1. Introduction

The BN-350 is the first industrial fast neutron reactor with a liquid metal coolant in the history of nuclear energy. It was commissioned on 16 July 1973 in the city of Aktau (Kazakhstan). The primary goal of its development was to demonstrate the practical feasibility of fast sodium reactor technology on an industrial scale [

1].

The reactor facility operated as part of the Mangyshlak Atomic Energy Combine (MAEC). The primary purpose of MAEC was to supply Aktau city and its industrial facilities with thermal and electric energy. Additionally, as part of MAEC, a pilot industrial facility for seawater desalination powered by nuclear energy was implemented [

2].

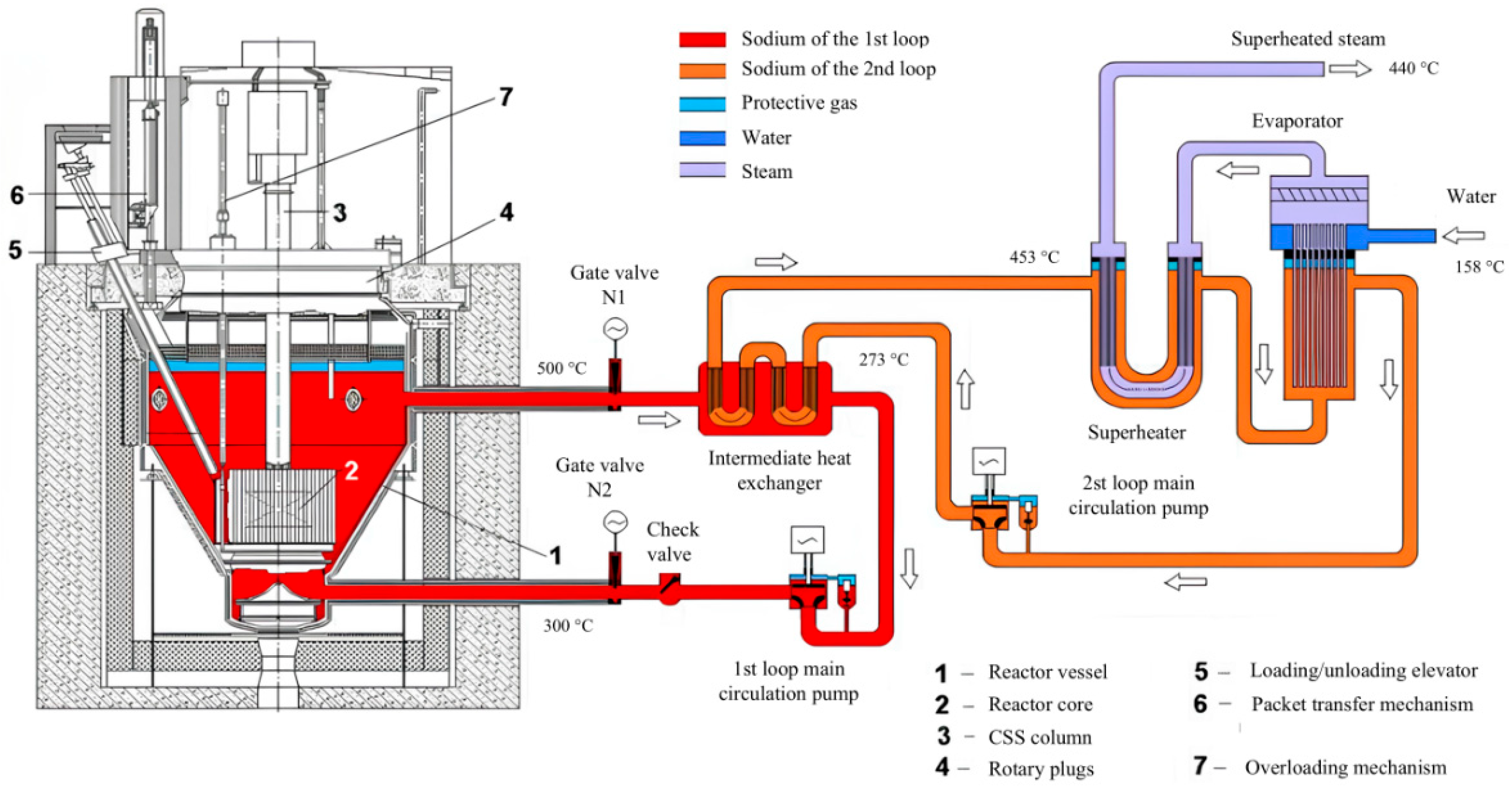

The BN-350 reactor featured a loop-type design with the main reactor equipment housed in separate vessels connected by pipelines. A three-loop system was used for reactor cooling and steam generation. Liquid sodium was used as the coolant in the first and second loops, while water circulated in the third loop. The reactor vessel was constructed from stainless steel.

Figure 1 shows the schematic diagram of the BN-350 reactor [

3].

The Government of the Republic of Kazakhstan decided to discontinue the operation of the BN-350 reactor in 1999. Subsequently, the reactor facility was shut down and placed into decommissioning mode [

4]. As part of this process, a priority action plan was developed, taking into account the structural and technological features. All decommissioning activities were divided into five technological stages [

5].

The first stage was related to spent fuel and was completed in 2010. Currently, the spent fuel is placed for long-term storage in the «Baikal-1» complex on the territory of the former Semipalatinsk test site. The second stage is related to radioactive sodium management. The fourth stage is related to liquid radioactive waste management. The last and fifth stage is related to bringing the BN-350 reactor complex to a safe state for long-term storage.

The third stage of the reactor decommissioning process involves the management of solid radioactive waste (SRW). A major challenge in implementing this stage is the lack of completed decommissioning projects for industrial fast reactors in global practice. To date, similar facilities are either in a state of long-term conservation or at the initial stages of dismantling [

6,

7,

8,

9,

10].

Thus, today, there is no full international experience in the processing and final disposal of significant volumes of solid radioactive waste generated during the operation of fast reactors. Excluding fuel, radioactive waste from fast and thermal reactors differs mainly in material activation and coolant type. Thermal reactors use water, which hardly becomes radioactive. Their structural materials are weakly irradiated, producing larger but less radioactive waste. Fast reactors use liquid sodium, which becomes radioactive under neutron flux. Their materials are more strongly activated. As a result, fast reactors generate less waste by volume, but it is more radiotoxic and harder to handle.

In this regard, the waste accumulated at the BN-350 reactor requires a special scientific and technical approach for its processing and safe disposal in order to minimize negative impacts on humans and the environment.

The need for pre-processing of solid radioactive waste before its disposal is due to a number of key factors:

Significant volumes of waste combined with their low bulk density require large areas for disposal without pre-processing, as well as significant costs for expensive structural materials (metals, alloys) for the construction of storage facilities.

Solid radioactive waste is a potential environmental threat due to the possible deterioration of the physical and mechanical properties of storage materials under the influence of ionizing radiation [

11].

Secondary radioactive materials (contaminated liquids, dust, deposits, etc.) are formed during waste management. They are also subject to safe management [

12].

A comprehensive approach to processing the solid radioactive waste accumulated during the operation of the BN-350 reactor will significantly improve the efficiency of its subsequent storage and disposal. At the same time, a scientifically based strategy for the development and implementation of processing technologies is required. This strategy should ensure reliability, safety and compliance with environmental standards.

Thus, this review is devoted to highlighting the current state of the problem of accumulated solid radioactive waste from the BN-350 reactor, their classification, and possible technical solutions for their processing and disposal.

2. Storage Facility for SRW from the BN-350 Reactor

At the moment, the accumulated SRW is placed on the territory of a specially built storage facility as part of the BN-350 reactor complex [

13].

Figure 2 shows the general scheme of the storage facility [

14].

The following buildings are located on the territory of the SRW storage:

- -

Building 156. Storage of low- and intermediate-level SRW which consists of the two parallel earthen trenches No. 1 and No. 2. The trenches were filled with waste in bulk, filled with earth, compacted and concreted.

- -

Building 158. A reinforced concrete storage facility for highly active SRW, consisting of a bunker with twelve loading hatches

- -

Building 159. A storage facility for large-sized SRW, consisting of the two parallel earthen trenches No. 1 and No. 2.

- -

Building 216. A storage facility for SRW with a dose rate ≤ 1 µSv/h which is an earthen trench.

- -

Building «Ch». A storage facility in the form of an earthen trench for special vehicles.

- -

Arched warehouse. Temporary storage of dismantled equipment is located on the concrete platform of building 159.

In addition to the buildings on the site of the storage, the storage facility also contains reinforced concrete protective containers of the type NZK-150-1.5 P [

15]. They are designed for storage and transportation of low-level and intermediate-level SRW.

3. Analysis of the Current Status of SRW Accumulated from the BN-350 Reactor

3.1. Strategy for Management SRW

The SRW of the BN-350 reactor has been accumulated as a result of the operation of the reactor, as well as during its decommissioning. At first glance, it may seem that the delay in the implementation of the project for the complex processing of SRW is less challenging. However, it requires timely completion, as the last fifth stage cannot be completed before the other stages.

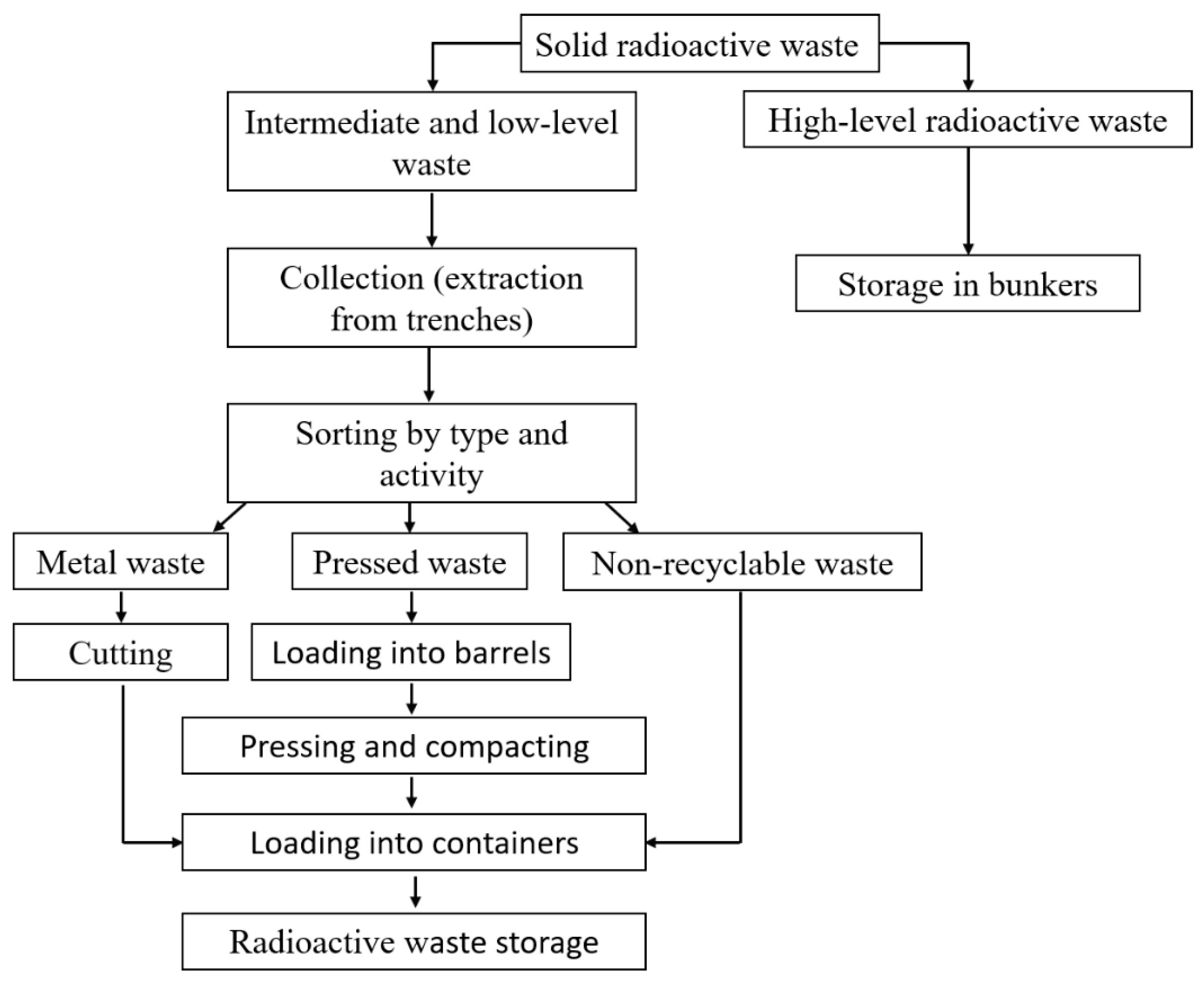

The concept of the management of the BN-350 reactor SRW (see

Figure 3) consists of the following main stages [

16,

17]:

- -

Sorting of SRW by type and activity level;

- -

Transportation of solid waste for sorting;

- -

Sorting and processing of SRW with subsequent placement;

- -

Transportation of processed SRW for long-term storage.

The metal waste will be cut and packed into containers, while some waste (pressed waste) will be compressed to reduce its volume. The final stage of SRW management is the disposal of processed waste in storage facilities in protective containers. As can be seen from the scheme, only intermediate-level and low-level waste are subject to processing. High-level SRW will be placed in the same containers and sent to the storage facility without pre-processing. At the same time, it is first necessary to classify and sort the waste in order to determine the appropriate recycling technology for complete long-term waste disposal.

3.2. Description and Classification of SRW from the BN-350 Reactor

An assessment of the accumulated SRW was performed based on morphological characteristics in order to complete the main stages of the technological scheme for management of the BN-350 reactor SRW. This made it possible to classify the accumulated SRW into several groups.

Table 1 shows the morphological composition of the accumulated SRW divided by groups.

An assessment of the accumulated radioactive waste showed that there are currently more than ~7262 tons in the storage facility.

Table 2 shows an assessment of the mass of SRW divided into three groups (low-level, intermediate-level and high-level) depending on their activity within the framework of the rules of the IAEA and the Republic of Kazakhstan [

18,

19].

Based on the results of the study of samples of various types of SRW, they were evaluated to the appropriate groups depending on their activity:

- -

High-level waste to group III;

- -

Intermediate-level waste to group II;

- -

Low-level waste to group I.

Table 3 shows the specific activity of low-level and intermediate-level SRW samples.

Table 4 shows the specific activity of high-level SRW samples.

Materials with low activity are the main part of the accumulated SRW and account for ~89% of the total mass. At the same time, high-activity SRW accounts for ~2% of the total mass, but they provide ~93% of the main activity. Ground trenches were used to place the bulk of low- and intermediate-level solid radioactive waste.

As noted earlier, only low- and intermediate-level activity SRW are recyclable with the exception of some waste. High-level SRW is not recyclable. The low- and intermediate-level activity SRW was classified into different categories depending on the available processing methods for the convenience of systematization.

Figure 4 and

Figure 5 show the scheme of material balance of low- and intermediate-level activity SRW in storage.

Non-recyclable high- and intermediate-level SRW includes sodium metal, special equipment, radionuclide sources, etc. (

Table 5). After sorting, these wastes will be placed in protective containers and placed for long-term storage.

Special attention was paid to metal SRW as it accounts for the majority of all SRW and requires special research methods to study the nature of its contamination. As a result of the work, data were obtained on the types of metal SRW. Their classification by activity was conducted and their mass and volume were estimated (

Table 6).

4. Analysis of the Possibility of Processing BN-350 Reactor Metal Radioactive Waste for Reuse

At the current stage of managing solid radioactive waste (SRW) from the BN-350 reactor, the waste has been successfully sorted based on its physical characteristics and contamination levels. After sorting, the waste was placed in temporary storage under safe conditions, creating the necessary groundwork for subsequent processing steps.

According to the current waste management strategy, the next step involves fragmentation. This process reduces the volume and alters the shape of large equipment, structures, and other waste materials, facilitating easier packaging, transportation, temporary storage, and further processing [

20].

The primary fragmentation methods selected for the BN-350 SRW are pressing and mechanical cutting [

21,

22]. Approximately 5500 tons of low-level waste and around 360 tons of intermediate-level waste will be compacted through pressing (see

Figure 3), while over 3000 tons of metallic radioactive waste will be cut into smaller pieces. After fragmentation, the waste will be packed into specialized containers and moved to long-term storage.

In recent years, a promising area in radioactive waste management has been the processing of metallic radioactive waste (MRW) for reuse [

23]. This approach is especially relevant because much of the metal waste generated during nuclear facility decommissioning is contaminated mainly on the surface. Such surface contamination usually results from radionuclide deposition on equipment during operation [

24].

Given the substantial volume of MRW (more than 1660 tons of valuable carbon and alloy steels) accumulated from the BN-350 reactor decommissioning, successful processing technologies could recover valuable and costly metals and alloys. These processed materials have potential applications in various industries [

25], including the construction of radioactive waste storage facilities. This approach not only helps reduce total MRW volume but also promotes the efficient use of resources, leading to significant cost savings in construction and disposal [

26].

Currently, the main method for processing metallic radioactive waste is remelting in metallurgical furnaces, such as induction, arc, and plasma furnaces [

27,

28,

29,

30,

31,

32,

33,

34,

35]. Research shows that remelting significantly lowers the overall radioactivity of the metals and confirms the feasibility of processing contaminated metals for reuse across different sectors.

Experiments on MRW processing were carried out using an electroslag remelting (ESR) facility. This facility is part of the experimental base at the Institute of Atomic Energy within the National Nuclear Center of the Republic of Kazakhstan, which specializes in nuclear energy development [

36,

37].

The feature of electroslag remelting is that electroslag furnaces melt electrodes from radioactively contaminated metal using ohmic heating. The molten radioactive metal passes through the molten flux and falls into the molten pool. In this case, selective extraction of radioactive nuclides from the radioactive metal composition occurs during the processes of electrochemical interaction of the metal with the components of the flux.

The facility is an electroslag furnace with a water-cooled crystallizer of a closed type. The crystallizer provides melting of the electrode metal and the working flux at a temperature of ~2000 °C, forming an ingot.

Figure 6 shows the schematic of the ESR facility.

Steel pipes of technological channels of the research high-temperature gas cooled reactor IVG.1 were used as a source of MRW. These channels were used to test fuel elements and fuel assemblies of nuclear thermal rocket before upgrading the cooling system of the IVG.1 reactor [

38].

Table 7 shows the results of radionuclide activity measurements in the electrode before the start of the experiments and in samples taken from the electrodes after remelting. The «Canberra» gamma-ray spectrometer was used to determine the isotopic composition and activity of the samples. The minimum detectable activity (MDA) for various radionuclides was measured within 1-h ranges from 0.15 Bq to 1 Bq.

As we can see, the steel pipes could be classified as low-radioactive waste in the initial state. Gamma-ray spectrometric measurements have shown that radionuclides Co-60, Cs-137 and U-235 contribute to the main activity of MRW. The activity of the metal decreases due to its purification from radioactive purification after remelting. The use of ESR is characterized by high efficiency in cleaning the steel pipes from uranium and caesium.

Uranium was not detected in the studied samples. Most likely, its concentration in the samples was lower than the minimum detectable value in the used gamma-ray spectrometer. At the same time, the activity of the Co-60 remains almost at the initial level and is due to the choice of flux for ESR.

In this regard, it is obvious that the next step in this direction is the quantitative or mechanical analysis of the behavior of radionuclides during electroslag remelting for a more complete understanding of the underlying processes. The analysis will include kinetic studies and the development of mathematical models. Experimental data will be used to verify the developed models.

Thus, the application of electroslag remelting to steel pipes resulted in a significant reduction in the total radioactivity of the metallic radioactive waste. The obtained results confirm the fundamental feasibility of effectively decontaminating MRW using this method.

5. Conclusions

The main purpose of decommissioning the BN-350 reactor is to ensure safe storage conditions for its key equipment. This is essential for protecting both people and the environment. A critical part of this process is managing the accumulated solid radioactive waste. To support effective waste management, a detailed classification and assessment of the waste was conducted. This assessment took into account several factors, including mass, volume, and levels of radioactivity.

An analysis of the accumulated solid radioactive waste has shown that over ~7262 tons have been collected. The majority of this waste (~89% of the total mass) consists of low-activity materials. At the same time, it was found that ~93% of the total radioactivity is concentrated in high-activity materials with a total mass of 170 tons. The solid radioactive waste includes a wide range of materials, such as metal structures, contaminated insulation, used protective clothing, and residues from liquid radioactive waste treatment processes.

Thus, the classification and sorting process was successfully completed taking into account both the physical properties and contamination levels of the waste. All waste is now safely stored under controlled conditions. This lays the groundwork for the next stages of waste management. The next planned stage is fragmentation. This process aims to reduce the volume and modify the shape of large-sized materials. It will help simplify subsequent packaging, transportation, and processing.

In particular, metallic radioactive waste will be cut into smaller components. These fragments will then be packaged into specialized containers for long-term storage. Processing a portion of the metallic waste will not only reduce the overall volume but also allow for the recovery of valuable materials. This approach supports both economic efficiency and environmental sustainability through the reuse of recycled resources.

Recent studies on the melting of radioactive metal waste have confirmed the practical feasibility of processing metals and alloys for future use. In this regard, it is recommended to revise and update the current BN-350 waste management strategy. Special attention should be given to the integration of recycling technologies that enable material recovery and enhance the overall efficiency of waste management.