Study on Determining the Efficiency of a High-Power Hydrogenerator Using the Calorimetric Method

Abstract

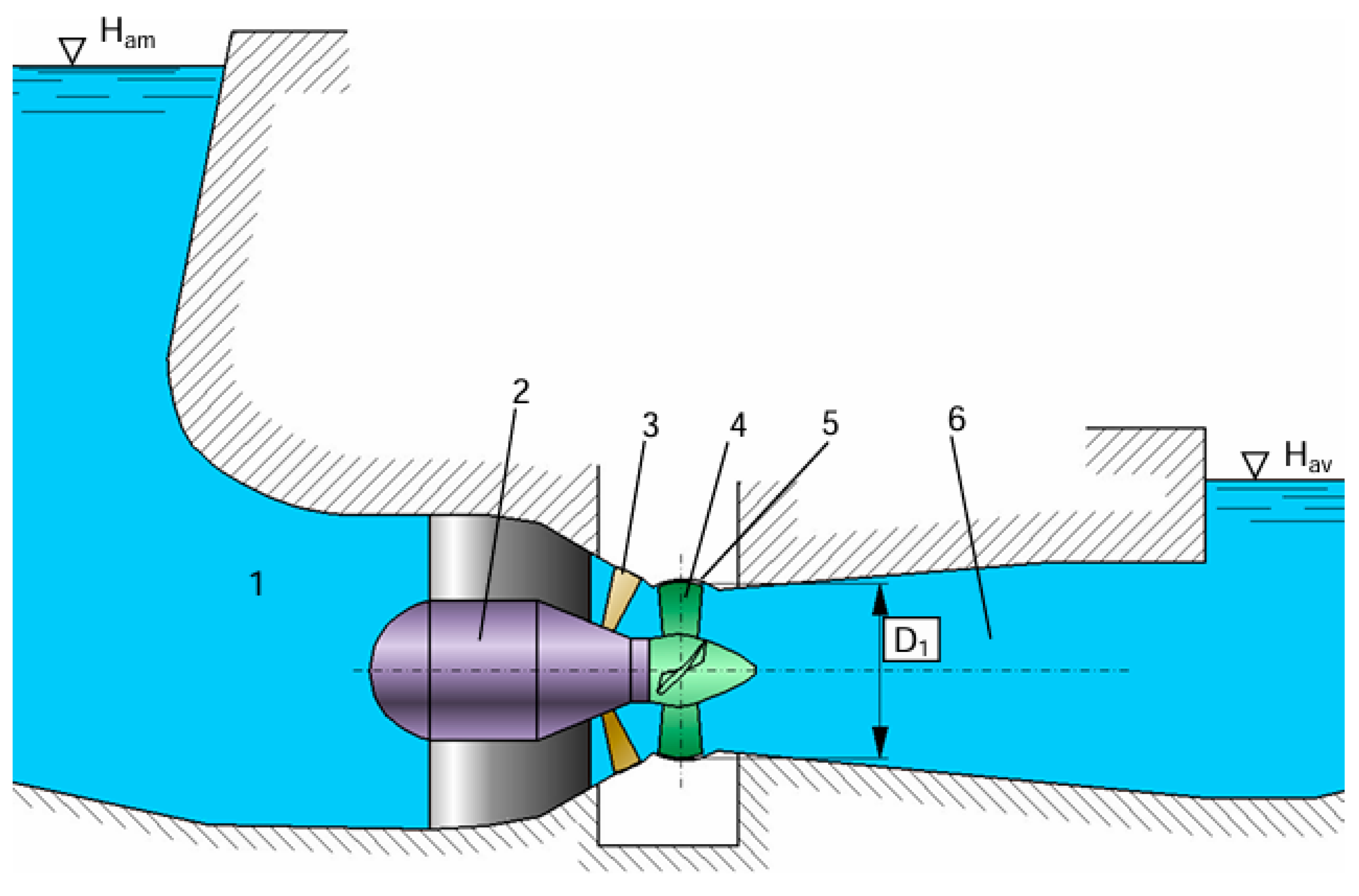

1. Introduction

2. Testing Method

2.1. Generalities and Objectives in Determining Efficiency

- No-load unexcited operation (the excitation winding is not powered), when the generator operates at nominal speed;

- No-load excited operation, when the excitation winding is powered at nominal voltage and the rotor speed is nominal;

- Three-phase short-circuit operation, when the current value in the stator winding is at its nominal value.

- Measuring the ohmic resistances of the stator and rotor windings;

- Measuring the flow rate and the inlet and outlet temperatures of the coolant in the cooling units;

- Determining the nominal excitation current by directly measuring it at the generator’s nominal apparent power;

- Determining the loss values in the axial and radial bearings of the generator;

- Selecting and installing the measurement transducers according to the manufacturer’s technical specifications;

- Connecting the transducers to the data acquisition systems;

- Calibrating the equipment in accordance with required standards.

2.2. Measuring Devices Used

2.2.1. Devices for Measuring Electrical Quantities

2.2.2. Devices for Measuring Temperatures

2.2.3. Devices for Measuring the Cooling Water Flow in Bearings

2.3. Determination of Efficiency Using the Calorimetric Method

2.3.1. Determination of Losses Transmitted by the Cooling Agent Water

- QAi0 is the flow rate of the cooling water through cooler unit i (L/min);

- ΔTi0 is the temperature difference between hot and cold water i (°C);

- ρA is the density of the cooling water (997 kg/m3);

- CpA is the specific heat of water (4176 J/kg·°C).

- TARm—average temperature of cold water, at the cooler inlet, was calculated for all cooler units (°C);

- TACm—average temperature of hot water at the cooler outlet, was calculated for all cooler units (°C);

- TAm—average temperature of the cooling water for all cooler units calculated from the average temperatures of cold and hot water (°C).

2.3.2. Determination of Non-Transmitted Losses Through the Cooling Agent

- P2—losses due to radiation and convection [W];

- hi—heat transfer coefficient through surface i [W/m2·°C];

- Ai—surface area i [m2];

- ΔTi—the temperature difference between surface i and the ambient temperature at 1 m distance [°C].

- A1—area of the downstream shield of the generator, with a value of 20.68 m2;

- A2—area of the upstream shield of the generator, with a value of 17.33 m2.

2.3.3. Determination of Separate Losses of the Generator

3. Results

- Nominal apparent power, Sn = 13,330 kVA;

- Nominal voltage, Un = 6300 V ± 5%;

- Nominal stator current, In = 1221.6 A;

- Nominal excitation voltage, UEn = 300 V;

- Nominal excitation current, IEn = 288 A;

- Speed, n = 107.1 r.p.m.;

- Power factor, cosφ = 0.975.

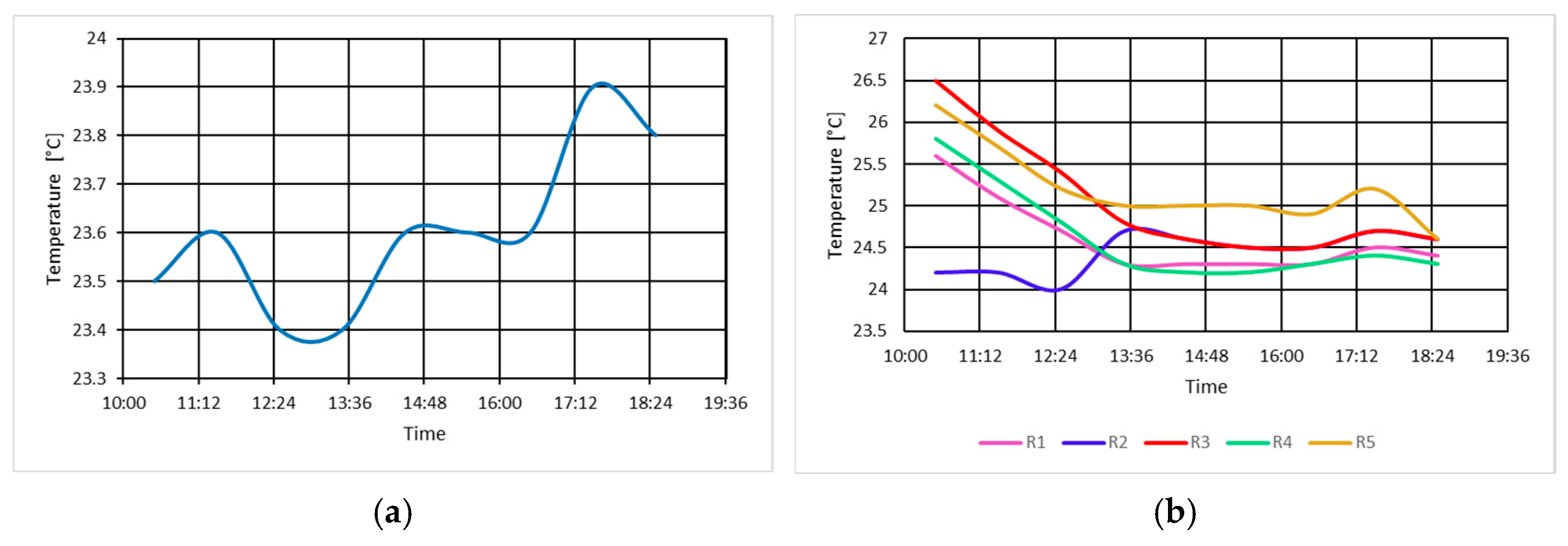

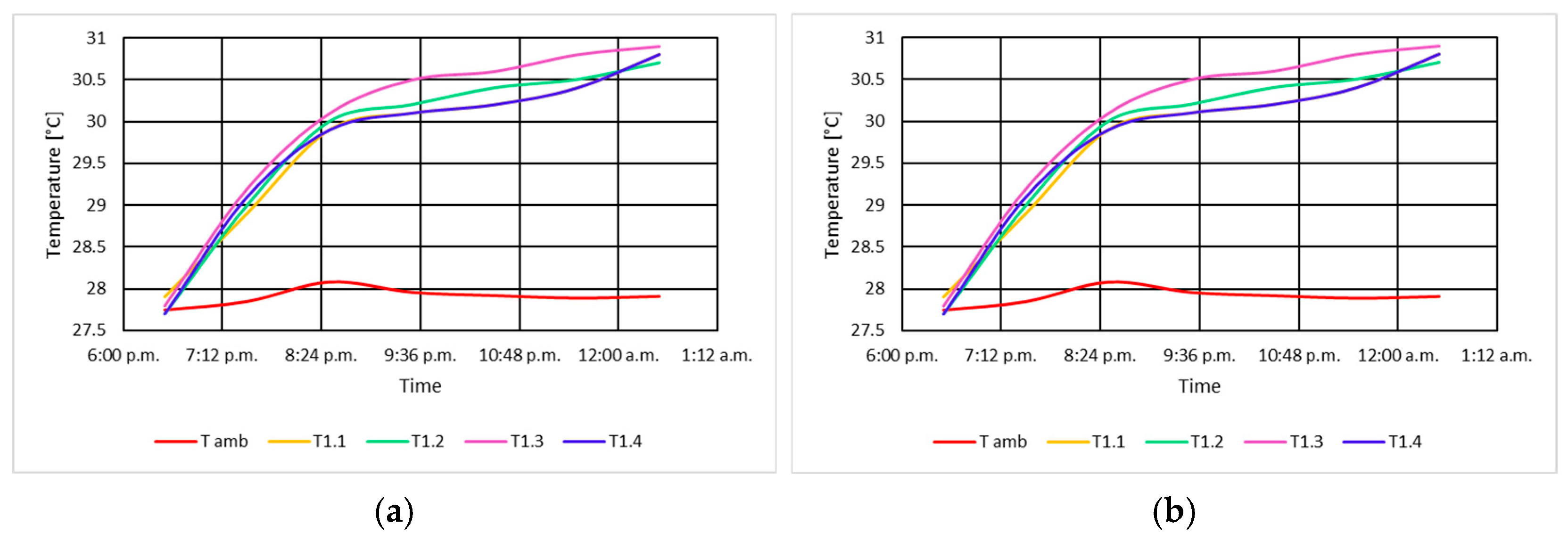

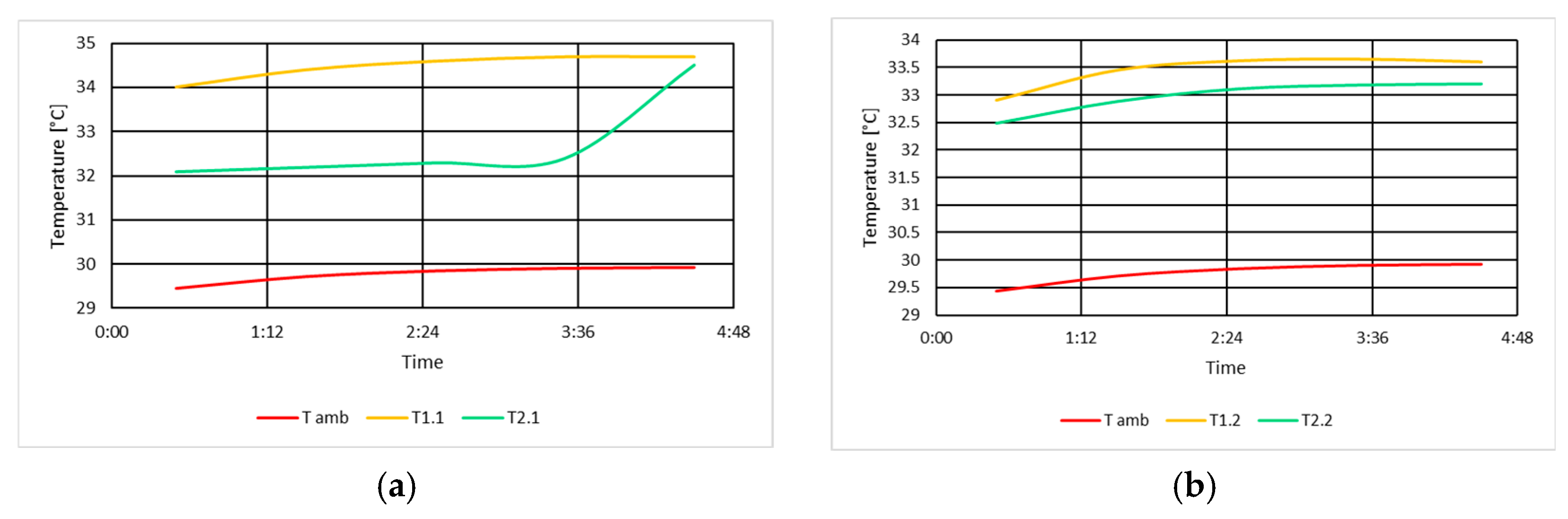

3.1. Measurements for the No-Load Unexcited Operating Mode

3.1.1. Determination of Mechanical and Ventilation Losses by Measuring Cold and Hot Water Temperatures in No-Load Unexcited Mode

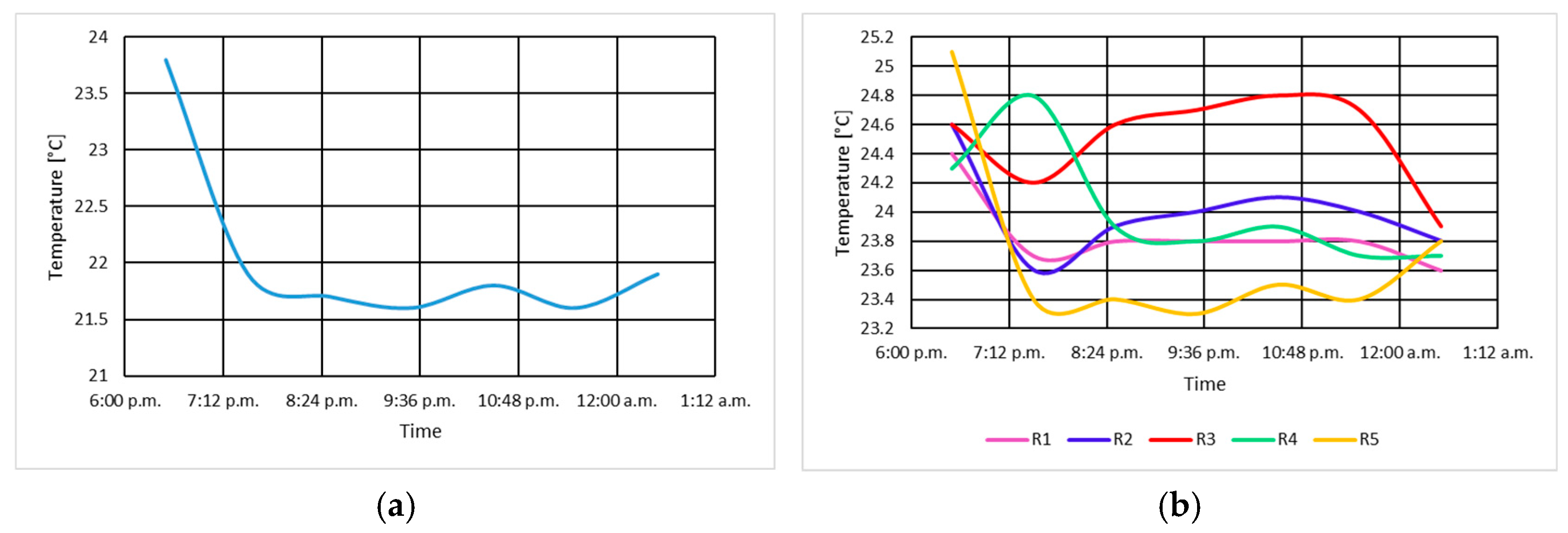

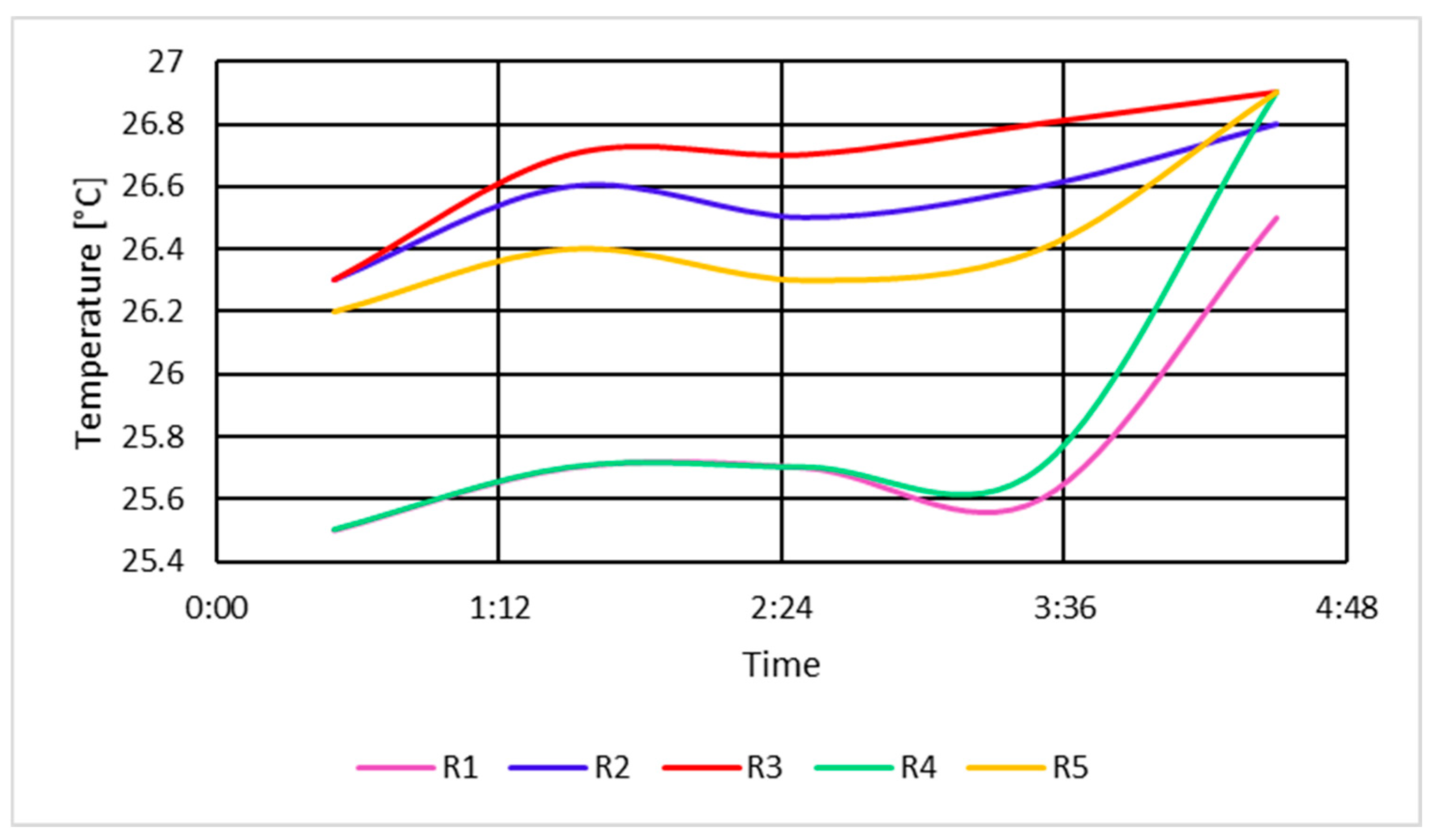

3.1.2. Determination of Air Temperatures Through Cooler Units in No-Load Unexcited Mode

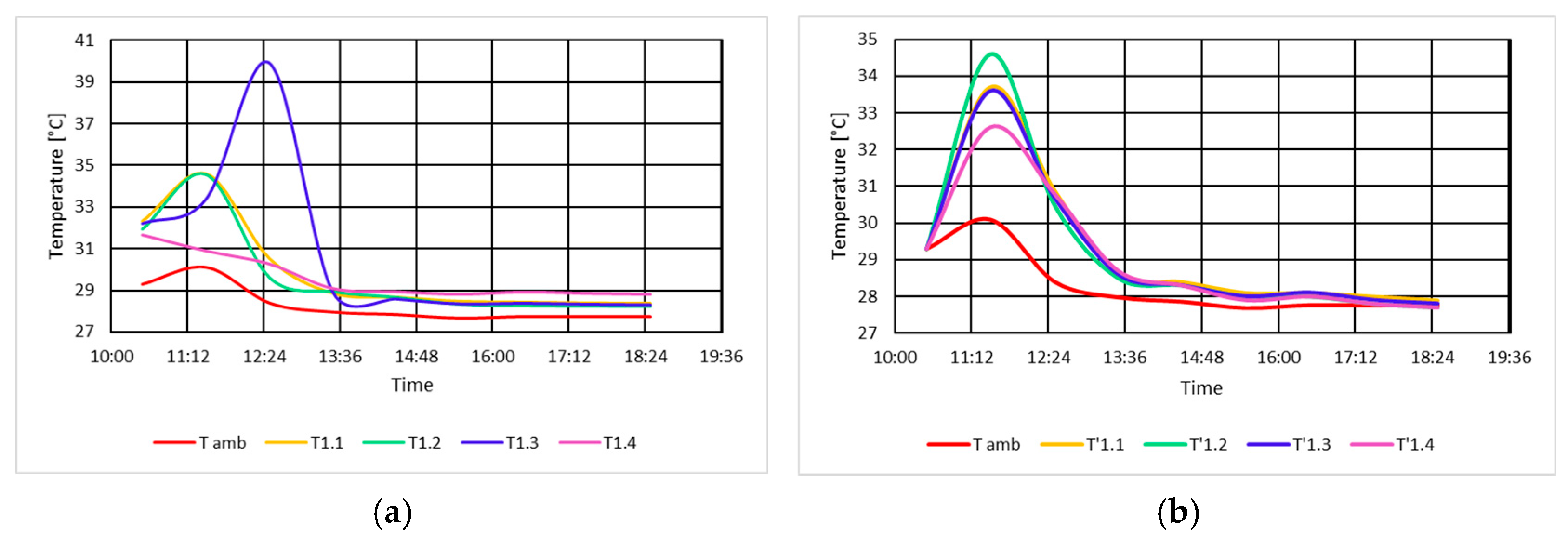

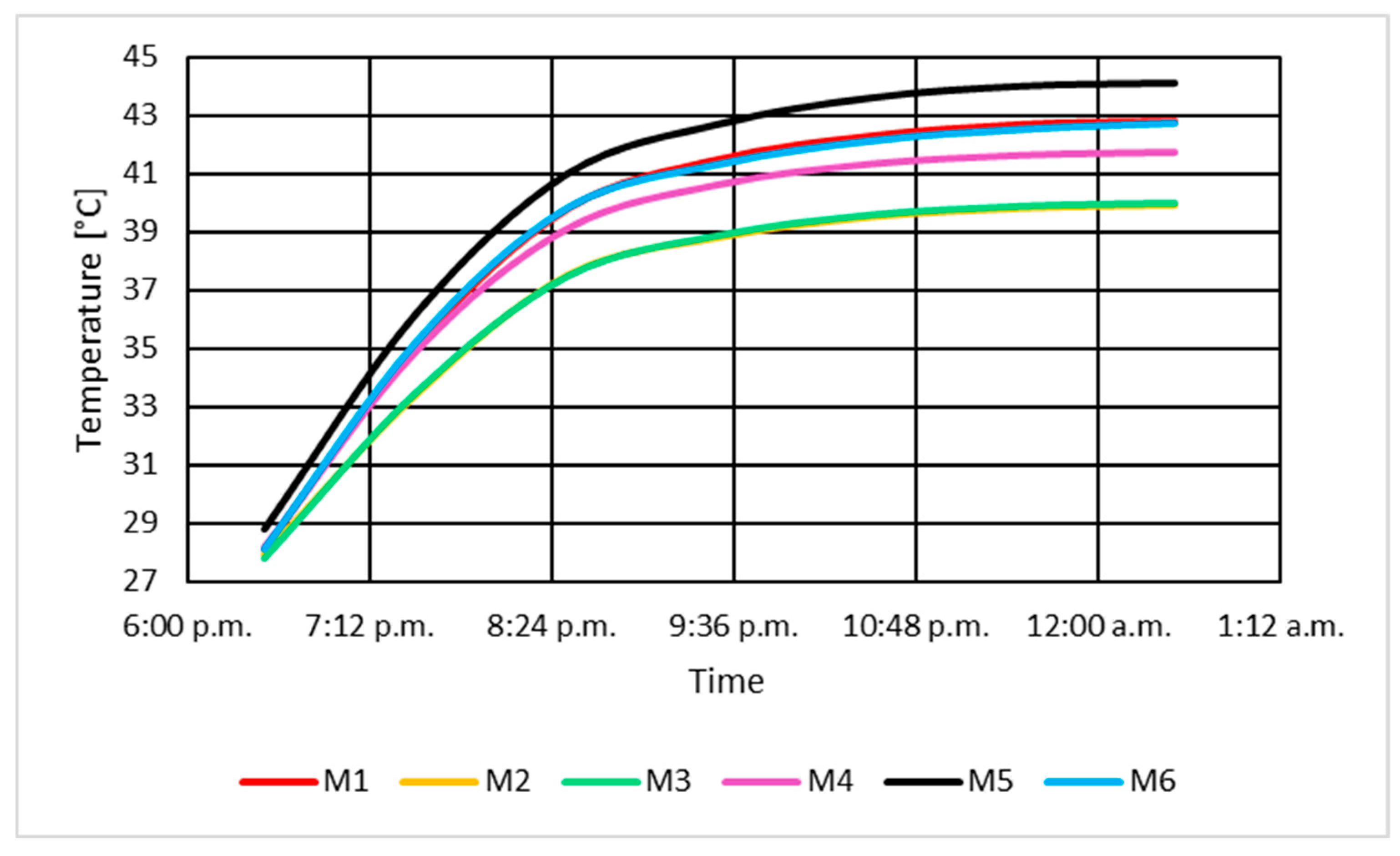

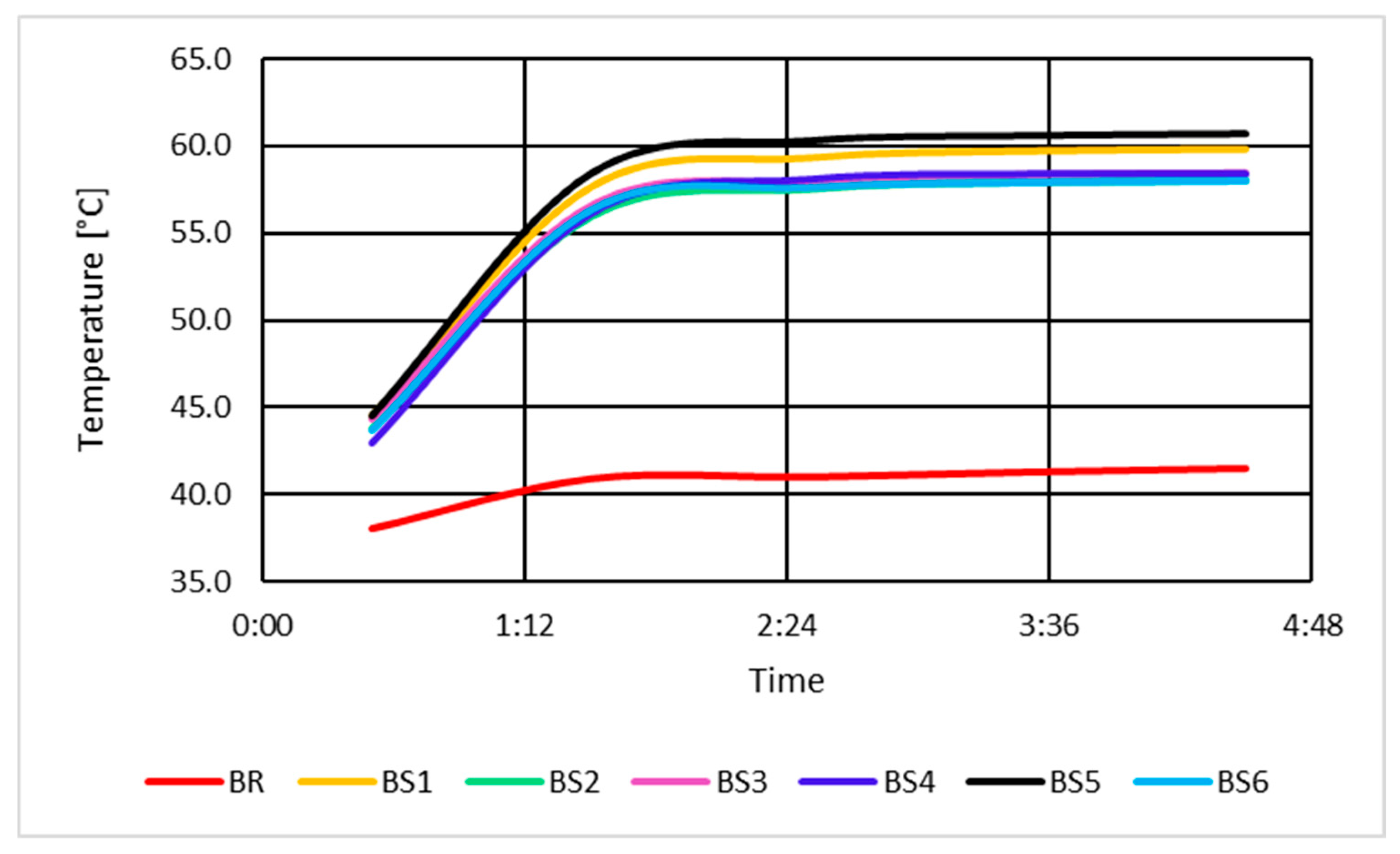

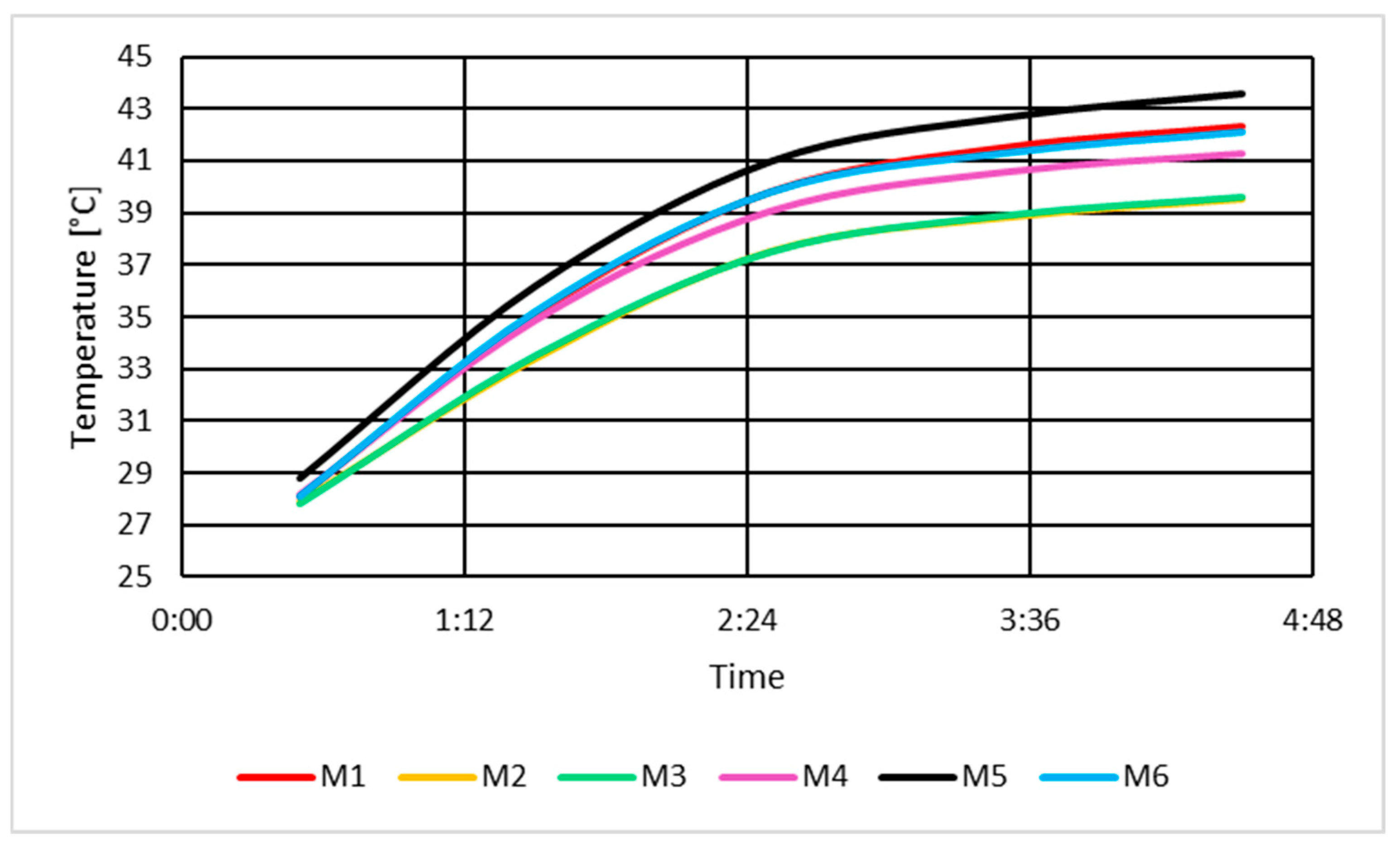

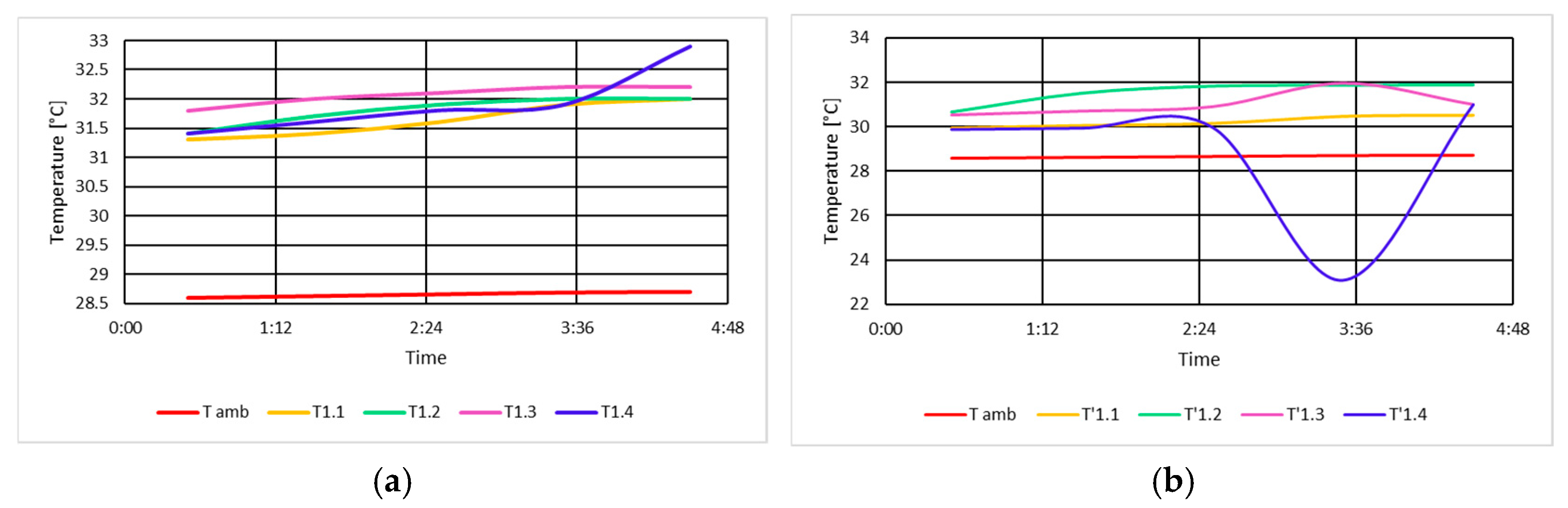

3.1.3. Determination of Winding Temperatures in No-Load Unexcited Mode

3.1.4. Determination of Magnetic Core Temperatures in No-Load Unexcited Condition

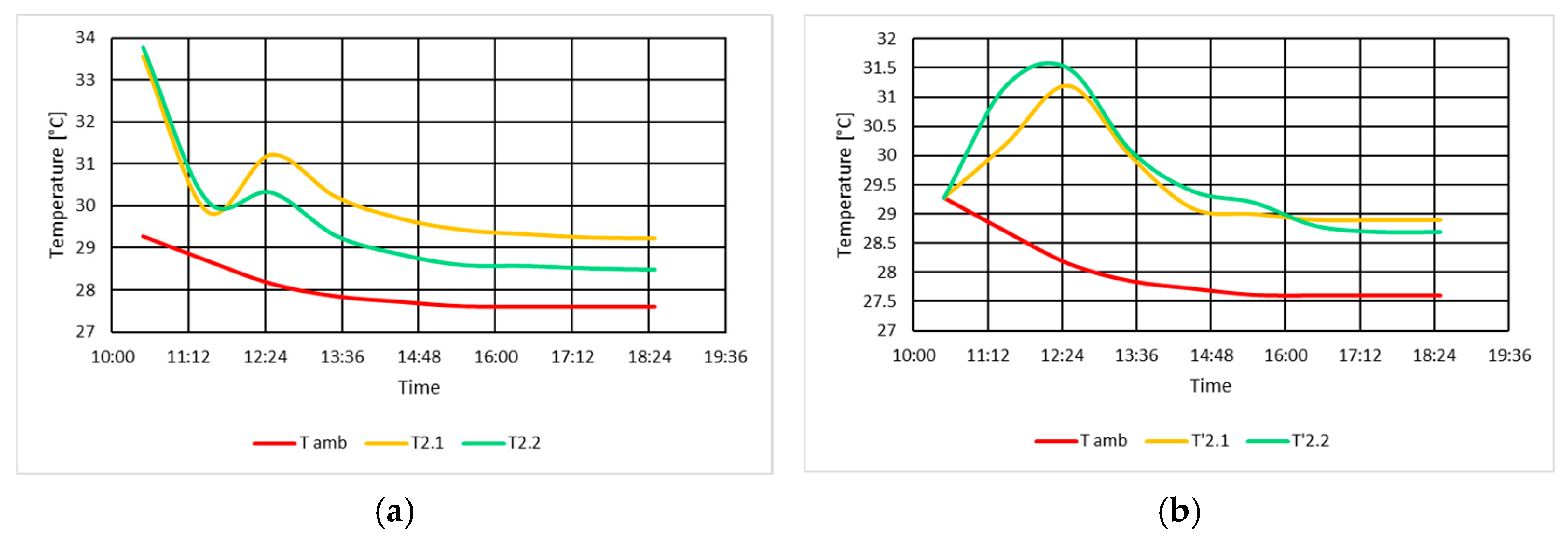

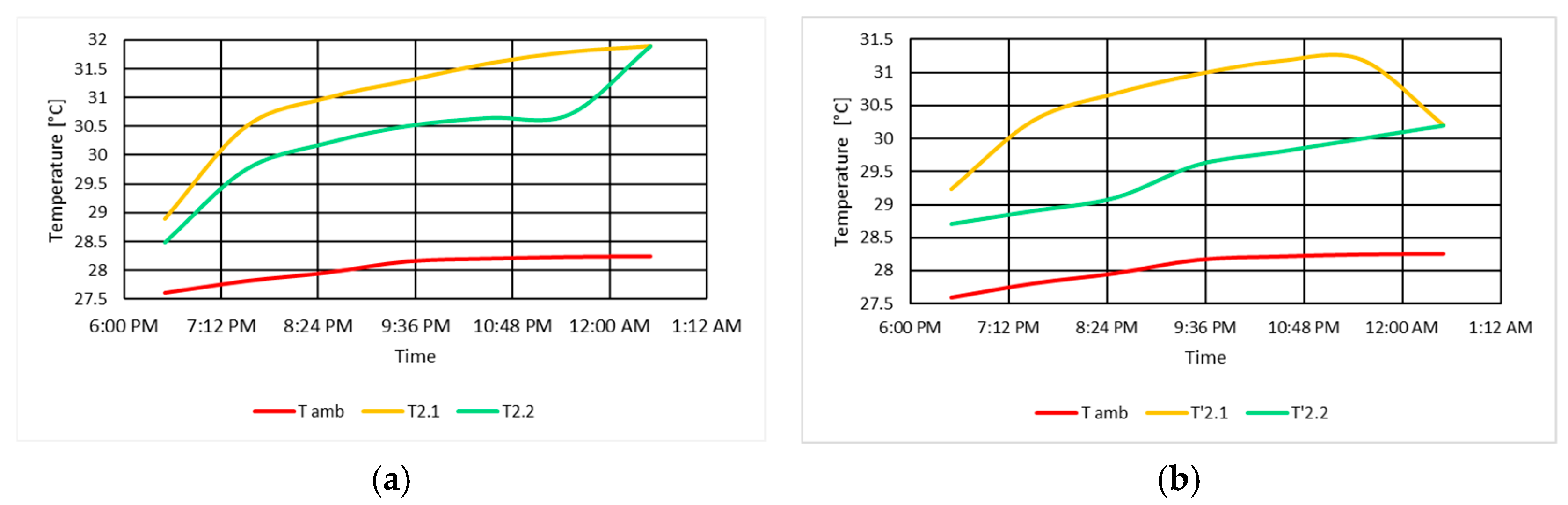

3.1.5. Determination of Measured Temperatures at the Upstream Shield and 1 m from the Shield in No-Load Unexcited Condition

3.1.6. Determination of Measured Temperatures at the Downstream Shield and 1 m from the Shield in No-Load Unexcited Condition

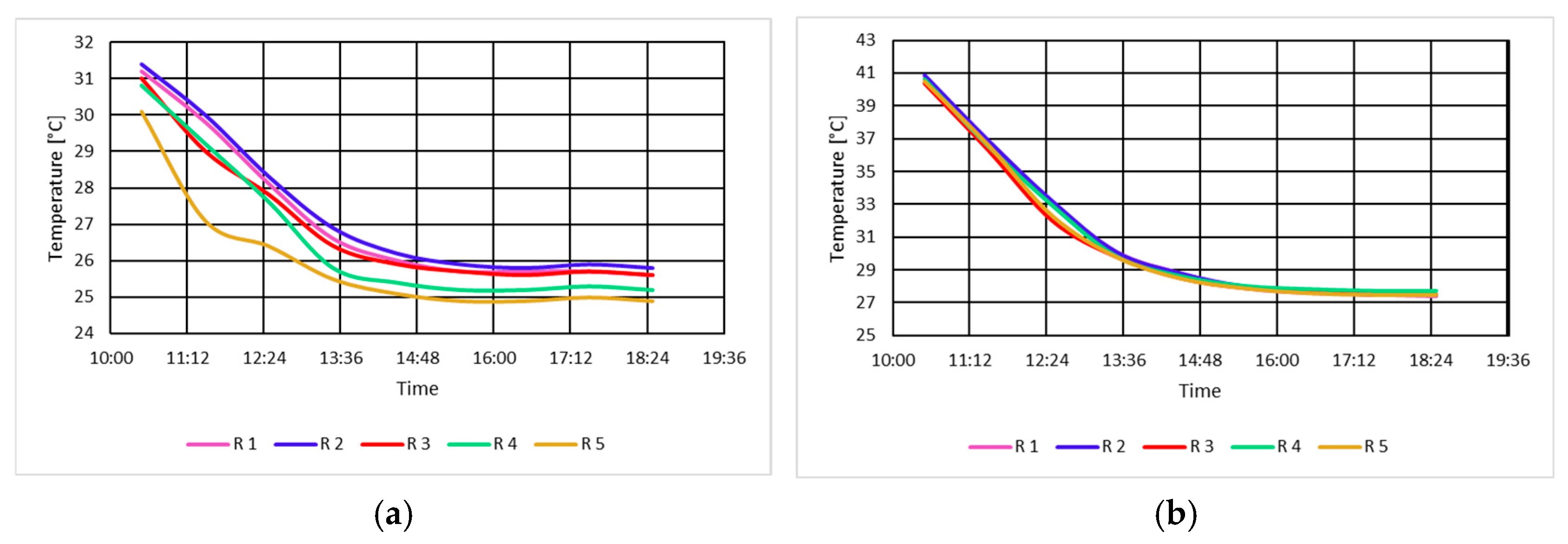

3.2. Measurements Conducted for the No-Load Excited Operating Condition

3.2.1. Determination of Mechanical and Ventilation Losses by Measuring Cold and Hot Water Temperatures in No-Load Excited Condition

- QAi0e—is the cooling water flow rate through cooler unit i (L/min) in the no-load excited condition;

- ΔTi0e—is the temperature difference between hot and cold water for cooler unit i (°C) in the no-load excited condition.

3.2.2. Determination of Air Temperatures Through Cooler Units in No-Load Excited Condition

3.2.3. Determination of Winding Temperatures in No-Load Excitation Mode

3.2.4. Determination of Magnetic Core Temperatures in No-Load Excitation Mode

3.2.5. Determination of Temperatures Measured at the Upstream Shield and 1 m from the Shield in No-Load Excitation Mode

3.2.6. Determination of Temperatures Measured at the Shield Downstream and 1 m from the Shield in No-Load Excitation Mode

3.3. Measurements Performed for the Short-Circuit Operating Mode

3.3.1. Determination of Mechanical and Ventilation Losses by Measuring the Temperatures of Cold and Hot Water in Short-Circuit Mode

- QAisc is the flow rate of cooling water through cooler unit i (L/min) in short-circuit mode;

- ΔTisc is the temperature difference between hot and cold water for cooler unit i (°C) in short-circuit mode.

3.3.2. Determination of Air Temperatures Through Cooler Units in Short-Circuit Mode

3.3.3. Determination of Winding Temperatures in Short-Circuit Mode

3.3.4. Determination of Magnetic Core Temperatures in Short-Circuit Mode

3.3.5. Determination of Measured Temperatures at the Upstream Shield and 1 m from the Shield Under Short-Circuit Conditions

3.3.6. Determination of Measured Temperatures at the Downstream Shield and 1 m from the Shield Under Short-Circuit Conditions

3.4. Determination of the Separate Losses of the Generator

3.4.1. Determination of Losses During the Generator’s Operation in No-Load Unexcited Mode

- The amount of heat that the cooling water absorbs during passage through the cooler units, quantified as power losses P10;

- The amount of heat transmitted through radiation and convection, quantified as P20 losses.

3.4.2. Determination of Losses During the Generator’s Operation in No-Load Excited Mode

- The amount of heat that the cooling water absorbs during passage through the cooler units, transformed into P10e power losses;

- Losses through radiation and convection, quantified as P20e losses;

- The voltage at the stator terminals of the generator;

- The excitation voltage at the rotor terminals of the generator;

- The excitation current of the generator.

- P10e represents the mechanical losses through ventilation and air friction determined during the no-load excited operation of the generator;

- P20e represents the losses through radiation and convection through the two shields determined for the same regime;

- IE0 is the excitation current in no-load operation of the generator, which had a value of 186 A;

- RE0e-20 is the resistance of the excitation winding at 20 °C, which in the analyzed case was 0.6941 Ω;

- RE0e-40 is the resistance of the excitation winding at 40 °C during no-load operation of the generator, which in the analyzed case was 0.7485 Ω.

3.4.3. Determination of Losses During the Generator’s Operation in Short-Circuit Mode

- The amount of heat that the cooling water absorbs during passage through the cooler units, transformed into P1sc power losses;

- The amount of heat transmitted through radiation and convection, quantified in P2sc;

- The voltages at the rotor terminals of the generator;

- The current in the generator’s stator;

- The excitation current of the generator;

- The temperatures of the stator winding of the generator;

- The resistance of the generator’s excitation winding at the temperature corresponding to the short-circuit regime;

- The resistance of the stator winding in the R1sc phase corresponding to the short-circuit regime.

- The excitation current in short-circuit mode, at nominal current, IEsc = 198 A;

- The current through the stator winding in short-circuit mode, at nominal current, I1sc = 1221 A;

- The resistance of the excitation winding at 20 °C, REsc-20 = 0.6941 Ω;

- The resistance of the excitation winding at 42 °C, REsc-42 = 0.7539 Ω;

- The resistance of the excitation winding at 75 °C, REsc-75 = 0.8438 Ω;

- The resistance of the stator winding at 20 °C, R1sc-20 = 0.01662 Ω;

- The resistance of the stator winding at 59 °C, R1sc-59 = 0.0192 Ω.

3.5. Determination of the Generator’s Efficiency

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| IEC | International Electrotechnical Commission |

| IEA | International Energy Agency |

| IECS | Intelligent Energy Control System |

| ηG | Efficiency of the generator |

| P | Active power |

| Σp | Losses from the generator |

| PT | Sensor made of platinum |

| QA | Total flow of cooling water |

| QAi0 | Flow rate of the cooling water through cooler unit |

| ΔTi0 | Temperature difference between hot and cold water |

| ρA | Density of the cooling water |

| CpA | Specific heat of water |

| TARm | Average temperature of cold water, at the cooler inlet, calculated for all cooler units |

| TACm | Average temperature of hot water at the cooler outlet, calculated for all cooler units |

| TAm | Average temperature of the cooling water for all cooler units |

| P2 | Losses due to radiation and convection transmitted through the generator shields |

| hi | Heat transfer coefficient through surface |

| Ai | Surface area i |

| ΔTi | Temperature difference between surface i and the ambient temperature at 1 m distance |

| A1 | Area of the downstream shield of the generator |

| A2 | Area of the upstream shield of the generator |

| Sn | Nominal apparent power |

| Un | Nominal voltage |

| In | Nominal stator current |

| UEn | Nominal excitation voltage |

| IEn | Nominal excitation current |

| m | Number of phases of the generator |

| n | Speed |

| cosφ | Power factor |

| P10 | Total value of mechanical losses due to ventilation and friction with air determined in the no-load unexcited operation mode |

| TArr | Temperatures of cold air |

| TArc | Temperatures of hot air at the outlet of the cooler units |

| BS | Stator winding |

| BR | Rotor winding |

| TBR | Temperatures of rotor winding in no-load unexcited stabilized condition |

| TBS | Temperatures of stator winding in no-load unexcited stabilized condition |

| TM | Temperatures of magnetic core in no-load unexcited stabilized condition |

| T1m | Average temperature at the upstream shield in no-load unexcited stabilized condition |

| T′1m | Average temperature at 1 m from the upstream shield in no-load unexcited stabilized condition |

| Tamb | Stabilized ambient temperature |

| T2m | Average temperature at the downstream shield in no-load unexcited stabilized condition |

| T′2m | Average temperature at 1 m from the downstream shield in no-load unexcited stabilized condition |

| P20 | Losses due to radiation and convection through the two shields (upstream and downstream) |

| P10e | Total value of mechanical losses due to ventilation and friction with air determined in the no-load excited condition |

| QAi0e | Cooling water flow rate through cooler unit i, in no-load excited condition |

| ΔTi0e | Temperature difference between hot and cold water for cooler unit i, in no-load excited condition |

| TArre | Temperatures of cold air in no-load excited condition |

| TArce | Temperatures of hot air at the outlet of the cooler units in no-load excited condition |

| TBRe | Temperatures of rotor winding in no-load excited condition |

| TBSe | Temperatures of stator winding in no-load excited condition |

| TM3 | Temperatures of magnetic core in no-load unexcited stabilized condition |

| T1me | Average temperature at the upstream shield in no-load excited stabilized condition |

| T′1me | Average temperature at 1 m from the upstream shield in no-load excited stabilized condition |

| T2me | Average temperature at the downstream shield in no-load excited stabilized condition |

| T′2me | Average temperature at 1 m from the downstream shield in no-load excited stabilized condition |

| P20e | Losses due to radiation and convection through the two shields (upstream and downstream) in no-load excited condition |

| QAisc | Flow rate of cooling water through cooler unit i in short-circuit mode |

| ΔTisc | Temperature difference between hot and cold water for cooler unit i in short-circuit mode. |

| P1sc | Total value of mechanical losses through ventilation and air friction determined in short-circuit mode |

| TArrsc | Temperatures of cold air in short-circuit condition |

| TArcsc | Temperatures of hot air at the outlet of the cooler units in short-circuit condition |

| TBRsc | Temperatures of rotor winding in short-circuit condition |

| TBSsc | Temperatures of stator winding in short-circuit condition |

| TMsc | Temperatures of magnetic core in short-circuit stabilized condition |

| T1msc | Average temperature at the upstream shield in short-circuit stabilized condition |

| T′1msc | Average temperature at 1 m from the upstream shield in short-circuit stabilized condition |

| T2msc | Average temperature at the downstream shield in short-circuit stabilized condition |

| T′2msc | Average temperature at 1 m from the downstream shield in short-circuit stabilized condition |

| P2sc | Losses due to radiation and convection through the two shields (upstream and downstream) in short-circuit condition |

| Pv | Ventilation losses |

| PFe | Iron losses |

| IEsc | Excitation current in short-circuit mode |

| I1sc | Current through the stator winding in short-circuit mode |

| REsc-20 | Resistance of the excitation winding at 20 °C |

| R1sc-20 | Resistance of the stator winding at 20 °C |

| PCu1 | Copper losses in the stator winding |

| Psuplim | Additional losses |

| Pm | Mechanical losses |

| ∑P | Total losses |

| η | Efficiency |

| Ham | Upstream water level |

| Hav | Downstream level |

References

- Yahya, A.K.; Munim, W.N.W.A.; Othman, Z. Pico-hydro power generation using dual pelton turbines and single generator. In Proceedings of the 8th IEEE International Power Engineering and Optimization Conference (PEOCO), Shah Alam, Malaysia, 24–25 March 2014. [Google Scholar]

- Reducing Global Energy Consumption. Available online: https://www.agg-net.com/resources/articles/ancillary-equipment/reducing-global-energy-consumption (accessed on 12 July 2022).

- Renewable Energy. Available online: https://ourworldindata.org/renewable-energy (accessed on 12 July 2022).

- REPowerEU: Affordable, Secure and Sustainable Energy for Europe. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal/repowereu-affordable-secure-and-sustainable-energy-europe_en (accessed on 12 July 2022).

- Pistelok, P.; Baranski, M. Highly efficient synchronous generators with permanent magnets intended to small hydropower station. In Proceedings of the 5th International Conference on Clean Electrical Power (ICCEP), Taormina, Italy, 16–18 June 2015. [Google Scholar]

- Rozowicz, S.; Goryca, Z.; Peczkis, G.; Korczak, A. Pico hydro generator as an effective source of renewable energy. Prz. Elektrotechniczny 2019, 95, 200–204. [Google Scholar]

- Tanutwutthigorn, K.; Suntivarakorn, R. Efficiency improvement and economic analysis of micro hydro power plant by using twin vertical hydro turbine. In Proceedings of the 9th International Conference on Future Environment and Energy (ICFEE), Osaka, Japan, 9–11 January 2019. [Google Scholar]

- Pomoja, F.; Manescu, T.S.; Hopota, A. Improving efficiency of an micro-hydro aggregate using a banky 10 kw micro-turbine, by blade design optimization. In Proceedings of the 7th International Symposium on Machine and Industrial Design in Mechanical Engineering (KOD 2012), Balatonfured, Hungary, 24–26 May 2012. [Google Scholar]

- Rubes, O.; Cervinka, D. Efficiency optimization of small hydro power plant in low power operation. In Proceedings of the IEEE International Conference on Environment and Electrical Engineering and 2017 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Milan, Italy, 6–9 June 2017. [Google Scholar]

- Rubes, O.; Cervinka, D. Increasing the Efficiency of Induction Generator in Small Hydro Power Plant for Varying River Flow Rate. In Proceedings of the 12th International Conference on Mechatronics, Brno, Czech Republic, 6–8 September 2017. [Google Scholar]

- Rubes, O.; Knobloch, J.; Cervinka, D. Techniques to Increase the Efficiency of Small Hydro Power Plants with Induction Machine. In Proceedings of the IEEE International Conference on Environment and Electrical Engineering (EEEIC)/IEEE Industrial and Commercial Power Systems Europe (ICPS Europe), Palermo, Italy, 12–15 June 2018. [Google Scholar]

- IEEE Standard 115-2009; IEEE Guide Test Procedures for Synchronous Machines, Acceptance and Performance Testing and Parameter Determination for Dynamic Analysis. IEEE: New York, NY, USA, 2010.

- IEC 60034-2-2; Rotating Electrical Machines. Part 2-2: Specific Methods for Determining Separate Losses of Large Machines from Tests. IEC: Geneva, Switzerland, 2020.

- Li, W.L.; Liang, D.W.; Zhang, Y. Calculation of Iron Loss in Large Hydro-Generator under Non-Load. In Proceedings of the International Conference on Materials Science and Information Technology (MSIT 2011), Singapore, 16–18 September 2011. [Google Scholar]

- Merkhouf, A.; Guillot, E.; Hudon, C.; Desnoyers, M.; Aguiar, A.B.M.; Al-Haddad, K. Electromagnetic Loss Computation in Large Hydro Electrical Generator Using Different Existing Models. In Proceedings of the 20th International Conference on Electrical Machines (ICEM), Marseille, France, 2–5 September 2012. [Google Scholar]

- Aguiar, A.B.M.; Merkhouf, A.; Al-Haddad, K. Influence of the Air Gap Length on the Magnetic Core Loss in Large Hydro Generator. In Proceedings of the 20th International Conference on Electrical Machines (ICEM), Marseille, France, 2–5 September 2012. [Google Scholar]

- Ćalasan, M.; Ostojić, M.; Petrović, D. The retardation method for bearings loss determination. In Proceedings of the International Symposium on Power Electronics Power Electronics, Electrical Drives, Automation and Motion, Sorrento, Italy, 20–22 June 2012. [Google Scholar]

- Rehfeldt, A.; Fricke, T.; Schwarz, B.; Bresemann, E.; Ponick, B. Measurement of Sub-Conductor Circulating Currents in Roebel Bars of a Hydro Generator. In Proceedings of the 13th International Conference on Electrical Machines (ICEM), Alexandroupoli, Greece, 3–6 September 2018. [Google Scholar]

- Traxler-Samek, G.; Langmayr, D. Three-dimensional temperature distribution in large hydro-generators: Efficient simulation and optimization. Elektrotechnik Informationstechnik 2019, 136, 216–223. [Google Scholar] [CrossRef]

- Bortoni, E.C.; Siniscalchi, R.T.; Jardini, J.A. Hydro Generator Efficiency Assessment using Infrared Thermal Imaging Techniques. In Proceedings of the IEEE-Power-and-Energy-Society General Meeting, Minneapolis, MN, USA, 25–29 July 2010. [Google Scholar]

- Bortoni, E.C.; Siniscalchi, R.T.; Jardini, J.A. Determination of Hydro Generator Efficiency Using Infrared Thermal Imaging Techniques. IEEE Trans. Energy Convers. 2012, 27, 1134–1139. [Google Scholar]

- Bortoni, E.C.; Siniscalchi, R.T. Hydro generators losses measurement in accordance to IEEE-STD-115 and IEC-60034-2. In Proceedings of the 2012 IEEE Power and Energy Society General Meeting, San Diego, CA, USA, 22–26 July 2012. [Google Scholar]

- Baholo, B.; Mellor, P.H.; Howe, D.; Birch, T.S. An automated calorimetric method of loss measurement in electrical machines. J. Magn. Magn. Mater. 1994, 133, 433–436. [Google Scholar] [CrossRef]

- Bertalanic, Z.; Pavlica, M.; Maljkovic, Z. Analysis of hydro-generator’s losses determined by calorimetric method. In Proceedings of the XIX International Conference on Electrical Machines—ICEM 2010, Rome, Italy, 6–8 September 2010. [Google Scholar]

- Hudon, C.; Levesque, M.; Torriano, F.; Gingras, S.; Picard, J.; Petit, A. On-Line Rotor Temperature Measurements. In Proceedings of the 32nd Electrical Insulation Conference (EIC), Philadelphia, PA, USA, 8–11 June 2014. [Google Scholar]

- Guerrero, R.C.; Aller, J.M. Efficiency Calculation for a 90 MVA Vertical Shaft Hydro-Alternator using the Calorimetric Method. In Proceedings of the 2024 IEEE ANDESCON, Cusco, Peru, 11–13 September 2024. [Google Scholar]

- Indra, B.B.; Suresh, R. Generator Efficiency Measurement by Calorimetric Method: Case of UT3A HEP 60MW. Proc. IOE Grad. Conf. 2019, 7, 29–36. [Google Scholar]

- Rasilo, P.; Ekström, J.; Haavisto, A.; Belahcen, A.; Arkkio, A. Calorimetric System for Measurement of Synchronous Machine Losses. IET Electr. Power Appl. 2012, 5, 286–294. [Google Scholar] [CrossRef]

- Battisti, L.; Tieghi, L.; Fattahi, S. Heat-Loss Based Method for Real-Time Monitoring Method for Hydroelectric Power Plant Efficiency. Energies 2025, 18, 2586. [Google Scholar] [CrossRef]

- Xinjie, G.; Chunqiang, P.; Hongtao, L.; Xuhui, X.; Cuiwei, J. Measuring uncertainty of hydraulic generator efficiency by calorimetric method. In Journal of Physics: Conference Series, Proceedings of the 4th IAHR Asian Working Group Symposium on Hydraulic Machinery and Systems, Kashgar, China, 12–16 August 2023; IOP Publishing: Philadelphia, PA, USA, 2024; Volume 2752, p. 012218. [Google Scholar]

- Widiyanto, P.; Irasari, P.; Hikmawan, M.F. Suitability Analysis of Cross-Flow Turbine and Synchronous Generator Characteristics for Very Low Head Hydro Power Application. In Proceedings of the International Conference on Sustainable Energy Engineering and Application (ICSEEA)—Innovative Technology Toward Energy Resilience, Tangerang, Indonesia, 23–24 October 2019. [Google Scholar]

- Jiang, F.; Bo, Z.Q.; Li, R.M. Performance of induction generator in parallel with an unbalanced three phase system. In Proceedings of the 1998 International Conference on Power System Technology (POWERCON 98), Beijing, China, 18–21 August 1998. [Google Scholar]

- Safdar, I.; Sultan, S.; Raza, H.A.; Umer, M.; Ali, M. Empirical analysis of turbine and generator efficiency of a pico hydro system. Sustain. Energy Technol. Assess. 2020, 37, 100605. [Google Scholar] [CrossRef]

- Kunckel, S.; Klaus, G.; Liese, M. Calculation of eddy current losses and temperature rises at the stator end portion of hydro generators. In Proceedings of the International Conference on Electrical Machines (ICEM 2002), Brugge, Belgium, 26–28 August 2002. [Google Scholar]

- Valsan, V.; Kanakasabapathy, P. Design and Implementation of Smart Energy Management System for Stand-alone Micro-hydro Systems. In Proceedings of the IEEE International Conference on Technological Advancements in Power and Energy (IEEE TAP Energy)—Exploring Energy Solutions for an Intelligent Power Grid, United Nat Acad Impact, Kollam, India, 21–23 December 2017. [Google Scholar]

- Barboianu, I.; Grigoriu, M.; Popescu, M.C. Application Software for Analyzing the Dynamic Stability of Hydro-aggregates. Int. J. Comput. Sci. Netw. Secur. 2020, 17, 227–234. [Google Scholar]

- IEC 60034-2-1:2024; Rotating Electrical Machines—Part 2-1: Standard Methods for Determining Losses and Efficiency from Tests (Excluding Machines for Traction Vehicles). IEC: Geneva, Switzerland, 2024.

- IEC 60034-2A:1974; Rotating Electrical Machines—Part 2: Methods for Determining Losses and Efficiency of Rotating Electrical Machinery form Tests (Excluding Machines for Traction Vehicles)—Measurement of Losses by the Calorimetric Method. IEC: Geneva, Switzerland, 1974.

- IEC 60034-4:1967; Recommendations for Rotating Electrical Machinery (Excluding Machines for Traction Vehicles)—Part 4: Methods for Determining Synchronous Machine Quantities from Tests. IEC: Geneva, Switzerland, 1967.

- IEC 61000-4-30 Consolidated version; Electromagnetic Compatibility (EMC)—Part 4-30: Testing and Measurement Techniques—Power Quality Measurement Methods. IEC: Geneva, Switzerland, 2021.

| Cooling Unit Number | Water Flow Rate [L/min] | Water Temperature [°C] | Losses P1i0 [kW] | ||

|---|---|---|---|---|---|

| Ti0Ac | Ti0Ar | ΔTi0 | |||

| 1 | 230 | 24.4 | 23.8 | 0.6 | 9.576 |

| 2 | 200 | 24.6 | 23.8 | 0.8 | 11.103 |

| 3 | 190 | 24.6 | 23.8 | 0.8 | 10.548 |

| 4 | 215 | 24.3 | 23.8 | 0.5 | 7.460 |

| 5 | 200 | 24.6 | 23.8 | 0.8 | 11.103 |

| Total losses P10 [kW] | 49.788 | ||||

| Cooling Unit Number | Water Flow Rate [L/min] | Water Temperature [°C] | Losses P1i0e [kW] | ||

|---|---|---|---|---|---|

| Ti0Ace | Ti0Are | ΔTi0e | |||

| 1 | 225 | 23.6 | 21.9 | 1.7 | 26.542 |

| 2 | 200 | 23.8 | 21.9 | 1.9 | 26.369 |

| 3 | 185 | 23.9 | 21.9 | 2.0 | 25.675 |

| 4 | 215 | 23.7 | 21.9 | 1.8 | 26.854 |

| 5 | 200 | 23.8 | 21.9 | 1.9 | 26.369 |

| Total losses P10e [kW] | 131.809 | ||||

| Cooler Unit Number | Water Flow Rate [L/min] | Water Temperature [°C] | Losses P1isc [kW] | ||

|---|---|---|---|---|---|

| TiAcsc | TiArsc | ΔTisc | |||

| 1 | 230 | 26.5 | 24.3 | 2.2 | 35.112 |

| 2 | 200 | 26.8 | 24.3 | 2.5 | 34.696 |

| 3 | 190 | 26.9 | 24.3 | 2.6 | 34.279 |

| 4 | 215 | 26.9 | 24.3 | 2.6 | 38.790 |

| 5 | 210 | 26.9 | 24.3 | 2.6 | 37.888 |

| Total losses P1sc [kW] | 180.764 | ||||

| Quantity | U.M. | 0.25·Pn | 0.5·Pn | 0.75·Pn | Pn | 1.1·Pn |

|---|---|---|---|---|---|---|

| Apparent power | kVA | 3332.5 | 6665 | 9997.5 | 13,330 | 14663 |

| Active power | kW | 3249.19 | 6498.38 | 9747.56 | 12,996.75 | 14,296.43 |

| Stator voltage | V | 6300 | 6300 | 6300 | 6300 | 6300 |

| Stator current | A | 305.4 | 610.8 | 916.2 | 1221.6 | 1343.76 |

| Excitation current | A | 224 | 243 | 274 | 288 | 315 |

| Mechanical losses | kW | 73.26 | 73.26 | 73.26 | 73.26 | 73.26 |

| Iron losses | kW | 56.591 | 56.591 | 56.591 | 56.591 | 56.591 |

| Stator copper losses | kW | 5.372 | 21.489 | 48.351 | 85.957 | 104.008 |

| Rotor copper losses | kW | 42.339 | 49.826 | 63.349 | 69.988 | 99.225 |

| Additional losses | KW | 1.055 | 4.220 | 9.496 | 16.883 | 20.427 |

| Total losses | kW | 178.617 | 205.386 | 251.047 | 302.679 | 353.511 |

| Efficiency | % | 94.789 | 96.936 | 97.489 | 97.724 | 97.586 |

| Quantity | U.M. | Values | |

|---|---|---|---|

| Guaranteed | Evaluated | ||

| Mechanical losses | kW | 65 | 73.26 |

| Iron losses | kW | 65.25 | 56.591 |

| Stator copper losses | kW | 98.89 | 85.957 |

| Rotor copper losses | kW | 81.49 | 69.988 |

| Additional losses | KW | 11.303 | 16.833 |

| Total losses | kW | 321.946 | 302.676 |

| Efficiency | % | 97.58 | 97.724 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spunei, E.; Anghel, D.; Liuba, G.; Chioncel, C.P.; Martin, M. Study on Determining the Efficiency of a High-Power Hydrogenerator Using the Calorimetric Method. Energies 2025, 18, 4813. https://doi.org/10.3390/en18184813

Spunei E, Anghel D, Liuba G, Chioncel CP, Martin M. Study on Determining the Efficiency of a High-Power Hydrogenerator Using the Calorimetric Method. Energies. 2025; 18(18):4813. https://doi.org/10.3390/en18184813

Chicago/Turabian StyleSpunei, Elisabeta, Dorian Anghel, Gheorghe Liuba, Cristian Paul Chioncel, and Mihaela Martin. 2025. "Study on Determining the Efficiency of a High-Power Hydrogenerator Using the Calorimetric Method" Energies 18, no. 18: 4813. https://doi.org/10.3390/en18184813

APA StyleSpunei, E., Anghel, D., Liuba, G., Chioncel, C. P., & Martin, M. (2025). Study on Determining the Efficiency of a High-Power Hydrogenerator Using the Calorimetric Method. Energies, 18(18), 4813. https://doi.org/10.3390/en18184813