1. Introduction

The energy transition involves a shift in electricity generation from fossil fuels (i.e., oil, coal, and natural gas) to clean energy systems [

1,

2,

3]. The energy transition effort worldwide is driven by the facts of environmental pollution and climate change, which are deepened by the intense use of fossil resources that dominate the energy market, accounting for approximately 73% of greenhouse gases (GHGs) [

4]. Large-scale actions such as the Paris Climate Agreement 2012–2015, the 2030 Agenda adopted by the United Nations, and the 26th Conference of the Parties (COP26) are the most representative in achieving this energy transition. The Paris Agreement has as one of its pillars the development of new technologies to displace the transformation of energy from polluting sources, thus reducing CO

2 emissions by 2030. The 2030 Agenda proposes goals and targets for sustainable development, encompassing social, economic, political, and environmental aspects. The COP26 (held in 2021) establishes climate change as a priority, emphasizing the achievement of carbon neutrality in all countries and regions [

5].

In this sense, the study of renewable energies has been promoted, highlighting their competitiveness with traditional energy sources, depending on the location and available resources. These energy systems have gained increased applicability in recent years, with wind energy being a notable example [

6]. In particular, small wind turbines (SWTs) offer energy transition solutions for decentralized systems where grid connection is not feasible [

7] or non-interconnected areas [

8] where diesel plants currently meet the load [

9].

However, the design of SWTs faces a complexity balance in terms of efficient operation and suitability for various environments [

10]. Particularly, SWTs are placed in unfavorable wind conditions, such as low ground clearance and terrain obstacles that limit wind speed and cause turbulence [

11,

12]. In this regard, aerodynamic design strategies and different control approaches have been explored to improve SWTs [

13,

14]. In practice, SWTs are often installed in suboptimal wind environments, characterized by low ground clearance and the presence of terrain obstacles that reduce wind speed and increase turbulence [

11,

12].

To address the challenges posed by suboptimal wind conditions, different aerodynamic design strategies and control approaches have been developed to improve the performance of small wind turbines. Among these, the most common control methods are stall and pitch control. The stall control system is often preferred in SWTs due to cost and nacelle space limitations as it allows manufacturers to avoid implementing a blade pitch mechanism, thereby reducing installation expenses [

15]. However, this approach typically compromises the aerodynamic design of the blades, resulting in lower annual energy production (AEP) and limiting peak performance to maintain smooth energy regulation above the rated wind speed. Conversely, pitch control actively adjusts the blade angle to regulate the rotational speed, optimizing the turbine’s performance according to the wind resource at the operating site [

15]. In this sense, it functions as an aerodynamic control strategy that modulates power output by altering the rotor’s aerodynamic behavior [

16]. While pitch control enables enhanced power regulation and performance, it can also influence the structural loads acting on the turbine, either reducing or increasing them depending on the operating conditions [

14].

There are two primary methods for implementing pitch control: active and passive. Active pitch control regulates the pitch angle of the blades actively, i.e., by a mechanism that rotates the blade, thereby adjusting the response of the wind turbine rotor to the existing wind conditions [

17]. This mechanism can be integrated into a feedback control system [

18]. The high costs of active pitch control systems [

14] have compelled many small-scale turbines to adopt a fixed pitch control methodology, resulting in a suboptimal power regulation effect. The use of fixed blades is a primary technical disadvantage compared to large-scale horizontal wind turbines, which include active pitch control strategies to improve performance [

19]. Meanwhile, passive pitch control only depends on the blade structure and the aerodynamic load on the blade [

16,

18].

One approach to enhancing rotor energy capture and reducing loads through passive pitch control is the use of rotor blades with bend–twist coupling. This concept has been numerically investigated to induce a passive torsional response in the blades, with Maheri et al. [

20] reporting increases in annual energy production (AEP) of up to 13%. Similarly, Nicholls-Lee and Turnock [

21] observed AEP gains of 2.65% for a rotor incorporating variable pitch and curvature. Notably, several studies have focused on large-scale turbines in the megawatt range; for example, Barr and Jaworski [

22] reported a 14% increase in AEP for a 5 MW rotor. Passive bend–twist coupling incorporates several technologies for torsional blade actuation, including composite anisotropy, as demonstrated in aeroelastic and structural design work by Capuzzi et al. [

23,

24,

25]. Recently, Tamayo-Avendaño et al. [

26] employed a fluid–structure analysis in ANSYS 2023 R1 to evaluate the behavior of bending–torsional coupling in wind turbine blades, finding that the blade structure successfully undergoes torsional deflection along its longitudinal axis in response to an aerodynamic load, resulting in a 3% increase in annual energy production considering a wind resource with a Rayleigh distribution at an average speed of 11 m/s, an increase achieved without compromising key aspects of the technology, such as costs and structural integrity.

The use of pitch control is not only aimed at increasing generation power but is also used for load reduction. Some studies, such as the research by Sun et al. [

27], have analyzed and optimized load reduction in large-scale wind turbine blades, explicitly focusing on the 15 MW IEA blade model. The methodology encompassed the introduction of bend–twist coupling (BTC) load reduction parameters, geometric sweep change (GSC) in GXBeam software, calculation of blade aeroelastic loading using BEM theory, followed by obtaining the steady-state analysis model of the rotating blade. Additionally, in the context of small wind turbines, a two-part study by Papadakis and Condaxakis [

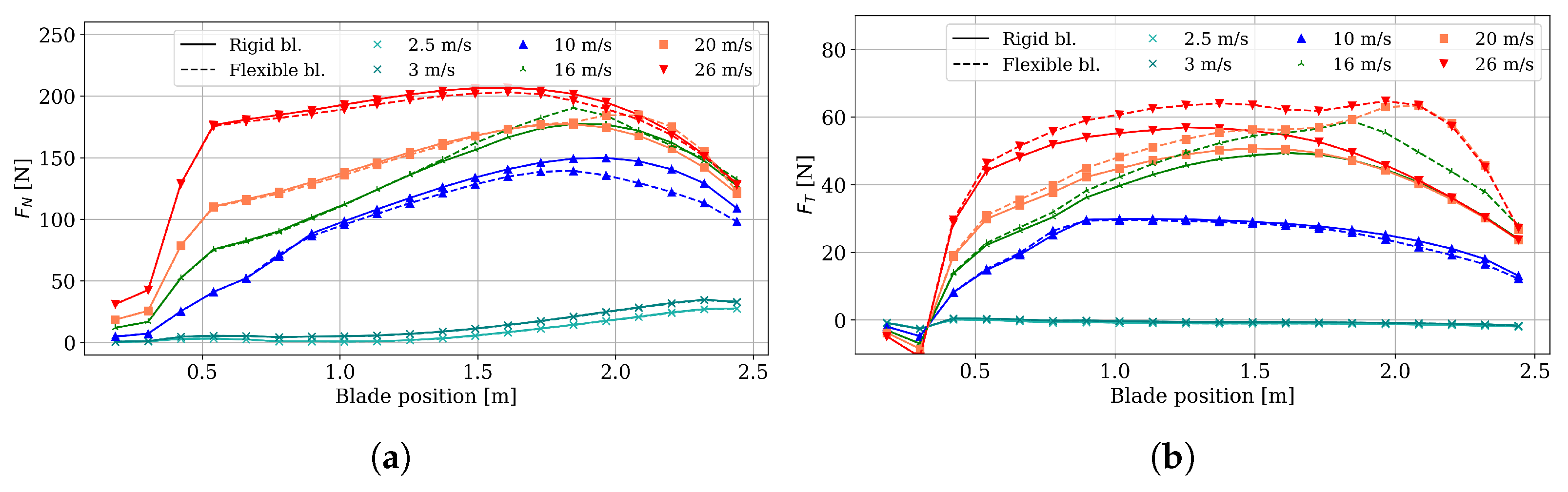

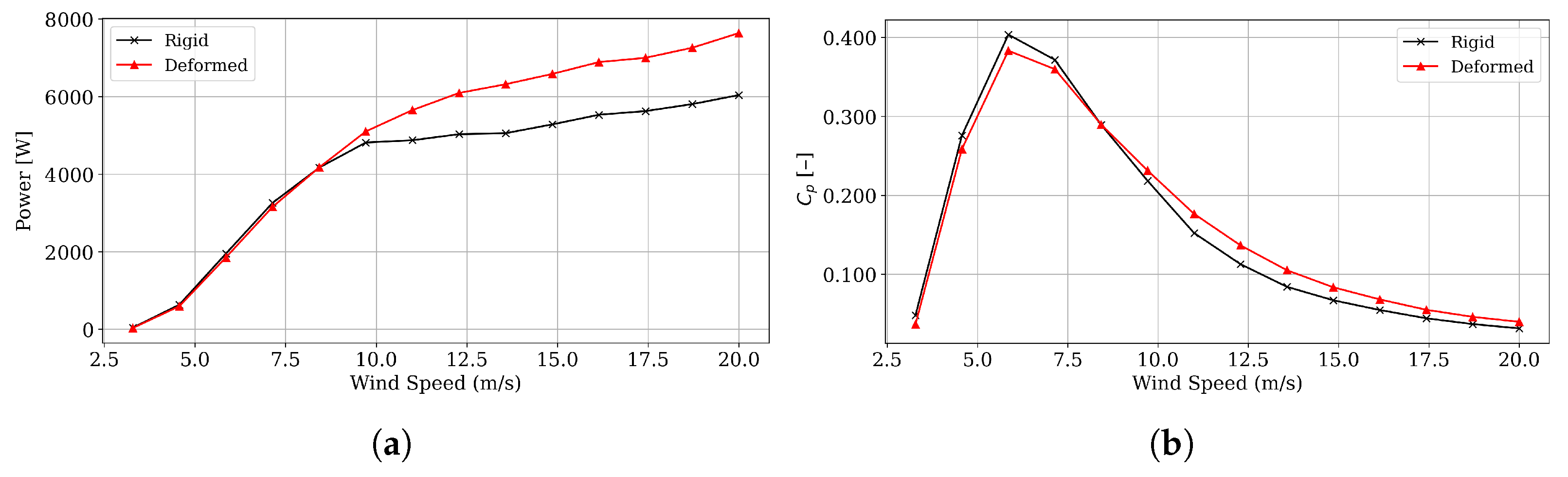

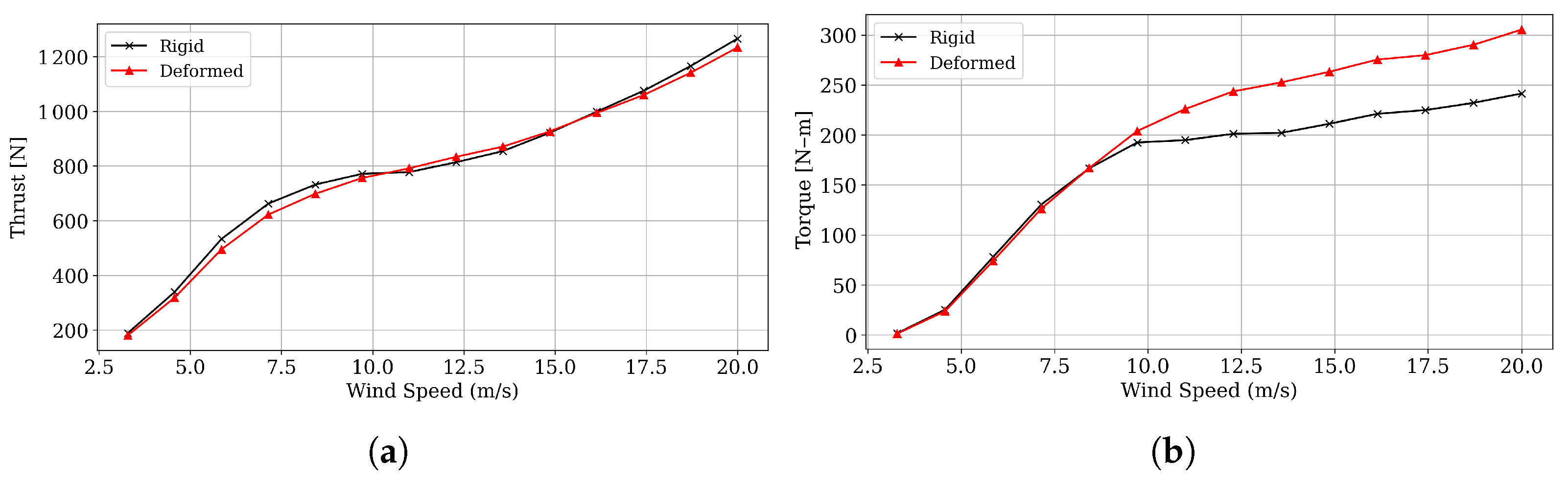

28,

29] analyzed the performance of flexible curved blades of a small-scale wind turbine for passive control, comparing them with rigid blades. The flexible blades limited maximum rotational speed and power at high wind speeds, started generating power earlier (4 m/s vs. 6 m/s), and showed stable output. The same work tested layered GFRP blades with fibers at 20°, which achieved quick startup, stable power between nominal and cutoff speeds, and safe shutdown, confirming the effectiveness of passive regulation, although with a need for design refinement. Furthermore, Farias et al. [

30] optimized the lamination sequence of a 660 W unidirectional composite blade to tailor BTC for passive load alleviation. Using BEM, ANSYS ACP/Fluent with two-way FSI, and surrogate models optimized via genetic algorithms, they constrained the axial displacement to 5% of the span length. The results showed that the torque increased by 8.3% compared to a spanwise unidirectional configuration. In comparison, the axial displacement remained below 3%, demonstrating that BTC-based tailoring is an effective passive pitch control strategy under overload conditions.

Given the complexity in the design of passive control by bend–twist coupling, some studies have opted for optimization techniques, such as Restrepo-Montoya et al. [

31], who proposed a meta-model-based methodology to design laminates with a bend–twist coupling effect using genetic algorithms (GAs) and artificial neural networks (ANNs) integrated with a finite element model (FEA) capable of defining the stacking sequence that a laminate needs to reach a certain torsion angle when subjected to a bending load. This type of strategy resembles that of Herath et al. [

32], who used a GA approach to optimize the composite layout in a morphing blade with differential stiffness element-induced bend–twist coupling. In other cases, the application of GA was used in the joint design of rotor geometry and structures by taking global parameters such as the AEP or the levelized cost of energy (LCOE) as the objective function of the optimization exercise [

33,

34,

35]. Techniques that decrease the computational cost for performing a bend–twist coupling analysis have also been evaluated. Babuska et al. [

36] developed a method involving the stiffness matrix (SMM) to analyze composite blades with bend–twist coupling, comparing it with commercial finite element models and analytical solutions. The technique proved to be accurate and versatile, enabling the efficient prediction of structural behavior in composite blades. The coupling resulted in a significant reduction in blade stiffness. Modal shapes and vibration frequencies were also significantly affected by coupling, and the analysis shows that correct predictions of natural frequencies are crucial due to their significant impact on operation.

Other studies have examined the integration of passive and active control to enhance wind turbine performance while mitigating structural loads. In this approach, blades are designed to rotate with flexure, thereby reducing the effective wind loads and lowering the demand on collective pitch actuators. For instance, Hayat and Ha [

37] investigated bend–twist coupling (BTC) in a 5 MW wind turbine blade, showing that it can reduce fatigue loads and decrease the reliance on active pitch actuators. Their results indicated that the effectiveness of active pitch control decreased as BTC increased. However, this effect diminished at higher wind speeds due to the reduced torsional deformation induced by the bending of the blades. Similarly, Zahle et al. [

38] demonstrated numerically that combining passive–active pitch control in large rotors can effectively relieve loads, with active blade pitch used to enhance energy capture below rated wind speeds and to alleviate structural loads above the rated range. Manolas et al. [

39] extended this line of research by analyzing passive and active load control methods on the DTU 10 MW Reference Turbine, showing that, while BTC alone reduced flapwise fatigue loads by about 7%, the greatest alleviation (≈30%) was achieved when combined with active strategies such as Individual Pitch Control (IPC) and Individual Flap Control (IFC). These works, however, focused on large-scale turbines, an idea supported by the conclusions of relatively recent studies such as [

40]. In contrast, the integration of passive–active hybrid pitch control in small wind turbines remains understudied, which underscores the novelty and relevance of the present study.

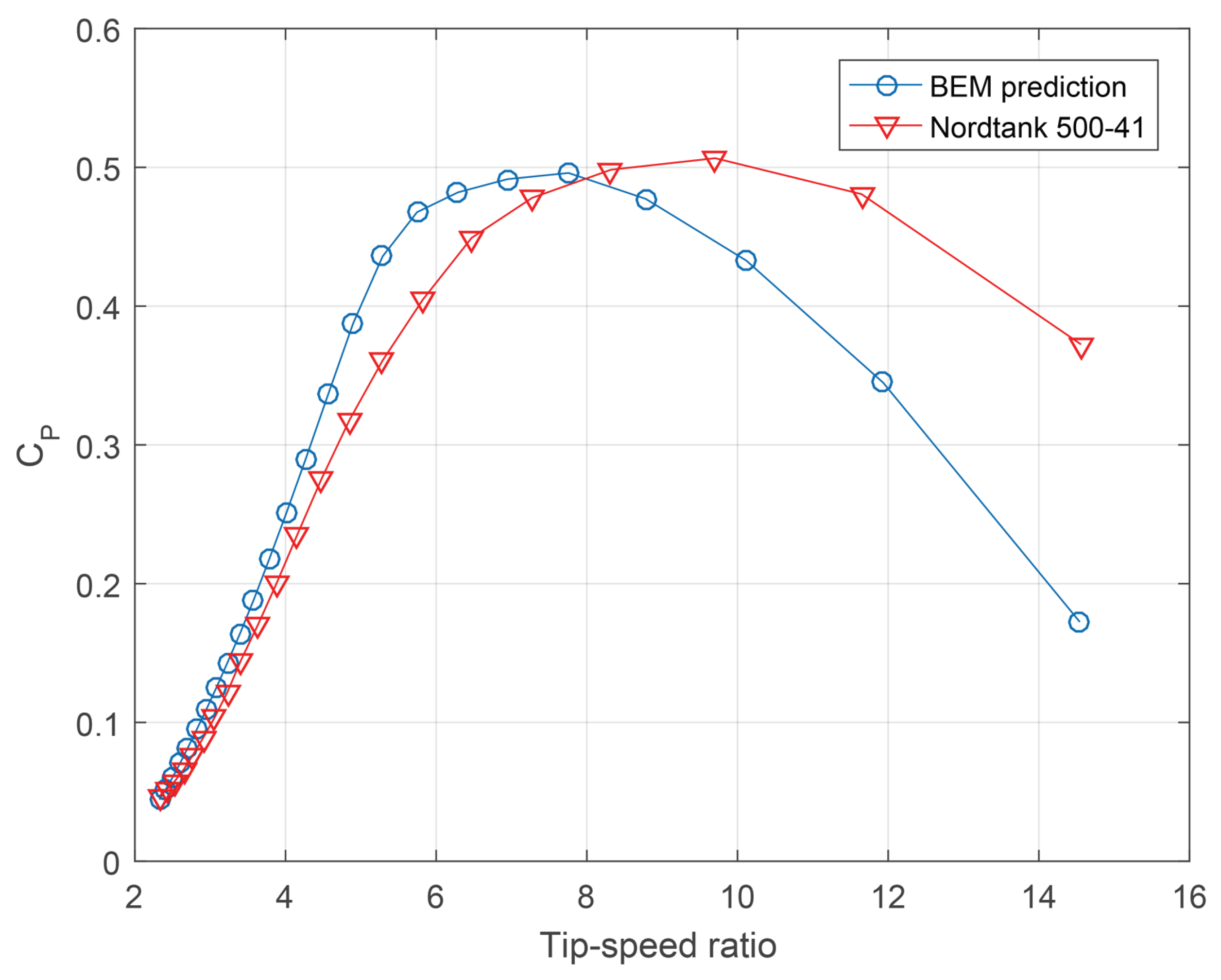

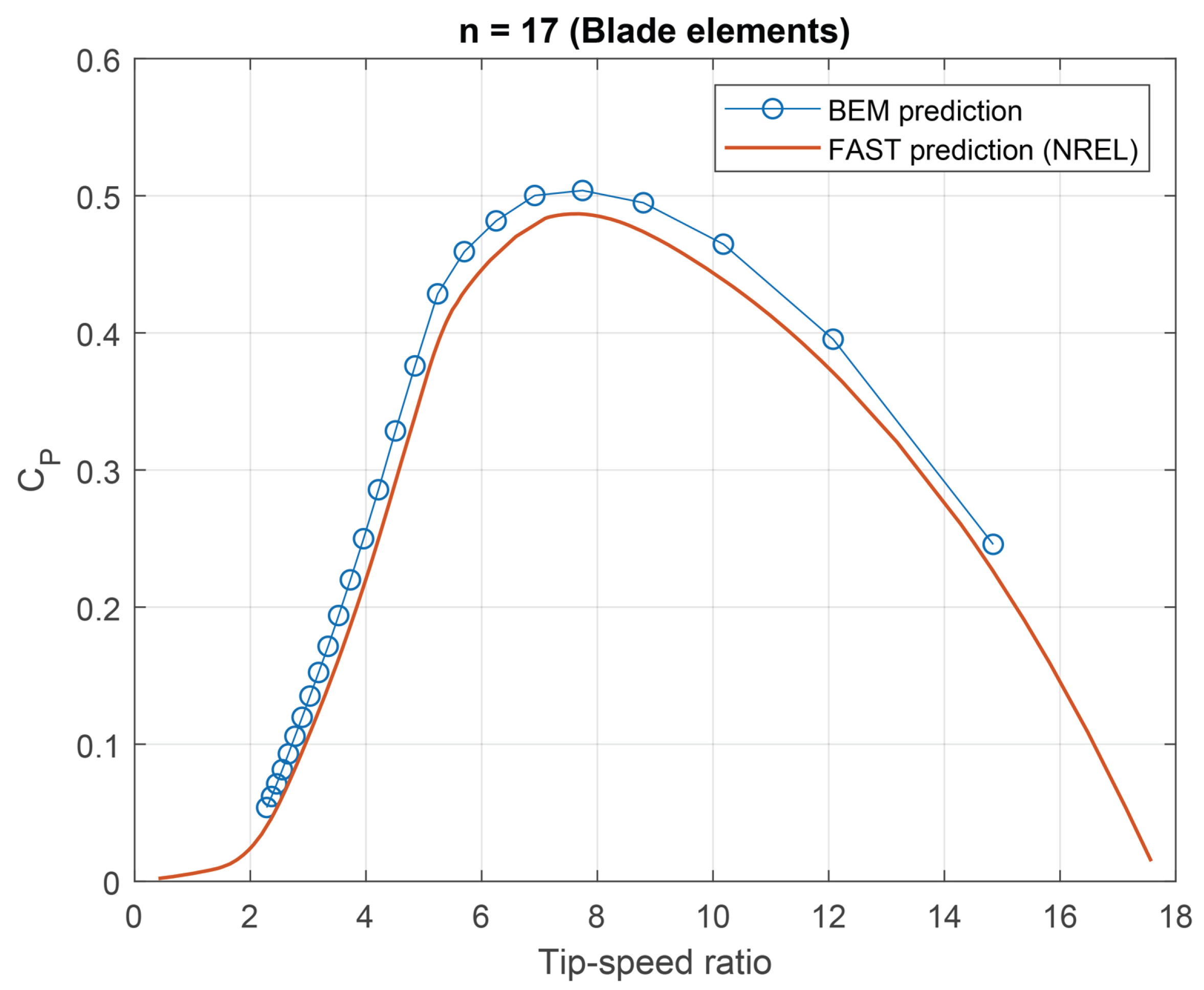

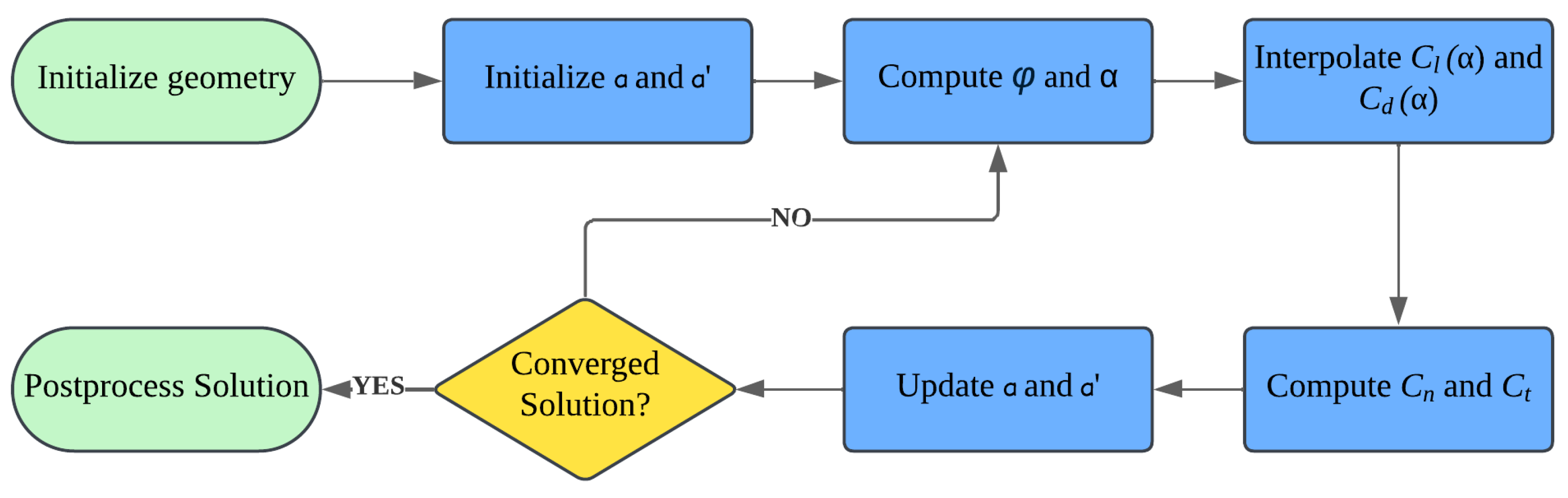

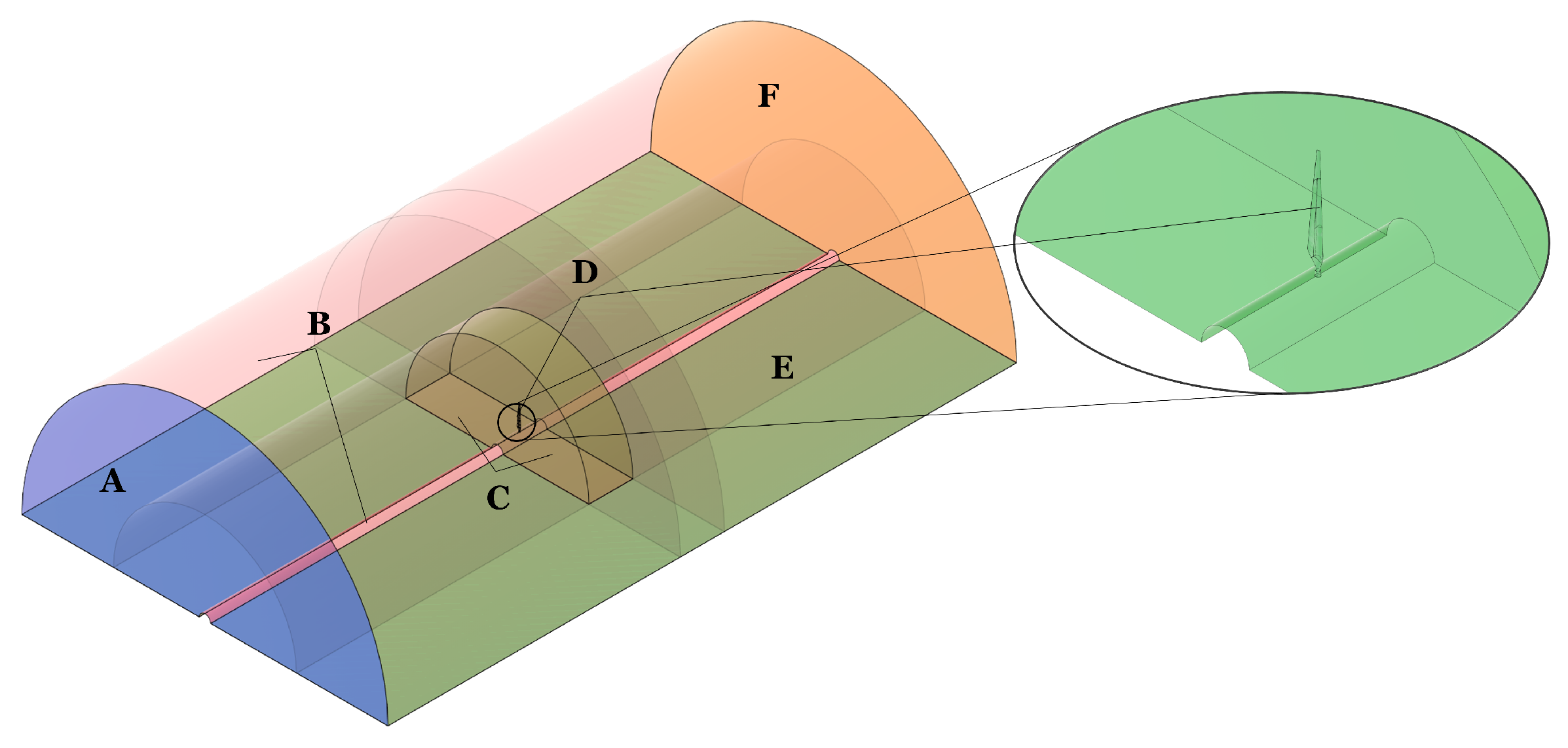

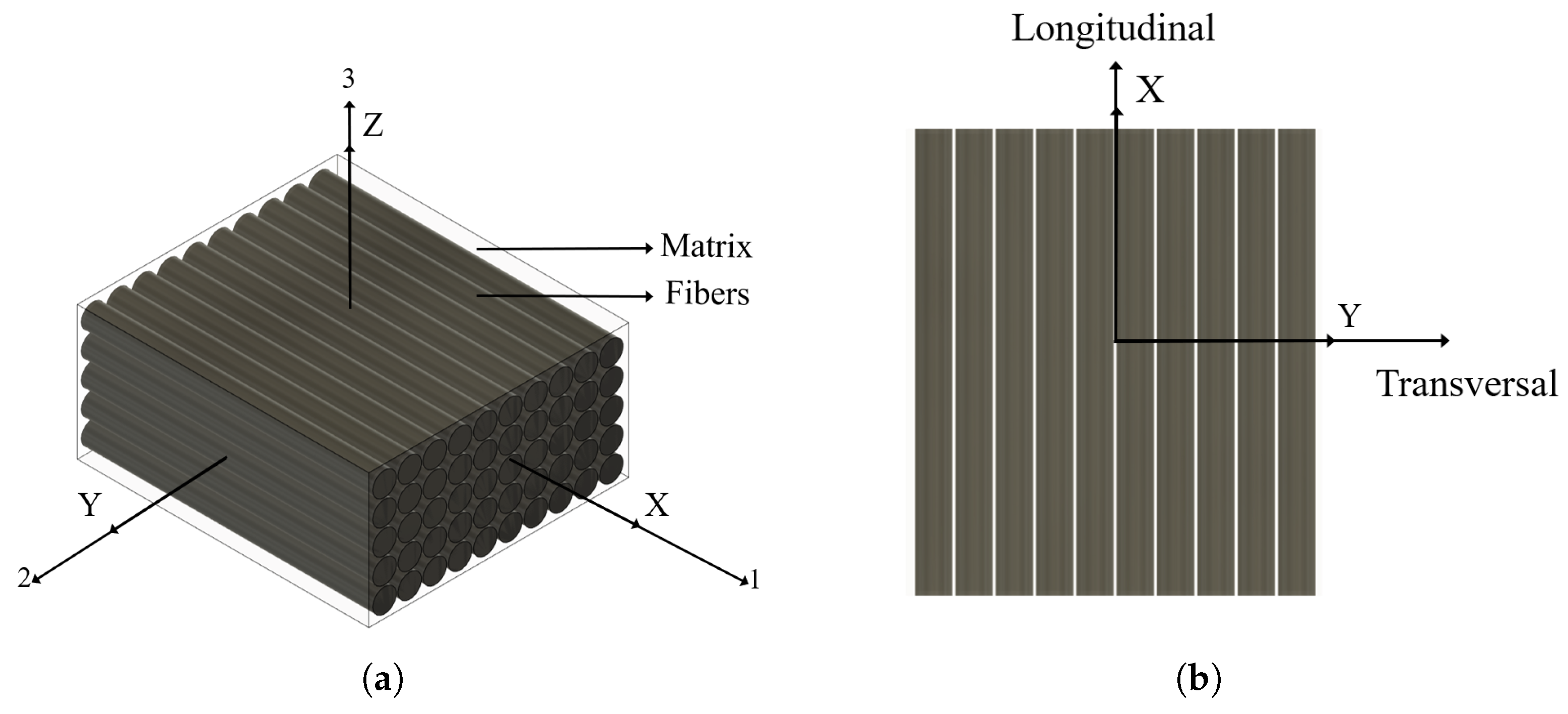

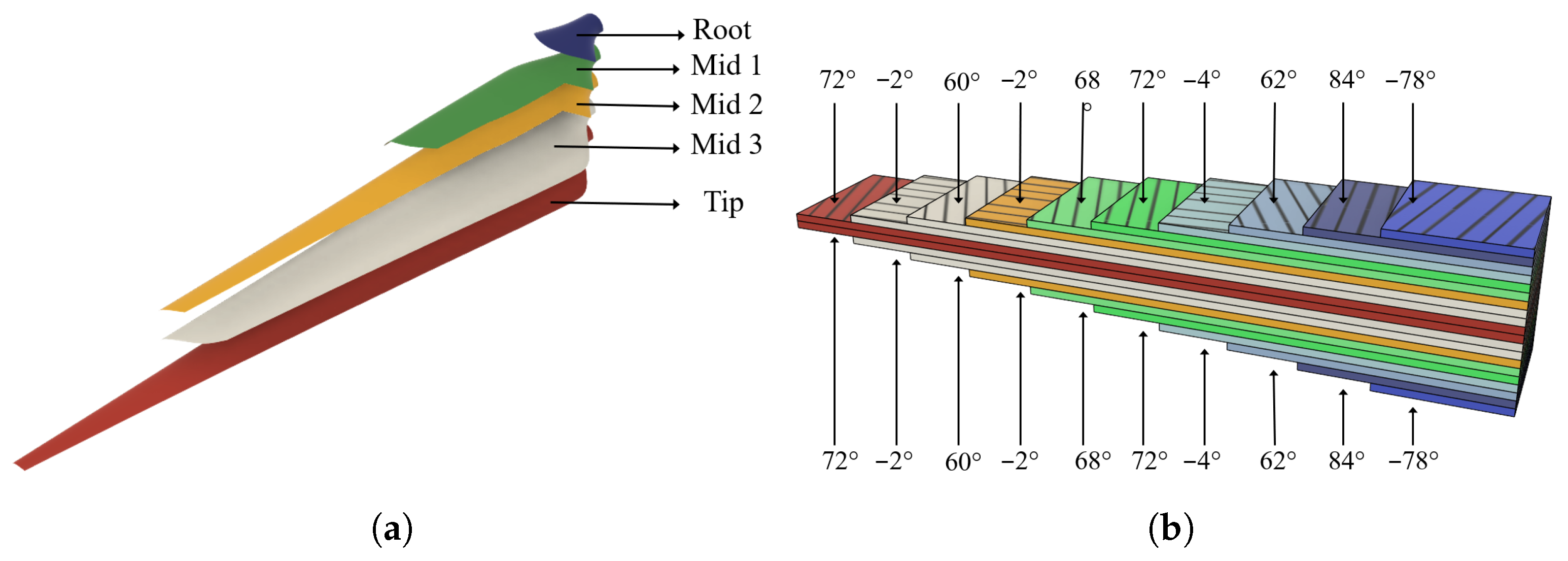

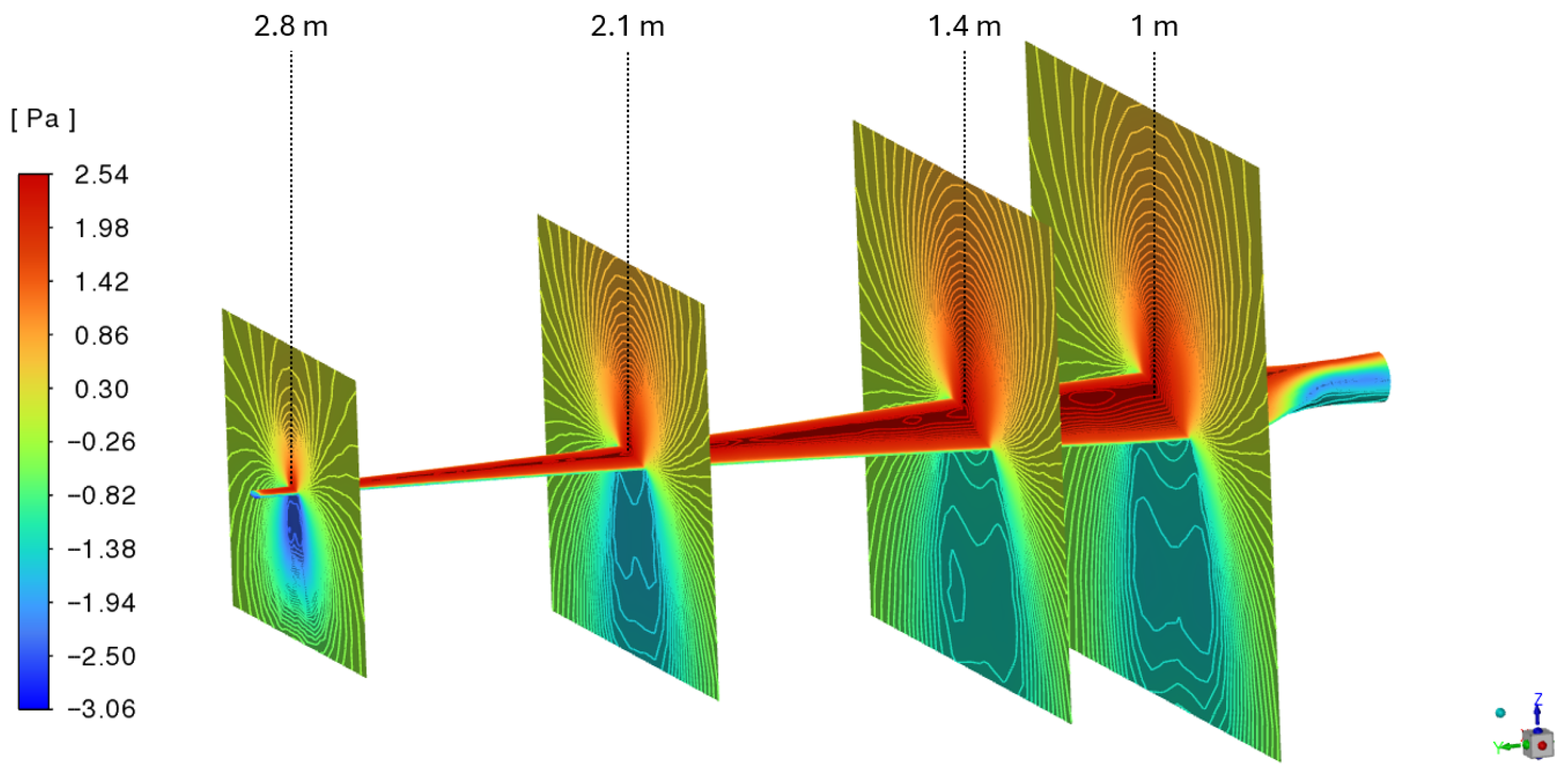

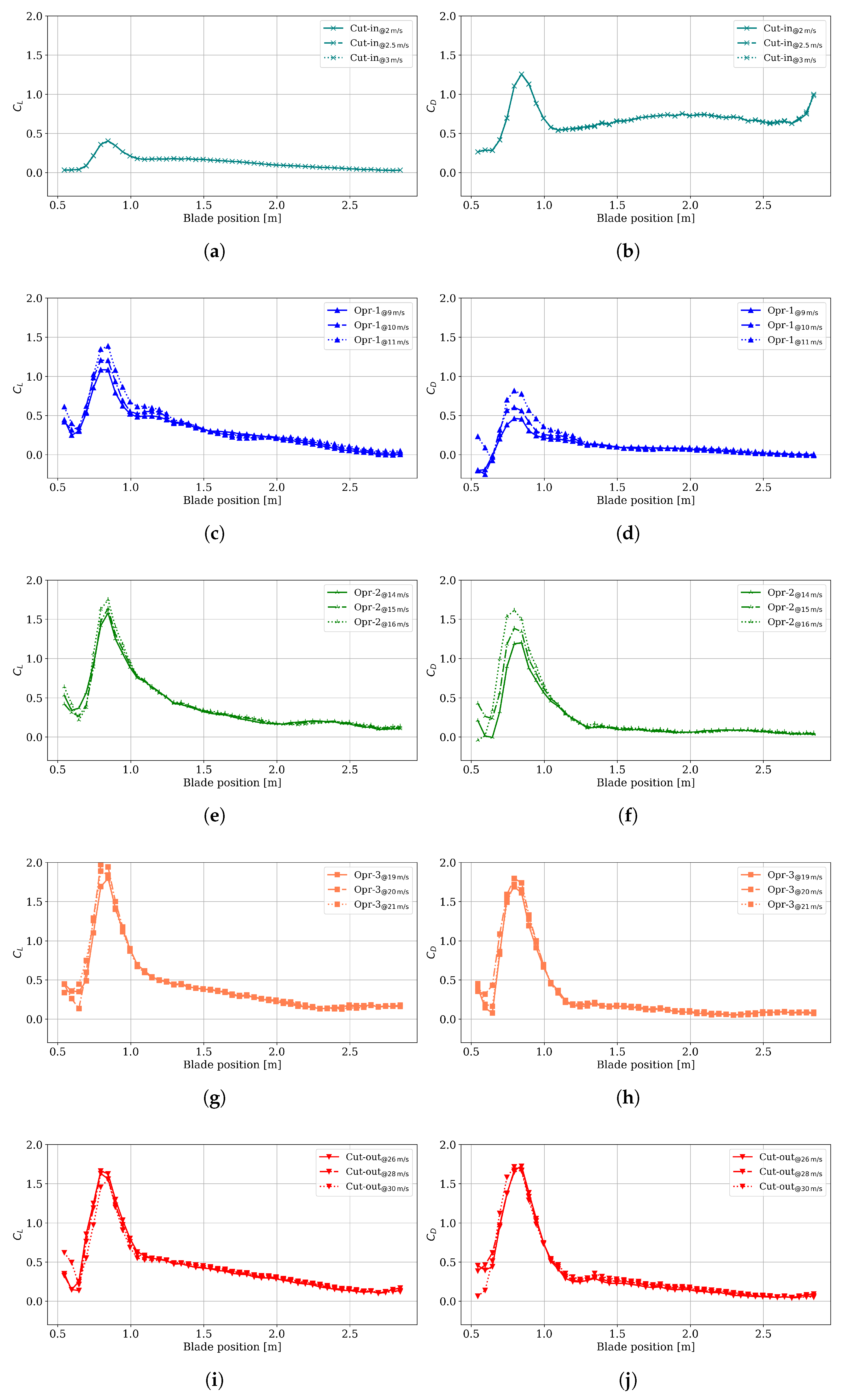

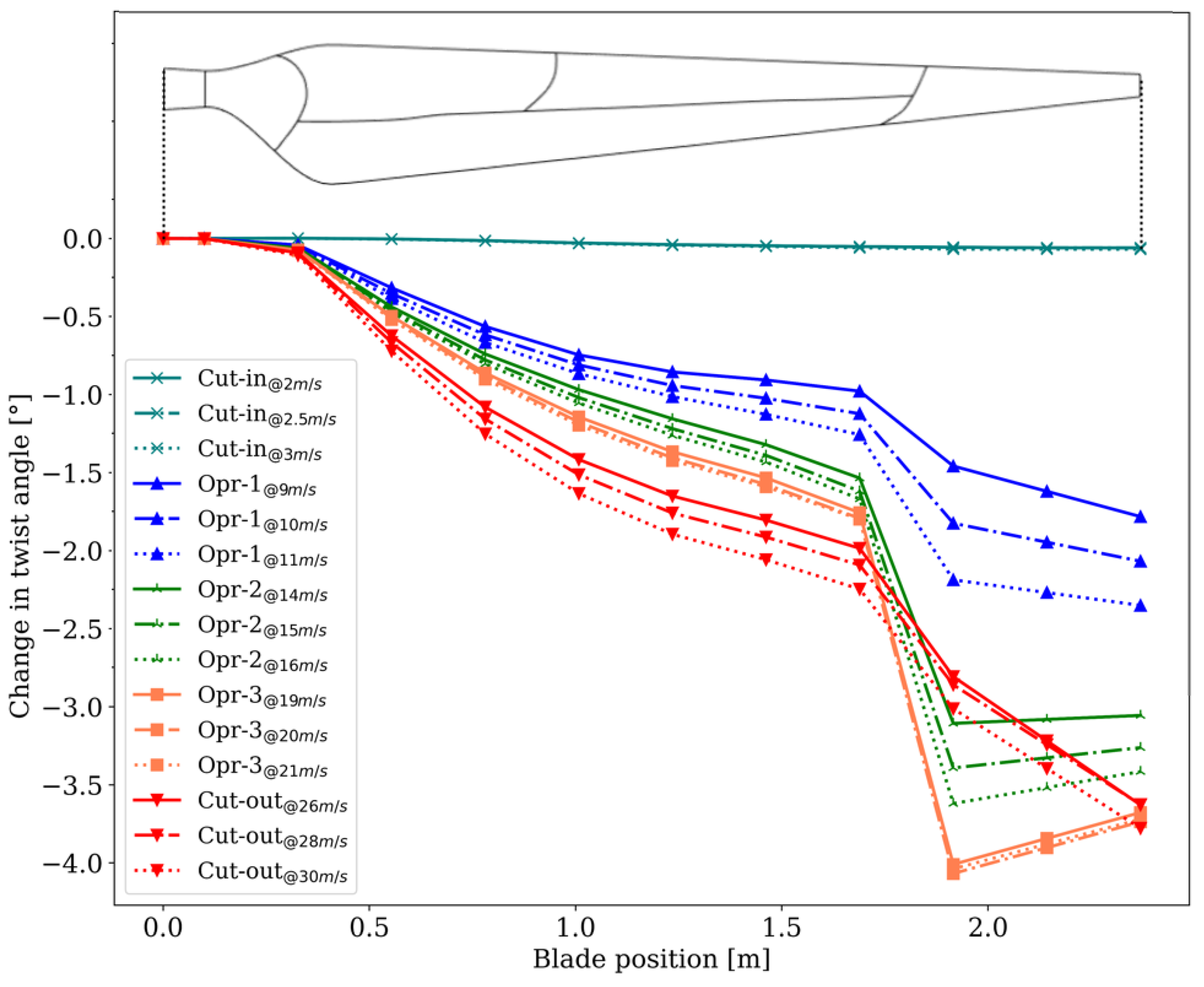

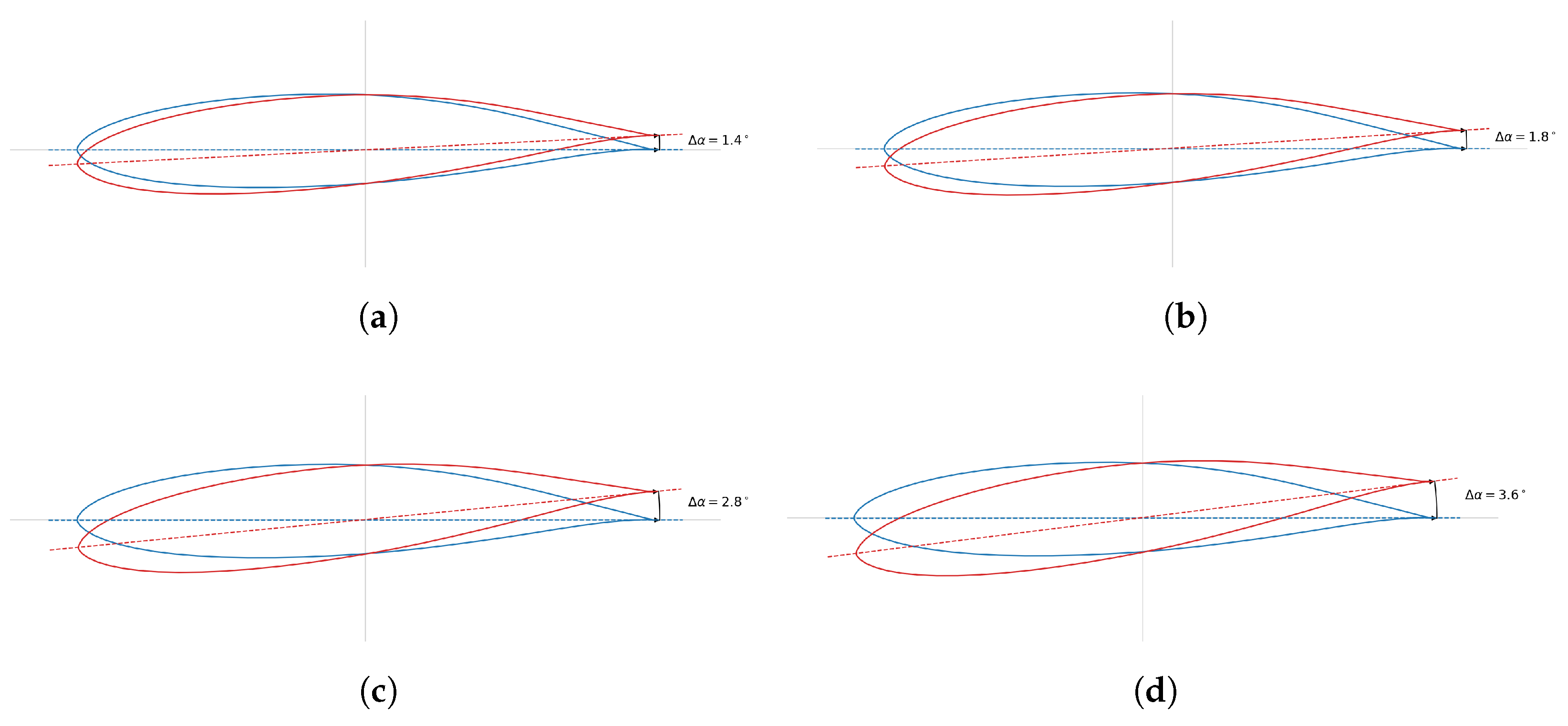

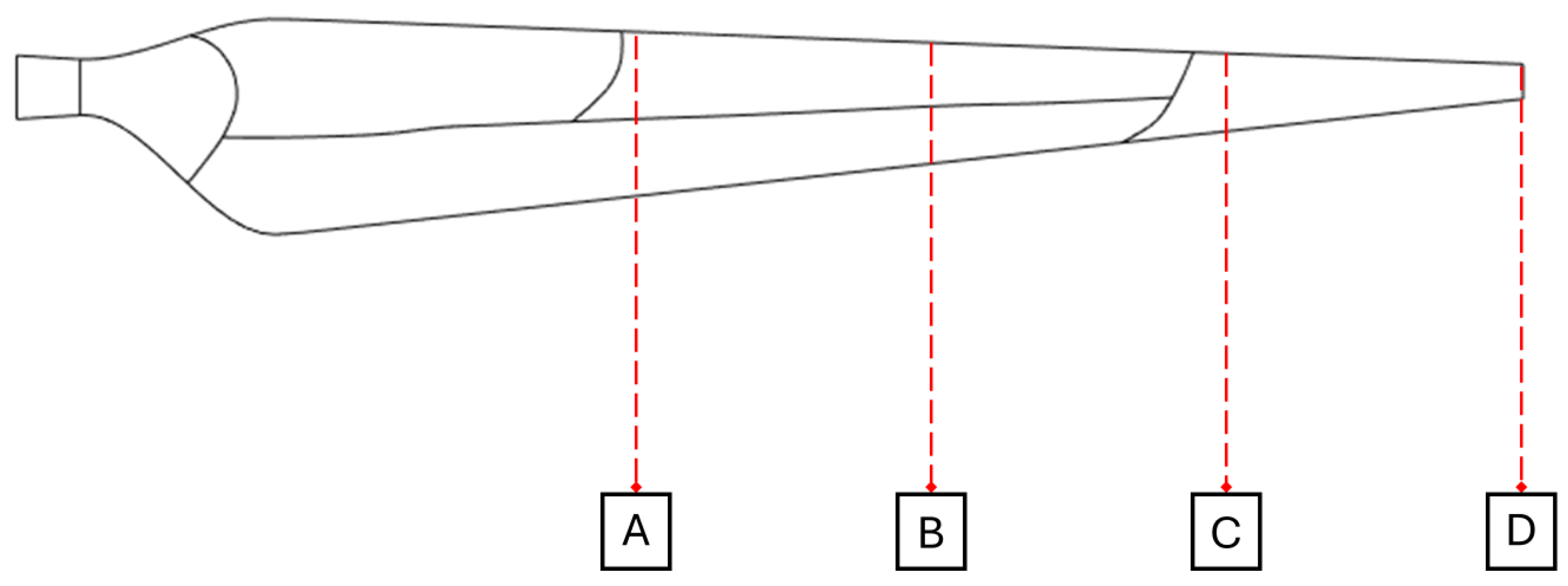

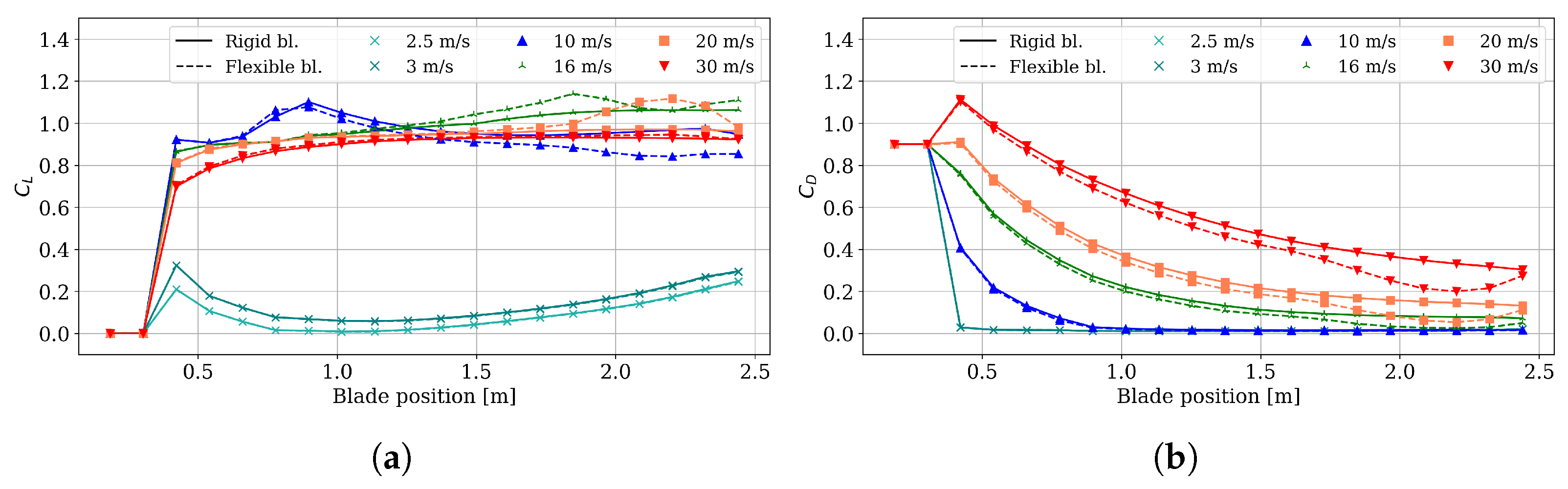

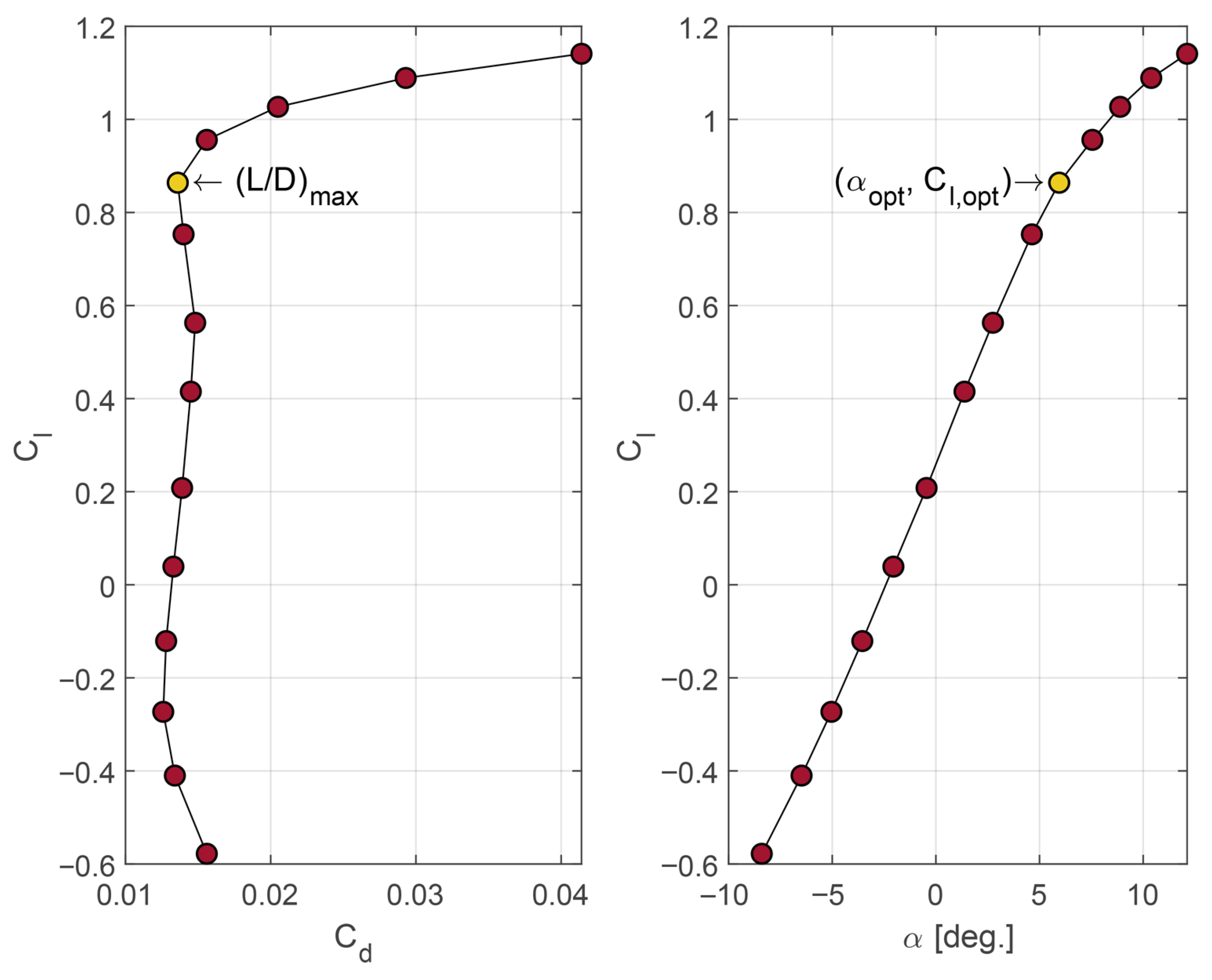

The previous passive–active pitch control strategy has not been extensively studied for small wind turbines, and even the concept of using passive–active control to increase generation, which is ideal for small wind turbines, is not evident in the literature. For all the above reasons, this study proposes assessing the blade design of a 5 kW small wind turbine, incorporating passive pitch control using bend–twist coupling, and its effect if the pitch angle is actively changed from cut-in operation to nominal operation. For this purpose, this study addresses the blade design for passive–active control, considering aerodynamic and geometric design, material characterization, and the design of composite laminates. The resulting blade design is evaluated using a one-way numerical fluid–structure simulation to assess the aerodynamic and twist behavior; then, a post-processing BEM model is used to determine the performance improvements by the passive–active control. In this sense, in

Section 2, this article presents the methodology of each design stage (aerodynamic geometry, material characterization, laminate design, and numerical approach); in

Section 3, the results obtained from the blade design are presented and discussed for fifteen typical operating cases that characterize the power–wind speed curve.

4. Conclusions

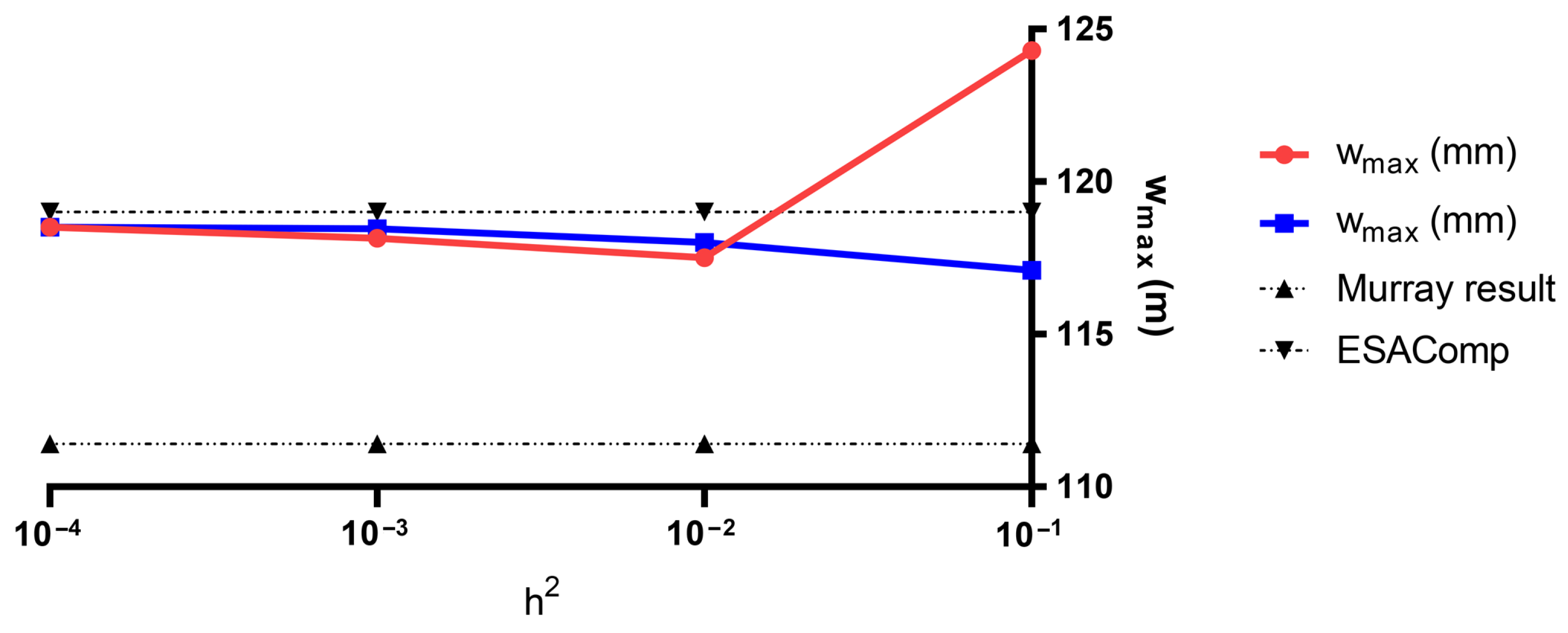

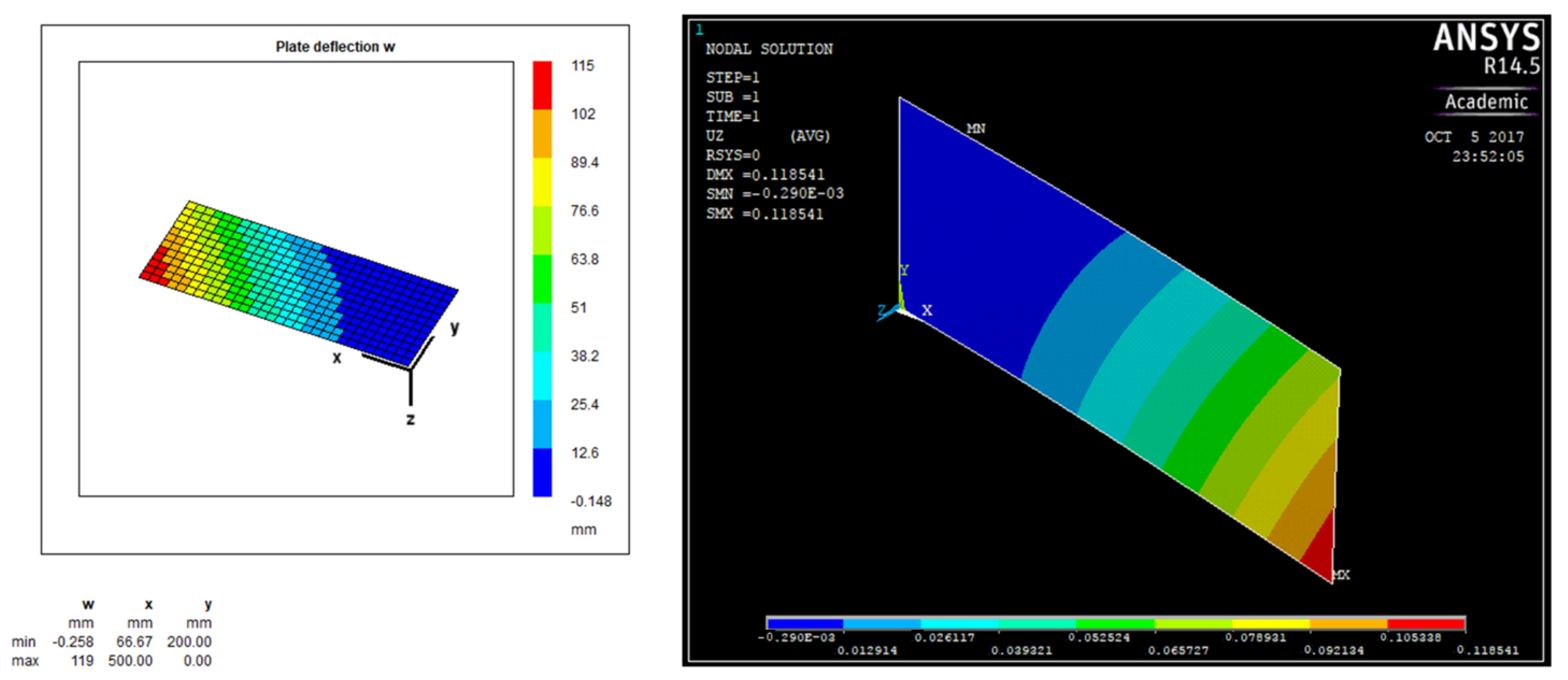

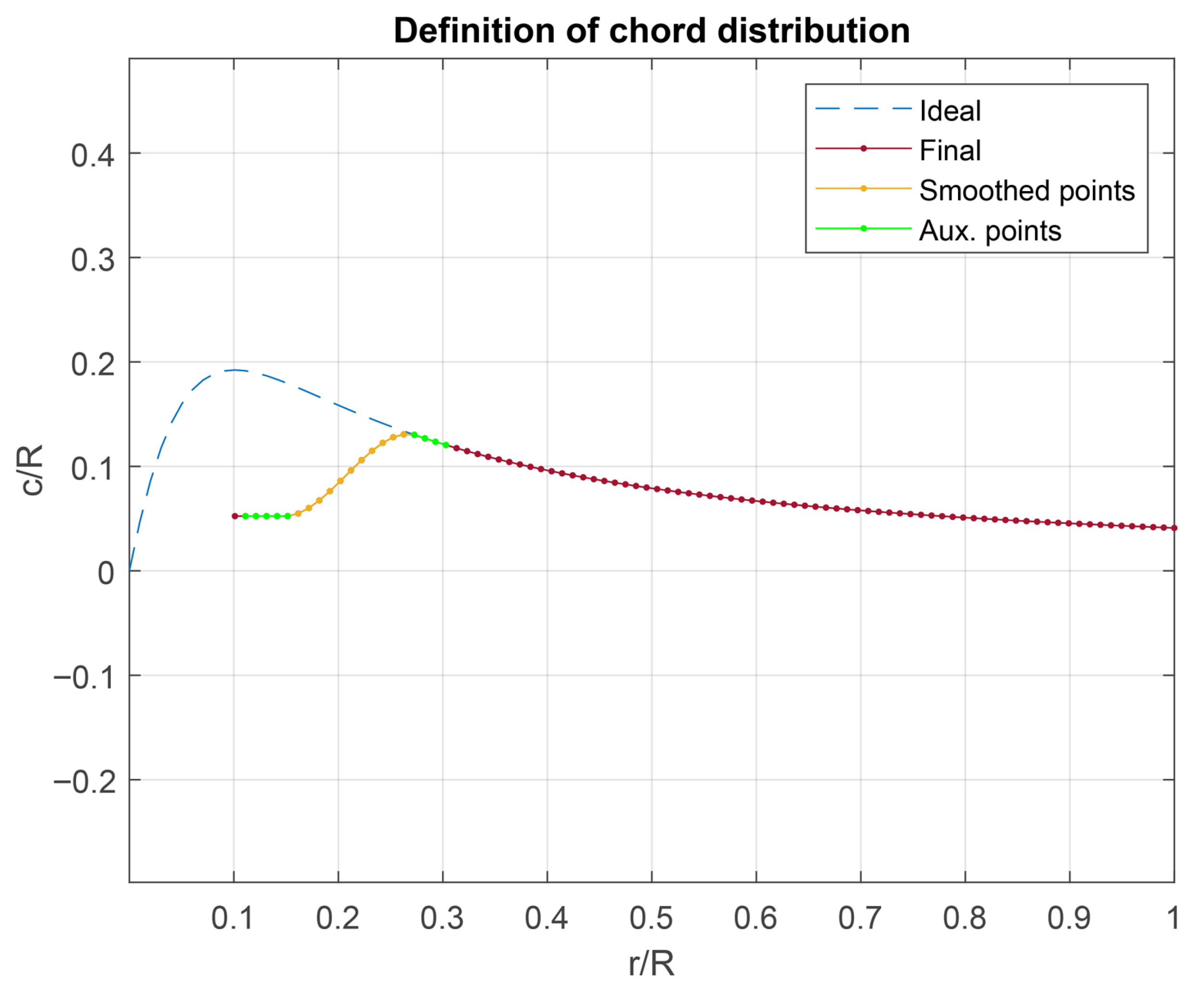

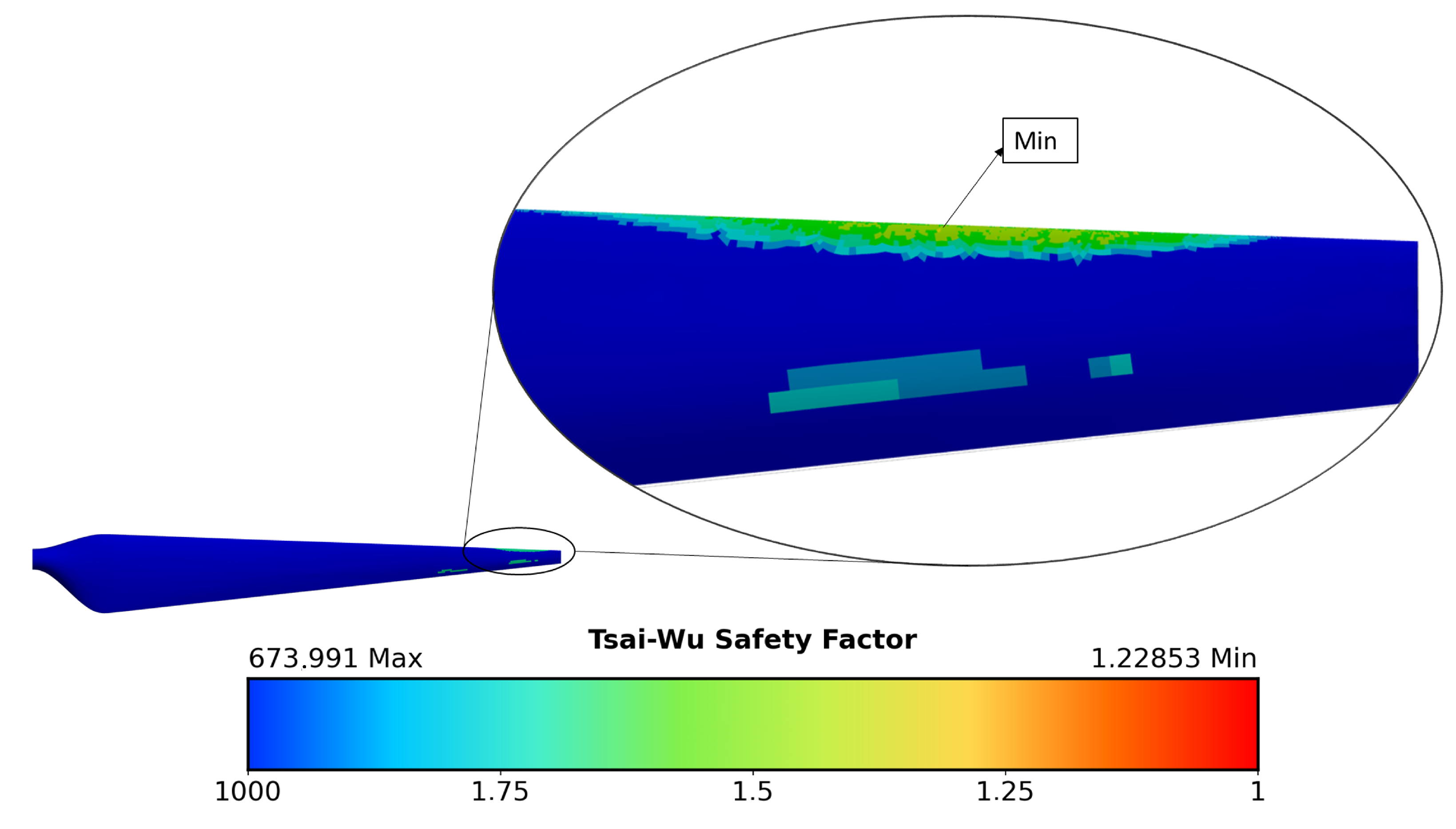

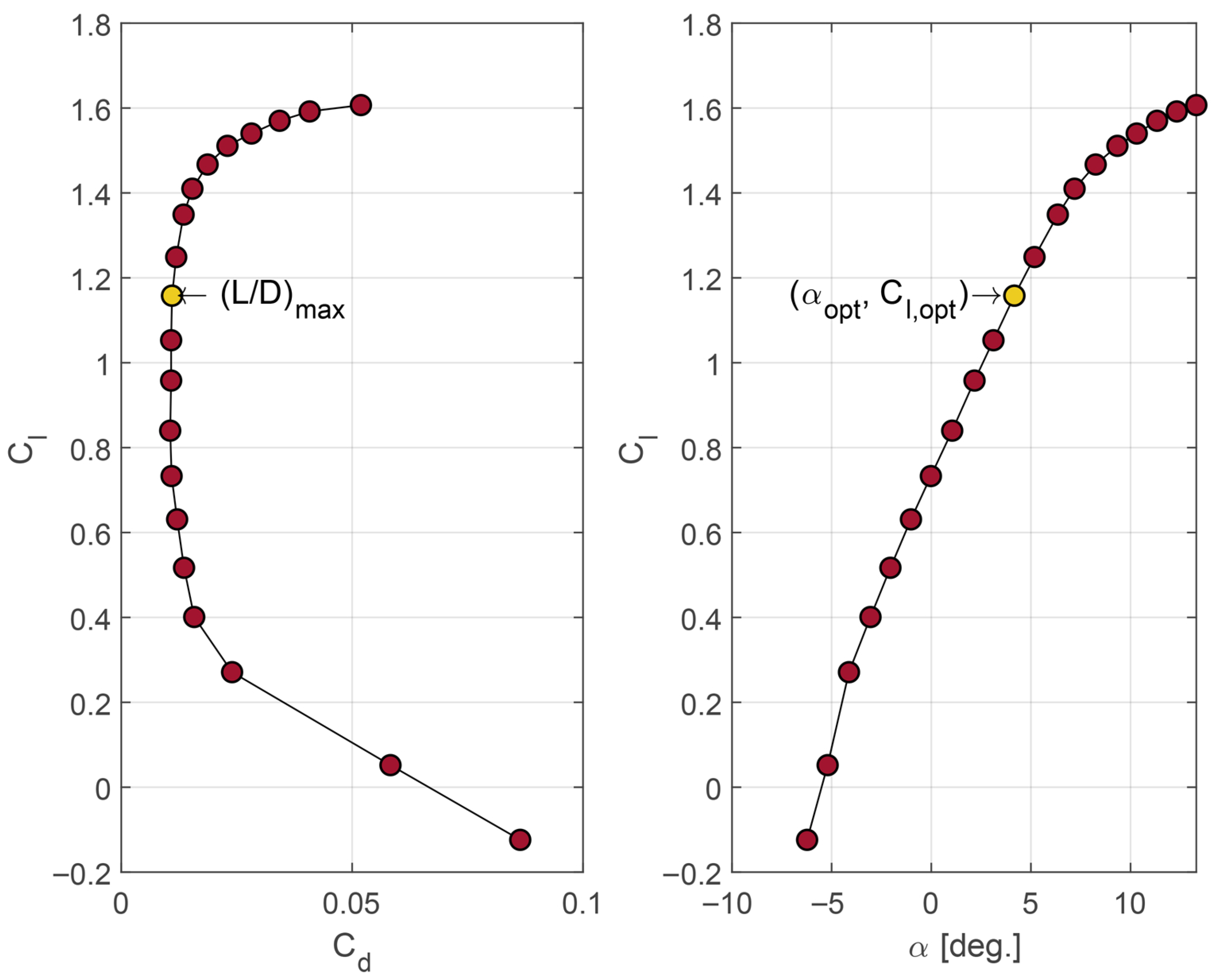

The primary objective of this work was to design a wind turbine blade incorporating a passive control system based on a smart composite laminate layup to assess the potential benefits and limitations of such a system in operation. The aerodynamic design was carried out for a turbine with a nominal power of and a rotor diameter of . Although aerodynamic performance was the primary design criterion, structural considerations were also essential to ensure that the blade maintained sufficient stiffness while implementing the smart laminate. To achieve the appropriate laminate orientation for the bend–twist coupling mechanism, a material characterization campaign was conducted. This characterization provided the data required to calibrate the numerical model, which in turn guided the definition of the laminate stacking sequence forming the passive control system. One of the main challenges in defining the layup was not only to obtain the desired twist distribution but also to do so while preserving the structural integrity of the blade, particularly at higher wind speeds, where the passive control system is the most effective but the bending moments are also the largest. While the laminate orientation was optimized using a genetic algorithm, the ply cut patterns were defined iteratively to simplify the design process and maximize structural robustness.

Within the possibilities offered by the proposed methodology, it is reasonable to consider, under a sensitivity analysis framework, how the configuration of laminates can change with new forms of heuristic optimization or machine learning tools. Moreover, although the present study employed a one-way fluid–structure interaction (FSI) approach, the methodology proved robust by combining high-fidelity aerodynamic loading, detailed finite element modeling of the composite layup, and a validated multiaxial failure criterion (Tsai–Wu). This framework ensured that the critical structural responses of the blade were captured with sufficient accuracy across the operating envelope despite the absence of feedback from structural deformation to the aerodynamic field. Given that the blade deflections remained small relative to the chord length, one-way FSI represented a practical and reliable method of analysis. Nevertheless, extending the work to a two-way FSI formulation remains an essential avenue for future research, particularly in scenarios where aeroelastic coupling or large deformations are expected to play a more dominant role.

The comprehensive blade design methodology was evaluated up to the stage of a numerical model; however, one of the challenges posed, which is clearly promising, is the manufacture of the blade, where, by guaranteeing the properties of the composite material and the proposed geometry, it would be possible to evaluate the challenges in fiber orientation, resin matrix filling control, intrados and extrados adhesion, and the curing process, among others. Additionally, another future task would be the operational integration into a rotor that also involves an active control system, achieving the operational curves of power generated and . In this regard, although the 4% increase in AEP is in line with the order of magnitude reported by some studies, it may be the subject of future research, where evaluations are carried out under different wind conditions, or the effect of increasing the size and capacity of small wind turbines is studied.

Regarding the scalability of the improvement in AEP, it must be noted that, as long as the increase in blade twist is maintained, there should be a proportional response in power output since both angular displacement and aerodynamic coefficients are non-dimensional quantities. Nevertheless, the question of whether a larger blade would benefit from a bend–twist coupling approach remains open. On one hand, assuming a finite torsional response is reasonable for larger blades with similar structural configurations, but a rigorous estimation regarding the scalability of the improvement should include further numerical analysis so that the inevitable changes in blade stiffness are taken into consideration along with the aerodynamic scaling problem. On the other hand, larger multi-MW wind turbines do not struggle so much with power capture as they do with structural integrity, thus rendering the current design proposal less of an issue compared to power regulation and load reduction.