Optimization of Low-Carbon Operation and Capacity Expansion of Integrated Energy Systems in Synergy with Incremental Distribution Network for Industrial Parks

Abstract

1. Introduction

1.1. Literature Review

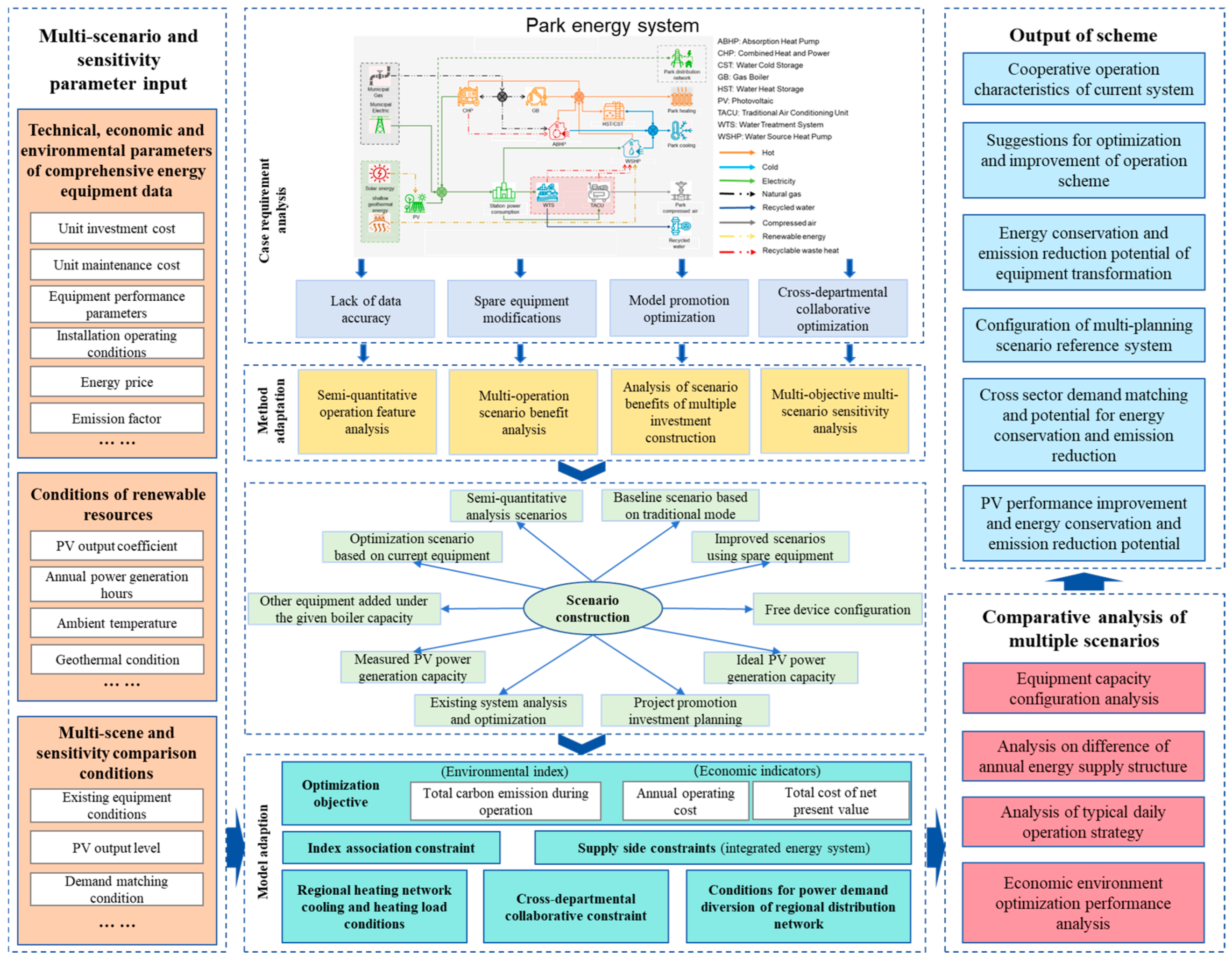

1.2. Motivation and Contribution

- (1)

- Characterizing data with limited accuracy and gaps establishes quantitative references for operational optimization.

- (2)

- Multi-scenario assessment of economic–environmental feasibility for retrofit participation in energy supply, comparing the feasibility of equipment retrofitting and system deployment.

- (3)

- Multi-scenario sensitivity analysis of cross-sector optimization feasibility, identifying coordinated optimization potential and impacts of varying electric-heating/cooling load ratios.

2. Methods

2.1. Objectives Functions of IES Model

2.1.1. Economic Objectives

2.1.2. Environmental Objectives

2.2. Energy Balance Constraints of IES Model

2.2.1. Energy Flow Balance Within Hub

2.2.2. Energy Conversion Balance

2.2.3. Energy Storage Balance

2.3. Capacity Constraints

3. Case Study

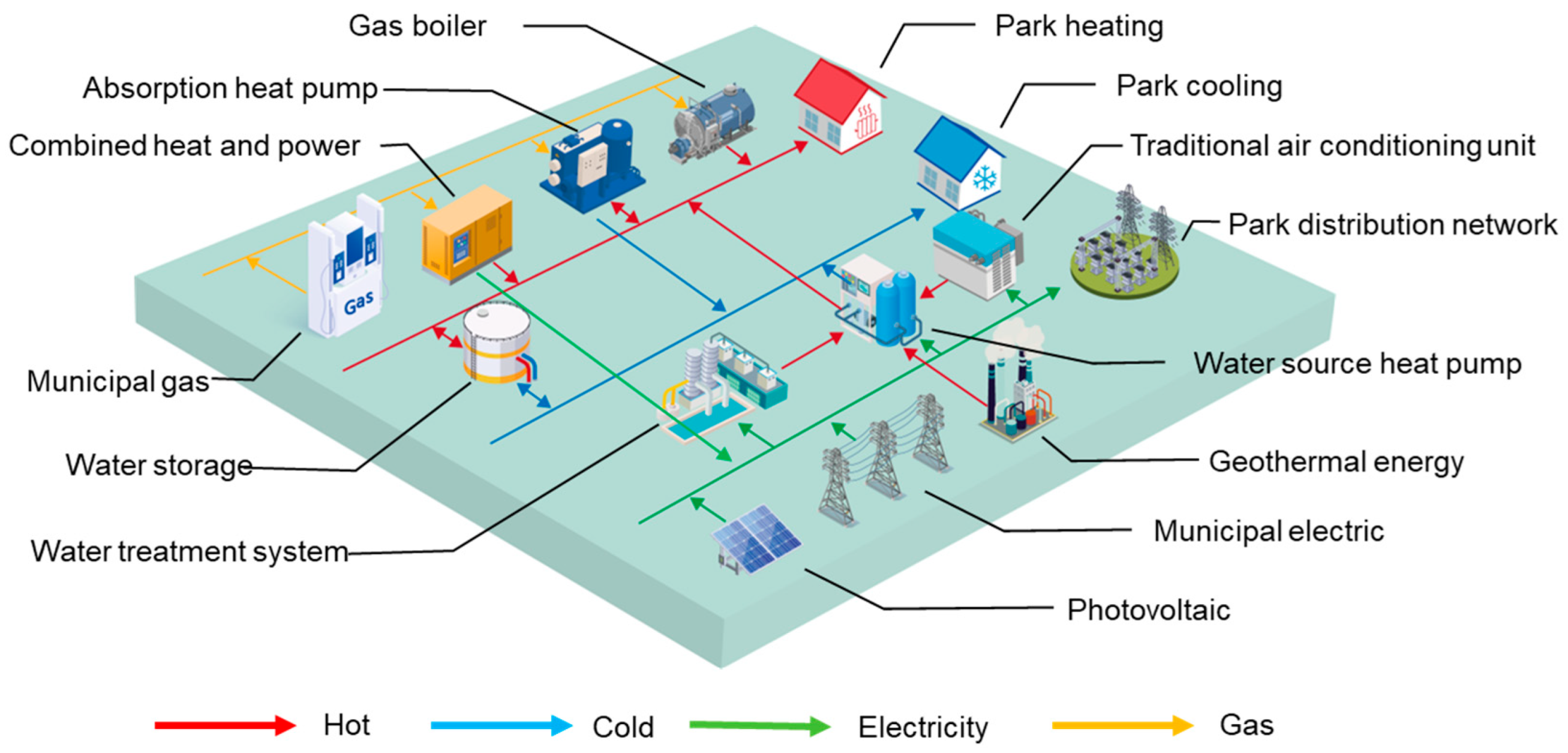

3.1. Case Overview

3.2. Comparison Optimization Scenario Basic Condition Setting

3.2.1. Scenario Group (S1) for Comparison of System Operation Mode Analysis and Program Optimization Based on Different Equipment Conditions

3.2.2. Comparison of System Design Optimization Scenario Groups Based on Different Pre-Existing Equipment Situations and Planning Conditions (S2)

4. Results and Discussion

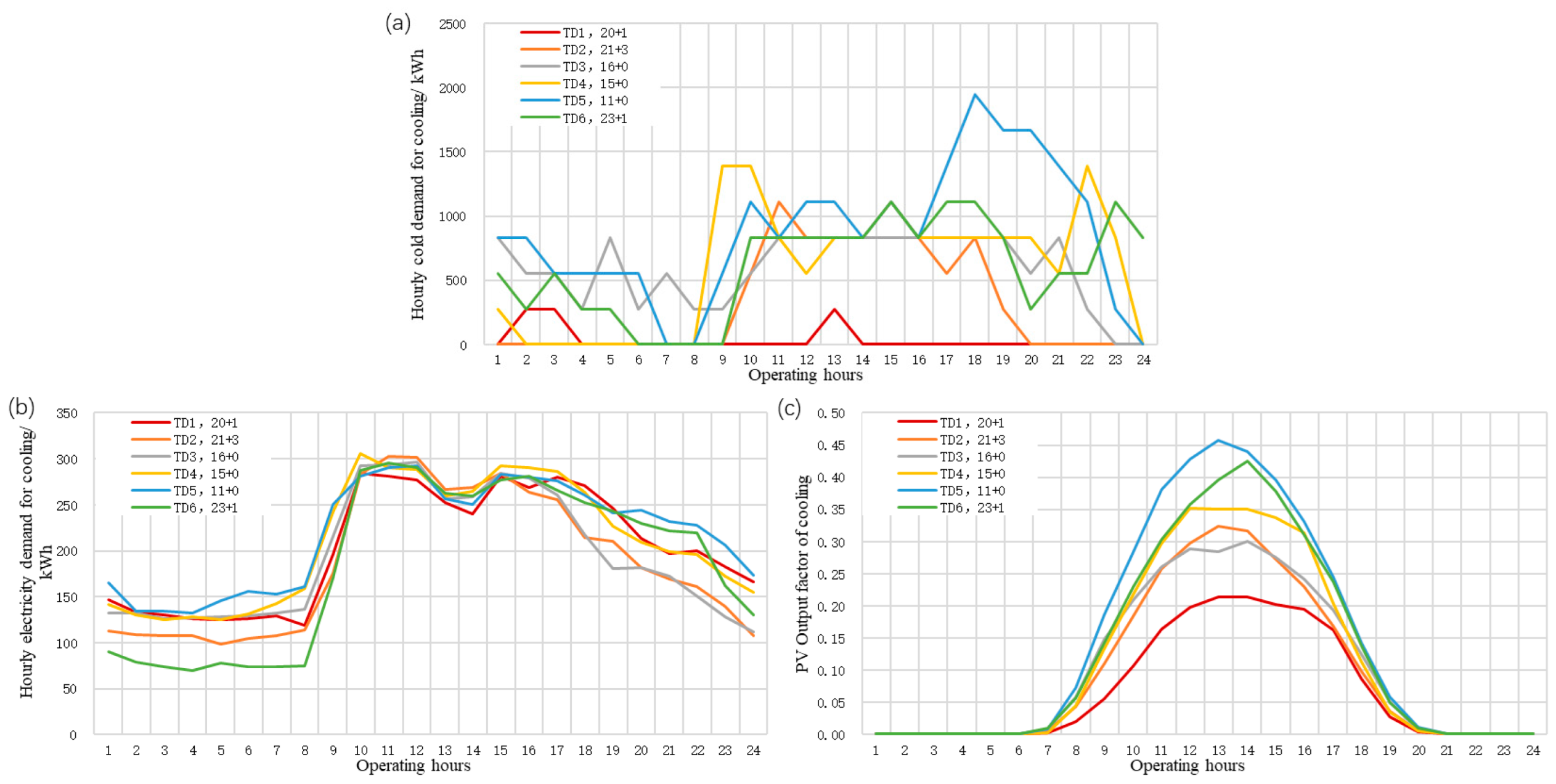

4.1. Characterization of the System’s Annual Operating Conditions and Typical Day’s Operation

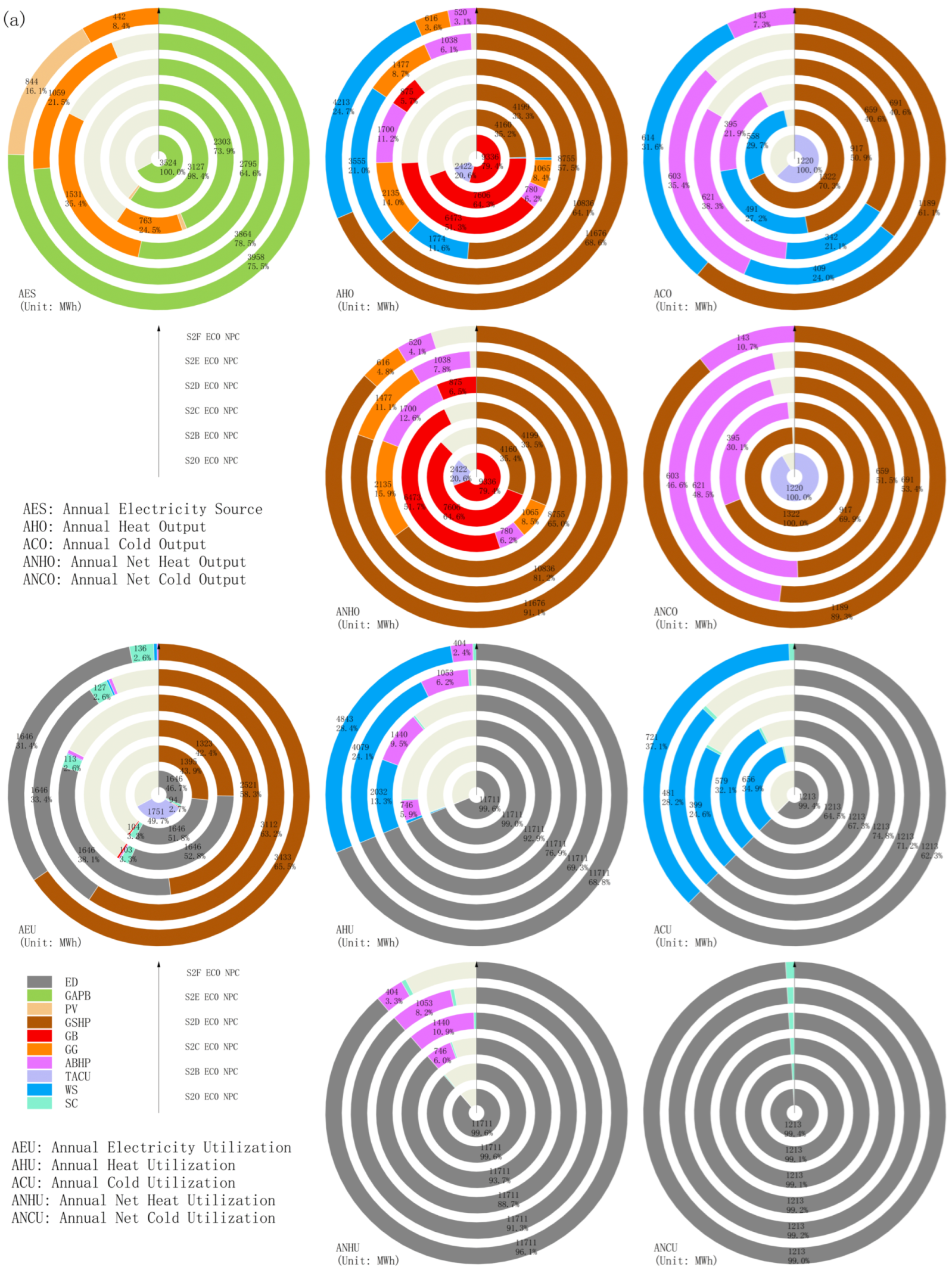

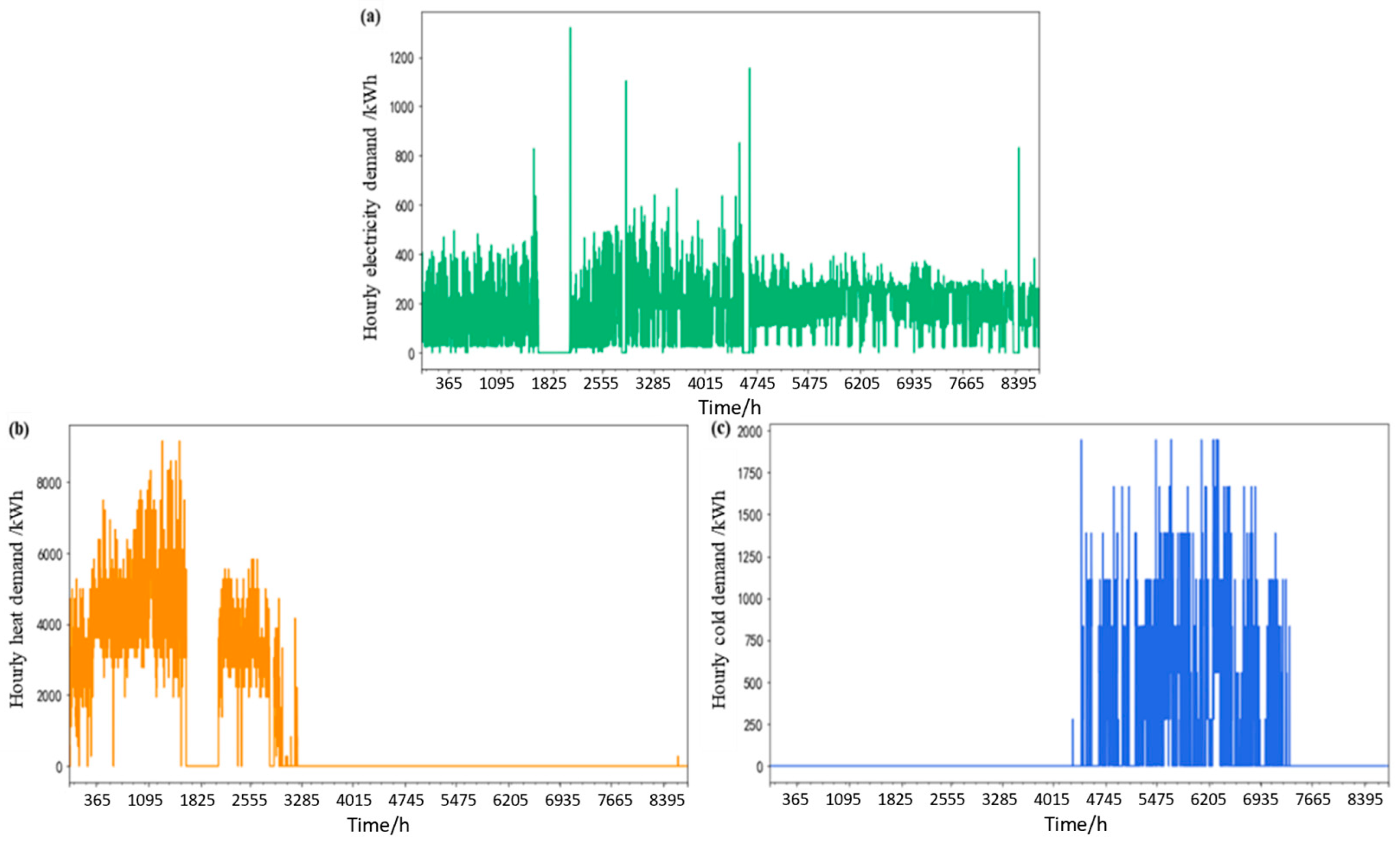

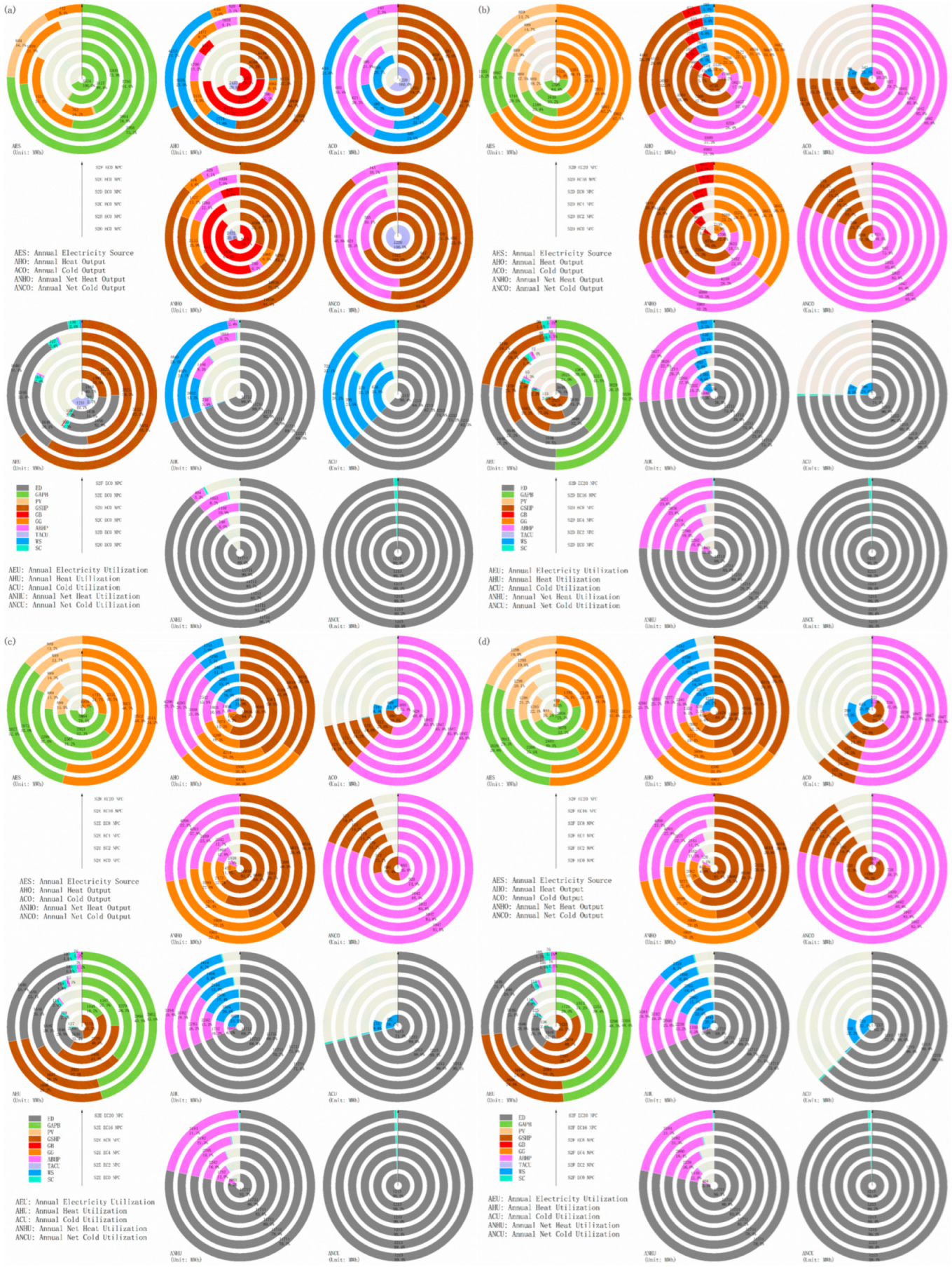

4.1.1. Overview of the Overall Energy Supply in a Typical Operating Year

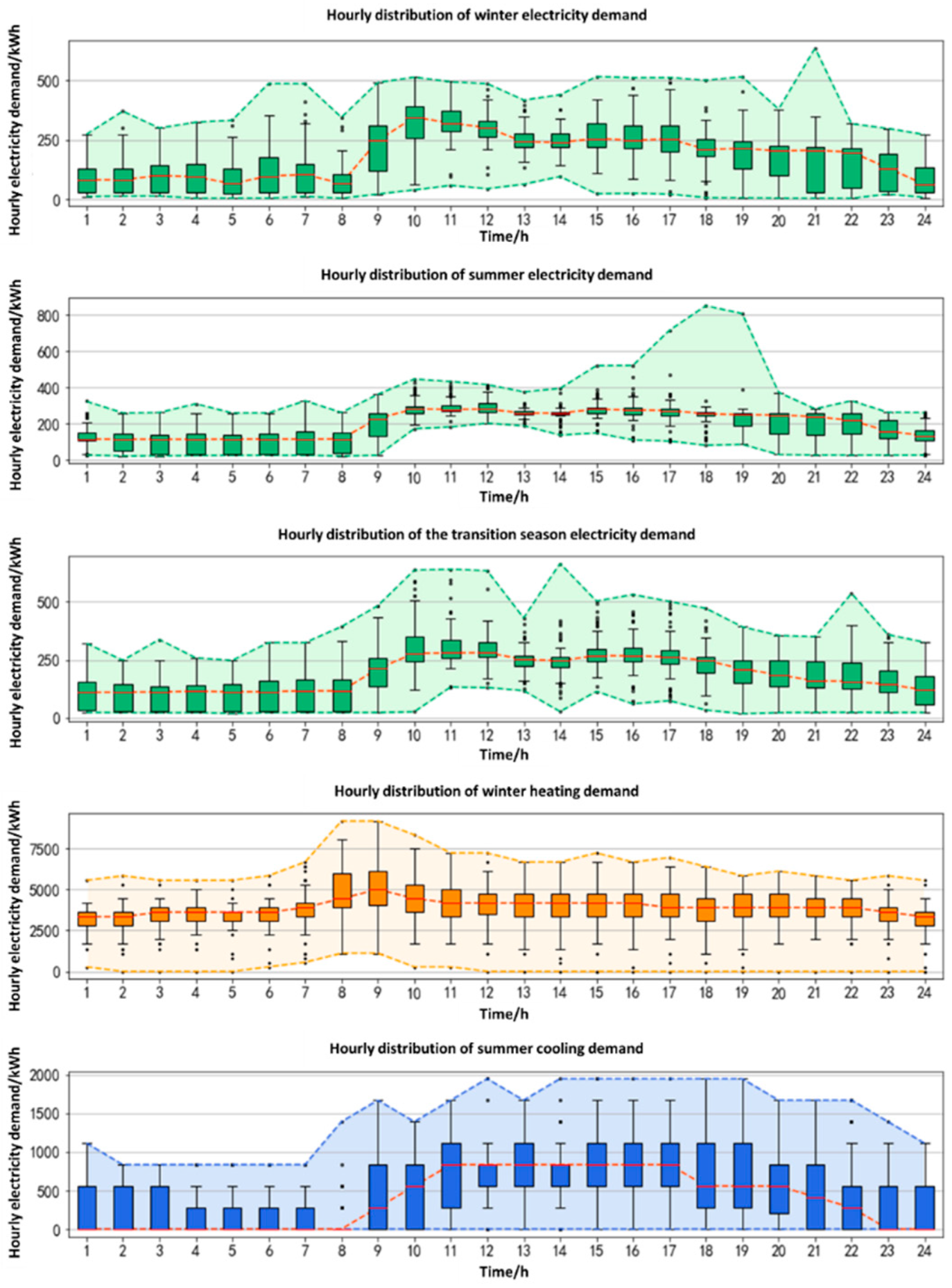

4.1.2. Analysis of the Distribution of Multi-Energy Demand by Season

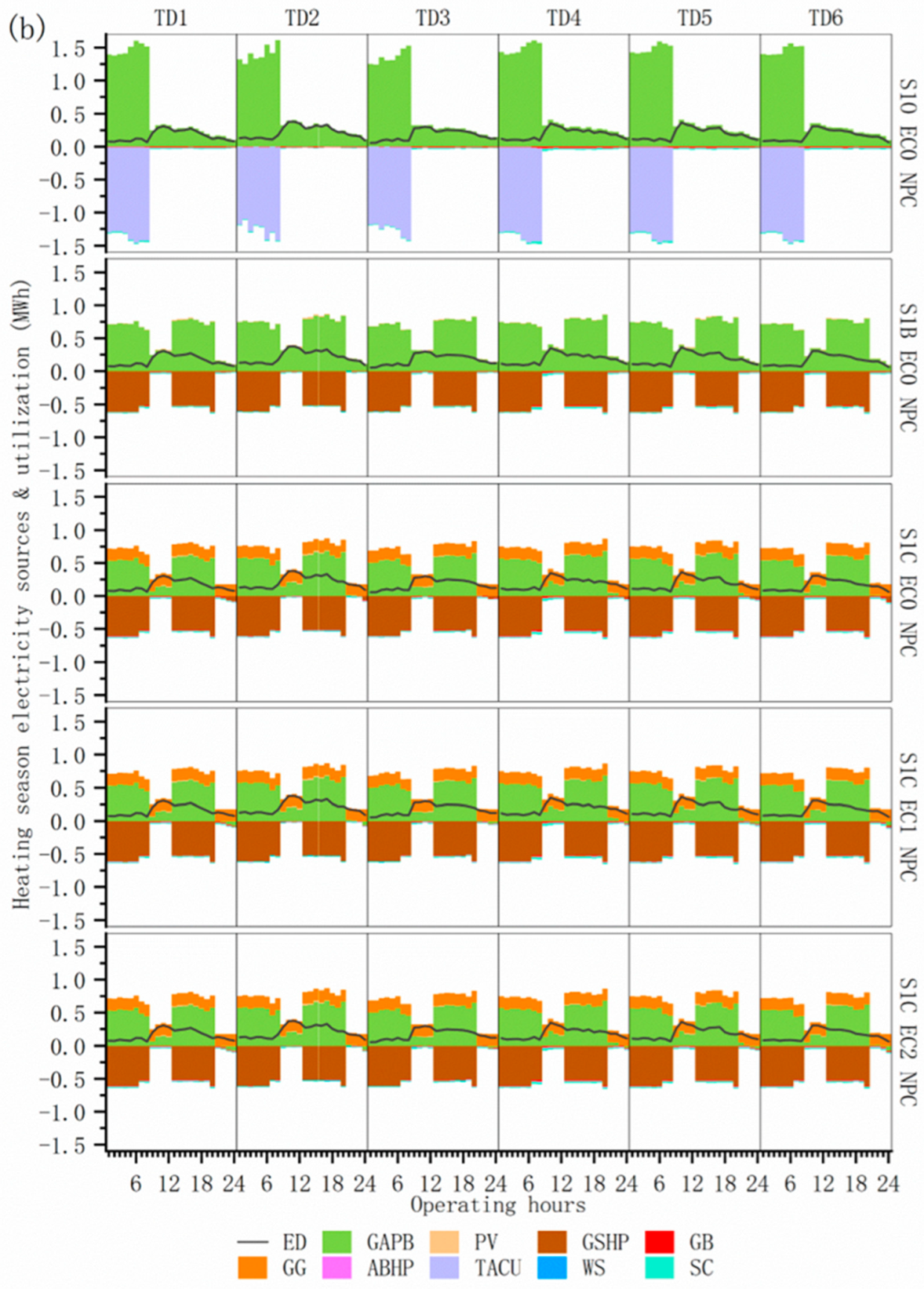

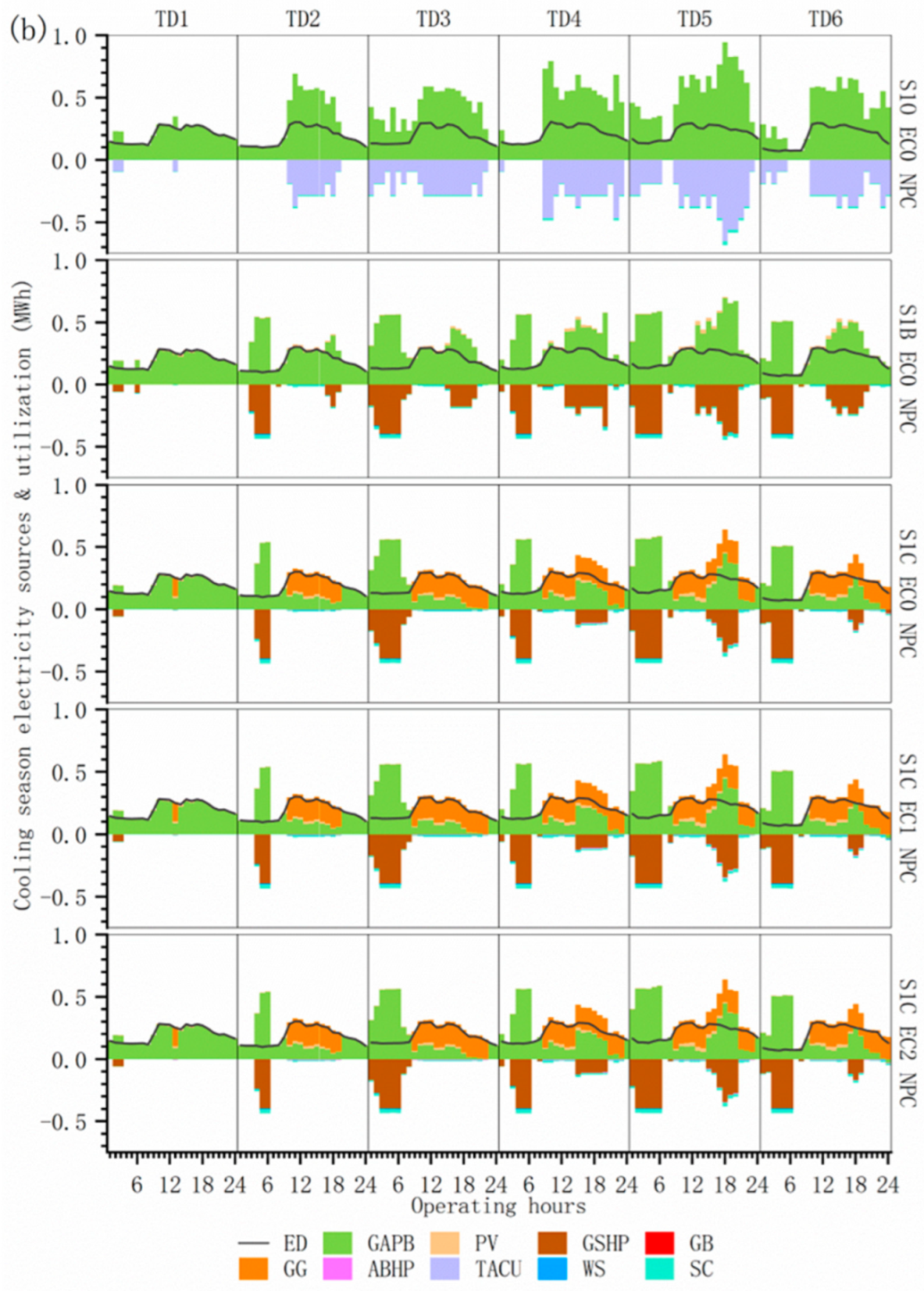

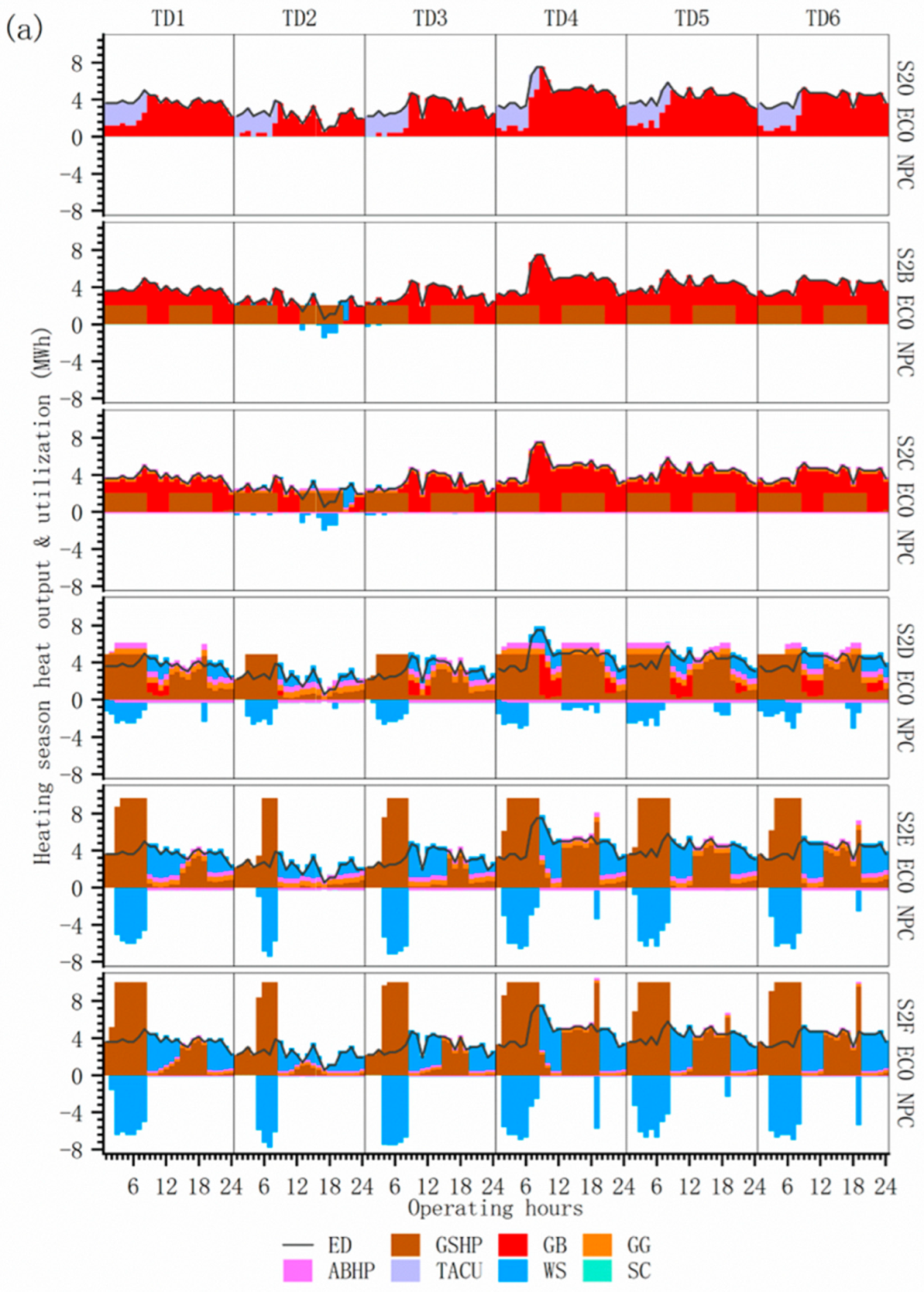

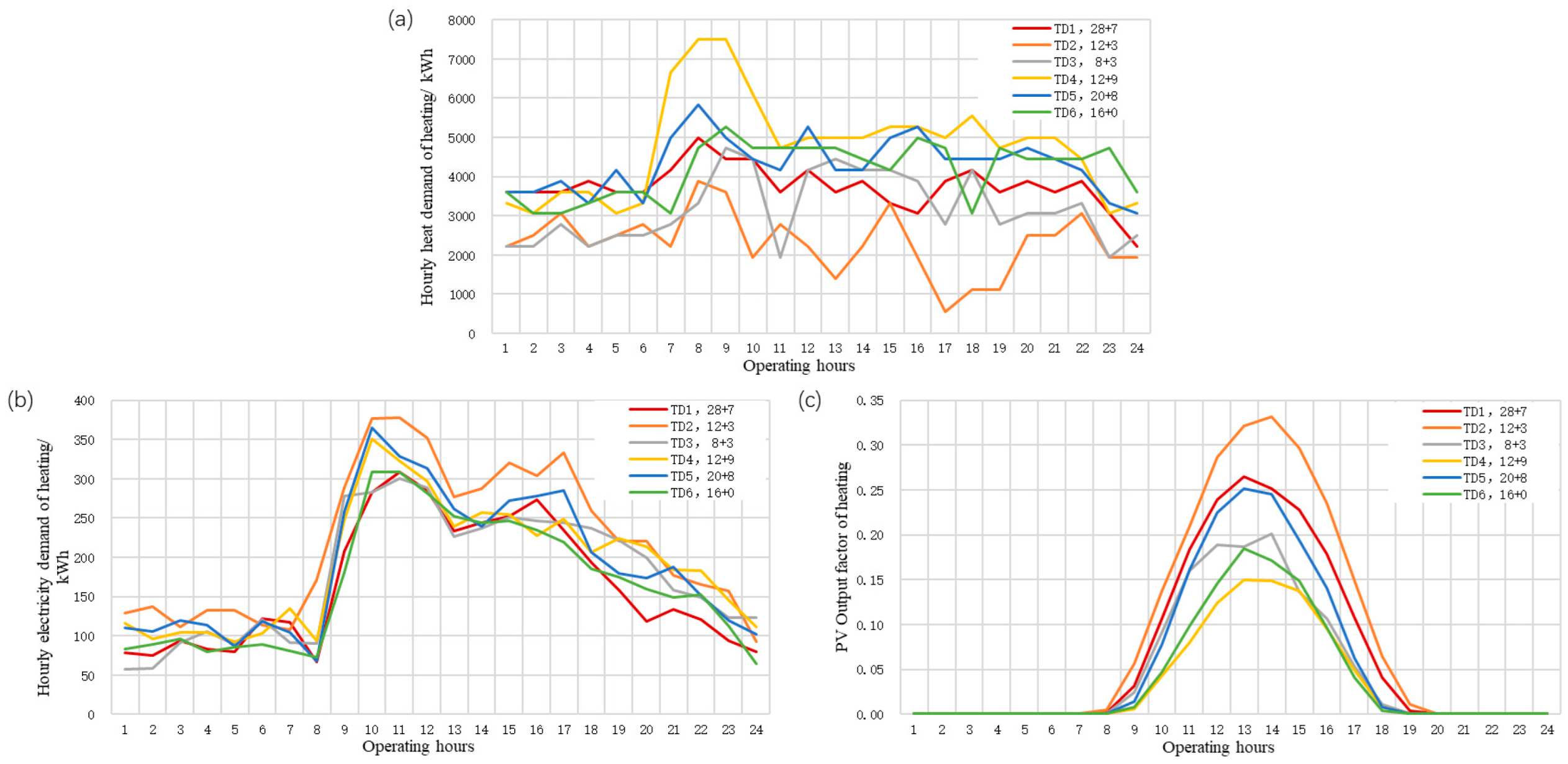

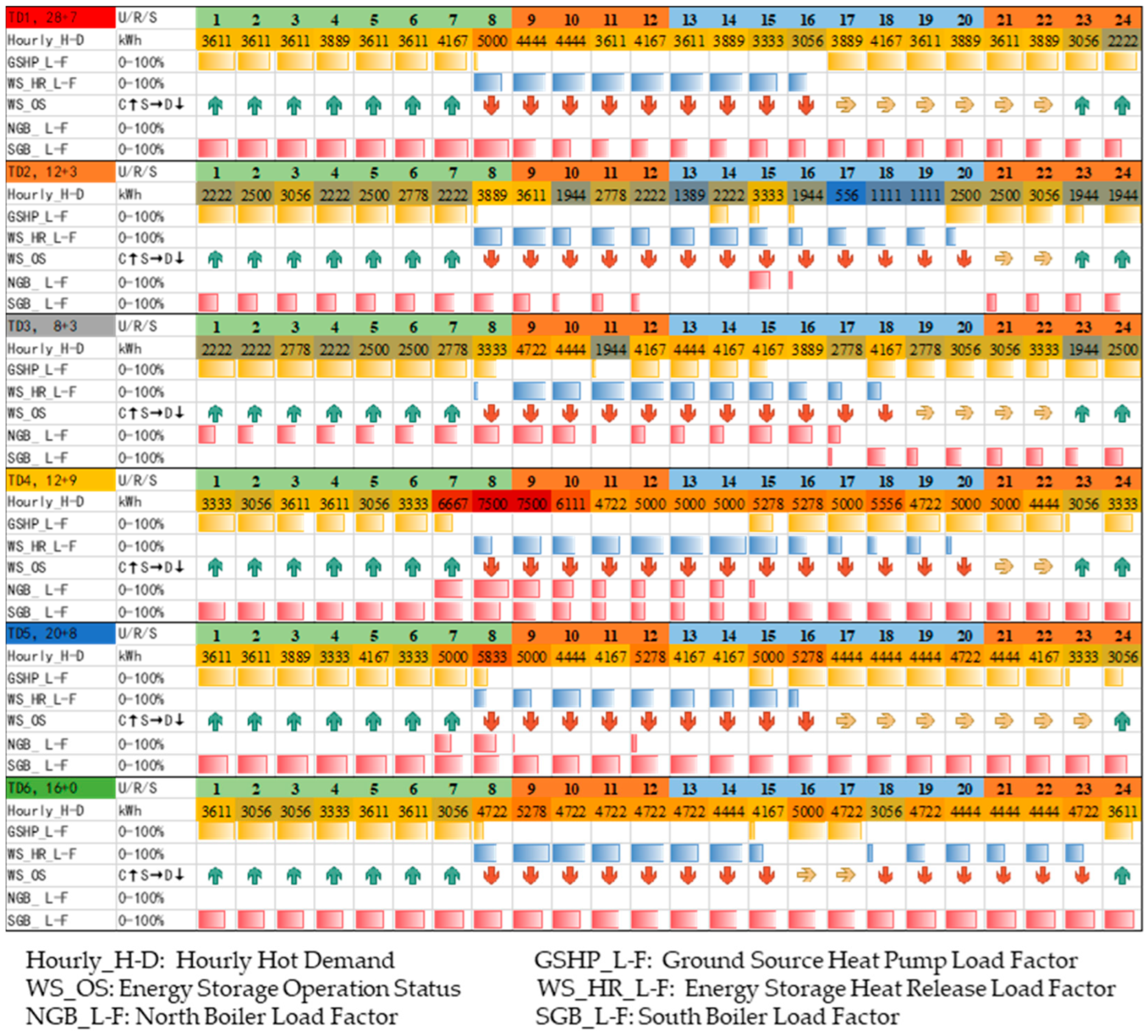

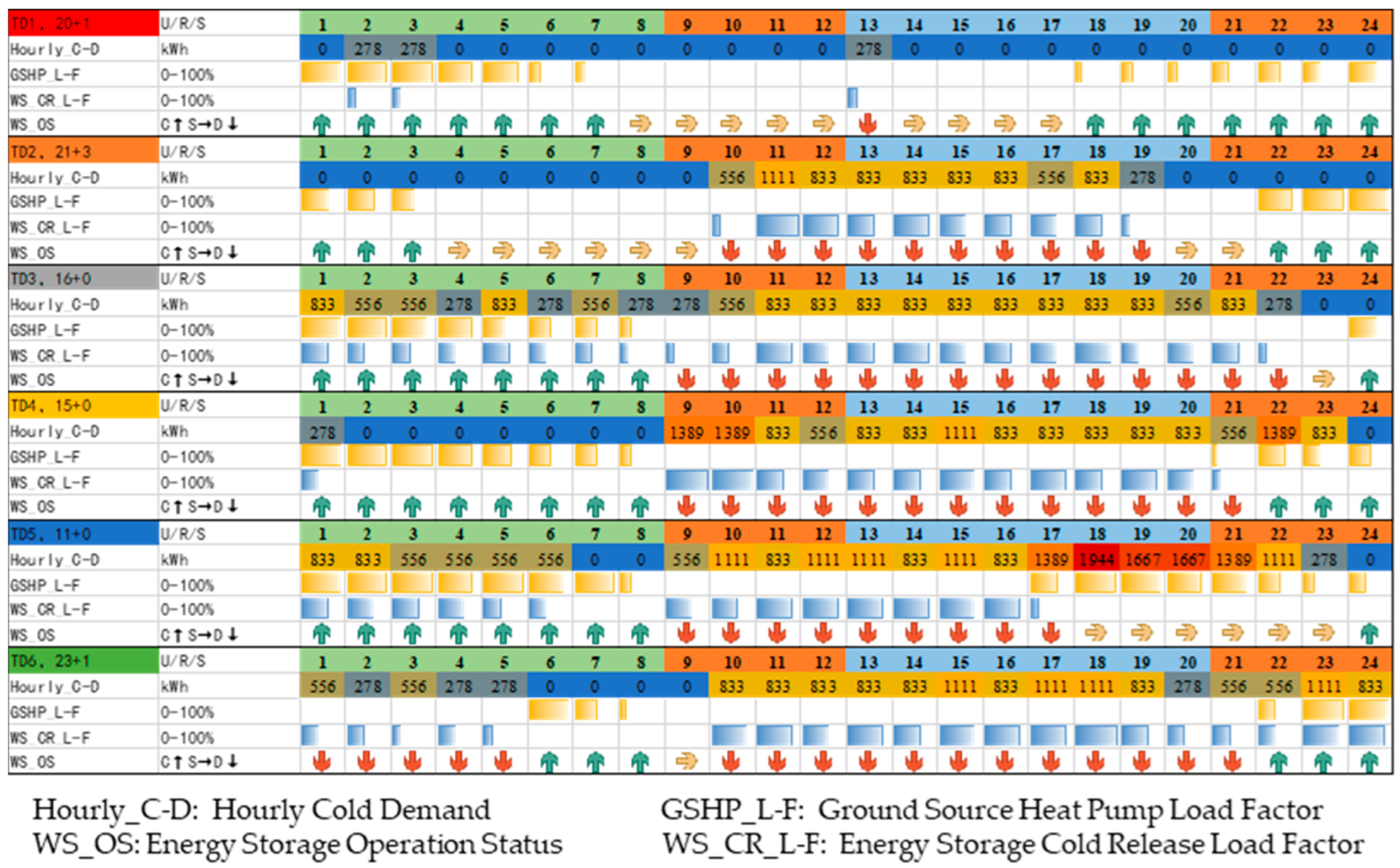

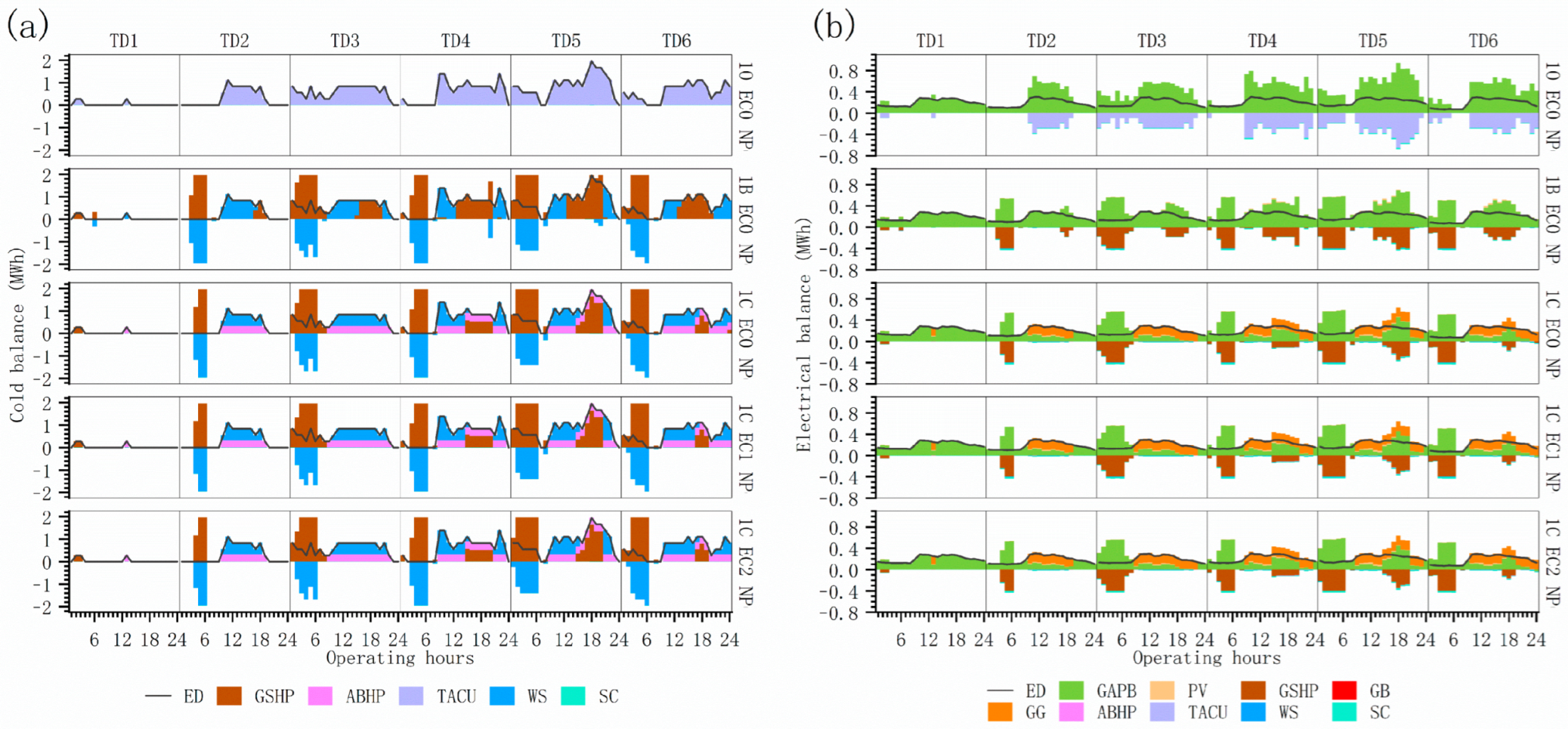

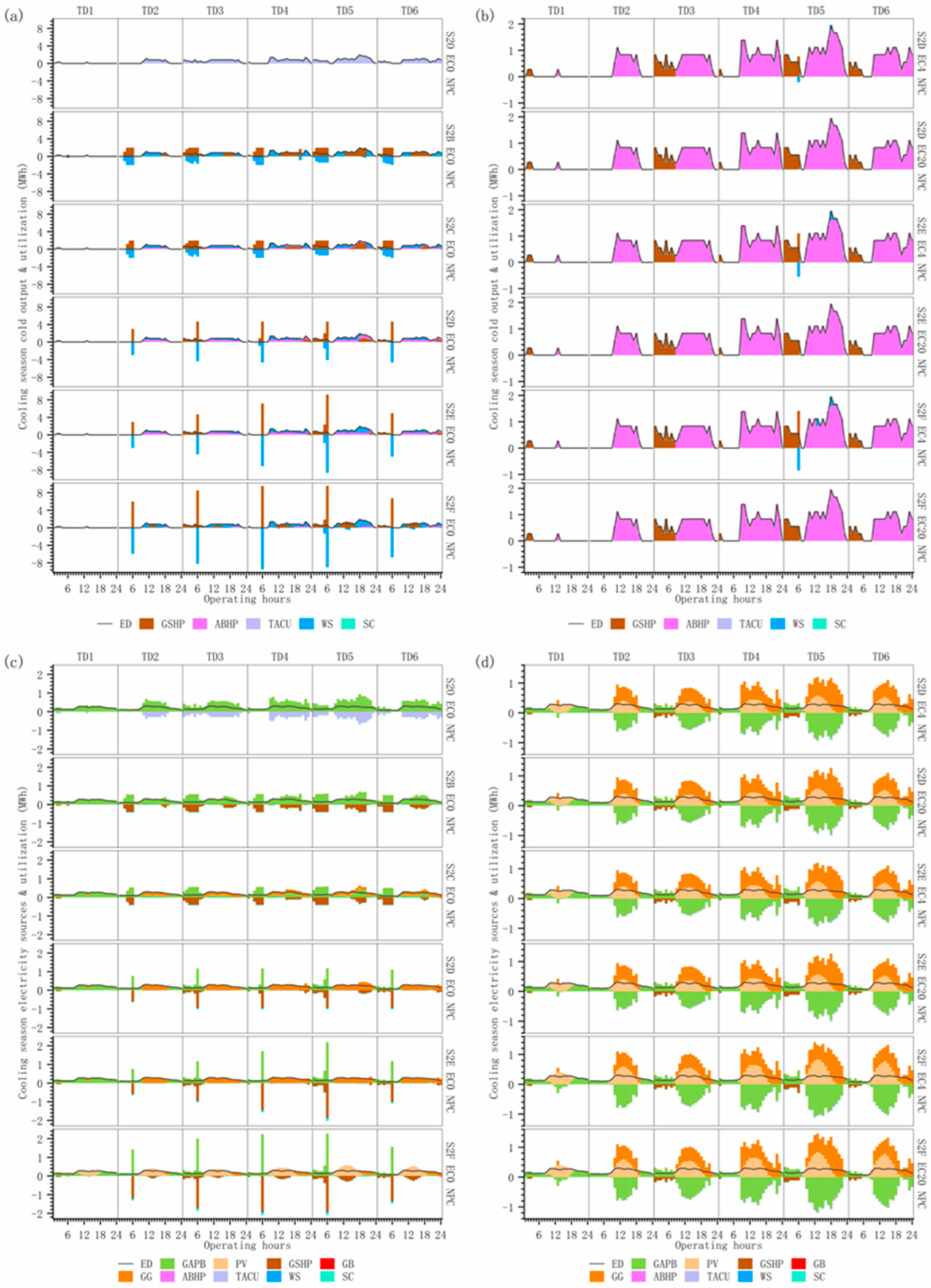

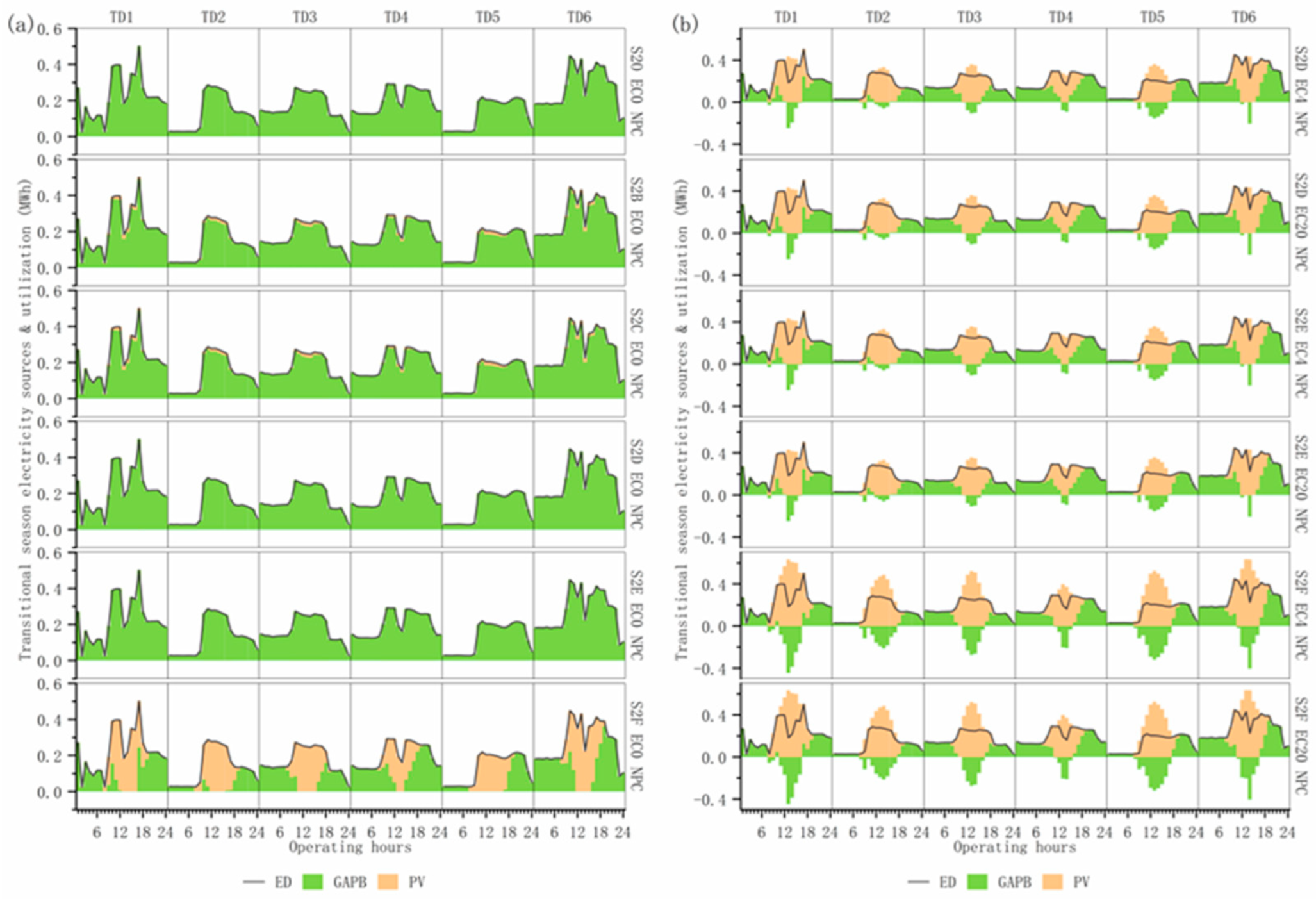

4.1.3. Characterization of Energy Supply and Multi-Equipment Operation on a Typical Day

4.2. Optimization of Multi-Scenario Operating Scenarios with Differences in Equipment Usage Conditions

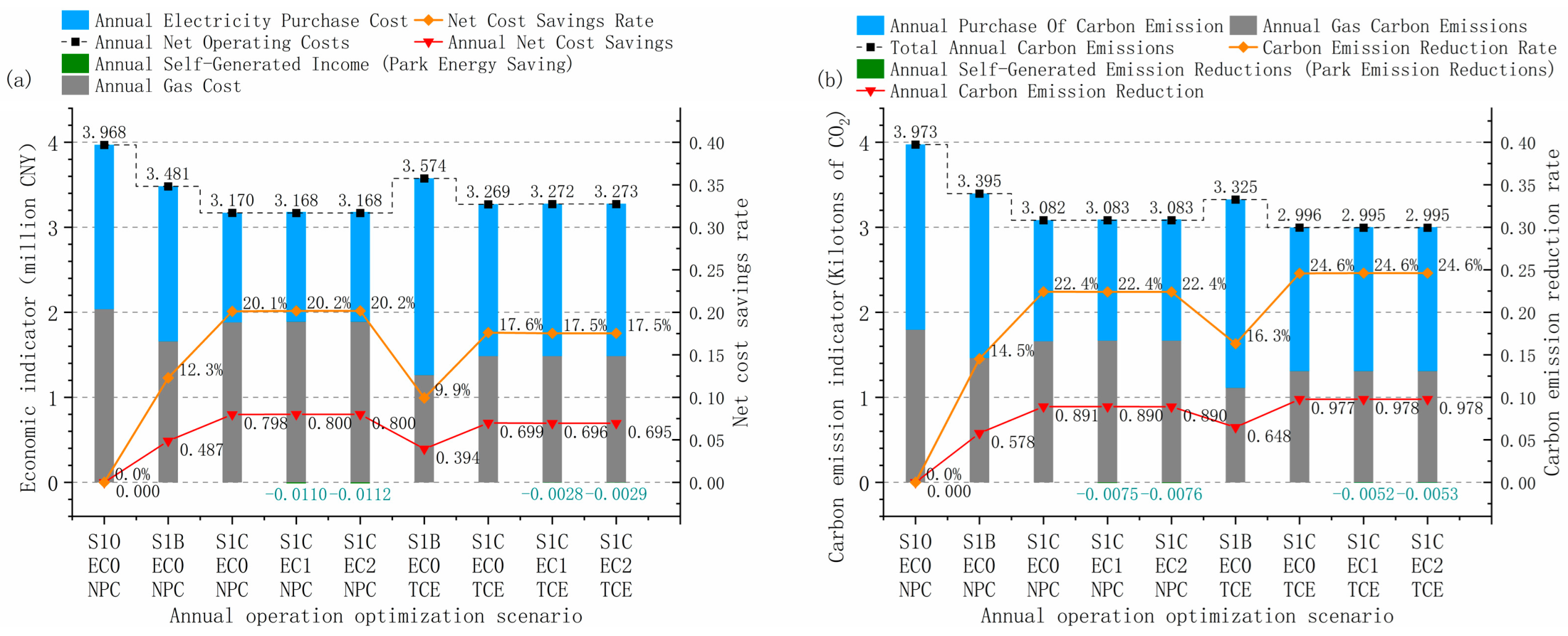

4.2.1. Multi-Run Optimization Scenario Optimization Performance Analysis

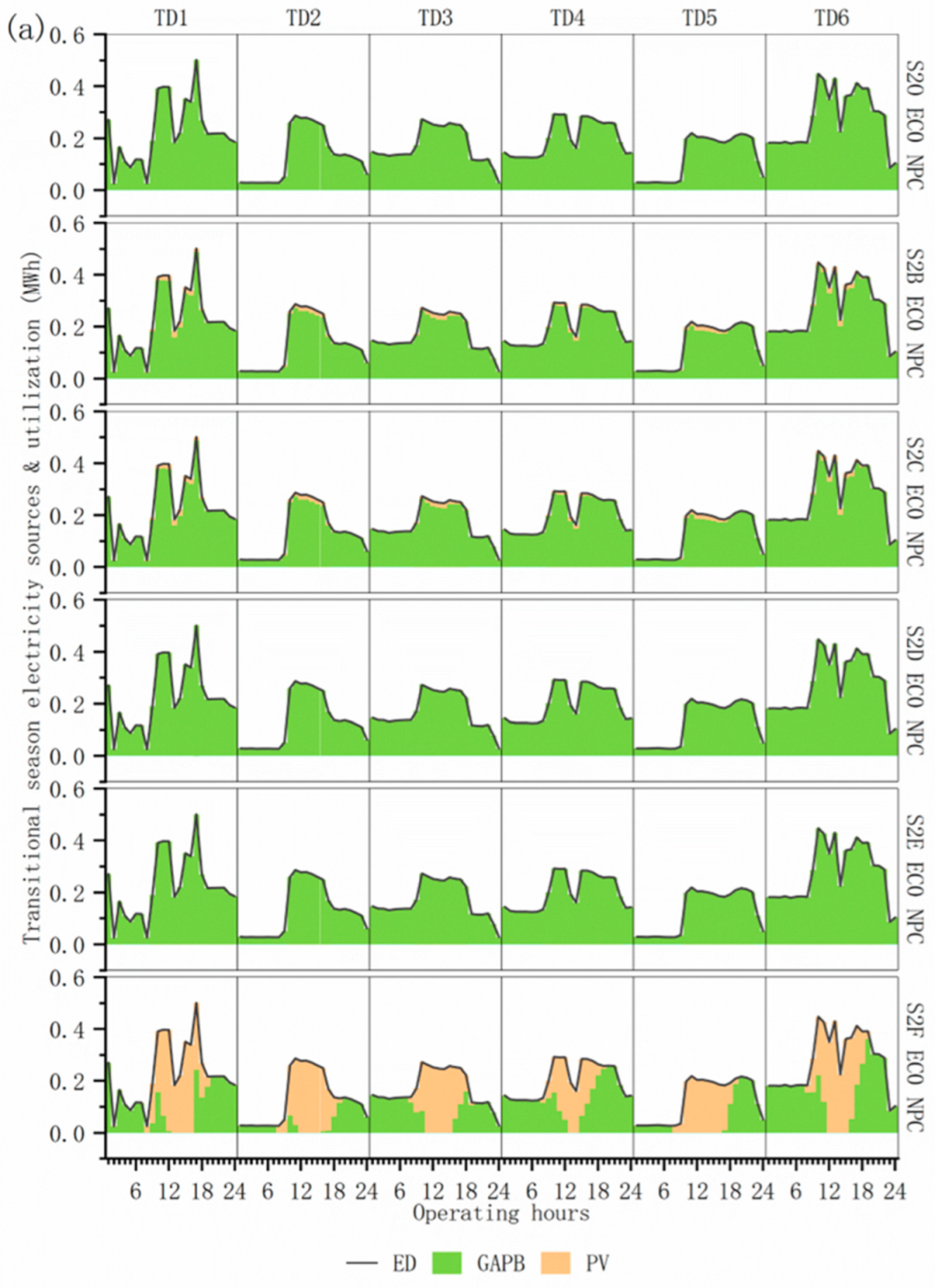

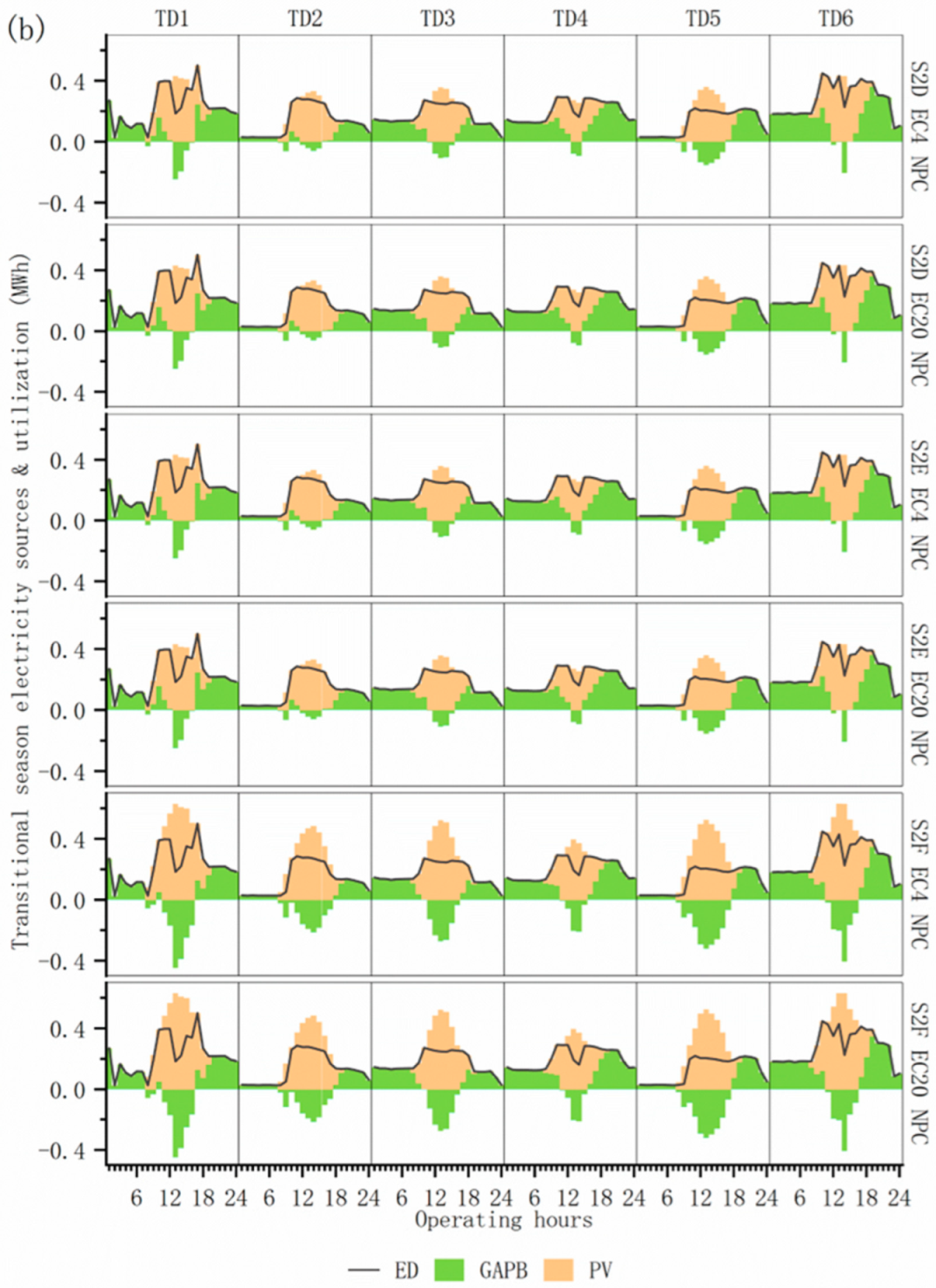

4.2.2. Energy Supply–Demand Structure Under Multiple Operational Optimization Scenarios

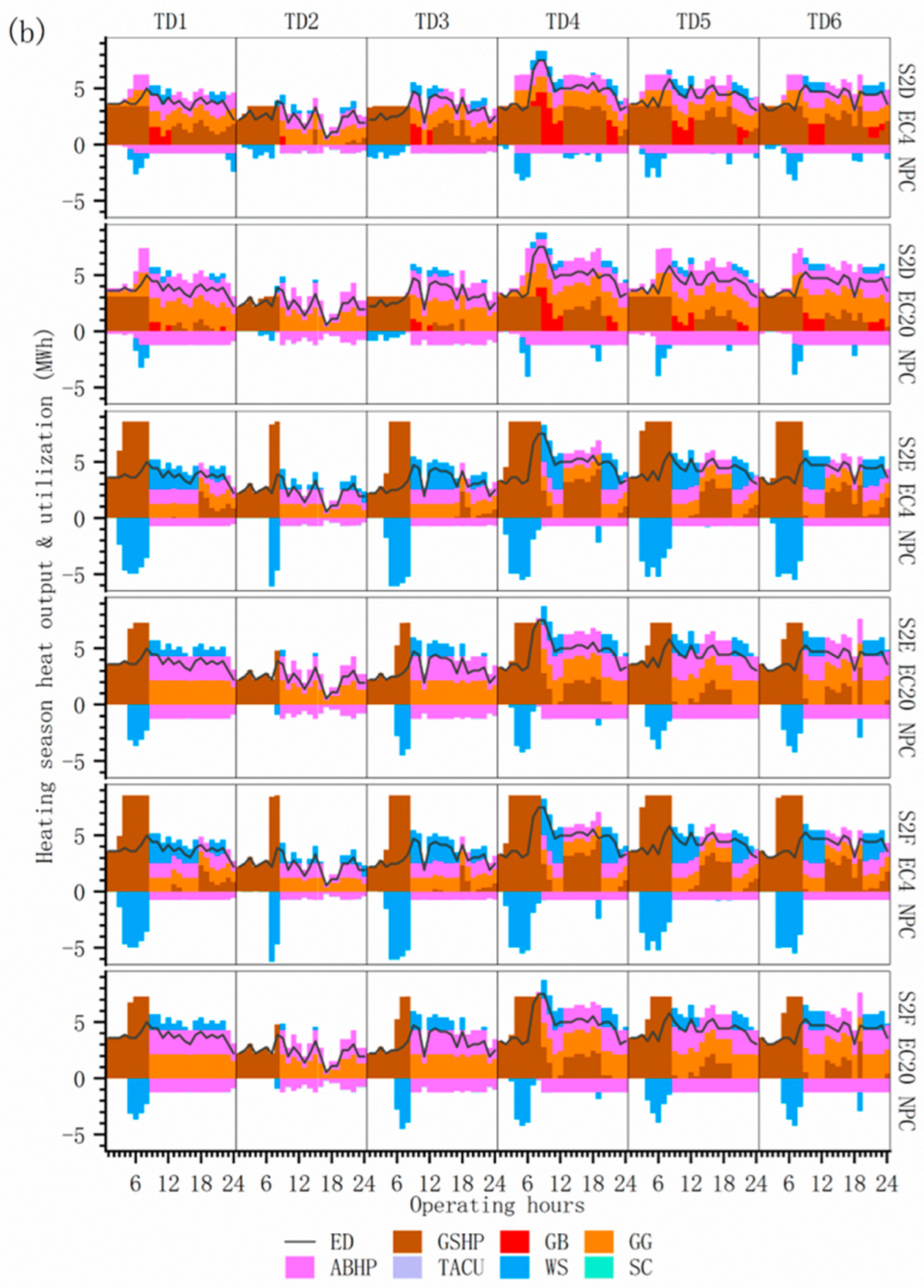

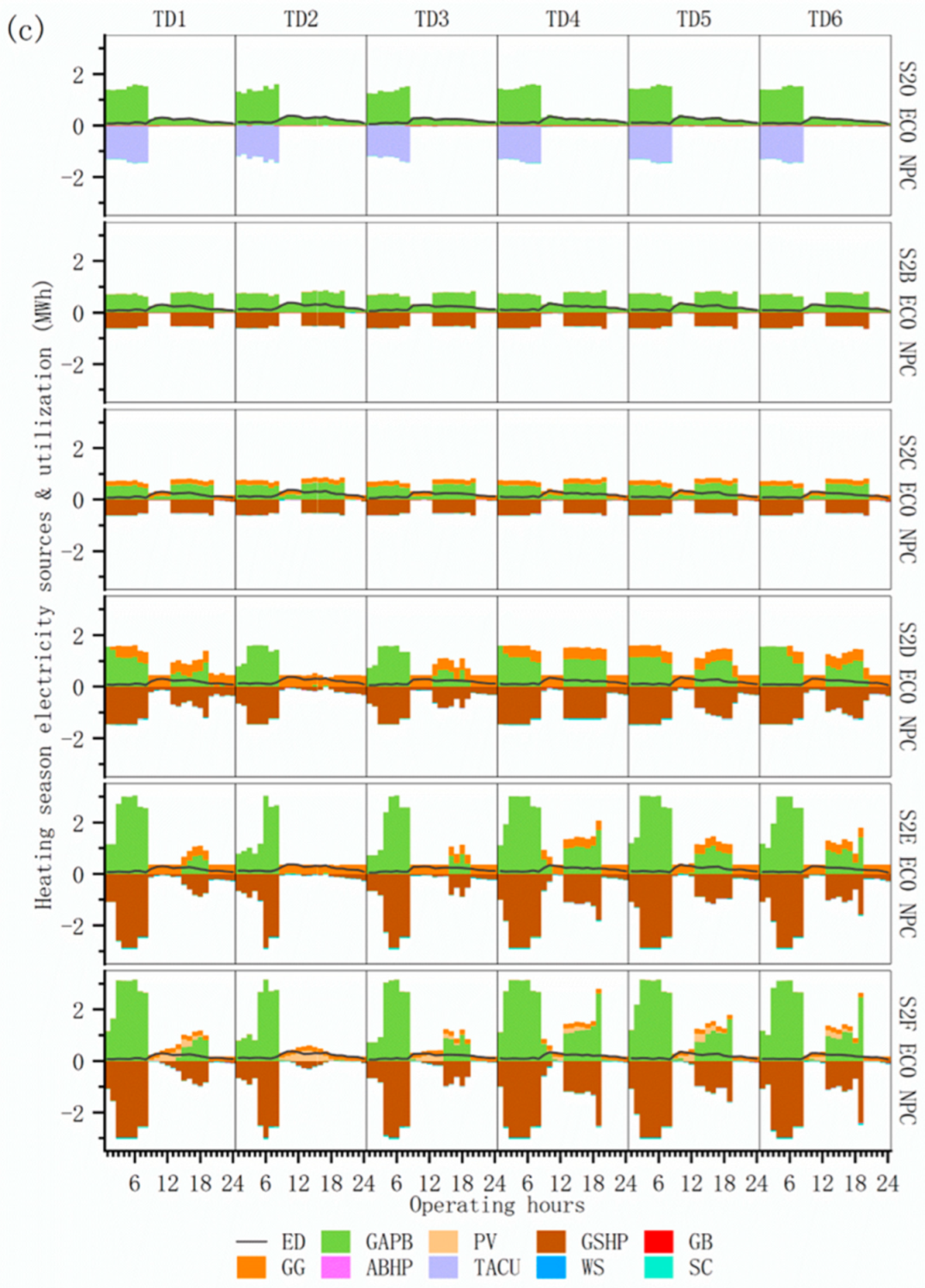

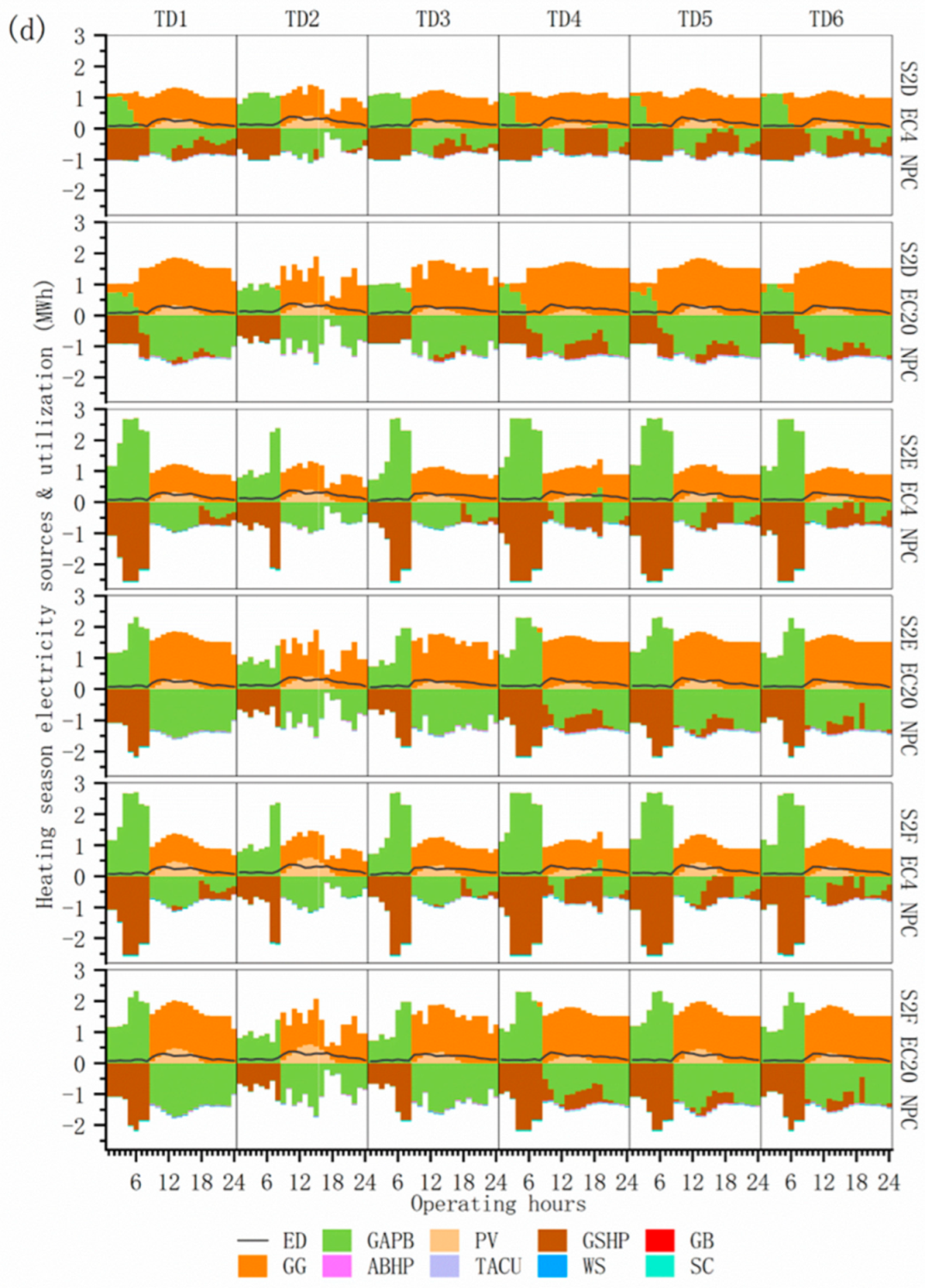

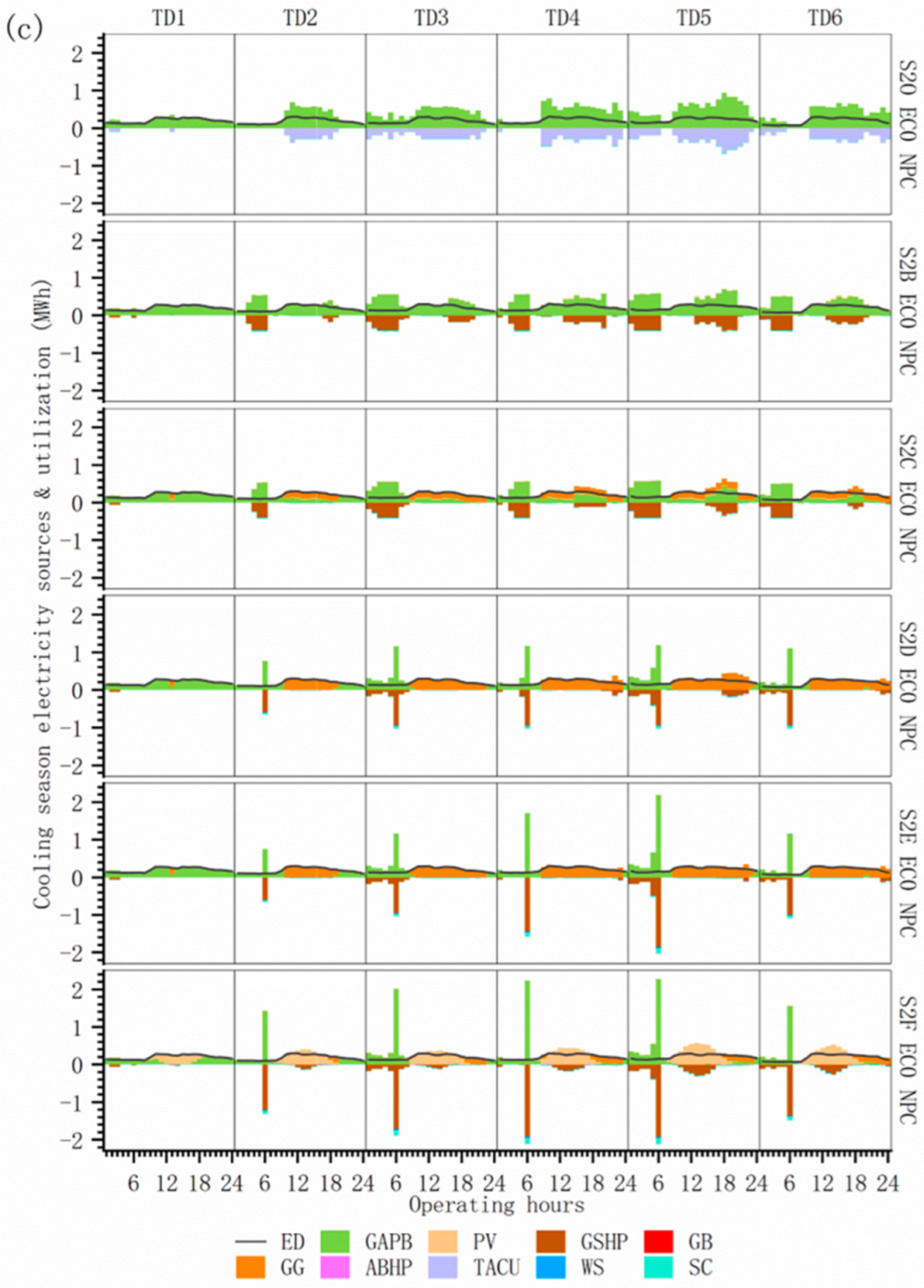

4.2.3. Comparative Analysis of Multiple Operational Optimization Scenarios

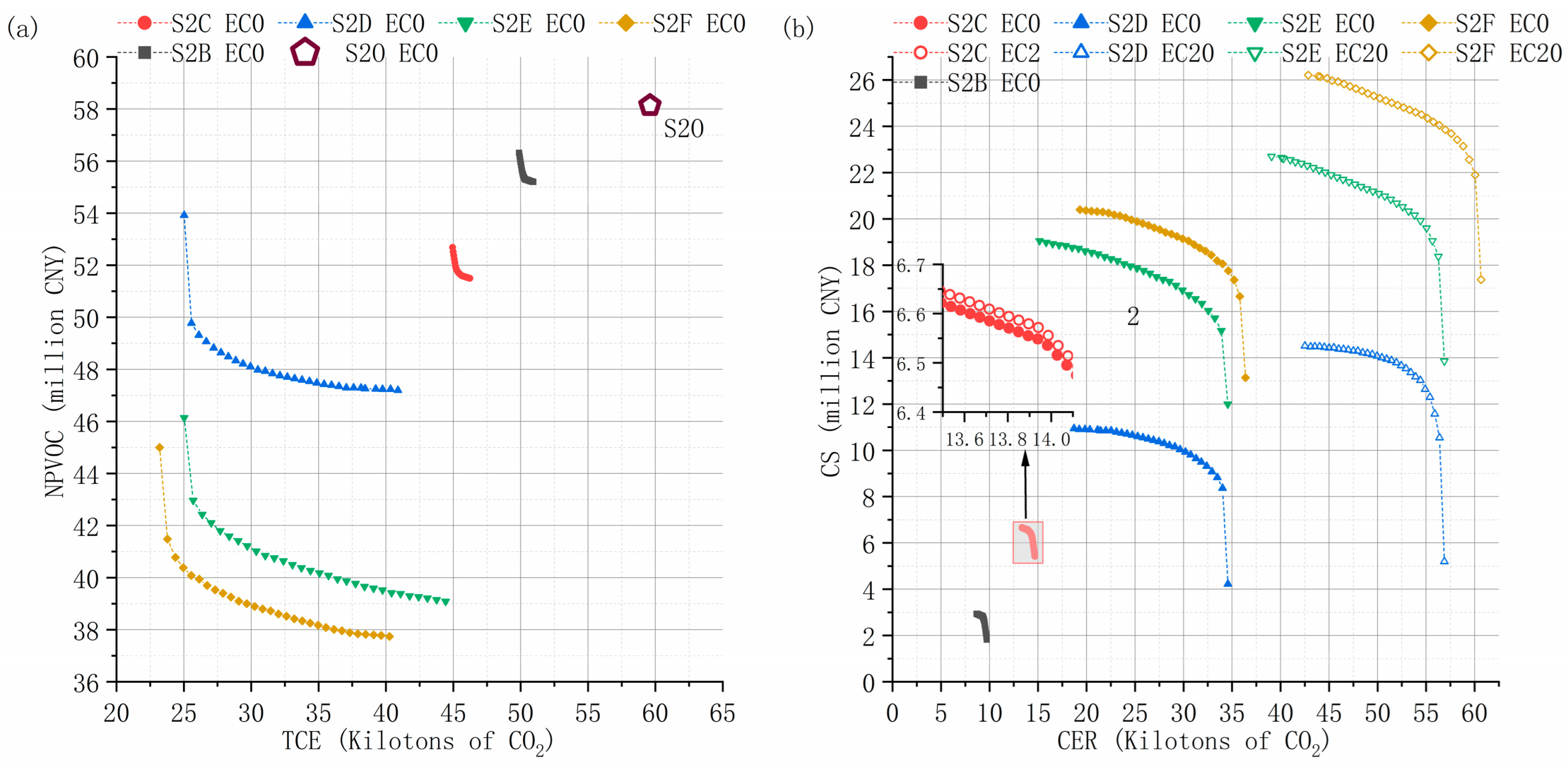

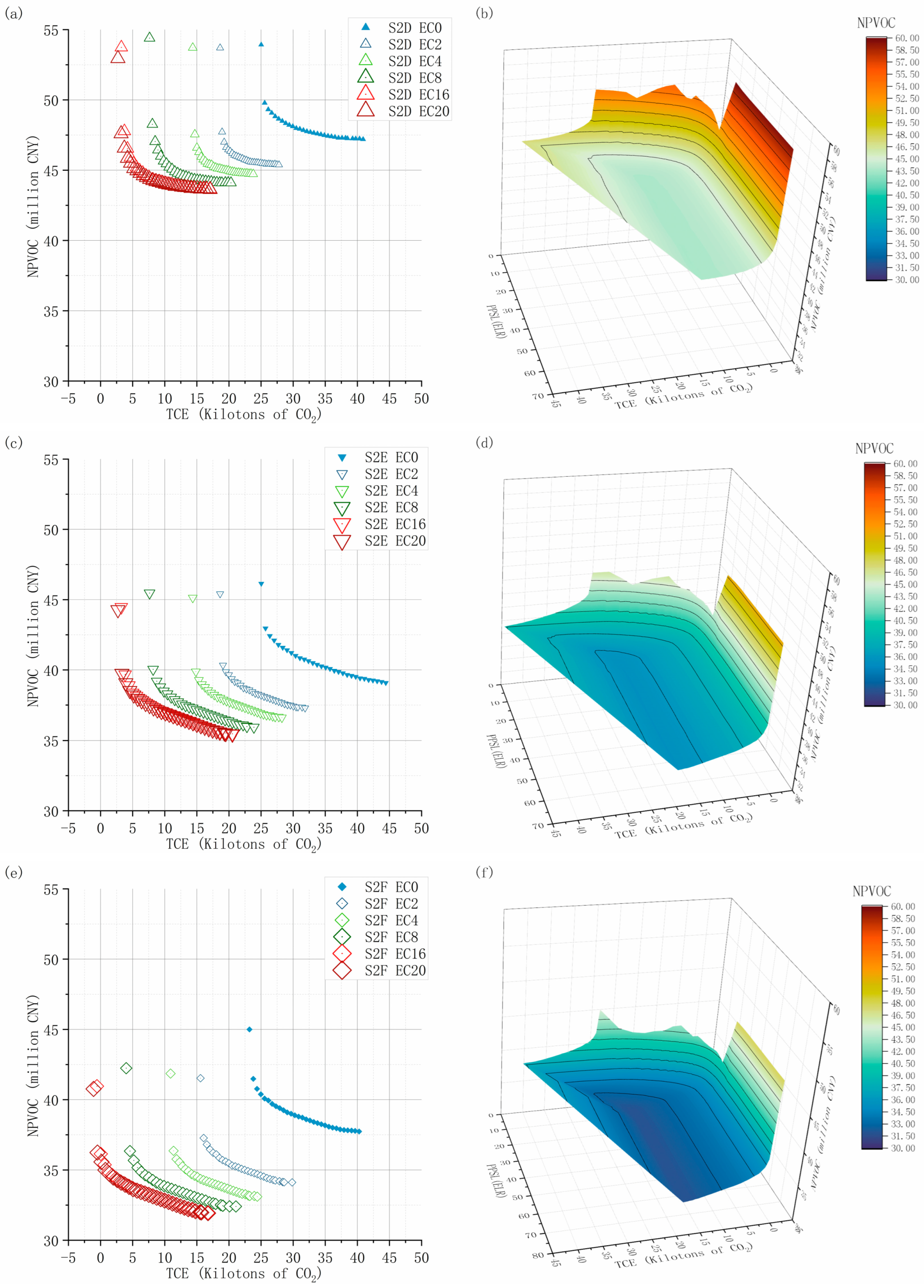

4.3. Optimization of Multi-Scenario Investment Approaches with Differences in Investment Planning Conditions

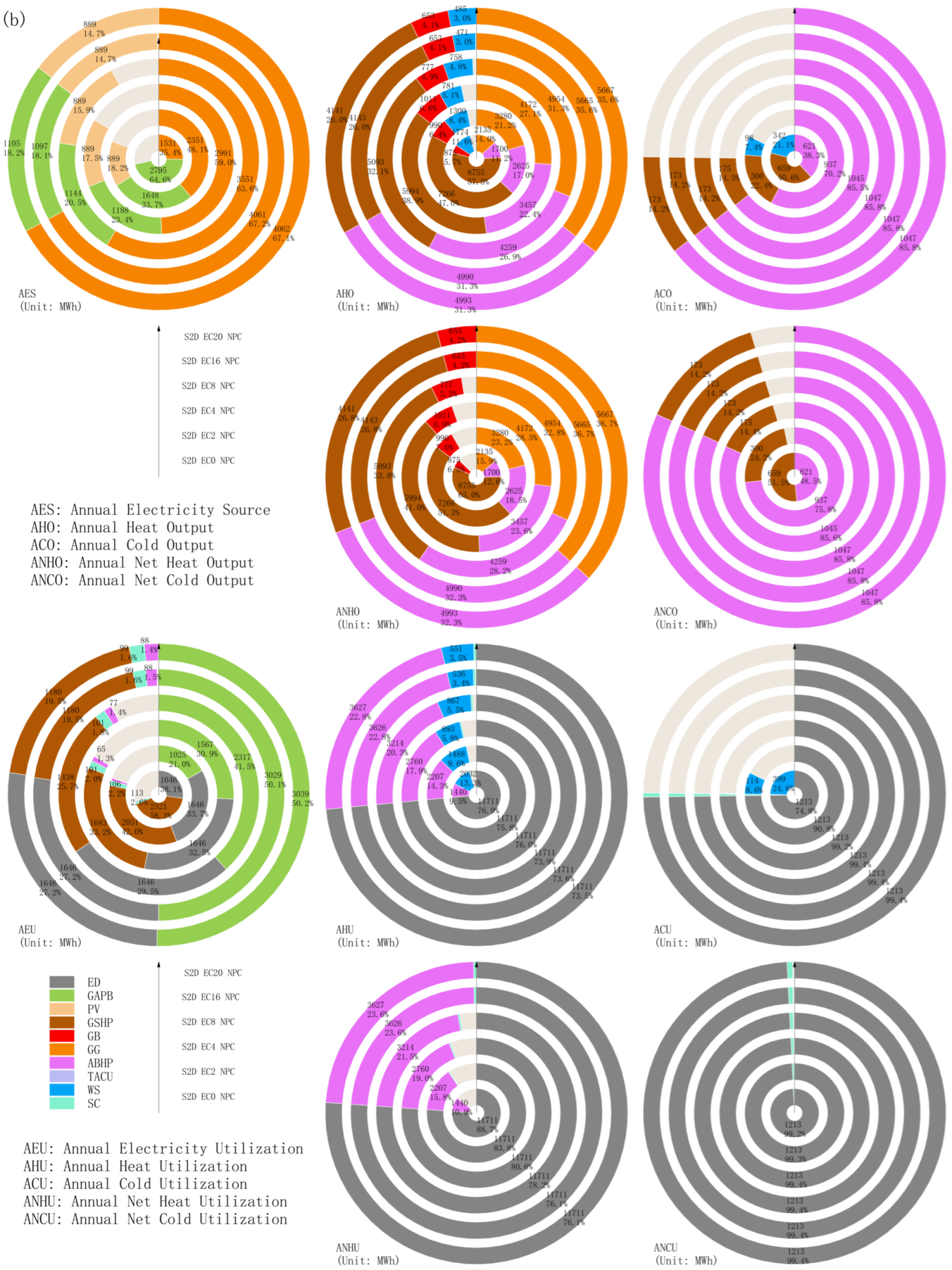

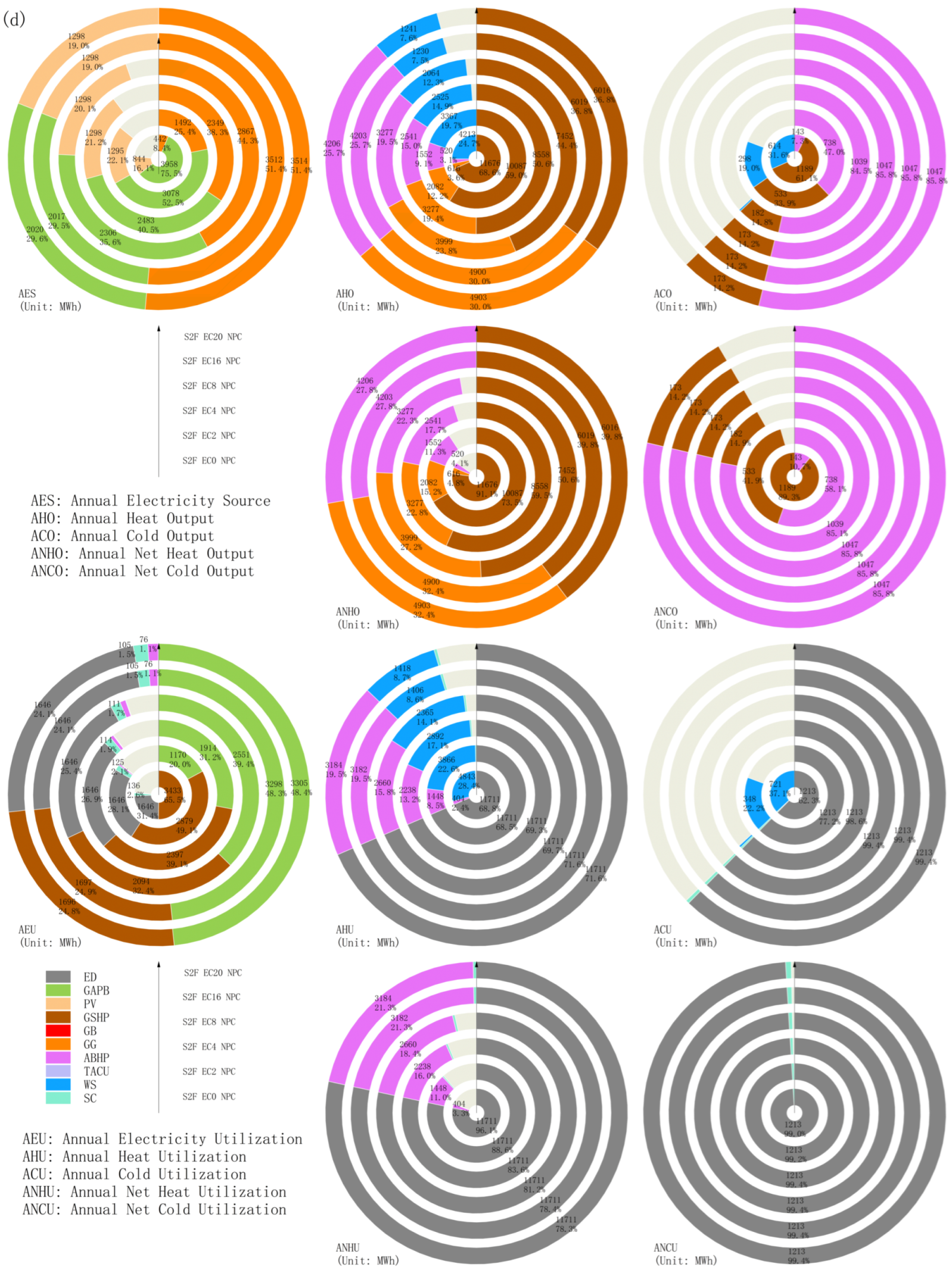

4.3.1. Multi-Investment Planning Scenario Optimization Performance Analysis

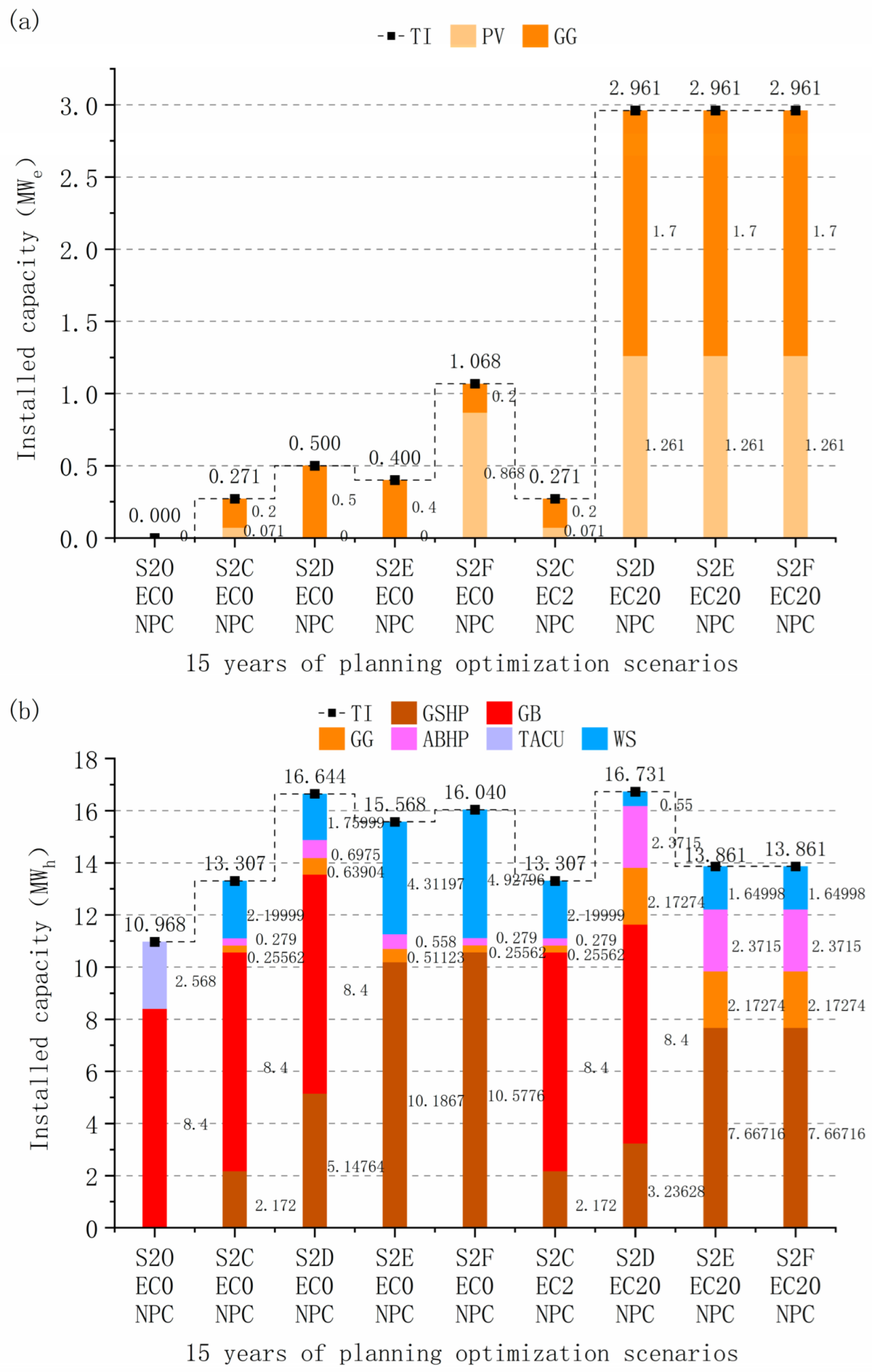

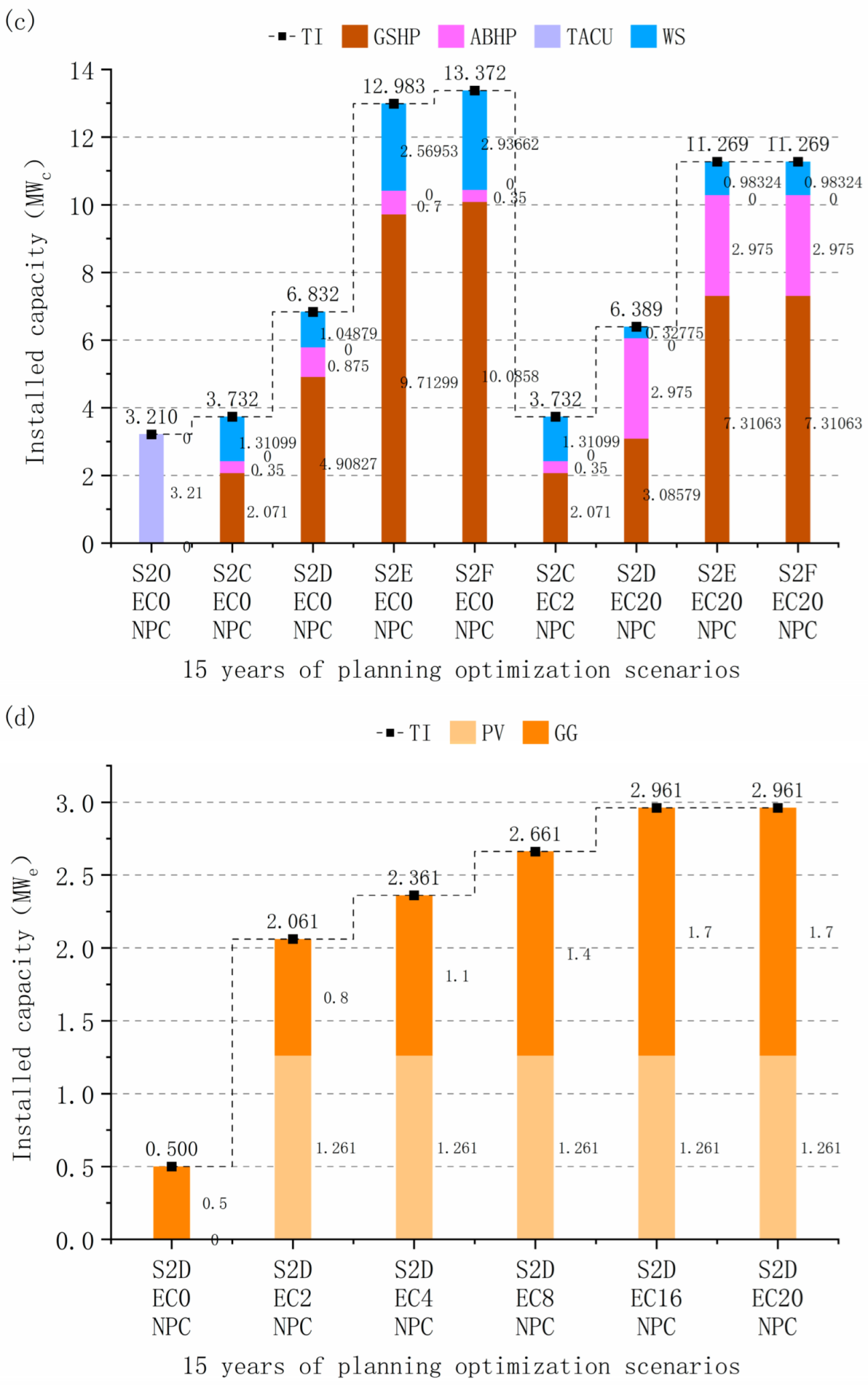

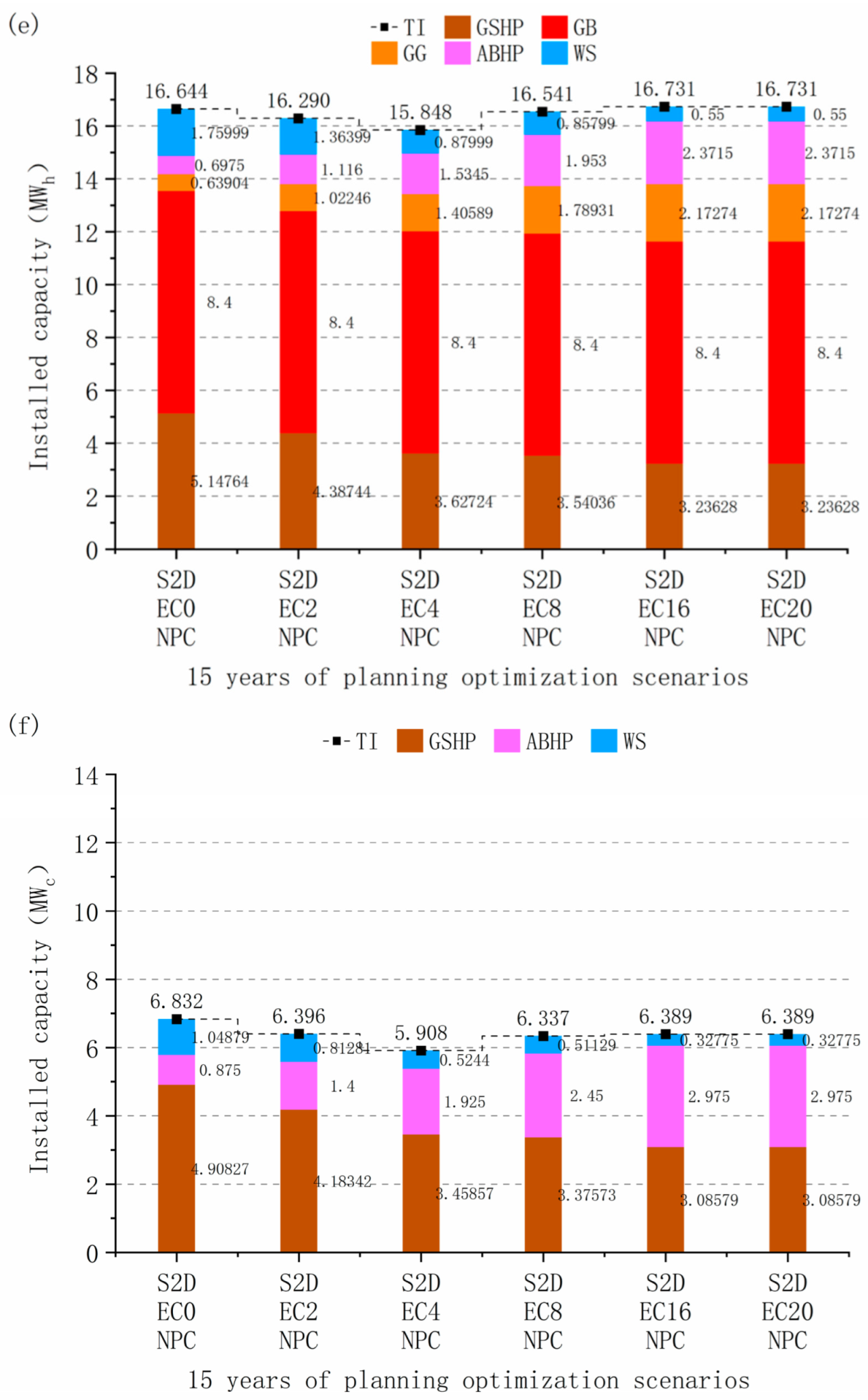

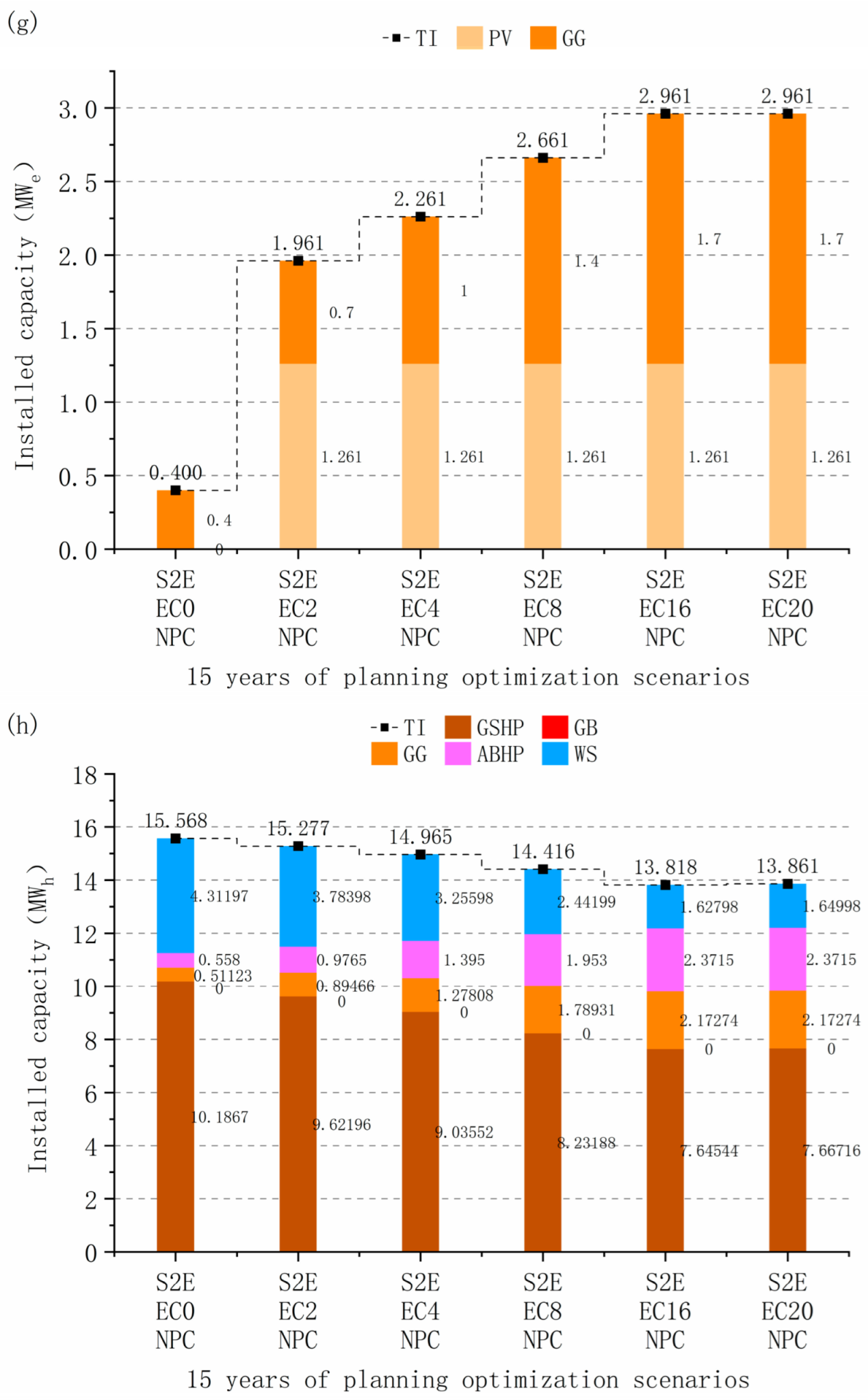

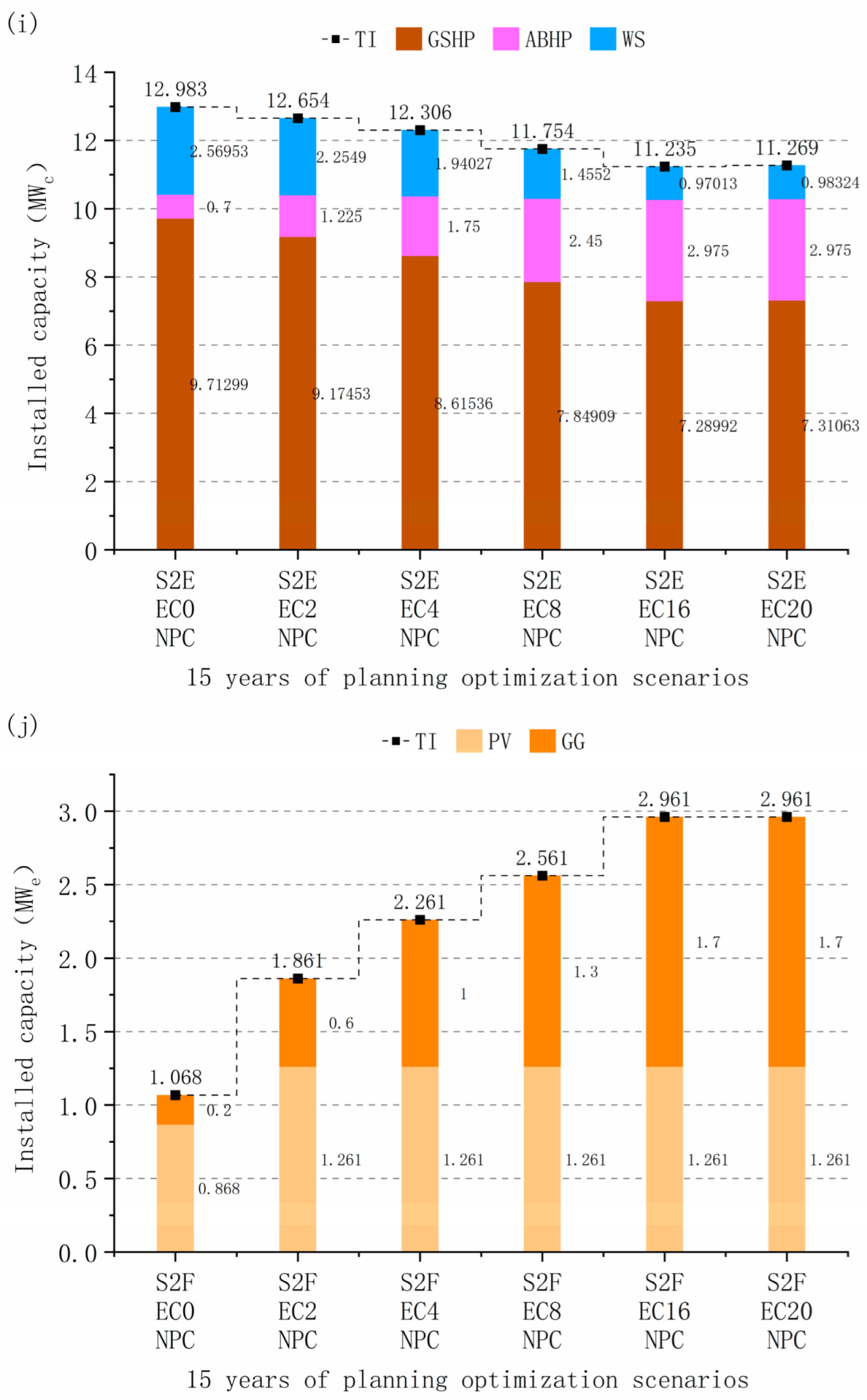

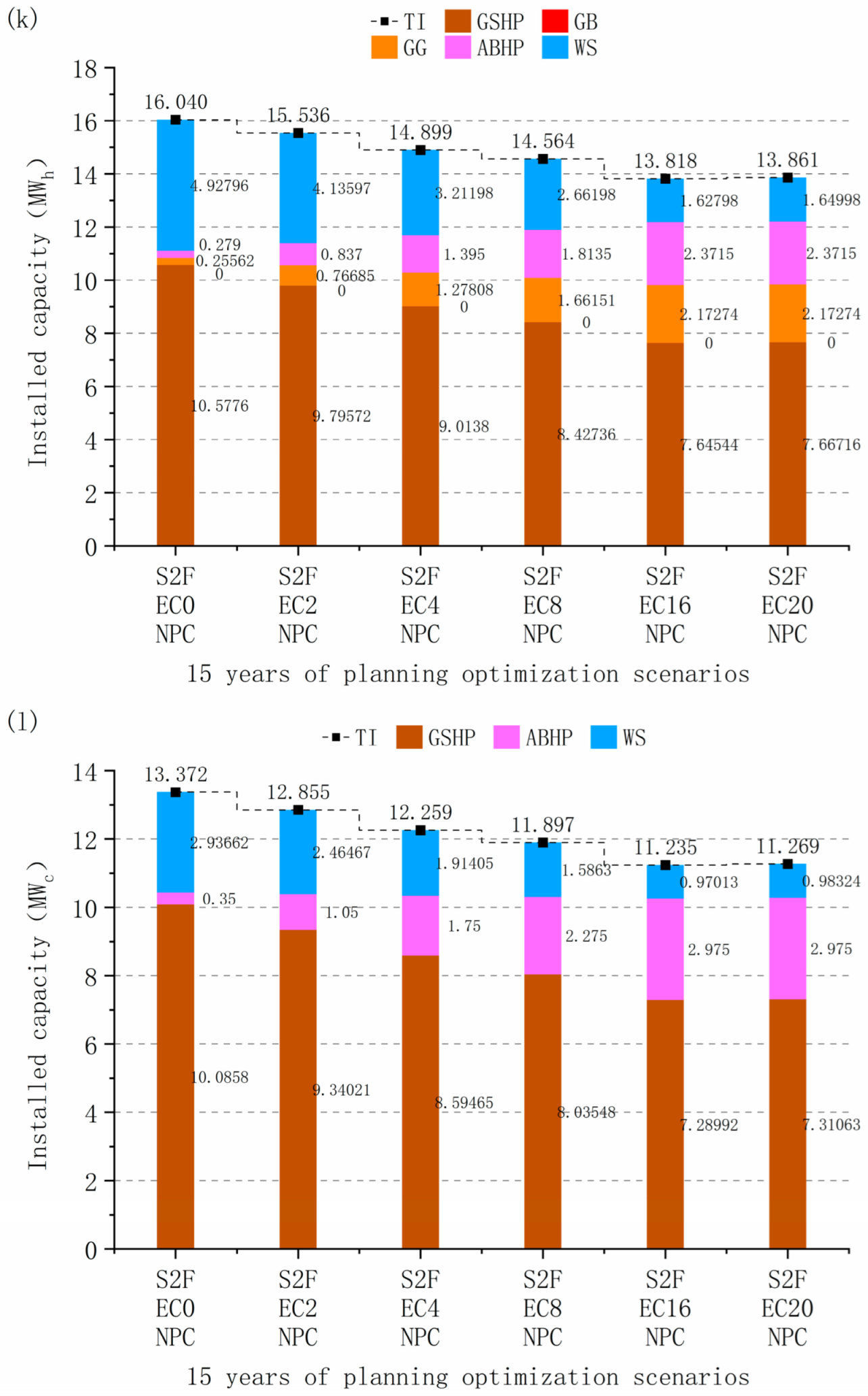

4.3.2. Economically Optimal System Configuration for Multiple Planning Scenarios

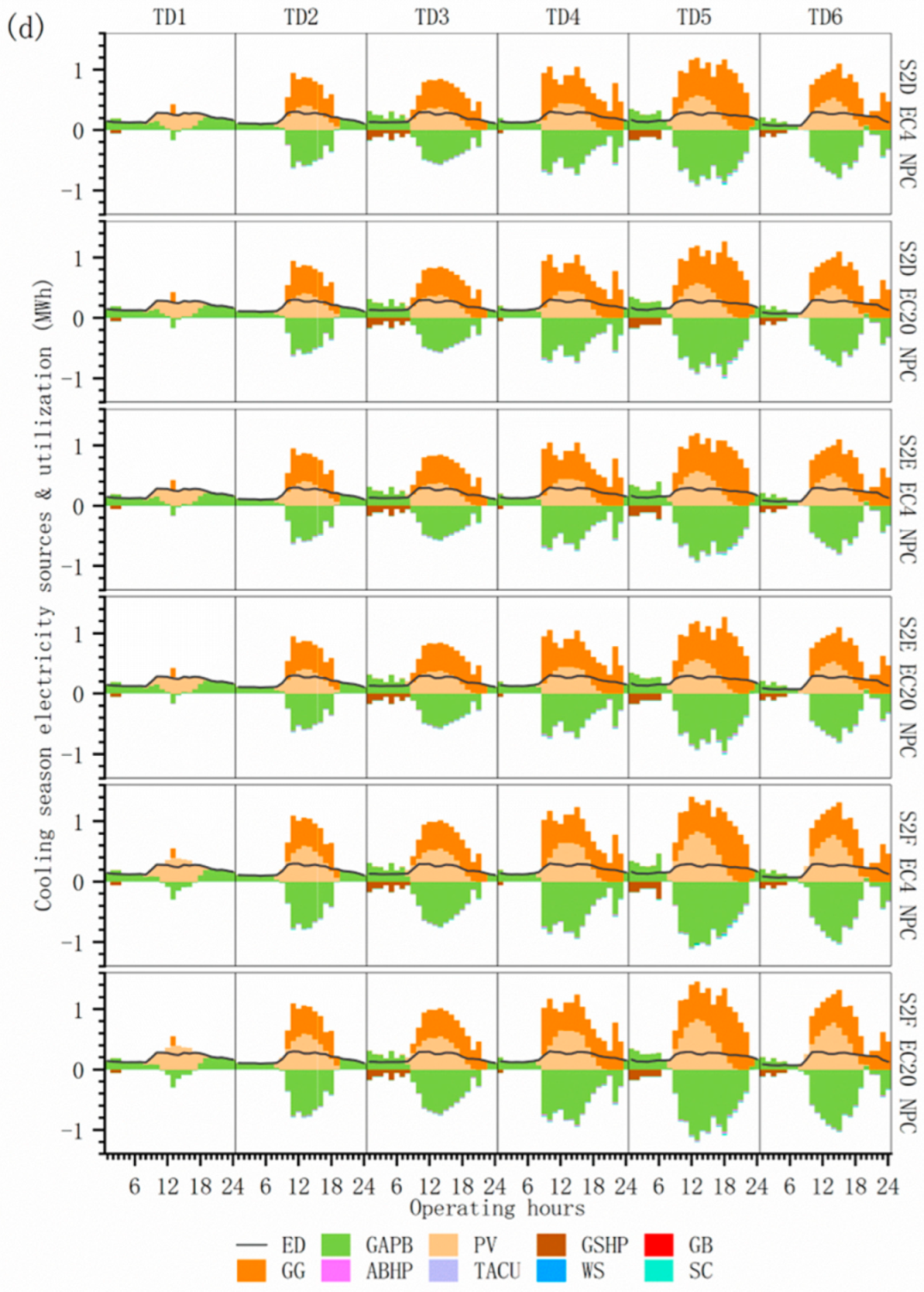

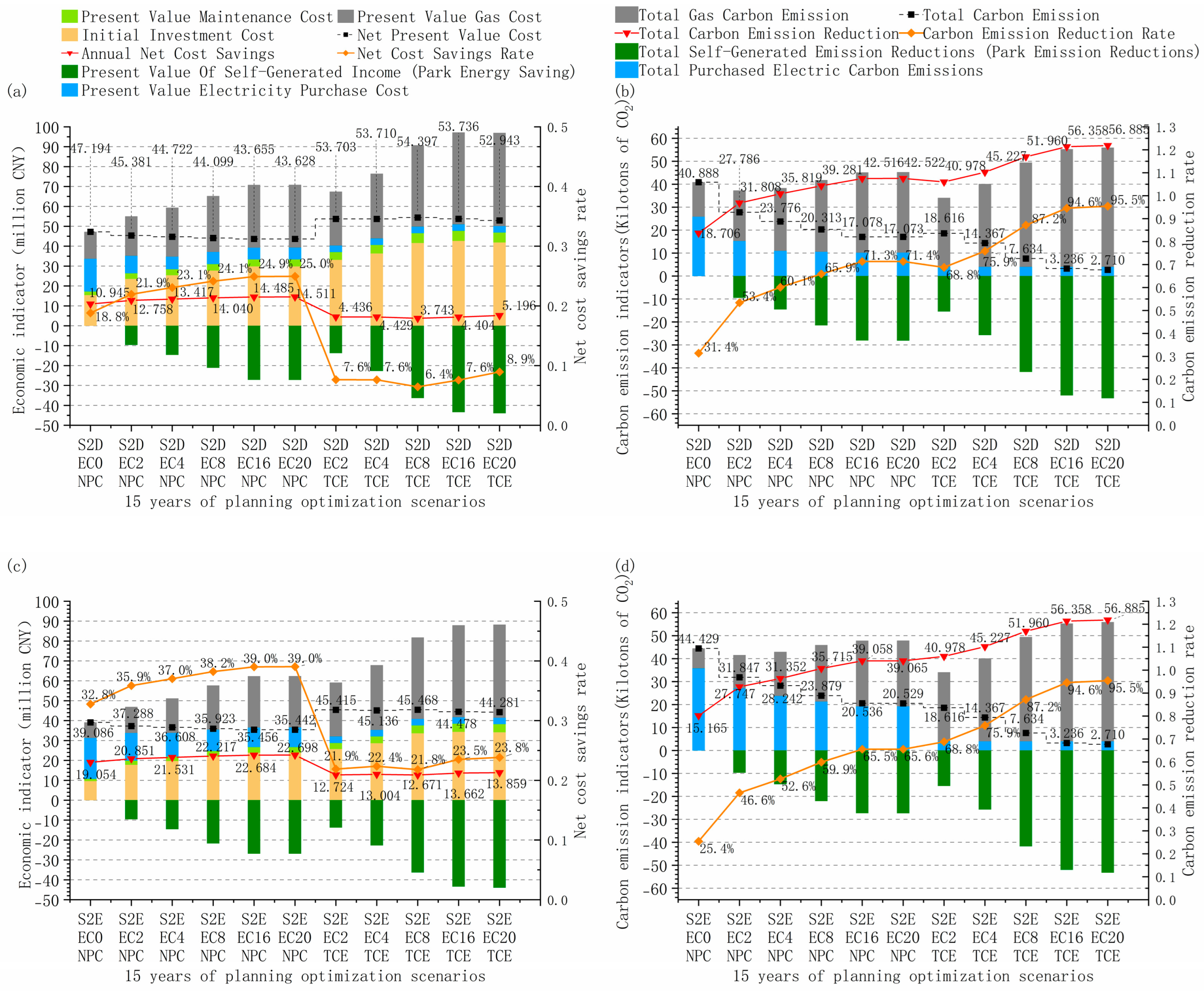

4.3.3. Multi-Investment Planning Scenarios Energy Supply and Demand Structure

4.3.4. Comparison of Operational Options for Multi-Investment Planning Scenarios

5. Conclusions

- (1)

- Under standard operating conditions, ground source heat pumps (GSHP) are contraindicated during nocturnal peak tariff windows. When nocturnal thermal loads surpass GSHP rated capacity while redundant demand is addressable by auxiliary systems, direct GSHP operation without thermal storage integration becomes feasible. In scenarios where nocturnal loads exceed GSHP capacity thresholds yet auxiliary systems maintain low-load operation with aggregate output surplus, integrated thermal storage operation becomes strategically viable.

- (2)

- Under extended thermal dispatch cycles, GSHP–storage integration utilizing off-peak electricity may not demonstrate superior economic performance compared to direct standard-rate electricity utilization. Therefore, thermal energy storage charging operations should be temporally proximal to discharge periods within cost-optimal charging windows, provided that storage capacity requirements are satisfied, to minimize thermal losses associated with prolonged storage duration. Optimal operational strategies require dynamic optimization based on forecasted diurnal demand profiles.

- (3)

- Annual operational optimization analyses demonstrate that retrofitted CCHP systems maintain significant economic viability and carbon mitigation potential even under current specific conditions characterized by low electricity and elevated gas pricing regimes, with energy cost savings potentially offsetting retrofit investments while yielding long-term operational benefits.

- (4)

- Comparative analyses between baseline operations (S2B/S2C) and optimized schemes reveal inherent inefficiencies in empirically derived operational strategies. Implementation of intelligent operation optimization becomes imperative for coordinated multi-device operations and maximization of energy conservation and emission mitigation potential in district energy systems.

- (5)

- Comparative assessments with multiple benchmark optimization schemes reveal suboptimal capacity allocations for GSHP and CCHP systems in current configurations. This suboptimal configuration results in partial realization of integrated energy system advantages, with substantial unexploited potential for long-term economic gains and carbon mitigation persisting.

- (6)

- Benchmarking against current installations under fixed boiler capacity constraints reveals that long-term economic-optimal configurations necessitate expanded GSHP and CCHP capacities. Strategic acceptance of equipment redundancy becomes economically justifiable within feasible capital expenditure frameworks, enabling enhanced economic returns and carbon mitigation benefits, rather than being constrained by legacy system capacities.

- (7)

- Systematic assessments of coordinated electrical load sensitivity reveal that grid-parallel non-export scenarios enable enhancement in energy cascade utilization efficiency through synergistic optimization of district thermal networks and power distribution systems compared to standalone energy station operations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ABHP | Absorption Heat Pump |

| ACER | Annual Carbon Emission Reduction |

| ACO | Annual Cold Output |

| ACU | Annual Cold Utilization |

| AEPC | Annual Electricity Purchase Cost |

| AES | Annual Electricity Source |

| AEU | Annual Electricity Utilization |

| AGC | Annual Gas Cost |

| AGCE | Annual Gas Carbon Emissions |

| AHO | Annual Heat Output |

| AHU | Annual Heat Utilization |

| ANCO | Annual Net Cold Output |

| ANCS | Annual Net Cost Savings |

| ANCU | Annual Net Cold Utilization |

| ANHO | Annual Net Heat Output |

| ANHU | Annual Net Heat Utilization |

| ANOC | Annual Net Operating Costs |

| APCE | Annual Purchase of Carbon Emission |

| ASGER(PER) | Annual Self-Generated Emission Reductions (Park Emission Reductions) |

| ASGI(PES) | Annual Self-Generated Income (Park Energy Saving) |

| CCHP | Combined Cooling, Heating, and Power Systems |

| CER | Carbon Emission Reduction |

| CERR | Carbon Emission Reduction Rate |

| CHP | Combined Heat and Power |

| CS | Cost Savings |

| CST | Water Cold Storage |

| DEN | District Energy Network |

| DHS | District Heating Systems |

| ED | Energy Demand |

| GAPB | Grid Power Purchase/Park Power Supply |

| GB | Gas Boiler |

| GG | Gas Generator |

| GSHP | Ground Source Heat Pump |

| GSHP_L-F | Ground Source Heat Pump Load Factor |

| H-D | Hot Demand |

| Hourly_C-D | Hourly Cold Demand |

| Hourly_H-D | Hourly Hot Demand |

| HST | Water Heat Storage |

| IC | Installed Capacity |

| IDN | Incremental Distribution Network |

| IES | Integrated Energy Systems |

| IIC | Initial Investment Cost |

| IPDHS | Industrial Park District Heating Systems |

| IQR | Interquartile Range |

| L-F | Load Factor |

| NCR | Net Cost Ratio |

| NCSR | Net Cost Savings Rate |

| NGB_L-F | North Boiler Load Factor |

| NPVC | Net Present Value Cost |

| NPVOC | Net Present Value Operating Costs |

| PPSL(ELR) | Park’S Power Supply Level (Electric Load Ratio) |

| PV | Photovoltaic |

| PVEPC | Present Value Electricity Purchase Cost |

| PVGC | Present Value Gas Cost |

| PVMC | Present Value Maintenance Cost |

| PVSGI(PES) | Present Value of Self-Generated Income (Park Energy Saving) |

| RCE | Relative Carbon Emissions |

| RNCR | Relative Net Cost Ratio |

| SC | System Consumption |

| SGB_L-F | South Boiler Load Factor |

| TACE | Total Annual Carbon Emissions |

| TACU | Traditional Air Conditioning Unit |

| TCE | Total Carbon Emission |

| TCER | Total Carbon Emission Reduction |

| TD | Typical Day |

| TGCE | Total Gas Carbon Emission |

| TI | Total Installed |

| TPECE | Total Purchased Electric Carbon Emissions |

| TSGER(PER) | Total Self-Generated Emission Reductions (Park Emission Reductions) |

| U/R/S | Unit/Range/State |

| WTS | Water Treatment System |

| WS | Water Storage |

| WS_CR_L-F | Energy Storage Cold Release Load Factor |

| WS_HR | Energy Storage Heat Release |

| WS_HR_L-F | Energy Storage Heat Release Load Factor |

| WS_OS | Energy Storage Operation Status |

| WSHP | Water Source Heat Pump |

Appendix A

References

- Nan, J.; Feng, J.; Deng, X.; Guan, L.; Sun, K.; Zhou, H. A two-stage robust generation expansion planning framework for regional integrated energy systems with carbon growth constraints. Front. Energy Res. 2023, 11, 1106628. [Google Scholar] [CrossRef]

- Hast, A.; Syri, S.; Lekavičius, V.; Galinis, A. District heating in cities as a part of low-carbon energy system. Energy 2018, 152, 627–639. [Google Scholar] [CrossRef]

- Koohi-Fayegh, S.; Rosen, M.A. A Review of Renewable Energy Options, Applications, Facilitating Technologies and Recent Developments. Eur. J. Sustain. Dev. Res. 2020, 4, em0138. [Google Scholar] [CrossRef] [PubMed]

- Autelitano, K.; Famiglietti, J.; Aprile, M.; Motta, M. Towards Life Cycle Assessment for the Environmental Evaluation of District Heating and Cooling: A Critical Review. Standards 2024, 4, 102–132. [Google Scholar] [CrossRef]

- Gong, Y.; Ma, G.; Jiang, Y.; Wang, L. Research progress on the fifth-generation district heating system based on heat pump technology. J. Build. Eng. 2023, 71, 106533. [Google Scholar] [CrossRef]

- Jiao, X.; Wu, J.; Mao, Y.; Luo, W.; Yan, M. An Optimal Method of Energy Management for Regional Energy System with a Shared Energy Storage. Energies 2023, 16, 886. [Google Scholar] [CrossRef]

- Li, W.; Tang, M.; Zhang, X.; Gao, D.; Wang, J. Optimal Operation for Regional IES Considering the Demand- and Supply-Side Characteristics. Energies 2022, 15, 1594. [Google Scholar] [CrossRef]

- Feng, P.; Jiang, G.; Li, K.; Xu, J.; Shen, Y.; Xu, W.; Wang, S. Two-stage stochastic robust optimization scheduling of electric–thermal microgrid with solid electric thermal storage. AIP Adv. 2024, 14, 015018. [Google Scholar] [CrossRef]

- Abbaspour, A.; Yousefi, H.; Aslani, A.; Noorollahi, Y. Economic and Environmental Analysis of Incorporating Geothermal District Heating System Combined with Radiant Floor Heating for Building Heat Supply in Sarein, Iran Using Building Information Modeling (BIM). Energies 2022, 15, 8914. [Google Scholar] [CrossRef]

- Dromart, C.; Puthod, L.; Kämpf, J.H.; Gunten, D.V. District heating network modelling for future integration of solar thermal energy. J. Phys. Conf. Ser. 2021, 2042, 012089. [Google Scholar] [CrossRef]

- Schmidt, D. Low Temperature District Heating for Future Energy Systems. Energy Procedia 2018, 149, 595–604. [Google Scholar] [CrossRef]

- Wang, J.; Pan, Z.; Li, S.; Ge, H.; Yang, G.; Wang, B. Optimal Scheduling of Virtual Power Plant Considering Reconfiguration of District Heating Network. Electronics 2023, 12, 3409. [Google Scholar] [CrossRef]

- Bareiss, K. Potential of power-to-heat from excess wind energy on the city level. Energy Sources Part B Econ. Plan. Policy 2020, 15, 26–43. [Google Scholar] [CrossRef]

- Zhao, R.; Zheng, W. Efficient operation of combined residential and commercial energy hubs incorporating load management and two-point approximation for uncertainty modeling. Comput. Electr. Eng. 2024, 116, 109197. [Google Scholar] [CrossRef]

- Sai Pandraju, T.K.; Samal, S.; Saravanakumar, R.; Yaseen, S.M.; Nandal, R.; Dhabliya, D. Advanced metering infrastructure for low voltage distribution system in smart grid based monitoring applications. Sustain. Comput. Inform. Syst. 2022, 35, 100691. [Google Scholar] [CrossRef]

- Leitner, B.; Widl, E.; Gawlik, W.; Hofmann, R. A method for technical assessment of power-to-heat use cases to couple local district heating and electrical distribution grids. Energy 2019, 182, 729–738. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, X.; Zhang, R.; Gu, W.; Cao, G. N-1 Evaluation of Integrated Electricity and Gas System Considering Cyber-Physical Interdependence. IEEE Trans. Smart Grid 2025, 16, 3728–3742. [Google Scholar] [CrossRef]

- Lyu, J.; Zhang, S.; Cheng, H.; Yuan, K.; Song, Y.; Fang, S. Optimal Sizing of Energy Station in the Multienergy System Integrated With Data Center. IEEE Trans. Ind. Appl. 2021, 57, 1222–1234. [Google Scholar] [CrossRef]

- Raja Guru, R.; Kumar, P. Self-restrained energy grid with data analysis and blockchain techniques. Energy Sources Part A Recovery Util. Environ. Eff. 2025, 47, 3441–3459. [Google Scholar] [CrossRef]

- Ting, Y.; Guoliang, L.; Yong, W.; Siyuan, S.; Meiling, Z.; Zhenning, Y. A tensor completion algorithm for missing user data in spot trading of electricity market. Comput. Electr. Eng. 2025, 122, 109988. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, Z.; Sun, Q.; Gu, W.; Zheng, S.; Zhao, J. Application and progress of artificial intelligence technology in the field of distribution network voltage Control: A review. Renew. Sustain. Energy Rev. 2024, 192, 114282. [Google Scholar] [CrossRef]

- Capone, M.; Guelpa, E.; Verda, V. Exploring opportunities for temperature reduction in existing district heating infrastructures. Energy 2024, 302, 131871. [Google Scholar] [CrossRef]

- Stock, J.; Schmidt, T.; Xhonneux, A.; Müller, D. Optimisation of district heating transformation for the efficient integration of a low-temperature heat source. Energy 2024, 308, 132461. [Google Scholar] [CrossRef]

- De Souza, R.; Casisi, M.; Micheli, D.; Reini, M. A Review of Small–Medium Combined Heat and Power (CHP) Technologies and Their Role within the 100% Renewable Energy Systems Scenario. Energies 2021, 14, 5338. [Google Scholar] [CrossRef]

- Naimaster, E.J.; Sleiti, A.K. Potential of SOFC CHP systems for energy-efficient commercial buildings. Energy Build. 2013, 61, 153–160. [Google Scholar] [CrossRef]

- Chew Hernandez, M.L.; Velazquez Hernandez, E.K.; Leon Dominguez, S. A Decision-Analytic Feasibility Study of Upgrading Machinery at a Tools Workshop. Eng. Technol. Appl. Sci. Res. 2012, 2, 182–189. [Google Scholar] [CrossRef]

- Yue, B.; Su, B.; Xiao, F.; Li, A.; Li, K.; Li, S.; Yan, R.; Lian, Q.; Li, A.; Li, Y.; et al. Energy-oriented control retrofit for existing HVAC system adopting data-driven MPC—Methodology, implementation and field test. Energy Build. 2023, 295, 113286. [Google Scholar] [CrossRef]

- Shcherbakova, N.A. Feasibility Analysis of Overhaul and Modernization of Equipment. In Proceedings of the International Scientific Conference “Far East Con” (ISCFEC 2018); Atlantis Press: Vladivostok, Russia, 2019. [Google Scholar] [CrossRef]

- Sun, F.; Wang, Z.; Xu, W.; Chen, B. Configuration optimization of a novel multi-energy coupled low temperature district heating system based on distributed absorption and compression heat pumps. Energy 2025, 330, 136997. [Google Scholar] [CrossRef]

- Zhu, Y.; Song, K.; Wu, J.; Zhang, Y.; Zhang, W.; Thinsurat, K.; Jiang, L. District heating system assisted by thermochemical sorption heat storage. Energy Built Environ. 2025, in press. [CrossRef]

- Mi, P.; Zhang, J.; Han, Y.; Guo, X. Study on energy efficiency and economic performance of district heating system of energy saving reconstruction with photovoltaic thermal heat pump. Energy Convers. Manag. 2021, 247, 114677. [Google Scholar] [CrossRef]

- Liu, S.; Guo, Y.; Wagner, F.; Liu, H.; Cui, R.; Mauzerall, D. Diversifying heat sources in China’s urban district heating systems will reduce risk of carbon lock-in. Nat. Energy 2024, 9, 1021–1031. [Google Scholar] [CrossRef]

- Pompei, L.; Nardecchia, F.; Miliozzi, A.; Groppi, D.; Astiaso Garcia, D.; De Santoli, L. Assessment of the Optimal Energy Generation and Storage Systems to Feed a Districting Heating Network. Buildings 2024, 14, 2370. [Google Scholar] [CrossRef]

- Abokersh, M.H.; Saikia, K.; Cabeza, L.F.; Boer, D.; Vallès, M. Flexible heat pump integration to improve sustainable transition toward 4th generation district heating. Energy Convers. Manag. 2020, 225, 113379. [Google Scholar] [CrossRef]

- Sinha, R.; Bak-Jensen, B.; Radhakrishna Pillai, J.; Zareipour, H. Flexibility from Electric Boiler and Thermal Storage for Multi Energy System Interaction. Energies 2019, 13, 98. [Google Scholar] [CrossRef]

- Hnydiuk-Stefan, A.; Otawa, A.; Stefan, K.; Zmarzły, D. Technical and Economic Analysis of Low-Emissions Modernization of Existing Heating Plants in Poland. Energies 2021, 14, 7426. [Google Scholar] [CrossRef]

- Yuan, M.; Thellufsen, J.Z.; Sorknæs, P.; Lund, H.; Liang, Y. District heating in 100% renewable energy systems: Combining industrial excess heat and heat pumps. Energy Convers. Manag. 2021, 244, 114527. [Google Scholar] [CrossRef]

- Tian, C.; Shao, Z.; Wang, R.; Yan, Y.; Wang, X.; Ren, A. Optimal Design of Integrated Energy Supply System for Continuous Greenhouse Effect: A Study on Carbon Emission and Operational Cost. Front. Energy Res. 2022, 10, 819420. [Google Scholar] [CrossRef]

- Lu, N.; Pan, L.; Arabkoohsar, A.; Liu, Z.; Wang, J.; Pedersen, S. Power-heat conversion coordinated control of combined-cycle gas turbine with thermal energy storage in district heating network. Appl. Therm. Eng. 2023, 220, 119664. [Google Scholar] [CrossRef]

- Pelda, J.; Stelter, F.; Holler, S. Potential of integrating industrial waste heat and solar thermal energy into district heating networks in Germany. Energy 2020, 203, 117812. [Google Scholar] [CrossRef]

- Theisinger, L.; Kohne, T.; Borst, F.; Weigold, M. Modeling approach and simulation study to assess the utilization potential of industrial waste heat in district heating systems. Procedia CIRP 2022, 105, 339–344. [Google Scholar] [CrossRef]

- Zhang, Y.; Campana, P.E.; Yang, Y.; Stridh, B.; Lundblad, A.; Yan, J. Energy flexibility from the consumer: Integrating local electricity and heat supplies in a building. Appl. Energy 2018, 223, 430–442. [Google Scholar] [CrossRef]

- Fambri, G.; Mazza, A.; Guelpa, E.; Verda, V.; Badami, M. Power-to-heat plants in district heating and electricity distribution systems: A techno-economic analysis. Energy Convers. Manag. 2023, 276, 116543. [Google Scholar] [CrossRef]

- Kubín, A.; Knápek, J.; Koltsaklis, N. A long-term energy transition planning model for a district heating and cooling sector incorporating sector coupling approach: A case study of the Czech district heating and cooling sector. Energy Convers. Manag. 2025, 341, 120058. [Google Scholar] [CrossRef]

- Guan, X.; Terada, Y. Sparse kernel k-means for high-dimensional data. Pattern Recognit. 2023, 144, 109873. [Google Scholar] [CrossRef]

- Naldi, M.C.; Campello, R.J.G.B. Comparison of distributed evolutionary k-means clustering algorithms. Neurocomputing 2015, 163, 78–93. [Google Scholar] [CrossRef]

- Yang, X.; Zhao, W.; Xu, Y.; Wang, C.; Li, B.; Nie, F. Sparse K-means clustering algorithm with anchor graph regularization. Inf. Sci. 2024, 667, 120504. [Google Scholar] [CrossRef]

| No. | Name | Quantity (Sets) | Unit Price (CNY) | Main Equipment Parameters | |

|---|---|---|---|---|---|

| 1 | GG | 1 | 985,000 | generating power (kW) | 200.0 |

| gas consumption rate (Nm3/h) | 57.00 | ||||

| cylinder liner water heat transfer power (kW) | 114.0 | ||||

| gas flow (kg/s) | 0.3000 | ||||

| flue gas temperature (°C) | 570.0 | ||||

| parasitic electric power (kW) | 5.500 | ||||

| cooling power (kW) | 350.0 | ||||

| heating power (kW) | 279.0 | ||||

| hot water inlet and outlet water temperature (°C) | 40.00/60.00 | ||||

| 2 | ABHP | 1 | 809,090 | inlet and outlet water temperature of heat source (°C) | 80.00/70.00 |

| cylinder liner water heat transfer power (kW) | 114.0 | ||||

| flue gas temperature (°C) | 570.0 | ||||

| gas flow (kg/s) | 0.3000 | ||||

| refueling gas consumption rate (Nm3/h) | 30.20 | ||||

| parasitic electric power (kW) | 3.000 | ||||

| heating power (kW) | 4200 | ||||

| 3 | GB | 2 | 4,200,000 | gas consumption rate (Nm3/h) | 436.3 |

| parasitic electric power (kW) | 15.00 | ||||

| cooling power (kW) | 2071 | ||||

| refrigeration daytime cold source heat transfer power (kW) | 1974 | ||||

| refrigeration daytime input power (kW) | 370.0 | ||||

| refrigeration night cold source heat transfer power (kW) | 1756 | ||||

| 4 | WSHP | 1 | 985,000 | refrigeration night input power (kW) | 350.0 |

| heating power (kW) | 2172 | ||||

| heating daytime cold source heat transfer power (kW) | 1995 | ||||

| heating daytime input power (kW) | 480.0 | ||||

| heat exchange power of heating night cooling source (kW) | 1840 | ||||

| heating night input power (kW) | 575.0 | ||||

| effective volume (m3) | 950.0 | ||||

| cooling capacity (kWh) | 8141 | ||||

| 5 | WS | 1 | 930,000 | release cooling power (kW) | 1311 |

| heat storage capacity (kWh) | 19,770 | ||||

| heat release power (kW) | 2200 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Long, G.; Zhong, X.; Liu, X.; Zhang, H.; Zhang, F.; Xiao, N.; He, Y.; Sun, Y.; Jiang, C.; Xie, S.; et al. Optimization of Low-Carbon Operation and Capacity Expansion of Integrated Energy Systems in Synergy with Incremental Distribution Network for Industrial Parks. Energies 2025, 18, 5206. https://doi.org/10.3390/en18195206

Long G, Zhong X, Liu X, Zhang H, Zhang F, Xiao N, He Y, Sun Y, Jiang C, Xie S, et al. Optimization of Low-Carbon Operation and Capacity Expansion of Integrated Energy Systems in Synergy with Incremental Distribution Network for Industrial Parks. Energies. 2025; 18(19):5206. https://doi.org/10.3390/en18195206

Chicago/Turabian StyleLong, Guangchen, Xiaoyi Zhong, Xianjie Liu, Hanlin Zhang, Fuzheng Zhang, Ning Xiao, Yi He, Yifei Sun, Chenxing Jiang, Shan Xie, and et al. 2025. "Optimization of Low-Carbon Operation and Capacity Expansion of Integrated Energy Systems in Synergy with Incremental Distribution Network for Industrial Parks" Energies 18, no. 19: 5206. https://doi.org/10.3390/en18195206

APA StyleLong, G., Zhong, X., Liu, X., Zhang, H., Zhang, F., Xiao, N., He, Y., Sun, Y., Jiang, C., Xie, S., Jing, R., Lin, J., & Zhao, Y. (2025). Optimization of Low-Carbon Operation and Capacity Expansion of Integrated Energy Systems in Synergy with Incremental Distribution Network for Industrial Parks. Energies, 18(19), 5206. https://doi.org/10.3390/en18195206