Optimizing Load Dispatch in Iron and Steel Enterprises Aligns with Solar Power Generation and Achieves Low-Carbon Goals

Abstract

1. Introduction

- Integration of load scheduling with estimated solar generation in a steelmaking context, enabling renewable utilization even in the absence of measured solar data.

- A practical optimization framework based on demand response and linear programming, designed to balance solar utilization, load priorities, and grid dependence.

- Introduction of a three-dimensional evaluation system (SUR, GIF, EE) to assess system performance from both energy efficiency and grid interaction perspectives.

- Simulation-based validation using real industrial load data. The datasets used in this study, including the User Gate Load Data and User Loop Load Data, are described in detail in the Appendix A, demonstrating the potential for significant solar utilization improvements under realistic operating constraints.

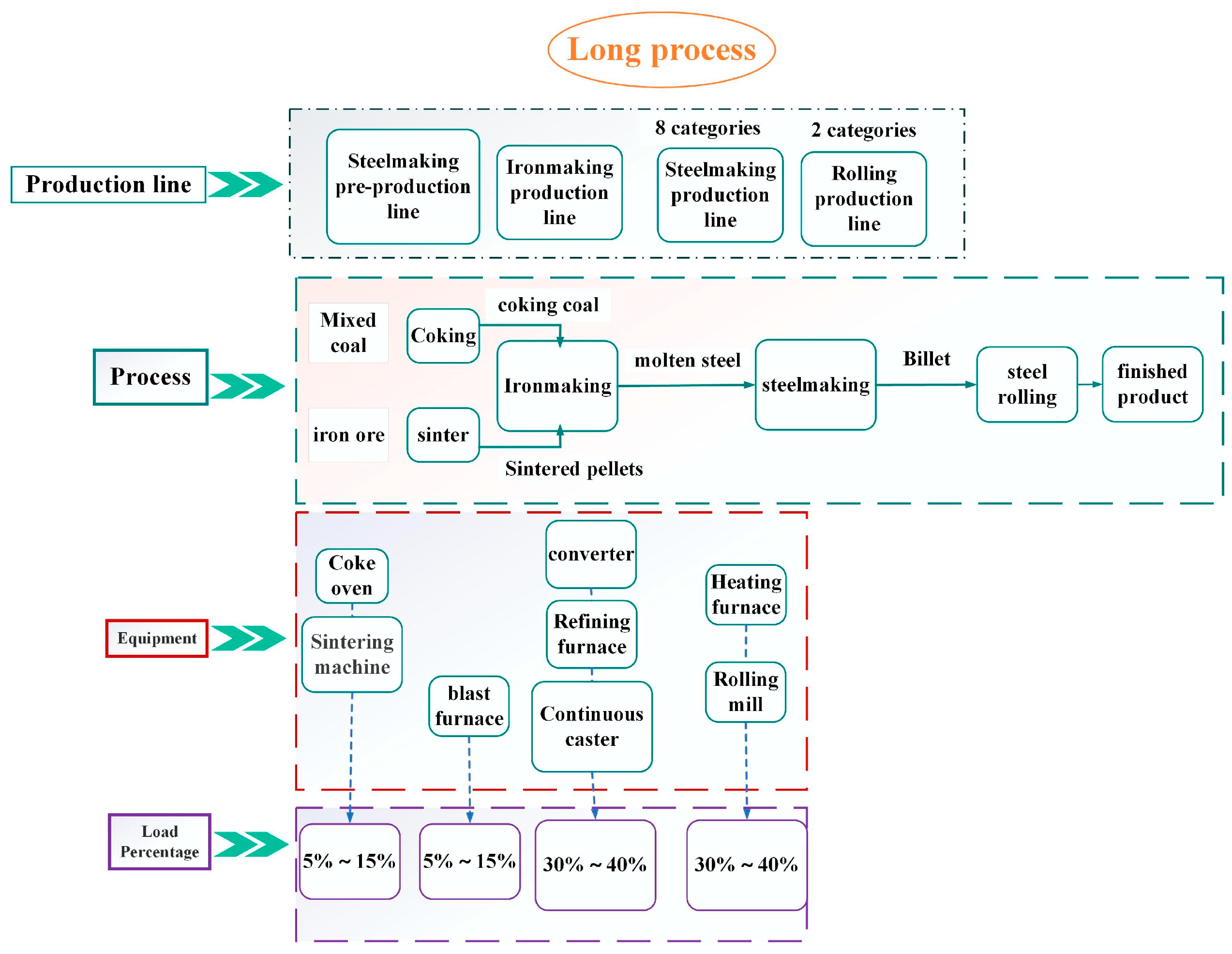

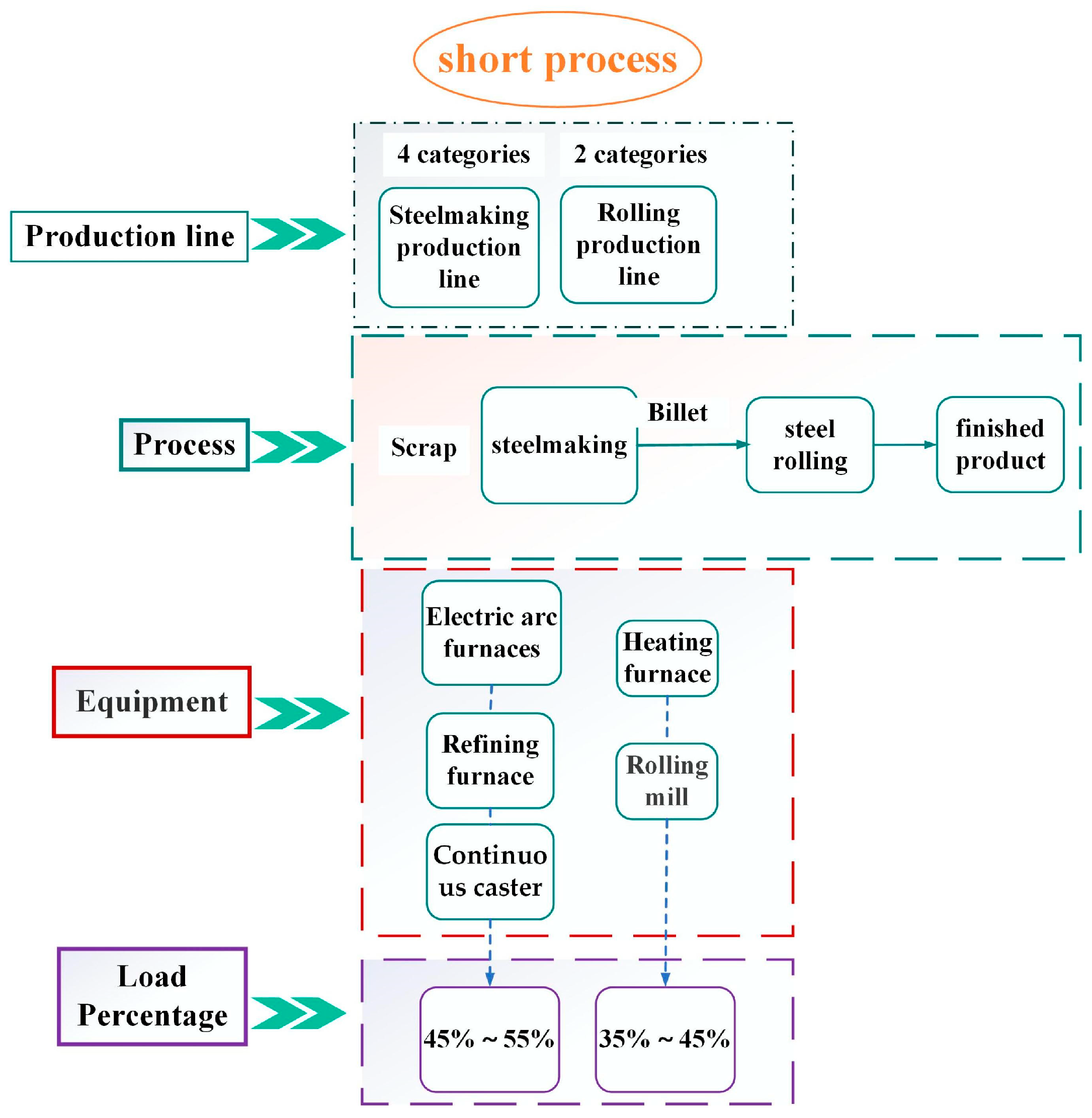

2. Data Collection Methodology and Industry Mechanism Models

2.1. Data Collection

- System Inquiries: Accessing user systems remotely to retrieve data such as wiring diagrams and power loads.

- Telephone Inquiries: Conduct interviews to clarify operational details and verify available energy data.

- Questionnaires: Distributing structured questionnaires to gather insights into the following:

- –

- User wiring diagrams.

- –

- Historical power loads.

- –

- Major energy-consuming equipment.

- –

- Historical responses to energy management programs, such as demand response events.

- Energy Consumption Profiles: Measuring and recording the energy consumption of various equipment.

- Production Control Systems: Examining internal production systems to evaluate how energy usage aligns with production schedules.

- Adjustable Capacity Analysis: Assessing the actual flexibility in the production line and equipment to determine the potential for load adjustments.

2.2. Accurate Construction Industry Mechanism Models

3. Methodology

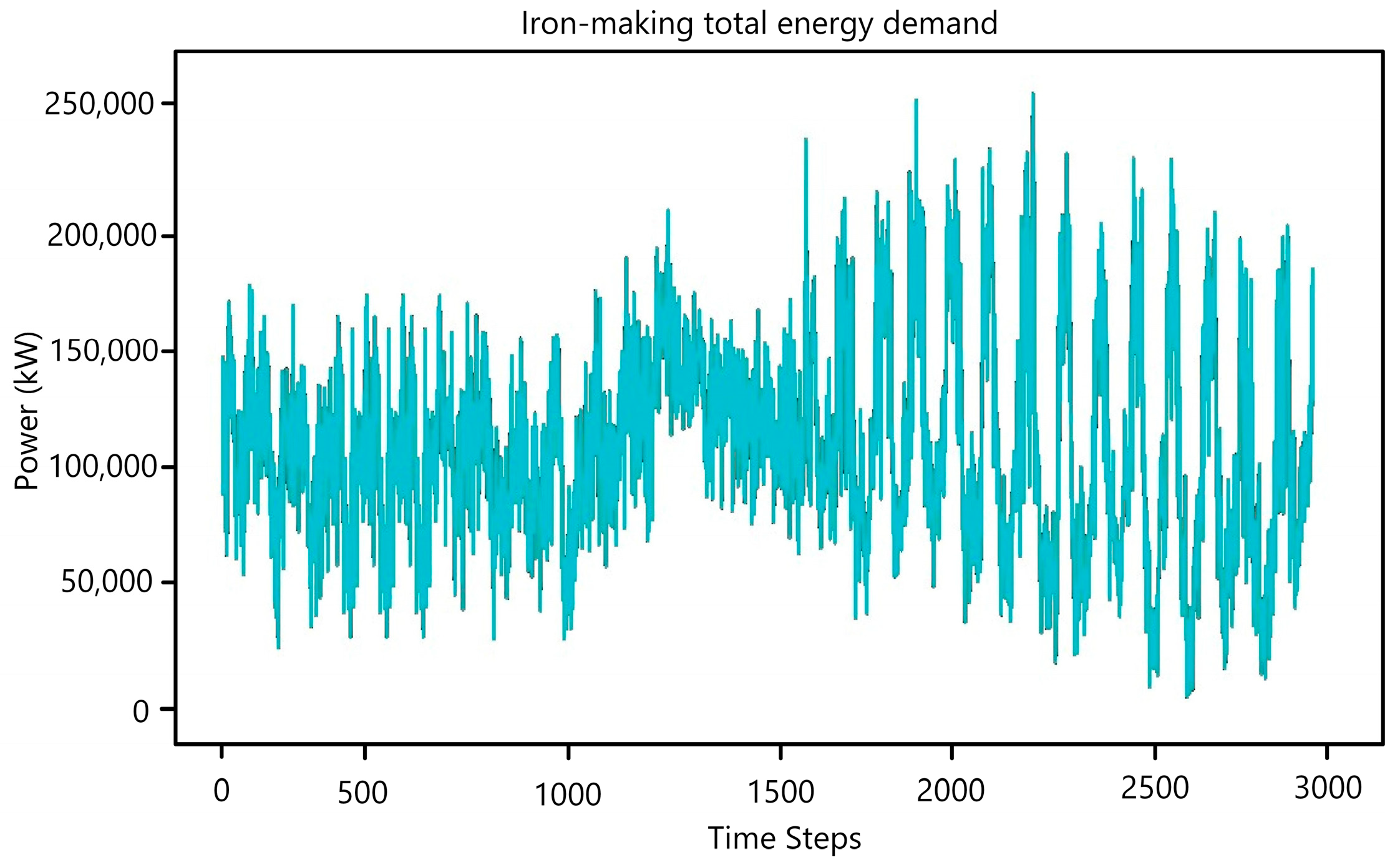

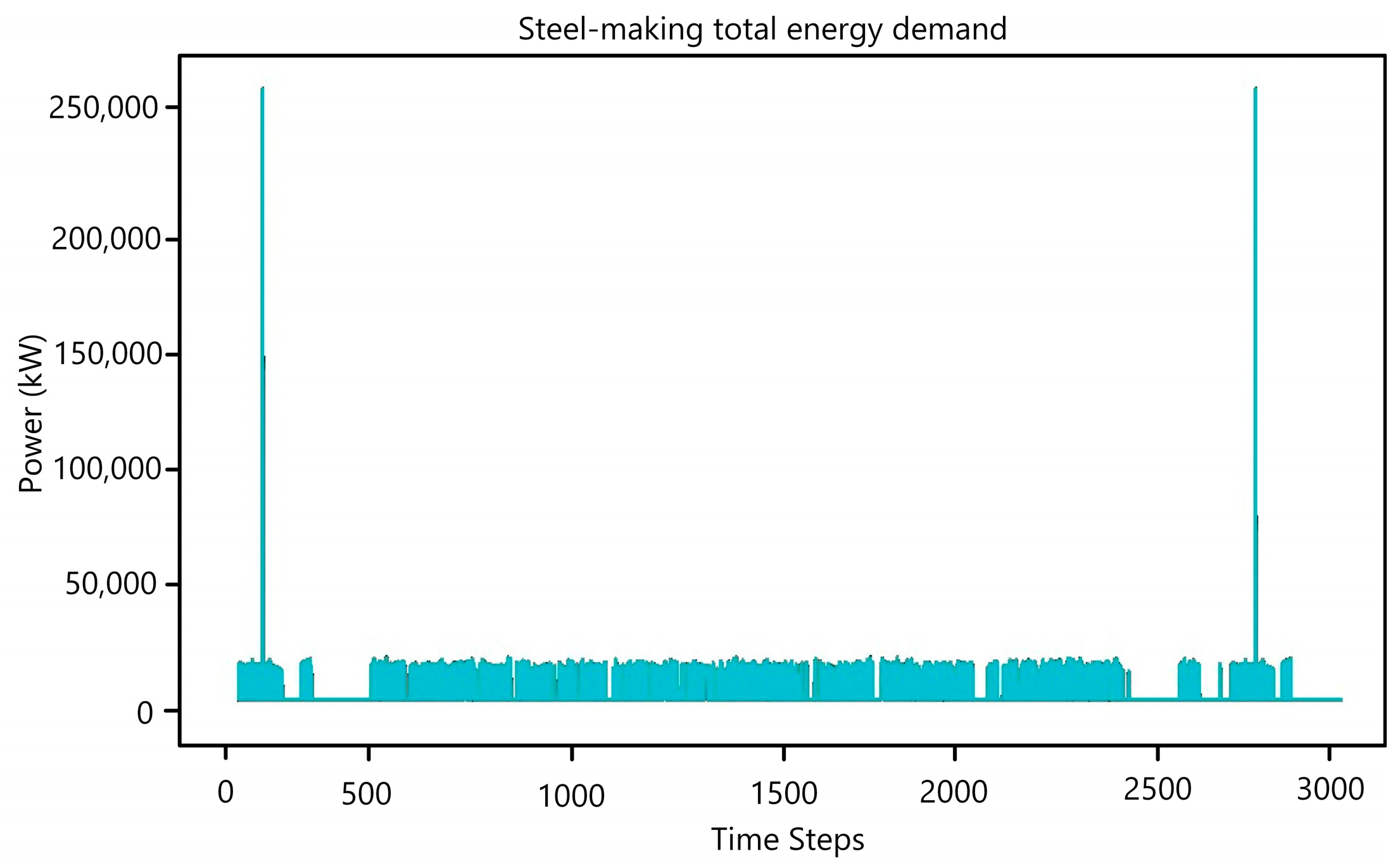

3.1. Data Overview

- 1.

- User gate load data: This section captures the total power demand or energy consumption across two primary processes:

- Ironmaking processes: Transformation of raw materials into molten iron.

- Steelmaking processes: Convert molten iron into finished steel products.

- 2.

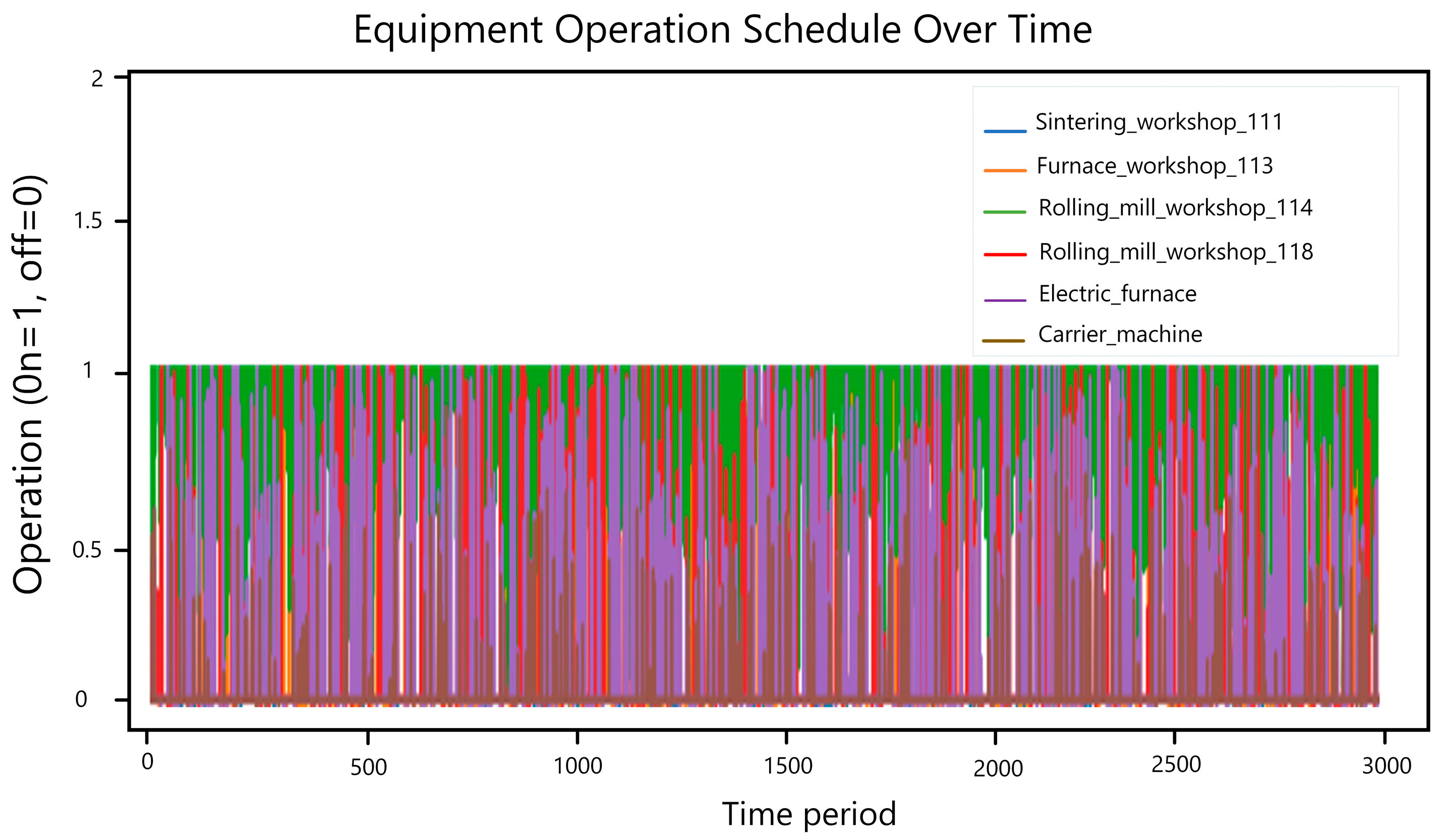

- User loop load data: The details of the power consumption of individual workshops and equipment within the ironmaking and steelmaking processes. These are the following:

- Ironmaking Smart Factory Sintering Workshop 111: Handles the sintering of raw iron ore.

- Steelmaking New Fourth Furnace Workshop 113: Comprising subcomponents:

- –

- Blast Furnace Body

- –

- Blast Furnace Pumping Station

- –

- Fan

- Steelmaking II Workshop 114: Includes rolling mill and casting machine

- Steelmaking I Workshop 118: Includes rolling mill and casting machine

- Electric furnace: Engaging in steel melting operations

- Carrier machine: Engaging in steel melting operations

- 3.

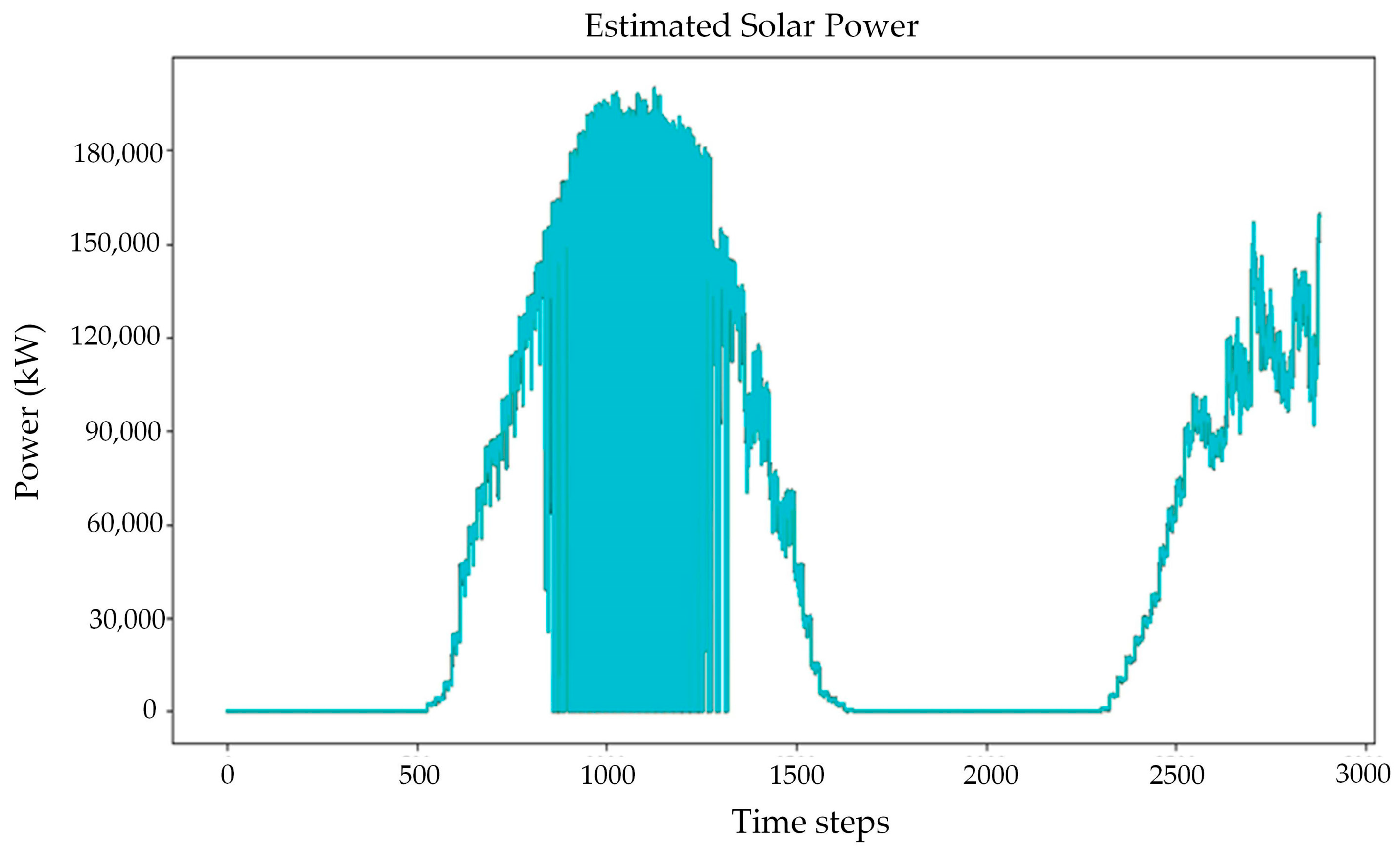

- Solar power energy estimation: due to the unavailability of real-time solar power energy data, we utilize estimated solar power generation values, denoted as . These values are derived from a predictive model and provide crucial insights into the potential of renewable energy sources to displace non-renewable energy consumption within iron and steelmaking operations. This integration model is built on informed assumptions surrounding solar power energy capabilities.

3.1.1. Data Structure

3.1.2. Data Specifications and Preprocessing

3.2. Optimization Model

- : Represents the priority weight assigned to equipment

- : The power demand for equipment at a time , and for each contributes to or , depending on whether the equipment belongs to the ironmaking or steelmaking operations.

- : Represents the power demand of ironmaking operations at a time

- Represents the power demand of steelmaking operations at a time

- : Is the binary decision variable indicating whether the equipment operates at a time .

- : Total number of time intervals in 31 days (T = 31 × 96 = 2976)

- : Index for equipment

- : Total number of equipment/workshops in operation.

- : Represents the weight factor for penalizing grid power usage.

- : Grid power usage at a time .

- The solar estimate is deterministic.

- Equipment can be either ON or OFF (binary decision).

- Critical equipment must always run; flexible equipment can be scheduled.

- No energy storage is included in the model.

Mathematical Modelling of Indirect Carbon Reduction Metrics

- : Total number of time intervals.

- =

- Useful Energy () = : The energy used by the equipment at time .

- : The theoretical power demand of equipment at time .

- α, β, γ: Weighting factors representing the relative importance of each metric.

- α + β + γ = 1

4. Results and Discussion

4.1. The Energy Consumption of Ironmaking and Steelmaking

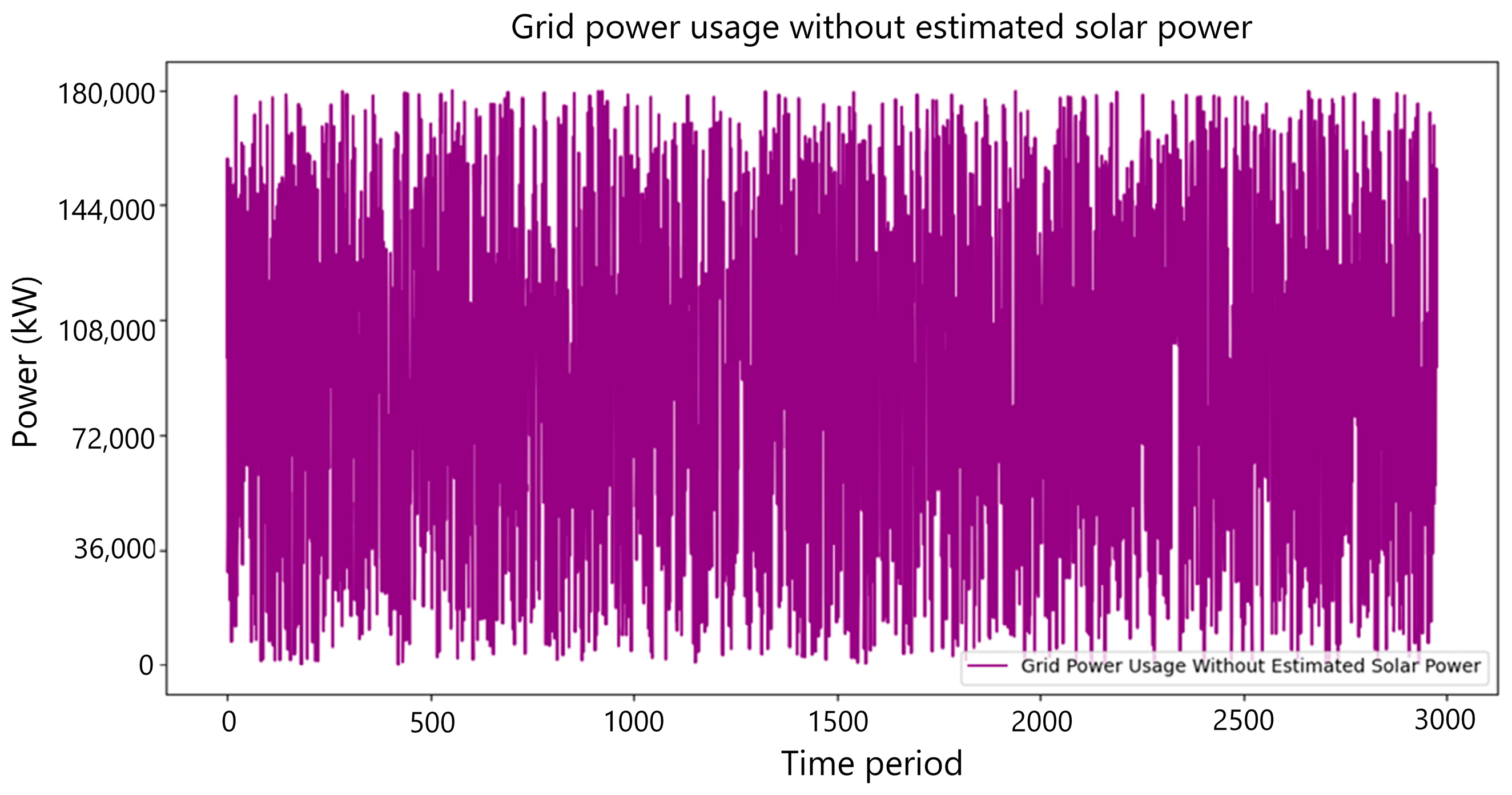

4.2. Grid Power Usage Without Incorporating Estimated Solar Power Energy

4.3. Estimated Solar Power Data

Handling of Solar Variability

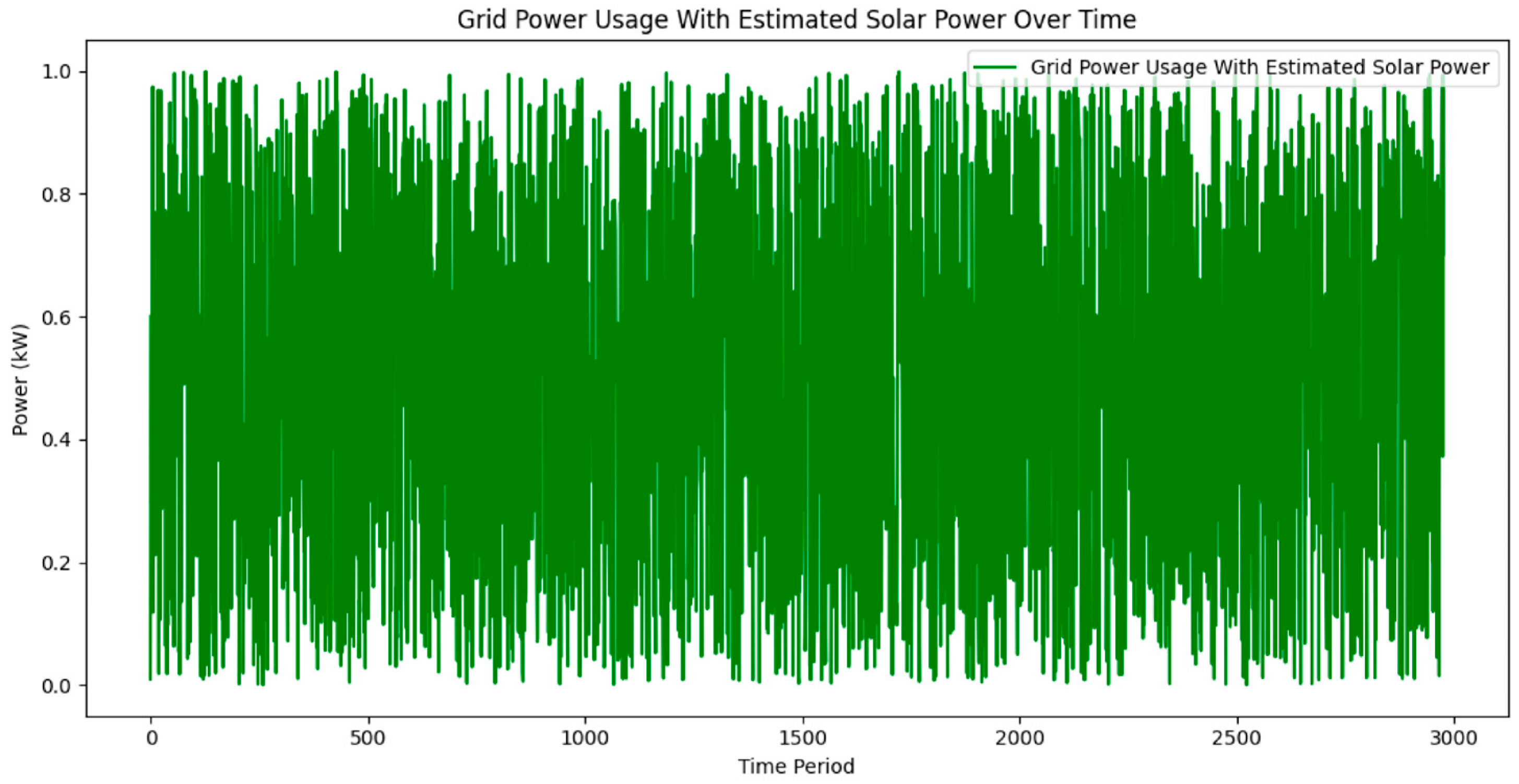

4.4. Grid Power Usage with Estimated Solar Energy

- 1.

- Maximum Solar Utilization: The reduction in grid power and the requirement of only 1 kW of grid power signify that the system effectively leveraged the estimated solar power to meet nearly all operational demands. This indicates the optimization model’s ability to prioritize solar power for industrial processes, demonstrating its effectiveness in maximizing the utilization of renewable energy resources.

- 2.

- Energy Cost Savings: Reducing grid power usage leads to a substantial reduction in operating costs, particularly in energy-intensive industries such as the iron and steel industry. Therefore, minimizing reliance on the grid power facility achieves greater energy autonomy.

- 3.

- Decarbonization and Sustainability: Aligning with grid electricity often involves carbon-intensive energy sources; therefore, even without carbon emission data, eliminating grid dependency achieves a significant decarbonization goal.

- 4.

- Operational Flexibility: This optimization strategy demonstrates the flexibility of the load scheduling strategy by prioritizing solar energy. Furthermore, achieving such low grid power usage demonstrates that industrial operations can adapt to renewable energy variability while maintaining productivity.

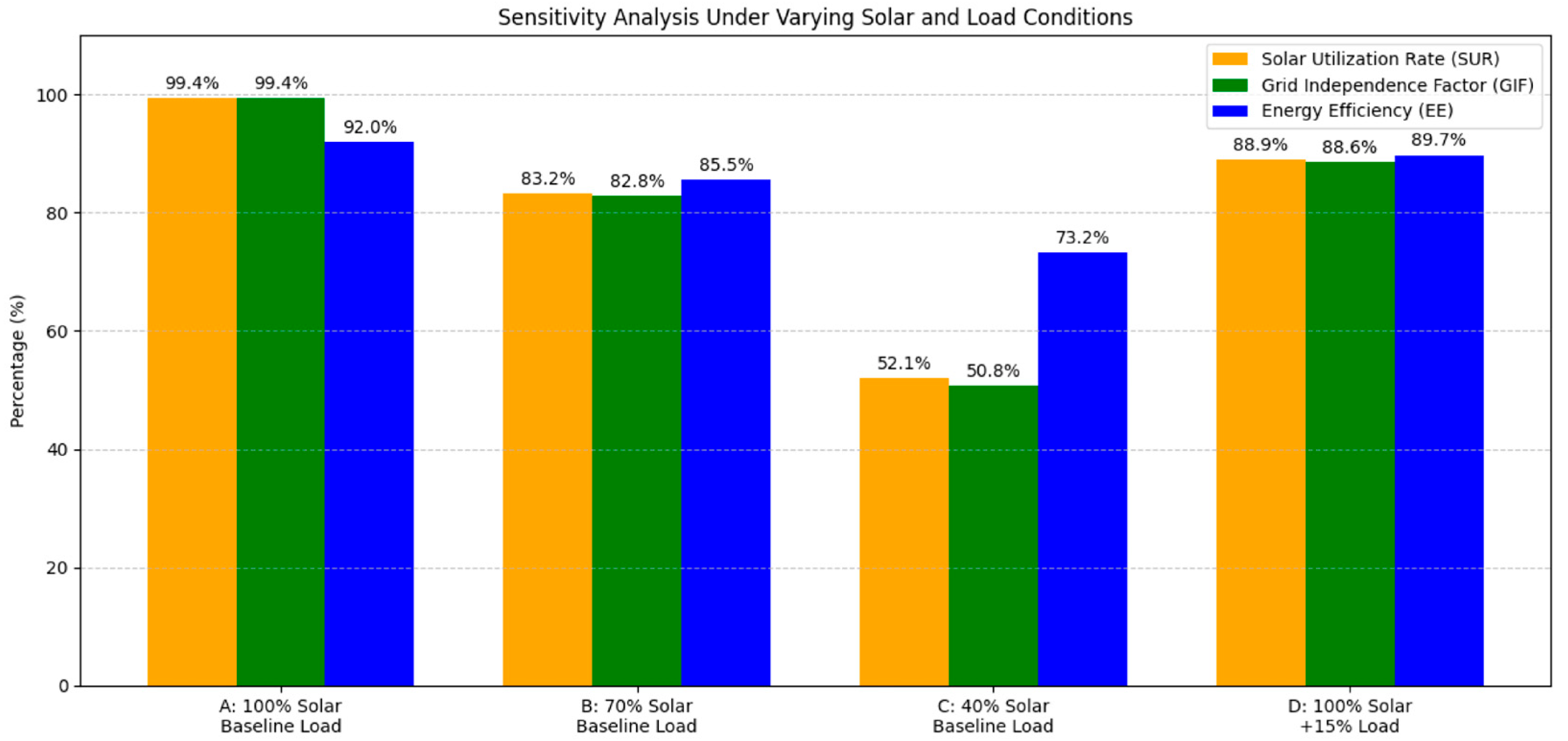

4.5. Sensitivity Analysis: Impact of Solar and Load Variations

4.6. Equipment Operational Schedule over Time

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Bilici, S.; Holtz, G.; Jülich, A.; König, R.; Li, Z.; Trollip, H.; Mc Call, B.; Tönjes, A.; Vishwanathan, S.S.; Zelt, O.; et al. Global trade of green iron as a game changer for a near-zero global steel industry?—A scenario-based assessment of regionalized impacts. Energy Clim. Change 2024, 5, 100161. [Google Scholar] [CrossRef]

- Lundmark, R.; Wetterlund, E.; Olofsson, E. On the green transformation of the iron and steel industry: Market and competition aspects of hydrogen and biomass options. Biomass Bioenergy 2024, 182, 107100. [Google Scholar] [CrossRef]

- Vigneswaran, V.S.; Gowd, S.C.; Rajendran, K. Pathways for decarbonizing the sponge iron industries: Effect of energy balance and impact assessment. J. Clean. Prod. 2024, 450, 141962. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, L.; Yuan, Y.; Sun, J.; Che, Z.; Qiu, Z.; Du, T.; Na, H.; Che, S. Muti-objective optimization on energy consumption, CO2 emission and production cost for iron and steel industry. J. Environ. Manag. 2023, 347, 119102. [Google Scholar] [CrossRef] [PubMed]

- Inayat, A. Current progress of process integration for waste heat recovery in steel and iron industries. Fuel 2023, 338, 127237. [Google Scholar] [CrossRef]

- Li, Q.; Wang, J.S.; She, X.F.; Xue, Q.G.; Wang, G.; Zuo, H.B. Feasibility and comprehensive evaluation of the application of different low-carbon technologies in the iron and steel industry. Fuel 2025, 381, 133434. [Google Scholar] [CrossRef]

- Ja’fari, M.; Khan, M.I.; Al-Ghamdi, S.G.; Jaworski, A.J.; Asfand, F. Waste heat recovery in iron and steel industry using organic Rankine cycles. Chem. Eng. J. 2023, 477, 146925. [Google Scholar] [CrossRef]

- Shen, J.; Zhang, Q.; Tian, S.; Li, X.; Liu, J.; Tian, J. The role of hydrogen in iron and steel production: Development trends, decarbonization potentials, and economic impacts. Int. J. Hydrogen Energy 2024, 92, 1409–1422. [Google Scholar] [CrossRef]

- Zhang, L.; Yuan, Y.; Xi, J.; Sun, J.; Yan, S.; Du, T.; Na, H. Synergistic enhancement for energy-saving, emission reduction and profit improvement in iron and steel manufacturing system: Strategies for parameter regulation and technologies integration. Energy Convers. Manag. 2024, 322, 119101. [Google Scholar] [CrossRef]

- Liu, Z.; Zheng, L.; Liu, X.; Guo, X.; Dai, S. Study on the influence of high permeability magnetic iron on energy consumption reduction in high gradient magnetic separator. Miner Eng. 2024, 219, 109064. [Google Scholar] [CrossRef]

- Yousuf, M.U.; Irshad, M.A.; Umair, M. Identifying barriers and drivers for energy efficiency in steel and iron industries of Karachi, Pakistan: Insights from executives and professionals. Energy Nexus 2024, 14, 100284. [Google Scholar] [CrossRef]

- Liu, X.; Li, J.; Bai, C.; Peng, R.; Chi, Y.; Liu, Y. Optimum low-carbon transformation pathways of China’s iron and steel industry towards carbon neutrality based on a dynamic CGE model. Energy 2024, 313, 134023. [Google Scholar] [CrossRef]

- Narasipuram, R.P.; Mopidevi, S. Assessment of E-mode GaN technology, practical power loss, and efficiency modelling of iL2C resonant DC-DC converter for xEV charging applications. J. Energy Storage 2024, 91, 112008. [Google Scholar] [CrossRef]

- Ray, S.; Kasturi, K.; Nayak, M.R. Multi-objective electric vehicle charge scheduling for photovoltaic and battery energy storage based electric vehicle charging stations in distribution network. Green Energy Intell. Transp. 2025, 4, 100296. [Google Scholar] [CrossRef]

- Zhao, J.; Ma, L.; Zayed, M.E.; Elsheikh, A.H.; Li, W.; Yan, Q.; Wang, J. Industrial reheating furnaces: A review of energy efficiency assessments, waste heat recovery potentials, heating process characteristics and perspectives for steel industry. Process. Saf. Environ. Prot. 2021, 147, 1209–1228. [Google Scholar] [CrossRef]

- Laasri, S.; El Hafidi, E.M.; Mortadi, A.; Chahid, E.G. Solar-powered single-stage distillation and complex conductivity analysis for sustainable domestic wastewater treatment. Environ. Sci. Pollut. Res. 2024, 31, 29321–29333. [Google Scholar] [CrossRef]

- Banothu, C.S.; Gorantla, S.R.; Attuluri, R.V.B.; Evuri, G.R. Impacts of wireless charging system for electric vehicles on power grid. e-Prime Adv. Electr. Eng. Electron. Energy 2024, 8, 100561. [Google Scholar] [CrossRef]

- Tabassum, S.; Babu, A.R.V.; Dheer, D.K. Real-time power quality enhancement in smart grids through IoT and adaptive neuro-fuzzy systems. Sci. Technol. Energy Transit. (STET) 2024, 79, 89. [Google Scholar] [CrossRef]

- Banothu, C.S.; Rao, G.S.; Vijay Babu, A.R. Magnetic Coupling Spiral-Square Coil Mutual Inductance Evaluation for Interoperable Conditions with Different Misalignments. In Proceedings of the 2023 3rd International Conference on Emerging Frontiers in Electrical and Electronic Technologies, ICEFEET 2023, Patna, India, 21–22 December 2023; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2023. [Google Scholar] [CrossRef]

- Tikadar, B.; Swami, D.; Chowdhary, V. Process-level emission analysis and decarbonization pathway for BF-BOF route in Indian iron and steel industry. J. Environ. Manag. 2024, 373, 123483. [Google Scholar] [CrossRef]

- Dhasan, K.S.; Sathyamurthy, R.; Mohanasundaram, K.; Sudalaimuthu, P. Performance analysis on single slope solar still with absorber coated using iron oxide nanoparticles at different water thickness. Solar Energy 2023, 264, 112083. [Google Scholar] [CrossRef]

- Fang, H.; Gao, J.; Tong, Y.; Liu, Q.; Cheng, S.; Li, G.; Yue, T. Advances in the sources, chemical behaviour, and whole process distribution of Hg, As, and Pb in the iron and steel smelting industry. J. Hazard. Mater. 2024, 480, 135912. [Google Scholar] [CrossRef]

- Liu, D.; Wang, P.; Sun, Y.; Zhang, H.; Xu, S. Co-abatement of carbon and air pollutants emissions in China’s iron and steel industry under carbon neutrality scenarios. Renew. Sustain. Energy Rev. 2024, 191, 114140. [Google Scholar] [CrossRef]

- Xin, H.; Wang, S.; Chun, T.; Xue, X.; Long, W.; Xue, R.; Zhang, R. Effective pathways for energy conservation and emission reduction in iron and steel industry towards peaking carbon emissions in China: Case study of Henan. J. Clean. Prod. 2023, 399, 136637. [Google Scholar] [CrossRef]

- Andrade, C.; Desport, L.; Selosse, S. Net-negative emission opportunities for the iron and steel industry on a global scale. Appl. Energy 2024, 358, 122566. [Google Scholar] [CrossRef]

- Elsheikh, H.; Eveloy, V. Assessment of variable solar- and grid electricity-driven power-to-hydrogen integration with direct iron ore reduction for low-carbon steel making. Fuel 2022, 324, 124758. [Google Scholar] [CrossRef]

- Abanades, S.; Rodat, S. Solar-aided direct reduction of iron ore with hydrogen targeting carbon-free steel metallurgy. Renew Energy 2024, 235, 121297. [Google Scholar] [CrossRef]

- Sanglard, B.; Huneau, B.; Carrey, J.; Lachaize, S. Towards solar iron metallurgy: Complete hydrogen reduction of iron ore pellets under a concentrated light flux. Solar Energy 2024, 284, 113072. [Google Scholar] [CrossRef]

- Amir, M.; Ahmad, I.; Waseem, M.; Tariq, M. A Critical Review of Compensation Converters for Capacitive Power Transfer in Wireless Electric Vehicle Charging Circuit Topologies. Green Energy Intell. Transp. 2024, 4, 100196. [Google Scholar] [CrossRef]

- Gargari, L.S.; Joda, F.; Ameri, M.; Nami, H. Optimization and exergoeconomic analyses of water-energy-carbon nexus in steel production: Integrating solar-biogas energy, wastewater treatment, and carbon capture. Int. J. Hydrogen Energy 2024, 86, 275–292. [Google Scholar] [CrossRef]

- Purohit, S.; Brooks, G.; Rhamdhani, M.A.; Pownceby, M.I. Evaluation of concentrated solar thermal energy for iron ore agglomeration. J. Clean. Prod. 2021, 317, 128313. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fesseha, S.B.; Li, B.; Qi, B.; Chen, S.; Gong, F. Optimizing Load Dispatch in Iron and Steel Enterprises Aligns with Solar Power Generation and Achieves Low-Carbon Goals. Energies 2025, 18, 4662. https://doi.org/10.3390/en18174662

Fesseha SB, Li B, Qi B, Chen S, Gong F. Optimizing Load Dispatch in Iron and Steel Enterprises Aligns with Solar Power Generation and Achieves Low-Carbon Goals. Energies. 2025; 18(17):4662. https://doi.org/10.3390/en18174662

Chicago/Turabian StyleFesseha, Samrawit Bzayene, Bin Li, Bing Qi, Songsong Chen, and Feixiang Gong. 2025. "Optimizing Load Dispatch in Iron and Steel Enterprises Aligns with Solar Power Generation and Achieves Low-Carbon Goals" Energies 18, no. 17: 4662. https://doi.org/10.3390/en18174662

APA StyleFesseha, S. B., Li, B., Qi, B., Chen, S., & Gong, F. (2025). Optimizing Load Dispatch in Iron and Steel Enterprises Aligns with Solar Power Generation and Achieves Low-Carbon Goals. Energies, 18(17), 4662. https://doi.org/10.3390/en18174662