Hybrid Human–AI Collaboration for Optimized Fuel Delivery Management

Abstract

1. Introduction

- The frequency of negative events affecting the service processes’ stability has increased;

- The relationships’ complexity has grown, consuming more time and financial resources;

- Nonlinear development trajectories have become less predictable, which contributes to mistakes in managerial decisions due to lack of appropriate knowledge.

- RQ1: How can the SPOF (Single Point Of Failure) problem be solved for compound delivery systems supplying petrol filling stations (PFSs)?

- RQ2: How can the mechanism integrating human knowledge (HK) and artificial intelligence (AI) be improved?

- RQ3: How and how much can iterative adaptation techniques be successful?

2. The Literature Analysis

2.1. Human Collaboration with AI in Transport Management

2.2. AI Technology Integration and the Challenges for Businesses

3. Conceptual Framework

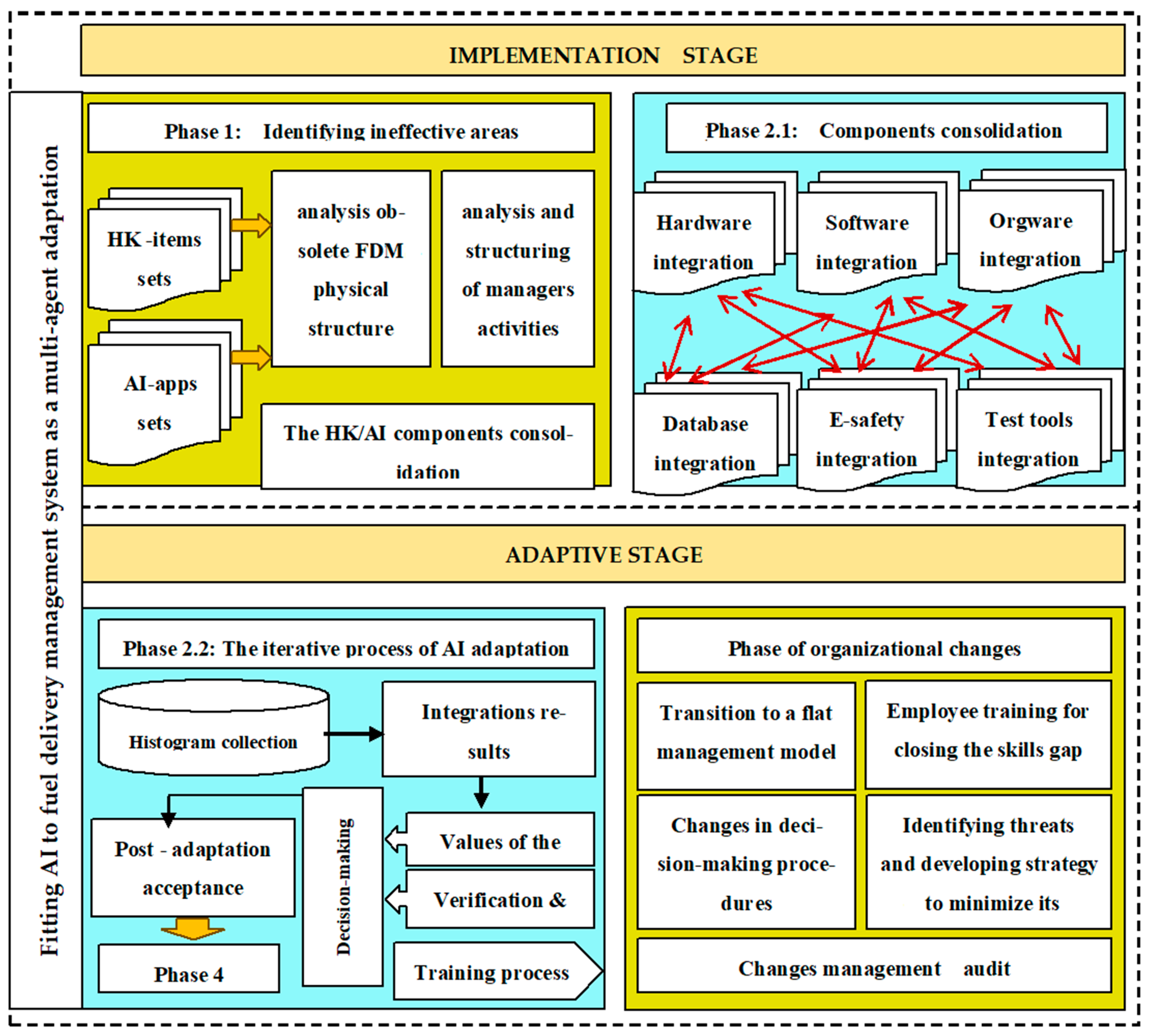

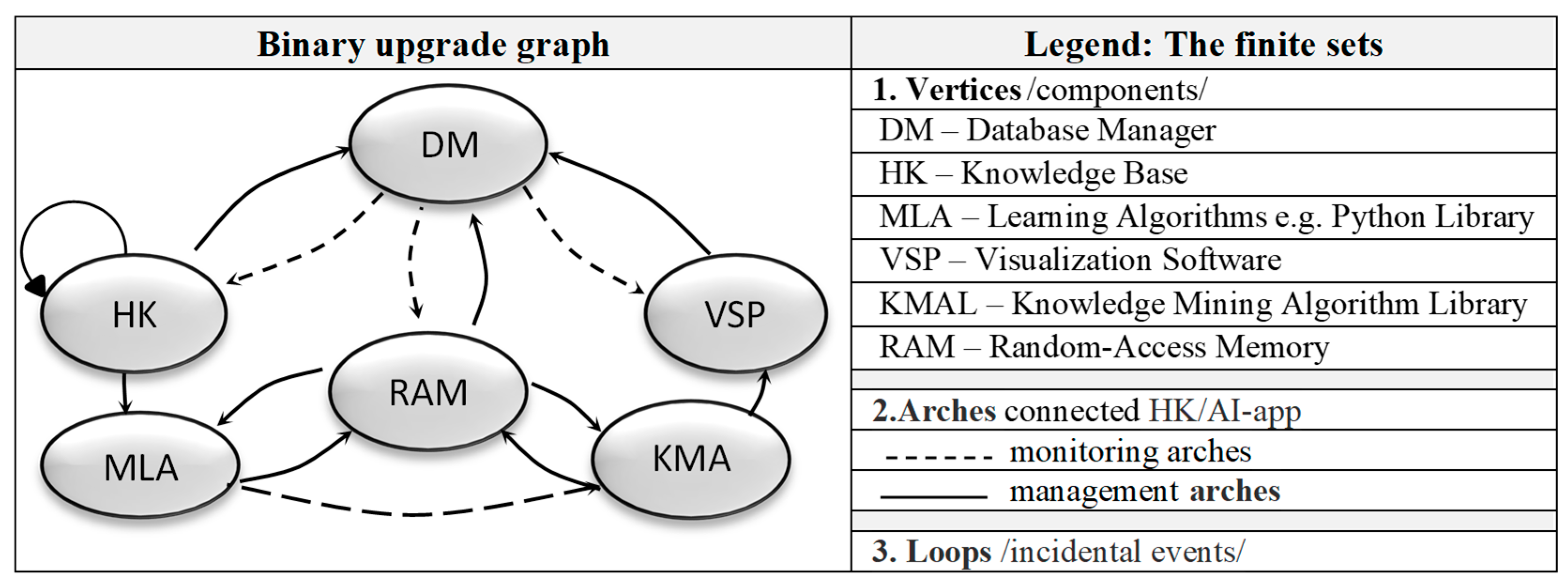

3.1. The Upgrade Concept for FDM Architecture

3.2. Research Problem Statement

- Assumptions:

- Procedures:

- Procedure 1: Before starting the upgrade process, ensure that the FDM architecture is open to innovative AI app implementation.

- Procedure 2: The upgrade’s effectiveness should be assessed for each embedded AI app.

- Procedure 3: If the process is unsuccessful, adaptation should be resumed based on feedback.

- A—Hardware status configuration [21]. This has an impact on such critical parameters as operation speed and memory, energy use and physical size of the FDM, etc. This level includes the development of a coherent structure of computers and network devices (servers, switches, etc.) working together via cabling and/or fiber optic cables to transfer information between users. It lays the groundwork for maximum positive synergies and its new upgrade.

- B—Information integration [53]. It is implemented within the framework of the “Data-Centric Approach” in terms of consistency and accessibility of the collected information and knowledge. It is based on processes for linking structured information, ensuring that it is used for different operational and decision making purposes. This level is oriented towards the integration of various DBs into a united HK/AI dataset. This consolidation involves resolving format mismatches, merging datasets with common formats, and handling inconsistencies in data received from different sources.

- C—Software status configuration [54]. It integrates the execution schedules of applications and services running within an FDM, enabling managers to share information and unconflicted collaboration. It is important because the used software may come from different producers, have separate purposes, and require special information support.

- D—Orgware status configuration [51,55]. The orgware deals with different actors and their different working tasks, linking, e.g., transport and logistics departments. Process integration is the glue that binds together the functional capabilities of an integrated FDM architecture. It ensures the redundancy of the combined components managing information flows, indicates decision errors, and improves outcome efficiency.

- E—Cybersecurity integration [56]. The increase in the number of cyber threats complicates the deployment and integration of an AI app into a conventional FDM, threatening to create gaps in their resilience, and it can be exploited for phishing or malware attacks. In addition, employees who face dismissal as a result of their replacement by AI-powered tools may try to discredit their effectiveness. Countering this process is possible through the use of security features, such as LANs (Local Area Networks) or WANs (Wide Area Networks), linking different FDMs within a unified platform, or using such software as ASPM (Application security posture management) [56].

- F—Integration testing procedures [57]. Validating upgrades helps mitigate risks associated with deploying untested or faulty software, safeguarding against potential disruptions to business operations and petrol filling stations (PFSs). Testing plays a key role by identifying gaps in infrastructure and checking that tasks are performed correctly.

3.3. Materials and Methods of Research Process Organization

- Analysis and structuring of activities performed by fleet managers during the development of fuel delivery schedules and solving random problems.

- Research on the tuning principles of AP apps both in terms of the TTC development strategy and the techniques for achieving maximum compatibility parameters of HK/AI items, information databases, communication protocols, and cybersecurity procedures. Research during this phase led to the important conclusion that the tuning of implemented AI apps can be an important internal cognitive factor indicating both the fleet managers’ weaknesses (e.g., rapid fatigue or attachment to personal preferences) and their strengths (e.g., the ability to make non-standard decisions). The final conclusions of this phase of the study were as follows:

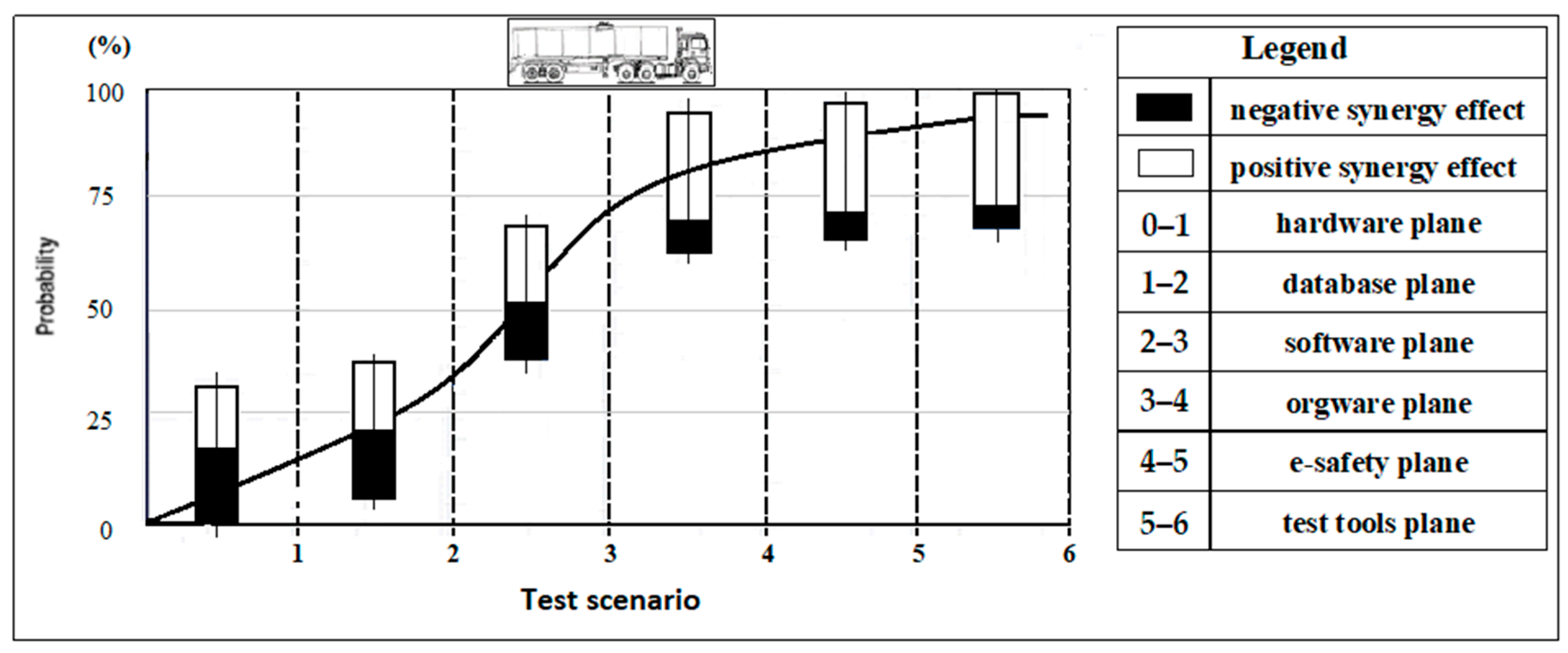

- ESE’s “Expected Synergy Effects” function can be used to integrally measure the effectiveness of the AI app adaptation process:where

- —the probability of generating positive effects in the -iteration of the adaptation process;

- —the probability of generating negative effects in the -iteration of the adaptation process.

- b.

- Accepting the MDP theory (Markov Decision Process) as a mathematical framework for modeling adaptive processes based on both random and manual control actions.

- c.

- The accumulated experience makes it possible to identify the compatibility of implemented AI apps with fleet managers on a probability level of success achievement only.

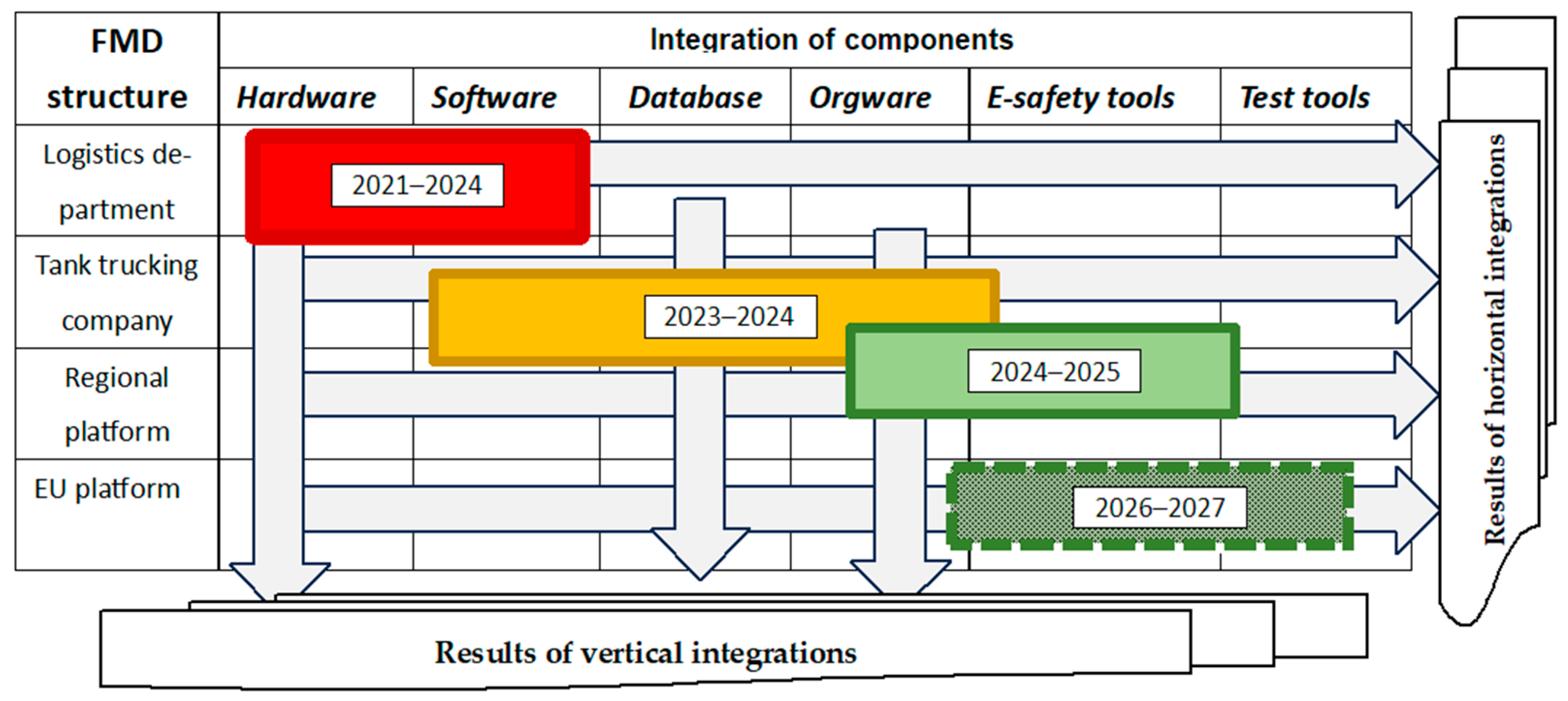

- The first part concerns adaptation activities in the design space and, in particular, AI learning to cooperate with fleet managers. Effective AI app learning requires the use of an interactive mode (in our experience, max 4–6 iterations) on such horizontal integration planes as hardware, software, orgware, etc. In the case of further use of AI apps, e.g., as an NPC (Non-Player Character) with the aim of vertical integration (TTC as whole, regional platforms, etc.), customizing the AI is based on early acquired abilities.

- The second part concerns introducing a collaborative framework and engaging fleet managers in both subtasks that require “manual control action” and AI assistance in solving the computation of complicated computational subtasks, such as assessment of the ESE values or verification and validation. The integral upgrade schedule is shown in Figure 4.

3.4. Organization of Research Process

- Identifying Improvement Areas: A complete assessment of FDM architecture efficiencies is essential to identify zones that need updating and to understand the problem’s causes.

- Data-Driven Analysis: It is essential to gain insights into process performance, identify bottlenecks, and measure key metrics.

- Task 1: The results appraisal for horizontal integration using sets of negative and positive synergy effects. This problem is described in Section 4.1.

- Task 2: Evaluation of the synergy effects as a result of the FDM’s scalability at three levels based on the logistics department, the TTC as a whole, and the local TTC platform. This problem is described in Section 4.2.

3.5. Data Collection and Preprocessing

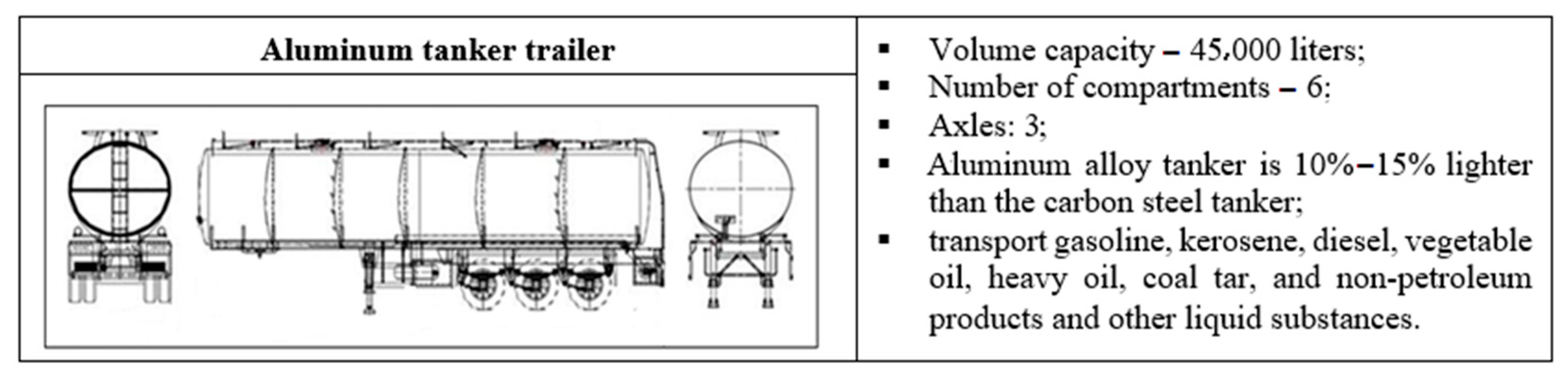

3.5.1. Basic Input Information

3.5.2. Road Infrastructure Datasets

3.5.3. Additional Databases

3.5.4. Identifying Failed AI Deployments

- Errors in planned adaptation activities in sensitive AI apps.

- Absence of a proposition for adaptation measures based on relevant study results.

- Each decision from the set can be assigned

- Any correct decision has a value equal to 1.0;

- Any incorrect decision has a value equal to 0.

- —decision to implement the AI app, ensuring SuS 2 ACE transition; ;

- —compatibility status of the SuS 2 ACE immediately after implementation;

- —component incompatibility status after implementation activities at moment ;

- ]—the level of exposure to these events;

- —likelihood of generating positive synergies in the state at moment ;

- —likelihood of generating negative synergies in the state at moment

- —decision to adapt the deployed AI app transition to state

- —state of compatibility of the SuS 2 ACE at moment after adaptation activities;

- —the state of incompatibility of the SuS 2 ACE at moment after adaptation starting;

- ]—the level of exposure to these events;

- —likelihood of generating positive synergy after SuS 2 ACE transition to state ;

- —likelihood of generating negative synergy after the SuS 2 ACE has moved on to .

- —probability of the SuS 2 transition from state to state.

4. Method

- —the Heaviside unit step function the value of which is zero for negative arguments and one for positive arguments [with , if and otherwise];

- —involved part of the knowledge (treated as part of tasks solved with AI support);

- —knowledge (treated as all tasks solved by C-fleet managers).

- —probability that TTC could lose competitiveness in the fuel deliveries market;

- —number of all AI apps randomly sampled in groups of size ;

- —number of adaptive AI apps (has the consent of C-fleet managers to cooperate);

- —number of positive cooperations.

- —measure of selection strength for the adaptation process;

- —the so-called degeneracy factor goes back to the Fermi function.

4.1. Task 1: Evaluating Synergies as Upgrade Success

- —the current FDM value (before the upgrade);

- —the additional FDM value (after the upgrade; can be positive or negative).

4.2. Task 2: Evaluating Synergies as Scalability Success

- —the set of vertices corresponding to (number of PFSs);

- —the set of edges corresponding to fuel delivery routes.

- Each PFS is visited exactly once by exactly one road tanker;

- All tanker routes start and end at the refinery;

- All constraints are satisfied.

- : The binary variable indicates a tanker active arc from node to node .

- : The binary variable indicates synergy effects.

- The synergy effect is marginal when the value of the HK item depends on the value of the AI item, but the HK item’s value has no influence on the value of the AI item. This assumption was confirmed by the study results when the FDM upgrade (starting point) at the department and at the TTC level resulted in negative synergy effects, thus decreasing the number of serviced orders to (10–12)/(1–3) per year.

- Such a situation required additional adaptation work caused by inconclusive goal setting, an attempt to implement an overcomplicated AI app, using the principle of a one-size-fits-all AI app, poor change management, and employees’ reluctance or refusal to accept changes.

- Most synergy effects occurred when using regional platforms.

5. Discussion

- Route optimization through an analysis of historical databases, optimizing traffic modes and schedules, and dynamically planning fuel delivery routes. By considering factors like delivery windows, vehicle capacities, and customer preferences, AI apps can reduce operation costs and improve on-time fuel distribution. For this, one of the surveyed TTCs uses the EasyRoutes AI app as an advanced HK/AI-driven tool to integrate route optimization.

- Predictive analytics for fuel demand forecasting by analyzing weather patterns and market trends to predict future fuel demand. By combining state-of-the-art sequence modeling and machine learning techniques, a TTC can anticipate demand fluctuations, adjust inventory levels accordingly, and optimize supply chain operations. For this, one of the surveyed TTCs updated the RapidMiner AI app to easily integrate it with a wide range of data sources, including historical databases, cloud storage, and big data platforms, providing fleet managers with easy access and comfortable use of needed information.

- AI technologies provide last mile visibility, giving both logistics teams and consumers real-time access to delivery progress, including inventory level assessment, fleet status evaluation, and traffic mode. By integrating data from sensors and GPS tracking devices, AI systems enable a TTC to monitor fuel distribution more effectively, reducing downtime risks and improving responses to unsafe events.

6. Conclusions and Recommendations

- The obtained findings indicate that a key factor inhibiting the improvement of the management process and increasing the associated risks is the incompatibility of innovative AI apps and traditional FDM architectures. Therefore, the integration of human capital with AI emerges as a company efficiency driver to the extent that the impact is also tied to organizational characteristics. This supports the fusion of human creativity with AI technology’s accuracy to foster resource-efficient and human-centric development.

- The paper highlights the various ways in which ineffective FDM architecture can be integrated with pioneering AI apps to achieve maximum productivity. The research provided proof using the example of implementing an AI app in an FDM architecture.

- The obtained findings show that immediately after the upgrade activities, positive effects are possible at the TTC level, and the probability of achieving them varies by 0.423 ± 0.05 to 0.893 ± 0.02. On the other hand, when the update concerns the logistics department level, the probability of achieving positive synergy effects is much lower, i.e., from 0.296 ± 0.07 to 0.629 ± 0.03. The relatively low value for achieving positive synergy effects is due to the high probability of an SPOF problem, poor changes in management, as well as employees’ reluctance or refusal to accept upgrade plans.

- Reduction of the aforementioned risks is possible by eliminating barriers to upgrade success by using a strategy of incremental deployment of AI apps supported by adaptive techniques. In this case, the probability of achieving positive synergy within the FDM platforms ranges from 0.708 ± 0.03 to 0.964 ± 0.01 and has a range of up to 0.538 ± 0.03 to 0.809 ± 0.01 at the logistics department level.

7. Future Research

- Further mining and structuring of knowledge about cooperation between humans and rapidly developing AI apps, which could have intertwined influences on the co-learning process.

- Improving the decision making process based on familiarizing managers with AI’s possibilities, bridging the gap between real-world problems and management practice.

- Ensuring both the dynamics and continuity of business development.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Haenlein, M.; Kaplan, A. A Brief History of Artificial Intelligence: On the Past, Present, and Future of Artificial Intelligence. Calif. Manag. Rev. 2019, 61, 5–14. [Google Scholar] [CrossRef]

- Semenov, I.; Auguściak, I. Building the Enterprises Capacity Through Specialized-Self-Learning Knowledge Platforms (SLKP) Connected to Omnichannel Networks. In Emerging Challenges in Intelligent Management Information Systems; Hernes, M., Wątróbski, J., Rot, A., Eds.; ECAI 2024; Lecture Notes in Networks and Systems; Springer: Cham, Switzerland, 2024; Volume 1218, pp. 16–29. [Google Scholar] [CrossRef]

- Dashaputre, T. Enhancing Logistics Efficiency through a Hybrid AI-Human Collaboration Model: A Case for Operational Optimization. 2024. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=4993111 (accessed on 9 August 2025).

- Aktürk, C. Artificial Intelligence in Enterprise Resource Planning Systems: A Bibliometric Study. J. Int. Logist. Trade 2021, 19, 69–82. [Google Scholar] [CrossRef]

- Bankins, S.; Ocampo, A.C.; Marrone, M.; Restubog, S.L.D.; Woo, S.E. A multilevel review of artificial intelligence in organizations: Implications for organizational behavior research and practice. J. Organ. Behav. 2024, 45, 159–182. [Google Scholar] [CrossRef]

- Mikalef, P.; Gupta, M. Artificial intelligence capability: Conceptualization, measurement calibration, and empirical study on its impact on organizational creativity and firm performance. Inf. Manag. 2021, 58, 103434. [Google Scholar] [CrossRef]

- Challapally, A.; Pease, C.; Raskar, R.; Chari, P. The GenAI Divide: State of AI in Business 2025. MIT NANDA, July 2025. Available online: https://mlq.ai/media/quarterly_decks/v0.1_State_of_AI_in_Business_2025_Report.pdf (accessed on 27 August 2025).

- Abduljabbar, R.; Dia, H.; Liyanage, S.; Bagloee, S.A. Applications of Artificial Intelligence in Transport: An Overview. Sustainability 2019, 11, 189. [Google Scholar] [CrossRef]

- Arinze, C.A.; Agho, M.O.; Eyo-Udo, N.L.; Abbey, A.B.N.; Onukwulu, E.C. AI-Driven Transport and Distribution Optimization Model (TDOM) for the downstream petroleum sector: Enhancing sme supply chains and sustainability. Magna Sci. Adv. Res. Rev. 2025, 13, 137–153. [Google Scholar] [CrossRef]

- Chen, W.; Men, Y.; Fuster, N.; Osorio, C.; Juan, A.A. Artificial Intelligence in Logistics Optimization with Sustainable Criteria: A Review. Sustainability 2024, 16, 9145. [Google Scholar] [CrossRef]

- Kolbjørnsrud, V. Designing the Intelligent Organization: Six Principles for Human-AI Collaboration. Calif. Manag. Rev. 2023, 66, 44–64. [Google Scholar] [CrossRef]

- Fernández Gil, A.; Lalla-Ruiz, E.; Gómez Sanchez, M.; Castro, C. The cumulative vehicle routing problem with time windows: Models and algorithm. Ann. Oper. Res. 2025, 350, 325–353. [Google Scholar] [CrossRef]

- Izdebski, M.; Jacyna-Gołda, I.; Gołda, P. Minimisation of the probability of serious road accidents in the transport of dangerous goods. Reliab. Eng. Syst. Saf. 2022, 217, 108093. [Google Scholar] [CrossRef]

- Jepsen, M.; Petersen, B.; Spoorendonk, S.; Pisinger, D. Subset-Row Inequalities Applied to the Vehicle-Routing Problem with Time Windows. Oper. Res. 2008, 56, 497–511. [Google Scholar] [CrossRef]

- Godbole, M.V. Revolutionizing Enterprise Resource Planning (ERP) Systems through Artificial Intelligence. Int. Numer. J. Mach. Learn. Robot. 2023, 7, 1–15. Available online: https://injmr.com/index.php/fewfewf/article/view/31 (accessed on 9 August 2025).

- Izdebski, M.; Jacyna-Gołda, I.; Wasiak, M. The application of genetic algorithm for warehouse location in logistic network. J. Kones Powertrain Transp. 2016, 23, 201–208. Available online: https://scispace.com/pdf/the-application-of-genetic-algorithm-for-warehouse-location-4f43sa63it.pdf (accessed on 28 July 2025).

- Izdebski, M.; Jacyna-Gołda, I.; Wasiak, M.; Jachimowski, R.; Kłodawski, M.; Pyza, D.; Żak, J. The application of the genetic algorithm to multi-criteria warehouses location problems on the logistics network. Transport 2018, 33, 741–750. [Google Scholar] [CrossRef]

- Wasiak, M.; Zdanowicz, P.; Nivette, M. Research on the effectiveness of alternative propulsion sources in high-tonnage cargo transport. Arch. Transp. 2021, 60, 259–273. [Google Scholar] [CrossRef]

- Pattnaik, S.; Liew, N.; Kures, A.O.; Pinsky, E.; Park, K. Catalyzing Supply Chain Evolution: A Comprehensive Examination of Artificial Intelligence Integration in Supply Chain Management. Eng. Process. 2024, 68, 57. [Google Scholar] [CrossRef]

- Perifanis, N.A.; Kitsios, F. Investigating the Influence of Artificial Intelligence on Business Value in the Digital Era of Strategy: A Literature Review. Information 2023, 14, 85. [Google Scholar] [CrossRef]

- Sun, X.; Song, Y. Unlocking the Synergy: Increasing productivity through Human-AI collaboration in the industry 5.0 Era. Comput. Ind. Eng. 2025, 200, 110657. [Google Scholar] [CrossRef]

- Daios, A.; Kladovasilakis, N.; Kelemis, A.; Kostavelis, I. AI Applications in Supply Chain Management: A Survey. Appl. Sci. 2025, 15, 2775. [Google Scholar] [CrossRef]

- Fahnenstich, H.; Rieger, T.; Roesler, E. Trusting under risk—Comparing human to AI decision support agents. Comput. Hum. Behav. 2024, 153, 108107. [Google Scholar] [CrossRef]

- Goundar, S. Introduction to Enterprise Systems and Technological Convergence. In Enterprise Systems and Technological Convergence: Research and Practice; Information Age Publishing Inc.: Charlotte, NC, USA, 2021; Chapter 1; pp. 1–21. Available online: https://www.researchgate.net/publication/353430514_Introduction_to_Enterprise_Systems_and_Technological_Convergence_Research_and_Practice (accessed on 15 July 2025).

- Borges, A.F.S.; Laurindo, F.J.B.; Spínola, M.M.; Gonçalves, R.F.; Mattos, C.A. The strategic use of artificial intelligence in the digital era: Systematic literature review and future research directions. Int. J. Inf. Manag. 2021, 57, 102225. [Google Scholar] [CrossRef]

- Farrow, E. Determining the human to AI workforce ratio—Exploring future organisational scenarios and the implications for anticipatory workforce planning. Technol. Soc. 2022, 68, 101879. [Google Scholar] [CrossRef]

- Regulation (EU) 2024/1689 of the European Parliament and of the Council, of 13 June 2024, Laying Down Harmonised Rules on Artificial Intelligence and Amending Regulations (EC) No 300/2008, (EU) No 167/2013, (EU) No 168/2013, (EU) 2018/858, (EU) 2018/1139 and (EU) 2019/2144 and Directives 2014/90/EU, (EU) 2016/797 and (EU) 2020/1828 (Artificial Intelligence Act). Available online: https://eur-lex.europa.eu/eli/reg/2024/1689/oj/eng (accessed on 30 July 2025).

- Chai, H.; He, R.; Jia, X.; Ma, C.; Dai, C. Generalized route planning approach for hazardous materials transportation with equity consideration. Arch. Transp. 2018, 46, 33–46. [Google Scholar] [CrossRef]

- Kaczorek, M.; Jacyna, M. Fuzzy logic as a decision-making support tool in planning transport development. Arch. Transp. 2022, 61, 51–70. [Google Scholar] [CrossRef]

- Gorobchenko, O.; Holub, H.; Zaika, D. Theoretical basics of the self-learning system of intelligent locomotive decision support systems. Arch. Transp. 2024, 71, 169–186. [Google Scholar] [CrossRef]

- Monteiro Nunes, T.M.; Borst, C.; van Kampen, E.-J.; Hillburn, B.; Westin, C. Human-interpretable input for Machine Learning in Tactical Air Traffic Control 2021. In Proceedings of the 11th SESAR Innovation Days, Online, 7–9 December 2021. [Google Scholar] [CrossRef]

- Bonelli, S.; Borst, C.; Brambati, F.; Cocchioni, M.; Hilburn, B.; Monteiro-Nunes, T. Transparent and Personalised AI Support in Air Traffic Control: First Empirical Results 2022. In Proceedings of the International Conference on Cognitive Aircraft Systems ICCAS 2022, Toulouse, France, 1–2 June 2022. [Google Scholar] [CrossRef]

- Li, S.; Liu, Y.; Qu, X. Model Controlled Prediction: A Reciprocal Alternative of Model Predictive Control. IEEE/CAA J. Autom. Sin. 2022, 9, 1107–1110. [Google Scholar] [CrossRef]

- Jia, R.; Chamoun, R.; Wallenbring, A.; Advand, M.; Yu, S.; Liu, Y.; Gao, K. A spatio-temporal deep learning model for short-term bike-sharing demand prediction. Electron. Res. Arch. 2023, 31, 1031–1047. [Google Scholar] [CrossRef]

- Wu, F.; Lyu, C.; Liu, Y. A personalized recommendation system for multi-modal transportation systems. Multimodal Transp. 2022, 1, 100016. [Google Scholar] [CrossRef]

- Pan, Z.; Chen, M.; Lu, S.; Tian, Z.; Liu, Y. Integrated Timetable Optimization for Minimum Total Energy Consumption of an AC Railway System. IEEE Trans. Veh. Technol. 2020, 69, 3641–3653. [Google Scholar] [CrossRef]

- Liang, Y.; Liu, H.; Qian, C.; Wang, G. A Modified Genetic Algorithm for Multi-Objective Optimization on Running Curve of Automatic Train Operation System Using Penalty Function Method. Int. J. Intell. Transp. Syst. Res. 2019, 17, 74–87. [Google Scholar] [CrossRef]

- Yang, J.; Jia, L.; Fu, Y.; Lu, S. Speed Tracking Based Energy-Efficient Freight Train Control Through Multi-Algorithms Combination. IEEE Intell. Transp. Syst. Mag. 2017, 9, 76–90. [Google Scholar] [CrossRef]

- Saki, S.; Soori, M. Artificial Intelligence, Machine Learning and Deep Learning in. Advanced Transportation Systems, A Review. Multimodal Transp. 2025; in press. [Google Scholar] [CrossRef]

- Yan, H.; Li, Y. Generative AI for Intelligent Transportation Systems: Road Transportation Perspective. ACM Comput. Surv. 2025, 57, 315. [Google Scholar] [CrossRef]

- Taran, I.; Olzhabayeva, R.; Oliskevych, M.; Danchuk, V. Structural optimization of multimodal routes for cargo delivery. Arch. Transp. 2023, 67, 49–70. [Google Scholar] [CrossRef]

- Peng, Y.; Mo, Z.; Liu, S. Passenger’s routes planning in stochastic common-lines’ multi-modal transportation network through integrating Genetic Algorithm and Monte Carlo simulation. Arch. Transp. 2021, 59, 73–92. [Google Scholar] [CrossRef]

- Lee, Y.; Wei, C.-H.; Chao, K.-C. Non-parametric machine learning methods for evaluating the effects of traffic accident duration on freeways. Arch. Transp. 2017, 43, 91–104. [Google Scholar] [CrossRef]

- Tarapata, Z.; Kulas, W.; Antkiewicz, R. Machine learning algorithms for the problem of optimizing the distribution of parcels in time-dependent networks: The case study. Arch. Transp. 2022, 61, 133–147. [Google Scholar] [CrossRef]

- Vaze Kadam, S. Leveraging Artificial Intelligence to Reinvent Enterprise Resource Planning (ERP) Functionality. Voice Creat. Res. 2025, 7, 266–272. [Google Scholar] [CrossRef]

- Attaluri, V. Real-Time Monitoring and Auditing of Role Changes in Databases. Int. Numer. J. Mach. Learn. Robot. 2023, 7. Available online: https://injmr.com/index.php/fewfewf/article/view/184/43 (accessed on 25 August 2025).

- Qu, C.; Kim, E. Reviewing the Roles of AI-Integrated Technologies in Sustainable Supply Chain Management: Research Propositions and a Framework for Future Directions. Sustainability 2024, 16, 6186. [Google Scholar] [CrossRef]

- Kunduru, A.R. Effective Usage of Artificial Intelligence in Enterprise Resource Planning Applications. Int. J. Comput. Trends Technol. 2023, 71, 73–80. [Google Scholar] [CrossRef]

- Panek, A.; Jacyna, M.; Jachimowski, R.; Szczepański, E. Reliability and efficiency in technology selection in logistics facilities—Multi-criteria decision support using the AHP method. Maint. Reliab. 2025, 27, 21. [Google Scholar] [CrossRef]

- Sedera, D.; Zakaria, N.H. Adaptive structuration theory view of post implementation knowledge management for enterprise systems. In Proceedings of the Pacific Asia Conference on Information System PACIS 2008 Proceedings: AIS, Suzhou, China, 3–7 July 2008; p. 179. Available online: https://aisel.aisnet.org/pacis2008/179 (accessed on 25 September 2025).

- Jarrahi, M.H. Artificial intelligence and the future of work: Human-AI symbiosis in organizational decision making. Bus. Horiz. 2018, 61, 577–586. [Google Scholar] [CrossRef]

- Shao, Z.; Li, X.; Wang, Q. From ambidextrous learning to digital creativity: An integrative theoretical framework. Inf. Syst. J. 2022, 32, 544–572. [Google Scholar] [CrossRef]

- Rangineni, S.; Marupaka, D.; Bhardwaj, A.K. An Examination of Machine Learning in the Process of Data Integration. Int. J. Comput. Trends Technol. 2023, 71, 79–85. [Google Scholar] [CrossRef]

- Venugopal, M.; Nanda, M.; Anand, G.; Voora, H.C. An integrated Hardware/Software Verification and Validation methodology for Signal Processing Systems. ITM Web Conf. 2022, 50, 02001. [Google Scholar] [CrossRef]

- Wang, J.; Nie, Y. Managing the dynamic change of organizational knowledge base in collaboration networks. Balt. J. Manag. 2022, 17, 321–337. [Google Scholar] [CrossRef]

- Stine, K.; Quinn, S.; Witte, G.; Gardner, R.K. Integrating Cybersecurity and Enterprise Risk Management (ERM); NISTIR 8286; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2020; p. 64. [Google Scholar] [CrossRef]

- Wilson, H.J.; Daugherty, P.R. Collaborative Intelligence: Humans and AI Are Joining Forces. Harv. Bus. Rev. 2018, 114–123. Available online: https://hometownhealthonline.com/wp-content/uploads/2019/02/ai2-R1804J-PDF-ENG.pdf (accessed on 18 August 2025).

- Lasota, M.; Jacyna, M.; Wasiak, M.; Zabielska, A. The Use of Multi-criteria Methods in the Problem of Selecting Vehicles for Oversize Cargo Transport. In Challenges and Solutions for Present Transport Systems; Sierpiński, G., Masoumi, H., Macioszek, E., Eds.; TSTP 2022; Lecture Notes in Networks and Systems; Springer: Cham, Switzerland, 2023; Volume 609, pp. 22–47. [Google Scholar] [CrossRef]

- Wei, Q.; Zhang, Q.; Yan, R.; Wu, X. A Theoretical Framework for the Inter-Organizational Knowledge Collaboration of Knowledge Network. In Proceedings of the Thirteenth International Conference on Management Science and Engineering Management, St. Catharines, ON, Canada, 5–8 August 2019; Xu, J., Ahmed, S., Cooke, F., Duca, G., Eds.; ICMSEM 2019; Advances in Intelligent Systems and Computing. Springer: Cham, Switzerland, 2020; Volume 1001, pp. 772–782. [Google Scholar] [CrossRef]

- Szabó, G.; Fáth, G. Evolutionary games on graphs. Phys. Rep. 2007, 446, 97–216. [Google Scholar] [CrossRef]

- Semenov, I.N.; Filina-Davidovich, L. Topology-based approach to the modernization of transport and logistics systems with hybrid architecture. Part 1. Proof-of-concept study. Arch. Transp. 2017, 43, 105–124. [Google Scholar] [CrossRef]

- Pani, A.; Mishra, S.; Sahu, P. Developing multi-vehicle freight trip generation models quantifying the relationship between logistics outsourcing and insourcing decisions. Transp. Res. Part E Logist. Transp. Rev. 2022, 159, 102632. [Google Scholar] [CrossRef]

- Available online: https://conadrogach.pl/wojewodztwo/zachodniopomorskie/#goog_rewarded (accessed on 10 May 2025).

- Terrucha, I.; Fernández Domingos, E.; Santos, F.C.; Simoens, P.; Lenaerts, T. The art of compensation: How hybrid teams solve collective-risk dilemmas. PLoS ONE 2024, 19, e0297213. [Google Scholar] [CrossRef] [PubMed]

- Mai, Z.; Wang, W.; Liu, X.; Feng, X.; Wang, J.; Fu, W. A Reinforcement Learning Approach for Graph Rule Learning. Big Data Min. Anal. 2025, 8, 31–44. [Google Scholar] [CrossRef]

- Lasota, M.; Zabielska, A.; Jacyna, M.; Gołębiowski, P.; Żochowska, R.; Wasiak, M. Method for Delivery Planning in Urban Areas with Environmental Aspects. Sustainability 2024, 16, 1571. [Google Scholar] [CrossRef]

- Nehring, K.; Lasota, M.; Zabielska, A.; Jachimowski, R. A multifaceted approach to assessing intermodal transport. Sci. J. Silesian Univ. Technol. 2023, 121, 141–165. [Google Scholar] [CrossRef]

- Cho, W.; Shaw, M.J.; Kwon, H.D. The effect of synergy enhancement on information technology portfolio selection. Inf. Technol. Manag. 2013, 14, 125–142. [Google Scholar] [CrossRef]

- Skačkauskienė, I.; Hrušecká, D.; Katinienė, A.; Čepel, M. Evaluation of knowledge synergy components. Ekon. A Manag. 2018, 21, 144–158. [Google Scholar] [CrossRef]

- Eglese, R.; Zambirinis, S. Disruption management in vehicle routing and scheduling for road freight transport: A review. TOP 2018, 26, 1–17. [Google Scholar] [CrossRef]

- Eliiyi, U. Artificial Intelligence for Smart Cities: Locational Planning and Dynamic Routing of Emergency Vehicles. In The Impact of Artificial Intelligence on Governance, Economics and Finance; Bozkuş Kahyaoğlu, S., Ed.; Accounting, Finance, Sustainability, Governance & Fraud: Theory and Application; Springer: Singapore, 2022; Volume 2, pp. 41–63. [Google Scholar] [CrossRef]

- Semenov, I.; Jacyna, M.; Milewska, B. Maximizing uptime of the aging road tanker fleets in labor shortages and economic uncertainty by implementing preventive maintenance practices. Maint. Reliab. 2026, 28, 205976. [Google Scholar] [CrossRef]

| Sector | Application Areas | Number of Implementations | ||

|---|---|---|---|---|

| XX Century | XXI Century | |||

| 1 | Industrial production |

| 5–8 | 74–82 |

| 2 | Transport and logistics services |

| 3–4 | 61–72 |

| 3 | Financial institutions |

| 2–3 | 56–69 |

| 4 | Retail trade |

| 2–3 | 37–41 |

| Integration Plane | Integration Levels | |||||

|---|---|---|---|---|---|---|

| Management Subsystem /Logistics Department | Management System /Tank Trucking Company | Multiple Managing Systems /Regional Platform | ||||

| Hardware | 0.462 ± 0.05 | 0.537 ± 0.04 | 0.416 ± 0.05 | 0.584 ± 0.03 | 0.493 ± 0.04 | 0.507 ± 0.04 |

| Database | 0.524 ± 0.04 | 0.476 ± 0.05 | 0.496 ± 0.04 | 0.504 ± 0.05 | 0.575 ± 0.03 | 0.425 ± 0.05 |

| Software | 0.395 ± 0.07 | 0.605 ± 0.03 | 0.308 ± 0.06 | 0.692 ± 0.04 | 0.428 ± 0.05 | 0.572 ± 0.03 |

| Orgware | 0.386 ± 0.09 | 0.614 ± 0.03 | 0.289 ± 0.08 | 0.711 ± 0.03 | 0.423 ± 0.05 | 0.577 ± 0.04 |

| E-safety | 0.629 ± 0.03 | 0.371 ± 0.08 | 0.579 ± 0.06 | 0.421 ± 0.05 | 0.814 ± 0.03 | 0.186 ± 0.09 |

| Test tools | 0.296 ± 0.07 | 0.704 ± 0.02 | 0.278 ± 0.07 | 0.722 ± 0.04 | 0.893 ± 0.02 | 0.107 ± 0.09 |

| Integration Plane | Integration Levels | |||||

|---|---|---|---|---|---|---|

| Management Subsystem /Logistics Department | Management System /Tank Trucking Company | Multiple Managing Systems /Regional Platform | ||||

| Hardware | 0.672 ± 0.02 | 0.328 ± 0.05 | 0.792 ± 0.04 | 0.208 ± 0.08 | 0.708 ± 0.03 | 0.292 ± 0.06 |

| Database | 0.756 ± 0.01 | 0.244 ± 0.06 | 0.831 ± 0.05 | 0.169 ± 0.08 | 0.822 ± 0.02 | 0.178 ± 0.08 |

| Software | 0.568 ± 0.03 | 0.432 ± 0.04 | 0.902 ± 0.05 | 0.098 ± 0.09 | 0.943 ± 0.02 | 0.057 ± 0.09 |

| Orgware | 0.538 ± 0.03 | 0.462 ± 0.04 | 0.936 ± 0.05 | 0.064 ± 0.08 | 0.929 ± 0.01 | 0.071 ± 0.08 |

| E-safety | 0.809 ± 0.01 | 0.191 ± 0.07 | 0.893 ± 0.05 | 0.107 ± 0.08 | 0.964 ± 0.01 | 0.036 ± 0.10 |

| Test tools | 0.758 ± 0.03 | 0.242 ± 0.06 | 0.951 ± 0.04 | 0.049 ± 0.08 | 0.902 ± 0.01 | 0.098 ± 0.08 |

| Pi(Si)—probability of generating positive synergies in FDM after two adaptation steps; Pi*(Si)—probability of generating negative synergies in FDM after two adaptation steps. | ||||||

| Basic Supply Patterns | Scalability Index | Synergy Effects |

|---|---|---|---|

| Department level: one refinery—one petrol station |  | Negative synergy Incompatible operation, resulting in wasted time and resources Positive synergy Decreased delivery times | |

| Tank trucking company level: shuttle delivery |  | Negative synergy Conflicting priorities—a lack of alignment and cooperation Positive Synergy Increased demand and servicing quality | |

| Local platform level: one refinery—several petrol stations |  | Negative synergy Lack of collaboration and, as a result, duplicated efforts, conflicting goals, and ineffective resource use Positive synergy | |

| |||

| Regional platform level: few refineries—numerous petrol stations |  | Negative synergy Incompatibility of usability and, as a result, wastefulness and reduced overall effectiveness Positive synergy | |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Semenov, I.; Jacyna, M.; Auguściak, I.; Wasiak, M. Hybrid Human–AI Collaboration for Optimized Fuel Delivery Management. Energies 2025, 18, 5203. https://doi.org/10.3390/en18195203

Semenov I, Jacyna M, Auguściak I, Wasiak M. Hybrid Human–AI Collaboration for Optimized Fuel Delivery Management. Energies. 2025; 18(19):5203. https://doi.org/10.3390/en18195203

Chicago/Turabian StyleSemenov, Iouri, Marianna Jacyna, Izabela Auguściak, and Mariusz Wasiak. 2025. "Hybrid Human–AI Collaboration for Optimized Fuel Delivery Management" Energies 18, no. 19: 5203. https://doi.org/10.3390/en18195203

APA StyleSemenov, I., Jacyna, M., Auguściak, I., & Wasiak, M. (2025). Hybrid Human–AI Collaboration for Optimized Fuel Delivery Management. Energies, 18(19), 5203. https://doi.org/10.3390/en18195203