Design and Implementation of a Misalignment Experimental Data Management Platform for Wind Power Equipment

Abstract

1. Introduction

2. Methods: Overall System Architecture Design

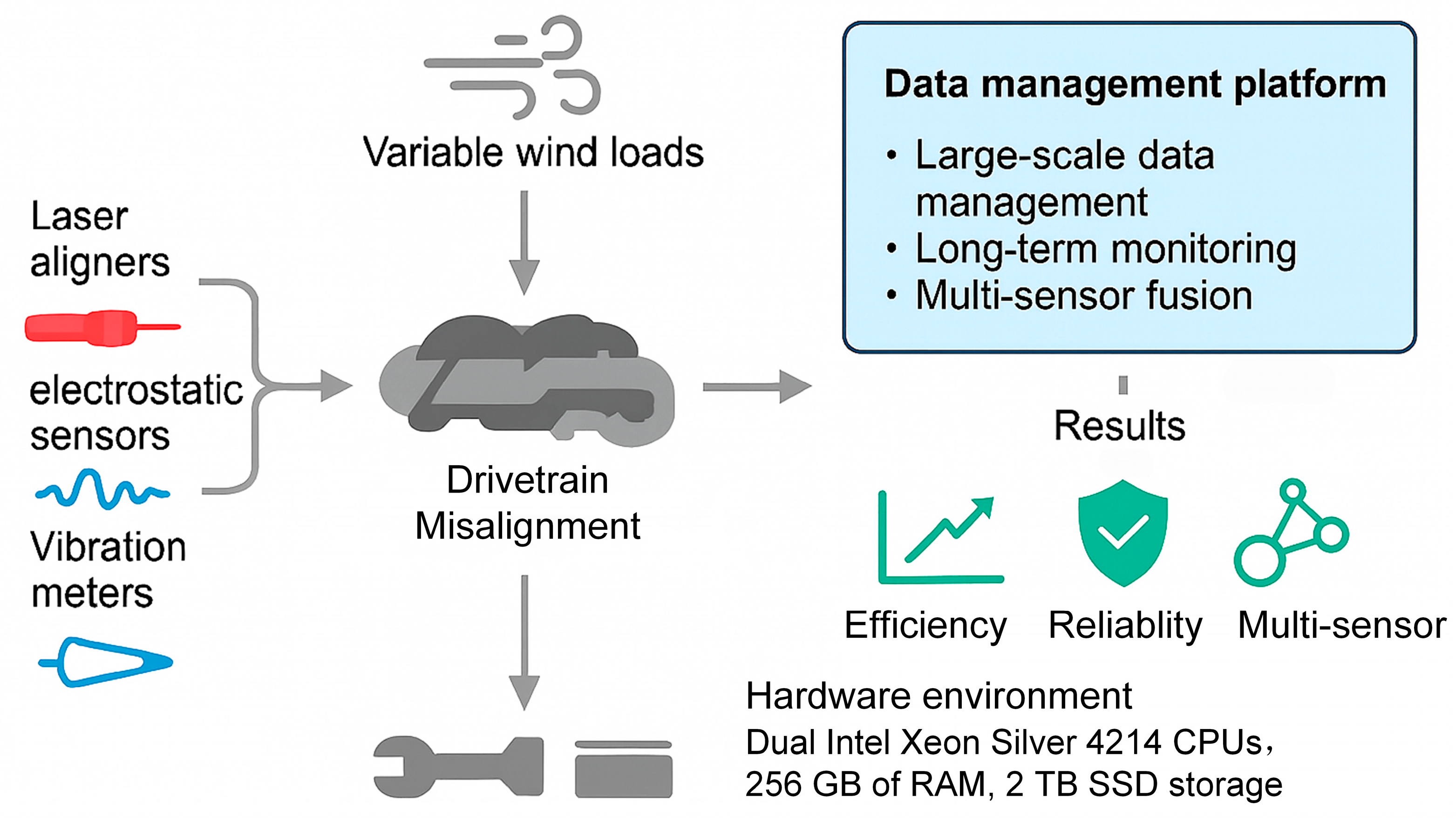

2.1. Process Description and Requirements Analysis

- Laser alignment instruments provide direct displacement measurements but require turbine shutdown, making them suitable for offline validation only.

- Vibration and electrostatic induction sensors enable online monitoring, but their signals must be processed through advanced feature extraction and pattern recognition algorithms to infer misalignment levels indirectly.

- The platform must accommodate this multimodal sensing architecture and synchronize time series data for long-duration tests under varying wind loads.

2.2. Geographical Distribution and Collaboration Structure

2.3. Technical Framework

2.4. Core Technologies

3. Methods: Key Functional Implementation

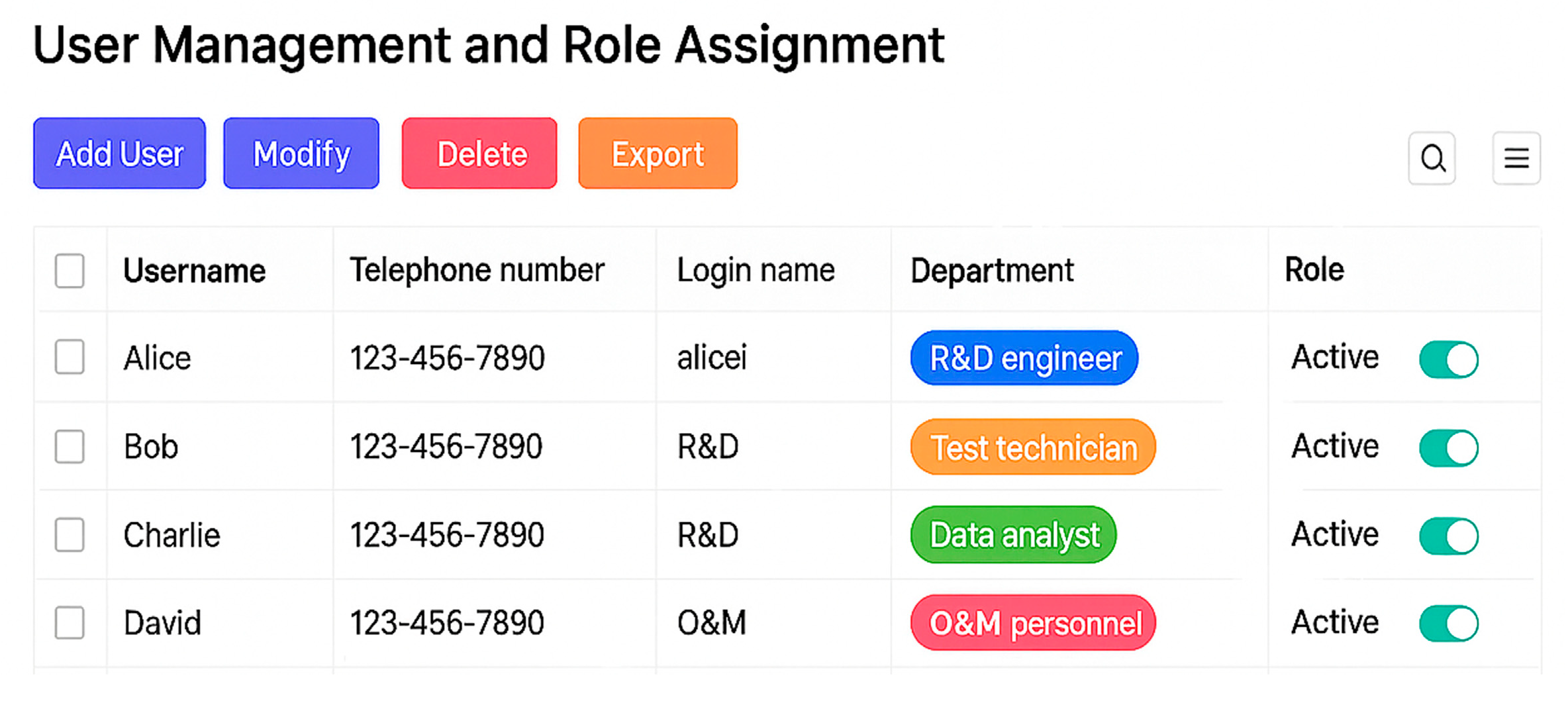

3.1. User and Permission Management

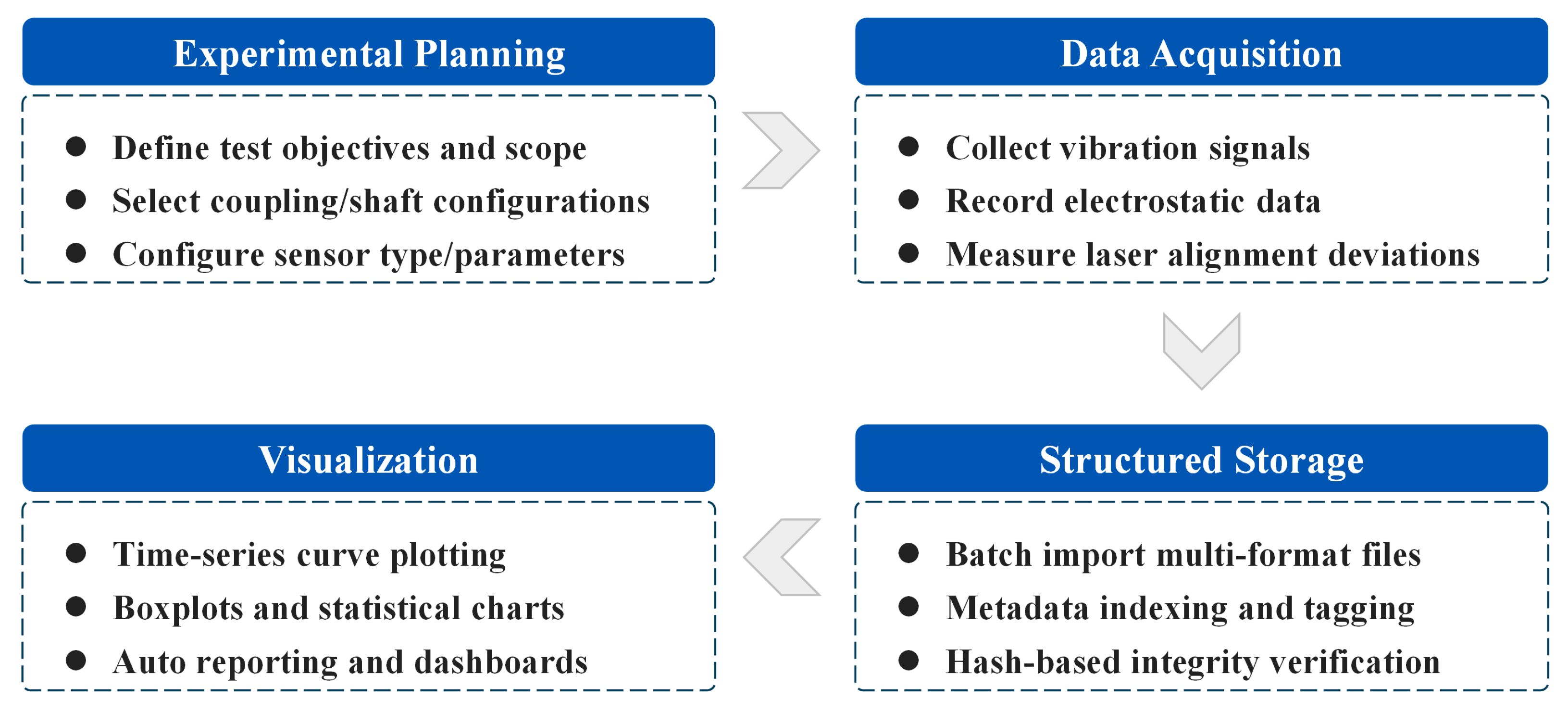

3.2. Full Lifecycle Management of Experimental Data

3.3. Data Sharing and Security

4. Results and Discussion: Case Validation

4.1. Database Construction

- Laser alignment instruments, providing direct but offline displacement measurements,

- Vibration sensors, offering high-frequency online monitoring of dynamic response, and

- Electrostatic sensors, capturing electrostatic induction intensity variations associated with shaft misalignment.

4.2. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, X.F.; Guo, Y.J.; Xu, C.B.; Shang, H.B. Review of Fault Diagnosis and Health Monitoring for Wind Power Equipment. China Mech. Eng. 2020, 31, 175–189. [Google Scholar] [CrossRef]

- Cornel, J.; Gutiérrez Guzmán, F.; Jacobs, G.; Neumann, S. Condition Monitoring of Roller Bearers Using Acoustic Emission. Wind Energy Sci. 2021, 6, 367–376. [Google Scholar] [CrossRef]

- Qu, Y.Z.; He, D.; Yoon, J.; Van Hecke, B.; Bechhoefer, E.; Zhu, J.D. Gearbox Tooth Cut Fault Diagnostics Using Acoustic Emission and Vibration Sensors—A Comparative Study. Sensors 2014, 14, 1372–1393. [Google Scholar] [CrossRef]

- Jalan, A.K.; Patil, S.; Mittal, G. A Review on Fault Diagnosis of Misaligned Rotor Systems. Int. J. Perform. Eng. 2020, 16, 499–509. [Google Scholar] [CrossRef]

- Umbrajkaar, A.M.; Krishnamoorthy, A.; Dhumale, R.B. Vibration Analysis of Shaft Misalignment Using Machine Learning Approach under Variable Load Conditions. Shock Vib. 2020, 2020, 1650270. [Google Scholar] [CrossRef]

- Patil, S.; Jalan, A.K.; Marathe, A.M. Support Vector Machine for Misalignment Fault Classification under Different Loading Conditions Using Vibro-Acoustic Sensor Data Fusion. Exp. Tech. 2022, 46, 957–971. [Google Scholar] [CrossRef]

- Liu, Q.; Yang, K.; Feng, S.M. Application of LIMS Laboratory Information Management System in Testing Laboratory. Highlights Sci. Eng. Technol. 2023, 56, 572–576. [Google Scholar] [CrossRef]

- Kong, K.Y.G.; Dyer, K.; Payne, C.; Hamerton, I.; Weaver, P.M. Progress and Trends in Damage Detection Methods, Maintenance, and Data-driven Monitoring of Wind Turbine Blades—A Review. Renew. Energy Focus 2023, 44, 390–412. [Google Scholar] [CrossRef]

- Pratt, R.; Allen, C.; Masoum, M.A.S.; Seibi, A. Defect Detection and Classification on Wind Turbine Blades Using Deep Learning with Fuzzy Voting. Machines 2025, 13, 283. [Google Scholar] [CrossRef]

- Civera, M.; Surace, C. Non-Destructive Techniques for the Condition and Structural Health Monitoring of Wind Turbines: A Literature Review of the Last 20 Years. Sensors 2022, 22, 1627. [Google Scholar] [CrossRef]

- Duan, J.; van Kooten, G.C.; Islam, A.T.M.H. Calibration of Grid Models for Analyzing Energy Policies. Energies 2023, 16, 1234. [Google Scholar] [CrossRef]

- Ahn, S.-H.; Hyun, J.-H.; Choi, J.-H.; Lee, S.-G.; Kim, G.-G.; Bhang, B.-G.; Cha, H.-L.; Lim, B.-Y.; Choi, H.-J.; Ahn, H.-K. Load-Following Operation of Small Modular Reactors under Unit Commitment Planning with Various Photovoltaic System Conditions. Energies 2023, 16, 2946. [Google Scholar] [CrossRef]

- Maestro-Prieto, J.A.; Ramírez-Sanz, J.M.; Bustillo, A.; Rodríguez-Díez, J.J. Semi-Supervised Diagnosis of Wind-Turbine Gearbox Misalignment and Imbalance Faults. Appl. Intell. 2024, 54, 4525–4544. [Google Scholar] [CrossRef]

- Moghadam, F.K.; Gao, Z.; Chabaud, V.; Chapaloglou, S. Yaw Misalignment in Powertrain Degradation Modeling for Wind Farm Control in Curtailed Conditions. Front. Energy Res. 2024, 12, 1272967. [Google Scholar] [CrossRef]

- Meng, N.; Nagy, S.; Yao, D.F.; Zhuang, W.J.; Argoty, G.A. Secure Coding Practices in Java: Challenges and Vulnerabilities. In Proceedings of the 40th International Conference on Software Engineering (ICSE), Gothenburg, Sweden, 27 May–3 June 2018; pp. 739–749. [Google Scholar] [CrossRef]

- Islam, M.; Rahaman, S.; Meng, N.; Hassanshahi, B.; Krishnan, P.; Yao, D.F. Coding Practices and Recommendations of Spring Security for Enterprise Applications. In Proceedings of the 2020 IEEE Secure Development (SecDev), San Francisco, CA, USA, 28–30 September 2020; pp. 49–57. [Google Scholar] [CrossRef]

- Tahvonen, M. A minimal zero-downtime deployment using NGINX & Spring Boot. J. Web Oper. DevOps 2022, 5, 12–21. [Google Scholar]

- Gadban, F.; Kunkel, J. Analyzing the Performance of the S3 Object Storage API for HPC Workloads. Appl. Sci. 2021, 11, 8540. [Google Scholar] [CrossRef]

- Liu, Q.G.; Sun, X.Y. Research of Web Real-Time Communication Based on WebSocket. Int. J. Commun. Netw. Syst. Sci. 2012, 5, 797–801. [Google Scholar] [CrossRef]

- Gupta, Y.; Dewan, H.; Leekha, A. Real-Time Monitoring Using AJAX and WebSockets. J. Stat. Manag. Syst. 2020, 23, 125–134. [Google Scholar] [CrossRef]

- Bucko, A.; Vishi, K.; Krasniqi, B.; Rexha, B. Enhancing JWT Authentication and Authorization in Web Applications Based on User Behavior History. Computers 2023, 12, 78. [Google Scholar] [CrossRef]

- Navitsky, M. Developing a Spring Boot Application with Elasticsearch Integration. Elinext Tech. J. 2024, 1, 45–58. [Google Scholar]

- ISO/IEC 11179; Information Technology—Metadata Registries (MDR). International Organization for Standardization/International Electrotechnical Commission: Geneva, Switzerland, 2015.

- Oyucu, S.; Aksöz, A. Integrating Machine Learning and MLOps for Wind Energy Forecasting: A Comparative Analysis and Optimization Study on Türkiye’s Wind Data. Appl. Sci. 2024, 14, 3725. [Google Scholar] [CrossRef]

- Kandemir, E.; Hasan, A.; Kvamsdal, T.; Abdel-Afou Alaliyat, S. Predictive Digital Twin for Wind Energy Systems: A Literature Review. Energy Inform. 2024, 7, 68. [Google Scholar] [CrossRef]

| Technology | Function | Advantage in Wind Power Context |

|---|---|---|

| Spring Boot Auto-Configuration | Auto-configuration of REST, JPA, Security | Allows seamless access to APIs from diverse sensor devices (laser aligners, electrostatic sensors, vibration meters) |

| RBAC + JWT | Role-based access control with stateless sessions | Enables collaborative fault labeling and data validation across roles |

| Elasticsearch | Multi-dimensional tag-based search | Millisecond retrieval by test ID, sensor type, or misalignment condition |

| MinIO Object Storage | Attachment management | Efficiently stores multi-gigabyte datasets from various sensors, including vibration, electrostatic, and laser alignment signals. |

| WebSocket | Real-time data push | Supports live dashboards for tracking test progression and detecting abnormal deviations |

| Test Module | Function | Metric | Result | Remarks |

|---|---|---|---|---|

| Data Import | Batch import (CSV/TDMS) | Import speed | 320 GB/h (2.4 TB in 9 h) | Verified under full load |

| Metadata Management | Tagging & version control | Indexing latency | <0.8 s/query | Stable with >1 M records |

| Search & Retrieval | Elasticsearch multi-condition | Retrieval latency | <1.0 s | Consistent across 100 queries |

| Visualization & Plotting | Auto Python–Highcharts plotting | Plot generation time | <3 s/plot | Supports multi-sensor overlays |

| Access Control | RBAC + JWT | Authorization response latency | <0.5 s | 50 concurrent users supported |

| Backup & Protection | Dual-backup + CDP | Recovery Point Objective (RPO) | 15 min | Zero data loss over 12 months |

| Platform/System | Domain | Performance Metric/Value | Performance Dimension |

|---|---|---|---|

| Proposed platform (this study) | Wind turbine misalignment | Import speed: 320 GB/h (2.4 TB in 9 h) | Bulk data import & structuring efficiency |

| Industrial IoT MLOps latency [24] | Wind Energy Real-time Systems | Response latency: ~9 ms | Low-latency SCADA-integrated response |

| Predictive Wind Energy Digital Twin [25] | Wind energy monitoring systems | Multi-source fusion capability | Real-time integration of heterogeneous data |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, J.; Fu, Q.; Li, P.; Zhao, B.; Liu, Z.; Guo, Y. Design and Implementation of a Misalignment Experimental Data Management Platform for Wind Power Equipment. Energies 2025, 18, 5047. https://doi.org/10.3390/en18195047

Cao J, Fu Q, Li P, Zhao B, Liu Z, Guo Y. Design and Implementation of a Misalignment Experimental Data Management Platform for Wind Power Equipment. Energies. 2025; 18(19):5047. https://doi.org/10.3390/en18195047

Chicago/Turabian StyleCao, Jianlin, Qiang Fu, Pengchao Li, Bingchang Zhao, Zhichao Liu, and Yanjie Guo. 2025. "Design and Implementation of a Misalignment Experimental Data Management Platform for Wind Power Equipment" Energies 18, no. 19: 5047. https://doi.org/10.3390/en18195047

APA StyleCao, J., Fu, Q., Li, P., Zhao, B., Liu, Z., & Guo, Y. (2025). Design and Implementation of a Misalignment Experimental Data Management Platform for Wind Power Equipment. Energies, 18(19), 5047. https://doi.org/10.3390/en18195047