A Direct-Drive Rotary Actuator Based on Modular FSPM Topology for Large-Inertia Payload Transfer

Abstract

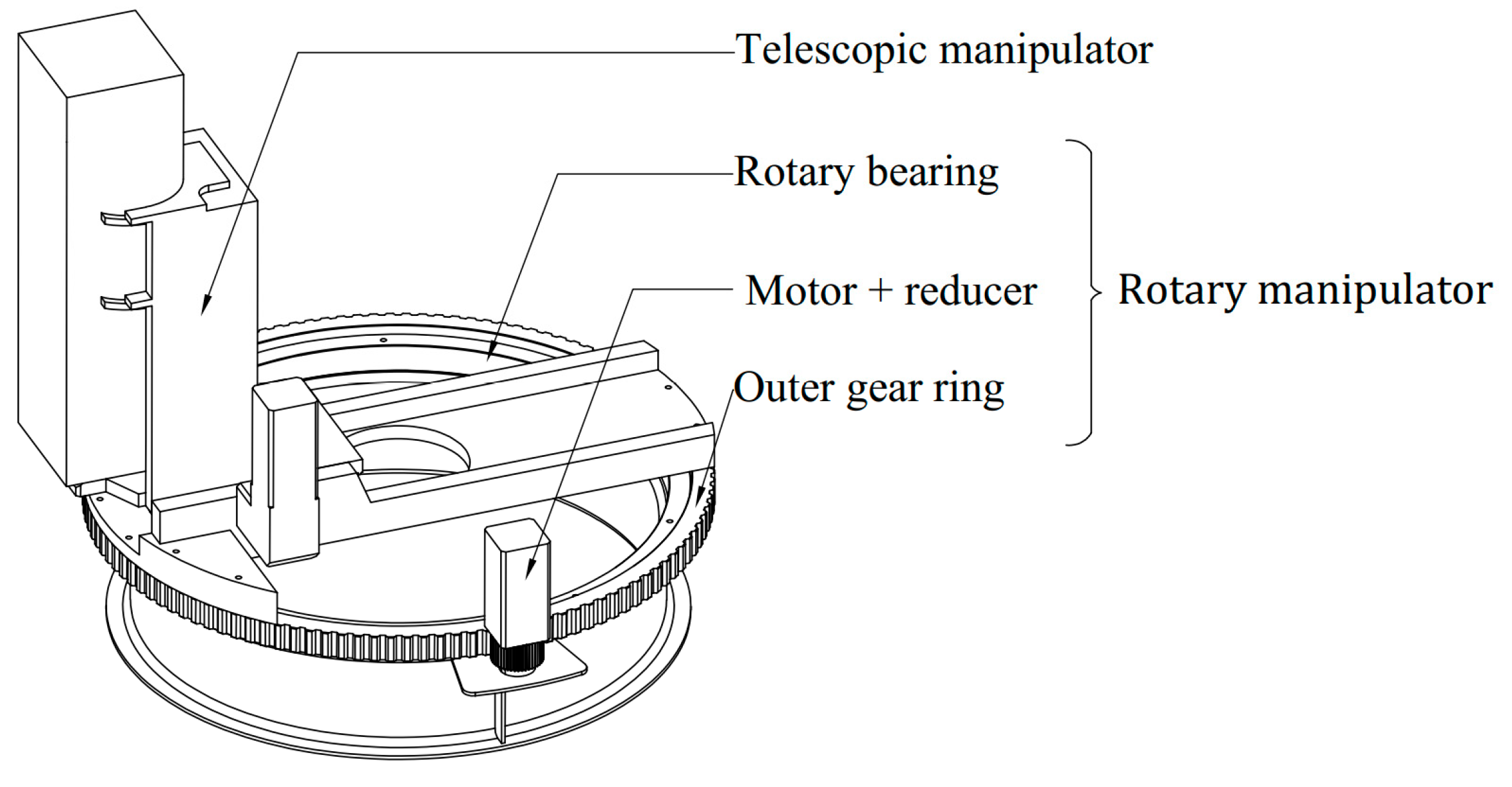

1. Introduction

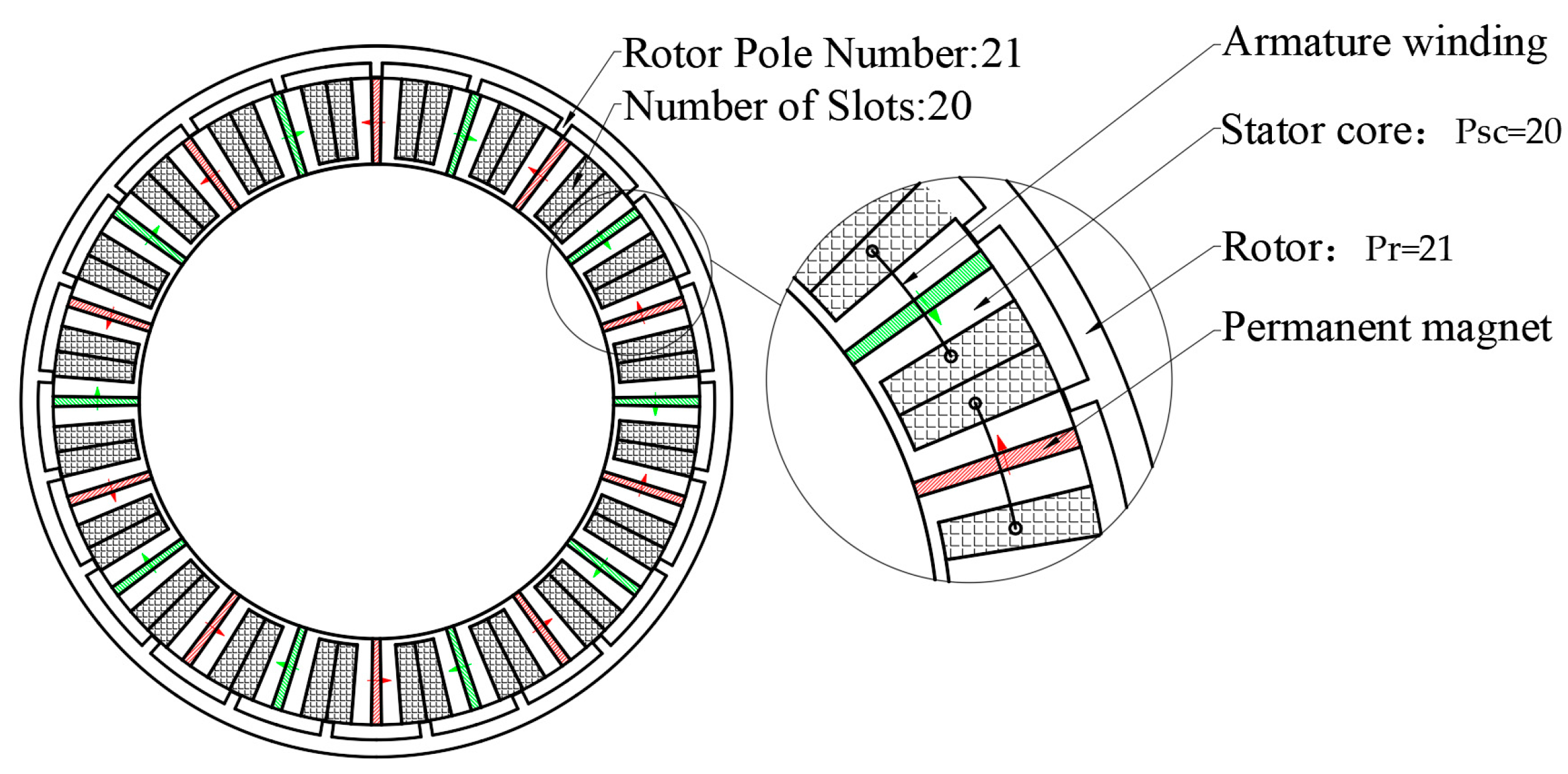

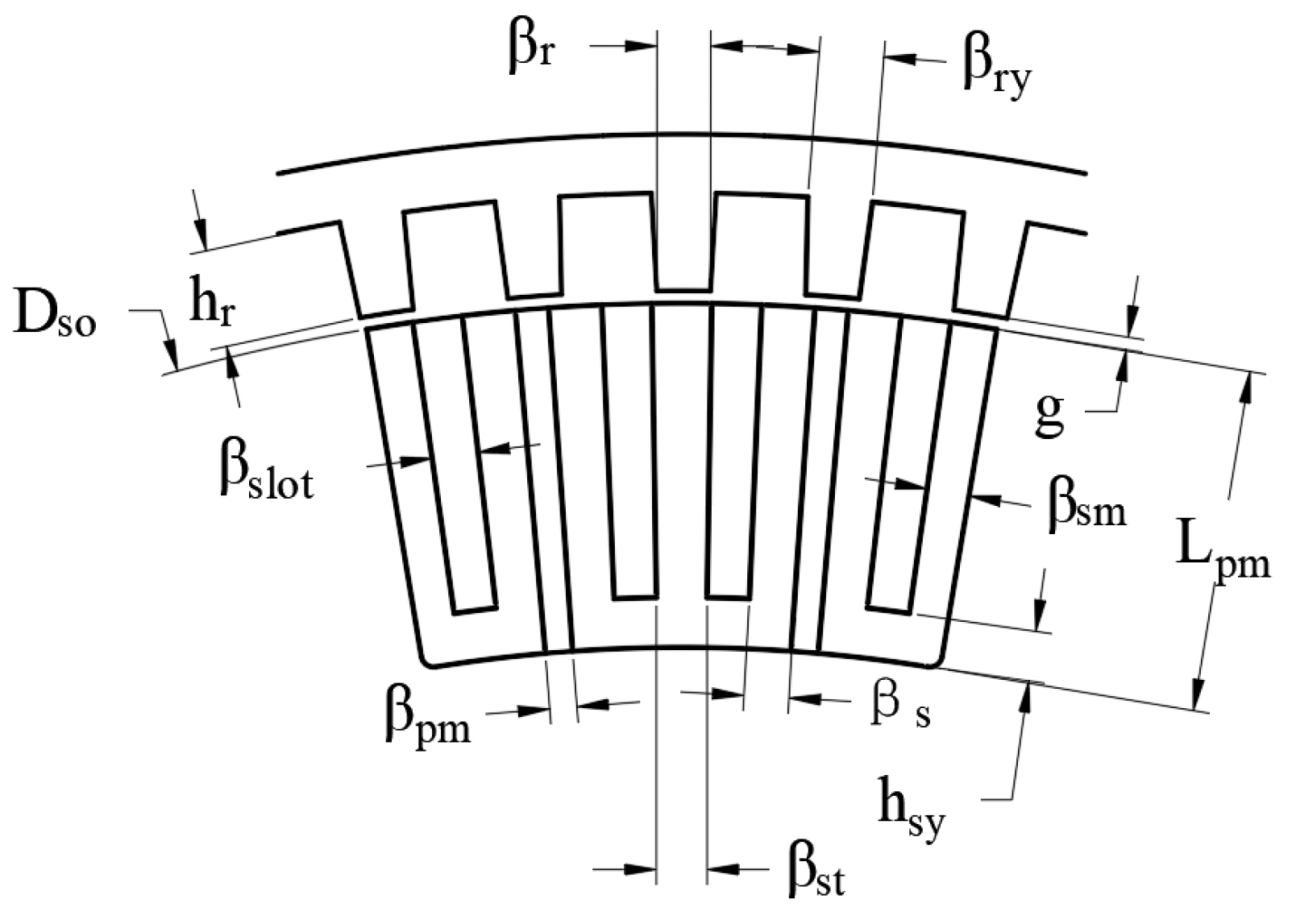

2. Machine Topology

2.1. Conventional Five-Phase FSPM Solution

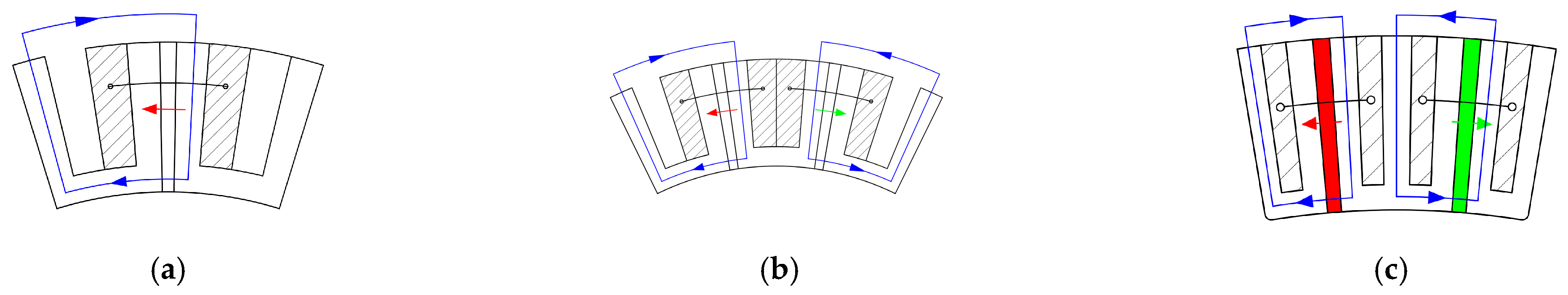

2.2. The Stator Module Topology Design of Modular Phase-Unit FSPM

2.3. Topology Design of Modular 5-Phase FSPM

- Number of Phases ;

- Slots per pole per phase ;

- Complementary coil groups per phase .

- (1)

- First, obtain the complete topology of a five-phase E-core FSPM motor, as shown in Figure 6a.

- (2)

- By removing the complementary stator modules, the structure shown in Figure 6b is obtained.

- (3)

- The final topology in Figure 6c is achieved by substituting E-core configurations with U-cores at modular boundaries, optimizing both structural integrity and magnetic circuit performance.

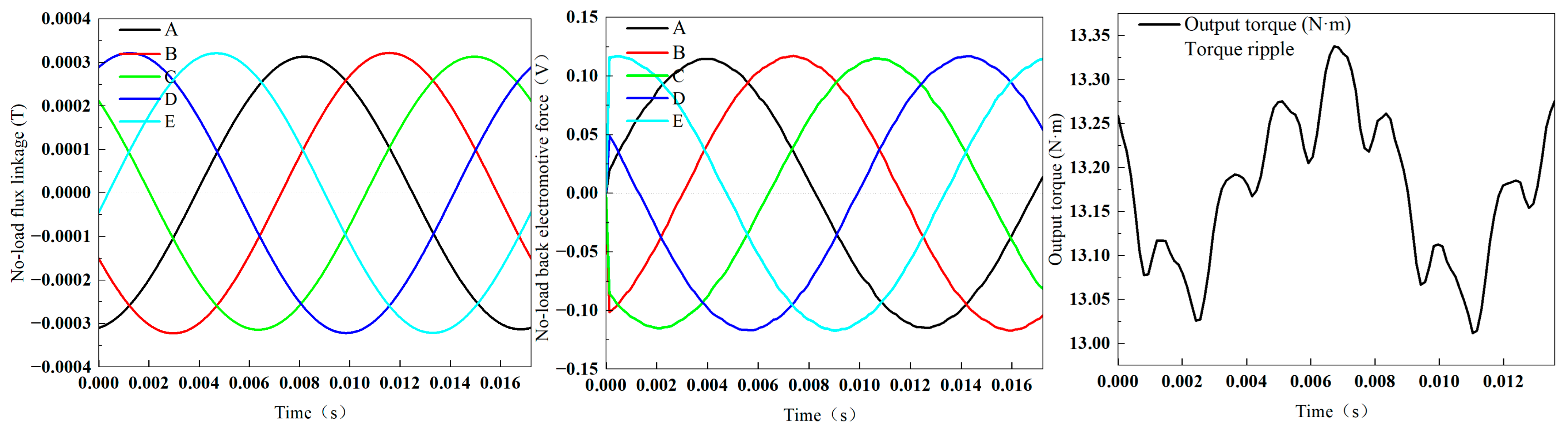

3. Optimization of Electromagnetic Performance

3.1. Main Mechanical Size Design

3.2. Optimization Procedure

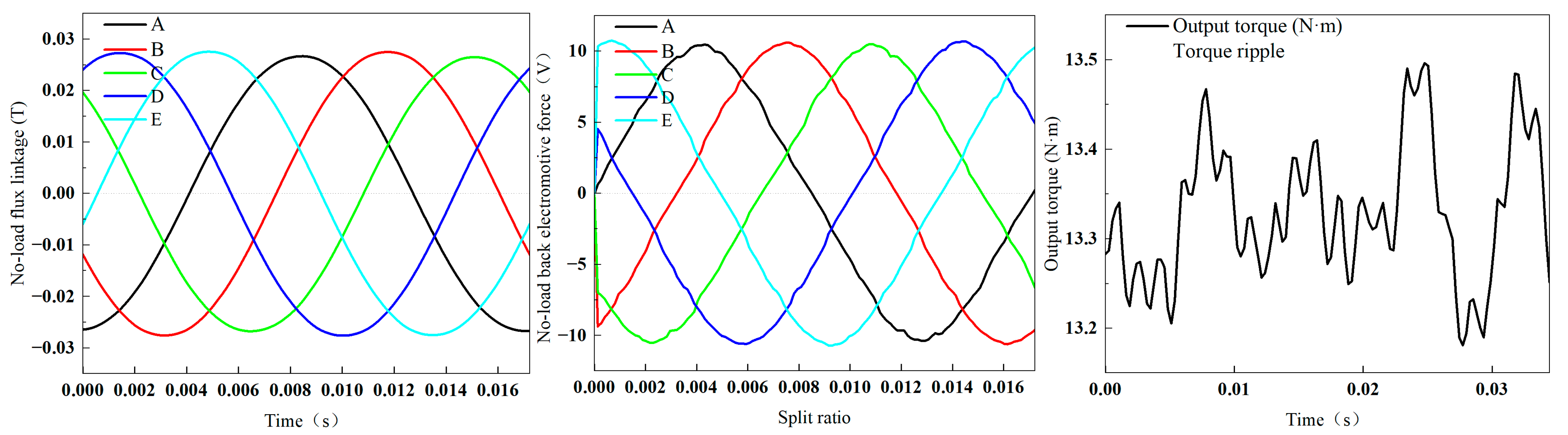

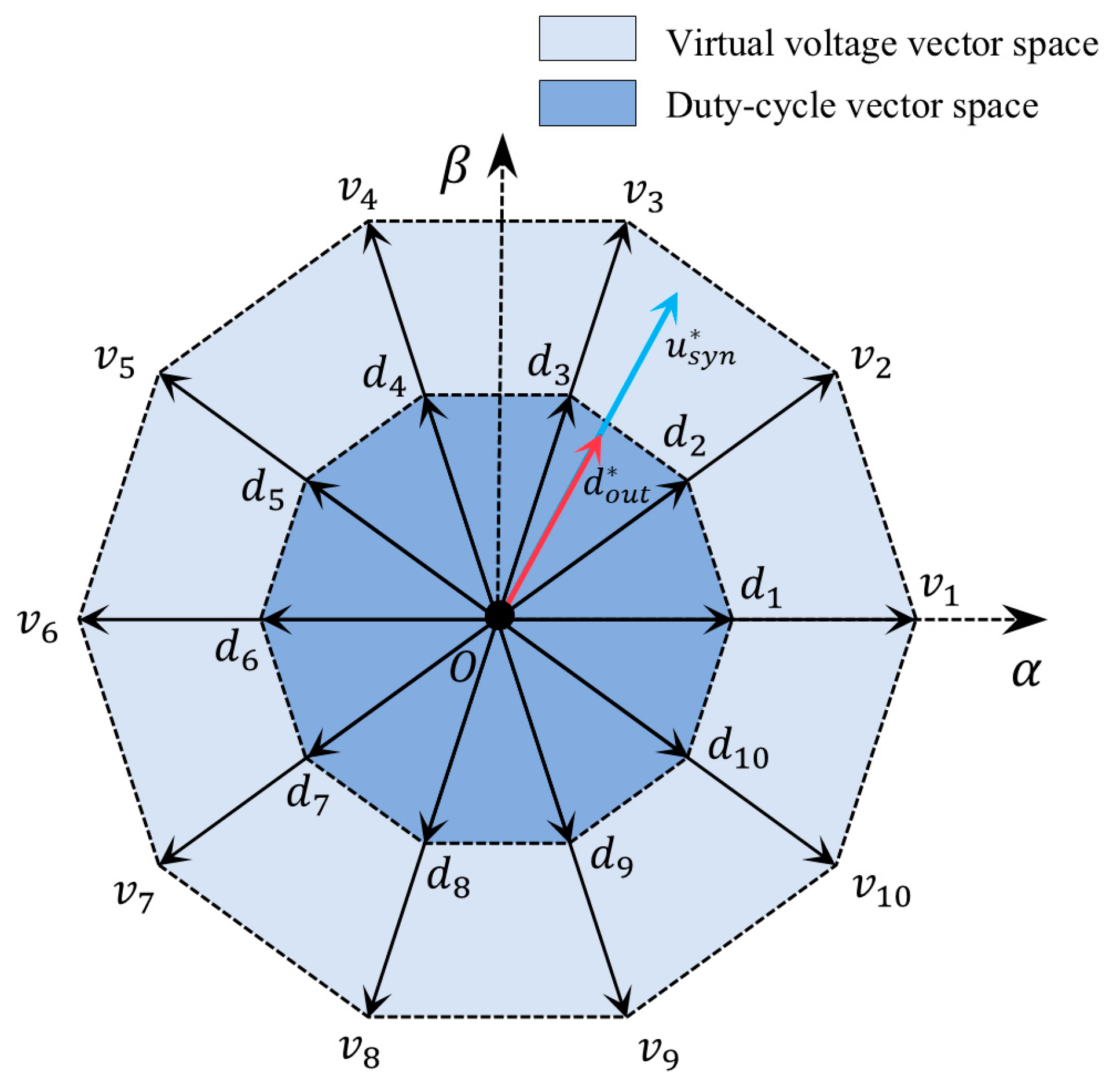

4. The Proposed Control Strategy

4.1. Modeling of Five-Phase FSPM Motor

4.2. Current Bias Computation and Delay Compensation

4.3. Cost Function Minimization

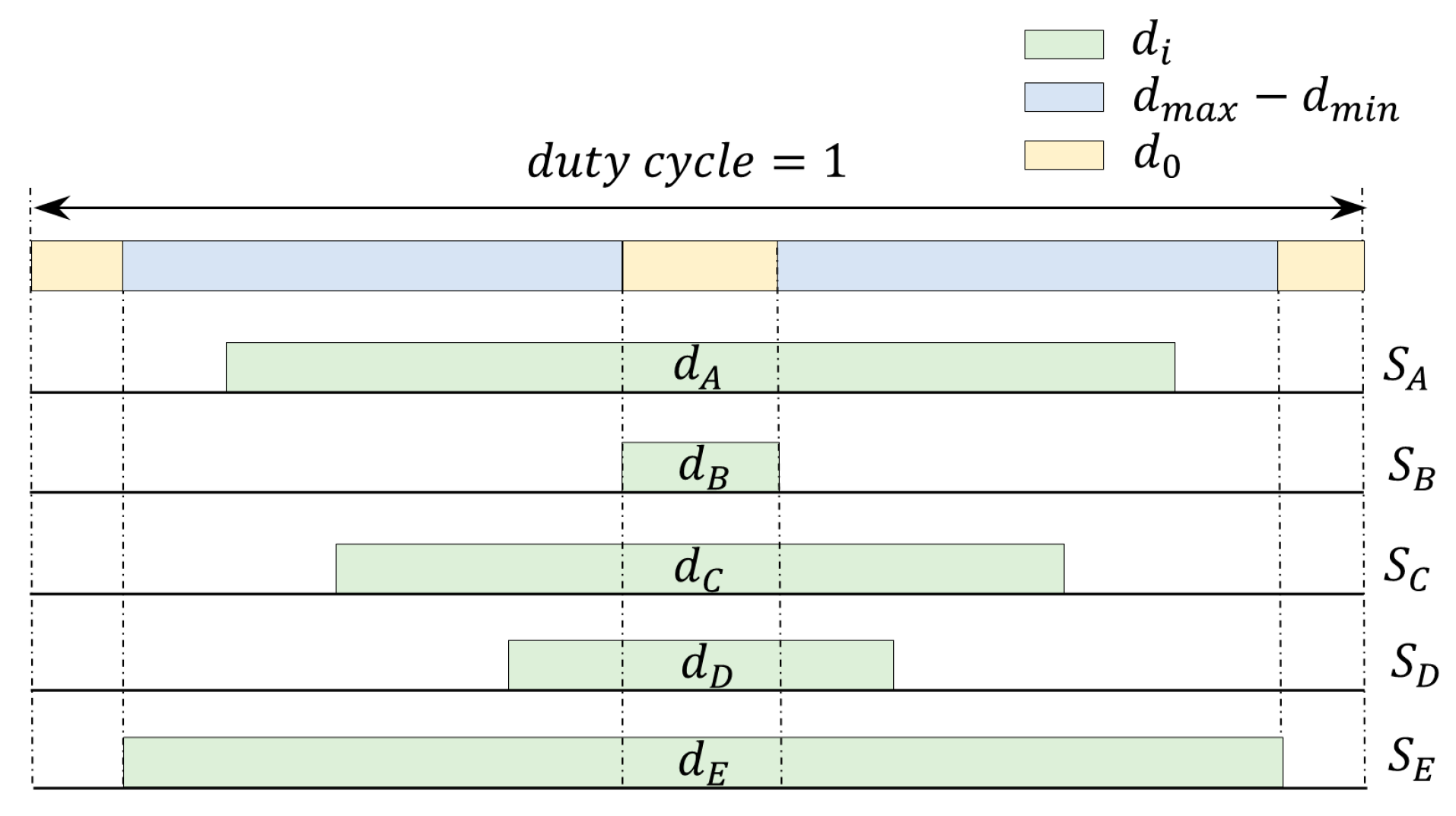

4.4. Duty-Cycle Transformation

4.5. Duty-Cycle Regeneration

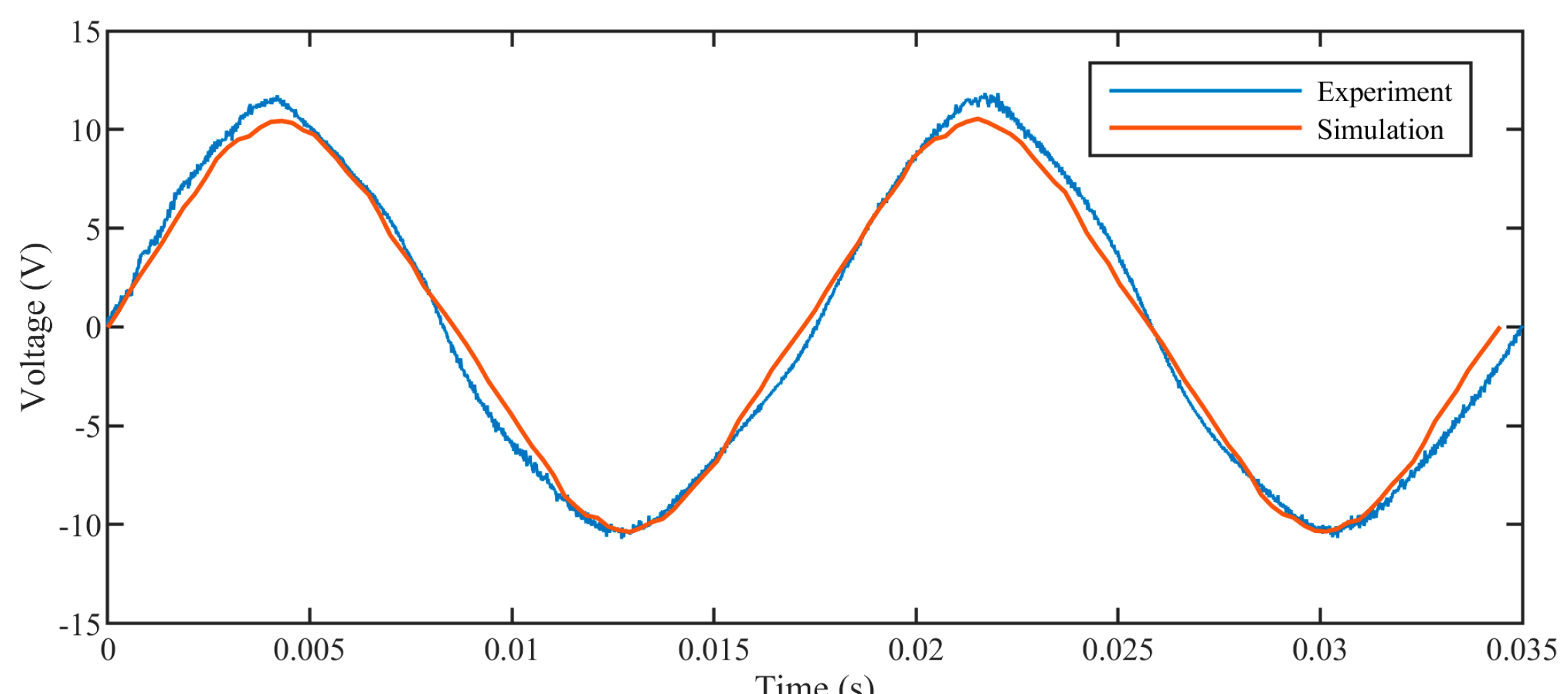

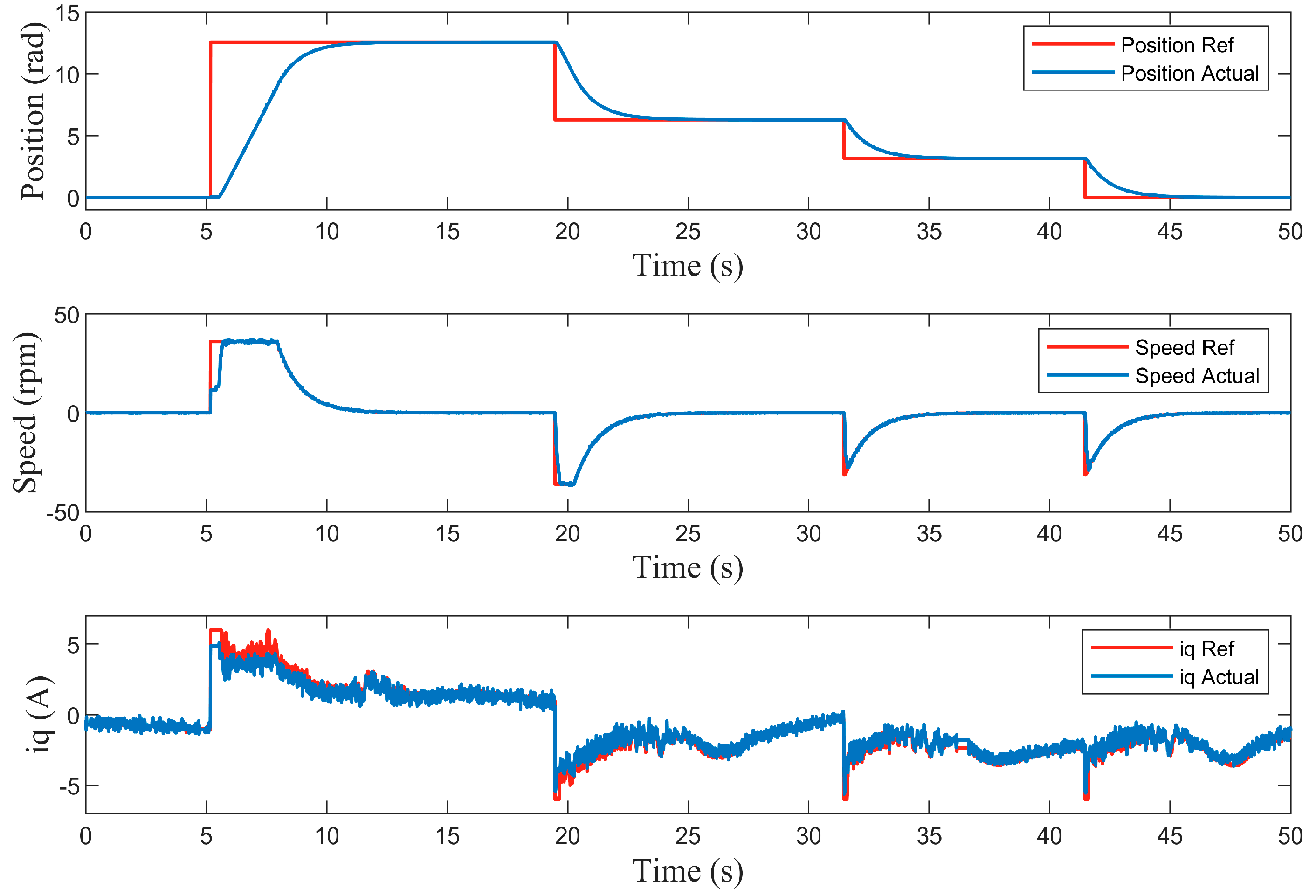

5. Experiment Validation

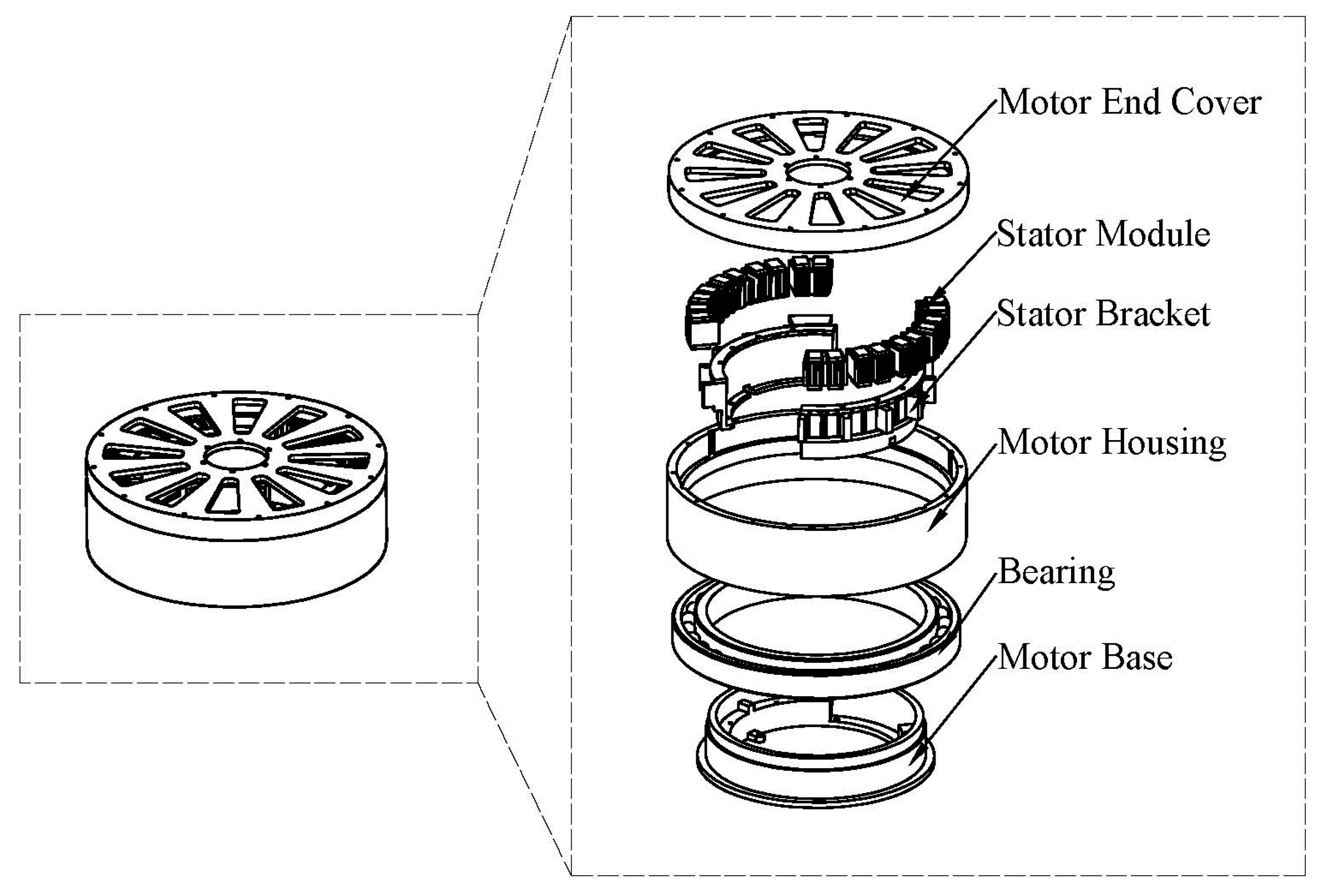

5.1. Machine Manufacturing

5.2. Experiment Platform Establishment

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, T.; Yi, X.; Lu, S. Intelligent manufacturing for the process industry driven by industrial artificial intelligence. Engineering 2021, 7, 1224–1230. [Google Scholar] [CrossRef]

- Liu, X.; Cheng, Q.; Guo, K. Influencing Factors of Intelligent Manufacturing: Empirical Analysis Based on SVR Model. Procedia Comput. Sci. 2017, 122, 1024–1030. [Google Scholar] [CrossRef]

- Zhou, Y.; Zang, J.; Miao, Z.; Minshall, T. Upgrading Pathways of Intelligent Manufacturing in China: Transitioning across Technological Paradigms. Engineering 2019, 5, 691–701. [Google Scholar] [CrossRef]

- Zeng, X.; Li, C.; Li, X.; Mao, C.; Li, Z.; Li, Z. Energy Efficiency Optimization of Air Conditioning Systems Towards Low-Carbon Cleanrooms: Review and Future Perspectives. Energies 2025, 18, 3538. [Google Scholar] [CrossRef]

- Rojek, I.; Mikołajewski, D.; Kopowski, J.; Bednarek, T.; Tyburek, K. Energy Efficiency and Sustainability of Additive Manufacturing as a Mass-Personalized Production Mode in Industry 5.0/6.0. Energies 2025, 18, 3413. [Google Scholar] [CrossRef]

- Różycki, R.; Solarska, D.A.; Waligóra, G. Energy-Aware Machine Learning Models—A Review of Recent Techniques and Perspectives. Energies 2025, 18, 2810. [Google Scholar] [CrossRef]

- Li, B.; Li, X.; Gao, H.; Wang, F. Advances in Flexible Robotic Manipulator Systems—Part I: Overview and Dynamics Modeling Methods. IEEE Trans. Mechatron. 2024, 29, 1100–1110. [Google Scholar] [CrossRef]

- Pistone, A.; Ludovico, D.; De Mari Casareto Dal Verme, L. Modelling and control of manipulators for inspection and maintenance in challenging environments: A literature review. Annu. Rev. Control. 2024, 57, 100949. [Google Scholar] [CrossRef]

- Friederich, J.; Lazarova-Molnar, S. Reliability assessment of manufacturing systems: A comprehensive overview, challenges and opportunities. J. Manuf. Syst. 2024, 72, 38–58. [Google Scholar] [CrossRef]

- Tao, B.; Gong, Z.; Ding, H. Robotic cluster machining: Manufacturing revolution for large and complex components. Sci. China Technol. 2022, 65, 2215–2217. [Google Scholar] [CrossRef]

- Recker, T.; Heilemann, F.; Raatz, A. Handling of large and heavy objects using a single mobile manipulator in combination with a roller board. Procedia CIRP 2021, 97, 21–26. [Google Scholar] [CrossRef]

- Zhu, J.; Tong, M.; Wang, Z.; Chen, L.; Xu, Z. Investigation of a vector-controlled dual 5-phase motor driving system in artillery automatic loading applications. In Proceedings of the International Conference on Defence Technology, Xi’an, China, 23–26 September 2024. [Google Scholar]

- Wang, Z.; Tong, M.; Zhu, J.; Chen, L.; Xu, Z.; Huangfu, B. Optimization design of a dual 5-phase flux-switching permanent-magnet machine for a direct-drive manipulator in artillery automatic loading applications. In Proceedings of the International Conference on Defence Technology, Xi’an, China, 23–26 September 2024. [Google Scholar]

- Heng, T.; Ding, T.; Chang, C.; Ping, T.; Yian, H.; Dahari, M. Permanent Magnet Synchronous Generator design optimization for wind energy conversion system: A review. Energy Rep. 2022, 8, 277–282. [Google Scholar] [CrossRef]

- Dali, A.; Abdelmalek, S.; Bakdi, A.; Bettayed, M. A new robust control scheme: Application for MPP tracking of a PMSG-based variable-speed wind turbine. Renew. Energy 2021, 172, 1021–1034. [Google Scholar] [CrossRef]

- Cai, S.; Kirtley, J.; Lee, C. Critical Review of Direct-Drive Electrical Machine Systems for Electric and Hybrid Electric Vehicles. IEEE Trans. Energy Convers. 2022, 37, 2657–2668. [Google Scholar] [CrossRef]

- Nerg, J.; Rilla, M.; Ruuskanen, V.; Pyrhonen, J.; Ruotsalainen, S. Direct-Driven Interior Magnet Permanent-Magnet Synchronous Motors for a Full Electric Sports Car. IEEE Trans. Ind. Electron. 2014, 61, 4286–4294. [Google Scholar] [CrossRef]

- Zhao, G. Research on Key Issues of Flux-Switching Machines. Ph.D. Thesis, Southeast University, Nanjing, China, 2019. [Google Scholar]

- Sermeno, B.; Santos, R.; Tria, L. Modeling of a Modular Stator Segmented Rotor Switched Reluctance Motor for Circuit Simulation. In Proceedings of the International Power Electronics Conference, Himeji, Japan, 15–19 May 2022. [Google Scholar]

- Mese, E.; Yasa, Y.; Ertugrul, B.; Sincar, E. Design of a high performance servo motor for low speed high torque application. In Proceedings of the International Conference on Electrical Machines (ICEM), Berlin, Germany, 2–5 September 2014. [Google Scholar]

- Khoshoo, B.; Aggarwal, A.; Barron, M.; Foster, S.N. Analysis of Segmented Stator and Rotor Design in PMSM Using a Physics-Based MEC Model. In Proceedings of the 2024 IEEE Energy Conversion Congress and Exposition (ECCE), Phoenix, AZ, USA, 20–24 October 2024; pp. 5240–5246. [Google Scholar]

- Zhang, H. Analysis and Design of a Novel Fractional-Slot Concentrated-Winding Permanent Magnet Hub Motor. Master’s Thesis, Southeast University, Nanjing, China, 2020. [Google Scholar]

- Wang, L.; Wang, X. Torque Ripple Analysis and Reduction of Interior Permanent Magnet Synchronous Motors. IEEE Trans. Appl. Supercond. 2024, 34, 1–5. [Google Scholar] [CrossRef]

- Hua, W.; Chen, F.; Huang, W.; Zhang, G.; Wang, W.; Xia, W. Multivector-Based Model Predictive Control with Geometric Solution of a Five-Phase Flux-Switching Permanent Magnet Motor. IEEE Trans. Ind. Electron. 2020, 67, 10035–10045. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, Y.; Shen, F.; Yang, M.; Wu, T.; Huang, S. Equivalent Three-Vector-Based Model Predictive Control with Duty-Cycle Reconstruction for PMSM. IEEE Trans. Ind. Electron. 2024, 71, 2395–2404. [Google Scholar] [CrossRef]

- Gao, Y.; Dong, B.; Yang, H. Research progress, application and development of high performance 6000 series aluminum alloys for new energy vehicles. J. Mater. Res. Technol. 2024, 32, 1868–1900. [Google Scholar] [CrossRef]

- Wu, Q.; Wang, L.; Yang, G.; Tang, E. Structural design and performance prediction of novel modular tubular permanent magnet linear synchronous motor. J. Magn. Magn. Mater. 2022, 564, 170158. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Motor outer diameter | 354 |

| Rated motor torque | 13 |

| Rated motor speed | 43 |

| DC bus voltage | 24 |

| Phases number | 5 |

| Stack Length h/mm | 5 |

| Parameters | Value |

|---|---|

| 330 | |

| 81 | |

| 1.5 | |

| 1.5 | |

| the auxiliary stator tooth width | 1.5 |

| the marginal stator tooth width | 1.5 |

| permanent magnet (PM) angle | 1.5 |

| Rotor tooth width | 1.5 |

| Rotor yoke width | 1.5 |

| Air gap length | 1 |

| the stator yoke height | 4.4 |

| the rotor tooth height | 4.4 |

| Parameters | Value | Step |

|---|---|---|

| 320–350 | 2 | |

| 0.5–0.9 | 0.02 | |

| 1–3 | 0.1 | |

| 1–3 | 0.1 | |

| 1–10 | 0.5 | |

| 1–3 | 0.1 | |

| 1–3 | 0.1 | |

| 1–3 | 0.1 | |

| 1–3 | 0.1 | |

| 1–3 | 0.1 | |

| 1–10 | 0.5 |

| Parameters | Value |

|---|---|

| 322 | |

| 0.75 | |

| 1.6 | |

| 1.8 | |

| 4.8 | |

| 1–3 | |

| 1.5 | |

| 1.8 | |

| 1.4 | |

| 1 | |

| 4 |

| Parameters | Value | Symbol |

|---|---|---|

| Number of rotor poles | 81 | |

| Rated bus voltage | 24 V | |

| Rated power | 60 W | |

| Rated speed | 43 rpm | |

| Rated torque | 13.33 Nm | |

| Stator resistance | 3.4 Ω | |

| -axes inductance | 10 | |

| -axes inductance | 10 |

| Target position (rad) | 0.000 | |||

| Actual position (rad) | 12.566 | 6.283 | 3.142 | 0.001 |

| Positioning error (mil) | 0.354 | 0.177 | 0.389 | 0.955 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, J.; Wang, Z.; Tong, M.; Chen, L.; Qian, L. A Direct-Drive Rotary Actuator Based on Modular FSPM Topology for Large-Inertia Payload Transfer. Energies 2025, 18, 5272. https://doi.org/10.3390/en18195272

Zhu J, Wang Z, Tong M, Chen L, Qian L. A Direct-Drive Rotary Actuator Based on Modular FSPM Topology for Large-Inertia Payload Transfer. Energies. 2025; 18(19):5272. https://doi.org/10.3390/en18195272

Chicago/Turabian StyleZhu, Jianlong, Zhe Wang, Minghao Tong, Longmiao Chen, and Linfang Qian. 2025. "A Direct-Drive Rotary Actuator Based on Modular FSPM Topology for Large-Inertia Payload Transfer" Energies 18, no. 19: 5272. https://doi.org/10.3390/en18195272

APA StyleZhu, J., Wang, Z., Tong, M., Chen, L., & Qian, L. (2025). A Direct-Drive Rotary Actuator Based on Modular FSPM Topology for Large-Inertia Payload Transfer. Energies, 18(19), 5272. https://doi.org/10.3390/en18195272