Experimental Investigation of Hydraulic Fracturing Damage Mechanisms in the Chang 7 Member Shale Reservoirs, Ordos Basin, China

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Samples

2.2. Experimental Methods

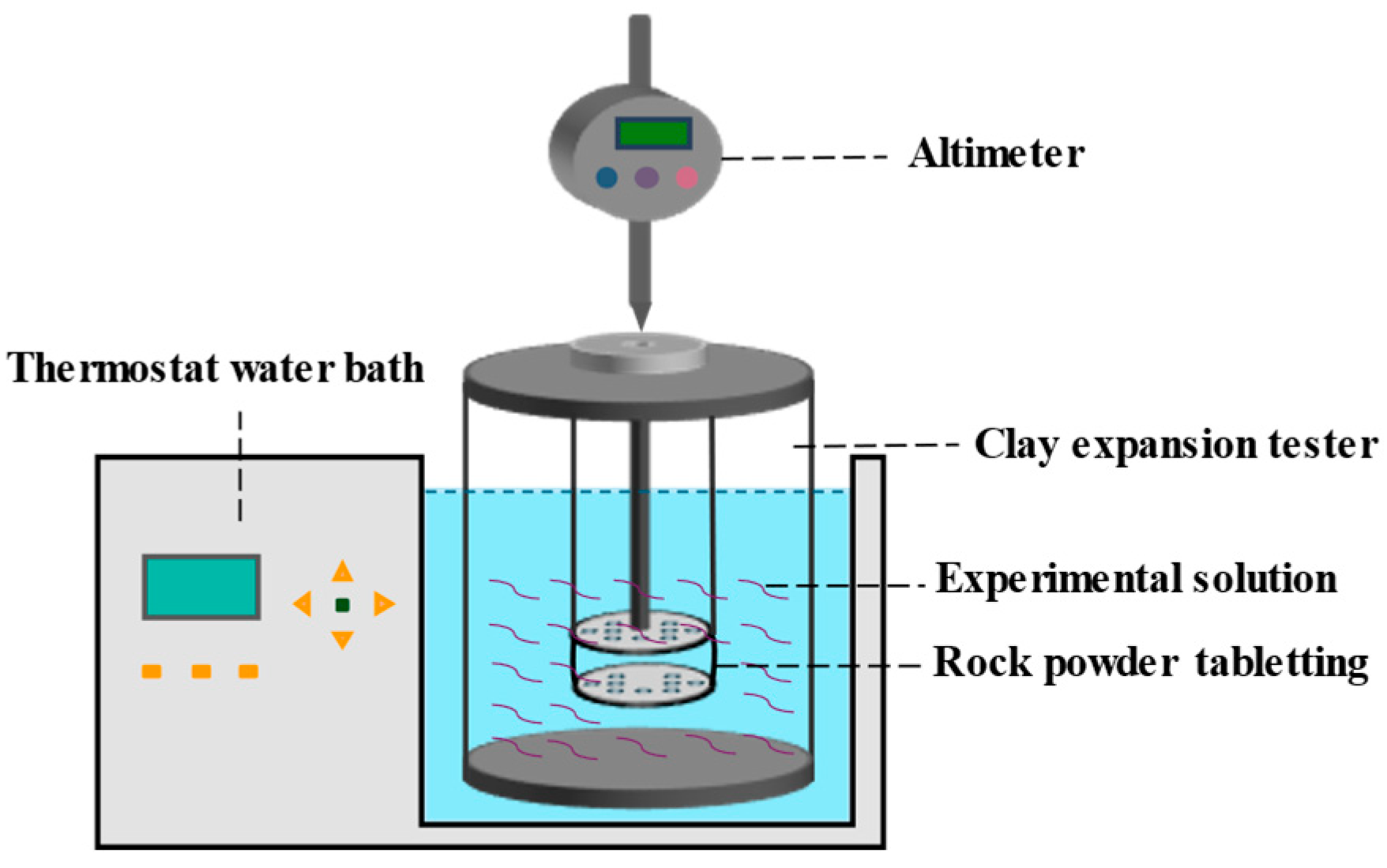

2.2.1. High-Temperature Expansion Test

2.2.2. Nuclear Magnetic Resonance Experiment

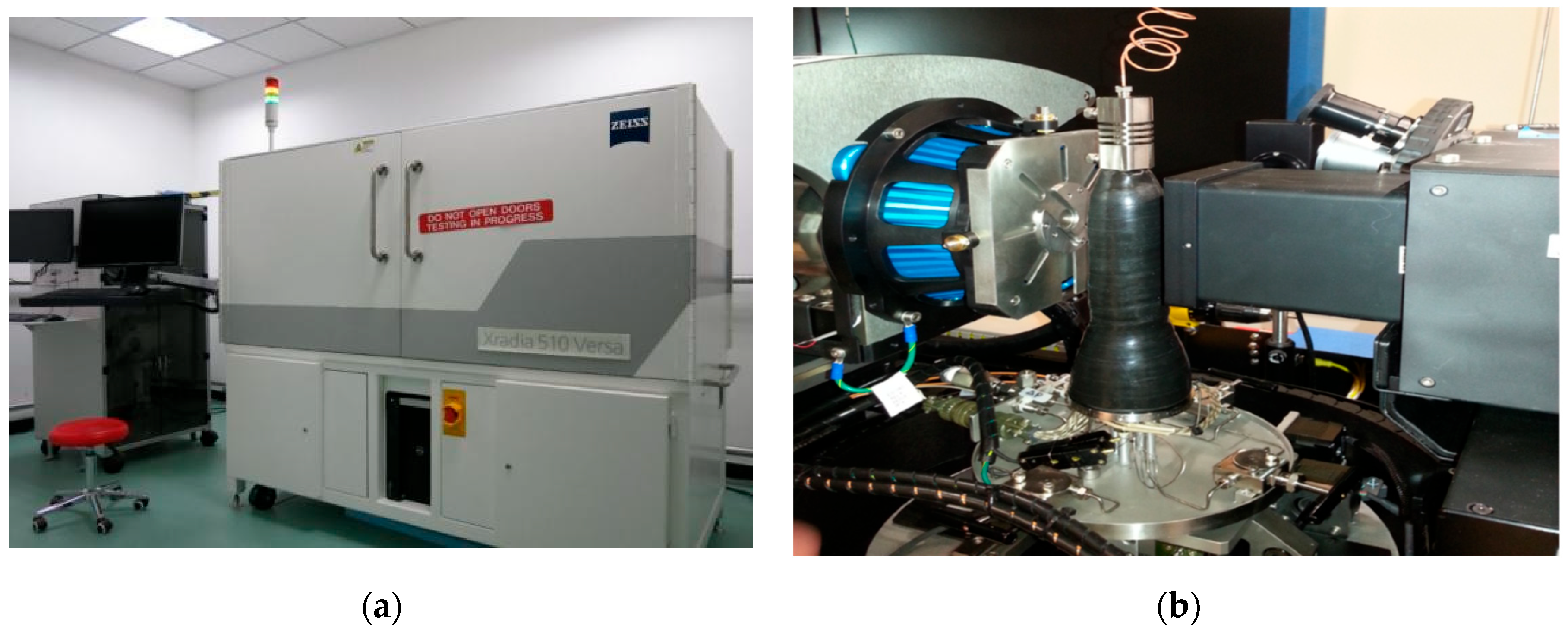

2.2.3. Micro Computed Tomography

3. Results and Discussion

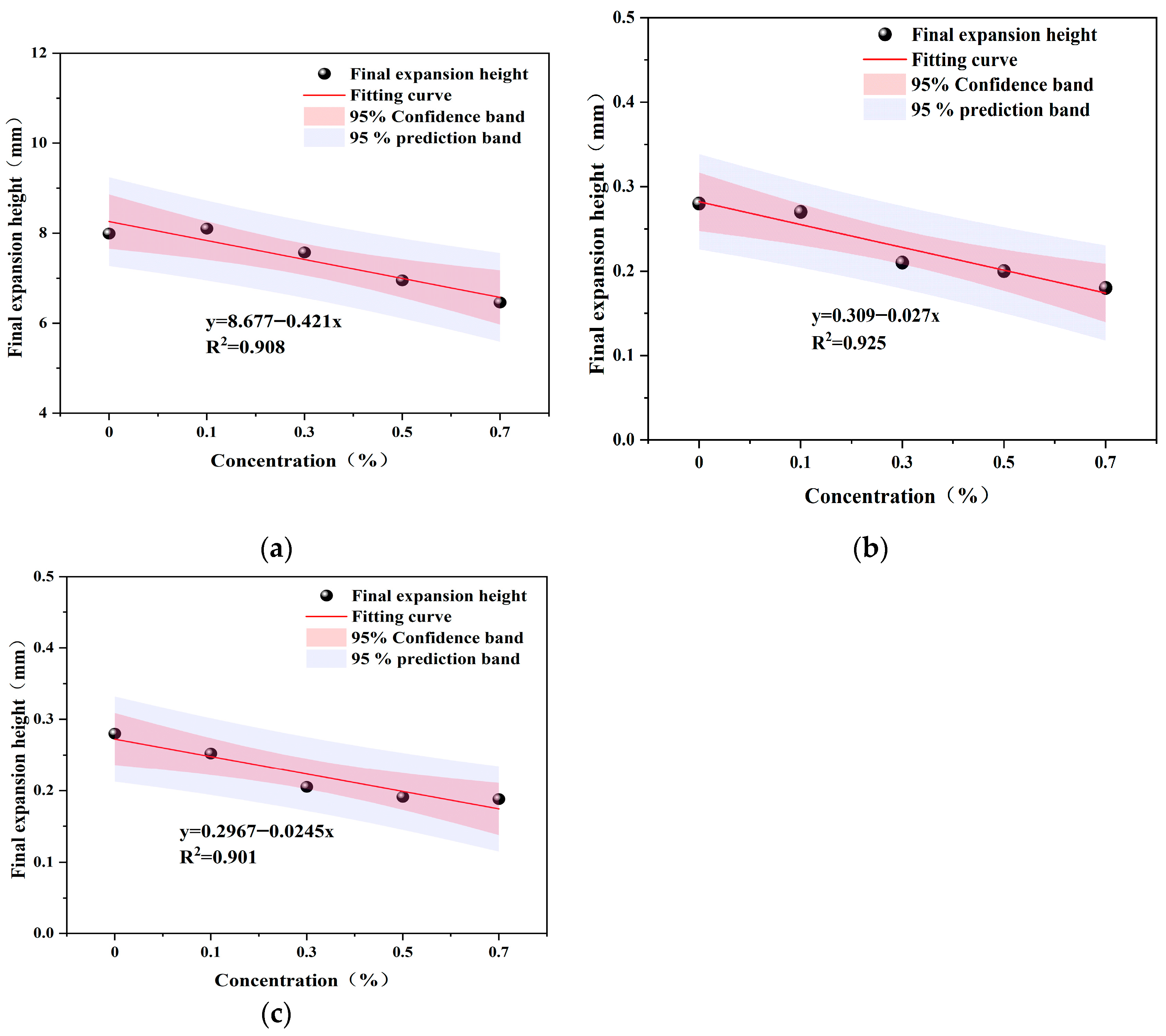

3.1. Hydration Expansion Characteristics of Minerals

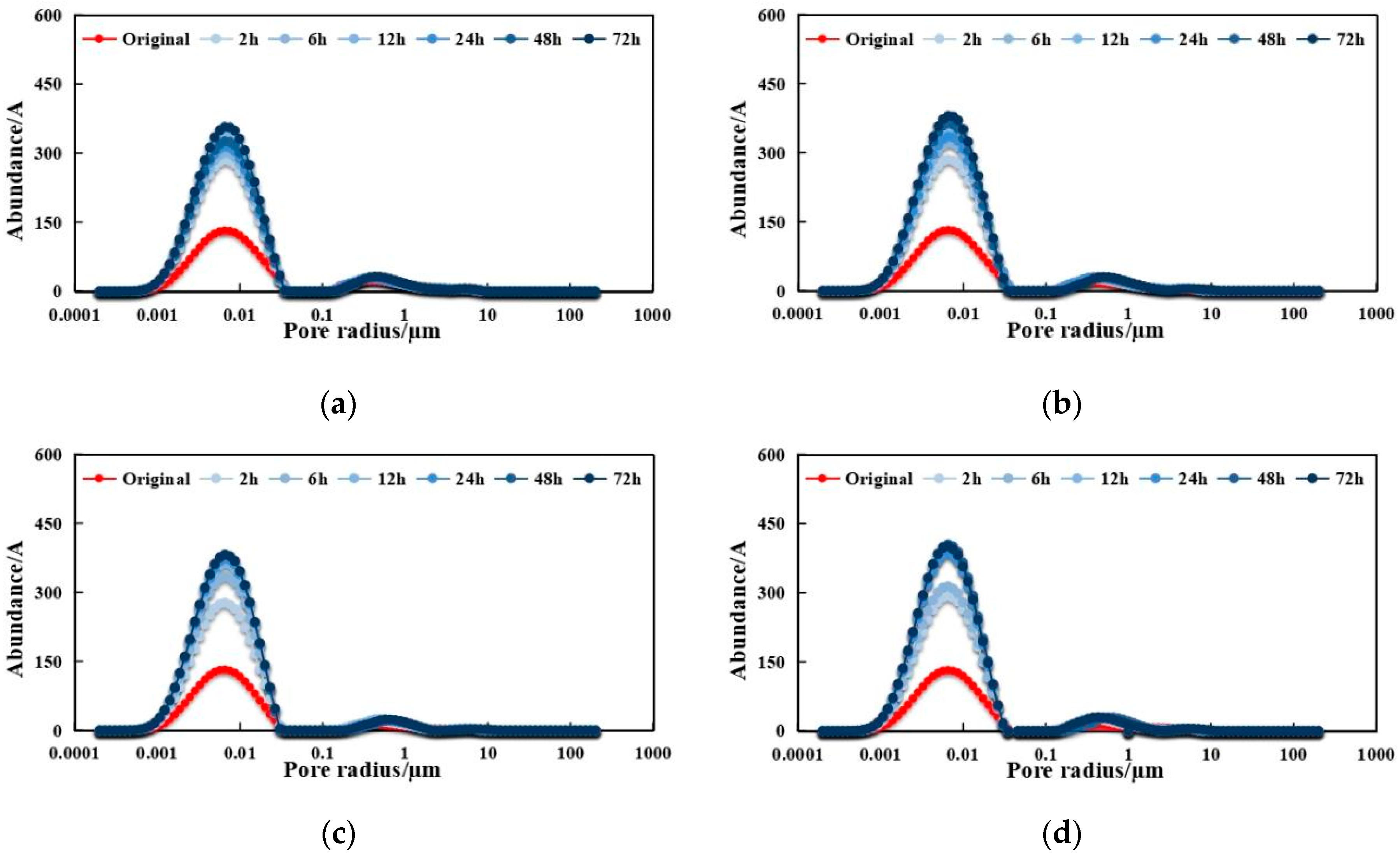

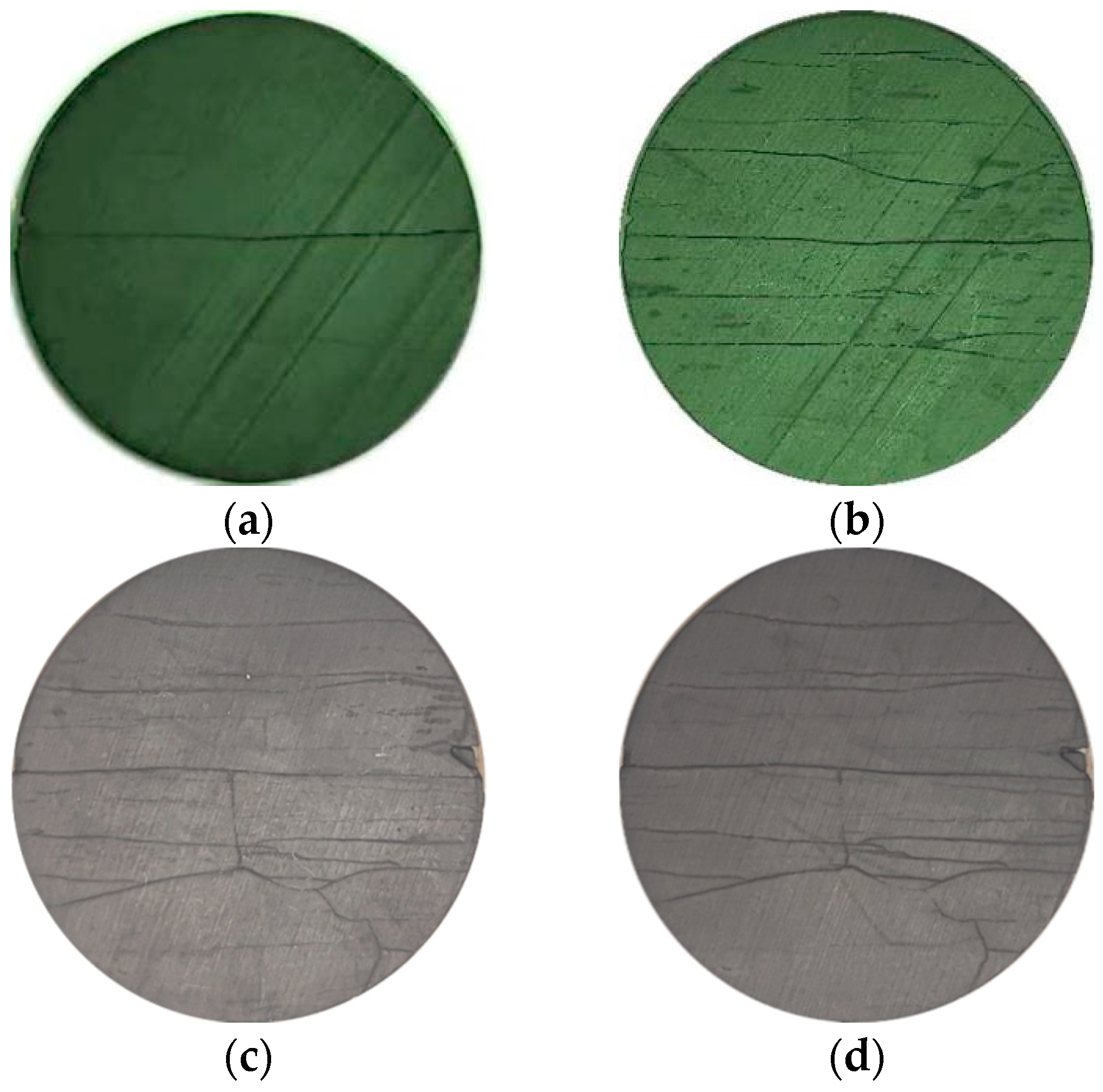

3.2. Dynamic Evolution Characteristics of Pore Structure

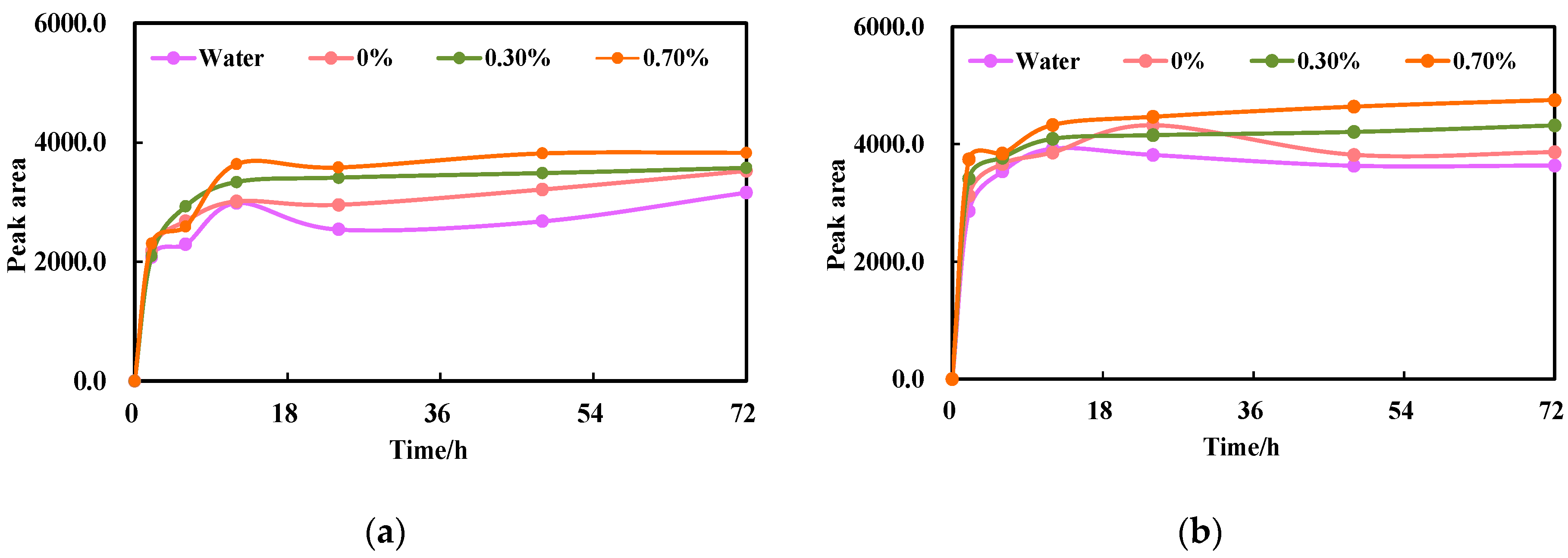

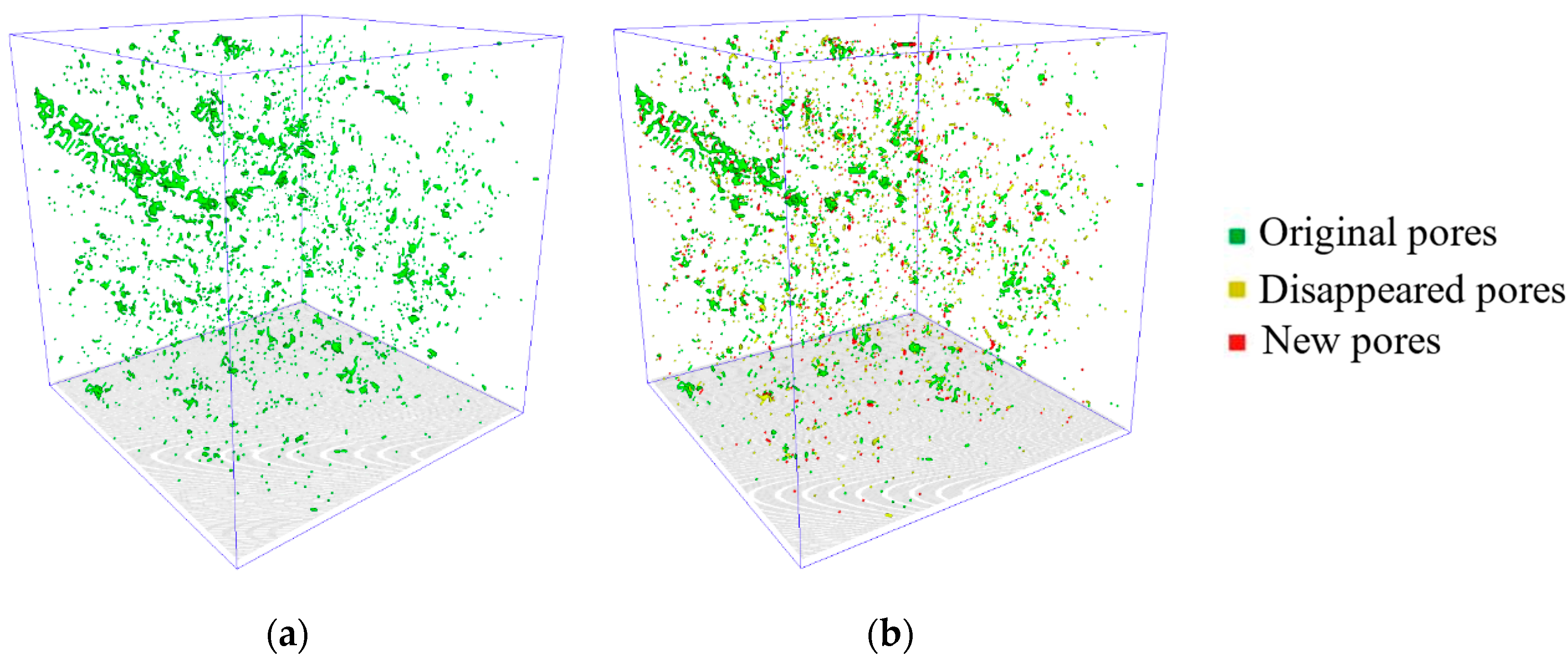

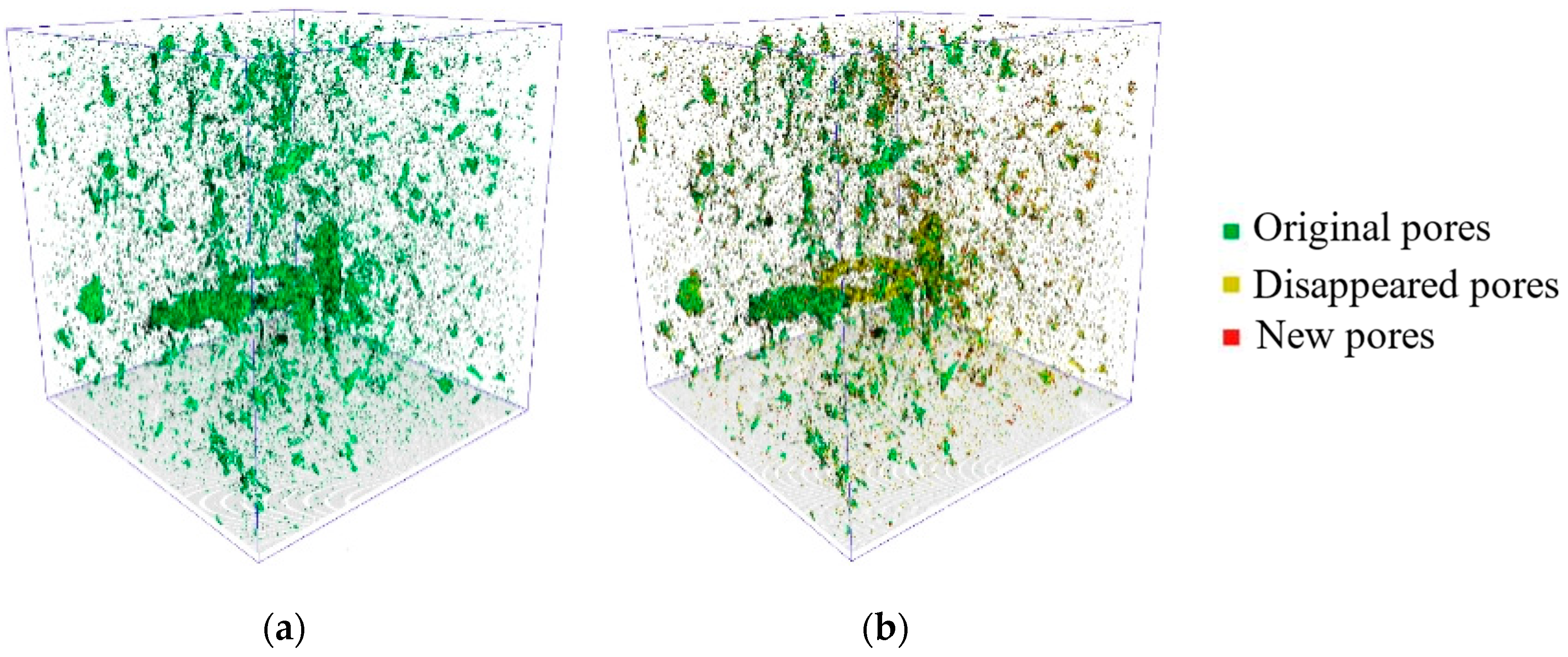

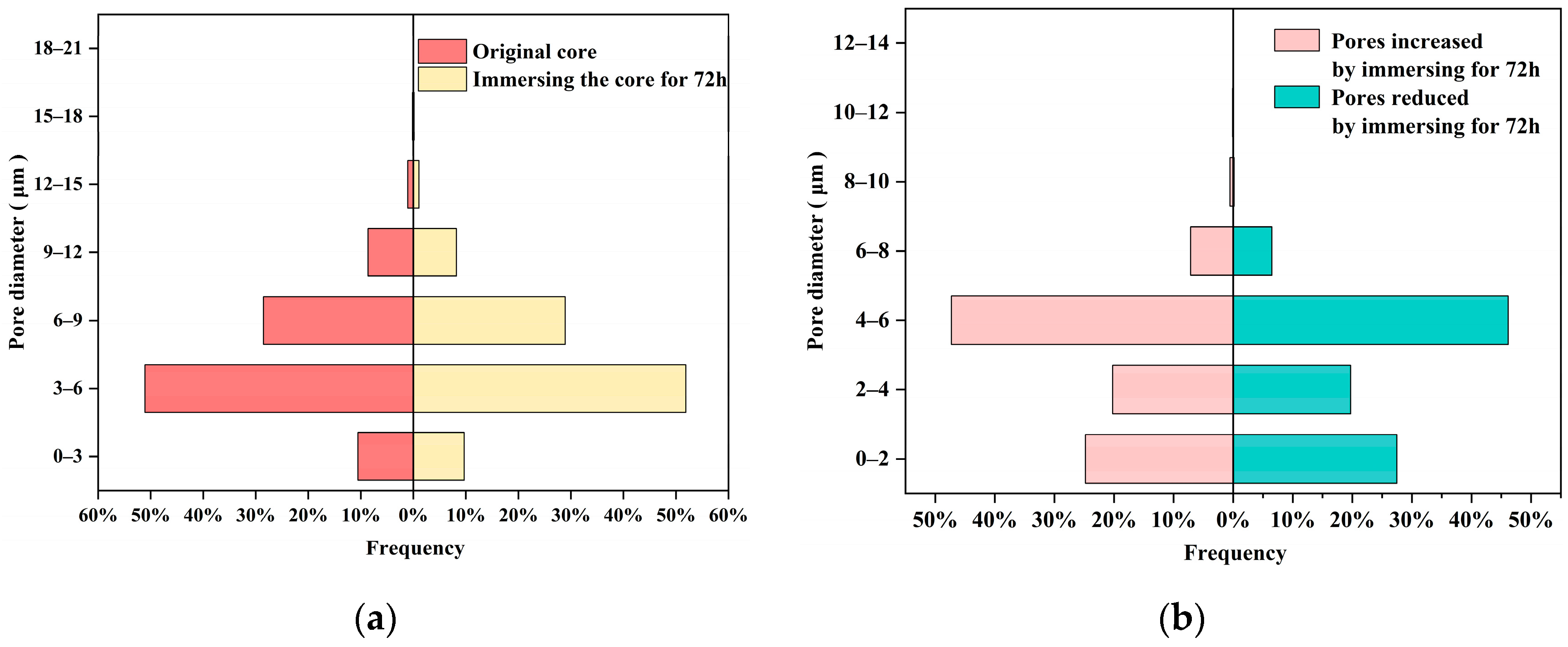

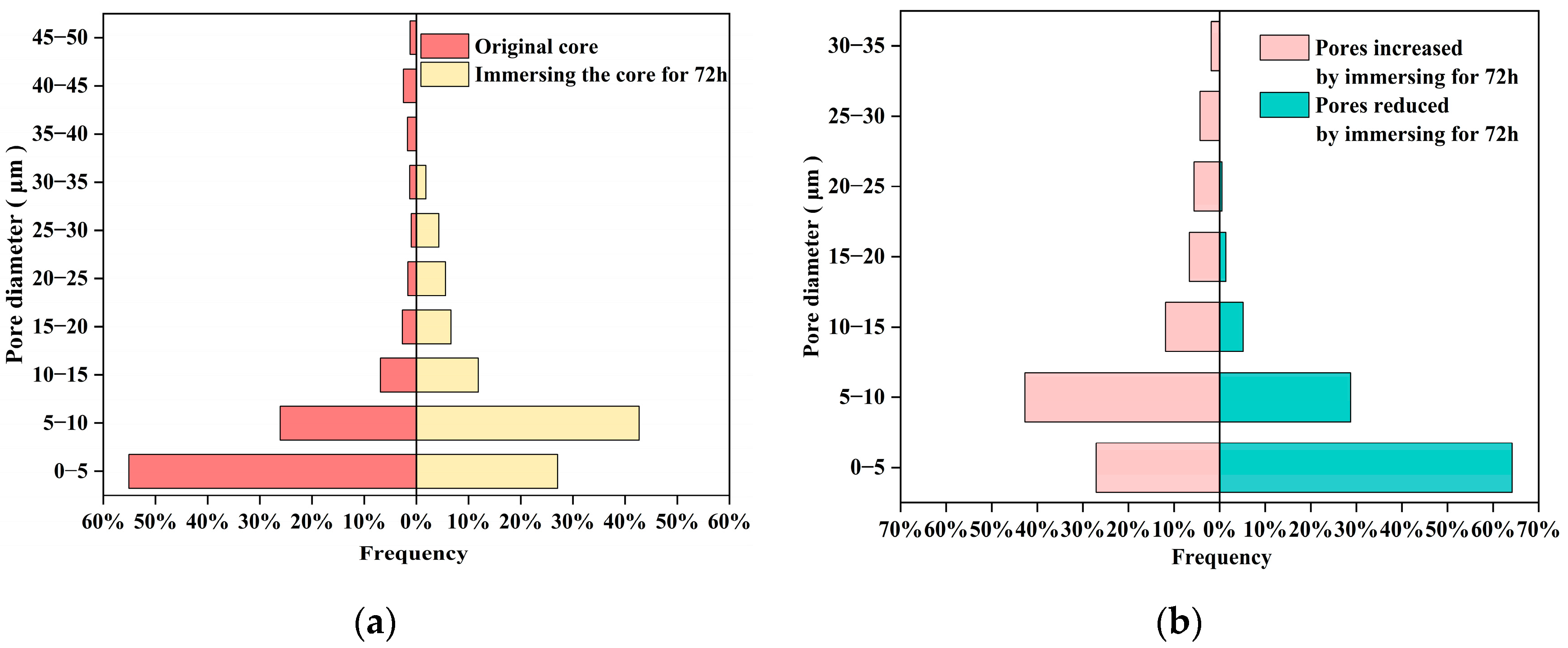

3.3. Evolution Law of Pore Structure

4. Conclusions

- (1)

- Both shale oil and gas reservoir cores exhibit water-sensitive expansion characteristics upon exposure to fracturing fluids, yet they display distinct reaction kinetics and processes. Shale gas cores, characterized by pronounced microporosity, narrow fractures, and strong capillary forces, undergo rapid and intense hydration expansion. This heightened reactivity increases the risk of water-lock damage and permeability impairment. Conversely, shale oil cores exhibit slower hydration reactions and a more stable expansion process, reflecting greater resilience to hydration-induced damage.

- (2)

- Hydration by fracturing fluids induces a dynamic evolution in reservoir pore structures, termed “damage–reconstruction.” After 72 h of hydration, both core types experience a net reduction in pore volume. However, shale oil cores demonstrate a superior capacity for pore reconstruction, wherein original micropores interconnect and coalesce to form larger pore networks, highlighting their enhanced potential for structural modification compared to gas cores.

- (3)

- NMR results reveal a biphasic imbibition pattern in both shale oil and gas cores, characterized by an initial rapid-imbibition phase followed by a saturation–equilibrium stage during fracturing fluid uptake. The incorporation of clay stabilizers, particularly at a 0.7% concentration, significantly mitigates hydration-induced damage, enhances pore connectivity, and augments fluid absorption capacity, thereby bolstering reservoir integrity.

- (4)

- Micro-CT imaging and pore size distribution analyses corroborate that shale oil cores undergo substantial pore expansion and structural reorganization during hydration, driven by the formation of larger pore networks. In contrast, shale gas cores, constrained by denser matrices and hydration-induced particle migration and pore blockage, exhibit a more intricate pore evolution process, resulting in limited overall changes to pore structure.

- (5)

- For the Chang 7 shale oil reservoir, its pore reconstruction potential indicates that the fracturing fluid can be used as a “matrix transformation” tool, not just a crack maker. By optimizing the fluid chemical formula to enhance dissolution and controlling clay expansion, it is expected to significantly increase the effective transformation volume and improve single-well productivity. In the shale gas development area, the “remodeled” pore network with improved connectivity may form more persistent flow channels, leading to a gentler production decline and higher ultimate recovery.

- (6)

- To further combine the microscopic mechanism with the macroscopic application, future research should focus on the following three directions: (1) according to the mineral characteristics of different lithofacies in Chang 7 member, a “customized” fracturing fluid formula is developed; (2) core displacement experiments under real confining pressure conditions are conducted to understand the coupling relationship between chemical action and stress-induced changes; and (3) the “damage–reconstruction” dual-mechanism reaction migration model is established and verified to more accurately simulate the effective transformation volume and mass, fracturing fluid filtration and ultimate recovery at the reservoir scale.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Micro-CT | Micro-Computed Tomography |

| CT | Computed Tomography |

| NMR | Nuclear Magnetic Resonance |

| SRV | Stimulated Reservoir Volume |

| T2 | Transverse Relaxation Time |

| 3D | Three-Dimensional |

References

- Yang, H.; Niu, X.; Xu, L.; Feng, S.; You, Y.; Liang, X.; Wang, F.; Zhang, D. Exploration potential of shale oil in Chang7 member, upper Triassic Yanchang formation, Ordos Basin, NW China. Pet. Explor. Dev. 2016, 43, 560–569. [Google Scholar] [CrossRef]

- Fu, J.; Li, S.; Niu, X.; Deng, X.; Zhou, X. Geological characteristics and exploration of shale oil in Chang 7 member of Triassic Yanchang Formation, Ordos Basin, NW China. Pet. Explor. Dev. 2020, 47, 931–945. [Google Scholar] [CrossRef]

- Fu, J.; Niu, X.; Dan, W.; Feng, S.; Liang, X.; Xin, H.; You, Y. The geological characteristics and the progress on exploration and development of shale oil in Chang7 Member of Mesozoic Yanchang Formation, Ordos Basin. China Pet. Explor. 2019, 24, 601–614. [Google Scholar]

- Guo, Q.; Li, S.; Jin, Z.; Zhou, X.; Liu, C. Characteristics and exploration targets of Chang 7 shale oil in Triassic Yanchang Formation, Ordos Basin, NW China. Pet. Explor. Dev. 2023, 50, 878–893. [Google Scholar] [CrossRef]

- Chen, G.; Gang, W.; Chang, X.; Wang, N.; Zhang, P.; Cao, Q.; Xu, J. Paleoproductivity of the Chang 7 unit in the Ordos Basin (North China) and its controlling factors. Palaeogeogr. Palaeoclimatol. Palaeoecol. 2020, 551, 109741. [Google Scholar]

- Cui, J.-W.; Zhu, R.-K.; Luo, Z.; Li, S. Sedimentary and geochemical characteristics of the Triassic Chang 7 member shale in the southeastern Ordos Basin, Central China. Pet. Sci. 2019, 16, 285–297. [Google Scholar] [CrossRef]

- He, X.; Chen, S.; Hu, C.; Zhang, H.; Mou, F.; Dai, L.; Lu, Y.; Fu, X.; Han, M. Pore Structure Change in the Continental Shale Oil Reservoir and Its Main Influencing Factors: A Case Study of the Chang 7 Member in the Ordos Basin. Processes 2023, 11, 2314. [Google Scholar] [CrossRef]

- Zou, C.; Pan, S.; Horsfield, B.; Yang, Z.; Hao, S.; Liu, E.; Zhang, L. Oil retention and intrasource migration in the organic-rich lacustrine Chang 7 shale of the Upper Triassic Yanchang Formation, Ordos Basin, central China. AAPG Bull. 2019, 103, 2627–2663. [Google Scholar] [CrossRef]

- Li, Q.; You, X.; Li, J.; Zhou, Y.; Lu, H.; Wu, S.; Yue, D.; Zhang, H. Pore structure and factors controlling shale reservoir quality: A case study of Chang 7 Formation in the Southern Ordos Basin, China. Energies 2024, 17, 1140. [Google Scholar] [CrossRef]

- Cao, S.; Li, S.; Dang, H.; Xing, H.; Zhang, L.; Zhang, T.; Bai, P. Pore Characteristics and controlling factors of Chang 7 shale in southeastern Ordos Basin. Xinjiang Pet. Geol. 2022, 43, 11–17. [Google Scholar]

- Zhang, F.; Li, G.; Zheng, X.; Wu, Q.; Li, Z.; Qi, Z.; Wang, J.; Zhang, L. Enlightenment from the post shale revolution era in North America. China Pet. Explor. 2022, 27, 26–39. [Google Scholar]

- He, X.; Zhang, P.; Gao, Y.; Wang, K.; He, G.; Ren, J.; Gao, Q.; Zang, S. Challenges and countermeasures for beneficial development of unconventional oil and gas resources in China. China Pet. Explor. 2025, 30, 26–41. [Google Scholar]

- You, L.; Xie, Y.; Chen, Y.; Kang, Y.; Huang, C.; Zhai, H. Development directions of formation damage evaluation and fracturing fluids in tight and shale oil reservoirs. Petroleum 2025, 11, 125–142. [Google Scholar] [CrossRef]

- Nath, F.; Garcilazo, R., Jr.; Collazo, J., Jr. Optimizing Hydraulic Fracturing in Water-Sensitive Shales: A Comparative Study of Frac Fluid Performance. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Houston, TX, USA, 9–11 June 2025. [Google Scholar]

- Ding, Y.; Yu, X.; Liu, X.; Gan, R.; Liang, L.; Xiong, J. Investigating dynamic spontaneous imbibition and hydration damage in shale. Fuel 2025, 386, 134243. [Google Scholar] [CrossRef]

- Chen, M.; Ning, X.; Kang, Y.; Wu, J.; Li, B.; Shi, Y.; Lai, Z.; Bai, J.; Yan, M. Effect of Fracturing Fluid Properties on the Flowback Efficiency of Marine and Continental Transitional Shale Gas Reservoirs in Ordos Basin. Processes 2025, 13, 1398. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Cao, H.; Wu, J.; Wang, F.; Wang, Y. The crack propagation behaviour of CO2 fracturing fluid in unconventional low permeability reservoirs: Factor analysis and mechanism revelation. Processes 2025, 13, 159. [Google Scholar] [CrossRef]

- Pang, J.; Wu, T.; Yu, X.; Zhou, C.; Chen, H.; Gao, J. The Effect of Water–Rock Interaction on Shale Reservoir Damage and Pore Expansion. Processes 2025, 13, 1265. [Google Scholar] [CrossRef]

- Zhao, P.; Fan, X.; Zhang, Q.; Yao, B.; Zhang, M.; He, L.; Qiang, Y.; Liu, J. Characteristics of Hydration Damage and Its Influence on Permeability of Lamellar Shale Oil Reservoirs in Ordos Basin. Geofluids 2021, 2021, 6646311. [Google Scholar] [CrossRef]

- Liu, K.; Sheng, J.J. Experimental study of the effect of stress anisotropy on fracture propagation in Eagle Ford shale under water imbibition. Eng. Geol. 2019, 249, 13–22. [Google Scholar] [CrossRef]

- Lyu, Q.; Ranjith, P.; Long, X.; Kang, Y.; Huang, M. A review of shale swelling by water adsorption. J. Nat. Gas Sci. Eng. 2015, 27, 1421–1431. [Google Scholar] [CrossRef]

- Lu, Q.; Kuang, B.; Guo, J.; Mu, Q.; Bai, J.; Gong, X. Research on the mechanism of fracture propagation induced by shale hydration. Geosystem Eng. 2025, 28, 375–389. [Google Scholar] [CrossRef]

- Liu, K.; Ding, W.; Peng, M.; Song, F.; Zhuang, Y.; Zhao, X.; Wang, C. Experimental Study on the Expansion Mechanism of Secondary Fractures Formed by Shale Hydration in Fracturing Development. ACS Omega 2025, 10, 13928–13942. [Google Scholar] [CrossRef] [PubMed]

- SY/T 5613-2016; Testing of Drilling Fluids–Testing Method of Physical and Chemical Properties for Shale. National Energy Administration: Beijing, China, 2016.

- Wang, L.; Du, Y.; Wu, G.; Fu, X.; Xu, C.; Pan, Z. Application of nuclear magnetic resonance technology in reservoir characterization and CO2 enhanced recovery for shale oil: A review. Mar. Pet. Geol. 2025, 177, 107353. [Google Scholar] [CrossRef]

- Cheng, Y.; Li, Z.; Xu, L. Effects of Fracturing Fluids on Properties of Shale Reservoir: A Case Study of the Longmaxi Formation in the Sichuan Basin. Minerals 2025, 15, 392. [Google Scholar] [CrossRef]

- Zheng, H.; Yang, F.; Guo, Q.; Liu, K. Upscaling characterizing pore connectivity, morphology and orientation of shale from nano-scale to micro-scale. Mar. Pet. Geol. 2025, 172, 107213. [Google Scholar]

- Yang, F.; Ma, D.; Duan, Z.; Ren, D.; Tian, T.; Fu, D. Micropore Structural Characteristics and Influence Factors of Triassic Shale Gas Adsorption in the Ordos Basin. Front. Phys. 2022, 10, 851131. [Google Scholar] [CrossRef]

- Shi, P.; Zhou, W.; Zhang, J.; Yin, J.; Chen, Y. Geological Characteristics and Exploration Practices of Multilayer Shale Oil and Gas in the Yanchang Formation, Fuxian–Ganquan Area, Ordos Basin. Appl. Sci. 2024, 14, 7013. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Bai, L.; Xiao, P.; Feng, Z.; Wang, M.; Wang, B.; Zeng, F. Experimental Investigation of Hydraulic Fracturing Damage Mechanisms in the Chang 7 Member Shale Reservoirs, Ordos Basin, China. Energies 2025, 18, 5355. https://doi.org/10.3390/en18205355

Wang W, Bai L, Xiao P, Feng Z, Wang M, Wang B, Zeng F. Experimental Investigation of Hydraulic Fracturing Damage Mechanisms in the Chang 7 Member Shale Reservoirs, Ordos Basin, China. Energies. 2025; 18(20):5355. https://doi.org/10.3390/en18205355

Chicago/Turabian StyleWang, Weibo, Lu Bai, Peiyao Xiao, Zhen Feng, Meng Wang, Bo Wang, and Fanhua Zeng. 2025. "Experimental Investigation of Hydraulic Fracturing Damage Mechanisms in the Chang 7 Member Shale Reservoirs, Ordos Basin, China" Energies 18, no. 20: 5355. https://doi.org/10.3390/en18205355

APA StyleWang, W., Bai, L., Xiao, P., Feng, Z., Wang, M., Wang, B., & Zeng, F. (2025). Experimental Investigation of Hydraulic Fracturing Damage Mechanisms in the Chang 7 Member Shale Reservoirs, Ordos Basin, China. Energies, 18(20), 5355. https://doi.org/10.3390/en18205355