Online Junction Temperature Measurement for Power MOSFETs Using the Body Diode Under Varying Forward Currents

Abstract

1. Introduction

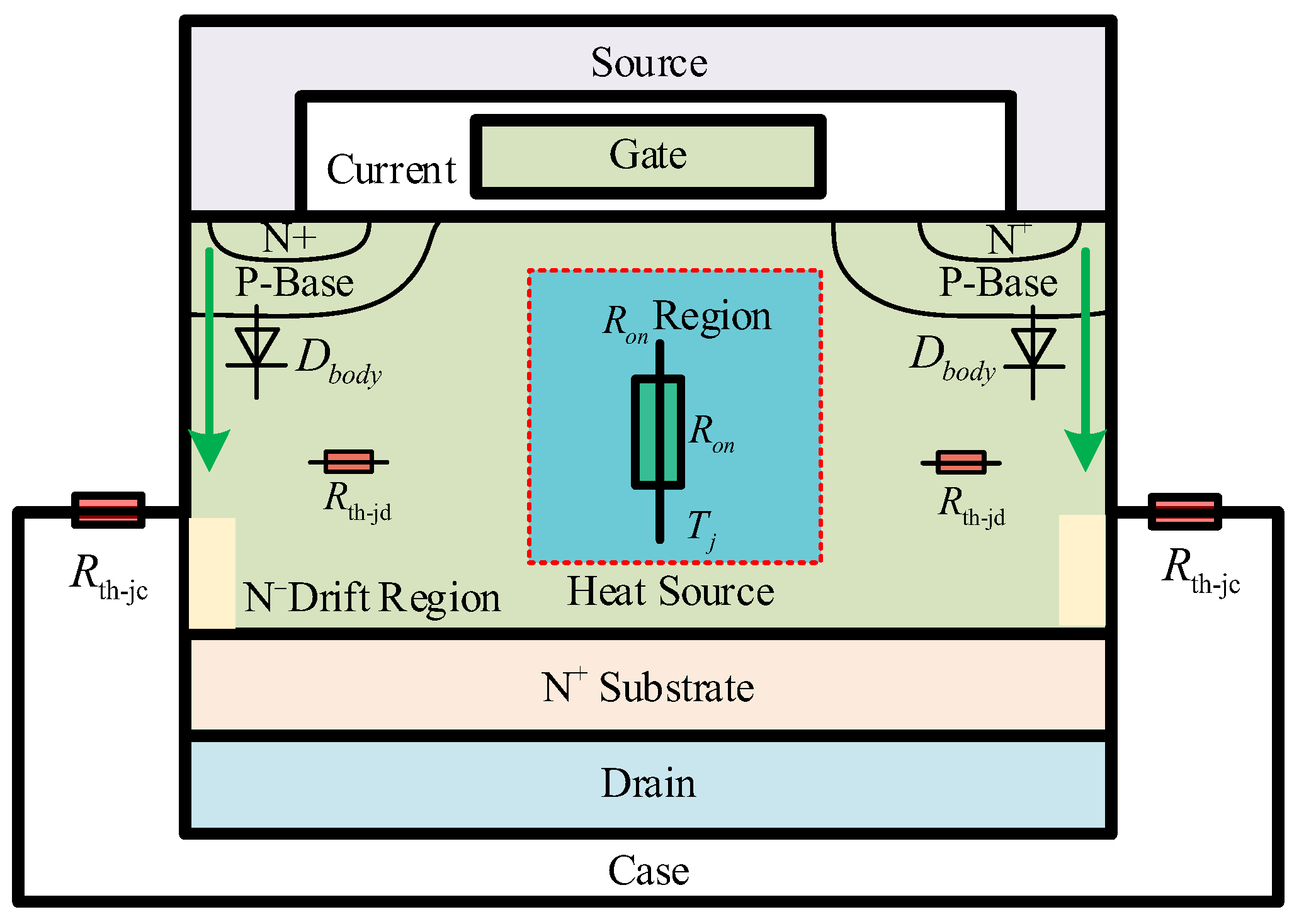

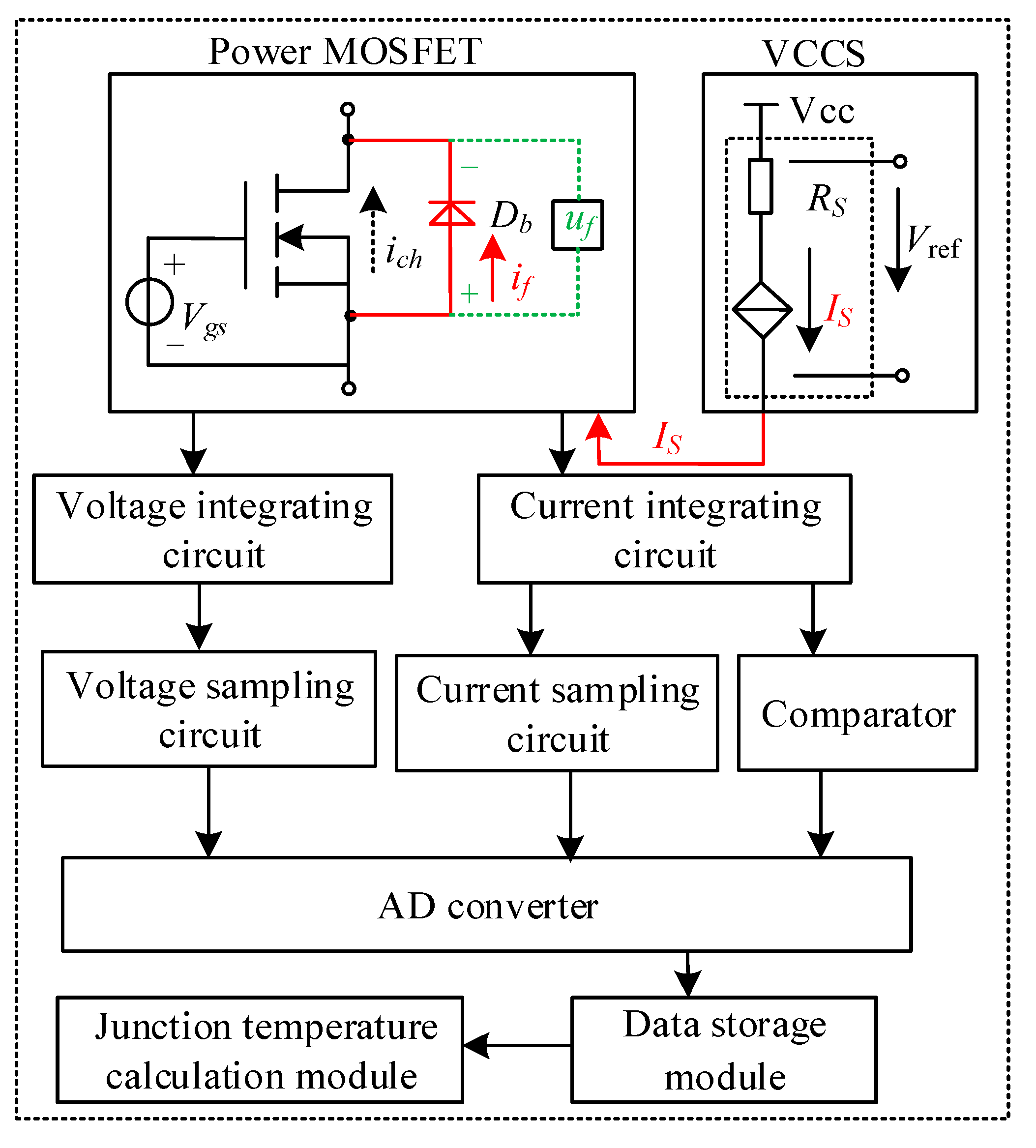

2. Theoretical Analysis of Junction Temperature Measurement for Power MOSFETs Using Body Diode Under Varying Forward Currents

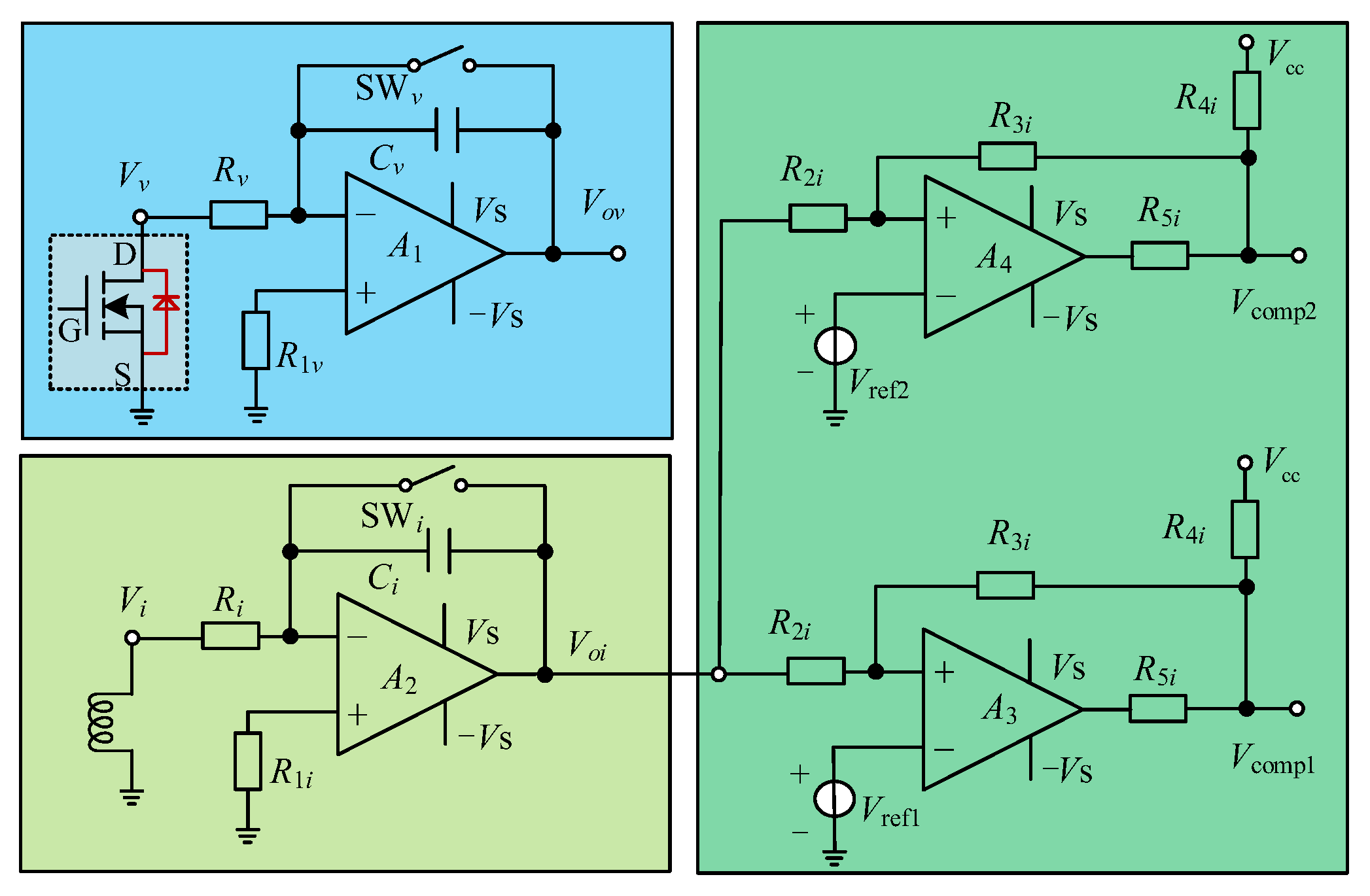

3. Online Junction Temperature Measurement System for Power MOSFETs

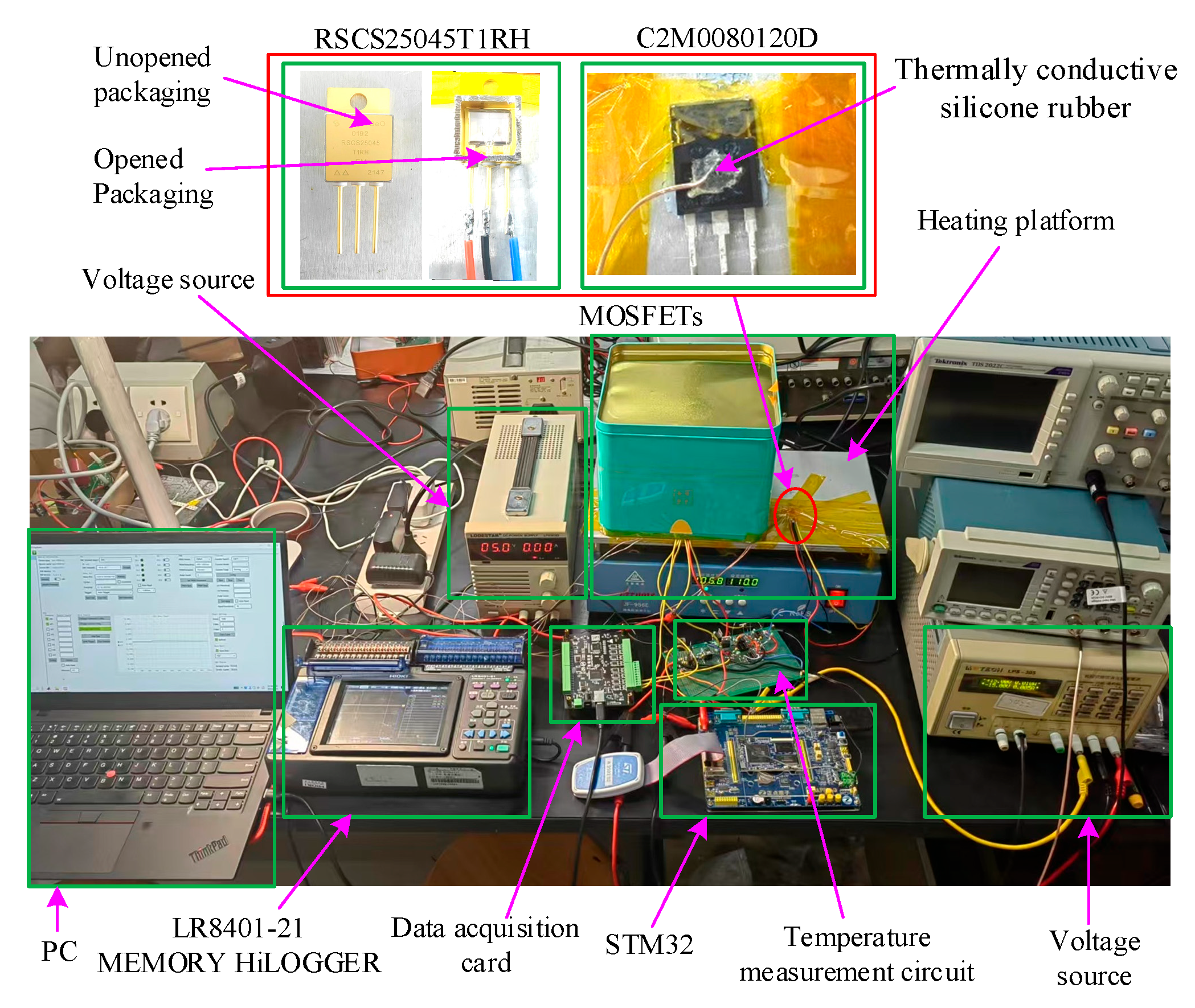

4. Experimental Verification of Junction Temperature Measurement for MOSFET Before Aging

4.1. Experimental Verification of Junction Temperature Measurement for Si Power MOSFET

4.2. Experimental Verification of Junction Temperature Measurement for SiC Power MOSFET

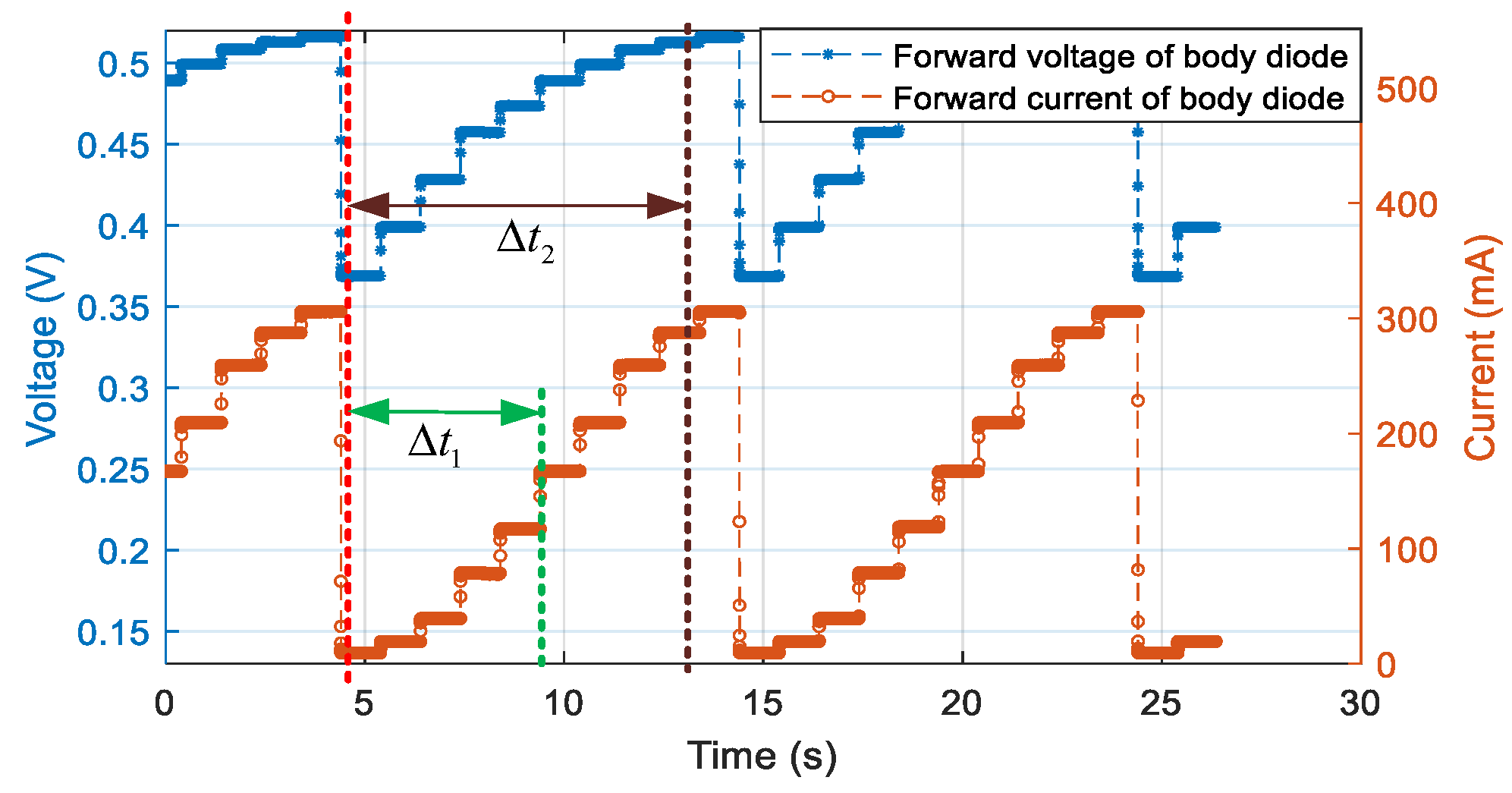

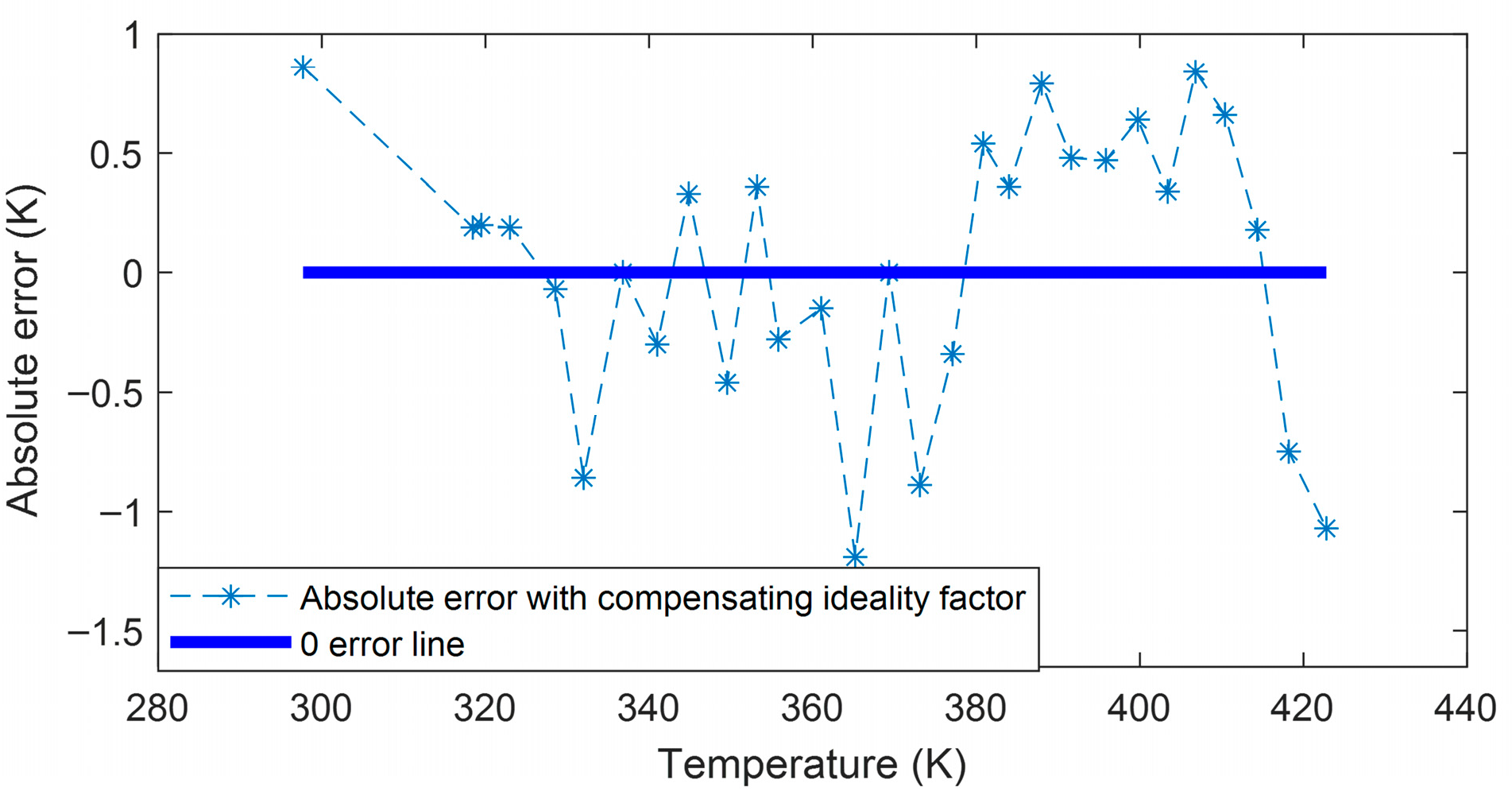

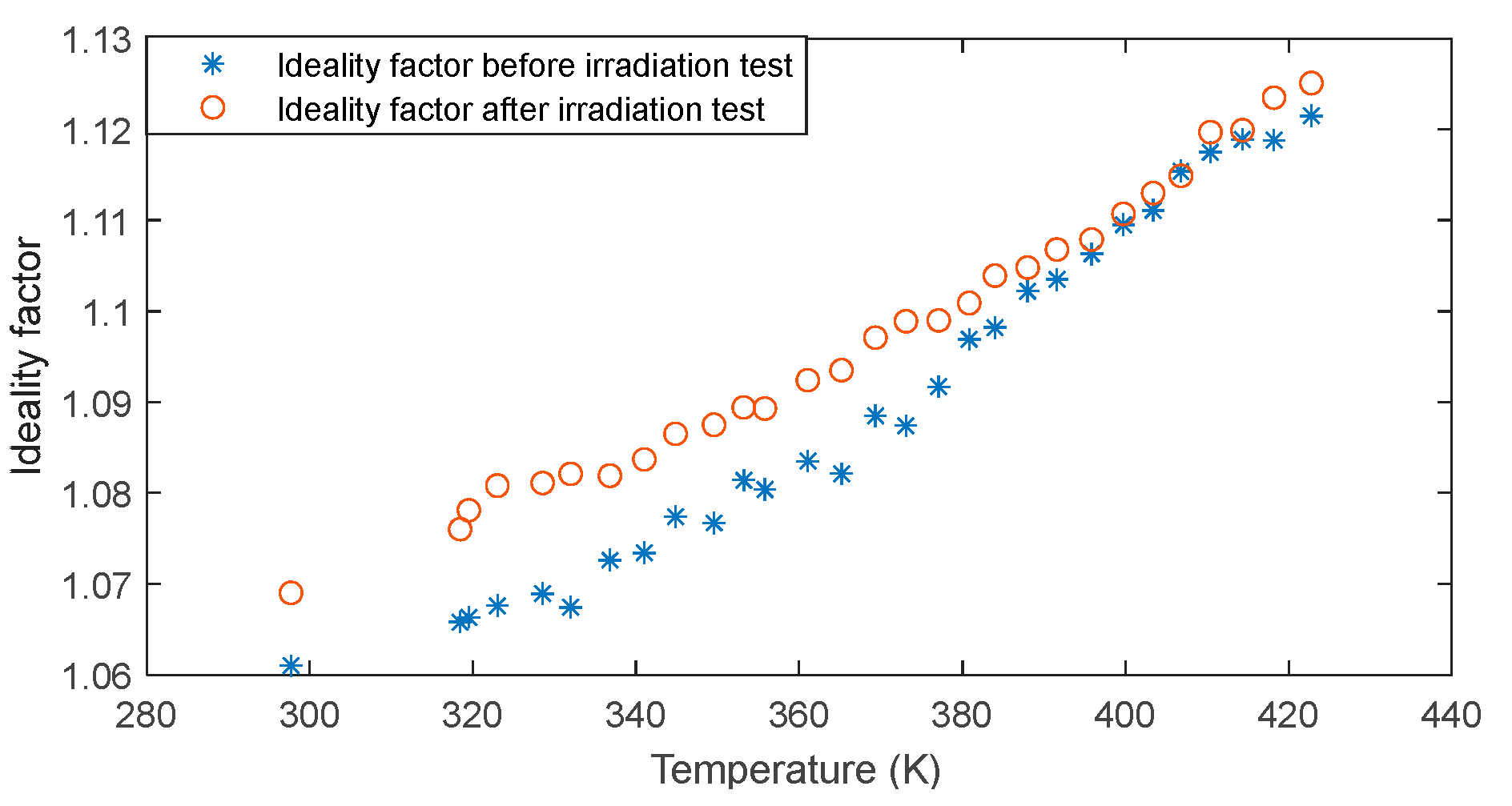

4.3. Experimental Verification of Junction Temperature Measurement for Radiation-Resistant Power MOSFET

5. Experimental Verification of Junction Temperature Measurement for Power MOSFET After Irradiation

5.1. Experimental Verification of Junction Temperature Measurement for Si Power MOSFET After Irradiation

5.2. Experimental Verification of Junction Temperature Measurement for Radiation-Resistant Power MOSFET After Irradiation

6. Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, H.; Liserre, M.; Blaabjerg, F. Toward Reliable Power Electronics: Challenges, Design Tools, and Opportunities. IEEE Ind. Electron. Mag. 2013, 7, 17–26. [Google Scholar] [CrossRef]

- Yang, S.; Xiang, D.; Bryant, A.; Mawby, P.; Ran, L.; Tavner, P. Condition Monitoring for Device Reliability in Power Electronic Converters: A Review. IEEE Trans. Power Electron. 2010, 25, 2734–2752. [Google Scholar] [CrossRef]

- Ramees, M.M.; Ahmad, M.W. Advances in Capacitor Health Monitoring Techniques for Power Converters: A Review. IEEE Access 2023, 11, 133540–133576. [Google Scholar] [CrossRef]

- Ghadrdan, M.; Peyghami, S.; Mokhtari, H.; Blaabjerg, F. Condition Monitoring of DC-Link Electrolytic Capacitor in Back-to-Back Converters Based on Dissipation Factor. IEEE Trans. Power Electron. 2022, 37, 9733–9744. [Google Scholar]

- Yang, S.; Bryant, A.; Mawby, P.; Xiang, D.; Ran, L.; Tavner, P. An Industry-Based Survey of Reliability in Power Electronic Converters. IEEE Trans. Ind. Appl. 2011, 47, 1441–1451. [Google Scholar] [CrossRef]

- Venet, P.; Perisse, F.; El-Husseini, M.H.; Rojat, G. Realization of a Smart Electrolytic Capacitor Circuit. IEEE Ind. Appl. Mag. 2002, 8, 16–20. [Google Scholar] [CrossRef]

- Ghadrdan, M.; Abdi, B.; Peyghami, S.; Mokhtari, H.; Blaabjerg, F. On-Line Condition Monitoring System for DC-Link Capacitor of Back-to-Back Converters Using Large-Signal Transients. IEEE J. Emerg. Sel. Top. Power Electron. 2023, 11, 1132–1142. [Google Scholar] [CrossRef]

- Pecht, M.; Rafanelli, A.J. Handbook of Electronic Package Design; Marcel Dekker: New York, NY, USA, 1991; Volume 76, pp. 23–24. [Google Scholar]

- Gasperi, M.L. Life Prediction Model for Aluminum Electrolytic Capacitors. In Proceedings of the IAS ‘96. Conference Record of the 1996 IEEE Industry Applications Conference Thirty-First IAS Annual Meeting, San Diego, CA, USA, 6–10 October 1996; pp. 1347–1351. [Google Scholar]

- Barlini, D.; Ciappa, M.; Mermet-Guyennet, M.; Fichtner, W. Measurement of the Transient Junction Temperature in MOSFET Devices under Operating Conditions. Microelectron. Reliab. 2007, 47, 1707–1712. [Google Scholar]

- Stella, F.; Pellegrino, G.; Armando, E. Coordinated Online Junction Temperature Estimation of MOSFETs and Antiparallel Diodes in Three-Phase SiC Inverters. IEEE J. Emerg. Sel. Top. Power Electron. 2023, 11, 6102–6111. [Google Scholar]

- Meng, X.; Zhang, M.; Duan, K.; Zheng, X.; Zhai, Y.; Feng, S.; Zhang, Y. Research on Transient Temperature Rise Measurement Method for Semiconductor Devices Based on Photothermal Reflection. IEEE Trans. Instrum. Meas. 2023, 72, 1–9. [Google Scholar] [CrossRef]

- Chang, J.; Yin, Y.; Du, J.; Wang, H.; Li, H.; Zhao, C.; Yang, S. On-Chip Integrated High-Sensitivity Temperature Sensor Based on p-GaN/AlGaN/GaN Heterostructure. IEEE Electron. Device Lett. 2023, 44, 594–597. [Google Scholar]

- Du, M.; Xin, J.; Wang, H.; Ouyang, Z.; Wei, K. Estimating Junction Temperature of SiC MOSFET Using Its Drain Current During Turn-On Transient. IEEE Trans. Electron. Devices. 2020, 67, 1911–1918. [Google Scholar] [CrossRef]

- Xu, G.; Shao, L.; Feng, W.; Zhu, W.; Pan, Z.; Li, C.; Zhang, Y.; Xia, L. A Novel IGBT Junction Temperature Detection Based on High-Frequency Model of Inductor Element. IEEE Trans. Instrum. Meas. 2023, 72, 1–10. [Google Scholar] [CrossRef]

- Gachovska, T.K.; Tian, B.; Hudgins, J.L.; Qiao, W.; Donlon, J.F. A Real-Time Thermal Model for Monitoring of Power Semiconductor Devices. IEEE Trans. Ind. Appl. 2015, 51, 3361–3367. [Google Scholar] [CrossRef]

- Yang, F.; Ugur, E.; Akin, B. Evaluation of Aging’s Effect on Temperature-Sensitive Electrical Parameters in SiC MOSFETs. IEEE Trans. Power Electron. 2020, 35, 6315–6331. [Google Scholar] [CrossRef]

- Yu, H.; Jiang, X.; Chen, J.; Shen, Z.J.; Wang, J. Comparative Study of Temperature Sensitive Electrical Parameters for Junction Temperature Monitoring in SiC MOSFET and Si IGBT. In Proceedings of the IPEMC2020-ECCE Asia, Nanjing, China, 29 November–2 December 2020; pp. 905–909. [Google Scholar]

- Xin, J.; Du, M.; Ouyang, Z.; Wei, K. Online monitoring for threshold voltage of SiC MOSFET considering the coupling impact on BTI and junction temperature. IEEE Trans. Electron. Devices 2021, 68, 1772–1777. [Google Scholar] [CrossRef]

- Zhang, Q.; Lu, G.; Zhang, P. A high-sensitivity online junction temperature monitoring method for SiC MOSFETs based on the turn-on drain–source current overshoot. IEEE Trans. Power Electron. 2022, 37, 15505–15516. [Google Scholar] [CrossRef]

- Gonzalez, J.O.; Alatise, O. Bias Temperature Instability and Junction Temperature Measurement Using Electrical Parameters in SiC Power MOSFETs. IEEE Trans. Ind. Appl. 2021, 57, 1664–1676. [Google Scholar] [CrossRef]

- Pu, S.; Ugur, E.; Yang, F.; Akin, B. In Situ Degradation Monitoring of SiC MOSFET Based on Switching Transient Measurement. IEEE Trans. Ind. Electron. 2020, 67, 5092–5100. [Google Scholar]

- Yang, H.; Simanjorang, R.; See, K.Y. A Method for Junction Temperature Estimation Utilizing Turn-On Saturation Current for SiC MOSFET. In Proceedings of the IPEC-Niigata 2018-ECCE Asia, Niigata, Japan, 20–24 May 2018; pp. 2296–2300. [Google Scholar]

- Jiang, X.; Wang, J.; Yu, H.; Chen, J.; Zeng, Z.; Yang, X.; Shen, Z.J. Online Junction Temperature Measurement for SiC MOSFET Based on Dynamic Threshold Voltage Extraction. IEEE Trans. Power Electron. 2021, 36, 3757–3768. [Google Scholar] [CrossRef]

- Stella, F.; Pellegrino, G.; Armando, E.; Daprà, D. On-Line Temperature Estimation of SiC Power MOSFET Modules Through On-State Resistance Mapping. In Proceedings of the ECCE, Cincinnati, OH, USA, 1–5 October 2017; pp. 5907–5914. [Google Scholar]

- Stella, F.; Pellegrino, G.; Armando, E.; Daprà, D. Online Junction Temperature Estimation of SiC Power MOSFETs Through On-State Voltage Mapping. IEEE Trans. Ind. Appl. 2018, 54, 3453–3462. [Google Scholar] [CrossRef]

- Cao, H.; Ning, P.; Huang, Y.; Wen, X. Online Monitoring Method for Junction Temperature of SiC MOSFETs Based on Temperature Sensitive Electrical Parameter. CSEE J. Power Energy Syst. 2024, 10, 1799–1807. [Google Scholar]

- Yang, F.; Pu, S.; Xu, C.; Akin, B. Turn-On Delay Based Real-Time Junction Temperature Measurement for SiC MOSFETs with Aging Compensation. IEEE Trans. Power Electron. 2021, 36, 1280–1294. [Google Scholar]

- Sun, P.; Guo, Y.; Wu, T.; Zhao, Z.; Lai, P.; Zhen, Z. An Online Junction Temperature Monitoring Correction Method for SiC MOSFETs at Different Parasitic Parameters. IEEE J. Emerg. Sel. Top. Power Electron. 2022, 10, 5007–5018. [Google Scholar] [CrossRef]

- Wei, W.; Zhu, W.; Liu, T.; Xu, G. Junction Temperature Online Extraction Method for Power MOSFET by Current Fall Time. IEEE Trans. Electron. Devices 2022, 69, 3811–3819. [Google Scholar] [CrossRef]

- Quan, Y.; Pan, R.; Liu, T.; Zhou, X.; Feng, J.; Tian, Y.; Cheng, X. Online Junction Temperature Monitoring Method for SiC MOSFETs Based on Turn-Off Miller Plateau Voltage. IEEE Trans. Power Electron. 2024, 39, 15800–15810. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, X.; Shi, X.; Liu, Q.; Zhang, S.; Ouyang, R.; Gong, X. Online Junction Temperature Estimation for SiC MOSFETs Using Drain Voltage Falling Edge Time. IEEE Trans. Electron. Devices 2023, 70, 5228–5235. [Google Scholar] [CrossRef]

- Zhang, Y.; Xie, L.; Yan, Y.; Zhao, Y.; Huang, Y.; Deng, E. Investigation on Vsd(T) and Vds,on(T) Methods for Cascode GaN Device Junction Temperature Measurement. In Proceedings of the CIEEC, Hefei, China, 12–14 May 2023; pp. 3095–3098. [Google Scholar]

- Meng, X.; Zhang, M.; Feng, S.; Tang, Y.; Zhang, Y. Online Temperature Measurement Method for SiC MOSFET Device Based on Gate Pulse. IEEE Trans. Power Electron. 2024, 39, 4714–4724. [Google Scholar] [CrossRef]

- Luo, M.; Tan, K.; Tang, X.; Hu, C.; Li, Z.; Ji, B.; Cao, W. Load-Independent Junction Temperature Estimation via Combined TSEPs Modeling for SiC MOSFETs. IEEE Trans. Power Electron. 2025, 40, 851–861. [Google Scholar] [CrossRef]

- Zeng, G.; Cao, H.; Chen, W.; Lutz, J. Difference in Device Temperature Determination Using p-n-Junction Forward Voltage and Gate Threshold Voltage. IEEE Trans. Power Electron. 2019, 34, 2781–2793. [Google Scholar] [CrossRef]

- Zhang, Q.; Lu, G.; Yang, Y.; Zhang, P. A High-Frequency Online Junction Temperature Monitoring Method for SiC MOSFETs Based on On-State Resistance with Aging Compensation. IEEE Trans. Ind. Electron. 2023, 70, 7393–7405. [Google Scholar] [CrossRef]

- Zheng, D.; Kang, Y.; Cao, H.; Chai, X.; Fan, T.; Ning, P. Monitoring of SiC MOSFET Junction Temperature with On-State Voltage at High Currents. Chin. J. Electr. Eng. 2020, 6, 1–7. [Google Scholar] [CrossRef]

- Shi, B.; Feng, S.; Shi, L.; Shi, D.; Zhang, Y.; Zhu, H. Junction Temperature Measurement Method for Power MOSFETs Using Turn-On Delay of Impulse Signal. IEEE Trans. Power Electron. 2018, 33, 5274–5282. [Google Scholar] [CrossRef]

- Lu, X.; Wang, L. A Novel Method for Real-Time Junction Temperature Monitoring of SiC MOSFET Through Sensitivity Amplification of Turn-Off Delay Time. IEEE Trans. Power Electron. 2025, 40, 11326–11338. [Google Scholar] [CrossRef]

- Dou, J.; Wang, Z.; Xin, G.; Shi, X. High-Accuracy Online Junction Temperature Measurement of Medium-Voltage SiC MOSFETs Based on Passive Turn-On Delay Time Integrator. IEEE Trans. Power Electron. 2025, 40, 4775–4779. [Google Scholar] [CrossRef]

- Zhu, X.; Huang, Y.; Zhang, D.; Li, A. A Junction Temperature Measurement Method for Power MOSFETs Through Body Diode with Compensation Ideality Factor. IEEE Trans. Instrum. Meas. 2025, 74, 9520013. [Google Scholar] [CrossRef]

- Xie, M.; Sun, P.; Wang, K.; Luo, Q.; Du, X. Online Gate-Oxide Degradation Monitoring of Planar SiC MOSFETs Based on Gate Charge Time. IEEE Trans. Power Electron. 2022, 37, 7333–7343. [Google Scholar] [CrossRef]

- Jiang, X.; Wang, J.; Chen, J.; Li, Z.; Zhai, D.; Yang, X.; Shen, Z.J. Investigation on Degradation of SiC MOSFET Under Surge Current Stress of Body Diode. IEEE J. Emerg. Sel. Top. Power Electron. 2020, 8, 77–89. [Google Scholar] [CrossRef]

- Zhang, Z.; Liang, L.; Fei, H.; Han, L.; Shang, H. An Online Correction Method for Inaccuracy of Junction Temperature Monitoring Caused by Degradation of SiC MOSFETs. IEEE J. Emerg. Sel. Top. Power Electron. 2024, 12, 5511–5522. [Google Scholar] [CrossRef]

- Wen, H.; Li, X.; Zhang, F.; Qu, Z.; Jiang, Y.; Luo, N.; Zhao, Y. Junction Temperature Extraction for Silicon Carbide Power Devices: A Comprehensive Review. IEEE Trans. Power Electron. 2025, 40, 3090–3111. [Google Scholar] [CrossRef]

- Farhadi, M.; Sajadi, R.; Vankayalapati, B.T.; Akin, B. Switching Transient-Based Junction Temperature Estimation of SiC MOSFETs with Aging Compensation. IEEE Trans. Power Electron. 2024, 39, 12424–12434. [Google Scholar] [CrossRef]

- Kestler, T.; Bakran, M. Junction Temperature Measurement of SiC MOSFETs: Straightforward as It Seems? In Proceedings of the PCIM Europe 2018, Nuremberg, Germany, 5–7 June 2018; pp. 1–6. [Google Scholar]

- Chen, H.; Zhang, Y.; He, P.; Zhang, Y.; Chen, S.; Li, S.; Zhang, B. Integrated Lateral SBD Temperature Sensor of a 4H-SiC VDMOS for Real-Time Temperature Monitoring. IEEE Trans. Electron. Devices 2023, 70, 3813–3819. [Google Scholar] [CrossRef]

- Mo, J.; Li, J.; Zhang, Y.; Romijn, J.; May, A.; Erlbacher, T.; Vollebregt, S. A Highly Linear Temperature Sensor Operating up to 600 °C in a 4H-SiC CMOS Technology. IEEE Electron. Device Lett. 2023, 44, 995–998. [Google Scholar] [CrossRef]

- Bai, Q.; Nan, C.; Zhou, L.; Yang, Y.; Mao, S.; Han, H.; Wang, H. Effect of Temperature on Ideality Factor for PERC Monofacial Crystalline Silicon Solar Module. In Proceedings of the 2021 IEEE 48th Photovoltaic Specialists Conference (PVSC), Fort Lauderdale, FL, USA, 20–25 June 2021; pp. 0244–0247. [Google Scholar]

- Zeghdar, K.; Bencherif, H.; Dehimi, L.; Pezzimenti, F.; Della Corte, F.G. Analysis of the Current-Voltage-Temperature Characteristics of W 4H-SiC Schottky Barrier Diodes for High Performance Temperature Sensors. In Proceedings of the CAS, Sinaia, Romania, 9–11 October 2019; pp. 277–280. [Google Scholar]

- Yang, Y.; Wu, Y.; Ding, X.; Zhang, P. Online Junction Temperature Estimation Method for SiC MOSFETs Based on the DC Bus Voltage Undershoot. IEEE Trans. Power Electron. 2023, 38, 5422–5431. [Google Scholar] [CrossRef]

- Iero, D.; Merenda, M.; Polimeni, S.; Carotenuto, R.; Corte, F.G.D. A Technique for the Direct Measurement of the Junction Temperature in Power Light Emitting Diodes. IEEE Sens. J. 2021, 21, 6293–6299. [Google Scholar] [CrossRef]

- Zhang, D.; Zhu, X.; Huang, Y. PN Junction Temperature Measurement Method and System and Computer Readable Storage Medium. CN Patent 116106712 A, 5 May 2023. [Google Scholar]

- Duan, L.; Yi, H.; Xu, C.; Upama, M.B.; Mahmud, M.A.; Wang, D.; Uddin, A. Relationship between the Diode Ideality Factor and the Carrier Recombination Resistance in Organic Solar Cells. IEEE J. Photovolt. 2018, 8, 1701–1709. [Google Scholar] [CrossRef]

- Tress, W.; Yavari, M.; Domanski, K.; Yadav, P.; Niesen, B.; Baena, J.P.C.; Graetzel, M. Interpretation and Evolution of Open-Circuit Voltage, Recombination, Ideality Factor and Subgap Defect States during Reversible Light-Soaking and Irreversible Degradation of Perovskite Solar Cells. Energy Environ. Sci. 2018, 11, 151–165. [Google Scholar] [CrossRef]

- Al-Haidari, R.; Richmond, D.; Obeidat, A.; Alhendi, M.; Abbara, E.M.; Somarathna, U.S.; Poliks, M.; Gowda, A.V.; Erlbaum, J.; Xiong, H.; et al. SiC Power Module Packaging Using Printed Electronics Materials and Processes. IEEE Trans. Compon. Packag. Manuf. Technol. 2024, 14, 2196–2210. [Google Scholar] [CrossRef]

- Li, N.; Liu, Z.; Lotfi, A.; Jiang, X.; Long, E.; Sahasrabudhe, S.S.; Bolton, C.; Ashraf, H.; Ayazi, F. Advances in High-Aspect-Ratio Deep Reactive Ion Etching of 4H-Silicon Carbide Wafers. J. Microelectromech. Syst. 2024, 33, 776–784. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, P. An online junction temperature monitoring method for SiC MOSFETs based on a novel gate conduction model. IEEE Trans. Power Electron. 2021, 36, 11087–11096. [Google Scholar] [CrossRef]

- Zhang, Q.; Yang, Y.; Zhang, P. A novel method for monitoring the junction temperature of SiC MOSFET on-line based on on-state resistance. In Proceedings of the 2019 22nd International Conference on Electrical Machines and Systems (ICEMS), Harbin, China, 11–14 August 2019; pp. 1–5. [Google Scholar]

- Zhang, Z.; Dyer, J.; Wu, X.; Wang, F.; Costinett, D.; Tolbert, L.M.; Blalock, B.J. Online junction temperature monitoring using intelligent gate drive for SiC power devices. IEEE Trans. Power Electron. 2018, 34, 7922–7932. [Google Scholar] [CrossRef]

| Reference | TSEPs | Sensitivity | Linearity | Aging Effect | Integration |

|---|---|---|---|---|---|

| [18] | Turn-on di/dt rate | Good at large gate resistor | Medium | Decreases with aging | Medium |

| [24,36] | Threshold voltage | Medium | Good | Increases with aging | Medium |

| [25,37] | On-state resistance | Small | Small | Increases with aging | Medium |

| [26,27,38] | On-state voltage | Good at high current | Small | Increases with aging | Good |

| [29] | Turn-off delay time | Good at large gate resistor | Good | Decreases with aging | Medium |

| [39,40,41] | Turn-on delay time | Good at large gate resistor | Good | Shift with aging | Medium |

| [42] and this paper | Body diode forward voltage | Good | Good | Unaffected under low current and negative gate bias | Good |

| Set Temperature (K) | Ideality Factor | Measured Temperature (K) | Absolute Error (K) |

|---|---|---|---|

| 297.70 | 1.0610 | 298.56 | 0.86 |

| 318.45 | 1.0658 | 318.64 | 0.19 |

| 319.50 | 1.0663 | 319.70 | 0.20 |

| 323.00 | 1.0676 | 323.19 | 0.19 |

| 328.55 | 1.0689 | 328.48 | −0.07 |

| 332.00 | 1.0674 | 331.14 | −0.86 |

| 336.80 | 1.0726 | 336.80 | 0.00 |

| 341.00 | 1.0734 | 340.70 | −0.30 |

| 344.85 | 1.0774 | 345.18 | 0.33 |

| 349.55 | 1.0767 | 349.09 | −0.46 |

| 353.20 | 1.0814 | 353.56 | 0.36 |

| 355.80 | 1.0804 | 355.52 | −0.28 |

| 361.05 | 1.0835 | 360.90 | −0.15 |

| 365.20 | 1.0821 | 364.01 | −1.19 |

| 369.35 | 1.0885 | 369.35 | 0.00 |

| 373.10 | 1.0874 | 372.21 | −0.89 |

| 377.10 | 1.0917 | 376.76 | −0.34 |

| 380.85 | 1.0969 | 381.39 | 0.54 |

| 384.00 | 1.0982 | 384.36 | 0.36 |

| 388.00 | 1.1022 | 388.79 | 0.79 |

| 391.60 | 1.1035 | 392.08 | 0.48 |

| 395.85 | 1.1063 | 396.32 | 0.47 |

| 399.75 | 1.1095 | 400.39 | 0.64 |

| 403.40 | 1.1111 | 403.74 | 0.34 |

| 406.80 | 1.1154 | 407.64 | 0.84 |

| 410.40 | 1.1175 | 411.06 | 0.66 |

| 414.35 | 1.1189 | 414.53 | 0.18 |

| 418.20 | 1.1188 | 417.45 | −0.75 |

| 422.80 | 1.1215 | 421.73 | −1.07 |

| References | Methods | Junction Temperature Measurement Accuracy |

|---|---|---|

| [16] | RC model | Temperature deviation of 10 °C at 125 °C |

| [28] | Turn-on delay time | Measurement error < 1 °C |

| [60] | Gate current | Measurement error < 3 °C |

| [61] | On-state resistance | Measurement error of 0.68% at 64.5 °C and 1.19% at 79.2 °C |

| [62] | Turn-off delay time | The error varies with design parameters, it reports an error of 3 °C under a specific set of design parameters. |

| This paper | Body diode forward current and voltage | The error varies significantly across MOSFET types. Across the full operating temperature range, the errors from multiple sets are consistently confined within a narrow bound of 2 K. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, X.; Huang, Y.; Zhang, D.; Zhang, Y.; Wu, J.; Jiang, B.; Xia, L.; Gao, B.; Lv, C. Online Junction Temperature Measurement for Power MOSFETs Using the Body Diode Under Varying Forward Currents. Energies 2025, 18, 5045. https://doi.org/10.3390/en18195045

Zhu X, Huang Y, Zhang D, Zhang Y, Wu J, Jiang B, Xia L, Gao B, Lv C. Online Junction Temperature Measurement for Power MOSFETs Using the Body Diode Under Varying Forward Currents. Energies. 2025; 18(19):5045. https://doi.org/10.3390/en18195045

Chicago/Turabian StyleZhu, Xueli, Yajie Huang, Donglai Zhang, Yuepeng Zhang, Jun Wu, Bowen Jiang, Linzhong Xia, Bo Gao, and Changwei Lv. 2025. "Online Junction Temperature Measurement for Power MOSFETs Using the Body Diode Under Varying Forward Currents" Energies 18, no. 19: 5045. https://doi.org/10.3390/en18195045

APA StyleZhu, X., Huang, Y., Zhang, D., Zhang, Y., Wu, J., Jiang, B., Xia, L., Gao, B., & Lv, C. (2025). Online Junction Temperature Measurement for Power MOSFETs Using the Body Diode Under Varying Forward Currents. Energies, 18(19), 5045. https://doi.org/10.3390/en18195045