A Comprehensive Review of Green Methane Production from Biogas and Renewable H2 and Its Techno-Economic Assessment: An Australian Perspective

Abstract

1. Introduction

2. Biogas Resources

2.1. Biogas Composition

| Component | Agricultural Waste | Industrial Waste | Wastewater | Landfill (Extremes) | Refs. |

|---|---|---|---|---|---|

| Methane (CH4), vol% | 50–80 | 50–70 | 60–70 | 50–80 (30–80) | [7,8,9] |

| Carbon dioxide (CO2), vol% | 30–50 | 30–50 | 19–40 | 20–50 (15–50) | [7,8,9] |

| Water (H2O), vol% | <6 | 1–5 | 1–5 | (≤5) | [7,9] |

| Hydrogen (H2), vol% | 0–2 | 0–2 | 0 | 0–5 | [7,8,9] |

| Nitrogen (N2), vol% | 0–1 | 0–1 | 0–1 | 0–3 (≤50) | [7,8,9] |

| Oxygen (O2), vol% | 0–1 | 0–1 | <0.5 | 0–1 (≤10) | [7,8,9] |

| Siloxanes, vol% | - | - | - | (≤0.004) | [7,9] |

| Hydrogen sulphide (H2S), ppm | 2160–10,000 | 0.8 | 0–4000 | 0.1 | [7,8,9] |

| Ammonia (NH3), ppm | 50–144 | - | 100 | (≤5) | [7,9] |

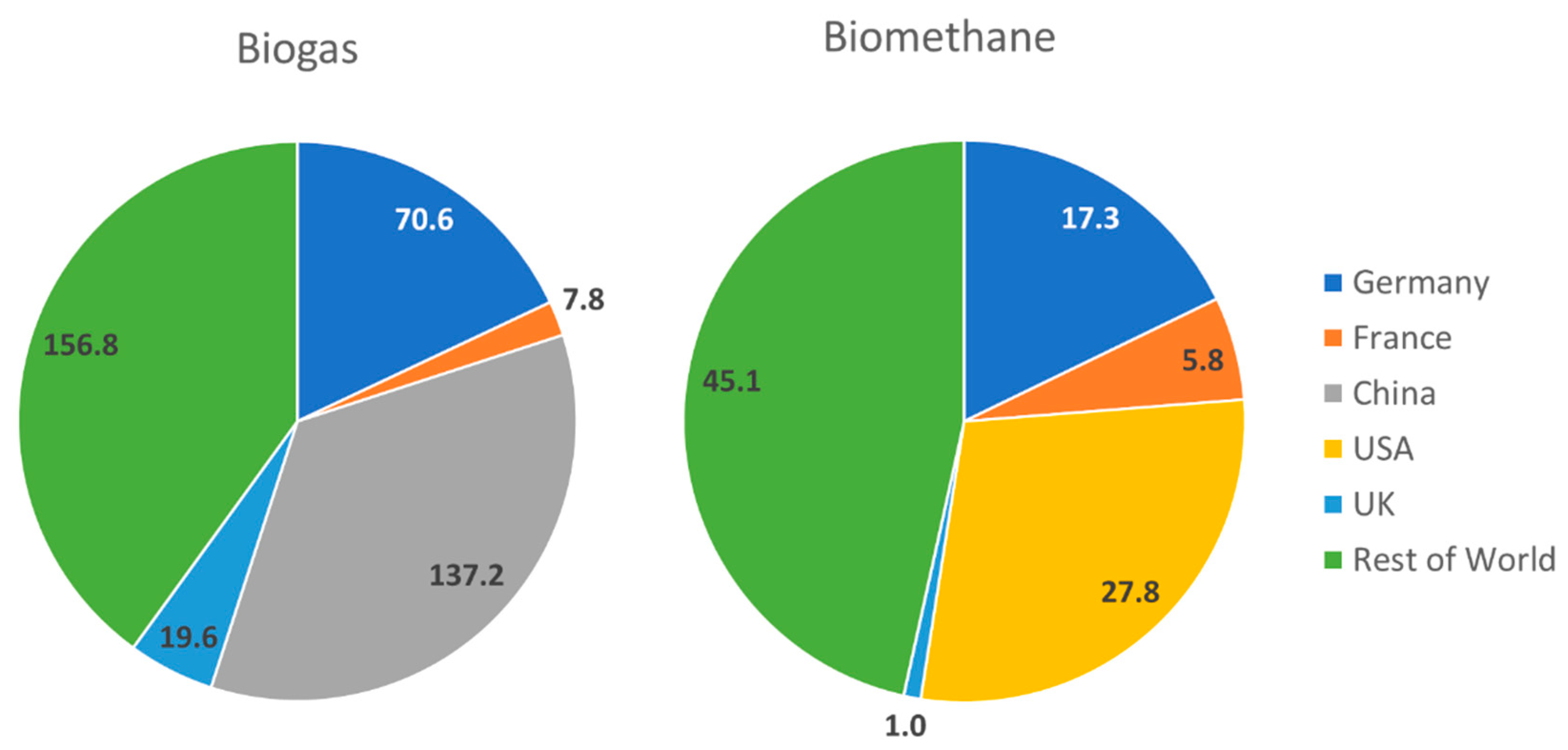

2.2. Global Biogas and Green Methane Production

2.2.1. China

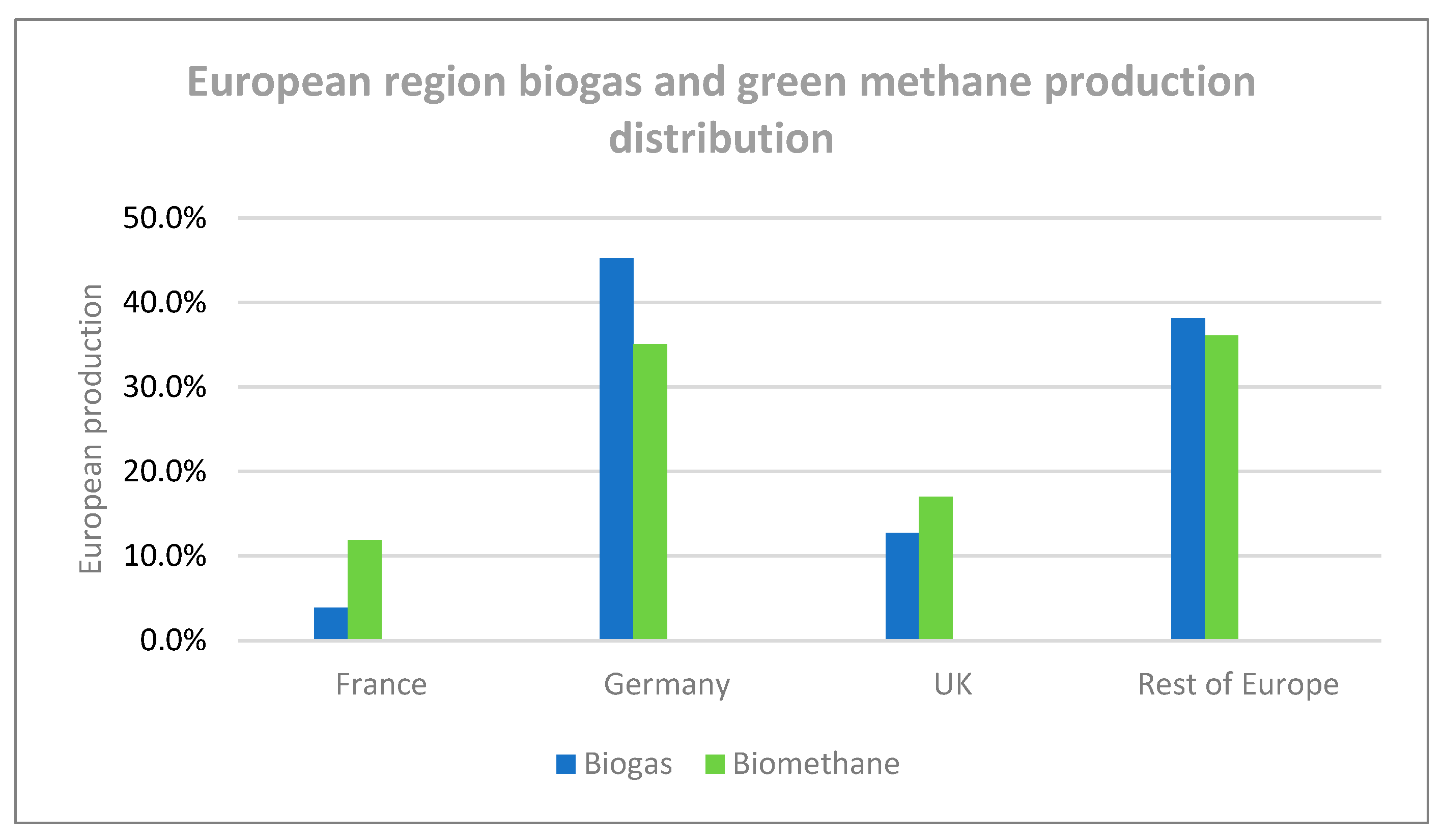

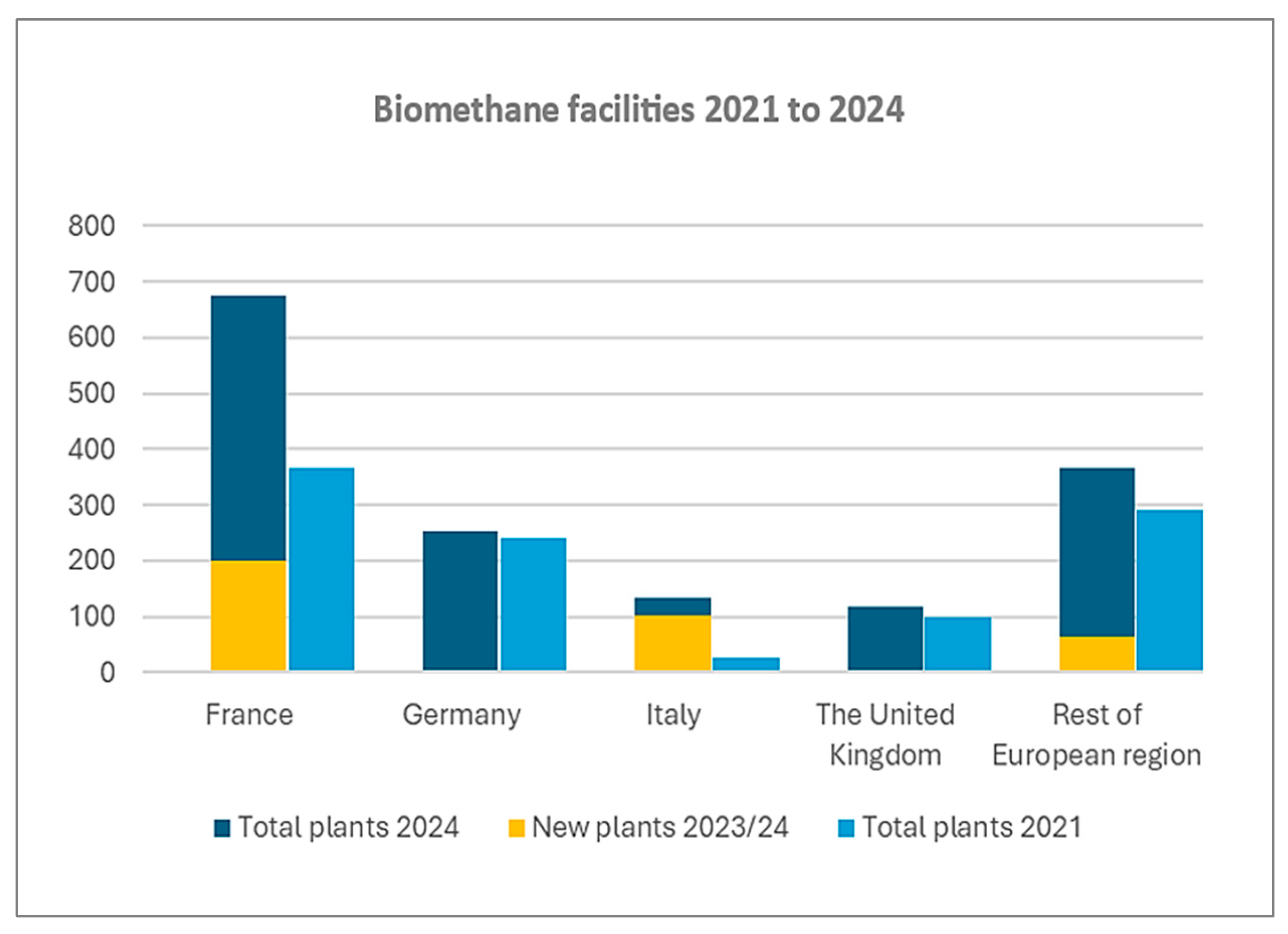

2.2.2. Europe

2.2.3. USA

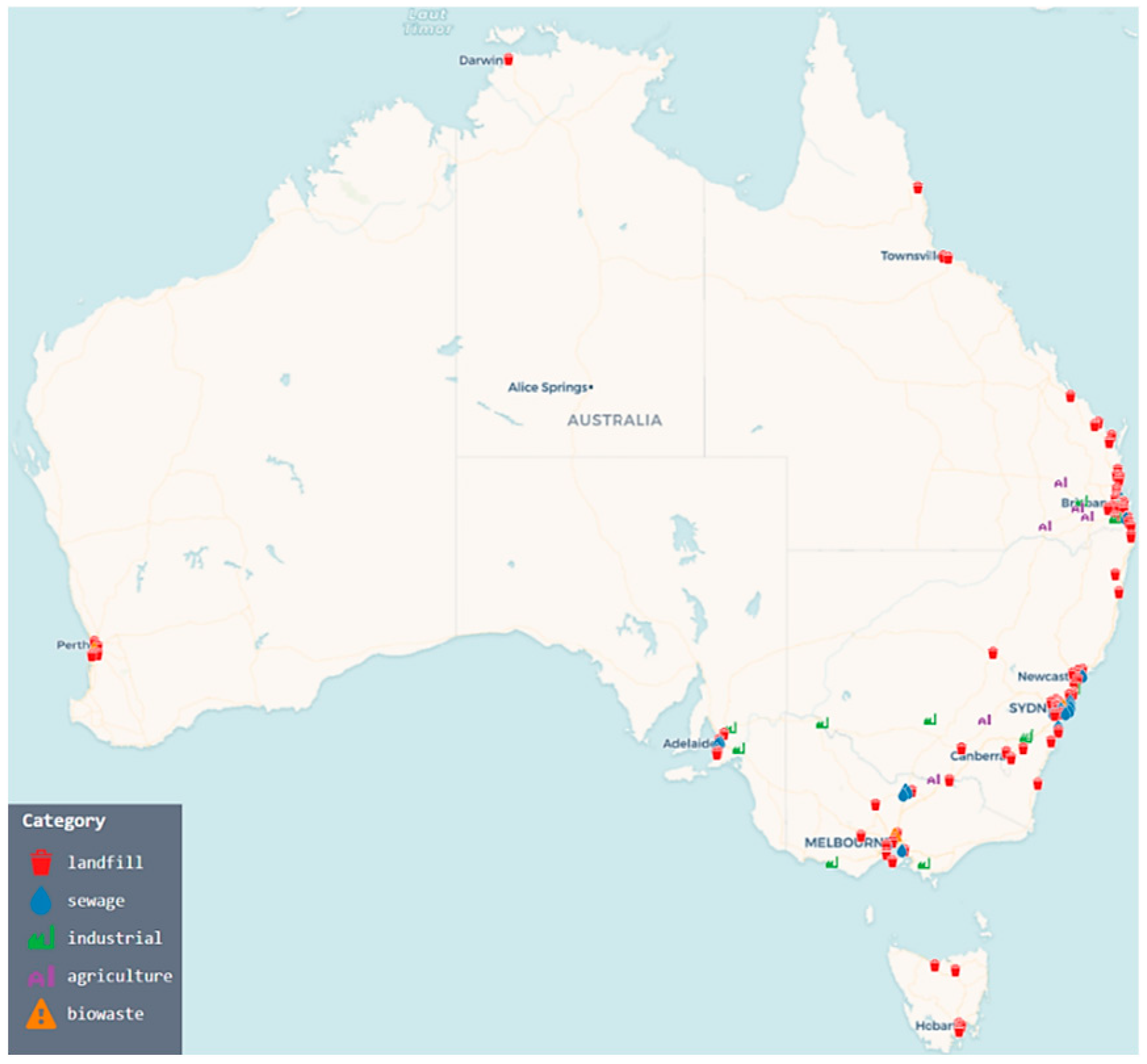

2.2.4. Australia

2.3. Australia’s Future Biogas Potential

3. Biogas Cleaning and Upgrading Technologies

3.1. Biogas Cleaning Technologies

3.2. Biogas Upgrading Technologies by Absorption and Adsorption

| PSA | Membrane Separation | Water Scrubbing | Organic Physical Scrubbing | Chemical Scrubbing | Cryogenic Separation | Ref. | |

|---|---|---|---|---|---|---|---|

| Energy demand, (kWh/Nm3 cleaned gas) | 0.3–1 | 0.25–0.43 | 0.3–0.5 | 0.4–0.67 | 0.1–0.3 Regeneration heat 0.5–1 | 0.8–1.54 | [7,8,42,44,45,46,47] |

| Energy efficiency, (%) | 89.2 (84.8–93.6) | 90.2 (82.4–98.0) | 94.4 (92.7–96.0) | 92.8 (90.0–95.5) | 93.1 (88.5–97.7) | 90.8 (84.9–96.7) | [42] |

| Flow rate, (m3/h) | 100–500 | 100–500 | 100–500 | 100–500 | 100–500 | — | [8,43,47] |

| Pre-treatment | H2S removal, compression, gas cooling, and gas drying | H2S removal, compression, gas cooling, and gas drying | Gas compression and cooling | Compression, H2S removal, and gas drying | H2S removal | Compression, H2S removal, and gas drying | [8,43,44,47] |

| * Upgrading cost, (EUR/m3) | 0.092–0.101 | 0.065–0.116 | 0.091–0.103 | 0.090–0.102 | 0.175–0.225 | — | [8,43] |

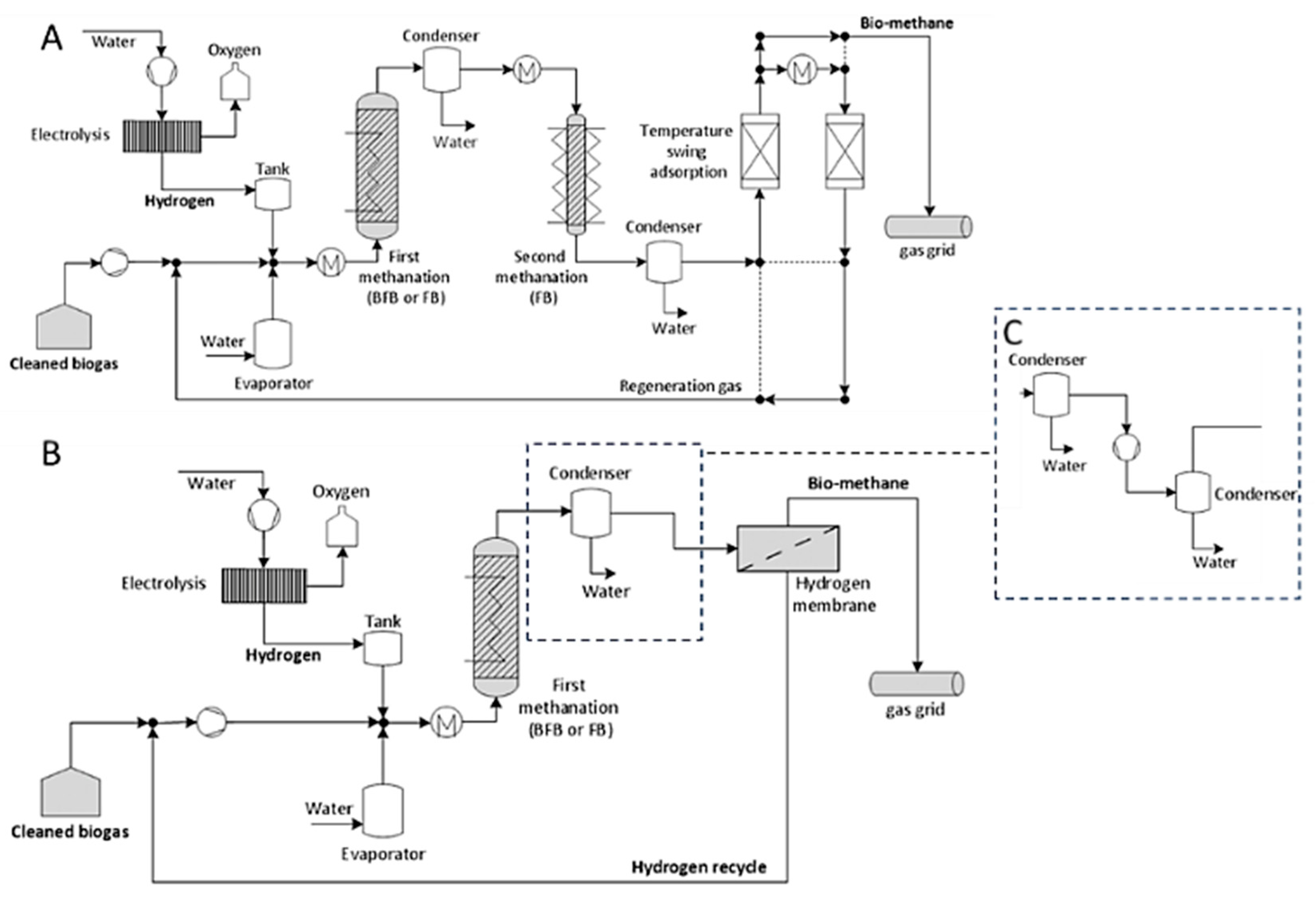

3.3. Biogas Upgrading Technologies by Thermal Chemical Methanation

4. Biogas Methanation Pilot Studies

4.1. M. Spect et al. Pilot Plant Design and Set-Up

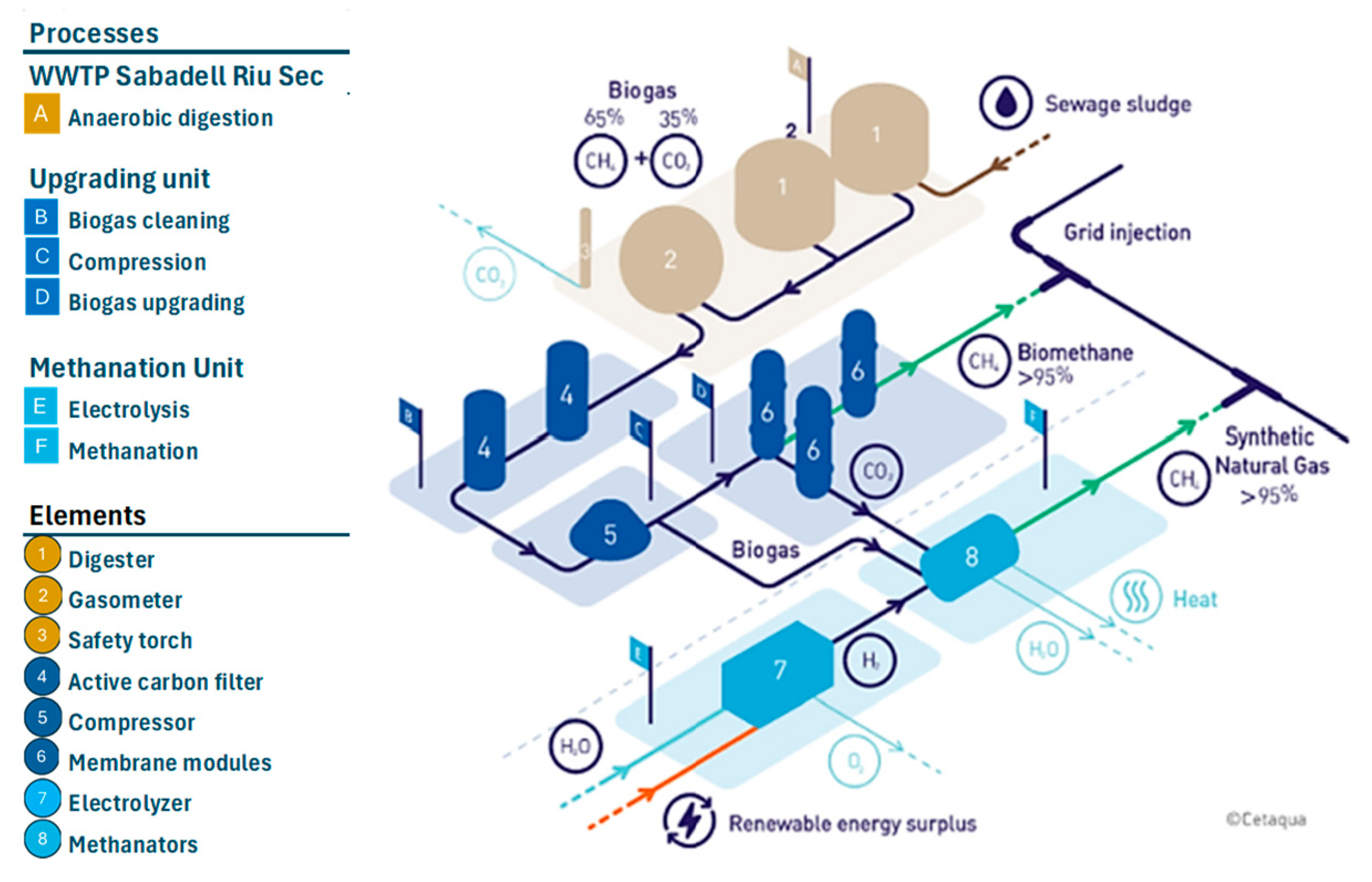

4.2. J. Guilera et al. Pilot Plant Design and Set-Up

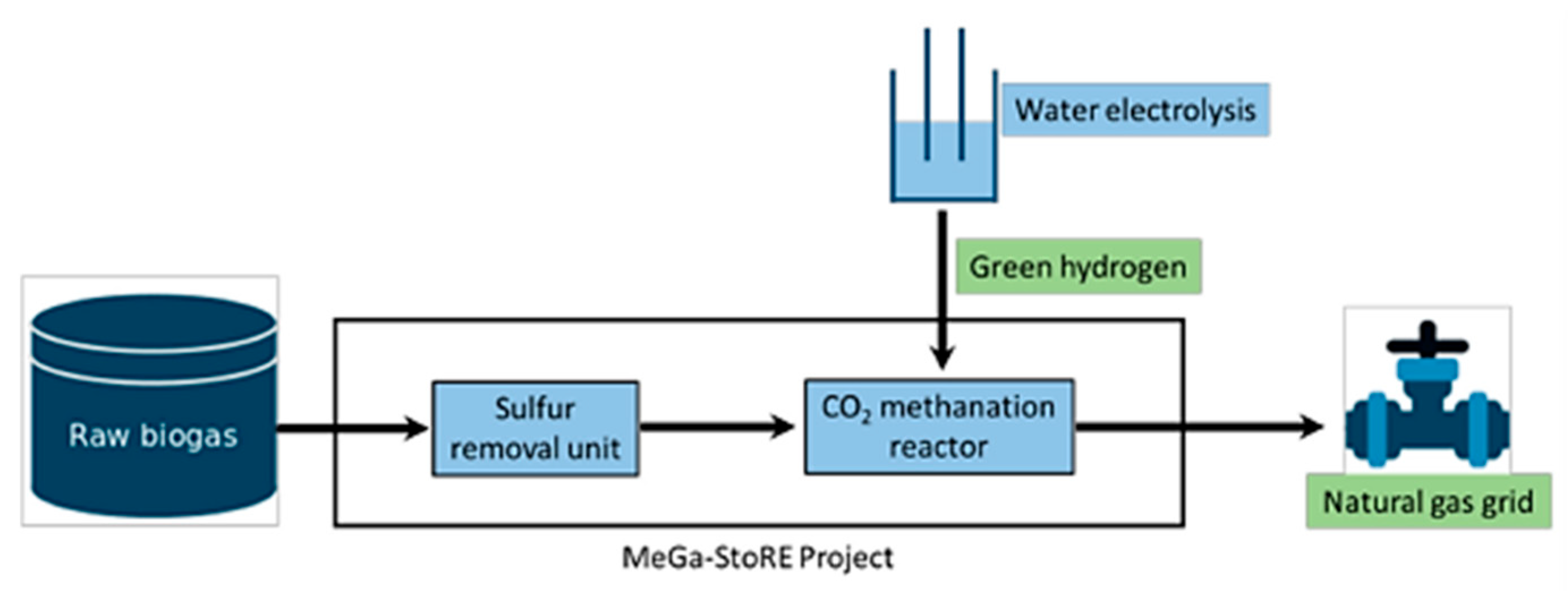

4.3. C. Dannesboe et al. Pilot Plant Design and Set-Up

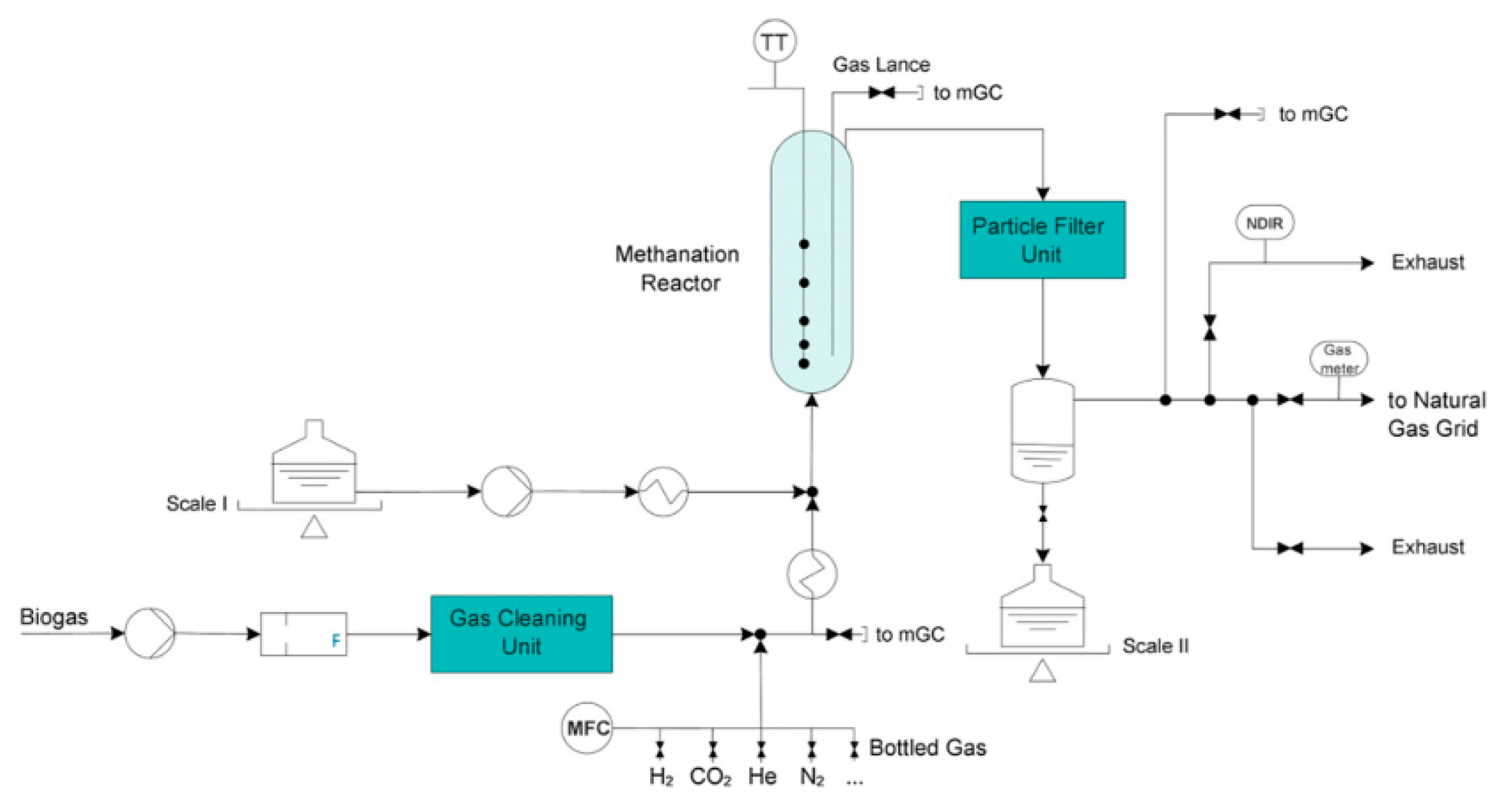

4.4. J. Witte et al. Pilot Plant Design and Set-Up

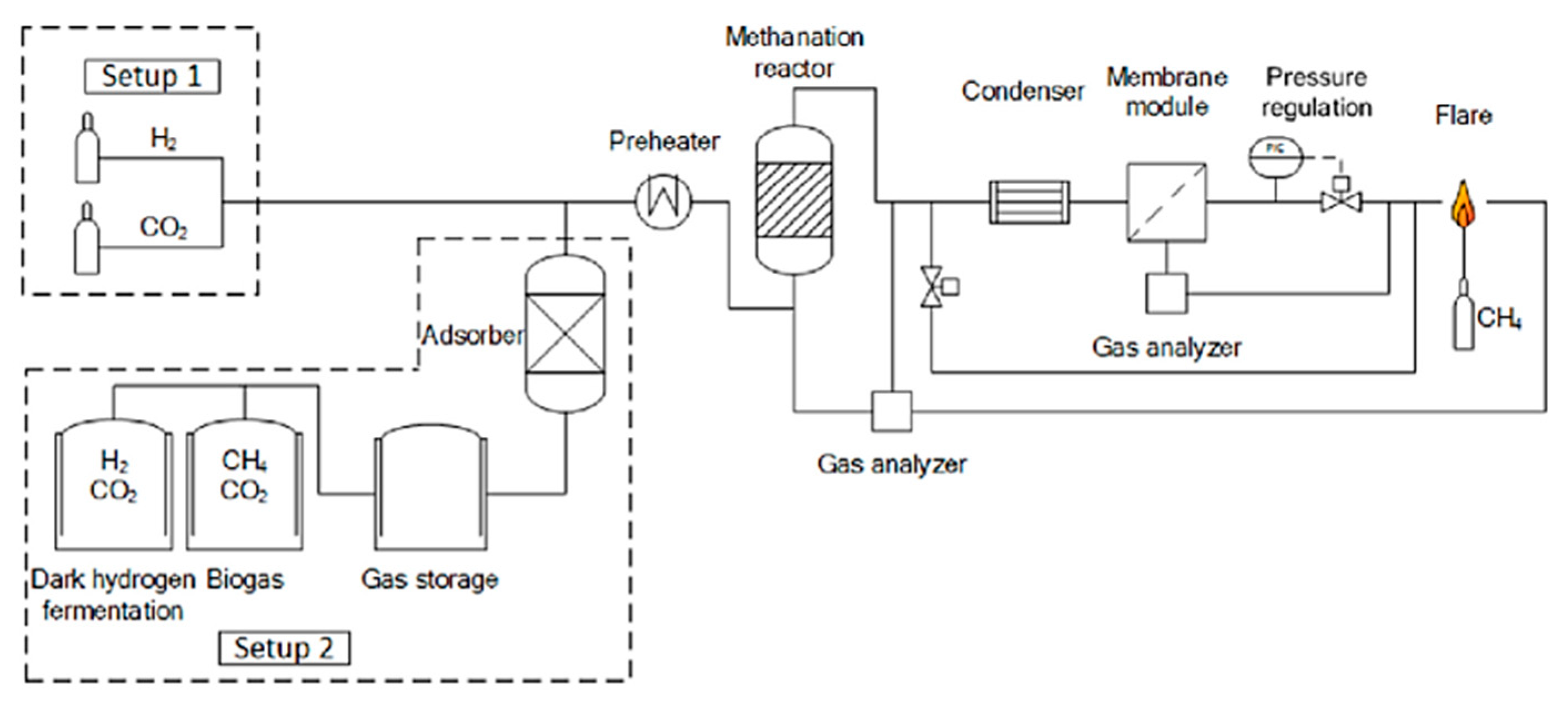

4.5. F. Kirchbacher et al. Pilot Plant Design and Set-Up

4.6. R. Gaikwad Pilot Plant Design and Set-Up

4.7. Australia Pilot Plant Design and Set-Up

4.8. Summary of Pilot Plant Studies

5. TEA Status for Biogas Methanation

5.1. TEA Status for Biogas Catalytic Methanation

5.2. TEA Methodologies for Catalytic Biogas Methanation

6. Future Perspectives and Challenges

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| Acronym | Expanded Text |

| AD | Anerobic digestion |

| CAPEX | Capital expenditure |

| CCS | Carbon capture and storage |

| CHP | Combined heat and power |

| GJ | Giga joule |

| Kw | Kilowatt |

| LCOH | Levelized cost of hydrogen |

| Mt | Million tons |

| OPEX | Operating expenditure |

| P2G | Power to gas |

| PJ | Peta joule |

| PSA | Pressure swing absorption |

| SNG | Synthetic natural gas |

| STP | Standard temperature and pressure |

| TEA | Techno economic assessment |

| TWh | Terawatt hour |

References

- DISR. Future Gas Strategy-Analytical Report; Department of Industry Science and Resources: Canberra, Australia, 2024. [Google Scholar]

- Kundevski, M.; Truong, T.; Carlu, E. Biogas Opportunities for Australia; Enea Consulting: Bioenergy, Australia, 2019. [Google Scholar]

- Bruce, S.; Temminghoff, M.; Hayward, J.; Schmidt, E.; Munnings, C.; Palfreyman, D.; Hartley, P. National Hydrogen Roadmap; CSIRO: Clayton South, Australia, 2018. [Google Scholar]

- Lehtomaki, A.; Huttunen, S.; Rintala, J.A. Laboratory investigations on co-digestion of energy crops and crop residues with cow manure for methane production: Effect of crop to manure ratio. Resour. Conserv. Recycl. 2007, 51, 591–609. [Google Scholar] [CrossRef]

- Koonaphapdeelert, S.; Aggarangsi, P.; Moran, J. Biogas Cleaning and Pretreatment. In Biomethane: Production and Applications; Springer Singapore: Singapore, 2020; pp. 17–45. [Google Scholar]

- Deng, L.; Liu, Y.; Wang, W. Biogas Cleaning and Upgrading. In Biogas Technology; Deng, L., Liu, Y., Wang, W., Eds.; Springer Singapore: Singapore, 2020; pp. 201–243. [Google Scholar]

- Atelge, M.R.; Senol, H.; Djaafri, M.; Hansu, T.A.; Krisa, D.; Atabani, A.; Eskicioglu, C.; Muratcobanoglu, H.; Unalan, S.; Kalloum, S.; et al. A Critical Overview of the State-of-the-Art Methods for Biogas Purification and Utilization Processes. Sustainability 2021, 13, 11515. [Google Scholar] [CrossRef]

- Chen, X.Y.; Vinh-Thang, H.; Ramirez, A.A.; Rodrigue, D.; Kaliaguine, S. Membrane gas separation technologies for biogas upgrading. RSC Adv. 2015, 5, 24399–24448. [Google Scholar] [CrossRef]

- Persson, M.; Jonsson, O.; Wellinger, A. Biogas Upgrading to Vehicle Fuel Standards and Grid Injection; IEA: Paris, France, 2006. [Google Scholar]

- Werkneh, A.A. Biogas impurities: Environmental and health implications, removal technologies and future perspectives. Heliyon 2022, 8, e10929. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Larson, R.A.; Runge, T. Impacts to hydrogen sulfide concentrations in biogas when poplar wood chips, steam treated wood chips, and biochar are added to manure-based anaerobic digestion systems. Bioresour. Technol. Rep. 2019, 7, 100232. [Google Scholar] [CrossRef]

- Nieß, S.; Armbruster, U.; Dietrich, S.; Klemm, M. Recent Advances in Catalysis for Methanation of CO2 from Biogas. Catalysts 2022, 12, 374. [Google Scholar] [CrossRef]

- Petersson, A. Biogas cleaning. In Biogas Handbook: Science, Production and Applications; Woodhead Publishing: New Delhi, India, 2013; pp. 329–341. [Google Scholar]

- Inaba, M.; Zhang, Z.G.; Matsuoka, K.; Soneda, Y. Effect of coexistence of siloxane on production of hydrogen and nanocarbon by methane decomposition using Fe catalyst. Int. J. Hydrogen Energy 2021, 46, 11556–11563. [Google Scholar] [CrossRef]

- IRENA. Off-Grid Renewable Energy Statistics 2022; International Renewable Energy Agency: Abu Dahbi, United Arab Emirates, 2022; p. 50. [Google Scholar]

- IEA. Gas Market Report Q1-2023; International Energy Agency: Paris, France, 2023; pp. 1–70. [Google Scholar]

- IEA. Renewables 2023/Analysis and forecast to 2028. In Renewables; International Energy Agency: Paris, France, 2024. [Google Scholar]

- Tercinier, P.; Degonfreville, A.; Guyot, T.; Bouvet, C. 6th European Biomethane Benchmark. In European Biomethane Benchmark; Sia Partners: Paris, France, 2022; Available online: https://www.sia-partners.com/en/insights/publications/6th-european-biomethane-benchmark (accessed on 23 October 2023).

- Giwa, A.S.; Ali, N.; Ahmad, I.; Asif, M.; Guo, R.B.; Li, F.L.; Lu, M. Prospects of China’s biogas: Fundamentals, challenges and considerations. Energy Rep. 2020, 6, 2973–2987. [Google Scholar] [CrossRef]

- Wang, Y.B.; Zhi, B.Y.; Xiang, S.M.; Ren, G.X.; Feng, Y.Z.; Yang, G.H.; Wang, X.J. China’s Biogas Industry’s Sustainable Transition to a Low-Carbon Plan-A Socio-Technical Perspective. Sustainability 2023, 15, 5299. [Google Scholar] [CrossRef]

- AirLiquide. Air Liquide Launches Its Biomethane Activity in China. 2022. Available online: https://www.airliquide.com/group/press-releases-news/2022-07-12/air-liquide-launches-its-biomethane-activity-china (accessed on 23 October 2023).

- Brémond, U.; Bertrandias, A.; Steyer, J.P.; Bernet, N.; Carrere, H. A vision of European biogas sector development towards 2030: Trends and challenges. J. Clean. Prod. 2021, 287, 125065. [Google Scholar] [CrossRef]

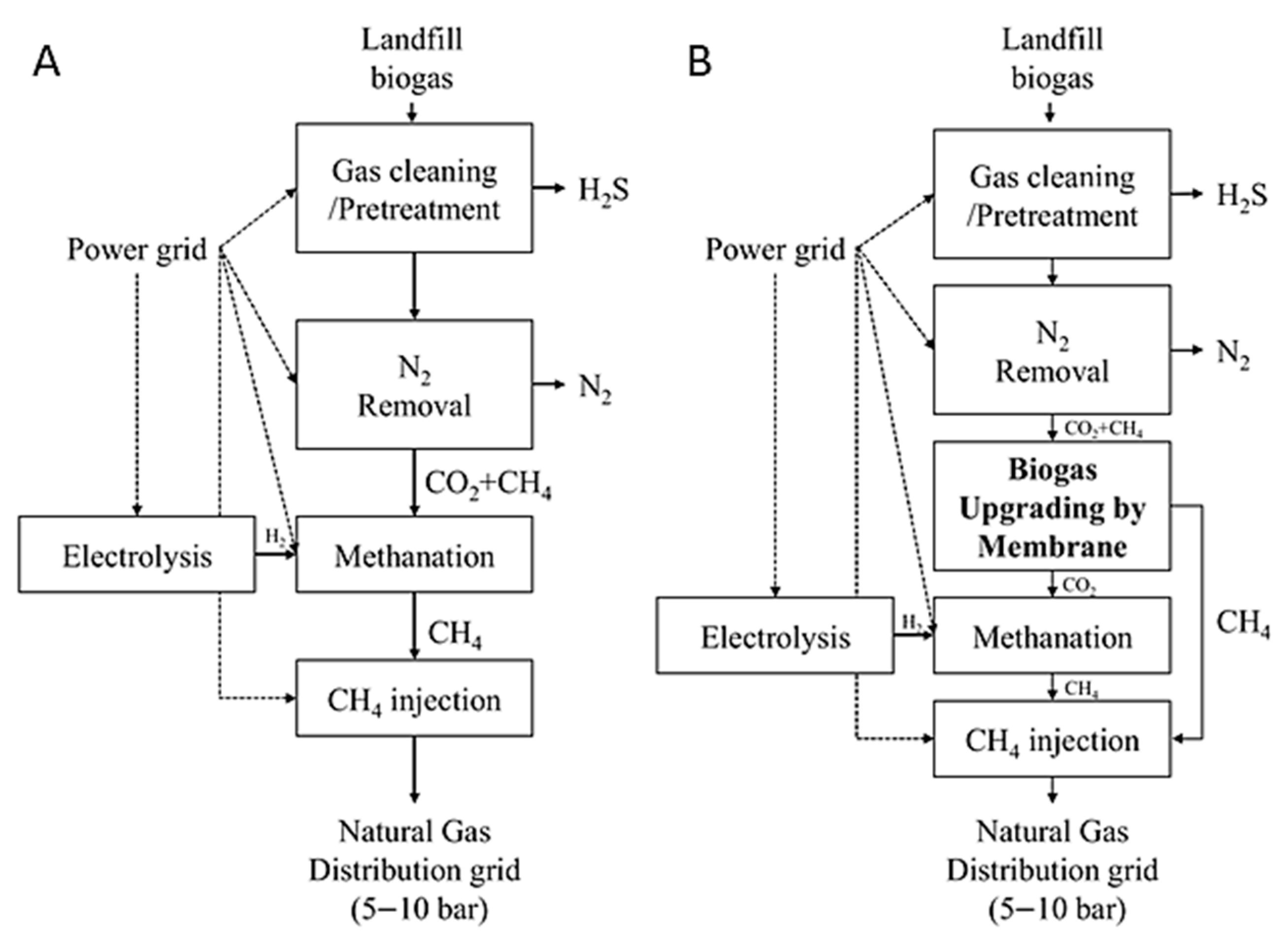

- Ghafoori, M.S.; Loubar, K.; Marin-Gallego, M.; Tazerout, M. Techno-economic and sensitivity analysis of Biomethane production via landfill biogas upgrading and power-to-gas technology. Energy 2022, 239, 122086. [Google Scholar] [CrossRef]

- Philip Hazewinkel, J.Z.; Yang, Y. Final Report for KS Green Methane Production from Biogas and Renewable H2—Feasibility Study; Bu, E., Ed.; CSIRO: Clayton South, Australia, 2022. [Google Scholar]

- Tercinier, P.; Menu, T.; Hoetmer, J. 7th European Biomethane Benchmark. In European Biomethane Benchmark; Sia Partners: Paris, France, 2023. [Google Scholar]

- GIE; EBA. European Biomethane Map 2021; Gas Infrastructure Europe: Bruxelles, Belgium; European Biogas Association: Brussels, Belgium, 2022. [Google Scholar]

- GIE; EBA. European Biomethane Map 2024; Gas Infrastructure Europe: Bruxelles, Belgium; European Biogas Association: Brussels, Belgium, 2024. [Google Scholar]

- EBA. EBA Statistical Report 2022; European Biogas Association: Brussels, Belgium, 2022. [Google Scholar]

- U.S. Department of Energy. Renewable Natural Gas Production. 2023. Available online: https://afdc.energy.gov/fuels/natural_gas_renewable.html (accessed on 21 June 2023).

- O’Malley, J.; Pavlenko, N.; Kim, Y.H. 2030 California Renewable Natural Gas Outlook: Resource Assessment, Market Opportunities, and Environmental Performance; International Council on Clean Transportation: Washington, DC, USA, 2023; p. 35. [Google Scholar]

- US EPA. Landfill Gas Energy Project Data. In United States Environmental Protection Agency: Landfill Methane Outreach Program (LMOP); United States Environmental Protection Agency: Washington, DC, USA, 2023. [Google Scholar]

- IEA. Outlook for biogas and biomethane. In Outlook for Biogas and Biomethane: Prospects for Organic Growth; International Energy Agency: Paris, France, 2020. [Google Scholar]

- US EPA. AgSTAR Data and Trends. 2022. Available online: https://www.epa.gov/agstar/agstar-data-and-trends#biogasfacts (accessed on 14 June 2023).

- Ellis, D. Global Biomethane Production Hits Record 7bcm in 2022. Available online: https://www.gasworld.com/story/global-biomethane-production-hits-record-7bcm-in-2022/#:~:text=The%20US%20remains%20by%20far,30%25%20of%20global%20biomethane%20output (accessed on 28 June 2023).

- Kaparaju, P.; Conde, E.; Nghiem, L.; Trianni, A.; Cantley–Smith, R.; Leak, J.; Katic, M.; Nguyen, L.; Jacobs, B.; Cunningham, R. B5: Opportunity Assessment Anaerobic digestion for electricity, transport and gas Final Report. In Race to 2023; AusIndustry Cooperative Research Centres Program; Australian Government/Departmentt of Industry, Science, Energy and Resources: Canberra, Australia, 2023; p. 192. [Google Scholar]

- AREMI. National Map/Biogas Facilities. 2023. Available online: https://www.nationalmap.gov.au/renewables (accessed on 17 August 2023).

- Jemana. Malabar Biomethane Injection Plant. 2023. Available online: https://jemena.com.au/about/innovation/renewable-gas/key-projects/malabar-biomethane-project (accessed on 14 June 2023).

- Lima, D.; Appleby, G.; Li, L. A Scoping Review of Options for Increasing Biogas Production from Sewage Sludge: Challenges and Opportunities for Enhancing Energy Self-Sufficiency in Wastewater Treatment Plants. Energies 2023, 16, 2369. [Google Scholar] [CrossRef]

- ORG. Katunga Biogas/Biomethane Project. 2023. Available online: https://optimalrenewablegas.com.au/project/katunga-biogas-biomethane-project/ (accessed on 23 October 2023).

- ORG. Westbury Bio Hub Project. 2023. Available online: https://optimalrenewablegas.com.au/project/westbury-bio-hub-project/ (accessed on 23 October 2023).

- HyResource. Hazer Commercial Demonstration Plant. 2023. Available online: https://research.csiro.au/hyresource/hazer-commercial-demonstration-plant/ (accessed on 23 October 2023).

- Sun, Q.; Li, H.; Yan, J.; Liu, L.; Yu, Z.; Yu, X. Selection of appropriate biogas upgrading technology-a review of biogas cleaning, upgrading and utilisation. Renew. Sustain. Energy Rev. 2015, 51, 521–532. [Google Scholar] [CrossRef]

- Fajrina, N.; Yusof, N.; Ismail, A.F.; Aziz, F.; Bilad, M.R.; Alkahtani, M. A crucial review on the challenges and recent gas membrane development for biogas upgrading. J. Environ. Chem. Eng. 2023, 11, 110235. [Google Scholar] [CrossRef]

- Sahota, S.; Shah, G.; Ghosh, P.; Kapoor, R.; Sengupta, S.; Singh, P.; Vijay, V.; Sahay, A.; Vijay, V.K.; Thakur, I.S. Review of trends in biogas upgradation technologies and future perspectives. Bioresour. Technol. Rep. 2018, 1, 79–88. [Google Scholar] [CrossRef]

- Kaparaju, P.; Rasi, S.; Rintala, J. Biogas upgrading and compression. In Bioenergy Production by Anaerobic Digestion; Korres, N., O’Kiely, P., Benzie, J.A.H., West, J.S., Eds.; Routledge: London, UK, 2013; pp. 152–182. [Google Scholar]

- Muñoz, R.; Meier, L.; Diaz, I.; Jeison, D. A review on the state-of-the-art of physical/chemical and biological technologies for biogas upgrading. Rev. Environ. Sci. Bio Technol. 2015, 14, 727–759. [Google Scholar] [CrossRef]

- TUV. Biogas to Biomethane Technology Review; Vienna University of Technology: Vienna, Austria; Intelligent Energy Europe: Pikermi, Greece, 2012; pp. 1–15. [Google Scholar]

- Rodero, M.R.; Ángeles, R.; Marín, D.; Díaz, I.; Colzi, A.; Posadas, E.; Lebrero, R.; Muñoz, R. Biogas Purification and Upgrading Technologies. In Biogas: Fundamentals, Process, and Operation; Tabatabaei, M., Ghanavati, H., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 239–276. [Google Scholar]

- AEMO. Gas Quality Guidelines; Australian Energy Market Operator: Melbourne, Australia, 2017; p. 38. [Google Scholar]

- Angelidaki, I.; Treu, L.; Tsapekos, P.; Luo, G.; Campanaro, S.; Wenzel, H.; Kougias, P.G. Biogas upgrading and utilization: Current status and perspectives. Biotechnol. Adv. 2018, 36, 452–466. [Google Scholar] [CrossRef]

- Khan, M.U.; Lee, J.T.E.; Bashir, M.A.; Dissanayake, P.D.; Ok, Y.S.; Tong, Y.W.; Shariati, M.A.; Wu, S.; Ahring, B.K. Current status of biogas upgrading for direct Biomethane use: A review. Renew. Sustain. Energy Rev. 2021, 149, 111343. [Google Scholar] [CrossRef]

- Galloni, M.; Di Marcoberardino, G. Biogas Upgrading Technology: Conventional Processes and Emerging Solutions Analysis. Energies 2024, 17, 2907. [Google Scholar] [CrossRef]

- Adnan, A.I.; Ong, M.Y.; Nomanbhay, S.; Chew, K.W.; Show, P.L. Technologies for Biogas Upgrading to Biomethane: A Review. Bioengineering 2019, 6, 92. [Google Scholar] [CrossRef] [PubMed]

- Gkotsis, P.; Kougias, P.; Mitrakas, M.; Zouboulis, A. Biogas upgrading technologies—Recent advances in membrane-based processes. Int. J. Hydrogen Energy 2023, 48, 3965–3993. [Google Scholar] [CrossRef]

- Roozitalab, A.; Hamidavi, F.; Kargari, A. A review of membrane material for biogas and natural gas upgrading. Gas Sci. Eng. 2023, 114, 204969. [Google Scholar] [CrossRef]

- Tomczak, W.; Gryta, M.; Daniluk, M.; Żak, S. Biogas Upgrading Using a Single-Membrane System: A Review. Membranes 2024, 14, 80. [Google Scholar] [CrossRef] [PubMed]

- Rotunno, P.; Lanzini, A.; Leone, P. Energy and economic analysis of a water scrubbing based biogas upgrading process for Biomethane injection into the gas grid or use as transportation fuel. Renew. Energy 2017, 102, 417–432. [Google Scholar] [CrossRef]

- Ryckebosch, E.; Drouillon, M.; Vervaeren, H. Techniques for transformation of biogas to Biomethane. Biomass Bioenergy 2011, 35, 1633–1645. [Google Scholar] [CrossRef]

- Chen, Y.; Xie, C.; Li, Y.; Song, C.; Bolin, T.B. Sulfur poisoning mechanism of steam reforming catalysts: An X-ray absorption near edge structure (XANES) spectroscopic study. Phys. Chem. Chem. Phys. 2010, 12, 5707–5711. [Google Scholar] [CrossRef]

- Gao, J.; Wang, Y.; Ping, Y.; Hu, D.; Xu, G.; Gu, F.; Su, F. A thermodynamic analysis of methanation reactions of carbon oxides for the production of synthetic natural gas. RSC Adv. 2012, 2, 2358–2368. [Google Scholar] [CrossRef]

- Méndez-Mateos, D.; Barrio, V.L.; Requies, J.M.; Cambra, J.F. A study of deactivation by H2S and regeneration of a Ni catalyst supported on Al2O3, during methanation of CO2. Effect of the promoters Co, Cr, Fe and Mo. RSC Advances. RSC Adv. 2020, 10, 16551–16564. [Google Scholar] [CrossRef] [PubMed]

- Bartholomew, C.H.; Weatherbee, G.D.; Jarvi, G.A. Sulfur poisoning of nickel methanation catalysts: I. in situ deactivation by H2S of nickel and nickel bimetallics. J. Catal. 1979, 60, 257–269. [Google Scholar] [CrossRef]

- Neuberg, S.; Pennemann, H.; Shanmugam, V.; Thiermann, R.; Zapf, R.; Gac, W.; Greluk, M.; Zawadzki, W.; Kolb, G. CO2 Methanation in Microstructured Reactors—Catalyst Development and Process Design. Chem. Eng. Technol. 2019, 42, 2076–2084. [Google Scholar] [CrossRef]

- Gac, W.; Zawadzki, W.; Rotko, M.; Słowik, G.; Greluk, M. CO2 Methanation in the Presence of Ce-Promoted Alumina Supported Nickel Catalysts: H2S Deactivation Studies. Top. Catal. 2019, 62, 524–534. [Google Scholar] [CrossRef]

- Alarcón, A.; Guilera, J.; Soto, R.; Andreu, T. Higher tolerance to sulfur poisoning in CO2 methanation by the presence of CeO2. Appl. Catal. B Environ. 2020, 263, 118346. [Google Scholar] [CrossRef]

- Rodriguez, J.A.; Hrbek, J. Interaction of Sulfur with Well-Defined Metal and Oxide Surfaces: Unraveling the Mysteries behind Catalyst Poisoning and Desulfurization. Acc. Chem. Res. 1999, 32, 719–728. [Google Scholar] [CrossRef]

- Dannesboe, C.; Hansen, J.B.; Johannsen, I. Removal of sulfur contaminants from biogas to enable direct catalytic methanation. Biomass Convers. Biorefinery 2021, 11, 1823–1834. [Google Scholar] [CrossRef]

- Argyle, M.D.; Bartholomew, C.H. Heterogeneous Catalyst Deactivation and Regeneration: A Review. Catalysts 2015, 5, 145–269. [Google Scholar] [CrossRef]

- Stangeland, K.; Kalai, D.Y.; Li, H.; Yu, Z. Active and stable Ni based catalysts and processes for biogas upgrading: The effect of temperature and initial methane concentration on CO2 methanation. Appl. Energy 2018, 227, 206–212. [Google Scholar] [CrossRef]

- Han, D.; Kim, Y.; Byun, H.; Cho, W.; Baek, Y. CO2 Methanation of Biogas over 20 wt% Ni-Mg-Al Catalyst: On the Effect of N2, CH4, and O2 on CO2 Conversion Rate. Catalysts 2020, 10, 1201. [Google Scholar] [CrossRef]

- Gac, W.; Zawadzki, W.; Rotko, M.; Greluk, M.; Słowik, G.; Pennemann, H.; Neuberg, S.; Zapf, R.; Kolb, G. Direct Conversion of Carbon Dioxide to Methane over Ceria- and Alumina-Supported Nickel Catalysts for Biogas Valorization. ChemPlusChem 2021, 86, 889–903. [Google Scholar] [CrossRef]

- Pastor-Pérez, L.; Patel, V.; Le Saché, E.; Reina, T. CO2 methanation in the presence of methane: Catalysts design and effect of methane concentration in the reaction mixture. J. Energy Inst. 2020, 93, 415–424. [Google Scholar] [CrossRef]

- Mhadmhan, S.; Ngamcharussrivichai, C.; Hinchiranan, N.; Kuchonthara, P.; Li, Y.; Wang, S.; Reubroycharoen, P. Direct biogas upgrading via CO2 methanation to high-quality Biomethane over NiMg/CNT-SiO2 fiber catalysts. Fuel 2022, 310, 122289. [Google Scholar] [CrossRef]

- Zhuang, Y.; Simakov, D.S.A. Single-Pass Conversion of CO2/CH4 Mixtures over the Low-Loading Ru/γ-Al2O3 for Direct Biogas Upgrading into Renewable Natural Gas. Energy Fuels 2021, 35, 10062–10074. [Google Scholar] [CrossRef]

- Specht, M.; Hansen, J.B.; Johannsen, I. The Power to Gas Process: Storage of Renewable Energy in the Natural Gas Grid via Fixed Bed Methanation of CO2/H2. In Synthetic Natural Gas from Coal, Dry Biomass, and Power-to-Gas Applications; Wiley: Hoboken, NJ, USA, 2016; pp. 191–220. [Google Scholar]

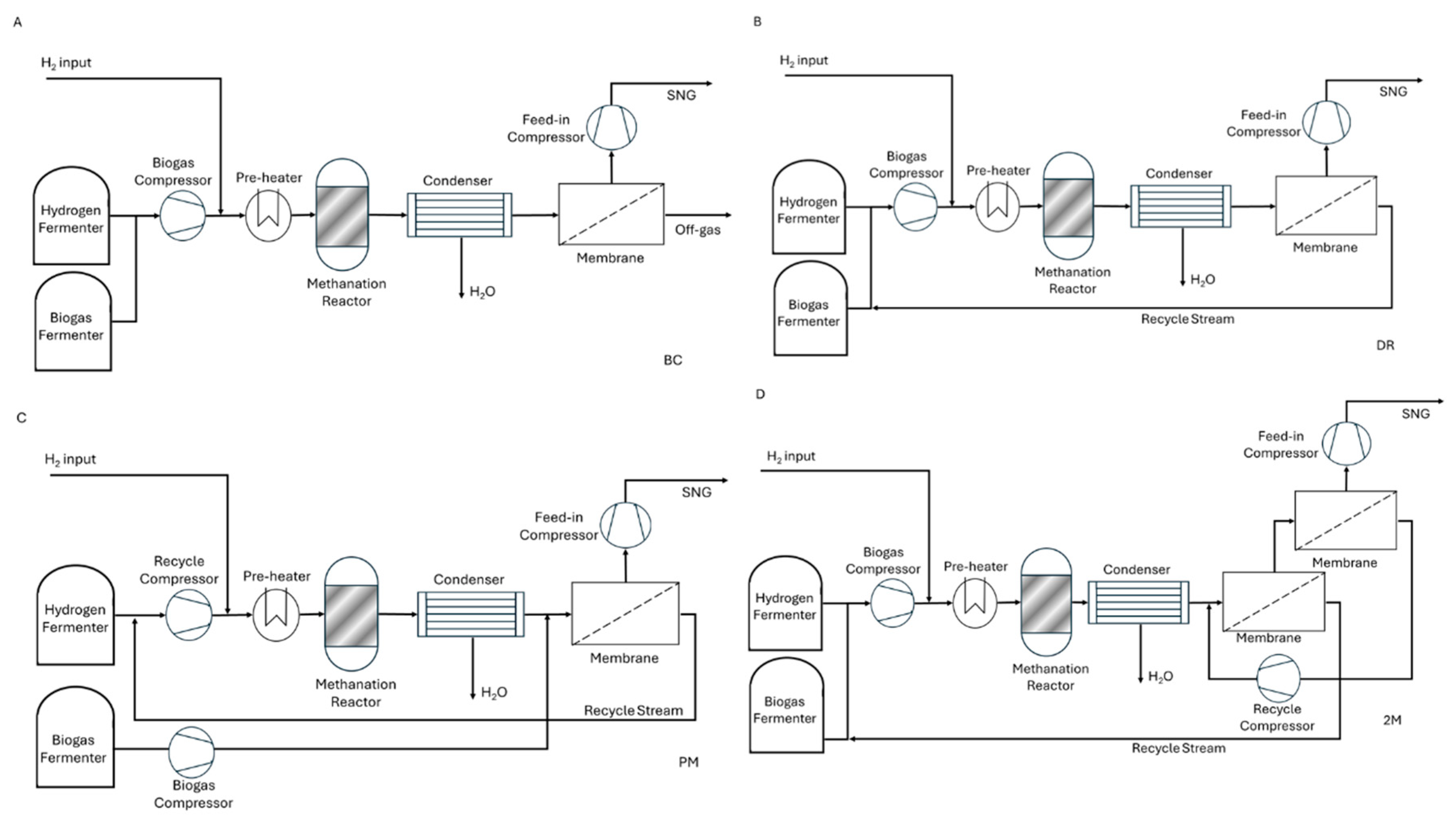

- Guilera, J.; Andreu, T.; Basset, N.; Boeltken, T.; Timm, F.; Mallol, I.; Morante, J.R. Synthetic natural gas production from biogas in a waste water treatment plant. Renew. Energy 2020, 146, 1301–1308. [Google Scholar] [CrossRef]

- Dannesboe, C.; Hansen, J.B.; Johannsen, I. Catalytic methanation of CO in biogas: Experimental results from a reactor at full scale. React. Chem. Eng. 2020, 5, 183–189. [Google Scholar] [CrossRef]

- Witte, J.; Calbry-Muzyka, A.; Wieseler, T.; Hottinger, P.; Biollaz, S.M.; Schildhauer, T.J. Demonstrating direct methanation of real biogas in a fluidised bed reactor. Appl. Energy 2019, 240, 359–371. [Google Scholar] [CrossRef]

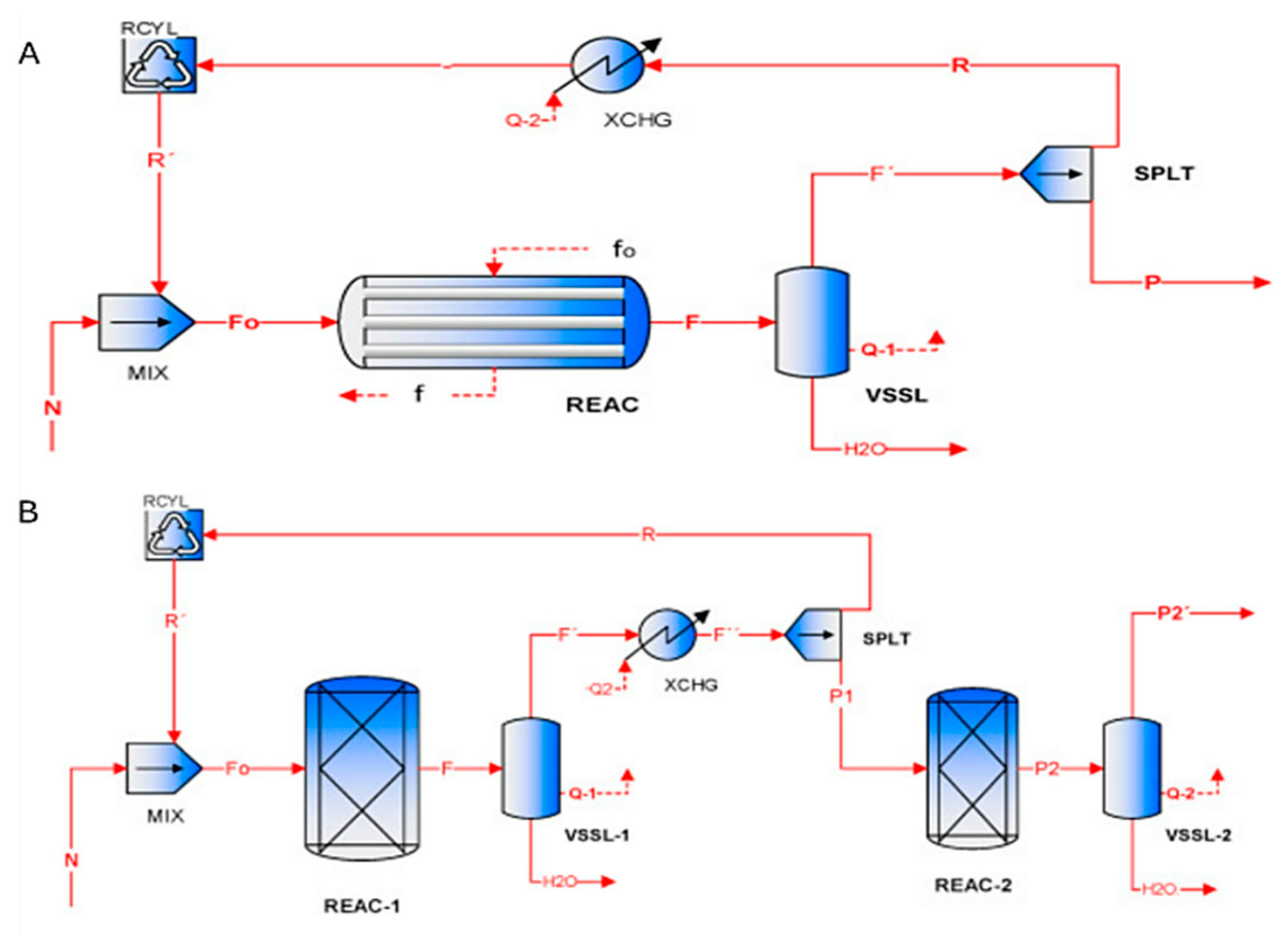

- Kirchbacher, F.; Biegger, P.; Miltner, M.; Lehner, M.; Harasek, M. A new methanation and membrane based power-to-gas process for the direct integration of raw biogas–Feasability and comparison. Energy 2018, 146, 34–46. [Google Scholar] [CrossRef]

- Gaikwad, R.; Villadsen, S.N.B.; Rasmussen, J.P.; Grumsen, F.B.; Nielsen, L.P.; Gildert, G.; Møller, P.; Fosbøl, P.L. Container-Sized CO to Methane: Design, Construction and Catalytic Tests Using Raw Biogas to Biomethane. Catalysts 2020, 10, 1428. [Google Scholar] [CrossRef]

- Calise, F.; Cappiello, F.L.; Cimmino, L.; Dentice d’Accadia, M.; Vicidomini, M. Dynamic simulation and thermoeconomic analysis of a power to gas system. Renew. Sustain. Energy Rev. 2023, 187, 113759. [Google Scholar] [CrossRef]

- Gutiérrez-Martín, F.; Rodríguez-Antón, L.M.; Legrand, M. Renewable power-to-gas by direct catalytic methanation of biogas. Renew. Energy 2020, 162, 948–959. [Google Scholar] [CrossRef]

- Kirchbacher, F.; Miltner, M.; Wukovits, W.; Harasek, M. Economic assessment of membrane-based power-to-gas processes for the European biogas market. Renew. Sustain. Energy Rev. 2019, 112, 338–352. [Google Scholar] [CrossRef]

- Leonzio, G. Design and feasibility analysis of a Power-to-Gas plant in Germany. J. Clean. Prod. 2017, 162, 609–623. [Google Scholar] [CrossRef]

- Peters, R.; Baltruweit, M.; Grube, T.; Samsun, R.C.; Stolten, D. A techno economic analysis of the power to gas route. J. CO2 Util. 2019, 34, 616–634. [Google Scholar] [CrossRef]

- Skorek-Osikowska, A.; Martín-Gamboa, M.; Dufour, J. Thermodynamic, economic and environmental assessment of renewable natural gas production systems. Energy Convers. Manag. X 2020, 7, 100046. [Google Scholar] [CrossRef]

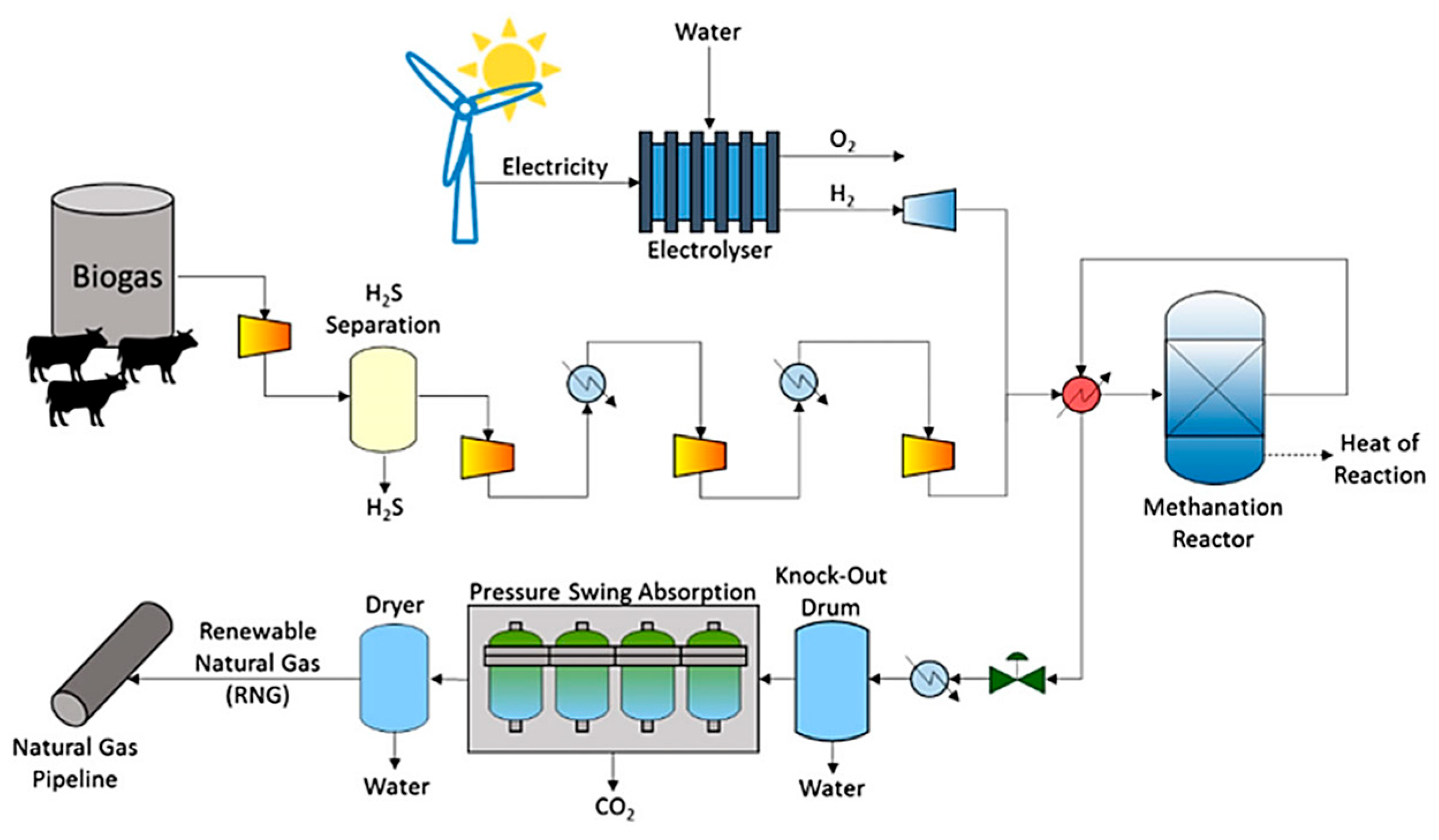

- Walker, S.B.; Sun, D.; Kidon, D.; Siddiqui, A.; Kuner, A.; Fowler, M.; Simakov, D.S. Upgrading biogas produced at dairy farms into renewable natural gas by methanation. Int. J. Energy Res. 2018, 42, 1714–1728. [Google Scholar] [CrossRef]

- Witte, J.; Kunz, A.; Biollaz, S.M.; Schildhauer, T.J. Direct catalytic methanation of biogas—Part II: Techno-economic process assessment and feasibility reflections. Energy Convers. Manag. 2018, 178, 26–43. [Google Scholar] [CrossRef]

- Qu, X.; Zeng, H.; Gao, Y.; Mo, T.; Li, Y. Bio-hydrogen production by dark anaerobic fermentation of organic wastewater. Front. Chem. 2022, 10, 978907. [Google Scholar] [CrossRef] [PubMed]

- Mao, K. Engineering Economy: Overview and Application in Process Engineering Industry. 10.490 ICE. Microsoft PowerPoint—Engineering Economics Lecture.ppt. 2006. Available online: https://ocw.mit.edu/courses/10-490-integrated-chemical-engineering-i-fall-2006/98288885a32c8a4054460082cb87a426_eng_econ_lecture.pdf (accessed on 17 November 2023).

- Ullah, S.; Gao, Y.; Dou, L.; Liu, Y.; Shao, T.; Yang, Y.; Murphy, A.B. Recent Trends in Plasma-Assisted CO2 Methanation: A Critical Review of Recent Studies. Plasma Chem. Plasma Process. 2023, 43, 1335–1383. [Google Scholar] [CrossRef]

| Feedstock | Biomass Production, (106 Tonnes of Feedstock Solids) | Collection Rates, (%) | ||

|---|---|---|---|---|

| Low | Medium | High | ||

| Agricultural crop residues | 43.13 | 31 | 45 | 60 |

| Livestock manure | 2.98 | 70 | 80 | 100 |

| Agro-industry waste | 6.92 | 50 | 75 | 90 |

| Food processing waste | 0.73 | 75 | 79 | 89 |

| Biowaste | 7.91 | 30 | 45 | 60 |

| Sewage sludge | 0.37 | 100 | 100 | 100 |

| Total | 62.03 | 36 | 51 | 66 |

| PSA | Membrane Separation | Water Scrubbing | Organic Physical Scrubbing | Chemical Scrubbing | Amine Scrubbing | Cryogenic Separation | Refs. | |

|---|---|---|---|---|---|---|---|---|

| Methane (vol%) | 95–99 | 90–99 | 93–99 | 93–99 | 97–99.5 | >99 | 91–98 | [7,8,10,42,43,44,45,46,47] |

| Methane loss (%) | 2–5 | 0.5–10 | 1–5 | 2–13 | <10 | <1 | <1 | [7,8,42,43,44,45,47] |

| Pressure (bar) | Operation: 4–10 Regeneration: 0.5 | Operation: 6–20 Pressure driven dense membranes: 20–36 | Absorption: 6–10 Flash: 2–4 Regeneration: 1 | 4–8 | 1–2 | 1–200 | [8,10,42,43,45,46,47] | |

| Temperature, (°C) | 50–60 | 20 | 40 | Ambient | Operation: 20 Regeneration: 100–150 | −25 to −125 | [8,42,43,46,47] | |

| Catalysts | Active Metal Loading, wt% | Pressure Bar | Temp. °C | CH4/CO2 | XCO2 % | SCH4 % | STY (molCH4·gcat−1·h−1) | Time on Stream (no H2S in Feed) | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Ni/Al2O3 | 20 | 1 | 350 | 0/100 | 71.5 | 99.7 | 0.25443 | 24 h | [69] |

| 50/50 | 70.8 | 99.5 | 0.25144 | ||||||

| 67/33 | 70.6 | 99.4 | 0.25047 | ||||||

| NiRu/Al2O3 | 20% Ni + 0.5% Ru | 1 | 350 | 0/100 | 85 | 100 | 0.30302 | 14 h | [69] |

| 67/33 | 81 | >99 | — | ||||||

| NiMg/Al2O3 | 20% Ni + 3% Mg | 1 | 400 | 0/100 | 76 | 96 | 0.194 | 200 h | [70] |

| 40/60 | 67 | 97 | 0.154 | ||||||

| 50/50 | 64 | 97 | 0.139 | ||||||

| 65/35 | 54 | 97 | 0.102 | ||||||

| Ni/Al2O3 | 20 | 2 | 350 | 0/100 | 88.5 | 100 | 0.182 | 20 h | [71] |

| 50/50 | 82 | 79 | 0.134 | ||||||

| Ni/Al2O3 | 40 | 2 | 350 | 0/100 | 91.4 | 100 | 0.188 | 20 h | [71] |

| 50/50 | 81 | 79 | 0.132 | ||||||

| Ni/Al2O3 | 20 | 12.5 | 350 | 50/50 | 93.7 | 100 | 0.193 | 70 h | [71] |

| Ni/Al2O3 | 40 | 12.5 | 350 | 50/50 | 95.7 | 100 | 0.197 | 70 h | [71] |

| Ni/CeO2 | 20 | 2 | 350 | 0/100 | 91.7 | 100 | 0.189 | 20 h | [71] |

| 50/50 | 81 | 75 | 0.125 | [71] | |||||

| Ni/CeO2 | 20 | 12.5 | 350 | 50/50 | 94.6 | 100 | 0.195 | 70 h | [71] |

| NiCo/CeO2-ZrO2 | 15% Ni + 3% Co | 1 | 350 | 0/100 | 71 | 98 | 0.075 | - | [72] |

| 21/79 | 72 | 97 | 0.071 | - | |||||

| 36/64 | 74 | 98 | 0.070 | - | |||||

| 47/53 | 78 | 99 | 0.070 | 38 h | |||||

| Ni/CNT-silica | 10 | 10 | 350 | 60/37 | 86.3 | 97 | 0.067 | <14 h | [73] |

| NiMg/CNT-silica | 10% Ni + 2% Mg | 10 | 350 | 60/37 | 95 | 98 | 0.074 | 4 h | [73] |

| Ru/γ-Al2O3 | 0.5 | 3 | 450 | 50/50 | ~80 | ~100 | ~0.535 | 60–70 h | [74] |

| Study | Reactor Type | Feedstock | Operating Temp (°C) | Pressure (bar) | Catalyst | CO2 Conversion (%) | Scale, Nm3/h/ Capacity | Runtime | Refs. |

|---|---|---|---|---|---|---|---|---|---|

| Specht et al. (2016) | Fixed-bed | CO2/H2 and CH4/CO2/H2 | ~300–400 | 5–10 | Ni | ~100 | -/25 kW, 250 kW | — | [75] |

| Guilera et al. (2020) | Fixed-bed | Biogas (CO2 from upgrading) + H2 | ~350 | 12 | Ni | ~80–90 | 50/37 kW | >600 h | [76] |

| Dannesboe et al. (2020) | Packed Bed (cooled) | Raw biogas | ~300–350 | Atmospheric | Ni | — | 10/- | 1000 h | [77] |

| Witte et al. (2019) | Bubbling fluidised bed | Real/simulated biogas | ~350–400 | 1–5 | Ni | ~95 | 1.4–2.3/10–20 kW, | 1100 h | [78] |

| Kirchbacher et al. (2018) | Fixed-bed + membrane | Real/simulated biogas | ~300–400 | Variable (optimised for GHSV) | Ni | ~85–95 | 0.5/- | — | [79] |

| Gaikwad et al. (2020) | 4 reactors in series | Raw biogas | 350–400 | Atmospheric | Ni | >90 | 10/- | — | [80] |

| Australia (Jemena–Sydney Water) | Membrane Separation | Biogas | Ambient | — | — | — | 1100/- | — | [37] |

| Units | Year | Processes Modelled | |

|---|---|---|---|

| 21.67–41.67 | EUR/GJ | 2022 | Membrane separation and methanation |

| 13.72–14.74 | EUR/GJ | 2020 | Single and double bed methanation |

| 32.48 | EUR/GJ | 2020 | Amine scrubbing and methanation |

| 35.34 | EUR/GJ | 2019 | Amine scrubbing and methanation |

| 31.54–37.55 | EUR/GJ | 2019 | Membrane separation, methanation, and gas recycling |

| 40 | USD/GJ | 2018 | PSA and methanation |

| 26.49–60.56 | EUR/GJ | 2018 | Methanation and hydrogen membrane gas recycling |

| 36.91 | EUR/GJ | 2017 | Biogas cleaning and multistage methanation |

| Capital Costs | Operational Costs | Financial Feasibility Considerations |

|---|---|---|

| Construction | Finance and taxation | Income/Offsets |

| Anaerobic digester | Carbon pricing | Feed-in tariffs |

| Cooling unit | Corporate/business tax rate | Primary product sale |

| Compressor | Loan repayment rate | Discount rate |

| Condenser unit | Loan lifetime | Secondary product sales |

| Desiccator unit | Interest rate | Tax offsets |

| Desulphurisation unit | Insurance | Expenditure |

| Feedstock storage | Maintenance and operation | Capital costs |

| Gas holding/export equipment | Catalyst material | Insurance |

| Gas piping | Computers and equipment | Loans |

| Gas quality monitoring equipment | Feedstock | Operational costs |

| Gas recycling unit | Gas piping repair | Taxation |

| Gas separation unit | Liquid piping repair | Size, capacities, and efficiencies |

| Gas turbine | Maintenance consumables | Annual operational hours |

| Heat exchanger | Reagents and inoculum | Compression pressure |

| Heating unit | Specialised software/licences | Corrosion protection |

| Liquid and solid separation unit | Waste disposal | Efficiency of renewable energy source |

| Liquid piping | Staff | Energy efficiency |

| Liquid pump | Bonus rates | Export capacity |

| Liquid waste holding | Number of staff | Gas canister dimensions |

| Methanation reactor | Staff hours | Gas canister material |

| Solar panels | Staff pay | Gas canister pressure |

| Solid waste holding | Staff holidays | Heat transfer efficiency |

| Utility installation | Sick leave | Lifetime of equipment |

| Wind turbine | Utilities | Pipe dimensions |

| Investment costs | Electricity | Pipe gauge |

| Specialised software | Gas supply | Pipe material |

| Computers and equipment | Heating oil | Pipe pressure |

| Initial feedstock | Water | Plant capacity |

| Initial reagents and inoculum | Production efficiency | |

| Land acquisition | Renewable energy averages | |

| Non-plant construction | Storage capacity | |

| Site offices | ||

| Staff facilities | ||

| Utility installation |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hazewinkel, P.; Swinbourn, R.; Li, C.; Zhao, J.; Yang, Y. A Comprehensive Review of Green Methane Production from Biogas and Renewable H2 and Its Techno-Economic Assessment: An Australian Perspective. Energies 2025, 18, 4657. https://doi.org/10.3390/en18174657

Hazewinkel P, Swinbourn R, Li C, Zhao J, Yang Y. A Comprehensive Review of Green Methane Production from Biogas and Renewable H2 and Its Techno-Economic Assessment: An Australian Perspective. Energies. 2025; 18(17):4657. https://doi.org/10.3390/en18174657

Chicago/Turabian StyleHazewinkel, Philip, Ross Swinbourn, Chao’en Li, Jiajia Zhao, and Yunxia Yang. 2025. "A Comprehensive Review of Green Methane Production from Biogas and Renewable H2 and Its Techno-Economic Assessment: An Australian Perspective" Energies 18, no. 17: 4657. https://doi.org/10.3390/en18174657

APA StyleHazewinkel, P., Swinbourn, R., Li, C., Zhao, J., & Yang, Y. (2025). A Comprehensive Review of Green Methane Production from Biogas and Renewable H2 and Its Techno-Economic Assessment: An Australian Perspective. Energies, 18(17), 4657. https://doi.org/10.3390/en18174657