Temperature Field Analysis and Experimental Verification of Mining High-Power Explosion-Proof Integrated Variable-Frequency Permanent Magnet Motor

Abstract

1. Introduction

2. Research Object and Methods

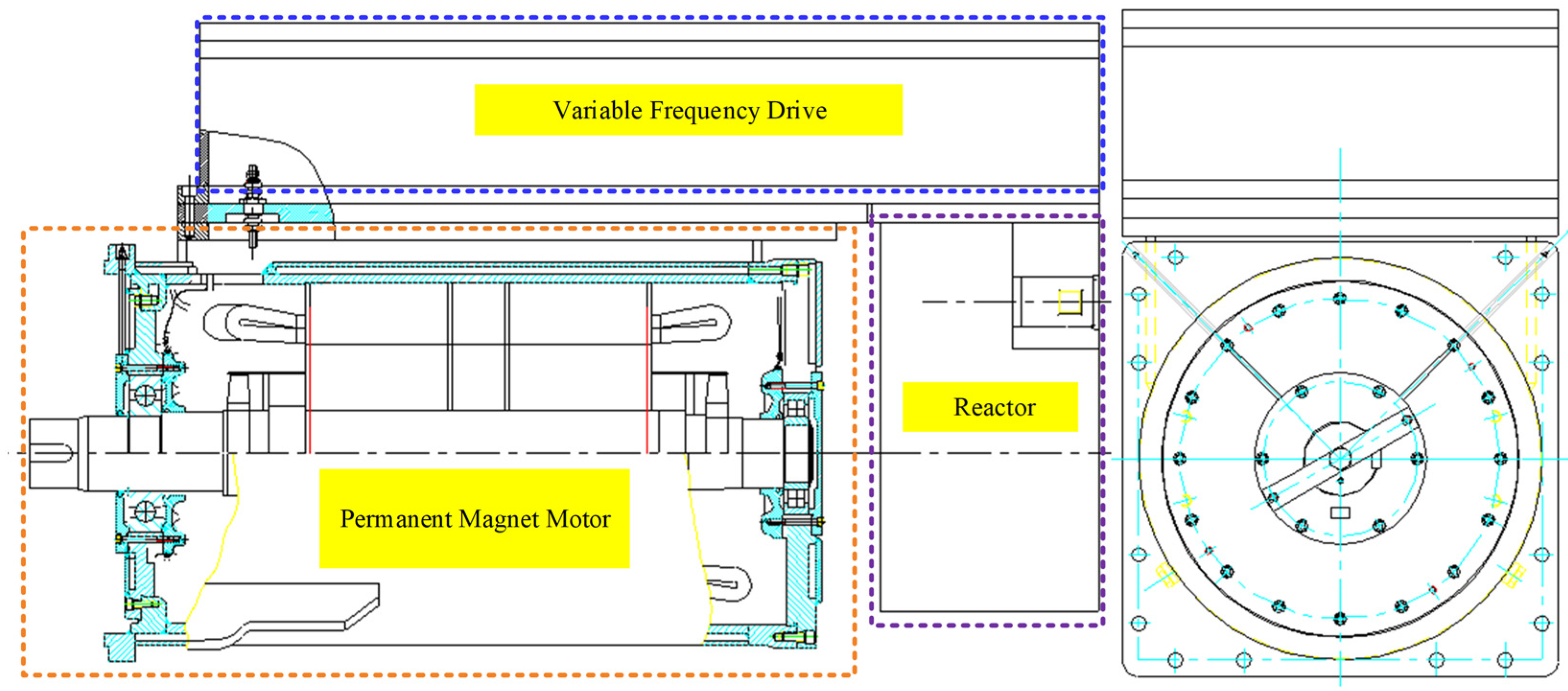

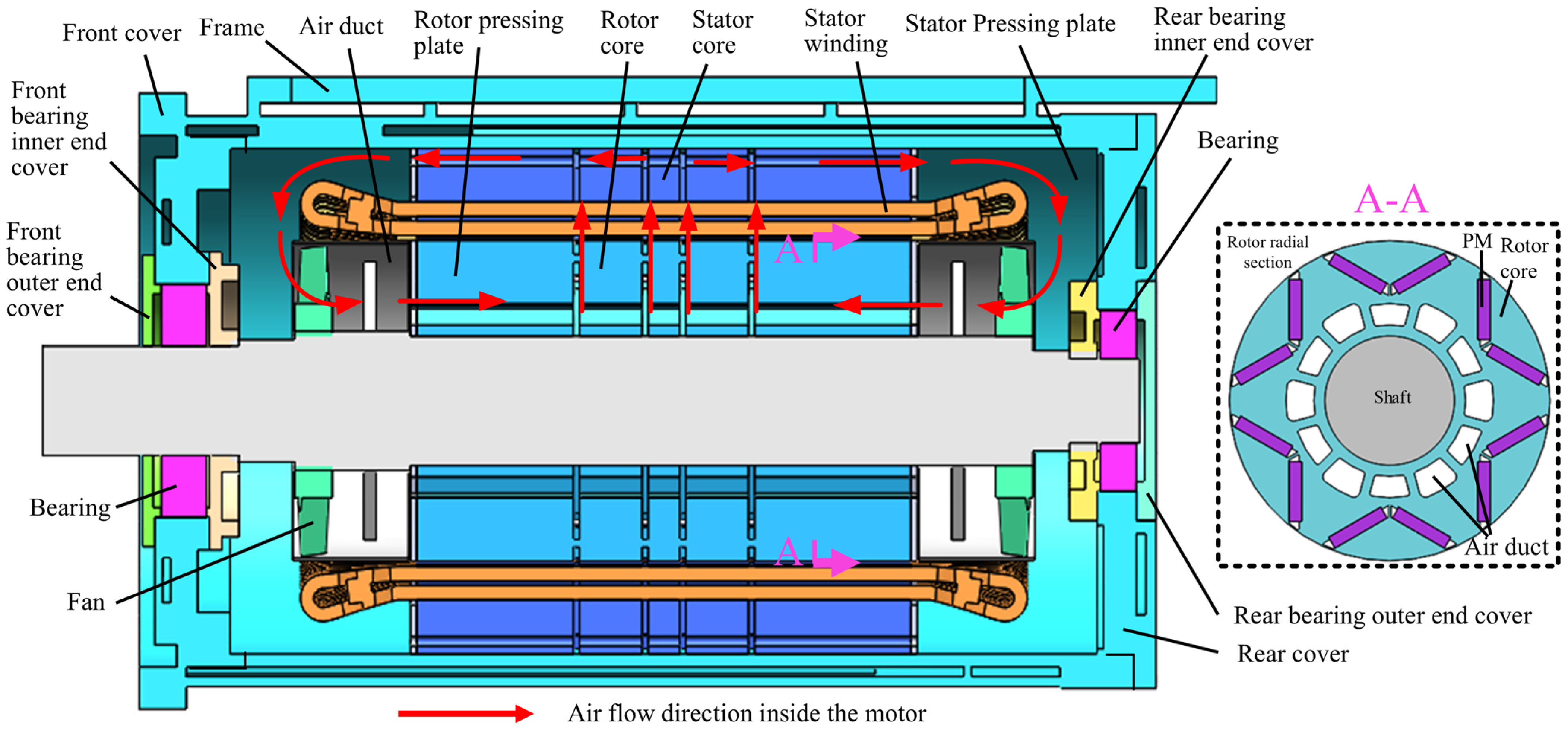

2.1. Structural Design of High-Power Explosion-Proof Variable-Frequency Permanent Magnet Motors

- Axial Aspect: The axial flow fan provides a strong main airflow, ensuring basic cooling performance.

- Radial Aspect: Radial air ducts accurately direct cold air to internal heat sources, such as the rotor and stator core, effectively reducing the temperature of hotspots.

- Synergistic Effect: The integration of the two systems (axial and radial) achieves an optimal balance between overall axial heat dissipation and localized radial intensive cooling, significantly enhancing cooling uniformity and efficiency. Notably, this combined scheme is not a simple superposition of individual components but a systematic optimization targeting the inherent drawbacks of pure axial and pure radial ventilation schemes.

2.2. Mathematical Model and Boundary Conditions

2.2.1. Mathematical Model

2.2.2. Boundary Conditions

- (1)

- The losses in each part of the motor did not change with temperature and were applied as heat sources at the corresponding heat-generating locations. Stray losses were applied to the stator and rotor cores at a proportional ratio of 4:1, respectively.

- (2)

- The physical parameters of each medium in the water cooling system did not change with temperature.

- (3)

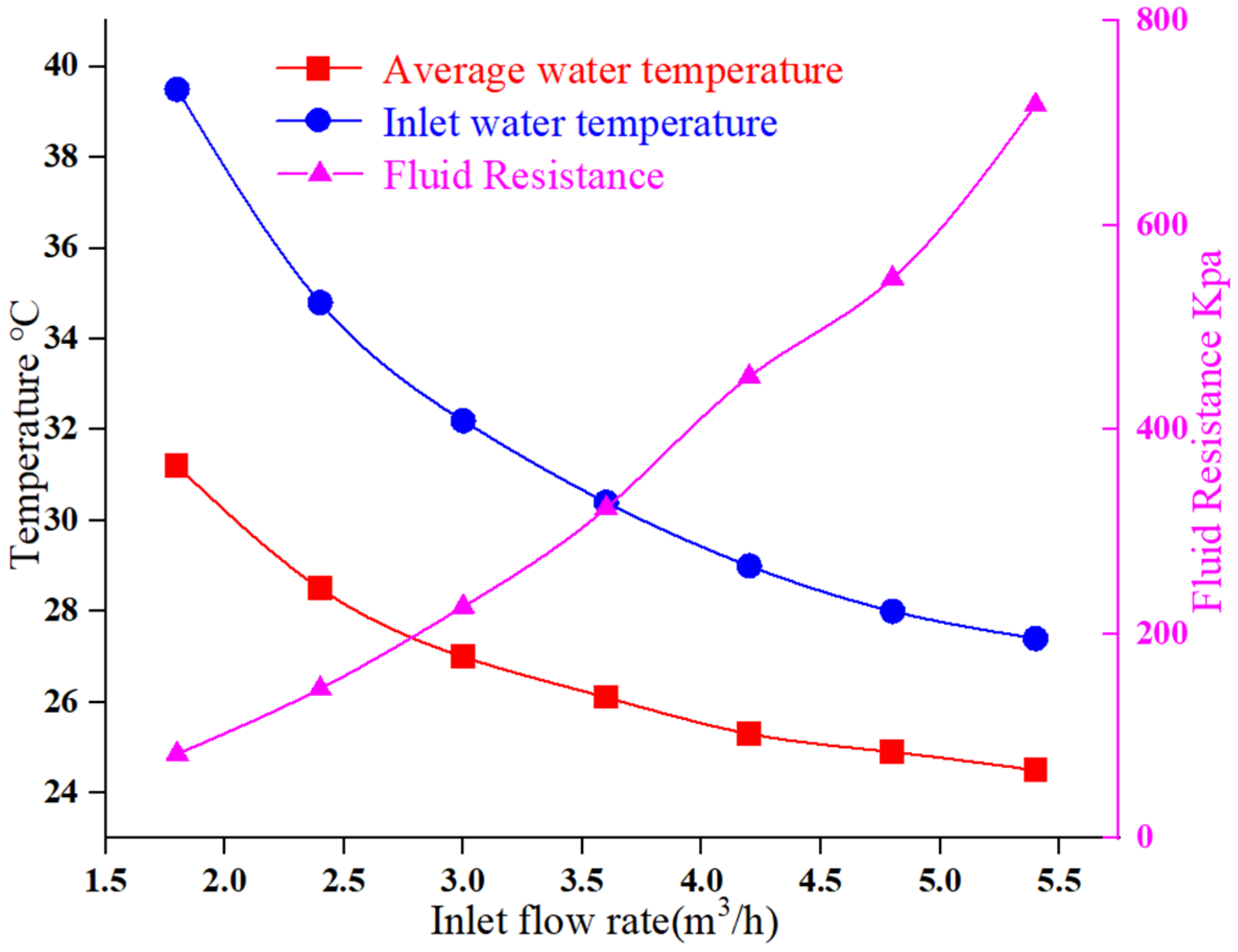

- The inlet boundary adopted a mass flow inlet, and inlet flow rates of 1.8, 2.4, 3, 3.6, 4.2, 4.8, and 5.4 m3/h were selected for verification. The outlet was set as a standard atmospheric pressure outlet, and both the initial water temperature and ambient temperature were set to 21 °C.

- (4)

- The motor was a rotating machine, and a multiple reference frame was adopted. The contact surfaces between the fluid and solid were set as no-slip wall boundaries. The RNG k-ε turbulence model was used, and an enhanced wall treatment was recommended.

3. Analysis of Motor Flow Field and Temperature Field

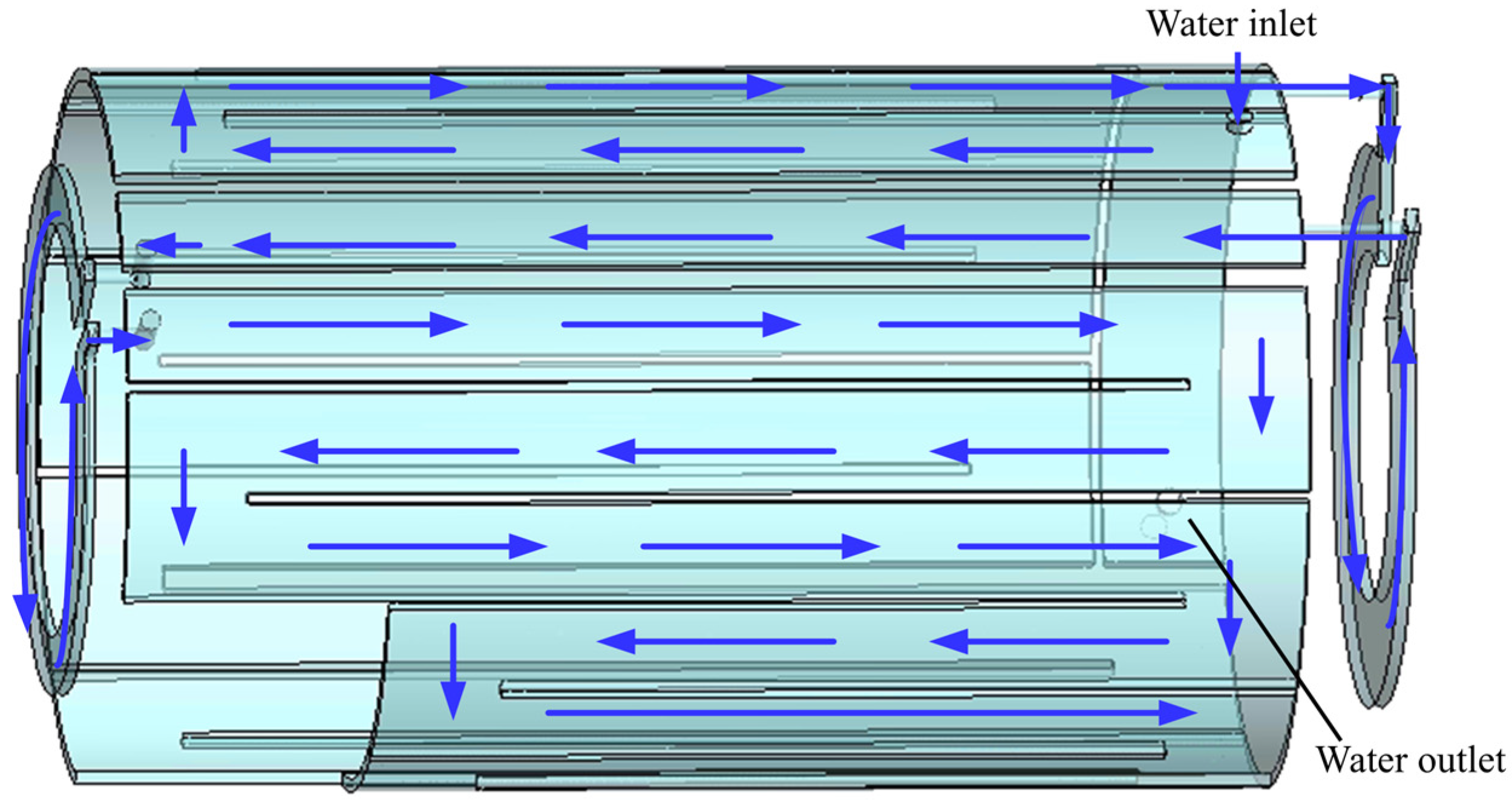

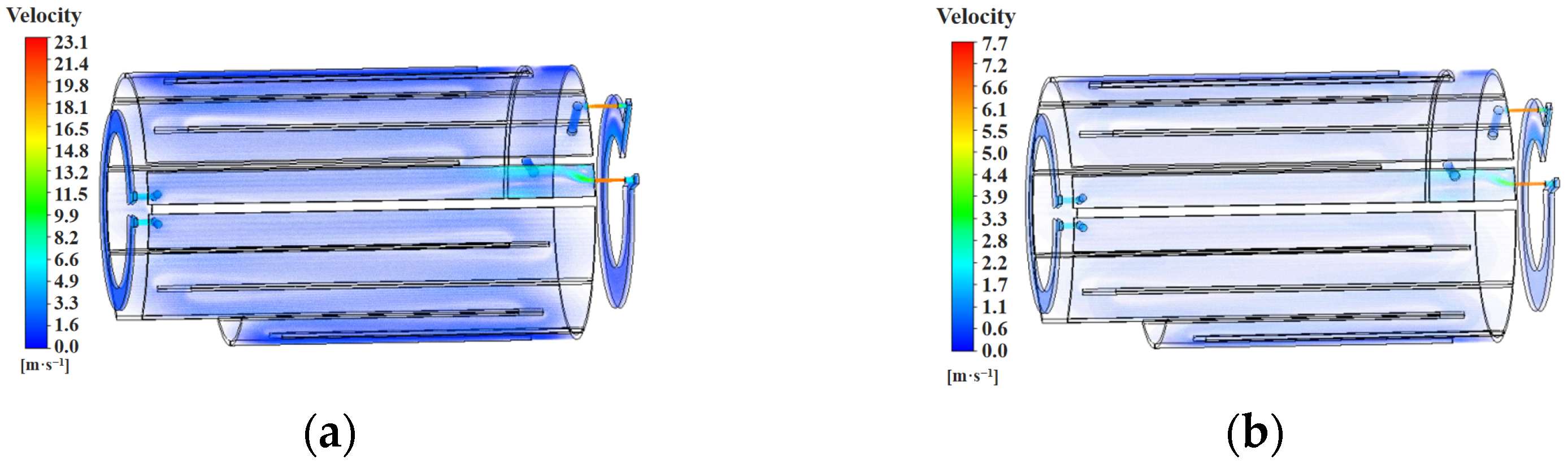

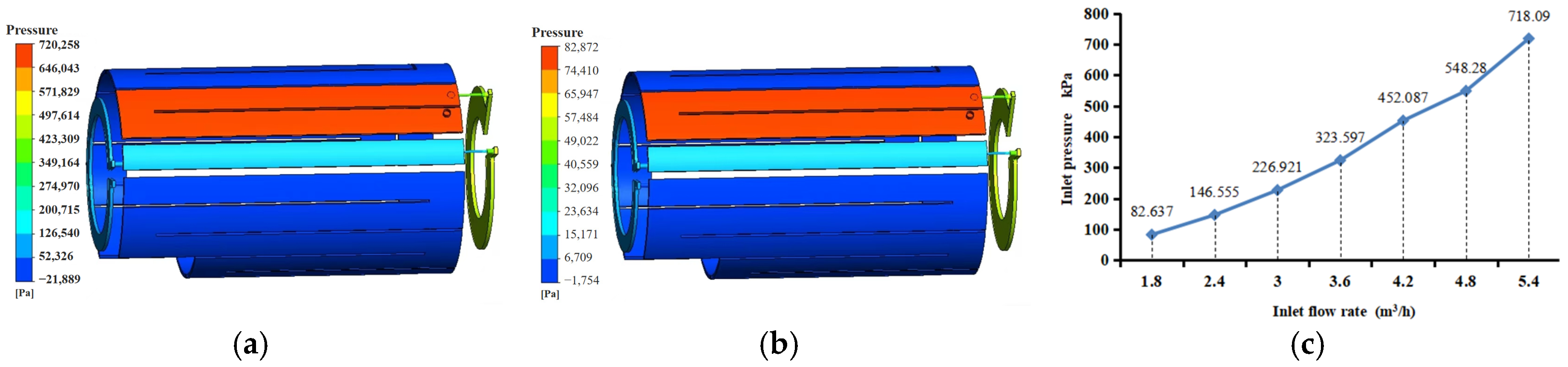

3.1. Analysis of Cooling Water Flow Performance

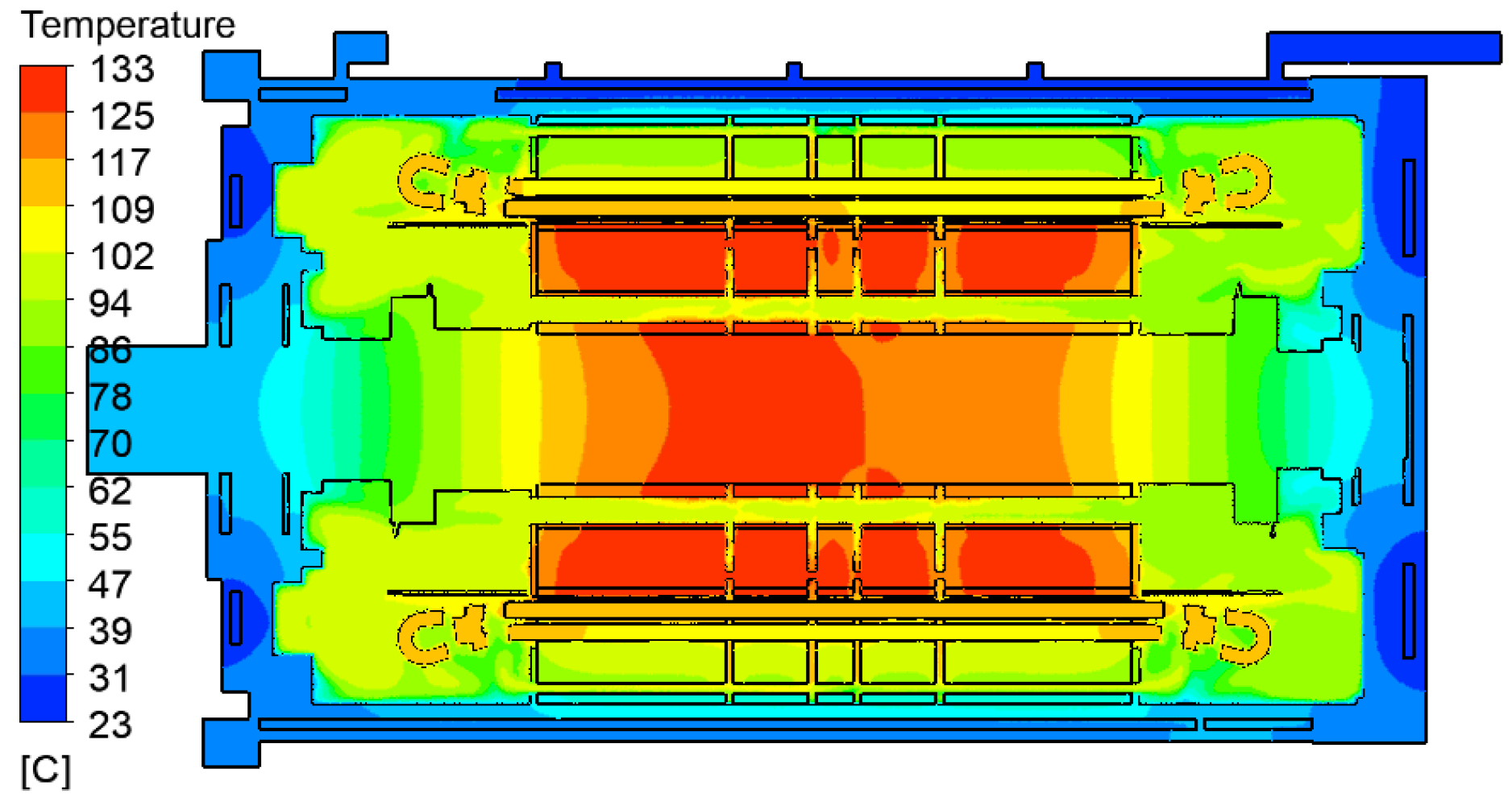

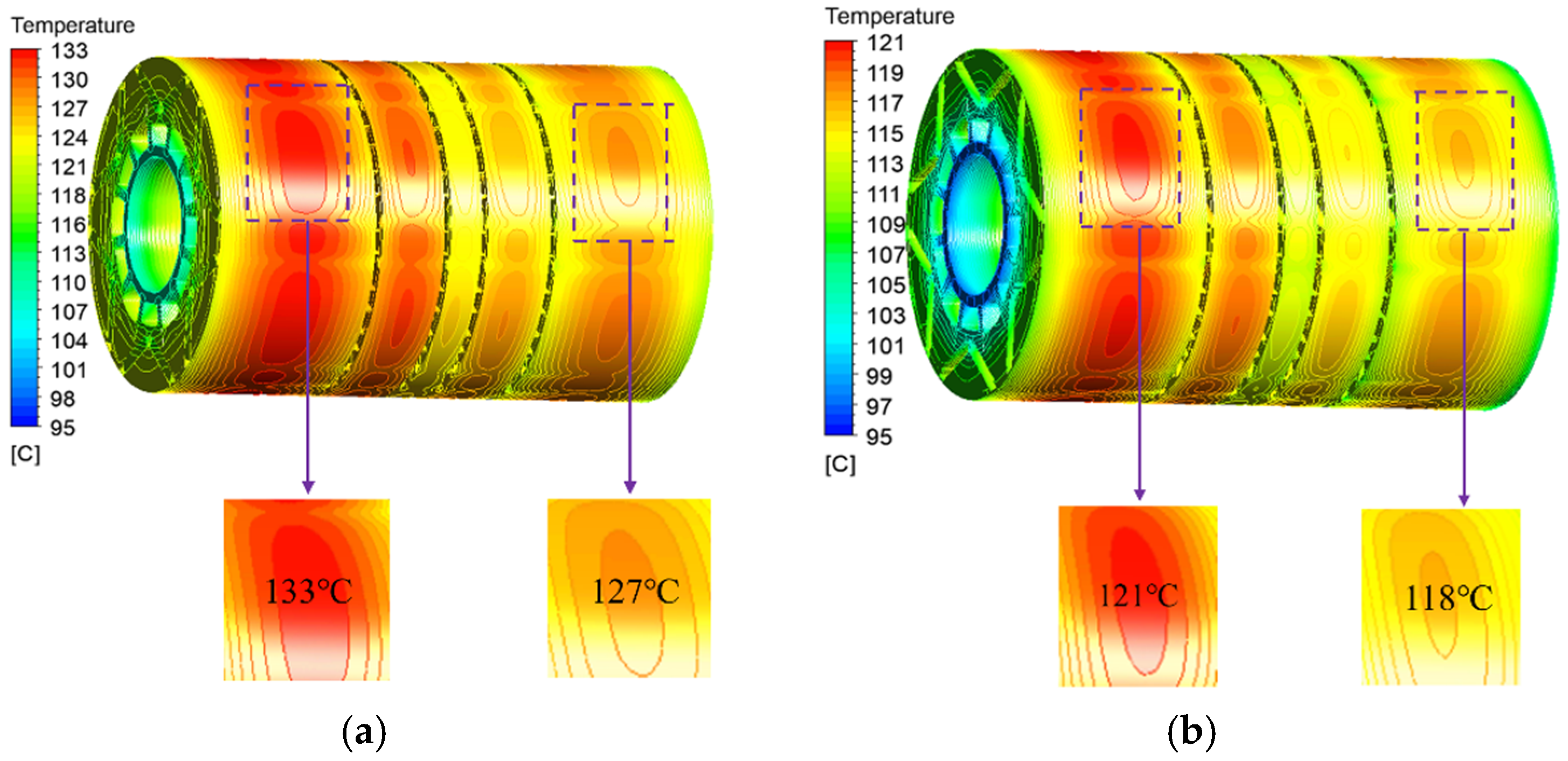

3.2. Analysis of Temperature Characteristics

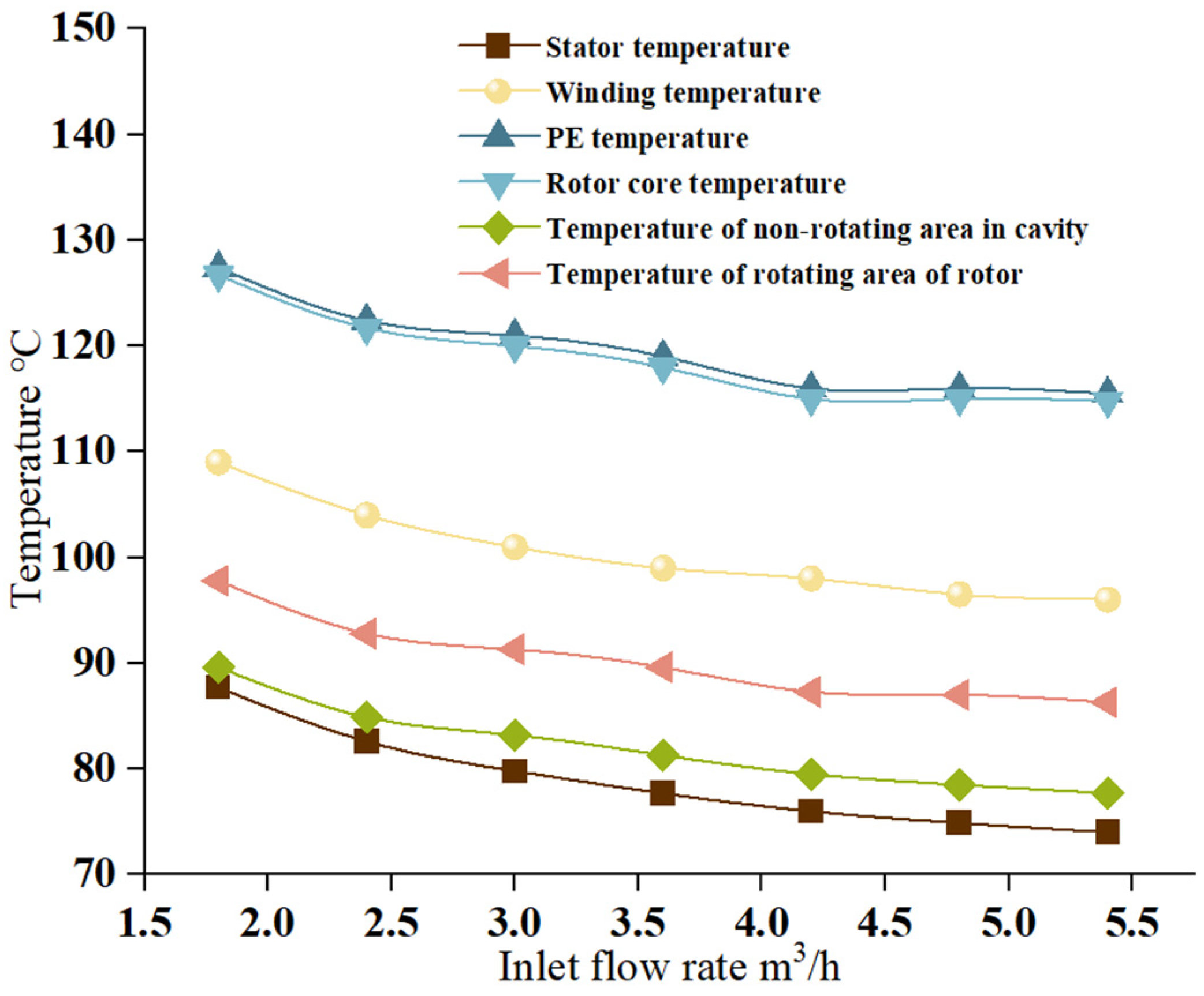

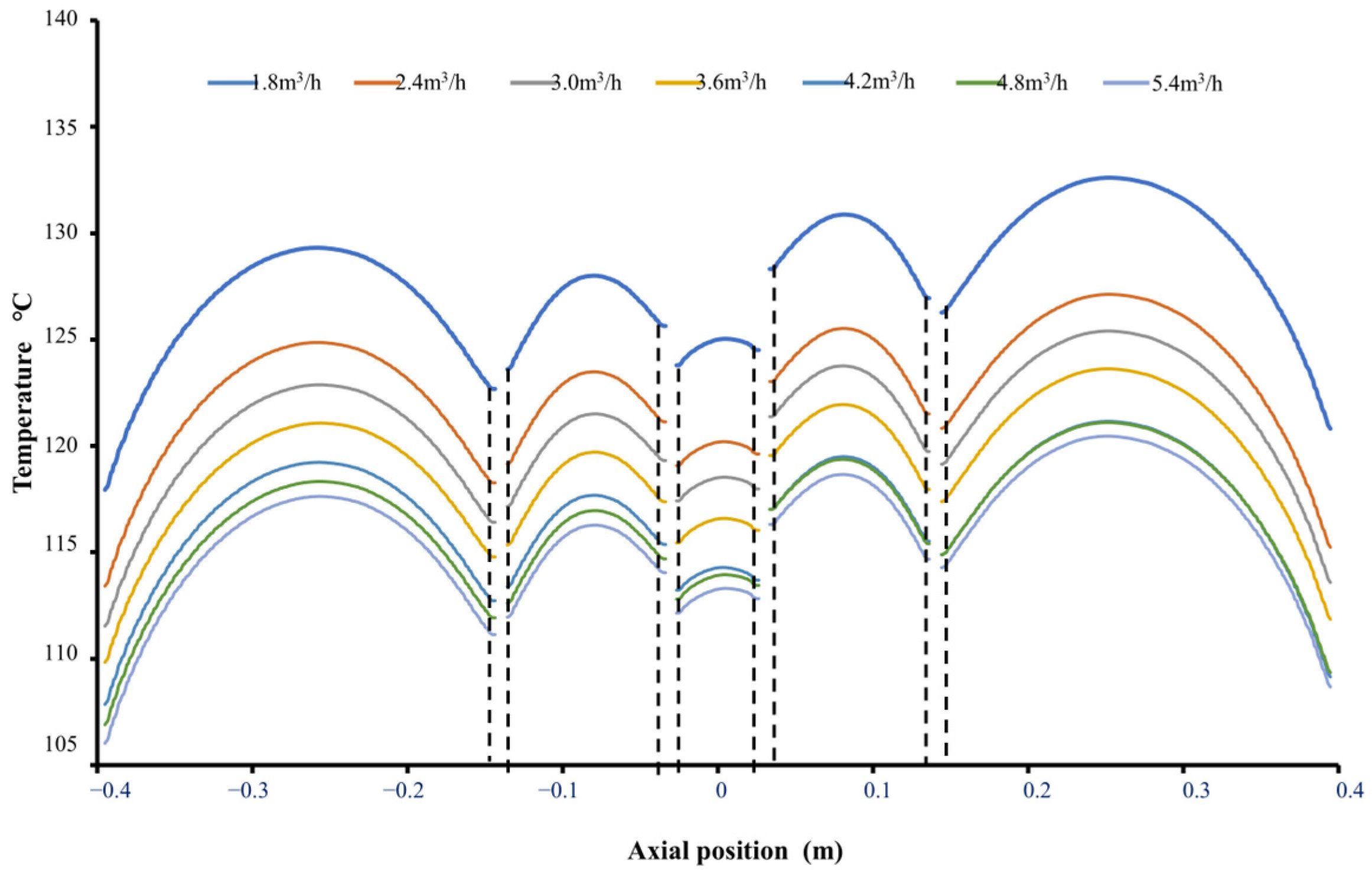

3.3. The Influence of Different Water Flow Rates on the Temperature of Motor Components and Pressure Drop

4. Discussion

5. Conclusions

- Within the water flow rate range of 1.8–5.4 m3/h, the temperature difference between the various components of the motor remained constant and was independent of the water flow rate. The temperature in the stator region was approximately 20 °C lower than that in the rotor region. The new cooling scheme can transfer heat to the low-temperature region of the stator through axial and radial ventilation ducts for effective heat dissipation, thereby solving the problem of difficult heat dissipation in the rotor.

- The simulation results showed that changes in the inlet flow rate of the cooling water led to differences in the motor-temperature distribution. As the water flow rate increased, the overall temperature of the motor decreased; however, the temperature reduction in the permanent magnet was limited, resulting in low cooling efficiency. When the cooling water flow rate was 3.6 m3/h, the pressure loss in the water channel was reduced by 54.9%. The winding temperature differed by only 3 °C compared with that at the maximum water flow rate of 5.4 m3/h, indicating high cooling efficiency. Considering the flow rate and pressure requirements of the water supply system, a cooling water flow rate of 3.6 m3/h can achieve optimal cooling performance under the premise of minimizing costs, thereby improving the operational economy and reliability of the motor.

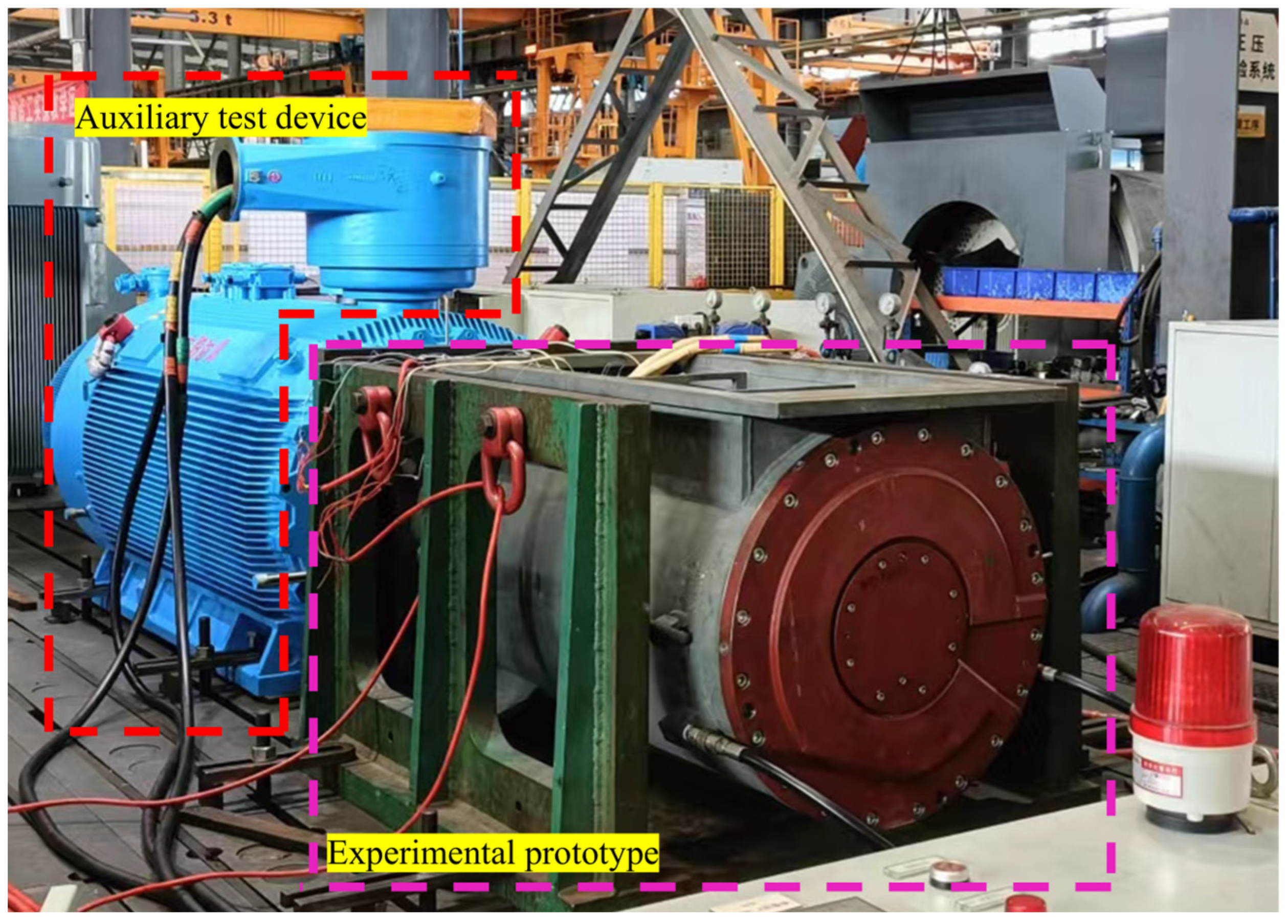

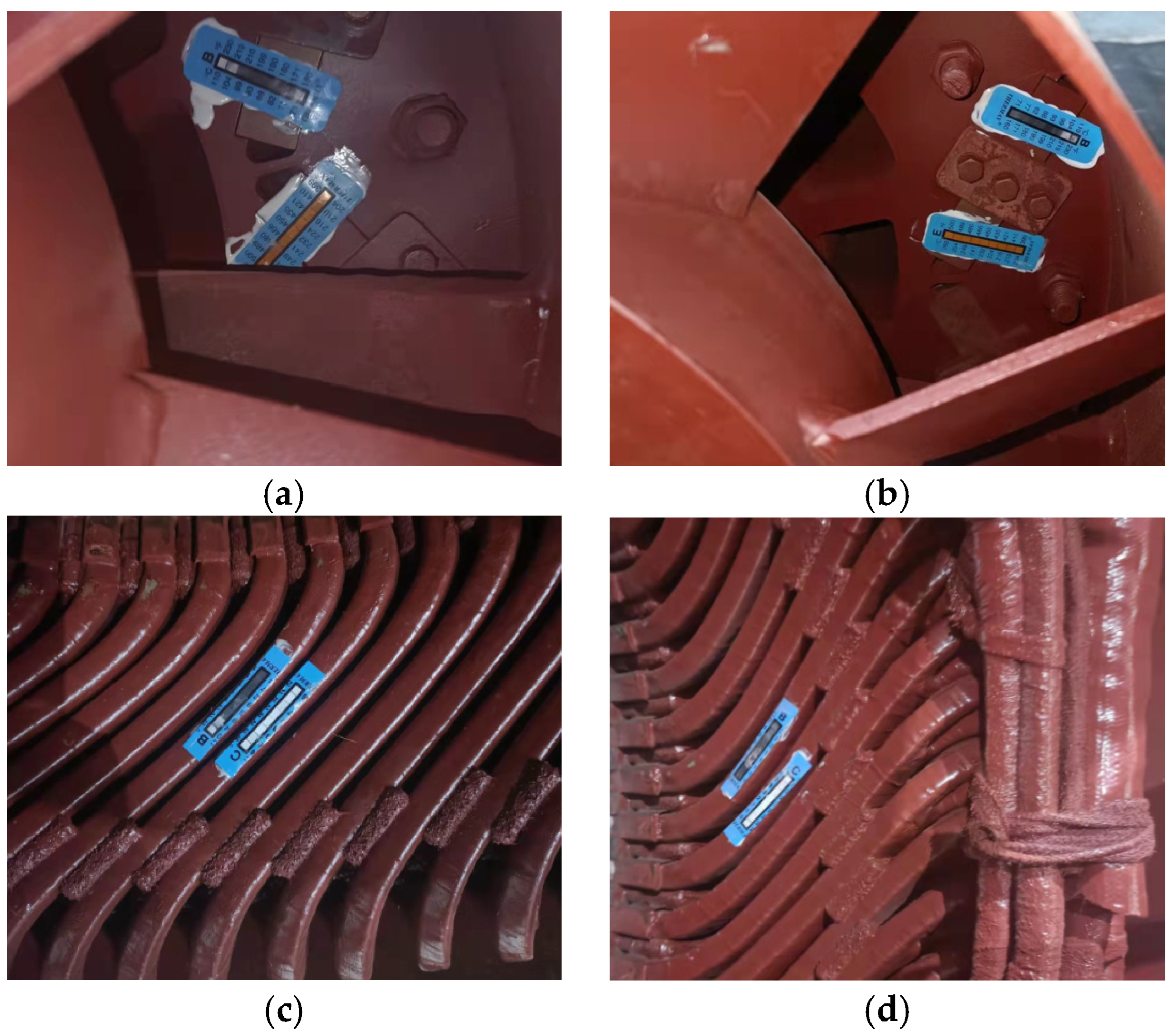

- Compared with the experimental test data, the maximum temperature error at the measurement points of the winding ends and rotor was 4.8%. Additionally, the motor temperature increase obtained from the simulation was 78 K, with an error of 2.7% compared with the experimental result. These results verify the effectiveness and accuracy of the proposed approach.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tang, R.Y.; Zhao, Q.; Zhou, T. Rare earth permanent magnet electrical machines stepping a new period of rapid development. J. Shenyang Univ. Technol. 2011, 33, 1–8. [Google Scholar]

- Zhang, F.G.; Du, G.H.; Wang, T.Y.; Liu, G.W. Review on Development and Design of High Speed Machines. Trans. China Electrotech. Soc. 2016, 31, 1–18. [Google Scholar]

- Dong, J.N.; Huang, Y.K.; Jin, L.; Lin, H.Y. Review on High Speed Permanent Magnet Machines Including Design and Analysis Technologies. Proc. CSEE 2010, 30, 78–83. [Google Scholar]

- Yang, M.; Zhao, L.H.; Ma, J.Z.; He, Z.Q.; Li, Y.X. Investigation of Distributed Winding Topologies on Surface-Mounted Permanent Magnet Machines. Small Spec. Electr. Mach. 2011, 50, 14–21. [Google Scholar]

- Hou, H.W.; Qin, Z. Research and analysis of temperature field on mine permanent magnet direct drive motor. Coal Sci. Technol. 2021, 49, 219–224. [Google Scholar]

- Xie, B.C.; Zhang, Y.; Wang, J.Q.; Liang, B.X.; Zhang, F.G. An efficient multidisciplinary design research for the integrated low speed permanent magnet motor system based on analytical and numerical hybrid analysis. Energy Rep. 2022, 8, 199–208. [Google Scholar] [CrossRef]

- Wei, Q.; Feng, G.H.; Zhang, B.Y. Cooling system of direct drive PMSM for mining belt conveyor. J. Mech. Electr. Eng. 2019, 36, 873–878. [Google Scholar]

- Xia, W.G. Design of Water-Cooling System for Mine-Used Flameproof Permanent Magnet Synchronous Motor. New Technol. New Prod. China 2020, 3, 12. [Google Scholar]

- Han, J.D.; Sun, P.; Zhu, L.B.; Lu, Y.P.; Zhu, J.N. 3D CFD thermal calculation for a vertical asynchronous motor with a squirrel-cage rotor. Electr. Mach. Control 2020, 24, 55–61. [Google Scholar]

- Karakatsanis, T.S. Optimization and Performance Evaluation of PM Motor and Induction Motor for Marine Propulsion Systems. Appl. Syst. Innov. 2025, 8, 58. [Google Scholar] [CrossRef]

- Cao, Z.B.; Li, W.L.; Zhang, X.C.; Fan, Y.; Zeng, J.J. Influence of single/dual ventilation path on fluid field and temperature field of HVLSSR-PMSM with air-cooled hybrid ventilation systems. Energies 2018, 11, 1343. [Google Scholar] [CrossRef]

- Wang, S.W.; Jiang, M.; Zhu, B.L.; Liu, M.L. Three-Dimensional Temperature Field Investigation of Variable-Frequency Adjustable-Speed Water-Cooled Permanent Magnet Synchronous Motor for Vehicle. Electr. Mach. Control Appl. 2017, 231, 43–51. [Google Scholar]

- Li, C.; Huang, F.C.; Wang, Y.Q. An applicable real-time thermal model for temperature prediction of permanent magnet synchronous motor. J. Syst. Control Eng. 2017, 231, 43–51. [Google Scholar] [CrossRef]

- Du, G.H.; Xu, W.; Zhu, J.G.; Huang, N. Power Loss and Thermal Analysis for High-Power High-Speed Permanent Magnet Machines. IEEE Trans. Ind. Electron. 2020, 67, 2722–2733. [Google Scholar] [CrossRef]

- Wu, S.N.; Hao, D.Q.; Tong, W.M. Temperature Field Analysis of Mine Flameproof Outer Rotor Permanent Magnet Synchronous Motor with Different Cooling Schemes. CES Trans. Electr. Mach. Syst. 2022, 6, 162–169. [Google Scholar] [CrossRef]

- Sebastien, S.; Kevin, B.; Emily, C.J.; Sreekant, N.; Gilberto, M.; Satish, K.; Yogendra, J. Validation and Parametric Investigations of an Internal Permanent Magnet Motor Using a Lumped Parameter Thermal Model. J. Electron. Packag. 2022, 144, 021114. [Google Scholar] [CrossRef]

- Zhang, W.; Li, G.J.; Zhu, Z.Q.; Ren, B.; Chong, Y.C. Semi-flooded cooling for high torque density modular permanent magnet machines. IET Electr. Power Appl. 2024, 18, 756–765. [Google Scholar] [CrossRef]

- Nguyen, M.D.; Woo, J.H.; Shin, H.S.; Lee, Y.K.; Lee, H.K.; Shin, K.H.; Phung, A.T.; Choi, J.Y. Thermal analysis and experimental verification of permanent magnet synchronous motor by combining lumped parameter thermal networks with analytical method. AIP Adv. 2023, 13, 025140. [Google Scholar] [CrossRef]

- Zhu, E.H.; Liang, Y.P.; He, L.L. Research on Temperature Rise of the Large-Capacity Air-Cooled Synchronous Condenser. J. Electr. Eng. Technol. 2025, 20, 1679–1689. [Google Scholar] [CrossRef]

- Gao, L.L.; Liu, X.; Liu, H. Analytical Calculation of Magnetic Field and Temperature Field of Surface Mounted Permanent Magnet Synchronous Motor. J. Electr. Eng. Technol. 2025, 20, 2249–2262. [Google Scholar] [CrossRef]

- Yi, Y.L.; Ma, S.; Zhang, B.; Feng, W. Application of High Efficiency and High Precision Network Algorithm in Thermal Capacity Design of Modular Permanent Magnet Fault-Tolerant Motor. Energies 2025, 18, 3967. [Google Scholar] [CrossRef]

- Liu, H.; Chen, W.W.; Liu, D.; Chu, N.N. Design and Analysis of Cooling System for Dual-Stator Permanent Magnet Wind Power Generator. J. Electr. Eng. Technol. 2025, 20, 4135–4147. [Google Scholar] [CrossRef]

- Cao, L.F.; Fan, X.G.; Li, D.W.; Qu, R.H.; Liu, J.Y. Semi-Analytical and Efficient Calculation Method of Eddy Current Loss in Windings of Permanent Magnet Machines Based on Fast Finite Element Method. Trans. China Electrotech. Soc. 2023, 38, 153–165. [Google Scholar]

- Shi, W.; Luo, K.C.; Zhang, Z.Y. On-Line Temperature Estimation of Permanent Magnet Motor Based on Lumped Parameter Thermal Network Method. Trans. China Electrotech. Soc. 2023, 38, 2686–2697. [Google Scholar]

- Wu, Y.; Zhang, Z.F.; Ping, J.Q. New Type Water Cooling Structure Design and Temperature Field Analysis of High Power Density Axial Flux Permanent Magnet Motor. Proc. CSEE 2021, 41, 8295–8305. [Google Scholar]

- Han, X.Y.; Zhang, H.W.; Xu, X.; Lan, Y.H. Design of Cooling System for Amorphous Alloy Axial Flux Permanent Magnet Motor Based on Computational Fluid Dynamics. Trans. China Electrotech. Soc. 2017, 32, 189–197. [Google Scholar]

- Chen, L.X.; Liu, D.; Zhang, C.; Sun, N. Design and analysis of ultra-high speed permanent magnet motor cooling system based on multi-physical field. Electr. Mach. Control 2023, 27, 113–123. [Google Scholar]

| Parameter | Value |

|---|---|

| Rated Power/kW | 1600 |

| Rated Voltage/V | 3300 |

| Rated Speed/rpm | 1500 |

| Number of Stator Slots | 72 |

| Air Gap/mm | 2.5 |

| Stator Winding Loss (W) | 8756 |

| Stator Core Loss (W) | 15,138 |

| Rotor Core Loss (W) | 1744 |

| Permanent Magnet Loss (W) | 282 |

| Mechanical Loss (W) | 2419 |

| Stray Loss (W) | 8000 |

| Temperature of the Measuring Point at the Winding End of the Shaft Extension End | Temperature of the Measuring Point at the Winding End of the Non-Shaft Extension End | Temperature of the Rotor Measuring Point at the Shaft Extension End | Temperature of the Rotor Measuring Point at the Non-Shaft Extension End | |

|---|---|---|---|---|

| Simulation (℃) | 114 | 109 | 103 | 102 |

| Experimental Value (℃) | 110 | 104 | 99 | 99 |

| Error (%) | 3.6 | 4.8 | 4 | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Tian, G.; Lü, Q.; Zhao, K.; Wu, X.; Yang, L.; Li, G. Temperature Field Analysis and Experimental Verification of Mining High-Power Explosion-Proof Integrated Variable-Frequency Permanent Magnet Motor. Energies 2025, 18, 5369. https://doi.org/10.3390/en18205369

Wang X, Tian G, Lü Q, Zhao K, Wu X, Yang L, Li G. Temperature Field Analysis and Experimental Verification of Mining High-Power Explosion-Proof Integrated Variable-Frequency Permanent Magnet Motor. Energies. 2025; 18(20):5369. https://doi.org/10.3390/en18205369

Chicago/Turabian StyleWang, Xiaojun, Gaowei Tian, Qingqing Lü, Kun Zhao, Xuandong Wu, Liquan Yang, and Guangxi Li. 2025. "Temperature Field Analysis and Experimental Verification of Mining High-Power Explosion-Proof Integrated Variable-Frequency Permanent Magnet Motor" Energies 18, no. 20: 5369. https://doi.org/10.3390/en18205369

APA StyleWang, X., Tian, G., Lü, Q., Zhao, K., Wu, X., Yang, L., & Li, G. (2025). Temperature Field Analysis and Experimental Verification of Mining High-Power Explosion-Proof Integrated Variable-Frequency Permanent Magnet Motor. Energies, 18(20), 5369. https://doi.org/10.3390/en18205369