Assessment of the Energy Parameters of Pedicels and Pomace of Selected Grapevine Varieties from the PIWI Group

Abstract

1. Introduction

2. Materials and Methods

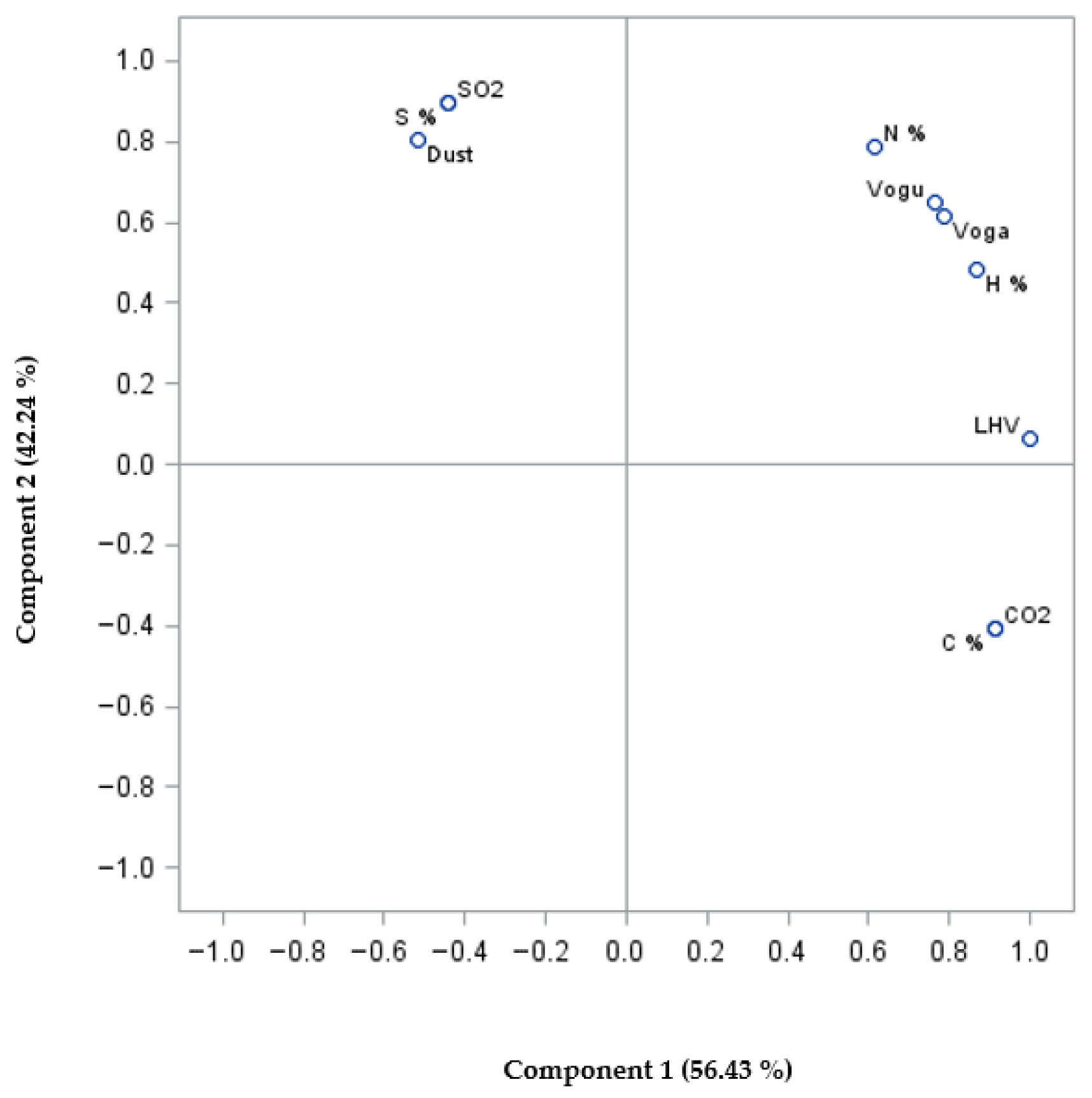

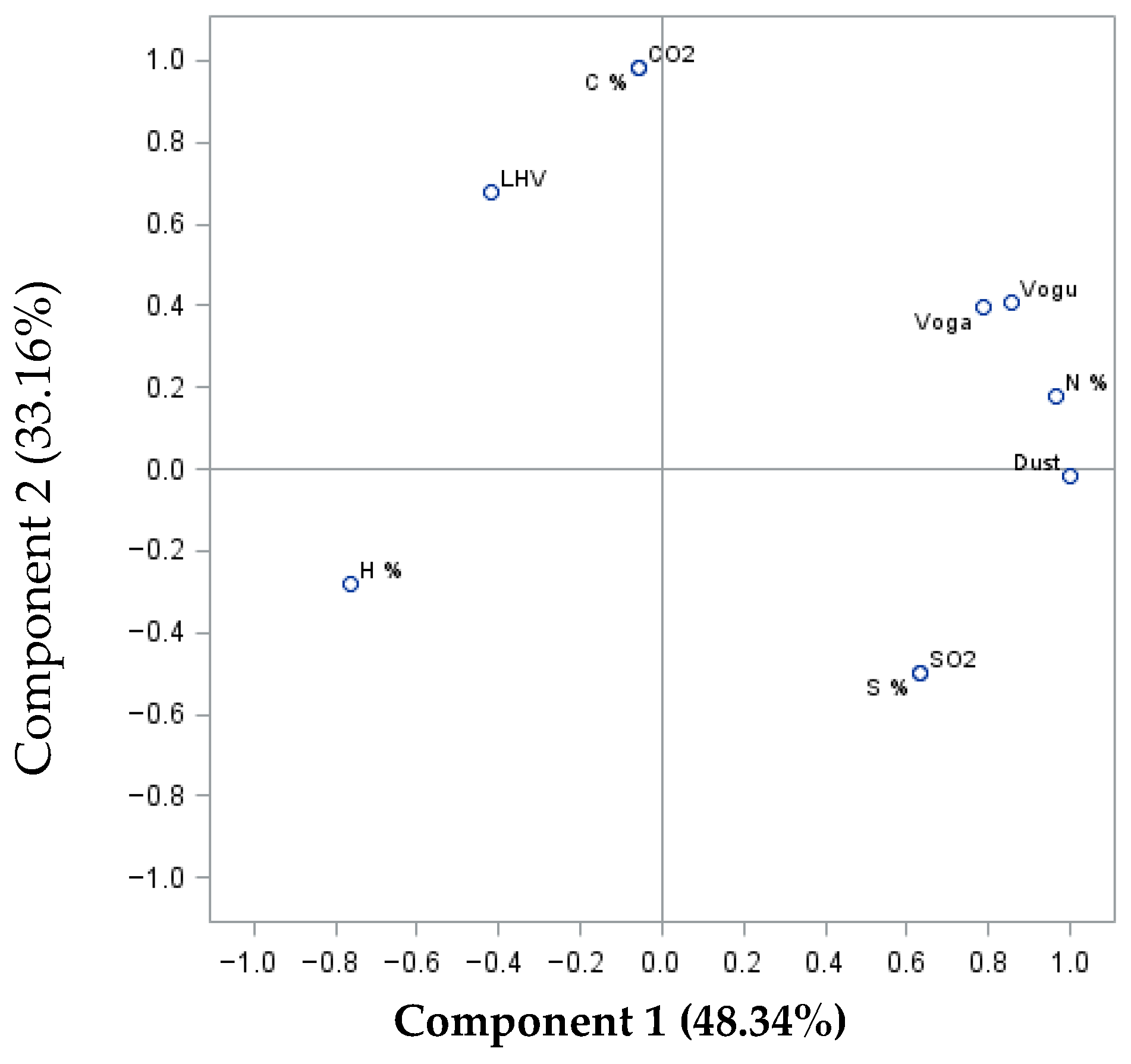

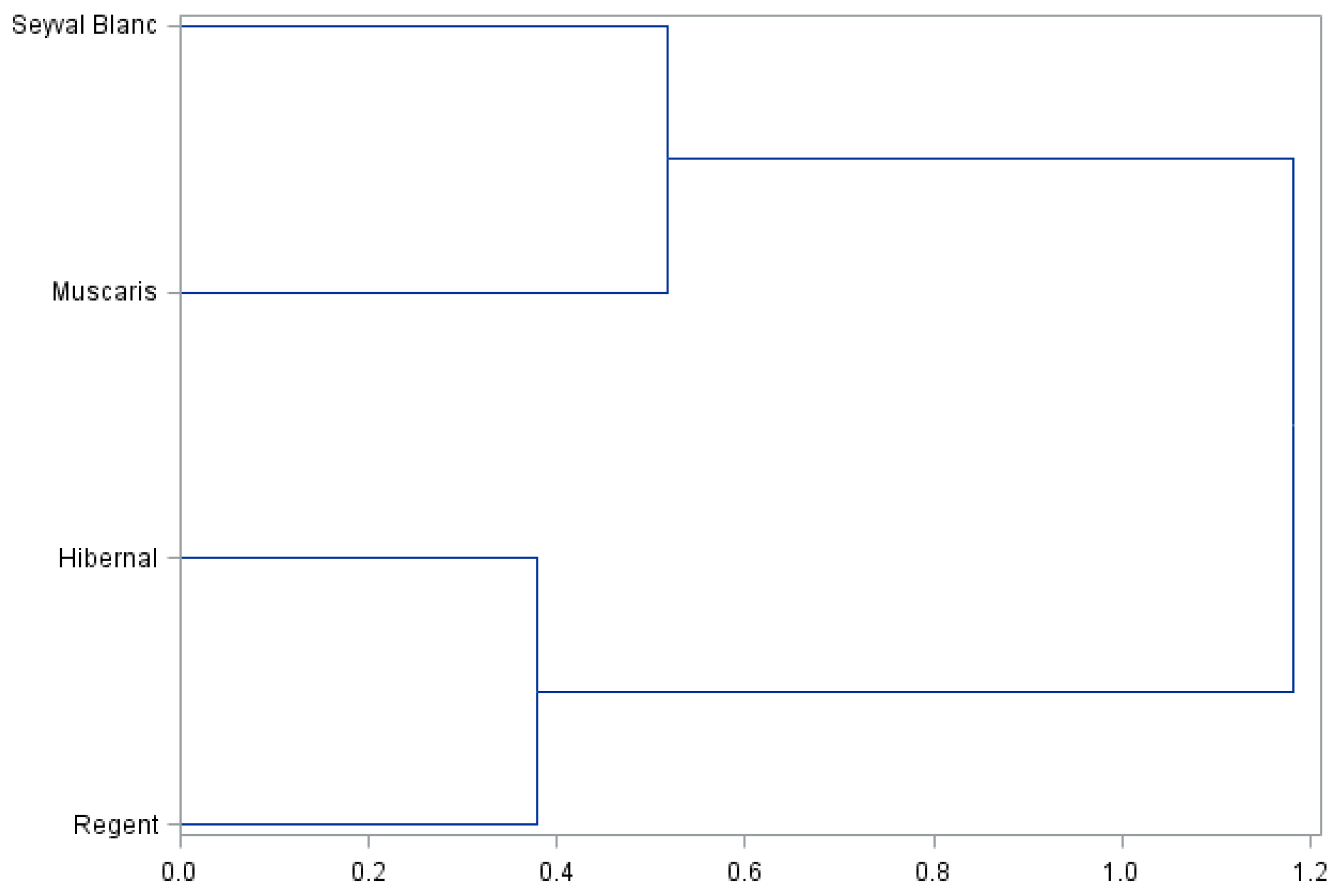

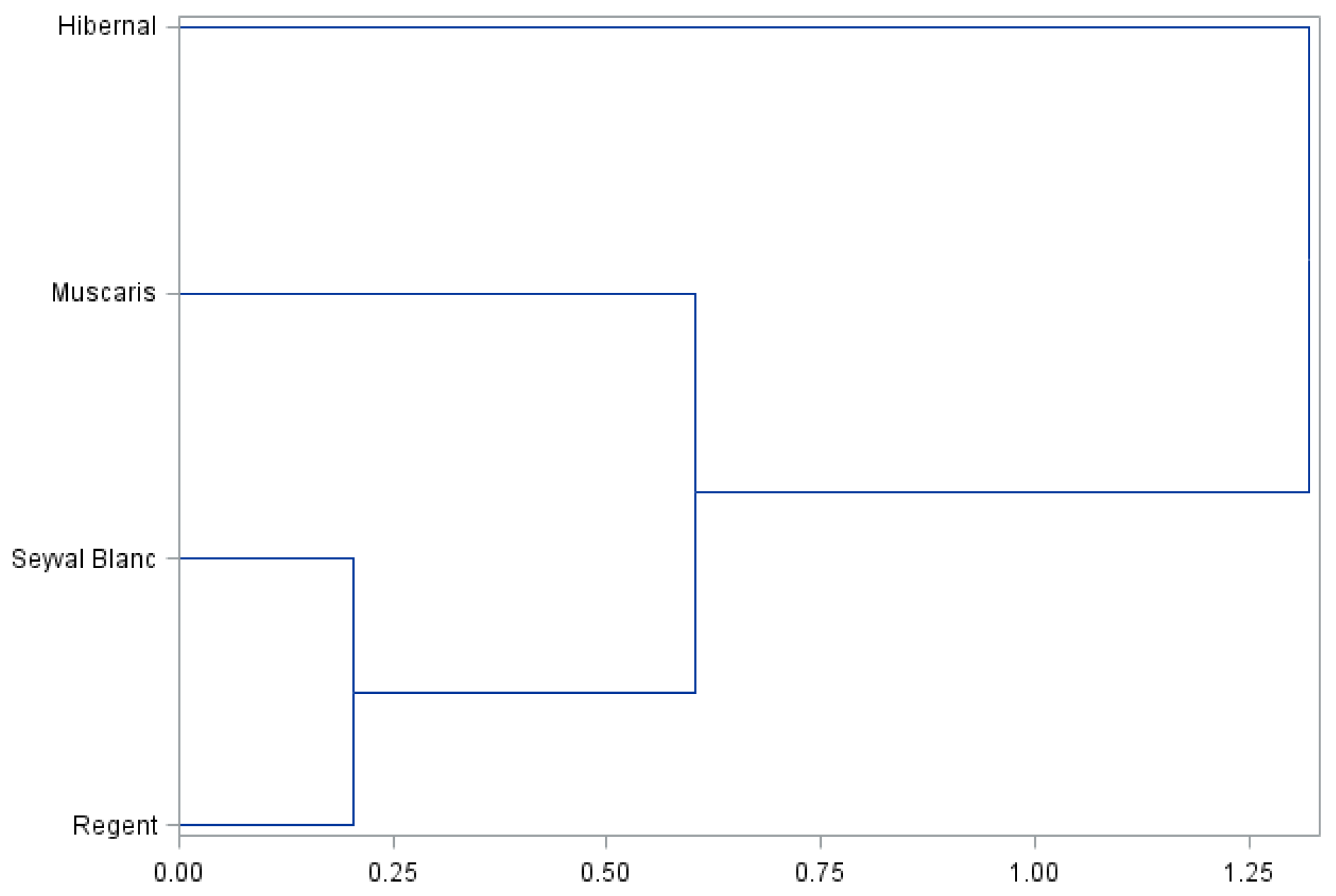

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Paschalidou, A.; Tsatiris, M.; Kitikidou, K.; Papadopoulou, C. Bioenergy–Biomass–Energy Crops. In Using Energy Crops for Biofuels or Food: The Choice; Green Energy and Technology; Springer International Publishing: Cham, Switzerland, 2018; pp. 11–24. ISBN 978-3-319-63942-0. [Google Scholar]

- Martínez-Jaramillo, J.E.; Van Ackere, A.; Larsen, E. Long Term Impacts of Climate Change on the Transition towards Renewables in Switzerland. Energy 2023, 263, 126089. [Google Scholar] [CrossRef]

- Shi, Z.; Ferrari, G.; Ai, P.; Marinello, F.; Pezzuolo, A. Bioenergy Potential from Agricultural By-Product in 2030: An AI-Based Spatial Analysis and Climate Change Scenarios in a Chinese Region. J. Clean. Prod. 2024, 436, 140621. [Google Scholar] [CrossRef]

- Salcedo-Puerto, O.; Mendoza-Martinez, C.; Vakkilainen, E. Solid Residues from Cocoa Production Chain: Assessment of Thermochemical Valorization Routes. Renew. Sustain. Energy Rev. 2025, 208, 115048. [Google Scholar] [CrossRef]

- Agrawal, A.; Bakshi, B.R.; Kodamana, H.; Ramteke, M. Multi-Objective Optimization of Food-Energy-Water Nexus via Crops Land Allocation. Comput. Chem. Eng. 2024, 183, 108610. [Google Scholar] [CrossRef]

- Guzović, Z.; Duić, N.; Piacentino, A.; Markovska, N.; Mathiesen, B.V.; Lund, H. Paving the Way for the Paris Agreement: Contributions of SDEWES Science. Energy 2023, 263, 125617. [Google Scholar] [CrossRef]

- Polak, R.; Dziki, D.; Krzykowski, A.; Rudy, S.; Biernacka, B. RenewGeo: An Innovative Geothermal Technology Augmented by Solar Energy. Agric. Eng. 2025, 29, 49–62. [Google Scholar] [CrossRef]

- Shi, Z.; Marinello, F.; Ai, P.; Pezzuolo, A. Assessment of Bioenergy Plant Locations Using a GIS-MCDA Approach Based on Spatio-Temporal Stability Maps of Agricultural and Livestock Byproducts: A Case Study. Sci. Total Environ. 2024, 947, 174665. [Google Scholar] [CrossRef] [PubMed]

- Adnane, I.; Taoumi, H.; Elouahabi, K.; Lahrech, K.; Oulmekki, A. Valorization of Crop Residues and Animal Wastes: Anaerobic Co-Digestion Technology. Heliyon 2024, 10, e26440. [Google Scholar] [CrossRef]

- Van Dijk, M.; Goedegebure, R.; Nap, J.-P. Public Acceptance of Biomass for Bioenergy: The Need for Feedstock Differentiation and Communicating a Waste Utilization Frame. Renew. Sustain. Energy Rev. 2024, 202, 114670. [Google Scholar] [CrossRef]

- Shinde, R.; Shahi, D.K.; Mahapatra, P.; Singh, C.S.; Naik, S.K.; Thombare, N.; Singh, A.K. Management of Crop Residues with Special Reference to the On-Farm Utilization Methods: A Review. Ind. Crops Prod. 2022, 181, 114772. [Google Scholar] [CrossRef]

- Arora, J.; Ramawat, K.G.; Mérillon, J.-M. Disposal of Agricultural Waste and Its Effects on the Environment, Production of Useful Metabolites and Energy: Potential and Challenges. In Agricultural Waste: Environmental Impact, Useful Metabolites and Energy Production; Ramawat, K.G., Mérillon, J.-M., Arora, J., Eds.; Sustainable Development and Biodiversity; Springer Nature: Singapore, 2023; Volume 31, pp. 3–20. ISBN 978-981-19877-3-1. [Google Scholar]

- Perea-Moreno, A.-J.; Muñoz-Rodríguez, D. Agro-Industrial Wastes Valorisation to Energy and Value-Added Products for Environmental Sustainability. In Biomass Valorization; Kapoor, R.T., Sillanpää, M., Zdarta, J., Rafatullah, M., Eds.; Springer Nature: Singapore, 2024; pp. 1–25. ISBN 978-981-9785-56-8. [Google Scholar]

- Salcedo-Puerto, O.; Mendoza-Martinez, C.; Vakkilainen, E. Colombian Agroindustrial Crop Residues: Thermochemical Characterization and Evaluation of Their Energy Potential. Energy Rep. 2025, 13, 1802–1816. [Google Scholar] [CrossRef]

- Kumari, R.; Singh, A.; Sharma, R.; Malaviya, P. Conversion of Food Waste into Energy and Value-Added Products: A Review. Environ. Chem. Lett. 2024, 22, 1759–1790. [Google Scholar] [CrossRef]

- Trigo, A.; Marta-Costa, A.; Fragoso, R. Improving Sustainability Assessment: A Context-Oriented Classification Analysis for the Wine Industry. Land Use Policy 2023, 126, 106551. [Google Scholar] [CrossRef]

- Kassim, F.O.; Sohail, M.; Somorin, T.; Blanch, G.; Yaman, R.; Afolabi, O.O.D. Optimised Mixed Agri-Food Waste Simulant for Enhanced Bioenergy Production via Hydrothermal Carbonisation and Supercritical Plant Modelling. Energy Rep. 2025, 13, 184–195. [Google Scholar] [CrossRef]

- Bordiga, M.; Travaglia, F.; Locatelli, M. Valorisation of Grape Pomace: An Approach That Is Increasingly Reaching Its Maturity—A Review. Int. J. Food Sci. Technol. 2019, 54, 933–942. [Google Scholar] [CrossRef]

- Abbate, S.; Centobelli, P.; Di Gregorio, M. Wine Waste Valorisation: Crushing the Research Domain. Rev. Manag. Sci. 2025, 19, 963–998. [Google Scholar] [CrossRef]

- Maicas, S.; Mateo, J.J. Sustainability of Wine Production. Sustainability 2020, 12, 559. [Google Scholar] [CrossRef]

- Evtuguin, D.; Aniceto, J.P.S.; Marques, R.; Portugal, I.; Silva, C.M.; Serafim, L.S.; Xavier, A.M.R.B. Obtaining Value from Wine Wastes: Paving the Way for Sustainable Development. Fermentation 2023, 10, 24. [Google Scholar] [CrossRef]

- Parrado-Hernando, G.; Pfeifer, A.; Frechoso, F.; Miguel González, L.J.; Duić, N. A Novel Approach to Represent the Energy System in Integrated Assessment Models. Energy 2022, 258, 124743. [Google Scholar] [CrossRef]

- Montalvo-Falcón, J.V.; Sánchez-García, E.; Marco-Lajara, B.; Martínez-Falcó, J. Sustainability Research in the Wine Industry: A Bibliometric Approach. Agronomy 2023, 13, 871. [Google Scholar] [CrossRef]

- Kokkinomagoulos, E.; Kandylis, P. Grape Pomace, an Undervalued by-Product: Industrial Reutilization within a Circular Economy Vision. Rev. Environ. Sci. Biotechnol. 2023, 22, 739–773. [Google Scholar] [CrossRef]

- Rosen, D.L.; Miculan Bradley, D. Wine Tourism, the Business of Wine, and the Impact of the Environöment and Sustainability. In Wine Tourism and Sustainability; Martínez-Falcó, J., Marco-Lajara, B., Sánchez-García, E., Millán-Tudela, L.A., Eds.; Springer Nature: Cham, Switzerland, 2024; pp. 123–146. ISBN 978-3-031-48936-5. [Google Scholar]

- EN-ISO 1928:2020; Coal and Coke—Determination of Gross Calorific Value. International Organization for Standardization: Geneva, Switzerland, 2020.

- EN-ISO 18122:2022; Solid Biofuels—Determination of Ash Content. International Organization for Standardization: Geneva, Switzerland, 2022.

- EN-ISO 18123:2023; Solid Fuels—Determination of Volatile Matter. International Organization for Standardization: Geneva, Switzerland, 2023.

- EN-ISO 18134-1:2023; Solid Biofuels—Determination of Moisture Content Part 1: Reference Method. International Organization for Standardization: Geneva, Switzerland, 2022.

- Choudhury, N.D.; Saha, N.; Phukan, B.R.; Kataki, R. Characterization and Evaluation of Energy Properties of Pellets Produced from Coir Pith, Saw Dust and Ipomoea Carnea and Their Blends. Energy Sources Part Recovery Util. Environ. Eff. 2021, 47, 4517–4534. [Google Scholar] [CrossRef]

- EN-ISO 16948:2015-07; Solid Biofuels—Determination of Total Content of Carbon, Hydrogen and Nitrogen. International Organization for Standardization: Geneva, Switzerland, 2015.

- ISO 16994:2016; Solid Biofuels—Determination of Total Content of Sulphur and Chlorine. International Organization for Standardization: Geneva, Switzerland, 2016.

- Alves, J.L.F.; da Silva, J.C.G.; Mumbach, G.D.; Domenico, M.D.; da Silva Filho, V.F.; de Sena, R.F.; Machado, R.A.F.; Marangoni, C. Insights into the Bioenergy Potential of Jackfruit Wastes Considering Their Physicochemical Properties, Bioenergy Indicators, Combustion Behaviors, and Emission Characteristics. Renew. Energy 2020, 155, 1328–1338. [Google Scholar] [CrossRef]

- Maj, G. Emission Factors and Energy Properties of Agro and Forest Biomass in Aspect of Sustainability of Energy Sector. Energies 2018, 11, 1516. [Google Scholar] [CrossRef]

- Kovacs, H.; Szemmelveisz, K.; Koós, T. Theoretical and Experimental Metals Flow Calculations during Biomass Combustion. Fuel 2016, 185, 524–531. [Google Scholar] [CrossRef]

- Paraschiv, L.S.; Serban, A.; Paraschiv, S. Calculation of Combustion Air Required for Burning Solid Fuels (Coal/Biomass/Solid Waste) and Analysis of Flue Gas Composition. Energy Rep. 2020, 6, 36–45. [Google Scholar] [CrossRef]

- Fernández-Puratich, H.; Hernández, D.; Tenreiro, C. Analysis of Energetic Performance of Vine Biomass Residues as an Alternative Fuel for Chilean Wine Industry. Renew. Energy 2015, 83, 1260–1267. [Google Scholar] [CrossRef]

- Enes, T.; Aranha, J.; Fonseca, T.; Matos, C.; Barros, A.; Lousada, J. Residual Agroforestry Biomass–Thermochemical Properties. Forests 2019, 10, 1072. [Google Scholar] [CrossRef]

- Torreiro, Y.; Pérez, L.; Piñeiro, G.; Pedras, F.; Rodríguez-Abalde, A. The Role of Energy Valuation of Agroforestry Biomass on the Circular Economy. Energies 2020, 13, 2516. [Google Scholar] [CrossRef]

- Ion, V.; Mot, A.; Popa, V.; Calcan, S.; Badulescu, L.; Ionut-Ovidiu, J.; Baniţă, C.; Parvulescu, O. Physicochemical Characterisation of Vine Waste Used for Producing Biochar. Sci. Papers. Ser. B Hortic. 2021, LXV, 268–273. [Google Scholar]

- Cereceda-Balic, F.; Toledo, M.; Vidal, V.; Guerrero, F.; Diaz-Robles, L.A.; Petit-Breuilh, X.; Lapuerta, M. Emission Factors for PM2.5, CO, CO2, NOX, SO2 and Particle Size Distributions from the Combustion of Wood Species Using a New Controlled Combustion Chamber 3CE. Sci. Total Environ. 2017, 584, 901–910. [Google Scholar] [CrossRef] [PubMed]

- Malaťák, J.; Velebil, J.; Malaťáková, J.; Passian, L.; Bradna, J.; Tamelová, B.; Gendek, A.; Aniszewska, M. Reducing Emissions from Combustion of Grape Residues in Mixtures with Herbaceous Biomass. Materials 2022, 15, 7288. [Google Scholar] [CrossRef] [PubMed]

- Malaťák, J.; Bradna, J.; Velebil, J. The Dependence of COX and NOX Emission Concentrations on the Excess Air Coefficient during Combustion of Selected Agricultural Briquetted By-Products. Agron. Res. 2017, 15, 1084–1093. [Google Scholar]

| PARAMETER | METHOD | EQUIPMENT |

|---|---|---|

| Energetic properties | ||

| Higher Heating Value (HHV; MJ·kg−1) | EN-ISO 1928:2020 [26] | isoperibolic calorimeter LECO AC 600 |

| Lower Heating Value (LHV; MJ·kg−1) | ||

| Proximate Analysis | ||

| Ash (A; %) | EN-ISO 18122:2022 [27] | thermogravimetric analyser LECO TGA 701 |

| Volatile matter (V; %) | EN-ISO 18123:2023 [28] | |

| Moisture (MC; %) | EN-ISO 18134:2023 [29] | |

| Fixed carbon (FC; %) | FC = 100 − V − A − M [30] | |

| Ultimate Analysis | ||

| Carbon (C; %) | EN-ISO 16948:2015 [31] | elemental analyser LECO CHNS 628 |

| Hydrogen (H; %) | ||

| Nitrogen (N; %) | ||

| Sulfur (S; %) | EN-ISO 16994:2016 [32] | |

| Oxygen (O; %) | O = 100 − A − H − C − S − N [33] | |

| PARAMETER | METHOD |

|---|---|

| Carbon monoxide emission factor (Ec) of chemically pure coal (CO; kg·Mg−1) | - molar mass ratio of carbon monoxide and carbon, EC—emission factor of chemically pure coal (kg·kg−1), C/CO—part of the carbon emitted as CO (for biomass 0.06). |

| Carbon dioxide emission factor (CO2; kg·Mg−1) | CO2—carbon dioxide emission factor (kg·kg−1)—molar mass ratio of carbon dioxide and pure coal—molar mass ratio of carbon dioxide and carbon monoxide—molar mass ratio of carbon and methane, ECH4—methane emission factor, ENMVOC—emission index of non-methane VOCs (for biomass 0.009). |

| Sulphur dioxide emission factor (SO2; kg·Mg−1) | SO2—sulphur dioxide emission factor (kg·kg−1), 2—molar mass ratio of SO2 and sulphur, S—sulphur content in fuel (%), r—coefficient determining the part of total sulphur retained in the ash. |

| Emission factor was calculated from (NOX; kg·Mg−1) | , NOX—NOX emission factor (kg·kg−1)—molar mass ratio of nitrogen dioxide to nitrogen. The molar mass of nitrogen dioxide is considered due to the fact that nitrogen oxide in the air oxidizes rapidly to nitrogen dioxide, N/C—nitrogen to carbon ratio in biomass, NNOX/N—part of nitrogen emitted as NOX (for biomass 0.122). |

| PARAMETER | METHOD |

|---|---|

| Theoretical oxygen demand ; Nm3·kg−1) | , C—biomass carbon content (%), H—biomass hydrogen content (%), S—biomass sulphur content (%), O—biomass oxygen content). |

| The stoichiometric volume of dry air required to burn 1 kg of biomass ; Nm3·kg−1) | Since the oxygen content in the air is 21%, which participates in the combustion process in the boiler, this is the stoichiometric volume of dry air required to burn 1 kg of biomass |

| Carbon dioxide content of the combustion products ; Nm3·kg−1) | |

| Content of sulphur dioxide ; Nm3·kg−1) | , |

| Water vapour content of the exhaust gas (; Nm3·kg−1) | , This is the component of water vapour volume from the hydrogen combustion process and the volume of moisture contained in the combustion air ; M-fuel moisture content (%), x-air absolute humidity (kg H2O·kg−1 dry air). |

| The theoretical nitrogen content in the exhaust gas (; Nm3·kg−1) | , Considering that the nitrogen in the exhaust comes from the fuel composition and the combustion air and that the nitrogen content in the air is 79%. |

| The total stoichiometric volume of dry exhaust gas Nm3·kg−1) | |

| The total volume of exhaust gases ; Nm3·kg−1) | Assuming that biomass combustion is carried out under stoichiometric conditions, i.e., using the minimum amount of air required for combustion (λ = 1), a minimum exhaust gas volume will be obtained. |

| Name | HHV | LHV | MC | A | V | FC | |

|---|---|---|---|---|---|---|---|

| Unit | MJ·kg−1 | % | |||||

| Variety (A) | Regent | 16.91 ± 1.04 b | 15.76 ± 1.03 b | 6.05 ± 0.40 a | 8.87 ± 1.22 b | 65.66 ± 1.09 b | 19.42 ± 0.55 b |

| Seyval Blanc | 17.00 ± 0.85 a | 15.82 ± 0.83 ab | 6.16 ± 0.66 a | 6.79 ± 2.36 d | 66.55 ± 2.83 ab | 20.51 ± 0.23 a | |

| Hibernal | 17.04 ± 1.36 a | 15.90 ± 1.34 a | 5.09 ± b 0.81 a | 8.23 ± 2.47 c | 67.34 ± 1.03 a | 19.36 ± 3.04 b | |

| Muscaris | 17.00 ± 0.61 a | 15.86 ± 0.61 a | 6.12 ± 0.11 a | 10.03 ± 0.17 a | 66.42 ± 1.65 ab | 17.44 ± 1.8 c | |

| p-value | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | |

| Material (B) | Stem | 16.11 ± 0.26 b | 14.96 ± 0.25 b | 6.25 ± 0.38 a | 9.85 ± 0.6 a | 65.14 ± 1.35 b | 18.76 ± 1.48 b |

| Pulp | 17.87 ± 0.28 a | 16.70 ± 0.28 a | 5.45 ± 0.72 b | 7.11 ± 2.13 b | 67.84 ± 0.94 a | 19.6 ± 2.43 a | |

| p-value | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | |

| A*B | p-value | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 |

| Material | LHV | HHV |

|---|---|---|

| MJ·kg−1 | ||

| Sauvignon blanc [37] | 17.3 | 18.7 |

| Pinot [37] | 15.1 | 16.5 |

| Cabernet Sauvignon [37] | 16.2 | 17.6 |

| Chardonnay [37] | 16.2 | 17.6 |

| Name | C | H | N | S | O | H/C | N/C | O/C | |

|---|---|---|---|---|---|---|---|---|---|

| Unit | % | ||||||||

| Variety (A) | Regent | 45.64 ± 1.91 a | 6.77 ± 0.36 a | 1.42 ± 0.06 b | 0.06 ± 0.01 ab | 37.24 ± 1.12 c | 0.03 ± 0.00 b | 11.21 ± 1.55 b | 0.61 ± 0.04 b |

| Seyval Blanc | 45.79 ± 0.38 a | 6.98 ± 0.56 a | 0.97 ± 0.05 d | 0.06 ± 0.03 b | 39.41 ± 1.47 a | 0.02 ± 0.00 d | 8.57 ± 2.98 d | 0.65 ± 0.02 a | |

| Hibernal | 45.60 ± 2.02 a | 6.62 ± 0.54 a | 1.11 ± 0.08 c | 0.07 ± 0.02 ab | 38.37 ± 0.6 b | 0.02 ± 0.00 c | 10.39 ± 3.12 c | 0.63 ± 0.03 ab | |

| Muscaris | 45.70 ± 0.64 a | 6.75 ± 0.44 a | 1.82 ± 0.27 a | 0.08 ± 0.03 a | 35.63 ± 0.74 d | 0.04 ± 0.01 a | 12.67 ± 0.21 a | 0.58 ± 0.02 c | |

| p-value | 0.9963 | 0.6458 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | |

| Material (B) | Stem | 44.60 ± 0.86 b | 6.52 ± 0.19 b | 1.35 ± 0.45 a | 0.05 ± 0.02 b | 37.63 ± 1.09 a | 0.03 ± 0.01 a | 12.44 ± 0.76 a | 0.63 ± 0.03 a |

| Pulp | 46.76 ± 0.7 a | 7.04 ± 0.52 a | 1.31 ± 0.24 a | 0.09 ± 0.01 a | 37.69 ± 2.25 a | 0.03 ± 0.01 b | 8.98 ± 2.69 b | 0.6 ± 0.04 b | |

| p-value | 0.0001 | 0.0001 | 0.7681 | 0.0001 | 0.9437 | 0.0001 | 0.0001 | 0.0001 | |

| A*B | p-value | 0.0001 | 0.1724 | 0.0001 | 0.0816 | 0.0001 | 0.0001 | 0.0001 | 0.0001 |

| Name | C | H | N | S | O | A | V | FC |

|---|---|---|---|---|---|---|---|---|

| Unit | % | |||||||

| Vitis vinifera (Sabor) [38] | 44.2 | 6.1 | 1.0 | 0.07 | 43.0 | 7.2 | - | - |

| Grape marc [40] | 50.10 | 6.30 | 2.20 | - | 41.40 | 10.27 | 75.92 | 14.98 |

| Grapevine prunings [40] | 48.39 | 6.65 | 0.49 | - | 44.47 | 1.99 | 83.03 | 14.98 |

| Pruning Vine [39] | 44.62 | 5.77 | 0.70 | 0.05 | 2.6 | |||

| Name | CO | NOX | CO2 | SO2 | Dust | |

|---|---|---|---|---|---|---|

| Unit | kg Mg−1 | |||||

| Variety (A) | Regent | 56.22 ± 2.35 a | 5.00 ± 0.21 b | 1376.80 ± 57.58 a | 0.13 ± 0.03 ab | 1.48 ± 0.02 a |

| Seyval Blanc | 56.41 ± 0.47 a | 3.44 ± 0.18 d | 1381.37 ± 11.44 a | 0.11 ± 0.06 b | 1.52 ± 0.11 a | |

| Hibernal | 56.18 ± 2.49 a | 3.93 ± 0.28 c | 1375.79 ± 60.92 a | ± 0.14 ± 0.04 ab | 1.45 ± 0.11 a | |

| Muscaris | 56.30 ± 0.79 a | 6.41 ± 0.95 a | 1378.64 ± 19.34 a | 0.16 ± 0.07 a | 1.48 ± 0.10 a | |

| p-value | 0.9963 | 0.0001 | 0.9963 | 0.0001 | 0.6054 | |

| Material (B) | Stem | 54.95 ± 1.06 b | 4.77 ± 1.6 a | 1345.56 ± 25.84 b | ± 0.09 ± 0.03 b | 1.46 ± 0.04 a |

| Pulp | 57.61 ± 0.86 a | 4.61 ± 0.86 a | 1410.74 ± 21.17 a | 0.18 ± 0.02 a | 1.51 ± 0.12 a | |

| p-value | 0.0001 | 0.7681 | 0.0001 | 0.0001 | 0.2202 | |

| A*B | p-value | 0.0001 | 0.0001 | 0.0001 | 0.8018 | 0.0834 |

| Name | CO | NOX | CO2 | SO2 | Dust |

|---|---|---|---|---|---|

| Unit | kg Mg−1 | ||||

| Radiata pine wood [41] | 49.85 | 0.41 | 1947.52 | 0.48 | - |

| Nothofagus obliqua [41] | 41.99 | 0.56 | 1801.67 | 0.41 | - |

| Jackfruit seeds [33] | 51.46 | 8.71 | 1232.43 | 0.11 | - |

| Wheat straw [34] | 50.57 | 1.83 | 1238.24 | 0.14 | 10.56 |

| Name | Voga | Vogu | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Unit | Nm3 kg−1 | ||||||||

| Variation (A) | Regent | 0.97 ± 0.06 a | 4.62 ± 0.3 a | 0.85 ± 0.04 a | 0.00 ± 0.00 ab | 0.83 ± 0.04 a | 4.79 ± 0.28 b | 7.22 ± 0.40 b | 5.64 ± 0.32 b |

| Seyval Blanc | 0.97 ± 0.03 a | 4.62 ± 0.13 a | 0.86 ± 0.01 a | 0.00 ± 0.00 b | 0.86 ± 0.05 a | 4.43 ± 0.14 c | 6.89 ± 0.22 c | 5.29 ± 0.15 c | |

| Hibernal | 0.95 ± 0.06 a | 4.54 ± 0.28 a | 0.85 ± 0.04 a | 0.00 ± 0.00 ab | 0.81 ± 0.06 a | 4.48 ± 0.27 c | 6.87 ± 0.38 c | 5.33 ± 0.30 c | |

| Muscaris | 0.98 ± 0.03 a | 4.68 ± 0.15 a | 0.85 ± 0.01 a | 0.00 ± 0.00a | 0.83 ± 0.05 a | 5.15 ± 0.22 | 7.59 ± 0.25 a | 6.00 ± 0.22 a | |

| p-value | 0.788 | 0.788 | 0.9963 | 0.0001 | 0.5583 | 0.0001 | 0.0001 | 0.0001 | |

| Material (B) | Stem | 0.93 ± 0.03 b | 4.45 ± 0.14 b | 0.83 ± 0.02 b | 0.00 ± 0.00 b | 0.81 ± 0.02 b | 4.60 ± 0.44 b | 6.96 ± 0.48 b | 5.43 ± 0.45 b |

| Pulp | 1.00 ± 0.03 a | 4.78 ± 0.15 a | 0.87 ± 0.01 a | 0.00 ± 0.00a | 0.86 ± 0.06 a | 4.83 ± 0.24 a | 7.33 ± 0.28 a | 5.70 ± 0.25 a | |

| p-value | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | |

| A*B | p-value | 0.0199 | 0.0199 | 0.0001 | 0.0816 | 0.2593 | 0.0001 | 0.0001 | 0.0001 |

| Material | Voga | Vogu |

|---|---|---|

| Unit | Nm3 kg−1 | |

| Pure white grape pomace [42] | 5.95 | 4.58 |

| Pure red grape pomace [42] | 6.22 | 4.79 |

| Czech knotweed (Reynoutria × bohemica) [43] | 4.20 | 4.13 |

| Rumex OK 2 (Rumex patientia × Rumex tianschanicus) [43] | 4.07 | 4.04 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kapłan, M.; Klimek, K.E.; Maj, G.; Buczyński, K.; Borkowska, A. Assessment of the Energy Parameters of Pedicels and Pomace of Selected Grapevine Varieties from the PIWI Group. Energies 2025, 18, 5444. https://doi.org/10.3390/en18205444

Kapłan M, Klimek KE, Maj G, Buczyński K, Borkowska A. Assessment of the Energy Parameters of Pedicels and Pomace of Selected Grapevine Varieties from the PIWI Group. Energies. 2025; 18(20):5444. https://doi.org/10.3390/en18205444

Chicago/Turabian StyleKapłan, Magdalena, Kamila E. Klimek, Grzegorz Maj, Kamil Buczyński, and Anna Borkowska. 2025. "Assessment of the Energy Parameters of Pedicels and Pomace of Selected Grapevine Varieties from the PIWI Group" Energies 18, no. 20: 5444. https://doi.org/10.3390/en18205444

APA StyleKapłan, M., Klimek, K. E., Maj, G., Buczyński, K., & Borkowska, A. (2025). Assessment of the Energy Parameters of Pedicels and Pomace of Selected Grapevine Varieties from the PIWI Group. Energies, 18(20), 5444. https://doi.org/10.3390/en18205444