Improved Adaptive PI-like Fuzzy Control Strategy of Permanent Magnet Synchronous Motor

Abstract

1. Introduction

2. Mathematical Modeling of PMSM

- (1)

- No regard is given to eddy current losses and hysteresis losses;

- (2)

- The air gap magnetic field of the PMSM is uniform and sinusoidally distributed;

- (3)

- The induced electromotive force in the phase windings is sinusoidal during steady state operation;

- (4)

- The effect of stator cogging is neglected, and the permeability of the permanent magnet is the same as that of air.

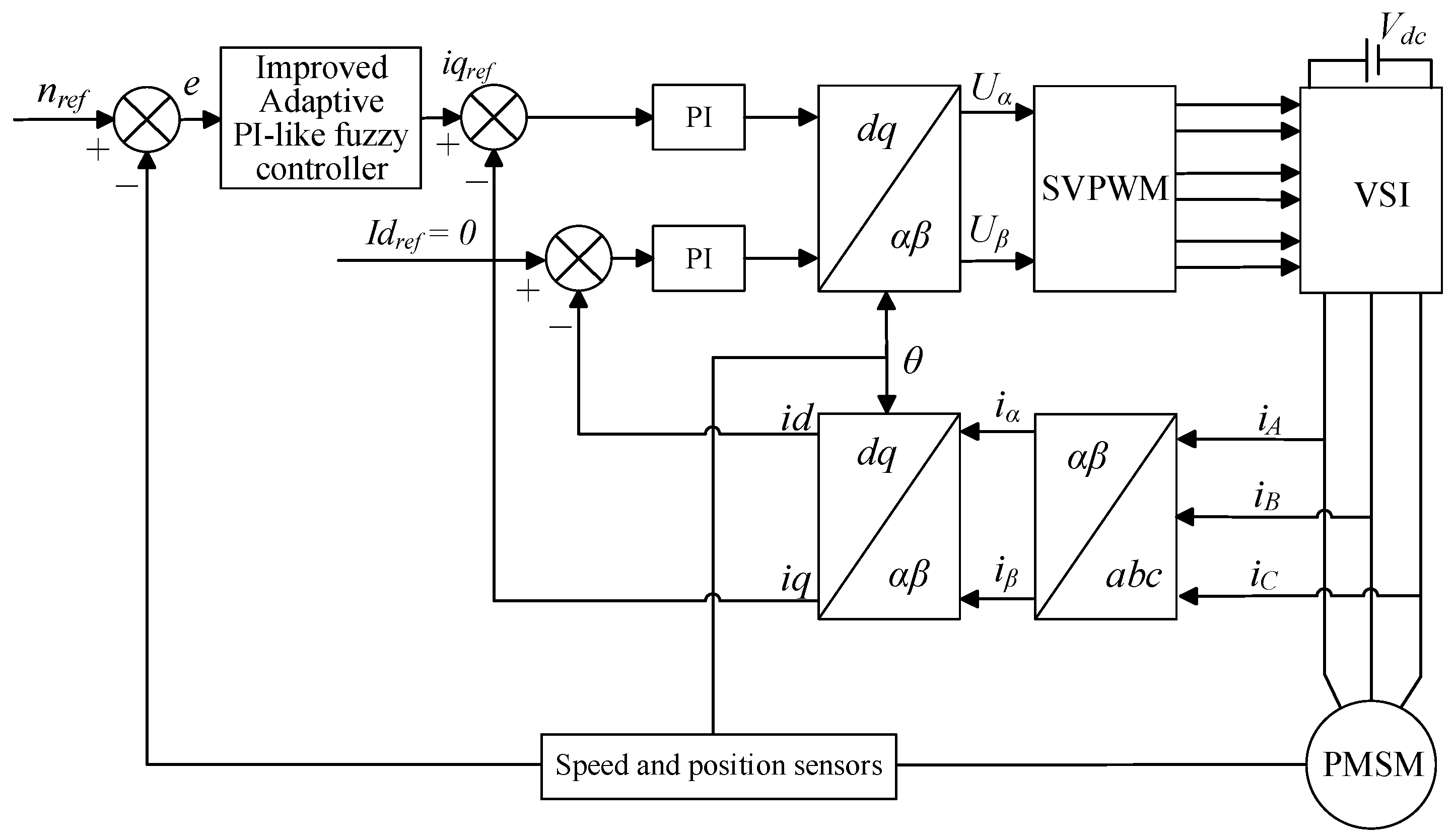

3. Fuzzy Adaptive Control System

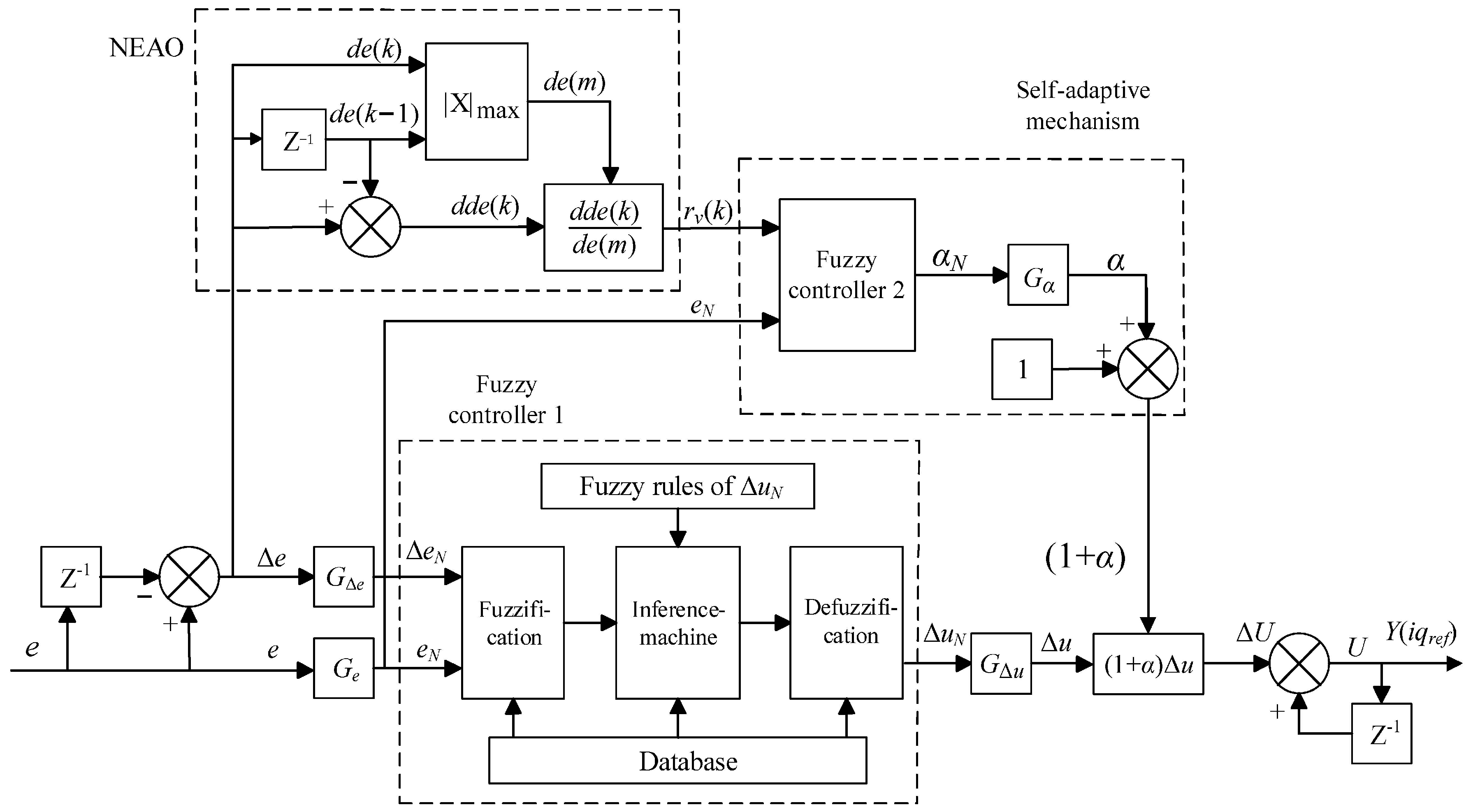

3.1. PI-like Fuzzy Controller

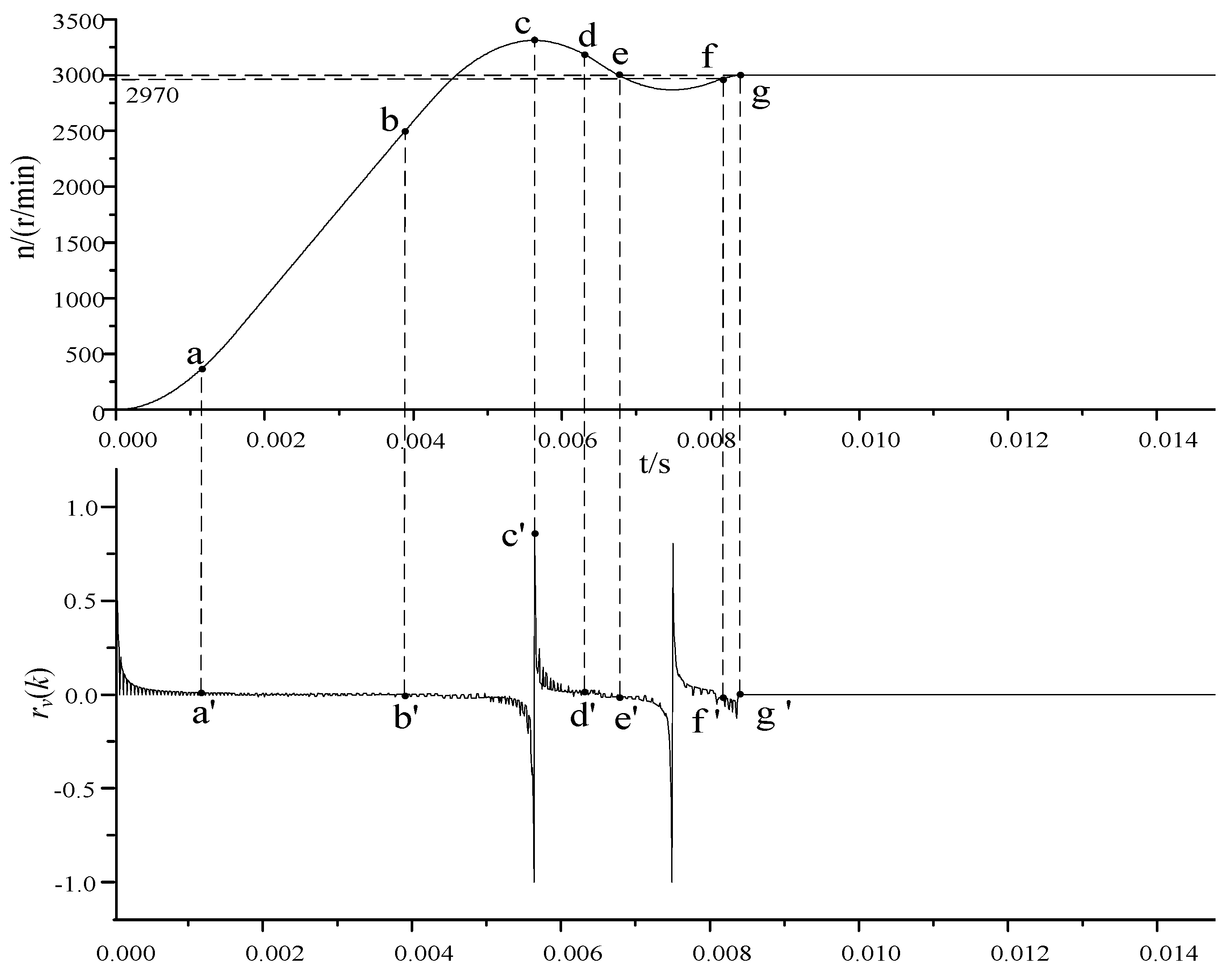

3.2. Selection of Observation Quantities for Self-Adaptive Mechanisms

- (1)

- When the system response speed is fast enough, the value of rv(k) is close to 1.

- (2)

- When the system response speed is slow, the value of rv(k) approaches −1.

- (3)

- When the system response speed rises or falls at a certain rate, the value of rv(k) tends to 0.

- (4)

- When the values of de(k) and de(k − 1) are same positive or same negative, and the values of |de(k)| and |de(k − 1)| are not 0 at the same time, the range of rv(k) is [−1, 1].

3.3. Design of Self-Adaptive Mechanisms

- (1)

- 0~a: When the system error is large and the response speed is fast, increase the output of fuzzy controller 2 so that the total output U of the controller increases positively and the system approaches the set value quickly.

- (2)

- b~c: When the system error is small and the response speed is constant or slow, adjust the output of fuzzy controller 2 so that the total output U of the controller decreases to avoid excessive overshooting.

- (3)

- c~d: When the system speed starts to fall back and the response speed is fast, the total output U of the controller should be further reduced to approach the steady state quickly.

- (4)

- d~e: When the system falls back to near the set point and the response speed is constant, fine-tune the output of fuzzy controller 2 so that the total output U of the controller increases in advance and the reverse overshoot is reduced.

- (5)

- e~f: When the system falls back excessively, regardless of the speed of response, adjust the output of fuzzy controller 2 so that the total output U of the controller increases continuously, suppressing the overshoot and speeding up the speed of response.

3.4. Performance Analysis of the Improved Adaptive PI-like Fuzzy Controller

- (1)

- Enhanced control stage

- (2)

- Attenuated control stage

- (3)

- Balance control stage

4. Simulation and Experimental Research

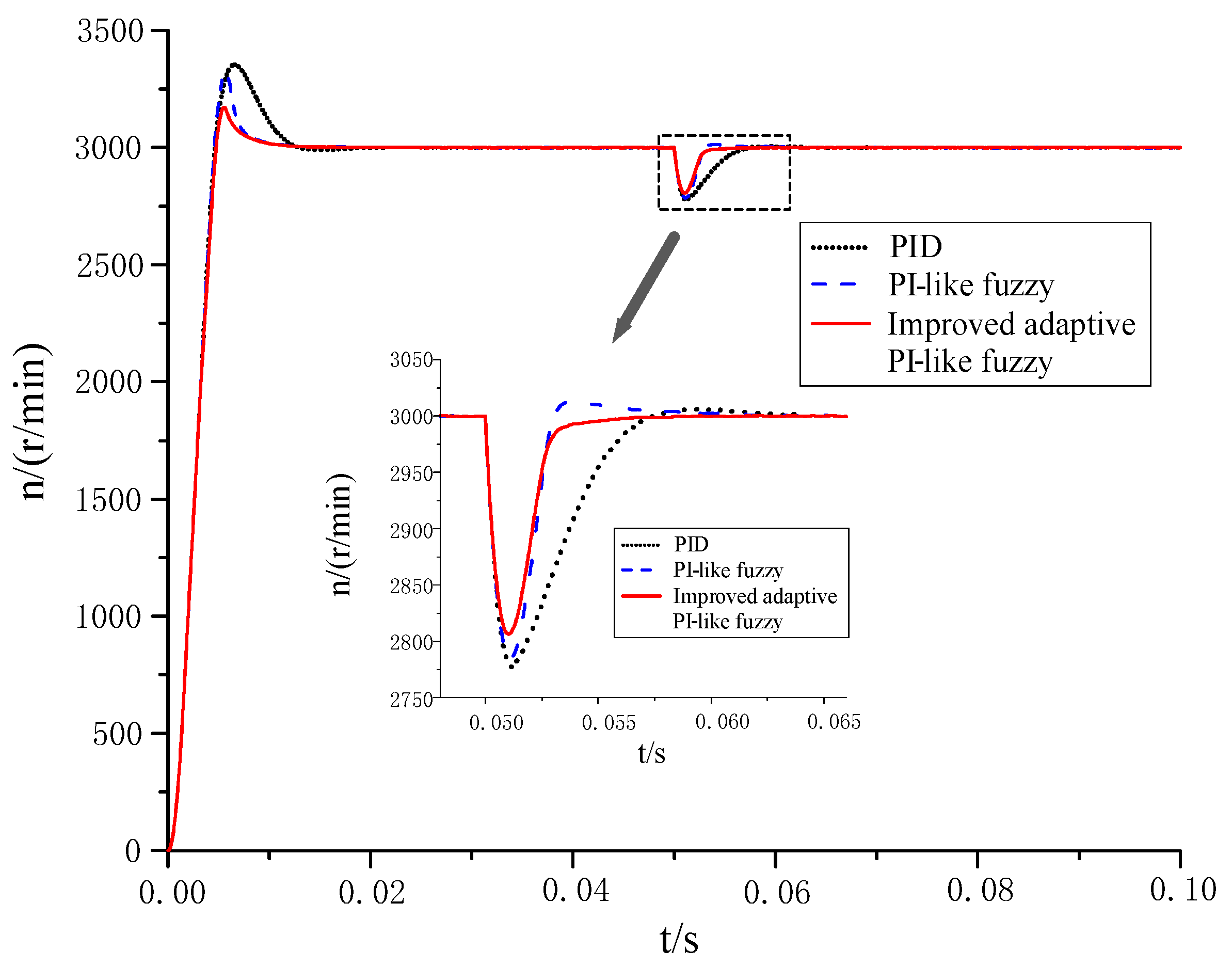

4.1. Simulation Research

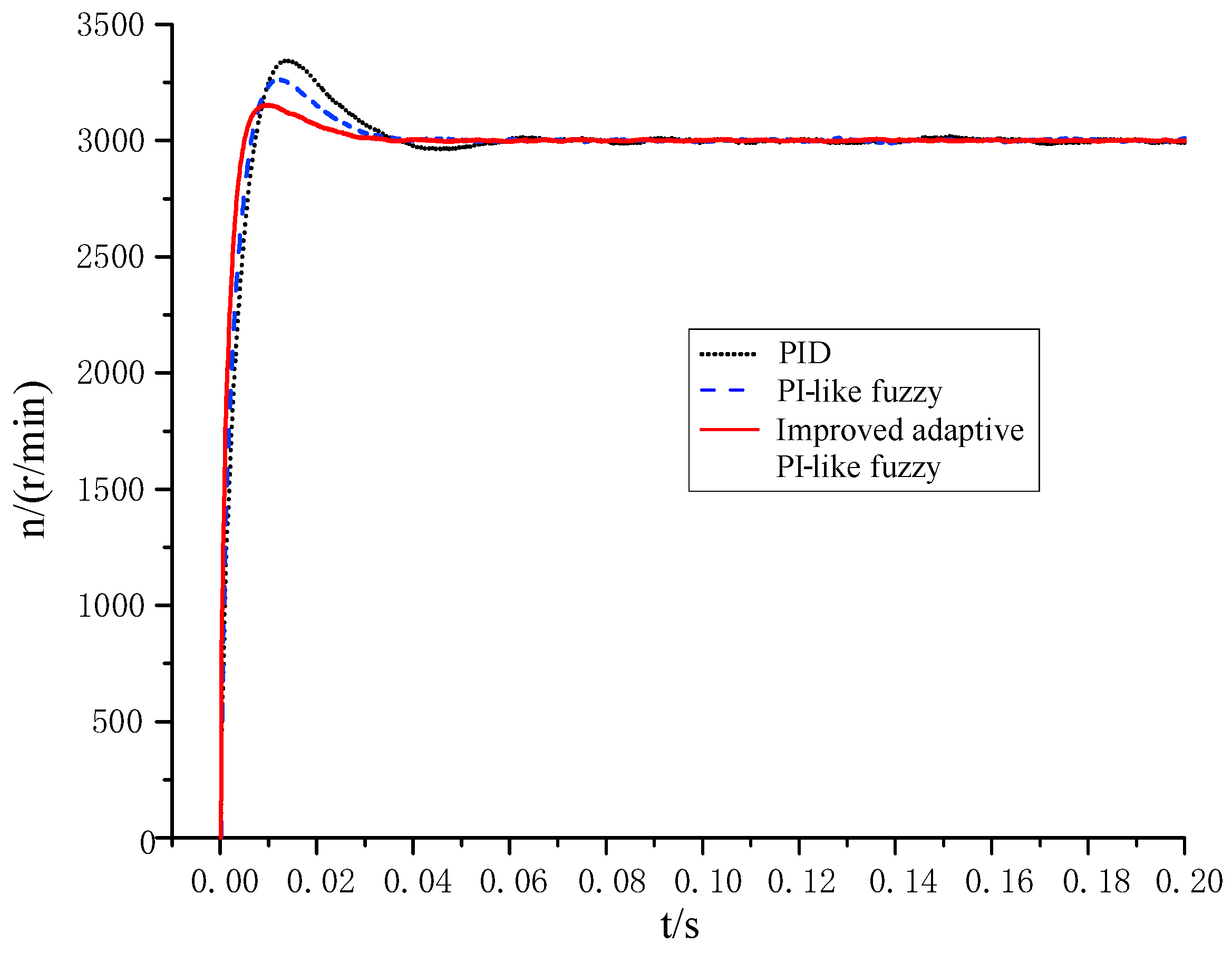

- (1)

- In the start-up stage of the PMSM system, when the improved adaptive PI-like fuzzy control algorithm is adopted, the overshoot of the system is obviously the smallest, about 5.7%, and the time to steady state is the shortest, about 0.007 s. Compared with the PID control system, the PI-like fuzzy control system has a smaller adjustment time: the former is about 0.0075 s, and the latter is about 0.012 s, but the overshoots of the two systems are not much different: the PID control is 11.8%, and the PI-like fuzzy is 10.5%.

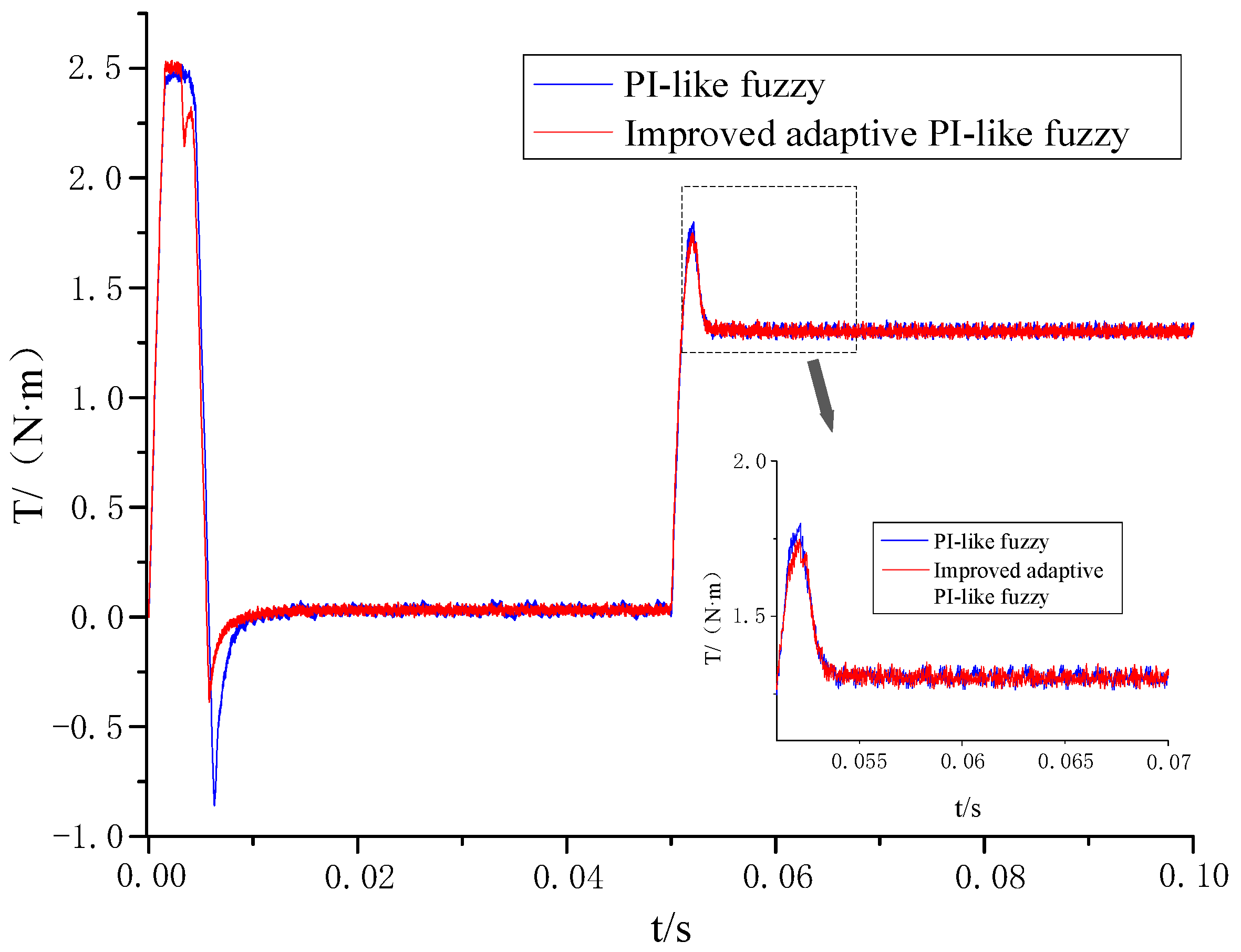

- (2)

- When the PMSM system is loaded suddenly, the improved adaptive PI-like fuzzy control system of the PMSM has the least dynamic speed drop, about 6.4%, and the shortest recovery time to the given speed about 0.0035 s. The recovery time of the PI fuzzy control system of the PMSM is about 0.0045 s, which is not very different to that of the improved adaptive PI-like fuzzy control system, but it has significantly more dynamic speed drop, about 7.2%, and the stability is worse. The PID control system of the PMSM has the worst anti-interference ability: the dynamic speed drop and system recovery time are about 7.4% and 0.007 s, respectively.

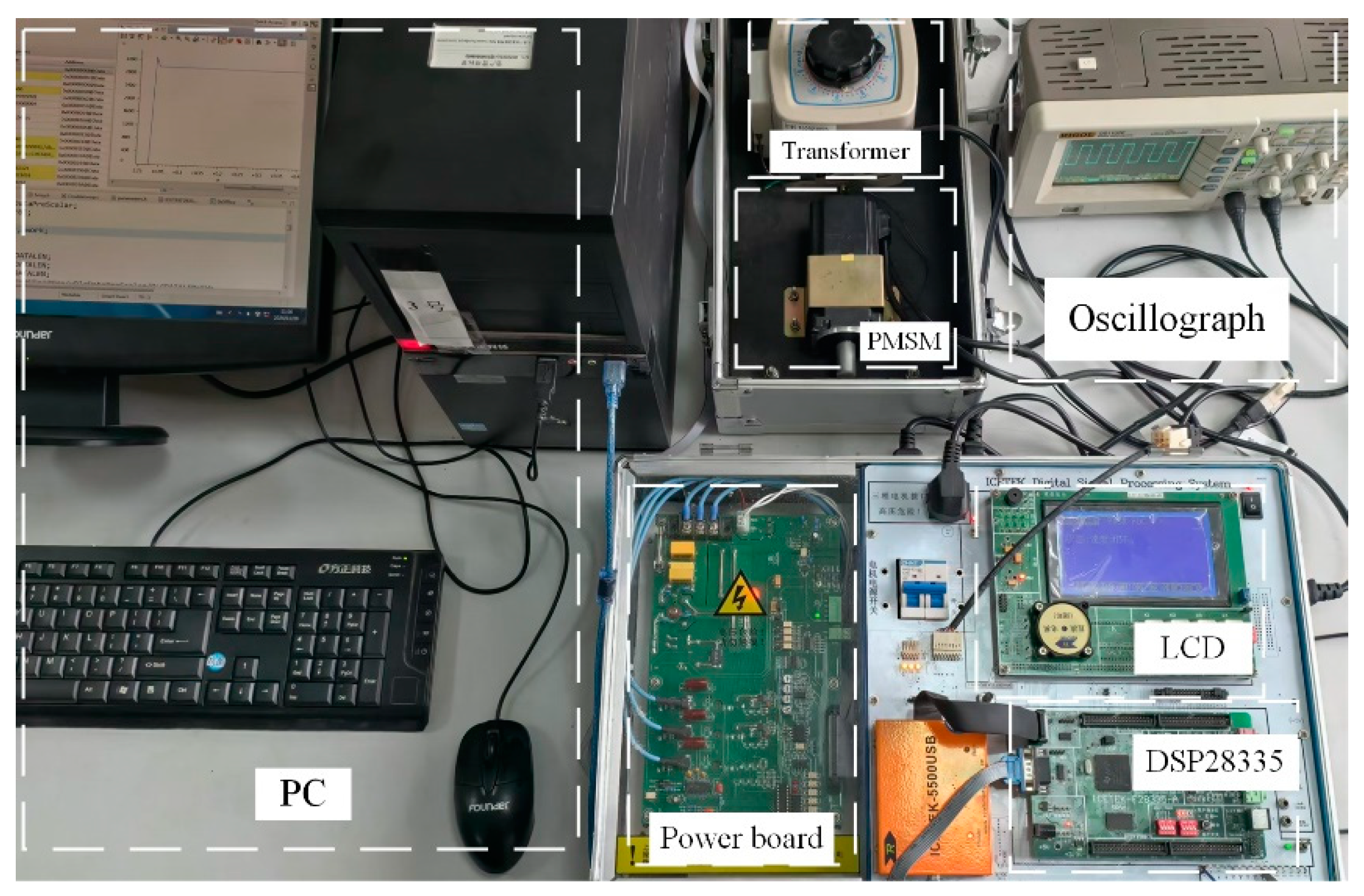

4.2. Experimental Research

- (1)

- When using the traditional PI controller, the overshoot of the speed is the largest (about 11.4%), and the regulation time is the longest (about 0.049 s).

- (2)

- When using the traditional PI-like fuzzy controller, the overshoot of the speed is smaller (about 8.7%), and the regulation time is shorter (about 0.03 s).

- (3)

- Compared with the traditional PI controller and PI-like fuzzy controller, when the improved adaptive PI-like fuzzy controller is adopted, the PMSM system has the optimal dynamic performance, with the smallest overshoot (about 5.1%) and the shortest regulation time (about 0.025 s).

- (4)

- The experimental results of the starting process are basically consistent with the simulation results.

5. Conclusions

- (1)

- Based on the real-time identification of the dynamic response state of the PMSM system, the proposed improved adaptive PI-like fuzzy control algorithm can adjust the output of the PI-like fuzzy controller online at different stages of the system response, thus effectively improving the adaptivity of the fuzzy control system of the PMSM.

- (2)

- Compared with the control algorithms of PID controller and pure PI-like fuzzy controller, when using the proposed improved adaptive PI-like fuzzy control algorithm, the PMSM system obtains good dynamic and static control performance, it obtains the relatively best dynamic performance index, and it has a larger adaptive adjustment range and stronger anti-interference ability. Whether during the no-load start-up or speed change process of the PMSM system, when the improved adaptive PI-like fuzzy control algorithm is used, it can enable the system to obtain smaller overshoot amount and shorter regulation time; when the load is applied suddenly, the motor speed has the smallest dynamic drop and can recover to the given speed in about 0.0035 s.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| PMSM | Permanent magnet synchronous motor |

| FLC | Fuzzy logic controller |

| NEAO | Normalized Error Acceleration Observer |

| UOD | Universe of discourse |

References

- Gierczynski, M.; Jakubowski, R.; Kupiec, E.; Seredyński, M.; Jaworski, M.; Grzesiak, L. Modeling of the fourth-generation Toyota Prius traction machine as the reference for future designs. Energies 2024, 17, 4796. [Google Scholar] [CrossRef]

- Kang, E.L.; Cai, S.C. Design of self-constructing fuzzy neural network controller for permanent magnet synchronous motor. Electr. Mach. Control 2023, 27, 92–101. [Google Scholar]

- Zeng, X.L.; Wang, W.Q.; Wang, H.Y. Adaptive PI and RBFNN PID Current decoupling controller for permanent magnet synchronous motor drives: Hardware-validated results. Energies 2022, 15, 6353. [Google Scholar] [CrossRef]

- Zhen, S.C.; Li, Y.Y.; Liu, X.L.; Wang, J.; Chen, F.; Chen, X. A Lyapunov-based robust control for permanent magnet synchronous motor in the modular joint of collaborative robot. Robotic 2023, 41, 1389–1406. [Google Scholar] [CrossRef]

- Li, Q.F.; Liu, S.C.; Fang, W.D.; Li, X.; Tse, Z. Sideband vibration suppression of interior permanent magnet synchronous motors for electric vehicles under multiple operating conditions. IEEE Trans. Transp. Electrif. 2023, 9, 322–335. [Google Scholar] [CrossRef]

- Cong, Y.; Kang, E.L. Design of fuzzy sliding mode speed controller for permanent magnet synchronous motor. Electr. Mach. Control 2022, 26, 98–104. [Google Scholar]

- Zhou, L.; Su, M.X.; Wang, J. Fuzzy multi-vector model predictive control of permanent magnet synchronous motor. J. Electr. Eng. 2022, 17, 181–192. [Google Scholar]

- Zhang, L.; Ma, J.Q.; Wu, Q.M.; He, Z.Q.; Qin, T.; Chen, C. Research on PMSM speed performance based on fractional order adaptive fuzzy backstepping control. Energies 2023, 16, 6922. [Google Scholar] [CrossRef]

- Lv, X.; Chen, J.; Lv, C.X.; Dong, Y.H. Adaptive control of permanent magnet synchronous motor based on fuzzy logic. Control Eng. China 2022, 29, 837–843. [Google Scholar]

- Makhloufi, K.; Bousserhane, I.K.; Zegnoun, S.A. Adaptive fuzzy sliding mode controller design for PMLSM position control. Int. J. Power Electron. Drive Syst. 2021, 12, 674. [Google Scholar] [CrossRef]

- Novak, Z.; Novak, M. Adaptive PLL-based sensorless control for improved dynamics of high-speed PMSM. IEEE Trans. Power Electron. 2022, 37, 10154–10165. [Google Scholar] [CrossRef]

- Liu, X.; Deng, Y.; Li, H.; Cao, H.; Sun, Z.; Yang, T. Composite control based on FNTSMC and adaptive neural network for PMSM system. ISA Trans. 2024, 151, 198–211. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.C.; Liu, Y.H. A modified PI-like fuzzy logic controller for switched reluctance motor drives. IEEE Trans. Ind. Electron. 2010, 58, 1812–1825. [Google Scholar] [CrossRef]

- Jiang, Y.; Chen, G.Z.; Jiang, J.W. Design of fuzzy adaptive control system for permanent magnet synchronous motor. Electron. Des. Eng. 2022, 30, 11–15+22. [Google Scholar]

- Damarla, I.; Venmathi, M.; Krishnakumar, V.; Anbarasan, P. Performance analysis of FEC based SR motor drive using fuzzy tuned PI controller. Circuit World 2024, 50, 293–307. [Google Scholar] [CrossRef]

- Mudi, R.K.; Pal, N.R. A robust self-tuning scheme for PI-and PD-type fuzzy controllers. IEEE Trans. Fuzzy Syst. 1999, 7, 2–16. [Google Scholar] [CrossRef]

- Centeno, E.; Mendoza, M.J.; Pinedo, C.F.; Kim, W.; Roche, E.; Vela, E.A. Incremental PI-like fuzzy logic control of a vacuum-powered artificial muscle for soft exoskeletons. In Proceedings of the IEEE International Conference on Advanced Robotics and Its Social Impacts (ARSO), Berlin, Germany, 5–7 June 2023; pp. 53–58. [Google Scholar] [CrossRef]

- Liu, X.; Zhou, Z.; Wu, Q.; Yang, Y.; Zhu, X. Research on Vector Control of PMSM Based on Fuzzy PI. In Lecture Notes in Electrical Engineering, Proceedings of the 15th Chinese Intelligent Systems Conference; Springer: Singapore, 2020; Volume 2, pp. 1–9. [Google Scholar]

- Mitra, P.; Dey, C.; Mudi, R.K. Fuzzy rule-based set point weighting for fuzzy PID controller. SN Appl. Sci. 2021, 3, 651. [Google Scholar] [CrossRef]

- Mastacan, L.; Dosoftei, C.C. Temperature fuzzy control system with Mamdani controller. In Proceedings of the International Conference and Exposition on Electrical and Power Engineering (EPE), Iasi, Romania, 18–19 October 2018; pp. 352–356. [Google Scholar]

- Mohamed, M.A.G.; Ghany, A.G.M.A.; Bensenouci, A.; Bensenouci, M.-A.; Syed-Ahmad, M.N. Fuzzy Fractional-Order PID Tuned via Relative Rate Observer for the Egyptian Load Frequency Regulation. In Proceedings of the Twentieth International Middle East Power Systems Conference (MEPCON), Cairo, Egypt, 18–20 December 2018; pp. 103–109. [Google Scholar]

- Nguyen, D.T.; Ho, J.R.; Tung, P.C.; Lin, C.K. A hybrid PSO–GWO fuzzy logic controller with a new fuzzy tuner. Int. J. Fuzzy Syst. 2022, 24, 1586–1604. [Google Scholar] [CrossRef]

- Kurucu, M.C.; Eksin, I.; Güzelkaya, M. Normalized acceleration based online tuning of variable-order fractional derivatives: A case study on quadcopter position control. Int. J. Syst. Sci. 2024, 55, 1–16. [Google Scholar] [CrossRef]

- Zhu, Y.H.; Xue, L.Y.; Wei, H. Design of fuzzy PID controller based on self-organizing adjustment factors. J. Syst. Simul. 2011, 23, 2732–2737. [Google Scholar]

| e | NB | NM | NS | ZE | PS | PM | PB | |

|---|---|---|---|---|---|---|---|---|

| Δe | ||||||||

| NB | NB | NB | NB | NM | PS | NS | ZE | |

| NM | NB | NM | NM | NM | ZE | ZE | PS | |

| NS | NB | NM | NS | NS | ZE | PS | PM | |

| ZE | NB | NM | NS | ZE | PS | PM | PB | |

| PS | NM | NS | ZE | PS | PS | PM | PB | |

| PM | NS | ZE | PS | PM | PM | PM | PB | |

| PB | ZE | PS | PS | PM | PB | PB | PB | |

| e | NB | NM | NS | ZE | PS | PM | PB | |

|---|---|---|---|---|---|---|---|---|

| rv(k) | ||||||||

| NB | PB | PM | PS | ZE | PS | PM | PB | |

| NM | PB | PM | PM | ZE | PM | PM | PB | |

| NS | PB | PB | PB | ZE | PB | PS | PM | |

| ZE | PM | ZE | NM | PS | NM | ZE | PS | |

| PS | PM | PS | ZE | ZE | ZE | PS | PM | |

| PM | PB | PM | PS | ZE | PS | PM | PB | |

| PB | PB | PB | PM | ZE | PS | PB | PB | |

| Parameters | Sign | Value | Unit |

|---|---|---|---|

| Rated power | 400 | W | |

| Rated speed | 3000 | r/min | |

| Number of poles | 4 | ||

| d/q axis inductance | 0.025995 | H | |

| Stator resistance | 5.58 | Ω | |

| Moment of inertia | 0.00003 | kg·m2 | |

| Permanent magnet flux linkage | 0.05987 | Wb | |

| Damping factor | 0.001 | N·m·s | |

| Rated torque | 1.27 | N·m |

| Case 1: n = 1500 r/min | Case 2: n = 3000 r/min | |||

|---|---|---|---|---|

| Controller Type | Overshoot (%) | Adjusting Time (s) | Overshoot (%) | Adjusting Time (s) |

| PID | 20.4% | 0.011 s | 10.2% | 0.01 |

| PI-like fuzzy | 6.3% | 0.0073 s | 5.7% | 0.007 |

| Improved adaptive PI-like fuzzy | 2.7% | 0.0063 | 3.2% | 0.0067 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bu, W.; Guo, S.; Fan, Z.; Li, J. Improved Adaptive PI-like Fuzzy Control Strategy of Permanent Magnet Synchronous Motor. Energies 2025, 18, 362. https://doi.org/10.3390/en18020362

Bu W, Guo S, Fan Z, Li J. Improved Adaptive PI-like Fuzzy Control Strategy of Permanent Magnet Synchronous Motor. Energies. 2025; 18(2):362. https://doi.org/10.3390/en18020362

Chicago/Turabian StyleBu, Wenshao, Shihao Guo, Zongang Fan, and Jinwei Li. 2025. "Improved Adaptive PI-like Fuzzy Control Strategy of Permanent Magnet Synchronous Motor" Energies 18, no. 2: 362. https://doi.org/10.3390/en18020362

APA StyleBu, W., Guo, S., Fan, Z., & Li, J. (2025). Improved Adaptive PI-like Fuzzy Control Strategy of Permanent Magnet Synchronous Motor. Energies, 18(2), 362. https://doi.org/10.3390/en18020362