Study on Numerical Simulation of Blast Furnace Injection of Low-Rank Coal by Hydrothermal Carbonization

Abstract

1. Introduction

2. Model Construction

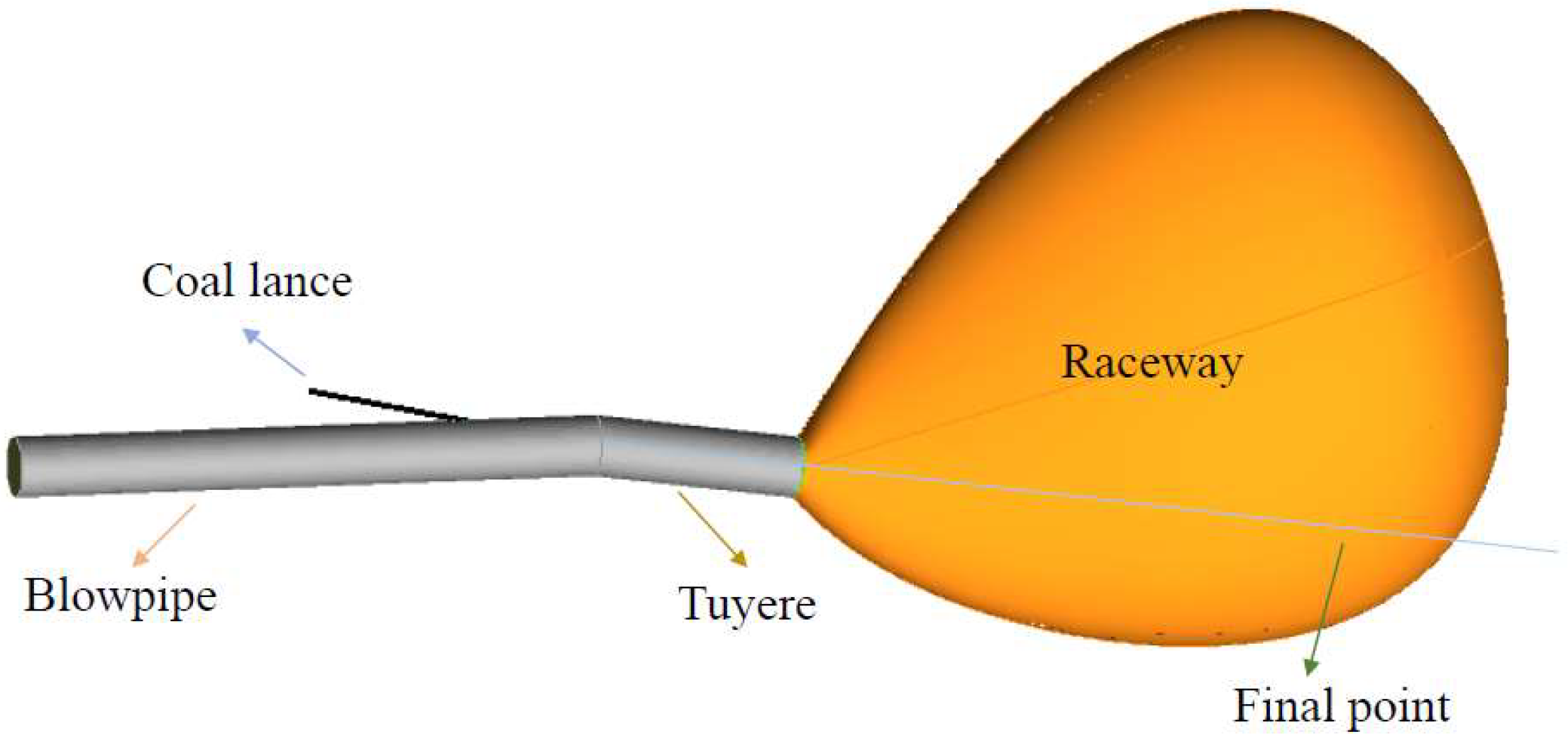

2.1. Physical Model and Simulation Conditions

2.2. Governing Equations

2.3. Chemical Reactions and Model Validity

3. Results and Discussions

3.1. Velocity Field

3.2. Particle Char Mass Distribution

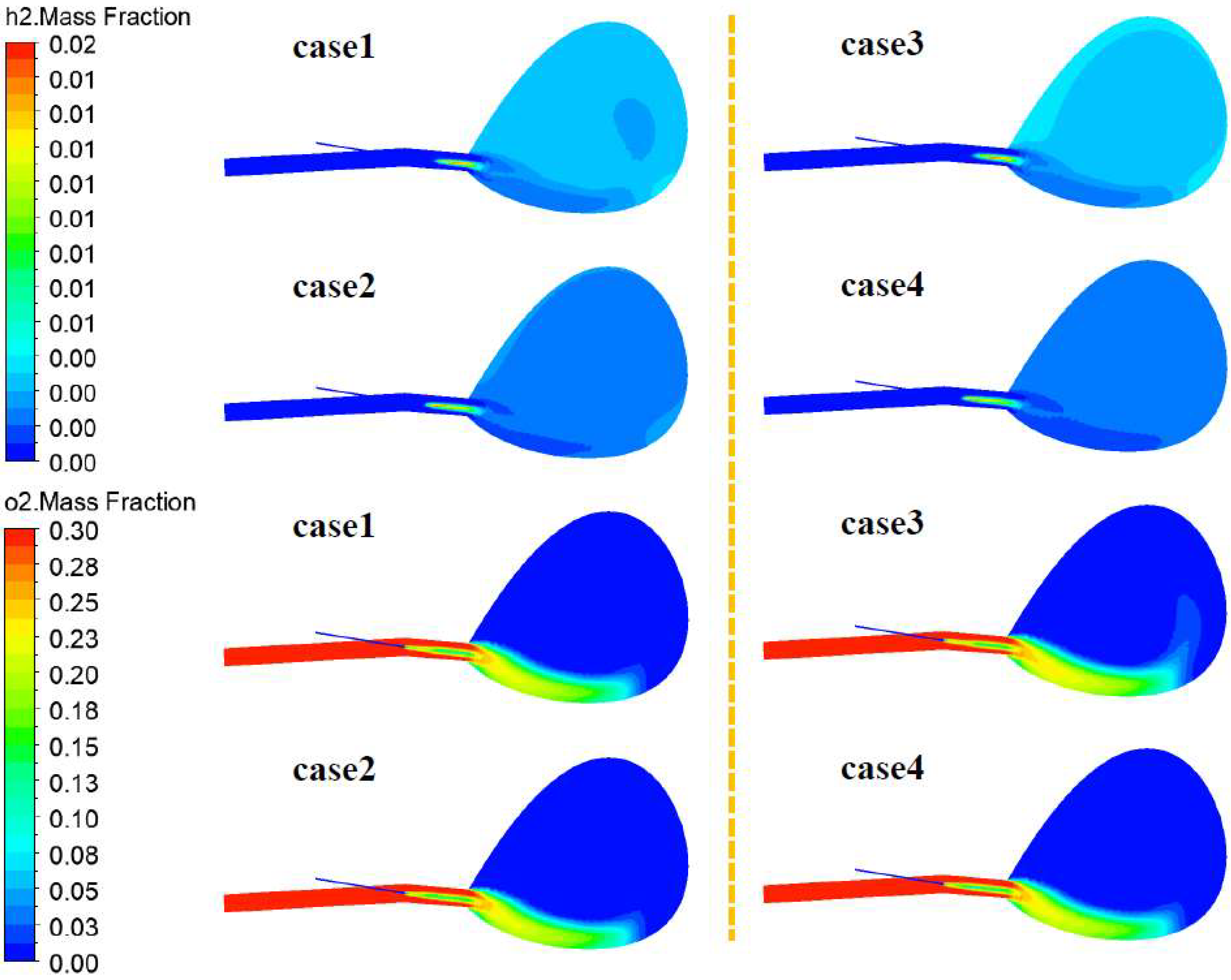

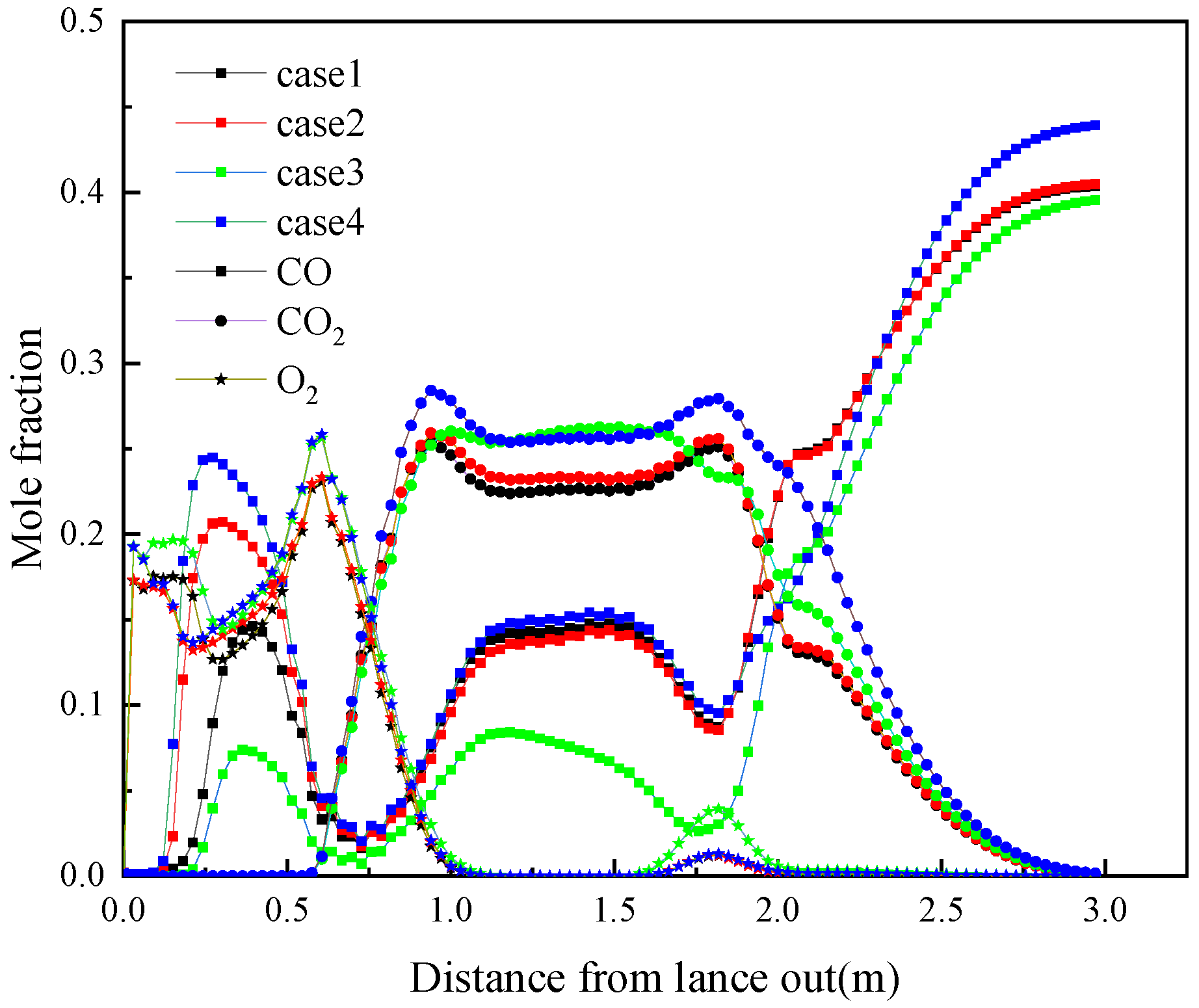

3.3. Gas Mass Fraction

3.4. Thermal Simulation Research

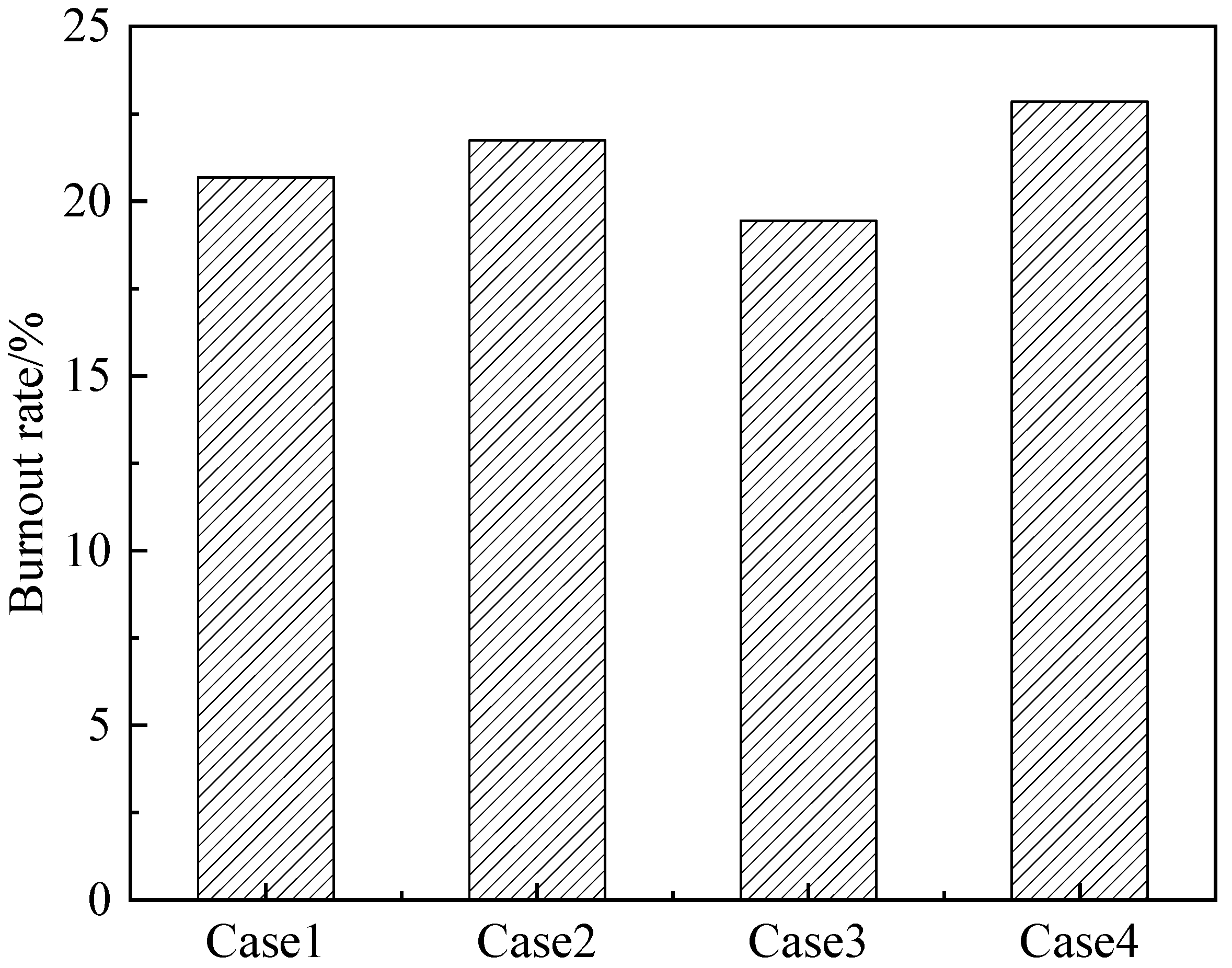

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Abbreviation | Paraphrase |

| HTC | Hydrothermal carbonization |

| Constants in turbulence models | |

| Constants in turbulence models | |

| Constants in turbulence models | |

| Constants in turbulence models | |

| Constants in turbulence models | |

| Absorption coefficient | |

| Heat in the reaction (J/kg) | |

| particle surface area (m2) | |

| Coefficient of resistance | |

| Particles specific heat (J/(g·K)) | |

| Particle equivalent radiation | |

| Drag force of particle (N) | |

| Incident radiation | |

| Enthalpy (J/kg) | |

| Radiation intensity (W/m2) | |

| Mass transfer rate (kg/s) | |

| Kinetic energy of the turbulent (m2/s2) | |

| The number of particles | |

| Medium refractive index | |

| The number of per unit volume particle (m3) | |

| Particle | |

| pressure (Pa) | |

| Radiation heat flux | |

| Particle heat transfer (W) | |

| Turbulence caused by viscous forces | |

| The temperature of gas (K) | |

| The temperature of the particle (K) | |

| The velocity of the particle (m/s) | |

| The velocity of the gas (m/s) | |

| The reaction rate of (kg/(m3·s)) | |

| The mass fraction of | |

| Density (kg/m3) | |

| Turbulent viscosity | |

| The constant that represents Stefan-Boltzmann | |

| The constant in turbulence model | |

| Thermal conductivity (W/(m·K)) | |

| molecular diffusivity of | |

| The rate of turbulent dissipation (m2/s3) | |

| Coal emissivity |

References

- Nechifor, V.; Calzadilla, A.; Bleischwitz, R.; Winning, M.; Tian, X.; Usubiaga, A. Steel in a circular economy: Global implications of a green shift in China. World Dev. 2020, 127, 104775. [Google Scholar] [CrossRef]

- Fan, Z.Y.; Friedmann, S.J. Low-carbon production of iron and steel: Technology options, economic assessment, and policy. Joule 2021, 5, 829–862. [Google Scholar] [CrossRef]

- Mele, M.; Magazzino, C. A machine learning analysis of the relationship among iron and steel industries, air pollution, and economic growth in China. J. Clean. Prod. 2020, 277, 123293. [Google Scholar] [CrossRef]

- Manzolini, G.; Giuffrida, A.; Cobden, P.D.; Van Dijk, H.A.J.; Ruggeri, F.; Consonni, F. Techno-economic assessment of SEWGS technology when applied to integrated steel-plant for CO2 emission mitigation. Int. J. Greenh. Gas Control 2020, 94, 102935. [Google Scholar] [CrossRef]

- Na, H.M.; Sun, J.C.; Qiu, Z.Y.; Yuan, Y.X.; Du, T. Optimization of energy efficiency, energy consumption and CO2 emission in typical iron and steel manufacturing process. Energy 2022, 257, 124822. [Google Scholar] [CrossRef]

- Sun, G.Y.; Li, B.; Guo, H.J.; Yang, W.S.; Li, S.Y.; Guo, J. Thermodynamic Study of energy consumption and carbon dioxide emission in ironmaking process of the reduction of iron oxides by carbon. Energies 2021, 14, 1999. [Google Scholar] [CrossRef]

- Na, H.M.; Sun, J.C.; Qiu, Z.Y.; He, J.F.; Yuan, Y.X.; Yan, T.Y.; Du, T. A novel evaluation method for energy efficiency of process industry—A case study of typical iron and steel manufacturing process. Energy 2021, 233, 121081. [Google Scholar] [CrossRef]

- Hu, Y.C.; Rufford, T.E.; Chen, J.; Hao, L.Y.; Li, M.R.; Qiu, Y.X.; Garg, S.; Rudolph, V.; Wang, G. Opportunities to reduce energy consumption and CO2 emissions from ironmaking blast furnace using CO2 electrolysis to CO for carbon recycling. J. Clean. Prod. 2023, 389, 135997. [Google Scholar] [CrossRef]

- Ma, K.H.; Deng, J.Y.; Wang, G.; Zhou, Q.; Xu, J. Utilization and impacts of hydrogen in the ironmaking processes: A review from lab-scale basics to industrial practices. Int. J. Hydrogen Energy 2021, 46, 26646–26664. [Google Scholar] [CrossRef]

- Zhang, N.; Zhang, J.L.; Wang, G.W.; Ning, X.J.; Meng, F.Y.; Li, C.H.; Ye, L.; Wang, C. Physicochemical characteristics of three-phase products of low-rank coal by hydrothermal carbonization: Experimental research and quantum chemical calculation. Energy 2022, 261, 125347. [Google Scholar] [CrossRef]

- Wang, Y.J.; Zuo, H.B.; Zhao, J. Recent progress and development of ironmaking in China as of 2019: An overview. Ironmak. Steelmak. 2020, 47, 640–649. [Google Scholar] [CrossRef]

- Li, J.; Kuang, S.B.; Jiao, L.L.; Liu, L.L.; Zou, R.P.; Yu, A.B. Numerical modeling and analysis of hydrogen blast furnace ironmaking process. Fuel 2022, 323, 124368. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, C.H.; Chen, X.J.; Jia, L.Q.; Guo, X.N.; Chen, R.S.; Zhang, M.S.; Chen, Z.Y.; Wang, H.D. Carbon peak and carbon neutrality in China: Goals, implementation path and prospects. China Geol. 2021, 4, 720–746. [Google Scholar] [CrossRef]

- Zhao, X.; Ma, X.W.; Chen, B.Y.; Shang, Y.P.; Song, M.L. Challenges toward carbon neutrality in China: Strategies and countermeasures. Resour. Conserv. Recycl. 2022, 176, 105959. [Google Scholar] [CrossRef]

- Yang, P.J.; Peng, S.A.; Benani, N.; Dong, L.Y.; Li, X.M.; Liu, R.P.; Mao, G.Z. An integrated evaluation on China’s provincial carbon peak and carbon neutrality. J. Clean. Prod. 2022, 377, 134497. [Google Scholar] [CrossRef]

- Wei, Y.M.; Chen, K.Y.; Kang, J.N.; Chen, W.M.; Wang, X.Y.; Zhang, X.Y. Policy and management of carbon peaking and carbon neutrality: A literature review. Engineering 2022, 14, 52–63. [Google Scholar] [CrossRef]

- Li, J.Q.; Li, C.Z.; Zhang, W.; Zhang, J.H.; Xue, Z.L. Material, energy and exergy flows of the oxygen blast furnace process with sintering flue gas injection. J. Clean. Prod. 2022, 371, 133294. [Google Scholar] [CrossRef]

- Gavel, D.J.; Adema, A.; van der Stel, J.; Peeters, T.; Sietsma, J.; Boom, R.; Yang, Y.X. A comparative study of pellets, sinter and mixed ferrous burden behaviour under simulated blast furnace conditions. Ironmak. Steelmak. 2021, 48, 359–369. [Google Scholar] [CrossRef]

- Luukkonen, T.; Olsen, E.; Turkki, A.; Muurinen, E. Ceramic-like membranes without sintering via alkali activation of metakaolin, blast furnace slag, or their mixture: Characterization and cation-exchange properties. Ceram. Int. 2023, 49, 10645–10651. [Google Scholar] [CrossRef]

- Xiao, L.Y.; Wang, Y.; Li, W.Y.; Zhang, Q.; Yue, Y.; Qian, G.R. Double high-value utilization of valuable resources in the process of co-sintering detoxification of high chlorine incineration fly ash and blast furnace dust. Resour. Conserv. Recycl. 2024, 204, 107506. [Google Scholar] [CrossRef]

- Du, Y.; Gao, J.T.; Lan, X.; Guo, Z.C. Preparation of TiC ceramics from hot Ti-bearing blast furnace slag: Carbothermal reduction, supergravity separation and spark plasma sintering. J. Eur. Ceram. Soc. 2022, 42, 2055–2061. [Google Scholar] [CrossRef]

- Jamil, N.H.; Abdullah, M.M.A.B.; Pa, F.C.; Mohamad, H.; Ibrahim, W.M.A.W.; Chaiprapa, J. Influences of SiO2, Al2O3, CaO and MgO in phase transformation of sintered kaolin-ground granulated blast furnace slag geopolymer. J. Mater. Res. Technol. 2020, 9, 14922–14932. [Google Scholar] [CrossRef]

- Bersenev, I.S.; Bragin, V.V.; Ugarov, A.A.; Efendiev, N.T.; Kretov, S.I.; Sharkovskii, D.O.; Chesnokov, Y.A. Improvement of technical and economic performance of blast-furnace smelting by pellet composition optimization. Steel Transl. 2020, 50, 171–178. [Google Scholar] [CrossRef]

- Wang, H.T.; Chu, M.S.; Bao, J.W.; Liu, Z.G.; Tang, J.; Long, H.M. Experimental study on impact of iron coke hot briquette as an alternative fuel on isothermal reduction of pellets under simulated blast furnace conditions. Fuel 2020, 268, 117339. [Google Scholar] [CrossRef]

- Silva, F.R.; Lemos, L.R.; de Freitas Nogueira, P.; Bressan, M. Effect of ternary basicity of iron ore-fluxed pellets on melting and softening properties in a blast furnace. Metall. Mater. Trans. B 2021, 52, 69–76. [Google Scholar] [CrossRef]

- Ye, L.; Peng, Z.W.; Ye, Q.; Wang, L.C.; Augustine, R.; Perez, M.; Liu, Y.; Liu, M.D.; Tang, H.M.; Rao, M.J.; et al. Toward environmentally friendly direct reduced iron production: A novel route of comprehensive utilization of blast furnace dust and electric arc furnace dust. Waste Manag. 2021, 135, 389–396. [Google Scholar] [CrossRef]

- Rahmatmand, B.; Tahmasebi, A.; Lomas, H.; Honeyands, T.; Koshy, P.; Hockings, K.; Jayasekara, A. A technical review on coke rate and quality in low-carbon blast furnace ironmaking. Fuel 2023, 336, 127077. [Google Scholar] [CrossRef]

- Niu, W.Q.; Li, Y.; Li, Q.; Wang, J.S.; Wang, G.; Zuo, H.B.; She, X.F.; Xue, Q.G. Physical and chemical properties of metallurgical coke and its evolution in the blast furnace ironmaking process. Fuel 2024, 366, 131277. [Google Scholar] [CrossRef]

- Babich, A.; Senk, D.; Gudenau, H.W. Effect of coke reactivity and nut coke on blast furnace operation. Ironmak. Steelmak. 2009, 36, 222–229. [Google Scholar] [CrossRef]

- Liu, Y.R.; Zhang, H.M.; Shen, Y.S. A data-driven approach for the quick prediction of in-furnace phenomena of pulverized coal combustion in an ironmaking blast furnace. Chem. Eng. Sci. 2022, 260, 117945. [Google Scholar] [CrossRef]

- Zhuo, Y.T.; Shen, Y.S. Three-dimensional transient modelling of coal and coke co-combustion in the dynamic raceway of ironmaking blast furnaces. Appl. Energy 2020, 261, 114456. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Arens, M.; Price, L. Alternative emerging ironmaking technologies for energy-efficiency and carbon dioxide emissions reduction: A technical review. Renew. Sustain. Energy Rev. 2014, 33, 645–658. [Google Scholar] [CrossRef]

- Wang, H.T.; Zhao, W.; Chu, M.S.; Feng, C.; Liu, Z.G.; Tang, J. Current status and development trends of innovative blast furnace ironmaking technologies aimed to environmental harmony and operation intellectualization. J. Iron Steel Res. Int. 2017, 24, 751–769. [Google Scholar] [CrossRef]

- Shen, Y.S.; Yu, A.B.; Zulli, P. CFD modelling and analysis of pulverized coal injection in blast furnace: An overview. Steel Res. Int. 2011, 82, 532–542. [Google Scholar] [CrossRef]

- Tang, J.; Chu, M.S.; Li, F.; Zhang, Z.D.; Tang, Y.T.; Liu, Z.G.; Yagi, J. Mathematical simulation and life cycle assessment of blast furnace operation with hydrogen injection under constant pulverized coal injection. J. Clean. Prod. 2021, 278, 123191. [Google Scholar] [CrossRef]

- Steer, J.; Greenslade, M.; Marsh, R. A comparison of laboratory coal testing with the blast furnace process and coal injection. Metals 2021, 11, 1476. [Google Scholar] [CrossRef]

- Okosun, T.; Street, S.J.; Zhao, J.; Wu, B.; Zhou, C.Q. Influence of conveyance methods for pulverised coal injection in a blast furnace. Ironmak. Steelmak. 2017, 44, 513–525. [Google Scholar] [CrossRef]

- Mathieson, J.G.; Truelove, J.S.; Rogers, H. Toward an understanding of coal combustion in blast furnace tuyere injection. Fuel 2005, 84, 1229–1237. [Google Scholar] [CrossRef]

- Kim, D.; Shin, S.; Sohn, S.; Choi, J.; Ban, B.C. Waste plastics as supplemental fuel in the blast furnace process: Improving combustion efficiencies. J. Hazard. Mater. 2002, 94, 213–222. [Google Scholar] [CrossRef]

- Liu, Y.R.; Shen, Y.S. Modelling and optimisation of biomass injection in ironmaking blast furnaces. Prog. Energy Combust. Sci. 2021, 87, 100952. [Google Scholar] [CrossRef]

- Zhang, C.L.; Zhang, J.L.; Zheng, A.Y.; Xu, R.S.; Jia, G.L.; Zhu, J.F. Effects of hydrogen-rich fuel injection on the states of the raceway in blast furnace. Energy 2023, 274, 127237. [Google Scholar] [CrossRef]

- Shen, Y.S.; Guo, B.Y.; Yu, A.B.; Zulli, P. Model study of the effects of coal properties and blast conditions on pulverized coal combustion. ISIJ Int. 2009, 49, 819–826. [Google Scholar] [CrossRef]

- Wang, Z.C.; Shui, H.F.; Pei, Z.N.; Gao, J.S. Study on the hydrothermal treatment of Shenhua coal. Fuel 2008, 87, 527–533. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Wind pressure/KPa | 380 |

| Air volume/m3/min | 5190 |

| Hot air temperature/K | 1470 |

| Oxygen concentration/% | 27 |

| Coal ratio/kg/t | 160 |

| Carrier gas flow/m3/h | 1820 |

| Carrier gas composition/% | N2 |

| Carrier gas temperature/K | 295 |

| Fuel Type | Proximate Analysis | Ultimate Analysis | ||||||

|---|---|---|---|---|---|---|---|---|

| FCd a | Ad | Vd | Cdaf | Hdaf | Odaf a | Ndaf | Sdaf | |

| Bituminous coal | 61.03 | 3.73 | 35.24 | 69.93 | 4.66 | 24.31 | 0.79 | 0.31 |

| Anthracite | 80.45 | 12.18 | 7.37 | 82.15 | 3.05 | 12.75 | 1.06 | 0.99 |

| hydrochar | 65.12 | 7.16 | 27.72 | 74.81 | 3.50 | 19.31 | 1.88 | 0.50 |

| 40% bituminous coal + 60% anthracite | 72.68 | 8.80 | 18.52 | 77.26 | 3.69 | 17.37 | 0.95 | 0.72 |

| 40% hydrochar + 60% anthracite | 74.32 | 10.17 | 15.51 | 79.21 | 3.23 | 15.37 | 1.39 | 0.79 |

| Num. | Combination | Oxygen Concentration/% | Average Particle Size/μm |

|---|---|---|---|

| 1 | 40% bituminous coal + 60% anthracite coal | 27 | <74 |

| 2 | 40% hydrochar + 60% anthracite | 27 | <74 |

| 3 | 40% bituminous coal + 60% anthracite coal | 30 | <74 |

| 4 | 40% hydrochar + 60% anthracite | 30 | <74 |

| Gas Phase Part | |

|---|---|

| Mass | |

| Momentum | |

| Energy | |

| Gas species i | |

| Turbulent kinetic energy | |

| Turbulent dissipation rate | |

| Solid Phase Part | |

| Mass | |

| Momentum | |

| Energy | |

| Num. | Reactions | A | E (J/kg·mol) |

|---|---|---|---|

| 1 | CαHβOγNδ + aO2→bCO2 + cH2O + dN2 | 2.119 × 1011 | 2.027 × 108 |

| 2 | CO + 0.5O2 = CO2 | 2.2 × 1012 | 1.67 × 108 |

| 3 | C + 0.5O2→CO | 1,360,000 | 1.3 × 108 |

| 4 | C + CO2→2CO | 67,800 | 1.63 × 108 |

| 5 | C + H2O→CO + H2 | 85,500 | 1.4 × 108 |

| 6 | C + O2→CO2 | 1225 | 9.977 × 107 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, Y.; Zhang, N.; Karasev, A.; Ning, X.; Wang, G.; Zhang, J.; Wang, C. Study on Numerical Simulation of Blast Furnace Injection of Low-Rank Coal by Hydrothermal Carbonization. Energies 2025, 18, 5141. https://doi.org/10.3390/en18195141

Zeng Y, Zhang N, Karasev A, Ning X, Wang G, Zhang J, Wang C. Study on Numerical Simulation of Blast Furnace Injection of Low-Rank Coal by Hydrothermal Carbonization. Energies. 2025; 18(19):5141. https://doi.org/10.3390/en18195141

Chicago/Turabian StyleZeng, Yu, Nan Zhang, Andrey Karasev, Xiaojun Ning, Guangwei Wang, Jianliang Zhang, and Chuan Wang. 2025. "Study on Numerical Simulation of Blast Furnace Injection of Low-Rank Coal by Hydrothermal Carbonization" Energies 18, no. 19: 5141. https://doi.org/10.3390/en18195141

APA StyleZeng, Y., Zhang, N., Karasev, A., Ning, X., Wang, G., Zhang, J., & Wang, C. (2025). Study on Numerical Simulation of Blast Furnace Injection of Low-Rank Coal by Hydrothermal Carbonization. Energies, 18(19), 5141. https://doi.org/10.3390/en18195141