elgowainy, A.A.; Wendt, D.S.; Boardman, R.D.; Marcinkoski, J. Techno-economic analysis and life cycle analysis of e-fuel production using nuclear energy. J. CO2 Util. 2023, 72, 102481. [Google Scholar] [CrossRef]

- Colelli, L.; Segneri, V.; Bassano, C.; Vilardi, G. E-fuels, technical and economic analysis of the production of synthetic kerosene precursor as sustainable aviation fuel. Energy Convers. Manag. 2023, 288, 117165. [Google Scholar] [CrossRef]

- Raab, M.; Dietrich, R.-U. Techno-economic assessment of different aviation fuel supply pathways including LH2 and LCH4 and the influence of the carbon source. Energy Convers. Manag. 2023, 293, 117483. [Google Scholar] [CrossRef]

- Rojas Michaga, M.F. Techno-Economic and Life Cycle Assessment of Jet Fuel Production Through Various Fischer Tropsch Pathways; University of Sheffield: Sheffield, UK, 2023. [Google Scholar]

- Cames, M.; Graichen, J.; Kasten, P.; Kühnel, S.; Faber, J.; Nelissen, D.; Shanthi, H.; Scheelhaase, J.; Grimme, W.; Maertens, S. Climate Protection in Aviation and Maritime Transport: Roadmaps for Achieving the Climate Goal; Institute of Air Transport: Montreal, Canada, 2023. [Google Scholar]

- Barke, A.; Bley, T.; Thies, C.; Weckenborg, C.; Spengler, T.S. Are sustainable aviation fuels a viable option for decarbonizing air transport in Europe? An environmental and economic sustainability assessment. Appl. Sci. 2022, 12, 597. [Google Scholar] [CrossRef]

- Agbo, S. Sustainable Aviation Fuels (SAF) Production. Process and Techno-Economic Assessment Modelling of Gas Fermentation with SCWG Heat Integration; University of Nottingham: Nottingham, UK, 2023. [Google Scholar]

- Umenweke, G.C.; Pace, R.B.; Santillan-Jimenez, E.; Okolie, J.A. Techno-economic and life-cycle analyses of sustainable aviation fuel production via integrated catalytic deoxygenation and hydrothermal gasification. Chem. Eng. J. 2023, 452, 139215. [Google Scholar] [CrossRef]

- Zang, G.; Sun, P.; Elgowainy, A.; Bafana, A.; Wang, M. Life cycle analysis of electrofuels: Fischer–Tropsch fuel production from hydrogen and corn ethanol byproduct CO2. Environ. Sci. Technol. 2021, 55, 3888–3897. [Google Scholar] [CrossRef]

- Cames, M.; Chaudry, S.; Göckeler, K.; Kasten, P.; Kurth, S. E-fuels versus DACCS. Total Costs of Electrofuels and Direct Air Capture and Carbon Storage While Taking into Account Direct and Upstream Emissions and Environmental Risks; Öko-Institut e.V.: Berlin, Germany, 2021; Available online: https://www.oeko.de/fileadmin/oekodoc/2021_08_TE_study_efuels_DACCS.pdf (accessed on 15 August 2025).

- Hombach, L.E.; Doré, L.; Heidgen, K.; Maas, H.; Wallington, T.J.; Walther, G. Economic and environmental assessment of current (2015) and future (2030) use of E-fuels in light-duty vehicles in Germany. J. Clean. Prod. 2019, 207, 153–162. [Google Scholar] [CrossRef]

- Trinh, J. Techno-Economic Assessment for Optimised Renewable Jet Fuel Production in Sweden. Master’s Thesis, KTH, School of Industrial Engineering and Management (ITM), Stockholm, Sweden, 2021; p. 133. Available online: https://urn.kb.se/resolve?urn=urn:nbn:se:kth:diva-300084 (accessed on 15 August 2025).

- Salladini, A.; Borgognga, A.; Agostini, E.; Annesini, M.C.; Iaquaniello, G. Power to liquid through waste as a carbon source: A technical and economic assessment. Int. J. Hydrogen Energy 2020, 45, 24467–24476. [Google Scholar] [CrossRef]

- Drünert, S.; Neuling, U.; Zitscher, T.; Kaltschmitt, M. Power-to-Liquid fuels for aviation–Processes, resources and supply potential under German conditions. Appl. Energy 2020, 277, 115578. [Google Scholar] [CrossRef]

- Romo Martínez, A.C. The Environmental Governance System Around the Implementation of Sustainable Aviation Fuels in Norway: A Case Study on E-Fuels and Carbon Capture and Utilization Value Chain. Master’s Thesis, Norwegian University of Life Sciences, As, Norway, 2021. [Google Scholar]

- Detsios, N.; Theodoraki, S.; Maragoudaki, L.; Atsonios, K.; Grammelis, P.; Orfanoudakis, N.G. Recent advances on alternative aviation fuels/pathways: A critical review. Energies 2023, 16, 1904. [Google Scholar] [CrossRef]

- Watson, M.; da Silva, A.V.; Machado, P.G.; de Oliveira Ribeiro, C.; do Nascimento, C.A.O.; Dowling, A. The case for bio-jet fuel from bioethanol in brazil: An optimization-based analysis using historical market data. ChemRxiv 2024. preprint. [Google Scholar]

- Grim, R.G.; Tao, L.; Abdullah, Z.; Cortright, R.; Oakleaf, B. The Challenge Ahead: A Critical Perspective on Meeting US Growth Targets for Sustainable Aviation Fuel; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2024.

- Tiwari, S.; Patrizio, P.; Leduc, S.; Stratton, A.; Kraxner, F. Fuel from air: A techno-economic assessment of e-fuels for low-carbon aviation in China. Energy Convers. Manag. 2025, 333, 119796. [Google Scholar] [CrossRef]

- Deuber, R.d.S.; Bressanin, J.M.; Fernandes, D.S.; Guimarães, H.R.; Chagas, M.F.; Bonomi, A.; Fregolente, L.V.; Watanabe, M.D.B. Production of sustainable aviation fuels from lignocellulosic residues in Brazil through hydrothermal liquefaction: Techno-economic and environmental assessments. Energies 2023, 16, 2723. [Google Scholar] [CrossRef]

- D’Ascenzo, F.; Vinci, G.; Savastano, M.; Amici, A.; Ruggeri, M. Comparative life cycle assessment of sustainable aviation fuel production from different biomasses. Sustainability 2024, 16, 6875. [Google Scholar] [CrossRef]

- Shehab, M.; Moshammer, K.; Franke, M.; Zondervan, E. Analysis of the potential of meeting the EU’s sustainable aviation fuel targets in 2030 and 2050. Sustainability 2023, 15, 9266. [Google Scholar] [CrossRef]

- Ng, K.S.; Farooq, D.; Yang, A. Global biorenewable development strategies for sustainable aviation fuel production. Renew. Sustain. Energy Rev. 2021, 150, 111502. [Google Scholar] [CrossRef]

- Sharma, R.O.; Rantala, T.; Hoggan, P.E. Selective hydrogen production at platinum surfaces investigated by the Quantum Monte Carlo approach to chemical reactions. arXiv 2019, arXiv:1908.10782. [Google Scholar] [CrossRef]

- Rogachuk, B.E.; Okolie, J.A. Comparative assessment of pyrolysis and Gasification-Fischer Tropsch for sustainable aviation fuel production from waste tires. Energy Convers. Manag. 2024, 302, 118110. [Google Scholar] [CrossRef]

- Papantoni, V.; Linke, F.; Dahlmann, K.; Kühlen, M.; Silberhorn, D.; Brand, U.; Vogt, T. Life cycle assessment of power-to-liquid for aviation: A case study of a passenger aircraft. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2022. [Google Scholar]

- Nguyen, T.T.; Edalati, K. Impact of high-pressure columbite phase of titanium dioxide (TiO2) on catalytic photoconversion of plastic waste and simultaneous hydrogen (H2) production. J. Alloys Compd. 2024, 1008, 176722. [Google Scholar] [CrossRef]

| Properties | E-Fuels | Fossil Fuels | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FTD | FTG | MtG | FTK | MtJ # | DME | OME | MCH | Gasoline | Diesel | Kerosene | LPG | |

| Density (kg/m3) | 765–845 | 720–755 | 720–755 | 730–770 | 730–770 | gas | 961–1100 | 792 | 715–780 | 815–855 | 780–810 | 540 (at bar) |

| Boiling point (°C) | 85–360 | 210 (FBP) ** | 210 (FBP) ** | 205–300 | 205–300 | −24.8 | 105–280 | 65 | 22–215 | 170–380 | 151–301 | −41 to −0.5 |

| LHV (MJ/l) | 33.1–34.3 | 30–33 | 30–33 | - | - | 18.3–19.3 | 19.5–19.7 | 15.4–15.6 | 31.2–32.2 | 35.3–36 | 35.3 | 24.8 |

| Octane number | - | Upto 85 | Upto 85 | - | - | - | - | 110–112 | 90–95 | - | - | 105–115 |

| Cetane number | 70–80 | - | - | - | - | Upto 55 | 63–110 | 5 | - | 45–33 | - | - |

| Miscibility | Diesel | Gasoline | Gasoline | Jet fuel | Jet fuel | LPG | Diesel | Gasoline, Diesel | ||||

| Pathway | Description | Feedstock | Blend Limit and (Year) | Energy Efficiency | Conversion Efficiency | Advantages | Challenges | FRL TRL | Accreditation |

|---|---|---|---|---|---|---|---|---|---|

| FT Synthetic Paraffinic Kerosene (FT-SPK) | Via FT, converting CO and H2 into LCHs. | Biomass, coal, natural gas | 50% (2009) | 50% | 40–50% | feedstock versatility, potential for large scale production | high capital costs, feedstock preprocessing complexity | 6–7 6–8 | ASTM D7566 Annex A1 |

| Fischer-Tropsch Synthetic Kerosene with Aromatics (FT-SPKA) | Like FT-SPK but includes synthetic aromatics to improve compatibility. | Biomass, coal, natural gas | 50% (2015) | Like FT-SPK | Like FT-SPK | compatible with legacy aircraft systems; contains essential aromatics | still emerging; limited commercial application | 6–7 6–8 | ASTM D7566 Annex A4 |

| Hydroprocessed Esters and Fatty Acids (HEFA-SPK) | Hydroprocessing technology to convert fats and oils into LCHs. | Bio-oil, animal fat, cooking oil, tallow | 50% (2011) | 65–70% | 75–85% | high commercial maturity, compatibility with existing infrastructure, feedstock flexibility | limited feedstock availability, land-use concern | 9 9 | ASTM D7566 Annex A2 |

| Alcohol-to-Jet (ATJ-SPK) | Converts alcohols to LCHs through dehydration, oligomerization, hydrogenation. | Alcohols like ethanol or isobutanol | 50% Ethanol (2018); 30% Isobutanol (2016) | 40–50% | 40–50% | abundant alcohol feedstocks, uses existing infrastructure | low conversion efficiency, high scaling costs | 7–8 7–8 | ASTM D7566 Annex A5 |

| Synthetic Iso-Paraffinic (SIP) Fuel from Hydroprocessed Fermented Sugar | Produced through biological fermentation of sugars into LCHs | Fermented sugars (sugarcane, corn, biomass) | 10% (2014) | 25–35% | 20–30% | high purity product; low sulfur | high cost; low yield; limited scale-up | 5–8 7–9 | ASTM D7566 Annex A3 |

| Catalytic Hydrothermolysis Jet (CHJ) | Converts lipids directly into SAF through catalytic hydrothermolysis | Lipid-rich biomass (oilseeds, algae) | 50% (2020) | 60% | 60–70% | produces aromatics; drop-in fuel properties | early stage technology; limited demonstration | 6–7 4–6 | ASTM D7566 Annex A6 |

| Hydrocarbons, Hydroprocessed Esters, and Fatty Acids SPK (HC HEFA-SPK) | Like HEFA but includes additional processing to convert fatty acids to LCHs | Lipid-rich oils (algae) | 10% (2020) | Like HEFA | Like HEFA | Like HEFA | Like HEFA | 6 5 | ASTM D7566 Annex A7 |

| Co-processed Biomass | Co-HEFA in a conventional petroleum refinery | Vegetable oil, animal fat, used cooking oil | 5% (2018) | Like HEFA | Like HEFA | Like HEFA | Like HEFA | 6–7 7–8 | ASTM D1655 Annex A1 |

| ATJ-SKA | ATJ derivative with the mixed alcohols | C2–C5 alcohols (Biomass) | 50% (2023) | Like AtJ | Like AtJ | Like AtJ | Like AtJ | - - | ASTM D7566 Annex A8 |

| Co-processed FT | FT hydrocarbons in a conventional petroleum refinery | co-processed with petroleum | 5% (2020) | Like FT | Like FT | Like FT | Like FT | 6–7 7–8 | ASTM D1655 Annex A1 |

| Co-processed HEFA | HEFA hydrocarbons co-processed with petroleum | Fats, oils, greases (FOG) | 10% (2018) | Like HEFA | Like HEFA | Like HEFA | Like HEFA | - - | ASTM D1655 Annex A1 |

| PtL | electrolysis, CO2 capture, synthesis | CO2, water, renewable electricity | 50% (2011) | 40–55% | 40–50% | ultralow carbon intensity, CO2 recycling, renewable integration | high costs, energy-intensive, dependence on renewable sources | 6–7 6–8 | ASTM D7566 Annex A1 |

| Aspect | Component | Description | Estimated Cost Range | Impact on Final Cost | Current Barriers | Potential for Cost Reduction | Projected Trend (2025–2035) |

|---|---|---|---|---|---|---|---|

| Renewable Electricity | Source Type | Primary energy input (Solar, Wind, Hydro); cost varies by location | $30–$80 per MWh | High | High initial investment, geographic limitations | Decreasing due to technology advances, economies of scale | Projected 30–50% reduction in renewable electricity costs by 2035 |

| CO2 Capture and Storage | Capture Method | Essential raw material (DAC, Point-source); cost depends on technology, CO2 purity | $80–$120 per ton CO2 | Moderate | High cost of DAC, energy-intensive | R&D into efficient DAC, adoption of modular capture units | Cost expected to decrease as DAC scales up |

| Electrolysis for H2 | Electrolysis Technology | Converts water to hydrogen; capital- and energy-intensive (PEM, Alkaline, SOEC) | $3.5–$7 per kg H2 | High | Electrolyzer cost, electricity intensity | Improvements in electrolyzer efficiency, lifetime expansion | Cost of H2 projected to halve by 2035 |

| Fuel Synthesis | Catalyst and Reactor Tech | Combines H2 and CO2 to form e-fuel; catalyst type and design affect cost/efficiency | $2–$5 per kg fuel | Moderate | High-cost catalysts, limited reactor scalability | Research in catalyst recycling, scalable reactors | High-performance catalysts could lower costs by 25% |

| Total e-Fuel Production Cost | Aggregated Cost | Combined expenses from each stage to produce 1 kg of e-fuel | $5.5–$15 per kg fuel | – | Competes with fossil fuel prices; high dependency on energy costs | System optimization, cost-effective scale-up | Projected cost parity with fossil fuels by 2035 with sufficient scale-up |

| Comparison with Alternatives | – | Cost competitiveness vs. traditional fuels (fossil fuels, hydrogen, biofuels) | $1–$3 per kg fossil fuels | Moderate | Currently less competitive without subsidies | Policy incentives, renewable energy subsidies | e-Fuels likely to gain competitiveness in aviation/marine sectors |

| Sensitivity Analysis | – | Assesses variable impacts (electricity price, CO2 efficiency, catalyst cost) | Varies by factor | High | Dependence on volatile electricity markets | Investment in low-cost electricity sources, efficient CO2 capture | Improved resilience with stable renewable prices and market evolution |

| Category | TEA | LCA |

|---|---|---|

| Goal and Scope | Evaluate the economic feasibility of PtL FT SAF plant in Australia | Assess cradle-to-grave environmental impact of PtL-FT SAF produced in Australia |

| System Boundary | Gate-to-gate or cradle-to-gate (depending on scope) | Cradle-to-grave (electricity generation → CO2 capture → fuel) |

| Geographical Context | Australia—focused on renewable-rich regions (e.g., South Australia, Western Australia) | Australia—aligned with local grid mix, renewable energy availability, and national emission factors |

| Time Horizon | Plant lifetime, 20–30 years | 100-year Global Warming Potential |

| Functional Unit | 1 L or 1 MJ of SAF | 1 MJ or 1 passenger-km (depending on study design) |

| Key Inputs |

|

|

| Key Outputs |

|

|

| Energy Source | 100% renewable (e.g., solar, wind, hybrid wind-PV) | 100% renewable (e.g., solar, wind-hybrid-PV with storage) |

| CO2 Source |

| Not directly considered (except for embodied energy inputs) |

| Hydrogen Production | Water electrolysis (PEM or alkaline using renewable electricity) | Water electrolysis (renewable electricity only for baseline scenario) |

| FT Synthesis Conditions | Low-temperature FT (200–240 °C) with iron/cobalt catalyst; product upgrading | Low-temperature FT (200–240 °C) with iron/cobalt catalyst; product upgrading included |

| Capital Cost Assumptions | Not applicable | Energy-based or system expansion for co-products (e.g., oxygen) |

| End-of-Life | Not included | Fuel combustion included (CO2 counted as biogenic if captured via DAC/biogenic sources) |

| Environmental Impact Categories |

|

|

| Allocation Method | Not applicable | Energy-based or system expansion for co-products (e.g., oxygen) |

| Uncertainty/Sensitivity |

| Not applicable |

| Date | Subject | Search Strings | Filter |

|---|---|---|---|

| January 2023–June 2025 (Web of Science, Scopus, Google Scholar, PubMed) | TEA | “TEA” OR “techno-economic analysis” OR “techno-economic assessment” OR “techno-economic viability” OR “techno-economic assessment” OR “economic viability” OR “economical assessment” OR “economic analysis” OR “technical” OR “technologies”. | Article title, Abstract, Keywords, Topic |

| LCA | “LCA” OR “life cycle analysis” OR “life cycle assessment” OR “life cycle viability” OR “environmental viability” OR “environmental assessment” OR “environmental analysis” OR “environmental impact” OR “environmental fact” OR “Sustainability”. | ||

| SAF | “SAF” OR “Synthetic fuel” OR “Sustainable aviation fuel” OR “E-Fuel” OR “Electro-Fuel” OR “Syn Fuel”. | ||

| PtL | “PtL” OR “Power to liquid” OR “PtL based Fuel”. | ||

| FT | “FT” OR “Fischer-Tropsch” OR “FT-SPK”. | ||

| “English” | Limit to | ||

| Country, yr. and Refs. | Method | Parameter | Highlight | Result | Others | Limitation |

|---|---|---|---|---|---|---|

| KSA, 2025 [13] | SAF: FT, AtJ, PtL, HEFA, CHJ, DSHC | TEA: Efficiency, Cost LCA: Carbon emission | GHG emission by 26–93% compared to fossil jet fuel. | MJSP ranging from 0.39 to 11 USD/L. | FT SAF for long-term sustainability. | lack of production facilities |

| Malaysia, 2025 [117] | E-fuel: Electrolysis, CCS | TEA: Efficiency, Cost LCA: Carbon emission | Achieved 20% efficiency and 30–40% cost reductions. | 70–90% carbon reduction vs. fossil fuel. | TEA requires costs below $3/kg. | Need for scalable e-fuel technologies. |

| Argentina, 2025 [118] | E-fuel: Electrolysis, CCU, FT, DAC | TEA: Capex, Opex and the profitability analysis. | Used 0.8 kgH2 and 3.1 kgCO2 /kg kerosene. | Achieved a kerosene yield of ~75 %. | NPV, IRR, Payback Period highlighted. | Sensitive to H2 costs and kerosene prices. |

| Turkey, 2025 [119] | E-fuel: Electrolysis, CCU, CCS | TEA: Technical feasibility | synthetic hydrocarbons and SNG are more compatible. | Green H2 presents the high decarbonization. | TEA is qualitative. | Lack of large-scale demonstration |

| USA, 2025 [120] | E-SAFs: CO2-based e-fuels. | TEA: Capex, Opex LCA: GWP | The potential of e-fuels to achieve net-zero emissions. | Capex, Opex for SAFs are higher than CJFs. | U.S. federal investments in SAF. | Uncertainty policy interventions |

| India, 2025 [121] | SAF: Renewable sources | LCA: GWP, technologies | Vital role in strengthening the circular bioeconomy. | SAF can decarbonizing the aviation sector. | sustainability assessment of SAF. | 2nd and 3rd-gen biomass feedstocks |

| China, 2024 [36] | SAF: Technologies | TEA: economic viability. LCA: emissions, resource usage | Evaluates sustainable aviation fuel technologies and their readiness levels. | Significantly reduce emissions compared to conventional jet fuels | Recommendations for sustainable SAF industry development | Crucial for sustainable development |

| Turkey, 2024 [122] | SAF: technological advancements in fuel production | Evaluation: energy densities and footprints | Presents critical data on the aviation industry’s energy consumption, which reached 12.1 MJ/RTK in 2022. | With projections indicating a potential increase by 2.8 to 3.9 times by 2040 | Aviation emissions could reach 2000 megatons by mid-century. | Economic incentives for SAF adoption require further exploration. |

| Poland, CZ, 2024 [39] | PtL: AtJ, FT | TEA: economic viability. LCA: carbon emissions. | SAFs can reduce carbon emissions by up to 80%. | SAF is currently more expensive than CJF. | Substantial energy required for AtJ fuel. | Energy density limitations of fuels. |

| Greece, DK, 2024 [43] | Alternatives fuels: production pathway | LCA: various alternative fuels | Various fuels assessed for environmental impact. | H2 is environmentally benign than other fuels. | quantifying carbon emissions, toxicity. | Require further exploration of TEA. |

| Australia, 2024 [123] | SAF: Three-step AtJet pathway, FT. | TEA: Economic analysis LCA: Carbon intensity | 84.6% renewable power needed for comparable emissions reduction. | levelized cost of supply is 14%–25% lower than AtJ of the FT process. | Three-step AtJ pathway yields 1.6 times more SAF. | Higher capital cost for syngas fermentation. |

| Australia, 2024 [35] | E-Fuel: FT, RWGS, Electrolysis, DAC | TEA: Capex, Opex LCA: GWP | Economic viability relies on optimizing production. | E-fuels can reduce carbon emissions. | Suggests areas for future research | Identifies gaps in e-fuel production. |

| Switzerland2024 [124] | SJF: CO2 hydrogenation. | LCA: emission, resource usage, cost analysis | CO2 hydrogenation to methanol reduces GHG emissions by almost 50%. | Production cost is 7.86 EUR kgJF-1, 7 times higher than petroleum. | Electricity sources affect cost and emissions. | Challenges remain in terms of cost and energy demand. |

| India, 2024 [125] | SAF: PtL, FT. | LCA: environmental and costing feasibility. | SAF reduce environmental facts with renewable energy. | SAF are more costly than fossil kerosene. | Production process is energy intensive. | Need for more cost-effective SAF. |

| Australia, 2024 [126] | SAF: ML, Quantum mechanical | TEA: cost analysis. LCA: emissions. | Optimization of potential strained hydrocarbon | Exploration of strain energy in cycloalkanes. | screening of high-performance SAF. | Limited widespread H2 usage in aviation. |

| France, NL 2024 [127] | PtL: FT process (Matlab simulation) | TEA: energy efficiency | Global efficiency linked to H2 production efficiency. | Energetic efficiency reaches 48.06%. | Aspen Hysys for efficiency estimation. | No LCA |

| UK, 2024 [128] | FT-SPK: FT, CCS | LCA: well-to-wake and carbon footprint | FT-SPK with CCS generates negative carbon flux. | Certified blend reduces JF emissions by 37%. | FT-SPK limited to 50% blend with CJF. | UK cover 0.7% of JF demand. |

| Spain, 2024 [63] | SAF: All pathway based SAFs | LCA: CO2 emissions & commitment to climate change mitigation. | Aviation sector aims to reduce its impact on climate change. | Commercial aviation emitted 915 million tonnes of CO2 in 2019. | SAFs are being developed to reduce the carbon emission. | Does not provide a TEA and LCA |

| China, 2024 [129] | SAF: Electrolysis, captured CO2 | Economic viability, and environmental benefits. | Analytical review of CO2 to jet fuel conversion methods. | High energy demands for carbon recycling. | H2 generation from renewable energy. | Limited exploration of TEA |

| USA, Brazil, 2024 [130] | SAF: All technologies. | TEA: technologies, Cost LCA: emission, policy | HEFA technology has highest readiness for commercial deployment. | SAF production operates at only 3.5% of potential capacity. | High production costs, 120% more than fossil fuels. | Only 38% of policies offer monetary incentives. |

| USA, 2024 [131] | PtL: FT e-kerosene, electrolysis, DAC | TEA: production costs, renewable energy expenses. | E-kerosene production cost expected to decrease significantly by 2050. | SAF production increased from 1.9 M to 15.8 M gallons in 6 yrs. | Cost reduction strategies for e-kerosene production. | High cost of kerosene produced with DAC. |

| Canada, 2024 [132] | SAF: PtL, FT, DAC | TEA: costs, resource and emissions | Negative emissions possible with cleaner electricity. | Resource and costs vary by province | Process highly resource intensive. | Requiring significant energy. |

| UK, 2023 [133] | SAF: 1sFT: noble Mn-Fe-K catalyst 2sFT: RWGS, FT | Enviro-economic: LCOP, GWP, environmental impacts | 1sFT process has 70% and 30% lower externalities cost and GWP compared to 2sFT. | MSP of the fuel blend from the 1sFT is 20% lower than the 2sFT. | This emphasizes the benefits of adopting the 1sFT method. | Lack of TEA |

| UK, Bolivia, 2023 [115] | SAF: PtL, FT, CCU, DAC, Electrolysis. | TEA: CAPEX, OPEX LCA: GWP, Well-to-Wake system. | Carbon conversion of 88%, H2 conversion of 39.16%, PtL efficiency of 25.6%. | MJSP: 5.16 £/kg GWP: 21.43 gCO2eq/MJSAF. | WtWa water footprint is 0.480 l/MJSAF. | GWP below UK mandate of 50% emission reduction. |

| Norway, Sweden, 2023 [134] | SAF: PBtL, FT, Electrolysis by Aspen Plus® (V10) | TEA: process, cost, mass & energy balances LCA: sensitivity analysis | EU goal: 32% of total aviation fuel demand by SAF in 2040 can be met. | 25 Mt a−1 fuel output achievable with direct renewable energy. | Only Norway and Sweden suitable as PBtL production. | Economic feasibility and environmental impact. |

| Italy, 2023 [135] | E-Fuel: Electrolysis by Aspen+ | TEA: economic analysis, cost estimation. | PtL plant for producing 500 kg/h renewable methanol | LCoM calculated to be 960€/t (175€/MWh). | LCoM affected by electricity. | Not economically competitive. |

| UAE, Italy, 2023 [136] | Syn E-Fuel: DAC, Electrolysis, CCU, Hydrogenation. | TEA: TPC, LCCR, LCOM, CAPEX, OPEX | Cities with uneven solar energy distribution might need high H2 storage tank. | LCOM: 4.9–8.2 € kgCH4−1 with DAC, 3.1–3.9 € kgCH4−1. | LCOM > current methane price; need economic incentives | Electrolyzer is most expensive |

| KSA, 2023 [137] | Syn E-Fuel: CCU, CCS, Electrolysis. | TEA: CAPEX, OPEX, LCOe and MFSP | e-gasoline: MFSP of 3.24 USD/L; e-diesel: 2.89 USD/L for with solar. | LCOe from 379 to 564 USD/MWh | E-fuels can become a carbon-neutral option with CO2 taxation. | Need economic implications for decarbonizing road. |

| USA, 2023 [138] | E-Fuel: electrolysis, RWGS, FT, CCS, Hydrocracking. | TEA: Capex, Opex, energy efficiency. LCA: GHG, GREET. | MFSP: $0.95/L, $0.74/L, & $0.70/L of SAF mix for 100, 400, 1000 MWe energy plant. | GHG: 7 & −25 gCO2e/ MJ. 70% process energy efficiency. | 99% carbon conversion by recycle CO2 & combustion. | WTW GHG emissions reduction of at least 92%. |

| Italy, 2023 [139] | SAF: E-Fuel, Syn-Kerosene, FT, DAC, Electrolysis. | TEA: Assumptions, sensitivity analysis, cost, process evaluations. | Indirect & direct processes produce 66.18 bbl/d & 38.46 bbl/d respectively. | Product cost varies: 460–1435 €/bbl & 752–2364 €/bbl. | Dependency on power energy and hydrogen prices. | Lack of LCA |

| Germany, 2023 [140] | SAF: LH2, LCH4, CCU, Electrolysis. | LCA: Holistic techno-economic assessment | LH2 costs: 157 €/MWh; LCH4: 217–228 €/MWh. | SAF costs: 279–302 €/MWh. | Limited CO2 reduction potential. | Focus on single fuel production costs. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uddin, M.N.; Wang, F. Sustainable Aviation Fuels: A Review of Current Techno Economic Viability and Life Cycle Impacts. Energies 2025, 18, 5510. https://doi.org/10.3390/en18205510

Uddin MN, Wang F. Sustainable Aviation Fuels: A Review of Current Techno Economic Viability and Life Cycle Impacts. Energies. 2025; 18(20):5510. https://doi.org/10.3390/en18205510

Chicago/Turabian StyleUddin, Md Nasir, and Feng Wang. 2025. "Sustainable Aviation Fuels: A Review of Current Techno Economic Viability and Life Cycle Impacts" Energies 18, no. 20: 5510. https://doi.org/10.3390/en18205510

APA StyleUddin, M. N., & Wang, F. (2025). Sustainable Aviation Fuels: A Review of Current Techno Economic Viability and Life Cycle Impacts. Energies, 18(20), 5510. https://doi.org/10.3390/en18205510