Optimization of Development Strategies and Injection-Production Parameters in a Fractured-Vuggy Carbonate Reservoir by Considering the Effect of Karst Patterns: Taking C Oilfield in the Tarim Basin as an Example

Abstract

1. Introduction

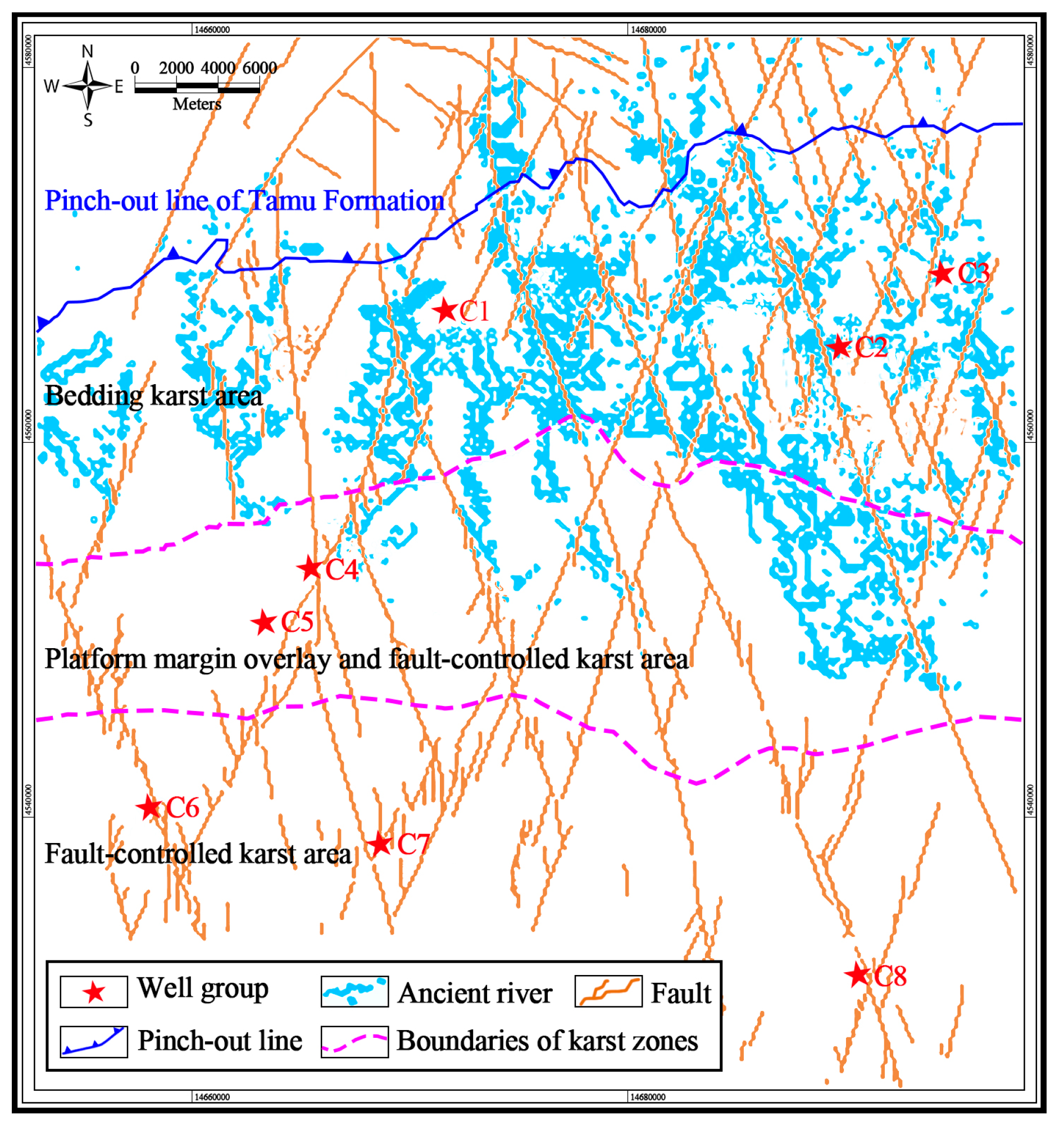

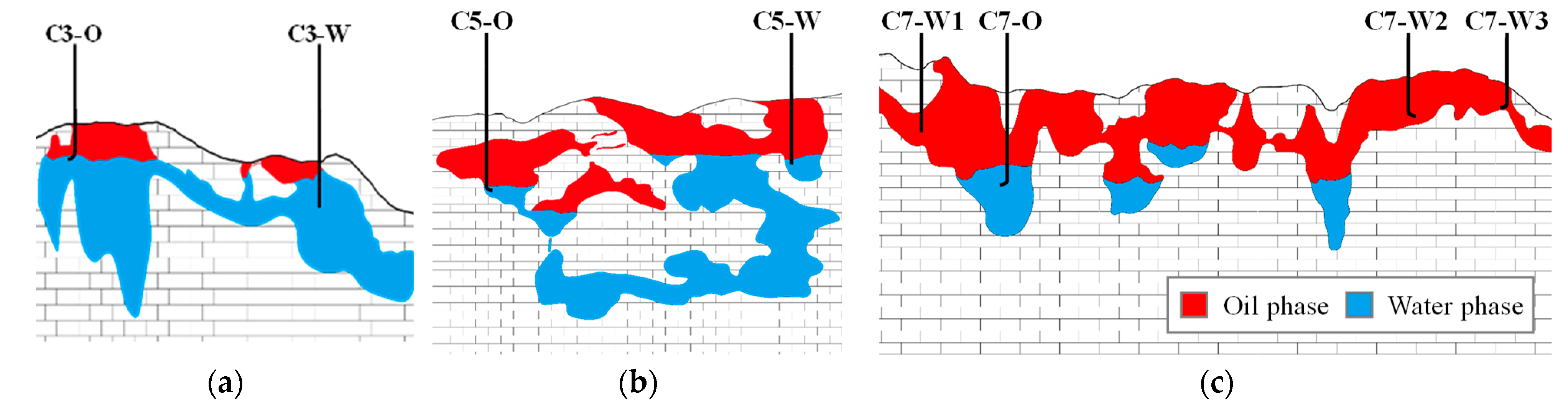

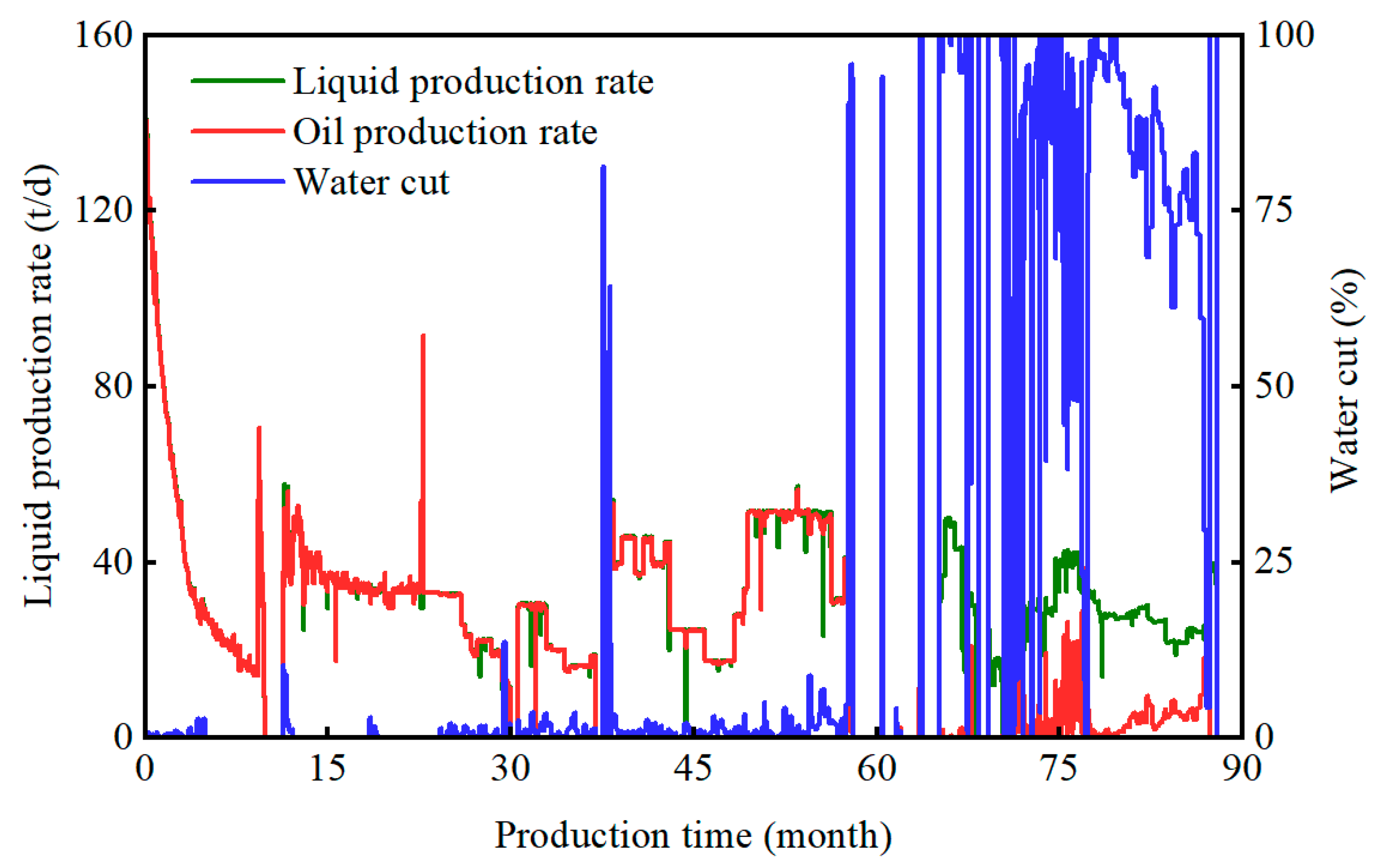

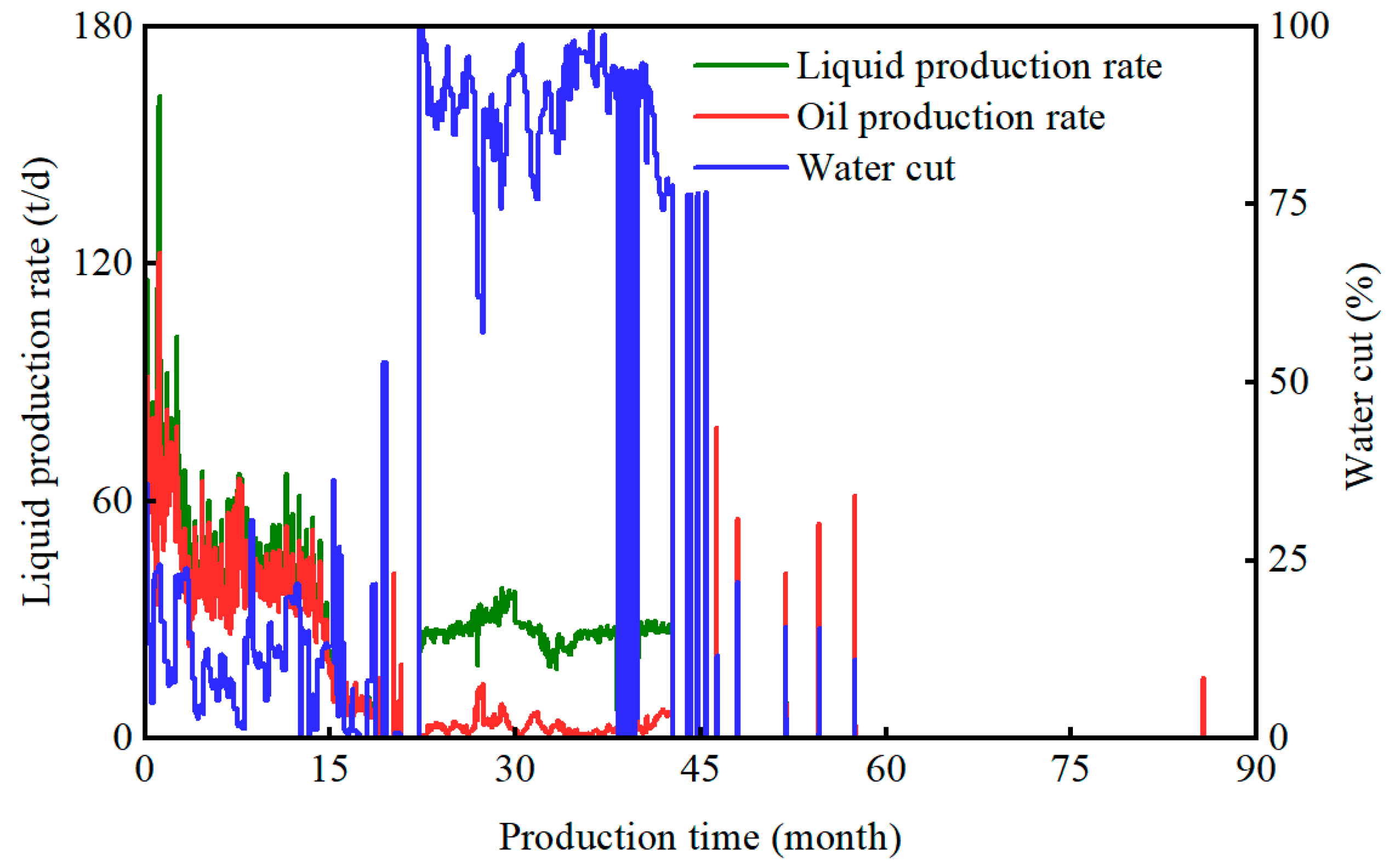

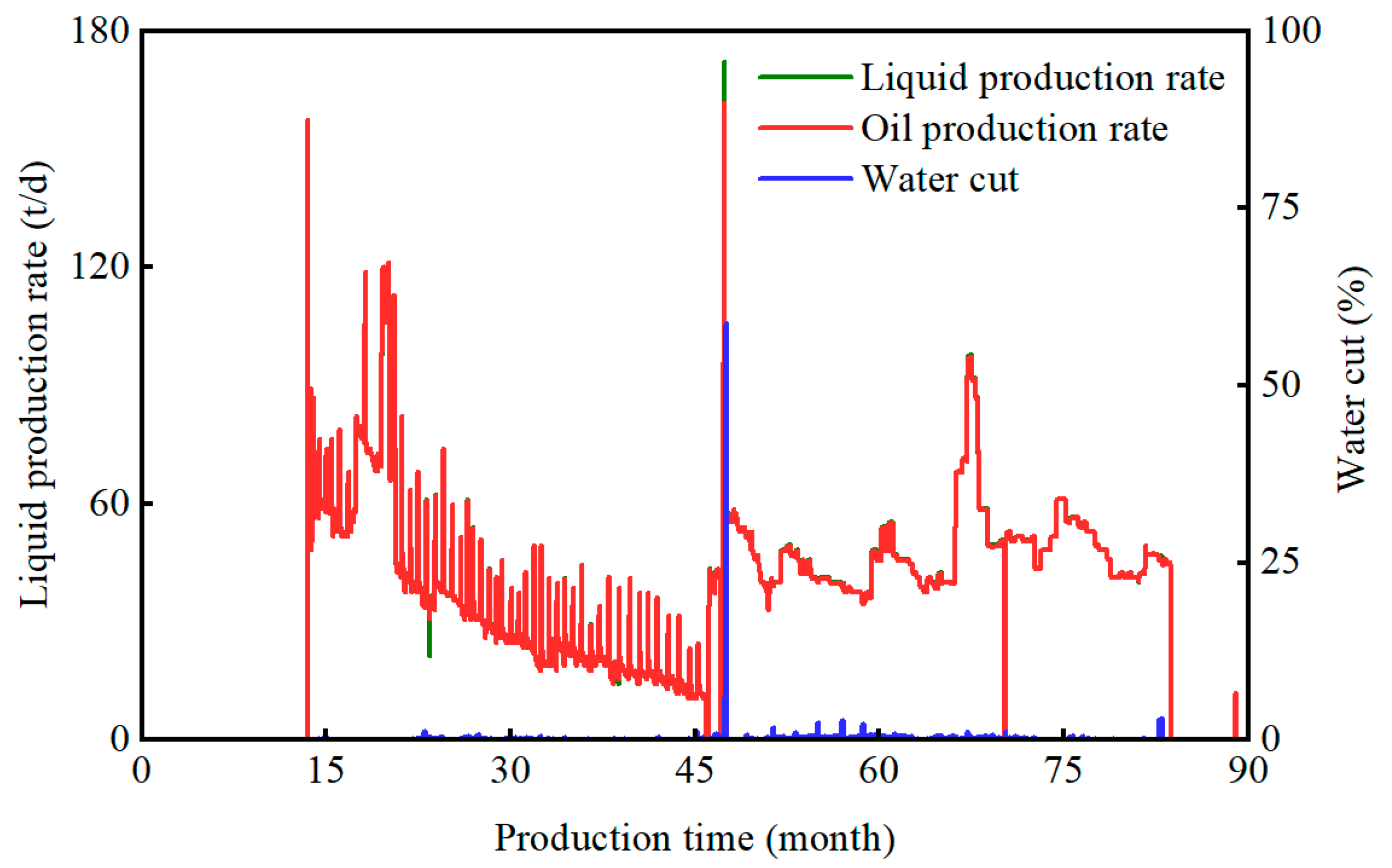

2. Production Dynamics of Different Karst-Controlled Fractured-Vuggy Units

3. Numerical Simulation Method for Fractured-Vuggy Reservoirs Considering the Vertical Equilibrium Mechanism

4. Determination of the Optimal Development Strategies

4.1. Bedding Karst Fractured-Vuggy Unit

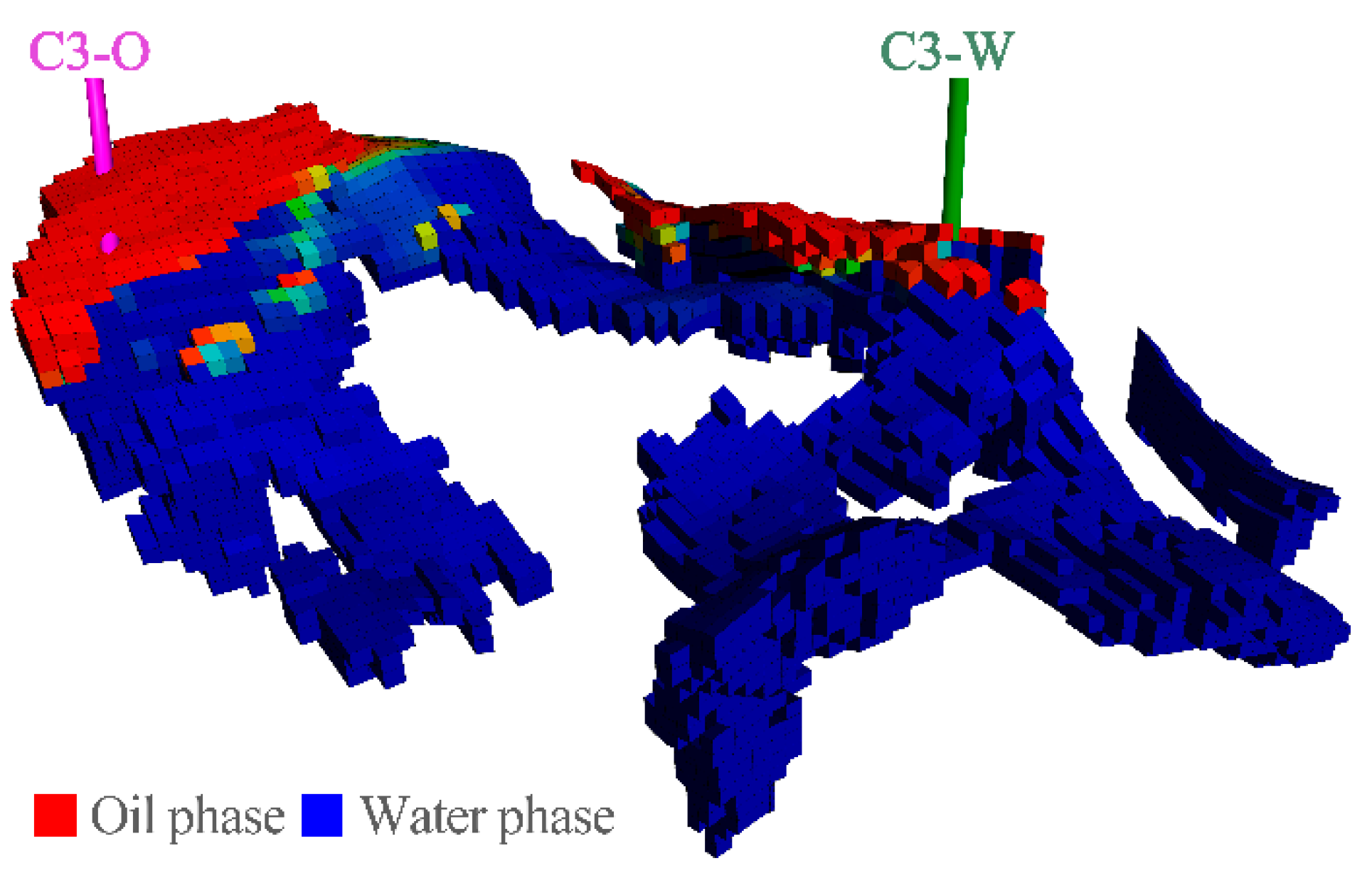

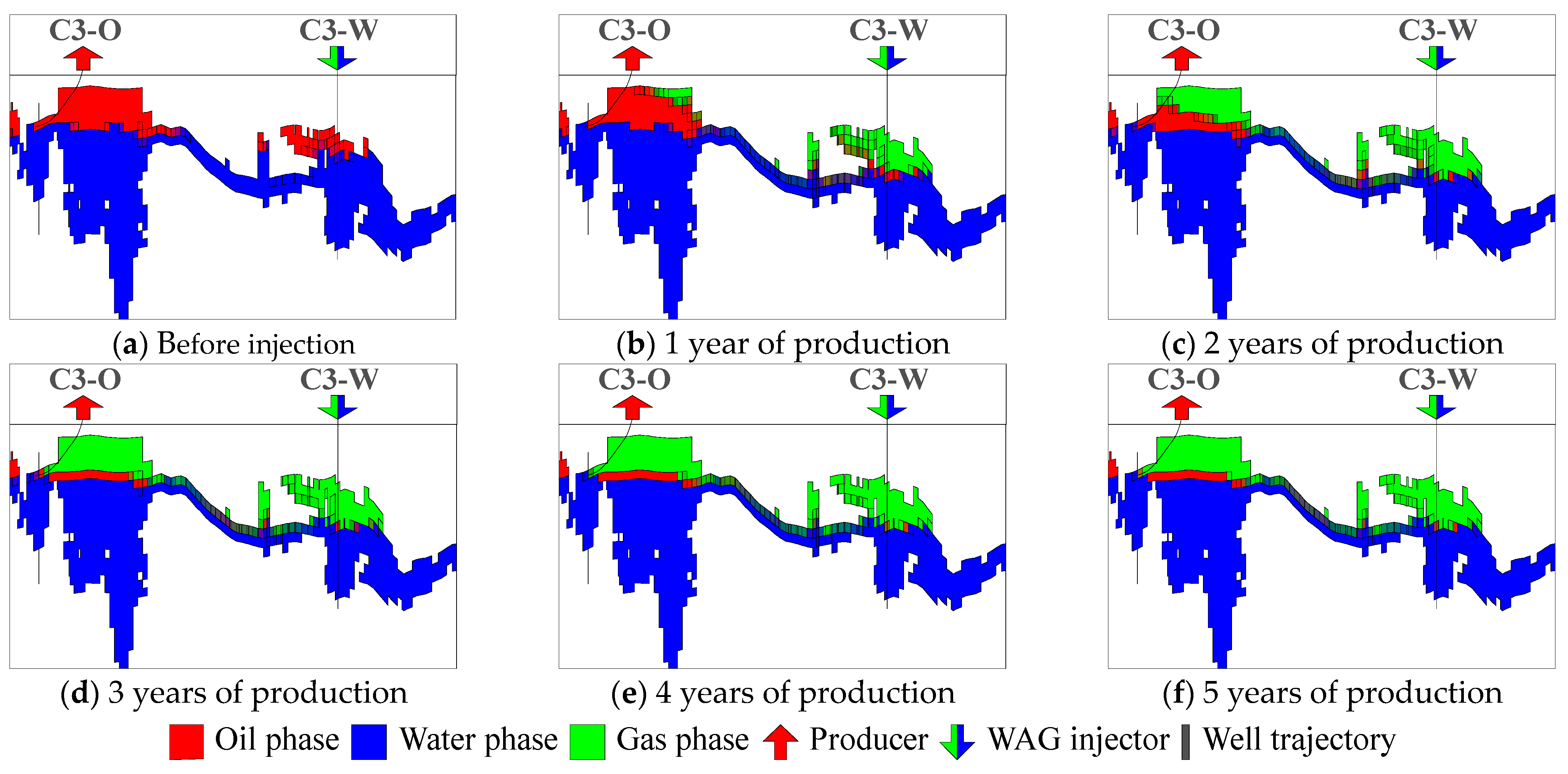

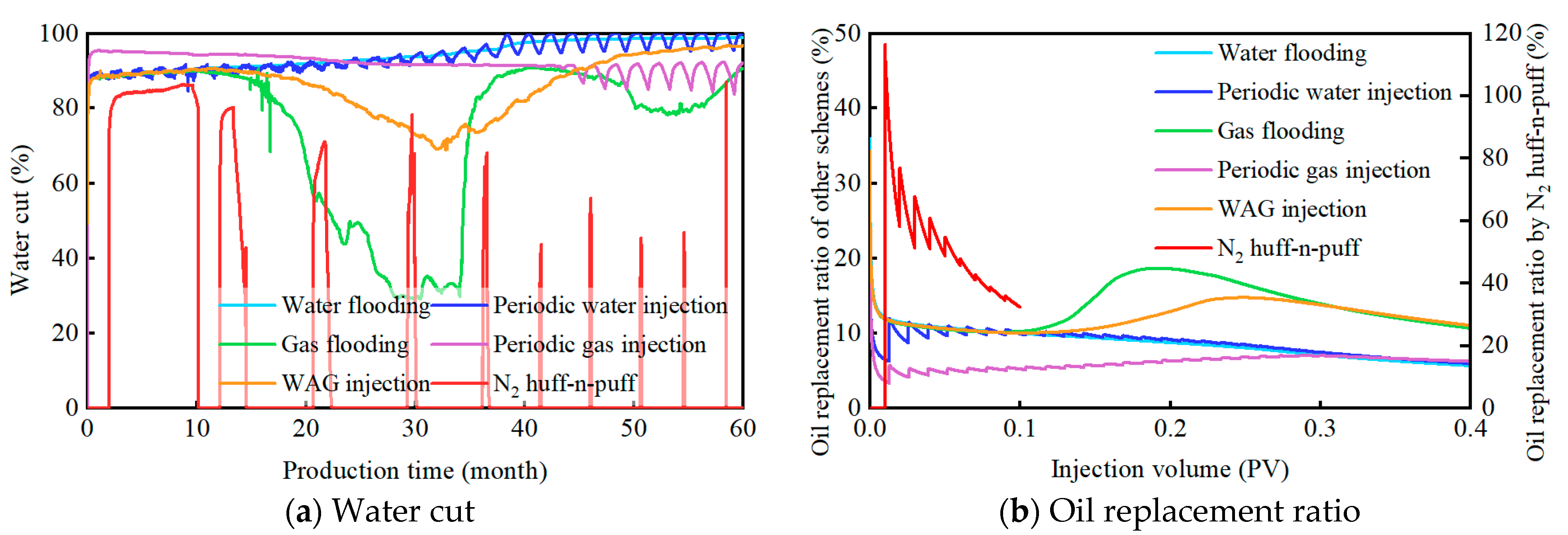

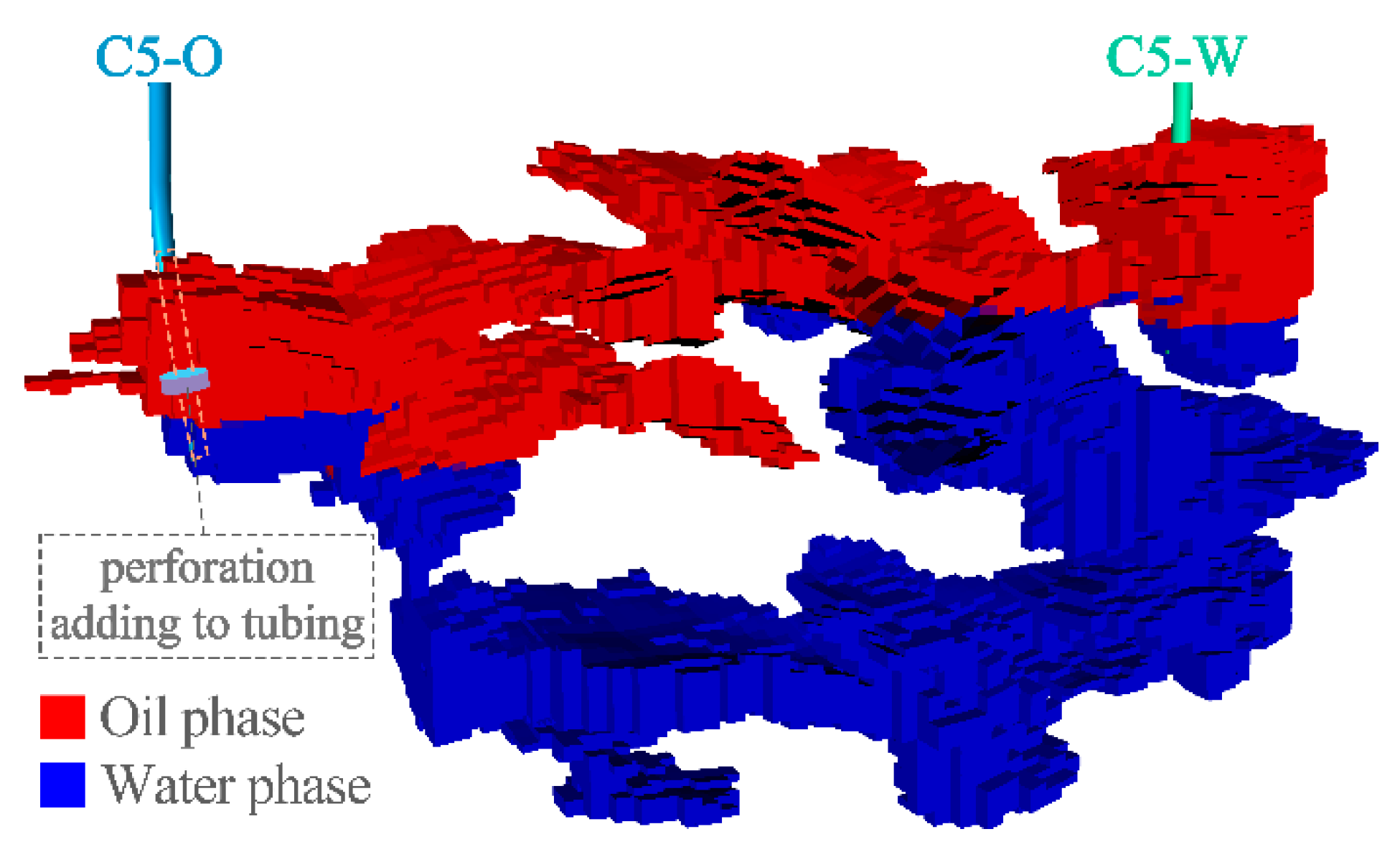

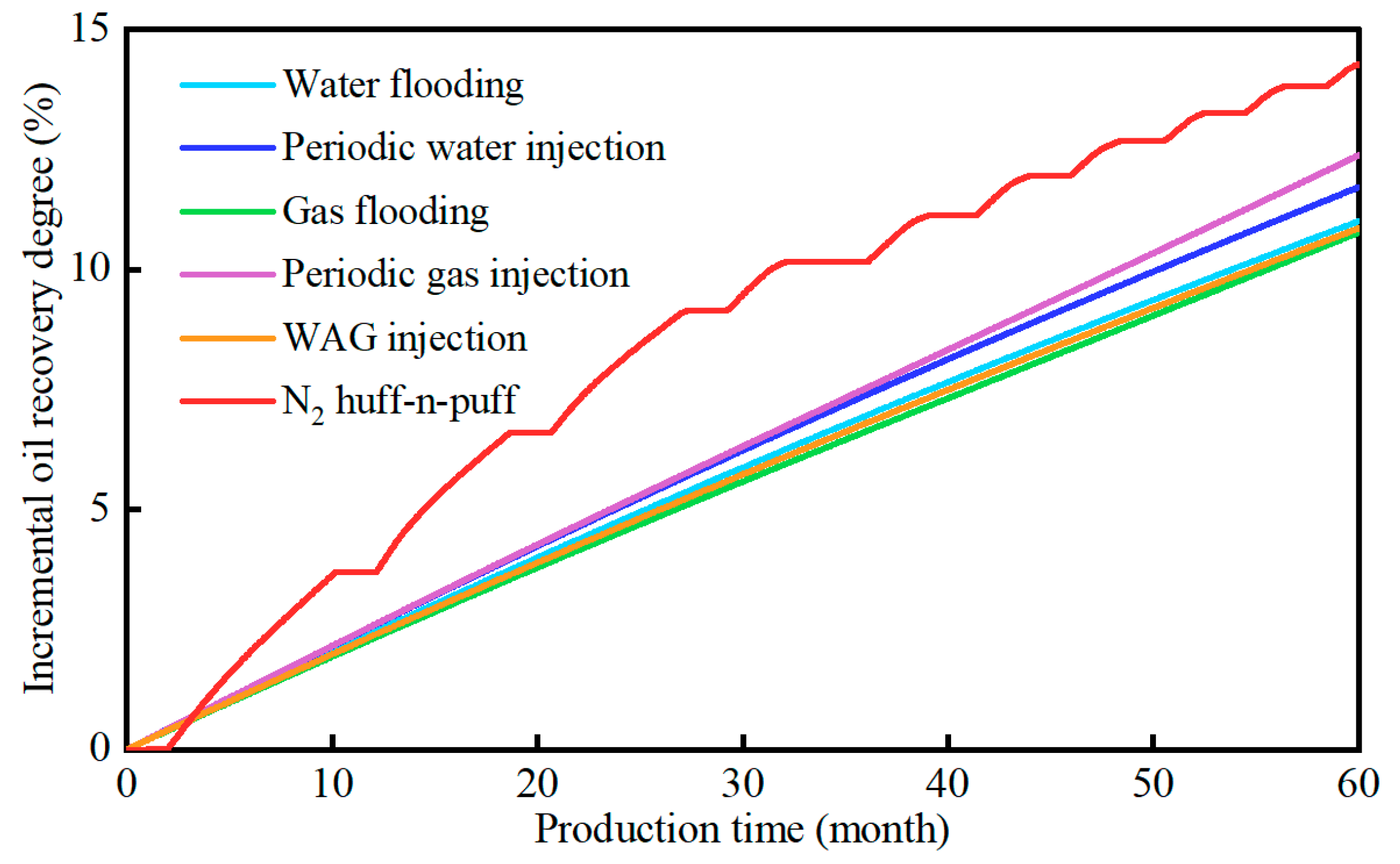

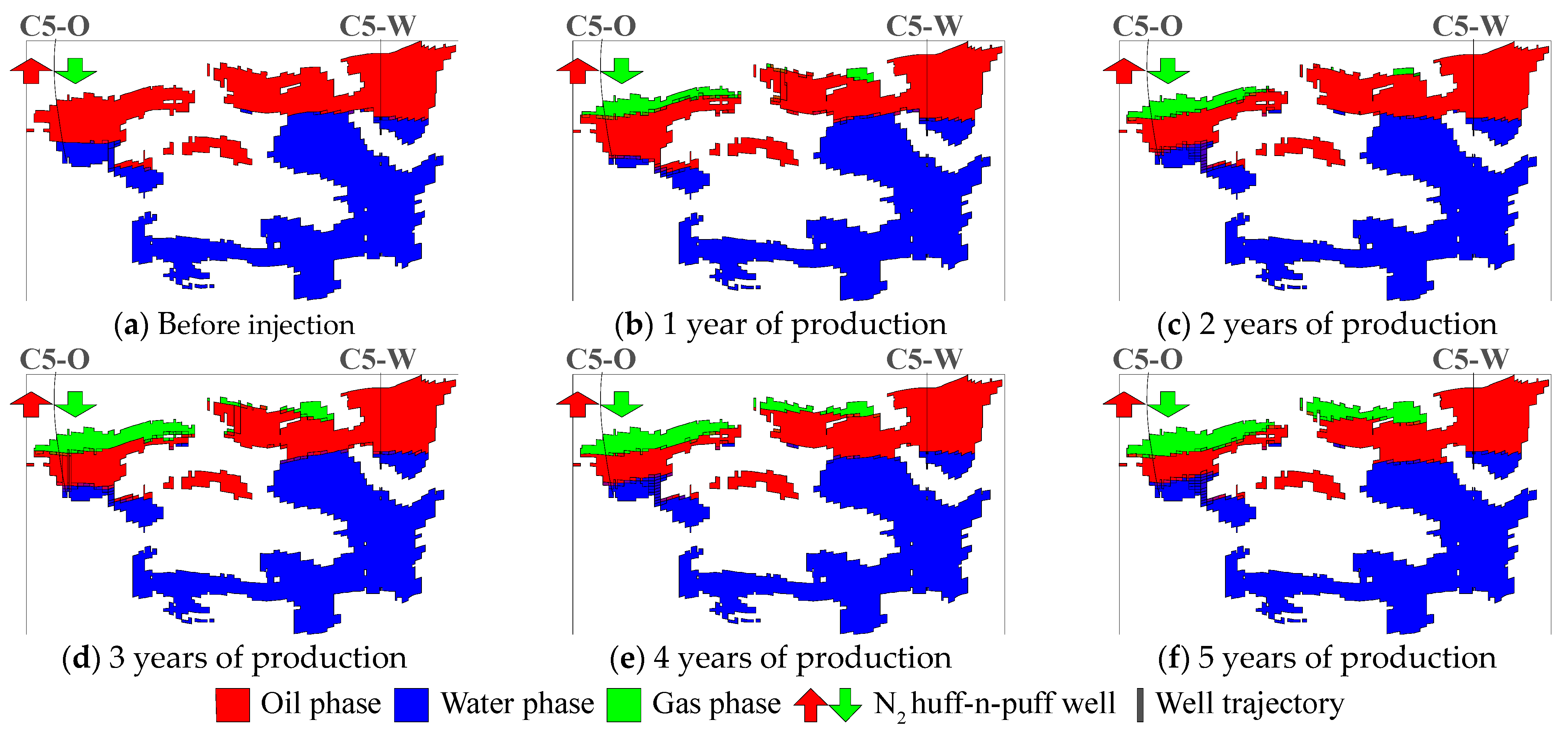

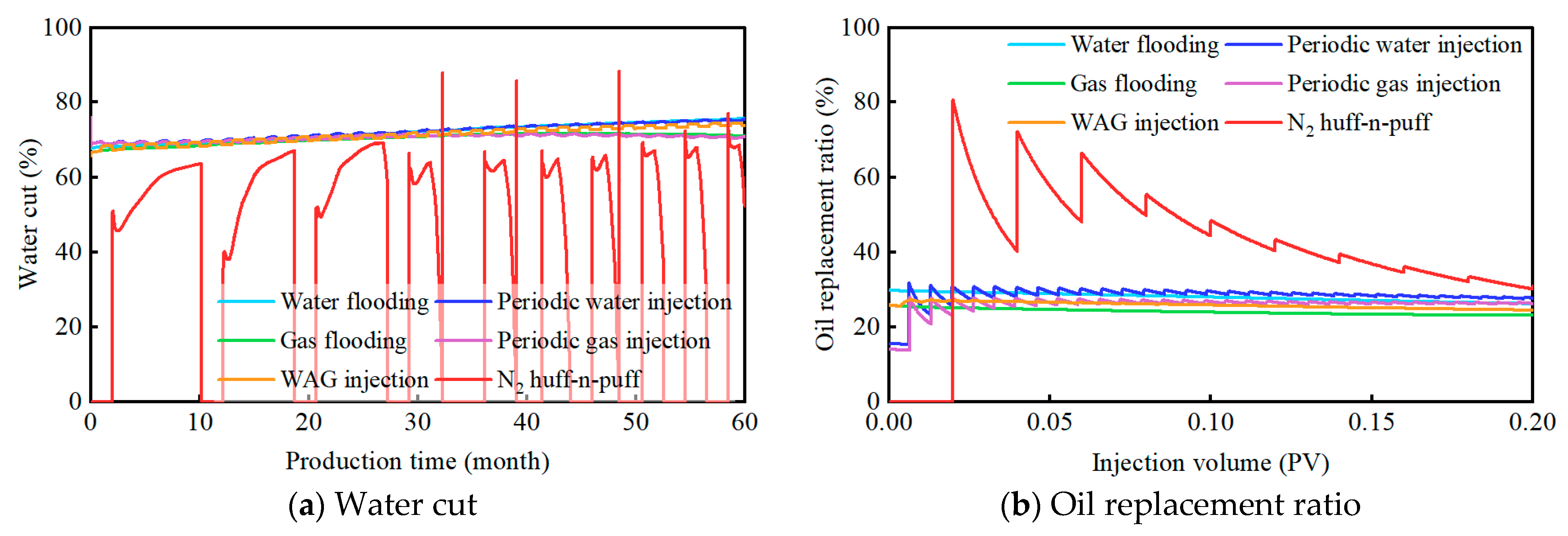

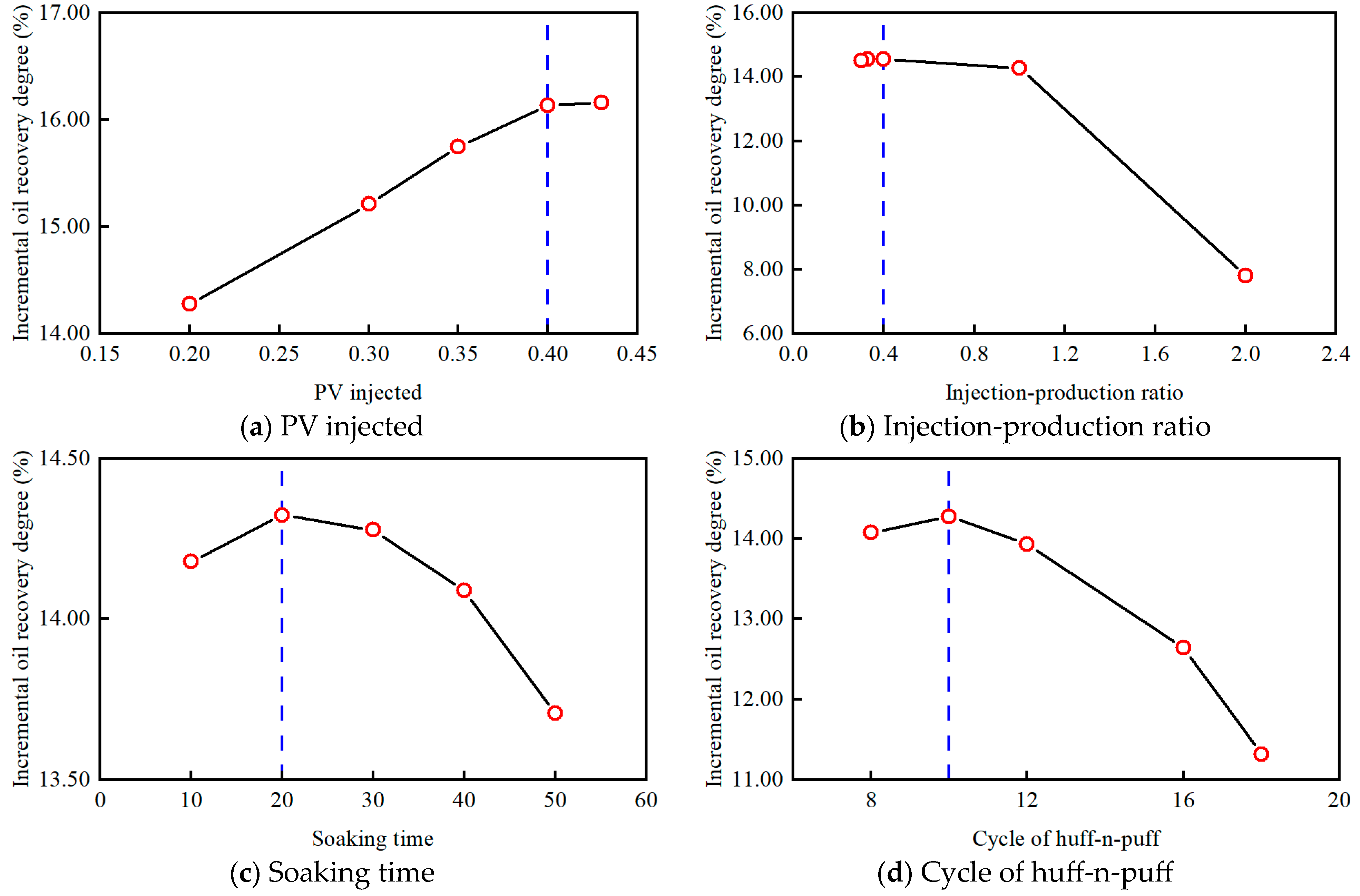

4.2. Platform Margin Overlay and Fault-Controlled Karst Fractured-Vuggy Unit

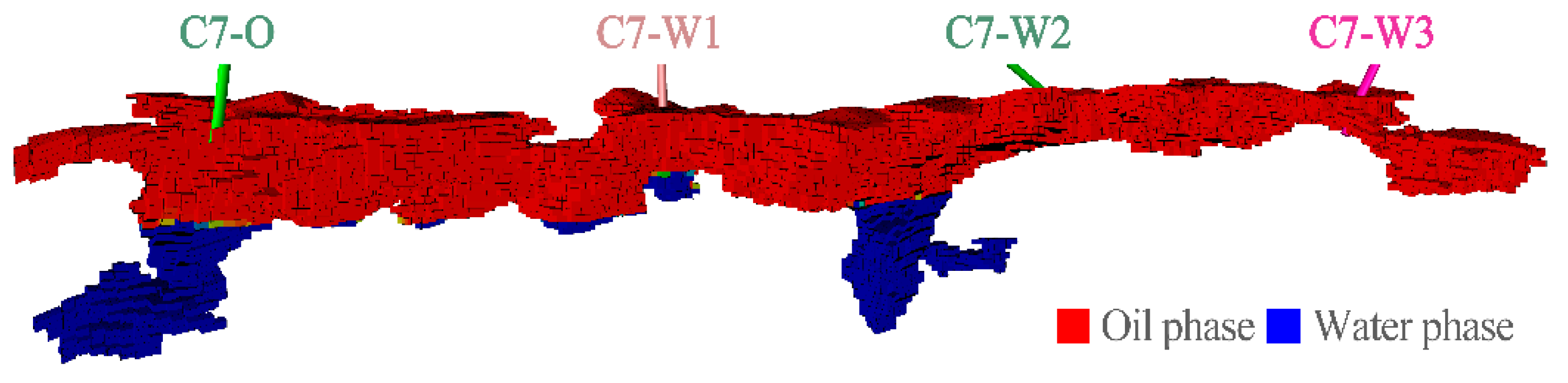

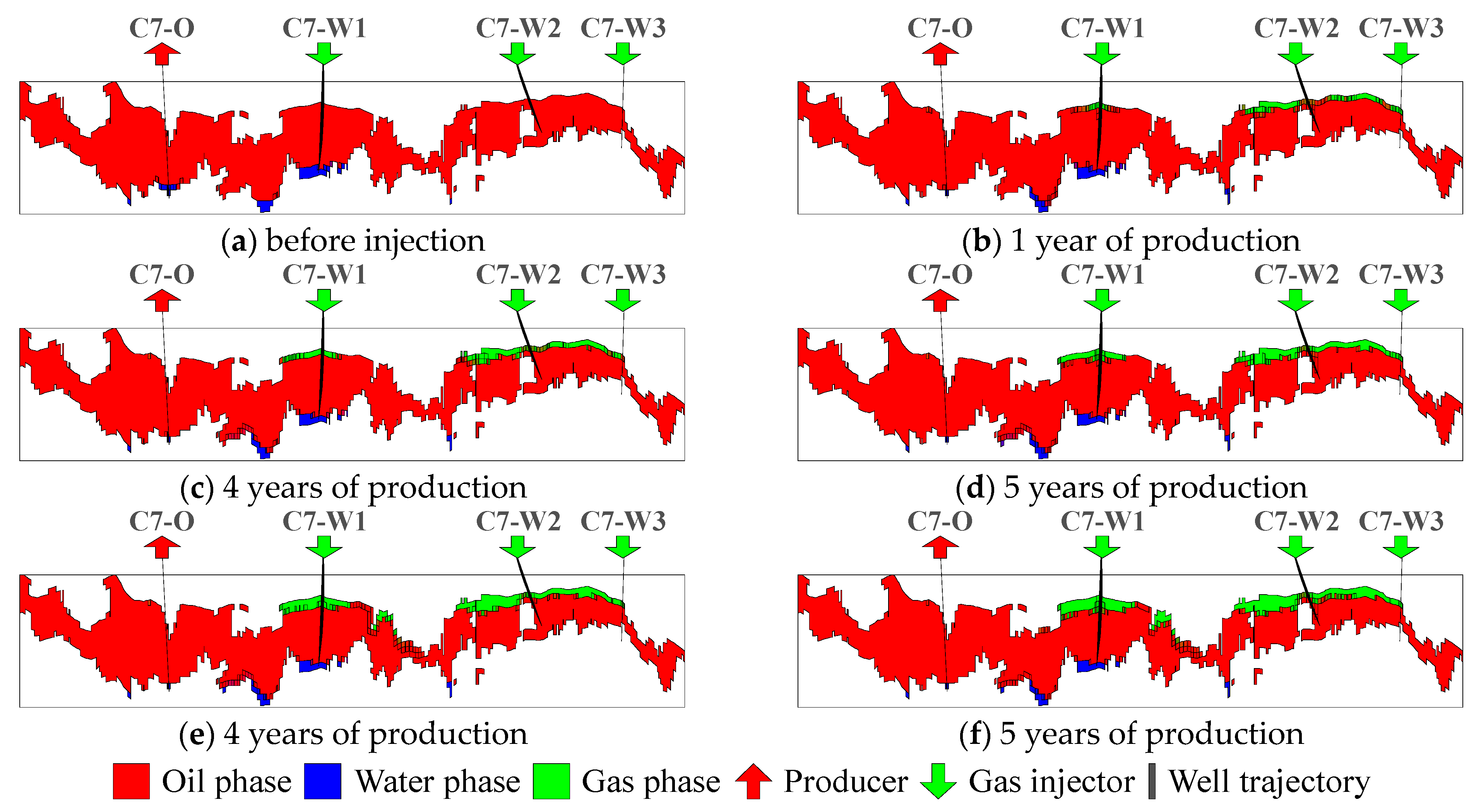

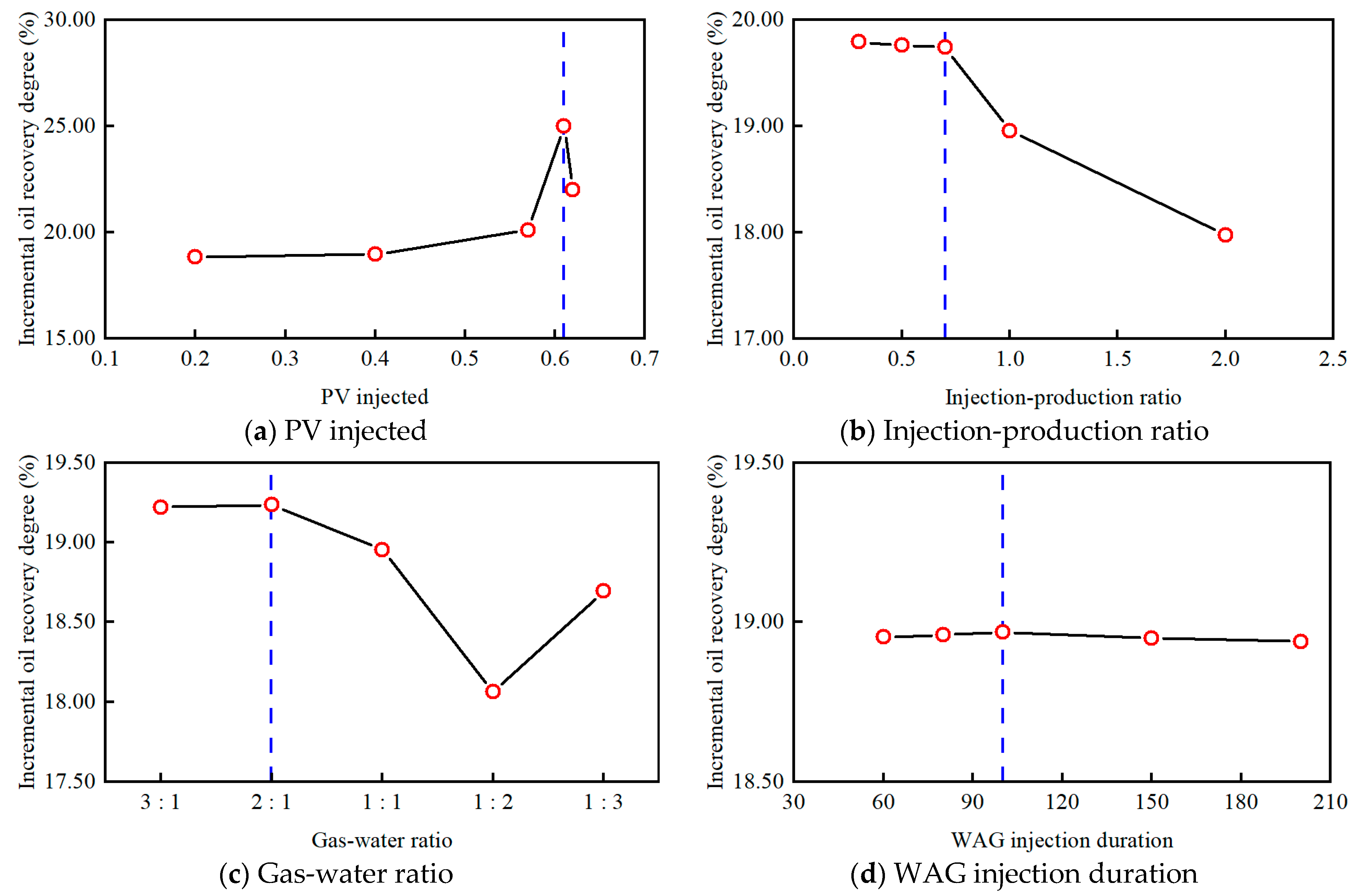

4.3. Fault-Controlled Karst Fractured-Vuggy Unit

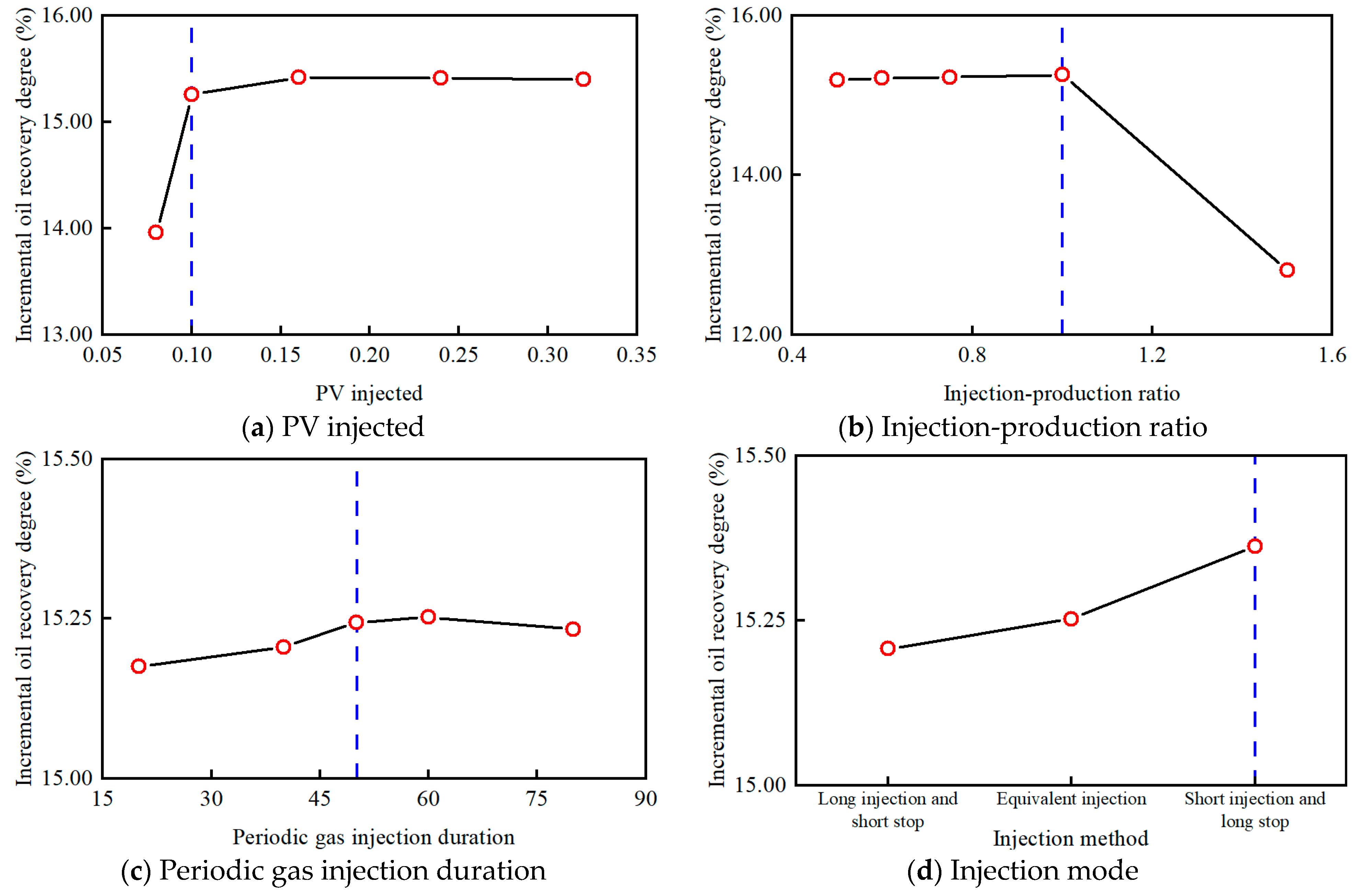

5. Optimization of Injection-Production Parameters

5.1. Bedding Karst Fractured-Vuggy Unit

5.2. Platform Margin Overlay and Fault-Controlled Karst Fractured-Vuggy Unit

5.3. Fault-Controlled Karst Fractured-Vuggy Unit

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Garland, J.; Neilson, J.; Laubach, S.E.; Whidden, K.J. Advances in carbonate exploration and reservoir analysis. In Advances in Carbonate Exploration and Reservoir Analysis; Geological Society, London, Special Publications: London, UK, 2012; Volume 370, pp. 1–5. [Google Scholar]

- Zhao, W.; Shen, A.; Qiao, Z.; Zheng, J.; Wang, X. Carbonate karst reservoirs of the Tarim Basin, northwest China: Types, features, origins, and implications for hydrocarbon exploration. Interpretation 2014, 2, SF65–SF90. [Google Scholar] [CrossRef]

- Li, Y.; Kang, Z.; Xue, Z.; Zheng, S. Theories and practices of carbonate reservoirs development in China. Pet. Explor. Dev. 2018, 45, 712–722. [Google Scholar] [CrossRef]

- Sheng, S.; Duan, Y.; Wei, M.; Yue, T.; Wu, Z.; Tan, L. Analysis of Interwell Connectivity of Tracer Monitoring in Carbonate Fractured-vuggy Reservoir: Taking T-Well Group of Tahe Oilfield as an Example. Geofluids 2021, 2021, 5572902. [Google Scholar] [CrossRef]

- Ahmatjan, A.; Zhong, J.; Li, Y.; Zhong, F.; Gao, Y. Study on Effect between karstification and Fracture in Carbonate Rocks. Geol. Rev. 2008, 54, 485–493. (In Chinese) [Google Scholar]

- Ni, X.F.; Zhang, L.J.; Shen, A.J.; Qiao, Z.F.; Han, L.J. Diagenesis and pore evolution of the Ordovician karst reservoir in Yengimahalla Hanilcatam region of Tarim Basin. J. Palaeogeogr. 2010, 12, 467–479. [Google Scholar]

- Wang, K.; Teng, J.; Deng, H.; Fu, M.; Lu, H. Classification of Void Space Types in Fractured-Vuggy Carbonate Reservoir Using Geophysical Logging: A Case Study on the Sinian Dengying Formation of the Sichuan Basin, Southwest China. Energies 2021, 14, 5087. [Google Scholar] [CrossRef]

- Li, Y. The theory and method for development of carbonate fractured-cavity reservoirs in Tahe oilfield. Acta Pet. Sin. 2013, 34, 115–121. [Google Scholar]

- Wang, Q.; Jiang, H.; Han, J.; Wang, D.; Li, J. Adaptive Prediction of Enhanced Oil Recovery by N2 huff-n-puff in Fractured-Cavity Reservoir Using an FNN-FDS Hybrid Model. Appl. Sci. 2021, 11, 8871. [Google Scholar] [CrossRef]

- Zhou, J.; Lyu, H.; Lin, Z.; Wu, C. Karstification models of the Ordovician carbonates and their influetial factors in the Tahe oilfield, the Tarim basin. Pet. Geol. Exp. 2009, 31, 547–550. [Google Scholar]

- Ni, X.; Zhang, L.; Shen, A. Characteristics and genesis of Ordovician carbonate karst reservoir in Yingmaili-Halahatang Area, Tarim Basin. Acta Sedimentol. Sin. 2011, 29, 465–474. [Google Scholar]

- Ni, X.; Zhang, L.; Shen, A.; Qiao, Z.; Zhao, K. Characteristics and karstification of the Ordovician carbonate reservoir, Halahatang area, northern Tarim Basin. Acta Petrol. Sin. 2012, 28, 815–826. [Google Scholar]

- You, X.; Sana, W.; Fan, X. The characteristics and main control factors of hydrocarbon accumulation of ultra-deep marine carbonates in the Tarim Basin, NW China—A review. Carpathian J. Earth Environ. Sci. 2018, 13, 135–144. [Google Scholar] [CrossRef]

- Zhang, Q. Development Mechanism of Ordovician Carbonate Paleokarst in the Halahatang Area of the Tarim Basin. Ph.D. Dissertation, China University of Geosciences, Wuhan, China, 2018. [Google Scholar]

- Firme, P.A.L.P.; Quevedo, R.J.; Roehl, D.; Pereira, L.C.; Cazarin, C.L. Mechanical behavior of carbonate reservoirs with single karst cavities. Geomech. Energy Environ. 2021, 25, 100209. [Google Scholar] [CrossRef]

- Wu, Y.-S.; Di, Y.; Kang, Z.; Fakcharoenphol, P. A multiple-continuum model for simulating single-phase and multiphase flow in naturally fractured vuggy reservoirs. J. Pet. Sci. Eng. 2011, 78, 13–22. [Google Scholar] [CrossRef]

- Liao, T.; Hou, J.; Chen, L.; Ma, K.; Yang, W.; Dong, Y. Evolutionary model of the Ordovician karst reservoir in Halahatang oilfield, northern Tarim Basin. Acta Pet. Sin. 2015, 36, 1380–1391. [Google Scholar]

- Wang, D.; Sun, J. Oil recovery for fractured-vuggy carbonate reservoirs by cyclic water huff and puff: Performance analysis and prediction. Sci. Rep. 2019, 9, 15231. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, H.; Li, J. Study on Water Injection Indicator Curve Model in Fractured Vuggy Carbonate Reservoir. Geofluids 2021, 2021, 5624642. [Google Scholar]

- Rong, Y.; Liu, X.; Yang, M. A Discussion on water flooding in the multi-well fractured-vuggy units of carbonate reservoirs in Tahe oilfield. Oil Gas Geol. 2010, 31, 28–32. [Google Scholar]

- Ma, X.; Liu, P.; He, C. Waterflooding Pattern for Fractured-Vuggy Reservoir in Tahe Oilfield, Tarim Basin. Xinjiang Pet. Geol. 2011, 32, 63–65. [Google Scholar]

- Ren, W.; Chen, X. Research on Asymmetric Unstable Water Injection in Fractured Carbonate Reservoirs. Sci. Technol. Eng. 2013, 13, 8120–8125. [Google Scholar]

- Rong, Y.; Li, X.; Liu, X.; Li, X. Discussion about pattern of water flooding development in multi-well fractured-vuggy units of carbonate fractured-vuggy reservoir in Tahe oilfield. Pet. Geol. Recovery Effic. 2013, 20, 58–61. [Google Scholar]

- Hu, G. Technological Policy Research of Cyclic Waterflooding in Fracture Cavity Carbonate Reservoir in Tahe Oilfield. Xinjiang Pet. Geol. 2014, 35, 59–62. [Google Scholar]

- Geng, J.; Xiao, L.; Yue, P.; Xiao, Y.; Yang, H.; Qu, S.; Wang, X. Evaluation Method of Water Injection Development Effects in Fractured Vuggy Carbonate Reservoirs: Case Study of FI7 Strike-Slip Fault Zone. Energies 2024, 17, 5611. [Google Scholar] [CrossRef]

- Chen, L.; Jia, C.; Zhang, R.; Yue, P.; Jiang, X.; Wang, J.; Su, Z.; Xiao, Y.; Lv, Y. High-pressure capacity expansion and water injection mechanism and indicator curve model for fractured-vuggy carbonate reservoirs. Petroleum 2024, 10, 511–519. [Google Scholar] [CrossRef]

- Hou, J.; LI, H.; Jiang, Y.; Luo, M.; Zheng, Z.; Zhang, L.; Yuan, D. Macroscopic three-dimensional physical simulation of water flooding in multi-well fractured-vuggy unit. Pet. Explor. Dev. 2014, 41, 717–722. [Google Scholar] [CrossRef]

- Zheng, S.; Liu, Z.; Qiu, L. Evaluation of Injected Water Utilization for Fractured-Vuggy Reservoirs in Tahe Oilfield. Xinjiang Pet. Geol. 2017, 38, 452–454. [Google Scholar]

- Wang, J.; Liu, H.; Ning, Z.; Zhang, H.; Hong, C. Experiments on water flooding in fractured-vuggy cells in fractured-vuggy reservoirs. Pet. Explor. Dev. 2014, 41, 74–81. [Google Scholar] [CrossRef]

- He, J.; Li, A.; Wu, S.; Tang, R.; Lv, D.; Li, Y.; Li, X. Experimental Investigation on Injection and Production Pattern in Fractured-Vuggy Carbonate Reservoirs. Energies 2020, 13, 603. [Google Scholar] [CrossRef]

- Zhao, Y.; Lu, G.; Zhang, L.; Yang, K.; Li, X.; Luo, J. Physical simulation of waterflooding development in large-scale fractured-vuggy reservoir considering filling characteristics. J. Pet. Sci. Eng. 2020, 191, 107328. [Google Scholar] [CrossRef]

- Hou, J.-R.; Zheng, Z.-Y.; Song, Z.-J.; Luo, M.; Li, H.-B.; Zhang, L.; Yuan, D.-Y. Three-dimensional physical simulation and optimization of water injection of a multi-well fractured-vuggy unit. Pet. Sci. 2016, 13, 259–271. [Google Scholar] [CrossRef]

- Lyu, X.; Liu, Z.; Hou, J.; Lyu, T. Mechanism and influencing factors of EOR by N2 injection in fractured-vuggy carbonate reservoirs. J. Nat. Gas Sci. Eng. 2017, 40, 226–235. [Google Scholar] [CrossRef]

- Yang, J.; Hou, J.; Qu, M.; Liang, T.; Wen, Y. Experimental study the flow behaviors and mechanisms of nitrogen and foam assisted nitrogen gas flooding in 2-D visualized fractured-vuggy model. J. Pet. Sci. Eng. 2020, 194, 107501. [Google Scholar] [CrossRef]

- Yue, P.; Xie, Z.; Huang, S.; Liu, H.; Liang, S.; Chen, X. The application of N2 huff and puff for IOR in fractured-vuggy carbonate reservoir. Fuel 2018, 234, 1507–1517. [Google Scholar] [CrossRef]

- Belazreg, L.; Mahmood, S.M. Water alternating gas incremental recovery factor prediction and WAG pilot lessons learned. J. Pet. Explor. Prod. Technol. 2019, 10, 249–269. [Google Scholar] [CrossRef]

- Afzali, S.; Rezaei, N.; Zendehboudi, S. A comprehensive review on Enhanced Oil Recovery by Water Alternating Gas (WAG) injection. Fuel 2018, 227, 218–246. [Google Scholar] [CrossRef]

- Qu, M.; Hou, J.; Qi, P.; Zhao, F.; Ma, S.; Churchwell, L.; Wang, Q.; Li, H.; Yang, T. Experimental study of fluid behaviors from water and nitrogen floods on a 3-D visual fractured-vuggy model. J. Pet. Sci. Eng. 2018, 166, 871–879. [Google Scholar] [CrossRef]

- Akbari Aghdam, K.; Moghaddas, J.S.; Moradi, B.; Dabiri, M.; Hassanzadeh, M. Maximizing the Oil Recovery Through Miscible Water Alternating Gas (WAG) Injection in an Iranian Oil Reservoir. Pet. Sci. Technol. 2013, 31, 2431–2440. [Google Scholar] [CrossRef]

- Tafty, M.F.; Masihi, M.; Momeni, A. Recovery improvement using water and gas injection scenarios. Pet. Sci. Technol. 2011, 29, 290–300. [Google Scholar] [CrossRef]

- Panjalizadeh, H.; Alizadeh, A.; Ghazanfari, M.; Alizadeh, N. Optimization of the WAG injection process. Pet. Sci. Technol. 2015, 33, 294–301. [Google Scholar] [CrossRef]

- Sadeghnejad, S.; Manteghian, M.; Ruzsaz, H. Simulation Optimization of Water Alternating Gas (WAG) Process under Operational Constraints: A Case Study in the Persian Gulf. Sci. Iran. 2019, 26, 3431–3446. [Google Scholar] [CrossRef]

- Bu, X.; Wang, L.; Zhu, L.; Huang, C.; Zhu, X. Characteristics and reservoir accumulation model of Ordovician fault-controlled fractured-vuggy reservoirs in Shunbei oil and gas field. Tarim Basin Lithol. Reserv. 2023, 35, 152–160. [Google Scholar]

- Wang, Q.; Jiang, H.; Shuoliang, W.; Wang, D.; Bao, R.; Zhang, J.; Li, J. A novel method for modeling oil-water two-phase flow in fractured-vuggy carbonate reservoirs considering fluid vertical equilibrium mechanism. J. Pet. Sci. Eng. 2022, 216, 110753. [Google Scholar] [CrossRef]

| Parameter | C3 Fractured-Vuggy Unit | C5 Fractured-Vuggy Unit | C7 Fractured-Vuggy Unit |

|---|---|---|---|

| Geological reserves/m3 | 106,140 | 870,442 | 3,480,383 |

| Current reservoir pressure/MPa | 61 | 62 | 43 |

| Rock compressibility/kPa−1 | 4.5 × 10−7 | 4.5 × 10−7 | 4.5 × 10−7 |

| Average oil saturation | 0.098 | 0.440 | 0.904 |

| Vug porosity | 0.1226 | 0.1968 | 0.1524 |

| Fracture porosity | 0.0312 | 0.0220 | 0.0412 |

| Vug permeability/mD | 10,000 | 500 | 500 |

| Fracture permeability/mD | 59.17 | 500 | 125.83 |

| Remaining Oil Distribution | Karst Pattern | Development Strategy | Typical Fractured-Vuggy Unit | Remaining Oil Distribution | Karst Pattern | Development Strategy | Typical Fractured-Vuggy Unit |

|---|---|---|---|---|---|---|---|

| Interwell oil trap type | Bedding karst | N2 huff-n-puff | C1 | Attic type | Platform margin overlay and fault- controlled karst | Periodic gas injection | C4 |

| Bedding karst | WAG injection | C3 | Fault-controlled karst | N2 huff-n-puff | C8 | ||

| Local blocking type | Bedding karst | Periodic water injection | C2 | Upper Continuous type | Fault-controlled karst | Periodic water injection | C6 |

| Platform margin overlay and fault-controlled karst | N2 huff-n-puff | C5 | Fault-controlled karst | Periodic water or gas injection | C7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Wang, Q.; Yao, C.; Chen, F.; Wang, Q.; Zhang, J. Optimization of Development Strategies and Injection-Production Parameters in a Fractured-Vuggy Carbonate Reservoir by Considering the Effect of Karst Patterns: Taking C Oilfield in the Tarim Basin as an Example. Energies 2025, 18, 319. https://doi.org/10.3390/en18020319

Li M, Wang Q, Yao C, Chen F, Wang Q, Zhang J. Optimization of Development Strategies and Injection-Production Parameters in a Fractured-Vuggy Carbonate Reservoir by Considering the Effect of Karst Patterns: Taking C Oilfield in the Tarim Basin as an Example. Energies. 2025; 18(2):319. https://doi.org/10.3390/en18020319

Chicago/Turabian StyleLi, Mengqin, Qi Wang, Chao Yao, Fangfang Chen, Qinghong Wang, and Jing Zhang. 2025. "Optimization of Development Strategies and Injection-Production Parameters in a Fractured-Vuggy Carbonate Reservoir by Considering the Effect of Karst Patterns: Taking C Oilfield in the Tarim Basin as an Example" Energies 18, no. 2: 319. https://doi.org/10.3390/en18020319

APA StyleLi, M., Wang, Q., Yao, C., Chen, F., Wang, Q., & Zhang, J. (2025). Optimization of Development Strategies and Injection-Production Parameters in a Fractured-Vuggy Carbonate Reservoir by Considering the Effect of Karst Patterns: Taking C Oilfield in the Tarim Basin as an Example. Energies, 18(2), 319. https://doi.org/10.3390/en18020319