Theoretical Approaches to the Heating of an Extensive Homogeneous Plate with Convective Cooling

Abstract

1. Introduction

- Energy in a very thin layer absorption of pulse,

- Homogeneity and isotropy of the slab material,

- Invariance of the property with temperature under experimental conditions;

- Uniform absorption of the pulse at the front surface,

- Infinitesimally short duration of the pulse;

- One-dimensional heat flow,

- No heat loss from the surfaces of the slab.

2. Mathematical Model

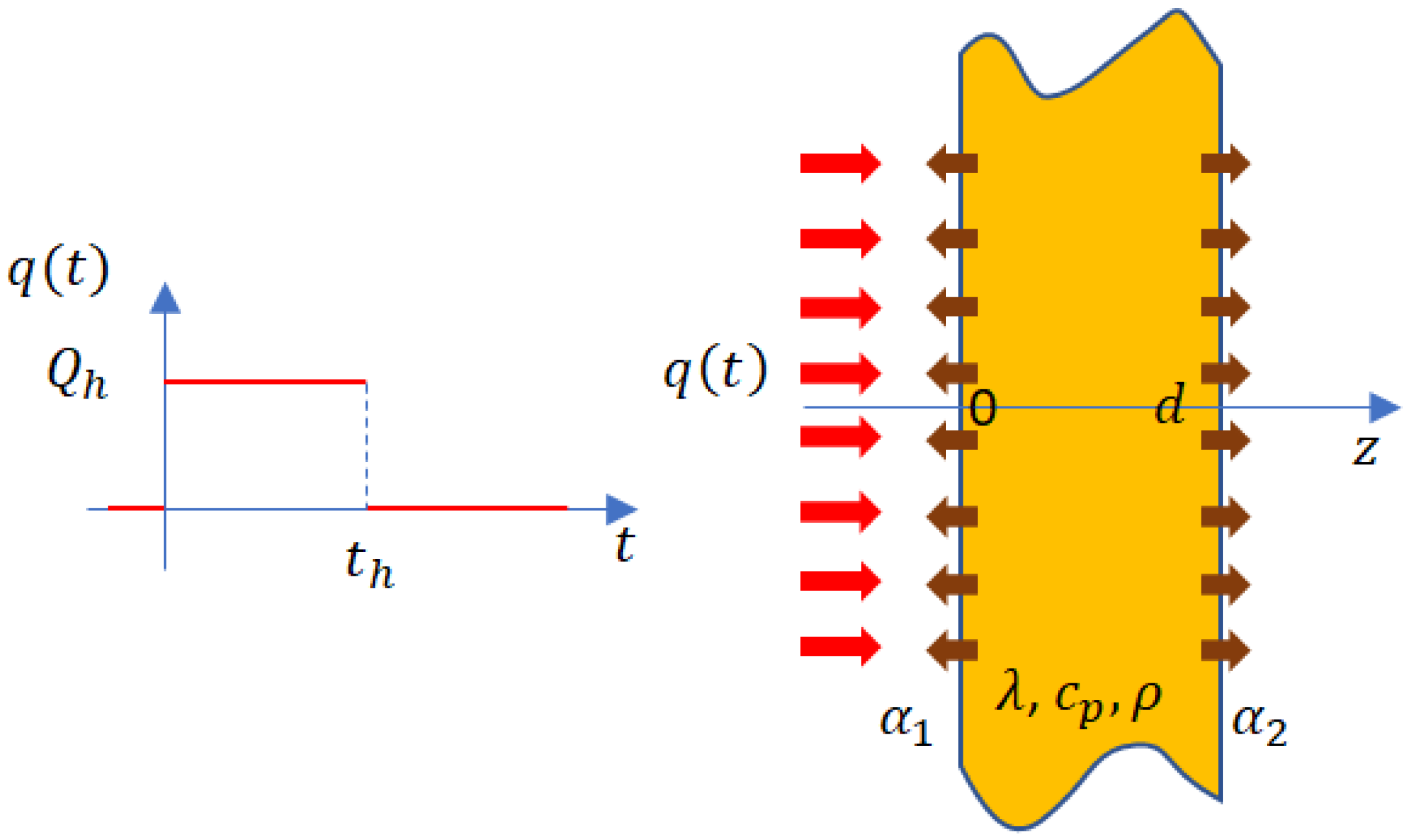

2.1. Problem Definition

- The slab has constant material parameters: thermal conductivity (), specific heat () and density ();

- The thickness of the slab () is constant and significantly smaller than its lateral dimensions;

- Heating occurs unilaterally and uniformly with a heat flux in the form of a rectangular pulse, having an intensity and duration , switched on at time ;

- The heat transfer between the plate and its surroundings occurs via convection, with a heat transfer coefficient on the heated side and on the opposite side;

- The initial temperature of the plate is equal to the ambient temperature , which is constant in both time and space.

2.2. Governing Equations

2.3. Literature Review for Solutions to Similar Problems

3. Results

3.1. Preliminary Remarks

3.2. Solution Obtained by Method of Separation of Variables

3.3. Solution Obtained by Means of Using the Laplace Transform

4. Discussion

4.1. Analysis of the Solution Obtained Using the Method of Separation of Variables

4.1.1. Values of the Components of the Solution

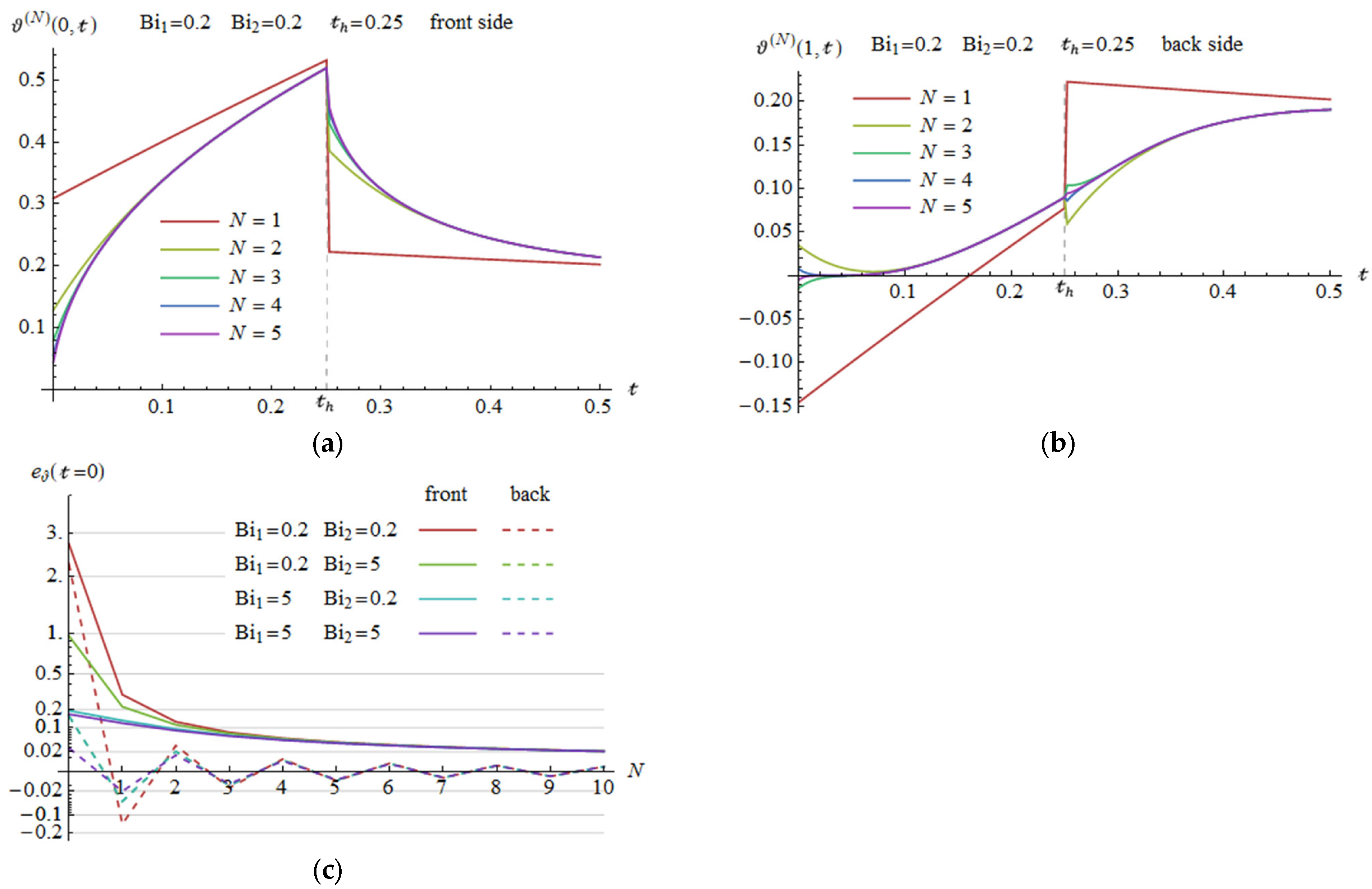

4.1.2. Analysis of the Truncation Error in Solution (16)

4.2. Analysis of the Solution Represented by Heat Waves

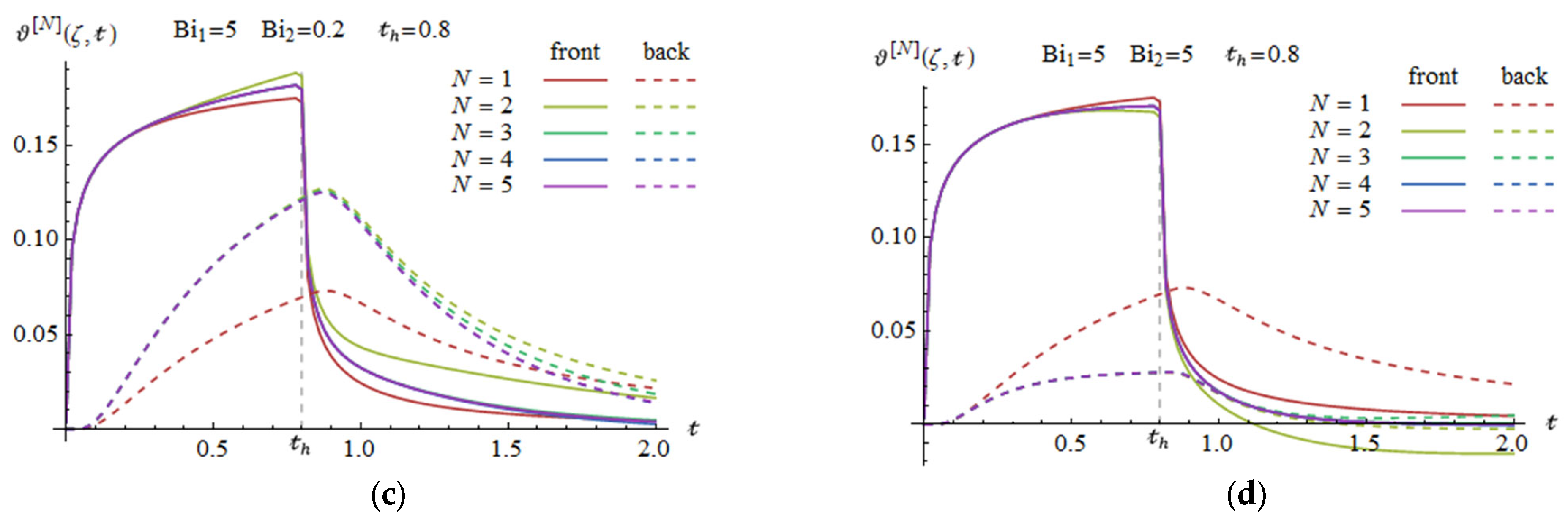

4.2.1. Influence of Successive Waves on the Solution Presented in Equation (23)

4.2.2. Approximations for Short Times

4.2.3. Numerical Evaluation of the Function

4.3. Comparison of the Two Solutions

4.4. Effect of Cooling Conditions on Relative Temperature Rise

4.4.1. Curves of Relative Temperature Rise on Slab Surfaces

4.4.2. Temperature Differences Between the Front and Rear Sides

5. Experimental Verification—Estimation of Thermal Diffusivity

6. Summary

- The solution obtained by applying the MSV is mathematically uncomplicated, whereas the solution described by heat waves is highly complex, especially for higher-order waves;

- In the limiting case of non-cooling conditions, both solutions require the use of a specific form; moreover, the heat-wave solution also demands a specific form if the cooling conditions are identical on both sides of the plate;

- The truncation error of the number of terms in the solution obtained by applying the MSV decreases rapidly over time after the heating pulse is switched on or off; therefore, the solution is most appropriate for sufficiently long times after the last change in boundary conditions;

- The wave number truncation error increases over time after the heating pulse is switched on; as a result, this solution is most effective for times that are sufficiently short after the first change in boundary conditions;

- The truncation error in both cases increases as the Biot numbers become smaller;

- The truncation error in the MSV method is smaller on the back side.

- The temperature value at the rear surface remains invariant due to the swap;

- The time required to reach maximum on the rear surface and the value of this maximum decrease as the Biot numbers increase;

- The temperature equalization between the slab sides occurs more slowly as the difference between the Biot numbers becomes greater.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Derivation of Formulae (16) and (22)

Appendix B. Derivation of Formula (23)

Appendix C. Notes on Eigenvalues

Appendix D. Model Implemented in Matlab Code

- % ---- Matlab code ----

- % heating and cooling of a homogeneous plate of a given thickness

- % as subjected to a constant force on the front side by rectangular pulse of known duration

- % method of separation of variables used to solve the problem

- % v1.0 created on 10 August 2025

- % plate parameters:

- % d—thickness, m

- % a—thermal diffusivity, m2/s

- % lambda—thermal conductivity, W/(m*K)

- % conditions:

- % To—initial temperature, °C

- % v—air velocity, m/s

- % power—forcing flux intensity, W

- % area—effective area of irradiation, m2

- % freq—sampling frequency, Hz

- % outputs: temperature increase over time for

- % dzeta = 0—heated (front side),

- % dzeta = (0,1)—inside the plate

- % dzeta = 1—unheated (back) side

- % th = 2—heating time, sec

- % tc = 58—cooling time sec

- % ---------------------------------------------------

- % PMMA—an example of material and parameters of measurements

- a = 1.05e-7; % PMMA

- lambda = 0.15; % PMMA

- d = 0.001;

- To = 25;

- power = 2500;

- area = 0.2*0.2;

- freq = 29.97;

- th = 10; % heating time in sec

- tc = 50; % cooling time in sec

- v = 0.2;

- dzeta = 1; % 0—for heated (front) side, 1—for unheated (back) side

- % --- calculations ---

- Alfa = 12.12 − 1.16*v + 11.6*sqrt(v);

- alfa1 = alfa % heat transfer coefficient, W/(m2*K)

- alfa2 = alfa

- Bi1 = alfa1*d/lambda + 0.001; % Biot number (Equation (12))

- Bi2 = alfa2*d/lambda + 0.001;

- tt = th + tc; % total time, sec

- Th = power*d/lambda; % ((Equation (12))

- tau = d^2/a; % ((Equation (12))

- tg = th*round(freq); % number of samples for heating phase

- N_terms = 20;

- theta_ss = (1+Bi2*(1-dzeta))/(Bi1+Bi2+Bi1*Bi2); % ((Equation (17))

- % ny = n*pi+atan(Bi1/ny)+atan(Bi2/ny); ((Equation (18))

- f = @(ny, n, Bi1, Bi2) ny—n*pi—atan(Bi1/ny)- atan(Bi2/ny);

- for n = 0:N_terms-1,

- If n == 0

- initial_value = n*pi + pi/2; % (conclusion from Appendix C)

- end

- [ny, fval, exitflag, output] = fsolve(@(ny) f(ny, n, Bi1, Bi2), initial_value);

- ny_n(n + 1) = ny;

- beta = atan(Bi1/ny); % ((Equation (19))

- beta_n(n + 1)=beta;

- theta = 2/(ny*sqrt(Bi1^2 + ny^2))/(Bi1/(Bi1^2 + ny^2) + Bi2/(Bi2^2 + ny^2) + 1); % ((Equation (20))

- theta_n(n + 1) = theta;

- psi = cos(ny*dzeta-beta);

- psi_n(n + 1) = psi;

- end

- % heating phase

- for t = 0:th*round(freq) − 1

- theta(t + 1) = theta_ss-sum(theta_n.*psi_n.*exp(-ny_n.^2*t/tau/freq));

- end

- % cooling phase

- for t = th*round(freq):tt*round(freq)-1

- theta(t + 1) = sum(theta_n.*psi_n.*(1-exp(-ny_n.^2*tg/tau/freq)).*exp(-ny_n.^2*(t-tg)/tau/freq));

- end

- temp = To + Th*theta; % ((Equation (15))

- plot(temp);

- %—end of code -

References

- Śniadecki, J. Pisma Rozmaite Jana Śniadeckiego. Tom 3 Zawierający Listy i Rozprawy w Naukach, (Various Writings of Jan Śniadecki. Volume 3 Containing Letters and Treatises in Sciences); Nakładem I Drukiem Jana Zawadzkiego Typografa Imperatorskiego Uniwersytetu: Vilnius, Lithuania, 1818; p. 205. Available online: https://bc.radom.pl/dlibra/publication/39788/edition/38555/content (accessed on 12 July 2025). (In Polish)

- Hobler, T. Ruch Ciepła i Wymienniki, (Heat Movement and Exchangers), 5th ed.; WN-T: Warsaw, Poland, 1979. (In Polish) [Google Scholar]

- Wark, K., Jr. Thermodynamics; McGraw-Hill Book Company: New York, NY, USA, 1998. [Google Scholar]

- Taler, J. Teoria i Praktyka Identyfikacji Procesów Przepływu Ciepła, (Theory and Practice of Identifying Heat Flow Processes); Ossolineum: Wrocław, Poland, 1995. (In Polish) [Google Scholar]

- Minkina, W. Theoretical Basics of Radiant Heat Transfer–Practical Examples of Calculation for the Infrared (IR) Used in Infrared Thermography Measurements. Quant. InfraRed Thermogr. J. 2021, 18, 269–282. [Google Scholar] [CrossRef]

- Szargut, J. (Ed.) Modelowanie Numeryczne pól Temperatury, (Numerical Modeling of Temperature Fields); WN-T: Warsaw, Poland, 1992. (In Polish) [Google Scholar]

- Vavilov, V.; Burleight, D. Infrared Thermography and Thermal Nondestructive Testing; Springer Nature: Cham, Switzerland, 2020. [Google Scholar]

- Wiśniewski, S.; Wiśniewski, T.S. Wymiana Ciepła, (Heat Transfer); WN-T: Warsaw, Poland, 1997. (In Polish) [Google Scholar]

- Gryś, S.; Minkina, W. Noninvasive Methods of Active Thermographic Investigation: Short Overview of Theoretical Foundations with an Example of Application. Energies 2022, 15, 4865. [Google Scholar] [CrossRef]

- Miculescu, M.; Cosmeleata, G.; Branzei, M.; Miculescu, F. Thermal diffusivity of materials using flash method applied on CoCr alloys. U.P.B. Sci. Bull. 2008, 70, 71–81. [Google Scholar]

- Kochanowski, K.; Oliferuk, W.; Płochocki, Z.; Adamowicz, A. Wyznaczanie dyfuzyjności cieplnej stali austenitycznej przy wykorzystaniu aktywnej termografii w podczerwieni, (Determination of thermal diffusivity of austenitic steel by active thermography in mobile telephony). Arch. Metall. Mater. 2014, 59, 893–897. (In Polish) [Google Scholar] [CrossRef]

- Wróbel, G.; Rdzawski, Z.; Muzia, G.; Pawlak, S. The application of transient thermography for the thermal characterisation of carbon fibre/epoxy composites. J. Achiev. Mater. Manuf. Eng. 2009, 36, 49–56. [Google Scholar]

- Parker, W.J.; Jenkins, R.J.; Butter, C.P.; Abbot, G.L. Flash method of determining thermal diffusivity, heat capacity and thermal conductivity. J. Appl. Phys. 1961, 32, 1679–1684. [Google Scholar] [CrossRef]

- Watt, D.A. Theory of Thermal Diffusivity of Pulse Technique. Br. J. Apply. Phys. 1966, 17, 231. [Google Scholar] [CrossRef]

- ASTM Standard E 1461–01; Standard Test Method for Thermal Diffusivity by the Flash Method. ASTM: West Conshohocken, PA, USA, 2022.

- Carslow, H.S.; Jaeger, J.C. Conduction of Heat in Solids; Oxford University Press: New York, NY, USA, 1959. [Google Scholar]

- Cape, J.A.; Lehman, G.W. Temperature and Finite Pulse-Time Effects in the Flash Method for Measuring Thermal Diffusivity. J. Appl. Phys. 1963, 34, 1909. [Google Scholar] [CrossRef]

- Taylor, R.E.; Cape, J.A. Finite Pulse-Time Effects in the Flash Diffusivity Technique. Appl. Phys. Lett. 1964, 5, 212. [Google Scholar] [CrossRef]

- Larson, K.B.; Koyama, K. Correction for Finite-Pulse-Time Effects in Very Thin Samples using the Flash Method of Measuring Thermal Diffusivity. J. Appl. Phys. 1967, 38, 465. [Google Scholar] [CrossRef]

- Clark, L.M.; Taylor, R.E. Radiation Loss in the Flash Method for Thermal Diffusivity. J. Appl. Phys. 1975, 46, 714–719. [Google Scholar] [CrossRef]

- Boulaoued, I.; Amara, I.; Mhimid, A. Experimental Determination of Thermal Conductivity and Diffusivity of New Building Insulating Materials. Int. J. Heat Technol. 2016, 34, 325–331. [Google Scholar] [CrossRef]

- Degiovanni, A. Correction de longueur d’impulsion pour la mesure de la diffusivité thermique par méthode flash (x). Int. J. Heat Mass Transf. 1987, 30, 2199–2200. (In French) [Google Scholar] [CrossRef]

- Maillet, D.; André, S.; Degiovanni, A. Les erreurs sur la diffusivité thermique mesurée par méthode flash: Confrontation théorie-expérience (Errors of thermal diffisivity measurement: Confrontation theory-experience). J. Phys. III Fr. 1993, 3, 883-809. (In French) [Google Scholar]

- Degiovanni, A.; Laurent, M. Une nouvelle technique d’identification de la diffusivité thermique pour la méthode flash. Rev. Phys. Appl. 1986, 21, 229–237. [Google Scholar] [CrossRef]

- Hay, B.; Filtz, J.R.; Hameury, J.; Rongione, L. Uncertainty of thermal diffusivity measurements by laser flash method. Revue Française de Métrologie. Int. J. Thermophys. 2005, 26, 1883–1898. [Google Scholar] [CrossRef]

- Hay, B.; Filtz, J.R.; Hameury, J.; Rongione, L. Estimation de l’incertitude de mesure de la diffusivité thermique par méthode flash-Application à cinq matériaux homogènes (Uncertainty assessment of thermal diffusivity measurements by flash method-Application to five homogeneous materials). Rev. Fr. Metrol. 2008, 14, 3–11. (In French) [Google Scholar]

- Chihab, Y.; Garoum, M.; Laaroussi, N. Thermophysical Characterization of Earthen Materials using the Flash Method. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 2534–2542. [Google Scholar] [CrossRef]

- Chihab, Y.; Garoum, M.; Laaroussi, N. A New Efficient Formula for the Thermal Diffusivity Estimation from the Flash Method Taking into Account Heat Losses in Rear and Front Faces. Int. J. Thermophys. 2020, 41. [Google Scholar] [CrossRef]

- Gryś, S.; Minkina, W.; Vokorokos, L. Automated characterisation of subsurface defects by active IR thermographic testing–Discussion of step heating duration and defect depth determination. Infrared Phys. Technol. 2015, 68, 84–91. [Google Scholar] [CrossRef]

- Zaręba, M.; Szczegielniak, T.; Jabłoński, P. Influence of the Skin and Proximity Effects on the Thermal Field in a System of Two Parallel Round Conductors. Energies 2023, 16, 6341. [Google Scholar] [CrossRef]

- Orlande, H.R.B.; Fudym, O.; Maillet, D.; Cotta, R.M. (Eds.) Thermal Problems and Inverse Techniques; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Bayazitoğlu, Y.; Özişik, M.N. Elements of Heat Transfer; McGraw-Hill Book Company: New York, NY, USA, 1988. [Google Scholar]

- Abramowitz, A.; Stegun, I.A. Handbook of Mathematical Functions with Formulas, Graphs, and Mathematical Tables; Dover Publications, Inc.: New York, NY, USA, 1972. [Google Scholar]

- Vavilov, V. Теплoвые метoды кoнтрoля структур и изделий радиoэлектрoники, (Thermal Methods of Control of Structures and Products of Radio Electronics; Радиo и связь, (Radio and Communication): Moscow, Russia, 1984. (In Russian) [Google Scholar]

- Monnier, J. Free convection with radiative thermal transfer of grey bodies: Analysis and approximation by finite element methods. Math. Models Methods Appl. Sci. 2000, 10, 1383–1424. [Google Scholar] [CrossRef]

- Efros, A.M. Some applications of operational calculus in analysis. Mat. Sb. 1935, 42, 699–705. [Google Scholar]

- Osiowski, J. Zarys Rachunku Operatorowego, (Outline of Operational Analysis); WN-T: Warsaw, Poland, 1981. (In Polish) [Google Scholar]

- Gradshteyn, I.S.; Ryzhik, I.M. Tables of Integrals, Sums, Series and Products, 17th ed.; Elsevier Academic Press: Cambridge, UK, 2007. [Google Scholar]

| Feature | MSV Solution (16) | Heat-Wave Solution (23) |

|---|---|---|

| Mathematical accuracy | Yes | |

| Generality of the solution | A specific formula is required for the case Bi1 = Bi2 = 0 | Specific formulae are required when Bi1 and Bi2 are equal or coincide with 0 |

| Mathematical complexity | Low—simple, identical formulae for all terms of the series | High—formulae of increasing complexity for successive heat waves |

| Dependence on Bi1 and Bi2 | Implicit—a transcendental equation must be solved to determine the eigenvalues | Explicit |

| Truncation error versus time | With a shorter time after the heating is switched on or off, a greater number of terms is required | The longer the time after the heat is switched on, the more waves are required |

| Truncation error versus the observation point | The front/rear surface results in the largest/smallest value | An odd/even number of waves results in a smaller error on the front/rear surface |

| Truncation error versus the Biot numbers | As the Biot numbers decrease, the truncation error increases | |

| Application scope | A sufficiently long time after switching the heating on or off (the impact of successive terms gradually decreases) | A sufficiently short time after the heating is switched on (the impact of successive waves increases over time) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jabłoński, P.; Kasprzak, T.; Gryś, S.; Minkina, W. Theoretical Approaches to the Heating of an Extensive Homogeneous Plate with Convective Cooling. Energies 2025, 18, 4785. https://doi.org/10.3390/en18174785

Jabłoński P, Kasprzak T, Gryś S, Minkina W. Theoretical Approaches to the Heating of an Extensive Homogeneous Plate with Convective Cooling. Energies. 2025; 18(17):4785. https://doi.org/10.3390/en18174785

Chicago/Turabian StyleJabłoński, Paweł, Tomasz Kasprzak, Sławomir Gryś, and Waldemar Minkina. 2025. "Theoretical Approaches to the Heating of an Extensive Homogeneous Plate with Convective Cooling" Energies 18, no. 17: 4785. https://doi.org/10.3390/en18174785

APA StyleJabłoński, P., Kasprzak, T., Gryś, S., & Minkina, W. (2025). Theoretical Approaches to the Heating of an Extensive Homogeneous Plate with Convective Cooling. Energies, 18(17), 4785. https://doi.org/10.3390/en18174785