Experimental Study on Wave Energy Conversion Performance of a Wave-Driven Profiler

Abstract

1. Introduction

2. Materials and Methods

2.1. Research on Wave-Driven Mechanisms

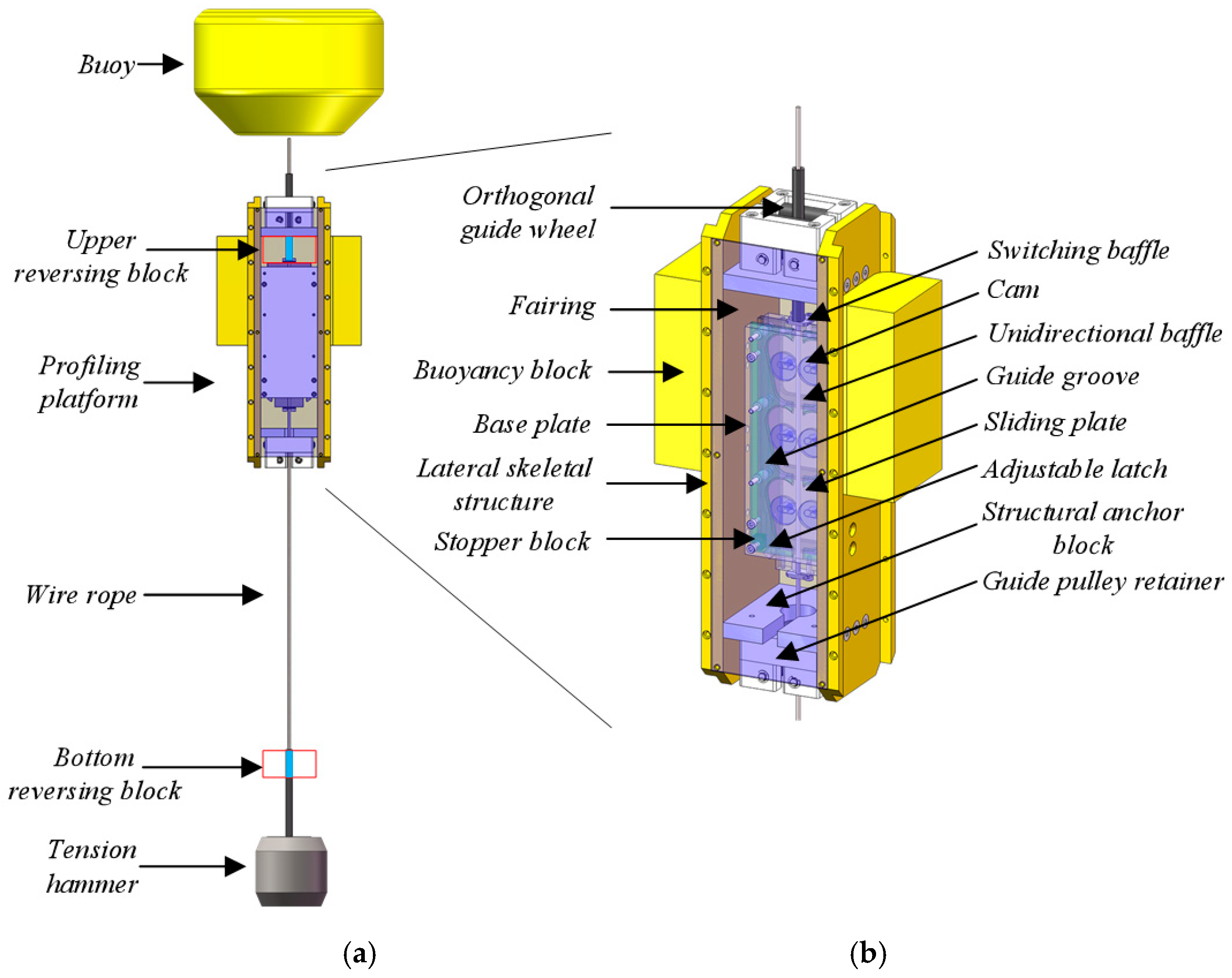

2.1.1. Composition and Working Mechanisms of WDPs

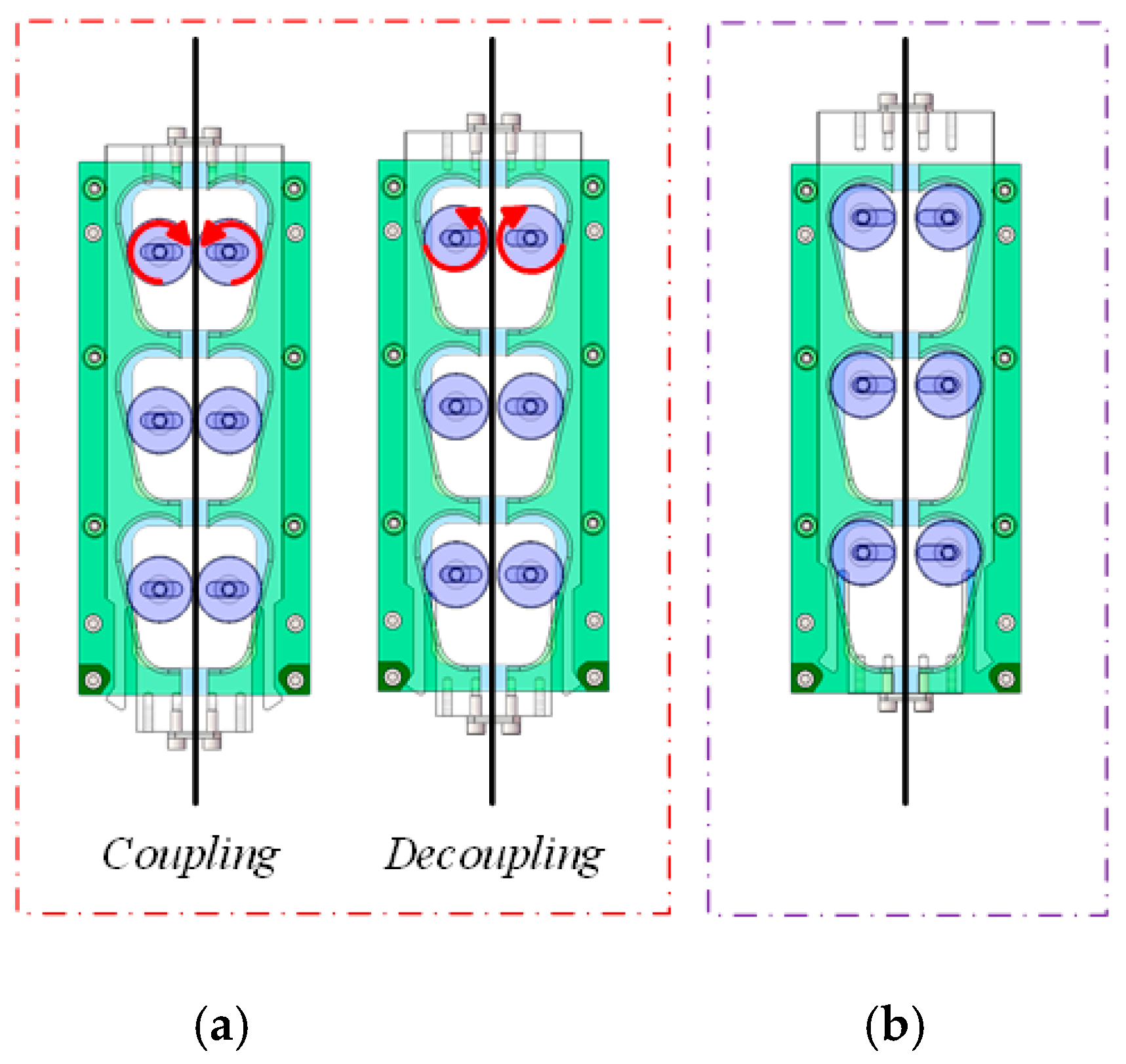

- Open state of the wave energy capture device

- (1)

- Coupling state

- (2)

- Decoupling state

- 2.

- Closed state of the wave energy capture device

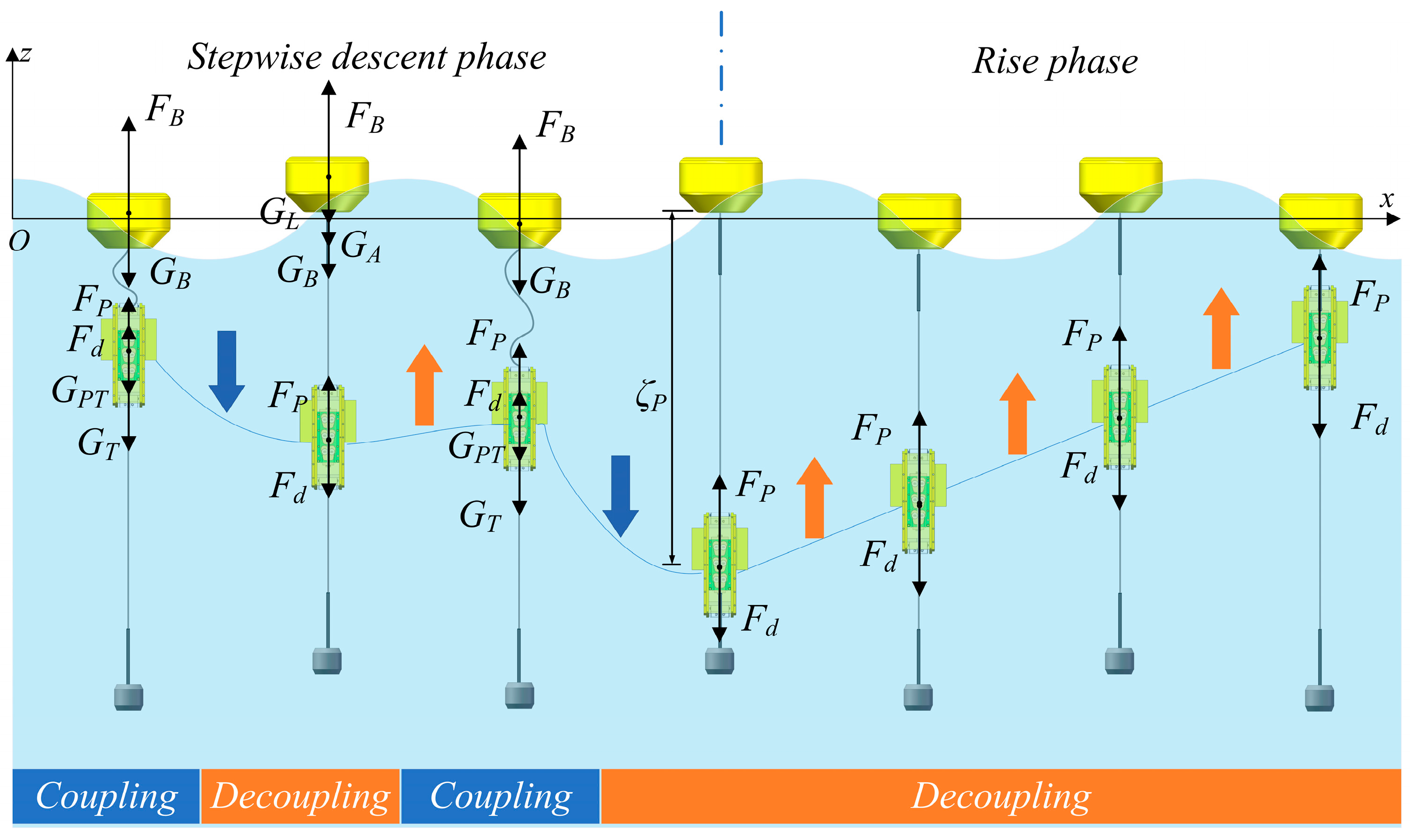

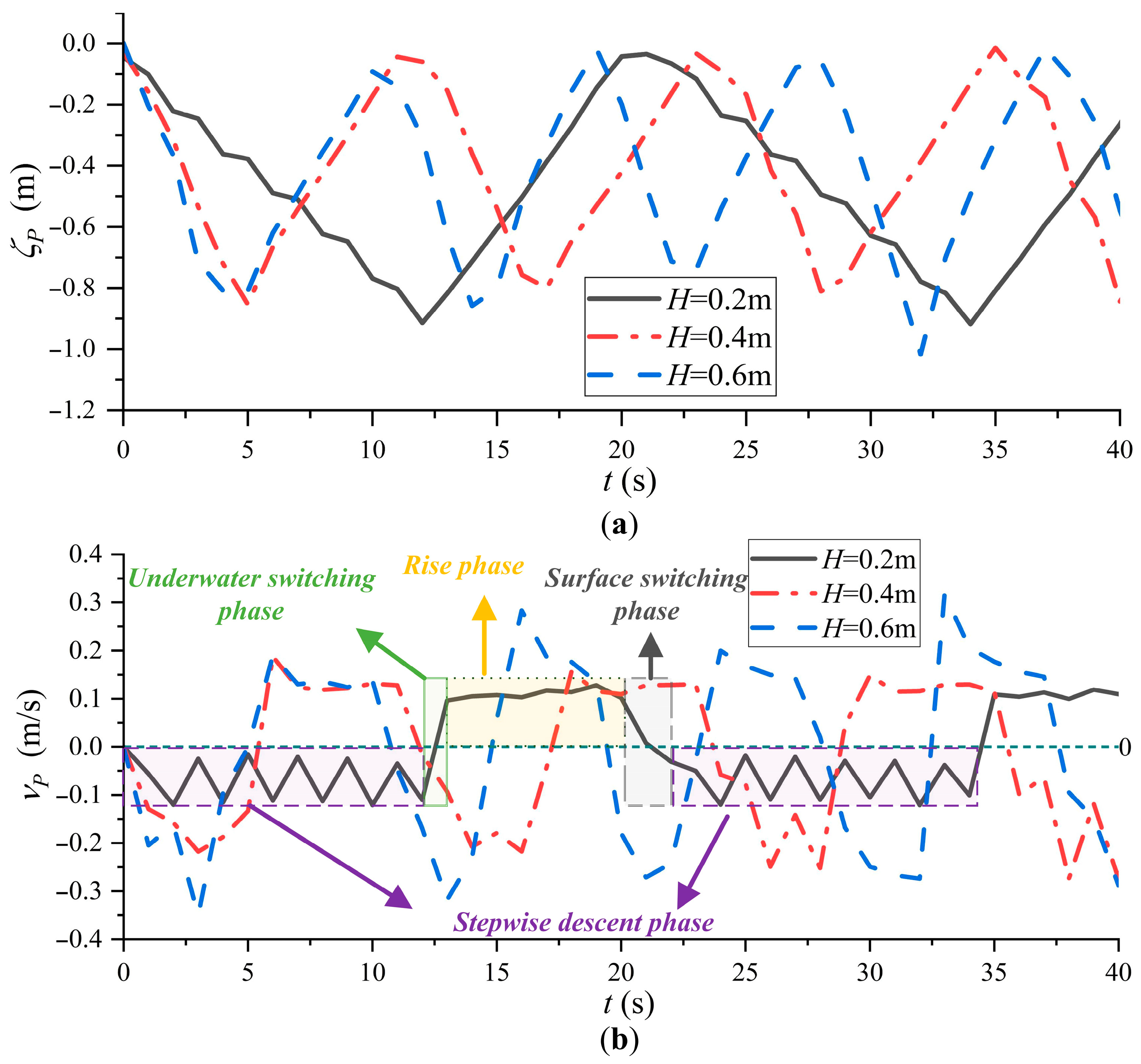

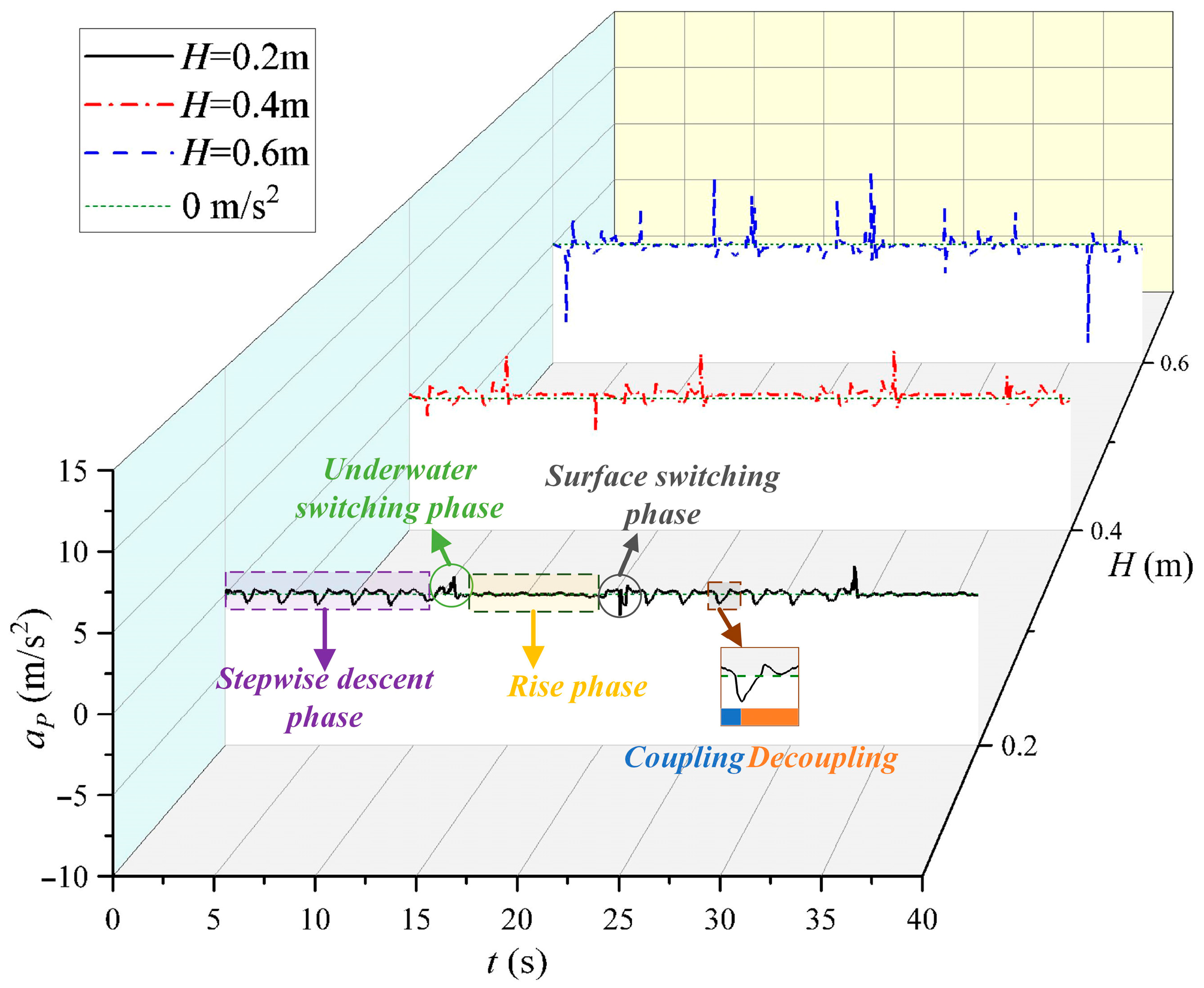

- Stepwise descent phase

- 2.

- Underwater switching phase

- 3.

- Rise phase

- 4.

- Surface switching phase

2.1.2. Dynamics Analysis of the WDP

- Based on linear wave theory, the buoy’s motion under wave excitation is assumed to be small amplitude [25], and the influence of water particle oscillation on the WDP is neglected.

- The vertical dynamics of the WDP are analyzed exclusively, with horizontal hydrodynamic forces being neglected.

- Neglecting the structural dimensions of each component, they are treated as equivalent to a mass point.

- The impact duration between the sliding plate and reversing blocks in the wave energy capture device is neglected.

- Neglect the cam’s actuation duration and stroke length in the wave energy capture device. Studies by Isaacs et al. and Pinkel et al. demonstrate that the engagement duration in the wave energy capture device is negligible compared with wave excitation or buoyancy cycles, with field experiments confirming the rapid locking of wire ropes via optimized cam mechanisms [24,28].

- The stepwise descent phase of the profiling platform

- 2.

- The rise phase of the profiling platform

- (1)

- Accelerating rise phase with decreasing acceleration

- (2)

- Constant-velocity rise phase

2.1.3. Analysis of Wave-Driven Performance

2.2. Description of Methodology

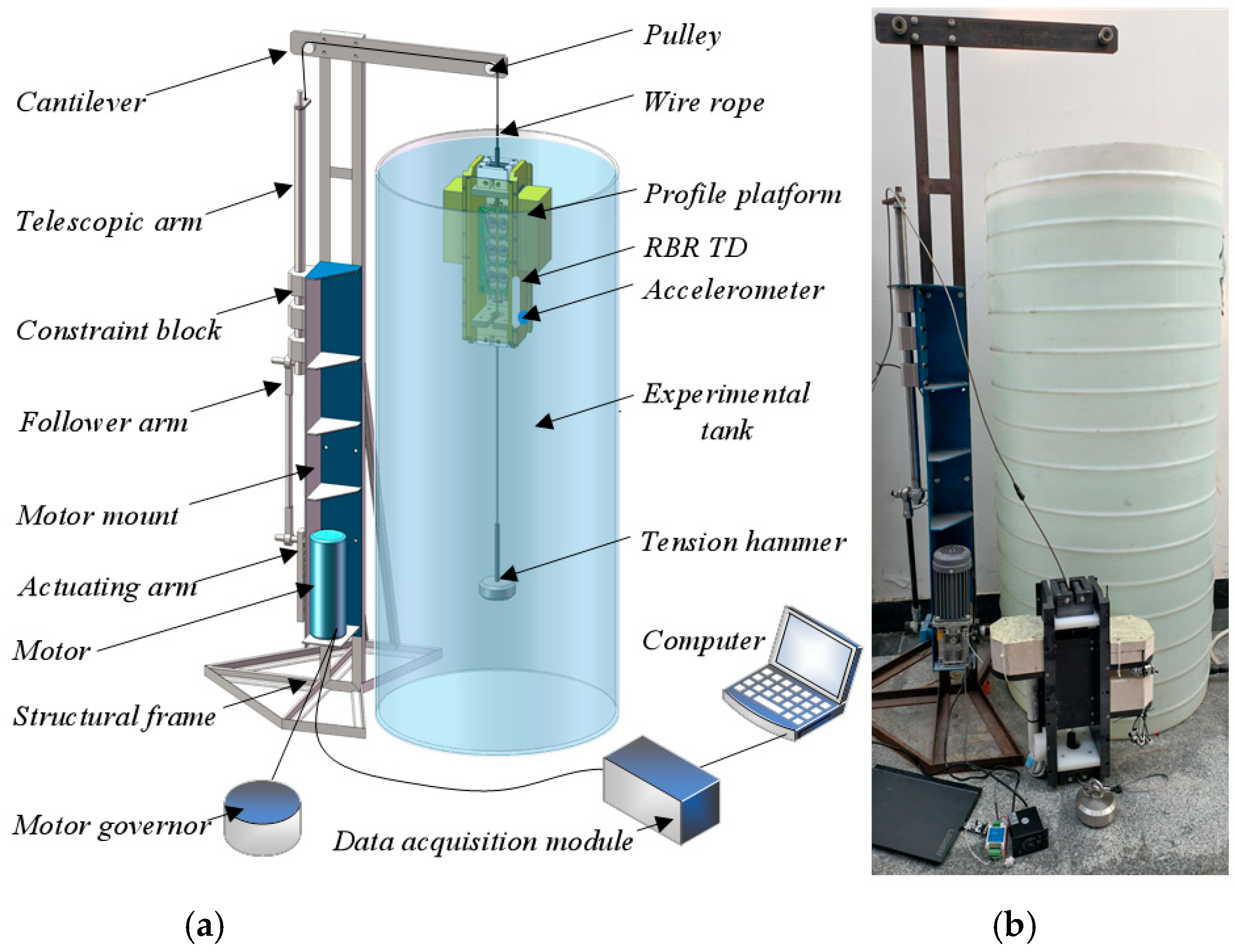

2.2.1. Construction of Experimental Facility

2.2.2. Experimental Parameters

3. Results

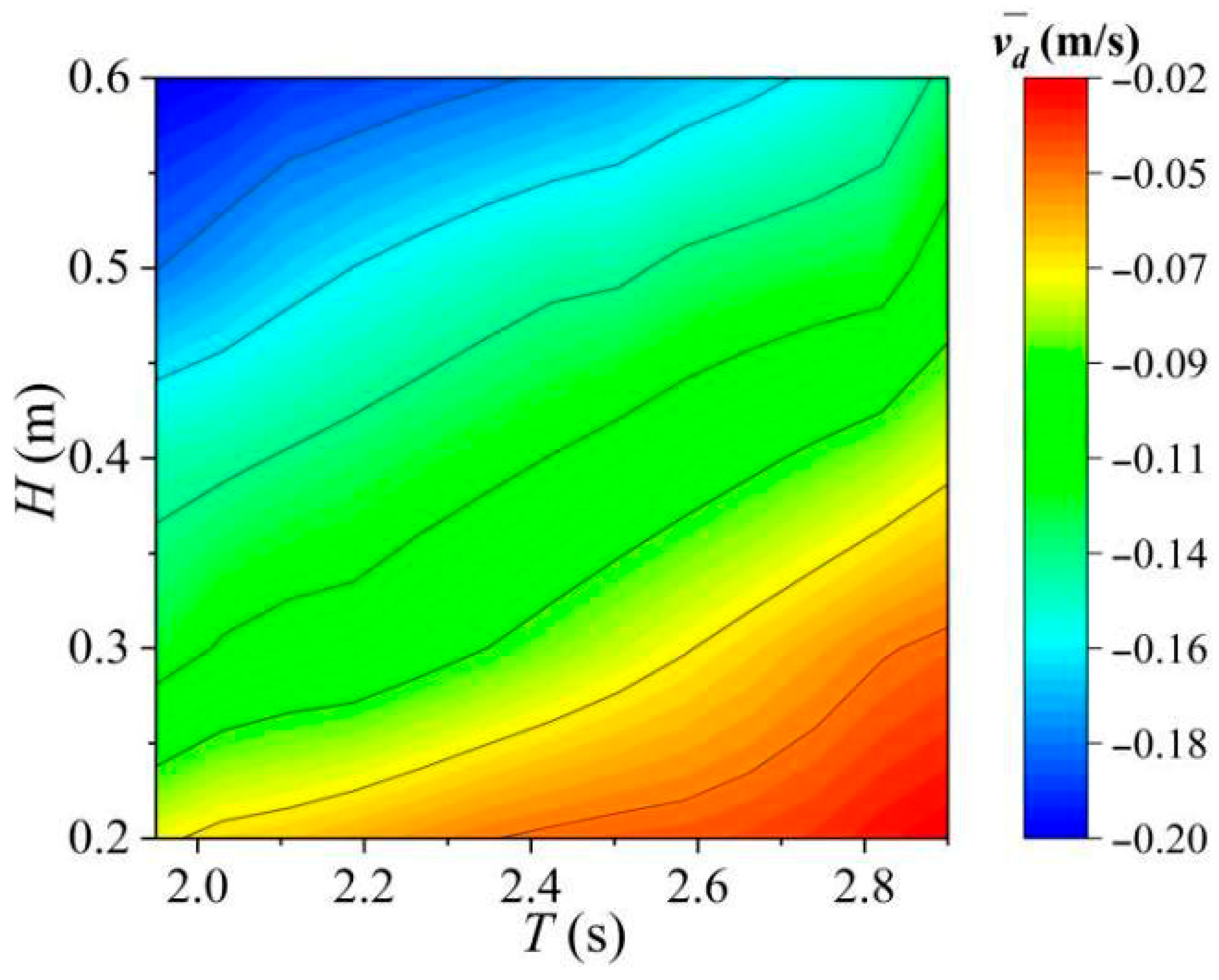

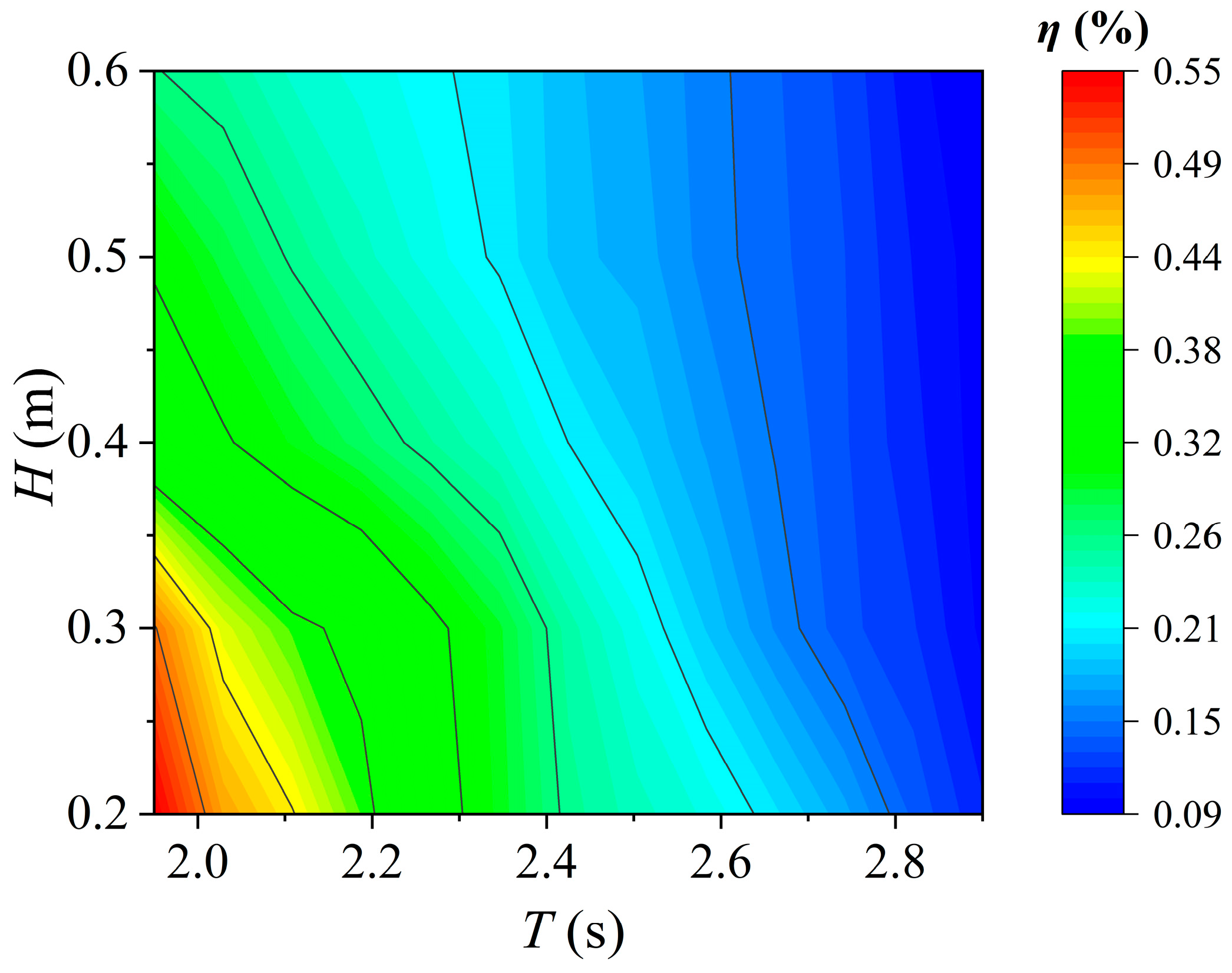

3.1. The Influence of Wave Parameters

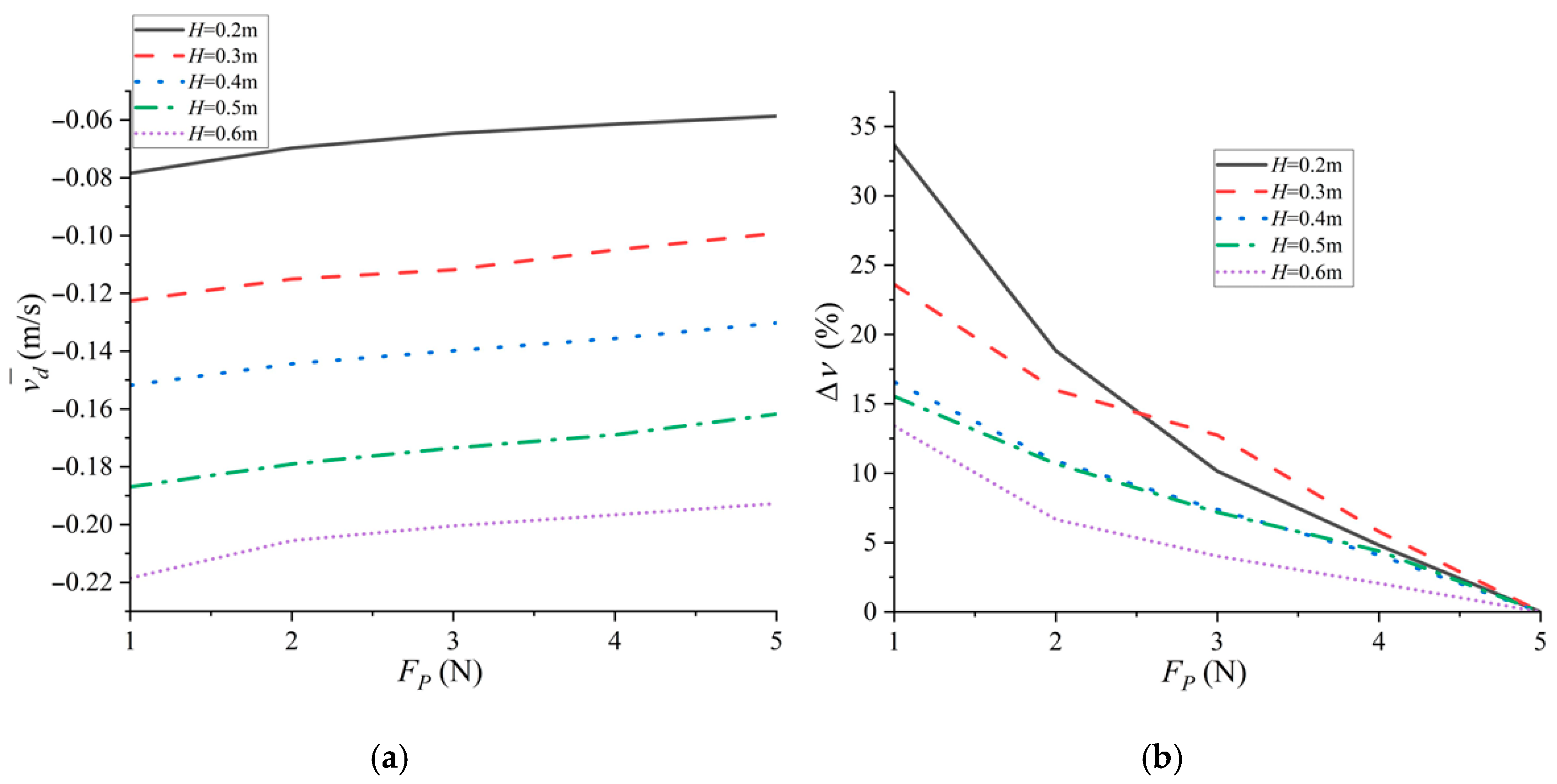

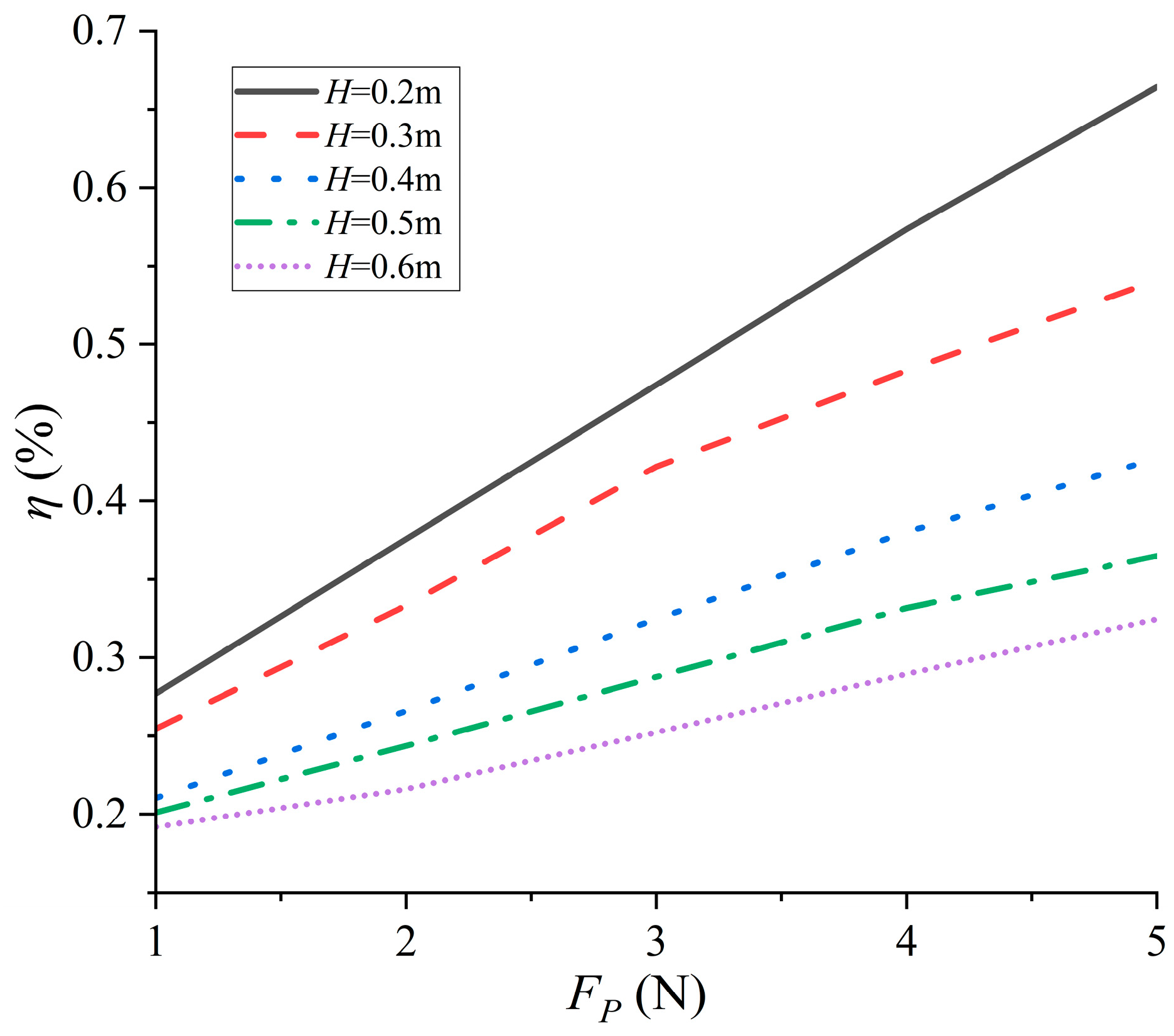

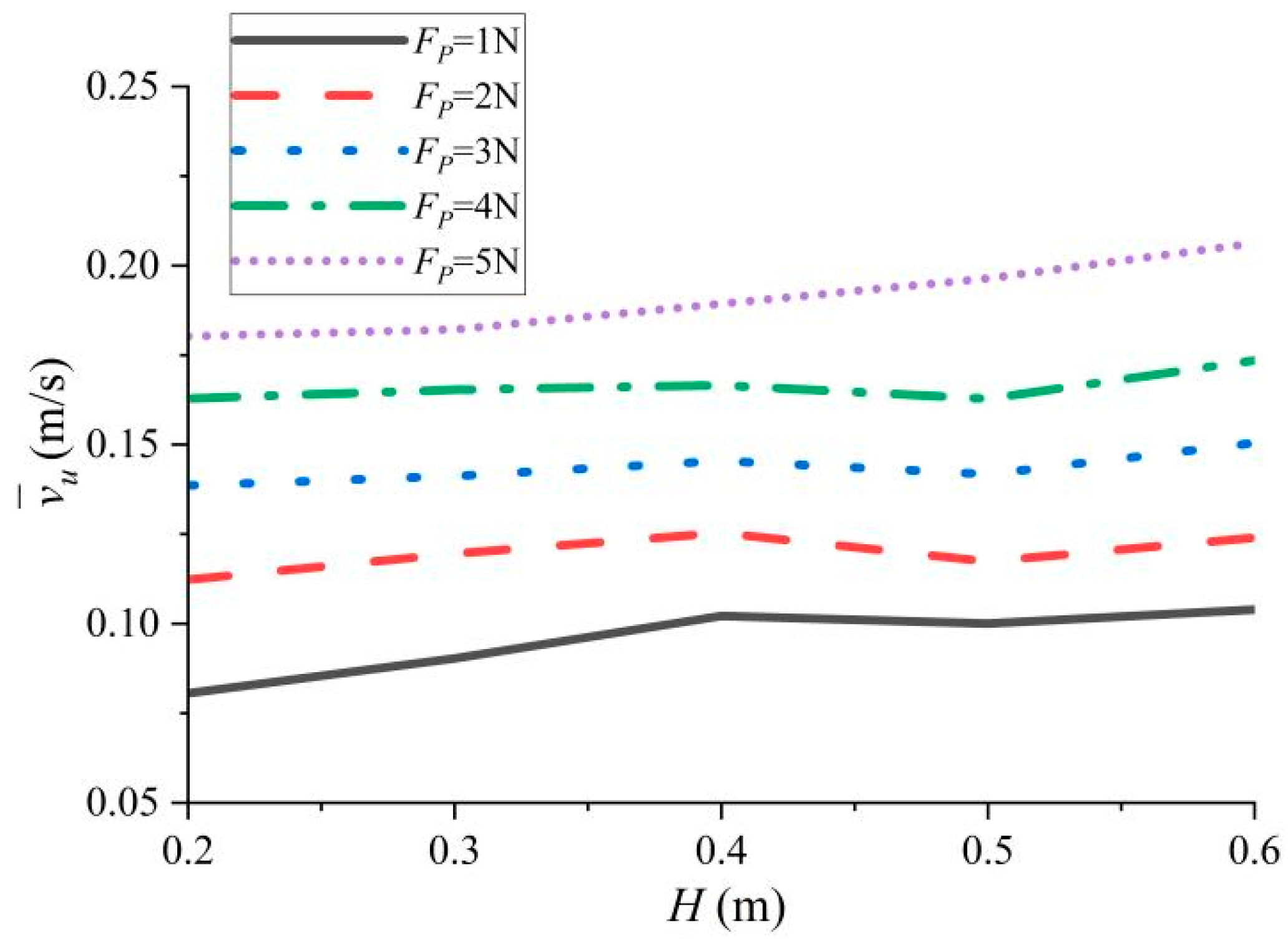

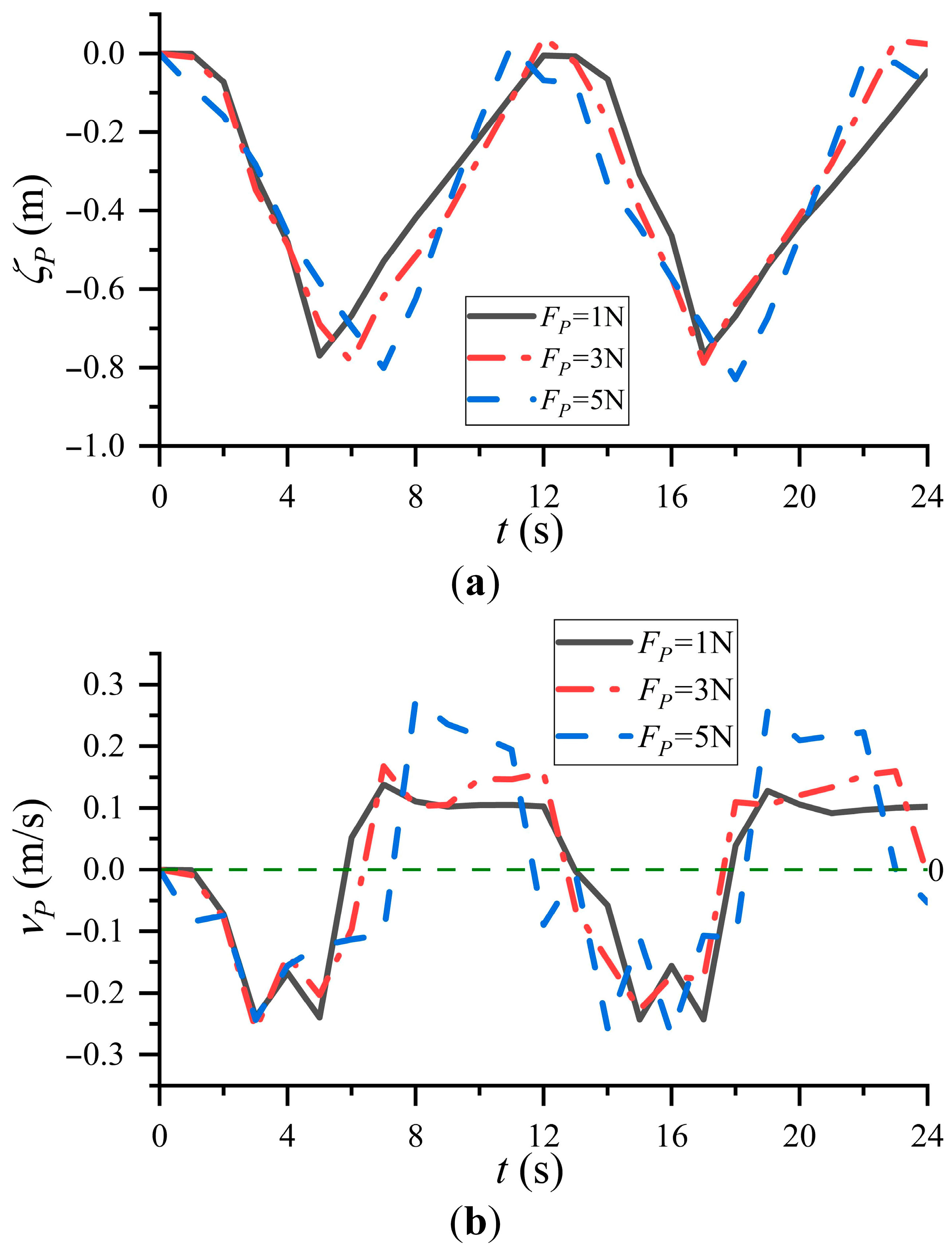

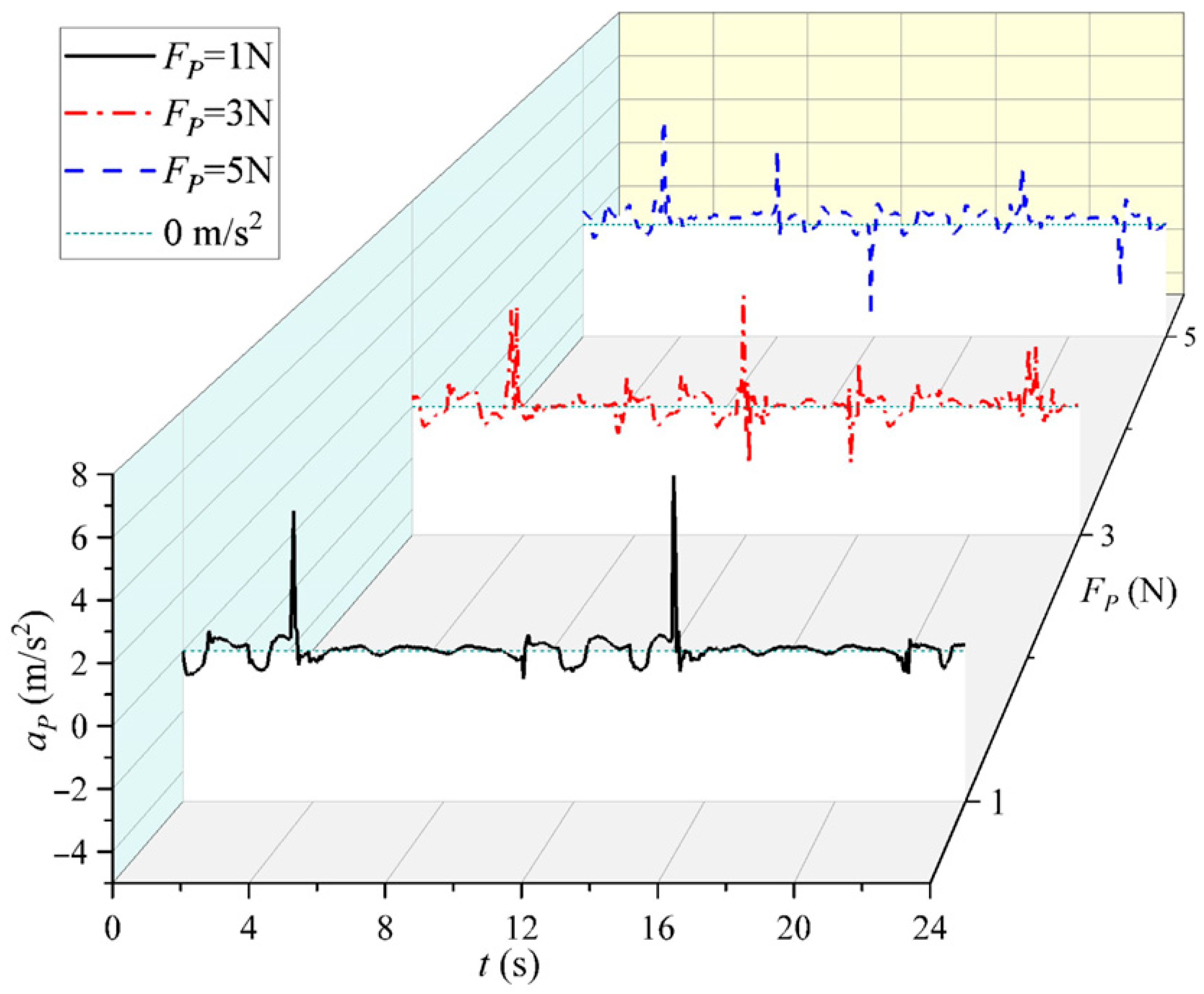

3.2. The Influence of Net Buoyancy of Profiling Platform

4. Discussion

4.1. Discussion on Wave Parameters

4.2. Discussion on Net Buoyancy of the Profiling Platform

4.3. Discussion on Limitations of Experimental Equipment

5. Conclusions

- Higher wave heights increase the wave energy captured by the WDP buoy, which is transmitted along the chain consisting of waves, buoys, tension hammers, and profiling platforms. The increase in captured energy enhances the WDP’s dynamic performance. However, better dynamic performance also exacerbates energy dissipation, including hydrodynamic resistance, the friction of the profiling platform, and collisions, and these factors reduce the wave energy conversion efficiency.

- Longer wave periods reduce the excitation frequency of waves, thereby slowing down the rhythm of energy transmission along the chain. Therefore, both the buoy’s velocity and the energy transmission frequency are reduced, resulting in decreased energy gained by the profiling platform. Although longer wave periods increase the wave energy captured by the buoy, they ultimately reduce the WDP’s wave energy conversion efficiency due to reduced transmission efficiency, cumulative resistance loss, and reduced energy gained by the profiling platform.

- The net buoyancy of the profiling platform has different impacts on the dynamic response of the WDP in different phases. In the coupling phase, increased net buoyancy offsets the downward driving force of the tension hammer more, thereby reducing the descent velocity of the profiling platform. In the decoupling phase, greater net buoyancy accelerates the attenuation of the profiling platform’s descent velocity. In the rise phase, the net buoyancy of the profiling platform is converted into an upward driving force, increasing the rising velocity of the profiling platform. Since useful work is positively correlated with net buoyancy, greater net buoyancy increases storable energy output, thereby improving the wave energy conversion efficiency.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| WDP | Wave-driven profiler |

| The buoy’s wave-induced displacement (m) | |

| The buoy’s wave-induced vertical velocity (m/s) | |

| The buoy’s wave-induced vertical acceleration (m/s2) | |

| The wave height (m) | |

| The wave number | |

| The wavelength (m) | |

| The horizontal position of the wave (m) | |

| The angular frequency of the wave (Hz) | |

| The wave period (s) | |

| The time during the wave motion (s) | |

| The free surface position (m) | |

| The water depth (m) | |

| The mass of the profiling platform (kg) | |

| The mass of the tension hammer (kg) | |

| The wire rope’s mass between the profiling platform and tension hammer (kg) | |

| The vertical velocity of the tension hammer (m/s) | |

| The combined velocity after the collision (m/s) | |

| PWT | The profiling platform, wire rope, and tension hammer |

| The net buoyancy of the profiling platform (N) | |

| The gravity of the tension hammer (N) | |

| The mass per unit length of the wire rope (kg/m) | |

| The wire rope’s length between the platform and the tension hammer (m) | |

| The combined acceleration of the PWT (m/s2) | |

| The hydrodynamic resistance to the profiling platform (N) | |

| The vertical coefficient of resistance of the profiling platform | |

| The projected frontal area of the profiling platform (m2) | |

| The density of water (kg/m3) | |

| The acceleration of the profiling platform (m/s2) | |

| BWT | The buoy, wire rope, and tension hammer |

| The buoyancy of the buoy (N) | |

| The gravity of the buoy (N) | |

| The gravity of the wire rope (N) | |

| The quality of the wire rope (kg) | |

| The combined acceleration of the BWT (m/s2) | |

| The vertical rising velocity of the profiling platform (m/s) | |

| The maximum rising velocity of the profiling platform (m/s) | |

| The useful work for a single profiling process (J) | |

| The length of the wire rope (m) | |

| The vertical angle of the wire rope (°) | |

| The descent velocity of the profiling platform (m/s) | |

| The useful power of the profiling platform (W) | |

| The descent time of the profiling platform (s) | |

| The mean useful power of the profiling platform (W) | |

| The mean descent velocity of the profiling platform (m/s) | |

| The mean wave power obtained by the buoy (W) | |

| The gravitational acceleration (N/kg) | |

| The dimension of the buoy (m) | |

| The wave energy conversion efficiency of the WDP | |

| The total uncertainty percentage | |

| The variation rate of the mean descent velocity of the profiling platform | |

| The mean descent velocity of the profiling platform for FP = 5N (m/s) | |

| The profiling platform’s length | |

| The profiling platform’s width | |

| The profiling platform’s height |

References

- Jiang, S.; Guo, Z.; Zhao, H.; Cui, Z.; Wang, W. OPO-CVI: Design and implementation of an ocean profiling observation system for wave-powered vertical profiler following an ISO standard. Front. Mar. Sci. 2024, 11, 1324523. [Google Scholar] [CrossRef]

- Zhao, H.; Guo, Z.; Jing, W. Numerical investigation of a Wave-Powered Vertical Profiler. Ocean Eng. 2023, 285, 115419. [Google Scholar] [CrossRef]

- Fowler, G.A.; Hamilton, J.M.; Beanlands, B.D.; Belliveau, D.J.; Furlong, A.R. A wave powered profiler for long term monitoring. In Proceedings of the Oceans ’97. MTS/IEEE Conference Proceedings, Halifax, NS, Canada, 6–9 October 1997; Volume 1, pp. 225–228. [Google Scholar]

- Wong, A.P.S.; Wijffels, S.E.; Riser, S.C.; Pouliquen, S.; Hosoda, S.; Roemmich, D.; Gilson, J.; Johnson, G.C.; Martini, K.; Murphy, D.J.; et al. Argo Data 1999–2019: Two Million Temperature-Salinity Profiles and Subsurface Velocity Observations From a Global Array of Profiling Floats. Front. Mar. Sci. 2020, 7, 700. [Google Scholar] [CrossRef]

- Johnson, G.C.; King, B.A. Zapiola Gyre, Velocities and Mixing, New Argo Insights. J. Geophys. Res. Oceans 2023, 128, e2023JC019893. [Google Scholar] [CrossRef]

- Hine, R.; Willcox, S.; Hine, G.; Richardson, T. The Wave Glider: A Wave-Powered autonomous marine vehicle. In Proceedings of the Oceans 2009, Biloxi, MS, USA, 26–29 October 2009. [Google Scholar]

- Song, Y.; Wang, Y.; Yang, S.; Wang, S.; Yang, M. Sensitivity analysis and parameter optimization of energy consumption for underwater gliders. Energy 2020, 191, 116506. [Google Scholar] [CrossRef]

- Ma, Z.; Wang, Y.; Wang, S.; Yang, Y. Ocean thermal energy harvesting with phase change material for underwater glider. Appl. Energy 2016, 178, 557–566. [Google Scholar] [CrossRef]

- Sangiuliano, S.J. Analysing the potentials and effects of multi-use between tidal energy development and environmental protection and monitoring: A case study of the inner sound of the Pentland Firth. Mar. Policy 2018, 96, 120–132. [Google Scholar] [CrossRef]

- Nazir, M.S.; Ali, N.; Bilal, M.; Iqbal, H.M.N. Potential environmental impacts of wind energy development: A global perspective. Curr. Opin. Environ. Sci. Health 2020, 13, 85–90. [Google Scholar] [CrossRef]

- Hou, H.; Arredondo Galeana, A.; Song, Y.; Xu, G.; Xu, Y.; Shi, W. Design of a novel energy harvesting mechanism for underwater gliders using thermal buoyancy engines. Ocean Eng. 2023, 278, 114310. [Google Scholar] [CrossRef]

- Zang, X.; Zhang, Z.; Fan, W. A Novel Profiler Driven by Tidal Energy for Long Term Oceanographic Measurements in Offshore Areas. J. Mar. Sci. Eng. 2021, 9, 534. [Google Scholar] [CrossRef]

- Hamilton, J.; Fowler, G.; Beanlands, B. Long-term monitoring with a moored wave-powered profiler. Sea Technol. 1999, 40, 68–69. [Google Scholar]

- Rainville, L.; Pinkel, R. Wirewalker: An Autonomous Wave-Powered Vertical Profiler. J. Atmos. Ocean Technol. 2001, 18, 1048–1051. [Google Scholar] [CrossRef]

- Wang, C.; Pawlowicz, R. Propagation speeds of strongly nonlinear near-surface internal waves in the Strait of Georgia. J. Geophys. Res. 2011, 116, C10021. [Google Scholar] [CrossRef]

- Wijesekera, H.W.; Shroyer, E.; Tandon, A.; Ravichandran, M.; Sengupta, D.; Jinadasa, S.U.P.; Fernando, H.J.S.; Agrawal, N.; Arulananthan, K.; Bhat, G.S.; et al. ASIRI: An Ocean–Atmosphere Initiative for Bay of Bengal. Bull. Am. Meteorol. Soc. 2016, 97, 1859–1884. [Google Scholar] [CrossRef]

- Lucas, A.; Nash, J.; Pinkel, R.; MacKinnon, J.; Tandon, A.; Mahadevan, A.; Omand, M.; Freilich, M.; Sengupta, D.; Ravichandran, M.; et al. Adrift Upon a Salinity-Stratified Sea: A View of Upper-Ocean Processes in the Bay of Bengal During the Southwest Monsoon. Oceanography 2016, 29, 134–145. [Google Scholar] [CrossRef]

- Omand, M.; Cetinić, I.; Lucas, A. Using Bio-Optics to Reveal Phytoplankton Physiology from a Wirewalker Autonomous Platform. Oceanography 2017, 30, 128–131. [Google Scholar] [CrossRef]

- Morales-Aragón, I.P.; Gilabert, J.; Torres-Sánchez, R.; Soto-Valles, F. Design and development of a new stand-alone profiler for marine monitoring purposes. Appl. Ocean Res. 2024, 152, 104199. [Google Scholar] [CrossRef]

- Jayathunga, B.J.C.L.; Karunasena, H.C.P. Development and Performance Analysis of a Small-Scale On-shore Wave Energy Converter. Eng. J. Inst. Eng. Sri Lanka 2022, 55, 47–60. [Google Scholar] [CrossRef]

- Khojasteh, D.; Kamali, R. Evaluation of wave energy absorption by heaving point absorbers at various hot spots in Iran seas. Energy 2016, 109, 629–640. [Google Scholar] [CrossRef]

- Berenjkoob, M.N.; Ghiasi, M.; Soares, C.G. Influence of the shape of a buoy on the efficiency of its dual-motion wave energy conversion. Energy 2021, 214, 118998. [Google Scholar] [CrossRef]

- Aja, A.; Bui, M.; Hughen, T.; Nguyen, S.; Sun, O.; Goldin, M.; Pinkel, R.; Smith, J.A. Wirewalker Dynamics. J. Atmos. Ocean Technol. 2011, 29, 103–115. [Google Scholar] [CrossRef]

- Hughen, T.; Bui, M.N.; Aja, A.A.; Sun, O.M.; Smith, J.A.; Goldin, M.A.; Pinkel, R. The Wirewalker: A Vertically Profiling Instrument Carrier Powered by Ocean Waves. J. Atmos. Ocean Technol. 2011, 28, 426–435. [Google Scholar] [CrossRef]

- El-Shahat, S.A.; Fu, L.; Li, G. Linear and non-linear wave theories coupled with a modified BEM model for quantifying dynamic loads of a tidal stream turbine. Ocean Eng. 2022, 243, 110334. [Google Scholar] [CrossRef]

- Hu, Z.; Wang, E.; Jia, F.; Dong, M. Experimental study on effect of additional torsional load on bending fatigue behavior and failure mechanism of steel wire rope. Int. J. Fatigue 2023, 167, 107399. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Wang, F.; Ye, J. Numerical studies on CALM buoy motion responses and the effect of buoy geometry cum skirt dimensions with its hydrodynamic waves-current interactions. Ocean Eng. 2022, 244, 110378. [Google Scholar] [CrossRef]

- Isaacs, J.D.; Castel, D.; Wick, G.L. Utilization of the energy in ocean waves. Ocean Eng. 1976, 3, 175–187. [Google Scholar] [CrossRef]

- Bayoumi, S.; Amin, I.; Oterkus, E.; Incecik, A. Experimentally validated simplified prediction model of unloaded spar-buoy wave energy converter motions’ responses in waves. Proc. Inst. Mech. Eng. Part A J. Power Energy 2022, 236, 1608–1620. [Google Scholar] [CrossRef]

- Eriksson, M.; Isberg, J.; Leijon, M. Theory and Experiment on an Elastically Moored Cylindrical Buoy. IEEE J. Ocean Eng. 2006, 31, 959–963. [Google Scholar] [CrossRef]

- Stelzer, M.A.; Joshi, R.P. Evaluation of wave energy generation from buoy heave response based on linear generator concepts. J. Renew. Sustain. Energy 2012, 4, 063137. [Google Scholar] [CrossRef]

- Longuet-Higgins, M.S.; Stewart, R.W. Radiation stresses in water waves; a physical discussion, with applications. Deep Sea Res. Oceanogr. Abstr. 1964, 11, 529–562. [Google Scholar] [CrossRef]

- Huang, L.; Yang, Y.; Khojasteh, D.; Ou, B.; Luo, Z. Floating solar power loss due to motions induced by ocean waves: An experimental study. Ocean Eng. 2024, 312, 118988. [Google Scholar] [CrossRef]

- Montasir, O.A.; Yenduri, A.; Kurian, V.J. Effect of mooring line configurations on the dynamic responses of truss spar platforms. Ocean Eng. 2015, 96, 161–172. [Google Scholar] [CrossRef]

- Barone, P.; Truscelli, F.; Castiglione, T.; Bova, S. Latching control of a point-absorber wave energy converter with a hydraulic power take-off system: A calabrian case study. Ocean Eng. 2024, 310, 118775. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, W.; Zhang, H.; Cui, L. A controllable-valve buoy for high-efficiency wave energy conversion under a wide range of wave conditions. Ocean Eng. 2023, 279, 114468. [Google Scholar] [CrossRef]

- Wang, L.; Yang, R.; Li, H.; Lin, J.; Wen, C. Investigating the influence of geometry on the performance of a wave-powered marine observation buoy: The wave-to-wire approach. Energy 2024, 309, 133022. [Google Scholar] [CrossRef]

- Casas-Prat, M.; Holthuijsen, L.H. Short-term statistics of waves observed in deep water. J. Geophys. Res. Oceans 2010, 115. [Google Scholar] [CrossRef]

- Praveen Kumar, S.; Kumar, A.; Petrov, A.S.; Velkin, V.I.; Shcheklein, S.E.; Qasim, M.A. Development of a laboratory test bench for the linear electric generator for micro power plant of a float-wave type: An experimental investigation. AIP Conf. Proc. 2023, 2800, 020253. [Google Scholar] [CrossRef]

- Ghani, M.H.; Hole, L.R.; Fer, I.; Kourafalou, V.H.; Wienders, N.; Kang, H.; Drushka, K.; Peddie, D. The SailBuoy remotely-controlled unmanned vessel: Measurements of near surface temperature, salinity and oxygen concentration in the Northern Gulf of Mexico. Methods Oceanogr. 2014, 10, 104–121. [Google Scholar] [CrossRef]

- Bao, J.; Yu, D. Hydrodynamic performance optimization of a cost-effective WEC-type floating breakwater with half-airfoil bottom. Renew. Energy 2024, 226, 120333. [Google Scholar] [CrossRef]

- Chen, W.; Lin, X.; Wu, Z.; Xu, Q.; Gao, F. Performance analysis of the SJTU-WEC based on the wave-to-wire model and the wave tank experiment. Ocean Eng. 2022, 264, 112537. [Google Scholar] [CrossRef]

- Zhang, B.; Song, B.; Li, B.; Su, L.; Ding, W. Numerical study of the effect of submergence depth on hydrokinetic energy conversion of an elastically mounted square cylinder in FIV. Ocean Eng. 2020, 200, 107030. [Google Scholar] [CrossRef]

| Sensors | Angular Displacement Sensor | Accelerometer | Temperature–Depth Sensor | Data Acquisition Module |

|---|---|---|---|---|

| Product model | GTCV13636 | WT901SDCL | RBRTDR-1060 | PH-mA20-485 |

| Full scale range | 0–360° | ±2/4/8/16 g | 500 m | \ |

| Accuracy | \ | 0.0005 (g/LSB) | ±0.05% | Better than 1‰ |

| Baud rate | 9600 bps | 115,200 bps | \ | \ |

| Sampling frequency | 20 Hz | 20 Hz | 1 Hz | \ |

| Sensors | Symbol | Uncertainty (%) |

|---|---|---|

| Angular displacement sensor | 1 | |

| Accelerometer | 0.5 | |

| Temperature–depth sensor | 0.1 | |

| Data acquisition module | 0.1 |

| Parameters | Symbol | Value | Unit |

|---|---|---|---|

| Profiling platform’s mass | mP | 14 | kg |

| Profiling platform’s length | LP | 0.62 | m |

| Profiling platform’s width | WP | 0.5 | m |

| Profiling platform’s height | HP | 0.16 | m |

| Tension hammer’s mass | mT | 5 | kg |

| Wire rope’s length | L | 1.8 | m |

| Wire rope’s mass per unit length | K | 0.05 | Kg/m |

| Water density | ρ | 1000 | Kg/m3 |

| Vertical resistance coefficient | Cd | 0.53 | |

| Buoy’s diameter | D | 0.636 | m |

| Wave height | H | 0.2–0.6 | m |

| Wave period | T | 1.95–2.9 | s |

| Profiling platform’s net buoyancy | FP | 1–5 | N |

| Gravitational acceleration | g | 9.81 | N/kg |

| Tank’s height | HT | 2 | m |

| Tank’s diameter | DT | 0.9 | m |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Liu, Y.; Qi, Z.; Chen, X.; Shang, Z.; Cheng, L.; Xing, Z. Experimental Study on Wave Energy Conversion Performance of a Wave-Driven Profiler. Energies 2025, 18, 5425. https://doi.org/10.3390/en18205425

Li H, Liu Y, Qi Z, Chen X, Shang Z, Cheng L, Xing Z. Experimental Study on Wave Energy Conversion Performance of a Wave-Driven Profiler. Energies. 2025; 18(20):5425. https://doi.org/10.3390/en18205425

Chicago/Turabian StyleLi, Haolei, Yan Liu, Zhanfeng Qi, Xuanyu Chen, Zhiyuan Shang, Liang Cheng, and Ziwen Xing. 2025. "Experimental Study on Wave Energy Conversion Performance of a Wave-Driven Profiler" Energies 18, no. 20: 5425. https://doi.org/10.3390/en18205425

APA StyleLi, H., Liu, Y., Qi, Z., Chen, X., Shang, Z., Cheng, L., & Xing, Z. (2025). Experimental Study on Wave Energy Conversion Performance of a Wave-Driven Profiler. Energies, 18(20), 5425. https://doi.org/10.3390/en18205425