1. Introduction

Cryogenic propellants are fuels and oxidizers stored at extremely low temperatures to maintain their liquid phase, thereby enabling high-performance rocket propulsion. They are indispensable for space exploration because of their high specific impulse, which directly enhances the efficiency of launch and in-space transportation systems. In practice, the primary cryogenic propellants are liquid hydrogen (LH

2, boiling point 20.27 K/−252.88 °C/−423.18 °F), liquid oxygen (LOX, 90.19 K/−182.96 °C/−297.33 °F), and liquid methane (LCH

4, 111.66 K/−161.49 °C/−258.68 °F), which serve as the main propulsive fuels and oxidizers. Other cryogenic fluids, such as liquid nitrogen (LN

2, 77.36 K/−195.79 °C/−320.42 °F), liquid argon (LAr, 87.30 K/−185.85 °C/−302.53 °F), and liquid fluorine (LF

2, 85.03 K/−188.12 °C/−306.62 °F), are not generally employed as power propellants but have critical roles in aerospace systems. For instance, LN

2 is widely used as a simulant for cryogenic propellant sloshing studies, as a pressurant and coolant in ground and flight systems, and as a working 6 fluid in cold-gas thrusters for satellite attitude control. Additionally, slush hydrogen (SLH

2) a solid–liquid mixture of hydrogen maintained below 20.27 K (−252.88 °C/−423.18 °F) has been developed to increase storage density and efficiency [

1,

2,

3,

4].

Cryogenic propellants have long enabled high-performance rocketry, but the real bottleneck today is not just storing very cold fluids; it is minimizing the relentless energy losses that erode mission margins.

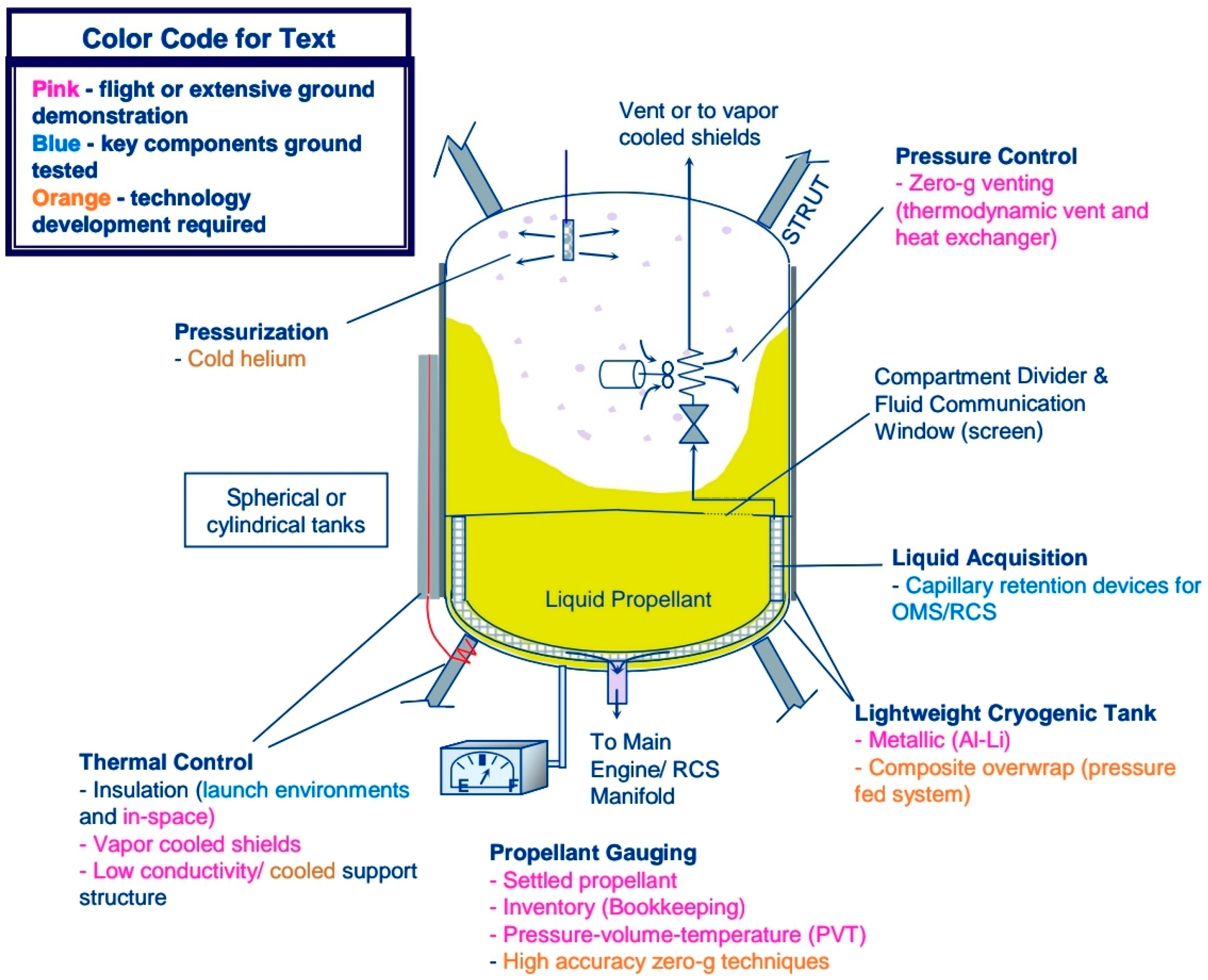

Figure 1 shows a representative cryogenic tank, where every watt of parasitic heat leak (through supports, penetrations, and imperfect MLI), every vented gram from boil-off control, and every transient during chill-down, pressurization, or settling translates directly into lost propulsive efficiency. In microgravity, additional penalties arise stratification and geysering complicate autogenous pressurization, sloshing and vapour ingestion force conservative throttle windows, and propellant management devices incur pressure drops that must be overcome each form of dissipated useful energy [

5,

6].

Historically, early Mercury-era drop-tower tests and the Centaur/S-IV operational stages proved cryogenic propulsion’s promise while revealing its inefficiencies over time: extended loiter meant mounting boil-off, venting losses, and thermal cycling of tanks. Since then, Cryogenic Fluid Management (CFM) research has increasingly targeted the full dissipation path from external heat leaks to internal mixing and vent control. Programs such as CONE, CFME, and the proposed COLD-Sat reframed the problem around quantifying and closing energy budgets in reduced gravity. Building on that, the CPST campaign focuses on system-level demonstrations: advanced thermal control to suppress boil-off, low-loss transfer and chill-down to cut start-up waste, and integrated operations that keep vapour generation and venting within tight bounds over mission timelines.

Densification is a powerful lever in this efficiency picture. Subcooling LH2 and LOX to boost density (≈8% and ≈10%, respectively) improves tankage fraction and can drive vehicle gross-mass reductions on the order of tens of percent. But that gain is only net-positive if the refrigeration work, ground-side handling penalties, and on-orbit heat-soak margins are managed so the saved structural and boil-off energy outweigh the extra cooling cost. Modern efforts including renewed interest in subcooled and slush propellants therefore treat densification not as a static property change, but as a system optimization: reduce boil-off, preserve pump NPSH margins, shorten chill-down, and limit venting, all while keeping the refrigeration energy and added complexity within the overall mission energy budget.

Research on cryogenic fluid management in microgravity has increasingly focused on identifying and minimizing sources of energy dissipation, since every inefficiency whether through boil-off, venting, pressure drop, or thermal cycling directly reduces mission performance. Technologies such as Propellant Management Devices (PMD), Zero Boil-Off (ZBO) tanks, Vapour Cooling Systems (VCS), Thermodynamic Vent Systems (TVS), Propellant Transfer and Chill-Down (PTCD/TO), and Heterogeneous/Autogenous Pressurization (HP/AP) are all ultimately aimed at mitigating these dissipative pathways. For example, Ming He et al. [

8] optimized the design of a cryo-compressed hydrogen refuelling station by developing a heat transfer model to evaluate dynamic temperature evolution during precooling. Their work compared different inlet-diameter strategies and showed that the constant mass flow approach not only reduced hydrogen losses and boil-off, but also minimized thermal stresses on the tank, effectively eliminating the need for auxiliary heating. This illustrates how proper thermal and flow control directly translates to improved energy efficiency and reduced dissipation.

Among the most prominent energy-related inefficiencies is sloshing, the oscillatory motion of propellant within partially filled tanks. In everyday terms, it resembles coffee sloshing in a cup, but in aerospace it generates unplanned energy transfers that couple into vehicle dynamics, degrading stability and wasting control authority. NASA’s early investigations in the 1960s revealed how sloshing not only dissipates energy internally through turbulence and wave breaking but also forces external corrective actions that consume additional propulsive energy. These findings shaped the design of Centaur and Saturn stages, where engineers had to account for venting, pressurization, and roll control losses tied to slosh-driven disturbances.

Energy dissipation from sloshing is not unique to spacecraft. In ships, it reduces ballast efficiency; in cars and trains, it alters handling and braking forces. But in launch vehicles where liquid propellants dominate the gross mass fraction sloshing losses are magnified by the extreme acceleration environment. Every uncontrolled oscillation can force actuators and control systems to counteract wasted dynamic loads, consuming propellant and potentially inducing resonant oscillations that amplify dissipation further. For instance, early Saturn I missions demonstrated how roll instabilities were linked to sloshing resonance, forcing additional energy expenditure in stabilization.

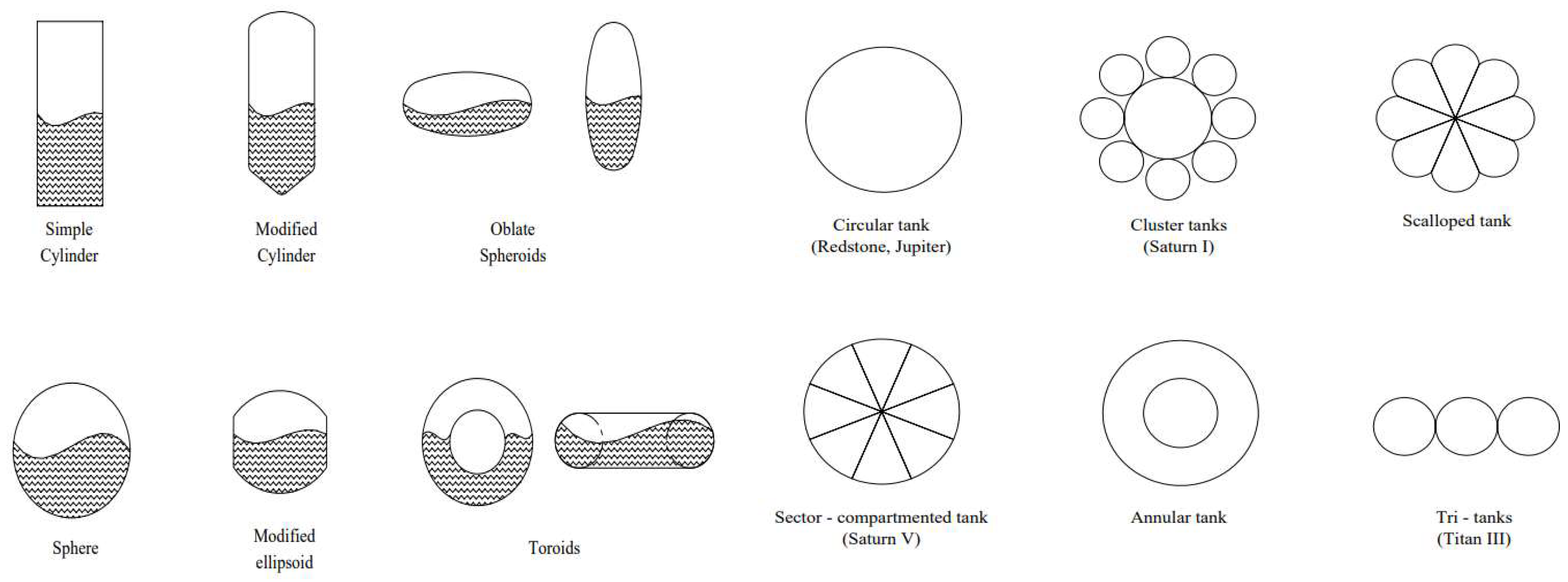

The degree of dissipation depends strongly on tank configuration. Large-diameter cylindrical tanks tend to have lower natural frequencies, making them more prone to resonance with structural or control-system modes, thus raising dissipation risks. Subdivided tanks or internal baffles can shift sloshing frequencies upward, but this introduces additional viscous losses and pressure drops, creating new energy pathways that must be balanced against control savings. As shown in

Figure 2, vehicle designers must therefore trade between slosh suppression (reducing dynamic losses) and structural efficiency (avoiding overbuilt, heavy solutions). Ultimately, sloshing is not just a fluid-mechanics curiosity it is a core energy challenge. Unchecked, it dissipates energy both internally (through mixing and turbulence) and externally (through unnecessary control work), reducing the overall efficiency of cryogenic propulsion systems [

9].

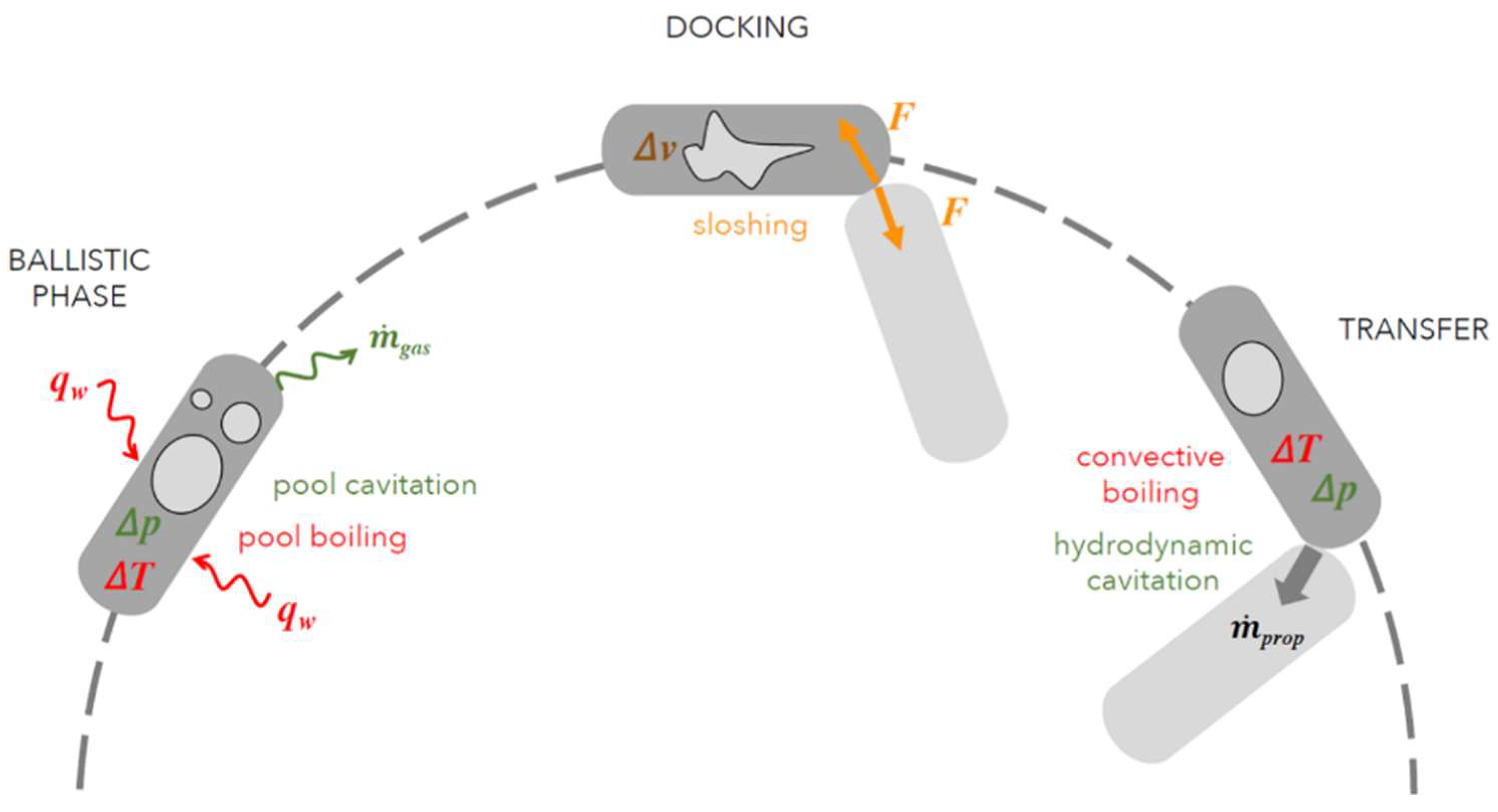

Sloshing manifests in multiple modes, each representing not just a stability issue but a pathway for energy dissipation that reduces overall propulsive efficiency. Lateral sloshing, driven by translational or pitching motions, dissipates energy into transverse oscillations that disturb trajectory control and force additional corrective thrusting. Vertical sloshing, induced by accelerations normal to the liquid surface, destabilizes propellant distribution and introduces interruptions in delivery, requiring pump or pressurization systems to expend extra energy to compensate. Swirl sloshing, triggered by vehicle roll or yaw, generates rotational flow structures that increase mixing losses and pressure drops, ultimately raising the energy cost of stable engine feed. At the extreme, vortex formation as illustrated in

Figure 3 and spray events represent direct propellant loss both wasted mass and wasted energy embedded in producing, storing, and cooling that propellant in the first place. In microgravity, where surface tension dominates, sloshing becomes highly unpredictable, creating irregular distributions that compromise the efficiency of transfer operations and orbital manoeuvres.

The absence of hydrostatic pressure in microgravity exacerbates these losses. Without gravity-driven stratification, cryogenic fluids can assume unstable or asymmetric configurations that shift the vehicle’s centre of mass, forcing continuous control corrections and wasting valuable propulsive energy. Uncontrolled sloshing also produces dynamic pressure fluctuations, transferring cyclic loads into tank walls and baffles. Over time, this leads to structural fatigue, a hidden form of energy dissipation was absorbed oscillatory energy gradually weakens materials. Sensor systems such as capacitance or thermal probes experience noise from sloshing, reducing the accuracy of gauging and often requiring redundant sensing or computational filtering, both of which add system-level energy cost. Interaction with internal structures (baffles, diaphragms) converts ordered oscillations into localized turbulence, raising heat transfer coefficients and increasing boil-off rates. In hydrogen systems, where density is low and volatility high, these localized disturbances translate into particularly high efficiency penalties.

Mitigating these losses requires accurate modelling and careful frequency management. If sloshing frequencies overlap with vehicle or control-system natural modes, resonance can amplify dissipation dramatically. Conversely, well-designed baffles or tank subdivisions can redirect slosh energy into higher-frequency modes where control systems can damp them more efficiently. Effective slosh mitigation is therefore not just a stability requirement it is an energy optimization strategy, ensuring that stored cryogens retain their useful enthalpy, control systems expend less corrective work, and mission energy budgets remain within acceptable bounds. This is especially vital for long-duration or reusable hydrogen-fueled vehicles, where even small rates of dissipation, if unchecked, accumulate into mission-threatening inefficiencies.

One of the most significant case studies highlighting the importance of understanding sloshing behaviour occurred during the Boeing Delta IV second-stage launch. In a particular mission, an independent review team from Analex Corporation identified discrepancies in the predicted behaviour of the second-stage cryogenic propellants, which differed significantly from the simulations conducted by Boeing and the Aerospace Corporation. Concerned about the potential risks, Boeing recommended delaying the launch until the inconsistencies were resolved. A collaborative investigation involving Boeing, the U.S. Air Force, the Aerospace Corporation, Flow Sciences, and Analex ultimately revealed that the liquid hydrogen (LH

2) in the second-stage tank was not constrained to the aft end during the coast phase, posing a serious mission risk. The unexpected presence of propellant in the forward dome of the tank venting could have resulted in propellant ingestion into the vent/relief system, leading to a thrust imbalance. To mitigate this issue, the team implemented a pulse-settling approach for propellant management, demonstrating the critical need for accurate sloshing behaviour predictions in spaceflight operations [

11].

2. Basic Equations of Sloshing and Heat Transfer in Cryogenic Pressure Vessel

Understanding the coupled dynamics of sloshing and heat transfer in cryogenic pressure vessels is essential for predicting vehicle stability, structural integrity, and long-term propellant retention. Sloshing defines the natural frequencies and hydrodynamic forces induced when the liquid mass oscillates under external excitations, directly influencing guidance and control margins as well as structural fatigue. Heat transfer, in parallel, governs the rate of energy ingress through conduction, convection, and radiation, ultimately driving liquid vaporization and boil-off that degrade performance and reduce mission endurance. Both phenomena are tightly linked: vigorous sloshing enhances internal convection, accelerates wall-to-fluid heat exchange, and can amplify boil-off in low-gravity environments. To capture these effects, simplified analytical models provide first-order estimates of slosh frequencies, forces, and pressure rise, while classical heat-transfer relations quantify thermal leakage and boil-off rates. Although these formulations rely on idealized assumptions rigid walls, small-amplitude motion, gray/diffuse surfaces they remain indispensable for preliminary design, system sizing, and control-law development. More advanced CFD, SPH, and FSI models can resolve nonlinearities and microgravity-specific behaviours, but the analytical framework presented here establishes the baseline equations used to characterize sloshing and heat transfer in cryogenic tanks [

12], and to highlight the trade-offs that drive insulation design, baffle placement, and thermal control strategies.

To calculate the natural frequency of a cylindrical tank, the equations are expressed as follows

where

means the angular frequency cylindrical tank (

, r is the tank radius, g is the gravitational acceleration, h is the liquid height, and

denotes the root of the eigenvalue equation. For the natural frequency of a spherical Tank the expressions used are:

where

is the natural angular frequency (spherical tank) g is the gravitational acceleration, R tank radius,

the empirical constant based on liquid height and tank radius.

The natural frequency for both planar and non-planar motion can be estimated using these equations:

is the excitation frequency,

The excitation amplitude

are the empirical constants [

13,

14,

15].

Equations (1) and (2) (natural slosh frequency in cylindrical tanks), consider small-amplitude eigenmodes in a right circular cylinder at a specified fill height under a given gravity level, assuming inviscid potential flow, rigid walls, and linear free-surface motion; it matters because it flags resonance with vehicle/attitude-control modes and informs baffle spacing and controller detuning; limitations: large amplitudes, internal hardware/baffles, and micro-g capillary effects shift frequencies and add damping beyond linear theory; for Equation (3) (natural slosh frequency in spherical tanks), consider the first-mode response with a fill-dependent parameter λ under linear potential-flow assumptions and rigid boundaries; it matters because spherical LH2/LOX tanks are common and the mode frequency bounds loads and control bandwidth; limitations: contact-line hysteresis and capillary dominance in low-g invalidate linear predictions and increase fill-ratio sensitivity; and for Equation (4) (nonlinear/empirical amplitude–frequency correction), consider frequency softening/stiffening under finite excitation amplitude relative to geometry R with coefficients , fitted over a tested range; it matters because it captures operational resonance shifts during large manoeuvres not seen in linear spectra; limitations: coefficients are not universal and must be re-identified for tank geometry, fill level, and the presence of baffles/internals.

Sloshing Forces and Moments. Under external excitation, the fluid exerts pressure and viscous shear on the wetted walls. The resultant hydrodynamic wall force and moment transmitted to the structure are obtained by integrating these stresses over all wall faces:

where

respectively, the pressure and viscous (shear) contributions integrated over wall face i,

and is the position vector from a chosen reference point O to the force application point (e.g., face centroid). When a scalar component along

unit direction is needed (e.g., body × load), use:

The scenario is hydrodynamic moment from wall stresses about a chosen origin via r × F the assumptions are the same as for force integration with a well-defined reference point; it matters because moments’ drive pointing errors and control saturation; limitations: sensitive to free-surface breakup resolution and ignores structural flexibility unless co-simulated.

Heat transfer in cryogenic pressure vessels occurs through three primary mechanisms: conduction, convection, and radiation. The extent of heat ingress is influenced by the thermal properties of the vessel materials, the effectiveness of insulation, and the surrounding environmental conditions. In cryogenic environments, conventional thermal behaviour is altered; properties such as thermal conductivity, specific heat capacity, and boundary layer characteristics are significantly affected. Even minimal heat leakage from the ambient environment can lead to rapid vaporization of the stored cryogenic liquid, which may compromise operational safety, efficiency, and mission duration, especially in aerospace applications. The scenario is partitioning external heat leaks (radiation/solid/gas paths) minus wall heat soak to obtain heat absorbed by the cryogen over Δt the assumptions are quasi-steady boundary fluxes and lumped wall thermal storage; it matters because it links insulation and structure to actual boil-off/pressurization; limitations: spatial transients and strong wall–fluid coupling are reduced to lumped terms, so early-time behaviour may be misrepresented.

The amount of heat absorbed by the contained hydrogen corresponds to the net heat transferred to the vessel through radiation, solid conduction, gaseous conduction, and natural convection, minus the amount of heat stored within the vessel’s structure. Natural convection arises both externally between the outer wall of the storage tank and the surrounding ambient environment and internally, between the inner wall and the vapour/liquid phases, as well as between the vapour and liquid phases.

where is

is the heat transfer by radiation,

the heat transfer by solid conduction.

the heat transfer by gaseous conduction,

heat stored in the vessel itself,

net heat absorbed by the cryogenic hydrogen.

Radiative heat transfer between concentric spherical surfaces is influenced by surface temperatures, emissivities, and geometric parameters such as sphere diameters. It contributes significantly to total heat ingress in cryogenic storage systems can be given as:

is the radiative heat transfer (W),

the surface area of the inner (smaller) sphere (

,

the surface area of the outer(larger) sphere (

,

the temperatures of the outer and inner surfaces (K),

the emissivites of the outer and inner surface,

The Stefan–Boltzmann constant (5.67

) based on the assumptions that both surfaces are gray, resulting in negligible calculation errors. It also assumes diffuse reflections, rather than specular ones, and that both surfaces have uniform temperatures. Given the use of flat black paint on the surfaces, diffuse reflections are highly likely. In calculating the radiant heat transfer, the temperature of each heater hemisphere was treated individually. The scenario is vacuum radiation between inner and outer shields/shells; the assumptions are gray, diffuse, isothermal surfaces with known areas/view factors; it matters because radiation sets the floor heat leak in well-evacuated systems and informs MLI/VCS design; limitations: real MLI is multilayered and non-gray with edge/leak paths not captured by the simple enclosure formula.

In cryogenic pressure vessels, solid conduction is a key mechanism of heat transfer, allowing heat to flow through the vessel’s walls or insulation layers. As heat moves from the hotter to the cooler side, particles within the material, such as atoms or molecules, vibrate or move, transferring their energy to neighbouring particles. The rate of heat transfer via conduction depends on the material’s thermal conductivity and the temperature gradient across it. This process can influence the stability and efficiency of the stored cryogenic fluid by affecting its temperature and phase state. It can be expressed by:

is the heat transferred by conduction,

is the cross-sectional area through which heat is transferred, while k the thermal conductivity of the material, indicating how easily heat can flow through the material,

is the thickness of the material through which heat is transferred.

is the temperature difference across the material.

Gaseous conduction is the transfer of heat through a gas due to a temperature gradient. In cryogenic systems, it occurs when a temperature difference exists between the gas inside the vessel and its surroundings. Heat flows from the warmer region to the cooler one, with gas molecules transferring energy through collisions. The rate of heat transfer depends on factors like the temperature difference, the gas’ thermal conductivity, and the space geometry. In cryogenic pressure vessels, gaseous conduction plays a crucial role in thermal management, influencing the cryogenic fluid’s stability and system efficiency. The rate of heat transfer is described by a simplified version of Fourier’s Law for gases. The scenario is heat transfer across an annulus when residual gas remains in insulation gaps; the assumptions are correlation parameters valid for the gas species, pressure, and Knudsen regime; it matters because vacuum quality drift can sharply raise heat leak and boil-off; limitations: continuum correlations fail in free-molecular flow, requiring rarefied-gas models. Expressed by:

The heat absorbed by the container wall is determined by the specific heat capacity of the material, the weight (or mass) of the container, and the temperature change. This relationship can be expressed by the equation:

where

is the heat absorbed or released by the system (in the container wall), W is the weight or mass of the container,

is the specific heat capacity at constant pressure (a material property),

the change in the temperature of the system container wall The scenario is energy absorbed by the tank structure as its temperature changes; the assumptions are lumped mass and specific heat with a representative wall temperature change; it matters because structural inertia delays pressurization and changes cryocooler/TVS duty cycles; limitations: gradients, coatings, and multilayer stacks violate the lumped assumption.

This equation is used to calculate the amount of heat absorbed or released by the walls of a cryogenic pressure vessel as its temperature changes. The equation considers the vessel’s mass (or weight), the specific heat capacity of the material, and the temperature change. In cryogenic pressure vessels, the container’s wall can absorb heat from the environment or release heat into the stored cryogenic fluid, depending on the temperature differential. The rate of heat absorption or release directly influences the thermal management of the vessel, potentially affecting the stability of the cryogenic fluid and the vessel’s overall performance. Understanding and calculating this heat transfer is crucial for ensuring the cryogenic liquid remains within its desired temperature range and for maintaining the safety and efficiency of the system.

The phenomenon that occurs in cryogenic pressure vessels, known as boil-off, involves the evaporation of a portion of the cryogenic liquid due to heat ingress from the external environment. As heat from external sources gradually enters the vessel, it raises the temperature of the cryogenic liquid, causing it to reach its boiling point and transition from liquid to gas. This process is inevitable to some extent, even with well-insulated vessels, though the rate of boil-off can vary depending on the insulation quality, heat transfer, and the duration of exposure to external heat sources.

In cryogenic pressure vessels, managing boil-off is essential for maintaining the stability and efficiency of the stored liquid. Excessive boil-off can lead to a reduction in the amount of stored cryogenic fluid, affecting the pressure inside the vessel and potentially impacting the performance of the system. Understanding and controlling this phenomenon is crucial in various applications, such as space exploration and liquid hydrogen storage, to ensure safety, reliability, and optimal performance over extended periods. Which can be expressed by:

where

The percentage of boil off, boil off rate is the rate at which the cryogenic liquid evaporates, time is the duration the boil off occurs, while

is the latent heat of vaporization of the cryogenic liquid. V is the volume of cryogenic liquid in the vessel,

is the density of the cryogenic liquid at an initial stage. The scenario is converting a boil-off mass-rate over time into a percentage of stored liquid using latent heat and initial inventory; the assumptions are constant latent heat, volume, and density over the interval; it matters because it provides a mission-level loss metric and vent sizing input; limitations ignore transient stratification, time-varying properties, and interfacial kinetics.

The heat input to the contained mass of hydrogen, both liquid and vapour, in a cryogenic pressure vessel can indeed be calculated using the heat-transfer equations discussed earlier. With this heat input and knowledge of the mass of hydrogen, the pressure inside the vessel can be determined for a constant volume system, assuming the contents are in thermal equilibrium.

The equation governing this process is derived from the first law of thermodynamics, which is based on the relationship between heat, work, and internal energy. The enthalpy definition also plays a role, as it relates the internal energy to the pressure and volume of the system.

For a constant volume process, the heat input (Q) leads to changes in both the internal energy and the enthalpy of the hydrogen. The relationship can be written as:

where

is the enthalpy change in the system. Enthalpy is a thermodynamic property that reflects both the internal energy and the pressure-volume work of a system, while v is the specific volume of the fluid, which is the volume occupied by a unit mass of the substance. In the case of hydrogen, the specific volume depends on whether it is in the liquid or vapour phase,

the change in pressure of the system. The scenario is relating net heat input to pressure rise in a sealed tank at fixed volume; the assumptions are near-equilibrium bulk phases and an effective specific volume; it matters because it gives a first-order prediction of ullage pressure growth for safety and control logic; limitations: two-temperature nonequilibrium, dissolved gases, and phase-change dynamics can cause significant deviations.

In practice, when heat is transferred to the system (through conduction, radiation, etc.), it increases the enthalpy of the hydrogen, which causes part of the liquid to vaporize and subsequently increases the pressure. The resulting pressure change (∆P) is linked to the specific volume of the hydrogen, contributing to the overall heat balance in the system [

16].

3. Sloshing in Microgravity Conditions

Sloshing, the oscillatory motion of a liquid free surface under external excitation, poses a significant challenge in cryogenic pressure vessel design, particularly in microgravity. Reduced gravity alters fluid behaviour, influencing liquid distribution, heat transfer, and system stability. These effects are especially pronounced in partially filled tanks, where slosh-driven oscillations lead to pressure fluctuations, stratification, and shifts in liquid positioning, all of which compromise the reliability of propellant storage and transfer. Numerical analyses show that sloshing is highly sensitive to both gravity level and fill fraction. Ji-Cheng Li et al. [

17] found that in capsule-shaped tanks under low to microgravity, damping behaviour varies with fill level, ranging from underdamped at very low or high levels to nearly critically damped at intermediate levels. Their results also revealed that residual gravity and fill ratio strongly influence contact line stability and oscillation frequency. These findings highlight the need for adaptive damping solutions, with composite baffles capable of tailored stiffness and energy dissipation offering advantages over traditional aluminum designs.

Experimental and numerical evidence further emphasize the role of excitation frequency in determining slosh severity. Chaoran Hou et al. [

18] investigated longitudinal excitation of liquid hydrogen and observed that low-frequency, large-amplitude disturbances promoted relatively stable free-surface behaviour, whereas high-frequency excitation caused pronounced gas–liquid interface deformation, jetting phenomena, and measurable propellant mass loss. Traditional baffles provided adequate mitigation at low frequencies but were ineffective at high-frequency excitation, demonstrating the limitations of conventional designs. These findings strengthen the case for composite baffles, which combine reduced mass with the potential for tailored damping and superior dynamic performance.

In addition to dynamic effects, thermal and phase-change phenomena critically influence cryogenic propellant management under microgravity conditions. Studies by Yaobin Jiang et al. [

19], Jiaojiao Wang et al. [

20], Jason Hartwig et al. [

21], and Zhan Liu et al. [

22] collectively revealed that in reduced-gravity environments, gravity levels, thermal gradients, fill ratios, and material interactions govern evaporation, bubble dynamics, and stratification in cryogenic tanks. As gravitational acceleration diminishes, surface tension and capillary forces become the primary drivers of liquid configuration and interface stability, dictating how the fluid adheres to tank walls and responds to perturbations. The overall fluid–structure interaction behaviour of the tank, as demonstrated by Weizhen Kong and Qiang Tian [

23], is also highly sensitive to small variations in the effective gravitational field such as those induced by spacecraft manoeuvres, attitude changes, or transient accelerations that modify the inertial forces acting on the liquid. These findings emphasize the importance of integrated design strategies for microgravity operations, in which baffle materials with low thermal conductivity such as composites can simultaneously enhance capillary containment, thermal control, and slosh damping performance.

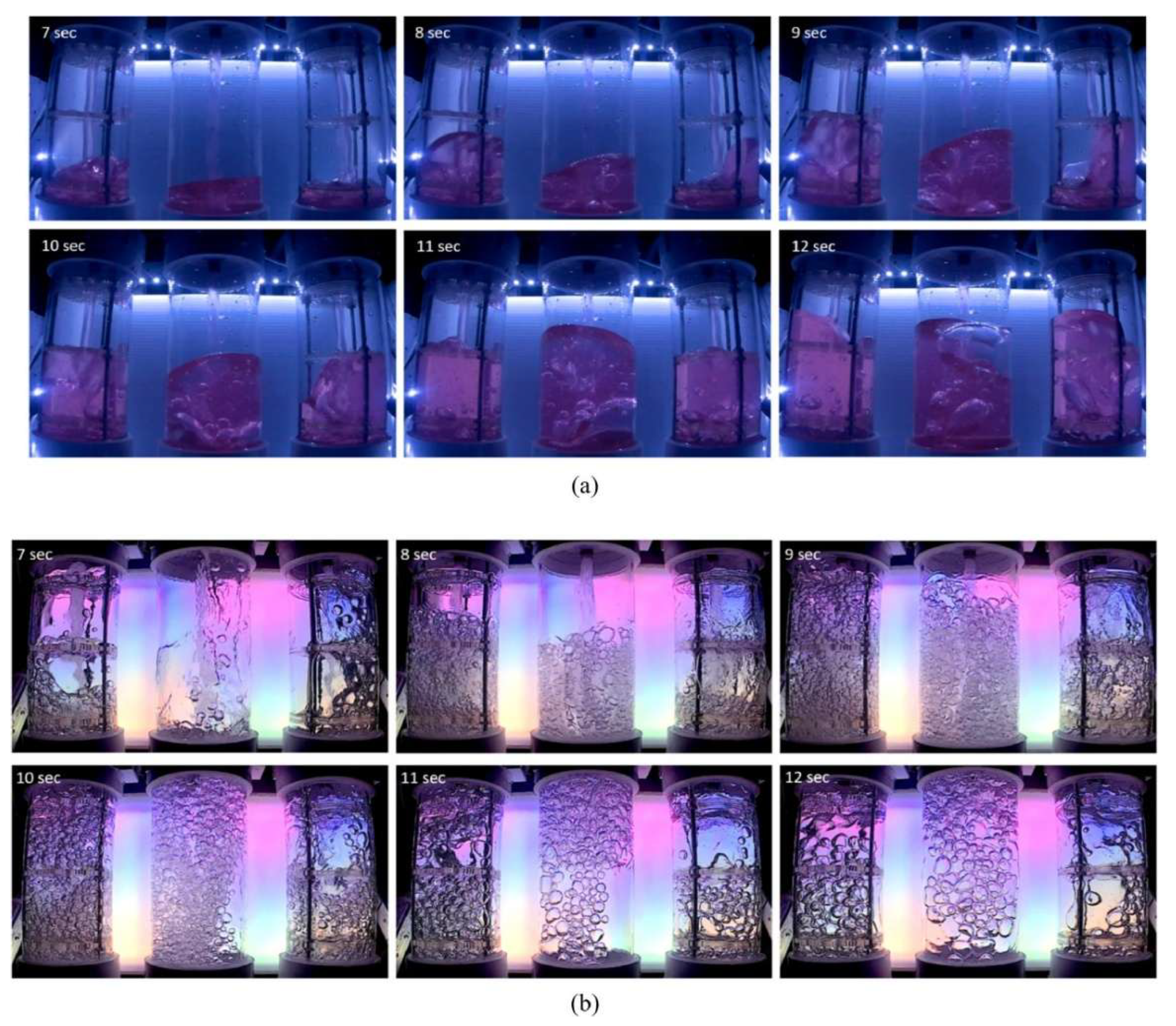

Finally, direct slosh mitigation devices such as slat screens have been explored as seen in

Figure 4. Sobia Nadeem et al. reported promising, though variable, performance of such devices under certain operating conditions [

24]. The partial effectiveness of these solutions suggests that more robust, broadly applicable baffle concepts are required. Within this context, advanced composite baffles emerge as highly promising, offering a pathway toward lightweight, thermally efficient, and dynamically robust designs for cryogenic propellant storage in space applications.

Romero-Calvo et al. [

25] examined the sloshing dynamics of magnetic liquids in microgravity, addressing an important challenge for spacecraft propulsion and attitude control. Their work was carried out as part of the UNOOSA DropTES StELIUM project, which aimed to investigate lateral sloshing of ferrofluid solutions in inhomogeneous magnetic fields under microgravity conditions. The campaign, conducted in November 2019 at ZARM’s Bremen drop tower, employed a carefully designed experimental platform integrating subsystems for actuation, detection, magnetic control, and structural stability, ensuring robust data collection.

To guarantee reliability, multiple redundant diagnostic systems including SDSs, GDS, and lateral cameras were deployed. This redundancy proved essential when two of the four experimental drops experienced partial subsystem failures due to high gravity accelerations. Despite these issues, the integrity of the scientific results was preserved. Free-surface deformation during sloshing was captured using a laser line technique, which enabled accurate surface reconstruction. Minor ripples caused by surface irregularities were observed but did not significantly affect the modal analysis.

Spectral analysis using Fast Fourier Transform (FFT) further revealed mode-dependent responses. Central measurements detected only the axisymmetric sloshing mode, whereas lateral sensors captured both the fundamental and second lateral modes. Notably, the largest amplitudes occurred at intermediate radial positions, while the tank wall exhibited mixed characteristics between free-edge and fixed-edge boundary conditions.

These results not only validated magnetic sloshing models but also contributed to a deeper understanding of ferrofluid behaviour in reduced gravity. The findings hold direct implications for the development of advanced magnetic liquid management strategies, which may enhance propellant handling and improve spacecraft stability and control in future missions.

Dalmon et al. [

26] extended the understanding of sloshing under microgravity by combining experimental data from the FLUIDICS experiment aboard the International Space Station (ISS) with Direct Numerical Simulations (DNS) using the in-house DIVA solver. The study focused on spherical tanks rotated about a fixed axis, partially filled with fluids analogous to spacecraft propellants, and tested at 50% and 75% fill ratios under varying angular velocities and accelerations. The comparative results demonstrated strong agreement between simulation and experiment. DNS predictions reproduced average centrifugal forces within 3–6% error and successfully captured key torque features, including peaks associated with Euler acceleration during spin-up and spin-down phases. Bubble oscillations observed during steady rotation were also replicated, with simulated oscillation frequencies deviating by less than 4% from measured values. Furthermore, higher fill levels were found to increase damping, thereby enhancing fluid stability.

Overall, the study reinforced the reliability of advanced numerical models in replicating complex fluid behaviours in microgravity. By validating DNS through the FLUIDICS experimental campaign, Dalmon et al. provided strong evidence that such modelling approaches can be applied with confidence to predict spacecraft propellant dynamics, supporting both mission planning and the design of slosh mitigation strategies.

To advance the modelling of sloshing in microgravity, several novel computational methods have been developed in recent years. Josip Bašić et al. [

27] applied the Lagrangian Differencing Dynamics (LDD) method to simulate fluid sloshing under variable motion in reduced gravity. Unlike traditional grid-based techniques, LDD is a mesh-free, volume-conservative, second-order accurate approach that effectively captures free-surface breakup and complex fluid–structure interactions. In their study, the method was employed to model sloshing inside a tank undergoing non-uniform motion representative of spacecraft manoeuvres. Notably, the approach required only the vessel geometry and initial free-surface configuration, eliminating the need for volumetric meshing, and was executed efficiently using GPU acceleration. Results confirmed LDD’s capability to reproduce pressure and velocity fields under variable gravity with high fidelity, extending earlier validations conducted in constant gravity. These findings demonstrate the method’s suitability for space applications involving transient fluid dynamics, with future extensions expected to incorporate surface tension and gas-phase interactions for more comprehensive modelling.

In a related development, Bole Ma et al. [

28]. introduced an arbitrary Lagrangian–Eulerian finite element method (ALE-FEM) tailored for liquid sloshing in microgravity. A key innovation of their microgravity. Explicit treatment of contact angle hysteresis is often oversimplified or neglected in conventional models. By employing a highly refined contact-free-surface mesh, their approach distinguished between advancing and receding contact angles, thereby capturing the directional resistance at the contact line caused by surface imperfections or material properties. Validation against experimental data showed close agreement in predicting contact line height along the tank wall and free-surface elevation along the axis. When extended to spherical tanks, the study revealed that neglecting hysteresis produced significant discrepancies in free-surface dynamics, underscoring its critical role in governing interface behaviour under low gravity, where capillary effects can dominate system responses.

Beyond numerical developments, several studies have emphasized the impact of sloshing on spacecraft dynamics and control. Da Fonseca et al. [

29] investigated Control Structure Interaction (CSI) in Low Earth Orbit (LEO) Launch Space Systems (LSS), with a focus on coupling between attitude/orbit control actions and structural flexibility. Their mathematical model incorporated flexible solar arrays and a water tank mounted on a tubular platform, with reaction wheels and thrusters providing actuation. Using equivalent spring–mass representations for the sloshing liquid and the assumed mode method for structural displacement, MATLAB simulations revealed that sloshing can significantly degrade spacecraft attitude stability, inducing residual oscillations and potentially destabilizing pointing systems.

The effects of sloshing during On-Orbit Refuelling (OOR) have also been examined. R. Sah, R. Srivastava [

30], and co-workers developed a nonlinear dynamic model of propellant transfer between chaser and target spacecraft, combining a time-varying spring–mass–damper system for axial sloshing with a pendulum model for radial dynamics. Validation against CFD simulations in Open FOAM demonstrated less than 10% deviation, while requiring far fewer computational resources. This balance of accuracy and efficiency positions the model as a practical alternative to high-fidelity CFD for mission design and operational analysis.

Rotary sloshing in launch vehicles has likewise received renewed attention. Jeb S. Orr et al. [

31] critiqued the limitations of linear spring–mass–damper models, showing that nonlinear effects, particularly rotary sloshing, can induce persistent oscillations and roll–coupling instabilities during ascent. By employing nonlinear representations such as the spherical pendulum and Bauer paraboloid models, validated against high-fidelity vehicle simulations, they demonstrated that even with ring baffles, rotary slosh-induced limit cycles may occur under large manoeuvres. These results highlight the necessity of integrating nonlinear slosh dynamics into flight control system design, especially for modern lightweight launch vehicles where inherent damping is reduced.

Finally, thermal effects have been increasingly recognized as inseparable from slosh dynamics. Monteiro et al. [

32] performed controlled microgravity experiments aboard ESA’s 83rd parabolic flight as part of the NT-SPARGE (Non-Isothermal Sloshing Parabolic Flight Experiment). Two identical cylindrical tanks, partially filled with HFE-7000, were employed: one under isothermal conditions, the other with a stratified temperature profile and active pressurization. The experiments revealed that sloshing in the non-isothermal tank triggered boiling when liquid contacted the warmer upper walls, leading to unpredictable surface motions, thermal disruptions, and sharp pressure spikes. In contrast, the isothermal tank exhibited relatively stable dynamics. These results provide a rare dataset capturing the coupling between sloshing motion and thermal processes in microgravity, underscoring the need for integrated thermal–fluid models in cryogenic propellant management.

In his 2023 doctoral dissertation, Experiments and Simulations of Liquid Mass Gauging and Slosh Dynamics in Microgravity, Storey advanced the field of propellant management by integrating innovative sensing methods with unique spaceflight experiments [

33,

34]. His work addressed two key challenges: reliable mass gauging of cryogenic propellants in reduced gravity, and the accurate characterization of slosh dynamics under long-duration microgravity conditions. The first major contribution was the evaluation of Electrical Capacitance Tomography (ECT) as a non-intrusive diagnostic technique for liquid mass distribution in propellant tanks. ECT reconstructs the internal fluid configuration in real time by processing capacitance measurements between electrodes placed around the tank perimeter. Storey successfully demonstrated, for the first time, the operation of an ECT-instrumented tank under true microgravity, thereby assessing its feasibility for accurate mass gauging in realistic flight environments. This achievement represents an important step toward sensor-driven fluid management systems capable of operating without intrusive hardware.

The second major component of his research was the SPHERES-Slosh Experiment (SSE) aboard the International Space Station (ISS). The SPHERES platform (Synchronized Position Hold Engage and Reorient Experimental Satellites) consists of free-flying, basketball-sized satellites designed to evaluate guidance, navigation, and control algorithms in microgravity. Within SSE, fluid-filled tanks were manipulated by the SPHERES units to generate controlled, long-duration slosh events with precisely defined initial conditions. The campaign enabled the collection of synchronized video and six-degree-of-freedom inertial data, yielding a benchmark dataset for the validation of computational fluid dynamics (CFD) models of sloshing in reduced-gravity environments. Building on these experimental foundations, Storey introduced the concept of an ECT-based “slosh sensor.” Unlike traditional analogue spring–mass approximations or computationally intensive CFD models, this sensor concept reconstructs sequential three-dimensional liquid volumes and estimates velocity fields in near real time. By providing direct estimates of fluid forces and torques, such a system could enable onboard detection and control of slosh-induced disturbances without excessive computational burden.

Overall, Storey’s work represents a significant advance toward sensing-driven, real-time control of sloshing phenomena, offering a pathway to safer and more efficient spacecraft propellant management. His integration of ECT with the ISS-based SSE campaign provides both a novel diagnostic capability and a uniquely valuable dataset for model validation, with broad implications for future spacecraft design and operations.

In microgravity environments such as aboard the International Space Station (ISS), bubbles in a sloshing tank emerge from the complex interaction of liquid and vapour phases during fluid motion. When the liquid encounters warmer boundaries such as the tank’s top wall localized boiling can occur, particularly under thermally stratified conditions. In contrast to terrestrial environments, the absence of buoyancy prevents bubbles from rising and coalescing, allowing them to persist and disperse throughout the liquid volume. Rapid accelerations and interface collapses during sloshing may also entrap vapour pockets, further contributing to bubble formation and highlighting the challenges of phase separation in cryogenic propellant systems [

35].

Analogous insights into bubble behaviour have been obtained in the realm of quantum fluids. Carollo et al. [

36] reported the formation of ultracold atomic bubbles in orbital microgravity using NASA’s Cold Atom Laboratory on the ISS. By applying a radiofrequency-dressing technique, they generated stable bubble-shaped configurations in ultracold atomic gases, with the potential for Bose–Einstein condensation. This experimental platform enabled the investigation of bubble thermodynamics under unprecedented conditions, revealing significant cooling effects during bubble inflation and novel dynamics of shell-like quantum structures.

Together, these studies illustrate the diverse and often counterintuitive phenomena associated with bubbles and vapour dynamics in microgravity—from persistent vapour pockets in cryogenic propellants to emergent quantum states in ultracold fluids. Both examples highlight how the absence of buoyancy fundamentally alters the mechanisms of energy storage, transfer, and dissipation within multiphase systems. These effects provide unique opportunities not only for advancing fundamental fluid physics but also for improving energy-efficient cryogenic management strategies critical to future space missions.

Because access to sustained microgravity remains limited and expensive, sloshing dynamics are typically investigated using short-duration experimental platforms that approximate weightlessness. Parabolic flights, offering 15–25 s of reduced gravity, are widely employed to visualize free-surface motion and quantify energy damping and transfer during oscillations. Drop towers extend exposure to several seconds of high-quality microgravity by releasing sealed capsules in free fall, enabling precise measurements of interface deformation, bubble motion, and slosh-induced pressure fluctuations—key contributors to viscous and interfacial energy loss. For longer observation windows, sounding rockets provide minutes of microgravity and have been used to capture the evolution of vapour–liquid distribution and thermally driven dissipation in cryogenic systems.

Ground-based simulators such as clinostats and random positioning machines reproduce certain diffusion-dominated aspects of microgravity by continuously altering tank orientation. However, they cannot replicate realistic inertial coupling or slosh-induced energy pathways, making them unsuitable for studying dynamic fluid oscillations and damping behaviour. While these facilities remain valuable for validating isolated thermophysical phenomena, they fall short of reproducing the nonlinear energy conversion between mechanical motion, heat transfer, and phase change that defines cryogenic sloshing in orbit.

Collectively, these experimental surrogates have been instrumental in validating computational models and advancing understanding of fluid–structure–thermal energy coupling. Yet their limited duration leaves open a critical frontier: the long-term evolution of sloshing-induced energy dissipation, vapour entrapment, and boil-off acceleration under continuous microgravity. Over mission-relevant timescales, trapped vapour pockets modify effective damping and redistribute energy between mechanical and thermal modes, directly linking sloshing dynamics to propellant energy loss and boil-off rates.

Addressing these challenges requires extending research into orbital testbeds capable of capturing the full energy-dissipation spectrum over sustained operation periods. Equally important is the co-design of active thermal control systems such as thermodynamic venting (TVS) and zero-boil-off (ZBO) technologies with structural damping mechanisms like composite baffles. Such integrated strategies would simultaneously stabilize the liquid interface, enhance thermal uniformity, and suppress slosh-induced energy losses, forming the foundation for high-efficiency, long-duration cryogenic propellant storage essential for lunar, Martian, and deep-space missions.

Critical Synthesis of Sloshing in Microgravity

The body of literature on microgravity sloshing reveals a progressive evolution from simplified analytical analogues toward data-driven, multi-physics, and energy-aware frameworks. Early analytical models such as linear spring–mass analogues provided initial insight into propellant motion but failed to capture how mechanical oscillations transform into heat, vapour generation, and energy loss under reduced gravity. Orr et al. demonstrated that linear models could not predict rotary sloshing instabilities even in baffled configurations, exposing their inability to represent nonlinear energy exchange and dissipation mechanisms that dominate low-gravity environments.

Modern computational methods—Direct Numerical Simulation (DNS), Arbitrary Lagrangian–Eulerian Finite Element Methods (ALE-FEM), and Lagrangian Differencing Dynamics (LDD) now resolve these phenomena with much greater fidelity. Bašić showed that LDD can efficiently reproduce free-surface breakup and viscous damping, while Ma et al. highlighted ALE-FEM’s strength in resolving contact-angle hysteresis and thermally driven interfacial deformation, both of which govern energy transfer between surface tension, inertia, and heat flux. However, trade-offs persist: GPU-accelerated LDD achieves computational efficiency at the cost of excluding capillary energy effects, whereas ALE-FEM remains computationally prohibitive despite its thermodynamic completeness. This recurring compromise reflects a central challenge in sloshing research—balancing numerical efficiency with accurate representation of energy dissipation and conversion under mission-relevant conditions.

Validation of these models relies heavily on orbital experiments that measure real energy loss and damping rates. Campaigns such as FLUIDICS (Dalmon et al.) and SPHERES-Slosh (Storey et al.) aboard the ISS provide benchmark data for tracking kinetic-to-thermal energy conversion, pressure fluctuations, and interfacial damping coefficients. In contrast, terrestrial surrogate parabolic flights, drop towers, and sounding rockets remain essential for calibration but are limited by seconds-long microgravity durations. They capture only the early stages of energy redistribution and phase-change onset, not the cumulative effects that govern long-term propellant stability. Consequently, sustained on-orbit testing remains indispensable for understanding how energy dissipates and re-enters the thermal domain during long-duration missions.

A persistent research gap lies in quantifying the coupled energy feedback between sloshing, damping, and boil-off acceleration during extended microgravity storage. Over time, trapped vapour bubbles modify viscous and capillary damping pathways, amplifying thermal stratification and pressurization energy. Current approaches often treat sloshing control and thermal management as independent problems, yet both define a single energy loop: oscillatory kinetic energy becomes internal energy through viscous losses, which then drives vaporization and mass loss. Future spacecraft must instead adopt co-designed architectures, coupling structural energy dissipation hardware (e.g., composite baffles) with active energy recovery and control systems such as Thermodynamic Venting Systems (TVS) and Zero-Boil-Off (ZBO) cryocoolers. These integrated frameworks could stabilize free-surface motion while simultaneously reclaiming or redirecting excess thermal energy, achieving both slosh damping and propellant energy efficiency.

A comparative review of Technology Readiness Levels (TRLs) further clarifies this energy-centric landscape. At higher TRLs, simplified mechanical models endure because of their reliability in controller design, despite their neglect of thermal energy pathways. Mid-TRL research focuses on CFD-based prediction of damping coefficients and heat-flux coupling, while low-TRL innovations explore experimental frontiers such as Romero-Calvo’s magnetic ferrofluids for active energy-based slosh suppression, Storey et al.’s ECT sensors for real-time dissipation mapping, and the development of thermo-functional composite baffles that absorb, redirect, or radiatively dissipate energy. Although experimental, these concepts embody the field’s shift toward energy-integrated, microgravity-resilient systems.

In synthesis, the literature reflects a decisive transformation from passive containment toward adaptive energy-management architectures. Early hardware such as slat screens (Nadeem et al.) offered limited, context-dependent energy damping, whereas emerging paradigms converge on sensing, modelling, and structural control systems that collectively predict, monitor, and dynamically minimize sloshing-induced energy losses. This convergence—linking fluid dynamics, structural mechanics, and thermodynamics into one coupled energy framework—marks both the greatest technical challenge and the most promising pathway toward high-efficiency, long-duration cryogenic operations in deep space.

4. Thermodynamic Effects on Cryogenic Sloshing

Sloshing in cryogenic propellant tanks cannot be regarded as a purely mechanical process; it is an energy conversion phenomenon governed by the coupled thermodynamic interactions between the liquid, vapour, and tank structure. Even minor surface disturbances modify local heat flux, temperature gradients, and phase-change processes such as evaporation, condensation, and film boiling transforming mechanical agitation into irreversible thermal losses. Because cryogens exhibit low thermal conductivity, high latent heat of vaporization, and strong temperature-dependent variations in density, viscosity, and surface tension, these disturbances strongly influence energy dissipation mechanisms. The resulting feedback modifies vapour pressure, interfacial tension, and density distribution, altering oscillation frequencies, damping behaviour, and free-surface stability.

In normal gravity, inertia-driven oscillations dominate the energy transfer, where sloshing converts mechanical input into turbulent mixing and convective heat exchange. Studies show that increased sloshing acceleration and higher fill ratios amplify both dynamic pressure fluctuations and heat generation. Xue et al. [

37] demonstrated that higher excitation intensifies pressure oscillations, while Sun et al. [

38] reported that reduced fill levels—though lowering hydrodynamic load—raise vapour temperature and pressure, doubling boil-off gas (BOG) losses at amplitudes of roughly 2 m. Similarly, Le et al. [

39] observed that abrupt motion cessation induces pressure collapse via rapid condensation on subcooled surfaces, and Liu et al. [

40,

41,

42] found that prolonged agitation yields chaotic condensation and asymmetric interfacial decay, with 60% fill conditions marking peak instability where mechanical and thermal losses reinforce each other [

43].

Under reduced or microgravity, the energy dissipation pathway shifts from bulk convection to surface-tension-controlled interfacial transport. The absence of buoyancy allows vapour films and bubbles to persist [

44], disrupting equilibrium and promoting local condensation and asymmetric pressure variations. Wang et al. [

45] showed that spherical tanks reduce total heat ingress and BOG generation, while Zuo et al. [

46] found that thermodynamic vent systems operate more efficiently in microgravity as vapour–liquid mixing enhances condensation. Conversely, Liu et al. [

47] reported that stratification develops more slowly in rotating tanks, yet even small oscillations can cause strong vapour condensation and temperature oscillations, reinforcing stratification as observed by Zhan Liu et al. [

48]. Thus, while the mechanisms differ, sloshing remains a key source of thermal and pressure instability across gravitational regimes.

Across both environments, the coupling between phase change and thermodynamics defines the main channel of energy loss [

49]. Heat ingress drives self-pressurization and stratification [

50,

51], while slosh-induced convection accelerates evaporation and BOG generation. Passive mitigation techniques—low-conductivity composite walls and internal baffles—reduce both heat ingress and slosh-induced mixing [

52], and advanced insulation, such as vapour-cooled shields or fibre–vacuum–deposited multilayer insulation, cuts total heat leakage by nearly 50% [

53]. When these are insufficient, active systems such as thermodynamic venting [

54], gas bubbling [

55], or cryocoolers [

56] are required. Neglecting phase-change effects in models leads to underestimation of ullage pressure by over 18% [

57]. Large-scale systems further exhibit dominant surface evaporation over bulk boiling [

58], and even trace contamination modifies stratification and BOG behaviour [

59], while ascent heating adds further thermodynamic stress [

60,

61].

Despite significant progress, predictive energy-dissipation modelling remains computationally demanding. Fully coupled thermo-fluid simulations are rarely feasible for real-time control, highlighting the need for reduced-order models (ROMs) that preserve nonlinear energy coupling for use in digital twins. Long-term effects of aging and contamination on coupled thermodynamics also remain poorly characterized. To close these gaps, large-scale and long-duration validation experiments are required to quantify how mechanical excitation energy is partitioned into turbulence, thermal storage, and irreversible vaporization.

Overall, thermodynamic coupling and phase change from the unifying thread of energy dissipation in cryogenic sloshing. In normal gravity, inertia-driven motions amplify heat and pressure oscillations, while in microgravity, capillary and film-dominated dynamics govern interfacial stability. Integrating validated Multiphysics and reduced-order frameworks into digital-twin architectures will enable adaptive control of slosh-induced energy loss, advancing the design of lighter, safer, and more energy-efficient cryogenic systems for long-duration aerospace missions [

62,

63].

Critical Synthesis of Thermodynamics Effects in Cryogenic Sloshing

A comprehensive synthesis of thermodynamic effects in cryogenic sloshing reveals a system defined by a strong dichotomy between normal- and microgravity environments and stratified by distinct gradients of technological maturity. In normal gravity, there is broad consensus that inertia-driven oscillations accelerate energy dissipation through amplified pressure fluctuations, chaotic condensation, and enhanced boil-off gas (BOG) generation. The process converts mechanical sloshing energy into thermal and latent energy, reducing overall propellant efficiency. Yet, the literature is not without nuance: while most studies depict sloshing as inherently detrimental, some experiments indicate that intermittent or low-amplitude oscillations can promote controlled condensation and gentler pressure decay—acting as stabilizing dissipative mechanisms under constrained conditions. Despite its maturity, this research domain remains constrained by methodological simplifications; most experimental work employs idealized sinusoidal or single-axis excitations, which fail to replicate the stochastic, multi-axis forcing characteristic of actual launch and orbital operations. Nonetheless, normal-gravity models are supported by extensive ground-based validation and operational flight data, corresponding to high TRLs (6–7).

By contrast, the reduced- and microgravity regime remains low-TRL (3–4) and less experimentally mature, governed primarily by surface-tension–driven interfacial dynamics. Here, energy dissipation manifests through capillary waves, vapour film formation, and asymmetric condensation cycles—phenomena often counterintuitive to terrestrial intuition. For example, thermodynamic vent systems (TVS) have been observed to perform more efficiently in microgravity due to enhanced vapour–liquid mixing and rapid condensation of superheated vapour, while natural stratification proceeds more slowly owing to the absence of buoyancy. Yet, sloshing remains a powerful destabiliser: even weak oscillations in LH2 tanks can induce asymmetric condensation, pressure collapse, and sharp temperature fluctuations, compounding stratification over long durations. These findings illustrate that, although sloshing and phase change jointly govern energy conversion pathways, our understanding of their coupling in low-gravity environments remains fragmentary due to short-duration testing and the lack of long-term orbital validation.

Across both regimes, one principle is universally acknowledged: accurate treatment of phase change as an energy dissipation mechanism is indispensable. Neglecting evaporation or condensation can inflate ullage pressure predictions by nearly 20%, compromising mission-critical design margins. This recognition exposes a central engineering tension—between high-TRL passive systems (e.g., multilayer insulation, vapour-cooled shields, composite walls) that ensure reliability but offer limited adaptability, and emerging active systems (e.g., TVS, cryocoolers, destratification bubbling) that enable dynamic thermal control but at higher mass and power cost. This trade-off defines the current frontier between static and adaptive energy management in cryogenic systems.

The path forward requires a dual trajectory: (1) advancing experimental infrastructure through full-scale, instrumented testbeds in both gravity regimes and extended on-orbit demonstrations to bridge the persistent validation gap, and (2) developing reduced-order and physics-informed models (PINNs) that preserve nonlinear coupling between sloshing, heat transfer, and phase change while remaining computationally tractable. Embedding these models within digital-twin architectures would enable real-time tracking of dissipative losses, predictive boil-off control, and autonomous venting optimization. Such frameworks represent a shift from descriptive modelling toward active energy management, transforming cryogenic tanks into adaptive systems capable of minimizing energy loss in real time.

Ultimately, while inertia-driven dynamics dominate in normal gravity and surface-tension physics define microgravity, the coupling of thermodynamics and phase change remains the unifying energy pathway governing pressurization, damping, and long-term stability. Addressing this continuum—through experimental maturity and model fidelity will elevate current low-TRL microgravity understanding to flight-proven reliability. Success in this endeavour will unlock the next generation of cryogenic propellant systems: lighter, safer, and more energy-efficient architectures capable of sustaining lunar, Martian, and deep-space operations.

5. Sloshing of Liquid in Composite Overwrapped Pressure Vessels

The inherent advantages of Composite Overwrapped Pressure Vessels (COPVs) in modern launch vehicles and spacecraft—primarily their superior strength-to-weight ratio and high-pressure tolerance for cryogenic propellants—are significantly counterbalanced by complex challenges that extend beyond simple dynamic loading. The combined effects of sloshing, extreme cryogenic temperatures, and the unique anisotropic nature of COPV materials create a multifaceted threat to structural integrity and mission reliability.

During dynamic phases such as liftoff, stage separation, or critical attitude control manoeuvres, the partially filled cryogenic liquid within COPVs is highly susceptible to sloshing. This phenomenon introduces a cascade of detrimental effects: unsteady pressure loads, complex fluid–structure interactions, and severe disturbances to thermal equilibrium. Unlike the more forgiving isotropic behaviour of traditional metallic tanks, the anisotropic mechanical properties of COPVs make them uniquely vulnerable. Asymmetric sloshing impacts do not merely distribute stress; they can cause highly localized stress amplifications that concentrate forces in specific directions, potentially leading to localized delamination, liner buckling, or even catastrophic failure in areas that might otherwise appear robust.

Compounding these dynamic challenges are the critical thermo-mechanical interactions intrinsic to cryogenic storage. Repeated boil-off cycles, a necessity for managing propellant pressure, and the agitation caused by sloshing collaboratively induce significant thermal cycling stress. This cycle of cooling and warming, often localized and rapid, stresses the interface between the polymer liner and the composite overwrap. Localized cooling can lead to condensate formation, exacerbating temperature gradients and promoting material degradation. In regions with even minor manufacturing defects—such as imperfect bonding, voids, or material heterogeneity—these thermal stresses are magnified. The polymer liner, typically designed for flexibility, can undergo cryogenic embrittlement, lose its ductility and become prone to microcracking. Simultaneously, the composite overwrap can experience matrix–fibre debonding, where the resin matrix separates from the high-strength fibres, and further microcracking within the matrix itself. This degradation compromises the load-bearing capacity and sealing function of the COPV.

Furthermore, the long-term exposure to cryogenic propellants introduces insidious chemical and physical degradation mechanisms. Hydrogen diffusion, particularly with propellants like liquid hydrogen, can infiltrate the resin matrix of the composite, leading to plasticization or embrittlement of the polymer chains. This chemical attack, combined with sustained temperature gradients across the vessel wall, can further weaken the critical interface between the liner and the composite fibres. This gradual degradation diminishes the vessel’s ability to withstand both operational pressures and dynamic slosh-induced loads, potentially leading to slow leaks, reduced burst pressure capability, or sudden structural failure over the mission lifetime.

Recent investigations into sloshing dynamics in composite vessels have further emphasized the role of structural anisotropy in influencing fluid–structure interactions. Pratik Tiwari et al. [

64] developed a robust three-dimensional finite element formulation to analyze sloshing in partially filled laminated composite cylindrical tanks under external excitations, using a direct coupling method for efficient fluid–structure interaction. Their work employed degenerated shell elements for the composite tank and 20-noded brick elements for the fluid domain, validated through both literature comparisons and experimental results.

Their findings emphasize that radial stiffness, rather than overall structural stiffness, plays a dominant role in sloshing suppression. This insight is particularly valuable for COPV design, where ply orientation can be tailored to enhance performance under dynamic loading. The study revealed that optimized ply orientations can significantly reduce slosh height, even allowing thinner tank walls to outperform thicker configurations with suboptimal layups. This aligns with the growing emphasis on customizing composite architecture to not only meet mechanical strength requirements but also minimize dynamic instabilities like sloshing.

Expanding on the complexities of sloshing dynamics in composite structures, Mahdi Karimi et al. [

65] investigated the free vibration behaviour of vertically oriented composite laminate plates coupled with sloshing fluids. Their work introduces both hybrid composite laminates (HCL), composed of multiple fibre types, and variable stiffness composite laminates (VSCL), featuring curvilinear fibre paths, as structural configurations interfacing with sloshing liquid. Using Reddy’s shear deformation plate theory combined with the Rayleigh–Ritz method, they formulated a fluid–structure interaction (FSI) model that accounts for both sloshing and bulging fluid modes, emphasizing the critical role of fibre orientation and laminate tailoring on vibrational response. This study is particularly relevant to COPVs, where composite behaviour is highly dependent on layup design and fibre alignment. Karimi et al.’s [

65] findings demonstrate that VSCL and HCL configurations can significantly widen the spectrum of natural frequencies, enabling more flexible and targeted design strategies for dynamic environments. Importantly, such fibre architecture modifications not only influence stiffness and damping properties but also affect how sloshing energy is absorbed or amplified at the structural interface.

Furthermore, P. Pal et al. [

66] took a unique approach by using a meshless method, specifically the meshless local Petrov–Galerkin (MLPG) technique, to study sloshing in partially filled rectangular composite containers. Instead of relying on traditional mesh-based models, their method used a more flexible, point-based system to calculate pressure changes and fluid motion, which is especially useful for handling complex interactions like fluid–structure coupling. They explored how different fibre orientations and wall thickness affect the way the liquid moves and how much stress it puts on the tank walls. One key takeaway was that composite tanks with thinner walls or certain ply orientations can experience much stronger sloshing-induced vibrations, which is important when thinking about cryogenic applications where structural integrity is already at risk from thermal stress and potential embrittlement. Their method also gives a peek into the future of 3D slosh modelling for more complex tank geometries, like those found in COPVs, where understanding localized stress and pressure buildup could make all the difference in preventing damage during critical phases like launch or maneuvering.

Furthermore, Dong-Hyeop Kim et al. [

67] conducted a comprehensive numerical investigation into the impact-induced damage behaviour of a composite fuel tank assembly, particularly under drop impact conditions relevant to helicopter applications. Utilizing a Coupled Eulerian–Lagrangian (CEL) method, the study incorporated fluid–structure interaction (FSI) analysis to account for the dynamic interplay between the sloshing liquid fuel and the composite tank structure. The Hashin failure criteria were applied to evaluate structural failure, enabling the characterization of various composite damage modes.

Key parameters such as the amount of fuel and drop impact angle were varied to assess their influence on structural integrity. The results indicated that while sloshing itself did not significantly contribute to damage, an increased fuel volume led to greater impact energy transmission to the tank, thereby aggravating the extent and severity of damage. Similarly, oblique impact angles introduced localized stress concentrations, particularly near the tank edges, further exacerbating structural failure. On the other hand, design features such as foam core layers and reinforced lower edges were shown to effectively absorb impact energy, mitigating damage to some extent. The findings provide valuable insights for the design and certification of composite fuel tank assemblies, especially in the context of airworthiness assessments and drop impact test planning. The methodology demonstrated and observed failure trends serve as a useful reference for enhancing the safety and resilience of fuel systems in rotary-wing aircraft.

In addition, Dipak K. Maiti et al. [

68] developed a 3D finite element model to analyze sloshing frequencies in partially filled cylindrical laminated composite containers, focusing on fluid–structure interaction. Using Reissner–Mindlin theory and the Helmholtz wave equation, they accurately captured the coupled dynamics between the composite tank and the sloshing fluid. Their parametric study showed that ply orientation, tank geometry, and fill level significantly affect natural sloshing frequencies, with the (0/45)

2s layup offering the highest frequency. The model is validated and serves as a reliable, efficient tool for studying composite tank sloshing under dynamic conditions.

In addition, E. Kormanikova et al. [

69] developed a multiscale model to analyze liquid-filled laminated composite cylindrical tanks. Using a hexagonal microstructure model and numerical homogenization, they derived the effective properties of the composite. The study emphasized the importance of laminate layup and material anisotropy in influencing fluid–structure interaction, particularly the pressure effects of sloshing fluid on tank walls.

Similarly, Hamid Reza Moghaddasi et al. [

70] explored the nonlinear dynamics of simply supported, thin laminated circular cylindrical shells coupled with large amplitude sloshing fluid. Using the Flügge–Lure–Byrne nonlinear shell theory and potential flow theory for the fluid domain, they analyzed the interaction between shell deformation and nonlinear sloshing, particularly under harmonic excitation. Their findings reveal that nonlinear sloshing reduces the beating effect in the shell’s response but increases radial deformation compared to linear models. The study also shows that for flexible shells, nonlinear sloshing notably alters the frequency–response curves, especially at higher fluid fill levels, while having minimal impact on the free surface profile. Conversely, in stiffer shells, the dynamic response is less sensitive, but the fluid surface elevations are significantly affected. This work emphasizes the importance of considering nonlinear sloshing effects in the vibration analysis of fluid-filled laminated shell structures.

In the same vein, Sirwan Farhadi et al. [

71] conducted a hydrostatic vibration analysis of laminated composite rectangular plates partially in contact with fluid. Using the Rayleigh–Ritz method and shear deformation theories, they showed that fluid–structure interaction significantly alters natural frequencies and mode shapes. Results revealed that increasing fluid depth lowers frequencies, while increasing plate thickness, tank width, or clamped constraints raises them. Fibre orientation and aspect ratio also notably affect the vibrational response.

While traditional sloshing studies have emphasized short-term control in single-flight missions, the rise of reusable launch vehicles demands a broader framework that explicitly considers cumulative deformation and fatigue under repeated cryogenic cycling. Sustained exposure to sloshing loads, coupled with steep thermal gradients, introduces long-term risks such as progressive shell deformation, micro-crack initiation in composite overwrapped pressure vessels (COPVs), and performance loss in composite baffles.

Recent investigations reveal that nonlinear vibrations in cantilevered cylindrical shells containing cryogenic fluids not only alter mechanical response but also modulate energy transfer pathways within the tank structure. At high fill levels, vibration modes transition from softening to hardening behaviour, reflecting a redistribution of mechanical energy between the fluid and structural modes. In thin-walled shells, intensified thickness deformation amplifies internal friction and viscous dissipation, demonstrating that classical small-amplitude sloshing theory is insufficient for reusable cryogenic tanks. These nonlinear effects convert oscillatory kinetic energy into localized heating and cyclic stress accumulation, directly influencing fatigue life and thermal energy buildup within the structure. Consequently, fatigue assessments must integrate nonlinear fluid–structure interaction (FSI) with repeated-cycle thermomechanical analysis—particularly for composite overwrapped pressure vessels (COPVs) where cyclic stresses and thermal gradients evolve concurrently.

Parallel studies examining sloshing under realistic seismic and launch excitations using turbulence-based and multiphase CFD models further confirm that energy dissipation efficiency depends on excitation frequency, fill ratio, and structural coupling. Low-frequency, high-energy events generate the most violent free-surface oscillations, with strong wave–wall impacts driving rapid mechanical-to-thermal energy conversion. The geometry of internal baffles emerges as a decisive control factor: combined horizontal–vertical configurations maximize damping efficiency and wave energy attenuation, while purely planar or perforated geometries exhibit uneven dissipation patterns. Yet, experimental evidence shows that baffle effectiveness degrades over time as thermal cycling and repeated mechanical stresses reduce structural damping, lowering the system’s overall capacity to absorb and dissipate sloshing energy.

Collectively, these findings highlight that sloshing-induced deformation, cyclic fatigue, and energy dissipation degradation are interdependent phenomena governing the durability of cryogenic tanks. Sustainable tank design therefore demands an integrated modelling framework that unites nonlinear FSI, fatigue-life prediction, and energy dissipation analysis under repeated cryogenic cycling. Simultaneously, baffle systems must be engineered for energy endurance—optimizing both wave damping and thermal resilience over multiple operational cycles. Recognizing sloshing as both a structural and thermodynamic energy process reframes it as a key driver of efficiency, reusability, and certification standards for next-generation cryogenic aerospace systems.

Critical Synthesis of Liquid in COPVs

Recent research on sloshing within composite cryogenic overwrapped pressure vessels (COPVs) has converged on a key understanding: the anisotropic stiffness and damping characteristics of composite laminates directly govern energy transfer and dissipation during dynamic fluid–structure interaction. Unlike metallic tanks, whose isotropy simplifies the mechanical response, composite structures exhibit direction-dependent stiffness that redistributes vibrational energy through the laminate architecture. Studies by Tiwari et al. and Karimi et al. demonstrate that optimizing ply orientation, stacking sequence, and hybridization can significantly reduce sloshing-induced energy amplification and structural resonance, thereby enhancing damping efficiency. However, this consensus is tempered by alternate findings from Kim et al., who show that under impact or high-energy excitation, fluid inertia contributes more strongly to total energy input than resonance itself—implying that energy dissipation mechanisms must be tuned not only to material anisotropy but also to excitation spectrum. Similarly, Moghaddasi et al. establish that nonlinear shell–fluid coupling governs both energy absorption and re-radiation, challenging the adequacy of classical linear FSI formulations that neglect these conversion dynamics.