Gas Injection Gravity Miscible Displacement Development of Fractured-Vuggy Volatile Oil Reservoir in the Fuman Area of the Tarim Basin

Abstract

1. Introduction

2. Regional Geological Overview

3. Reservoir Characteristics

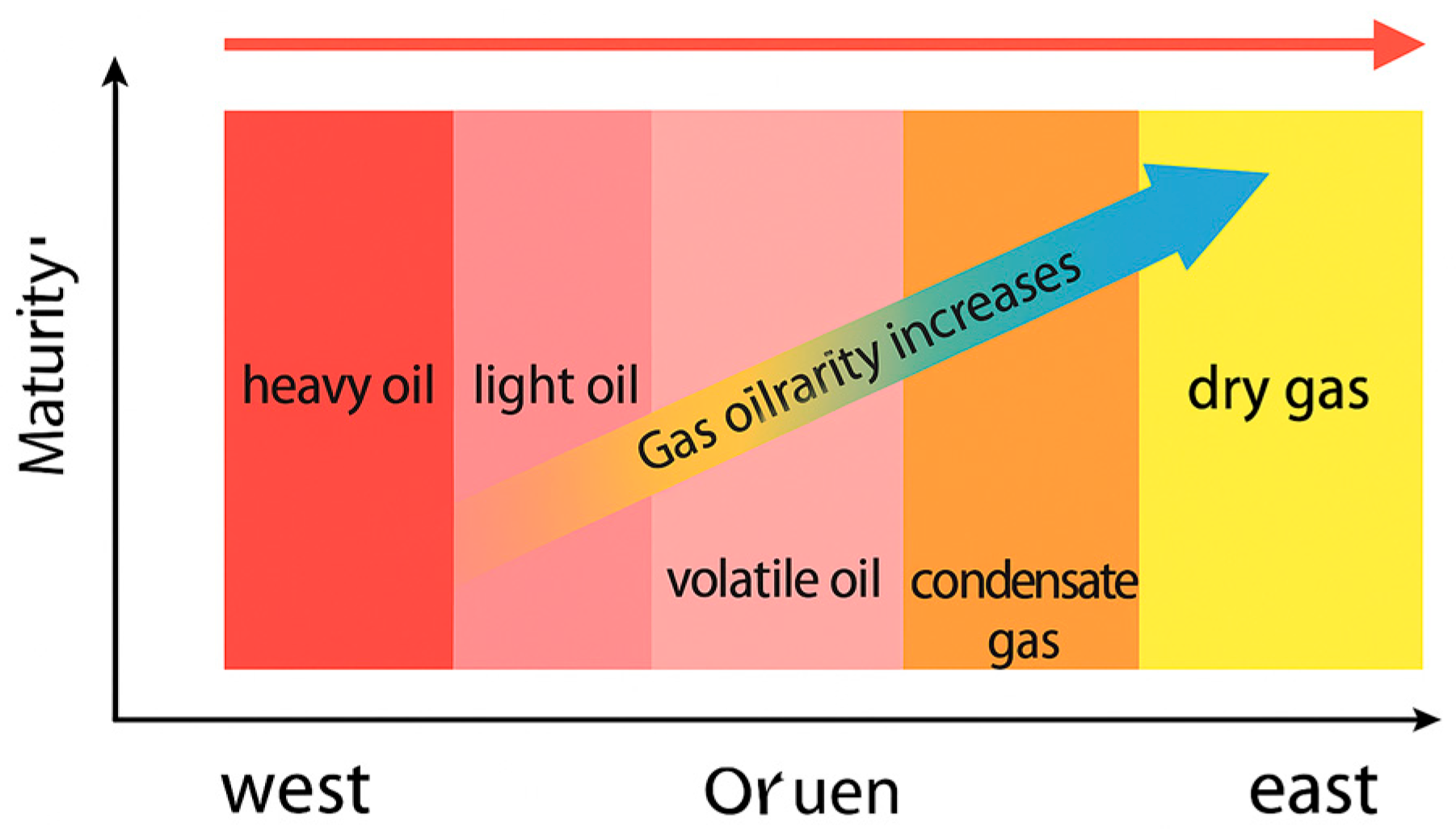

3.1. Crude Oil Characteristics

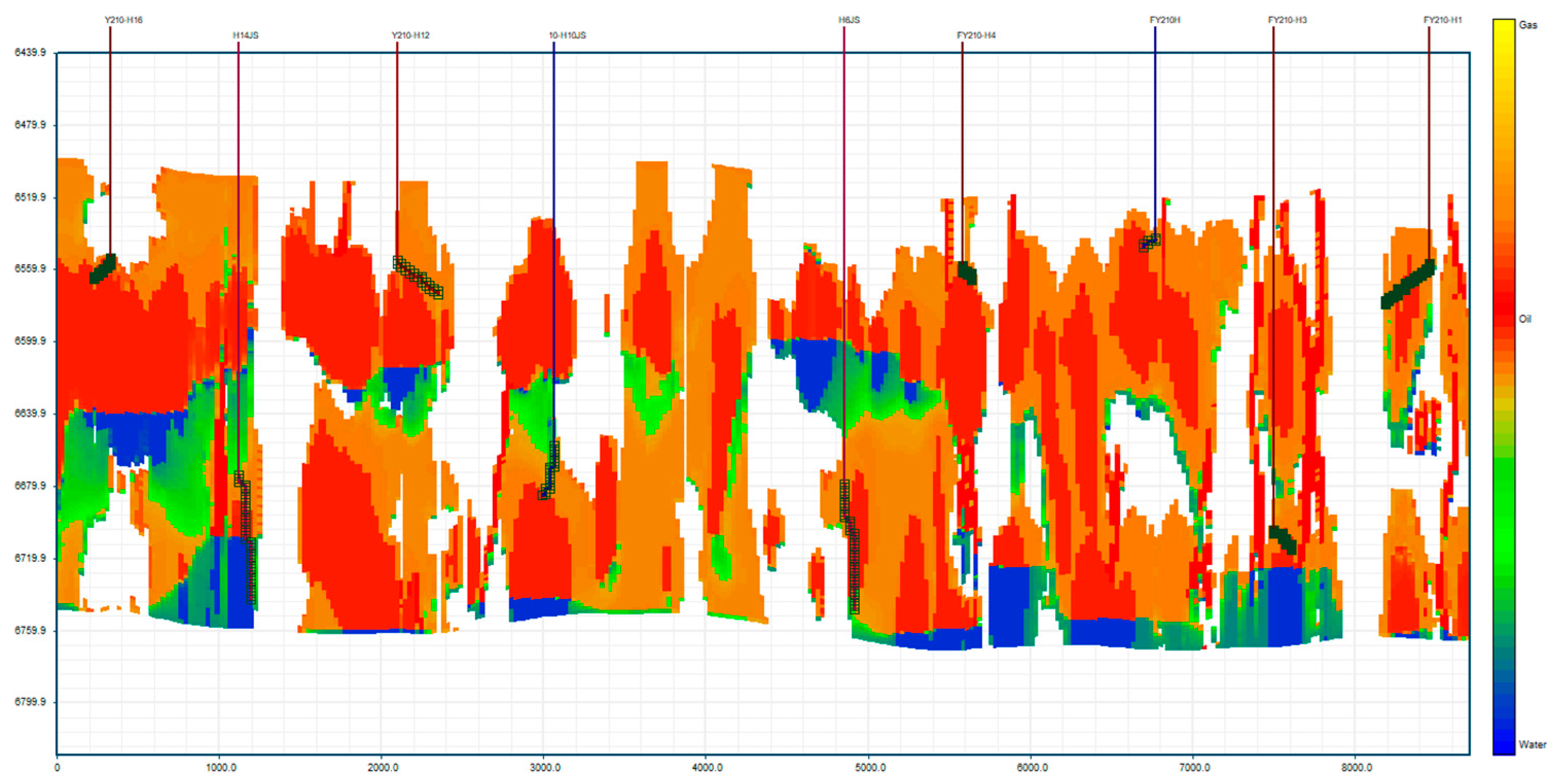

3.2. Reservoir Characteristics and Distribution

4. Materials and Methods

4.1. Experimental Equipment and Calibration

4.2. Reservoir Condition Simulation

4.3. Core Samples

4.4. Experimental Design

4.5. Data Acquisition and Processing

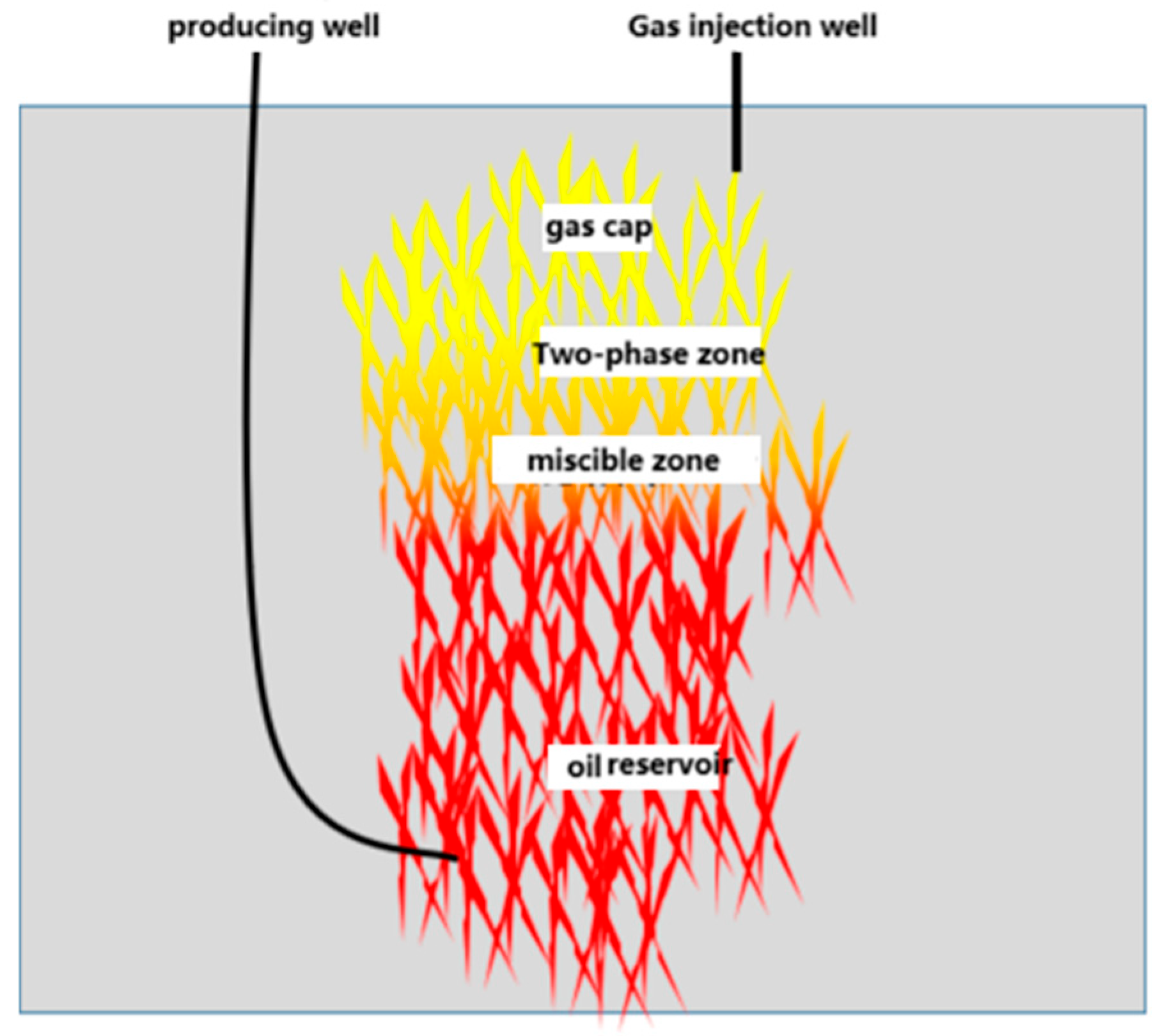

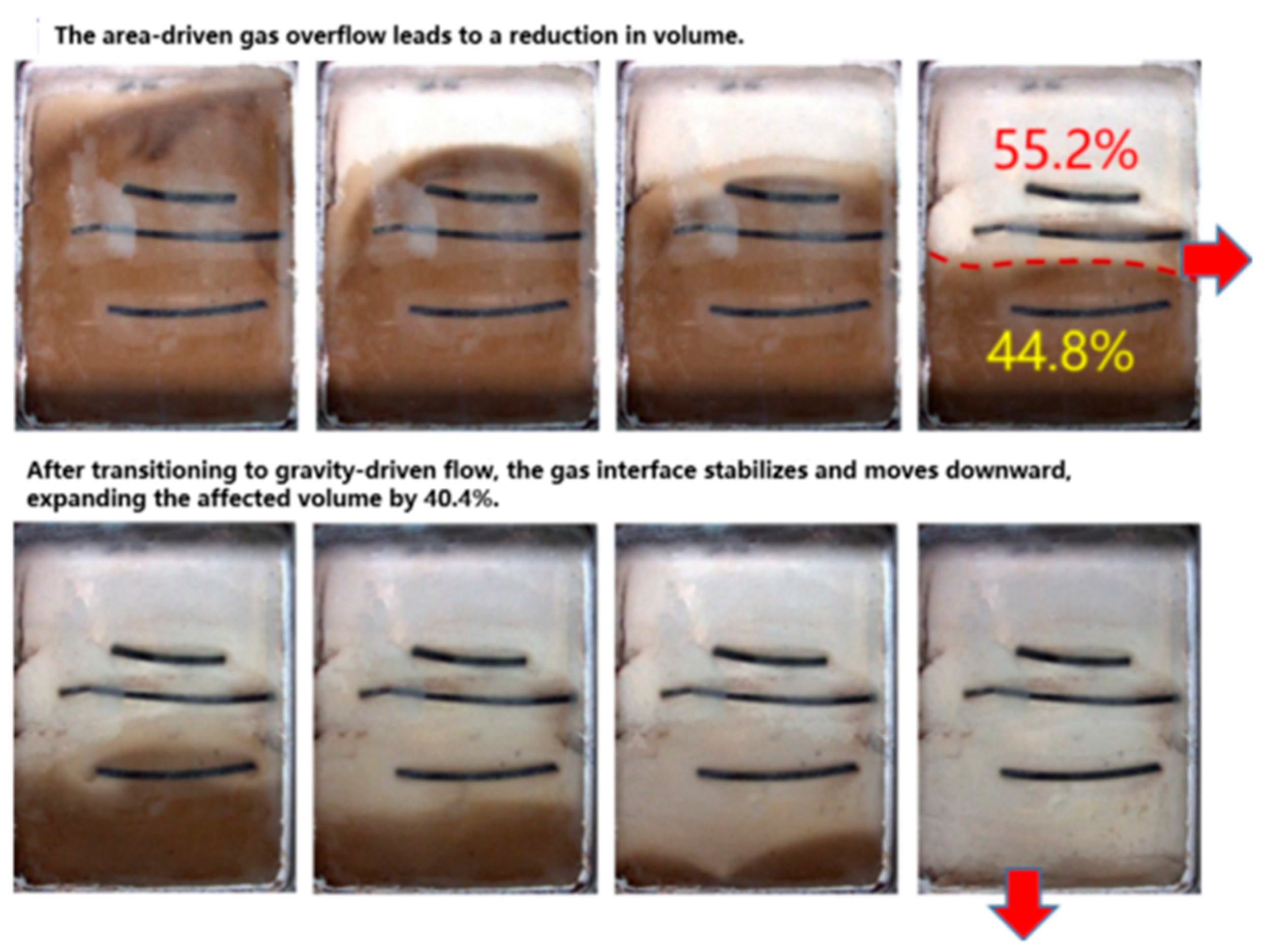

5. Mechanisms of Enhanced Oil Recovery Through Gas Injection Gravity Miscible Displacement

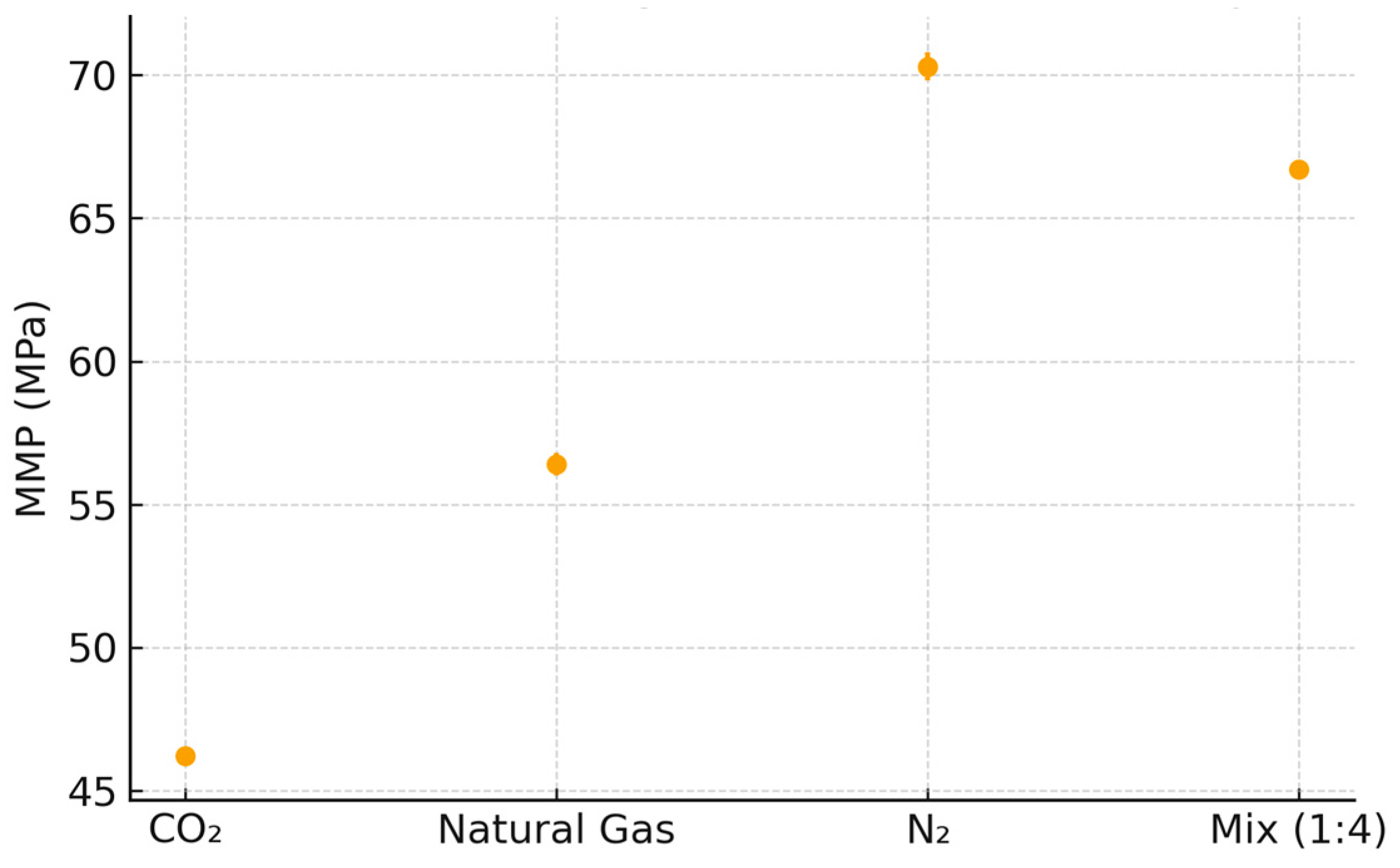

5.1. Evaluation of Injection Gases

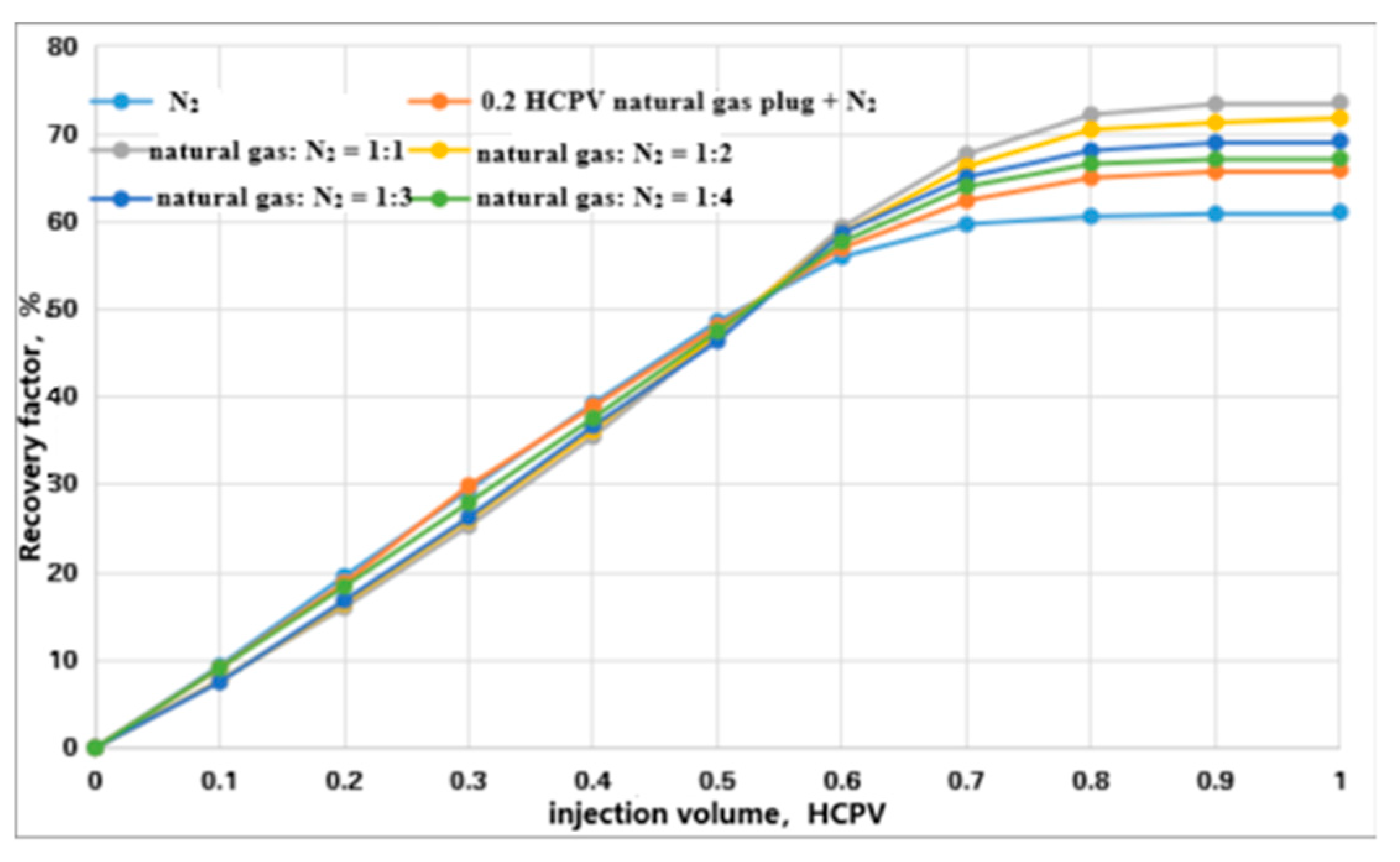

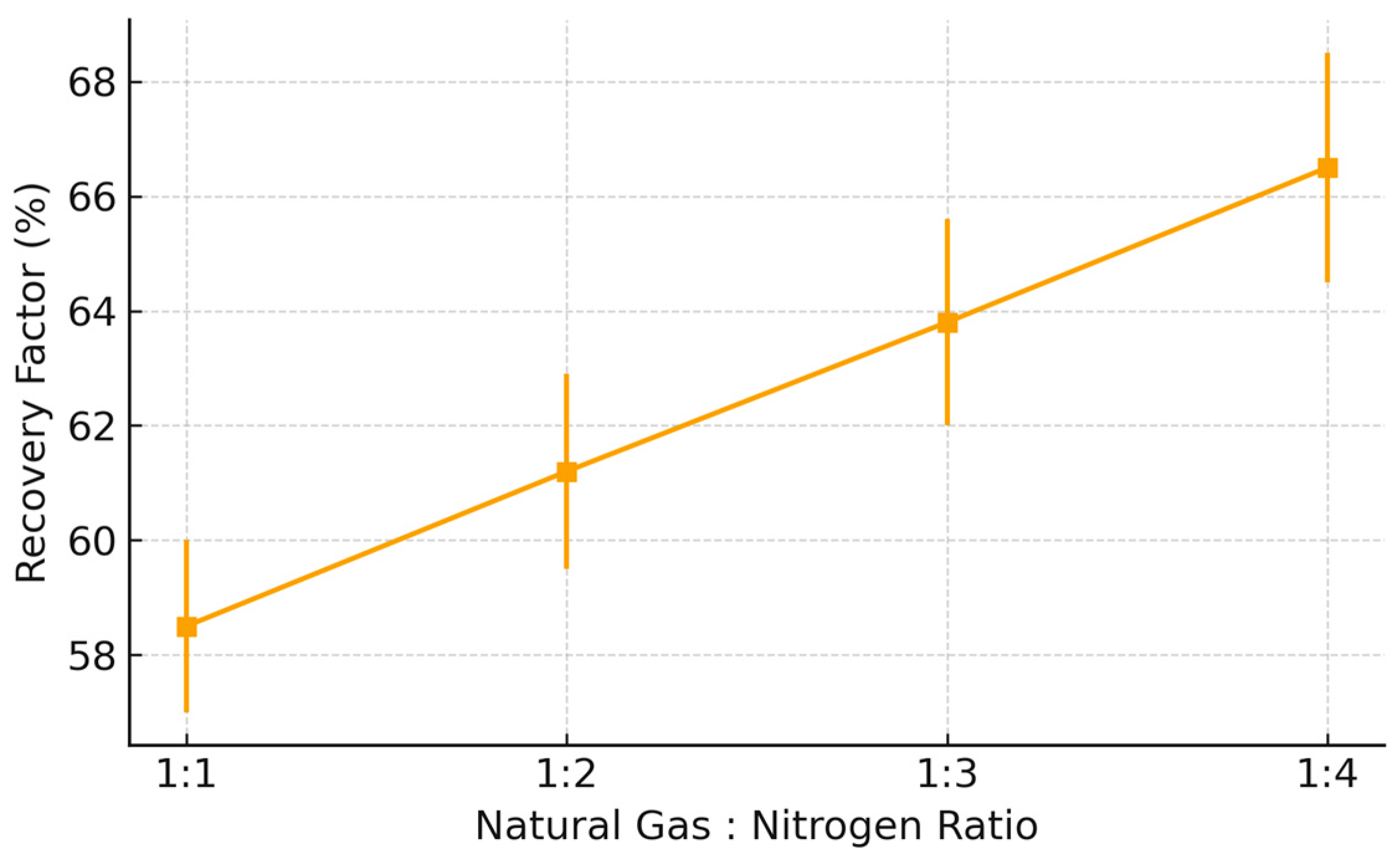

5.2. Optimal Selection of Gas Injection Medium

5.3. Gas Injection Method

5.4. Gas Injection Rate

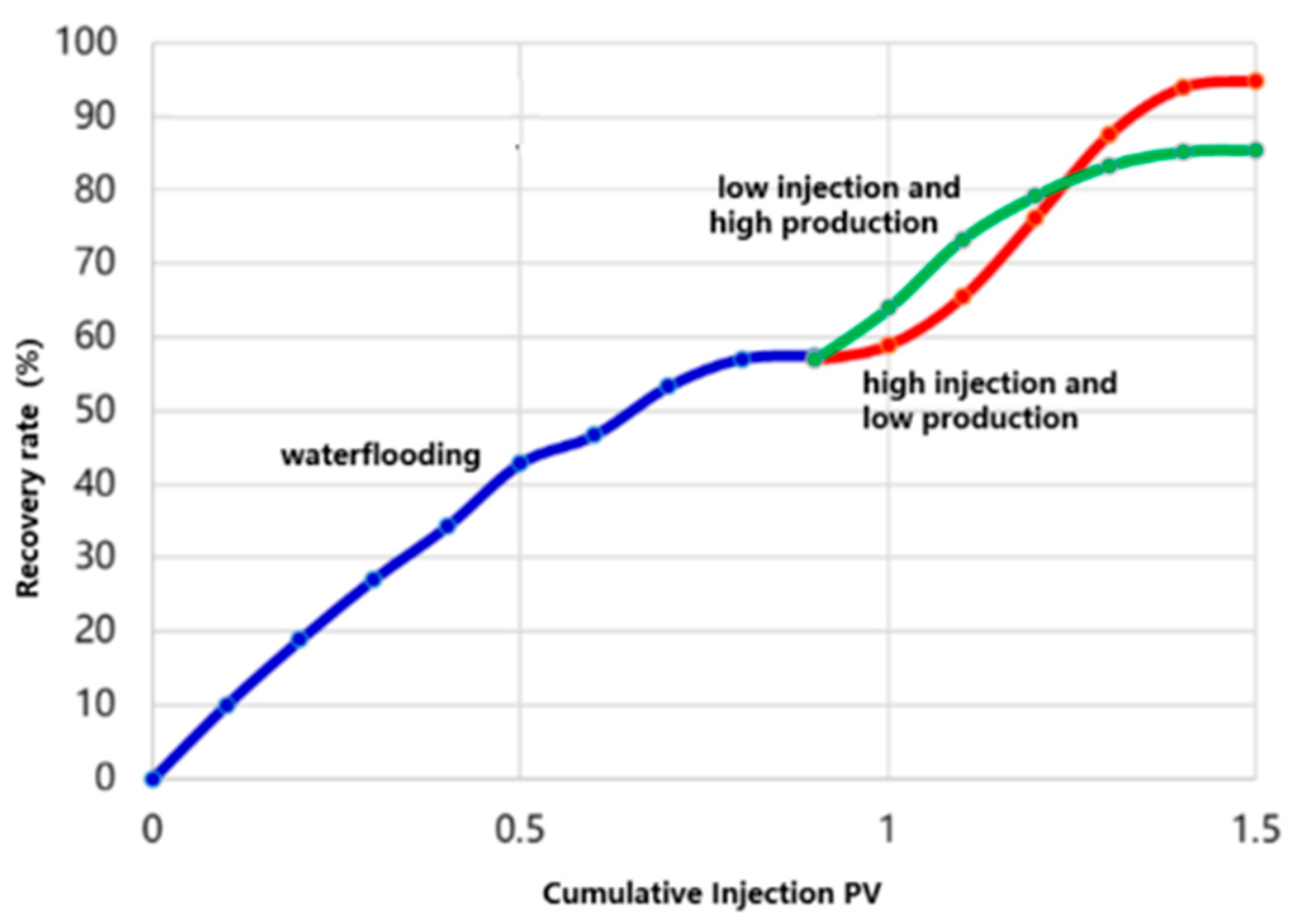

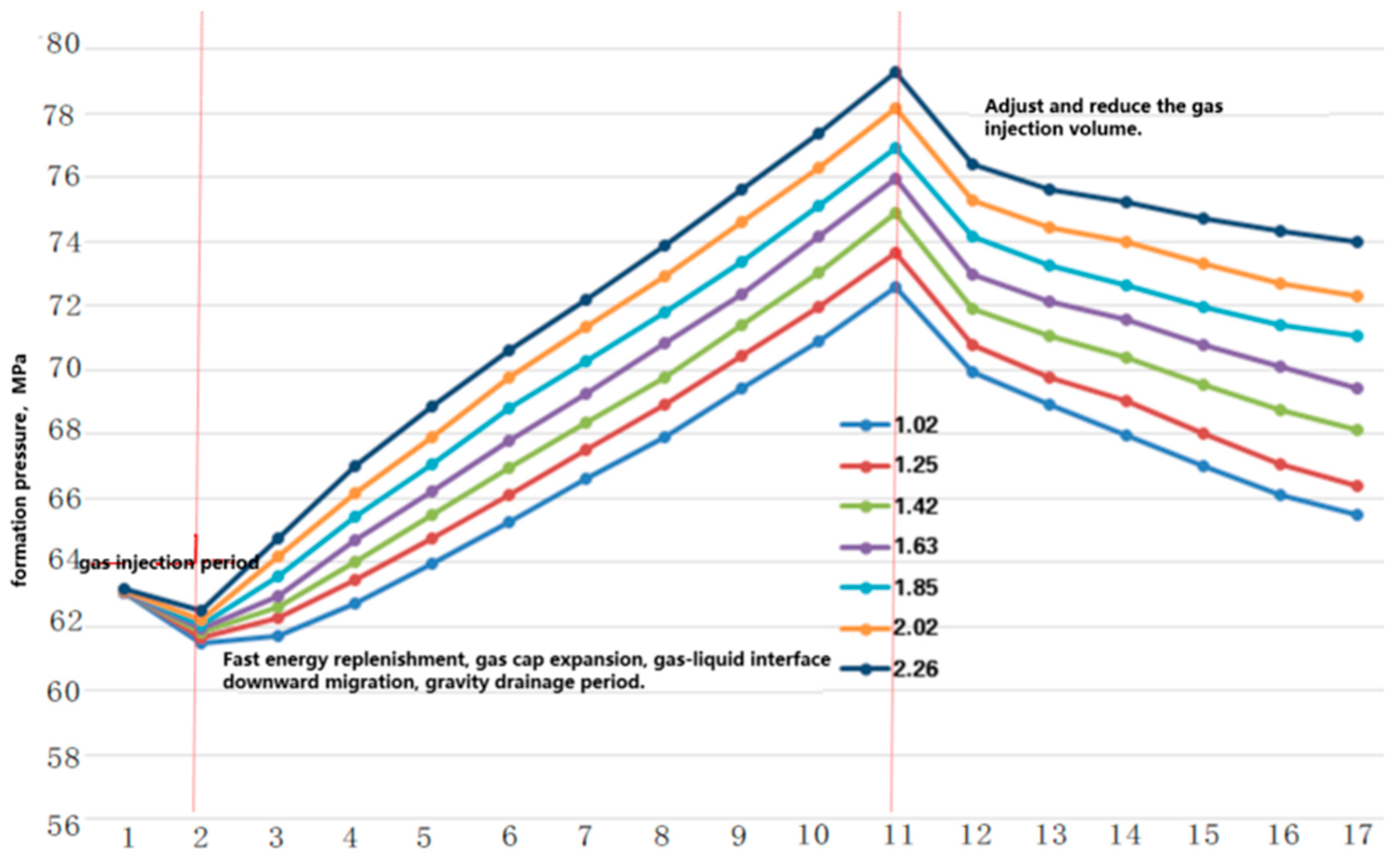

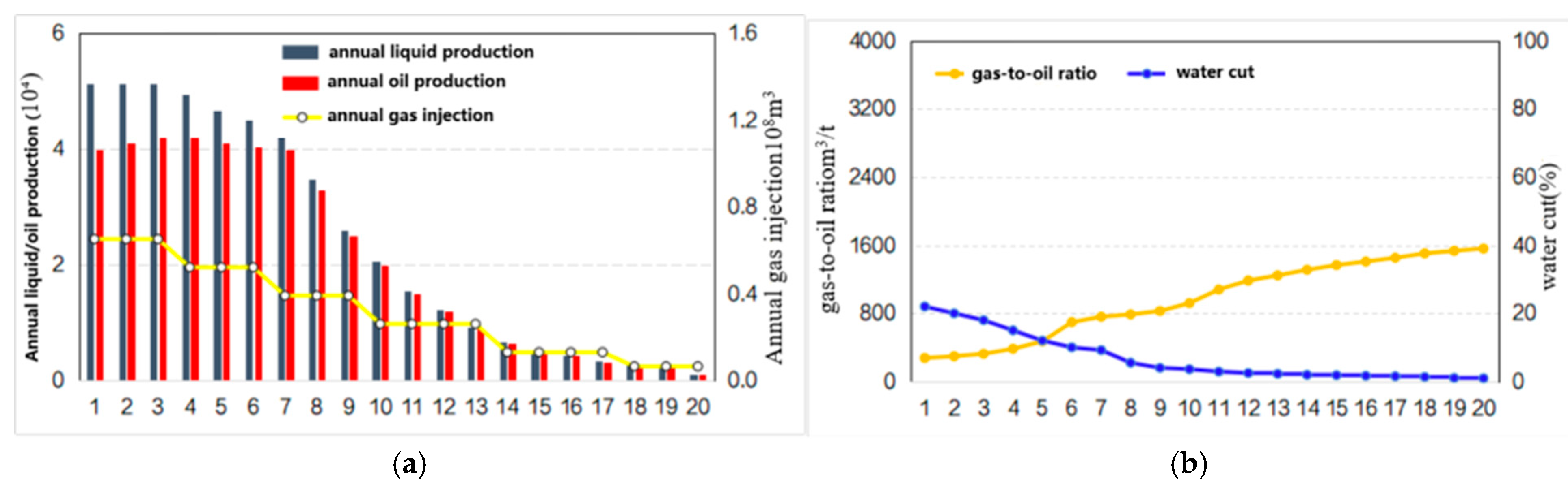

5.5. Injection–Production Ratio

5.6. Impact of Gas Injection Gravity-Enhanced Miscible Displacement on Recovery Efficiency

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhu, Y.; Zhang, Y.; Zhao, X.; Xie, Z.; Wu, G.; Li, T.; Yang, S.; Kang, P. The Fault Effects on the Oil Migration in the Ultra-Deep Fuman Oilfield of the Tarim Basin, NW China. Energies 2022, 15, 5789. [Google Scholar] [CrossRef]

- Zhu, G.; Milkov, A.V.; Li, J.; Xue, N.; Chen, Y.; Hu, J.; Li, T.; Zhang, Z.; Chen, Z. Deepest oil in Asia: Characteristics of petroleum system in the Tarim basin, China. J. Pet. Sci. Eng. 2021, 199, 108246. [Google Scholar] [CrossRef]

- He, Y.; Liu, Y.; Chen, W.; Chi, L.; He, Y.; Li, H.; Sun, Y.; Wang, L. Evaluating and study of natural gas injecting in Shunbei-1 block fault-controlled fractured-cavity type reservoir. Front. Earth Sci. 2024, 12, 1399921. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, J.; Liu, X.; Zhao, H.; Ren, D.; Qi, Y.; Yuan, Y.; Kang, Q. Influence of Aspect Ratio of Migration Space on Gas Migration and Accumulation Mechanisms of Different Types of Gas Reservoirs. Nat. Resour. Res. 2025, 34, 427–457. [Google Scholar] [CrossRef]

- Zhijiang, K.; Yun, Z. Key Technologies for Oil and Gas Development from Deep Carbonate Fractured-Vuggy Reservoirs. J. Immunol. Res. Rep. 2023, 123, 2–11. [Google Scholar] [CrossRef]

- Zhao, M.; Xin, X.; Yu, G.; Hu, R.; Gong, Y. Mechanistic study and optimization of high water cut phase management strategies in fracture-vuggy carbonate reservoirs with bottom water. Processes 2023, 11, 3135. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, Y.; Chen, F.; Li, M.; Wen, Z.; Luo, X.; Ding, Z.; Li, B.; Xue, Y. Hydrocarbon fluid evolution and accumulation process in ultradeep reservoirs of the northern Fuman Oilfield, Tarim Basin. Front. Earth Sci. 2024, 12, 1399595. [Google Scholar] [CrossRef]

- Chun, L.I.; Zhongshun, M.I.N.; Haiyan, H.E.; Jie, L.I.U.; Kun, T.U.; Haitao, W.U. New trend and development suggestions for change of underground gas storage sites in China. Pet. Drill. Tech. 2024, 52, 153–158. [Google Scholar] [CrossRef]

- Zhou, F.; Fang, B.; Zhang, Y.T.; Zhang, Q.; Ma, X.P.; Zhao, L.F.; Peng, Y.C.; Li, M.Q.; Xiao, C.Y.; Jiao, Y.W. A New Method for Water Drive Indication Curve Analysis of Ultra-Deep Fracture-Caved Carbonate Reservoirs: A Case Study of Fuman Reservoir in Tarim Basin. In Proceedings of the International Field Exploration and Development Conference, Xi’an, China, 12–14 September 2024; Springer Nature: Singapore, 2024; pp. 871–885. [Google Scholar]

- Xuewen, Y.A.N.G.; Rujun, W.A.N.G.; Xingliang, D.E.N.G.; Shiyin, L.I.; Chao, Y.A.O. Theoretical exploration of water injection gravity flooding oil in ultra-deep fault-controlled fractured-cavity carbonate reservoirs. Pet. Explor. Dev. 2022, 49, 133–143. [Google Scholar]

- Zhang, Y.; Lin, C.; Ren, L.; Sun, C.; Li, J.; Wang, Z.; Xu, G. Study on Connectivity of Fractured-Vuggy Marine Carbonate Reservoirs Based on Dynamic and Static Methods. J. Mar. Sci. Eng. 2025, 13, 435. [Google Scholar] [CrossRef]

- Wang, Q. Origin of gas condensate reservoir in Fuman oilfield, Tarim basin, NW China. Pet. Explor. Dev. 2023, 50, 1295–1307. [Google Scholar] [CrossRef]

- Guo, W.; Huang, Z.; Li, A.; An, G.; Cui, S. Visual experiments of bottom water and multi-well water and gas injection flooding for fault-controlled fractured-vuggy reservoirs. Phys. Fluids 2023, 35, 083319. [Google Scholar] [CrossRef]

- Wang, J.; Xu, Z.; Liu, J.; Feng, J.; Wang, Q.; Jiao, Y.; Liu, H. Distribution rules of remaining oil by bottom water flooding and potential exploitation strategy in fault-controlled fractured-vuggy reservoirs. Pet. Explor. Dev. 2024, 51, 1271–1286. [Google Scholar] [CrossRef]

- Li, M.; Wang, Q.; Yao, C.; Chen, F.; Wang, Q.; Zhang, J. Optimization of development strategies and injection-production parameters in a fractured-vuggy carbonate reservoir by considering the effect of karst patterns: Taking c oilfield in the tarim basin as an example. Energies 2025, 18, 319. [Google Scholar] [CrossRef]

- Qasem, F.H.; Nashawi, I.S. Simulation and performance prediction of partially naturally fractured reservoirs under solution gas drive primary recovery and gas injection processes. J. Pet. Explor. Prod. Technol. 2024, 14, 1259–1282. [Google Scholar] [CrossRef]

- Dindoruk, B.; Johns, R.; Orr, F.M., Jr. Measurement and modeling of minimum miscibility pressure: A state-of-the-art review. SPE Reserv. Eval. Eng. 2021, 24, 367–389. [Google Scholar] [CrossRef]

- Zhang, Y.; Barrouillet, B.; Skadsem, H.J. Experimental investigation of laminar and turbulent displacement of residual oil film. Sci. Rep. 2023, 13, 21120. [Google Scholar] [CrossRef]

- Wang, R.; Yang, J.; Chang, L.; Zhang, Y.; Sun, C.; Wan, X.; Wu, G.; Bai, B. 3D Modeling of Fracture-Cave Reservoir from a Strike-Slip Fault-Controlled Carbonate Oilfield in Northwestern China. Energies 2022, 15, 6415. [Google Scholar] [CrossRef]

- Zeng, L.; Song, Y.; Han, J.; Han, J.; Yao, Y.; Tan, X.; Li, H. Control of structure and fluid on ultra-deep fault-controlled carbonate fracture-vug reservoirs in the Tarim Basin, NW China. Pet. Explor. Dev. 2025, 52, 143–156. [Google Scholar] [CrossRef]

- LI, Y.; Wu, S.; Hou, J.; Liu, J. Progress and prospects of reservoir development geology. Pet. Explor. Dev. 2017, 44, 603–614. [Google Scholar] [CrossRef]

- Li, X.; Li, J.; Li, L.; Wan, Z.; Liu, Y.; Ma, P.; Zhang, M. Seismic wave field anomaly identification of ultra-deep heterogeneous fractured-vuggy reservoirs: A case study in Tarim Basin, China. Appl. Sci. 2021, 11, 11802. [Google Scholar] [CrossRef]

- Li, F.; Lin, C.; Ren, L.; Zhu, Y.; Guan, B. Connectivity and residual oil distribution patterns of fractured-vuggy karst reservoirs in strike-slip fault zone: A case study of the Tarim Basin. Oil Gas Geol. 2025, 46, 315–334. [Google Scholar]

- Zhang, S.; Zhang, B. Adjustment and alteration of hydrocarbon reservoirs during the late Himalayan period, Tarim Basin, NW China. Pet. Explor. Dev. 2012, 39, 712–724. [Google Scholar] [CrossRef]

- Feng, Y.X.; Wang, X.C.; Yuan, X.M.; Lu, Z.Y.; Lu, Y.F. Optimal Design of Gas Injection and Recovery in Ultra-Deep Carbonate Reservoir-Taking Fuyuan 210 Block as an Example. In Proceedings of the International Field Exploration and Development Conference, Xi’an, China, 12–14 September 2024; Springer Nature: Singapore, 2024; pp. 973–987. [Google Scholar]

- Almobarak, M.; Wu, Z.; Zhou, D.; Fan, K.; Liu, Y.; Xie, Q. A review of chemical-assisted minimum miscibility pressure reduction in CO2 injection for enhanced oil recovery. Petroleum 2021, 7, 245–253. [Google Scholar] [CrossRef]

- Ozowe, W.; Daramola, G.O.; Ekemezie, I.O. Recent advances and challenges in gas injection techniques for enhanced oil recovery. Magna Sci. Adv. Res. Rev. 2023, 9, 168–178. [Google Scholar] [CrossRef]

- Kasala, E.E.; Wang, J.; Majid, A.; Nadege, M.N.; Nyakilla, E.E. Advancement Perspectives in Enhancing Heavy Oil Recovery Using N2-and CO2-Assisted Steam Injection: Exploring Molecular Interactions to Field Applications. Energy Fuels 2025, 39, 10200–10244. [Google Scholar] [CrossRef]

- Chen, X.; Mohanty, K.K. Pore-scale mechanisms of immiscible and miscible gas injection in fractured carbonates. Fuel 2020, 275, 117909. [Google Scholar] [CrossRef]

- Qu, M.; Hou, J.; Zhao, F.; Song, Z.; Ma, S.; Wang, Q.; Li, M.; Yang, M. 3-D visual experiments on fluid flow behavior of water flooding and gas flooding in fractured-vuggy carbonate reservoir. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 9–11 October 2017; SPE: Washington, DC, USA, 2017; p. D031S043R001. [Google Scholar]

| Injection Medium | Advantageous Conditions | Limiting Factors |

|---|---|---|

| Carbon Dioxide (Restricted gas supply) | ① Can achieve miscibility with crude oil, enhancing oil recovery efficiency. ② Easily dissolves in crude oil, reducing its viscosity and flow resistance. | Restricted gas supply (remote sources, insufficient volume), high surface investment, poor gravity segregation, high gas consumption, and pipeline corrosion are issues. |

| Natural Gas (Non-economic) | ① It can form a miscible phase with crude oil, improving oil displacement efficiency; ② Rich practical experience in Yaha and Donghe can be referenced. | 1. High surface investment required, insufficient gas supply, with significant economic value of natural gas; 2. Neighboring Shunbei area has already conducted natural gas injection experiments, with limited experimental scope. |

| Nitrogen (Non-miscible) | ① In near-miscible state, the small volume coefficient is advantageous for energy supplementation; ② The on-site preparation of nitrogen and injection technology is well-develop; ③ Inert gas, with low operational risk. | The cost of dispersed gas injection is high, and there are corrosion issues with the tubing. |

| Nitrogen-Mixed Natural Gas | ① Can be miscible with crude oil, improving oil recovery efficiency; ② Requires less natural gas, with objective economic benefits; ③ Significant for major development trials, exploring the first nationwide application of nitrogen miscible gravity displacement effects. | The surface pipeline network is complex. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, X.; Zhou, W.; Liu, Z.; Ding, Y.; Zhang, C.; Lian, L. Gas Injection Gravity Miscible Displacement Development of Fractured-Vuggy Volatile Oil Reservoir in the Fuman Area of the Tarim Basin. Energies 2025, 18, 5317. https://doi.org/10.3390/en18195317

Deng X, Zhou W, Liu Z, Ding Y, Zhang C, Lian L. Gas Injection Gravity Miscible Displacement Development of Fractured-Vuggy Volatile Oil Reservoir in the Fuman Area of the Tarim Basin. Energies. 2025; 18(19):5317. https://doi.org/10.3390/en18195317

Chicago/Turabian StyleDeng, Xingliang, Wei Zhou, Zhiliang Liu, Yao Ding, Chao Zhang, and Liming Lian. 2025. "Gas Injection Gravity Miscible Displacement Development of Fractured-Vuggy Volatile Oil Reservoir in the Fuman Area of the Tarim Basin" Energies 18, no. 19: 5317. https://doi.org/10.3390/en18195317

APA StyleDeng, X., Zhou, W., Liu, Z., Ding, Y., Zhang, C., & Lian, L. (2025). Gas Injection Gravity Miscible Displacement Development of Fractured-Vuggy Volatile Oil Reservoir in the Fuman Area of the Tarim Basin. Energies, 18(19), 5317. https://doi.org/10.3390/en18195317