1. Introduction

Industrial agricultural production systems, especially greenhouse complexes, are considered highly complex biotechnical systems. Their performance is assessed based on the ratio of energy consumption to the quantity, quality, and timeliness of marketable yields. Due to their high energy demands, particularly for microclimate regulation, greenhouses must operate under resource-efficient regimes—this is especially critical given the rising costs of energy carriers.

Improvements in greenhouse designs and microclimate control algorithms have been intensively developed in recent years, but mostly in countries of northern and central Europe. Unfortunately, in Ukraine, the implementation of closed-soil cultivation technologies significantly lags behind the best foreign examples. Often, outdated equipment and control systems for such equipment continue to operate. Additionally, modern foreign technologies for closed-soil cultivation are often accompanied by only the simplest stabilization algorithms that do not contribute significantly to saving energy resources—this issue is particularly noticeable in Ukraine, where the energy consumption of buildings used for closed-soil cultivation can reach 50–70%.

The automation of greenhouse complexes requires maintaining technological parameters at optimal levels, particularly under non-equilibrium thermodynamic conditions where dissipative space–time structures may form [

1]. In such systems, it is essential to identify and analyze the interrelationships between multiple variables that affect the microclimate within the greenhouse. By monitoring changes in microclimate parameters throughout the crop growth cycle, researchers can assess the influence of external disturbances, trace energy flow dynamics, and detect deficiencies in the technological regulation of vegetable cultivation processes.

Creating favorable conditions for plant growth is crucial, as approximately 90% of yield depends on maintaining an optimal microclimate. The key parameters include temperature, light intensity, CO2 concentration, and relative humidity. Achieving maximum productivity requires minimizing plant stress and maintaining a balanced interaction among these factors. Indicators of optimal plant development include uniform flowering and fruiting (generative development) as well as consistent leaf formation and root growth (vegetative development).

Given the increasing complexity of greenhouse systems and agricultural machinery, conventional methods of condition monitoring may not suffice [

2].

The management of such systems exhibits an intermittent nature, characterized by alternating phases of determinacy, stochasticity, and randomness. Chaotic processes occurring within the controlled object, frequently originating from intrinsic factors, may, in many instances, exert a constructive influence by facilitating the adaptation of complex systems through mechanisms of self-organization. The formulation of effective management strategies—topologically consistent, inherently resource-efficient, and resonant in their operational nature—necessitates a comprehensive investigation of the greenhouse complex employing recurrent analysis techniques.

In the present study, an automated control system was designed and implemented to ensure the optimal operational regime of technological equipment within a greenhouse environment. This system integrates advanced intelligent methodologies and supports both fully automated and semi-automated control modes. Predefined algorithmic control scenarios are employed to sustain optimal microclimatic conditions, thereby enhancing the efficiency and stability of greenhouse operations.

Research has shown that a greenhouse, as a structural component of a greenhouse plant, is a nonlinear control object with non-stationary dynamic characteristics. In view of the above, formalizing the relationship between technological parameters of such an object using classical approaches is a difficult task. That is why there is a need to use controllers whose settings are adapted to changing object parameters while providing an appropriate quality criterion for the functioning of the automation control system.

Real technological control objects are complex nonlinear systems. They can be characterized by various behaviors, including determinism, stochasticity, and chaos. Depending on the mode, it is necessary to apply a certain control strategy. Gao, Chen, Hou, and Xie [

3] proposed a synergistic approach to controlling complex process facilities, including the definition and description of areas of attraction of the attractor as centers of formation of dissipative spatiotemporal structures. These research results allow us to evaluate the behaviors of a complex system from the point of view of self-organization in cases of chaotic influences, both external and internal. However, the issue of synergistic management of complex systems, namely, the management of greenhouse complexes—remains unresolved. This may be because special attention should be paid not to the power of the system, but to the accuracy and nature of the informational support for decision-making [

4]. The accuracy of information support is crucial for developing an effective organizational and technical structure.

To synthesize effective strategies for controlling nonlinear open systems, methods such as pacification, backstepping [

5,

6], robust control [

7], and synergistic control [

8,

9] have been applied. Among these, the most promising for complex greenhouse objects are methods of synergistic management, which are the focus of this work [

10].

From the standpoint of unresolved issues, these studies describe algorithms for adaptive control of nonlinear systems, the application of complex synergistic approaches to nonlinear objects, and successful implementation of proposed solutions. This gives reason to assert that it is expedient to use these approaches, which enable obtaining physicochemical features of technological processes and reflect natural self-organization phenomena.

The proposed method combines three complementary techniques:

Fuzzy logic, used to formalize expert knowledge and to construct decision-making rules in the presence of uncertainty.

Neural network-based disturbance prediction, applied to forecast changes in external factors (such as temperature and humidity), enabling anticipatory regulation.

PI controller parameter optimization, employed for real-time adaptation of controller settings in response to environmental variability and efficiency criteria (e.g., energy consumption or temperature stability).

The developed system enables self-tuning of the controllers and ensures robust operation of the control object under dynamic conditions typical of greenhouse production.

By combining the synergistic approach with artificial neural networks, resource-saving modes of operation are offered. These modes are characterized by resistance to external disturbances, structural and parametric changes, and allow for effective searching of target states under various conditions. Resource-saving modes possess the necessary flexibility to adapt to changing goals and task variations, while ensuring high reliability and the ability to prevent critical situations.

The issues of optimal planning and synergistic control of multiparameter objects with input, output, and disturbance coordinates remain unresolved. Ref. [

9] describes modern approaches to object control methods based on synergistic control. Controlling by changing parameters can result in instability, symmetry violations, and boundary changes in a complex nonlinear system, leading to several possible behavioral scenarios after phase transitions. Controlling by changing initial conditions can lead the system to develop in several directions, including chaotic behavior. The difficulty with this approach lies in the fact that it is not always possible to change initial conditions, especially when regulation is rigidly fixed. Each method may be applied when the other cannot.

If there is a clear set of system characteristics and parameters to determine order parameters and no possibility to change input conditions, control by changing order parameters is used. Conversely, if the parameter set is too large or too complex to determine, control by changing initial conditions is necessary.

Moreover, ref. [

11] demonstrated that neuro-fuzzy control systems yield satisfactory results when applied to idealized models of real systems. This suggests that researching new approaches to managing complex nonlinear technological systems such as greenhouse complexes is advisable. This problem can be addressed by combining synergistic approaches and artificial neural networks. The synthesis of a neural network regulator based on a dynamic regulator with synergistic control law (parallel and sequential consideration of invariant manifolds for controlling temperature and humidity inside the greenhouse) can be solved by learning a given artificial neural network configuration.

Optimization of renewable energy systems such as photovoltaics and heat pumps is a key issue in modern building engineering. A similar approach is applied in agriculture, where artificial neural networks (ANNs) enable modeling of technological process efficiency [

12].

The necessity of implementing intelligent energy management systems, which are relevant for analyzing the performance of renewable energy systems including photovoltaics integrated with heat pumps, is emphasized by the authors. Utilizing bio-waste as a heat source is an important energy management strategy, as demonstrated in greenhouse heating studies [

13].

Additionally, modern control methods including expert systems, which are increasingly used in the energy industry, were analyzed [

14]. The integration of artificial intelligence with renewable energy systems can enhance operational efficiency and optimize energy management.

Effective automation of greenhouse systems involves handling control objects far from thermodynamic equilibrium and characterized by dissipative spatiotemporal structures. These systems exhibit hybrid dynamics—alternating between deterministic, stochastic, and chaotic behaviors. Therefore, advanced control strategies capable of accommodating nonlinear and non-stationary dynamics are required.

The objective of this research is to develop and validate intelligent, resource-efficient production regimes for greenhouse complexes by combining fuzzy logic, ANN prediction, and genetic algorithm optimization. This approach aims to enhance energy efficiency, stabilize agrotechnical parameters, and increase overall profitability.

2. Materials and Methods

Reviewing the operation of process facilities along with the peculiarities of the dynamics of natural disturbances and the states of living organisms, as well as the rational use of energy resources, will increase production profits. Experimental studies focusing on the main quality parameters of biological objects under varying microclimatic conditions have led to the establishment of mathematical models of plant states, which were later used to form control strategies [

15]. Appropriate technological conditions for plant growth and development are created within greenhouses. Ambient temperature and solar radiation intensity are the primary natural disturbances that affect plant vegetation in greenhouses. Therefore, developing an intelligent system capable of predicting these natural disturbances is a pressing task.

To synthesize and analyze the corresponding neural networks, we use the Statistica Neural Networks software package and a multilayer perceptron—a conventional approach for solving time-series forecasting problems [

16]. The main criterion for model performance is the minimization of neural network prediction errors. The best result was demonstrated by the MLP 2-8-1 network, which provided the effectiveness of 99.7% in all the samples it presented the forecast with the maximum accuracy.

For an 8 h forecasting horizon, the predictive models demonstrated generally high accuracy, with the mean squared error ranging from 1.19 °C to 3.43 °C. An intelligent forecasting system based on neural networks was developed to predict external temperature and solar radiation. The most accurate ambient temperature prediction was achieved by the MLP 2-8-1 architecture, yielding an effectiveness of 99.70% across all samples. In the case of solar radiation forecasting, the best performance was obtained with the MLP 2-9-1 architecture, which achieved an effectiveness of 99.74% across all samples. The proposed intelligent system enables maximum precision in predicting external natural disturbances and radiation, which are subsequently incorporated into the control strategy formulation.

Furthermore, an intelligent greenhouse temperature control system was designed, integrating temperature and solar radiation analysis with forecasting results. This approach facilitates the development of adaptive control strategies for greenhouse complexes, aiming to optimize microclimate regulation while reducing energy consumption in agricultural production.

A method for neural network prediction of natural external disturbances in biotechnical objects was described in [

17].

Each type of vegetable crop has specific biological characteristics that influence its growing technology. For example, tomato plants are thermophilic, and according to cultivation technology, the air temperature in the greenhouse varies depending on the plant development phase. After transplanting seedlings, the optimal night temperature is 15–16 °C, while during the day it should be 18–20 °C in cloudy weather and 20–22 °C in sunny weather. During the flowering phase, the optimal night temperature increases to 16–18 °C, with day temperatures of 18–20 °C in cloudy weather and 22–24 °C in sunny weather. In the fruiting period, the temperature requirements rise further to 18–20 °C at night, 20–22 °C in cloudy weather, and 24–26 °C in sunny weather. Tomato plants are very sensitive to frost; small frosts of −0.5 °C to −1 °C and even short-term positive temperatures between 1 and 3 °C can cause plant death. Additionally, soil temperature should be maintained at 20–25 °C, with air humidity at 60–70% and soil moisture at 70–80%.

The parametric diagram of the temperature and humidity regime in the greenhouse is shown below (

Figure 1):

The authors synthesized a mathematical model of the greenhouse as a control object; its structure is shown in

Appendix A.

The automation of greenhouse complexes requires maintaining technological parameters at optimal levels, particularly under non-equilibrium thermodynamic conditions where dissipative space-time structures may form [

18]. In such systems, it is essential to identify and analyze the interrelationships between multiple variables that affect the microclimate within the greenhouse. By monitoring changes in microclimate parameters throughout the crop growth cycle, researchers can assess the influence of external disturbances, trace energy flow dynamics, and detect deficiencies in the technological regulation of vegetable cultivation processes.

Creating favorable conditions for plant growth is crucial, as approximately 90% of yield depends on maintaining an optimal microclimate. The key parameters include temperature, light intensity, CO2 concentration, and relative humidity. Achieving maximum productivity requires minimizing plant stress and maintaining a balanced interaction among these factors. Indicators of optimal plant development include uniform flowering and fruiting (generative development) as well as consistent leaf formation and root growth (vegetative development).

Given the increasing complexity of greenhouse systems and agricultural machinery, conventional methods of condition monitoring may not suffice [

19].

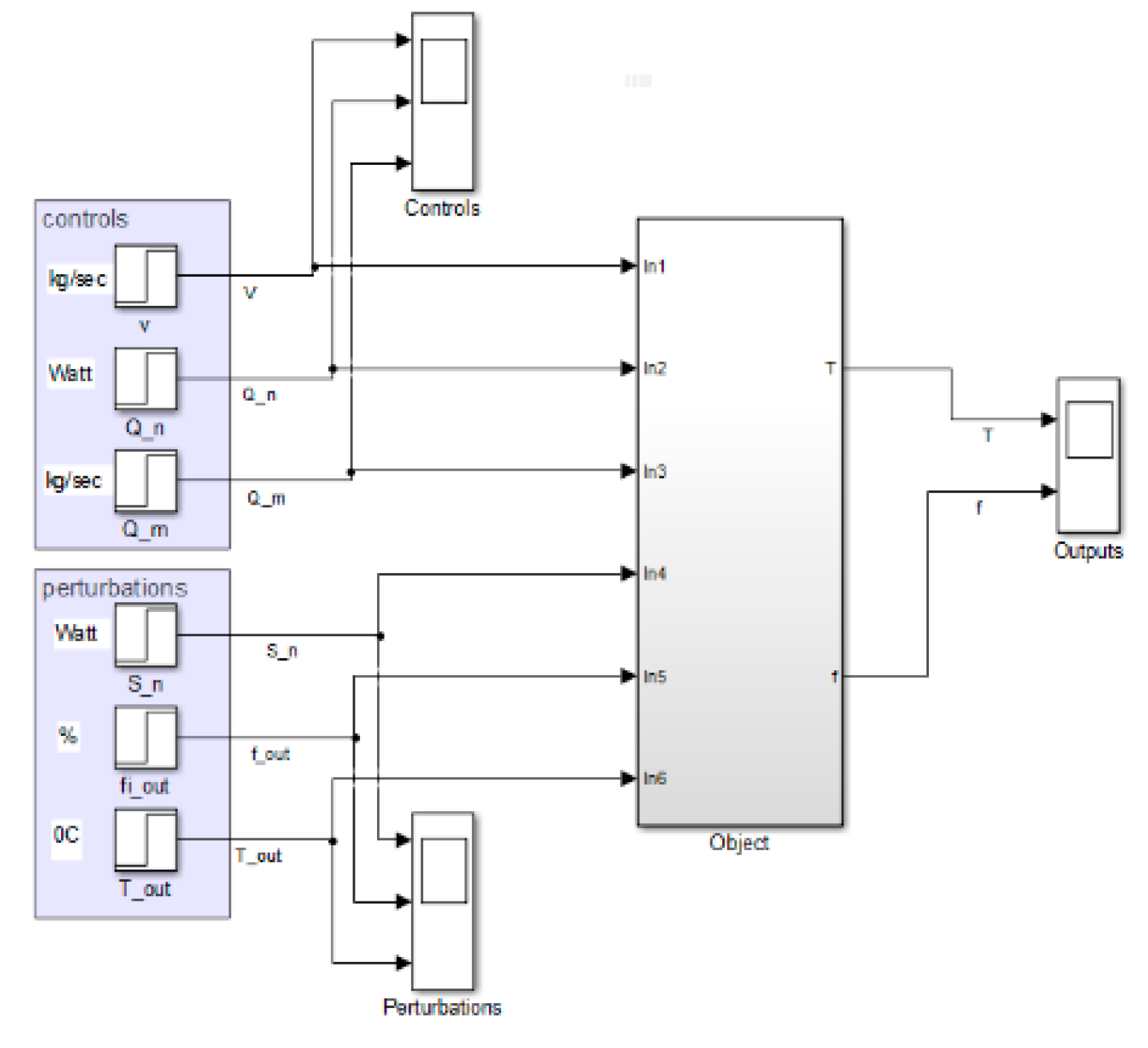

Based on previous research, a model of the greenhouse complex (

Figure 2) was developed, accounting for external influences (solar radiation intensity, external temperature, and air humidity) as well as control variables (modes of operation).

Most technological processes in agriculture are multidimensional management objects with complex relationships between variables characterized by non-stationary dynamic characteristics. This causes a deterioration in control quality, as typical systems’ control depends on the changing dynamics of the object over time. Therefore, there is a need to build regulators whose parameters adapt so that the accuracy and quality of the automatic regulation system remain constant despite changes in object parameters.

Continuity of optimal control can be achieved by synthesizing an adaptive system with a reference model, the output of which describes the desired control goal for a given input action. However, the drawback of such a system is the difficulty of deriving a reference mathematical model that completely and accurately corresponds to the object.

The authors developed an automatic control system where the optimal regulator settings are determined using a genetic algorithm, considering system limitations and the chosen control criterion.

Since the studied object is non-stationary, the proportional–integral (PI) regulator executes control actions according to the selected criterion to maintain the process within specified limits.

Values of the error and integral of error were obtained in the Simulink environment and input into a neuro-fuzzy control program to determine optimal PI controller settings. A genetic algorithm—a method inspired by natural selection involving random selection, combination, and mutation—was applied to optimize these settings. The genotype for the problem consisted of a set of regulator parameters.

The main hypothesis is that greenhouse complexes are complex multiparameter systems, whose efficiency is expressed by the ratio of production energy consumption to the volume, quality, and timing of marketable products. Constructing a complete flow graph of the greenhouse complex, a path matrix, and an auxiliary matrix showed that the studied object exhibits all characteristics of a complex system with distinct subsystems. Since each subsystem has its local goals, conflicting situations may arise in the overall system’s functioning. Therefore, coordinating the subsystems’ operation is necessary, ensuring that controls optimal for each subsystem’s efficiency criteria are also optimal for the overall process. This confirms the hypothesis about the complexity of the researched object and the need to isolate subsystems and apply a coordination approach to find rational, optimal cultivation modes.

To develop and analyze the implementation of the energy efficiency control system for a greenhouse facility, experimental data and the list of main electrotechnological equipment were obtained from the greenhouse complex of Public Joint Stock Company (PJSC) “Kombinat Tepluchnyi”, located in Kalynivka (urban-type settlement), Brovary District, Kyiv Region, Ukraine. The cultivated crop in the study was tomatoes.

Experimental results showed that the measured parameters change nonlinearly, and the processes are non-stationary, which greatly complicates further studies on the influence of maintained microclimate parameters on energy flows during vegetable cultivation.

3. Results

The results of this work led to the development of scientifically based, resource-efficient modes of vegetable production in greenhouse complexes. These modes are determined by considering predicted changes in external natural disturbances and information about the biological component’s quality, which minimize resource consumption and maximize enterprise profit. A conceptual model of the object (the greenhouse complex and the cultivation process) was constructed, highlighting technological, material, and energy flows.

Based on mathematical models, optimal operation modes of equipment were determined using a global profit maximization criterion, while ensuring product quality according to previously developed models analyzing the state of the biological component. The developed methods, models, and techniques were implemented at the real enterprise PJSC Kombinat Teplichnyi, enabling evaluation of the decisions’ effectiveness and approbation of resource-efficient mode determination. This confirmed the possibility of extending these methods to other biotechnical agricultural objects both in Ukraine and abroad.

The expected outcomes of the project, namely resource-efficient cultivation modes for vegetable crops in greenhouse complexes, are scientifically substantiated and supported by the authors’ previous results, including patents and test reports. A comprehensive approach to the cultivation process and the determination of optimal electrotechnological equipment operation modes, together with coordinated management of individual cultivation technology subsystems, increased company profits by reducing energy consumption while maintaining product quality.

Modern information technologies enable rapid and accurate monitoring of biological component states, and neural network modeling and forecasting methods allow identification of natural disturbance changes under uncertainty. The developed software and informational support for vegetable cultivation regimes represent a valuable practical and methodological advancement that can be extended to other agrarian facilities in Ukraine and internationally. This is evidenced by the authors’ long-term scientific collaboration with colleagues from Warsaw University of Life Sciences and the Polish Academy of Sciences.

Comparison of the project’s expected results with domestic and foreign analogs supports considering the development of resource-efficient cultivation modes based on neural network disturbance prediction, biological state monitoring, optimization algorithms for electrotechnological equipment operation, and profit maximization criteria as a novel and promising scientific direction nationally and globally. Most foreign scientific works focus on cultivation control systems using stabilization algorithms aimed solely at maintaining fixed microclimatic parameters. This approach is inadequate in conditions of rising energy prices since it does not incorporate forecasts of external weather conditions or plant state changes, which this project uniquely addresses.

Furthermore, leading greenhouse enterprises prefer to purchase ready cultivation technologies, which limit opportunities to intervene and optimize electrotechnological equipment operation modes. The scientific results obtained by the authors can be adapted for other agricultural production facilities (e.g., poultry complexes, pig farms, mushroom cultivation), thanks to their high adaptability and dedicated software and informational support.

The configuration algorithm for the adaptive neural controller comprises the following stages: (i) development of the automation system architecture; (ii) acquisition of object state data under perturbation conditions; (iii) formulation of production rules that account for technological characteristics and the sequencing of input/output parameters; (iv) design of the neural network architecture and selection of appropriate training methods; (v) training of the neuro-fuzzy expert system; and (vi) validation of the automation control system through simulation-based testing.

Optimal PI controller settings were identified using control object data and expert knowledge expressed in IF–THEN rule form within the expert system. The algorithm was implemented following fuzzy logic theory, using the Fuzzy Logic Toolbox software, which employs Mamdani’s algorithm [

20]. According to this approach, optimal controller settings were

Kp = 12.85 and

Ti = 0.075.

The fuzzy output system derives conclusions about the object’s state based on fuzzy conditions and premises (e.g., uncertainty in external natural disturbances), also considering current object status information.

To ensure neuro-fuzzy decision support system functionality, operational rules were developed (

Figure 3).

For instance, when the external temperature falls within a specific range at certain times, and the internal temperature is within a given interval, corresponding heating circuits are activated or deactivated accordingly.

The intelligent control system structure for biotechnological objects was optimized using a neural network prediction unit with noise filtration and a fuzzy controller operating in real-time. The approach distinguishes itself by employing fuzzy logic mathematics to predict and coordinate energy consumption and supply processes (

Figure 4).

Fuzzy Logic Designer software is used to tune the fuzzy controller. Inputs specify temperature ranges that adjust the actuator valve’s rotation angle (

Figure 3). Based on fuzzy rules, the optimal rotation angle is selected according to greenhouse temperature. Simulation results comparing the intelligent control system using a fuzzy controller to a traditional automatic control system with an OVEN TRM148 regulator show reduced adjustment time.

As it is shown in [

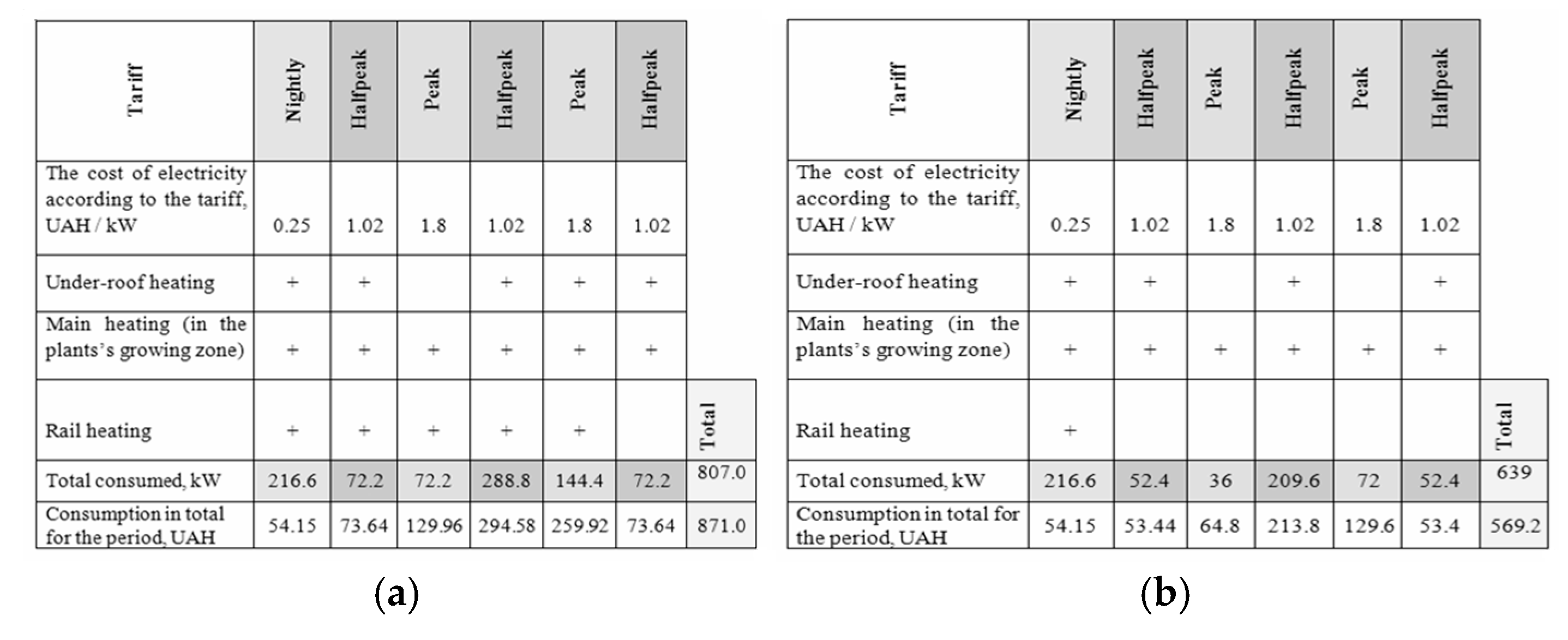

1] the engine load during the day directly influences electricity costs, particularly in greenhouse heating system where engines consume significant electrical power. When engine load is high, it indicates greater energy consumption, which leads to higher electricity usage and, consequently, increased electricity costs. Conversely, during periods of lower engine load, less electricity is required, resulting in reduced operational costs. The greenhouse is equipped with three heating circuits, which are controlled using a fuzzy inference system. Expert rules were developed that take into account temperature and humidity values—the main microclimate parameters—and, based on their values, a decision is made to activate one or another heating circuit. This approach has led to a reduction in the electricity consumption of the heating system.

Implementing the fuzzy regulator improves the control system by increasing energy efficiency and reducing economic costs associated with heating and humidification. Comparative results (

Figure 5) under initial conditions of external temperature below −7 °C and greenhouse temperature at 20 °C demonstrate this improvement.

By comparing data from

Figure 5a,b, it is concluded that neuro-fuzzy decision support system implementation for electrotechnical equipment control modes reduces electricity costs by 25–30%.

The genetic algorithm, an optimization method based on random selection, combination, and variation mechanisms akin to natural selection, enhances the automation system’s adaptation process since it requires no special methods for explicit object parameter identification [

21]. The search for optimal PI controller settings is based on a classical genetic algorithm where the initial chromosome population is randomly selected and fitness evaluated via membership functions. The algorithm terminates upon reaching the optimal integral criterion value.

For control, the genotype comprises a set of controller settings. The optimal settings identified are Kp = 13.07 and Ti = 0.069.

Quality of transients in systems with different control parameters was evaluated using Matlab Simulink (Version R2024a) [

22] (

Figure 6). Quantitative indicators of transient quality refer to numerical measures that evaluate the performance of a system during the transient phase —the period between the initial response to an input (or disturbance) and the moment the system reaches a steady state. These indicators help determine how quickly, accurately, and stably a system reacts to changes. Such indicators as Overshoot (%) and Settling Time (s) are essential for designing and tuning control systems, as they provide insights into system responsiveness, stability, and accuracy under dynamic conditions.

Overshoot indicates how aggressively the system responds. A high overshoot may lead to instability or unwanted oscillations and Settling Time—how fast the system stabilizes after a change. Quantitative indicators of transient quality are provided in

Table 1.

4. Discussion

This study proposes a resource-efficient greenhouse microclimate control system that integrates neural network-based forecasting of external disturbances, a neuro-fuzzy decision support system, and PI-controller parameter optimization using a genetic algorithm. The proposed approach ensures a high level of adaptability and control accuracy under changing environmental conditions. To assess the system’s effectiveness, we compare it with several existing solutions presented in recent scientific literature.

In the work of Robles Algarín et al. [

23], a low-cost greenhouse control system based on a classical fuzzy controller integrated with web monitoring is implemented. Despite its simplicity, this system lacks the capability to adapt to rapidly changing external disturbances. In contrast, our architecture combines fuzzy logic with neural networks and evolutionary PID tuning, enabling greater microclimate stability.

The adaptive control system described by Nicolosi et al. [

24] is based on variable control rules and can respond to environmental fluctuations. However, it does not incorporate forecasting models or machine learning techniques. Unlike this, our system enables proactive regulation through neural network forecasting, allowing not only a reaction to but also an anticipation of the controlled object’s behavior.

Huang et al. [

25] applied a modified PI controller with a single neuron for temperature and humidity regulation in vegetable greenhouses. Although this approach improves the system’s dynamic performance, the absence of mechanisms for handling complex external influences and parameter optimization limits its applicability in variable conditions. In comparison, our system additionally employs a genetic algorithm for online optimization, ensuring stable operation even under unexpected weather changes.

The intelligent control system proposed by Lee et al. [

26] uses hybrid artificial intelligence models to make decisions about greenhouse conditions. It shows great potential for improving agricultural resilience and efficiency. However, its implementation complexity and computational cost may hinder widespread adoption. Our system achieves a balanced integration of intelligent subsystems with acceptable computational complexity, making it suitable for practical deployment.

A similar approach is used by Chen et al. [

27], where microclimate control is based on a combination of system dynamics and machine learning techniques. This system is effective for strategic planning but less flexible in real-time operation. Our design, in contrast, focuses on real-time forecasting and adaptation to short-term fluctuations, which is critical for the stable functioning of greenhouse operations.

The study by Riahi et al. [

28] proposes an energy-efficient greenhouse system powered by renewable energy sources. While it offers advantages in terms of energy autonomy, its control logic is relatively simple and lacks complex adaptation to microclimatic conditions. In our system, by contrast, the primary focus is on high-precision and flexible microclimate control, enabling efficient use of both resources and energy.

Finally, the lighting system presented by Serale et al. [

29] employs a supervisory strategy to enhance energy efficiency by utilizing natural light. However, as it is solely focused on lighting control, its capabilities in terms of multiparameter microclimate control are limited. Our proposed system encompasses a full range of controllable parameters—including temperature, humidity, lighting, and others—providing a comprehensive control approach.

In general, the simulation results (

Figure 6) show that a neural network controller, synthesized based on a genetic algorithm and fuzzy logic system, demonstrates better quality indicators for transient responses compared to conventional approaches. It also performs reliably across a wide range of parameter variations, including temperature, air humidity in the greenhouse, and the capacity of the air heating system. It is capable of adapting to both parametric and external disturbances.

The practical value of the research lies in applying this approach to artificial systems characterized by the ideology of unification in the processes of directed self-organization and control, which has also been the subject of earlier studies in systems for assessing the operational quality of machines and reliability indicators [

19,

30]. The invariant manifolds considered in this work enabled the construction of control laws for greenhouse temperature and humidity regulation, supporting optimal operating conditions. Consequently, predictive information can be generated to facilitate the design of a variety of such systems.

The use of artificial neural networks (ANNs) in greenhouse complexes—specifically their ability to learn from experimental datasets and perform parallel information processing—ensures high system performance. The developed neural network controller includes an original problem-solving algorithm that generalizes temperature and humidity data received from the greenhouse. The algorithm is formulated independently of time. Furthermore, the study enables simultaneous real-time monitoring of ongoing processes in operational facilities, made possible through distributed internal process handling.

Following synthesis, the neural network controller was placed within a closed-loop control system, and its performance was evaluated. The integrated use of fuzzy logic and neural network structures allowed the synthesis of an intelligent greenhouse control system characterized by parallel pattern computation and adherence to internal self-organization principles.

A current limitation of this study is the insufficient examination of ANN redundancy, which is crucial to ensure functionality during communication loss or control disruptions.

A system-experimental study of the greenhouse complex identified its main components, described their characteristics, and examined energy flows within them. Relationships were established among the complex’s subsystems, including correlations between technological parameters and the heating system, the influence of external disturbances on production parameters, and the interdependence between electricity and gas consumption with external environmental conditions. Based on this, a neural network mathematical model of electrotechnical system operation under environmental uncertainty was developed for the first time. A situational and target structural diagram of the vegetable production process was also constructed, establishing a novel scientific concept.

The authors developed a mathematical model of the technological process of vegetable cultivation in greenhouse complexes, incorporating energy flows and various modes of electrical equipment operation, using a conceptual object model. Based on identified issues in resource conservation and prior studies, they designed a structural–functional scheme and algorithmic framework for controlling equipment operation and cultivation modes. The proposed system includes a neural network forecasting module for external disturbances, a decision support block that incorporates both the biological state (vegetable crop conditions) and technological growing requirements, and a neuro-fuzzy control subsystem with a genetic algorithm-based optimization module.

Through the combination of modern disturbance forecasting techniques, a synergistic control algorithm, and a fuzzy expert subsystem, the researchers developed a mathematical framework for determining resource-efficient modes and optimizing control parameters.

A conceptual model of the greenhouse complex was also developed to reflect both its static and dynamic properties. Class and state diagrams were used to describe its behavioral features and potential actions. The model employs a decomposition-based structure. Formalization yielded a mathematical framework for managing energy flows. Sequence diagrams were used to depict process interactions on a timeline aligned with technological regulations. These diagrams mapped stage sequences and their dependency on equipment characteristics and process control parameters. From these static models and the microclimate control system, key parameters were identified and validated at the production site to improve energy efficiency.

Despite chaotic dynamics and external influence, greenhouse systems exhibit internal organization. This occurs when dominant system elements, referred to as attractors, affect the overall system. Among these, internal air temperature stands out as a primary attractor due to its critical role in plant development. Therefore, synergistic processes are described using a limited set of parameters (e.g., air temperature, humidity, solar radiation). These parameters serve as inputs for control laws that govern greenhouse electrotechnical equipment operation.

These control laws are fulfilled by regulating indoor temperature and humidity using greenhouse heating power, ventilation air exchange, fogging system productivity, and absorbed solar radiation. These indoor parameters are also significantly influenced by outdoor temperature and humidity.

The control functions were implemented via fuzzy regulators. The fuzzy adaptive temperature controller is a two-level system comprising a fuzzy controller and an intelligent adaptation loop. The adaptation mechanism uses logic-based transitions between temperature regimes from the greenhouse model’s logic block. It retrieves the relevant regime’s membership function and target value, determined by a synergistic sensor, and passes these to the fuzzification units. The fuzzy controller maintains a fixed rule base, applying Mamdani inference and center-of-gravity defuzzification.

Implementation was conducted using MATLAB’s built-in problem-solving tools. Due to the complexity of modeling greenhouse microclimate processes, an ANN was constructed using classical mathematical techniques to forecast energy consumption. Passive experimental data were applied to the network input. The goal was to predict electricity and heat consumption for specific cultivation processes. The Bayesian method of linear regression was selected for ANN training due to its low root-mean-square error. As a result, predicted values for gas and electricity consumption allowed for 10–15% energy savings compared to existing methods.

It was confirmed that a key feature of ANN-based control is the presence of forward and feedback loops. In intelligent greenhouse control systems, the following principles must be observed:

- -

Close informational interaction with the external environment through structured communication channels;

- -

Fundamental system openness for evolving intelligence and behavior improvement;

- -

Availability of forecasting mechanisms for environmental conditions and internal behavior in dynamic, innovative contexts;

- -

A multi-level hierarchical structure, where higher layers require lower precision but exhibit greater intelligence;

- -

The ability to function despite the disconnection or loss of higher-level management signals.

Through ANN implementation, the network controller was “trained,” integrated into a closed control system, and evaluated. Results show that the ANN-based regulator, derived from a synergistic dynamic model, demonstrated superior transient response quality versus traditional methods. It also maintained adaptability across wide parameter variations, including temperature, humidity, fogging capacity, solar radiation absorption, heat of vaporization, and ventilation rates.

Controlling chaotic behavior—one of the most challenging aspects—was addressed using nonlinear dynamics, which provided both qualitative and quantitative efficiency metrics. These insights laid the groundwork for modern resource-efficient systems using synergistic control in chaotic greenhouse processes.

While several greenhouse models and analytical tools already exist, their limitations are increasingly apparent given the complexity of current greenhouse operations. Classical models are often inadequate for tasks involving real-time optimization and adaptation. Modern greenhouse systems—complex, organizationally layered, and technologically intensive—require new forecasting strategies based on deterministic chaos theory to manage irregular and dynamic system behavior.

The combined use of ANN and synergistic approaches enabled the synthesis of a robust intelligent control system for greenhouse environments. A current limitation is the insufficient analysis of ANN redundancy, necessary for ensuring uninterrupted functionality. Future research will address full modeling of all technological parameters and material flows in greenhouse operations.

Ukrainian agribusinesses face challenges such as rising energy costs and heavy taxation, which hinder modernization. Energy costs in greenhouse crop production may reach up to 80% of total production expenses. Therefore, implementing resource-efficient modes for managing energy flows is crucial.

Implementation of the proposed resource-efficient cultivation regimes may result in savings of up to 13% in natural gas, up to 10% in electricity, and an 8–10% improvement in maintaining agrotechnical parameters, ultimately increasing profitability by 5–9%.

The scientific and technical solutions proposed in this study have been translated into formal recommendations for greenhouse enterprises. The proposed methods can also be extended to other agricultural biotechnical systems.

Market analysis shows promising demand for these results. Greenhouse enterprises in Ukraine, Poland, the Czech Republic, Slovakia, and Belarus are actively seeking scientifically grounded, cost-effective technologies to replace costly Dutch alternatives. The implementation act received from the “Greenhouses of Ukraine” Association confirms industry readiness to adopt these innovations.

Experimental investigations of the greenhouse microclimate were carried out under passive observation conditions, along with performance testing of the heating control subsystem equipped with a neuro-fuzzy regulator. An official act of implementation confirmed the system’s readiness for broader application in other subsystems of the greenhouse complex during the initial phases of tomato production.

The practical significance of the synergistic approach in artificial systems lies in its foundation on the unified principles of directed self-organization and intelligent control. By applying analytical design methods for aggregated regulators, the research enabled the development of effective control strategies for greenhouse management.

As a result, it becomes possible to generate predictive data that supports the design and implementation of a wide range of intelligent, adaptive control systems.

In summary, the proposed system combines the strengths of existing solutions, including fuzzy logic, neural networks, genetic algorithm, and forecasting mechanisms. This integration enables high precision, adaptability, and energy efficiency under real-world greenhouse production conditions.

5. Conclusions

The non-stationary nature of greenhouses as automation objects necessitates the use of adaptive algorithms for tuning controllers within automatic control systems. This study confirmed that classical control strategies are insufficient under such dynamic conditions and must be supplemented with intelligent methods of regulation.

Comparative analysis of different tuning methods for the PI controller yielded the following optimal parameters:

- -

Genetic algorithm: Kp = 13.072, Ti = 0.069;

- -

Fuzzy inference-based adaptation: Kp = Kp = 12.85, Ti = 0.075;

- -

Traditional tuning method: Kp = 13.3, Ti = 0.0009.

Among these, the genetic algorithm demonstrated the best performance. In addition to its adaptation capabilities, it provided the most favorable transient response—characterized by only 1.5% overshoot and a settling time of 6500 s—outperforming both fuzzy and traditional approaches.

This paper presents a method for developing an intelligent control system based on artificial neural networks and fuzzy control. The research results demonstrate that the proposed system significantly enhances energy efficiency. Specifically, it enables a reduction in energy consumption by 10–12% compared to conventional positional stabilization algorithms. It improves the effectiveness of decision-making regarding the operating modes of electric drives used in greenhouse subsystems such as heating, ventilation, and humidification.

The integration of intelligent control elements, including fuzzy logic and neural networks, provides a robust foundation for adaptive greenhouse management under varying environmental and internal conditions. This approach contributes to both resource conservation and production efficiency in modern greenhouse complexes.