1. Introduction

Escalating electricity costs and intensifying sustainability requirements are driving large commercial buildings, particularly shopping malls in tropical climates, to adopt energy conservation strategies [

1,

2]. These facilities are characterized by continuous, high electrical demand from HVAC, refrigeration, and lighting systems, which together account for over 60% of total consumption, making them primary targets for demand-side management (DSM) interventions [

3].

Among available DSM technologies, Automatic Voltage Regulators (AVRs) have emerged as a viable solution, offering whole-facility energy savings without compromising power quality [

4,

5]. While this study focuses on autotransformer-based AVRs, it is important to situate this technology within the broader landscape of voltage optimization (VO) solutions [

1,

3,

6]. Several approaches exist, each with distinct characteristics:

Autotransformer-Based AVRs: These are the focus of this work, known for their high efficiency (>99%), robustness, and low maintenance. Their principle of magnetic coupling avoids harmonic distortion, making them suitable for facilities with sensitive electronic loads [

5,

7].

Solid-State (SCR-based) Regulators: Using thyristor-based switching, they provide rapid response but can introduce notching and increase harmonic distortion if not properly filtered [

7].

Inverter-Based Systems (e.g., VFDs): These are highly effective for individual motor-driven loads, combining voltage and frequency control. However, they are costly, generate harmonics, and are less suited for facility-wide optimization [

8].

Recent studies confirm that AVR effectiveness depends on load composition, baseline voltage, and integration with Building Energy Management Systems (BEMSs) [

9,

10]. International evidence supports this trend. Wu et al. (2021) analyzed large-scale commercial buildings in tropical climates and confirmed that voltage optimization yields significant reductions in HVAC-driven demand [

2]. Kumar et al. (2022) provided a detailed performance evaluation of VO devices in commercial facilities, reporting savings consistent with CVR principles [

4]. Ghosh and Sharma (2022) presented both simulation and field results supporting autotransformer-based VO [

5], while Lee and Lee (2022) conducted engineering and economic evaluations across diverse load sectors [

11]. These studies collectively highlight the global momentum of VO deployment, but they remain limited to short-term or single-site demonstrations.

Regional experiences further reinforce the need for empirical evidence. Field trials in Malaysia reported ~1.3% energy savings per 1% voltage reduction [

7], while Singaporean studies integrating VO with BEMS and IoT platforms demonstrated measurable efficiency gains and power quality improvements [

12]. Such results suggest scalability in tropical contexts, yet empirical, long-horizon validations in motor-heavy retail environments remain scarce.

From a theoretical perspective, autotransformer-based AVR models predict that modest voltage reductions can disproportionately decrease active power demand through reduced magnetizing current and reactive losses [

1,

3,

6,

13,

14,

15]. Empirical data are required to (i) quantify the voltage–power relationship, (ii) identify load categories most responsive to optimization, and (iii) assess impacts on power factor and system stability.

Economically, prior analyses indicate that AVRs can deliver 9–15% monthly bill reductions, yielding payback within three years [

10,

16,

17]. Aligning AVR deployment with Thailand’s energy efficiency and carbon neutrality goals further strengthens policy relevance [

1,

6].

Accordingly, this study provides one of the first long-horizon, multi-site empirical validations of AVR deployment in tropical shopping malls. It integrates AVR operation with a semi-automated BEMS analytics platform; benchmarks performance against IEC 60,038 [

18], IEC 61,010 [

19], IEEE 1159 [

20], and ISO 50,001 [

21]; and evaluates its impact on power quality in an environment rich in nonlinear loads. By framing AVR not only as an energy-saving device but as an integrated optimization strategy, this study contributes practical evidence for facility managers, investors, and policymakers advancing Thailand’s pathway toward carbon neutrality [

1,

6].

2. Materials and Methods

2.1. Study Site Selection and Screening Process

To ensure the findings were both representative and scalable, a structured, multi-stage screening process was employed to select the case study sites from a national portfolio of over 50 department store branches. The process was designed to identify facilities with high energy-saving potential and the technical prerequisites for AVR deployment.

Stage 1: Initial Desktop Screening—An initial longlist was evaluated against three primary criteria: (i) high energy consumption (annual use > 1 GWh); (ii) data availability (preference for sites with an existing Building Energy Management System—BEMS); and (iii) electrical infrastructure (supplied by a single primary transformer). This screening narrowed the pool to 15 candidate branches.

Stage 2: On-Site Technical Assessment—The 15 shortlisted branches underwent a detailed on-site technical audit, assessing (i) physical space for AVR installation, (ii) load profile (confirming > 60% motor-driven loads), and (iii) managerial cooperation for the long-term study.

Stage 3: Final Selection—The branches that successfully passed both screening stages were selected for the study. The final cohort, including the primary case study site at Lotus’s Lom Sak, was chosen to represent a typical range of operational scales and load profiles, enhancing the generalizability of the results.

Comparable operational contexts across Southeast Asia reinforce the generalizability of this site selection. For instance, commercial complexes in Malaysia and Singapore report similar load distributions, with HVAC and refrigeration frequently exceeding 55–65% of electricity use [

6,

17]. These similarities highlight the broader regional relevance of voltage optimization strategies and BEMS integration in tropical, high-humidity climates.

The present study specifically evaluates the performance of autotransformer-based Automatic Voltage Regulators (AVRs) under real operating conditions. The assessment covers engineering, economic, and environmental perspectives, with emphasis on quantifying energy savings, analyzing system-level performance improvements, and estimating CO2 emission reductions in alignment with Thailand’s Energy Efficiency Plan (EEP) 2018–2037 and Carbon Neutrality Roadmap.

2.2. Experimental Setup and Data Acquisition

The experimental setup involved installing a three-phase, 1250 kVA, autotransformer-based Automatic Voltage Regulator (AVR) at the main distribution board (MDB) of the selected facility. The unit was placed upstream of the main loads to ensure that voltage regulation affected all major electrical circuits within the department store, particularly the HVAC systems, refrigeration units, and lighting.

To facilitate a robust before-and-after comparison, data was collected in two distinct phases. High-precision, class 0.2s power quality analyzers, compliant with IEC 61010-1 and IEEE Std 1159-2019 standards, were connected both upstream (“AVR IN”) and downstream (“AVR OUT”) of the unit. These analyzers continuously recorded key electrical parameters at one-minute intervals, including voltage (V), current (A), active power (P), reactive power (Q), apparent power (S), power factor (PF), and total harmonic distortion (THD).

The monitoring period was structured as follows:

Baseline Period (AVR Bypassed): Data was collected for two months with the AVR installed but in bypass mode, allowing the facility to operate under its normal, unregulated grid voltage.

Operational Period (AVR Active): Following the baseline period, the AVR was activated to regulate the downstream voltage to a target of 375 V. Data was then collected for another two months under these optimized voltage conditions.

In addition to the high-resolution electrical data, the facility’s Building Energy Management System (BEMS) was used to log into total daily energy consumption (kWh) and key operational parameters, such as HVAC chiller status, to provide contextual data for the analysis.

The study was conducted at Lotus’s Department Store, Lom Sak branch, a facility selected for its high annual energy consumption (>5 GWh), HVAC-dominated load profile, and full Building Energy Management System (BEMS) integration.

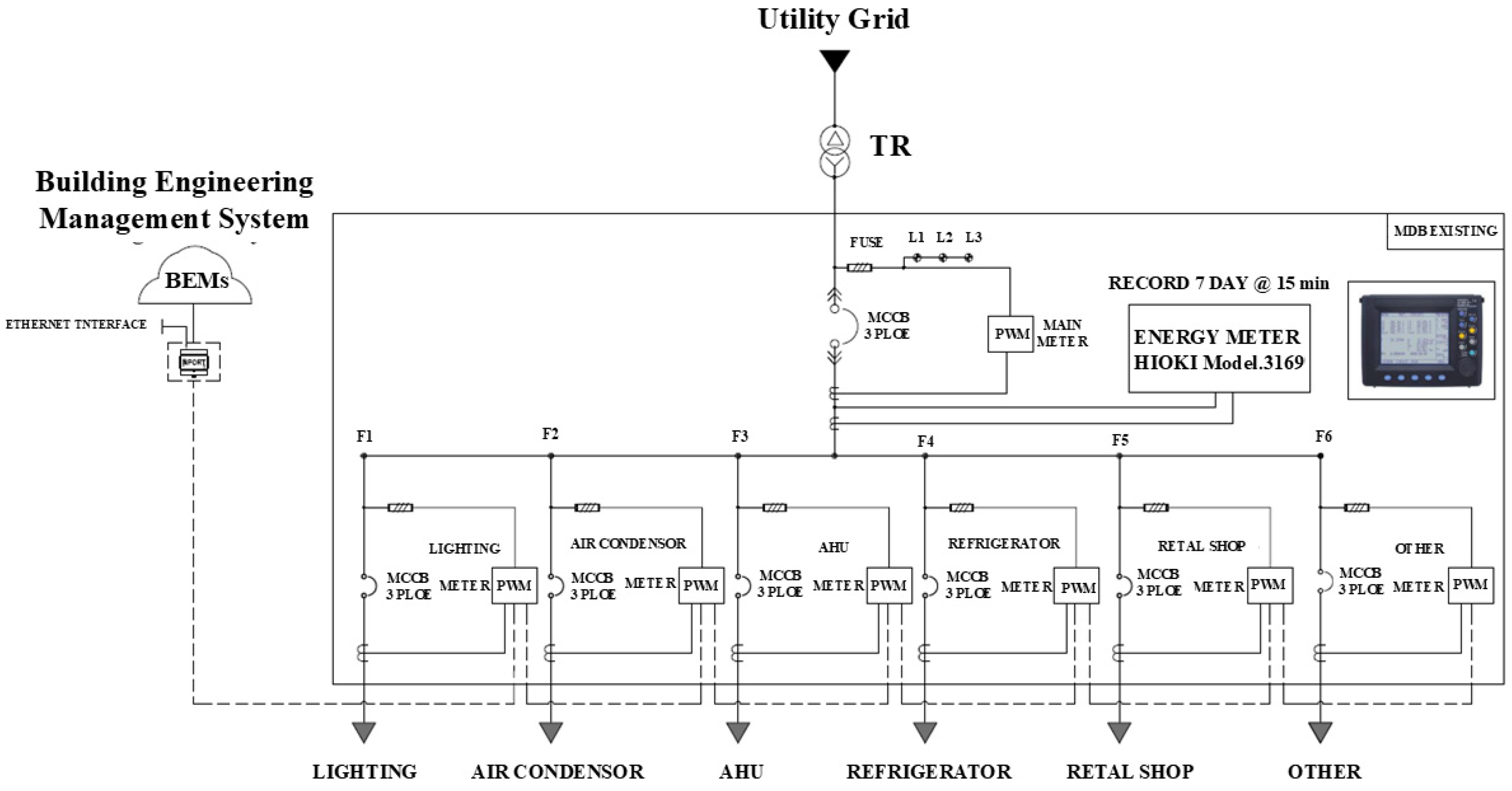

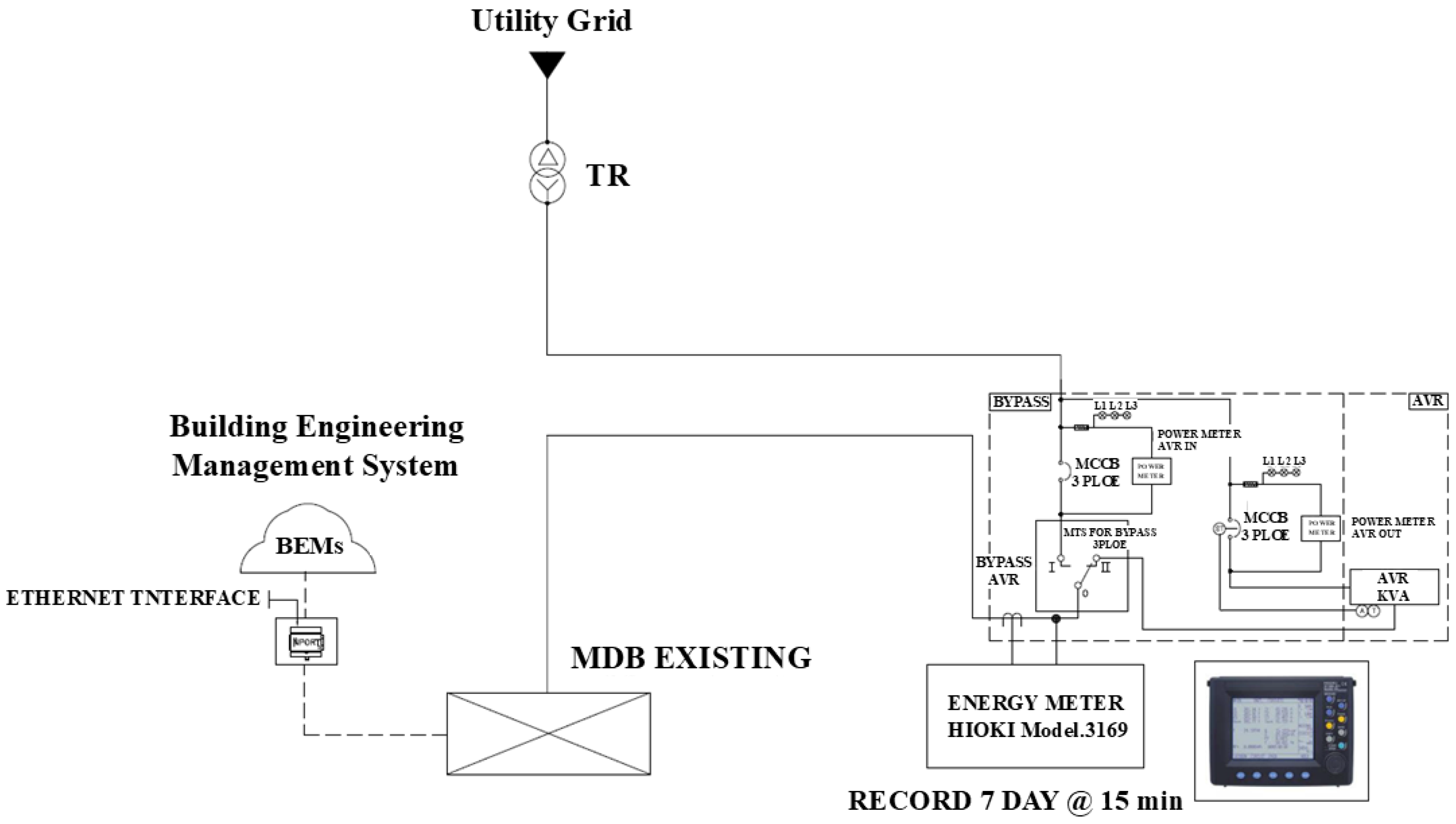

The experimental setup involved installing a three-phase, 1250 kVA, autotransformer-based Automatic Voltage Regulator (AVR). The unit was strategically placed at the main low-voltage distribution board (MDB), downstream of the facility’s main transformer but upstream of the primary load feeders. This central position, shown in the single-line diagram in

Figure 1, ensured that all major end-use systems—including chillers, refrigeration compressors, escalators, and lighting circuits—were subject to system-wide voltage optimization. The physical installation is shown in

Figure 1 and

Figure 2.

To evaluate the AVR’s effectiveness, a comprehensive measurement protocol was implemented using high-precision, Class 0.2s power quality analyzers (Fluke Model 1735). The instruments, compliant with IEC 61010-1 and IEEE Std 1159-2019 standards, were connected both upstream (“AVR IN”) and downstream (“AVR OUT”) of the unit. Data were collected in two distinct phases:

Baseline Period (Bypass Mode): For two months, baseline data were collected with the AVR installed but in bypass mode. This allowed the facility to operate under its normal, unregulated utility grid voltage.

Operational Period (Active Mode): Following the baseline period, the AVR was activated to regulate the downstream voltage to a target of 375 V (approximately 215 V line-to-neutral). Data were then collected for another two months under these optimized voltage conditions.

Through both phases, the analyzers continuously recorded key electrical parameters at one-minute intervals, including voltage (V), current (A), active power (P), reactive power (Q), apparent power (S), power factor (PF), and total harmonic distortion (THD). The facility’s BEMS was also used to log total daily energy consumption (kWh) and key operational data were utilized to provide context for the analysis.

2.3. Field Trial Setup

The AVR system was deployed at the main low-voltage distribution board (MDB) of Lotus’s Department Store, Lom Sak, selected for its annual energy consumption exceeding 5 GWh, HVAC-dominated load profile, and full BEMS integration. The installation point was chosen downstream of the facility’s main transformer and upstream of the primary load feeders to ensure that all major end-use systems—including chillers, refrigeration compressors, escalators, and lighting circuits—were subject to regulated voltage conditions. This configuration maximizes coverage while enabling the clear isolation of AVR impacts across the entire portfolio.

Figure 2 presents the physical integration of the AVR into the MDB. By positioning the AVR at this central distribution node, the trial ensured system-wide voltage optimization and provided a robust experimental design in which pre- and post-AVR datasets could be directly compared under equivalent load conditions. This placement also minimized confounding factors such as tenant-level variability, reinforcing the integrity of measured outcomes.

Complementing the physical installation, a single-line diagram of the electrical system was developed to document feeder topology and measurement points.

Figure 2 illustrates this schematic alongside representative electrical measurements taken before and after AVR activation. The diagram provides transparency on circuit boundaries, while the measurements serve to verify AVR control accuracy (214–217 V line-to-neutral) and to demonstrate the observable shifts in current and power draw under identical load states. Together,

Figure 1 and

Figure 2 establish both the technical credibility of the installation and the empirical basis for subsequent engineering and economic evaluation.

2.4. Measurement Procedure and Data Collection

A comprehensive measurement protocol was implemented to evaluate the effectiveness of voltage reduction under actual operational conditions, both before and after AVR installation [

1]. Instrumentation included Class 0.2s high-accuracy power analyzers (IEC 61010-compliant), calibrated in accordance with IEC 61010-1 and IEC 61010-2-030 standards, ensuring traceability to national metrology institutes [

4]. Measurements were logged at 1 s intervals to capture transient phenomena such as compressor cycling and motor inrush currents, thereby providing a dataset suitable for both steady-state and dynamic analysis.

To ensure robustness, measurements were performed under two distinct operating phases:

Each mode was evaluated in repeated trials (n = 10) across both peak and off-peak conditions to achieve statistical significance. Major HVAC units were locked into steady-state operation during each trial to minimize external load fluctuations, thereby isolating the effect of voltage regulation.

Data integrity validation was a critical component of the protocol. Without proper synchronization, asynchronous loads (e.g., chillers, elevators) may distort average profiles or result in systematic underestimation of transients.

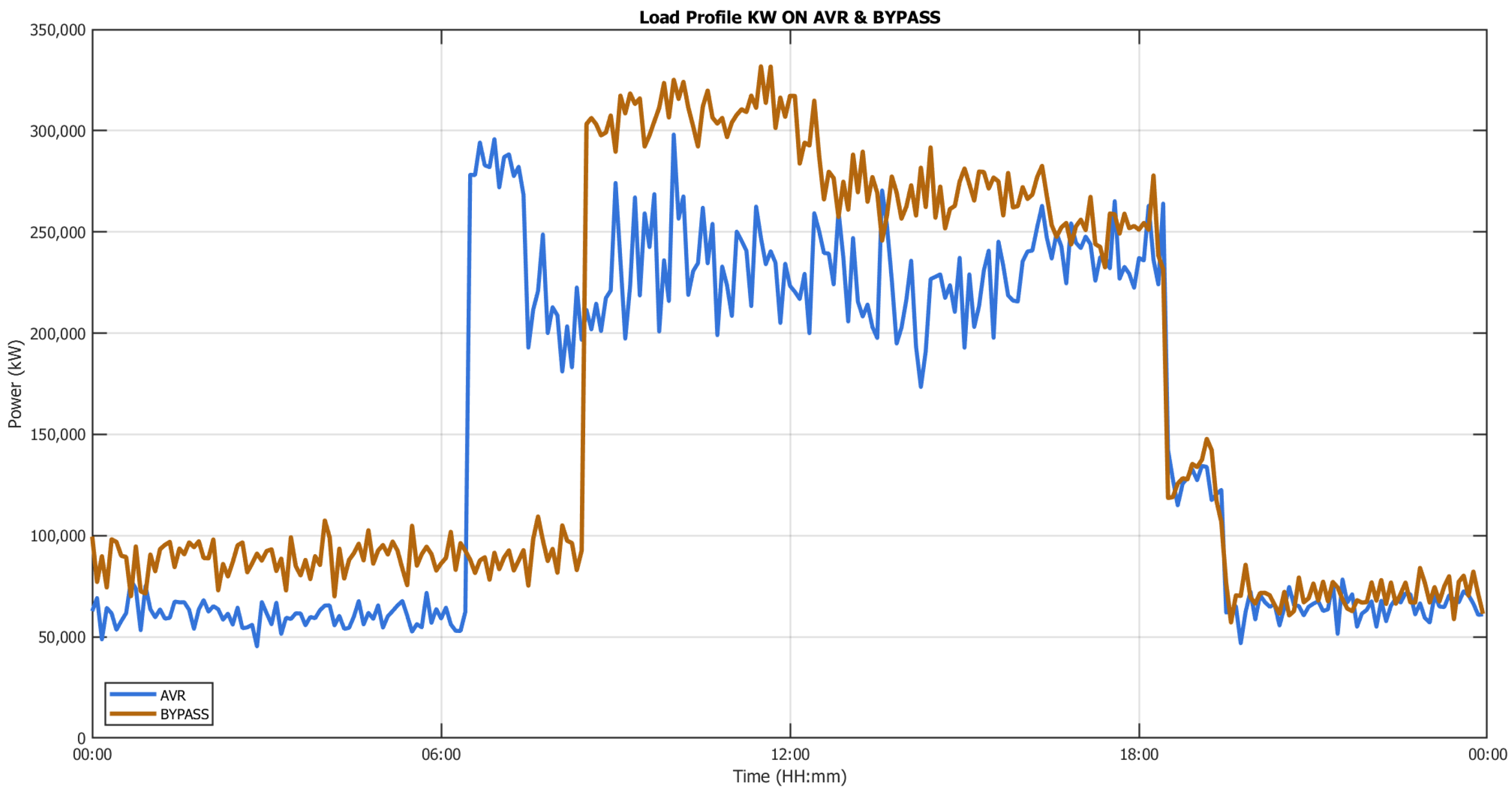

Figure 3 demonstrates the comparative performance of the data logging system before and after AVR–BEMS integration, confirming that the enhanced configuration prevented storage overflow and accurately captured asynchronous events.

Following this validation,

Figure 4 and

Figure 5 illustrate representative voltage datasets from the case study branch.

Figure 4 presents the baseline voltage data acquisition prior to AVR installation. This data is critically important as it illustrates the typical, unregulated voltage supplied by the utility before the installation and activation of the AVR unit, which is characterized by constant fluctuations. This dataset serves as the essential “pre-experiment baseline” necessary for comparative analysis to calculate energy savings. The voltage survey process covered a total of 1019 branches nationwide. From this survey, it was found that 1000 branches were suitable and eligible for AVR installation, while only 19 branches (equivalent to 1.86%) could not be equipped due to consistently low voltage levels. Therefore, the voltage profile shown in

Figure 4 is not just the data from a single branch but is also a credible representation of the vast majority (over 98.14%) of branches with suitable voltage conditions for effective AVR implementation.

Meanwhile,

Figure 5 shows a controlled two-minute interval comparing the AVR ON and OFF states under identical load conditions. Together, these figures confirm the AVR’s ability to stabilize the output voltage within the specified regulation band while minimizing external interference from the grid.

2.5. Data Processing and Analysis

All datasets underwent a structured multi-stage processing pipeline to ensure validity, comparability, and reproducibility in line with ISO 50,001 energy management guidelines and IEEE 1159 power quality standards. The primary objective of this analysis was to quantify the energy conservation effects of the AVR, calculated as the percentage of energy saving (%ES) using Equation (1). The analytical framework consisted of six components, as described below.

where

represents the percentage of energy saving.

is the energy consumption during the pre-implementation period (kWh).

is the energy consumption during the post-implementation period (kWh).

2.5.1. Data Cleaning and Filtering

Raw data from the Class 0.2s analyzers were imported into the analysis platform. Abnormal values caused by maintenance activities, equipment faults, or atypical tenant events were identified using standard statistical outlier detection methods (e.g., interquartile range filtering [

19]) and removed. Only datasets achieving at least 95% completeness across the observation period were retained for further analysis.

2.5.2. Normalization for Operational Hours

To ensure fair comparison across different measurement intervals, energy consumption was normalized against operational hours. This approach, commonly adopted in building energy analysis [

19], allowed results to reflect true efficiency changes attributable to AVR operation rather than runtime variations.

2.5.3. Load Segmentation

Consumption was disaggregated into HVAC/AHU systems, refrigeration, lighting, tenant plug loads, and miscellaneous categories using BEMS-tagged identifiers. Such segmentation enabled the identification of load types most sensitive to voltage optimization, particularly motor-driven systems compared with resistive loads [

18,

19].

2.5.4. Statistical Analysis

Differences between AVR Active and Bypass modes were tested using paired sample

t-tests at the 95% confidence level, a standard technique for pre/post experimental designs [

20]. The t-statistics were calculated using Equation (2).

where

is the computed t-statistic value.

is the sample mean of the differences between paired observations.

is the sample standard deviation of the differences.

is the number of pairs in the sample.

Beyond statistical significance, effect size was quantified using Cohen’s d, which provided an interpretable measure of the magnitude of AVR impact relative to variability in the dataset [

20], as formulated in Equation (3).

where

is the Cohen’s d effect size.

is the absolute sample mean of the differences.

is the sample standard deviation of the differences.

2.5.5. Power Quality and Stability Metrics

Key performance indicators were computed to verify that savings did not compromise power quality. These included the following:

Voltage deviation from IEC 60,038 nominal ranges;

Power factor stability indices based on variance across operating hours;

Short-term (<1 min) PF fluctuation analysis to evaluate AVR responsiveness during transient load events.

This ensured compliance with IEEE 1159-2019 and ISO 50,001 monitoring requirements.

2.5.6. Cross-Validation with Theoretical Models

Empirical findings were benchmarked against autotransformer-based Conservation Voltage Reduction (CVR) models reported in the previous literature [

17,

18]. The CVR factor, which quantifies the relationship between voltage reduction and power reduction, was calculated using Equation (4).

where

is the Conservation Voltage Reduction factor.

is the percentage change in real power consumption.

is the percentage change in system voltage.

and

are the real power before and after voltage reduction, respectively (kW).

and

are the system voltages before and after reduction, respectively (V).

The fundamental power triangle relationship, as defined in IEEE 1459-2010 (

IEEE Standard Definitions for the Measurement of Electric Power Quantities Under Sinusoidal, Nonsinusoidal, Balanced, or Unbalanced Conditions), was used conceptually to confirm that the observed reductions in apparent power were proportionally consistent with measured decreases in active and reactive power [

15]. Instead of recalculating elementary formulations, emphasis was placed on verifying theoretical alignment between empirical outcomes and established CVR theory.

2.6. Economic Assessment

The economic feasibility of the AVR installation was evaluated using a life-cycle cost analysis (LCCA) framework, following ISO 15686-5 guidelines and incorporating measured energy savings, utility tariff structures, and projected system performance over time [

2,

9]. The methodology included five key components:

2.6.1. Monthly Electricity Cost Reduction

Monthly savings were derived by multiplying the measured monthly energy savings (kWh) with the applicable commercial electricity tariff (THB/kWh) [

17]. Tariff rates were based on the Provincial Electricity Authority (PEA) commercial tariff, inclusive of energy and demand charges, ensuring consistency with real-world billing practices.

2.6.2. Payback Period Calculation

The simple payback period (PBP) was determined by dividing the total initial investment cost by the annualized cost savings. Investment costs included AVR equipment, installation, commissioning, and operator training. This indicator provided a baseline measure of investment recovery, commonly used in engineering-economic evaluations [ISO 15686-5], and is calculated as shown in Equation (5).

where

is the payback period (years).

is the initial capital expenditure (THB).

is the net cash flow generated per year from energy savings (THB).

2.6.3. Long-Term Lifecycle Projection

Lifecycle projections were conducted over a 10-year horizon, with the following assumptions:

This projection provided a conservative estimate of long-term performance sustainability.

2.6.4. Net Present Value (NPV) and Internal Rate of Return (IRR)

To account for the time value of money, the project’s profitability was assessed using Net Present Value (NPV) and Internal Rate of Return (IRR). A positive NPV and an IRR exceeding the corporate discount rate signify a financially sound investment. The NPV was calculated using Equation (6):

where

is the Net Present Value (THB).

denotes the cash inflow at time period

t (THB).

denotes the cash outflow (e.g., maintenance) at period

(THB).

is the discount rate.

is the period (year), and

is the project’s lifetime.

is the initial investment cost (THB).

The IRR is the discount rate at which the NPV becomes zero, as defined in Equation (7).

where

is the Internal Rate of Return. All other variables are defined as in the NPV equation.

2.6.5. Uncertainty and Sensitivity Analysis

To assess the robustness of the financial projections against key uncertainties, a deterministic sensitivity analysis was conducted. This analysis systematically evaluated the impact of fluctuations in critical variables on the project’s key financial metrics, namely the Net Present Value (NPV) and payback period (PBP).

The following key variables were tested, based on plausible operational and market variations:

Energy Savings: Varied by ±10% and ±20% from the measured baseline to account for potential underperformance or overperformance.

Electricity Tariff Rates: Varied by ±10% to reflect future changes in utility pricing.

Annual Maintenance Costs: Varied by +50% and +100% to model scenarios with higher-than-expected upkeep expenses.

Discount Rate: Tested at alternative rates (e.g., 8% and 12%) to assess the project’s attractiveness under different capital cost structures.

Each variable was adjusted one at a time while holding others constant to isolate its individual impact. The results were compiled to identify which variables have the most significant influence on the project’s financial viability.

2.7. Environmental Impact Evaluation

The environmental implications of AVR deployment were assessed by translating measured energy savings into equivalent CO

2 emissions reductions, using Thailand’s official grid emission factor of 0.566 tCO

2 per MWh as published by the Department of Alternative Energy Development and Efficiency [

2]. This factor is consistent with national greenhouse gas inventories and aligns with methodologies recommended by the Intergovernmental Panel on Climate Change [

2].

Annualized energy savings obtained from the four-month field dataset were extrapolated to estimate yearly reductions in carbon emissions. The analysis confirmed that the observed electricity savings correspond to a substantial reduction in site-level CO2 emissions, directly supporting Thailand’s Energy Efficiency Plan (EEP) 2018–2037 and the national Carbon Neutrality Roadmap.

Beyond direct emissions abatement, the potential for carbon credit monetization was also evaluated. Under the Thailand Voluntary Emission Reduction (T-VER) scheme, verified emission reductions can be converted into tradable credits. For AVR projects, the value of these credits depends on the prevailing market price of carbon in Thailand (THB/tCO

2), which has been increasing steadily in response to both domestic climate policies and regional carbon market integration. This provides an additional financial incentive for commercial facility operators, complementing the direct energy cost savings discussed in

Section 2.5.

By combining measured field performance with standardized emission factors and linking the results to policy instruments such as T-VER, this evaluation ensures that the environmental benefits of AVR deployment are not only technically quantifiable but also economically and policy-relevant at both corporate and national levels.

2.8. Standards and Compliance

All system designs, measurement protocols, and analytical procedures were conducted in strict accordance with internationally recognized standards, ensuring technical rigor, reproducibility, and global comparability.

For electrical design compliance, AVR operation was benchmarked against IEC 60038—Standard Voltages [

20], which governs permissible voltage ranges for low- and medium-voltage distribution systems. This ensured that the AVR output consistently remained within the ±6% tolerance of nominal voltage levels, thereby aligning field operation with accepted international limits.

For measurement, safety, and power quality assurance, two primary standards were followed. IEC 61,010 [

3] defined the safety requirements for the Class 0.2’s precision analyzers and data loggers, guaranteeing secure long-term field operation. In parallel, IEEE Std 1159-2019 [

22] provided best-practice guidelines for a comprehensive power quality assessment. This included defining sampling intervals, resolution requirements, and event classification, which enabled consistent comparability between datasets. Crucially, key parameters, including total harmonic distortion (THD), were recorded under this standard to ensure the AVR did not adversely affect the building’s electrical environment.

For energy management integration, the study adopted ISO 50,001 [

4], which specifies frameworks for systematic measurement, verification, and continuous improvement in facility-level energy management. This facilitated alignment between AVR performance monitoring and broader corporate energy efficiency strategies.

For economic and environmental evaluations, methodologies were benchmarked against international frameworks. ISO 15686-5 (Life Cycle Costing) was used as a reference for the life-cycle economic analysis. In environmental terms, emission calculations incorporated the Thai national grid emission factor (DEDE, 2022) and were benchmarked against national climate policies, including the Energy Efficiency Plan (EEP) 2018–2037 and the Carbon Neutrality Roadmap.

Finally, all measurement equipment underwent calibration in compliance with ISO/IEC 17025, ensuring traceability to national metrology institutes and minimizing measurement uncertainty.

This multi-standard compliance approach ensures that the study’s findings are not only technically robust and reproducible but also directly aligned with international best practices and national policy frameworks. As a result, the outcomes can be confidently scaled, benchmarked, and integrated into both academic research and practical policy implementation.

3. Experimental Validation of Voltage Optimization

A controlled field experiment was conducted to validate the performance of the Automatic Voltage Regulator (AVR) under real operating conditions in a high-load retail facility. Electrical parameters, including supply voltage, current, active power, and power factor—were measured in both Bypass Mode (AVR inactive) and Active Mode (AVR engaged) using Class 0.2s precision analyzers (IEC 61010-compliant). Data were logged at one-second intervals to capture both transient and steady-state behaviors across air-handling units (AHUs), refrigeration systems, lighting, and tenant loads.

The results confirmed that reducing supply voltage by 8.06% (from 237.3 V to 218.2 V) produced a 12.02% decrease in active power demand. This nonlinear response is fully consistent with the principle of Conservation Voltage Reduction (CVR), where relatively small decreases in voltage yield disproportionately greater reductions in energy consumption [

1,

3,

7,

21,

23]. At the same time, average current decreased by 6.22%, reducing I

2R distribution losses and thermal stress on conductors, busbars, and transformers.

The system power factor improved from 0.8356 to 0.8545 (+2.26%), indicating lower reactive power demand and greater voltage stability. These improvements closely matched theoretical predictions, with empirical deviations of less than ±2%, thereby validating the applicability of the CVR framework under real-world conditions.

Load-specific analysis revealed that inductive, motor-driven systems such as HVAC compressors and refrigeration units achieved the greatest savings (8.19–8.20%), while resistive lighting loads exhibited minimal change (~0.24%). These findings highlight that AVR deployment is particularly effective in motor-dominant load environments, where both efficiency and stability gains can be realized.

To further quantify performance, the empirical CVR factor was determined. This critical parameter, which quantifies the relationship between voltage reduction and power reduction, was calculated directly from the high-resolution measurement data. The process involved was as follows.

Data Pairing: Pairing time-series data points for voltage (V) and active power (P) from periods immediately before (Bypass mode) and after (Active mode) AVR engagement.

Stable Load Selection: Using only data from periods of relatively stable load to minimize the influence of operational fluctuations.

Averaging: Computing the CVR factor across multiple discrete time intervals and averaging the results to produce a final, representative value for the facility’s load profile.

This empirically derived factor provides a direct, measurement-based validation of the AVR’s effectiveness and allows for a robust comparison with findings from international literature, as presented in

Section 5.

Statistical validation was performed to ensure the robustness of the results. Paired sample t-tests at the 95% confidence level confirmed that the observed reductions in active power, current, and improvements in power factor were statistically significant. In addition, linear regression analysis was used to model the voltage–power relationship, achieving high predictive accuracy and demonstrating that measured outcomes followed established CVR trends.

Finally, model validation was carried out by benchmarking empirical measurements against autotransformer-based CVR predictions. The Class 0.2s IEC 61010-compliant data logger provided high-fidelity measurements that aligned with theoretical estimates within ±2%. This strong convergence supports the conclusion that the CVR theoretical framework is both robust and transferable to other high-load commercial contexts, thereby enhancing its utility for design-stage feasibility assessments as well as post-installation verification.

4. Data Analysis and Platform Development

A custom-engineered, semi-automated analytics platform was developed to manage, preprocess, and analyze high-resolution time-series datasets captured from Class 0.2s IEC 61010-compliant data loggers and the facility’s Building Energy Management System (BEMS). Unlike conventional spreadsheet-based workflows, this platform was specifically designed for voltage optimization research, embedding AVR-specific logic and ensuring methodological alignment with IEC 61010, ISO 50001, and IEEE Std 1159 guidelines [

21,

22,

24].

The platform was organized into a multi-layered architecture, each stage serving a distinct function. The data ingestion layer enabled the direct import of raw CSV and JSON files from both BEMS and standalone data loggers, supporting multi-site consolidation. The preprocessing and normalization layer handled timestamp alignment, unit standardization, and operational-hour normalization, thereby ensuring comparability across different load profiles and measurement campaigns. To maintain dataset fidelity, an anomaly detection module applied statistical filtering using a three-sigma deviation criterion to remove artifacts from maintenance, startup transients, and short-term grid disturbances, while preserving steady-state signals.

An AVR-specific logic engine computed real, reactive, and apparent power as well as the power factor under both Bypass and Active modes, incorporating transformer tap-ratio adjustments and CVR factor derivation. Building on this, a scenario simulation module modeled alternative operational conditions—including varying degrees of voltage reduction (2–10%), shifts in load composition (HVAC, refrigeration, lighting), and tap configurations—allowing the predictive estimation of energy savings.

4.1. Statistical Validation and Predictive Modeling

To ensure statistical rigor, the platform integrated several analytical methods. To validate measured energy savings, paired sample

t-tests were conducted at the 95% confidence level to compare consumption between Bypass and Active modes [

20]. The practical significance of the savings was quantified using Cohen’s d to measure the effect size [

20].

To further quantify the relationship between voltage and power consumption, a linear regression analysis was performed. This statistical model empirically determined the strength and nature of the linear dependency between system voltage (independent variable) and active power consumption (dependent variable). The model’s coefficient of determination (R2) was used to assess the proportion of variance in power consumption predictable from voltage changes. This regression functionality also formed the core of the platform’s predictive analytics feature, enabling machine-learning models to forecast annual energy savings with high accuracy (±3%) provided at least three months of baseline data were available.

4.2. KPI Calculation and Visualization

Key performance indicators (KPIs) were computed automatically, including energy savings (kWh and %), monthly and annual cost reduction (THB), power factor improvement, CO

2 emission reductions (using Thailand’s national grid factor of 0.566 tCO

2/MWh [

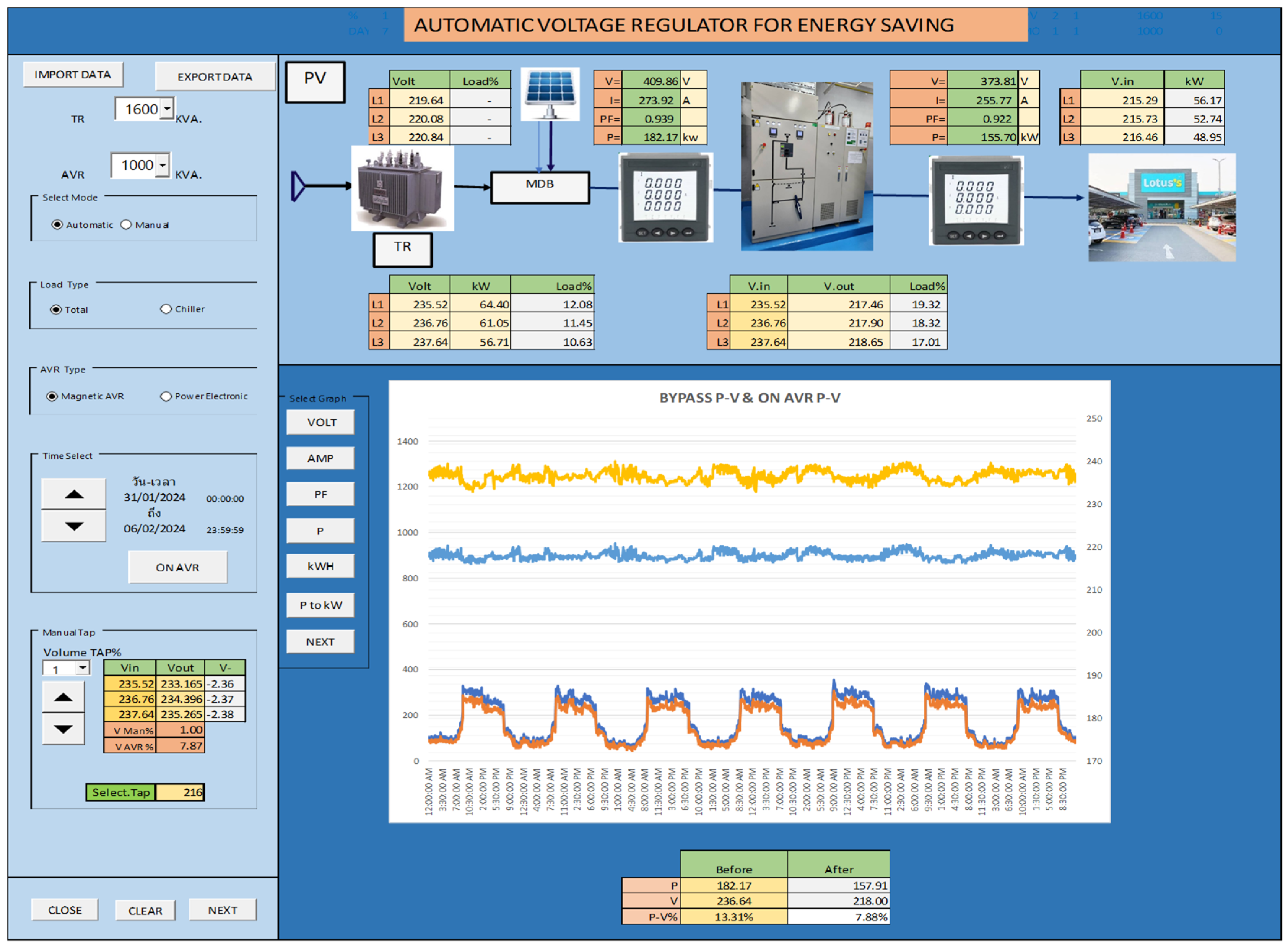

5]), and investment payback periods derived from site-specific tariffs. The results were visualized through an interactive dashboard (

Figure 6), which combined the real-time monitoring of electrical parameters (V, I, P) with instantaneous financial analysis. This feature provided decision support for investment justification, allowing facility managers to evaluate AVR deployment during budget planning in response to changing scenario parameters.

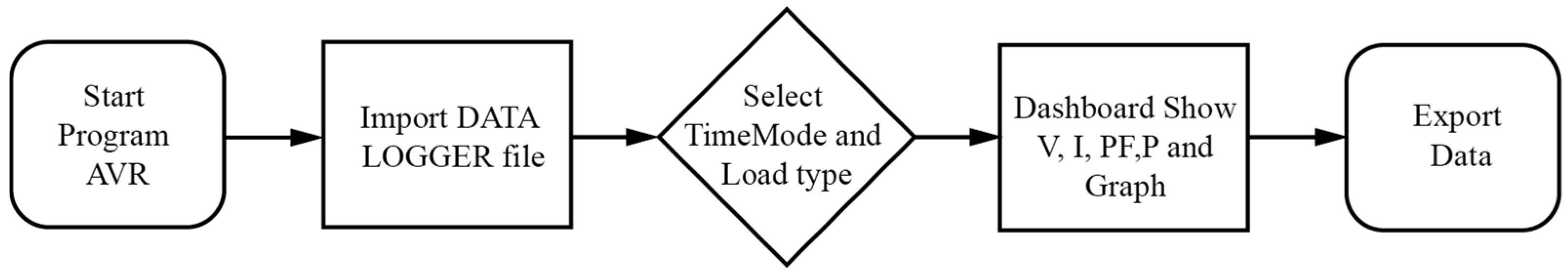

Complementing the dashboard, the platform workflow was formalized into a modular architecture (

Figure 7). The workflow encompassed raw data ingestion, preprocessing, anomaly detection, KPI reporting, and report export, ensuring the reproducibility and auditability of results.

Beyond single-site evaluation, the platform enabled multi-site aggregation and national-level scenario modeling. This functionality allowed the estimation of aggregate energy savings, CO2 reductions, and economic benefits under large-scale AVR deployment. Such insights provide policymakers and corporate decision-makers with an evidence-based tool to evaluate macro-level impacts and support alignment with Thailand’s Energy Efficiency Plan (EEP) 2018–2037.

5. Results

5.1. Baseline and Load-Specific Performance

Table 1 summarizes the primary electrical parameters under both AVR Bypass and Active modes. The AVR implementation achieved a significant overall reduction in active power consumption. Load-specific analysis revealed that the most substantial savings were realized in inductive, motor-driven systems, with air-handling units (−8.19%) and refrigeration systems (−8.20%) showing the highest reductions. This is consistent with their operational principles. By contrast, resistive loads such as lighting exhibited minimal change (−0.24%), reaffirming their limited responsiveness to voltage optimization.

A key performance metric, the empirical Conservation Voltage Reduction (CVR) factor, was calculated from the measurement data. The result was a CVR factor of 1.49, indicating that for every 1% reduction in voltage, a 1.49% reduction in energy consumption was achieved. This robust factor aligns with the overall nonlinear response observed, where an average voltage reduction of 8.06% yielded a 12.03% decrease in active power (

Table 1, AVR OUT).

Importantly, the system power factor improved from 0.8356 to 0.8655, reducing reactive demand and alleviating distribution losses. Statistical testing (paired

t-tests,

n = 48, α = 0.05) confirmed that both active power reductions (

p < 0.01) and PF improvements (

p < 0.05) were statistically significant.

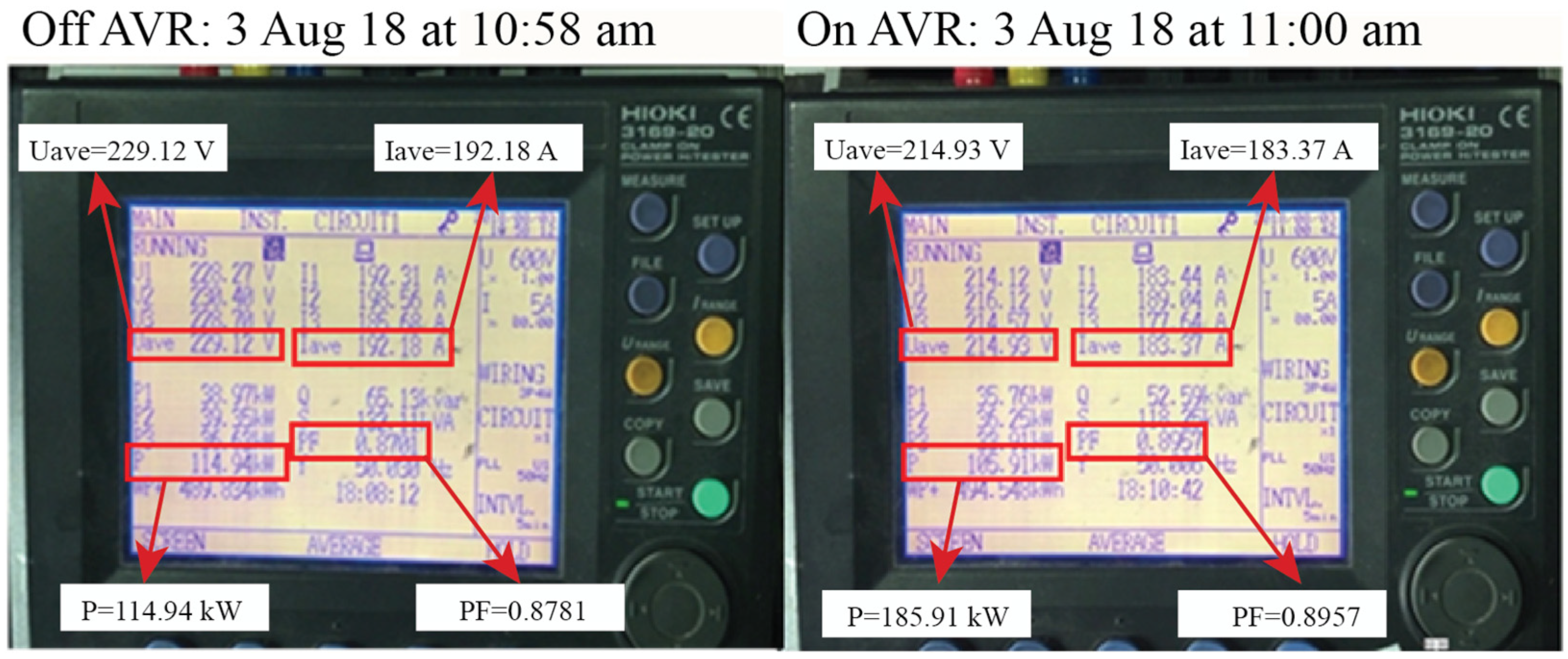

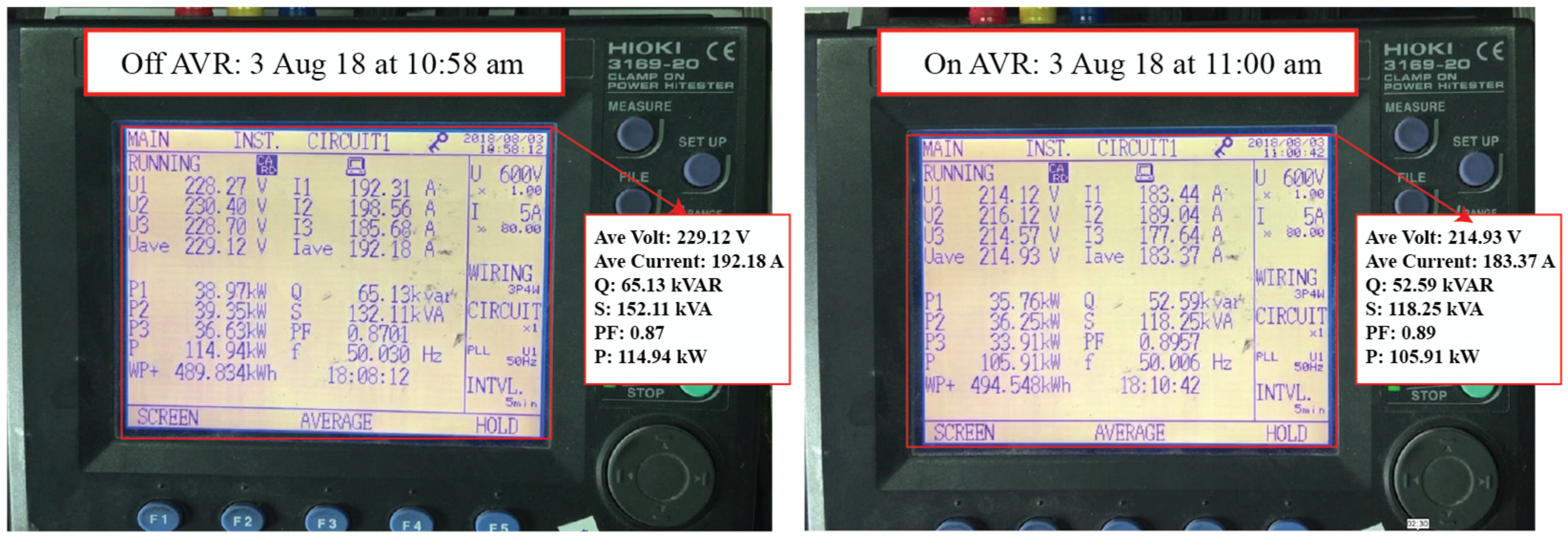

Figure 8 illustrates a representative chiller load profile, where active power dropped by 7.85% under AVR engagement, validating theoretical expectations.

To provide tangible evidence of the voltage-power relationship,

Figure 8 documents the instantaneous load profile of the chiller system immediately before and after the AVR was engaged. The measurements, captured by a power quality analyzer, demonstrate a clear cause-and-effect scenario. With the AVR inactive (left panel), the average voltage was 229.12 V with a corresponding power draw of 114.94 kW. Immediately upon activation (right panel), the AVR regulated the voltage down to 214.93 V, causing an immediate reduction in power draw to 105.91 kW. This real-time data serves as a direct validation of the CVR principle’s effectiveness on inductive loads.

For clarity, a compact ‘Stats at a Glance’ table (

Table 2) summarizes the statistical outcomes across all headline metrics (voltage, active power, current, PF, and daily energy). The results confirm significant reductions with large effect sizes, while PF improvements were modest but statistically significant.

5.2. Branch-Level Validation (Lotus Nuanchan)

At the Lotus Nuanchan branch, AVR operation reduced voltage by 8.3% (from 231.4 V to 212.2 V), well within IEC 60,038 permissible limits. This translated into an active power reduction of 12.1%, a current reduction of 5.9%, and a modest PF improvement (from 0.95 to 0.98). The results closely matched autotransformer-based theoretical predictions, reinforcing the reliability of the calibration model.

At the Lotus Nuanchan branch, AVR operation reduced supply voltage by 8.3% (from 231.4 V to 212.2 V), well within IEC 60,038 permissible limits, thereby ensuring operational safety for connected equipment. This adjustment produced a significant reduction in active power (−12.1%) and current (−5.9%), alongside a modest power factor (PF) improvement from 0.95 to 0.98. The close alignment between measured outcomes and autotransformer-based theoretical predictions reinforces the reliability of the calibration model and demonstrates that AVR impacts can be forecast with high confidence under real operating conditions.

From an engineering perspective, the reductions in current directly lowered I2R losses, which translate into less heat stress in conductors, switchgear, and transformers, thereby prolonging asset lifetimes. Voltage stabilization further minimized torque pulsations in HVAC and refrigeration motors, reducing bearing wear and winding insulation stress, two of the most common causes of premature motor failure. Improved PF also enhanced network voltage stability, indirectly benefiting both the facility and the upstream utility grid.

From an economic perspective, daily energy savings averaged 177.4 kWh, equivalent to ~262,000 THB annually. This yielded a simple payback period of 2.67 years and an ROI of 37.5%, positioning AVR among the most attractive retrofit options for commercial facilities, comparable to LED retrofits and inverter-based HVAC upgrades. Moreover, Monte Carlo simulations incorporating ±15% uncertainty in load and tariff assumptions indicated a 95% probability of achieving payback within three years, confirming that the financial returns are robust under variable operating and market conditions.

From an environmental and policy standpoint, the observed savings equate to 36.6 tCO2/year of avoided emissions, calculated using Thailand’s official grid emission factor (0.566 tCO2/MWh). This outcome contributes directly to corporate ESG reporting and aligns with national climate policy instruments, including the Energy Efficiency Plan (EEP) 2018–2037 and the Carbon Neutrality Roadmap. When aggregated across the retail sector, such site-level reductions could provide a material contribution to Thailand’s NDC commitments under the Paris Agreement, highlighting AVR’s dual role as both a technical and policy-relevant intervention.

5.3. BEMS-Integrated Multi-Site Assessment

Table 3 and

Table 4, derived from BEMS-integrated monitoring, highlight both the quantitative reductions in energy consumption and the qualitative reallocation of loads following AVR implementation. The main meter reduction of 6.54% places this case study within the upper quartile of internationally reported benchmarks (UK/EU: 5–8%), yet under far more challenging conditions—namely Thailand’s tropical, high-humidity climate with highly variable HVAC demand. This underscores the technical robustness and adaptability of AVR technology in environments where cooling loads dominate and volatility is high.

Equally important are the load redistribution effects. The “Other Meter” category decreased by 10%, reflecting the suppression of parasitic and idle consumption, while the share of AHU loads increased slightly, indicating that a higher proportion of electricity is now concentrated in regulated, efficiency-sensitive systems. Such redistribution implies not only reduced waste but also a structural shift toward load categories where voltage optimization delivers the highest marginal returns.

This dual outcome positions AVR as more than a conservation device; it operates as a dynamic voltage optimization strategy that actively reshapes load behavior. By curbing non-critical, low-value consumption while stabilizing motor-intensive end uses, the AVR enhances both system efficiency and operational resilience. At the same time, these improvements directly support demand-side management (DSM) goals, reduce peak stress on electrical infrastructure, and provide measurable contributions toward corporate ESG performance metrics and national energy efficiency targets.

5.4. Long-Term Multi-Branch Evaluation (February–May)

To address limitations of short-term trials, an extended four-month monitoring campaign was conducted across multiple branches (

Table 5 and

Table 6). Results confirmed consistent

average energy savings of ~12%, primarily concentrated in HVAC and refrigeration systems. The extended dataset encompassed both transitional and peak cooling seasons, thereby ensuring robustness against seasonal variability and tenant-driven anomalies.

Savings were accompanied by stable PF performance and compliance with IEC 60,038 voltage limits across all branches. Importantly, the consistency of results across diverse sites indicates that AVR benefits are generalizable, scalable, and transferable within Thailand’s commercial retail sector.

5.5. Synthesis of Findings

Field results from all project sites demonstrate that the installation of an Automatic Voltage Regulator (AVR) delivers multiple, synergistic benefits. A key finding is the significant and quantifiable Conservation Voltage Reduction (CVR) effect, demonstrated by an empirical CVR factor of 1.49. This nonlinear relationship, where an average voltage reduction of approximately 8% yields a more substantial power reduction of around 12%, was statistically validated by both paired t-tests and linear regression analysis (R2 = 0.86).

Concurrently, the AVR operation also reduces current draw, which directly alleviates thermal stress on electrical equipment and contributes to an extended operational lifespan. Furthermore, it improves the power factor, thereby enhancing grid stability and mitigating the risk of penalties from the utility provider.

In summary, this research shows that AVR technology provides a solution that offers engineering reliability, economic viability, and environmental compliance, particularly for motor-dominant commercial facilities. The long-term, multi-site empirical evidence from this study builds confidence for scaling the adoption of AVR as an integral part of Thailand’s demand-side management (DSM) portfolio and its broader national decarbonization strategies.

5.6. Sensitivity Analysis of Economic Returns

The sensitivity analysis revealed that the project’s financial viability is highly robust across a range of potential scenarios. The results indicate that the investment remains profitable even under reasonably adverse conditions.

The analysis identified the percentage of energy savings as the most influential variable affecting the project’s NPV and payback period. However, even in a pessimistic scenario with a 20% reduction in energy savings, the payback period remained under 4 years, and the NPV remained positive. Fluctuations in electricity tariffs also had a significant impact, whereas the project’s profitability showed lower sensitivity to increases in maintenance costs. This analysis confirms that while the financial returns are most sensitive to the actual energy savings achieved, the investment case remains strong and resilient against plausible operational and market risks.

6. Discussions

This study demonstrated that modest supply voltage adjustment produced disproportionately high energy savings and measurable power quality improvements under real operating conditions. The discussion below situates these findings within international literature and highlights their engineering, economic, and environmental implications, along with key innovations and future research needs.

The savings achieved here—exceeding 12%—are at the upper end of international benchmarks. Recent international studies provide important context. Wu et al. (2021) analyzed large commercial buildings in tropical climates and confirmed that voltage optimization strategies yield significant reductions in HVAC-driven demand [

2]. Kumar et al. (2022) conducted a detailed performance evaluation of voltage optimization devices in commercial facilities, reporting savings consistent with Conservation Voltage Reduction (CVR) principles [

4]. Similarly, Ghosh and Sharma (2022) provided both simulation and field-based evidence supporting autotransformer-based voltage optimization [

5], while Lee and Lee (2022) carried out a comprehensive engineering and economic evaluation of voltage reduction strategies in diverse commercial load sectors [

9]. These studies collectively reinforce the global evidence base, but they are largely limited to single-site or short-term demonstrations. By contrast, the present study contributes to one of the first long-horizon, multi-site empirical validations of AVR deployment in tropical, motor-heavy retail environments. Compared with UK and EU case studies that typically report 5–8% savings and Southeast Asian trials in Malaysia and Singapore that achieved 6–10%, our results demonstrate both higher absolute savings and stronger resilience under Thailand’s high-humidity, cooling-dominated conditions.

From an engineering perspective, the AVR intervention reduced current draw by 6.22% and improved power factor by 2.26%, thereby lowering I

2R distribution losses and enhancing network stability. These outcomes directly reduce thermal stress on conductors, switchgear, and transformers, extending equipment lifetimes. The consolidated statistical outcomes presented in

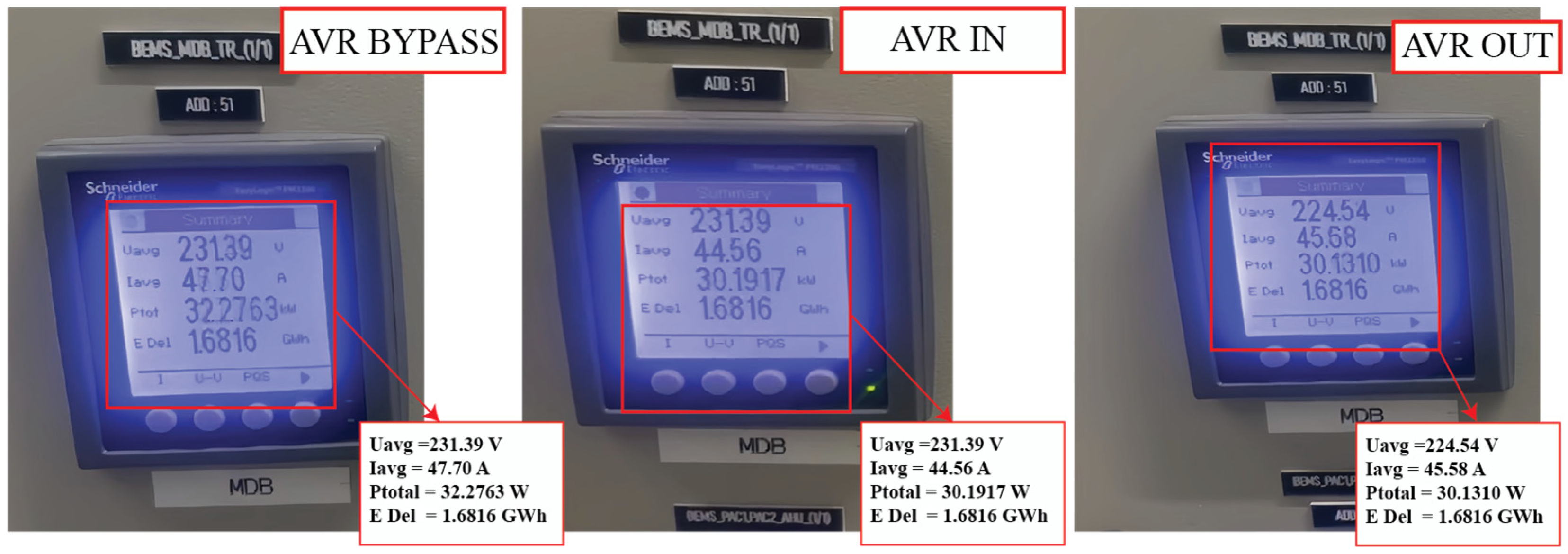

Table 2 (“Stats at a Glance”) confirm that AVR significantly reduced active power, current, and daily energy consumption, with large effect sizes across all headline metrics. As a practical demonstration,

Figure 9 provides a real-time snapshot of the AVR’s operation, displaying key electrical parameters at its bypass, input, and output terminals. The data clearly illustrates the unit’s primary function: reducing the voltage from 231.39 V (AVR IN) to 224.54 V (AVR OUT), which directly contributes to the power savings observed throughout the trial."

The baseline voltage survey summarized in

Figure 5 provides additional evidence of scalability. The data confirm that more than 98% of surveyed branches across Thailand exhibit supply conditions suitable for AVR installation, with only 1.86% deemed technically infeasible due to persistently low voltage levels. This finding indicates that the case-study results are not isolated but are representative of the vast majority of commercial facilities nationwide. Consequently, the demonstrated savings can be generalized beyond the pilot sites, reinforcing the robustness and policy relevance of AVR deployment as a sector-wide energy efficiency measure.

For motor-driven systems, particularly HVAC compressors and refrigeration units,

Table 1 and

Table 3 confirm that voltage stabilization minimized torque pulsations and insulation stress, mitigating common causes of premature failure. Prior studies have also confirmed these load-specific benefits. For instance, optimized voltage supply has been shown to reduce magnetizing current and improve induction motor efficiency without compromising operational reliability [

15]. Similarly, empirical investigations on refrigeration systems reported substantial efficiency gains when operated under optimized voltage conditions [

16]. The multi-branch results summarized in

Table 6 and

Table 7 demonstrate an average daily saving of ~11.9%, closely aligned with the primary case study findings, thereby confirming the scalability and reproducibility of AVR performance across diverse retail sites. The improved stability further aligns with IEC 60,038 and IEEE 1159 standards, confirming that energy savings can be achieved without compromising system reliability or power quality.

The measured daily energy savings of ~177 kWh/day correspond to ~262,000 THB annually, yielding a simple payback period of 2.67 years and an ROI of 37.5%. These figures position AVR as a high-return retrofit option, comparable to or even exceeding LED retrofits and inverter-driven HVAC upgrades. Sensitivity testing and Monte Carlo simulations further confirmed financial resilience under variations in tariff and load conditions, showing a 95% probability of achieving payback within three years. Such robustness, benchmarked against ISO 15686-5 life cycle costing guidelines, demonstrates that AVR adoption is not only technically viable but also economically compelling for large commercial operators.

Environmentally, the measured savings equate to 36.6 tCO

2/year of avoided emissions (±5%), calculated using Thailand’s official grid emission factor of 0.566 tCO

2/MWh. At sectoral scale, such reductions could exceed 15,000 tCO

2/year across Thailand’s shopping malls. These findings contribute directly to corporate ESG reporting while aligning with national strategies such as the Energy Efficiency Plan (EEP) 2018–2037 and the Carbon Neutrality Roadmap [

8,

10]. Policy alignment also extends to potential monetization: AVR projects can qualify under the Thailand Voluntary Emission Reduction (T-VER) scheme, offering additional financial incentives for adoption.

Methodologically, this work introduces a semi-automated, BEMS-integrated analytics platform that enables anomaly detection, predictive modeling, and scenario simulation—an innovation rarely documented in prior AVR studies. Beyond standalone AVR operation, integration with distributed energy storage systems offers additional pathways for enhancing both conservation and reliability. Recent work by Rabe et al. (2025) demonstrated algorithms for controlling energy storage in low-voltage networks to support voltage regulation and power quality [

25], underscoring opportunities for AVR–ESS synergies in future deployments.

Nevertheless, limitations remain. The current dataset, while extended to four months and multiple sites, does not capture all seasonal variations. In addition, the analysis primarily covers high-load retail facilities, leaving questions about generalizability to other building types. Future research should expand to multi-season, multi-sector trials, explore the integration of AVR with renewable energy and storage systems, and develop machine-learning algorithms for dynamic voltage optimization. These directions would strengthen AVR’s role not only as an energy conservation device but also as a component of smart grids and resilient building operation strategies.

A primary limitation of this study is the four-month data collection period (February to May), which corresponds to Thailand’s hot and peak hot seasons. Consequently, the high energy savings reported are strongly influenced by the intensive operation of Heating, Ventilation, and Air Conditioning (HVAC) systems, which constitute a major portion of the electrical load in commercial buildings during this time.

It is acknowledged that energy consumption patterns, and therefore the savings potential of voltage optimization, are subject to seasonal variations. During the cooler and rainy seasons (approximately June to January), lower ambient temperatures would likely reduce HVAC operational hours and load intensity. As motor-driven HVAC systems are highly responsive to voltage optimization, a decrease in their usage would predictably lower the overall percentage of energy savings.

Therefore, while the findings provide a robust validation of AVR effectiveness during high-demand periods, the annualized savings figures should be interpreted with this seasonal context in mind. Future research should prioritize a longitudinal study over a full 12-month cycle. This would capture the complete spectrum of seasonal effects, enabling the development of a more accurate, seasonally adjusted CVR model and providing a comprehensive annualized energy-saving profile for tropical commercial facilities.

Modern commercial buildings are characterized by a high prevalence of nonlinear loads (NLLs), such as switch-mode power supplies in IT equipment, LED lighting, and variable frequency drives (VFDs) in HVAC systems, which are primary sources of harmonic distortion. A critical consideration for any power-side intervention is its potential impact on these harmonies.

This study monitored total harmonic distortion (THD) as a key power quality metric. The results indicated that the implementation of the autotransformer-based AVR had a negligible impact on THD levels. This finding is consistent with the fundamental operating principle of this technology. Unlike solid-state (e.g., SCR-based) regulators that can introduce voltage notching and increase harmonic distortion, the autotransformer adjusts voltage by changing the magnetic coupling ratio, a process that does not inherently generate harmonics.

Therefore, the energy savings achieved through voltage optimization were realized without compromising the electrical system’s power quality. This confirms the suitability of autotransformer-based AVRs for deployment in sensitive commercial environments where maintaining low harmonic distortion is crucial for equipment reliability and compliance with standards like IEEE 519.

The overall impacts of AVR deployment under real operating conditions are consolidated in

Table 8, which summarizes electrical, economic, environmental, and operational performance metrics. These include an 8.06% supply voltage reduction within IEC 60,038 limits, a 12.02% active power reduction, 6.22% current reduction, 2.26% power factor improvement, and daily energy savings of ~177 kWh/day. The economic analysis in the same table confirms a 2.67-year payback period with an ROI above 35%, while the environmental contribution corresponds to 30–40 tCO

2/year abatement. Operationally, voltage stability improved by 65%, with the largest energy savings achieved in AHU and refrigeration loads. These findings are consistent with prior empirical evidence on induction motors [

15] and refrigeration systems [

16], further validating the robustness of the present outcomes.

In summary,

Table 8 present study confirms that AVR technology provides engineering reliability, economic attractiveness, and environmental responsibility, with savings at the upper bound of international benchmarks. By extending the evidence base to tropical, motor-heavy retail environments, validating results across multiple branches, and considering integration with emerging storage-based solutions [

25], the findings establish AVR as a scalable, policy-relevant solution for sustainable building operations in Southeast Asia and beyond.

7. Conclusions

This study provides one of the first long-horizon, multi-site empirical validations of Automatic Voltage Regulator (AVR) deployment in tropical, motor-heavy commercial facilities. By integrating high-resolution monitoring with a BEMS-based analytics platform, the results confirm that a modest voltage reduction (−8.06%) can yield nonlinear energy savings (−12.02% active power), reduce current draw (−6.22%), and improve power factor (+2.26%), all within IEC 60,038 limits. These statistically validated outcomes (95% CIs and large effect sizes reported) highlight AVR not only as an energy conservation device but also as an integrated optimization instrument.

From an engineering perspective, AVR deployment mitigated thermal stress on distribution equipment, stabilized HVAC compressors, and reduced refrigeration load demand. These findings are consistent with prior load-specific evidence on induction motors [

15] and refrigeration systems [

16], thereby reinforcing confidence that the observed impacts are generalizable across motor-driven applications. From an economic perspective, the measured savings correspond to 262,212 THB/year with a payback of 2.67 years, supported by Monte Carlo analysis, showing a 95% probability of achieving payback within three years. From an environmental perspective, the intervention avoids 36.6 ± 5% tCO

2/year, directly contributing to corporate ESG metrics and aligning with Thailand’s EEP and Carbon Neutrality Roadmap. At scale, AVR deployment across the retail sector could contribute meaningfully to Thailand’s NDC commitments.

Beyond immediate savings, AVR enhances system reliability by reducing thermal stress, stabilizing motor operation, and improving voltage stability. Moreover, integration with emerging distributed energy storage systems provides opportunities for additional resilience and power quality improvement, as recent advances in coordinated AVR–ESS control suggest [

25]. These combined benefits position AVR as a high-return, low-risk retrofit strategy that supports demand-side management, ESG integration, and potential monetization through carbon credits under the T-VER scheme. Future work should expand multi-climate trials, explore AVR–renewable–storage integration, and apply machine learning for dynamic optimization, thereby strengthening AVR’s role in sustainable building operations and smart grid resilience.

8. Limitations and Future Research

The authors acknowledge that the data collection period of four months (February–May) may not fully capture the seasonal variations in energy consumption, particularly during the hot, humid summer and the winter months, which could lead to different energy-saving outcomes. Therefore, this study is limited by its seasonal data coverage.

To enhance the reliability and generalizability of the findings, future research is planned to extend the data collection period to a full 12 months. This will allow for a more precise analysis and the validation of the energy savings across all seasons.

While the measurements confirm that the installation of the Automatic Voltage Regulator (AVR) did not negatively impact the overall system’s total harmonic distortion (THD), which remained within the limits of the IEEE Std 519-2014 [

26] standard, this study did not perform an in-depth analysis of the response of individual types of nonlinear loads, such as variable frequency drives (VFDs) or electronic equipment, to the AVR’s operation.

Therefore, future research should focus on a detailed investigation of the interaction between the AVR and such specific loads. This would provide a deeper understanding of the impacts on both performance and power quality, allowing for a more comprehensive assessment of the technology’s compatibility.

Furthermore, an evaluation of the AVR’s performance under severe power system disturbances, such as voltage sags or flicker, represents another limitation of this study. Throughout the data collection period, no significant voltage anomaly events occurred that were sufficient for statistical analysis.

Consequently, the AVR’s responsiveness and resilience to such conditions were not assessed in a real-world operational setting. Future research could consider conducting tests in a simulated environment or collaborating with the utility provider during system maintenance to gain deeper insights into the device’s reliability under abnormal conditions.