Comparison of a Solar Driven Absorption Chiller and Photovoltaic Compression Chiller Under Different Demand Profiles: Technological, Environmental and Economic Performance †

Abstract

1. Introduction

- Under different demand profiles. Taking a variable and a constant approach.

- Under different sizing considerations. Measuring the impact of photovoltaic panels and in the case of absorption chillers, how much impact has the possibility of having a usable surplus of energy to supply the heating needs of the equipment.

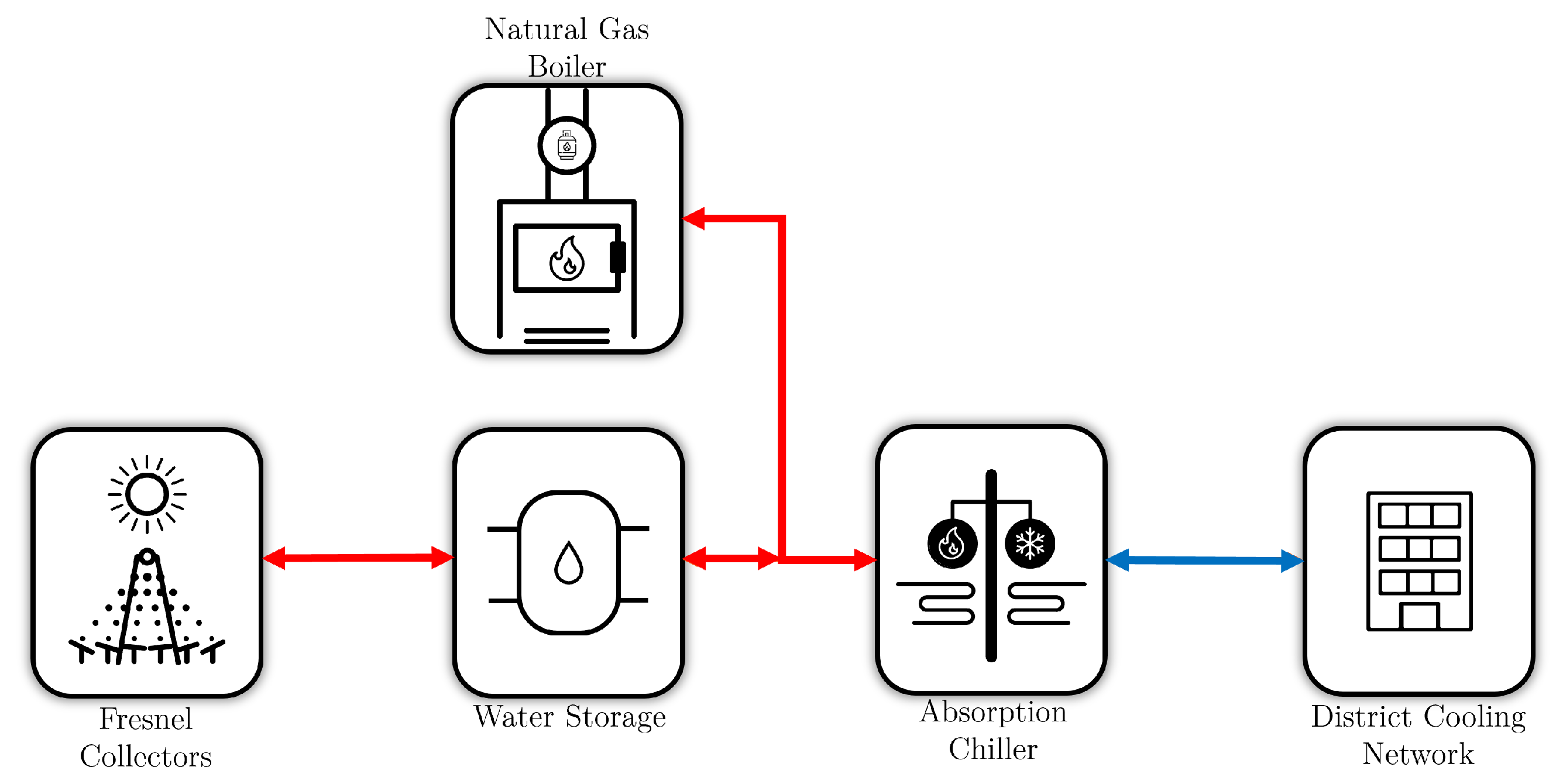

2. System Description

2.1. Technologies Considered

2.2. Cases Evaluated

2.3. Location and Demand

- 1

- For Madrid, a “cooling season” (warm months where cooling demand peaks and heating demand tends to be domestic hot water production alone) is defined. This has been chosen by looking at the temperature profile from the climate data obtained from Figure 4. And assuming that cooling production occurs between dates that the daily average ambient temperature of the three last consecutive days remains above 15 °C and is turned off when this condition is not fulfilled two days in a row (4 May to 29 September).

- 2

- Within the cooling season, an occupation schedule is assumed, indicating when the building is occupied. Indeed, two occupation schedules are used, depending on the time of the year:

- Occupation schedule 1: A high cooling season, corresponding to the warmest months in summer. For this period, a value of 1 for the weight factor was used for the occupied hours (from 6 a.m. to 6 p.m. on weekdays and 8 a.m. to 4 p.m. on weekends).

- Occupation schedule 2: Shoulder cooling periods, corresponding to the late spring/early autumn months. For this period, a value of 0.8 for the weight factor was used for the occupied hours (same assumed occupation hours as occupation schedule 1).

- 3

- The dimensionless hourly cooling load is estimated based on conversion tables (one for hours with occupation, the other for hours with no occupation) relating the ambient temperature with the fraction of peak cooling load, as shown in Figure 5. The peak cooling load (100%) is assigned to the highest hourly ambient temperature. Hourly dimensionless cooling demand profile is developed for Madrid following Equation (1).where:

- : Dimensionless cooling demand profile;

- : 1 or 0.8 according to described schedules;

- : Taken from Figure 5.

3. Methodology

3.1. Software

- 1

- Nomenclature: Guidelines for naming macros, types, and variables are established.

- 2

- Variables used for input and output are exchanged between different macros via equation blocks. This method streamlines the process, minimizes the number of connections, and facilitates the efficient replacement of one macro with another, requiring changes to only a few connectors.

- 3

- Parametrization procedure: A Python script has been developed to update the input data used in each simulation.

- 4

- Control strategy: Each macro features a specific control strategy based on its technology. This approach allows the same macro to be integrated into different systems, reducing the number of control parameters that need to be configured.

- 5

- Results: Each macro presents its own results along with internal calculations, including energy and mass balance.

TRNSYS Simulation Models

- : Intercept (maximum) collector’s efficiency [-];

- : Negative of the first-order coefficient in collector efficiency equation [];

- : Negative of the second-order coefficient in collector efficiency equation [];

- : Temperature difference between the collector’s inlet temperature () and the ambient temperature () [K];

- : Effective total radiation incident on the solar collector tilted surface per unit area including the impact of off-normal solar radiation (incidence angle modifiers) [].

3.2. KPIs Definition

3.2.1. Levelized Cost of Energy

- LCOE: Levelized cost of cooling energy [EUR/MWh];

- CAPEX: Capital expenditure for the equipment [EUR/MWh];

- CRF: Capital recovery factor;

- OPEXf: Fix operational costs for cooling [EUR/year];

- OPEXv: Variable operational costs for cooling [EUR/year];

- QC: Cooling energy supplied per year [MWh/year];

- i: interest rate;

- n: project lifetime and number of annuities received.

3.2.2. CO2 Emissions Coefficient

- : CO2 emission coefficient [/MWh];

- : energy supplied by energy carrier i per year [MWh/year];

- : Emissions coefficient of energy carrier i [/MWh];

- : Cooling energy supplied per year [MWh/year].

4. Results

4.1. Absorption Chiller

4.2. Compression Chiller

4.3. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Abbreviations | |

| CDD | Cooling degree days |

| COP | Coefficient of performance |

| DHC | District heating and cooling |

| KPI | Key performance parameters |

| HVAC | Heating, ventilation, and air conditioning |

| LCA | Life cycle assessment |

| NPV | Net present value |

| PVGIS | Photovoltaic geographical information system |

| TESS | Thermal energy systems specialists |

| TMY | Yypical Meteorological year |

| TRNSYS | Transient systems simulation program |

| Symbols | |

| Intercept collector’s efficiency [-] | |

| First-order coefficient in collector efficiency equation [] | |

| Second-order coefficient in collector efficiency equation [] | |

| Capital expenditure for the equipment [EUR/MWh] | |

| : | Dimensionless cooling demand profile |

| Capital recovery factor | |

| Energy supplied by energy carrier i per year [MWh/year] | |

| CO2 emission coefficient [kg CO2/MWh] | |

| Emissionscoefficient of energy carrier i [kg CO2/MWh] | |

| i | interest rate [-] |

| Effective total radiation incident on the solar collector [] | |

| Levelized cost of cooling energy [EUR/MWh] | |

| n | project lifetime [years] |

| Fix operational costs for cooling [EUR/year] | |

| Variable operational costs for cooling [EUR/year] | |

| Percentage of peak cooling load | |

| Cooling energy supplied per year [MWh/year] | |

| Schedule weight factor | |

| Greek symbols | |

| Solar collector efficiency [-] | |

| Temperature difference [K]. | |

References

- Eurostat. Complete Energy Balances. Available online: https://ec.europa.eu/eurostat/databrowser/bookmark/7ca9ba65-355b-459c-9236-0e3746f7cf01?lang=en (accessed on 25 August 2025).

- Disaggregated Final Energy Consumption in Households—Quantities. Available online: https://ec.europa.eu/eurostat/databrowser/product/page/NRG_D_HHQ (accessed on 25 August 2025).

- Eurostat. Share of Energy from Renewable Sources. Available online: https://ec.europa.eu/eurostat/databrowser/bookmark/30a7feb0-41cc-42d3-b6a8-1e2ed60eb101?lang=en (accessed on 25 August 2025).

- Thom, H.C.S. The rational relationship between heating degree days and temperature. Mon. Weather. Rev. 1954, 82, 1–6. [Google Scholar] [CrossRef]

- Heating and Cooling Degree Days—Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Archive:Heating_and_cooling_degree_days_-_statistics (accessed on 25 August 2025).

- Hampo, C.C.; Ya, H.H.; Majid, M.A.A.; Mokhtar, A.A.; Kalpani Rasangika, A.H.D.; Muhammed, M. Life cycle assessment of a vapor compression cooling system integrated within a district cooling plant. Sustainability 2021, 13, 11940. [Google Scholar] [CrossRef]

- Arabkoohsar, A.; Sadi, M. A solar PTC powered absorption chiller design for Co-supply of district heating and cooling systems in Denmark. Energy 2020, 193, 116789. [Google Scholar] [CrossRef]

- Jannatabadi, M.; Rahbari, H.R.; Arabkoohsar, A. District cooling systems in Iranian energy matrix, a techno-economic analysis of a reliable solution for a serious challenge. Energy 2021, 214, 118914. [Google Scholar] [CrossRef]

- Sun, F.; Li, J.; Fu, L.; Li, Y.; Wang, R.; Zhang, S. New configurations of district heating and cooling system based on absorption and compression chillers driven by waste heat of flue gas from coke ovens. Energy 2020, 193, 116707. [Google Scholar] [CrossRef]

- Ayou, D.S.; Coronas, A. New developments and progress in absorption chillers for solar cooling applications. Appl. Sci. 2020, 10, 4073. [Google Scholar] [CrossRef]

- Khliyeva, O.; Shestopalov, K.; Ierin, V.; Zhelezny, V.; Chen, G.; Neng, G. Environmental and energy comparative analysis of expediency of heat-driven and electrically-driven refrigerators for air conditioning application. Appl. Therm. Eng. 2023, 219, 119533. [Google Scholar] [CrossRef]

- Gonzalez, R.C.; Diaz, A.J.; Rojas, D.; Sarmiento-Laurel, C. Assessing solar absorption chillers for data center cooling across diverse climatic conditions. Energy Build. 2025, 331, 115376. [Google Scholar] [CrossRef]

- Sayadi, S.; Akander, J.; Hayati, A.; Gustafsson, M.; Cehlin, M. Comparison of space cooling systems from energy and economic perspectives for a future city district in Sweden. Energies 2023, 16, 3852. [Google Scholar] [CrossRef]

- Roncal-Casano, J.J.; Taddeo, P.; Rodriguez-Martín, J.; Muñoz-Antón, J.; Velasco, A.A. Techno-economic comparison of a solar absorption chiller and photovoltaic compression chiller. In Proceedings of the 36th International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems (ECOS 2023), Las Palmas de Gran Canaria, Spain, 25–30 June 2023; pp. 2661–2672. [Google Scholar] [CrossRef]

- WEDISTRICT Project. Available online: https://www.wedistrict.eu/ (accessed on 25 August 2025).

- Ivančić, A.; Romaní, J.; Salom, J.; Cambronero, M.V. Performance assessment of district energy systems with common elements for heating and cooling. Energies 2021, 14, 2334. [Google Scholar] [CrossRef]

- Climaveneta. Chillers comfort R410A NX2.G02.G06. Available online: https://in.climaveneta.com/en/products/2596/chiller-air-source-for-outdoor-installation (accessed on 25 August 2025).

- Cabeza, L.F. Thermal Energy Storage In Comprehensive Renewable Energy; Sayigh, A., Ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2022; pp. 246–293. [Google Scholar]

- Module_Datasheet_550W_JAM72D30 MB. Available online: https://www.jasolar.com/statics/gaiban/pdfh5/pdf.html?file=https://www.jasolar.com//uploadfile/2022/1122/20221122050252648.pdf (accessed on 25 August 2025).

- González-González, E.; Martín-Jiménez, J.; Sánchez-Aparicio, M.; Del Pozo, S.; Lagüela, S. Evaluating the standards for solar PV installations in the Iberian Peninsula: Analysis of tilt angles and determination of solar climate zones. Sustain. Energy Technol. Assess. 2022, 49, 101684. [Google Scholar] [CrossRef]

- Soltigua. Linear Fresnel Collector—Manufacturer. Available online: https://www.soltigua.com/flt-introducion/ (accessed on 25 August 2025).

- Carbó, A.; Oró, E.; Salom, J.; Canuto, M.; MacÍas, M.; Guitart, J. Experimental and numerical analysis for potential heat reuse in liquid cooled data centres. Energy Convers. Manag. 2016, 112, 135–145. [Google Scholar] [CrossRef]

- European Commission. JRC Photovoltaic Geographical Information System (PVGIS). Available online: https://re.jrc.ec.europa.eu/pvg_tools/en/ (accessed on 25 August 2025).

- Klein, S.A. TRNSYS 18: A Transient System Simulation Program; Solar Energy Laboratory, University of Wisconsin: Madison, WI, USA, 2017; Available online: https://www.trnsys.com/ (accessed on 25 August 2025).

- Roncal-Casano, J.J. Modular Simulation Methodology for the Economical and Environmental Optimization of District Heating/Cooling Systems to Achieve Net Zero. Ph.D. Thesis, Universidad Politécnica de Madrid, Madrid, Spain, 22 November 2024. [Google Scholar] [CrossRef]

- Eurostat. Natural Gas Price Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Natural_gas_price_statistics (accessed on 25 August 2025).

- Eurostat. Electricity Prices for Non-Household Consumers–Bi-Annual Data (from 2007 Onwards). Available online: https://ec.europa.eu/eurostat/databrowser/view/nrg_pc_205/default/table?lang=en (accessed on 25 August 2025).

- Sifnaios, I.; Jensen, A.R.; Furbo, S.; Fan, J. Performance comparison of two water pit thermal energy storage (PTES) systems using energy, exergy, and stratification indicators. J. Energy Storage 2022, 52, 104947. [Google Scholar] [CrossRef]

- Dittmann, F.; Rivière, P.; Stabat, P. Space Cooling Technology in Europe. Technology Data and Demand Modelling. 2016. Available online: https://heatroadmap.eu/wp-content/uploads/2018/11/HRE4_D3.2.pdf (accessed on 25 August 2025).

- Hyvönen, J.; Mori, T.; Saunavaara, J.; Hiltunen, P.; Pärssinen, M.; Syri, S. Potential of solar photovoltaics and waste heat utilization in cold climate data centers. Case study: Finland and northern Japan. Renew. Sustain. Energy Rev. 2024, 201, 114619. [Google Scholar] [CrossRef]

- Nérot, B.; Lamaison, N.; Bavière, R.; Lacarrière, B.; Mabrouk, M.T. Techno-economic relevance of absorption chillers to enhance existing 3GDH. Energy Rep. 2021, 7, 282–293. [Google Scholar] [CrossRef]

- Barnetche, M.; Abbas, R.; González-Portillo, L.F. Reducing costs in solar heat: A comparative study of rotatory Fresnel and parabolic trough systems. Therm. Sci. Eng. Prog. 2025, 61, 103526. [Google Scholar] [CrossRef]

- Papatsounis, A.G.; Botsaris, P.N.; Lymperopoulos, K.A.; Rotas, R.; Kanellia, Z.; Iliadis, P.; Nikolopoulos, N. Operation assessment of a hybrid solar-biomass energy system with absorption refrigeration scenarios. Energy Sources Part A Recover. Util. Environ. Eff. 2022, 44, 700–717. [Google Scholar] [CrossRef]

- Montenon, A.C.; Papanicolas, C. Economic assessment of a PV hybridized linear Fresnel collector supplying air conditioning and electricity for buildings. Energies 2020, 14, 131. [Google Scholar] [CrossRef]

- ISO 52000-1:2017; Energy Performance of Buildings Overarching EPB Assessment Part 1: General Framework and Procedures. ISO: Geneva, Switzerland, 2017. Available online: https://www.iso.org/standard/65601.html (accessed on 25 August 2025).

- European Environment Agency. Greenhouse Gas Emission Intensity of Electricity Generation. Available online: https://www.eea.europa.eu/data-and-maps/daviz/co2-emission-intensity-13/#tab-chart_4 (accessed on 25 August 2025).

| Cooling Technology | Demand | Parametric Study | PV Panels | Heat Source Price Considered |

|---|---|---|---|---|

| Absorption chiller | Variable | Yes | - | Yes |

| Absorption chiller | Variable | No | - | No |

| Absorption chiller | Constant | Yes | - | Yes |

| Absorption chiller | Constant | No | - | No |

| Compression chiller | Variable | No | Yes | - |

| Compression chiller | Variable | No | No | - |

| Compression chiller | Constant | No | Yes | - |

| Compression chiller | Constant | No | No | - |

| Case | Value | Reference |

|---|---|---|

| Specific cost for TES [EUR/m3] | 235 | [28] |

| Specific cost for compression chiller [EUR/kW] | 196 | [29] |

| Specific cost for PV [EUR/kW] | 1100 | [30] |

| Specific cost for natural gas boiler [EUR/kW] | 60 | [31] |

| Specific cost for Fresnel collector [EUR/m2] | 200 | [32] |

| Specific cost for absorption chiller [EUR/kW] | 472 | [33] |

| OM fixed [%] | 5 | [7] |

| Discount rate [%] | 8.5 | [34] |

| Life [year] | 25 | [34] |

| Price natural gas [EUR/MWh] | 54.1 | [26] |

| Price electricity [EUR/MWh] | 142.6 | [27] |

| Energy Carrier | CO2 Emissions Factor [kg CO2/MWh] |

|---|---|

| Fossil Fuel | 220 |

| PV electricity | 0 |

| Solar thermal | 0 |

| Grid electricity | 165 |

| Technology | Initial Value | Final Value | Step | Simulations |

|---|---|---|---|---|

| Solar field [m2] | 1500 | 3000 | 250 | 7 |

| Storage volume [m3] | 100 | 1000 | 25 | 36 |

| Solar Field [m2] | TES Volume [m3] | Emissions Coef. [kg CO2/MWh] | LCOE [EUR/MWh] |

|---|---|---|---|

| 1500 | 100 | 222.56 | 211.06 |

| 1750 | 150 | 210.87 | 222.25 |

| 2000 | 225 | 202.25 | 235.34 |

| 2250 | 275 | 195.67 | 247.83 |

| 2500 | 425 | 189.87 | 265.02 |

| 2750 | 525 | 185.11 | 280.14 |

| 3000 | 550 | 181.08 | 291.87 |

| Solar Field [m2] | Tank Volume [m3] | Emissions Coef. [kg CO2/MWh] | LCOE [EUR/MWh] |

|---|---|---|---|

| 1500 | 100 | 284.97 | 103.42 |

| 1750 | 125 | 278.48 | 103.89 |

| 2000 | 200 | 272.03 | 104.77 |

| 2250 | 250 | 265.55 | 105.44 |

| 2500 | 300 | 259.07 | 106.12 |

| 2750 | 400 | 252.56 | 107.15 |

| 3000 | 450 | 246.06 | 107.60 |

| Var. Profile with Heat | Cons. Profile with Heat | Var. Profile Without Heat | Cons. Profile Without Heat | |

|---|---|---|---|---|

| CAPEX [EUR/MWh] | 130.78 | 21.77 | 47.52 | 8.95 |

| OPEX [EUR/MWh] | 161.09 | 85.83 | 67.95 | 21.49 |

| LCOE [EUR/MWh] | 291.87 | 107.60 | 115.47 | 29.64 |

| [kgCO2/MWh] | 181.08 | 246.06 | 50.41 | 20.05 |

| Var. Profile with PV | Cons. Profile with PV | Var. Profile Without PV | Cons. Profile Without PV | |

|---|---|---|---|---|

| CAPEX [EUR/MWh] | 32.14 | 5.51 | 11.2 | 1.92 |

| OPEX [EUR/MWh] | 48.93 | 64.86 | 86.94 | 79.16 |

| LCOE [EUR/MWh] | 81.07 | 70.37 | 98.13 | 81.08 |

| [kgCO2/MWh] | 35.13 | 46.57 | 62.42 | 56.84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roncal-Casano, J.J.; Rodríguez-Martín, J.; Taddeo, P.; Muñoz-Antón, J.; Abánades-Velasco, A. Comparison of a Solar Driven Absorption Chiller and Photovoltaic Compression Chiller Under Different Demand Profiles: Technological, Environmental and Economic Performance. Energies 2025, 18, 5334. https://doi.org/10.3390/en18205334

Roncal-Casano JJ, Rodríguez-Martín J, Taddeo P, Muñoz-Antón J, Abánades-Velasco A. Comparison of a Solar Driven Absorption Chiller and Photovoltaic Compression Chiller Under Different Demand Profiles: Technological, Environmental and Economic Performance. Energies. 2025; 18(20):5334. https://doi.org/10.3390/en18205334

Chicago/Turabian StyleRoncal-Casano, Juan José, Javier Rodríguez-Martín, Paolo Taddeo, Javier Muñoz-Antón, and Alberto Abánades-Velasco. 2025. "Comparison of a Solar Driven Absorption Chiller and Photovoltaic Compression Chiller Under Different Demand Profiles: Technological, Environmental and Economic Performance" Energies 18, no. 20: 5334. https://doi.org/10.3390/en18205334

APA StyleRoncal-Casano, J. J., Rodríguez-Martín, J., Taddeo, P., Muñoz-Antón, J., & Abánades-Velasco, A. (2025). Comparison of a Solar Driven Absorption Chiller and Photovoltaic Compression Chiller Under Different Demand Profiles: Technological, Environmental and Economic Performance. Energies, 18(20), 5334. https://doi.org/10.3390/en18205334