Abstract

This study evaluates eight biodiesel blend types and determines the overall optimal blend by applying two established multi-criteria decision-making methods: the Analytic Hierarchy Process (AHP) and the Technique for Order Preference by Similarity to Ideal Solution (TOPSIS). The selected blends represent widely produced and utilized feedstocks that are reported in the previous literature. In the proposed methodology, AHP is employed to determine the weights for both emissions-related subcriteria, quantified through Global Warming Potential scores and property-related subcriteria, thereby reducing the subjectivity often encountered in earlier studies. Furthermore, two boundary alternatives, defined as the “Best” and “Worst” based on international standards, are introduced to enhance the robustness of the normalization procedure. The weights determined via AHP are subsequently integrated into the TOPSIS framework to rank the biodiesel alternatives. This combined AHP-TOPSIS approach addresses a gap in the literature, as no previous study has compared the best performing blends from different sources to identify a single optimal alternative. The results indicate that a 20% sunflower biodiesel blend (SN20) achieves the highest ranking. Sensitivity analyses, including the incorporation of an additional economic criterion, consistently reaffirm SN20’s superior performance. This study offers a transparent and reproducible method that can guide future biodiesel blend evaluations and reduce subjectivity in comparative assessment.

1. Introduction

Climate change, largely driven by rising greenhouse gas (GHG) emissions, is a major challenge. The energy sector contributes the highest share (34%) of these emissions, primarily from fossil fuel consumption [1]. Reducing dependance on fossil fuels and transitioning to cleaner energy sources is critical for sustainable development. Among renewable alternatives, biodiesel has gained attention due to its ability to reduce Carbon Dioxide (CO2) emissions while maintaining a comparable engine performance [2]. The world demand of biofuels is driven primarily by the transport sector, netting 4 EJ (159.2 billion Liters) in 2021, with a biodiesel share of around 35% [3].

Biodiesel is produced through the transesterification reaction of oils with alcohol, mainly methanol, and is classified into three categories according to the oil feedstock: first-generation (edible oils and oilseeds), second-generation (non-edible oils and organic waste) and third-generation (algae and used cooking oils) [4]. The use of biodiesel alone in diesel engines is not yet favorable. Despite its environmental advantages and improved fuel properties and engine performance, biodiesel presents challenges such as poor cold flow properties, lower oxidation stability and higher Nitrogen Oxide (NOx) emissions compared to petroleum diesel [5]. Blending biodiesel with petroleum diesel is a practical solution to improve fuel properties while maintaining cost-effectiveness [6]. The world is realizing the importance of fuel source diversification. Argentina, for example, being the number one exporter, is setting a 10% mandate on diesel blending, while the European Union, being the number one producer, is requiring that 10% of its transport energy be based on renewable energy. Brazil, Indonesia, Thailand, China and others have implemented mandates for biodiesel blending [7]. However, the challenge remains of finding the best feedstock and blending volume.

Multi-criteria decision-making (MCDM) techniques, such as the “Analytic Hierarchy Process” (AHP), “Technique for Order Preference by Similarity to an Ideal Solution” (TOPSIS), “Vlsekriterijumska Optimizacija I Kompromisno Resenje” (VIKOR), fuzzy methods, etc., have been widely applied to identify optimal biodiesel blends based on performance, fuel properties and emissions. Sivaraja et al. (2017) [8] explored fish oil biodiesel blends ranging from B0 to B100 (with 20% increment) using three different hybrid techniques: the “Fuzzy Analytic Hierarchy Process” (FAHP) for computing weights, coupled with TOPSIS, VIKOR or “ELimination Et Choix Traduisant la REalité” (ELECTRE). A 20% biodiesel blend (B20) was found to be the best. Erdoğan et al. (2019) [9] used two hybrid techniques, AHP coupled with MOORA and “Stepwise Weight Assessment Ratio Analysis” (SWARA) coupled with “Multi-Objective Optimization on the basis of Ratio Analysis” (MOORA), to choose the best blend among vegetable oil biodiesel and animal fat biodiesel blends. The best was the 20% vegetable oil biodiesel blend. In another study, biodiesel blends from algae have been studied using TOPSIS. B20 was chosen to be the best [10]. An AHP-TOPSIS hybrid technique was implemented by Mehra et al. (2023) [11] to choose the best among B10-B20 to B100 (with 20% increment) blends, with B10 found to be the best. AHP is a very common technique used to assign weights to criteria because of its simplicity and ability to give scores as percentages. On the other hand, unlike ELECTRE and “Preference Ranking Organization Method for Enrichment Evaluation” (PROMETHEE), which utilize a pairwise comparison between alternatives, TOPSIS is the method that allows for using the raw data, without prior normalization or subjective judgment [12]. The combination of these two techniques is not new and was used by Abdulvahitoglu & Kilic (2022) [13] to evaluate the best oilseed for biodiesel among soybean, cotton, camelina and rapeseed. However, this study did not target any blends. Therefore, it is evident that the AHP and TOPSIS methods complement each other, as the former sets the relative importance of evaluation criteria and the latter ranks the alternatives based on their proximity to the ideal solution, thereby providing a comprehensive framework for the best biodiesel blend selection.

Previous studies have primarily focused on selecting the best blend from individual feedstocks or even by comparison through individual criteria such as the study of Chaitanya et al. 2020 [14], which assessed Pungam oil biodiesel blends via the combination of AHP-TOPSIS methods, using only engine emissions as comparative criteria. To our knowledge, no studies tried conducting a comparative analysis of the top-performing blends across different biodiesel types. No study has systematically evaluated the best blend from each biodiesel source and ranked them as alternatives to determine the overall optimal biodiesel blend. This leaves a gap in the ability to identify which source and which blending volume offers the optimal performance across both technical and environmental criteria. This paper addresses this gap by evaluating the top biodiesel blends from eight of the most widely used feedstocks worldwide in biodiesel production. This novel approach not only ranks the “best among the best” blends, but also provides a comprehensive framework for decision-makers to select biodiesel blends that balance performance, emissions and cost-effectiveness.

2. Materials and Methods

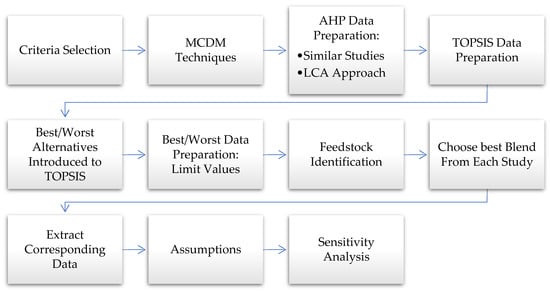

The work plan as outlined in Figure 1 begins with the selection of evaluation criteria, followed by the identification of the appropriate MCDM techniques. AHP is then used to determine the relative weight of the selected criteria, with data sourced from similar studies for the first set of criteria and generated through a Life Cycle Assessment (LCA) approach for the second set of criteria. For TOPSIS, data preparation includes defining two reference alternatives, named “Best” and “Worst”, based on criteria limits and standards. The study reviewed different biodiesel blends and identified the best one from each feedstock. The selected blends constitute the “alternatives” for the TOPSIS analysis. The TOPSIS data matrix is then built while using assumptions to fill data gaps. A sensitivity analysis is conducted to validate the results.

Figure 1.

Methodology steps from criteria selection to sensitivity analysis.

2.1. Criteria Selection

The common criteria used to assess biodiesel blends in a Compression Ignition (CI) diesel engine are performance and emissions [13]. While performance criteria such as brake power (BP), torque and Brake-Specific Fuel Consumption (BSFC) vary with engine types, speeds, power, etc. [15], fuel properties directly influence engine performance and can be used to assess, indirectly, the performance of the selected biodiesel blends. Density, viscosity, heating value and flash point are the fuel properties selected as subcriteria for this study, with density and viscosity to be minimized, and heating value and flash point to be maximized, following the subsequent logic.

- Density: Higher density reduces brake thermal efficiency (BTE) and increases fuel consumption due to greater fuel mass per injection [16,17].

- Viscosity: Higher viscosity hinders fuel atomization, increases exhaust temperatures and reduces engine torque.

- Heating Value: This determines the energy released during combustion. Lower values increase fuel consumption and reduce engine power.

- Flash Point: This indicates fuel safety for proper storage and handling. The higher the flash point the better and safer it is to operate with [17].

On the other hand, the emission subcriteria selected are Carbon Dioxide (CO2), Carbon Monoxide (CO), Nitrogen Oxides (NOx) and Unreacted Hydrocarbon (UHC). These subcriteria need to be minimized.

2.2. Decision-Making Methods

2.2.1. AHP

The Analytic Hierarchy Process (AHP) is a method created by L. Saaty (1980) [18] and is an MCDM technique that enables decision-makers to divide problems into a hierarchy of criteria and subcriteria, using a pairwise comparison to obtain their weights. The AHP technique transforms decision-makers’ assessments into numerical scores that can be used to determine the overall importance of each alternative. Its scale of values ranges from 1 (equal importance) to 9 (extreme importance) and from 1 to 1/9 (lesser importance). AHP can be used either with quantifiable or with intangible criteria. It alleviates subjectivity and gives a score between 0 and 1 that can be directly used as a weight [19]. However, it can be very sensitive to a weight shift in complex problems, so a consistency check is of major importance [20].

The AHP begins by structuring the decision problem into a hierarchy composed of the overall objective, the evaluation criteria, the subcriteria and the set of alternatives. Subsequently, pairwise comparisons are carried out at each hierarchical level. These comparisons are represented in an n × n judgment matrix, where the element in the ith row and jth column (aij) reflects the relative importance of element i over element j.

- -

- Normalization of the matrix: Each element of the matrix is divided by the sum of its corresponding column. This procedure produces a normalized matrix in which the sum of each column is equal to one.

- -

- Derivation of local weights: The local weight of each subcriterion is obtained by averaging the normalized values across each row of the matrix.

- -

- Computation of global weights: To determine the overall contribution of each subcriterion, the local weights are aggregated through multiplication with the corresponding weights of the higher-level criteria, yielding the global weights.

- -

- Total score determination: The global weights of each alternative are then summed according to the additive model of Multi-Attribute Utility Theory (MAUT), thereby producing the total score for each alternative. It is worth mentioning that this step was not carried out. The global weights of the subcriteria were obtained using AHP to be used later in TOPSIS for the alternatives ranking.

- -

- Inconsistency check: AHP provides a measure of inconsistency, while comparing the pairwise elements. The consistency ratio CR is calculated by dividing the consistency index CI by the random index RI. The consistency index CI is defined as follows:

The random consistency index (RCI) is a reference value that depends on the size of the matrix and is obtained from Table 1:

Table 1.

Random consistency index table based on matrix size.

Consistency Ratio:

When the consistency ratio is less than 0.1, CR ≤ 0.1, the pairwise comparisons are considered consistent [18].

2.2.2. TOPSIS

“Technique for Order Preference by Similarity to an Ideal Solution” is a method created by Hwan and Yoon in 1981 to provide a multi-criteria decision-making technique that ranks alternatives based on their closeness to the ideal solution [21]. This method requires constructing a decision matrix formed from the alternatives and criteria, their relative weights and the objective of each criterion, whether it is to be minimized or maximized. Then the decision matrix is normalized and weighed. The positive and negative ideal solutions are then determined so that the distance between the alternatives and the positive and negative ideal solutions can be calculated. Finally, ranking the alternatives is carried out by calculating the relative closeness of the alternatives to the ideal solution. The mathematical model of TOPSIS is as follows:

- -

- Normalize the decision matrix: The following formula can be used for data normalization.

- -

- Calculate the weighted normalized decision matrix: According to the following formula, the normalized matrix is multiplied by the weight of the criteria.

- -

- Determine the positive ideal and negative ideal solutions: The aim of the TOPSIS method is to calculate the distance of each alternative from positive and negative ideals. Therefore, in this step, the positive and negative ideal solutions are determined according to the following formulas.

- -

- Distance from the positive and negative ideal solutions: In this step, the calculation of the distances between each alternative and the positive and negative ideal solutions is obtained by using the following formulas.

- -

- Calculate the relative closeness degree of alternatives to the ideal solution: In this step, the relative closeness of each alternative to the ideal solution is obtained by the following formula. If the relative closeness degree has value near to 1, it means that the alternative has a shorter distance from the positive ideal solution and longer distance from the negative ideal solution.

In this study, TOPSIS is implemented to rank the biodiesel blends and determine the best option. The criteria weights were obtained from AHP computation as stated above. An innovative approach is introduced by adding two reference alternatives representing the best and worst solutions based on the upper and lower limits of each subcriterion. When a limit value is unavailable, the optimum value from the existing alternative is used.

2.3. Criteria Weights

Previous studies developed the relationships among property subcriteria based on their impact on engine performance and safety. The expert-assigned property weights used by Abdulvahitoglu & Kilic (2022) [13] were isolated, normalized and converted back to an AHP scale in order to build the comparison matrix. As for the emission subcriteria, an LCA approach is used to quantify the impact of these emissions on the “Climate Change” impact category by using the Global Warming Potential (GWP) of each substance. GWP can be defined as a measurement for the greenhouse effectivity to an equal mass of CO2, measured in kilograms of CO2 equivalent (kgCO2-eq). So, in order to normalize the data, CO2 is chosen as a reference substance. According to the Intergovernmental Panel on Climate Change (IPCC) sixth report, the GWPs for CO and NOx are, respectively, nine times and four times more important than CO2 for a time horizon of 100 years [1,22]. UHC is mainly composed of VOCs, namely C1 and C2 hydrocarbons, followed by aldehydes, paraffins and aromatics, respectively [23]. In this context, the GWP of UHC is considered as the arithmetic mean of the halogen-free VOCs that have a published GWP factor, taken to the nearest unit. This includes methane (25), ethane (6), propane (3), butane (4), isobutane (3), pentane (5) and isopentane (5). The GWPs for the emission subcriteria are summarized in Table 2.

Table 2.

GWP of the emission subcriteria.

2.4. TOPSIS Data Preparation

2.4.1. Limit Values

According to the American Society of Testing and Material (ASTM) and the Euronorm (EN), limit values of physical parameters can be found, related to petroleum diesel, B100 and B6 to B20 diesel. Limits of viscosity and flash point are defined by ASTM D7467 [24]. EN 14213 [25] specifies the limits for heating value, while EN 14214 [26] is the reference for the upper limit of density and EN 590 [27] is the one for the lower limit of density. Values of property limits are found in Table 3.

Table 3.

Property subcriteria limits.

Limits for emissions differ from one country to another and from one region to another. EU test limits are used to assess the criteria according to the EU emission standards, stage EURO VI, revised in 2021. Only CO2 values were taken from the US Emission Standards for medium-heavy-duty (MHD) diesel engines. Values brought in g/bhph are converted to g/kwh following the conversion formula:

Values of emission limits can be found in Table 4.

Table 4.

Emission subcriteria limits.

Conversions from g/kWh unit to ppm or vol% are performed according to the following formulas [30]:

2.4.2. Best Blends Based on Feedstock

Based on statistics provided by the International Energy Agency (IEA) report on the world production volumes of biodiesel, rapeseed, soybean, palm and waste cooking methyl esters are selected. Corn, sunflower, jatropha and mahua methyl esters complete the list, as they show a promising future for industrial production [31].

The alternatives to be selected from these feedstocks are biodiesel blends that have already been studied, with values for properties and emissions being presented and published. The best blend from each feedstock is selected by comparing the criteria studied to choose the optimum values. A lower Brake-Specific Fuel Consumption (BSFC), a higher torque and lower emissions were the basis for the selection. Table 5 provides the full data set needed for conducting the MCDM analysis.

Table 5.

Main data table containing all alternatives and respective values with respect to the subcriteria, engine details, references, rationale behind choosing the specific blend and objective of the criteria to be minimized or maximized to be used in TOPSIS.

2.5. Assumptions and Working Mode

- Upper limits of flash point and heating value are not regulated, as the higher it is the better. The lower limit for the emission subcriteria is zero.

- As emission values vary with engine type, power and speed, and to ensure consistency, these values were taken from studies that used a single-cylinder, four-stroke engine operating at 1500 rpm with a BP of less than 7.5 kW.

- These engines can be considered light-duty diesel engines mainly because of their low power output.

- The main criteria, properties and emissions are considered to be equally weighted for the first part of the simulation.

2.6. Sensitivity Analysis Method

After the TOPSIS analysis, a sensitivity analysis is performed to verify the reliability of the results, in four steps. First, the main criteria weights are adjusted to observe their effect on the ranking. Second, the “Best” and “Worst” reference alternatives are removed to assess their impact on the final results. Third, the emission data are adjusted by considering the effect of aftertreatment systems to simulate real-life conditions. Finally, the break-even blend price is added as a third criterion to provide a more realistic assessment.

3. Results and Discussion

3.1. Criteria Weights Evaluation by AHP

3.1.1. The Hierarchy

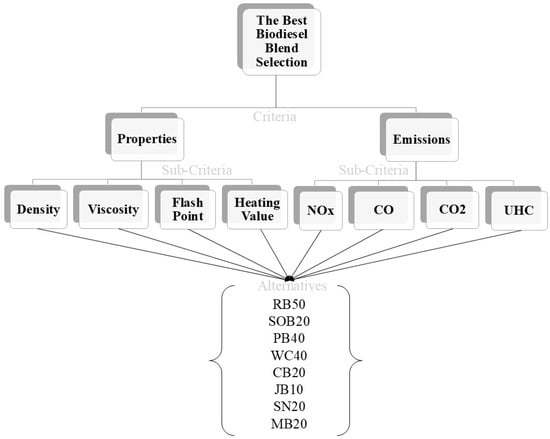

Figure 2 shows the hierarchy followed to calculate the AHP scores.

Figure 2.

Hierarchy model of best biodiesel blend selection.

3.1.2. AHP Calculations

The pairwise comparison for the property subcriteria is based on the normalized weights of Abdulvahitoglu & Kilic (2022) [13]. However, the pairwise comparison of the emission subcriteria is based on the scientific value developed in Section 2.3. Table 6 shows the comparative matrices.

Table 6.

Comparative matrix of subcriteria.

After computing using the AHP method, the local weights were represented in Table 7.

Table 7.

Local and global weights of the subcriteria.

The highest weight is attributed to “Heating Value”, as this property directly affects engine performance in terms of brake power and torque. Viscosity comes in second place, as it affects atomization and fuel consumption. Density is in third place, as it is a relative measure to viscosity and heating value, and it affects both [17]. Flash point has the least importance because it is a property related to safety, in a study that lays importance on performance.

Carbon Monoxide has a higher impact on climate change and thus the highest weight value, followed by UHC and NOx. Stepwise calculations can be found in Tables S1 and S2 in the Supplementary Materials.

3.1.3. Comparison of AHP Scores

The expert-assigned AHP scores are based on the subjective judgment of the experts in the field. The subjectivity creates a limitation in the AHP application. The use of GWP-based AHP scores, alleviates subjectivity and provides scientific numbers for a better comparison and improved decision-making process. Table 8 shows the difference between the expert-assigned and the GWP-based AHP scores.

Table 8.

Comparison on local weights of the subcriteria.

The discrepancy is clear mainly in NOx weight, which has 81% less of an effect because of its lower effect on GWP, and in CO and UHC, with a 253% and 340% increase because of their higher GWP effect. This is reflected in the difference in scores of the GWP-based weights compared to the subjective judgment of the experts.

3.1.4. AHP Global Weights

The global weights shown in Table 9 are calculated, assuming the two main criteria, properties and emissions to be equally weighted. Heating value has the highest impact, followed by CO, UHC and viscosity.

Table 9.

Global subcriteria weights.

3.1.5. AHP Inconsistency Check

Tables S3 and S4 in the Supplementary Materials show the inconsistency check tables for matrix 1. The ratio CI/RI is less than 0.1, so matrix 1 is consistent. The inconsistency check tables for matrix 2 are in Tables S5 and S6 in the Supplementary Materials. The ratio CI/RI is less than 0.1, so matrix 2 is also consistent.

3.2. Biodiesel Blend Ranking

TOPSIS Calculations

TOPSIS analysis is implemented on the data of Table 5. Tables S7–S12 in the Supplementary Materials show the steps for TOPSIS calculations, from normalization, the weighted normalized decision matrix, the positive and negative ideal solutions, and , the positive and negative ideal distance values, di+ and di−, and the relative closeness to the ideal solution Ci*. Finally, the alternative rankings are presented in Table 10.

Table 10.

Final ranking of biodiesel blends.

SN20 was found to be the best alternative, with a score of 0.884. Two more alternatives were ranked above the worst, CB20 and WC40, with scores of 0.834 and 0.821, respectively. The other alternatives were ranked below the worst, with a score less than 0.778. A reasonable explanation is that emission values were way above the higher limits.

3.3. Sensitivity Analysis

3.3.1. Sensitivity Analysis on Criteria Weights

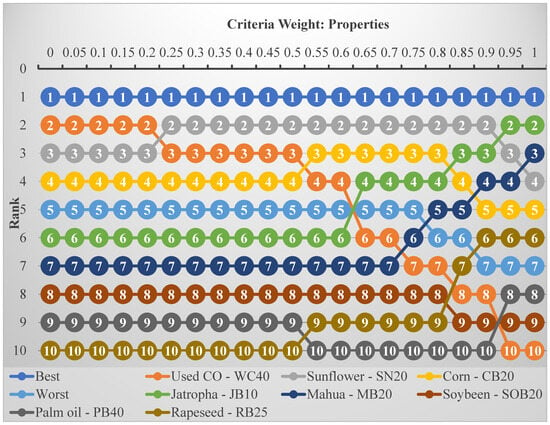

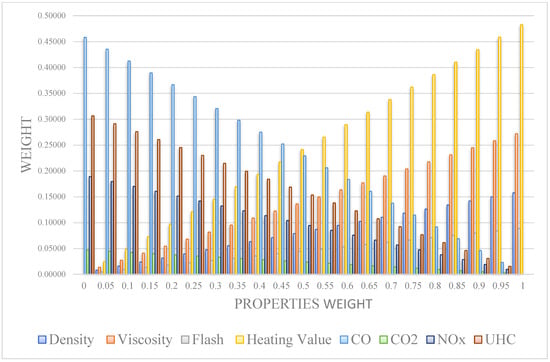

Varying the main criteria weights can seriously affect the final results. Weights of the two main criteria, properties and emissions are varied between 0 and 1 in a step of 0.05, and so the subcriteria weights change accordingly, affecting the final ranking results.

Figure 3 shows how the final alternative rankings change as the weight of the “Properties” criterion increases. The “Best” alternative remains in the first position, as it represents the ideal solution. However, increasing the weight of the “Properties” and reducing the importance of “Emissions” causes significant shifts in ranking. WC40, initially ranked second, drops to the last position due to its poor fuel properties, despite being the best performer in emissions. In contrast, JB10 improves from 6th to 2nd, and MB20 rises from 7th to 3rd. CB20 achieved relative stability, while SN20 consistently ranks among the top alternatives ranging between 2nd and 4th place. SOB20 remains at the bottom of the list, fluctuating between 8th and 9th place. As the importance of “Emissions” decreases, more alternatives make it above the worst rank limit. Only PB40 and SOB20 remain outside the acceptable range. Figure 4 further clarifies that at low “Properties” weights, the ranking is primarily influenced by CO emissions. As the weight of “Properties” increases, “Heating Value” becomes the dominant factor affecting the final decision.

Figure 3.

Chart of varying ranking with sensitivity analysis on main criteria weight.

Figure 4.

Sensitivity analysis on subcriteria weights.

3.3.2. Sensitivity Analysis on Alternatives

The effect of adding the two boundary alternatives is studied. By removing the “Best” and “Worst” alternatives, no changes in the TOPSIS ranking were seen; however, the only change was in the relative closeness values (Table 11). Therefore, the addition of these two alternatives was essential to define acceptable limits and place the alternatives within an acceptable blend range for better selection.

Table 11.

Blend ranking without best and worst alternatives.

3.3.3. Exhaust Emission Reduction

As seen in the data in Table 5, not all emission values meet regulatory limits. This is because the data reflects direct exhaust measurements without aftertreatment. Aftertreatment systems are essential for diesel engines to comply with strict regulations like EURO VI. Electronic-controlled fuel injection improves emission control, but is not sufficient on its own [50]. Exhaust aftertreatment systems like Exhaust Gas Recirculation (EGR) reduce NOx emissions by lowering combustion temperatures, but they increase UHC and CO emissions. The Diesel Oxidation Catalyst (DOC) oxidizes UHC and CO into CO2, achieving reductions of 73% and 80%, respectively [51]. The Selective Catalytic Reduction (SCR) system removes over 90% of NOx using NH3 as a reductant, while CO2 emissions can be reduced by 12.4% [52].

By applying the new reduction percentages to the emission values from the data in Table 5, Table 12 is generated.

Table 12.

Table of data after applying exhaust aftertreatment systems.

The new TOPSIS results, based on these adjusted values, are shown in Table 13.

Table 13.

Blend ranking with exhaust aftertreatment.

The new ranking, based on equal weights for “Properties” and “Emissions”, places SN20 at the top, followed by CB20 and WC40. The best–worst window now includes more blends, with only RB25 and PB40 outside the acceptable range.

3.3.4. Effect of Blend Prices on Final Selection

The economic aspect is crucial for the study. Biodiesel prices vary by feedstock and production location. Table 14 shows the break-even prices for the eight biodiesel blends, the final blend prices calculated based on Brazilian diesel prices [53] and the percentage of biodiesel only [54].

Table 14.

Blend break-even prices.

The model was updated to include a new criterion, “Break-Even Price”, equally weighted, and the TOPSIS analysis data in Table 12 (data with exhaust aftertreatment) was updated with the break-even price of blends. The updated ranking is shown in Table 15.

Table 15.

Blend ranking with break-even price criterion.

Based on the equal weight approach, the results after including the economic analysis are the same as Section 3.3.3 but with different scores. SN20 remains at the top of the list, followed by CB20 and WC40.

3.3.5. Discussion of Results

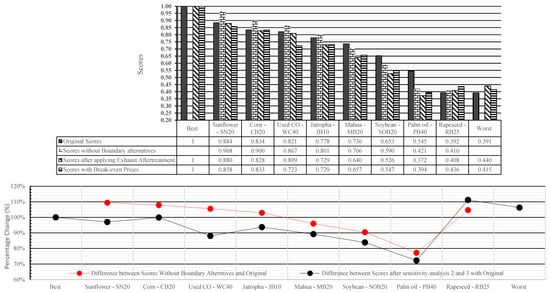

In order to better understand the results of the sensitivity analysis in accordance with the original results, Figure 5 better visualizes the blend scores in comparison to the original results. After removing the boundary alternatives, the top four blends increased their scores by less than 10%, while the bottom four blends show a decrease in score by a maximum of 23%, except for RB25, which showed an increase of about 5%, all without a change in ranking. After applying the exhaust aftertreatment reduction percentage to the emissions data, all blends showed a decrease in their scores, except for RB25, which slightly increased from 0.392 to 0.408, while moving up one place to rank number 7. Finally, and most importantly, after introducing the economic factor, denoted by the break-even price of the blends, the CB20 score was not affected; however, all other blend scores showed a decrease of up to 28%, except for the RB25 score, which increased by around 12%, moving also one place to rank number 7. It is important to note that the results highlighted SN20 as the optimal blend, demonstrating its superiority in emission control and operational efficiency. Moreover, Figure 5’s trends emphasized the robustness of SN20 and indicated a notable decrease in performance consistency among other blends when various changes were applied.

Figure 5.

Sensitivity analysis results comparison.

SN20 is approved to be suitable for direct use in engines without any modifications, achieving emission reductions with a high engine performance [56].

In contrast, other blends do perform well in specific scenarios, especially WC40. When prioritizing emission values, WC20 is ranked 2nd, but drops to the bottom of the ranking when it comes to its properties. In fact, blends with a higher oxygen content often yield lower emissions, but may present trade-offs in terms of energy content [15].

On the other hand, corn biodiesel proved it is one of the most consistent blends in the upper ranks, not only due to its properties and low emissions values but also to its economic viability [42,43]. Rahman et al. (2021) [57] assessed up to 71 biodiesel types through computational software using only their properties as criteria. Even though the alternatives assessed were not blends of biodiesel, sunflower, along with corn biodiesel, performed fairly in the ranking. Abdulvahitoglu & Kilic (2022) [13] compared four biodiesel types, rapeseed, camelina, soybean and cottonseed, by means of three criteria, properties, performance and emissions. Rapeseed biodiesel was found to be the best, surpassing soybean biodiesel. These findings do not align with this study, as SOB20 outperformed RB25. This is mainly due to the difference in comparing pure biodiesel to its corresponding blend. A comparison with similar literature cannot be performed because no studies compared the best blends of biodiesel from different types.

This study refines the selection criteria for biodiesel blends and incorporates a comprehensive approach encompassing economic viability through a break-even pricing analysis. Such integration is vital, as economic considerations often dictate the feasibility of adopting the blend use in commercial applications. However, this study is not without limitations. The reliance on data from one specific geographic region, i.e., Brazil, may not universally apply, and further validation across different regional settings would enhance the robustness of the findings. Moreover, while the AHP-TOPSIS method minimizes subjectivity, it is crucial to acknowledge that the property subcriteria weights are still assigned based on the assumptions drawn from the literature.

4. Conclusions

This study applied a combined AHP–TOPSIS framework to identify the best-performing biodiesel blend among the eight most widely used biodiesel feedstocks worldwide. The methodology introduced two key innovations. First, the weighting of emissions-related subcriteria was determined through AHP method by using the GWP values as basis for comparison. Thereby reducing subjectivity compared to expert judgment approaches. Second, two boundary alternatives, “Best” and “Worst”, were constructed using international standard norms, so that TOPSIS classification could provide a clear border line and ensure a clearer benchmarking reference.

The results consistently indicated that the 20% sunflower biodiesel blend (SN20) achieved the highest ranking across both technical and environmental criteria. Sensitivity analyses further demonstrated the stability of this finding, as SN20 maintained its top position even when introducing an additional economic criterion through break-even prices. In contrast, WC40 performed best when emissions alone were prioritized, while JB10 was preferred when only properties were considered. These findings underline the strength of the integrated AHP–TOPSIS framework in capturing trade-offs among multiple criteria and reducing bias in biodiesel blend evaluations.

From a policy perspective, SN20 may serve as a benchmark option in regions with reliable access to sunflower oil feedstock. Meanwhile, WC40 represents a sustainable pathway in regions where waste cooking oil is abundant, aligning with circular economy goals and minimizing competition with food crops. The framework developed in this study therefore provides decision-makers with a robust, transparent and reproducible tool to guide biodiesel blend adoption strategies tailored to local resource availability and policy priorities.

Future research should extend this approach by considering additional life cycle impact categories, such as photooxidant formation for emissions-based weighting. Furthermore, applying alternative MCDM techniques alongside AHP–TOPSIS would enable a cross-validation of results and strengthen the methodological robustness. Expanding the analysis to include crop yields in specific regions would improve the realism of feedstock selection and enhance policy relevance. Finally integrating fourth-generation biodiesel feedstocks, such as algae and other non-food crops, would also provide insights into the long-term sustainability and scalability of biodiesel production.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/en18205398/s1, Table S1. Normalized matrix 1. Table S2. Normalized matrix 2. Table S3. Inconsistency check for matrix 1. Table S4. Inconsistency parameters for matrix 1. Table S5. Inconsistency check for matrix 2. Table S6. Inconsistency parameters for matrix 2. Table S7. Decision matrix for TOPSIS. Table S8. Normalized decision matrix. Table S9. Weighted normalized decision matrix with positive and negative ideal solutions. Table S10. Positive distance to ideal solution. Table S11. Negative distance to ideal solution. Table S12. Relative closeness to ideal solution Ci*.

Author Contributions

Conceptualization, Y.F. and N.S.; Methodology, J.E.; Writing—review & editing, J.C.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research has been internally funded by the University of the corresponding authors.

Data Availability Statement

The original contributions presented in this study are included in the article/Supplementary Material. Further inquiries can be directed to the corresponding author(s).

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| AHP | Analytic Hierarchy Process |

| ASTM | American Society for Testing and Materials |

| B0 | 0% Biodiesel |

| B20 | 20% Biodiesel Blend |

| B100 | 100% Biodiesel |

| BP | Brake Power |

| BSFC | Brake-Specific Fuel Consumption |

| BTE | Break Thermal Efficiency |

| CB20 | 20% Corn Biodiesel Blend |

| CI | Compression Ignition |

| CO | Carbon Monoxide |

| CO2 | Carbon Dioxide |

| DOC | Diesel Oxidation Catalyst |

| EGR | Exhaust Gas Recirculation |

| EJ | ExaJoule |

| ELECTRE | Elimination Et Choix Traduisant la Realite |

| EN | Euronorm |

| EU | European Union |

| FAHP | Fuzzy Analytic Hierarchy Process |

| g/bhph | Gram Per Brake Horsepower Per Hour |

| g/kWh | Gram Per Kilowatt Hour |

| GGE | Gasoline Gallon Equivalent |

| GHG | Greenhouse Gases |

| GtCO2-eq | Giga Tons Carbon Dioxide Equivalent |

| GWP | Global Warming Potential |

| HC | Hydrocarbons |

| IEA | International Energy Agency |

| IPCC | Intergovernmental Panel on Climate Change |

| JB10 | 10% Jatropha Biodiesel Blend |

| MAUT | Multi-Attribute Utility Technique |

| MB20 | 20% Mahua Biodiesel Blend |

| MCDM | Multi-Criteria Decision-Making |

| MHD | Medium-Heavy-Duty |

| MOORA | Multi-Objective Optimization on the basis of Ratio Analysis |

| NOx | Nitrogen Oxides |

| PAH | Polycyclic Aromatic Hydrocarbons |

| PB40 | 40% Palm Biodiesel Blend |

| Pd | Palladium |

| PM | Particulate Matter |

| PROMETHEE | Preference Ranking Organization Method for Enrichment Evaluation |

| Pt | Platinum |

| RB25 | 25% Rapeseed Biodiesel blend |

| SCR | Selective Catalytic Reduction |

| SN20 | 20% Sunflower Biodiesel Blend |

| SOB20 | 20% Soybean Biodiesel Blend |

| SWARA | Stepwise Weight Assessment Ratio Analysis |

| TOPSIS | Technique for Order Preference by Similarity to an Ideal Solution |

| UHC | Unreacted Hydrocarbon |

| UN | United Nations |

| USA | United States of America |

| VIKOR | Vlsekriterijumska Optimizacija I Kompromisno Resenje |

| VOC | Volatile Organic Compounds |

| WC40 | 40% Waste Cooking Oil Biodiesel Blend |

References

- Pörtner, H. Climate Change 2022: Impacts, Adaptation and Vulnerability: Working Group II Contribution to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2022. [Google Scholar]

- Zidanšek, A.; Blinc, R.; Jeglič, A.; Kabashi, S.; Bekteshi, S.; Šlaus, I. Climate changes, biofuels and the sustainable future. Int. J. Hydrogen Energy 2009, 34, 6980–6983. [Google Scholar] [CrossRef]

- Bains, P.; Moorhouse, J.; Hannula, I. Biofuels–Analysis. 2022. Available online: https://www.iea.org/reports/biofuels (accessed on 19 June 2023).

- Chozhavendhan, S.; Vijay Pradhap Singh, M.; Fransila, B.; Praveen Kumar, R.; Karthiga Devi, G. A review on influencing parameters of biodiesel production and purification processes. Curr. Res. Green Sustain. Chem. 2020, 1–2, 1–6. [Google Scholar] [CrossRef]

- McCarthy, P.; Rasul, M.G.; Moazzem, S. Analysis and comparison of performance and emissions of an internal combustion engine fuelled with petroleum diesel and different bio-diesels. Fuel 2011, 90, 2147–2157. [Google Scholar] [CrossRef]

- Clean Cities Alternative Fuel Price Report. 2023. Available online: https://afdc.energy.gov/files/u/publication/alternative_fuel_price_report_july_2023.pdf (accessed on 25 November 2023).

- OECD; Food and Agriculture Organization of the United Nations. OECD-FAO Agricultural Outlook 2020–2029; OECD Publishing: Paris, France; FAO: Rome, Italy, 2020. [Google Scholar] [CrossRef]

- Sivaraja, C.M.; Sakthivel, G. Compression ignition engine performance modelling using hybrid MCDM techniques for the selection of optimum fish oil biodiesel blend at different injection timings. Energy 2017, 139, 118–141. [Google Scholar] [CrossRef]

- Erdoğan, S.; Balki, M.K.; Aydın, S.; Sayin, C. The best fuel selection with hybrid multiple-criteria decision making approaches in a CI engine fueled with their blends and pure biodiesels produced from different sources. Renew. Energy 2019, 134, 653–668. [Google Scholar] [CrossRef]

- Mehta, A.V.; Mehta, N.S. Extraction of algae biodiesel for power generation and comparison of sustainable fuels using MCDM. Int. J. Ambient. Energy 2022, 43, 3106–3116. [Google Scholar] [CrossRef]

- Mehra, K.S.; Goel, V.; Singh, S.; Pant, G.; Singh, A.K. Experimental investigation of emission characteristics of CI engine using biodiesel-diesel blends and best fuel selection: An AHP-TOPSIS approach. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Kaya, İ.; Çolak, M.; Terzi, F. Use of MCDM techniques for energy policy and decision-making problems: A review. Int. J. Energy Res. 2018, 42, 2344–2372. [Google Scholar] [CrossRef]

- Abdulvahitoglu, A.; Kilic, M. A new approach for selecting the most suitable oilseed for biodiesel production; the integrated AHP-TOPSIS method. Ain Shams Eng. J. 2022, 13, 101604. [Google Scholar] [CrossRef]

- Sunil Chaitanya, G.; Raj Kumar, M.; Deivanathan, R. Multi Criteria Decision Making Approach for Selection Of Biodiesel Blend Using AHP-TOPSIS Analysis; IOP Publishing: Bristol, UK, 2020. [Google Scholar] [CrossRef]

- Fatt Chuah, L.; Bokhari, A.; Asif, S.; Jaromir Klemes, J.; Daniel Joe, D.; El Enshasy, H.; Mohd Yudof, A.H. A review of performance and emission characteristic of engine diesel fueled by biodiesel. Chem. Eng. Trans. 2022, 94, 1099–1104. [Google Scholar] [CrossRef]

- Elangovan, T.; Anbarasu, G. Analysis of biodiesel properties from various oil resources and develop relationships among the properties. Asian J. Sci. Technol. 2016, 7, 2658–2664. [Google Scholar]

- Verma, T.N.; Shrivastava, P.; Rajak, U.; Dwivedi, G.; Jain, S.; Zare, A.; Verma, P. A comprehensive review of the influence of physicochemical properties of biodiesel on combustion characteristics, engine performance and emissions. J. Traffic Transp. Eng. (Engl. Ed.) 2021, 8, 510–533. [Google Scholar] [CrossRef]

- Saaty, T.L. Fundamentals of the analytic network process—Dependence and feedback in decision-making with a single network. J. Syst. Sci. Syst. Eng. 2004, 13, 129–157. [Google Scholar] [CrossRef]

- Vargas, L.G. An overview of the analytic hierarchy process and its applications. Eur. J. Oper. Res. 1990, 48, 2–8. [Google Scholar] [CrossRef]

- Ishizaka, A.; Labib, A. Analytic hierarchy process and expert choice: Benefits and limitations. OR Insight 2009, 22, 201–220. [Google Scholar] [CrossRef]

- Hwang, C.; Yoon, K.; Hwang, C.; Yoon, K. Methods for multiple attribute decision making. In Multiple Attribute Decision Making: Methods and Applications a State-of-the-Art Survey; CRC Press: Boca Raton, FL, USA, 1981; pp. 58–191. [Google Scholar]

- Berntsen, T.K.; Fuglestvedt, J.S.; Joshi, M.M.; Shine, K.P.; Stuber, N.; Ponater, M.; Sausen, R.; Hauglustaine, D.A.; Li, L. Response of climate to regional emissions of ozone precursors: Sensitivities and warming potentials. Tellus B Chem. Phys. Meteorol. 2005, 57, 283–304. [Google Scholar] [CrossRef]

- Xie, K. Investigation of Hydrocarbon Speciation in Diesel Low-Temperature Combustion. 2012. Available online: https://hdl.handle.net/20.500.14776/7076 (accessed on 20 October 2023).

- ASTM D7467-20a; Standard Specification for Diesel Fuel Oil, Biodiesel Blend (B6 to B20). Book of Standards Volume: 05.04. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- EN 14213:2003; Heating Fuels-Fatty Acid Methyl Esters (FAME)-Requirements and Test Methods. European Committee for Standardization: Brussels, Belgium, 2003. Available online: https://standards.iteh.ai/catalog/standards/cen/b25e0e36-b6b8-4765-92dd-2b247880f28c/en-14213-2003 (accessed on 20 October 2023).

- EN 14214:2012+A2:2019; Liquid Petroleum Products-Fatty Acid Methyl Esters (FAME) for Use in Diesel Engines and Heating Applications-Requirements and Test Methods. European Committee for Standardization: Brussels, Belgium, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/0a2c5899-c226-479c-b277-5322cc71395d/en-14214-2012a2-2019 (accessed on 13 October 2023).

- EN 590:2022; Automotive Fuels-Diesel-Requirements and Test Methods. European Committee for Standardization: Brussels, Belgium, 2022. Available online: https://standards.iteh.ai/catalog/standards/cen/4ea7758d-110a-4ad0-8fac-c7223c89af42/en-590-2022 (accessed on 13 October 2023).

- Emission Standards: Europe: Heavy-Duty Truck and Bus Engines. 2021. Available online: https://dieselnet.com/standards/eu/hd.php#stds (accessed on 13 October 2023).

- Emission Standards: USA: HD Vehicles Fuel Economy. 2023. Available online: https://dieselnet.com/standards/us/fe_hd.php#co2 (accessed on 17 October 2023).

- Vergel-Ortega, M.; Valencia-Ochoa, G.; Duarte-Forero, J. Experimental study of emissions in single-cylinder diesel engine operating with diesel-biodiesel blends of palm oil-sunflower oil and ethanol. Case Stud. Therm. Eng. 2021, 26, 101190. [Google Scholar] [CrossRef]

- Chauhan, B.S.; Singh, R.K.; Cho, H.M.; Lim, H.C. Practice of diesel fuel blends using alternative fuels: A review. Renew. Sustain. Energy Rev. 2016, 59, 1358–1368. [Google Scholar] [CrossRef]

- Roy, M.M.; Wang, W.; Bujold, J. Biodiesel production and comparison of emissions of a DI diesel engine fueled by biodiesel–diesel and canola oil–diesel blends at high idling operations. Appl. Energy 2013, 106, 198–208. [Google Scholar] [CrossRef]

- Hassan, U.; Al-Zubaidi, I.; Ibrahim, H. The effect of off-spec canola biodiesel blending on fuel properties for cold weather applications. ChemEngineering 2018, 2, 30. [Google Scholar] [CrossRef]

- Raman, L.A.; Deepanraj, B.; Rajakumar, S.; Sivasubramanian, V. Experimental investigation on performance, combustion and emission analysis of a direct injection diesel engine fuelled with rapeseed oil biodiesel. Fuel 2019, 246, 69–74. [Google Scholar] [CrossRef]

- Çelikten, İ.; Mutlu, E.; Solmaz, H. Variation of performance and emission characteristics of a diesel engine fueled with diesel, rapeseed oil and hazelnut oil methyl ester blends. Renew. Energy 2012, 48, 122–126. [Google Scholar] [CrossRef]

- Gangolu, N.R.; Chunchu, B.R.K.; Yallamati, A.; Gopidesi, R.K. Assessment of diesel engine characteristics by using soybean oil as a biofuel. Environ. Dev. Sustain. 2022, 24, 7579–7592. [Google Scholar] [CrossRef]

- Özener, O.; Yüksek, L.; Ergenç, A.T.; Özkan, M. Effects of soybean biodiesel on a DI diesel engine performance, emission and combustion characteristics. Fuel 2014, 115, 875–883. [Google Scholar] [CrossRef]

- Ghazanfari, J.; Najafi, B.; Faizollahzadeh Ardabili, S.; Shamshirband, S. Limiting factors for the use of palm oil biodiesel in a diesel engine in the context of the ASTM standard. Cogent Eng. 2017, 4, 1411221. [Google Scholar] [CrossRef]

- Deepanraj, B.; Dhanesh, C.; Senthil, R.; Kannan, M.; Santhoshkumar, A.; Lawrence, P. Use of palm oil biodiesel blends as a fuel for compression ignition engine. Am. J. Appl. Sci. 2011, 8, 1154–1158. [Google Scholar] [CrossRef]

- Canakci, M.; Ozsezen, A.N.; Arcaklioglu, E.; Erdil, A. Prediction of performance and exhaust emissions of a diesel engine fueled with biodiesel produced from waste frying palm oil. Expert Syst. Appl. 2009, 36, 9268–9280. [Google Scholar] [CrossRef]

- Gopal, K.N.; Pal, A.; Sharma, S.; Samanchi, C.; Sathyanarayanan, K.; Elango, T. Investigation of emissions and combustion characteristics of a CI engine fueled with waste cooking oil methyl ester and diesel blends. Alex. Eng. J. 2014, 53, 281–287. [Google Scholar] [CrossRef]

- Rama Krishna Reddy, E.; Subbalakshmi, Y.; Dhana Raju, V.; Appa Rao, K.; Harun Kumar, M.; Rami Reddy, S.; Tharun Sai, P. Assessment of performance, combustion and emission characteristics of the diesel engine powered with corn biodiesel blends. Int. J. Ambient. Energy 2022, 43, 435–443. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhong, Y.; Lu, S.; Zhang, Z.; Tan, D. A comprehensive review of the properties, performance, combustion, and emissions of the diesel engine fueled with different generations of biodiesel. Processes 2022, 10, 1178. [Google Scholar] [CrossRef]

- Raheman, H.; Kumari, S. Combustion characteristics and emissions of a compression ignition engine using emulsified jatropha biodiesel blend. Biosyst. Eng. 2014, 123, 29–39. [Google Scholar] [CrossRef]

- Chauhan, B.S.; Kumar, N.; Cho, H.M. A study on the performance and emission of a diesel engine fueled with jatropha biodiesel oil and its blends. Energy 2012, 37, 616–622. [Google Scholar] [CrossRef]

- Tutunea, D.; Dumitru, I. Analysis of performance and emissions of diesel engine using sunflower biodiesel. IOP Conf. Ser. Mater. Sci. Eng. 2017, 252, 012085. [Google Scholar] [CrossRef]

- Niyas, M.M.; Shaija, A. Effect of repeated heating of coconut, sunflower, and palm oils on their fatty acid profiles, biodiesel properties and performance, combustion, and emission, characteristics of a diesel engine fueled with their biodiesel blends. Fuel 2022, 328, 125242. [Google Scholar] [CrossRef]

- Vibhanshu, V.; Kumar, N.; Singh, A.; Mishra, C. An Experimental Investigation on Performance and Emission Studies of a Single Cylinder Diesel Engine Fuelled with Blends of Diesel and Mahua Oil Methyl Ester. 2013. Available online: https://saemobilus.sae.org/papers/experimental-investigation-performance-emission-studies-a-single-cylinder-diesel-engine-fuelled-blends-diesel-mahua-oil-methyl-ester-2013-01-1041 (accessed on 29 October 2023).

- Kumar, S.; Kumar, S.; Kumar, A.; Maurya, S.; Deswal, V. Experimental investigation of the influence of blending on engine emissions of the diesel engine fueled by mahua biodiesel oil. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 994–998. [Google Scholar] [CrossRef]

- Reşitoğlu, İ.A.; Altinişik, K.; Keskin, A. The pollutant emissions from diesel-engine vehicles and exhaust aftertreatment systems. Clean Technol. Environ. Policy 2015, 17, 15–27. [Google Scholar] [CrossRef]

- Gren, L.; Malmborg, V.B.; Falk, J.; Markula, L.; Novakovic, M.; Shamun, S.; Tunér, M. Effects of renewable fuel and exhaust aftertreatment on primary and secondary emissions from a modern heavy-duty diesel engine. J. Aerosol Sci. 2021, 156, 105781. [Google Scholar] [CrossRef]

- Hu, S.; Deng, B.; Wu, D.; Hou, K. Energy flow behavior and emission reduction of a turbo-charging and EGR non-road diesel engine equipped with DOC and DPF under NRTC (non-road transient cycle). Fuel 2021, 305, 121571. [Google Scholar] [CrossRef]

- Brazil Diesel Prices, 27-nov-2023. Available online: https://www.globalpetrolprices.com/Brazil/diesel_prices/ (accessed on 29 November 2023).

- Pires, V.D.; Cavalcante, R.M.; Young, A.F. Process simulation and economic evaluation of biodiesel production from several feedstocks in Brazil. Braz. J. Chem. Eng. 2023, 1–28. [Google Scholar] [CrossRef]

- Kumar, A.; Tirkey, J.V.; Shukla, S.K. Comparative energy and economic analysis of different vegetable oil plants for biodiesel production in India. Renew. Energy 2021, 169, 266–282. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Rakopoulos, D.C.; Hountalas, D.T.; Giakoumis, E.G.; Andritsakis, E.C. Performance and emissions of bus engine using blends of diesel fuel with bio-diesel of sunflower or cottonseed oils derived from Greek feedstock. Fuel 2008, 87, 147–157. [Google Scholar] [CrossRef]

- Rahman, S.; Fattah, I.; Maitra, S.; Mahlia, T. A ranking scheme for biodiesel underpinned by critical physicochemical properties. Energy Convers. Manag. 2021, 229, 113742. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).