1. Introduction

The global energy landscape is undergoing a significant transformation, shifting from a fossil fuel-based economy to one increasingly powered by renewable energy sources. This energy transition is driven by the urgent need to mitigate climate change, reduce greenhouse gas emissions, and enhance energy security.

This work was born from the need to contribute, even if only in an infinitesimal way, to the spread of awareness towards advanced energy solutions, which take into account the protection of the environment and people. Therefore, through an insight into the current energy context, and the energy transition, this work presents the synergization of anaerobic digestion technologies and solid oxide fuel cell ones.

An energy analysis aims to identify the technical parameters required to maximize system performance, while an economic analysis—based on current incentive schemes and legislation—assesses the investment’s feasibility, both for the case of biomethane sale alone and for integration with SOFC systems for subsequent electricity and thermal energy sales.

1.1. Energy Context

Over the past 50 years, global CO

2 equivalent emissions have shown a significant upward trajectory, driven primarily by industrial activities, energy production from fossil fuels, land use change, and other anthropogenic sources. In 1990, global CO

2 equivalent emissions were approximately 22 Gt. The latest data from 2023 indicate that global CO

2 equivalent emissions have continued to grow, overcoming 37 Gt, associated to energy consumption for 73% and reflecting over 64% increase in the latest 30 years [

1]. Clearly, an upward profile of energy consumption was registered in parallel. This was led by fossil-based (oil, coal, natural gas) energies that accounted for about 77% of the energy share in 2022, reaching over 137,000 TWh [

2]. This increasing tendency has been strictly accompanied by a very fast increase in the average temperature of the planet surface, overcoming the increase of 1.4 °C [

3]. Comparing these pieces of evidence, a strict correlation can be associated with CO

2 emissions in the atmosphere.

However, the latest World Energy Outlook by the International Energy Agency (IEA) indicates a deceleration in the growth of fossil-based energy, with a decreasing growth rate despite the absolute value continuing to increase up to 2030 [

4,

5]. Coal energy has approached its peak, while natural gas and oil are projected to reach their maximum around 2030. Specifically, 2030 is identified as a pivotal year where fossil-based energy demand will begin to decline, marking a significant shift in global energy trends. As we know, according to the Paris Agreement [

6], the energy offer will must be arranged in order to contain the temperature increase to 1.5 °C by 2050, indicating 2050 exactly as the year of “net zero”. For this reason, the international scientific and industrial community has taken action to give life and concreteness to this “energy transition”, in order to increase the penetration of renewable and clean energies, as well as to optimize processes and systems, and also rationalize and make the conventional energy systems more efficient [

7]. A series of actions a have been undertaken, also thanks to the push of incentive policies. Renewable power additions saw unprecedented growth in 2023, accounting for 87% of newly installed capacity (+473 GW to the global energy mix, with solar energy accounting for 73%) [

7].

In this, the European Union aims for a 45% share from renewables by 2030, as indicated by the RePowerEU plan [

8]. In the energy landscape, biomass exploitation stands as a cornerstone, particularly through the transformation of biomass waste into valuable, high-grade, energy. This process not only addresses the critical issue of waste management but also contributes significantly to the energy transition by converting impactful waste into a precious resource. The waste-to-energy chain is essential for advancing a circular bio-economy, where organic waste materials are recycled into energy, thus reducing reliance on fossil fuels and lowering greenhouse gas emissions. Biomass can be utilized either in its raw form (when possible) or processed to produce valuable by-products using suitable technologies and processes. For instance, hydrothermal treatment is a low-carbon method for converting lignocellulosic biomass into a variety of high-value bioproducts by breaking down and transforming the lignocellulosic materials [

9].

Biofuels derived from biomass processing hold immense potential for the future, offering a sustainable alternative that can seamlessly integrate with existing energy systems. These biofuels enhance the renewability of conventional energy architectures without necessitating major modifications, thereby providing a practical and impactful pathway towards a greener, more sustainable energy future.

1.2. Biofuel Energy

Biological and synthetic fuels, such as biogas and syngas, will play an important role in the coming decades. Therefore, the term biorefinery is increasingly entering the energy paradigm, and the anaerobic digestion process aimed at producing biogas from wet organic waste has recorded a rapid rise. It is known that waste such as the organic fraction of municipal waste, agro-industry waste, wastewater, up to zootechnical waste, and even dedicated energy crops, are highly suitable for producing quality biogas [

10]. In 2020, the worldwide production of biogas was 38.1 Gm

3, which had an energy content equivalent to 1.46 EJ. Europe was the largest producer, accounting for 53% of the total global production, followed by Asia with 32% [

11].

Beyond biofuel, to the use of clean hydrogen is promising too. Hydrogen has been strongly considered to decarbonize the energy, industry, and transport sectors [

12,

13]. It can be produced in several manners, with the most common technologies including electrolysis and reforming. Electrolysis is operated with an electrical source, converting water, while reforming considers a thermochemical conversion under the action of a thermal source facilitating the conversion of a hydrocarbon (like methane) [

14,

15,

16,

17]. Other types of generation include biological conversion as the photo and dark fermentation of organics (still far from being mature) [

16]. The production targets for green hydrogen are ambitious. The European Union aims to produce 10 million tons of green hydrogen annually by 2030 [

18], stimulating the national strategic energy plans.

The current trend in biofuel production largely focuses on the production of biomethane, with the aim of integrating it into the national natural gas grid [

19,

20]. Through RePowerEU, the European Commission has set the goal of producing 35 Gm

3 of biomethane from biogas per year by 2030 [

21]. In this regard, it should be underlined that a recent report by the European Biogas Association estimated a potential biomethane production of 111 Gm

3 in Europe by 2040, which represents more than 30% of EU natural gas consumption by 2022 [

22].

The potential for valorizing organic waste emerges from the study of a series of official documents. Furthermore, biofuel energy also demonstrates great flexibility and versatility of application, from small rural contexts to large consortia.

The next lines take a quick zoom on the regional and national context to which the authors of this work belong with regards to the production of biofuel from anaerobic digestion and the energy production systems that use it.

Biogas is produced 65% from agricultural waste, and the remaining portion from livestock effluents (20%), OFMSW (2%), and sewage sludge deriving from the wastewater treatment process (3%) [

23]. Italy can count on around 2200 plants and a production of around 2.5 Gm

3 of biogas. Traditionally, integrated energy systems based on anaerobic digestion use internal combustion engines [

24]; however, this limits both electrical and thermal efficiency. In fact, internal combustion engines have an electrical efficiency limited to 30–35% and, often, systems are not equipped with units for recovering waste heat.

The differentiated quantity of OFMSW is too low yet (39% in some regions [

25]).

The article [

26] demonstrates that small biogas production can even be useful in small rural contexts, with the aim of using the biofuel for heating, highlighting the resulting simplicity of the system using conventional boilers. According to a recent ISTAT (Italian National Statistics Institute) census (2022) [

27], there are 1,133,023 agricultural companies in Italy. Of these: 240,980 have less than 1 hectare, 209,662 have between 1 and 2 hectares, and 128,381 have between 2 and 3 hectares. Overall, this last class of companies represents 51.1% of the total and are family-run. Under these conditions, their wastes are capable of producing on average 1250 Nm

3 of methane per year, which is a sufficient quantity for the cooking, domestic hot water, and heating needs of the same users [

26].

Based on the previous analysis, it can be considered that the margin for exploiting bioenergy from wet waste biomass is large, both by forcing the recovery of organic municipal waste and by adopting more efficient energy technologies. The opportunity to convert organic waste into energy represents an important solution especially for remote rural areas, stimulating the creation of consortia and systems capable of producing electrical and thermal energy and mitigating the existing energy deficit.

1.3. AD-SOFC Synergy

Biological and synthetic fuels, such as biogas and syngas, will play an important role in the coming decades. Anaerobic digestion is a biological process that breaks down organic, in the absence of oxygen to produce biogas and digestate [

24]. Biogas, primarily composed of methane and carbon dioxide, in a typical proportion of 60:40, can be used as a renewable energy source for electricity and heat, or as a vehicle fuel [

28,

29].

Anaerobic digestion occurs in four stages. Complex organic matter first undergoes hydrolysis, where extracellular enzymes break large polymers into soluble sugars, amino acids, and long-chain fatty acids. These smaller molecules are then taken up by acidogenic bacteria, which ferment them into volatile fatty acids, alcohols, hydrogen, and carbon dioxide. In the third phase, acetogenic microbes convert the bulk of these fermentation products—especially longer-chain acids and alcohols—into acetate, hydrogen, and more CO2. Finally, methanogenic archaea exploit the resulting substrates, producing methane and carbon dioxide to yield the biogas that exits the digester.

An energy plant utilizing anaerobic digestion typically includes several key components [

30]: a feedstock preparation system, anaerobic digesters, biogas cleaning and upgrading units, and a combined heat and power (CHP) system. Advanced technologies such as continuous stirred-tank reactors (CSTRs) or plug-flow reactors are used to optimize the digestion process, ensuring maximum biogas yield. Anaerobic digestion performance can vary depending on the type of biomass and the specific technology used. Typical biogas from OFMSW ranges from 90 to 150 m

3 per ton of biomass treated. High organic content, particularly in the form of volatile solids (VSs), is crucial for effective biogas production. Biomass with vs. content above 50% is generally considered suitable for anaerobic digestion. The carbon-to-nitrogen (C/N) ratio is an important parameter. An optimal C/N ratio ranges from 20:1 to 30:1. Too high or too low ratios can inhibit microbial activity and biogas production. Adequate moisture is necessary for microbial activity. Biomass with 75–90% moisture content is ideal for anaerobic digestion processes. The pH level should be maintained between 6.5 and 7.5 for optimal microbial activity. Temperature is a critical factor, affecting microbial activity and biogas production. A Mesophilic Digestion occurs at 20–45 °C, with an optimum nearly around 35–37 °C. A Thermophilic Digestion occurs at 45–60 °C. Another parameter is the hydraulic retention time (HRT), that ranges from 15 to 30 days.

Among the advanced energy systems, the fuel cell ones emerge, especially solid oxide fuel cell (SOFC)-based, whose integration with anaerobic digester presents a promising pathway for sustainable energy generation.

SOFCs are electrochemical devices characterized by a high efficiency and fuel flexibility [

31,

32]. Operating at high temperatures (700–1000 °C), SOFCs can internally reform hydrocarbons, making them suitable for a variety of fuels, natural gas, and biogas beyond pure hydrogen [

15,

33,

34]. The system architecture is therefore arranged in order to create a hydrogen rich gas internally. This stream then feeds the thermo-electrochemical SOFC core generating electric and thermal power.

The primary materials used in SOFCs include a ceramic electrolyte, typically yttria-stabilized zirconia (YSZ). The anode is often made from a cermet (ceramic-metal composite), commonly a mixture of nickel and YSZ, which serves both as a catalyst and structural support. The cathode is typically composed of perovskite materials like lanthanum strontium manganite (LSM). Their solid-state construction ensures durability and a long operational lifespan. The high operating temperature of SOFCs allows for the use of inexpensive catalysts, such as nickel.

Integrating SOFCs with biogas systems offers several energy and efficiency advantages [

15,

31,

32,

33,

34]:

High electrical efficiency—SOFCs can achieve electrical efficiencies of 50–60%, significantly higher than conventional combustion-based power generation;

Combined heat and power (CHP)—the waste heat from the SOFC can be used to maintain the temperature of the anaerobic digester, as well as using the remaining for other thermal purposes, enhancing overall system efficiency;

Reduced CO2eq emissions: utilizing waste-derived biogas in SOFCs reduces CO

2eq emissions, beyond those originating from organic waste decomposition and decreases reliance on fossil fuels;

Lower pollutant emissions—SOFCs produce fewer/almost null pollutants (NOx, SOx, and particulates) compared to conventional systems.

Other advantages are: Scalability—modular design allows for customization and scalability, making SOFC systems suitable for a wide range of applications, from residential to industrial, this peculiarity allows the efficiencies to be kept unchanged even at different scales; Durability: the solid-state construction ensures long operational lifespans and high reliability (40,000 h).

Currently, integrated systems combining anaerobic digestion and solid oxide fuel cell power plants are predominantly at the experimental level. Only a handful of facilities have adopted this experimental layout. For example, the DEMOSOFC project installed and operated a 174 kW SOFC unit at a wastewater treatment plant in Turin, Italy, demonstrating the feasibility of using biogas in SOFC systems in real industrial settings [

35]. Additionally, the SOFCOM project conducted demonstrations of SOFC systems using biogas and bio-syngas in Turin, Italy, and Helsinki, Finland, respectively [

36]. These projects show that, while technically viable, the systems still require optimization. Therefore, despite the limited current applications, the prospects and potential of such integrated systems are considered substantial, especially in terms of improving energy efficiency and reducing greenhouse gas emissions.

1.4. Work Contribution

To overcome the current state of play that sees anaerobic digesters coupled with thermal engines for electricity purposes, or producing biomethane for dedicated injection into natural gas network, this work proposes an integrated anaerobic digester system with a solid oxide fuel cell system, for the energy valorization of organic waste.

This study makes several key contributions to the field of sustainable energy systems. Firstly, it highlights the immense potential of SOFC energy systems, which are poised to become highly efficient and cost-effective power sources in the coming years. Despite their current high acquisition costs, SOFCs are expected to see significant cost reductions while maintaining or even enhancing their energy performance. However, the challenge of providing high-quality biofuel as a primary feedstock for SOFCs remains a critical issue. This study also addresses this challenge by exploring the necessary functionalization processes to adjust biofuels to meet SOFC requirements. The upcoming section on system integration delves into the technical and energy aspects of integrating anaerobic digestion with SOFC systems, using detailed numerical modeling to optimize performance and resource utilization.

To the purpose, a numerical modelling for the integrated system is developed ad hoc and aimed at assessing energy performance, as electrical and thermal power and efficiency. This work passes by the dimensioning of the anaerobic digestion unit, whose output gas becomes input for the SOFC system.

KPIs are defined and used appropriately, which will allow us to understand the energy produced based on specific parameters such as the biomass entering the system (kJ/kg).

This study combines energy and economic analyses. The energy evaluation serves to assess technical conditions that maximize system performance, while the economic analysis assesses investment feasibility under current incentives, considering both biomethane sale alone (injected into the natural gas distribution pipeline) and integration with SOFC systems.

This comprehensive approach not only enhances the sustainability of the overall system but also provides a robust framework for future research and practical implementation.

2. Materials and Methods

This work represents the outcome of an intense and long-standing research effort dedicated to the understanding of the individual technologies, namely anaerobic digestion and solid oxide fuel cell-based and integrated energy systems. This study is carried out systematically, starting with an extensive literature review that encompassed scientific articles published in high-impact international journals. In parallel, the analysis drew on technical reports and datasets issued by recognized public authorities, official agencies, and organizations—particularly for assessing aspects related to the separate collection and recovery of municipal solid waste. This multidisciplinary approach ensured a solid foundation for modeling and evaluating the technologies under investigation.

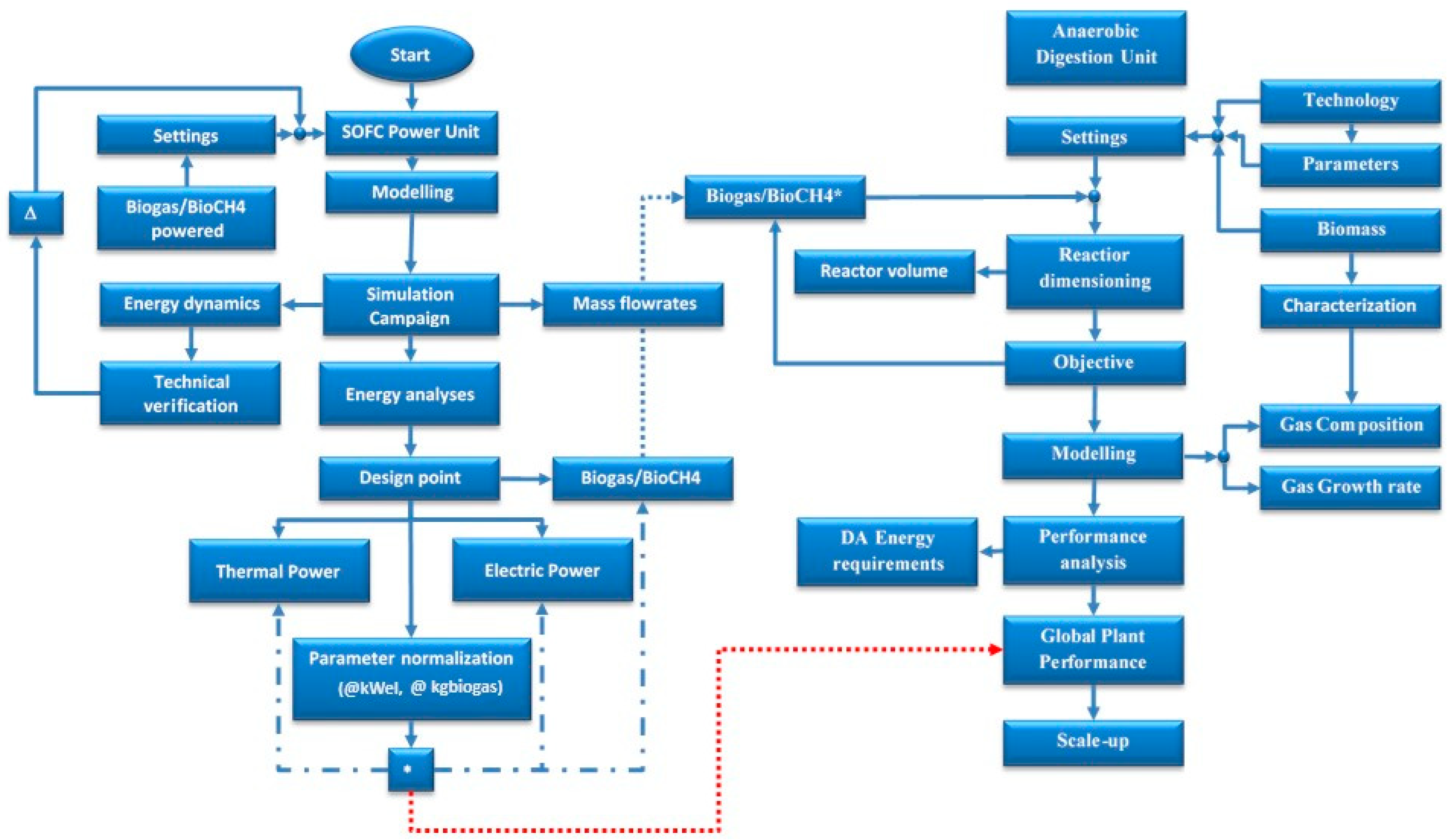

Figure 1 depicts the illustrative roadmap.

The methodological approach encompasses several key steps:

Comprehensive technical integration assessment: The initial phase involves an evaluation of technical integration. This entails a holistic examination of all components involved in the system integration and the challenges encountered. A key aspect is the study of the functionalization of biogas as a SOFC feedstock, particularly the removal of impurities.

Anaerobic digestion unit dimensioning: The anaerobic digestion unit is sized to yield 1 kg/s biogas as output. This yields specific parameters that can be readily utilized for subsequent scale-up analyses. The reactor-sizing phase follows an engineering procedure known as the “operating parameters.” Within this framework, biochemical and thermodynamic variables are defined according to the biomass type and the chosen plant technology.

Numerical modeling development: A numerical model of the integrated system is developed, commencing with the biogas growth rate and extending to the SOFC unit. It encompasses all components within the Balance of Plant (BoP) and delves into potential thermo-electrochemical processes occurring in both the fuel processing section and the electrochemical core, which govern energy generation. Numerical modeling is split into two sequential blocks: (i) biogas generation and reactor sizing, and (ii) SOFC dimensioning and performance assessment. Biogas production is predicted with a dynamic model (Hill’s model), and its composition is derived from Buswell stoichiometry. The resulting values are then fed into the reactor-sizing module (step 2). For the SOFC, multiple operating parameters are explored to identify the conditions that maximize both power output and energy conversion efficiency for the specific biogas feedstock.

Algorithm flowchart development: Detailed algorithm flowcharts are devised to delineate the computational steps involved in the modelling process, aligning with the chosen operational strategy for the plant and its sub-sections. The operation-flow is structured according to an inverse approach, it begins with the desired SOFC performance, from which the necessary biogas feed is back-calculated. This fuel requirement then drives the biogas model, which sizes the anaerobic digester and evaluates its performance to meet the specified conditions.

Extensive simulation campaign: A wide-ranging simulation campaign is conducted to explore the impact of varying operational parameters on system performance. Preliminary simulations are necessary to establish the set of operating parameters that allow the system to operate in a safe environment, free from unwanted phenomena. The modeling framework is therefore designed to perform simulations while varying additional process and system parameters, such as the electrical current supplied, reforming agents, fuel and oxidizer utilization factors, and the off-gas recirculation factor. This endeavor provides insights into how different management approaches can either enhance or alter system performance.

Technical feasibility analysis: A comprehensive technical feasibility analysis is conducted in terms of sensitivity assessments. At this stage, the calculation tool is configured to manipulate the key process and system parameters directly. Sensitivity analyses are aimed at understanding the range of action of certain parameters (such as the heat field released to the exchangers, the variation of steam to carbon, the recirculation factor of off-gases) and the margins for performance improvement.

Scale-up considerations: This study extends to evaluate the feasibility of scaling up the system, considering a real-world scenario. The numerical platform is devoted to provide a variety performance indexes as well as KPIs, such as specific energies delivered per unit of biogas/biomethane (for example the kJ or kWh per kg of biogas/biomethane processed in the SOFC energy unit, the m3 of reactor volume required to have that biogas at output, as well as the kg of raw waste biomass necessary to provide x kg of biogas or y kWh of electric and thermal energy). The numerical platform delivers a comprehensive set of performance indices and KPIs, including: specific energy output per unit biogas/biomethane (kJ or kWh per kg processed by the SOFC module); reactor volume required (m3) to yield the target biogas flow; mass of raw waste biomass (kg) needed to generate a given quantity of biogas (kg) or a specified amount of electrical and thermal energy (kWh).

Technical and economic assessment and feasibility: Finally, this study is completed with a comprehensive technical and economic analysis aimed at assessing the investment’s feasibility. This section is developed in accordance with current legislation, including applicable incentive tariffs and official energy selling prices. The economic evaluation is conducted under realistic scenario assumptions for two distinct configurations: (i) the construction of a standalone biogas plant with biomethane upgrading, where the produced biomethane is injected into the natural gas grid and sold accordingly; and (ii) the integration of a SOFC system into the biomethane plant, allowing the sale of both electric and thermal energies.

2.1. System Integration

System integration is key to approach to creating a unified and interconnected system where the two technologies work together synergistically. It is about optimizing their functions to achieve greater efficiency and mutual benefit.

It entails:

Connecting the energy flows: The biogas produced by the anaerobic digester becomes the fuel for the SOFC. This requires careful management of biogas flow, purification, and reforming it to a hydrogen-rich gas mixture.

Harnessing waste heat: SOFCs generate high-grade heat as a byproduct. The capture of this heat and its use serve to maintain the optimal temperature within the anaerobic digester. This reduces external energy needs, improving overall energy efficiency. Anaerobic digestion operates under either mesophilic or thermophilic conditions and demands a continuous heat supply—especially during winter—to sustain biological activity. Heat is also required in the pretreatment stage to pre-warm the substrate in dedicated tanks. This thermal energy is delivered via hot water circulating through appropriately arranged serpentine coils.

Optimizing control and operation: A sophisticated control system serves to monitor and regulate various parameters. Sensor networks continuously measure digester temperature, pH, redox potential, TS/VS, pressure, CH

4 fraction, and SOFC stack temperature, fuel-utilization factor, air excess ratio, and DC output. A digital twin fed by real-time data can predict digester gas yield 1–2 h ahead (using a calibrated ADM model) [

37] and the SOFC performance [

38]. These forecasts are sent to the model-predictive controller (MPC).

Safety layer: hardwired interlocks shut down the system in case of undesired working conditions, such as uncontrolled H2S content in the biogas.

Maximizing resource utilization: Integration aims to minimize waste and maximize resource utilization. For example, some by product may be recirculated into the system, further enhancing the sustainability.

Cloud/edge layer—KPI dashboards display live energy balances, GHG savings, and predictive-maintenance alerts, allowing operators to adjust set-points remotely and schedule maintenance during low-demand windows.

System integration faces the critical hurdle of conditioning biogas to SOFC-grade fuel: H2S must be cut below 1 ppm via robust, low-maintenance adsorption or biological filters to prevent irreversible Ni-anode poisoning, while simultaneous siloxane and halide removal is needed to avoid stack fouling and corrosion. Maintaining a steady, tar-free CH4 stream under dynamic digester loads demands fast-reacting buffer vessels and tight feedback control.

The

Figure 2 depicts the integrated energy system.

Anaerobic Digestion Plant

Pre-treatment: Depending on the type of organic waste used, pre-treatment might be necessary. This could involve size reduction (shredding, grinding), removing non-biodegradable materials, or adjusting the C/N ratio for optimal biogas production. For example, initial particle size 30–50 mm is shredded to <10 mm; ligno-cellulosic garden waste is hammer-milled from 100 mm to <5 mm. A mechanical screw-press separator removes 2–3 wt % of plastics and grit from source-sorted OFMSW, reducing inert content to <0.5 wt % and avoiding digester grit accumulation. Restaurant food waste alone (C/N ≈ 15) is blended with 25 wt % shredded dry leaves (C/N ≈ 60) to reach the target C/N ≈ 25–30, increasing the ultimate CH4 yield, etc.

Digester volume: It is the heart of the anaerobic digestion process. It is a sealed, oxygen-free tank where microorganisms break down the organic matter. Inside the digester, different groups of bacteria work in stages. Mesophilic CSTR are adopted for food-waste plant, while thermophilic CSTR are used dairy manure + maize silage. Two-stage reactors (splitting the fermentative processes into hydrolysis/acidogenesis + methanogenesis) can be adopted serially to reach higher volumetric methane productivity versus single-stage [

39].

Gas collection system: Biogas produced in the digester rises to the top and is collected. This system often includes a storage tank for the biogas. The gas collection dome channels the rising biogas into a low-pressure storage tank (typically 10–50 m3) that cushions flow fluctuations and feeds the downstream clean-up train at a steady 30–50 mbarg. Biogas is first polished by iron-oxide/activated-carbon beds that cut H2S from 1000–3000 ppm to <10 ppm and adsorb siloxanes to <5 mg m−3.

Hydrogen sulfide (H2S) removal: Biogas is passed through a desulfurization unit (e.g., activated carbon or iron sponge; cutting H2S from 1000–3000 ppm to <10 ppm) to remove H2S, which can poison the SOFC sites. To push H2S below 1 ppm, a two-step scheme is standard: the iron-sponge or iron-oxide pellet is followed by a catalytic activated-carbon or ZnO/CuO polishing filter at 150–200 °C scavenges the last traces, delivering < 0.5 ppm H2S to the SOFC anode.

Moisture removal: Biogas is dried using condensation and adsorption techniques. A chilled-water knock-out (≈4 °C) condenses heavier VOCs and moisture.

Siloxanes removal: Activated carbon filters or other adsorption materials are used to remove siloxanes, which can form deposits on the SOFC electrodes. Fuel cells require extremely low siloxane levels (<0.1 mg/m

3) compared to internal combustion engines (5–30 mg/m

3) [

41].

A final membrane or regenerative activated-alumina skid removes halogenated organics, bringing total contaminant levels below SOFC feed specifications.

Upgrading: It is used to remove CO

2 in order to increase the methane concentration [

42]. This technique is adopted when biomethane serves to feed the natural gas distribution network. Common upgrading methods include:

Water scrubbing: CO2 is separated as being more soluble in water than methane.

Pressure swing adsorption: adsorbent materials selectively capture CO2.

Membrane separation: membranes allow methane to pass through while blocking CO2.

A concise economic comparison of biogas purification options shows that biotrickling filters carry higher upfront capital costs but lower operating expenses, mainly because they eliminate the periodic purchase of activated carbon. In contrast, carbon-based systems demand media replacement every 3–6 months, driving up OPEX. Biological H

2S removal costs USD 0.002–0.005 per m

3 of biogas treated, whereas chemical adsorption ranges from USD 0.01–0.03 [

41,

43]. Consequently, most anaerobic digestion plants now integrate a dedicated clean-up unit; detailed designs for both the clean-up skid and the downstream biomethane upgrading section are available in [

44].

Solid Oxide Fuel Cell Plant

To feed an SOFC, biogas must be cleaned to <1 ppm H

2S, <0.05 mg Si m

−3 siloxanes, with a dew point <5 °C, preventing anode poisoning and solid deposition [

45,

46]. To this purpose The EU Horizon 2020 project “Bio-FlexGen” (Grant 869318) specifies the required biogas purity for SOFC operation; the full report is freely accessible online and further details can be found in [

47].

Fuel processing: Conversely to the low temperature fuel cells, SOFCs do not require pure hydrogen as feeding gas. Therefore, they are much devoted to hydrocarbon feeds, as methane-based stream or other carbon rich gases [

14,

48]. However, the flow requires subsequent processing, since the electrochemical section of the system must convert hydrogen. Fuel processing, often steam reforming, produces a gas very rich in hydrogen. This is possible owing to the SOFC exothermal reactions which combine well with reforming, providing it with the necessary heat. Operating at 700–1000 °C, an SOFC sits squarely within the thermal window needed for downstream thermochemical fuel processing. This demanding temperature regime makes the choice of materials for both the stack and the Balance of Plant decisive for durability and performance.

SOFC stack: It is the site where the electrochemical conversion to electricity happens. Multiple individual fuel cells are combined into a stack to increase power output. Key components of an SOFC include:

Anode: the negative electrode where hydrogen from the stream is oxidized, releasing electrons.

Cathode: the positive electrode where oxygen from the air reacts with electrons and hydrogen ions, forming water.

Electrolyte: media that conducts ions between the cathode and anode.

Power conditioning system: the DC electricity generated by the SOFC is converted to AC electricity, which is the standard form used in most applications.

Heat recovery system: SOFCs operate at high temperatures. This system captures waste heat and can use it for various purposes, such as the following:

Preheating the incoming biogas and air and furnishing heat to the fuel processing.

Providing heat for the anaerobic digester, reducing its energy requirements.

Generating hot water or steam for other industrial processes or space heating.

Integration and control systems: An AD-SOFC system requires sophisticated control systems to manage the flow of biogas, air, heat, and electricity between the different units. This ensures optimal performance, safety, and efficiency.

Key Balance-of-Plant requirements for the SOFC and its integration with the gasification unit are detailed in reference [

33].

2.2. Theory and Calculation

Anaerobic digestion plant

Modeling the anaerobic digestion process involves the use of mathematical and computational tools to simulate the biological and chemical reactions occurring within the digester. These models typically incorporate parameters such as substrate composition, microbial activity, temperature, pH, and hydraulic retention time to predict biogas yield and composition. Commonly used models include the Anaerobic Digestion Model No. 1 (ADM1), which provides a comprehensive framework for understanding the complex interactions between different microbial populations and substrates. In this work, the overall process of the anaerobic digestion is modeled by the Buswell Reaction [

49,

50,

51], reported in (1). The reaction considers a generic waste as a molecule of

, which is degraded into methane and carbon dioxide mainly, together to ammonia e hydrogen sulphide. This method represents a simplified and fast approach to determine the composition of the output gas.

As anticipated, the entire process takes place in four clearly distinct events: hydrolysis, acidogenesis, acetogenesis and methanogenesis. Hydrolysis is the process of converting insoluble complex biomass into soluble compounds. Carbohydrates, fats, and proteins are converted into sugars, fatty acids, and ammonia acids. In acidogenesis soluble organics from hydrolysis are converted into short-chain fatty acids and alcohols. Most acids are converted into acetic acid. Other organic acids are also produced, while hydrogen is produced by the fermentation of glucose. Subsequently, acetic acid is formed by hydrogenation and dehydrogenation processes in the acetogenesis. The final step is the conversion into methane. Conversion of acetic acid into methane comprises about 70%, while a second stage implies for 30% the conversion of hydrogen into methane utilizing the carbon dioxide. These four events are modeled, in this work, according to Hill’s model [

52,

53,

54]. Hill’s model consists of a set of coupled differential equations that describe the interactions between different components in the anaerobic digestion process. The model tracks the changes in biomass concentration, substrate concentration, and biogas production over time, considering factors like microbial growth rates, substrate utilization, and environmental conditions.

The four differential Equations are reported in (2)–(5). Equation (6) determines the biogas production retrieving the output of the previous ones.

The main parameters are the biogas flowrate (F

bio), the reactor volume (V

r), and the substrate feed (F

sub). For the other parameters, see refs. [

52,

53,

54]. During modeling and simulation of biogas generation from humid organics, key parameters such as kinetic constants or yield factors (e.g.,

k1,

k2,

k3,

k4) and specific growth rates (

μ,

μc) are typically set based on empirical data and literature values (functions of the reactor temperature). These parameters, along with decay rates (

Kd,

Kdc), are often calibrated to match experimental observations, ensuring the model accurately reflects the biogas generation process. All kinetic and stoichiometric parameters in Hill’s model are taken from the calibration datasets reported in the referenced studies, which cover the same substrate categories studied here.

The procedure of anaerobic digester dimensioning is performed through the known and conventionally adopted “operative parameters-based design” [

24,

28]. It is aimed at the determination of the reactor volume and of the quantity of organic material to be treated. The calculations depend on the plant technology and on the type of organic mixture treated. Hence, the design completion considers the characterization of the collected organic fractions and the quality of biogas deriving from it. Equations (7)–(9) summarize the methodology to calculate the reactor volume (9).

SGP, TVS, OLR represent the specific gas production, the total volatile solids, and the organic load rate. The symbol ‘%’ represents the associated parameters in percentage values.

The energy modeling is performed on considering all the energy contributions (10), observable from

Figure 3, competing in the reactor [

44].

In addition to the known variables, and represent the heat generated by the process and the supplied one. is the heat exchange with the external environment.

SOFC Balance of plant

Modeling the Balance of Plant (BoP) for solid oxide fuel cells (SOFCs) involves creating detailed simulations of all auxiliary components that support the operations (fuel processing unit, air supply system, thermal management system, power conditioning unit) [

15,

55,

56]. Specific blocks integrate heat transfer and thermo-electrochemical reactions to predict the performance and efficiency of the entire SOFC system under various operating conditions. By simulating the interactions between these components, the system design can be managed and improved. The SOFC BoP considered in this work is illustrated in

Figure 4. The plant layout considers a recirculation of the anodic exhaust, a pre-steam reforming and an indirect internal steam reforming, a post combustor section. The combusted stream is then used to pre-heat fresh fluids, vaporizing water and releasing its residual energy content to the outside in the form of thermal energy.

Equation blocks at Equations (11) and (12) report the fuel and electro-chemical processing. The fuel processing is based on steam reforming, where steam is the reforming promoter. Regarding the electro-chemical process, this accounts on the conversion of hydrogen and carbon monoxide contained in the stream. In addition, having a non-negligible content of CO and H2O in the anodic site, the water gas shift (WGS) process can occur too.

Equations (13)–(15) report the electrical parameter deriving from the core processes, through which electric power is calculated. Vc represents the cell voltage Equation (13), while Ic the electric current per cell. The cell voltage is calculated by means of the Nernst potential (), diminished by the polarization losses (). The electric current Equation (14) depends on the fuel conversion, for which represents the reacted fuel(s), specifically hydrogen and carbon monoxide generated in the fuel processors. The total electric power Equation (15) is calculated by multiplying by the number of cells (Nc). Equation (16) presents the energy balance of system (in which the reactions quotas are not in evidence, but included in the enthalpic contributions, as enthalpies are absolute values in this case). It is necessary to determine the power (Paux) absorbed by the auxiliaries (pump p and compressors c, expression Equation (17)), from which the net powers derive.

Electric variables and energy balance

2.3. Energy Analysis

The energy analysis is performed accounting on the electric and thermal efficiencies both at SOFC BoP level and at overall integrated energy plant Equations (18) and (19), where

and

represent the electric and thermal power as net values. Specific KPIs as the energy delivered as kJ per kg of biogas and/or biomass supplied (or kW/(kg·s)) are an additional tool to evaluate performance.

and

represent the specific electric and thermal energies in Equations (20)–(21), where the denominator can include the mass flow rate of input biomass and/or biogas (

). Their evaluation allows for a rapid system scale-up and associate real world application cases.

2.4. Economic Analysis

Due to the dynamics of these plants, several studies highlight the importance of assessing economic viability under different policy frameworks [

57,

58]. Subsidies are a critical factor in determining profitability, as their absence can lead to financial losses [

59,

60]. The cash flow method, along with the net present value (NPV) as a key metric, has been extensively validated in the literature. Expression (22) reports the known expression for NPV calculation (where:

is the initial expenditure at time ‘0’,

represents the cash flow at year ‘t’, intended as the annual revenue minus expenditure,

is the interest rate, while

is the lifetime of the investment).

Italy’s recent incentive decree (Ministerial Decree, 15 September 2022) sets a target of increasing biomethane production by at least 2.3 billion m3 by 30 June 2026. To promote biomethane integration into the natural gas grid, the decree introduces two key measures: (i) a capital grant covering up to 40% of eligible expenses, and (ii) an energy account incentive, which applies a fixed tariff to net biomethane production over 15 years.

A central feature of this policy is the All-Inclusive Tariff, a unified payment mechanism that combines the market value of natural gas with the Guarantee of Origin premium. The base tariff is set at €62/MWh for plants processing organic waste or agricultural feedstock, regardless of size. However, for facilities with a capacity of ≤100 m3/h, the tariff increases to €115/MWh, while larger plants receive €110/MWh. The final payable tariff is derived from this reference rate, adjusted according to bid reductions during the competitive process, and may include additional deductions.

2.4.1. Cost Analysis

SOFC Plant Integration Investment

This cost refers to the entire solid oxide fuel cell (SOFC) system, encompassing all functional sections, including fluid feeding systems (e.g., drivers and pipelines), the fuel thermochemical processing unit, heat exchangers, the SOFC electrochemical stack core, and other essential components. A comprehensive breakdown of these costs, categorized by individual components and sectors, is provided in reference [

61].

Table 1 summarizes the primary cost elements.

(annualized capital cost) is derived from

(total overnight cost) and the CRF (capital recovery factor).

depends on the total plant cost (

) and an adjustment factor (

).

is a function of the engineering, procurement, and construction costs (

) and its associated adjustment factor (

).

, in turn, is calculated based on the equipment cost (

) and its adjustment factor (

), where

represents the sum of all individual SOFC plant components. The total operational and maintenance cost (

) is typically estimated as 4% of

, in addition to a percentage of the SOFC unit cost (

). To account for potential stack replacements, a conservative yearly operational cost of 5% of

is also included.

Investment for the construction of a biomethane plant

When evaluating the economics biomethane production plant, several investment components need to be considered. These include the core processing facilities, the anaerobic digestion plant and composting infrastructure, as well as supporting components like civil works and partial costs for biomethane upgrading and polishing. The transformation process itself follows a well-defined sequence: first, raw biogas production through anaerobic digestion; second, purification through upgrading technologies; and finally, compression and distribution of the refined biomethane.

On the financial side, the revenue picture reveals multiple income streams. Beyond direct biomethane sales and government subsidies, operators can generate additional value from byproducts—notably nutrient-rich digestate for agriculture and food-grade CO2 for industrial applications. Facilities handling organic municipal waste enjoy further revenue opportunities through waste treatment fees, creating an economically attractive circular model.

The cost structure presents a more complex calculus. Capital depreciation represents a significant factor, particularly for sensitive mechanical and electrical components with limited operational lifespans. Operational expenditures span both fixed and variable costs: from predictable expenses like labor, insurance, and routine maintenance to more fluctuating costs such as electricity consumption, material inputs, and transportation logistics. For a comprehensive breakdown of these cost factors, readers may refer to the detailed analysis in [

66], with key components summarized for quick reference in

Table 2.

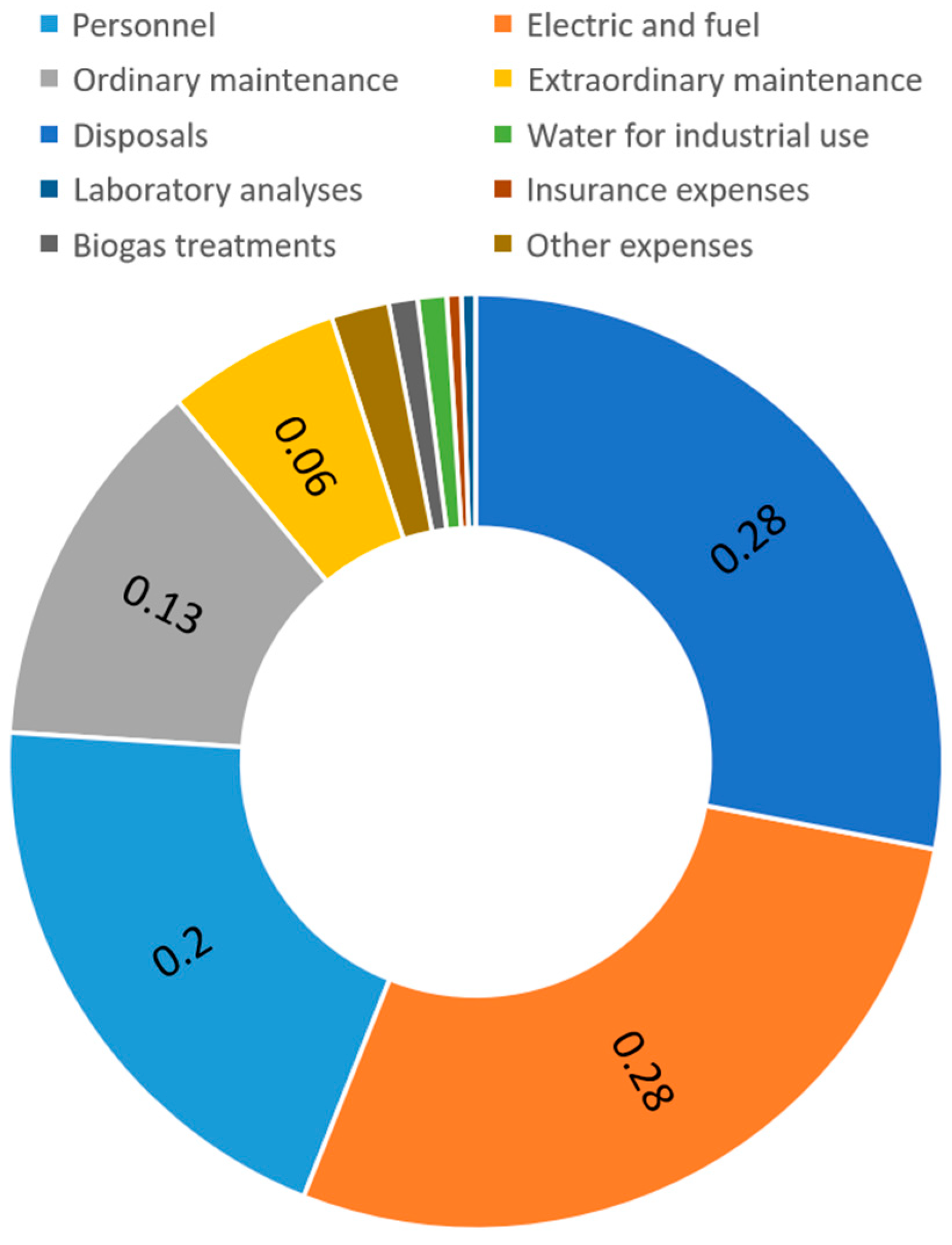

Figure 5 shows the percentage cost breakdown, including: personnel costs; electrical costs; ordinary and extraordinary maintenance costs (estimated every 5 years); disposal and structuring costs; insurance costs; biogas treatment line costs; industrial water service costs; laboratory analysis costs; and other miscellaneous costs.

2.4.2. Revenue Analysis

The revenue analysis for biomethane production plants under the incentive scheme established by the Ministerial Decree of 15 September 2022 (Third Biomethane Decree [

68]) examines two key components: capital grants and the energy account incentive (incentive tariff). The incentive tariff applies to the net biomethane injected into the natural gas grid, with its value determined by plant type and production capacity.

Regarding capital support, the decree offers grants covering up to 40% of eligible plant construction costs.

The energy account incentive serves as the primary remuneration mechanism for biomethane production, calculated based on the net quantity fed into the grid. The GSE (Gestore dei Servizi Energetici: Italy’s Energy Services Manager) administers these incentives. Additionally, incentive structures also apply when biomethane is used for cogeneration followed by electricity grid injection.

Revenues from biomethane production incentives

All-inclusive and Premium Tariff—when biomethane is injected into the natural gas grid, it blends with conventional natural gas and becomes indistinguishable due to its relatively small proportion of the total volume. Nevertheless, its origin must be documented through certification schemes, including Guarantees of Origin (GO) and Proof of Sustainability (PoS) or Sustainability Guarantees [

68].

Plants with a production capacity below 250 Sm3/h (approximately 2.2 MSm3/year) can opt for either the All-inclusive Tariff or the Premium Tariff, while larger facilities are automatically assigned the Premium Tariff.

Under the All-inclusive Tariff, producers sell biomethane directly to the GSE (Gestore dei Servizi Energetici) at a fixed rate of approximately €125/MWh.

Under the Premium Tariff, producers sell biomethane to a third-party buyer through a Contract for Difference (CfD), also referred to as a Contract for Subtraction (see Equation (23)).

The All-Inclusive Tariff for agricultural biomethane (Ta) is set at 125 €/MWh. Key reference prices include the following:

Historical data show pGO values have typically ranged between 1–8 €/MWh in recent years.

Certificates of Release for Consumption (CRC—CIC in Italy) [

69]—the Energy Services Manager (GSE) issues Consumption Release Certificates (Certificates of Immission into Consumption: CIC) to biomethane producers injecting biofuel into the national distribution network. These electronic documents verify the introduction of renewable biofuels into Italy’s energy system. The key features of CICs are that each certificate represents a defined energy quantity (10 Gcal for standard biofuels or 5 Gcal for advanced biofuels), the GSE assigns a fixed value of 375 €/CIC to producers. These certificates serve as incentives for biomethane utilization.

This incentive mechanism also applies to biomethane used in cogeneration systems (discussed in the following section).

Revenues through incentives on electricity production

Incentive Tariff—all plants defined as IAFR (in Italian: Plants Powered by Renewable Sources), which have achieved the recognition of Green Certificates (in Italy CV) [

70] are entitled to the conversion of these certificates into incentives. These incentives are calculated based on net energy production, and represent additional income beyond standard energy revenues.

The Green Certificates system, established under the inter-ministerial decree of 6 July 2012, was replaced in 2016 by a dedicated withdrawal mechanism. This new scheme serves as the incentive tariff, involves transferring electricity to the grid through the GSE, provides guaranteed compensation according to Equation (24).

where, ‘I

e’ is the incentive tariff, while ‘k’ is a factor that assumes variable values depending on the type of renewable source used. For biogas plants k = 1.3. ‘Re’ represents the sale price of electricity currently equal to 109.05 (

https://www.gse.it/servizi-per-te/news/ex-certificati-verdi-pubblicato-il-valore-del-parametro-re-registrato-nel-2024 (accessed on 20 July 2025)) (€/MWh) [

71]. For CV the reference value is 180 (€/MWh) [

71].

Electricity sales revenue

Sale of electricity—the electricity valorization mechanism operates through two primary channels: “dedicated withdrawal” or “free market participation”. This involves selling generated electricity to the grid, with remuneration for each injected kWh. Under the Dedicated Withdrawal scheme the GSE (Gestore dei Servizi Energetici) acts as the sole purchaser for all grid-fed electricity; while not a direct incentive, the scheme provides administrative simplification. ARERA (Regulatory Authority for Energy, Networks and Environment) establishes and updates minimum guaranteed prices [

72].

These minimum prices serve two key purposes: 1. supporting economic viability for small-scale plants utilizing marginal or residual resources; 2. ensuring baseline remuneration independent of electricity market fluctuations.

For biogas and biomass systems, the current minimum guaranteed price stands at 110.6 €/MWh [

72]. Any production exceeding this baseline is compensated at the electricity transfer price set by the Electricity Authority. Notably, the National Single Price (PUN) averaged 137.975 €/MWh between July 2024 and June 2025 [

73], exceeding the minimum guaranteed threshold.

CIC incentive—the incentive through the Certificates of Immission into Consumption (CIC) can also be provided for biomethane used in cogeneration, provided that: the biomethane is traceable and certified as advanced, the cogeneration is high-efficiency (in Italy CAR: cogenerazione ad alto rendimento), according to the criteria established by the Energy Services Manager (GSE), the biomethane produced is physically fed into the grid, or a mass balancing system is used. Instead, raw biogas used directly in cogeneration (without being transformed into biomethane) does not benefit from the CIC, but can access other support mechanisms, such as the following:

In order for the plant to be classified as CAR, the plant must: obtain a Primary Energy Saving (S

PE) ≥ 10% for units greater than 1 MW, for units less than 1 MW (micro-cogeneration and small cogeneration), a positive S

PE is sufficient, even if <10%. The S

PE is calculated with the following Formula (25).

where: Q

ref is the fuel needed to separately produce the amount of useful heat; E

ref is the fuel needed to separately produce the amount of electrical energy; F

CHP is the fuel actually consumed by cogeneration.

3. Algorithm Flowchart

Building on the preceding theory, sizing equations, and AD-SOFC integration rules, the algorithmic flowchart translates every physical relationship into an executable sequence. Data structures mirror the real plant hierarchy—feedstock batches, reactor nodes, gas streams, and SOFC stacks—while typed variables (floats for energy, arrays for gas compositions, booleans for safety and/or verification flags) guarantee dimensional consistency. Iterative solvers resolve Hill kinetics and thermo-electrochemical models in lock-step, so the chart not only reproduces the hand calculations but also exposes how design choices propagate through the coupled system.

The pathway of calculation for technical and energy performance is depicted in

Figure 6. The flowchart is structured according to an inverse approach, where the required fuel input for the SOFC system is calculated based on the desired electrical and thermal outputs, which themselves depend on the system’s operating parameters. Thus, two main algorithms can be clearly distinguished: one for the SOFC energy system and one for the biogas production plant.

For the SOFC section, the algorithm computes all interrelated input and output parameters based on the simulated electric current generated. The block of the parameter settings, as fluid utilization factors, recirculation factor, pressure and temperatures, electric currents, etc., serves as interacting with the modeling section, which after the preliminary compiling check run the simulations. The output of this block are the mass flowrates calculated, both the input ones and the output; the electrical and thermal powers and other parameters serving as a base of assessment for technical verifications, as the carbon deposition check. The simulation campaign gives the window of possible operations, that represent the base for working point choice to proceed with dimensioning and design accordingly. The main outcomes are generated in terms of KPIs, as energy delivered in kJ/kgbiogas or kW/(kgbiogas/s).

On the basis of 1 kgbiogas/s, the anaerobic digestion section is then modeled. The setting of the parameters is carried out accordingly, whose block provides instructions to the sizing block. Instead, the characterization block is used for the characterization and/or association of the biochemical parameters of the biomass to be treated. These cover elemental chemical analysis, knowledge of volatile solids, and more.

In succession, in interaction with the starting biomass characterization block, the modeling computation section receives the information and releases the determination of the quantitative and qualitative parameters of the biogas produced, such as the gaseous composition and the growth transient. Subsequently, the computational section of “global plant performance” determines the necessary energy, electrical and thermal requirements of the plant based on the plant technology, the required quantity of biomass, and the setting of the biochemical process.

Finally, this path facilitates the scale-up process with which a real-world case can be approached.

The flowchart implies the importance of detailing computational facts such as data flows, instructions, and structures. For instance, the use of arrays and matrices is important for registering temporary findings and managing state variables, while specific data types like long for numbers ensure precision and efficiency. Computational cycles, including ‘for’ and ‘while’ loops, are essential for iterating over time steps and ensuring convergence, respectively. ‘Struct’ structures are instead used to register characteristics on physical flows on performance. Additionally, computational flags are fundamental in monitoring the simulation’s progress and handling potential errors, thereby enhancing the robustness and reliability of the numerical tool.

4. Settings and Simulations

Table 3 includes the main settings and the output expected by the simulations. In particular, the table includes the setting of the operating parameters of the systems.

Preliminary simulations have been mandatory for the choice of some parameters, serving as working the plant efficiently and safely.

The models are codified, implemented, and run in the Matlab/Simulink computational environment.

The parameters U

f, λ

O2, j, X_R, p, STCR represent fuel utilization factor, oxygen excess factor, electric current density, anode off-gas recirculation, pressure ratio, and steam to carbon ratio. An extensive preliminary simulation campaign was carried out, leading to the selection of the operating parameters listed in

Table 3.

5. Technical and Energy Results

Anaerobic digestion unit

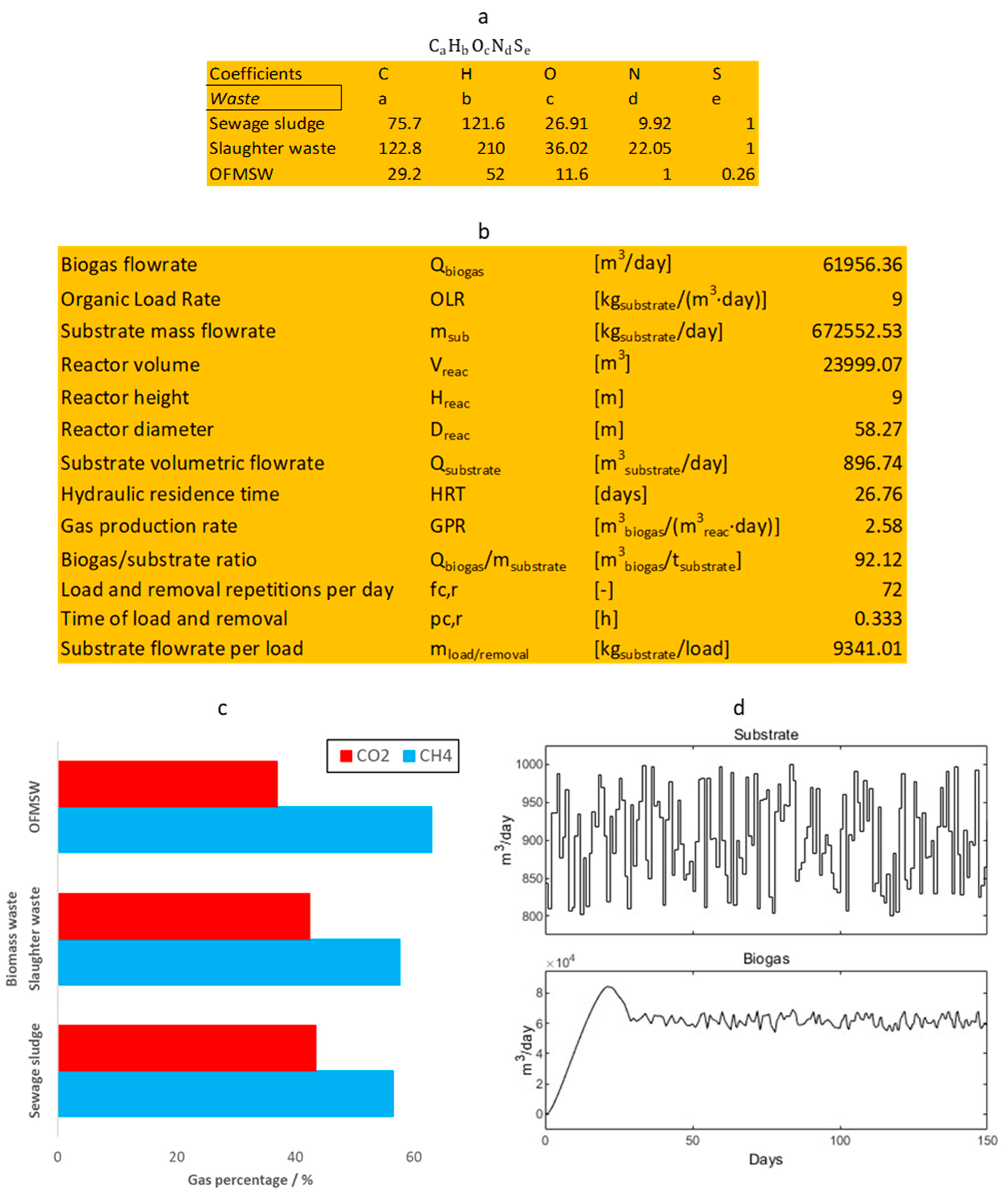

Figure 7 illustrates the results of the simulations for the anaerobic digestion unit. Three kinds of biomasses are taken into account: sewage sludge, slaughter waste, and organic fraction of municipal solid waste (OFMSW). The motivation for selecting these biomasses for biogas potential assessment stems from their significant presence in the reference regional and national waste streams. These biomasses collectively can contribute to a substantial portion of the biogas production potential, with sewage sludge and OFMSW being underutilized despite their availability, as reported above. Additionally, the context of small-scale biogas production in Italy, particularly from agricultural waste, highlights the potential for leveraging these biomasses to meet local energy needs, especially in family-run farms. The preliminary investigation suggests that improving the recovery of organic municipal waste and adopting more efficient energy technologies could significantly contribute to sustainability and enhance bioenergy exploitation.

Based on their elemental analysis (retrieved from [

24]), their associated molecules of

are calculated (

Figure 7a).

Figure 7b includes the general performance together to the determination of the reactor size. Leaving aside the details, which can be read from the same figure, the results show that a reactor volume of approximately 24,000 m

3 is required, which is used to process a daily quantity of organic substrate equal to approximately 900 m

3. A biogas yield of 92 m

3 per ton of substrate is calculated. According to Buswell model, the derived biogas compositions are determined. The methane content in the biogas (

Figure 7c) is calculated to be approximately 60% for all three treated biomasses. Among them, the organic fraction of municipal solid waste yields the highest quality biogas, while sewage sludge results in the lowest methane content.

Figure 7d reports the dynamics of biogas production, accordingly, starting from the first load. Simulating a biomass load, variable randomly in the window of 800–1000 m

3/day (reflecting a possible change that occurs in the structures), a biogas production around 61 thousand m

3/day follows a transient time of about 26 days. Clearly, the biogas fluctuations depend on the biomass feed that can occur in a real-world anaerobic digestion plant. All other outputs and details are shown in

Figure 7.

SOFC BoP

The validation of the SOFC system model is documented in previous publications by the same authors [

14,

15,

55].

Figure 8 includes the simulation results. The figure is arranged in four charts,

Figure 8a illustrates the BoP electric and thermal efficiencies,

Figure 8b illustrates the energies specifically to 1 kg/s of biogas fed,

Figure 8c presents the temperature at main process sections, while

Figure 8d reports the molar composition of the stream at output of main process sections. From the preliminary simulations it was deemed appropriate to operate with an electric current density of 0.4 A/cm, which is close to nominal conditions. A further parameter of analysis is the recirculation factor (X_R) of the anode off gas. This is changed in the window 0.05–0.4, which represent the limits within which the system operates. An excessive recirculation factor would constitute an overdilution of the convertible mixture, while a factor close to zero means no recirculation. Generally, without going into details that can be retrieved by the comprehensive

Figure 8, electric performance benefits from a higher recirculation factor. The electrical performance profile follows an increasing trend, starting from an efficiency value of approximately 46%, and then undergoing a decline around X_R of approximately 0.25. This means that higher values of off-gas recirculation improve performance, but less significantly. In fact, at high values of X_R, the performance profile tends to approximate the horizontal asymptote. Conversely for thermal performance. At X_R of 0.4 the net electric efficiency is higher than 51%, while the thermal one is about 39% (

Figure 8b). At null X_R, the thermal efficiency approaches the value of about 49%. Clearly, this is reflected in the specific energies (

Figure 8b). At the same working condition, 1 kg/s of biogas produces respectively 9.06 e3 kJ electric and about 6.85 e3 kJ thermal. At X_R of 0.4 SOFC operates at about 817 °C, and the post combustor elevates the temperature at about 950 °C. From

Figure 8d observing the molar concentrations, hydrogen reaches the maximum contents of about 30% in the stream at indirect internal steam reforming outlet, before being processed electrochemically inside the SOFC core. Methane is almost totally converted at same section. The traces of fuel as CH

4, CO and H

2 are successfully converted in the post combustor subsequently.

Integrated system

The integration of the AD unit and the SOFC one must consider the overall energy needs, that are functional to the self-sustenance of the system [

44].

Table 4 summarizes the overall performance data, in accordance with the energy absorption of similar facilities [

44], specified to 1 kg of substrate treated. The integrated system generates a net electrical energy of 1050 kJ/kg

sub and a net thermal energy of 792 kJ/kg

sub, implying respectively a net 47% and 35% of net electric and thermal efficiency.

This methodology facilitates a rapid scale-up analysis, by simply multiplying by the kg of organic substrate to be treated.

6. Economic Analysis Results

The methodology is applied to a biomethane production plant, whose characteristics are retrived from [

44]. The plant produces approximately 508 Sm

3/h of biomethane. Based on this capacity, it is coupled with a SOFC energy system delivering a net output of 2.36 MWel and 1.74 MWth (electric and thermal power, respectively, net of internal absorptions for integrated plant functioning). The overall system qualifies as a high-efficiency cogeneration (CAR) plant and thus benefits from the incentivized tariff described in the previous section for electricity sales. Additionally, the economic evaluation assumes that the thermal energy is sold to a private user. The resulting and associated revenues are considered in terms of the equivalent amount of methane saved and the avoided costs of dedicated boilers or other heat generation systems.

The economic results are obtained by considering the cost scenarios of the SOFC system in 2020, 2025, and 2030, considering the sale for the injection into the biomethane grid and the upgrade with the integration of the SOFC system, therefore considering the subsequent sale of electricity. In this analysis it is considered that the SOFC system cost is taken from. The 2025 SOFC system cost is estimated as an average between that of 2020 and that of 2030. In 2020 these have been estimated at 10,000 [€/kW], while a reduction of up to 2000 [€/kW] is expected for 2030 [

74,

75]. The management costs of the SOFC system include ordinary and extraordinary maintenance costs and have a value of 0.1 [€/kWh] in 2020, with a reduction that will settle at around 0.02 [€/kWh] for 2030 [

74,

75].

Regarding the costs of the anaerobic biodigestion plant, with pre-treatment section, pre-heating section, biodigestion section, digestate biostabilization section, post-treatment section, and biomethane upgrading section, with subsequent compression section for injection into the distribution network [

44], these amount to 19,600,000.17 [€], while the management costs amount to 2,908,169 [€].

Table 5 reports the cases considered in the economic assessments. Two possibilities are taken into account: the sole biomethane production plant, with the main technical sections devoted to biomethane production and upgrading and the integration with SOFC energy system, where biomethane is collected and sent to the energy plant devoted to electric and thermal energy production. In the first case, the biomethane is treated in order to reach quality standard required by the grid injection [

44]. It is then injected into the centralized gas distribution network to then be used by civilians and industries for private, transport and or industrial purposes. In the second case, an integration with the SOFC energy system is arranged to have green energy and thermal energy production [

33,

34]. In the first case the profits derive by the gas sale, while in the second one by the energy and thermal energies sales. For the second case, the economic assessments are based on three possible scenarios of system cost. Since SOFC systems do not lie on precise cost as being systems still in a pre-commercial phase, often their prices are arranged based on negotiations between customers and producers. Therefore, the three scenarios (2020, 2025, 2030) anticipated above are considered.

Figure 9 presents the economic results across four charts: (a) NPV vs. years, (b) annual cash flows, (c) total NPV after 20 years, and (d) payback period. Chart (a) illustrates the net present value progression over time, starting from the initial investment at year zero. The point where each curve intersects the zero line represents the payback time—indicating when the initial capital is fully recovered. These curves offer an intuitive reading of the investment’s performance: negative values indicate outstanding recovery gaps, while positive values reflect accumulated profits. At the end of the investment lifetime, the final NPV reflects the total economic gain or loss.

Charts (c) and (d) isolate the final NPV and corresponding payback periods.

Figure 9b shows the annual cash flow for each scenario. The highest annual cash flow (€3.97 million) corresponds to the most optimistic scenario (2030-SOFC), assuming a reduced system cost of €2000/kWel. Conversely, the 2020-SOFC scenario generates the lowest cash flow (€2.5 million). The biomethane-only plant scenario yields an intermediate value of €3.25 million, while the most probable case (2025-SOFC) shows a similar figure of €3.24 million.

Over a 20-year horizon, the 2020-SOFC scenario remains economically unfavorable, with a negative NPV of –€1.32 million. In contrast, the biomethane-only case achieves a positive margin of €33.61 million, while the 2025-SOFC and 2030-SOFC scenarios generate €19.29 million and €39.89 million, respectively. Payback periods for the biomethane-only, SOFC 2020, SOFC 2030, and SOFC 2025 cases are 6.46, 20.86, 6.58, and 11.55 years, respectively.

In conclusion, although the biomethane-only configuration ensures the fastest return on investment today, its profit potential is soon overtaken—after 7–8 years—by SOFC-integrated systems, particularly under improved economic conditions projected for 2030 (see

Figure 9a).

The economic analysis of the biomethane production plant and its integration with a SOFC energy system reveals significant insights. While the biomethane-only plant offers the fastest return on investment initially, its long-term profitability is surpassed by the SOFC-integrated systems, especially under the projected cost reductions for 2030. The 2030-SOFC scenario, with a reduced system cost of €2000/kWel, shows the highest annual cash flow and NPV over a 20-year horizon. The payback periods for the biomethane-only, SOFC 2020, SOFC 2025, and SOFC 2030 cases are 6.46, 20.86, 11.55, and 6.58 years, respectively. Overall, the integration with SOFC systems, particularly under future cost scenarios, demonstrates superior long-term economic viability and potential for higher returns.

7. Conclusions

The integration of anaerobic digestion (AD) with solid oxide fuel cells (SOFC) presents a highly promising pathway for sustainable and efficient waste-to-energy conversion. This study comprehensively analyzed the technical and energy aspects, highlighting its potential to significantly contribute to the global energy transition. To this purpose a numerical model for both anaerobic digestion unit and SOFC system has been developed.

Through detailed simulations, it was demonstrated that SOFC system can effectively utilize biogas produced from AD, facilitating efficient conversion into electricity and heat.

The biogas can be produced from various organic wastes, such as sewage sludge, slaughter waste, and the organic fraction of municipal solid waste (OFMSW), and contain around 60% methane, serving as a quality feedstock for the SOFC unit.

The simulations on AD process are set on thermophilic conditions and dry biomass. They indicate that a reactor volume of 24,000 m3 is necessary to produce 1 kg/s of biogas, processing around 900 m3 of organic substrate daily. This setup achieves a biogas yield of about 92 m3 per ton of substrate.

Several preliminary simulations have been run to choose the working point of SOFC BoP, setting scrupulously operating parameters and electric current, to work efficiently and safe.

The SOFC unit exhibits an electric efficiency exceeding 51% and a thermal efficiency of about 39%, pushing to a recirculation factor of anode off gas of 0.4. When integrated into the AD-SOFC layout, the system generates a net electrical electric and thermal efficiencies of 47% and 35%, respectively, due to the internal absorptions.

One of the key benefits of this integrated system is the effective utilization of waste heat. The high-grade heat generated by the SOFC can be redirected firstly to inner operation inside the BoP architecture (as fuel processing, gas heating etc.), but secondly to maintain the optimal temperature within the anaerobic digester, reducing external energy inputs and enhancing overall system efficiency. This synergy not only improves the energy balance but also contributes to the sustainability of the process by minimizing waste and maximizing resource utilization.

A comprehensive economic analysis was conducted to evaluate two investment strategies: (i) a biomethane-only production plant and (ii) its integration with a SOFC system for electric and thermal energy generation. The methodology included net present value (NPV) and payback period (PB) assessments across three cost scenarios regarding the SOFC system cost (2020, 2025, 2030), incorporating current incentive frameworks. A case study considering a biomethane facility producing 508 Sm3/h of biomethane was assessed. The integrated system AD-SOFC can account on a net generation of electric and thermal powers respectively of 2.36 MWel and 1.74 MWth. The biomethane-only plant showed a PB of 6.46 years and an NPV of €33.61 million. While the 2020-SOFC case remained economically unviable, the 2025 and 2030-SOFC scenarios reached positive margins of €19.29 million and €39.89 million, with PBs of 11.55 and 6.58 years, respectively. Although the biomethane-only case recovers the investment more rapidly, SOFC integration becomes more profitable in the medium term, especially under future cost reductions. The analysis underscores the relevance of policy incentives and technology advancements in determining financial feasibility.

The integration of AD and SOFC systems supports a circular bio-economy by transforming organic waste into valuable energy. This approach addresses critical waste management issues while reducing greenhouse gas emissions and reliance on fossil fuels. The production of renewable energy from biogas aligns with global efforts to mitigate climate change and transition to cleaner energy sources. In terms of scalability, the modular design of SOFC systems allows for customization and adaptation to various scales of operation.

Continued research and development, along with supportive policy frameworks, are essential to further optimize and promote the adoption.