Transient Injection Quantity Control Strategy for Automotive Diesel Engine Start-Idle Based on Target Speed Variation Characteristics

Abstract

1. Introduction

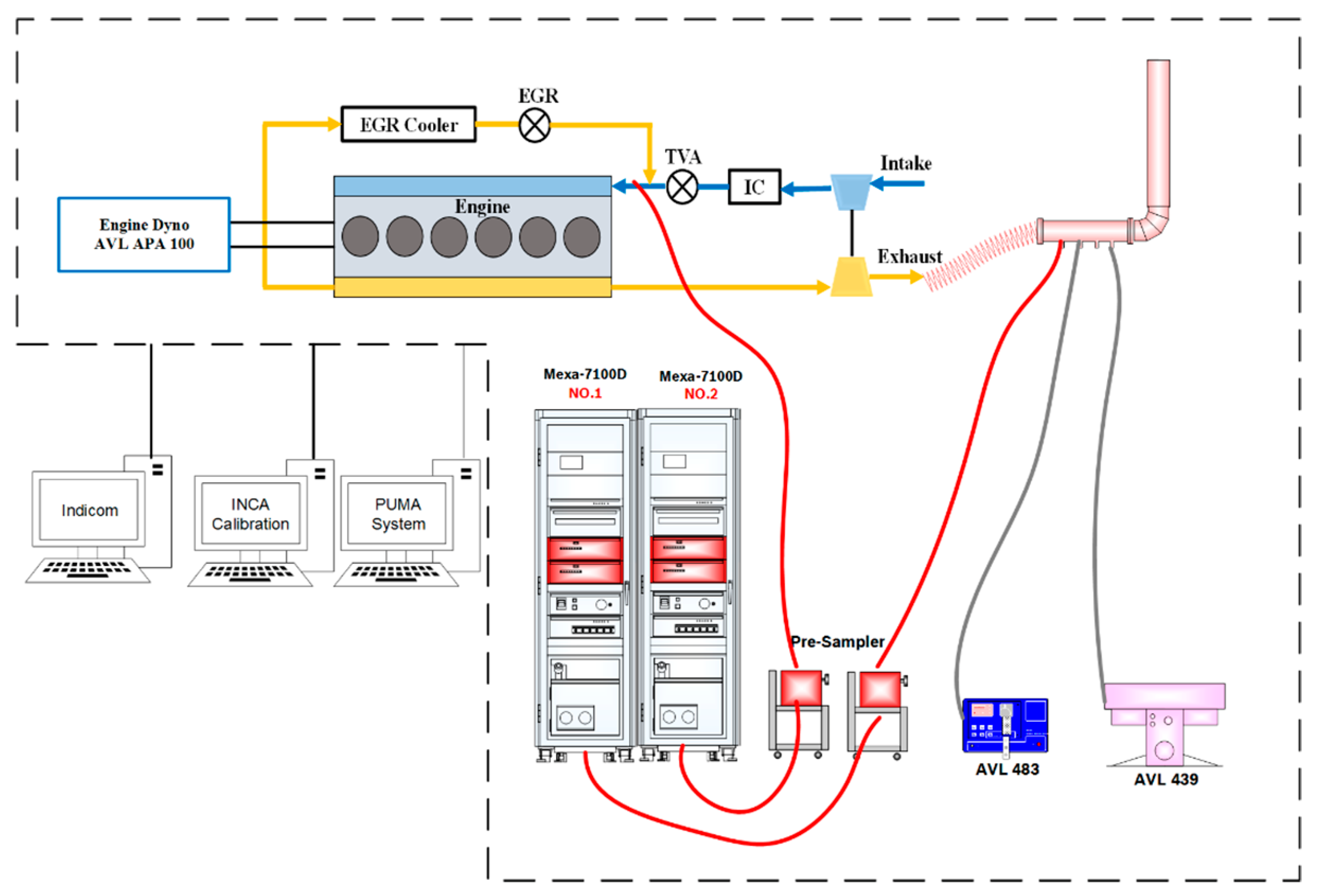

2. Experiment Setup

3. Design of Start-Idle Control Strategy Based on Target Speed Variation Characteristics

3.1. Design of Target Speed Variation Characteristics During the Start-Up Process

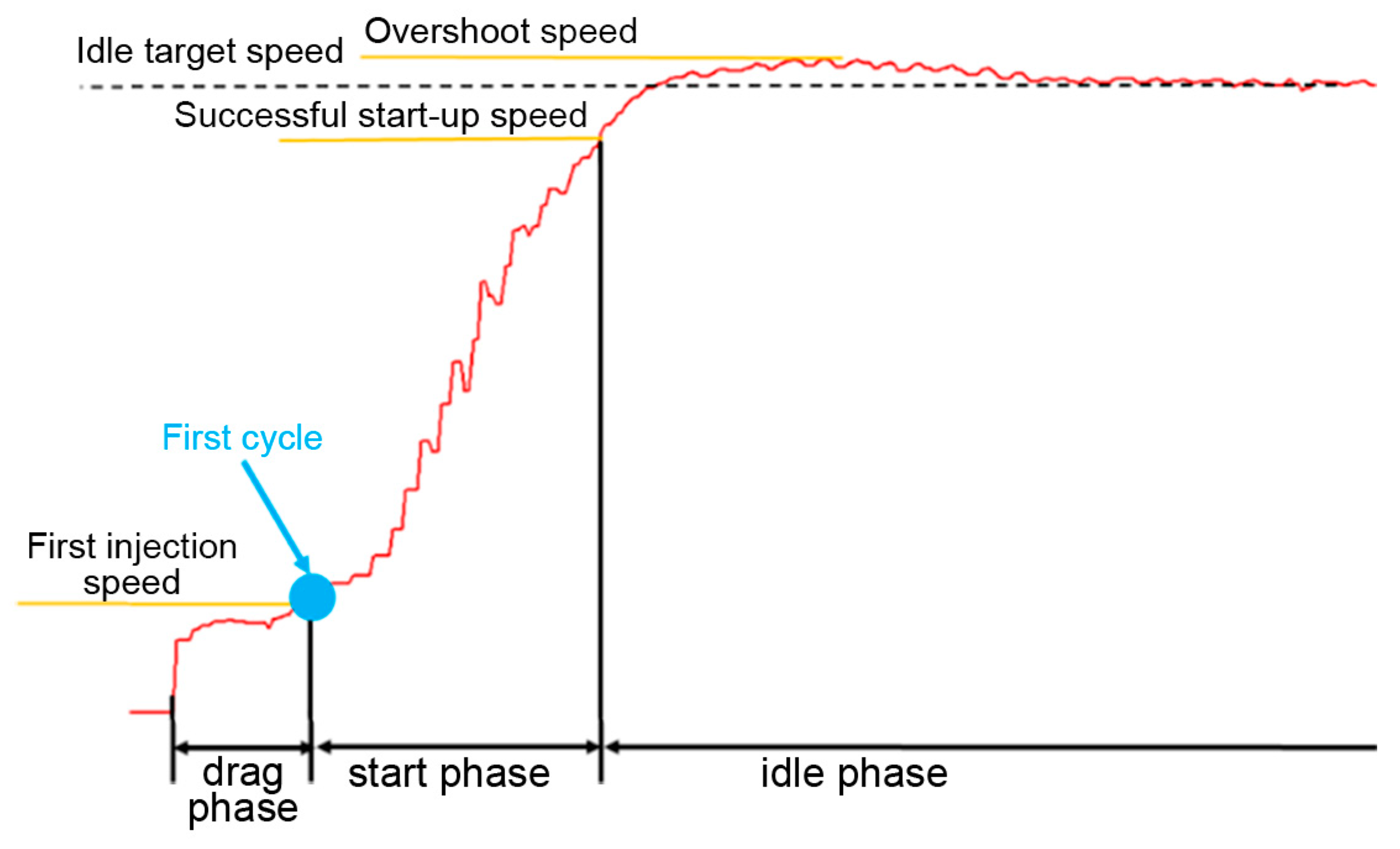

3.1.1. Characteristics of Speed Variation During the Start-Up Process

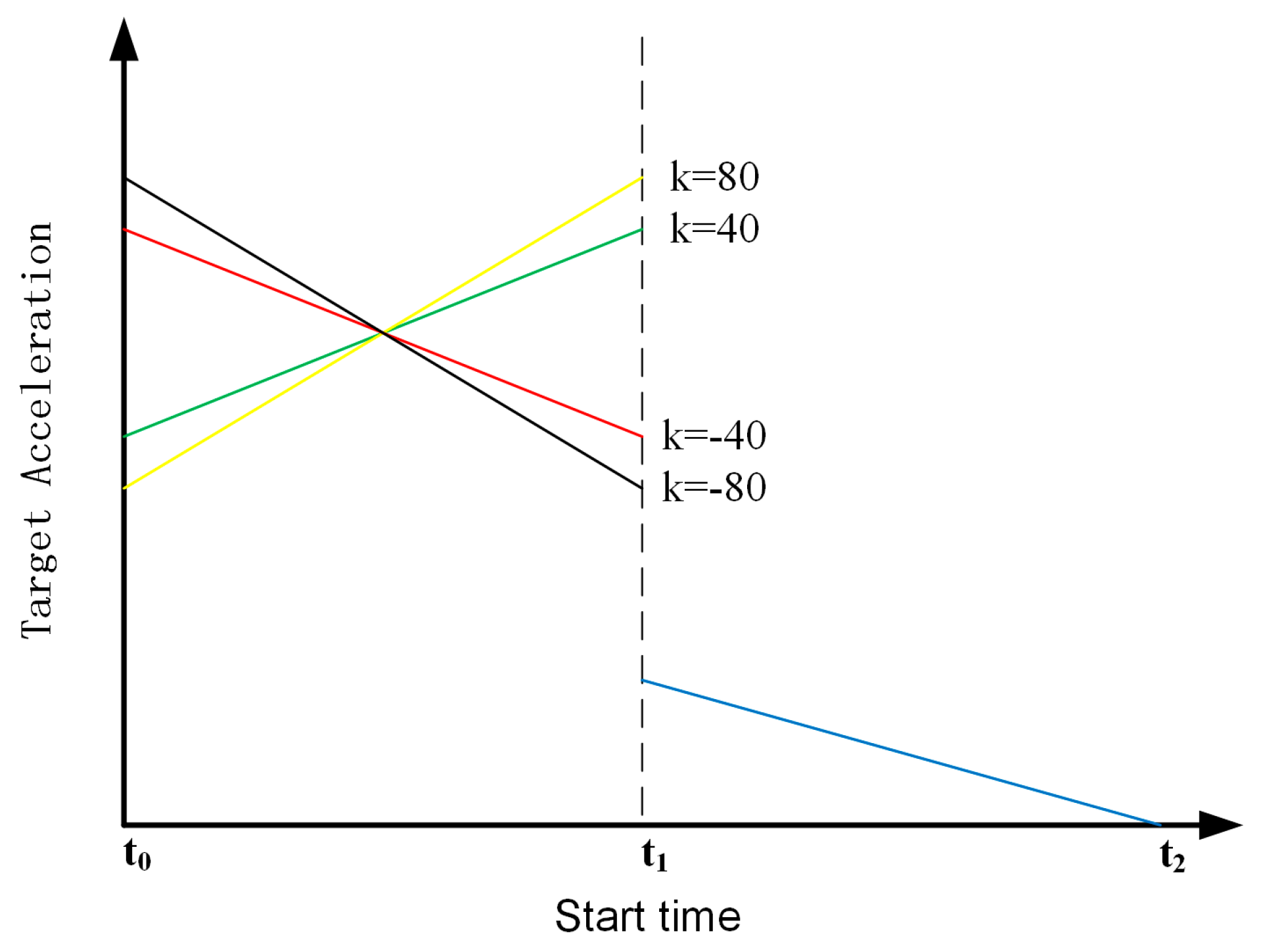

3.1.2. Optimization of Crankshaft Angular Acceleration During the Start-Up Process

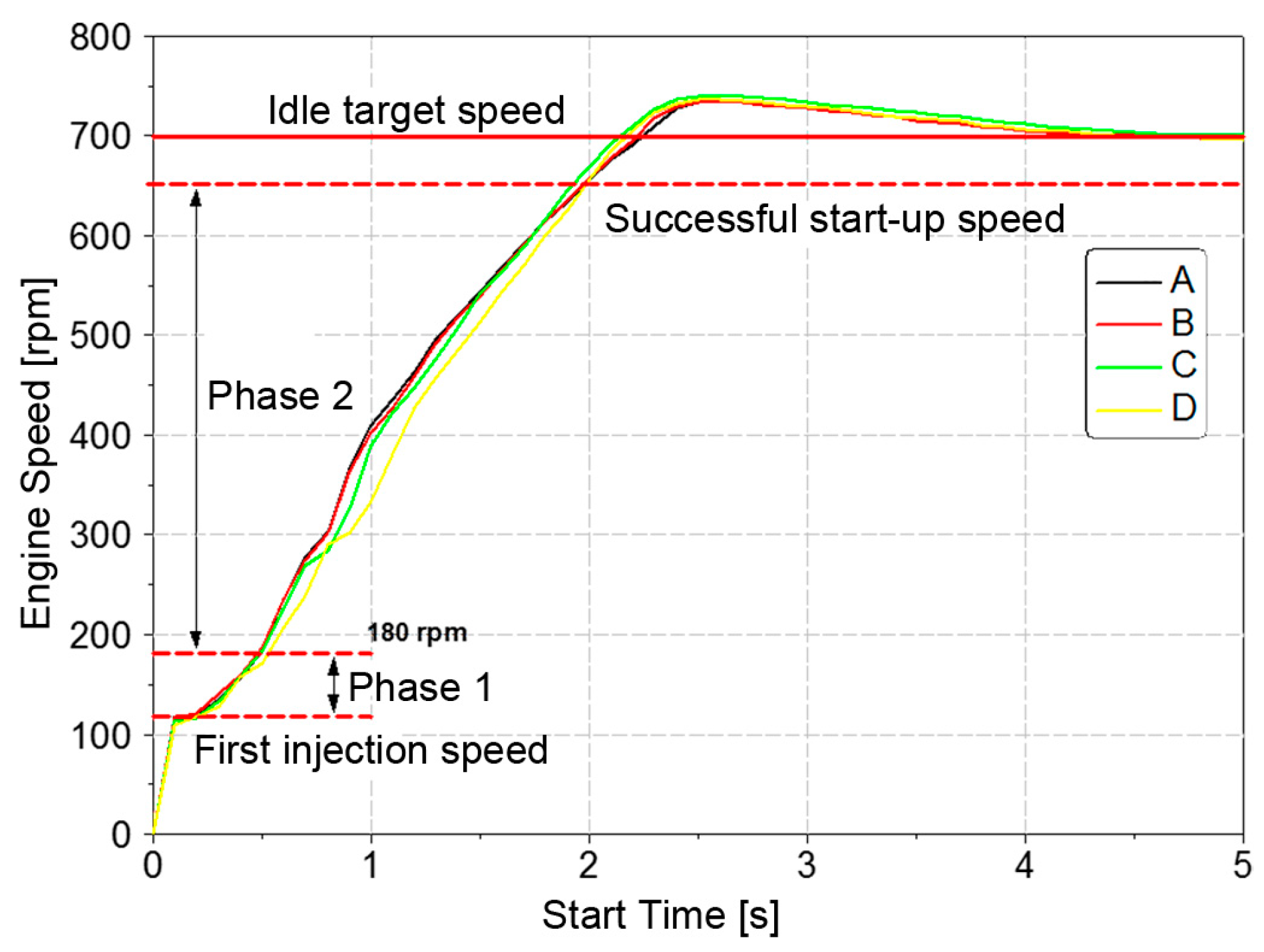

Effect of Angular Acceleration on the Variation Characteristics of Rotational Speed During the Start-Up Process

Effect of Angular Acceleration on Transient Combustion Process During the Start-Up Process

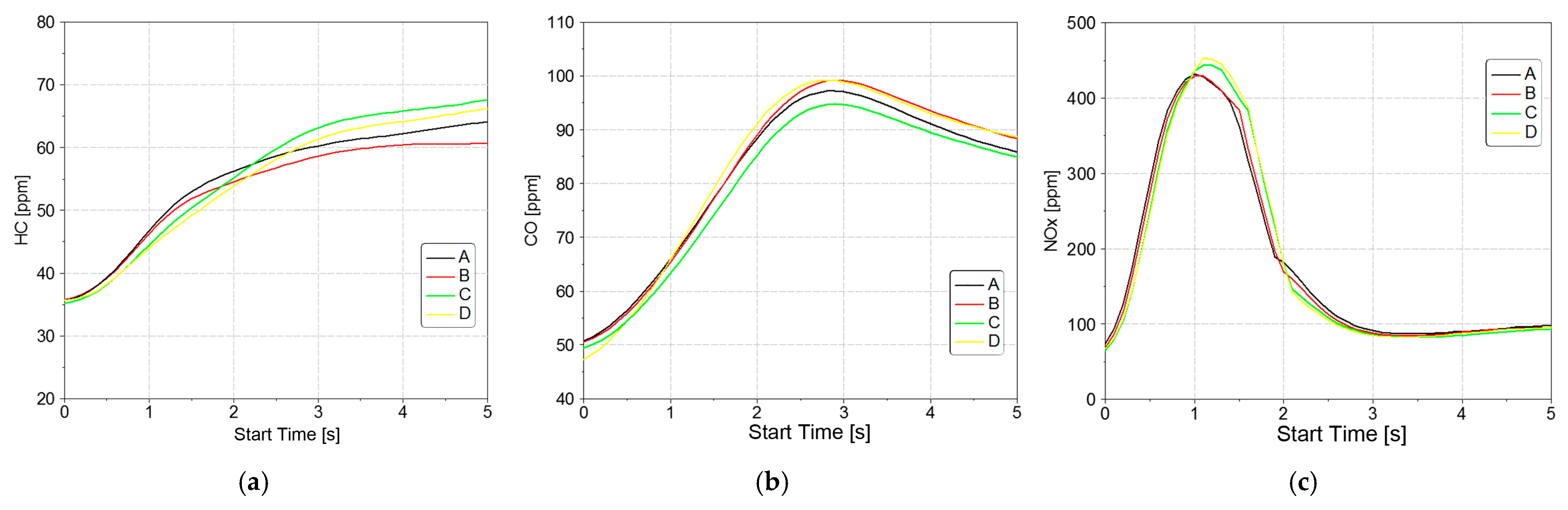

Effect of Angular Acceleration on Emissions of the Start-Up Process

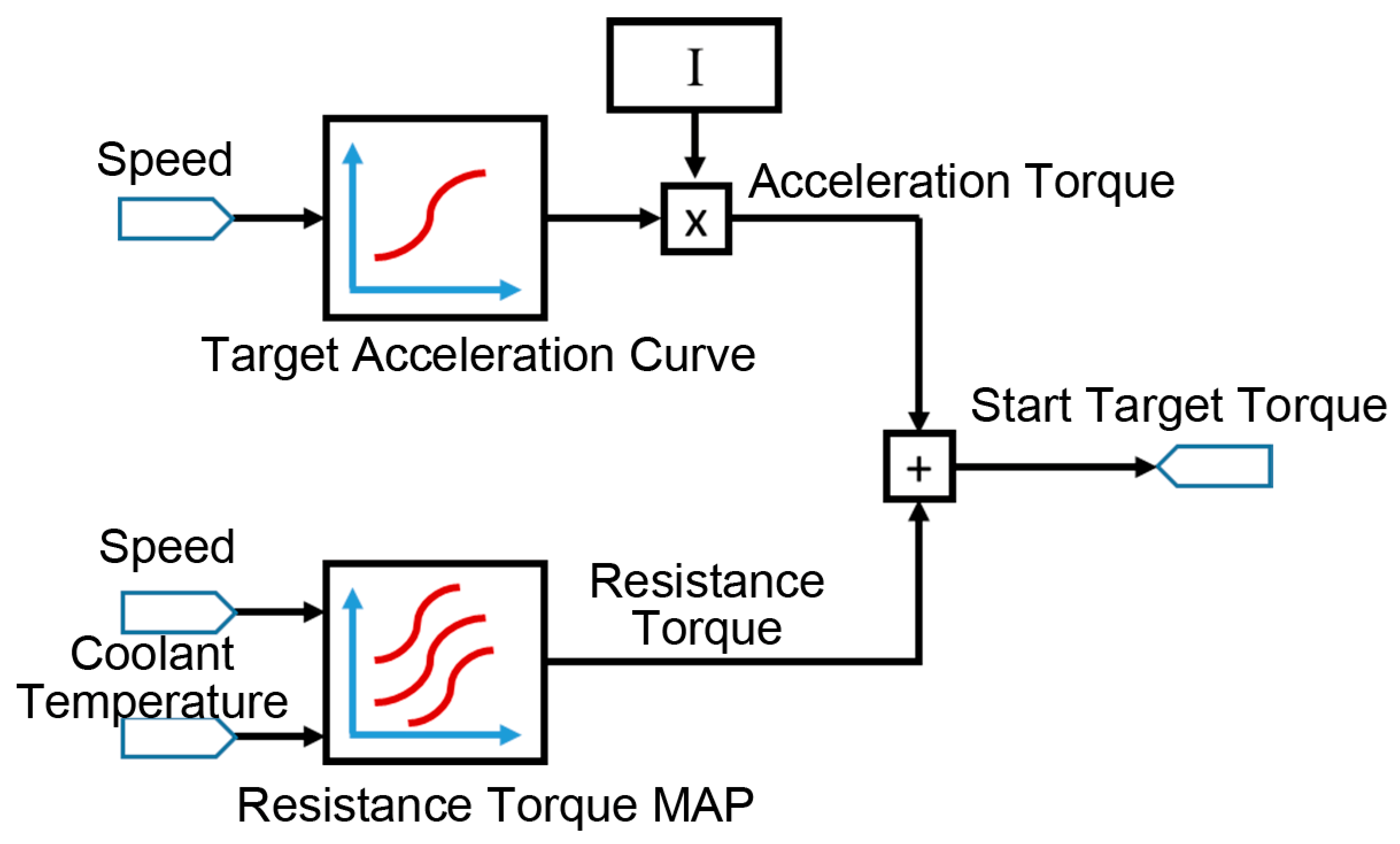

3.2. Injection Quantity Control Strategy Based on Start-Up Phase Target Speed Variation Characteristics

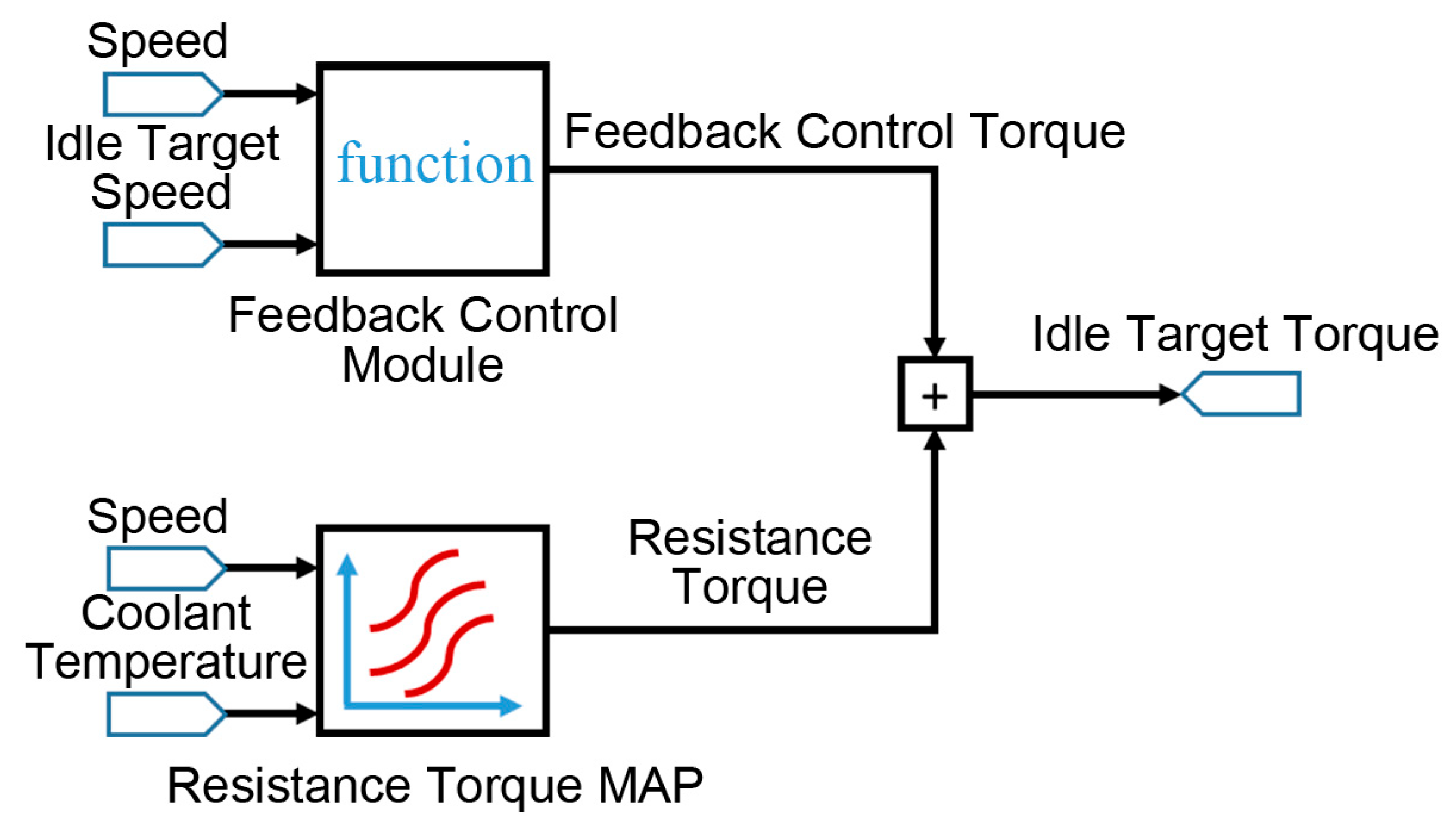

3.3. Idle Phase Injection Quantity Control Strategy

4. Results

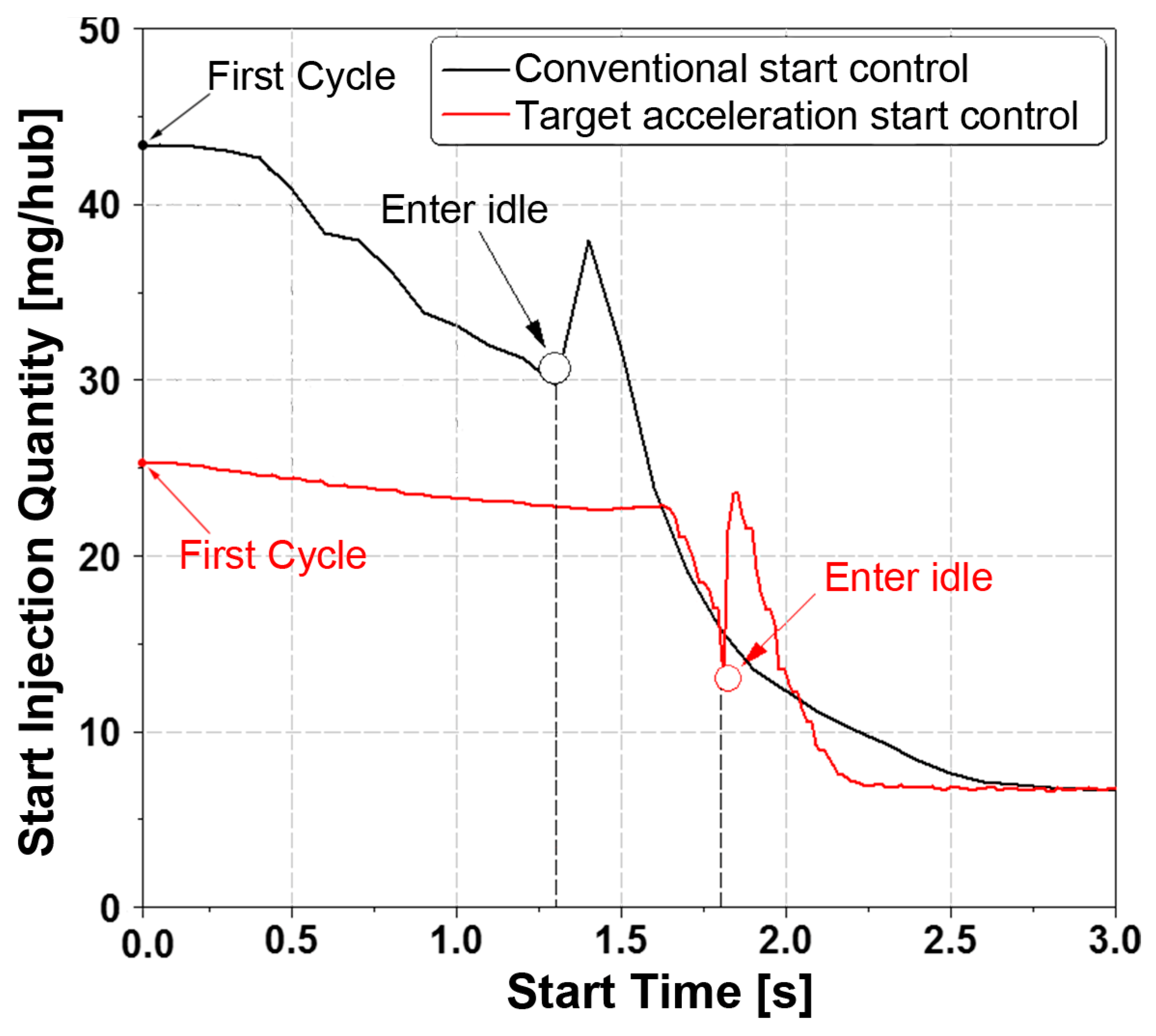

4.1. Comparison of Transient Injection Quantities Under Different Control Strategies

4.2. Effect of Different Starting Control Strategies on Starting Performance

5. Conclusions

- (1)

- To determine the target speed variation characteristics of the start-up process, linear functions with slopes of −80, −40, 40, and 80 were set as the target accelerations for comparison tests. It can be seen that the characteristics of speed variation based on different accelerations have a significant influence on the starting time, the stability of the transition to idle speed, and the cumulative fuel consumption and emission characteristics. When the speed variation characteristics corresponding to acceleration with a slope of 40 are the control target curve, the cumulative injection quantity of the start-up process is reduced by 25.9% compared to the traditional control method while maintaining minimal changes in start-up time and emission characteristics.

- (2)

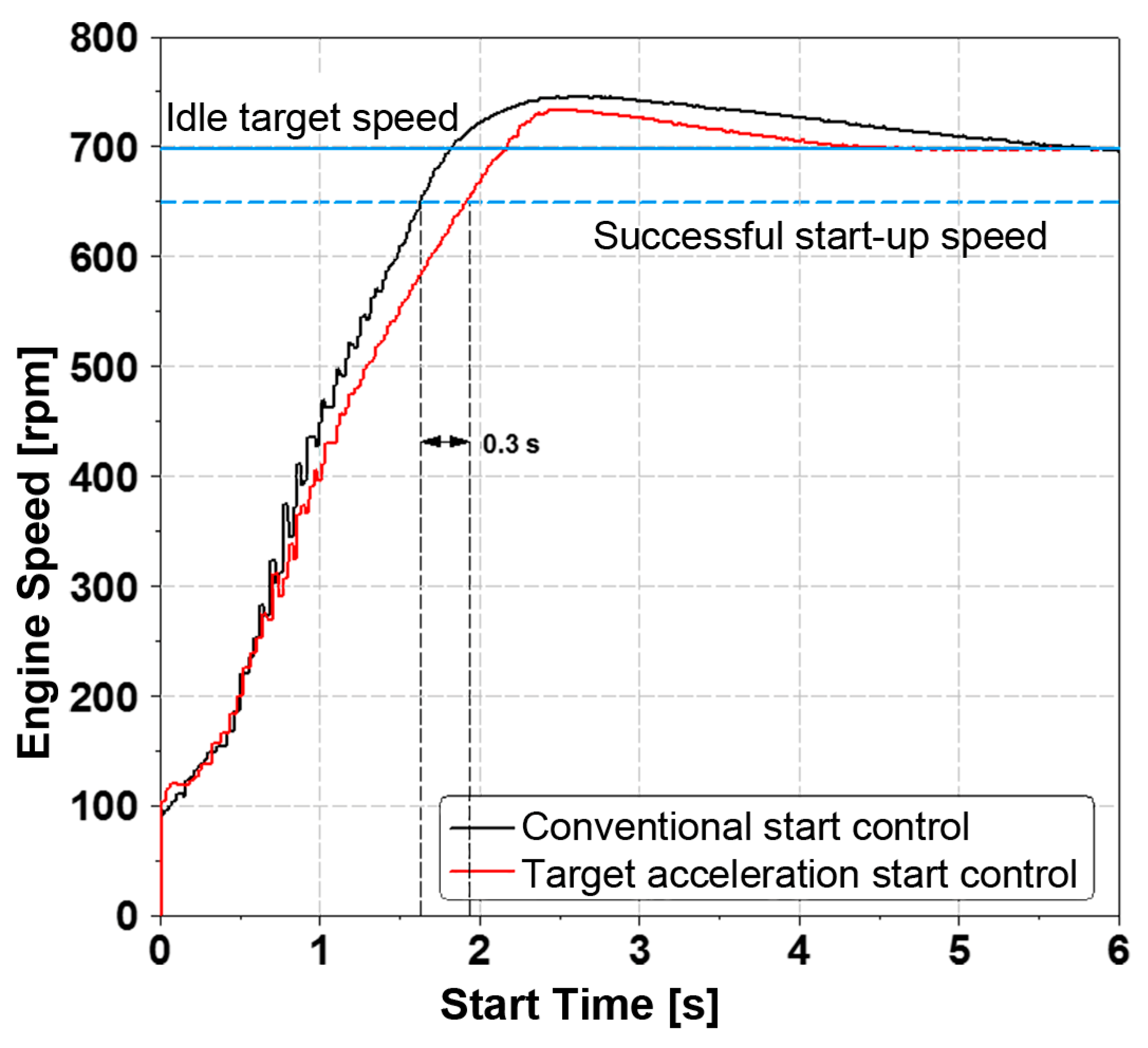

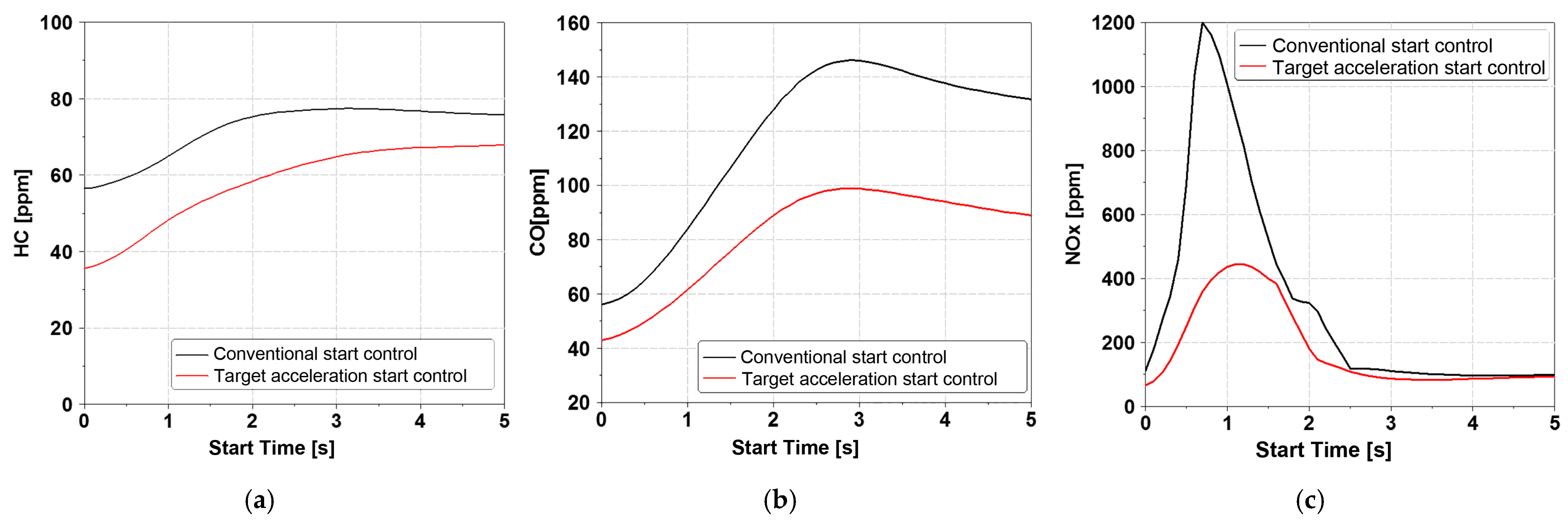

- To verify the advantages of the proposed control strategy, an emission comparison test was conducted with the conventional starting control strategy. The results show that the proposed control strategy significantly improves HC, CO, and NOx emissions, with peak concentrations reduced by 12.4%, 32.5%, and 62.9%, and average concentrations reduced by 27.2%, 35.1%, and 41.0%, respectively, under the premise that the starting time is extended by only 0.3 s. Meanwhile, the stability of the start-up process was significantly improved, with a 12 rpm reduction in overshooting speed, equivalent to 25% less, and a 1.3 s reduction in speed fluctuation time, which was 23.6% shorter. It demonstrates that the current control method effectively enhances the starting performance, which is of great significance for the diversified development of automotive power sources.

- (3)

- The control strategy proposed in this paper demonstrates significant effectiveness in enhancing the starting performance of automotive diesel engines. Moreover, it requires neither additional auxiliary equipment nor fuel replacement. This approach offers novel methods and insights for controlling and calibrating transient fuel injection quantities during the diesel engine starting process. This methodology also holds potential for reducing fuel consumption and pollutant emissions during the frequent starting cycles of hybrid vehicles while improving starting smoothness. This holds significant importance for the decarbonization and diversification of automotive power sources.

- (4)

- However, this study has several limitations. The ambient temperature during the experiments was set at 25 °C. Current research indicates that the cold-start combustion reliability of diesel engines progressively deteriorates at lower ambient temperatures. The control strategy proposed in this paper, when combined with auxiliary measures such as in-take air preheating, has the potential to further enhance starting performance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, L.J.; Lei, J.L.; Wang, Z.J.; Wang, D.F.; Chen, J.L.; Li, D.S.; Liu, K.; Sun, L. Impacts of different ambient temperatures on cold-start characteristics of speed-up duration of an ISAD hybrid diesel engine in plateau. Fuel 2025, 381, 133492. [Google Scholar] [CrossRef]

- Bielaczyc, P.; Merkisz, J.; Pielecha, J. Investigation of Exhaust Emissions from DI Diesel Engine During Cold and Warm Start; Technical Paper; SAE International: Warrendale, PA, USA, 2001. [Google Scholar]

- Henein, N.A.; Taraza, D.; Chalhoub, N.; Lai, M.-C.; Bryzik, W. Exploration of the Contribution of the Start/Stop Transients in HEV Operation and Emissions; Technical Paper; SAE International: Warrendale, PA, USA, 2000. [Google Scholar]

- Gao, J.B.; Chen, H.B.; Li, Y.; Chen, J.Y.; Zhang, Y.J.; Dave, K.; Huang, Y. Fuel consumption and exhaust emissions of diesel vehicles in worldwide harmonized light vehicles test cycles and their sensitivities to eco-driving factors. Energy Convers. Manag. 2019, 196, 605–613. [Google Scholar] [CrossRef]

- Baghani, A.; Chitsaz, I.; Teymoori, M.M. A novel method for real driving emission prediction utilizing an artificial neural network. Eng. Appl. Artif. Intel. 2024, 137, 109267. [Google Scholar] [CrossRef]

- Xu, K.; Liu, Y.L.; Zhang, H.; He, X.; Wei, W.; Duan, J.F. Experiments and modeling of the thermal spray-chasing phenomenon during split injection processes. Int. J. Therm. Sci. 2024, 205, 109255. [Google Scholar] [CrossRef]

- Wang, X.R.; Li, H.M.; Li, G.X.; Gao, Y.; Huo, H.B.; Zhang, X.Q.; Wang, Z.G.; Bai, H.L. Experimental investigation of atomization characteristics at low temperature environments during diesel engine cold start. J. Energy Inst. 2024, 113, 101544. [Google Scholar] [CrossRef]

- Wu, Z.K.; Deng, P.; Han, Z.Y. A numerical study on fuel film and emissions formations during cold start in a diesel engine using an improved spray-wall impingement model. Fuel 2022, 320, 123898. [Google Scholar] [CrossRef]

- He, X.; Xu, K.; Liu, Y.L.; Zhang, Z.; Zhang, H.; Zhao, J. Effects of ambient density and injection pressure on ignition and combustion characteristics in diesel spray under plateau cold-start conditions. Fuel 2023, 352, 129039. [Google Scholar] [CrossRef]

- Trivedi, M.J.; Raut, P.D.; Alkhayat, S.; Henein, N.A. Analysis of the ion current in misfiring and firing cycles during the cold starting of a compression ignition engine. Int. J. Engine Res. 2024, 25, 466–483. [Google Scholar] [CrossRef]

- Duan, L.S.; Tan, P.Q.; Liu, J.T.; Liu, Y.; Chen, Y.J.; Lou, D.M.; Hu, Z.Y. Emission characteristics of a diesel engine with an electrically heated catalyst under cold start conditions. J. Clean. Prod. 2022, 380, 134965. [Google Scholar] [CrossRef]

- Li, D.; Wu, D.Y.; Gui, X.L.; Liao, S.D.; Zhu, M.N.; Yu, F.; Zheng, J.Y. Exploring ultrafine particle emission characteristics from in-use light-duty diesel trucks in China using a portable measurement system. Environ. Res. 2024, 263, 120234. [Google Scholar] [CrossRef]

- Cho, S.; Wu, A.; Kim, N.; Busch, S.; Pintor, D.L. Formation of CH2O and UHC emissions during catalyst-heating operation compression ignition engines: High-speed FID and mid-IR extinction diagnostics. Fuel 2023, 342, 127832. [Google Scholar] [CrossRef]

- Wang, P.; Qin, B.; Shi, L.; Kang, W.; Zhao, B.; Deng, K.Y. Experimental investigation of the effects of preheating temperature on low-temperature cold start performance, emissions and energy conversion of diesel-electric hybrid. Energy Convers. Manag. 2023, 281, 116844. [Google Scholar] [CrossRef]

- Deng, Y.W.; Liu, H.W.; Zhao, X.H.; Jiaqiang, E.; Chen, J.M. Effects of cold start control strategy on cold start performance of the diesel engine based on a comprehensive preheat diesel engine model. Appl. Energy 2018, 210, 279–287. [Google Scholar] [CrossRef]

- Sun, H.; Zhang, W.G.; Wang, Y.X. Cold start performance of diesel engine at extremely low ambient temperatures and high altitudes: The superiority of premixing diethyl ether. Fuel 2024, 372, 132249. [Google Scholar] [CrossRef]

- Sun, H.; Zhang, W.G.; Wang, Y.X. Experimental study on improving cold start performance of diesel engines at extremely low ambient temperatures with diethyl ether. Energy 2023, 283, 129122. [Google Scholar] [CrossRef]

- Sun, H.; Zhang, W.G.; Wang, Y.X. Experimental study on the cerium oxide nanoparticles doped in diesel fuel improving the cold start performance of diesel engines at high-altitude and low-temperature environments. Fuel 2025, 381, 133333. [Google Scholar] [CrossRef]

- Zare, A.; Nabi, M.N.; Bodisco, T.A.; Hossain, F.M.; Rahman, M.M.; Van, T.C.; Ristovski, Z.D.; Brown, R.J. Diesel engine emissions with oxygenated fuels: A comparative study into cold-start and hot-start operation. J. Clean. Prod. 2017, 162, 997–1008. [Google Scholar] [CrossRef]

- Shen, K.; Matthews, R.D.; Chiu, J.P.; Darden, M.H.; Faidley, R.W.; Nichols, S.P.; Weldon, W.F. Initial Study of Railplugs as an Aid for Cold Starting of Diesels; Technical Paper; SAE International: Warrendale, PA, USA, 1994. [Google Scholar]

- Pastor, J.V.; Bermúdez, V.; García-Oliver, J.M.; Ramírez-Hernández, J.G. Influence of spray-glow plug configuration on cold start combustion for high-speed direct injection diesel engines. Energy 2011, 36, 5486–5496. [Google Scholar] [CrossRef]

- Xu, K.; Liu, Y.L.; Zhao, J.; Zhang, H.; He, X. Investigation of the dynamic interaction mechanism of split injections during the ignition process under diesel engine-like cold- and hot-start conditions. Fuel 2024, 370, 131830. [Google Scholar] [CrossRef]

- Lu, K.B.; Qiu, H.J.; Chen, Z.Q.; Shi, L.; Deng, K.Y. Environmental adaptability method for improving the cold start performance of the diesel engine based on pilot injection strategy. Energy 2023, 281, 128215. [Google Scholar] [CrossRef]

- Li, Y.K.; Wang, D.F.; Shi, Z.J.; Chen, H.Y.; Liu, F.S. Environment-adaptive method to control intake preheating for diesel engines at cold-start conditions. Energy 2021, 227, 120423. [Google Scholar] [CrossRef]

- Boehner, W.; Hummel, K. Common Rail Injection System for Commercial Diesel Vehicles; Technical Paper; SAE International: Warrendale, PA, USA, 1997. [Google Scholar]

- Liu, R.C.; Meng, X.H.; Li, P. Transient tribodynamic analysis of crankshaft-main bearing system during engines starting up. J. Eng. Tribol. 2018, 232, 535–549. [Google Scholar] [CrossRef]

- Liu, R.C.; Meng, X.H.; Cui, Y. Influence of numerous start-ups and stops on tribological performance evolution of engine main bearings. Int. J. Engine Res. 2020, 21, 1362–1380. [Google Scholar] [CrossRef]

- da Silva, L.F.M.; Adams, R.D.; Sato, C.; Dilger, K. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering. J. Automob. Eng. 2021, 235, 3223. [Google Scholar] [CrossRef]

- Su, Y.; Liu, Z.; Han, Y.; Guo, L.; Li, J. Improvements on the Start Performance of Diesel Engine by Fuel Control Strategy Optimization and Heating Measures; Technical Paper; SAE International: Warrendale, PA, USA, 2008. [Google Scholar]

- Yang, F.; Zhang, J.; Han, Q.; Ouyang, M. Optimization of a Common Rail Diesel Engine Start-Up Process; Technical Paper; SAE International: Warrendale, PA, USA, 2004. [Google Scholar]

- Miyaki, M.; Fujisawa, H.; Masuda, A.; Yamamoto, Y. Development of New Electronically Controlled Fuel Injection System ECD-U2 for Diesel Engines; Technical Paper; SAE International: Warrendale, PA, USA, 1991. [Google Scholar]

- Stotsky, A. Adaptive estimation of the engine friction torque. Eur. J. Control. 2007, 13, 618–624. [Google Scholar] [CrossRef]

- Konrad, R. Diesel Engine Management Systems and Components; Springer Vieweg: Wiesbaden, Germany, 2014; pp. 220–271. [Google Scholar]

- Huang, Y.; Yang, F.; Ouyang, M.; Chen, L.; Yang, X. Optimal Feedback Control with in-Cylinder Pressure Sensor Under Engine Start Conditions; Technical Paper; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Lin, X.D.; Han, X.M.; Li, D.G. Design and Evaluation for Target Indicated Torque Based Engine Starting Control Strategy in a High Pressure Common Rail Diesel Engine. Math. Probl. Eng. 2016. [Google Scholar] [CrossRef]

| Category | Measuring Instruments | Manufacturer/Location | Measurement Range | Accuracy |

|---|---|---|---|---|

| Dynamometer | APA100 | AVL (Graz, Austria) | 0–12,000 r/min | |

| Gas emission analyzer | MEXA-7100D | HORIBA (Kyoto, Japan) | THC: 0–50,000 ppm NOx: 0–10,000 ppm CO(L): 0–5000 ppm | <0.5% FS <0.5% FS <0.5% FS |

| Soot emission analyzer | 483 | AVL (Graz, Austria) | 0.005–50 mg/m3 | ~5 μg/m3 |

| Opaque smoke meter | 439 | AVL (Graz, Austria) | 0–100% | 0.01% |

| Fuel flow meter | 735S | AVL (Graz, Austria) | 0–125 kg/h | ≤0.0005 g/cm3 |

| Cylinder pressure sensor | 6058AS41 | Kistler (Winterthur, Switzerland) | 0–250 bar | ≤±0.4%/FSO |

| Charge amplifier | 5011 | Kistler (Winterthur, Switzerland) | ±10–999,000 pC | <±0.05% FS |

| Combustion analyzer | Indicom | AVL (Graz, Austria) |

| Description | Specification |

|---|---|

| Engine type | Four-stroke inline diesel |

| Number of cylinders | 6 |

| Bore | 102 mm |

| Stroke | 120 mm |

| Displacement volume | 7 L |

| Compression ratio | 16.1 |

| Rated power at speed | 248 kW@2100 r/min |

| Maximum torque at speed | 1150 Nm@1200–1800 r/min |

| Connecting rod length | 198 mm |

| Eddy current ratio | 1.5 |

| Groups | Start Time (s) | Cumulative Fuel Consumption (mg) | Speed Overshoot (rpm) | Overshooting Time (s) | Average HC (ppm) | Average CO (ppm) | Average NOx (ppm) |

|---|---|---|---|---|---|---|---|

| A | 1.84 | 919.0 | 35 | 2.18 | 54.14 | 72.55 | 191.92 |

| B | 1.81 | 889.3 | 34 | 2.02 | 52.43 | 76.29 | 194.68 |

| C | 1.7 | 858.7 | 40 | 2.35 | 59.71 | 73.73 | 188.11 |

| D | 1.73 | 872.2 | 37 | 2.23 | 53.119 | 76.68 | 193.41 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Li, D.; Yang, M.; Zhang, H.; Guo, L.; Qu, D.; Liu, J.; Lin, X. Transient Injection Quantity Control Strategy for Automotive Diesel Engine Start-Idle Based on Target Speed Variation Characteristics. Energies 2025, 18, 5256. https://doi.org/10.3390/en18195256

Liu Y, Li D, Yang M, Zhang H, Guo L, Qu D, Liu J, Lin X. Transient Injection Quantity Control Strategy for Automotive Diesel Engine Start-Idle Based on Target Speed Variation Characteristics. Energies. 2025; 18(19):5256. https://doi.org/10.3390/en18195256

Chicago/Turabian StyleLiu, Yingshu, Degang Li, Miao Yang, Hao Zhang, Liang Guo, Dawei Qu, Jianjiang Liu, and Xuedong Lin. 2025. "Transient Injection Quantity Control Strategy for Automotive Diesel Engine Start-Idle Based on Target Speed Variation Characteristics" Energies 18, no. 19: 5256. https://doi.org/10.3390/en18195256

APA StyleLiu, Y., Li, D., Yang, M., Zhang, H., Guo, L., Qu, D., Liu, J., & Lin, X. (2025). Transient Injection Quantity Control Strategy for Automotive Diesel Engine Start-Idle Based on Target Speed Variation Characteristics. Energies, 18(19), 5256. https://doi.org/10.3390/en18195256