Effect of Plum Seeds and Rosin Adding to Sawdust on the Pelletisation Process and Fuel Pellet Quality

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Determination of Moisture Content

2.3. Determination of Ash Content

2.4. Determination of Bulk Density

2.5. Determination of Particle Size Distribution

2.6. Elemental Composition Analysis

2.7. Determination of Calorific Value and Heat of Combustion

2.8. Pressure Agglomeration Process

- wm = 16—mixture humidity [%],

- zk = 10—content of crushed rosin [%],

- do = 6—diameter of holes in the matrix [mm],

- dm = 216—diameter of the matrix [mm],

- hm = 32—height of the matrix [mm],

- Qm = 50—mass flow rate of the mixture [kg·h−1],

- nr = 124—rotational speed of the compaction roller system [rpm],

- hr = 0.2—gap between the rollers and the matrix [mm].

2.9. Physical Properties of Pellets

2.9.1. Density of Pellets

2.9.2. Bulk Density of Pellets

2.9.3. Determination of the Kinetic Strength of the Pellets

- T = 60—duration of the test [s],

- p = 7—target pressure [kPa].

2.10. Research on Pellet Combustion and Determination of Exhaust Gas Composition

- Air flow rate: 22% (of maximum capacity),

- Burner power output: 19.7 kW,

- Fuel feed rate: 3 kg·h−1.

3. Results

3.1. Moisture Content of the Analysed Raw Materials

3.2. Granulometric Distribution of Sawdust and Crushed Plum Stones

3.3. Bulk Density of the Tested Raw Materials

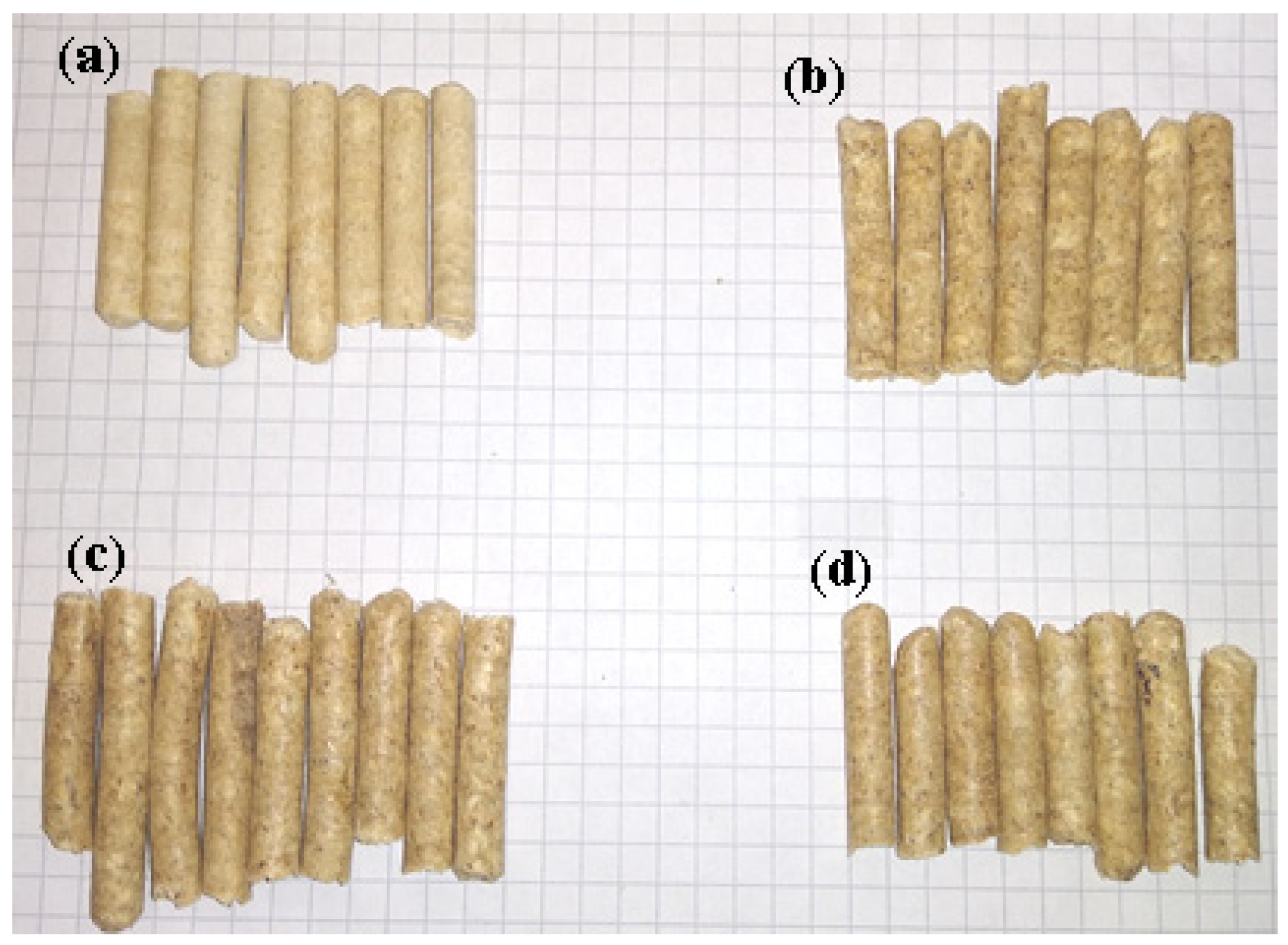

3.4. The Pelleting Process of a Mixture of Sawdust, Crushed Plum Stones, and Rosin

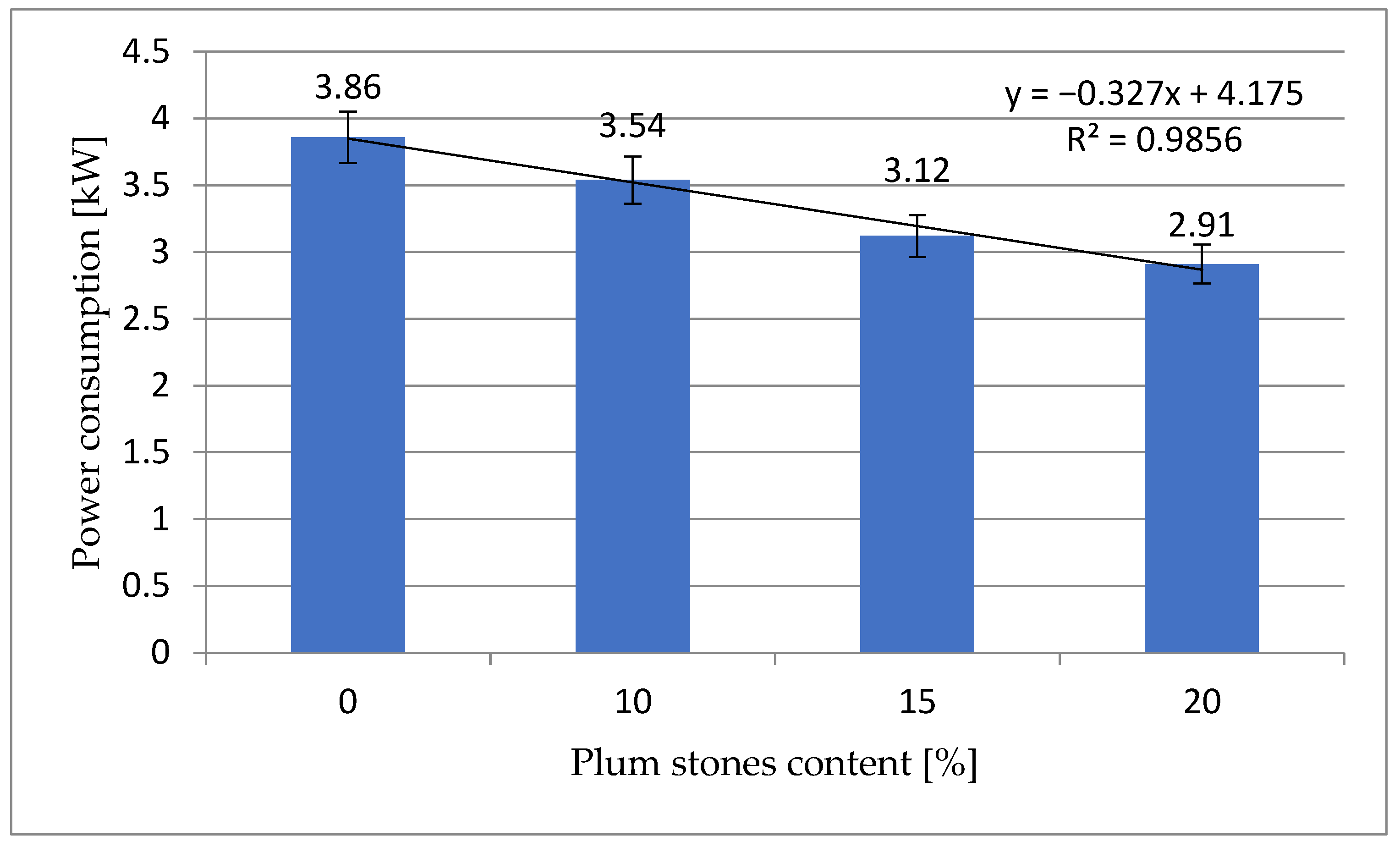

3.4.1. Effect of Plum Stones and Rosin on the Power Demand of the Pelletiser During the Pelleting of Pine Sawdust

3.4.2. Mechanical Durability of the Pellets

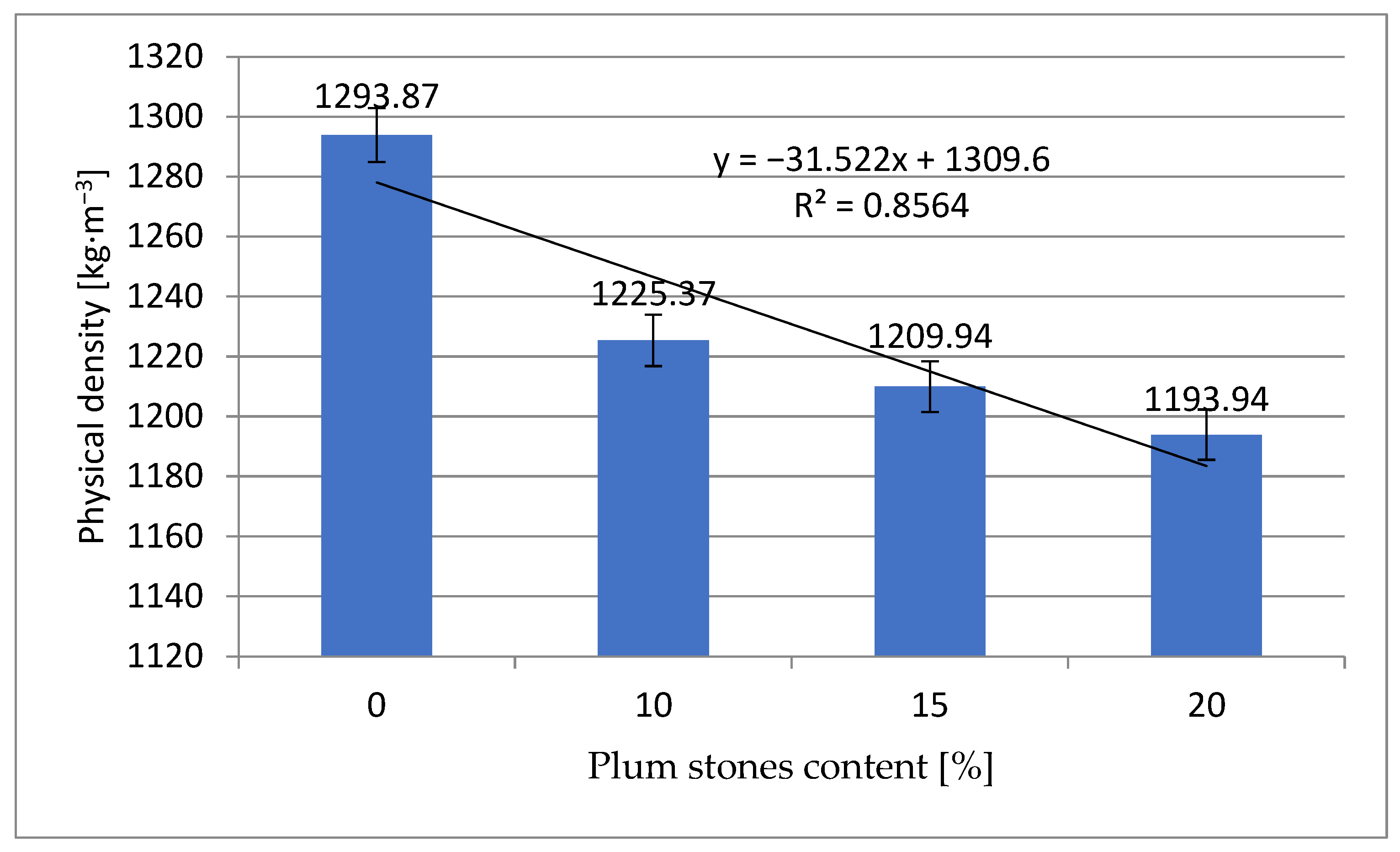

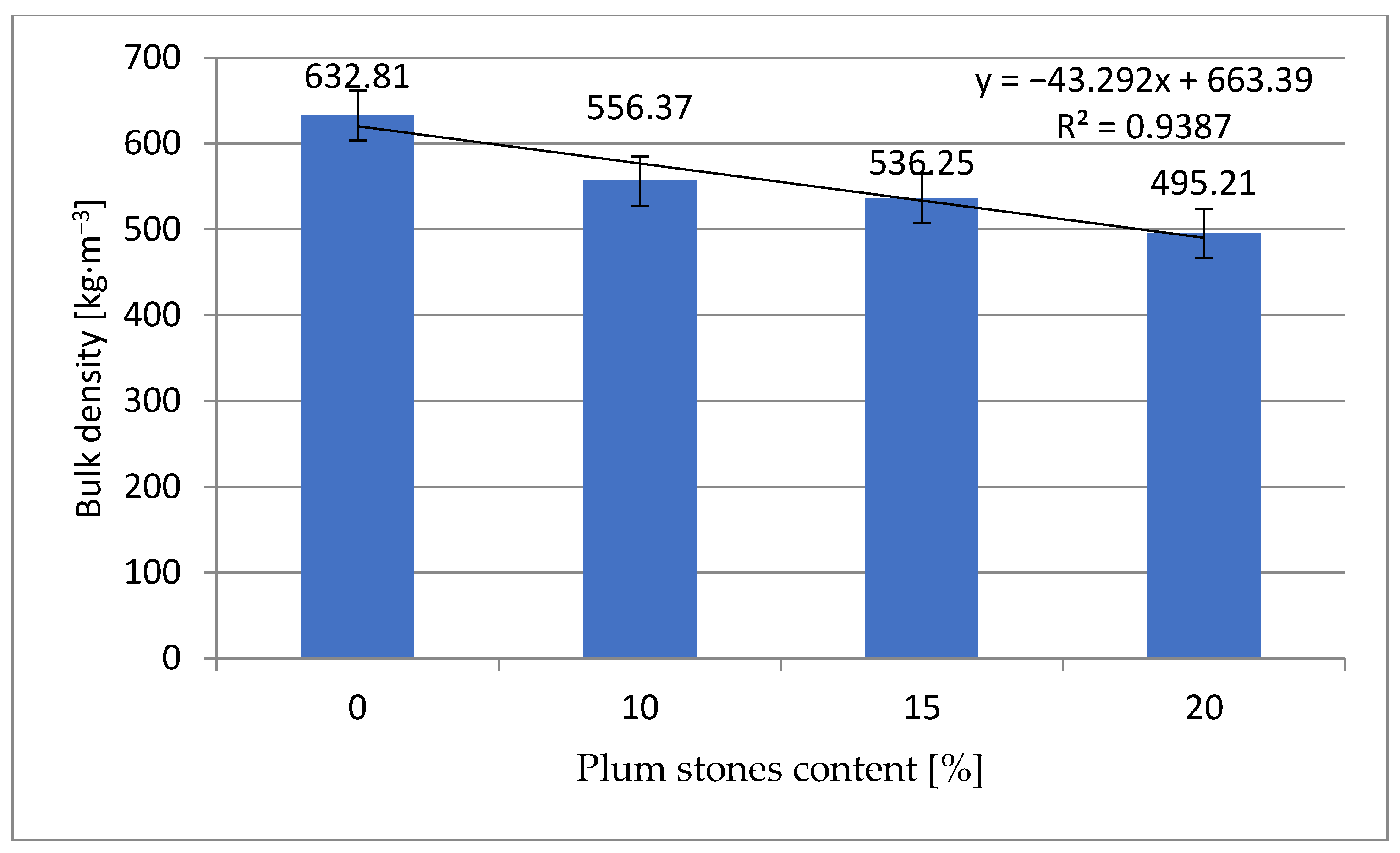

3.4.3. Particle Density and Bulk Density of the Pellets

3.5. Elemental Composition of Raw Materials

3.6. Heat of Combustion and Heating Value of Sawdust, Crushed Plum Stones, and Rosin

3.7. Emission Analysis of Combustion Gases from Pellets with Plum Stone Additives

4. Conclusions

- Pine sawdust is characterised by an average moisture content of 13.52% and a significant fraction of fine particles (<0.5 mm), accounting for ~13% of the mass. This fraction is unfavourable for pelletisation efficiency and process safety.

- The addition of crushed plum stones and 10% rosin enables partial compaction of the fine fraction without pressure, reducing the energy demand of the pelletisation process.

- Incorporating 10–20% crushed plum stones into the sawdust mixture with 10% rosin (moisture ~16%) significantly decreased the pelletiser power demand—by ~18% and 25%, respectively—compared to pelletisation of pure pine sawdust.

- The addition of crushed plum stones improved the energy parameters of pellets. The heating value increased up to 18.016 MJ∙kg−1, and the heat of combustion reached 20.042 MJ∙kg−1 at 20% plum stone content. An additional 10% rosin raised these values by ~1.67 MJ∙kg−1, an increase of 8.4%.

- Although plum stone addition slightly reduced pellet density and bulk density, at 10% addition, the kinetic durability improved to 97.24%, indicating enhanced mechanical properties of the final product.

- Pellets made from sawdust, plum stones, and rosin showed favourable combustion characteristics, including lower excess air coefficients (λ) and reduced emissions of CO, NO, and SO2. However, the relatively high rosin content (10%) caused a slight exceedance of CO emission limits according to the Ecodesign Directive. A reduction in rosin content to ~5% is therefore recommended.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, J.; Azam, W. Natural Resource Scarcity, Fossil Fuel Energy Consumption, and Total Greenhouse Gas Emissions in Top Emitting Countries. Geosci. Front. 2024, 15, 101757. [Google Scholar] [CrossRef]

- Wassie, S.B. Natural Resource Degradation Tendencies in Ethiopia: A Review. Environ. Syst. Res. 2020, 9, 1–29. [Google Scholar] [CrossRef]

- Scheelhaase, J.; Maertens, S.; Grimme, W. Synthetic Fuels in Aviation—Current Barriers and Potential Political Measures. Transp. Res. Procedia 2019, 43, 21–30. [Google Scholar] [CrossRef]

- Pradhan, P.; Mahajani, S.M.; Arora, A. Production and Utilization of Fuel Pellets from Biomass: A Review. Fuel Process. Technol. 2018, 181, 215–232. [Google Scholar] [CrossRef]

- Obidziński, S.; Cwalina, P.; Kowczyk-Sadowy, M.; Sienkiewicz, A.; Krasowska, M.; Szyszlak-Bargłowicz, J.; Zając, G.; Kryński, R. Effect of the Addition of Elderberry Waste to Sawdust on the Process of Pelletization and the Quality of Fuel Pellets. Energies 2024, 17, 1508. [Google Scholar] [CrossRef]

- Papaioannou, E.H.; Mazzei, R.; Bazzarelli, F.; Piacentini, E.; Giannakopoulos, V.; Roberts, M.R.; Giorno, L. Agri-Food Industry Waste as Resource of Chemicals: The Role of Membrane Technology in Their Sustainable Recycling. Sustainability 2022, 14, 1483. [Google Scholar] [CrossRef]

- Freitas, L.C.; Barbosa, J.R.; da Costa, A.L.C.; Bezerra, F.W.F.; Pinto, R.H.H.; de Carvalho, R.N., Jr. From Waste to Sustainable Industry: How Can Agro-Industrial Wastes Help in the Development of New Products? Resour. Conserv. Recycl. 2021, 169, 105466. [Google Scholar] [CrossRef]

- Amicarelli, V.; Bux, C. Food Waste Measurement toward a Fair, Healthy and Environmental-Friendly Food System: A Critical Review. Br. Food J. 2020, 123, 2907–2935. [Google Scholar] [CrossRef]

- Berenguer, C.V.; Perestrelo, R.; Pereira, J.A.M.; Câmara, J.S. Management of Agri-Food Waste Based on Thermochemical Processes towards a Circular Bioeconomy Concept: The Case Study of the Portuguese Industry. Processes 2023, 11, 2870. [Google Scholar] [CrossRef]

- Czekała, W.; Nowak, M.; Bojarski, W. Anaerobic Digestion and Composting as Methods of Bio-Waste Management. Agric. Eng. 2023, 27, 173–186. [Google Scholar] [CrossRef]

- Malenica, D.; Kass, M.; Bhat, R. Sustainable Management and Valorization of Agri-Food Industrial Wastes and By-Products as Animal Feed: For Ruminants, Non-Ruminants and as Poultry Feed. Sustainability 2023, 15, 117. [Google Scholar] [CrossRef]

- Yadav, S.; Malik, K.; Moore, J.M.; Kamboj, B.R.; Malik, S.; Malik, V.K.; Arya, S.; Singh, K.; Mahanta, S.; Bishnoi, D.K. Valorisation of Agri-Food Waste for Bioactive Compounds: Recent Trends and Future Sustainable Challenges. Molecules 2024, 29, 2055. [Google Scholar] [CrossRef]

- Żarczyński, P.J.; Krzebietke, S.J.; Sienkiewicz, S.; Wierzbowska, J. Yield and Energy Efficiency of Fallow Biomass Pelletized Using Different Pelletizing Technologies. Ind. Crops Prod. 2025, 233, 121446. [Google Scholar] [CrossRef]

- Garcia, D.P.; Caraschi, J.C.; de Protásio, T.P.; Scatolino, M.V.; Vieira, F.H.A.; da Viana, R.S. Limitations of Bamboo and Sugarcane Pellets in Domestic and Industrial Systems. Rev. Agronegócio Meio Ambiente 2024, 17, e11271. [Google Scholar] [CrossRef]

- Sanchumpu, P.; Suaili, W.; Nonsawang, S.; Junsiri, C.; Ansuree, P.; Laloon, K. Biomass Pellet Processing from Sugar Industry Byproducts: A Study on Pelletizing Behavior and Energy Usage. Sustainability 2024, 16, 6035. [Google Scholar] [CrossRef]

- Jekayinfa, S.O.; Enweremadu, C.C. Influence of Processing Parameters on the Quality of Cocoa Pod Husk Biomass Pellets. Biofuels 2025, 1–21. [Google Scholar] [CrossRef]

- Civitarese, V.; Del Giudice, A.; Acampora, A.; Fischetti, E.; Gasperini, T.; De Francesco, C.; Toscano, G.; Scarfone, A. Combustion of Pelletized Coffee Residues for Bioenergy Valorization Within a Circular Economy Vision. Energies 2024, 17, 5875. [Google Scholar] [CrossRef]

- Lajili, M.; Jeguirim, M.; Kraiem, N.; Limousy, L. Performance of a Household Boiler Fed with Agropellets Blended from Olive Mill Solid Waste and Pine Sawdust. Fuel 2015, 153, 431–436. [Google Scholar] [CrossRef]

- Rahaman, S.A.; Salam, P.A. Characterization of Cold Densified Rice Straw Briquettes and the Potential Use of Sawdust as Binder. Fuel Process. Technol. 2017, 158, 9–19. [Google Scholar] [CrossRef]

- Ferreira, G.; Brito, T.M.; Da Silva, J.G.M.; Minini, D.; Dias Júnior, A.F.; Arantes, M.D.C.; Batista, D.C. Wood Waste Pellets as an Alternative for Energy Generation in the Amazon Region. BioEnergy Res. 2023, 16, 472–483. [Google Scholar] [CrossRef]

- Matkowski, P.; Lisowski, A.; Świętochowski, A. Pelletising Pure Wheat Straw and Blends of Straw with Calcium Carbonate or Cassava Starch at Different Moisture, Temperature, and Die Height Values: Modelling and Optimisation. J. Clean. Prod. 2020, 272, 122955. [Google Scholar] [CrossRef]

- Chojnacki, J.; Zdanowicz, A.; Ondruška, J.; Šooš, Ľ.; Smuga-Kogut, M. The Influence of Apple, Carrot and Red Beet Pomace Content on the Properties of Pellet from Barley Straw. Energies 2021, 14, 405. [Google Scholar] [CrossRef]

- Chen, T.; Zhang, W.; Song, Y.; Wang, Y. Effects of Wet Soybean Dregs on Forming Relaxation Ratio, Maximum Compressive Force and Specific Energy Consumption of Corn Stover Pellets. Agriculture 2025, 15, 1727. [Google Scholar] [CrossRef]

- Njuguna, J.; Njoka, F.; Nthiga, E. Baobab Fruit Waste Pellets and Optimization of Selected Pelletization Parameters. Biomass Bioenergy 2025, 199, 107948. [Google Scholar] [CrossRef]

- PN-EN ISO 18134-1:2015-11; Solid Biofuels—Determination of Moisture Content—Drying Method—Part 1: Total Mois-Ture—Reference Method. ISO: Geneva, Switzerland, 2015.

- PN-EN ISO 18122:2023-05; Solid Biofuels—Determination of Ash Content. ISO: Geneva, Switzerland, 2023.

- PN-EN ISO 17828:2016-02; Solid Biofuels—Determination of Bulk Density. ISO: Geneva, Switzerland, 2016.

- PN-R-64798:2009; Feed—Determination of Fineness. ISO: Geneva, Switzerland, 2009.

- PN-EN ISO 16948:2015-07; Solid Biofuels—Determination of Total Carbon, Hydrogen and Nitrogen Content. ISO: Geneva, Switzerland, 2015.

- PN-EN ISO 16994:2016-10; Solid Biofuels—Determination of Total Sulfur and Chlorine Content. ISO: Geneva, Switzerland, 2016.

- PN-EN ISO 1928:2002; Solid Mineral Fuels—Determination of Gross Calorific Value by the Bomb Calorimetric Method, and Calculation of Net Calorific Value. ISO: Geneva, Switzerland, 2002.

- Obidziński, S.; Cwalina, P.; Kowczyk-Sadowy, M.; Krasowska, M.; Sienkiewicz, A.; Faszczewski, D.; Szyszlak-Bargłowicz, J. The Use of Bread Bakery Waste as a Binder Additive in the Production of Fuel Pellets from Straw. Energies 2023, 16, 7313. [Google Scholar] [CrossRef]

- PN-ISO 1928: 2020-05; Solid Fuels. Determination of the Heat of Combustion by the Bomb Calorimetric Method and Calculation of the Calorific Value. ISO: Geneva, Switzerland, 2020.

- Cwalina, P.; Obidziński, S.; Sienkiewicz, A.; Kowczyk-Sadowy, M.; Piekut, J.; Bagińska, E.; Mazur, J. Production and Quality Assessment of Fertilizer Pellets from Compost with Sewage Sludge Ash (SSA) Addition. Materials 2025, 18, 1145. [Google Scholar] [CrossRef] [PubMed]

- PN-EN ISO 17831-1:2016-02; Solid Biofuels—Determination of Mechanical Durability of Pellets and Briquettes. ISO: Geneva, Switzerland, 2016.

- Obidziński, S.; Dołżyńska, M. Study of the Grain Waste Thickening Process. Przem. Chem. 2017, 96, 1000–1003. [Google Scholar]

- Obidziński, S.; Cwalina, P.; Kowczyk-Sadowy, M.; Sienkiewicz, A.; Krasowska, M.; Szyszlak-Bargłowicz, J.; Zając, G.; Słowik, T.; Mazur, J.; Jankowski, M. Physical and Energy Properties of Fuel Pellets Produced from Sawdust with Potato Pulp Addition. Energies 2024, 17, 3960. [Google Scholar] [CrossRef]

- Technologia Produkcji Pelletu—TMB Polska. Available online: https://tmbpolska.pl/produkcji-pelletu-technologia/ (accessed on 8 July 2025).

- PN-EN ISO 17225-1:2021-11; Solid Biofuels—Fuel Specifications and Grades—Part 1: General Requirements. ISO: Geneva, Switzerland, 2021.

- Sarfraz, S.; Sherif, Z.; Jolly, M.; Salonitis, K. Towards Framework Development for Benchmarking Energy Efficiency in Foundation Industries: A Case Study of Granulation Process. In The Minerals, Metals & Materials Series; Springer Nature: Cham, Switzerland, 2023; pp. 245–256. ISBN 978-3-031-22764-6. [Google Scholar]

- Ghalandari, V.; Iranmanesh, A. Energy and Exergy Analyses for a Cement Ball Mill of a New Generation Cement Plant and Optimizing Grinding Process: A Case Study. Adv. Powder Technol. 2020, 31, 1796–1810. [Google Scholar] [CrossRef]

- Maj, G.; Krzaczek, P.; Gołębiowski, W.; Słowik, T.; Szyszlak-Bargłowicz, J.; Zając, G. Energy Consumption and Quality of Pellets Made of Waste from Corn Grain Drying Process. Sustainability 2022, 14, 8129. [Google Scholar] [CrossRef]

- Skonecki, S.; Potrec, M. Wpływ wilgotności na ciśnieniowe zagęszczanie biomasy roślinnej. Zesz. Probl. Postępów Nauk Rol. 2010, 546, 341–346. [Google Scholar]

- Mashek, D.G.; Wu, C. MUFAs. Adv. Nutr. 2015, 6, 276–277. [Google Scholar] [CrossRef] [PubMed]

- Stulpinaite, U.; Tilvikiene, V.; Zvicevicius, E. Co-Pelletization of Hemp Residues and Agricultural Biomass: Effect on Pellet Quality and Stability. Energies 2023, 16, 5900. [Google Scholar] [CrossRef]

- Miranda, T.; Montero, I.; Sepúlveda, F.J.; Arranz, J.I.; Rojas, C.V.; Nogales, S. A Review of Pellets from Different Sources. Materials 2015, 8, 1413–1427. [Google Scholar] [CrossRef] [PubMed]

- Wattana, W.; Montri, N.; Wongjanakul, M.; Naratta, Y.; Duangjinda, S. Influence of Blending Proportions of Teak Sawdust and Cajuput Leaves on Characteristics of Biomass Pellets. In Proceedings of the E3S Web of Conferences; EDP Sciences, Kenitra, Morocco, 25–27 December 2020; Volume 187, p. 03001. [Google Scholar]

- Masche, M.; Puig-Arnavat, M.; Jensen, P.A.; Holm, J.K.; Clausen, S.; Ahrenfeldt, J.; Henriksen, U.B. From Wood Chips to Pellets to Milled Pellets: The Mechanical Processing Pathway of Austrian Pine and European Beech. Powder Technol. 2019, 350, 134–145. [Google Scholar] [CrossRef]

- Monedero, E.; Portero, H.; Lapuerta, M. Combustion of Poplar and Pine Pellet Blends in a 50 Kw Domestic Boiler: Emissions and Combustion Efficiency. Energies 2018, 11, 1580. [Google Scholar] [CrossRef]

- Núñez-Retana, V.D.; Rosales-Serna, R.; Prieto-Ruíz, J.Á.; Wehenkel, C.; Carrillo-Parra, A. Improving the Physical, Mechanical and Energetic Properties of Quercus Spp. Wood Pellets by Adding Pine Sawdust. PeerJ 2020, 8, e9766. [Google Scholar] [CrossRef] [PubMed]

- Horabik, J.; Bańda, M.; Józefaciuk, G.; Adamczuk, A.; Polakowski, C.; Stasiak, M.; Parafiniuk, P.; Wiącek, J.; Kobyłka, R.; Molenda, M. Breakage Strength of Wood Sawdust Pellets: Measurements and Modelling. Materials 2021, 14, 3273. [Google Scholar] [CrossRef]

- Li, W.; Yu, R.; Luo, L.; Shi, H. Process Optimization of Pellet Manufacturing from Mixed Materials in Ultrasonic Vibration-Assisted Pelleting. Energies 2024, 17, 2087. [Google Scholar] [CrossRef]

- Santos, L.B.; Striebeck, M.V.; Crespi, M.S.; Capela, J.M.V.; Ribeiro, C.A.; De Julio, M. Energy Evaluation of Biochar Obtained from the Pyrolysis of Pine Pellets. J. Therm. Anal. Calorim. 2016, 126, 1879–1887. [Google Scholar] [CrossRef]

- Niedziółka, I.; Szpryngiel, M.; Kachel-Jakubowska, M.; Kraszkiewicz, A.; Zawiślak, K.; Sobczak, P.; Nadulski, R. Assessment of the Energetic and Mechanical Properties of Pellets Produced from Agricultural Biomass. Renew. Energy 2015, 76, 312–317. [Google Scholar] [CrossRef]

- Carrillo-Parra, A.; Contreras-Trejo, J.C.; Pompa-García, M.; Pulgarín-Gámiz, M.Á.; Rutiaga-Quiñones, J.G.; Pámanes-Carrasco, G.; Ngangyo-Heya, M. Agro-Pellets from Oil Palm Residues/Pine Sawdust Mixtures: Relationships of Their Physical, Mechanical and Energetic Properties, with the Raw Material Chemical Structure. Appl. Sci. 2020, 10, 6383. [Google Scholar] [CrossRef]

- Dawood, S.; Sen, T.K.; Phan, C. Synthesis and Characterisation of Novel-Activated Carbon from Waste Biomass Pine Cone and Its Application in the Removal of Congo Red Dye from Aqueous Solution by Adsorption. Water Air Soil Pollut. 2013, 225, 1818. [Google Scholar] [CrossRef]

- Keränen, A.; Leiviskä, T.; Gao, B.-Y.; Hormi, O.; Tanskanen, J. Preparation of Novel Anion Exchangers from Pine Sawdust and Bark, Spruce Bark, Birch Bark and Peat for the Removal of Nitrate. Chem. Eng. Sci. 2013, 98, 59–68. [Google Scholar] [CrossRef]

- García, R.; González-Vázquez, M.P.; Rubiera, F.; Pevida, C.; Gil, M.V. Co-Pelletization of Pine Sawdust and Refused Derived Fuel (RDF) to High-Quality Waste-Derived Pellets. J. Clean. Prod. 2021, 328, 129635. [Google Scholar] [CrossRef]

- Lei, T.; Mei, Y.; Li, Y.; Wang, Y.; Liu, S.; Yang, Y. Effect of Low-Temperature Preheating on the Physicochemical Properties and Energy Quality of Pine Sawdust. Energies 2025, 18, 3875. [Google Scholar] [CrossRef]

- Voca, N.; Bilandzija, N.; Jurisic, V.; Matin, A.; Kricka, T.; Sedak, I. Proximate, Ultimate, and Energy Values Analysis of Plum Biomass By-Products Case Study: Croatia’s Potential. J. Agric. Sci. Technol. 2016, 18, 1655–1666. [Google Scholar]

- Yessenbek, A.; Satayev, M.; Azimov, A. Activated Carbon Production from Plum Pit Shells for Oily Wastewater Treatment. Water Pract. Technol. 2023, 18, 563–573. [Google Scholar] [CrossRef]

- García, R.; Pizarro, C.; Lavín, A.G.; Bueno, J.L. Characterization of Spanish Biomass Wastes for Energy Use. Bioresour. Technol. 2012, 103, 249–258. [Google Scholar] [CrossRef] [PubMed]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An Overview of the Chemical Composition of Biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Xu, T.; Xu, J.; Wu, Y. Hydrogen-Rich Gas Production from Two-Stage Catalytic Pyrolysis of Pine Sawdust with Calcined Dolomite. Catalysts 2022, 12, 131. [Google Scholar] [CrossRef]

- Jado, A.; Morosuk, T.; Pan, J. Hydrogen Production Enhancement in Pine Sawdust Gasification by Numerical and Experimental Methods. J. Soil Sci. Agric. Eng. 2025, 16, 9–15. [Google Scholar] [CrossRef]

- Piskowska-Wasiak, J. Oczyszczanie i przetwarzanie gazu ze zgazowania biomasy w celu wytworzenia SNG (Substitute Natural Gas). Nafta-Gaz 2011, 67, 347–360. [Google Scholar]

- PN-EN 14961-2:2011; Część 2: Pellety Drzewne. ISO: Geneva, Switzerland, 2011.

- Obernberger, I. Physical characteristics and chemical composition of solid biomass fuels. In Script for the Lecture “Thermochemical Biomass Conversion”; Eindhofen University of Technology, Department for Mechanical Engineering, Section Process Technology: Eindhoven, The Netherlands, 2003; Chapter 3. [Google Scholar]

- Król, D.; Borsukiewicz-Gozdur, A. Energia z Odpadowej Biomasy Tartacznej i Rolniczej. Arch. Gospod. Odpad. Ochr. Śr. 2014, 16, 87–94. [Google Scholar]

- Hardy, T.; Kordylewski, W.; Mościcki, K. Zagrożenie korozją chlorkową w wyniku spalania i współspalania biomasy w kotłach. Arch. Spalania 2009, 9, 181–195. [Google Scholar]

- Pereira, A.B.; Zanuncio, A.J.V.; Carvalho, A.G.; de Cassia Oliveira Carneiro, A.; de Castro, V.R.; Carvalho, A.M.M.L.; Lopes, O.P.; Branco-Vieira, M.; Ferreira, M.V.; de Assunção, R.M.N.; et al. Sustainable Solid Biofuel Production: Transforming Sewage Sludge and Pinus Sp. Sawdust into Resources for the Circular Economy. Sustainability 2024, 16, 4554. [Google Scholar] [CrossRef]

- Kanwal, F.; Ahmed, A.; Jamil, F.; Rafiq, S.; Ayub, H.M.U.; Ghauri, M.; Khurram, M.S.; Munir, S.; Inayat, A.; Abu Bakar, M.S.; et al. Co-Combustion of Blends of Coal and Underutilised Biomass Residues for Environmental Friendly Electrical Energy Production. Sustainability 2021, 13, 4881. [Google Scholar] [CrossRef]

- Telmo, C.; Lousada, J. Heating Values of Wood Pellets from Different Species. Biomass Bioenergy 2011, 35, 2634–2639. [Google Scholar] [CrossRef]

- Garcia, D.P.; Caraschi, J.C.; Ventorim, G.; Vieira, F.H.A.; de Paula Protásio, T. Assessment of Plant Biomass for Pellet Production Using Multivariate Statistics (PCA and HCA). Renew. Energy 2019, 139, 796–805. [Google Scholar] [CrossRef]

- Sermyagina, E.; Mendoza Martinez, C.; Lahti, J.; Nikku, M.; Mänttäri, M.; Kallioinen-Mänttäri, M.; Vakkilainen, E. Characterization of Pellets Produced from Extracted Sawdust: Effect of Cooling Conditions and Binder Addition on Composition, Mechanical and Thermochemical Properties. Biomass Bioenergy 2022, 164, 106562. [Google Scholar] [CrossRef]

- Čajová Kantová, N.; Belány, P.; Holubčík, M.; Čaja, A. Energy Consumption Depending on the Durability of Pellets Formed from Sawdust with an Admixture of FFP2 Masks. Energies 2022, 15, 4813. [Google Scholar] [CrossRef]

- Commission Regulation (EU) 2015/1189 of 28 April 2015 Implementing Directive 2009/125/EC of the European Parliament and of the Council with Regard to Ecodesign Requirements for Solid Fuel Boilers (Text with EEA Relevance). 2015, Volume 193. Available online: https://eur-lex.europa.eu/eli/reg/2015/1189/oj/eng (accessed on 16 September 2025).

- Pudlik, W. Thermal Waste Treatment. Theoretical Basics; Wydawnictwo Politechniki Gdańskiej: Gdańsk, Poland, 2014. (In Polish) [Google Scholar]

- Paraschiv, L.S.; Serban, A.; Paraschiv, S. Calculation of Combustion Air Required for Burning Solid Fuels (Coal / Biomass / Solid Waste) and Analysis of Flue Gas Composition. Energy Rep. 2020, 6, 36–45. [Google Scholar] [CrossRef]

- Obernberger, I.; Brunner, T.; Bärnthaler, G. Chemical Properties of Solid Biofuels—Significance and Impact. Biomass Bioenergy 2006, 30, 973–982. [Google Scholar] [CrossRef]

| Raw Material | Moisture ± SD [%] |

|---|---|

| Pine sawdust | 13.52 ± 0.22 |

| Plum stones | 14.32 ± 0.19 |

| Rosin | 0.33 ± 0.02 |

| Raw Material | Fraction Share [%] | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 8 | 4 | 2 | 1 | 0.5 | 0.25 | 0.125 | 0.063 | <0.063 | |

| Pine sawdust | 1.063 | 22.707 | 30.625 | 31.813 | 10.511 | 2.387 | 0.535 | 0.09 | 0.015 |

| Plum stones | 0.00 | 0.237 | 27.399 | 41.586 | 15.546 | 8.668 | 5.798 | 0.288 | 0.012 |

| Raw Material | Bulk Density ± SD [kg∙m−3] | Ash Content [%] |

|---|---|---|

| Pine sawdust | 80.07 ± 1.17 | 1.05 ± 0.12 |

| Plum stones | 547.55 ± 6.01 | 0.85 ± 0.08 |

| Rosin | 561.02 ± 3.02 | - |

| Parameter | Plum Stone Content [%] | ISO 17225-1:2021-11 [39] | ||||

|---|---|---|---|---|---|---|

| 0 | 10 | 15 | 20 | Class A | Class B | |

| Kinetic strength ± SD [%] | 92.84 ± 0.31 | 97.24 ± 0.28 | 96.77 ± 0.33 | 93.06 ± 0.12 | ≥96.0 | ≥95.0 |

| Density of pellets ± SD [kg∙m−3] | 1293.87 ± 13.51 | 1225.37 ± 21.02 | 1209.94 ± 23.19 | 1193.94 ± 14.82 | - | - |

| Bulk density ± SD [kg∙m−3] | 632.81 ± 6.28 | 556.37 ± 8.11 | 536.25 ± 5.48 | 495.21 ± 6.63 | ≥600 | ≥550 |

| Pelletiser’s power demand ± SD [kW] | 3.86 ± 0.11 | 3.54 ± 0.19 | 3.12 ± 0.09 | 2.91 ± 0.13 | - | - |

| Raw Material | C ± SD [%] | H ± SD [%] | N ± SD [%] | S ± SD [%] | Cl [%] |

|---|---|---|---|---|---|

| Pine sawdust | 41.84 ± 0.44 | 6.65 ± 0.01 | 0.134 ± 0.001 | 0.023 ± 0.001 | 0.004 |

| Plum stones | 54.14 ± 0.32 | 6.42 ± 0.02 | 0.72 ± 0.002 | 0.103 ± 0.001 | 0.002 |

| Material | HHVar ± SD | HHVdry ± SD | LHVar ± SD | LHVdry ± SD |

|---|---|---|---|---|

| [MJ·kg−1] | ||||

| Pine sawdust | 19.980 ± 0.32 | 23.117 ± 0.32 | 18.231 ± 0.32 | 21.476 ± 0.32 |

| Plum stones | 20.485 ± 0.29 | 23.836 ± 0.29 | 18.741 ± 0.29 | 22.206 ± 0.29 |

| Rosin | 40.995 ± 0.41 | 41.131 ± 0.41 | 39.830 ± 0.41 | 39.970 ± 0.41 |

| Pellets with 10% plum stones and 10% rosin | 21.199 ± 0.38 | 24.954 ± 0.38 | 19.481 ± 0.38 | 23.361 ± 0.38 |

| Pellets with 15% plum stones and 10% rosin | 21.230 ± 0.41 | 24.993 ± 0.41 | 19.512 ± 0.41 | 23.398 ± 0.41 |

| Pellets with 20% plum stones and 10% rosin | 21.261 ± 0.30 | 25.026 ± 0.30 | 19.544 ± 0.30 | 23.434 ± 0.30 |

| Flue Composition at 10% O2 | Plum Stones Content [%] | Ecodesign Limit Value (at 10% O2) [77] | ||||

|---|---|---|---|---|---|---|

| 0 | 10 | 15 | 20 | 100 | ||

| CO2 [%] | 8.68 | 7.16 | 7.03 | 7.02 | 8.37 | - |

| CO [mg·Nm−3] | 337.21 | 633.76 | 603.79 | 572.89 | 1259.17 | 500 |

| NOx [mg·Nm−3] | 172.80 | 127.76 | 123.77 | 123.44 | 265.24 | 200 |

| SO2 [mg·Nm−3] | 14.76 | 8.12 | 5.17 | 5.00 | 50.87 | - |

| HCl [mg·Nm−3] | 3.03 | 1.19 | 0.39 | 0.32 | 10.62 | - |

| Excess air coefficient λ | 2.43 | 2.59 | 2.52 | 2.49 | 3.04 | - |

| Flue gas temperature in the boiler flue [°C] | 153 | 150 | 157 | 160 | 160 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Obidziński, S.; Cwalina, P.; Kowczyk-Sadowy, M.; Sienkiewicz, A.; Mazur, J. Effect of Plum Seeds and Rosin Adding to Sawdust on the Pelletisation Process and Fuel Pellet Quality. Energies 2025, 18, 5426. https://doi.org/10.3390/en18205426

Obidziński S, Cwalina P, Kowczyk-Sadowy M, Sienkiewicz A, Mazur J. Effect of Plum Seeds and Rosin Adding to Sawdust on the Pelletisation Process and Fuel Pellet Quality. Energies. 2025; 18(20):5426. https://doi.org/10.3390/en18205426

Chicago/Turabian StyleObidziński, Sławomir, Paweł Cwalina, Małgorzata Kowczyk-Sadowy, Aneta Sienkiewicz, and Jacek Mazur. 2025. "Effect of Plum Seeds and Rosin Adding to Sawdust on the Pelletisation Process and Fuel Pellet Quality" Energies 18, no. 20: 5426. https://doi.org/10.3390/en18205426

APA StyleObidziński, S., Cwalina, P., Kowczyk-Sadowy, M., Sienkiewicz, A., & Mazur, J. (2025). Effect of Plum Seeds and Rosin Adding to Sawdust on the Pelletisation Process and Fuel Pellet Quality. Energies, 18(20), 5426. https://doi.org/10.3390/en18205426