Low-Carbon Hydrogen Production and Use on Farms: European and Global Perspectives

Abstract

1. Introduction

2. The State of Development of the Hydrogen Economy

2.1. The Context of the Global Energy Transition

2.2. Analysis of the Economic Effects of Using Hydrogen Energy

2.3. Global Demand for Low-Carbon Hydrogen by 2050

2.4. European Hydrogen Initiatives—Practical Implementation and Development Strategies

2.4.1. From Strategy to Practice: Dutch Agricultural Hydrogen Model

2.4.2. HyPErFarm Initiative—Belgian, Danish and German Approach to Hydrogen Farming

2.4.3. Green Hydrogen Production in the Countries of South-Eastern Europe and the Black Sea Basin

2.4.4. Poland’s Position on the European Hydrogen Market

2.5. The Role of Low-Emission Hydrogen in Decarbonizing the Economy

3. Low-Emission Hydrogen Production Methods

3.1. Definition of Low-Carbon Hydrogen

3.2. Electrolysis Using Renewable Energy

3.3. Steam Reforming of Biogas and Biomethane

3.4. Biomass Fermentation, Pyrolysis and Gasification

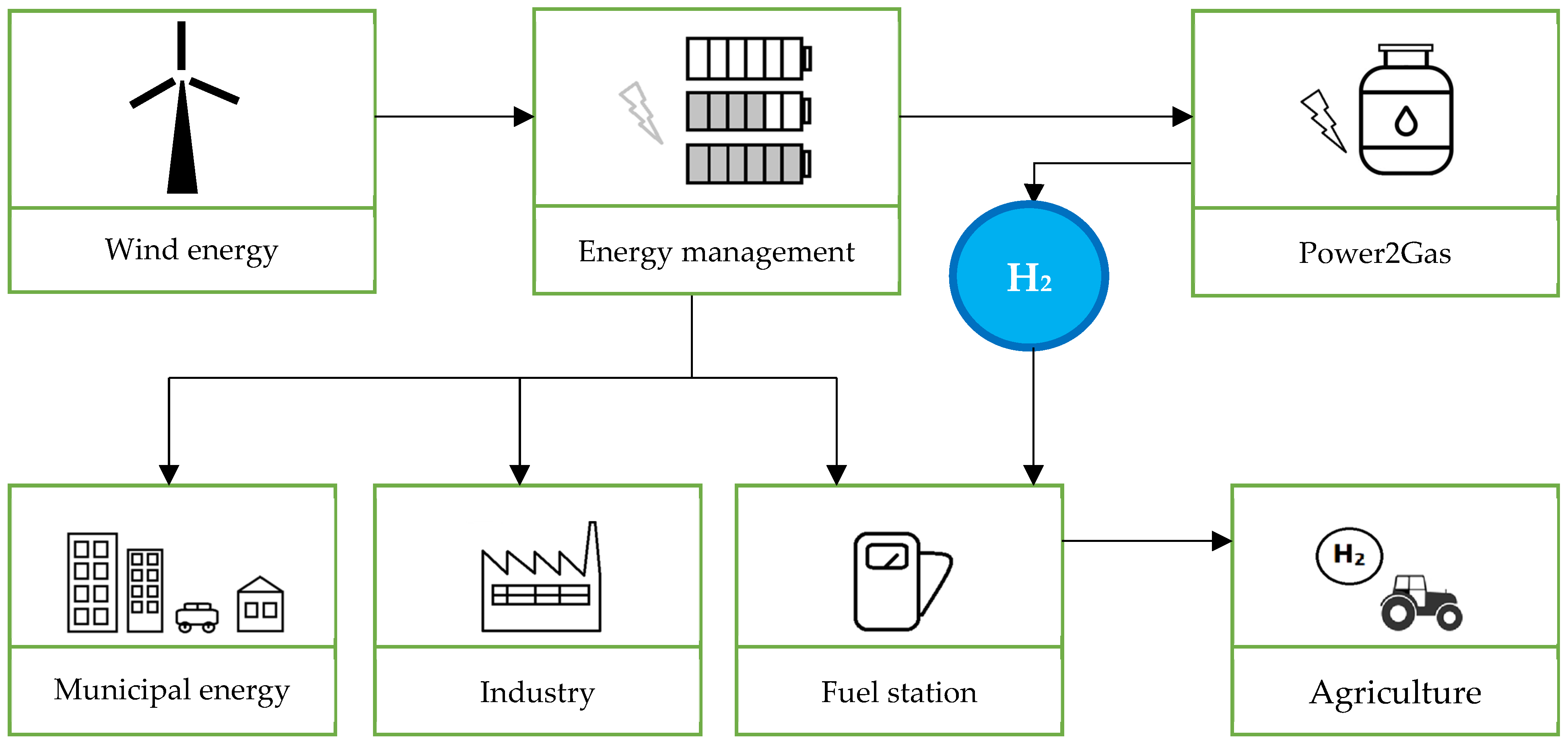

4. The Potential of Low-Emission Hydrogen Production on Farms

4.1. Low-Emission Hydrogen Production in the Context of Agriculture

4.2. Low-Carbon Hydrogen Applications in Agriculture

4.2.1. Drive of Agricultural Machines and Vehicles

4.2.2. Heating of Farm Buildings

4.2.3. Fertilizer Production

4.2.4. Energy Storage and Grid Stabilization

5. Integrated Challenges, Opportunities, and Support Mechanisms for Agricultural Hydrogen Systems

5.1. Durability of Electrolyzers

5.2. Economic Analysis and Production Costs of Hydrogen

5.3. Legal Framework and Hydrogen Certification Standards

5.4. Hydrogen Infrastructure and Rural System Planning

5.5. Environmental, Social Impacts, and Rural Energy Community Development

5.6. Financial Support and Development Programs for Hydrogen Technologies

6. Discussion

7. Conclusions and Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Directive-EU—2024/1788-EN-EUR-Lex. Available online: https://eur-lex.europa.eu/eli/dir/2024/1788/oj/eng (accessed on 8 September 2025).

- IEA Renewables 2024—Analysis. Available online: https://www.iea.org/reports/renewables-2024 (accessed on 21 July 2025).

- IEA Levelised Cost of Electricity Calculator—Data Tools. Available online: https://www.iea.org/data-and-statistics/data-tools/levelised-cost-of-electricity-calculator (accessed on 21 July 2025).

- IRENA. Off-Grid Renewable Energy Statistics 2023; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2023. [Google Scholar]

- IRENA; CPI. Global Landscape of Renewable Energy Finance 2023; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2023. [Google Scholar]

- Bett, A.; Henning, H.-M. Energy Research at the Fraunhofer Institute for Solar Energy Systems (2023). Energy Technol. 2023, 11, 2301092. [Google Scholar] [CrossRef]

- Hydrogen Council. Hydrogen Insights December 2023; Hydrogen Council: Brussels, Belgium, 2023. [Google Scholar]

- Rzeczycki, M. Zapotrzebowanie na wodór niskoemisyjny wzrośnie do 2050 r. aż 400-krotnie. Polski Instytut Ekonomiczny, 3 January 2024. [Google Scholar]

- Pilszyk, M.; Juszczak, A.; Gonera, Ł. Wyścig po Wodór: Państwa i Ich Strategie Wodorowe; Policy paper; Polski Instytut Ekonomiczny: Warszawa, Poland, 2023; ISBN 978-83-67575-58-4. [Google Scholar]

- Ayodele, T.R.; Munda, J.L. Potential and Economic Viability of Green Hydrogen Production by Water Electrolysis Using Wind Energy Resources in South Africa. Int. J. Hydrogen Energy 2019, 44, 17669–17687. [Google Scholar] [CrossRef]

- Shin, H.; Jang, D.; Lee, S.; Cho, H.-S.; Kim, K.-H.; Kang, S. Techno-Economic Evaluation of Green Hydrogen Production with Low-Temperature Water Electrolysis Technologies Directly Coupled with Renewable Power Sources. Energy Convers. Manag. 2023, 286, 117083. [Google Scholar] [CrossRef]

- Yang, B.; Zhang, R.; Shao, Z.; Zhang, C. The Economic Analysis for Hydrogen Production Cost towards Electrolyzer Technologies: Current and Future Competitiveness. Int. J. Hydrogen Energy 2023, 48, 13767–13779. [Google Scholar] [CrossRef]

- Morgan, E. Hydrogen Production Costs Trends 2025. Available online: https://montel.energy/resources/blog/hydrogen-production-cost-trends-2025 (accessed on 10 September 2025).

- Alabbadi, A.A.; Obaid, O.A.; AlZahrani, A.A. A Comparative Economic Study of Nuclear Hydrogen Production, Storage, and Transportation. Int. J. Hydrogen Energy 2024, 54, 849–863. [Google Scholar] [CrossRef]

- Navarrete, A.; Zhou, Y. The Price of Green Hydrogen: How and Why We Estimate Future Production Costs. International Council on Clean Transportation, 20 May 2024. [Google Scholar]

- IEA. The Future of Hydrogen—Analysis. Available online: https://www.iea.org/reports/the-future-of-hydrogen (accessed on 10 September 2025).

- He, H.; Huang, Y.; Nakadomari, A.; Masrur, H.; Krishnan, N.; Hemeida, A.M.; Mikhaylov, A.; Senjyu, T. Potential and Economic Viability of Green Hydrogen Production from Seawater Electrolysis Using Renewable Energy in Remote Japanese Islands. Renew. Energy 2023, 202, 1436–1447. [Google Scholar] [CrossRef]

- Kost, C.; Muller, P.; Sepulveda Schweiger, J.; Fluri, V.; Thomsen, J. Levelized Cost of Electricity—Renewable Energy Technologies. Available online: https://www.ise.fraunhofer.de/en/publications/studies/cost-of-electricity.html (accessed on 10 September 2025).

- Halder, P.; Babaie, M.; Salek, F.; Haque, N.; Savage, R.; Stevanovic, S.; Bodisco, T.A.; Zare, A. Advancements in Hydrogen Production, Storage, Distribution and Refuelling for a Sustainable Transport Sector: Hydrogen Fuel Cell Vehicles. Int. J. Hydrogen Energy 2024, 52, 973–1004. [Google Scholar] [CrossRef]

- Lu, X.; Krutoff, A.-C.; Wappler, M.; Fischer, A. Key Influencing Factors on Hydrogen Storage and Transportation Costs: A Systematic Literature Review. Int. J. Hydrogen Energy 2025, 105, 308–325. [Google Scholar] [CrossRef]

- Zhang, X.; Abid, I. Cost-Effective Hydrogen Transport: Analyzing the Economics of Hydrogen Storage Systems. Int. J. Hydrogen Energy 2025, 137, 360–366. [Google Scholar] [CrossRef]

- Ivanova, I. Hydrogen and Agriculture. Available online: https://hydrogenera.eu/tpost/mm78rad441-hydrogen-and-agriculture-fostering-susta (accessed on 10 September 2025).

- Walsh, H. Green Hydrogen Solution for Australian Agriculture, Ready for Investment. evokeAG, 11 May 2022. [Google Scholar]

- Stargate Hydrogen Sustainable Agriculture and Hydrogen. Available online: https://stargatehydrogen.com/blog/hydrogen-on-sustainable-agriculture/ (accessed on 10 September 2025).

- Czekała, W.; Jasiński, T.; Dach, J. Profitability of the Agricultural Biogas Plants Operation in Poland, Depending on the Substrate Use Model. Energy Rep. 2023, 9, 196–203. [Google Scholar] [CrossRef]

- Łukomska, A.; Pulka, J.; Broński, M.; Dach, J. Demand-Driven Biogas Plants in Poland–Potential and Growth Perspectives. J. Ecol. Eng. 2024, 25, 236–248. [Google Scholar] [CrossRef]

- Kusz, D.; Kusz, B.; Wicki, L.; Nowakowski, T.; Kata, R.; Brejta, W.; Kasprzyk, A.; Barć, M. The Economic Efficiencies of Investment in Biogas Plants—A Case Study of a Biogas Plant Using Waste from a Dairy Farm in Poland. Energies 2024, 17, 3760. [Google Scholar] [CrossRef]

- Shrestha, S.; Parajuli, S.; Gorjian, S.; Rodriguez-Couto, S.; Angove, M.J.; Mainali, B.; Paudel, S.R. Scenario Based Techno-Economic Study of Surplus Hydropower-Based Urea Production from Cement Plant Flue-Gas Captured Using Piperazine-Absorption. Energy 2025, 315, 134463. [Google Scholar] [CrossRef]

- Turvill, C. Fertilizer Demand Could Kickstart Green Hydrogen Production—Tech Insights. Available online: https://eepower.com/tech-insights/fertilizer-demand-could-kickstart-green-hydrogen-production/ (accessed on 10 September 2025).

- Fasihi, M.; Weiss, R.; Savolainen, J.; Breyer, C. Global Potential of Green Ammonia Based on Hybrid PV-Wind Power Plants. Appl. Energy 2021, 294, 116170. [Google Scholar] [CrossRef]

- Teng, L.; Yin, P.; Nie, C.; Yan, F.; Zhao, L.; Dang, F.; Luo, Y.; Jiang, L. Research Progress on “Ammonia-Hydrogen” Green Energy Roadmap and Storage & Transportation Technology of Liquid Ammonia. Oil Gas Storage Transp. 2022, 41, 1115–1129. [Google Scholar]

- Sganzerla, W.G.; Buller, L.S.; Mussatto, S.I.; Forster-Carneiro, T. Techno-Economic Assessment of Bioenergy and Fertilizer Production by Anaerobic Digestion of Brewer’s Spent Grains in a Biorefinery Concept. J. Clean. Prod. 2021, 297, 126600. [Google Scholar] [CrossRef]

- Remme, U. Global Hydrogen Review 2024; IEA: Paris, France, 2024. [Google Scholar]

- Open Eyes Woda w Rolnictwie—Szanse i Zagrożenia. Kongres OEES. Available online: https://kongres.oees.pl/woda-w-rolnictwie-szanse-i-zagrozenia/ (accessed on 20 March 2025).

- Olgroup Wodór ma Rozwiązać Problemy Energetyczne w Europie. Available online: https://www.chemiaibiznes.com.pl/artykuly/wodor-ma-rozwiazac-problemy-energetyczne-w-europie (accessed on 23 March 2025).

- Eikeland, P.O.; Inderberg, T.H.J.; Skjærseth, J.B. Against All Odds? Explaining the New Clean Hydrogen Strategy of the European Union 2025. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=5387536 (accessed on 20 September 2025).

- PSEW. Premiera raportu “Zielony wodór z OZEw Polsce” Wodoryzacja polskiej gospodarki tylko przy rozwoju, O.Z.E. Polskie Stowarzyszenie Energetyki Wiatrowej, 8 December 2021. [Google Scholar]

- Invest in Holland. The Netherlands: Fueling a Green Hydrogen Future. NFIA, 5 December 2022.

- Hygro. Hydrogen for Sustainable Agriculture. Available online: https://hy-gro.nl/newsitem/hydrogen-for-sustainable-agriculture (accessed on 23 March 2025).

- Lunenborg, E. Green Hydrogen from Wind Turbine. Available online: https://hygro.nl/project/green-hydrogen-from-hygro-wind-turbine (accessed on 8 September 2025).

- Broen, B. Fieldlab Waterstof in Agri. New Energy Coalition, 15 August 2025. [Google Scholar]

- GH2 Green Hydrogen Organisation. Netherlands. Green Hydrogen Organisation. Available online: http://gh2.org/countries/netherlands (accessed on 23 March 2025).

- HyPErFarm. Pilot Plants. HyPErFarm, 10 December 2022. [Google Scholar]

- KU Leuven. TRANSfarm. Available online: https://set.kuleuven.be/over-ons/groepsdiensten-en-faciliteiten/transfarm (accessed on 23 March 2025).

- Krinner Carport Krinner Agri-Photovoltaik. Available online: https://www.krinner-solar.com/apv (accessed on 23 March 2025).

- Nakomčić Smaragdakis, B.; Brborić, M.; Berežni, I.; Jovović, A. Assessing Green Hydrogen Potential and Utilization for Sustainable Energy Production in Serbia. J. Renew. Sustain. Energy 2024, 16, 062701. [Google Scholar] [CrossRef]

- Bahrii, I.; Riepkin, O.; Kryl, I.; Csaba, H.; Abbasov, R.; Kovach, V. Justification of Global Environmental and Energy Decarbonization Projects of Ukraine, Moldova, Romania and Azerbaijan. Miner. Resour. Ukr. 2023, 2023, 4–11. [Google Scholar] [CrossRef]

- Kryl, I.M.; Paiuk, S.O.; Riepkin, O.O.; Kuzmenko, S.O.; Palamarchuk, V.O.; Svidenko, K.I. Status and Prospects of Renewable Hydrogen Use in Ukraine: Impact on Industry and Decarbonization Pathways. Miner. Resour. Ukr. 2023, 2023, 12–16. [Google Scholar] [CrossRef]

- Kalinowski, M. Grupa Azoty Członkiem Sojuszu na Rzecz Czystego Wodoru. Available online: https://www.tygodnik-rolniczy.pl/uprawa/grupa-azoty-czlonkiem-sojuszu-na-rzecz-czystego-wodoru-2383826 (accessed on 23 March 2025).

- Małek, A.; Karowiec, M.; Jóźwik, K. A Review of Technologies in the Area of Production, Storage and Use of Hydrogen in the Automotive Industry. Arch. Motoryz. 2023, 102, 41–67. [Google Scholar] [CrossRef]

- Pap-mediaroom. Zaprezentowano Raport “Prognoza Zapotrzebowania na Wodór Odnawialny w Polsce do 2030 r”. Available online: https://pap-mediaroom.pl/nauka-i-technologie/zaprezentowano-raport-prognoza-zapotrzebowania-na-wodor-odnawialny-w-polsce-do (accessed on 23 March 2025).

- ORLEN. Hydrogen Market in Poland and the Baltics Until 2040; ORLEN: Płock, Poland, 2024. [Google Scholar]

- Majewski, W.; Foltynowicz, M.; Pelc, T. Strategia-Rozwoju-Wielkopolski-Wodorowej-Do-2030-z-Perspektywa-Do-2040. Available online: http://iw.org.pl/wp-content/uploads/2023/05/Strategia-rozwoju-Wielkopolski-wodorowej-do-2030-z-perspektywa-do-2040.pdf (accessed on 23 March 2025).

- Olczak, A. Podziemne Magazyny Wodoru—Szansa dla Polski. Ecoekonomia.pl, 7 January 2025. [Google Scholar]

- GH2 Green Hydrogen Organisation Poland. Green Hydrogen Organisation. Available online: http://gh2.org/countries/poland (accessed on 8 September 2025).

- Czyżak, P.; Śniegocki, A.; Wetmańska, Z. PEP2040: Progress or Disappointment? EMBER: London, UK, 2023. [Google Scholar]

- Kryk, B.; Malicki, M. Rolnictwo w Kontekście Zrównoważonego Rozwoju Obszarów Wiejskich. Available online: http://www.wneiz.pl/katedry/kpsg/publikacje/rolnictwo_w_kontekscie.pdf (accessed on 20 March 2025).

- Niemiec, M.; Komorowska, M.; Atilgan, A.; Abduvasikov, A. Labelling the Carbon Footprint as a Strategic Element of Environmental Assessment of Agricultural Systems. Agric. Eng. 2024, 28, 235–250. [Google Scholar] [CrossRef]

- Andruszkiewicz, M. Wodór Jako Element Dekarbonizacji Gospodarki w Świetle Strategii Wodorowej Unii Europejskiej i Polski. Nowa Energ. 2021, 3, 54–58. [Google Scholar]

- van der Zwaan, B.; Fattahi, A.; Dalla Longa, F.; Dekker, M.; van Vuuren, D.; Pietzcker, R.; Rodrigues, R.; Schreyer, F.; Huppmann, D.; Emmerling, J.; et al. Electricity- and Hydrogen-Driven Energy System Sector-Coupling in Net-Zero CO2 Emission Pathways. Nat. Commun. 2025, 16, 1368. [Google Scholar] [CrossRef]

- ECA. Sprawozdanie Specjalne 11/2024: Unijna Polityka Przemysłowa w Dziedzinie Wodoru Odnawialnego; ECA: Luxembourg, 2024. [Google Scholar]

- Tchorek, G.; Targowski, F.; Mikusek, P.; Grzybowski, M. Łańcuch Wartosci Gospodarki Wodorowej w Polsce. Available online: https://www.wz.uw.edu.pl/wp-content/uploads/2023/05/2023-04-Hydrogen-Conference-konferencja-raport_21-DRUK.pdf (accessed on 20 March 2025).

- European Commission. Commission Sets out Rules for Renewable Hydrogen. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_23_594 (accessed on 23 March 2025).

- SES Hydrogen Energy Conducted Functional Tests of the First 0.5 MW Hydrogen-Oxygen Boiler in Poland. Ses Hydrogen. 8 August 2023. Available online: https://seshydrogen.com/en/ses-hydrogen-energy-conducted-functional-tests-of-the-first-0-5-mw-hydrogen-oxygen-boiler-in-poland/ (accessed on 20 September 2025).

- Ziobrowski, Z.; Rotkegel, A. Rola Wodoru w Zintegrowanym Systemie Energetycznym Unii Europejskiej. Pr. Nauk. Inst. Inżynierii Chem. Pol. Akad. Nauk 2022, 5–16. [Google Scholar]

- Pawłowski, K. Analiza Porównawcza Technologii Wytwarzania Wodoru. Gaz Woda I Tech. Sanit. 2023, 4, 1–9. [Google Scholar] [CrossRef]

- FERI. Raport Dotyczący Sektora Wodorowego Oraz Nowych Zawodów w Ramach Rozwijającej się Gospodarki Wodorowej. Available online: https://www.feri.org.pl/wp-content/uploads/2024/06/WODOR_PL_RAPORT-1.pdf (accessed on 20 March 2025).

- Małek, A.; Dudziak, A.; Marciniak, A.; Słowik, T. Designing a Photovoltaic–Wind Energy Mix with Energy Storage for Low-Emission Hydrogen Production. Energies 2025, 18, 846. [Google Scholar] [CrossRef]

- Ghavam, S.; Vahdati, M.; Wilson, I.A.G.; Styring, P. Sustainable Ammonia Production Processes. Front. Energy Res. 2021, 9, 580808. [Google Scholar] [CrossRef]

- Maganza, A.; Gabetti, A.; Pastorino, P.; Zanoli, A.; Sicuro, B.; Barcelò, D.; Cesarani, A.; Dondo, A.; Prearo, M.; Esposito, G. Toward Sustainability: An Overview of the Use of Green Hydrogen in the Agriculture and Livestock Sector. Animals 2023, 13, 2561. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, J.; Zong, K.; Chen, Z.; Yang, X.; Yang, L.; Wang, X.; Chen, Z. Recent Advances in Non-noble Metal-based Electrocatalysts for Hybrid Water Electrolysis Systems. Carbon Energy 2025, 7, e679. [Google Scholar] [CrossRef]

- Nair, K.M.; Kanthasamy, S.; Aruchamy, G.; Thangavelu, S. Hierarchical S-Doped Vanadium MOFs with Multiwalled Carbon Nanotubes: A Robust Bifunctional Catalyst for Efficient Water Electrolysis. Langmuir 2025, 41, 2763–2777. [Google Scholar] [CrossRef]

- Hashmi, S.M.; Noor, S.; Parveen, W. Advances in Water Splitting and Lithium-Ion Batteries: Pioneering Sustainable Energy Storage and Conversion Technologies. Front. Energy Res. 2025, 12, 1465349. [Google Scholar] [CrossRef]

- Angelico, R.; Giametta, F.; Bianchi, B.; Catalano, P. Green Hydrogen for Energy Transition: A Critical Perspective. Energies 2025, 18, 404. [Google Scholar] [CrossRef]

- Łosiewicz, B. Technology for Green Hydrogen Production: Desk Analysis. Energies 2024, 17, 4514. [Google Scholar] [CrossRef]

- Karim, S.; Tanwar, N.; Das, S.; Ranjit, R.; Banerjee, A.; Gulafshan; Gupta, A.; Kumar, A.; Dutta, A. Shaping the Future of Green Hydrogen Production: Overcoming Conventional Challenges with Molecular Catalysts, Immobilization, and Scalable Electrolyzers. ACS Catal. 2025, 15, 1073–1096. [Google Scholar] [CrossRef]

- Karl, A.; Jodat, E.; Kungl, H.; Dobrenizki, L.; Schmid, G.; Geskes, P.; Eichel, R.-A. Water Electrolysis Facing the Gigawatt Challenge—Comprehensive De-Risking of Proton Exchange Membrane and Anion Exchange Membrane Electrolyser Technology. Electrochem. Sci. Adv. 2025, 5, e202400041. [Google Scholar] [CrossRef]

- Dong, A.; Guo, C.; Zhang, S.; Song, Y.; Deng, X.; Gao, H. Energy-Saving Electrochemical Hydrogen Production via Amorphous CoMoP/NF Bifunctional Catalyst Coupled with HMF Oxidation Reactions in Alkaline Electrolyte. ChemSusChem 2025, 18, e202402313. [Google Scholar] [CrossRef] [PubMed]

- Czekała, W.; Nowak, M.; Bojarski, W. Anaerobic Digestion and Composting as Methods of Bio-Waste Management. Agric. Eng. 2023, 27, 173–186. [Google Scholar] [CrossRef]

- Krenkel, H.; Najafi, A.; Mahinpey, N.; Seyednajafi, F.; Isgandarova, S. Tri-Methane Reforming Process for Conversion of Biogas and CO2 into Chemicals and Fuels. In Proceedings of the 17th Greenhouse Gas Control Technologies Conference (GHGT-17), Calgary, AB, Canada, 20–24 October 2024. SSRN: Rochester, NY, USA, 2025. [Google Scholar] [CrossRef]

- Naufal Yudha Utama; Agus Setiyono; Zami Furqon Pengembangan Industri Metanol Dalam Negeri Dari Gas Alam Dengan Teknologi Steam Reforming. Pros. SNTEM 2024, 4, 398–411. [CrossRef]

- Grangeiro, L.C.; de Mello, B.S.; Rodrigues, B.C.G.; Rodrigues, C.V.; Marin, D.F.C.; de Carvalho Junior, R.P.; Pires, L.O.; Maintinguer, S.I.; Sarti, A.; Dussán, K.J. Dark Fermentation and Principal Routes to Produce Hydrogen. In Materials for Hydrogen Production, Conversion, and Storage; John Wiley & Sons: Hoboken, NJ, USA; Scrivener Publishing: Beverly, MA, USA, 2023; pp. 181–223. [Google Scholar]

- Me, M.F.H.; Salehmin, M.N.I.; Wong, H.S.J.; Mohamed, M.A. Hydrogen Production from Anaerobic Digestion. In Materials for Hydrogen Production, Conversion, and Storage; John Wiley & Sons: Hoboken, NJ, USA; Scrivener Publishing: Beverly, MA, USA, 2023; pp. 441–464. [Google Scholar]

- Gupta, S.; Fernandes, A.; Lopes, A.; Grasa, L.; Salafranca, J. Photo-Fermentative Bacteria Used for Hydrogen Production. Appl. Sci. 2024, 14, 1191. [Google Scholar] [CrossRef]

- Arizzi, M.; Morra, S.; Gilardi, G.; Pugliese, M.; Gullino, M.L.; Valetti, F. Improving Sustainable Hydrogen Production from Green Waste: [FeFe]-Hydrogenases Quantitative Gene Expression RT-qPCR Analysis in Presence of Autochthonous Consortia. Biotechnol. Biofuels 2021, 14, 182. [Google Scholar] [CrossRef]

- Rathinavel, L.; Jothinathan, D.; Choure, K.; Pandey, A. Unveiling the Green Alchemy: Waste Biomass to Hydrogen Production. ACS Symp. Ser. 2024, 1473, 305–343. [Google Scholar] [CrossRef]

- Yang, C.; Wang, S.; Li, Y.; Zhang, Y.; Cui, C. Thermodynamic Analysis of Hydrogen Production via Supercritical Water Gasification of Coal, Sewage Sludge, Microalga, and Sawdust. Int. J. Hydrogen Energy 2021, 46, 18042–18050. [Google Scholar] [CrossRef]

- Obiora, N.K.; Ujah, C.O.; Asadu, C.O.; Kolawole, F.O.; Ekwueme, B.N. Production of Hydrogen Energy from Biomass: Prospects and Challenges. Green Technol. Sustain. 2024, 2, 100100. [Google Scholar] [CrossRef]

- Chianese, S.; Loipersböck, J.; Malits, M.; Rauch, R.; Hofbauer, H.; Molino, A.; Musmarra, D. Hydrogen from the High Temperature Water Gas Shift Reaction with an Industrial Fe/Cr Catalyst Using Biomass Gasification Tar Rich Synthesis Gas. Fuel Process. Technol. 2015, 132, 39–48. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, M.; Raheem, A.; Wang, F.; Wei, J.; Xu, D.; Song, X.; Bao, W.; Huang, A.; Zhang, S. Syngas Production from Biomass Gasification: Influences of Feedstock Properties, Reactor Type, and Reaction Parameters. ACS Omega 2023, 8, 31620–31631. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.; Yao, J.; Liu, J.; Yan, B.; Shan, R. Biomass to Hydrogen-Rich Syngas via Catalytic Steam Reforming of Bio-Oil. Renew. Energy 2016, 91, 315–322. [Google Scholar] [CrossRef]

- Grammelis, P.; Margaritis, N.; Kourkoumpas, D.-S. Pyrolysis Energy Conversion Systems. In Comprehensive Energy Systems; Elsevier: Amsterdam, The Netherlands, 2018; Volume 4–5, pp. 1065–1106. [Google Scholar]

- Pereira, L.G.G.; Heeres, H.J.; Lima, S.B.; Pires, C.A.M. Development of Process-Product Relations for the Pyrolysis of Sisal Residue. J. Anal. Appl. Pyrolysis 2022, 165, 105583. [Google Scholar] [CrossRef]

- Fahmi, R.; Bridgwater, A.V.; Donnison, I.; Yates, N.; Jones, J.M. The Effect of Lignin and Inorganic Species in Biomass on Pyrolysis Oil Yields, Quality and Stability. Fuel 2008, 87, 1230–1240. [Google Scholar] [CrossRef]

- Li, F.; Yuan, Y.; Huang, Z.; Chen, B.; Wang, F. Sustainable Production of Aromatics from Bio-Oils through Combined Catalytic Upgrading with in Situ Generated Hydrogen. Appl. Catal. B Environ. 2015, 165, 547–554. [Google Scholar] [CrossRef]

- Fang, S.; Wang, Y.; Li, P.; Chang, C.; Wang, X.; Song, J.; Pang, S. A Theoretical and Experimental Study on Steam Reforming of Bio-Oil over Ni/Co Modified Carbon-Based Catalysts. Fuel 2022, 324, 124512. [Google Scholar] [CrossRef]

- Li, J.; Dan, W.; Jia, K.; Fan, G. Fuel Gas Production from Catalytic Pyrolysis of Palm Oil Wastes Using the Nano-Nio/γ-Al2O3 Catalyst. In Proceedings of the 2012 International Conference on Biobase Material Science and Engineering, Changsha, China, 21–23 October 2012; pp. 234–238. [Google Scholar]

- Zhang, X.; Huo, L.; Yao, Z.; Xie, T.; Sun, Y.; Liu, Z.; Zhao, Y.; Zhao, L. A Comparative Review on the Progress of Thermochemical Hydrogen Production Technologies from Agricultural Waste. Fuel 2024, 366, 131284. [Google Scholar] [CrossRef]

- Smoliński, A.; Howaniec, N.; Bąk, A. Utilization of Energy Crops and Sewage Sludge in the Process of Co-Gasification for Sustainable Hydrogen Production. Energies 2018, 11, 809. [Google Scholar] [CrossRef]

- Wiatr, J. Rewolucyjna Technologia Produkcji Zielonego Wodoru z Odpadów Rolniczych i Energii Słonecznej Zyskuje Uznanie na Całym Świecie—Audyt Energetyczny Przedsiębiorstwa, Efektywności Energetycznej Zakładu Przemysłowego i Budynków—Kraków—GS ENERGIA. Available online: https://gsenergia.pl/2024/06/03/rewolucyjna-technologia-produkcji-zielonego-wodoru-z-odpadow-rolniczych-i-energii-slonecznej-zyskuje-uznanie-na-calym-swiecie/ (accessed on 23 March 2025).

- ZUT. Szczecin Produkcja Wodoru z Wykorzystaniem Odpadów Przemysłowych—ZUTolizer. Available online: https://www.zut.edu.pl/zut-strona-glowna/informacje-biezace/article/produkcja-wodoru-z-wykorzystaniem-odpadow-przemyslowych-zutolizer.html (accessed on 25 March 2025).

- dos Santos, E.B.; de Nardi, G., Jr. Produção de Biogás a Partir de Dejetos de Origem Animal. Tekhne E Logos 2013, 4, 80–90. [Google Scholar]

- Peduruhewa, P.S.; Sandaruwan, H.H.P.B.; Hewawardhana, S.; Madhubhashini, M.N.; Madalagama, M.K.L.C.; Sugumaran, D.; Attigala, D.; Manatunga, D.C. Harnessing digitalization in a hydrogen economy for nurturing sustainable food security. In Accelerating the Transition to a Hydrogen Economy; Elsevier: Amsterdam, The Netherlands, 2025; pp. 131–173. [Google Scholar]

- Conklin, J.; Beresnyak, T. Exploring the Potential of Hydrogen in Agriculture: Farming with a Green Future. Available online: https://extension.psu.edu/exploring-the-potential-of-hydrogen-in-agriculture-farming-with-a-green-future (accessed on 23 March 2025).

- Rolniq. Ciągniki na Wodór: Przyszłość Czystej Energii w Rolnictwie. e-ursus, 23 April 2024. [Google Scholar]

- Błoński, R. To Pierwszy na Świecie Ciągnik Rolniczy Zasilany Wodorem. Available online: https://www.gramwzielone.pl/woddor/20146812/pierwszy-na-swiecie-ciagnik-rolniczy-zasilany-wodorem (accessed on 20 February 2025).

- Małek, A.; Caban, J.; Wojciechowski, Ł. Charging Electric Cars as a Way to Increase the Use of Energy Produced from RES. Open Eng. 2020, 10, 98–104. [Google Scholar] [CrossRef]

- Sezer, N.; Bayhan, S. Integrated Solar-Powered Freeze Desalination and Water Electrolysis System with Energy Recovery and Storage for Sustainable Agriculture in Desert Environments. Desalination 2025, 595, 118321. [Google Scholar] [CrossRef]

- Kłaczyński, R.; Beroud, A. Wykorzystanie Wodoru Jako Alternatywnego Źródła Pozyskiwania Energii w Strategii Energetycznej Federacji Rosyjskiej. Colloq. Pedagog.Political Adm. Sci. Q. 2021, 13, 57–70. [Google Scholar]

- Olszewski, P. Trendy Ciągnikowe. Rol. Przegląd Tech. 2023, 12, 18–25. [Google Scholar]

- Fendt H2Agrar Model Project Honored with DLG Agrifuture Concept Award 2022. Available online: https://www.fendt.com/int/h2agrar-model-project-receives-dlg-agrifuture-concept-aw (accessed on 23 April 2025).

- Fendt. H2 Traktor Fendt Helios Im Rahmen Der Woche Des Wasserstoffs. Available online: https://www.fendt.com/int/h2-fendt-helios-tractor-on-display-as-part-of-german-hydrogen-week-2024 (accessed on 23 April 2025).

- Vale, S. Steyr Tests Hydrogen Fuel Cell Concept. Profi, 4 July 2024. [Google Scholar]

- Vale, S. Massey Works on Hydrogen Powered Tractor. Profi, 19 March 2025. [Google Scholar]

- Lebrecht, T. Decarbonizing the Power Industry with Low-Carbon-Intensity Hydrogen. Available online: https://www.powermag.com/decarbonizing-the-power-industry-with-low-carbon-intensity-hydrogen/ (accessed on 20 March 2025).

- Bryner, M. Dow and FMC combine efforts to launch herbicide. Chem. Week 2006, 168, 11–12. [Google Scholar]

- Winiwarter, W.; de Vries, W.; Grizzetti, B.; Hicks, W.K.; van Grinsven, H.J.; Voss, M. The INI European Regional Nitrogen Centre: Concepts and Vision. In Just Enough Nitrogen: Perspectives on How to Get There for Regions with Too Much and Too Little Nitrogen; Springer: Berlin/Heidelberg, Germany, 2020; pp. 445–455. [Google Scholar]

- Zhang, W.-F.; Dou, Z.-X.; He, P.; Ju, X.-T.; Powlson, D.; Chadwick, D.; Norse, D.; Lu, Y.-L.; Zhang, Y.; Wu, L.; et al. New Technologies Reduce Greenhouse Gas Emissions from Nitrogenous Fertilizer in China. Proc. Natl. Acad. Sci. USA 2013, 110, 8375–8380. [Google Scholar] [CrossRef]

- Luo, L.; Wang, K.; Liu, S.; Liu, H.; Tong, L.; He, L.; Liu, K. Tracking Carbon and Ammonia Emission Flows of China’s Nitrogen Fertilizer System: Implications for Domestic and International Trade. Environ. Sci. Technol. 2024, 58, 17641–17649. [Google Scholar] [CrossRef]

- Alia, S.; Ding, D.; McDaniel, T.; Maria, F.; Dinh, H.N. Chalkboard 2—How to Make Clean Hydrogen. Electrochem. Soc. Interface 2021, 30, 50–56. [Google Scholar] [CrossRef]

- Vinardell, S.; Nicolas, P.; Sastre, A.M.; Cortina, J.L.; Valderrama, C. Sustainability Assessment of Green Ammonia Production To Promote Industrial Decarbonization in Spain. ACS Sustain. Chem. Eng. 2023, 11, 15975–15983. [Google Scholar] [CrossRef] [PubMed]

- Palys, M.J.; Daoutidis, P. Optimizing Renewable Ammonia Production for a Sustainable Fertilizer Supply Chain Transition. ChemSusChem 2023, 16, e202300563. [Google Scholar] [CrossRef]

- Fertilizers Europe. Green Ammonia the Workhorse of the Eu Hydrogen Economy- Annual Overview. Available online: https://www.fertilizerseurope.com/wp-content/uploads/2021/06/Annual-Overview-2021-1.pdf (accessed on 23 March 2025).

- h2wielkopolska. Jakie Jest Zastosowanie Wodoru? Available online: https://h2wielkopolska.pl/faq/7-jakie-jest-zastosowanie-wodoru/ (accessed on 20 March 2025).

- Bargiacchi, E.; Frigo, S.; Spazzafumo, G. Energetic and Exergetic Analysis of an Innovative Plant for the Production of Electricity and Substitute Natural Gas. Energy Procedia 2018, 148, 312–319. [Google Scholar] [CrossRef]

- Saccani, C.; Pellegrini, M.; Guzzini, A. Analysis of the Existing Barriers for the Market Development of Power to Hydrogen (P2H) in Italy. Energies 2020, 13, 4835. [Google Scholar] [CrossRef]

- Marocco, P.; Ferrero, D.; Lanzini, A.; Santarelli, M. Optimal Design of Stand-Alone Solutions Based on RES + Hydrogen Storage Feeding off-Grid Communities. Energy Convers. Manag. 2021, 238, 114147. [Google Scholar] [CrossRef]

- Jansons, L.; Zemite, L.; Zeltins, N.; Bode, I.; Vempere, L.; Jasevics, A. The Potential of the Hydrogen Underground Storages: Their Types, Development Chalannges and the Latvian Situation. In Proceedings of the 2022 IEEE 63th International Scientific Conference on Power and Electrical Engineering of Riga Technical University (RTUCON), Riga, Latvia, 10–12 October 2022. [Google Scholar]

- Witte, J.; Madi, H.; Elber, U.; Jansohn, P.; Schildhauer, T.J. Grid-Neutral Hydrogen Mobility: Dynamic Modelling and Techno-Economic Assessment of a Renewable-Powered Hydrogen Plant. Int. J. Hydrogen Energy 2024, 78, 52–67. [Google Scholar] [CrossRef]

- Arthurs, C.; Kusoglu, A. Mechanical Characterization of Electrolyzer Membranes and Components under Compression. J. Electrochem. Soc. 2024, 171, 094510. [Google Scholar] [CrossRef]

- Dang, J.; Yang, F.; Li, Y.; Deng, X.; Ouyang, M. Transient Behaviors and Mathematical Model of Proton Exchange Membrane Electrolyzer. J. Power Sources 2022, 542, 231757. [Google Scholar] [CrossRef]

- Papakonstantinou, G.; Algara-Siller, G.; Teschner, D.; Vidaković-Koch, T.; Schlögl, R.; Sundmacher, K. Degradation Study of a Proton Exchange Membrane Water Electrolyzer under Dynamic Operation Conditions. Appl. Energy 2020, 280, 115911. [Google Scholar] [CrossRef]

- Cai, X.; Lin, R.; Xu, J.; Lu, Y. Construction and Analysis of Photovoltaic Directly Coupled Conditions in PEM Electrolyzer. Int. J. Hydrogen Energy 2022, 47, 6494–6507. [Google Scholar] [CrossRef]

- Xu, Y.; Cheng, M.; Chen, H.; Gui, Y.; Deng, Z.; Tong, Y.; Li, G. Power Fluctuation of Renewable Energy Source Integrated System and Its Effect on Proton Exchange Membrane Water Electrolysis. In PEM Water Electrolysis; Elsevier: Amsterdam, The Netherlands, 2025; pp. 319–345. [Google Scholar]

- He, Q.; Sun, H.; Bi, W.-T.; Wang, X.-Y.; Li, B.; Li, F.; Guo, Z.-G.; Ding, J.; He, J.-B. Supercapacitor-Isolated Water Electrolysis for Renewable Energy Storage. Chem. Eng. J. 2024, 495, 153461. [Google Scholar] [CrossRef]

- Bazarah, A.; Majlan, E.H.; Husaini, T.; Zainoodin, A.; Alshami, I.; Goh, J.; Masdar, M.S. Factors Influencing the Performance and Durability of Polymer Electrolyte Membrane Water Electrolyzer: A Review. Int. J. Hydrogen Energy 2022, 47, 35976–35989. [Google Scholar] [CrossRef]

- Shen, J.; Jin, Q.; Chen, C.; Xu, S.; An, T.; Wei, Z.; Dong, W.; Fan, R.; Shen, M. A Strategy for Improving the Stability of Platinum-Containing Electrocatalyst toward Hydrogen Production in Industrial Alkaline Water Electrolysis. Appl. Phys. Lett. 2023, 123, 133902. [Google Scholar] [CrossRef]

- Sadeq, A.M.; Homod, R.Z.; Hussein, A.K.; Togun, H.; Mahmoodi, A.; Isleem, H.F.; Patil, A.R.; Moghaddam, A.H. Hydrogen Energy Systems: Technologies, Trends, and Future Prospects. Sci. Total Environ. 2024, 939, 173622. [Google Scholar] [CrossRef]

- Aly, K.; Bao, B.; Ellis, E.; Hart, D.P. Life-Cycle Assessment and Cost Analysis of Hydrogen Production via Aluminum-Seawater Reactions. Cell Rep. Sustain. 2025, 2, 100407. [Google Scholar] [CrossRef]

- Rouwenhorst, K. Global Hydrogen Review 2024: FID Doubles, Low-Emission Ammonia Takes Center Stage. Available online: https://ammoniaenergy.org/articles/global-hydrogen-review-2024-fid-doubles-low-emission-ammonia-takes-center-stage/ (accessed on 23 March 2025).

- Janke, L.; McDonagh, S.; Weinrich, S.; Nilsson, D.; Hansson, P.-A.; Nordberg, Å. Techno-Economic Assessment of Demand-Driven Small-Scale Green Hydrogen Production for Low Carbon Agriculture in Sweden. Front. Energy Res. 2020, 8, 595224. [Google Scholar] [CrossRef]

- Wawer, T.; Stroink, A. Hydrogen-Powered Agriculture: Cost Analysis of Hydrogen Logistics in Rural Areas. In Proceedings of the 2024 20th International Conference on the European Energy Market (EEM), Istanbul, Turkiye, 10–12 June 2024; IEEE: New York, NY, USA, 2024; pp. 1–6. [Google Scholar]

- Nyangon, J.; Darekar, A. Advancements in Hydrogen Energy Systems: A Review of Levelized Costs, Financial Incentives and Technological Innovations. Innov. Green Dev. 2024, 3, 100149. [Google Scholar] [CrossRef]

- Ahmadullah, A.B.; Rahimi, M.A.; Ulfat, D.S.; Irshad, A.S.; Doost, Z.H.; Wali, N.; Karimi, B.A. Decarbonizing Afghanistan: The Most Cost-Effective Renewable Energy System for Hydrogen Production. Energy 2025, 332, 136000. [Google Scholar] [CrossRef]

- Nemitallah, M.A.; Alnazha, A.A.; Ahmed, U.; El-Adawy, M.; Habib, M.A. Review on Techno-Economics of Hydrogen Production Using Current and Emerging Processes: Status and Perspectives. Results Eng. 2024, 21, 101890. [Google Scholar] [CrossRef]

- Baral, S.; Šebo, J. Techno-Economic Assessment of Green Hydrogen Production Integrated with Hybrid and Organic Rankine Cycle (ORC) Systems. Heliyon 2024, 10, e25742. [Google Scholar] [CrossRef]

- Alssalehin, E.; Holborn, P.; Pilidis, P. Preliminary Assessment of a Hydrogen Farm Including Health and Safety and Capacity Needs. Energies 2024, 17, 6395. [Google Scholar] [CrossRef]

- Calabrese, M.; Portarapillo, M.; Di Nardo, A.; Venezia, V.; Turco, M.; Luciani, G.; Di Benedetto, A. Hydrogen Safety Challenges: A Comprehensive Review on Production, Storage, Transport, Utilization, and CFD-Based Consequence and Risk Assessment. Energies 2024, 17, 1350. [Google Scholar] [CrossRef]

- Al-Douri, A.; Groth, K.M. Hydrogen Production via Electrolysis: State-of-the-Art and Research Needs in Risk and Reliability Analysis. Int. J. Hydrogen Energy 2024, 63, 775–785. [Google Scholar] [CrossRef]

- Tarkowski, R.; Uliasz-Misiak, B. Towards Underground Hydrogen Storage: A Review of Barriers. Renew. Sustain. Energy Rev. 2022, 162, 112451. [Google Scholar] [CrossRef]

- Gale, F.; Goodwin, D.; Lovell, H.; Murphy-Gregory, H.; Beasy, K.; Schoen, M. Renewable Hydrogen Standards, Certifications, and Labels: A State-of-the-Art Review from a Sustainability Systems Governance Perspective. Int. J. Hydrogen Energy 2024, 59, 654–667. [Google Scholar] [CrossRef]

- Goodwin, D.; Gale, F.; Lovell, H.; Beasy, K.; Murphy, H.; Schoen, M. Expert Views on the Legitimacy of Renewable Hydrogen Certification Schemes. Energy Res. Soc. Sci. 2025, 121, 103970. [Google Scholar] [CrossRef]

- Palmer, G.; Dargaville, R.; Wang, C.; Hamilton, S.; Hoadley, A. Considering the Greenness of Renewable Hydrogen Production in Australia. J. Clean. Prod. 2025, 516, 145776. [Google Scholar] [CrossRef]

- Kuehn, M. Transitioning from a Grey to Clean Hydrogen Economy: Considerations for Scaling Production and Making Use of Existing Transport Infrastructure. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 2–5 October 2023. [Google Scholar]

- Ghorbani, B.; Zendehboudi, S.; Saady, N.M.C.; Dusseault, M.B. Hydrogen Storage in North America: Status, Prospects, and Challenges. J. Environ. Chem. Eng. 2023, 11, 109957. [Google Scholar] [CrossRef]

- Abdin, Z.; Tang, C.; Liu, Y.; Catchpole, K. Chapter 3.1—Current State and Challenges for Hydrogen Storage Technologies. In Towards Hydrogen Infrastructure; Jaiswal-Nagar, D., Dixit, V., Devasahayam, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 101–132. ISBN 978-0-323-95553-9. [Google Scholar]

- Taiwo, G.O.; Tomomewo, O.S.; Oni, B.A. A Comprehensive Review of Underground Hydrogen Storage: Insight into Geological Sites (Mechanisms), Economics, Barriers, and Future Outlook. J. Energy Storage 2024, 90, 111844. [Google Scholar] [CrossRef]

- Shao, Z.; Cao, X.; Zhai, Q.; Guan, X. Risk-Constrained Planning of Rural-Area Hydrogen-Based Microgrid Considering Multiscale and Multi-Energy Storage Systems. Appl. Energy 2023, 334, 120682. [Google Scholar] [CrossRef]

- Stöhr, T.; Wohlmuth, B.; Kutz, J.; Lesemann, L.; Pletz, S.; Zimmermann, F.; Hujer, J. Analysis and Installation of H2 Value Chains in Rural Areas. Int. J. Hydrogen Energy 2024, 49, 530–537. [Google Scholar] [CrossRef]

- Segovia-Hernández, J.G.; Hernández, S.; Cossío-Vargas, E.; Juarez-García, M.; Sánchez-Ramírez, E. Green Hydrogen Production for Sustainable Development: A Critical Examination of Barriers and Strategic Opportunities. RSC Sustain. 2025, 3, 134–157. [Google Scholar] [CrossRef]

- Tonelli, D.; Rosa, L.; Gabrielli, P.; Caldeira, K.; Parente, A.; Contino, F. Global Land and Water Limits to Electrolytic Hydrogen Production Using Wind and Solar Resources. Nat. Commun. 2023, 14, 5532. [Google Scholar] [CrossRef]

- Das, S.; Peter, S.C. Green Hydrogen from Wastewater-A Dual Crisis Resolution. Energy Fuels 2024, 38, 17297–17308. [Google Scholar] [CrossRef]

- Shi, Z.; Liang, F.; Pezzuolo, A. Renewable Energy Communities in Rural Areas: A Comprehensive Overview of Current Development, Challenges, and Emerging Trends. J. Clean. Prod. 2024, 484, 144336. [Google Scholar] [CrossRef]

- Khan, S.A.; Tao, Z.; Agyekum, E.B.; Fahad, S.; Tahir, M.; Salman, M. Sustainable Rural Electrification: Energy-Economic Feasibility Analysis of Autonomous Hydrogen-Based Hybrid Energy System. Int. J. Hydrogen Energy 2025, 141, 460–473. [Google Scholar] [CrossRef]

- Li, C.; Zhang, L.; Ou, Z.; Ma, J. Using System Dynamics to Evaluate the Impact of Subsidy Policies on Green Hydrogen Industry in China. Energy Policy 2022, 165, 112981. [Google Scholar] [CrossRef]

- Stones, J. EU Hydrogen Bank Could Bring Renewable Hydrogen Costs below €1/Kg. ICIS Explore, 5 April 2023. [Google Scholar]

- EC Press Corner. EU Invests €4.8 Billion in Innovative in Net-Zero Projects. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_24_5423 (accessed on 17 July 2025).

- Reuters. EU Awards Italian Energy Groups $402 Mln for Green Hydrogen. Reuters, 26 February 2024.

- European Commission. Winners of First EU-Wide Renewable Hydrogen Auction Sign Grant Agreements, Paving the Way for New European Production. Available online: https://climate.ec.europa.eu/news-your-voice/news/winners-first-eu-wide-renewable-hydrogen-auction-sign-grant-agreements-paving-way-new-european-2024-10-07_en (accessed on 23 March 2025).

- ORLEN. Projekt ORLEN z Największą Dotacją z Unii Europejskiej w Obszarze Wodoru. Available online: https://www.orlen.pl/pl/o-firmie/media/komunikaty-prasowe/archiwum/2024/kwiecien-2024/projekt-orlen-z-najwieksza-dotacja-z-unii-europejskiej-w-obszarze-wodoru (accessed on 17 July 2025).

- ORLEN. Wodór. Available online: https://www.orlen.pl/pl/zrownowazony-rozwoj/projekty-transformacyjne/wodor (accessed on 25 March 2025).

- Stężowski, J. Powstaje Ustawa Która Przyspieszy Rozwój Gospodarki Wodorowej w Polsce. e-magazyny.pl, 5 July 2024. [Google Scholar]

- Ministerstwo Klimatu i Środowiska. Umowa MKiŚ z BGK na Realizację Inwestycji w Technologie Wodorowe w Ramach KPO—Ministerstwo Klimatu i Środowiska—Portal Gov.pl. Available online: https://www.gov.pl/web/klimat/umowa-mkis-z-bgk-na-realizacje-inwestycje-w-technologie-wodorowe-w-ramach-kpo (accessed on 17 July 2025).

- Saravanakumar, A.; Sudha, M.R.; Chen, W.-H.; Pradeshwaran, V. Hydrogen and Biomethane Pathways to Achieve Sustainable Transportation in Circular Economic Concept: A Review. Int. J. Hydrogen Energy 2025, 143, 403–419. [Google Scholar] [CrossRef]

- Dincer, M.; Agelin-Chaab, M. Sustainability Analysis of Electrolysis Based Green Hydrogen Production Pathways: A Life Cycle Perspective. Int. J. Hydrogen Energy 2025, 138, 617–625. [Google Scholar] [CrossRef]

- Dincer, I.; Acar, C. Review and Evaluation of Hydrogen Production Methods for Better Sustainability. Int. J. Hydrogen Energy 2015, 40, 11094–11111. [Google Scholar] [CrossRef]

- Gordon, J.A.; Balta-Ozkan, N.; Nabavi, S.A. Beyond the Triangle of Renewable Energy Acceptance: The Five Dimensions of Domestic Hydrogen Acceptance. Appl. Energy 2022, 324, 119715. [Google Scholar] [CrossRef]

- Maketo, L.; Ashworth, P. Social Acceptance of Green Hydrogen in European Union and the United Kingdom: A Systematic Review. Renew. Sustain. Energy Rev. 2025, 218, 115827. [Google Scholar] [CrossRef]

| Energy Source | Average Cost LCOE [USD/MWh] | Emission CO2 [g CO2-eq/kWh] | Comments |

|---|---|---|---|

| Hydrogen (green, with renewable) | 140–280 | ~1–5 | If produced exclusively from renewable energy sources. |

| Biogas plant (biomethane, biogas) | 55–120 | 10–50 | Low net emissions; dependent on how the substrate is obtained |

| Lithium-ion batteries (storage) | 120–250 | ~5–30 | Emissions depending on the charging source and battery production process. |

| Photovoltaics (ground-mounted PV) | 30–60 | 20–40 | Emissions mainly related to panel production. |

| Photovoltaics (roof PV) | 50–150 | 20–50 | Like terrestrial PV, it depends on the scale. |

| Onshore wind farms | 30–60 | 10–20 | One of the lowest life cycle emissions. |

| Offshore wind farms | 70–150 | 10–30 | Higher material consumption results in slightly higher emissions. |

| Small hydroelectric power plant | 45–100 | 1–30 | Very low emissions, depending on local conditions. |

| Geothermal energy | 40–90 | 5–45 | Low emissions, but possible trace gas emissions from the earth’s interior. |

| Sector | 2022 | 2030 (Forecast) | 2050 (Forecast) |

|---|---|---|---|

| Transport (including air and sea) | <1 | ~30 | 177 |

| Chemical industry (ammonia, methanol) | <1 | ~20 | 70 |

| Iron and steel production | <1 | ~10 | 40 |

| Oil refining | 41 | ~30 | 10 |

| Electric power engineering | <1 | ~15 | 75 |

| Other | <1 | ~5 | 28 |

| Total | <1 | ~110 * | 400 |

| Sector | Baseline Scenario (t) | Extended Scenario (t) |

|---|---|---|

| Industrial | 190,000 | 211,000 |

| Transport | 6900 | 22,000 |

| Total | 223,000 | 245,000 |

| Electrolyzer Type | Advantages | Challenges |

|---|---|---|

| Proton Exchange Membrane (PEM) | High efficiency, scalability, and suitability for large-scale applications. | Expensive due to precious metal catalysts; prone to degradation. |

| Alkaline Electrolyzer | Lower cost of materials compared to PEM; well-established technology. | Lower efficiency, larger footprint, and sensitivity to impurities in feedwater. |

| Anion Exchange Membrane (AEM) | Potential for lower costs and higher efficiency in the future. | Limited field data and operational experience; durability concerns. |

| Production Type | Emissions CO2 [kg/kg H2] | Advantages for Agriculture | Challenges |

|---|---|---|---|

| Electrolysis from renewable energy sources (green hydrogen) | 0 | Zero emissions, possibility of local production | High initial costs, water availability |

| Electrolysis with biochar | 0 | Utilization of agricultural waste, lower energy consumption | Required biochar processing technology |

| SMR with CCS (blue hydrogen) | 1.5–4.5 | Lower costs than green hydrogen | CCS infrastructure needed, local production impossible |

| Methane Pyrolysis (Turquoise Hydrogen) | 0 | Coal production as a by-product | Early stage of development |

| Factor | Impact on Durability | Mitigation Strategies |

|---|---|---|

| Degradation | Stress–strain response variability leading to mechanical failure | Improved material design and cell assembly strategies |

| Electrochemical Degradation | Resistive losses due to membrane degradation | Low-voltage sustenance post-shutdown, protective voltage application |

| Power Fluctuations | Increased charge transfer impedance and metal ion pollution | Optimized operating conditions and fluctuation management |

| Gas Crossover | Reduced efficiency and increased degradation | Supercapacitor-isolated systems |

| System Design and Parameters | Ohmic and mass losses, temperature and pressure effects | Novel stack designs, regulated operating parameters |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuranc, A.; Dudziak, A.; Słowik, T. Low-Carbon Hydrogen Production and Use on Farms: European and Global Perspectives. Energies 2025, 18, 5312. https://doi.org/10.3390/en18195312

Kuranc A, Dudziak A, Słowik T. Low-Carbon Hydrogen Production and Use on Farms: European and Global Perspectives. Energies. 2025; 18(19):5312. https://doi.org/10.3390/en18195312

Chicago/Turabian StyleKuranc, Andrzej, Agnieszka Dudziak, and Tomasz Słowik. 2025. "Low-Carbon Hydrogen Production and Use on Farms: European and Global Perspectives" Energies 18, no. 19: 5312. https://doi.org/10.3390/en18195312

APA StyleKuranc, A., Dudziak, A., & Słowik, T. (2025). Low-Carbon Hydrogen Production and Use on Farms: European and Global Perspectives. Energies, 18(19), 5312. https://doi.org/10.3390/en18195312