A Tie-Line Fault Ride-Through Strategy for PV Power Plants Based on Coordinated Energy Storage Control

Abstract

1. Introduction

2. Analysis of Tie-Line Faults in PV Power Plants

2.1. Tie-Line Fault

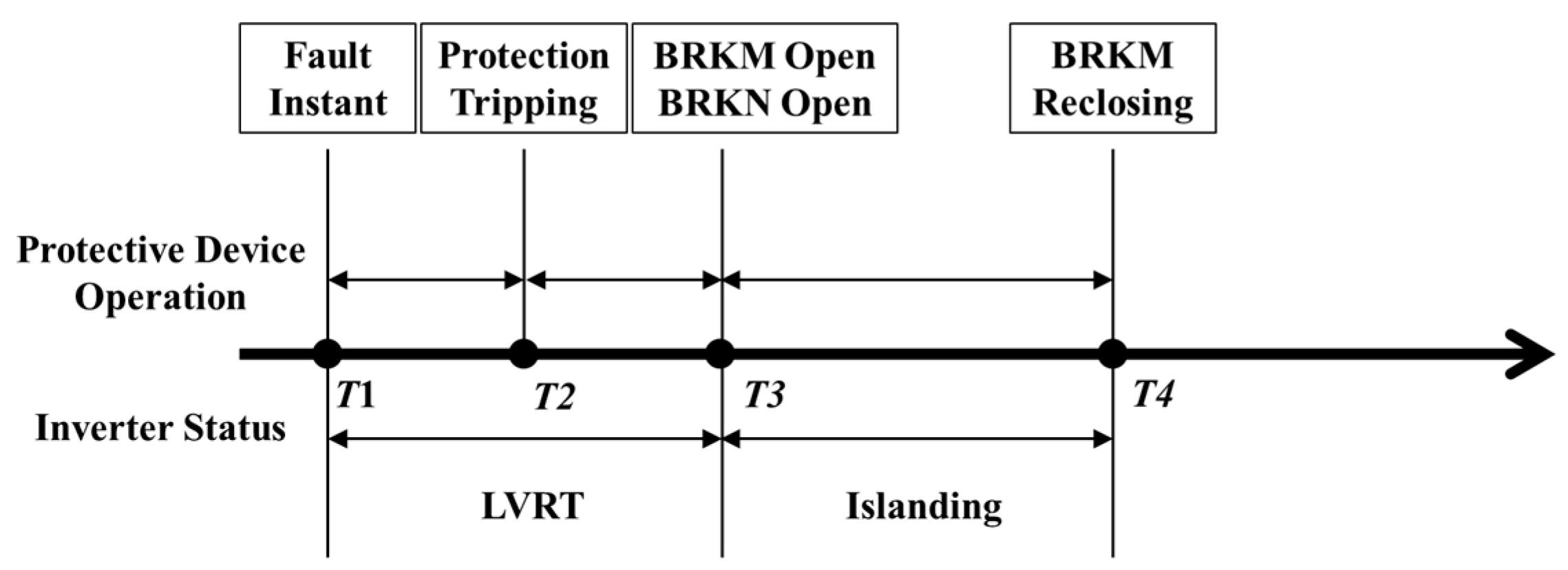

2.2. Post-Fault Dynamic Sequence of Protection Operation in PV Power Plant

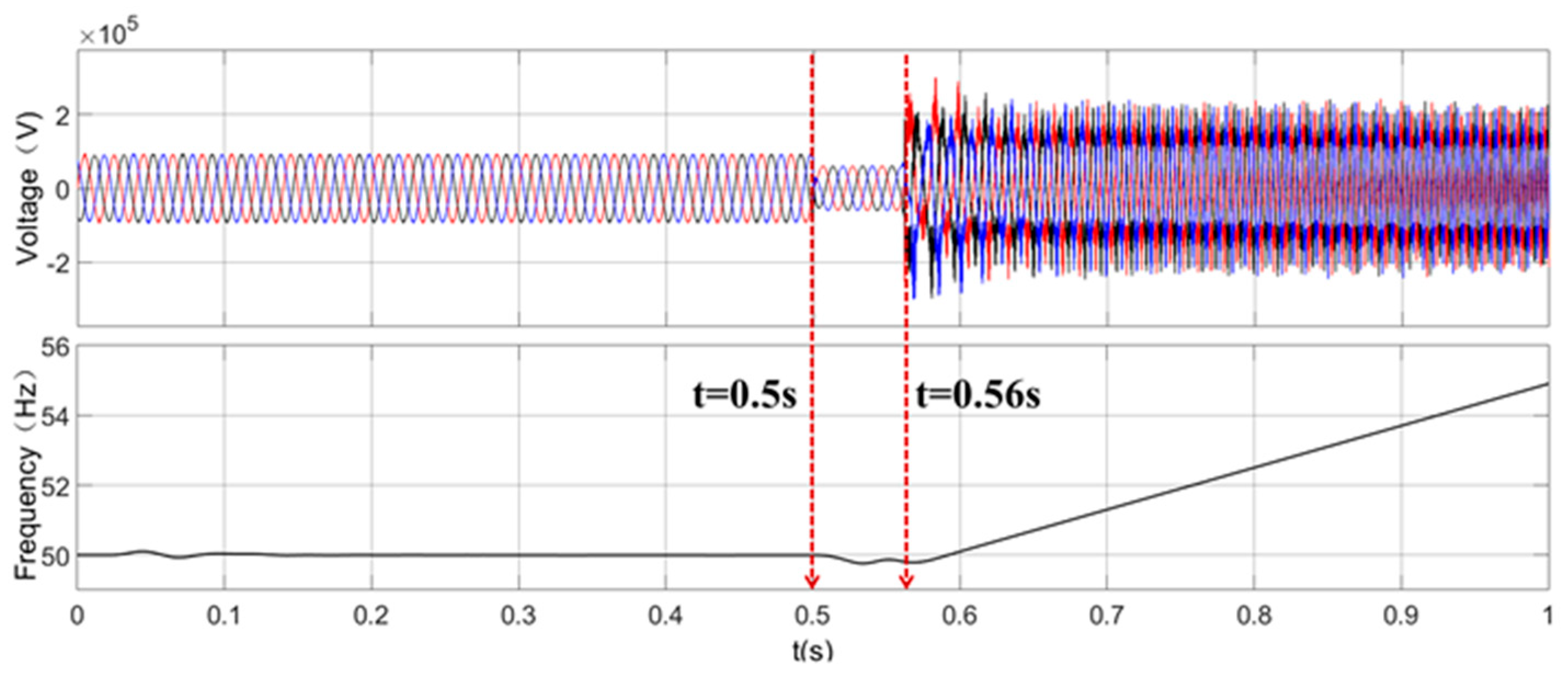

2.3. Post-Fault Variation in Voltage and Frequency in the PV Plant

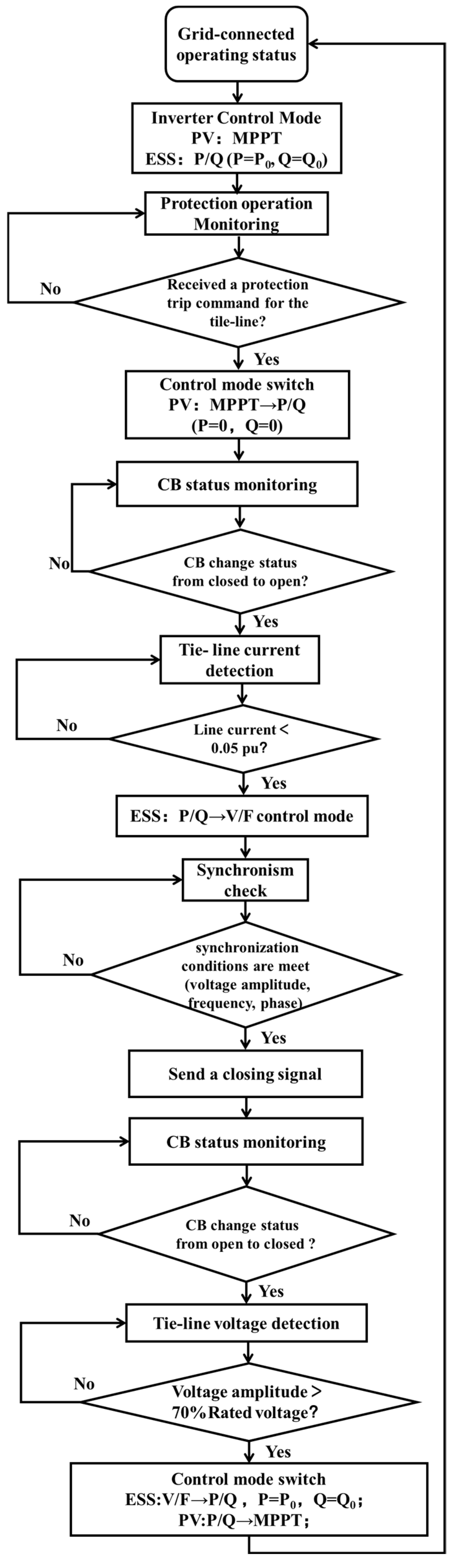

3. Fault Ride-Through (FRT) Strategy Based on Coordinated Regulation of Energy Storage Systems

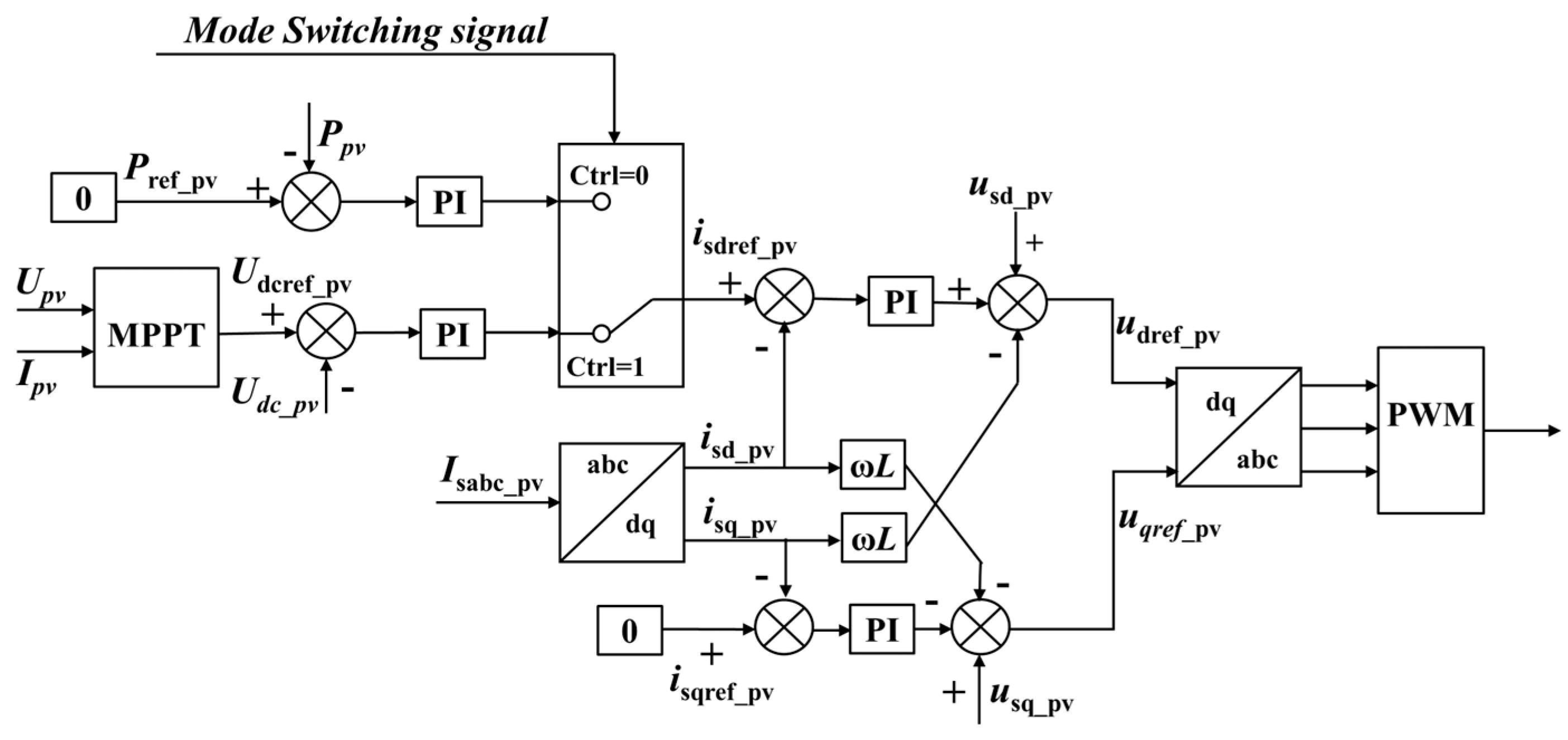

3.1. Classic Control Modes of Inverters

- (1)

- MPPT control mode

- (2)

- PQ control mode

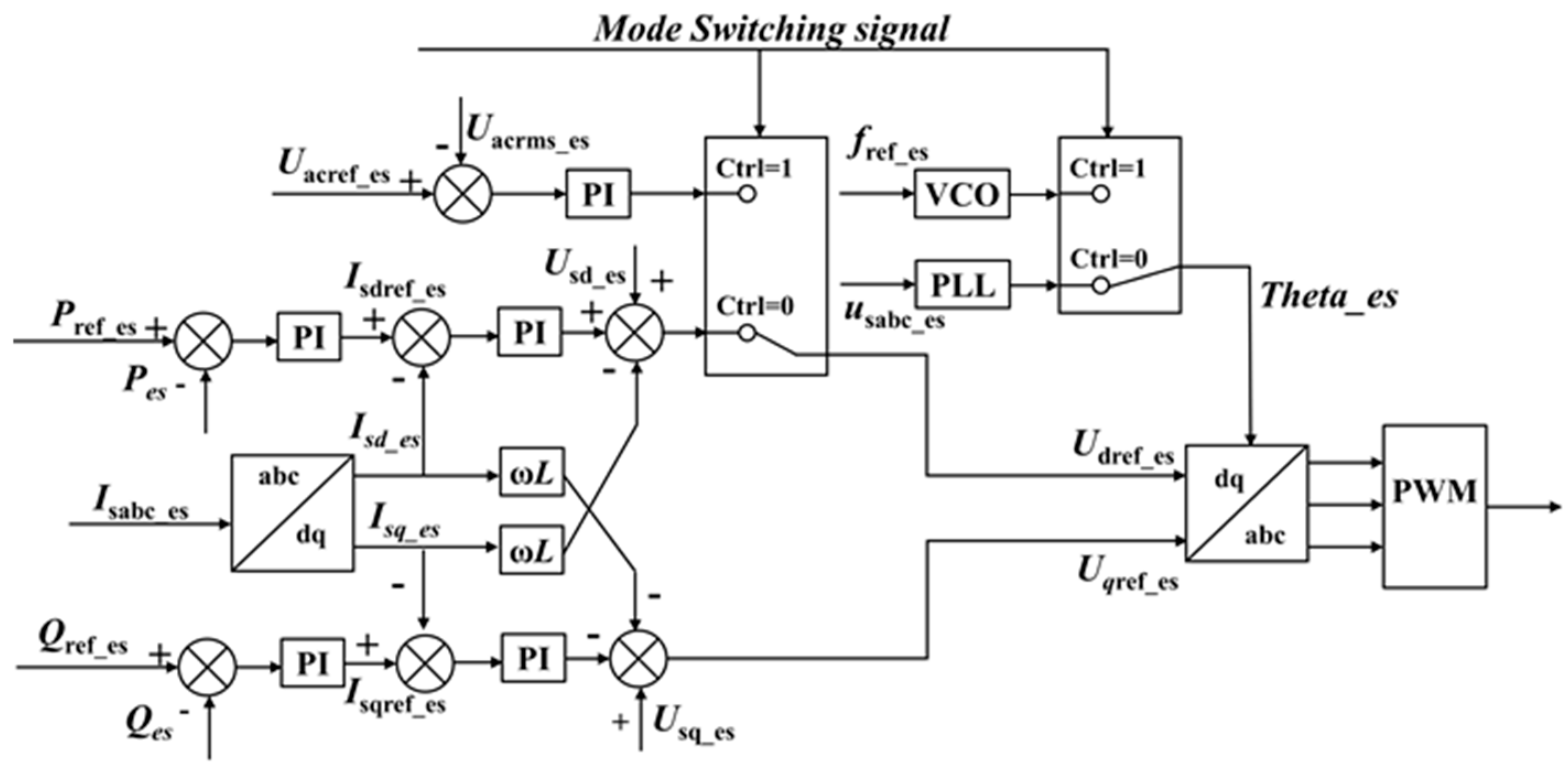

- (3)

- VF control mode

3.2. MPPT and PQ Control Modes for Inverters in PV Power Plants

3.3. PQ and VF Control Modes for Energy Storage Inverters

3.4. Stability Control and Re-Synchronization Strategy for Islanded PV Plant

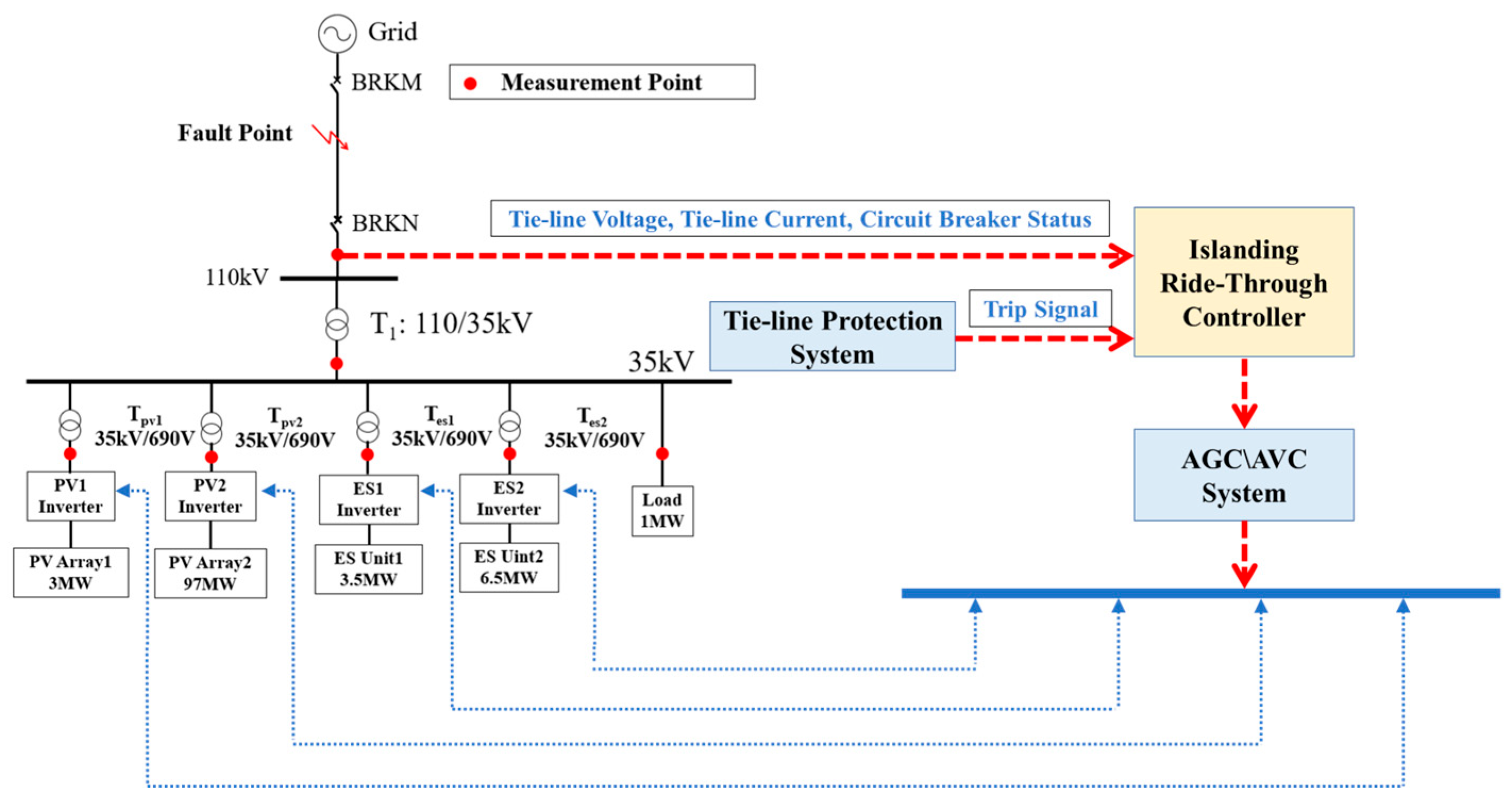

3.5. On-Site Engineering Scheme

4. Simulation Verification

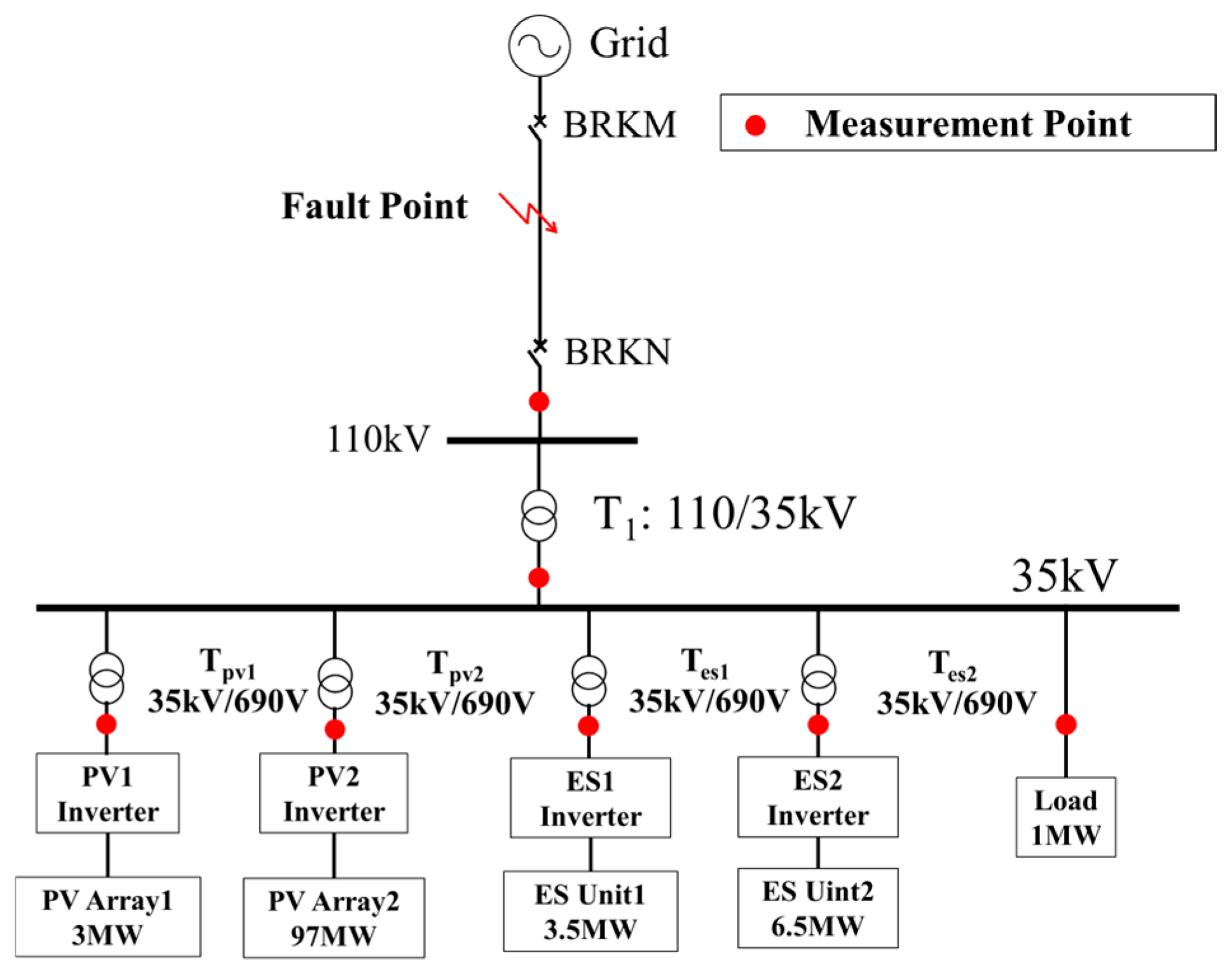

4.1. Simulation Model Construction

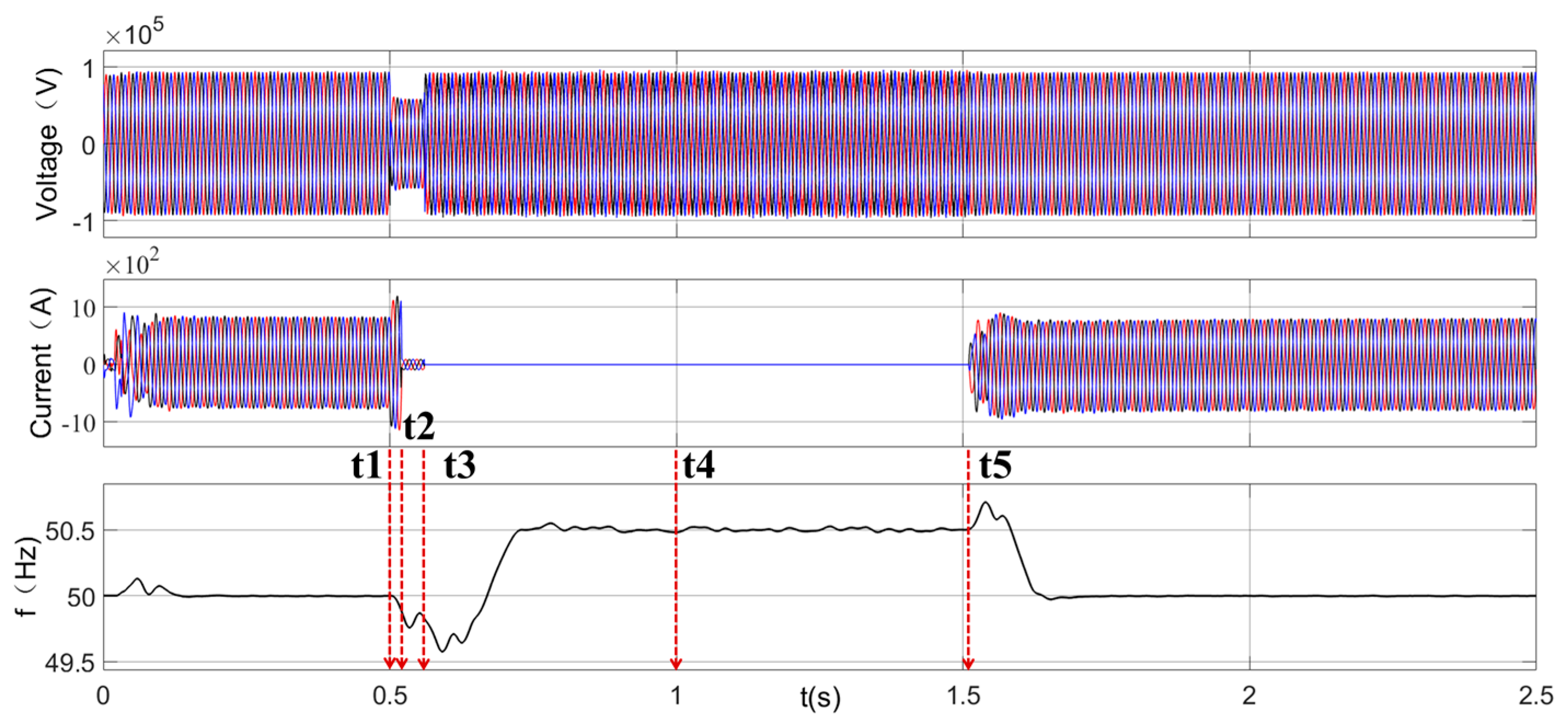

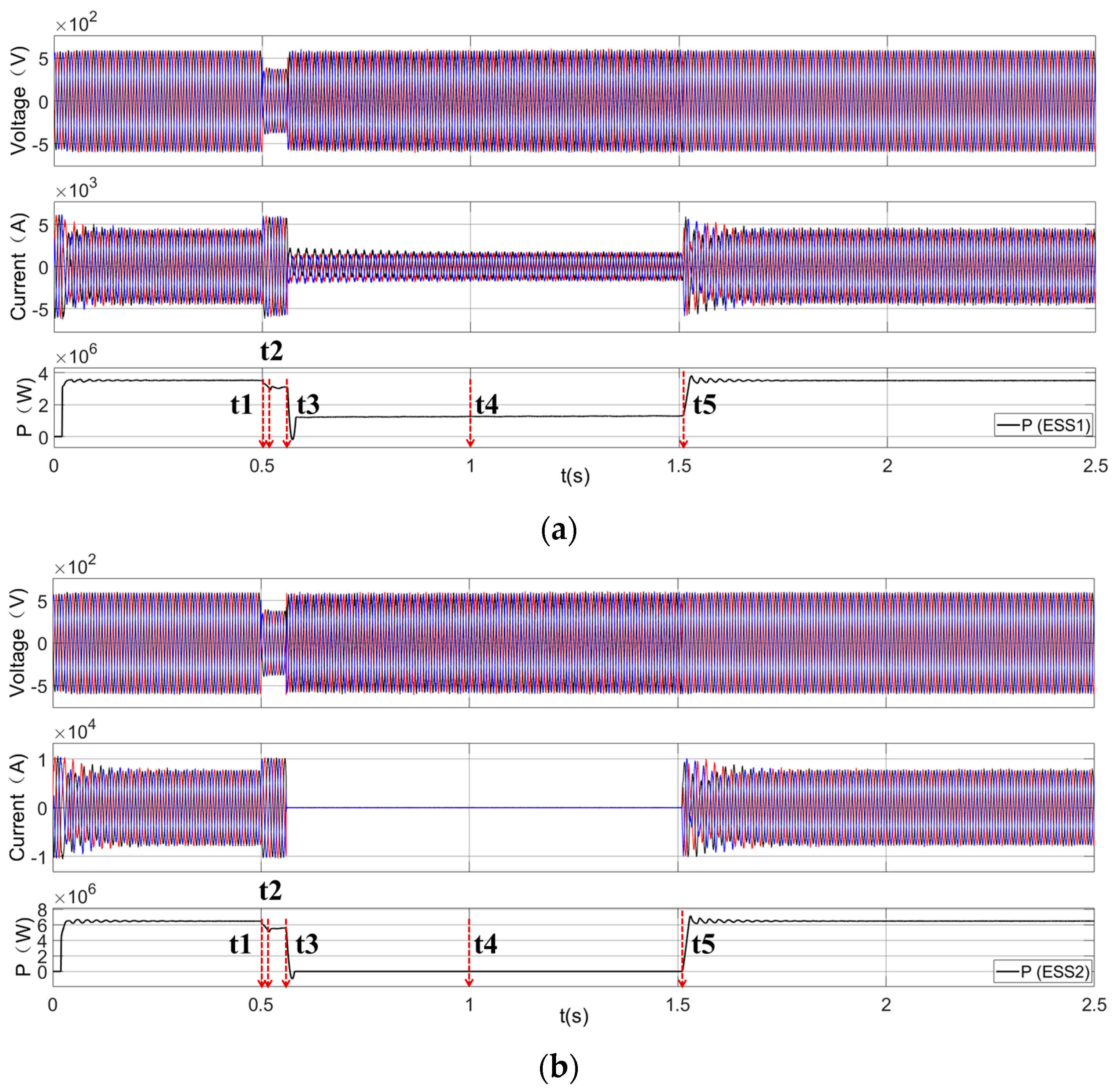

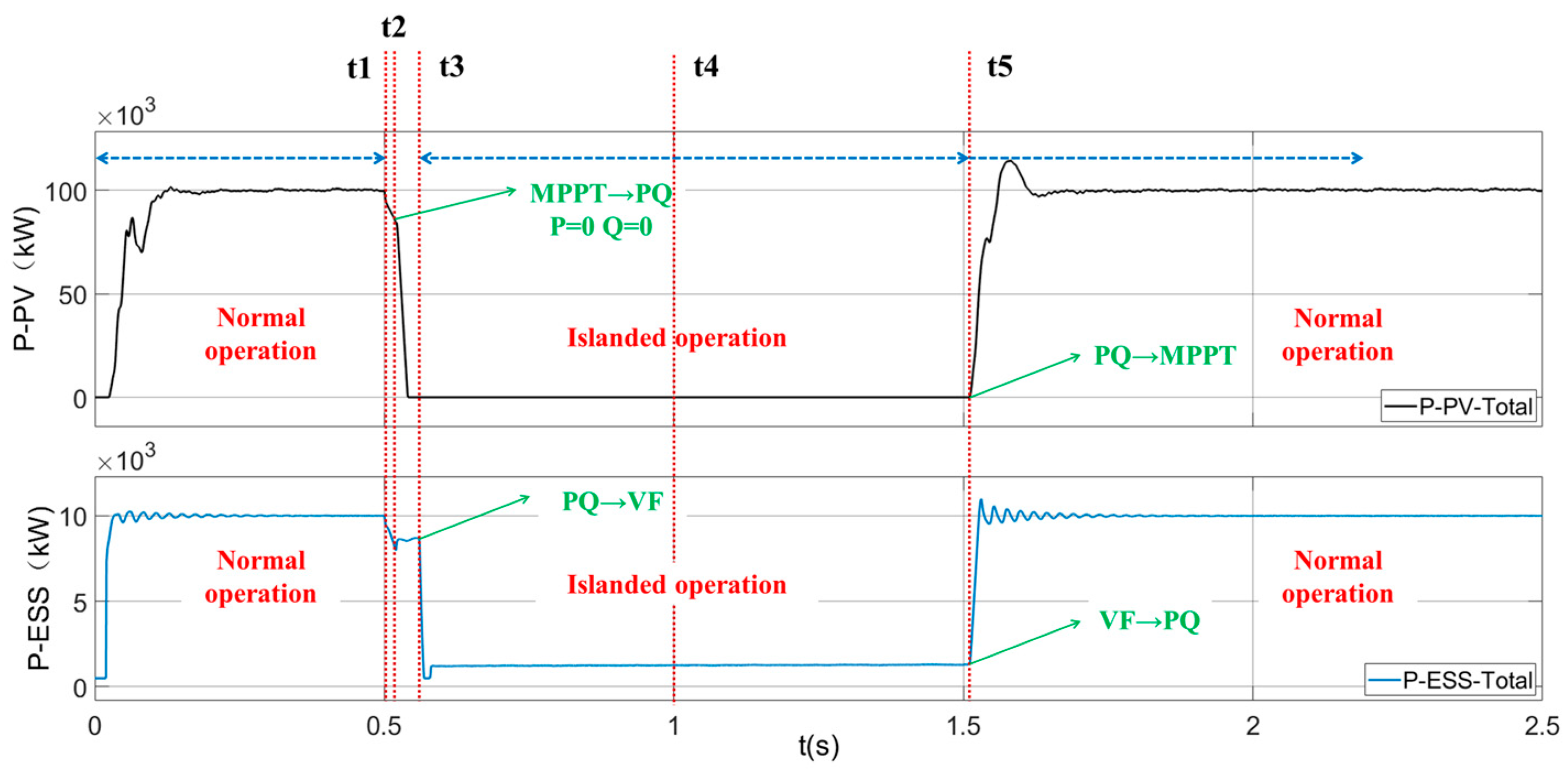

4.2. Simulation Results Analysis

4.3. Recommended Parameter Settings

- (1)

- To maintain stable islanded operation of the PV power plant, at least one energy storage unit must satisfy: Output power PESS > PLoad (where PLoad is the maximum station auxiliary load); Remaining energy capacity> PLoad × 60s.

- (2)

- Communication delays between devices should be limited to < 30 ms;

- (3)

- Plant anti-islanding protection operating time setting ≥ 2 s; Synchronism-check reclosing (no delay); Islanded stable frequency setpoint: 49.5 Hz.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- International Energy Agency (IEA). World Energy Outlook 2023 [R/OL]. (2023–10–01) [2024–04–21]. Available online: https://www.eia.gov/outlooks/ieo/index.php (accessed on 24 October 2023).

- International Renewable Energy Agency (IRENA). Renewable Capacity Statistics 2024 [R/OL]. (2024–03–01) [2024–04–21]. Available online: https://www.irena.org/Publications/2024/Mar/Renewable-capacity-statistics-2024 (accessed on 27 March 2024).

- He, J.; Ma, S.; Zhang, X.; Luo, M.; Li, L.; Niu, J.; Liu, H.; Jin, P.; Liang, Y. Transient equivalent modelling of a wind farm based on QPSO-Based wind turbine fault ride-through control. Energies 2025, 18, 1205. [Google Scholar] [CrossRef]

- Avilan-Losee, G.; Gao, H. Grid-Forming buck-type current-source inverter using hybrid model-predictive control. Energies 2025, 18, 4124. [Google Scholar] [CrossRef]

- Ojo, K.E.; Saha, A.K.; Srivastava, V.M. Review of advances in renewable energy-based microgrid systems: Control Strategies, Emerging Trends, and Future Possibilities. Energies 2025, 18, 3704. [Google Scholar] [CrossRef]

- Xu, S.; Wang, Y.; Sun, H.; Bi, J.; Lan, T. Insights from renewable energy outage accidents abroad for secure and stable operation of power grids in China. Autom. Electr. Power Syst. 2024, 48, 1–8. [Google Scholar]

- Zhao, H.; Wang, T.; Hu, P.; Han, J.; Liu, Y. Control strategy for stable operation of islanded microgrid with dual-drive of improved VSG and improved droop control. Proc. CSU-EPSA 2024, 36, 117–126. [Google Scholar] [CrossRef]

- Wang, Z. Research on Key Technologies for Frequency Stability Control of Virtual Synchronous Generator Parallel System in Island Microgrid. Ph.D. Thesis, Hunan University, Changsha, China, 2023. [Google Scholar]

- Sun, J.; Wang, X.; Huang, J.; Cao, H.; Mei, N.; Li, Z. MPC-VSG Based Control Strategy for Dynamic Stability of Frequency and Voltage in Islanded Microgrid. Electr. Power 2023, 56, 51–60. [Google Scholar]

- Xie, D.; Xiao, S. Research on static voltage stability during fault low voltage ride-through in renewable energy integrated power grids. Proc. CSEE 2024, 45, 6777–6790. [Google Scholar] [CrossRef]

- Xu, W.; Liu, S.; Wu, J.; Dong, Z. Research on fault-ride through strategy of Desert-Gobi-Wasteland new energy base connected with grid-forming energy storage. Inn. Mong. Electr. Power 2024, 42, 3–13. [Google Scholar] [CrossRef]

- Zhai, W.; Tian, X.; Kang, P.; Chen, S.; Kong, J.; Jia, K. Adaptive reclosing method based on PV fault transient outage control and capacity calculation. Electr. Power Autom. Equip. 2025, 45, 96–102. [Google Scholar]

- Dai, Z.; Luan, K.; Wu, T.; Zhou, J.; Shang, C. Multi-photovoltaic two-stage fault ride-through coordination control strategy. Proc. CSEE 2025, accepted, 1–13. [Google Scholar]

- Zheng, T.; Ma, Y.; You, Y.; Hu, S. A fast standby automatic switching scheme for photovoltaic power station considering energy storage cooperative Control. Trans. China Electrotech. Soc. 2025, accepted, 1–14. [Google Scholar] [CrossRef]

- Wei, C. Multi-Scenario Fault Fast Self-Healing Control Technology and Application for New Distribution Network Based on Energy Storage. Ph.D. Thesis, Hunan University, Changsha, China, 2023. [Google Scholar]

- Xie, X.; He, J.; Mao, H.; Li, H. New issues and classification of power system stability with high shares of renewables and power electronics. Proc. CSEE 2021, 41, 461–475. [Google Scholar] [CrossRef]

- Wang, G.; Huang, Y.; Wang, C.; Shahidephour, M.; Hao, Q. Voltage-adaptive strategy for transient stability enhancement of power systems with 100% renewable energy. IEEE Trans. Autom. Sci. Eng. 2025, 22, 1364–1376. [Google Scholar] [CrossRef]

- Alhasnawi, B.N.; Jasim, B.H.; Anvari-Moghaddam, A.; Blaabjerg, F. A new robust control strategy for parallel operated inverters in green energy applications. Energies 2020, 13, 3480. [Google Scholar] [CrossRef]

- Huang, R.; Wu, Z.; Xu, X.; Quan, X.; Li, M.; Liu, M. A Multi-Resonant based reference feedforward adaptive voltage control for Grid-Forming inverter in island mode to compensate system uncertain and harmonic distortions. Int. J. Electr. Power Energy Syst. 2025, 164, 110438. [Google Scholar] [CrossRef]

- Mothi, B.R.; Srinivas, L.R. Optimal power controller-based voltage and frequency control of DG unit in an island mode microgrid using hybrid differential evolution. J. Electr. Eng. 2021, 1, 88–97. [Google Scholar]

- Wen, W.; Niu, B.; Xu, A.; Guo, X.; Shang, Y. Fixed-Time extended state observer based sliding mode control design for voltage stability of island microgrid. IAENG Int. J. Comput. Sci. 2025, 52, 2637–2642. [Google Scholar]

- Yang, F.; Chen, H.; Fan, K.; Xu, B.; Chen, Y.; Cai, Y.; Yang, Z. A time-limited adaptive reclosing method in active distribution networks considering anti-islanding protection. Processes 2024, 12, 2781. [Google Scholar] [CrossRef]

- GB/T 19964-2012; Technical Requirements for Connecting Photovoltaic Power Station to Power System. Standardization Administration of China (SAC): Beijing, China, 2012.

| Delay Setting | Simulation Case | P-PV (MW) | P-ESS (MW) | LOAD (MW) | Fault Type | Fault Ride-Through | Reconnection Time (Post-Fault) |

|---|---|---|---|---|---|---|---|

| T_protec = 20 ms; T_C-PV = 20 ms; T_breaker = 40 ms; T_C-ESS = 0 ms; | case1 (50.5 Hz) | 100 | 10 | 1 | 3Ph-SC (R_f: 2 Ω) | Yes | 1.011 s |

| case2 (49.5 Hz) | 100 | 10 | 1 | 3Ph-SC (R_f: 2 Ω) | Yes | 1.676 s | |

| case3 (50.5 Hz) | 100 | 10 | 1 | L-L Fault (R_f: 2 Ω) | Yes | 1.011 s | |

| case4 (49.5 Hz) | 100 | 10 | 1 | L-L Fault (R_f: 2 Ω) | Yes | 1.675 s | |

| case5 (50.5 Hz) | 100 | 10 | 1 | SLG Fault (R_f: 5 Ω) | Yes | 1.011 s | |

| case6 (49.5 Hz) | 100 | 10 | 1 | SLG Fault (R_f: 5 Ω) | Yes | 1.675 s | |

| T_protec = 30 ms; T_C-PV = 20 ms; T_breaker = 100 ms; T_C-ESS = 20 ms; | case7 (49.5 Hz) | 100 | 10 | 1 | 3Ph-SC (R_f: 2 Ω) | Yes | 1.675 s |

| case8 (49.5 Hz) | 0 | 10 | 1 | 3Ph-SC (R_f: 2 Ω) | Yes | 1.675 s | |

| case9 (49.5 Hz) | 0 | 10 | 1 | L-L Fault (R_f: 2 Ω) | Yes | 1.675 s | |

| case10 (49.5 Hz) | 0 | 10 | 1 | SLG Fault (R_f: 5 Ω) | Yes | 1.675 s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, B.; Xu, F.; Bi, X.; Wan, D.; Huang, Z.; Yang, J.; Wen, A.; Shang, P. A Tie-Line Fault Ride-Through Strategy for PV Power Plants Based on Coordinated Energy Storage Control. Energies 2025, 18, 5335. https://doi.org/10.3390/en18205335

Pan B, Xu F, Bi X, Wan D, Huang Z, Yang J, Wen A, Shang P. A Tie-Line Fault Ride-Through Strategy for PV Power Plants Based on Coordinated Energy Storage Control. Energies. 2025; 18(20):5335. https://doi.org/10.3390/en18205335

Chicago/Turabian StylePan, Bo, Feng Xu, Xiangyi Bi, Dong Wan, Zhihua Huang, Jinsong Yang, An Wen, and Penghui Shang. 2025. "A Tie-Line Fault Ride-Through Strategy for PV Power Plants Based on Coordinated Energy Storage Control" Energies 18, no. 20: 5335. https://doi.org/10.3390/en18205335

APA StylePan, B., Xu, F., Bi, X., Wan, D., Huang, Z., Yang, J., Wen, A., & Shang, P. (2025). A Tie-Line Fault Ride-Through Strategy for PV Power Plants Based on Coordinated Energy Storage Control. Energies, 18(20), 5335. https://doi.org/10.3390/en18205335