Inkjet Printing for Batteries and Supercapacitors: State-of-the-Art Developments and Outlook

Abstract

1. Introduction

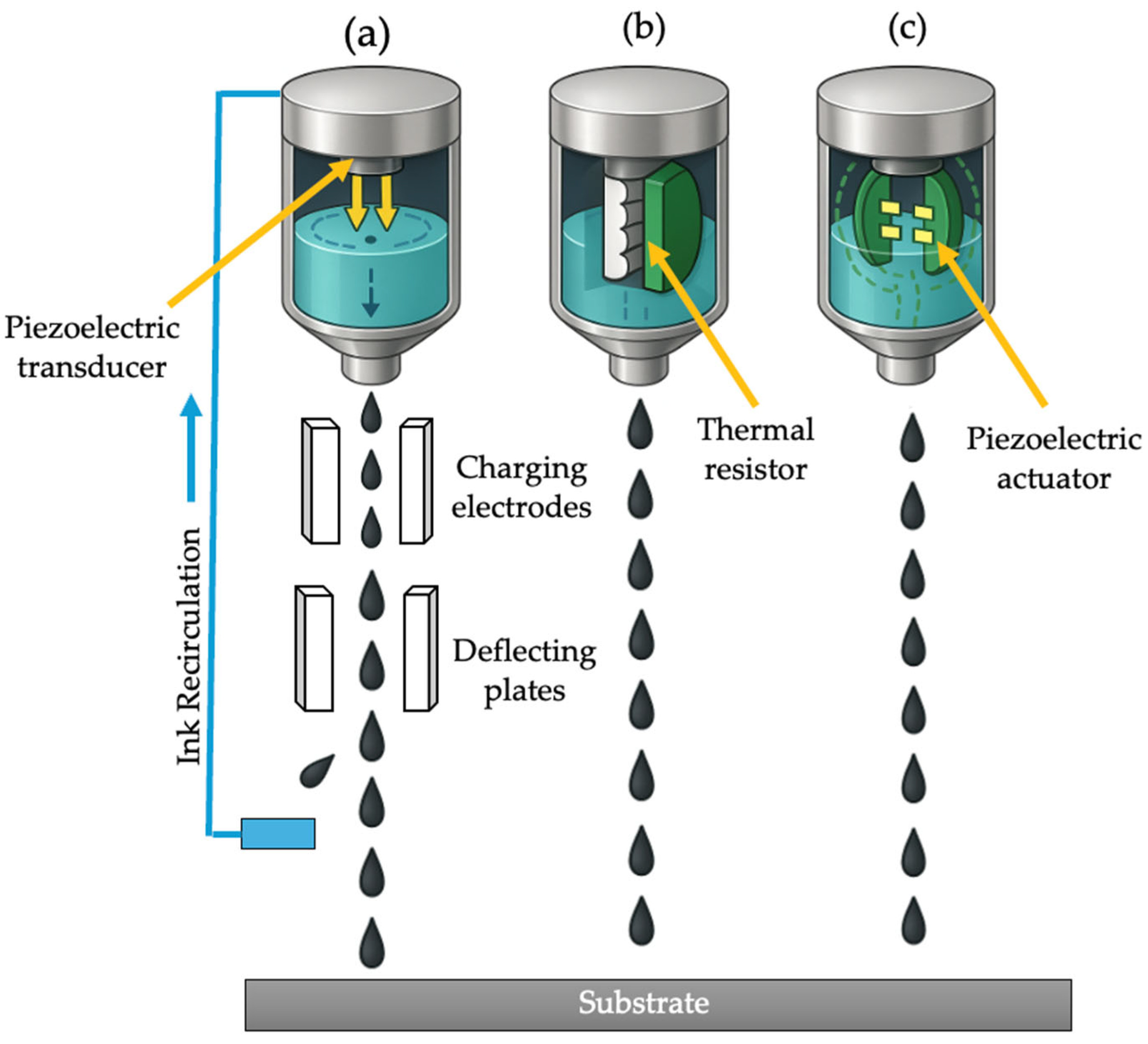

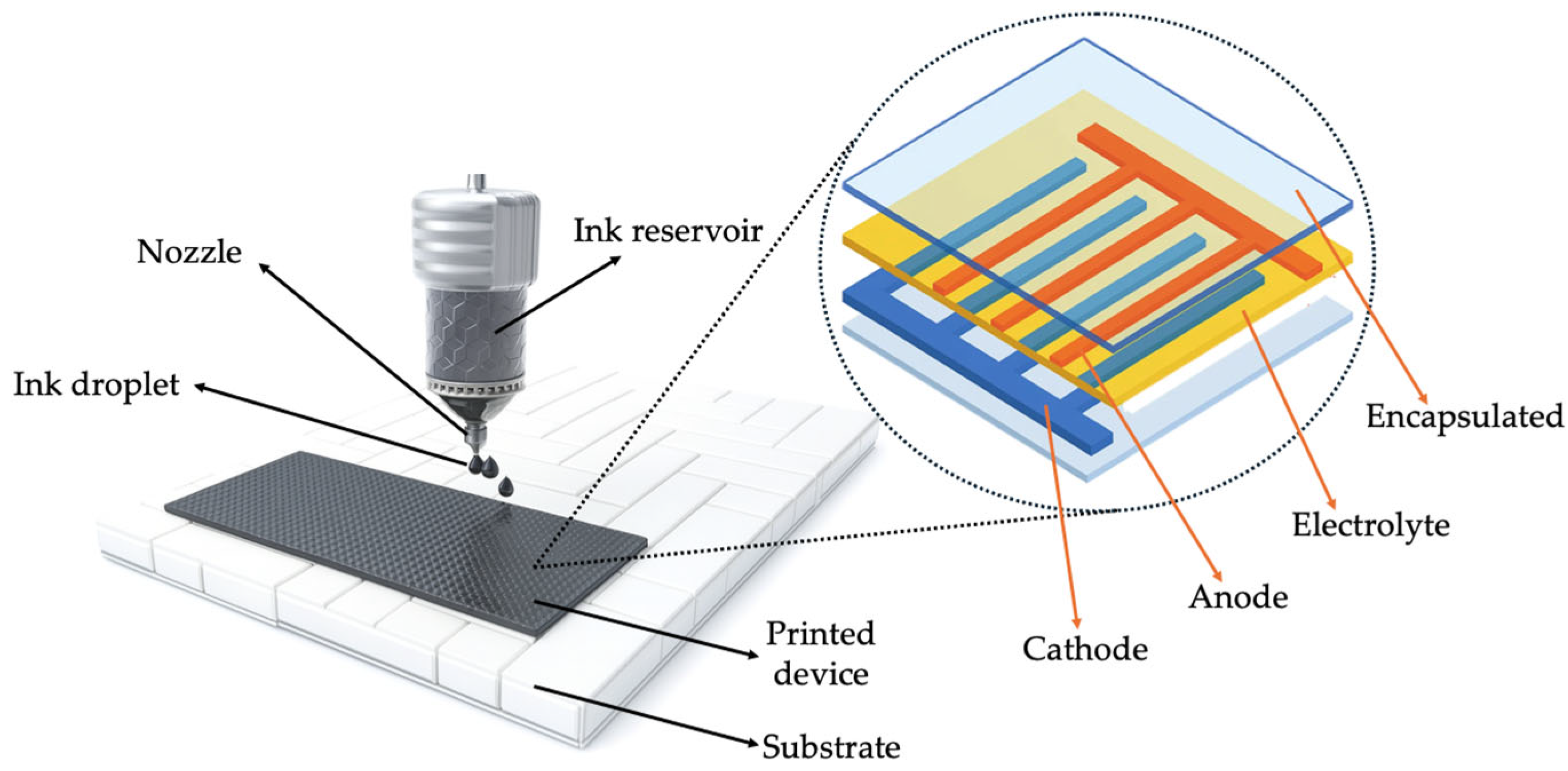

2. Inkjet Printing

| Printing Technique | Key Advantages | Main Limitations | Typical Printing Parameters | Battery Parameters | Supercapacitor Parameters |

|---|---|---|---|---|---|

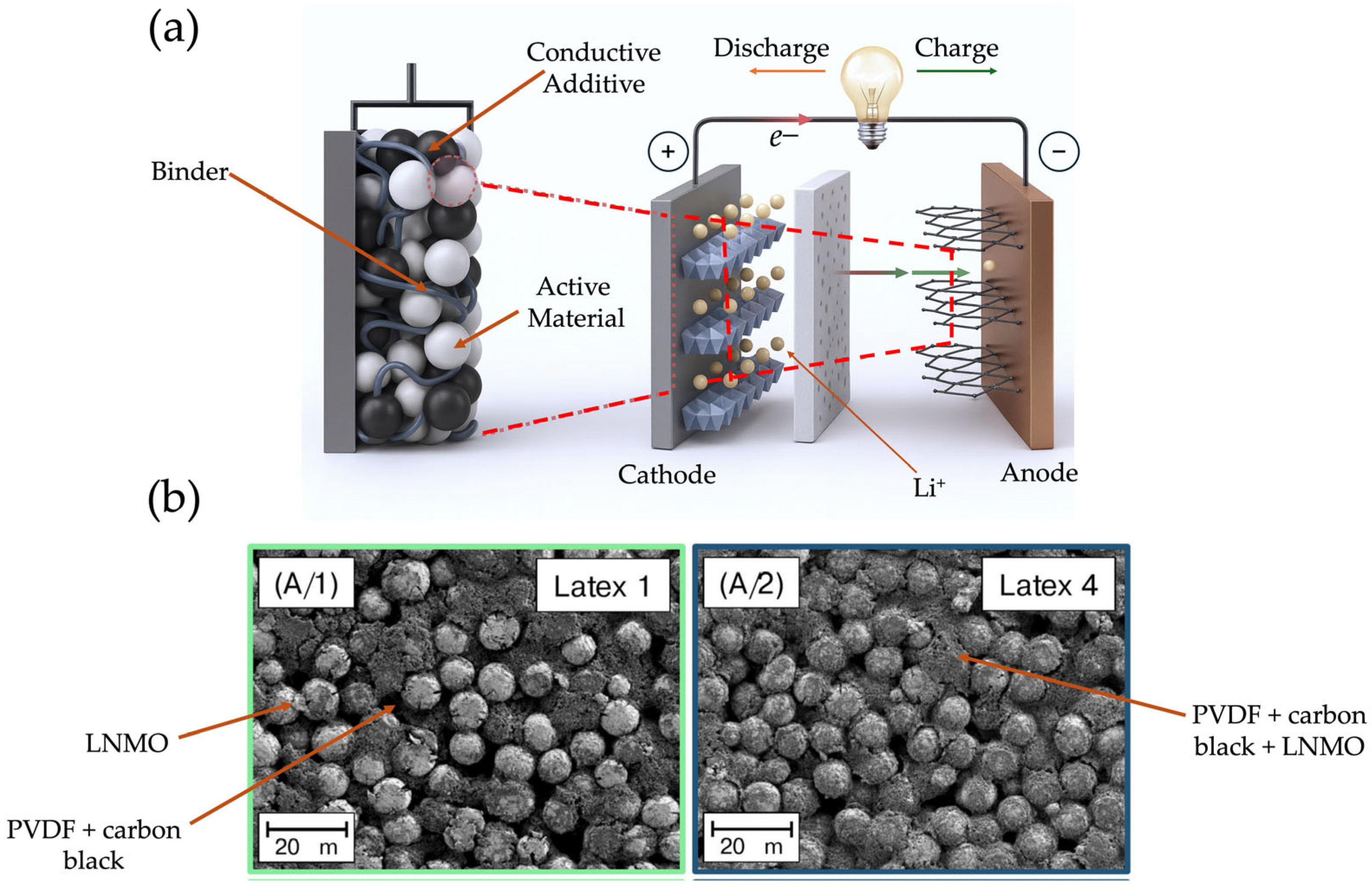

| Drop-on-Demand Inkjet [64,66] | High resolution (5–50 µm), accurate material deposition, low material waste | Limited to low solid loading (5–15 wt%), requires Ohnesorge number (Z) within 1–14 | Viscosity: 1–20 mPa·s; Throughput: 0.1–2 mL/min; X-Y Resolution: 10–50 µm; Z Resolution: 0.1–10 µm | Capacity 300–2500 mAh g−1; current 0.2–1 A g−1; energy 94–330 Wh kg−1; power 220–1650 W kg−1; cycle life 200–500 cycles; coulombic efficiency ≈ 99% [43,67] | Areal capacitance 22–29 mF cm−2; mass capacitance 829–1294 F g−1; volumetric capacitance 608–746 F cm−3; cycle life > 1000 cycles [68] |

| Super-fine Inkjet (SIJ) [1,62] | Ultra-high resolution (0.5–10 µm), broad viscosity range (0.5–10,000 mPa·s), femtoliter droplets | Complex setup; limited commercial availability; lower throughput | Viscosity: 0.5–10,000 mPa·s; Droplet volume: 0.1 fL–10 pL; X-Y Resolution: 0.5–10 µm; Z Resolution: 0.1–1 µm | Zn–Ag 3D microbattery: ~60% higher capacity than planar; current ≈ 1.1 mA cm−2 [69] | 3D micro-SC: areal capacitance 11–14 mF cm−2; capacitance retention ~ 80% after 2000 cycles [70] |

| Aerosol-Jet Printing [71] | Broad viscosity tolerance (1–1000 mPa·s), high precision (10–250 µm), compatible with non-planar substrates | Complex instrumentation; limited to thin films; moderate throughput | Viscosity: 1–1000 mPa·s; Solid loading: 10–40% wt%; X-Y Resolution: 10–250 µm; Z Resolution: 0.1–5 µm | Capacity ≈ 75–100 mAh g−1; current ≈ 50–150 mA g−1 (C/2–1C); cycle life >100 cycles [72] | MXene micro-SC: areal capacitance ~ 122 mF cm−2; volumetric capacitance ~ 611 F cm−3 [73] |

| Screen Printing [74,75] | High solid loading capacity (50–80 wt%), ideal for thick layers, scalable manufacturing | Limited resolution (>50 µm); requires specific rheological tuning | Viscosity: 1000–100,000 mPa·s; Throughput: 100–1000 cm2/min; X-Y Resolution: >50 µm; Z resolution (per-pass layer thickness): 10–50 µm, up to ~100 µm for thick films. | Capacity 120–170 mAh g−1 at 2–6C; current 0.7–2.2 A g−1; cycle life > 100 cycles [76] | Areal capacitance 200–250 mF cm−2; cycle life > 5000 cycles [77] |

| Gravure Printing [78] | High-speed roll-to-roll processing (~400 m/min), excellent film uniformity, scalable | High initial cost; limited to thin films; handling of complex inks can be challenging | Viscosity: 50–500 mPa·s; X-Y Resolution: 2–100 µm; Z Resolution: 1–50 µm | Na-ion battery anodes: initial capacity 400–440 mAh g−1; stabilized ~ 120 mAh g−1 after 100 cycles | MoS2@S-rGO micro-SC: areal capacitance 6.6 mF cm−2; energy density 0.58 mWh cm−3; power density 13.4 mW cm−3; cycle life > 1000 cycles |

| Extrusion Printing [79,80] | Very high viscosity inks (1000–10,000 cP), 3D structures, high loading | Slow printing speed, limited resolution (>100 µm) | Viscosity: 1000–50,000 mPa·s, Solid loading: 60–90 wt%, X-Y Resolution: >100 µm; Z Resolution: 50–500 µm | Capacity 30–90 mAh g−1; energy density ~ 110 Wh kg−1; cycle life > 100 cycles [81] | Planar rGO micro-supercapacitor: volumetric capacitance ≈ 41.8 F cm−3; areal energy density ≈ 7.6 mWh cm−2; areal power density ≈ 29.2 mW cm−2 [82] |

| Continuous Inkjet [50] | High-speed printing (80–100 kHz), suitable for large-area coverage | Compatible only with conductive inks; high material waste; low resolution X-Y (>100 µm) | Viscosity: 1–10 mPa·s; Throughput: 10–50 mL/min; X-Y Resolution: >100 µm; Z Resolution: N/A (continuous) | N/A | N/A |

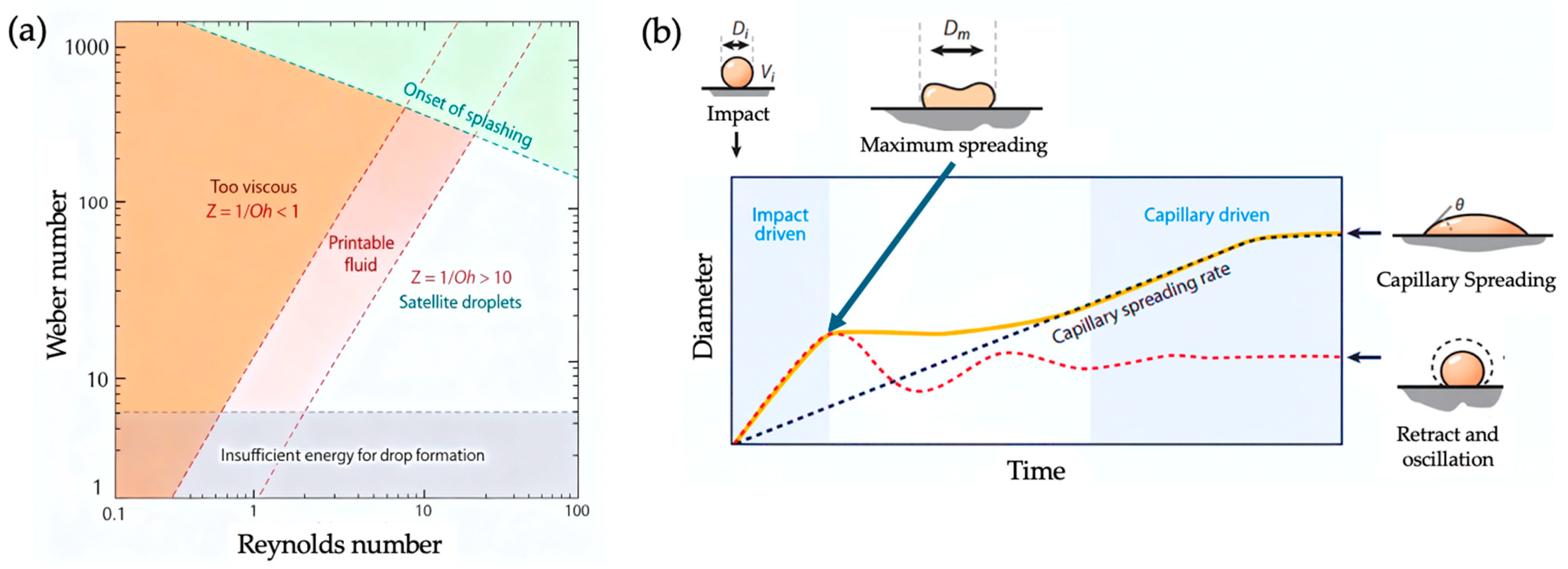

3. Ink Rheology

3.1. Colloidal Fundamentals for Ink Formulation

3.2. Printability Window and Defect Control

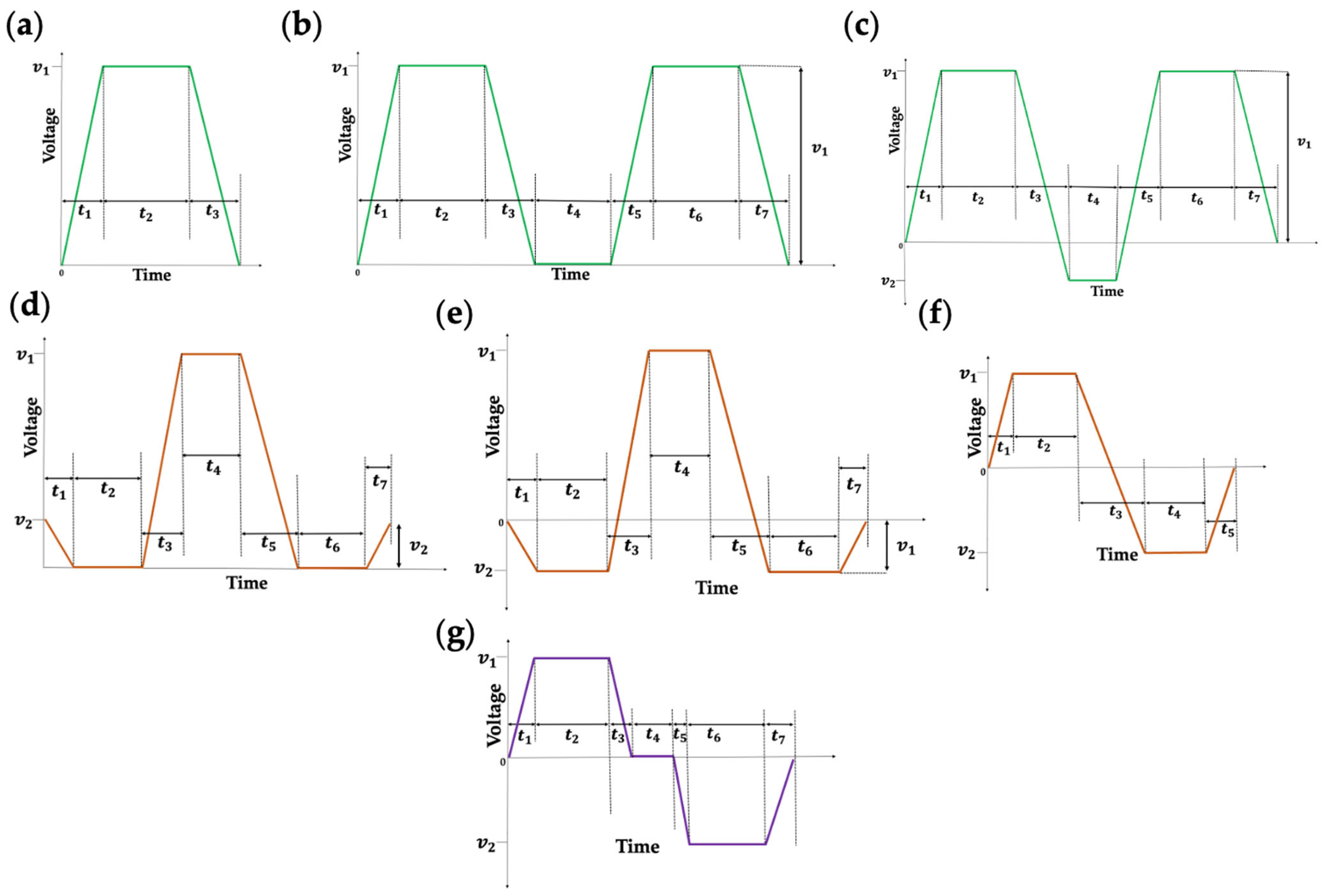

4. Voltage Waveforms in Piezoelectric Drop-on-Demand Inkjet Printing

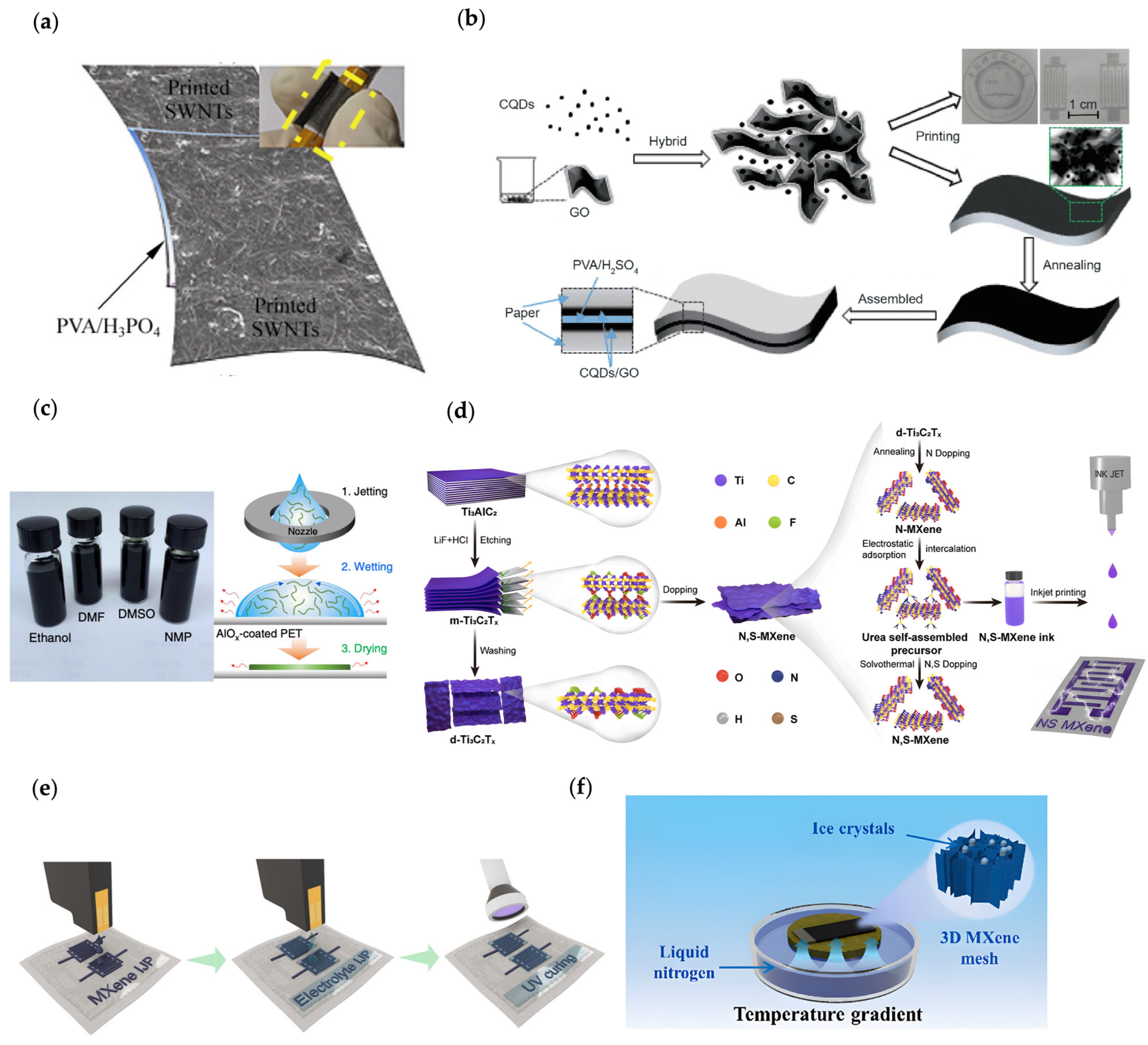

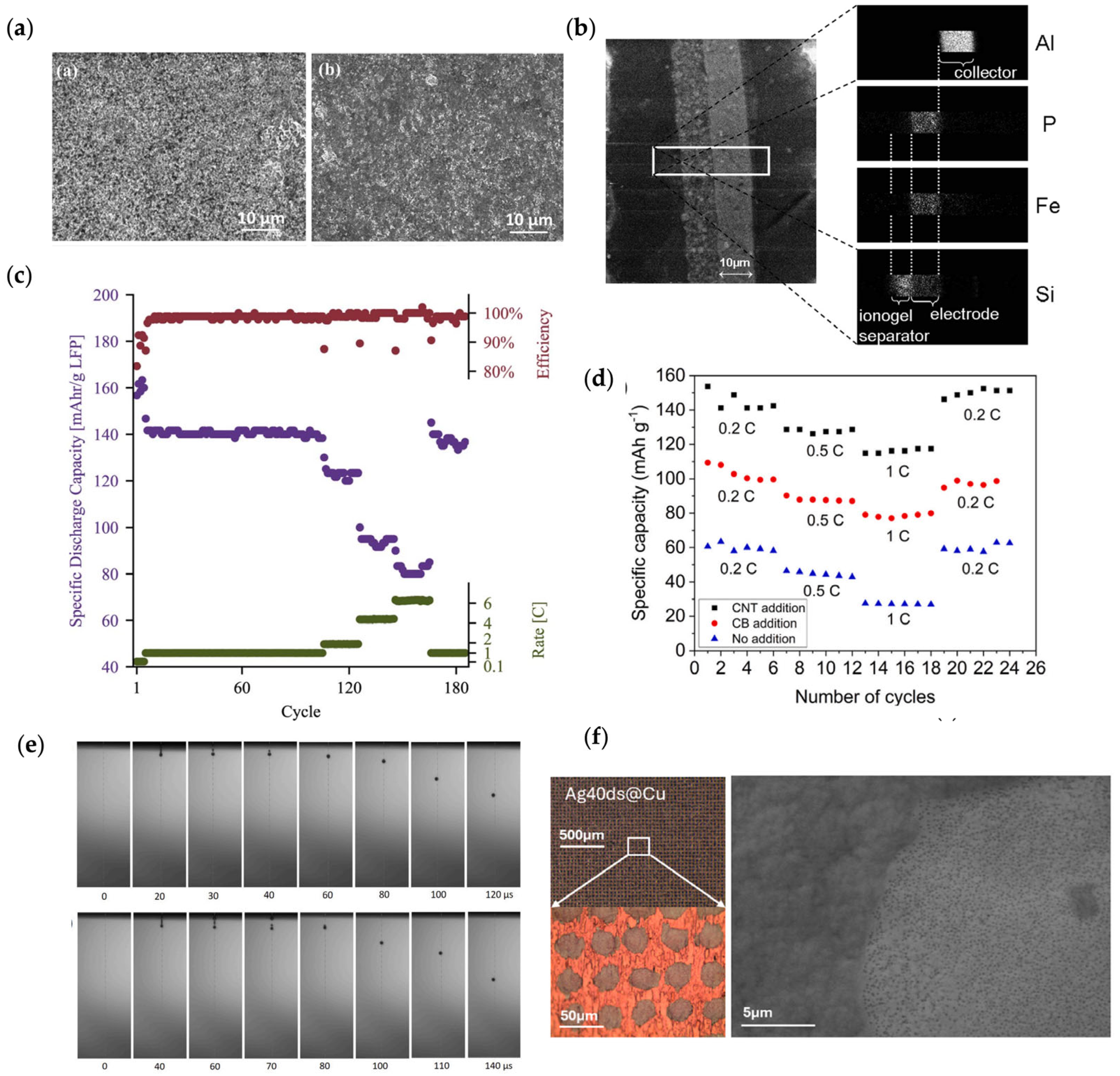

5. Development of Inks in Inkjet Printing

6. Development of Batteries in Inkjet Printing

7. Development of Supercapacitors in Inkjet Printing

| Device Type | Solvent | Additives | Viscosity | Printing Conditions | Substrate | Post-Treatment | Performance Results |

|---|---|---|---|---|---|---|---|

| Solar bifunctional supercapacitor with WO3 electrodes [42] | Cyclohexanone, terpineol | Ethyl cellulose | 8–15 mPa·s | Dimatix DMP-2800, 140 V, 70μs, 300 °C/30 min | Glass-FTO | Thermal annealing 300 °C/30 min | 0.3 mA cm−2 (500 W m−2); areal capacitance 7.9 mF cm−2; stability 500 cycles at 0.0003 A cm−2 (1000 W m−2) with ~50% retention |

| Flexible V2CTx film electrode for supercapacitor [22] | N-methyl-2-pyrrolidone (NMP) | None | 5.1–7.8 mPa·s | HP Deskjet 2132, 40 V, ambient | Al-coated PET | None | 5 mV s−1; areal capacitance 5787 μF cm−2; 83% retention after 7000 cycles at 75 μA cm−2; symmetric device: 23.4 μF cm−2 at 5 mV s−1; energy density 0.00034 μWh L−1; power 0.01 μW L−1 |

| Electrochromic device with zinc anode and WNO electrodes [142] | Water/ethylene glycol (70:30) | Triton X-100 (0.3 wt%) | 2.6 mPa·s | Microdrop MD-K-130, 188 °C, 8 min grinding | Glass FTO with 3D MXene mesh | Reduction with hypo phosphorous acid (HPA) | 0.2 A m−2; ≈70 mAh m−2; 1000 cycles with 91.2% capacity retention; round-trip energy efficiency 82.13% |

| All-inkjet-printed Ti3C2 MXene capacitor for textile energy storage [41] | Water (Ti3C2 ink), Water/2-propanol (IPA) for electrolyte | Sulphate-nanocellulose (SNC), sodium ascorbate, lithium dodecyl sulphate (LDS) | Ti3C2: 2.7 ± 0.09 mPa·s, Electrolyte: 6.5 ± 0.1 mPa·s | Breva iJet2L printer, 50 °C heated substrate, UV curing for electrolyte | TPU-coated cotton fabric | UV polymerization of electrolyte | 50 μA, 0–0.8 V; Areal capacitance 0.86 mF cm−2 (average over 2000 cycles); Coulombic efficiency ≈99.2%; Areal energy 0.08 μWh cm−2; Areal power 20 μW cm−2. |

| Asymmetric micro-supercapacitor (porous NiS/N-MXene//rGO) [135] | Ethanol, isopropanol | Polyvinylpyrrolidone (PVP) | Not specified | Jet lab II printer, 50 °C substrate, 192 dpi, 80 μm drop interval, 30 layers | PET, photo paper | KOH/PVA gel electrolyte | Volumetric capacitance 429 F cm−3; Areal capacitance 16.6 mF cm−2; Energy density 33.5 mWh cm−3 at 249 mW cm−3; ~80% retention after 10,000 cycles |

| Micro-supercapacitor (N,S-doped MXene ink) [23] | Ethanol, isopropanol | None (additive-free) | 3.02 mPa·s | Jet lab II printer, 45 °C substrate, 25 layers, 300 μm electrode spacing | Photo paper, PET | H2SO4/PVA gel electrolyte | Energy density 8.9 mWh cm−3 at 411 mW cm−3; Volumetric capacitance 710 F cm−3; 10,000 cycles with 94.6% retention |

| Nanoporous carbon micro-supercapacitor [143] | Deionized water | Sulfuric acid, ethanol, urea (for N-doping) | Not specified | Bio Scaffolder 3.2, 150 Hz, 90 μs, 55 V, 80 °C substrate | Glass | Pyrolysis 900 °C/2 h in argon | 5 mV s−1; Areal device capacitance 3.9 mF cm−2; Volumetric capacitance 151.4 F cm−3; Energy density 0.9 mWh cm−3 at 0.4 W cm−3; 10,000 cycles with 96% retention |

| Electric double-layer supercapacitor [18] | Cyclohexanone, terpineol | Ethyl cellulose | Not specified | HP Deskjet 3000, 600 dpi, 300 °C/30 min | Aluminum foil | Thermal annealing 300 °C/30 min | ~23 F g−1; Coulombic efficiency 97%; 250 cycles; Capacity 50 nAh |

| Micro-supercapacitor (Fe-doped MnO2 nanosheets) [144] | Water: propylene glycol (1:10) | Triton X-100 (0.06 mg/mL) | 1.7 mPa·s | Dimatix DMP-2800, 50 °C substrate, 20 μm drop spacing, 5 layers | Polyimide | PEDOT:PSS overlayer, annealing at 120 °C | 30 µA cm−2; Areal capacitance 1.2 mF cm−2; Volumetric capacitance 9.2 F cm−3; Energy density 1.13 mWh cm−3 at 0.11 W cm−3; 5200 cycles with 78.7% retention |

| All-MXene micro-supercapacitor [31] | Aqueous: water; Organic: NMP, DMSO, DMF, ethanol | None | NMP: ~2.2 Pa·s, ethanol: ~2.6 Pa·s, aqueous: 0.71 Pa·s | Dimatix DMP-2800 (FUJIFILM Dimatix, Santa Clara, CA, USA), Voxel8 (extrusion), ambient | AlOx-coated PET, paper | None | Volumetric capacitance 562 F cm−3; ~100% retention after 10,000 cycles; Energy density 0.32 µWh cm−2 at 11.4 µW cm−2 |

| Asymmetric supercapacitor with Ni-Co LDH/Ag/rGO electrodes [145] | Deionized water | Triton X-100, DF69 defoamer, ethylene glycol | Not specified | Jet-lab II, 140 V, −100 V echo, 70 μs, 50 μm step | Carbon cloth fabric | Annealing 800 °C/2 h N2, then 160 °C/1 h | 173 mAh g−1 at 1 A g−1; 79.8% capacity retention after 5000 cycles at 5 A g−1 |

| Laser-induced graphene pseudocapacitive electrode [146] | Dimethylformamide (DMF) | None | Not specified | Microdrop MD-K-130, 188 °C substrate | Laser-induced graphene (LIG) | None | 0.1 mA cm−2; >97% capacitance retention after 10,000 cycles; Coulombic efficiency ≈100% after the first 500 cycles |

| Flexible δ-MnO2 micro-supercapacitor [113] | Water: propylene glycol (10:1) | Triton X-100 (0.06 mg/mL) | 1.71 mPa·s | Dimatix DMP-2800, 10 pL, 40 μm spacing, 50 °C | Glass, polyimide film | Annealing 350 °C/1 h N2 | 0.05 A cm−3; Volumetric capacitance 2.4 F cm−3; Energy density 1.8 × 10−4 Wh cm−3 at 0.018 W cm−3; ~88% retention after 3600 cycles |

| Flexible graphene@polyaniline nano composite supercapacitor [140] | Cyclohexanone, terpineol | Ethyl cellulose | Not specified | Dimatix DMP-2800, 40 V, 40 °C | Flexible gold film | Reduction with HPA | 1 mV s−1; Volumetric capacitance 554 F cm−3; 2000 cycles with >96% retention; Energy density 76.94 Wh cm−3; Power density 5593.7 W cm−3 |

| All-2D material capacitors (Graphene/hBN/Graphene) [147] | Water-based biocompatible inks | Shear-thinning biocompatible binder | Not specified | Dimatix DMP-2800, ambient conditions | Glass substrates | None specified | Areal capacitance 2.0 ± 0.3 nF cm−2 (~3 µm hBN); Dielectric constant 6.1 ± 1.7; Breakdown field 1.9 ± 0.3 MV cm−1 |

| Solid-state flexible supercapacitors using CQDs/GO hybrid ink [141] | Water and ethanol mixture | Carbon quantum dots (CQDs) as nano-spacers | Not specified | HP Deskjet 1110, thermal annealing at 100–300 °C | A4 printing paper, weighing paper | Thermal annealing (optimized at 200 °C), PVA/H2SO4 gel electrolyte | Areal capacitance 4.2 mF cm−2 at 1 mV s−1; Energy density 0.078 mWh cm−3 at 0.28 mW cm−3; 10,000 cycles with 83% retention |

| All-inkjet-printed solid-state flexible supercapacitors on paper [148] | Water (SWNT/AC), Water/IPA (1:1, Ag NW) | SDBS (1.0 wt%), CNF primer layer | SWNT/AC: ~20 cP, Ag NW: ~18 cP, CNF: ~18 cP | HP Deskjet 1010, 60 °C platen, UV curing for electrolyte | A4 paper with CNF nanomat primer layer | UV-curing of [BMIM][BF4]/ETPTA electrolyte | 0.2 mA cm−2; ~100 mF cm−2 for >10,000 cycles; Coulombic efficiency ~100% |

| All-solid-state micro-supercapacitor (GO + pen ink hybrid) [149] | Water, ethylene glycol | Commercial pen ink (graphite carbon nanoparticles) | Not specified | Dimatix DMP-2800, ambient, 5 passes | PET | HI vapor reduction, 150 °C/2 h | 0.1 μA (GCD); Areal capacitance 19.18 μF cm−2; ~100% retention after 10,000 cycles |

| All-solid-state asymmetric micro-supercapacitor (K2Co3(P2O7)2·2H2O//graphene) [150] | Ethanol | PTFE (10 wt%), acetylene black | Not specified | Fujifilm Dimatix 3000, vacuum oven 100 °C, 3 layers | PET with inkjet-printed Ag current collectors | KOH/PVA gel electrolyte, dried in air | 10 mA cm−3; 6.0 F cm−3; 5000 cycles with 94.4% retention; Energy density 0.96 mWh cm−3; Power density 54.5 mW cm−3 |

| MWCNT/Ag nanoparticle based asymmetric supercapacitors [151] | Water | Sodium dodecylbenzene sulfonate (SDBS), MnO2 nanoparticles | Not specified | HP Deskjet 1010, ambient conditions | Paper substrate | 4 M LiCl electrolyte assembly | 1.8 V window; Energy density 1.28 mWh cm−3 at 96 mW cm−3; 96.9% retention after 3000 cycles |

| Supercapacitor electrodes with graphene/PANI [139] | Water | SDBS surfactant | ~1 mPa·s | Inkjet printing at room temp, 86 V, pulse 40 ms | Carbon fabric | Drying at 80 °C for 2 h | 20 mV s−1; Specific capacitance 82 F g−1; Energy density 2.4 Wh kg−1 at 124 kW kg−1; 1000 cycles (stable) |

| Carbon-based micro-supercapacitors with interdigital configuration [138] | Ethylene glycol | PTFE polymer binder (5 wt%), Triton X100 surfactant | Not specified | AltaDrop equipment, 140 °C substrate temperature, annealing 240 °C | Silicon with 150 nm SiO2, Ti/Au electrodes (150 Å Ti, 300 nm Au) | Thermal annealing at 240 °C | 1 mV s−1; Areal capacitance 2.1 mF cm−2 (2.5 V); Areal energy 0.00183 mWh cm−2 (6.6 mJ cm−2); Volumetric energy ≈2.34 mWh cm−3; Areal power 44.9 mW cm−2 |

| SWNT/RuO2 nanowire supercapacitors on cloth and flexible substrates [137] | Water with SDS | Sodium dodecyl sulfate (SDS, 1 wt%) | ~20 cP after centrifugation | Epson Artisan 50 piezoelectric printer, 1440 × 1440 dpi | PET sheets, cloth fabrics, SiO2/Si substrates | PVA/H3PO4 gel electrolyte preparation | 8 A g−1; Specific capacitance 138 F g−1; Coulombic efficiency >99%; Energy density 18.8 Wh kg−1; Power density 96 kW kg−1 |

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Abbreviation | Definition | Abbreviation | Definition |

| AC | Activated Carbon | LTO | Lithium Titanate Oxide |

| AM | Acrylamide | Li-PAA | Lithium Polyacrylic Acid |

| Ag NW | Silver Nanowires | LiAlO2 | Lithium Aluminate |

| AlPO4 | Aluminum Phosphate | LiCl | Lithium Chloride |

| Al2O3 | Aluminum Oxide | LiFePO4 | Lithium Iron Phosphate |

| CAGR | Compound Annual Growth Rate | LNMO | Lithium Nickel Manganese Oxide |

| CB | Carbon Black | mAh g−1 | milliampere hours per gram |

| CHP | Cyclohexylpyrrolidone | mAh cm−2 | milliampere hours per square centimeter |

| CIJ | Continuous Inkjet | mF cm−2 | millifarads per square centimeter |

| CMC | Carboxymethyl Cellulose | mPa·s | millipascal seconds |

| CNF | Carbon Nanofiber | mV s−1 | millivolts per second |

| CNT | Carbon Nanotube | mW cm−3 | milliwatts per cubic centimeter |

| CQDs | Carbon Quantum Dots | mWh cm−3 | milliwatt hours per cubic centimeter |

| DI | Deionized | MWCNT | Multi-Walled Carbon Nanotube |

| DLS | Dynamic Light Scattering | MXene | M stands for early transition metal, X for C or N |

| DMF | Dimethylformamide | NMP | N-methyl-2-pyrrolidone |

| DMSO | Dimethyl Sulfoxide | PAA | Poly(acrylic acid) |

| PANI | Polyaniline | ||

| DoD | Drop-on-Demand | PET | Polyethylene Terephthalate |

| dpi | dots per inch | PIJ | Piezoelectric Inkjet |

| EDC/NHS | 1-Ethyl-3-(3-dimethylaminopropyl) carbodiimide/N-Hydroxy succinimide | PLAL | Pulsed Laser Ablation in Liquid |

| EDX | Energy-Dispersive X-ray Spectroscopy | PTFE | Polytetrafluoroethylene |

| EG | Ethylene Glycol | PVA | Polyvinyl Alcohol |

| EHD | Electrohydrodynamic | PVB | Polyvinyl Butyral |

| ETPTA | Ethoxylated Trimethylolpropane Triacrylate | PVDF | Polyvinylidene Fluoride |

| F cm−3 | farads per cubic centimeter | PVP | Polyvinylpyrrolidone |

| F g−1 | farads per gram | rGO | reduced Graphene Oxide |

| FTO | Fluorine-doped Tin Oxide | RFID | Radio Frequency Identification |

| GNP | Graphene Nanoplatelets | RPM | revolutions per minute |

| GO | Graphene Oxide | SBR | Styrene-Butadiene Rubber |

| GSM | grams per square meter | SDBS | Sodium Dodecyl Benzene Sulfonate |

| hBN | hexagonal Boron Nitride | SDS | Sodium Dodecyl Sulfate |

| HP | Hewlett-Packard | SEM | Scanning Electron Microscopy |

| HPA | Hypo Phosphorous Acid | SIJ | Super-fine Inkjet |

| H2SO4 | Sulfuric Acid | SWNT | Single-Walled Carbon Nanotube |

| H3PO4 | Phosphoric Acid | TIJ | Thermal Inkjet |

| IJP | Inkjet Printing | TMOS | Tetramethyl Orthosilicate |

| IPA | Isopropanol | TPU | Thermoplastic Polyurethane |

| IoT | Internet of Things | µF cm−2 | microfarads per square centimeter |

| KOH | Potassium Hydroxide | µm | micrometers |

| kW kg−1 | kilowatts per kilogram | µWh cm−2 | microwatt hours per square centimeter |

| µW cm−2 | microwatts per square centimeter | ||

| LDH | Layered Double Hydroxide | V | Volts |

| LDS | Lithium Dodecyl Sulfate | W kg−1 | watts per kilogram |

| LFP | Lithium Iron Phosphate | Wh kg−1 | watt hours per kilogram |

| LIB | Lithium-Ion Battery | Wh L−1 | watt hours per liter |

References

- Willert, A.; Tran-Le, A.; Mitra, K.Y.; Clair, M.; Costa, C.M.; Lanceros-Méndez, S.; Baumann, R. Printing Techniques for Batteries. In Printed Batteries; Lanceros-Méndez, S., Costa, C.M., Eds.; Wiley: Chichester, UK, 2018; pp. 21–62. ISBN 978-1-119-28742-1. [Google Scholar]

- Zhang, R.; Sun, T. Ink-Based Additive Manufacturing for Electrochemical Applications. Heliyon 2024, 10, e33023. [Google Scholar] [CrossRef]

- Orisekeh, D.; Roh, B.M.; Xiao, X. Solid-to-Solid Manufacturing Processes for High-Performance Li-Ion Solid-State Batteries. Polymers 2025, 17, 1788. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.; Li, M.; Wang, P.; Cheng, L.; Chen, L.; Huang, Y.; Yu, S.; Mo, F.; Wei, J. Printed Solid-State Batteries. Electrochem. Energy Rev. 2023, 6, 34. [Google Scholar] [CrossRef]

- Liu, Y.; Ding, H.; Chen, H.; Gao, H.; Yu, J.; Mo, F.; Wang, N. Recent Progress on the Research of 3D Printing in Aqueous Zinc-Ion Batteries. Polymers 2025, 17, 2136. [Google Scholar] [CrossRef]

- Rassek, P.; Wendler, M.; Krebs, M. Industrial Perspective on Printed Batteries. In Printed Batteries; Lanceros-Méndez, S., Costa, C.M., Eds.; Wiley: Chichester, UK, 2018; pp. 185–229. ISBN 978-1-119-28742-1/978-1-119-28790-2. [Google Scholar]

- Wilkinson, N.J.; Smith, M.A.A.; Kay, R.W.; Harris, R.A. A Review of Aerosol Jet Printing—A Non-Traditional Hybrid Process for Micro-Manufacturing. Int. J. Adv. Manuf. Technol. 2019, 105, 4599–4619. [Google Scholar] [CrossRef]

- Secor, E.B. Principles of Aerosol Jet Printing. Flex. Print. Electron. 2018, 3, 035002. [Google Scholar] [CrossRef]

- Jiang, X.; Jia, H.; Chen, X.; Li, J.; Chen, Y.; Jia, J.; Zhao, G.; Yu, L.; Zhu, G.; Zhu, Y. Broadening the Voltage Window of 3D-Printed MXene Micro-Supercapacitors with a Hybridized Electrolyte. Molecules 2024, 29, 1393. [Google Scholar] [CrossRef]

- Li, Z.; He, Q.; Chen, H.; Chen, Y.; Zeng, C.; Xu, T.; Deng, S.; Zhang, C. Multifunctional MXene Inks for Printed Electrochemical Energy Storage Devices. Energy Mater. 2025, 5, 500005. [Google Scholar] [CrossRef]

- Nabi, S.; Isaev, A.; Chiolerio, A. Inkjet Printing of Functional Materials for Low-Temperature Electronics: A Review of Materials and Strategies. ACS Appl. Electron. Mater. 2024, 6, 7679–7719. [Google Scholar] [CrossRef]

- Omarsany Bappy, M.; Song, K.; Zhang, Y.; Zhang, Y. Recent Advances in Printed Devices for Next-Generation Sensing. APL Electron. Devices 2025, 1, 21505. [Google Scholar] [CrossRef]

- Azad, B.K.D.; Roozbahani, A.; Tabatabaei, S.M.; Valinejad, A.; Fazelian, A.; Shahmoradi, K.; Khatami, F.; Aghamir, S.M.K.; Kolahdouz, M. Inkjet-Printed Electronics for Rapid and Low-Cost Prototyping of Digital Microfluidic Devices Using an off-the-Shelf Printer. Sci. Rep. 2025, 15, 4578. [Google Scholar] [CrossRef] [PubMed]

- Najafabadi, S.A.N.; Huang, C.; Betlem, K.; van Voorthuizen, T.A.; de Smet, L.C.P.M.; Ghatkesar, M.K.; van Dongen, M.; van der Veen, M.A. Advancements in Inkjet Printing of Metal- and Covalent-Organic Frameworks: Process Design and Ink Optimization. ACS Appl. Mater. Interfaces 2025, 17, 11469. [Google Scholar] [CrossRef] [PubMed]

- Turković, E.; Vasiljević, I.; Drašković, M.; Obradović, N.; Vasiljević, D.; Parojčić, J. An Investigation into Mechanical Properties and Printability of Potential Substrates for Inkjet Printing of Orodispersible Films. Pharmaceutics 2021, 13, 468. [Google Scholar] [CrossRef] [PubMed]

- Tran, V.T.; Wei, Y.; Du, H. On-Substrate Joule Effect Heating by Printed Micro-Heater for the Preparation of ZnO Semiconductor Thin Film. Micromachines 2020, 11, 490. [Google Scholar] [CrossRef]

- Clement, B.; Lyu, M.; Sandeep Kulkarni, E.; Lin, T.; Hu, Y.; Lockett, V.; Greig, C.; Wang, L. Recent Advances in Printed Thin-Film Batteries. Engineering 2022, 13, 238–261. [Google Scholar] [CrossRef]

- Zub, K.; Winsberg, J.; Schubert, U.S.; Hoeppener, S. Inkjet-Printing of Supercapacitors. ChemistrySelect 2020, 5, 11322–11330. [Google Scholar] [CrossRef]

- Lee, J.M.; Huang, X.; Goh, G.L.; Tran, T.; Yeong, W.Y. Understanding Droplet Jetting on Varying Substrate for Biological Applications. Int. J. Bioprint 2023, 9, 758. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, R.; Zhang, H.; Cheng, K. Aqueous MXene Inks for Inkjet-Printing Microsupercapacitors with Ultrahigh Energy Densities. J. Colloid Interface Sci. 2023, 645, 359–370. [Google Scholar] [CrossRef]

- Yu, L.; Li, W.; Wei, C.; Yang, Q.; Shao, Y.; Sun, J. 3D Printing of NiCoP/Ti3C2 MXene Architectures for Energy Storage Devices with High Areal and Volumetric Energy Density. Nanomicro Lett. 2020, 12, 143. [Google Scholar] [CrossRef]

- Ji, Z.; Feng, Y.; Liu, L.; Zheng, W.; Wu, M.; Li, Y.; Sun, Z.; Ying, G. Inkjet-Printed Flexible V2CTx Film Electrodes with Excellent Photoelectric Properties and High Capacities for Energy Storage Device. J. Colloid Interface Sci. 2025, 678, 200–209. [Google Scholar] [CrossRef]

- Sun, P.; Liu, J.; Liu, Q.; Yu, J.; Chen, R.; Zhu, J.; Sun, G.; Li, Y.; Liu, P.; Wang, J. Nitrogen and Sulfur Co-Doped MXene Ink without Additive for High-Performance Inkjet-Printing Micro-Supercapacitors. Chem. Eng. J. 2022, 450, 138372. [Google Scholar] [CrossRef]

- Grillo, A.; Ahmad, T.I.; Wang, J.; Pelella, A.; Faella, E.; Capista, D.; Passacantando, M.; Di Bartolomeo, A.; Casiraghi, C. Electron Field Emission of Water-Based Inkjet Printed Graphene Films. Nanoscale Adv. 2025, 7, 5184–5192. [Google Scholar] [CrossRef]

- Anagnostou, K.; Urban, M.; Sotiropoulos, E.; Polyzoidis, C.; Kavalieraki, K.; Mouratis, K.; Rosati, G.; Merkoçi, A.; Rogdakis, K.; Kymakis, E. Water-Based Graphene Oxide Inks for Inkjet-Printed Flexible Moisture Energy Generators. Sci. Rep. 2025, 15, 24685. [Google Scholar] [CrossRef]

- Sztymela, K.; Bienia, M.; Rossignol, F.; Mailley, S.; Ziesche, S.; Varghese, J.; Cerbelaud, M. Fabrication of Modern Lithium Ion Batteries by 3D Inkjet Printing: Opportunities and Challenges. Heliyon 2022, 8, e12623. [Google Scholar] [CrossRef]

- Sztymela, K.; Rossignol, F.; Bienia, M.; Zapp, N.; Nikolowski, K.; Cerbelaud, M. Fabrication of 3D Silicon Anode by Inkjet Printing: Opportunities and Challenges. J. Energy Storage 2024, 75, 109567. [Google Scholar] [CrossRef]

- Mirbagheri, S.; Gibertini, E.; Magagnin, L. Inkjet-Printed Silver Lithiophilic Sites on Copper Current Collectors: Tuning the Interfacial Electrochemistry for Anode-Free Lithium Batteries. Batteries 2024, 10, 369. [Google Scholar] [CrossRef]

- Viviani, P.; Gibertini, E.; Fontana, P.; Lissandrello, F.; Gogotsi, Y.; Magagnin, L. Flexible Inkjet-Printed Lithium-Ion Batteries with Ti3C2Tx Current Collector. J. Power Sources 2024, 601, 234287. [Google Scholar] [CrossRef]

- Kolb, C.G.; Lehmann, M.; Teixeira, C.M.; Maleksaeedi, S.; Zaeh, M.F. A Priori Evaluation of the Printability of Water-Based Anode Dispersions in Inkjet Printing. Prod. Eng. 2024, 18, 61–74. [Google Scholar] [CrossRef]

- Zhang, C.; McKeon, L.; Kremer, M.P.; Park, S.H.; Ronan, O.; Seral-Ascaso, A.; Barwich, S.; Coileáin, C.; McEvoy, N.; Nerl, H.C.; et al. Additive-Free MXene Inks and Direct Printing of Micro-Supercapacitors. Nat. Commun. 2019, 10, 1795. [Google Scholar] [CrossRef] [PubMed]

- Guo, T.; Zhou, D.; Deng, S.; Jafarpour, M.; Avaro, J.; Neels, A.; Heier, J.; Zhang, C. Rational Design of Ti3C2Tx MXene Inks for Conductive, Transparent Films. ACS Nano 2023, 17, 3737–3749. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Cho, M.; Jung, S. The Design of an Inkjet Drive Waveform Using Machine Learning. Sci. Rep. 2022, 12, 4841. [Google Scholar] [CrossRef]

- Wang, J.; Chiu, G.T.C. Drop-on-Demand Inkjet Drop Control With One-Step Look Ahead Estimation of Model Parameters. IEEE/ASME Trans. Mechatron. 2023, 28, 1993–2002. [Google Scholar] [CrossRef]

- Hussain, Z.; Kiaee, Z.; Nazarzadeh, M.; Reichel, C.; Tepner, S.; Tuladhar, T.; Jahn, M.; Keding, R. High-Frequency Rheological and Piezo-Voltage Waveform Characterization of Inkjet-Printed Polymer-Based Dopant-Source Inks. Micromachines 2022, 14, 80. [Google Scholar] [CrossRef]

- Kim, S.; Choi, J.H.; Sohn, D.K.; Ko, H.S. The Effect of Ink Supply Pressure on Piezoelectric Inkjet. Micromachines 2022, 13, 615. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Tian, H.; Wang, C.; Li, X.; Chen, X.; Chen, X.; Shao, J. Piezoelectric Drop-on-Demand Inkjet Printing with Ultra-High Droplet Velocity. Research 2023, 6, 248. [Google Scholar] [CrossRef]

- Maîtrejean, G.; Cousin, M.; Truong, F.; Verdoot, V.; Hugenell, F.; Roux, D.C.D. Comprehensive Experimental Dataset on Large-Amplitude Rayleigh-Plateau Instability in Continuous InkJet Printing Regime. Data Brief 2024, 52, 109941. [Google Scholar] [CrossRef]

- Arya, P.; Wu, Y.; Wang, F.; Wang, Z.; Cadilha Marques, G.; Levkin, P.A.; Nestler, B.; Aghassi-Hagmann, J. Wetting Behavior of Inkjet-Printed Electronic Inks on Patterned Substrates. Langmuir 2024, 40, 5162–5173. [Google Scholar] [CrossRef] [PubMed]

- Arora, E.K.; Sharma, V.; Ravi, A.; Shahi, A.; Jagtap, S.; Adhikari, A.; Dash, J.K.; Kumar, P.; Patel, R. Polyaniline-Based Ink for Inkjet Printing for Supercapacitors, Sensors, and Electrochromic Devices. Energies 2023, 16, 6716. [Google Scholar] [CrossRef]

- Gibertini, E.; Lissandrello, F.; Bertoli, L.; Viviani, P.; Magagnin, L. All-Inkjet-Printed Ti3C2 MXene Capacitor for Textile Energy Storage. Coatings 2023, 13, 230. [Google Scholar] [CrossRef]

- Sangiorgi, N.; Sangiorgi, A.; Soccio, A.; Rancan, M.; Armelao, L.; Sanson, A. Bifunctional WO3 Photoelectrodes Decorated by Inkjet Printing for Solar Supercapacitors. Adv. Sustain. Syst. 2025, 9, e00478. [Google Scholar] [CrossRef]

- Sarma Choudhury, S.; Katiyar, N.; Saha, R.; Bhattacharya, S. Inkjet-Printed Flexible Planar Zn-MnO2 Battery on Paper Substrate. Sci. Rep. 2024, 14, 1597. [Google Scholar] [CrossRef]

- Nyabadza, A.; Titus, A.; McCarthy, É.; Azoulay-Younes, L.; Ryan, S.; Sreenilayam, S.; Nicolosi, V.; Vazquez, M.; Brabazon, D. Fabrication and Inkjet Printing of Manganese Oxide Electrodes for Energy Storage. Chem. Eng. J. Adv. 2025, 22, 100761. [Google Scholar] [CrossRef]

- Nyabadza, A.; Ryan, S.; Chatterjee, S.; Henry, D.D.; Muthusamy, S.P.; Santos, J.I.M.; Hashemi, T.S.; Nicolosi, V.; Brabazon, D.; Vazquez, M. Fabrication of Manganese-Tin Electrodes for Sodium-Ion Battery and Supercapacitor Applications via Laser Ablation, Laser Texturing, and Inkjet Printing. Chem. Eng. J. Adv. 2025, 23, 100799. [Google Scholar] [CrossRef]

- Kant, C.; Shukla, A.; McGregor, S.K.M.; Lo, S.C.; Namdas, E.B.; Katiyar, M. Large Area Inkjet-Printed OLED Fabrication with Solution-Processed TADF Ink. Nat. Commun. 2023, 14, 7220. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Zhu, H.; Xing, L.; Bu, Q.; Ren, D.; Sun, B. Recent Advances in Inkjet-Printing Technologies for Flexible/Wearable Electronics. Nanoscale 2023, 15, 6025–6051. [Google Scholar] [CrossRef]

- Boumegnane, A.; Douhi, S.; Batine, A.; Dormois, T.; Cochrane, C.; Nadi, A.; Cherkaoui, O.; Tahiri, M. Rheological Properties and Inkjet Printability of a Green Silver-Based Conductive Ink for Wearable Flexible Textile Antennas. Sensors 2024, 24, 2938. [Google Scholar] [CrossRef] [PubMed]

- Arango, J.C.; Pintro, C.J.; Singh, A.; Claridge, S.A. Inkjet Printing of Nanoscale Functional Patterns on 2D Crystalline Materials and Transfer to Soft Materials. ACS Appl. Mater. Interfaces 2024, 16, 8055–8065. [Google Scholar] [CrossRef]

- Li, C.; Bu, F.; Wang, Q.; Liu, X. Recent Developments of Inkjet-Printed Flexible Energy Storage Devices. Adv. Mater. Interfaces 2022, 9, 2201051. [Google Scholar] [CrossRef]

- Printing on Polymers: Fundamentals and Applications—Google Libros. Available online: https://books.google.ca/books?hl=es&lr=&id=IjROBQAAQBAJ&oi=fnd&pg=PA231&dq=CIJ+Rayleigh+Inkjet+printing&ots=D_AflRM94b&sig=XJxnG81MNhlcpN-g_0UDJsh9evM&redir_esc=y#v=onepage&q=CIJ%20Rayleigh%20Inkjet%20printing&f=false (accessed on 29 May 2025).

- Zhao, D.; Zhou, H.; Wang, Y.; Yin, J.; Huang, Y. Drop-on-Demand (DOD) Inkjet Dynamics of Printing Viscoelastic Conductive Ink. Addit. Manuf. 2021, 48, 102451. [Google Scholar] [CrossRef]

- Jo, B.W.; Lee, A.; Ahn, K.H.; Lee, S.J. Evaluation of Jet Performance in Drop-on-Demand (DOD) Inkjet Printing. Korean J. Chem. Eng. 2009, 26, 339–348. [Google Scholar] [CrossRef]

- Heilmann, J.; Lindqvist, U. The Effect of the Drop Size on the Print Quality in CIJ Printing. NIP Digit. Fabr. Conf. 1999, 15, 412–415. [Google Scholar] [CrossRef]

- Hutchings, I.M.; Martin, G.D. Inkjet Technology for Digital Fabrication. In Inkjet Technology for Digital Fabrication; Wiley: Chichester, UK, 2012; pp. 1–372. [Google Scholar] [CrossRef]

- Shah, M.A.; Lee, D.G.; Lee, B.Y.; Hur, S. Classifications and Applications of Inkjet Printing Technology: A Review. IEEE Access 2021, 9, 140079–140102. [Google Scholar] [CrossRef]

- HP PageWide T1195i Press—Digital Web Press for Printing Corrugated Boxes|HP® Official Site. Available online: https://www.hp.com/us-en/commercial-industrial-printing/pagewide-corrugated/t1195i-presses.html (accessed on 8 August 2025).

- Azizi Machekposhti, S.; Mohaved, S.; Narayan, R.J. Inkjet Dispensing Technologies: Recent Advances for Novel Drug Discovery. Expert Opin. Drug Discov. 2019, 14, 101. [Google Scholar] [CrossRef] [PubMed]

- EFI Nozomi Industrial Single-Pass Inkjet Printers for Corrugated Packaging and Displays. Available online: https://www.efi.com/lp/industrial-single-pass-inkjet-printers-for-corrugated-and-displays/ (accessed on 8 August 2025).

- Pro Z75 B2 Sheet-Fed Inkjet Digital Press|Ricoh USA. Available online: https://www.ricoh-usa.com/en/products/pd/equipment/commercial-and-industrial-printing/sheet-fed/pro-z75-b2-sheet-fed-inkjet-digital-press (accessed on 8 August 2025).

- Murata, K.; Matsumoto, J.; Tezuka, A.; Matsuba, Y.; Yokoyama, H. Super-Fine Ink-Jet Printing: Toward the Minimal Manufacturing System. Microsyst. Technol. 2005, 12, 2–7. [Google Scholar] [CrossRef]

- Murata, K. Super-Fine Ink-Jet Printing for Nanotechnology. In Proceedings of the International Conference on MEMS, NANO and Smart Systems, ICMENS 2003, Banff, AB, Canada, 23 July 2003; pp. 346–349. [Google Scholar] [CrossRef]

- Pavlovskii, A.A.; Pushnitsa, K.; Kosenko, A.; Novikov, P.; Popovich, A.A. 3D-Printed Lithium-Ion Battery Electrodes: A Brief Review of Three Key Fabrication Techniques. Materials 2024, 17, 5904. [Google Scholar] [CrossRef] [PubMed]

- Sajedi-Moghaddam, A.; Rahmanian, E.; Naseri, N. Inkjet-Printing Technology for Supercapacitor Application: Current State and Perspectives. ACS Appl. Mater. Interfaces 2020, 12, 34487–34504. [Google Scholar] [CrossRef]

- Gao, Y.; Guo, X.; Qiu, Z.; Zhang, G.; Zhu, R.; Zhang, Y.; Pang, H. Printable Electrode Materials for Supercapacitors. ChemPhysMater 2022, 1, 17–38. [Google Scholar] [CrossRef]

- Lawes, S.; Sun, Q.; Lushington, A.; Xiao, B.; Liu, Y.; Sun, X. Inkjet-Printed Silicon as High Performance Anodes for Li-Ion Batteries. Nano Energy 2017, 36, 313–321. [Google Scholar] [CrossRef]

- Reslan, J.; Kassem, O.; Barnier, V.; Sao-joao, S.; Vacandio, F.; Saadaoui, M.; Djenizian, T. Intense Pulsed Light-Induced Selective Conversion of Printed Silicon Nanoparticles into Graphene Embedding Silicon Carbide on Plastic for the next Generation Flexible Lithium-Ion Batteries. Energy Mater. 2025, 5, 500137. [Google Scholar] [CrossRef]

- Banti, A.; Charalampakis, M.; Pardalis, P.; Prochaska, C.; Sotiropoulos, S.; Binas, V. Electrochemical Studies of Inkjet Printed Semi-Transparent NiCo2O4/ITO Supercapacitor Electrodes. Catalysts 2023, 13, 1110. [Google Scholar] [CrossRef]

- Ho, C.C.; Murata, K.; Steingart, D.A.; Evans, J.W.; Wright, P.K. A Super Ink Jet Printed Zinc–Silver 3D Microbattery. J. Micromechanics Microengineering 2009, 19, 094013. [Google Scholar] [CrossRef]

- Sollami Delekta, S.; Laurila, M.M.; Mäntysalo, M.; Li, J. Drying-Mediated Self-Assembly of Graphene for Inkjet Printing of High-Rate Micro-Supercapacitors. Nanomicro Lett. 2020, 12, 40. [Google Scholar] [CrossRef]

- Deiner, L.J.; Reitz, T.L. Inkjet and Aerosol Jet Printing of Electrochemical Devices for Energy Conversion and Storage. Adv. Eng. Mater. 2017, 19, 1600878. [Google Scholar] [CrossRef]

- Rodriguez, R.; Deiner, L.J.; Tsao, B.H.; Fellner, J.P. Enhanced Rate Capability and Capacity of LIB Full Cells Achieved through Aerosol Jet Printing. J. Phys. Energy 2024, 6, 035009. [Google Scholar] [CrossRef]

- Kouchi, F.R.; Varghese, T.V.; Burgoyne, H.; Mansoor, N.E.; Seol, M.L.; McKibben, N.; Nirantar, S.; Chinnathambi, K.; Eixenberger, J.; Maryon, O.; et al. StableTi3C2Tx MXene Ink Formulation and High-Resolution Aerosol Jet Printing for High-Performance MXene Supercapacitors. Small Methods 2025. [Google Scholar] [CrossRef]

- Rubio, J.C.; Bolduc, M. Screen Printing for Energy Storage and Functional Electronics: A Review. Electron. Mater. 2025, 6, 7. [Google Scholar] [CrossRef]

- Shi, Z.; Sha, X.; Song, X.; Zeng, F.; Wu, X.; Yu, M.; Zhang, X.; Xu, R.; Jiang, C. Design and Fabrication of Carbon-Based Printable Inks for All-Solid-State Supercapacitors with High Capacitance and High Flexibility. ACS Appl. Energy Mater. 2025, 8, 4564–4573. [Google Scholar] [CrossRef]

- Emani, H.R.K.M.; Maddipatla, D.; Hanson, T.; Palaniappan, V.; Wang, G.; Narakathu, B.B.; Lu, W.; Wu, Q.; Atashbar, M.Z. Investigating the Effect of Screen-Printed Structured Graphite Electrodes with Low Tortuosity for High-Capacity and Fast-Charging Lithium-Ion Batteries. Sci. Rep. 2025, 15, 28700. [Google Scholar] [CrossRef]

- Xu, J.; Li, Y.; Wang, J.; Liu, H.; Hou, Q.; Wang, R.; Lang, T.; Cui, B.; Pan, H.; Chen, Y.; et al. Screen-Printed Highly Stretchable and Stable Flexible Electrodes with a Negative Poisson’s Ratio Structure for Supercapacitors. Nanoscale 2023, 15, 1260–1272. [Google Scholar] [CrossRef]

- Montanino, M.; De Girolamo Del Mauro, A.; Paoletti, C.; Sico, G. Gravure Printing of Graphite-Based Anodes for Lithium-Ion Printed Batteries. Membranes 2022, 12, 999. [Google Scholar] [CrossRef]

- Li, Y.; Gao, B.; Park, S.; Jang, S.; Son, H.; Bae, C.J. Printing Guidelines for Extrusion-Based Additive Manufacturing with Potential Use in Lithium-Ion Battery. J. Power Sources 2025, 640, 236777. [Google Scholar] [CrossRef]

- Wiegmann, E.; Kwade, A.; Haselrieder, W. Solvent Reduced Extrusion-Based Anode Production Process Integrating Granulate Coating, Drying, and Calendering. Energy Technol. 2022, 10, 2200020. [Google Scholar] [CrossRef]

- Glynn, C.; Jadhav, V.V.; McNulty, D.; Geaney, H.; O’Hanlon, S.; O’Dwyer, C. Voltammetric Priming for Electrochemically Stable 3D Printed Aqueous Gel Li-Ion Rechargeable Batteries in Various Form Factors. ECS Adv. 2025, 4, 030501. [Google Scholar] [CrossRef]

- Sun, G.; An, J.; Chua, C.K.; Pang, H.; Zhang, J.; Chen, P. Layer-by-Layer Printing of Laminated Graphene-Based Interdigitated Microelectrodes for Flexible Planar Micro-Supercapacitors. Electrochem. Commun. 2015, 51, 33–36. [Google Scholar] [CrossRef]

- Cheng, T.; Wu, Y.W.; Chen, Y.L.; Zhang, Y.Z.; Lai, W.Y.; Huang, W. Inkjet-Printed High-Performance Flexible Micro-Supercapacitors with Porous Nanofiber-Like Electrode Structures. Small 2019, 15, 1901830. [Google Scholar] [CrossRef] [PubMed]

- Shandra, A.; Li, K.; Spurling, D.; Ronan, O.; Nicolosi, V. Aerosol Jet Printed MXene Microsupercapacitors for Flexible and Washable Textile Energy Storage. Adv. Funct. Mater. 2025, e10255. [Google Scholar] [CrossRef]

- Barbosa, J.A.C.; Abdelsadig, M.S.E.; Conway, B.R.; Merchant, H.A. Using Zeta Potential to Study the Ionisation Behaviour of Polymers Employed in Modified-Release Dosage Forms and Estimating Their PKa. Int. J. Pharm. X 2019, 1, 100024. [Google Scholar] [CrossRef]

- Bihari, P.; Vippola, M.; Schultes, S.; Praetner, M.; Khandoga, A.G.; Reichel, C.A.; Coester, C.; Tuomi, T.; Rehberg, M.; Krombach, F. Optimized Dispersion of Nanoparticles for Biological in Vitro and in Vivo Studies. Part. Fibre Toxicol. 2008, 5, 14. [Google Scholar] [CrossRef] [PubMed]

- Gęca, M.; Wiśniewska, M.; Nowicki, P. Investigation of Ionic Polymers’ Stabilizing and Flocculating Properties in Dispersed Activated Carbons Systems. Materials 2024, 17, 693. [Google Scholar] [CrossRef]

- Worthen, A.J.; Tran, V.; Cornell, K.A.; Truskett, T.M.; Johnston, K.P. Steric Stabilization of Nanoparticles with Grafted Low Molecular Weight Ligands in Highly Concentrated Brines Including Divalent Ions. Soft Matter 2016, 12, 2025–2039. [Google Scholar] [CrossRef]

- Srivastava, M.; Anil, A.K.; Zaghib, K. Binders for Li-Ion Battery Technologies and Beyond: A Comprehensive Review. Batteries 2024, 10, 268. [Google Scholar] [CrossRef]

- Wang, R.; Feng, L.; Yang, W.; Zhang, Y.; Zhang, Y.; Bai, W.; Liu, B.; Zhang, W.; Chuan, Y.; Zheng, Z.; et al. Effect of Different Binders on the Electrochemical Performance of Metal Oxide Anode for Lithium-Ion Batteries. Nanoscale Res. Lett. 2017, 12, 575. [Google Scholar] [CrossRef]

- Guo, Y.; Patanwala, H.S.; Bognet, B.; Ma, A.W.K. Inkjet and Inkjet-Based 3D Printing: Connecting Fluid Properties and Printing Performance. Rapid Prototyp. J. 2017, 23, 562–576. [Google Scholar] [CrossRef]

- Fang, Y.; Zou, H.; Peng, S.; Dong, G.; Tentzeris, M.M. Full and In Situ Printing of Nanogenerators That Are Based on an Inherently Viscous Piezoelectric Polymer: An Effort to Minimize “Coffee Ring Effect” and Nonprinting Operations. ACS Appl. Electron. Mater. 2023, 5, 4157–4167. [Google Scholar] [CrossRef]

- Langer, F.; Yin, S.; Duvigneau, J.; Vancso, G.J.; Benson, N. Suppression of the Coffee Ring Effect in a Single Solvent-Based Silicon Nanoparticle Ink. ACS Appl. Mater. Interfaces 2024, 16, 4242–4248. [Google Scholar] [CrossRef]

- Fatimah Kamarudin, S.; Jaafar, M.; Abd Manaf, A.; Takamura, Y.; Masuda, T.; Yumoto, Y.; Kamarudin, S.F.; Mariatti, M.; Abd Manaf, A.; Takamura, Y.; et al. Performance Enhancement of Inkjet Printed Multi-Walled Carbon Nanotubes Inks Using Synthetic and Green Surfactants. Adv. Mater. Technol. 2021, 6, 2001026. [Google Scholar] [CrossRef]

- Varghese, N.; Sykes, T.C.; Quetzeri-Santiago, M.A.; Castrejón-Pita, A.A.; Castrejón-Pita, J.R. Effect of Surfactants on the Splashing Dynamics of Drops Impacting Smooth Substrates. Langmuir 2024, 40, 8781–8790. [Google Scholar] [CrossRef] [PubMed]

- Inkjet-Based Micromanufacturing—Google Libros. Available online: https://books.google.ca/books?hl=es&lr=&id=jLMqoirILhAC&oi=fnd&pg=PA173&dq=Surfactants+in+Inkjet+Ink+batteries&ots=7xAb5ycSiF&sig=ruLxiiANPVWSm0HcB4ngXCGxCFE&redir_esc=y#v=onepage&q&f=false (accessed on 9 August 2025).

- Claypole, A.; Claypole, J.; Holder, A.; Claypole, T.C.; Kilduff, L. Rheology of High-Aspect-Ratio Nanocarbons Dispersed in a Low-Viscosity Fluid. J. Coat. Technol. Res. 2020, 17, 1003–1012. [Google Scholar] [CrossRef]

- Basak, I.; Nowicki, G.; Ruttens, B.; Desta, D.; Prooth, J.; Jose, M.; Nagels, S.; Boyen, H.G.; D’haen, J.; Buntinx, M.; et al. Inkjet Printing of PEDOT:PSS Based Conductive Patterns for 3D Forming Applications. Polymers 2020, 12, 2915. [Google Scholar] [CrossRef] [PubMed]

- Chrétien, F.; Nikiforidis, G.; Damas, C.; Anouti, M. Lithium-Ion Batteries Containing Surfactants for the Protection of Graphite Anode against the Passivation Layer Byproducts. ChemElectroChem 2023, 10, e202300102. [Google Scholar] [CrossRef]

- Derby, B. Inkjet Printing of Functional and Structural Materials: Fluid Property Requirements, Feature Stability, and Resolution. Annu. Rev. Mater. Res. 2010, 40, 395–414. [Google Scholar] [CrossRef]

- Fromm, J.E. Numerical Calculation of the Fluid Dynamics of Drop-on-Demand Jets. IBM J. Res. Dev. 1984, 28, 322–333. [Google Scholar] [CrossRef]

- Zocca, A.; Colombo, P.; Gomes, C.M.; Günster, J. Additive Manufacturing of Ceramics: Issues, Potentialities, and Opportunities. J. Am. Ceram. Soc. 2015, 98, 1983–2001. [Google Scholar] [CrossRef]

- Akuzum, B.; Maleski, K.; Anasori, B.; Lelyukh, P.; Alvarez, N.J.; Kumbur, E.C.; Gogotsi, Y. Rheological Characteristics of 2D Titanium Carbide (MXene) Dispersions: A Guide for Processing MXenes. ACS Nano 2018, 12, 2685–2694. [Google Scholar] [CrossRef]

- Bogy, D.B.; Talke, F.E. Experimental and Theoretical Study of Wave Propagation Phenomena in Drop-on-Demand Ink Jet Devices. IBM J. Res. Dev. 1984, 28, 314–321. [Google Scholar] [CrossRef]

- Shah, M.A.; Lee, D.G.; Lee, B.Y.; Kim, N.W.; An, H.; Hur, S. Actuating Voltage Waveform Optimization of Piezoelectric Inkjet Printhead for Suppression of Residual Vibrations. Micromachines 2020, 11, 900. [Google Scholar] [CrossRef]

- Liu, Y.-F.; Tsai, M.-H.; Pai, Y.-F.; Hwang, W.-S. Control of Droplet Formation by Operating Waveform for Inks with Various Viscosities in Piezoelectric Inkjet Printing. Appl. Phys. A 2013, 111, 509–516. [Google Scholar] [CrossRef]

- Snyder, B.; Yang, M.; Singhal, S.; Abed, O.; Sreenivasan, S. V Automated Tuning of High-Order Waveforms for Picoliter Resolution Jetting of Rheologically Challenging Materials. Precis. Eng. 2019, 56, 143–155. [Google Scholar] [CrossRef]

- Chen, A.U.; Basaran, O.A. A New Method for Significantly Reducing Drop Radius without Reducing Nozzle Radius in Drop-on-Demand Drop Production. Phys. Fluids 2002, 14, L1–L4. [Google Scholar] [CrossRef]

- Wang, S.; Zhong, Y.; Fang, H. Deformation Characteristics of a Single Droplet Driven by a Piezoelectric Nozzle of the Drop-on-Demand Inkjet System. J. Fluid Mech. 2019, 869, 634–645. [Google Scholar] [CrossRef]

- Liu, Y.; Xie, J.; Liu, L.; Fan, K.; Zhang, Z.; Chen, S.; Chen, S. Inkjet-Printed Highly Conductive Poly(3,4-Ethylenedioxythiophene): Poly(Styrenesulfonate) Electrode for Organic Light-Emitting Diodes. Micromachines 2021, 12, 889. [Google Scholar] [CrossRef]

- Bernasconi, R.; Brovelli, S.; Viviani, P.; Soldo, M.; Giusti, D.; Magagnin, L. Piezoelectric Drop-On-Demand Inkjet Printing of High-Viscosity Inks. Adv. Eng. Mater. 2022, 24, 2100733. [Google Scholar] [CrossRef]

- Mau, R.; Seitz, H. Influence of the Volatility of Solvent on the Reproducibility of Droplet Formation in Pharmaceutical Inkjet Printing. Pharmaceutics 2023, 15, 367. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhang, Y.Z.; Dubbink, D.; ten Elshof, J.E. Inkjet Printing of δ-MnO2 Nanosheets for Flexible Solid-State Micro-Supercapacitor. Nano Energy 2018, 49, 481–488. [Google Scholar] [CrossRef]

- Cholewinski, A.; Si, P.; Uceda, M.; Pope, M.; Zhao, B. Polymer Binders: Characterization and Development toward Aqueous Electrode Fabrication for Sustainability. Polymers 2021, 13, 631. [Google Scholar] [CrossRef]

- Weber, A.; Keim, N.; Koch, P.; Müller, M.; Bauer, W.; Ehrenberg, H. The Impact of Binder Polarity on the Properties of Aqueously Processed Positive and Negative Electrodes for Lithium-Ion Batteries. Sci. Rep. 2025, 15, 10024. [Google Scholar] [CrossRef] [PubMed]

- Samuel, J.; Edwards, P. Solvent-Based Inkjet Inks. In The Chemistry of Inkjet Inks; World Scientific: Singapore, 2009; pp. 141–160. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, Y.; Liang, Q.; Zhang, Y.; Chi, H.; Shi, Y.; Fang, D. Solvent Inkjet Printing Process for the Fabrication of Polymer Solar Cells. RSC Adv. 2013, 3, 11925–11934. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, G.; Liu, L.; Jiang, Z. High-Performance Thin-Film Li4Ti5O12 Electrodes Fabricated by Using Ink-Jet Printing Technique and Their Electrochemical Properties. J. Solid State Electrochem. 2009, 13, 705–711. [Google Scholar] [CrossRef]

- Maximov, M.; Kolchanov, D.; Mitrofanov, I.; Vinogradov, A.; Koshtyal, Y.; Rymyantsev, A.; Popovich, A. Inks Development for 3D Printing Cathode of Li-Ion Microbatteries. Proceedings 2018, 3, 7. [Google Scholar] [CrossRef]

- Khan, J.; Mariatti, M.; Zubir, S.A.; Rusli, A.; Manaf, A.A.; Khirotdin, R.K. Eco-Friendly Alkali Lignin-Assisted Water-Based Graphene Oxide Ink and Its Application as a Resistive Temperature Sensor. Nanotechnology 2023, 35, 055301. [Google Scholar] [CrossRef]

- Silvestri, A.; Vázquez-Díaz, S.; Misia, G.; Poletti, F.; López-Domene, R.; Pavlov, V.; Zanardi, C.; Cortajarena, A.L.; Prato, M. An Electroactive and Self-Assembling Bio-Ink, Based on Protein-Stabilized Nanoclusters and Graphene, for the Manufacture of Fully Inkjet-Printed Paper-Based Analytical Devices. Small 2023, 19, 2300163. [Google Scholar] [CrossRef]

- Nalepa, M.A.; Panáček, D.; Dědek, I.; Jakubec, P.; Kupka, V.; Hrubý, V.; Petr, M.; Otyepka, M. Graphene Derivative-Based Ink Advances Inkjet Printing Technology for Fabrication of Electrochemical Sensors and Biosensors. Biosens. Bioelectron. 2024, 256, 116277. [Google Scholar] [CrossRef] [PubMed]

- Viviani, P.; Gibertini, E.; Iervolino, F.; Levi, M.; Magagnin, L. Carbon Additive Effect on the Electrochemical Performances of Inkjet Printed Thin-Film Li4Ti5O12 Electrodes. J. Manuf. Process. 2021, 72, 411–418. [Google Scholar] [CrossRef]

- Wang, Y.; Lubbers, T.; Xia, R.; Zhang, Y.-Z.; Mehrali, M.; Huijben, M.; Elshof, J.E. ten Printable Two-Dimensional V2O5/MXene Heterostructure Cathode for Lithium-Ion Battery. J. Electrochem. Soc. 2021, 168, 020507. [Google Scholar] [CrossRef]

- Kolchanov, D.S.; Mitrofanov, I.; Kim, A.; Koshtyal, Y.; Rumyantsev, A.; Sergeeva, E.; Vinogradov, A.; Popovich, A.; Maximov, M.Y. Inkjet Printing of Li-Rich Cathode Material for Thin-Film Lithium-Ion Microbatteries. Energy Technol. 2020, 8, 1901086. [Google Scholar] [CrossRef]

- Lou, X.; Zhao, L.; Gao, Y.; Nan, X. 3D-Printed Electrode/Electrolyte Architectures for High-Performance Lithium-Ion Batteries: Mechanisms, Materials, and Challenges. ACS Omega 2025, 10, 28630. [Google Scholar] [CrossRef]

- Maurel, A.; Grugeon, S.; Fleutot, B.; Courty, M.; Prashantha, K.; Tortajada, H.; Armand, M.; Panier, S.; Dupont, L. Three-Dimensional Printing of a LiFePO4/Graphite Battery Cell via Fused Deposition Modeling. Sci. Rep. 2019, 9, 18031. [Google Scholar] [CrossRef]

- Beydaghi, H.; Abouali, S.; Thorat, S.B.; Del Rio Castillo, A.E.; Bellani, S.; Lauciello, S.; Gentiluomo, S.; Pellegrini, V.; Bonaccorso, F. 3D Printed Silicon-Few Layer Graphene Anode for Advanced Li-Ion Batteries. RSC Adv. 2021, 11, 35051. [Google Scholar] [CrossRef]

- Chen, T.; Wang, Y.; Yang, Y.; Huang, F.; Zhu, M.; Ang, B.T.W.; Xue, J.M. Heterometallic Seed-Mediated Zinc Deposition on Inkjet Printed Silver Nanoparticles Toward Foldable and Heat-Resistant Zinc Batteries. Adv. Funct. Mater. 2021, 31, 2101607. [Google Scholar] [CrossRef]

- Ben-Barak, I.; Kamir, Y.; Menkin, S.; Goor, M.; Shekhtman, I.; Ripenbein, T.; Galun, E.; Golodnitsky, D.; Peled, E. Drop-on-Demand 3D Printing of Lithium Iron Phosphate Cathodes. J. Electrochem. Soc. 2019, 166, A5059–A5064. [Google Scholar] [CrossRef]

- Sollami Delekta, S.; Adolfsson, K.H.; Benyahia Erdal, N.; Hakkarainen, M.; Östling, M.; Li, J. Fully Inkjet Printed Ultrathin Microsupercapacitors Based on Graphene Electrodes and a Nano-Graphene Oxide Electrolyte. Nanoscale 2019, 11, 10172–10177. [Google Scholar] [CrossRef]

- Milroy, C.A.; Jang, S.; Fujimori, T.; Dodabalapur, A.; Manthiram, A. Inkjet-Printed Lithium–Sulfur Microcathodes for All-Printed, Integrated Nanomanufacturing. Small 2017, 13, 1603786. [Google Scholar] [CrossRef] [PubMed]

- Gu, Y.; Wu, A.; Sohn, H.; Nicoletti, C.; Iqbal, Z.; Federici, J.F. Fabrication of Rechargeable Lithium Ion Batteries Using Water-Based Inkjet Printed Cathodes. J. Manuf. Process. 2015, 20, 198–205. [Google Scholar] [CrossRef]

- Delannoy, P.E.; Riou, B.; Lestriez, B.; Guyomard, D.; Brousse, T.; Le Bideau, J. Toward Fast and Cost-Effective Ink-Jet Printing of Solid Electrolyte for Lithium Microbatteries. J. Power Sources 2015, 274, 1085–1090. [Google Scholar] [CrossRef]

- Sun, P.; Liu, J.; Liu, Q.; Yu, J.; Chen, R.; Zhu, J.; Sun, G.; Li, Y.; Liu, P.; Wang, J. An Inkjet-Printing Ink Based on Porous NiS/N-MXene for High-Performance Asymmetric Micro-Supercapacitors and Self-Powered Microelectronics. Chem. Eng. J. 2023, 474, 145466. [Google Scholar] [CrossRef]

- Reddygunta, K.K.R.; Šiller, L.; Ivaturi, A. Screen-Printed Stretchable Supercapacitors Based on Tin Sulfide-Decorated Face-Mask-Derived Activated Carbon Electrodes with High Areal Energy Density. ACS Appl. Energy Mater. 2024, 7, 3558–3576. [Google Scholar] [CrossRef]

- Chen, P.; Chen, H.; Qiu, J.; Zhou, C. Inkjet Printing of Single-Walled Carbon Nanotube/RuO2 Nanowire Supercapacitors on Cloth Fabrics and Flexible Substrates. Nano Res. 2010, 3, 594–603. [Google Scholar] [CrossRef]

- Pech, D.; Brunet, M.; Taberna, P.L.; Simon, P.; Fabre, N.; Mesnilgrente, F.; Conédéra, V.; Durou, H. Elaboration of a Microstructured Inkjet-Printed Carbon Electrochemical Capacitor. J. Power Sources 2010, 195, 1266–1269. [Google Scholar] [CrossRef]

- Xu, Y.; Hennig, I.; Freyberg, D.; James Strudwick, A.; Georg Schwab, M.; Weitz, T.; Chih-Pei Cha, K. Inkjet-Printed Energy Storage Device Using Graphene/Polyaniline Inks. J. Power Sources 2014, 248, 483–488. [Google Scholar] [CrossRef]

- Diao, J.; Yuan, J.; Ding, A.; Zheng, J.; Lu, Z. Flexible Supercapacitor Based on Inkjet-Printed Graphene@Polyaniline Nanocomposites with Ultrahigh Capacitance. Macromol. Mater. Eng. 2018, 303, 1800092. [Google Scholar] [CrossRef]

- Liu, J.; Ye, J.; Pan, F.; Wang, X.; Zhu, Y. Solid-State yet Flexible Supercapacitors Made by Inkjet-Printing Hybrid Ink of Carbon Quantum Dots/Graphene Oxide Platelets on Paper. Sci. China Mater. 2019, 62, 545–554. [Google Scholar] [CrossRef]

- Qiu, S.; Zhao, Y.; Wang, K.; Luo, J.; Wang, R.; Jiang, X.; Chen, J.; Elezzabi, A.Y.; Zhang, W.; Jia, H.; et al. Inkjet-Printing Assisted Engineering of Patternable Zinc Anode-Based Electrochromic Devices. Mater. Rep. Energy 2024, 4, 100293. [Google Scholar] [CrossRef]

- Brauniger, Y.; Lochmann, S.; Grothe, J.; Hantusch, M.; Kaskel, S. Piezoelectric Inkjet Printing of Nanoporous Carbons for Micro-Supercapacitor Devices. ACS Appl. Energy Mater. 2021, 4, 1560–1567. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.Z.; Gao, Y.Q.; Sheng, G.; ten Elshof, J.E. Defect Engineering of MnO2 Nanosheets by Substitutional Doping for Printable Solid-State Micro-Supercapacitors. Nano Energy 2020, 68, 104306. [Google Scholar] [CrossRef]

- Li, X.; Zhao, Y.; Yu, J.; Liu, Q.; Chen, R.; Zhang, H.; Song, D.; Li, R.; Liu, J.; Wang, J. Layer-by-Layer Inkjet Printing GO Film and Ag Nanoparticles Supported Nickel Cobalt Layered Double Hydroxide as a Flexible and Binder-Free Electrode for Supercapacitors. J. Colloid Interface Sci. 2019, 557, 691–699. [Google Scholar] [CrossRef]

- Li, G.; Meng, Z.; Qian, J.; Ho, C.L.; Lau, S.P.; Wong, W.Y.; Yan, F. Inkjet Printed Pseudocapacitive Electrodes on Laser-Induced Graphene for Electrochemical Energy Storage. Mater. Today Energy 2019, 12, 155–160. [Google Scholar] [CrossRef]

- Worsley, R.; Pimpolari, L.; McManus, D.; Ge, N.; Ionescu, R.; Wittkopf, J.A.; Alieva, A.; Basso, G.; MacUcci, M.; Iannaccone, G.; et al. All-2D Material Inkjet-Printed Capacitors: Toward Fully Printed Integrated Circuits. ACS Nano 2019, 13, 54–60. [Google Scholar] [CrossRef] [PubMed]

- Choi, K.H.; Yoo, J.T.; Lee, C.K.; Lee, S.Y. All-Inkjet-Printed, Solid-State Flexible Supercapacitors on Paper. Energy Environ. Sci. 2016, 9, 2812–2821. [Google Scholar] [CrossRef]

- Pei, Z.; Hu, H.; Liang, G.; Ye, C. Carbon-Based Flexible and All-Solid-State Micro-Supercapacitors Fabricated by Inkjet Printing with Enhanced Performance. Nanomicro Lett. 2017, 9, 19. [Google Scholar] [CrossRef] [PubMed]

- Pang, H.; Zhang, Y.; Lai, W.Y.; Hu, Z.; Huang, W. Lamellar K2Co3(P2O7)2·2H2O Nanocrystal Whiskers: High-Performance Flexible All-Solid-State Asymmetric Micro-Supercapacitors via Inkjet Printing. Nano Energy 2015, 15, 303–312. [Google Scholar] [CrossRef]

- Wang, S.; Liu, N.; Tao, J.; Yang, C.; Liu, W.; Shi, Y.; Wang, Y.; Su, J.; Li, L.; Gao, Y. Inkjet Printing of Conductive Patterns and Supercapacitors Using a Multi-Walled Carbon Nanotube/Ag Nanoparticle Based Ink. J. Mater. Chem. A Mater. 2015, 3, 2407–2413. [Google Scholar] [CrossRef]

| Device Type | Solvent | Additives | Viscosity | Printing Conditions | Substrate | Post-Treatment | Performance Results |

|---|---|---|---|---|---|---|---|

| Lithium anode-free with Ag lithophilic sites [28] | Aqueous solution with fluoropolymer | Ag nanoparticles (40 wt%) | Not specified | Dimatix DMP-2850, 20 kHz, 30 V, droplet spacing 10–40 μm, sintering at 150 °C for 3 h | Copper foil (15 μm) | Sintering at 150 °C for 3 h under N2 | Coulombic efficiency 97% at 0.2 mA cm−2 for 250 cycles; Nucleation overpotential 13.5 mV |

| Flexible planar Zn-MnO2 battery [43] | DI-water | Triton X-100, PVB | 3.3–8.2 mPa·s | Epson L130, high quality mode, 70 °C for 12 h | Bond paper (100 GSM) | Heat treatment at 70 °C for 12 h in vacuum | 600 mA g−1 (rate); 184.24 mAh g−1 after 500 cycles at that rate; Coulombic efficiency 99.24% (cycle 25); Energy density 330.15 Wh kg−1 at 220 W kg−1 |

| Flexible lithium-ion battery LTO/LFP [29] | Deionized water | Sodium ascorbate, LDS | 2.58 mPa·s | Breva thermal inkjet, 11.5 V, 2.2 μs | Flexible PET | Overnight drying | 12.5 μA cm−2; 6.09 mAh g−1; 100 cycles. |

| 3D silicon anode [27] | DI-water | Triton X-100, PVB or PEDOT:PSS | 3.3–8.2 mPa·s | CeraPrinter X-Series, max voltage 120 V, <15 μs | Copper foil | Heating at 80 °C for 16 h in vacuum | 0.2 C (after 4 formation cycles at 0.05 C); Lithiation capacity 2000 mAh g−1 (active material) for 100 cycles with no fading. |

| V2O5/MXene heterostructure cathode for LIB [124] | Deionized water | Not specified | Not specified | Dimatix DMP-2800, 10 pL cartridge | Not specified | Drying at 60 °C overnight | 10.5 C; 112 mAh g−1; 680 cycles with 91.7% capacity retention; Coulombic efficiency 96.5% |

| Li4Ti5O12 thin-film electrodes [123] | Water + ethylene glycol + 2-propanol | Li-PAA, LDS, CNT or CB | 2.58–2.82 cP | Breva thermal inkjet, 11.5 V, 2.2 μs, 600 dpi | Copper substrate with graphite spray | Drying at 80 °C for 3 h in vacuum | C/2; 128 mAh g−1 for 100 cycles (negligible fade); Coulombic efficiency 100% |

| Dendrite-free zinc anode [129] | Conductive silver ink | Ag nanoparticles | Not specified | Custom piezoelectric inkjet printer, ~20 V | 3D carbon cloth | Annealing at 180 °C for 1 h | 5.0 A g−1; 184 mAh g−1 after 1200 cycles |

| 3D LiFePO4 cathodes [130] | Deionized water | NaCMC, Triton X-100 | Not specified | PICO Pulse, 100 μm orifice | Carbon-coated aluminum current collector | Vacuum drying <1 mbar for 8 h at 100 °C | 1 C; ~140 mAh g−1 for 165 cycles; Coulombic efficiency 98.6% |

| Li-rich cathode material [125] | NMP | PVP | 8–10 cPs | Dimatix Material printer 2831, 10 pL cartridge | Aluminum foil | Heat treatment conditions varied | 0.1 C; 200 mAh g−1 after 80 cycles; Energy density 1037 Wh L−1; Specific energy 835 Wh kg−1 |

| All-graphene micro supercapacitor [131] | Deionized water, ethylene glycol, phosphoric acid | Nano-graphene oxide (nGO) | Not specified | Inkjet printing on Kapton, annealing to remove binder | Flexible Kapton | Annealing to remove binder | 5 mV s−1 (scan rate); Areal capacitance 313 µF cm−2; Volumetric energy density ~0.2 mWh cm−3 with power density ~4 mW cm−3; 11,000 cycles with >65% |

| Silicon nanoparticle anode for Li-ion battery [66] | Deionized water | Polymer binders: PEDOT:PSS, PVP, CMC, Na-alginate | ~10 mPa·s | HP Deskjet 2540, room temp, multiple passes | Copper foil | Vacuum drying at 60 °C overnight | 0.1 C; 1000 mAh g−1 for >1000 cycles; Coulombic efficiency ≈ 98.6% |

| Lithium-sulfur micro cathodes [132] | Cyclohexylpyrrolidone (CHP) | Not specified | Not specified | Fuji Dimatix 2800, 10 pL cartridges | Flexible aluminum foil or SiO2 wafers | Gradual annealing at 150 °C (~4°/min) | C/2; ~700 mAh g−1 after 100 cycles |

| LiFePO4 water-based cathodes [133] | Water + glycerol | CMC, carbon black, Triton X-100 | ~13 cP | Dimatix-2800 inkjet printer | Aluminum foil and CNT paper | Vacuum drying at 300 °C for 2 h | 0.1 C; 151.3 mAh g−1 (first discharge); Coulombic efficiency 94.4% note: test rate/window specified at 0.1 C, 2.0–4.0 V. |

| Solid electrolyte for microbatteries [134] | Ionogel sol precursor (TMOS + ionic liquid) | Silica-based ionogel | 10–12 mPa·s optimal | Dimatix DMP2800, 15 kHz, 16 V, 800 μm gap | Porous composite electrodes | Polycondensation after printing | C/10; Areal capacity ≈ 300 mAh cm−2 for 100 cycles (≈60 mAh g−1 on LFP) |

| Zinc-silver 3D microbattery [69] | Not specified (silver nanopaste + n-tetradecane) | Not specified | Not specified | Super inkjet printing, sintering at 250 °C for 1 h | Glass substrates | Sintering at 250 °C for 1 h | 0.1 mA (discharge); Energy density 3.95 mWh cm−2; Cycles: multiple with rapid fade (<20% by ~7 cycles) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rubio, J.C.; Bolduc, M. Inkjet Printing for Batteries and Supercapacitors: State-of-the-Art Developments and Outlook. Energies 2025, 18, 5348. https://doi.org/10.3390/en18205348

Rubio JC, Bolduc M. Inkjet Printing for Batteries and Supercapacitors: State-of-the-Art Developments and Outlook. Energies. 2025; 18(20):5348. https://doi.org/10.3390/en18205348

Chicago/Turabian StyleRubio, Juan C., and Martin Bolduc. 2025. "Inkjet Printing for Batteries and Supercapacitors: State-of-the-Art Developments and Outlook" Energies 18, no. 20: 5348. https://doi.org/10.3390/en18205348

APA StyleRubio, J. C., & Bolduc, M. (2025). Inkjet Printing for Batteries and Supercapacitors: State-of-the-Art Developments and Outlook. Energies, 18(20), 5348. https://doi.org/10.3390/en18205348