Simulation of Combustor Inlet Flow Field via Segmented Blade Twist and Leading-Edge Baffles

Abstract

1. Introduction

2. Materials and Methods

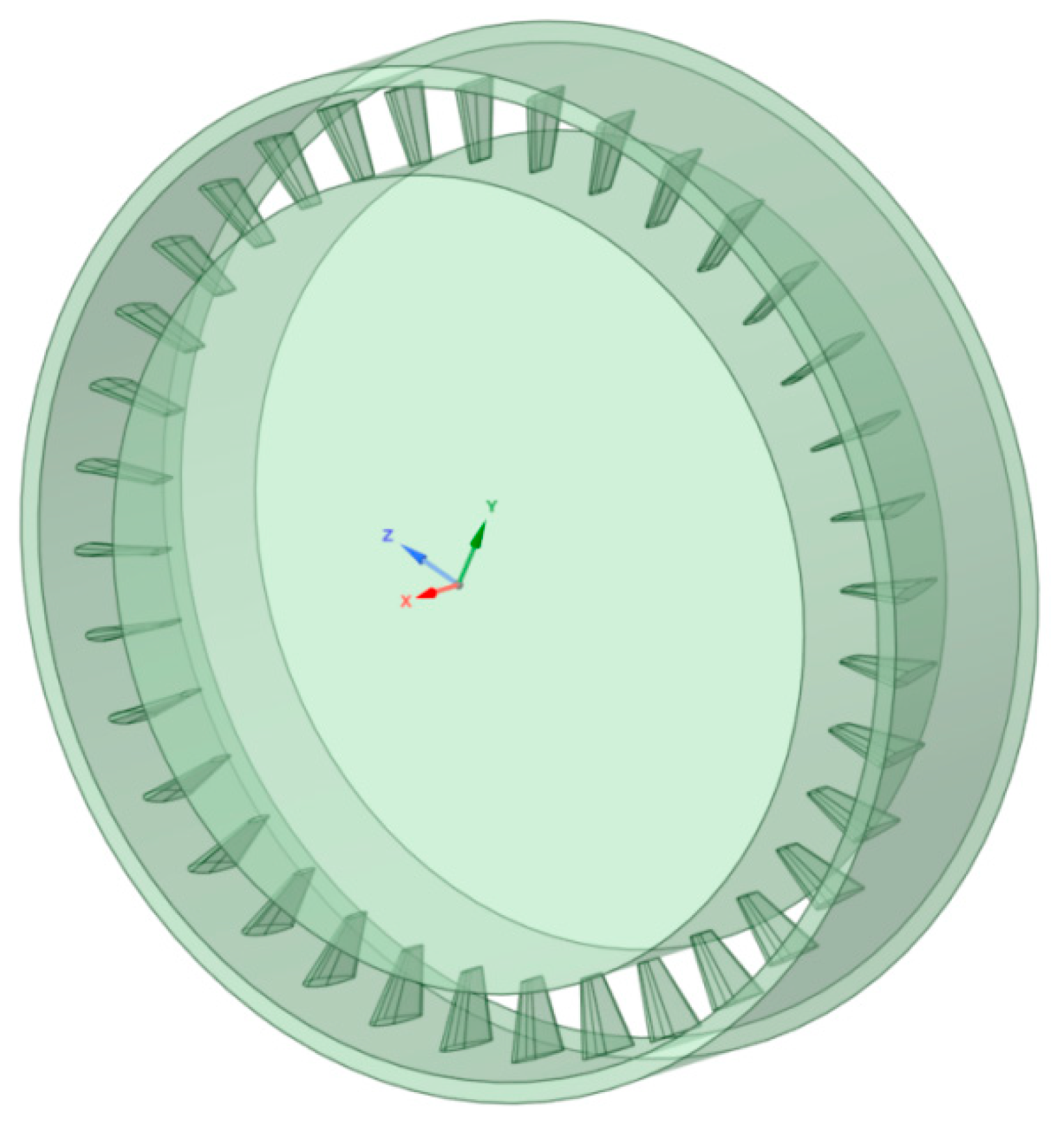

2.1. Physical Model

2.2. Governing Equations

- Continuity Equation:

- 2.

- Momentum Conservation Equation:

2.3. Turbulence Model

2.4. Boundary Conditions

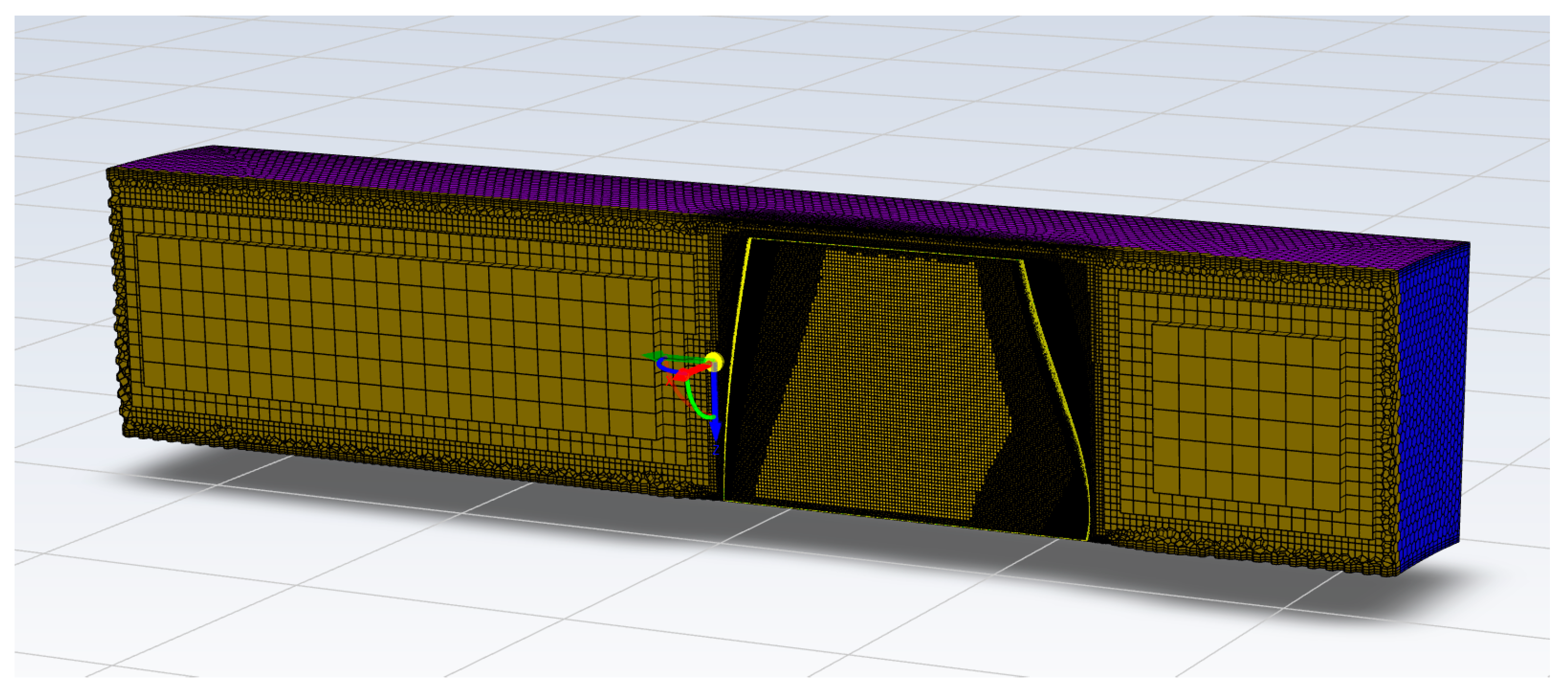

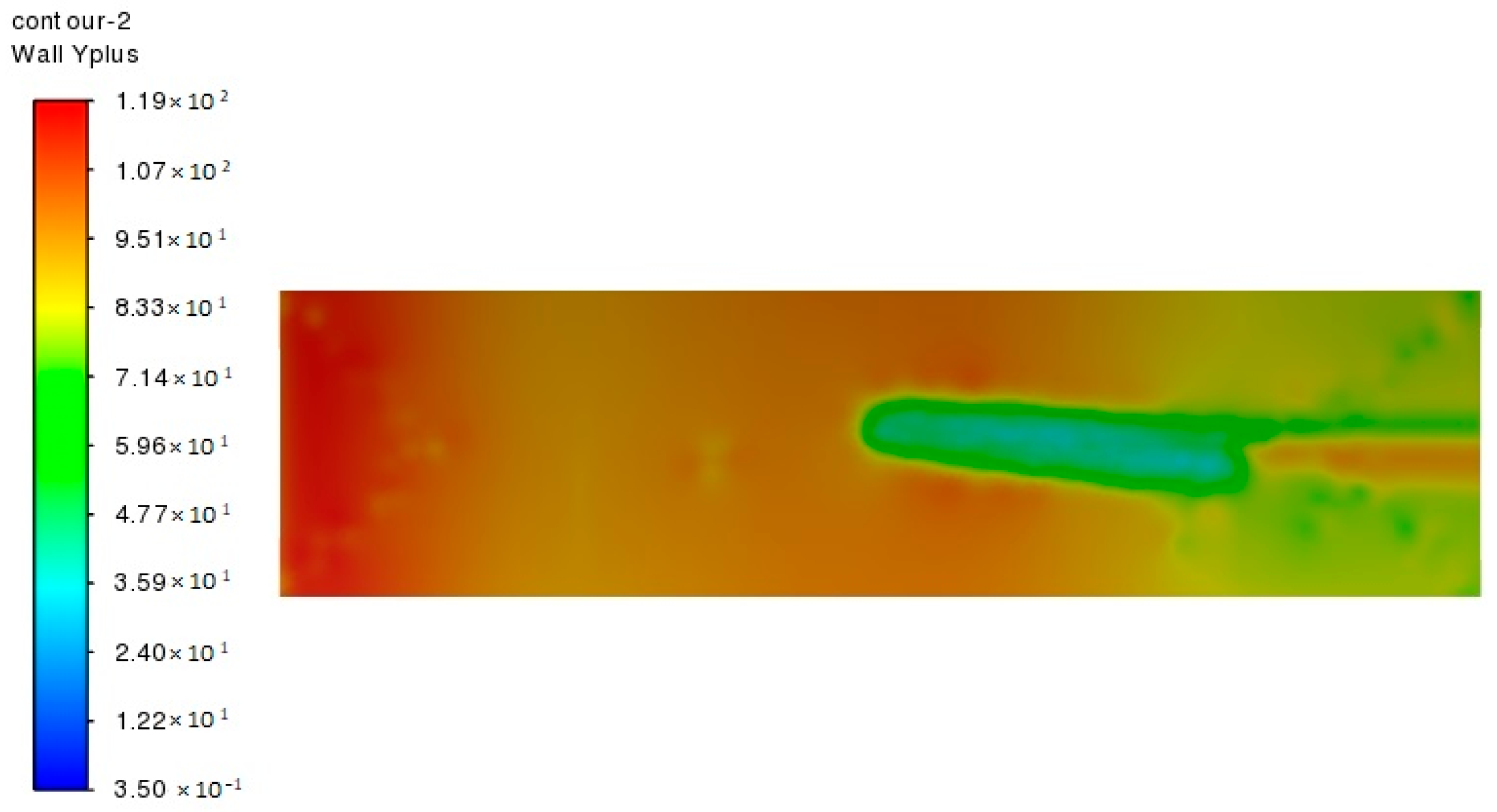

2.5. Grid Independence Verification

3. Results and Discussion

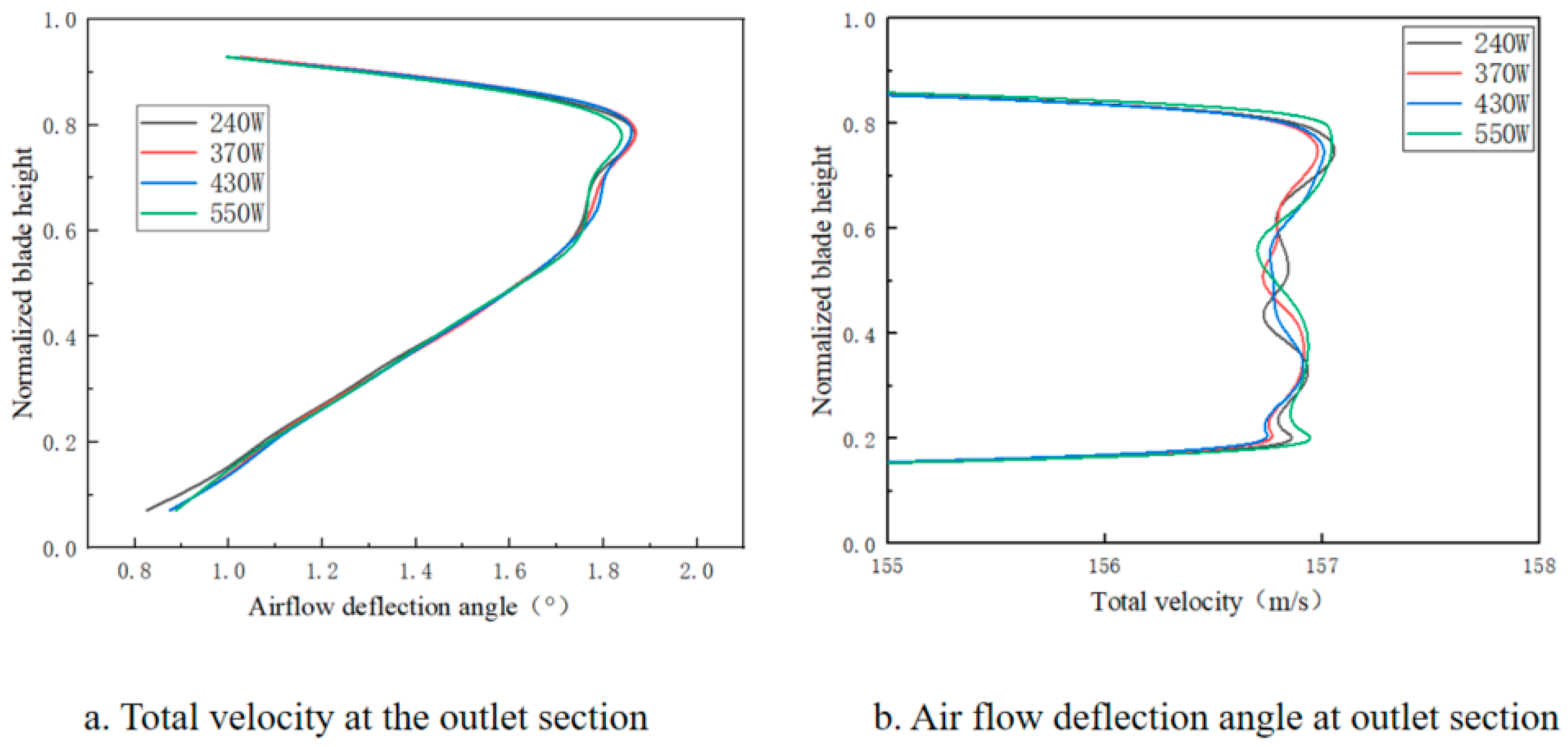

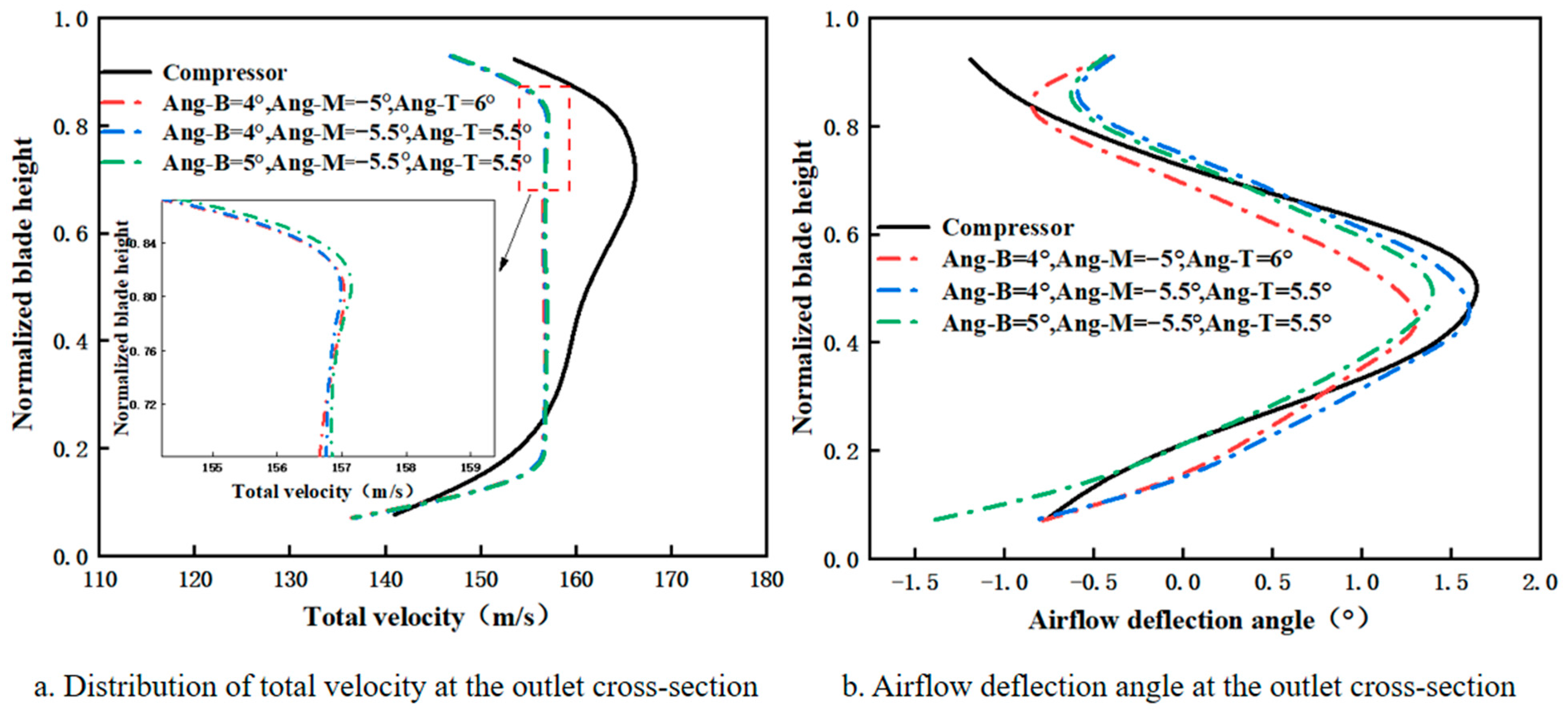

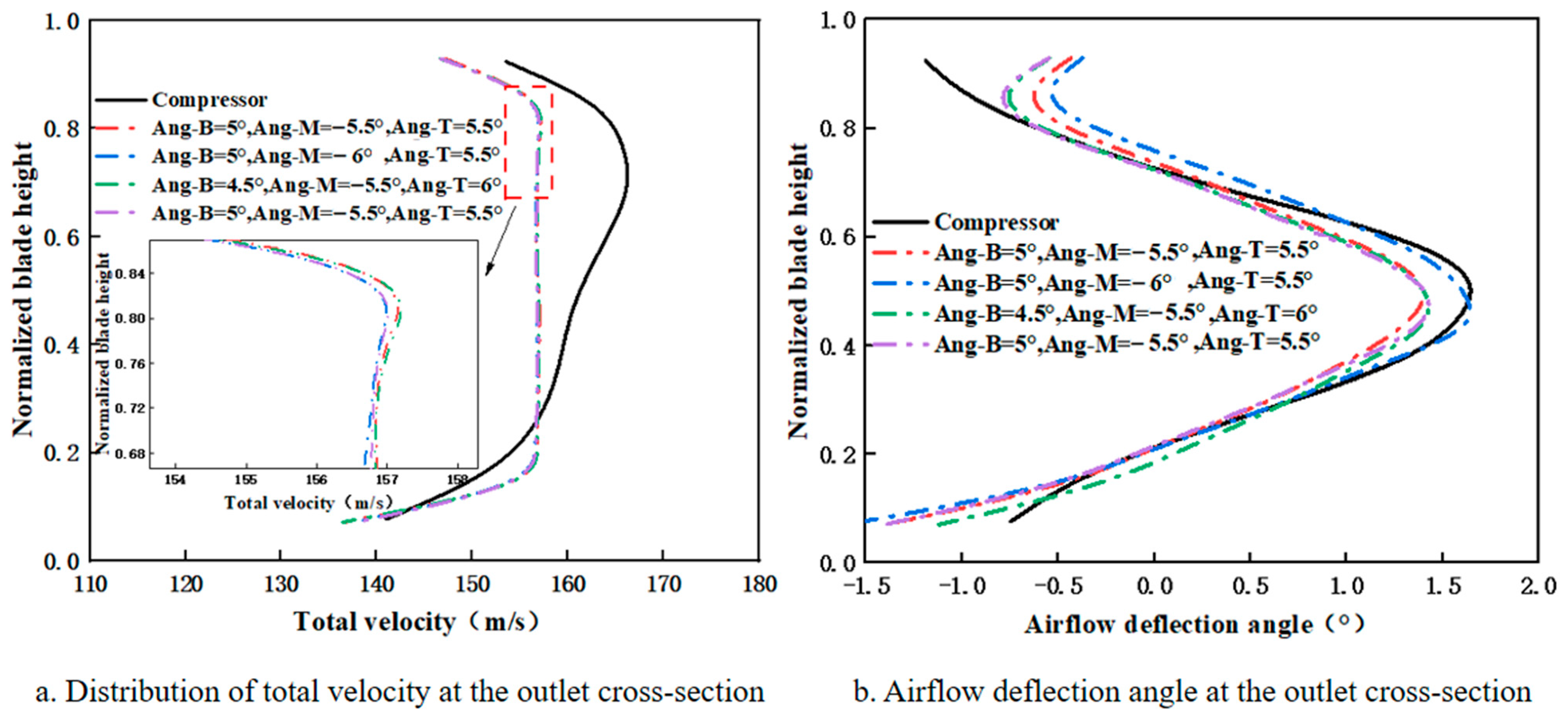

3.1. Effect of Two-Section Variable-Twist Blade Design on the Flow Field

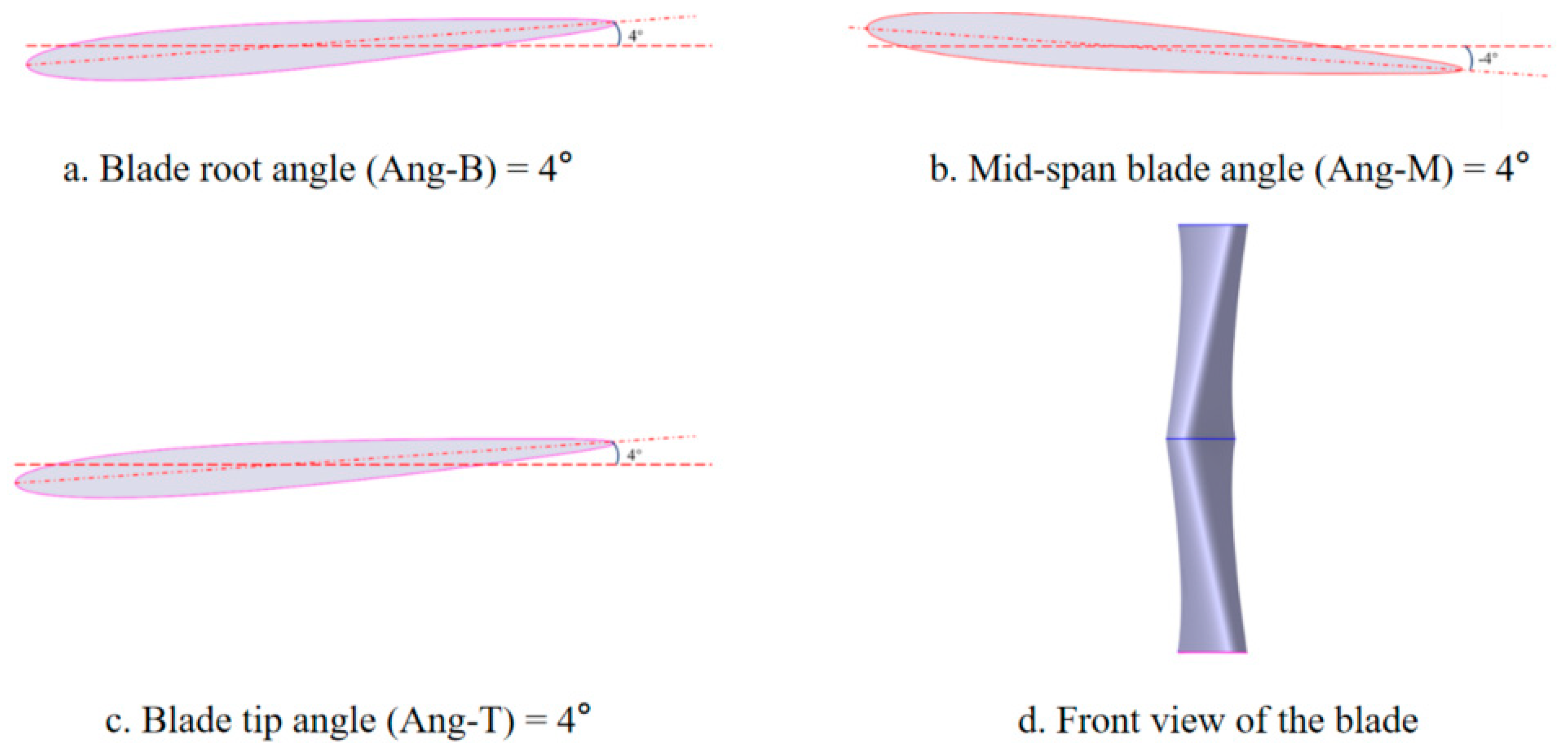

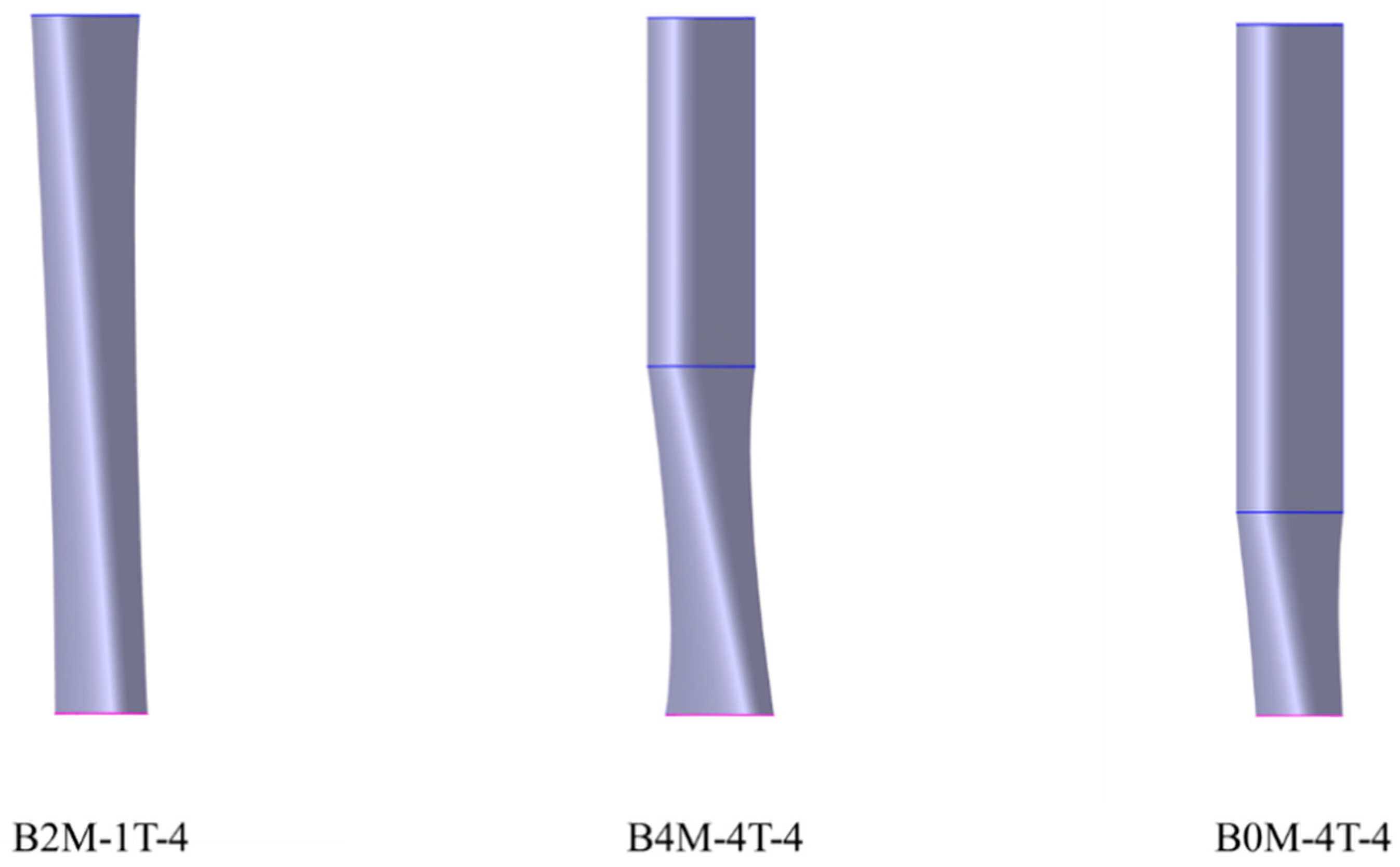

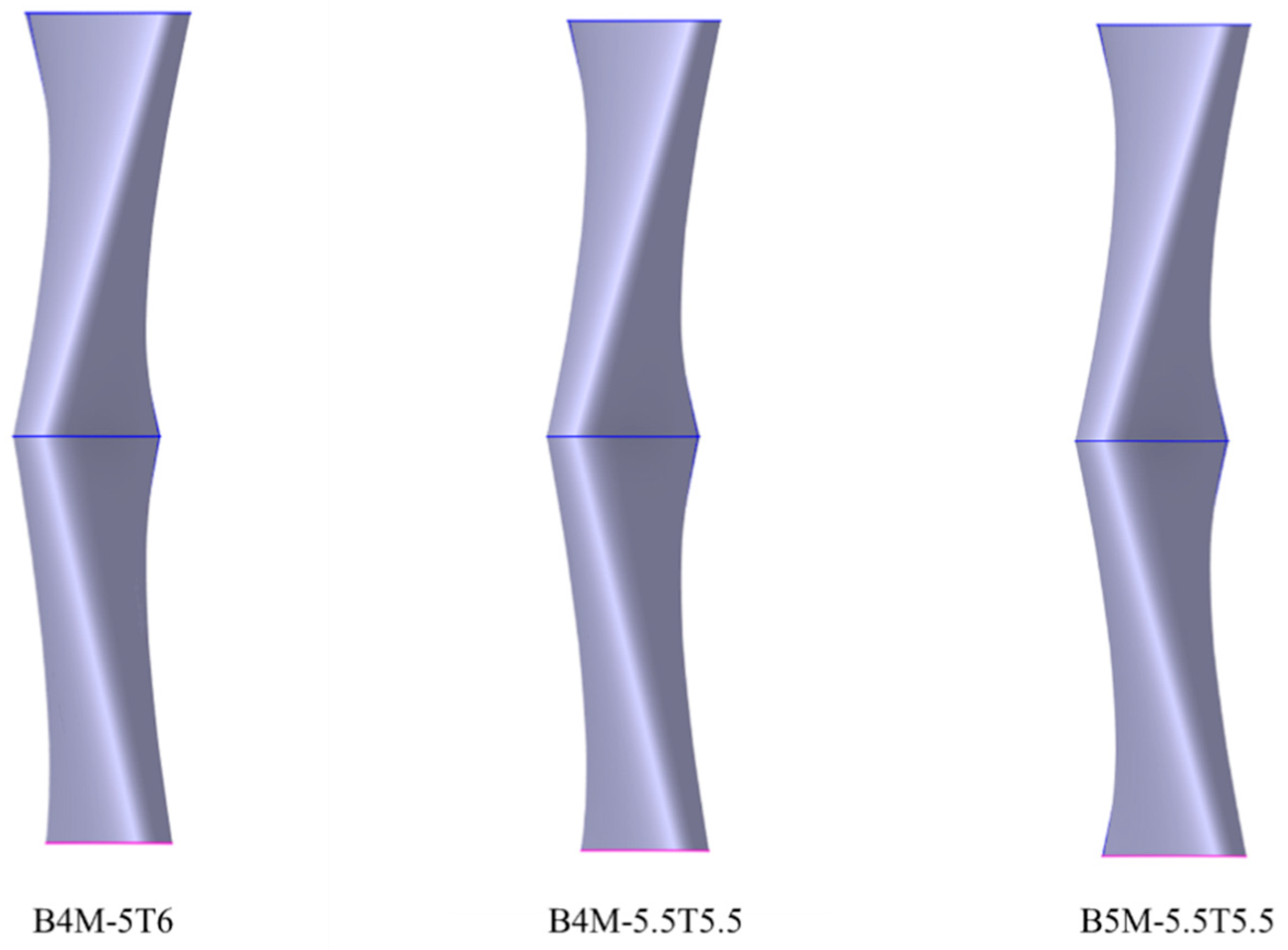

3.1.1. Variable-Twist Blade Structure

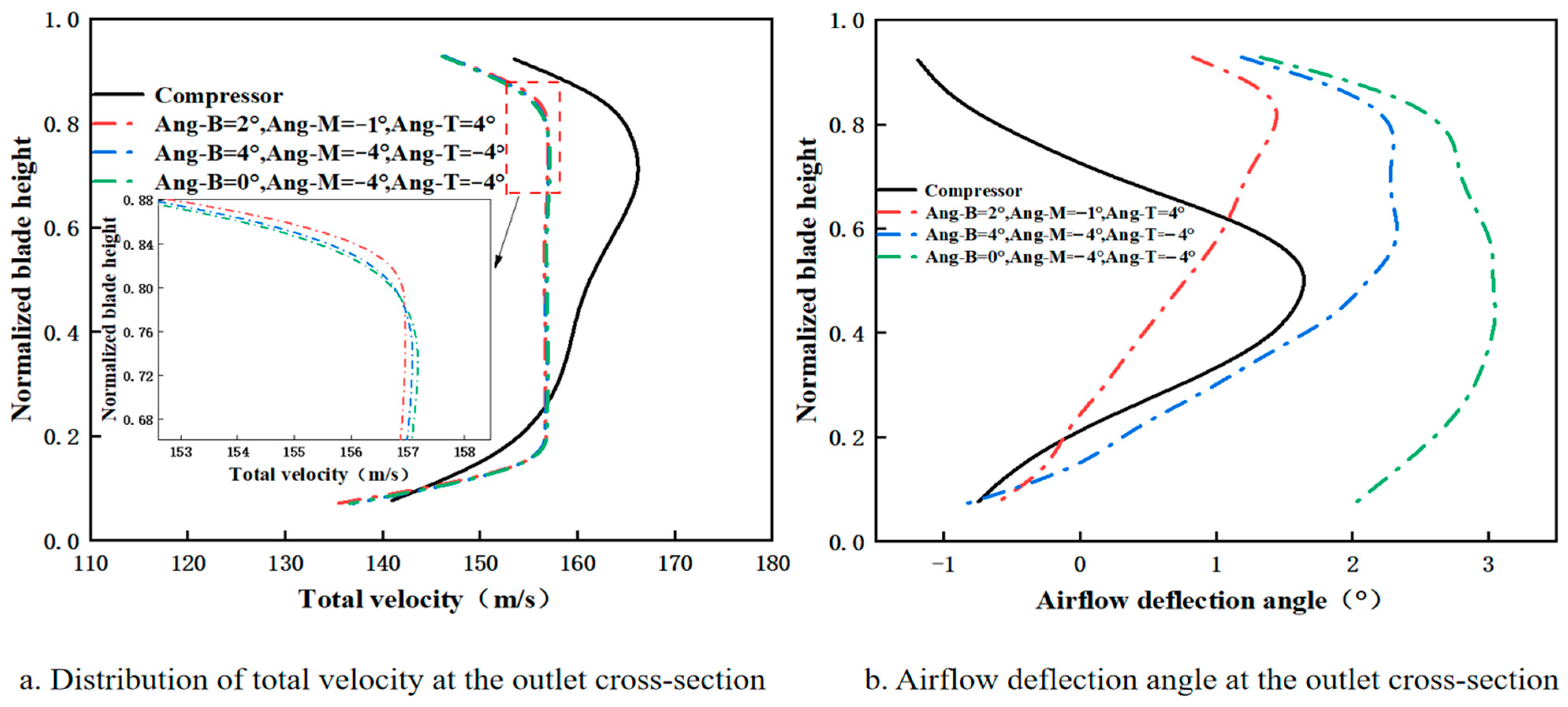

3.1.2. Effect of Opposite Twist Angles at Blade Root and Tip on Airflow Deflection Angle

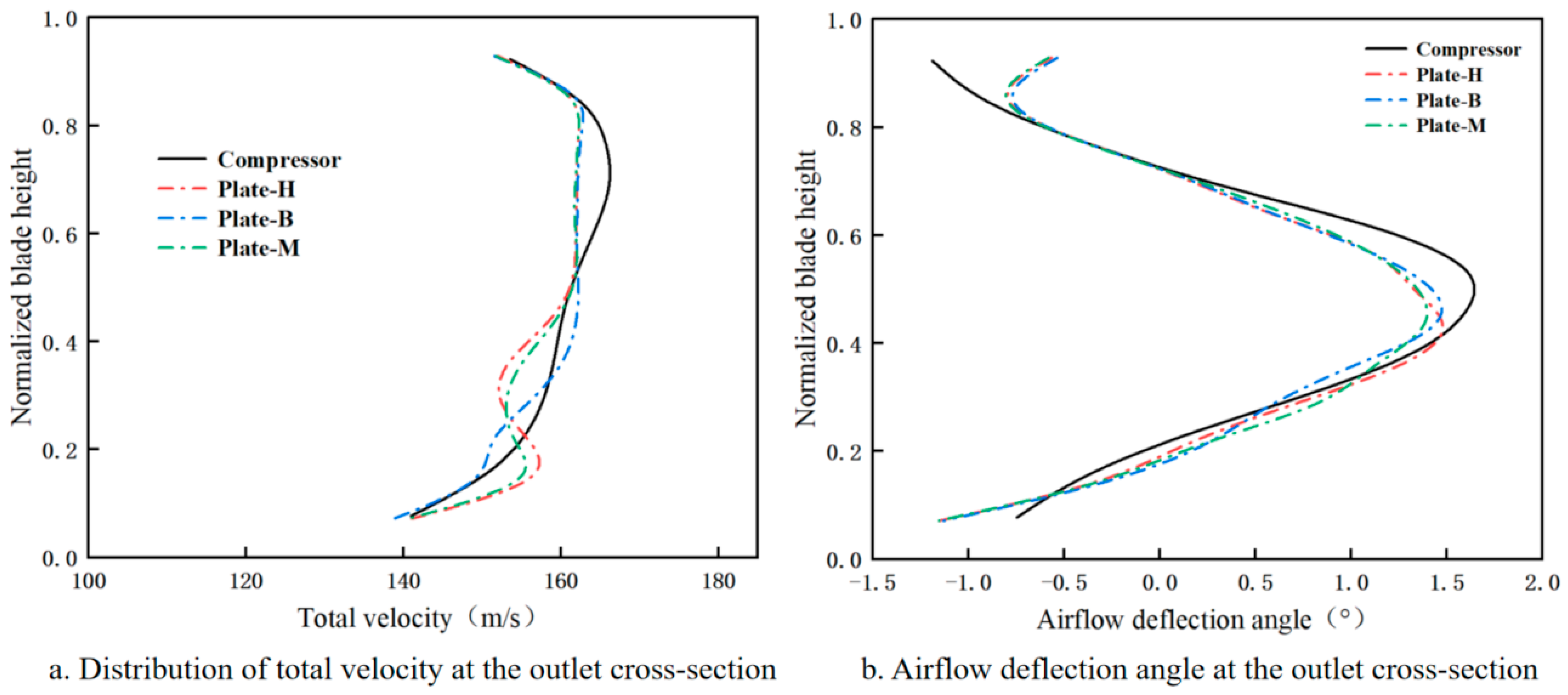

3.1.3. Effect of Aligned Twist Angles at Blade Root and Tip on Airflow Deflection Angle

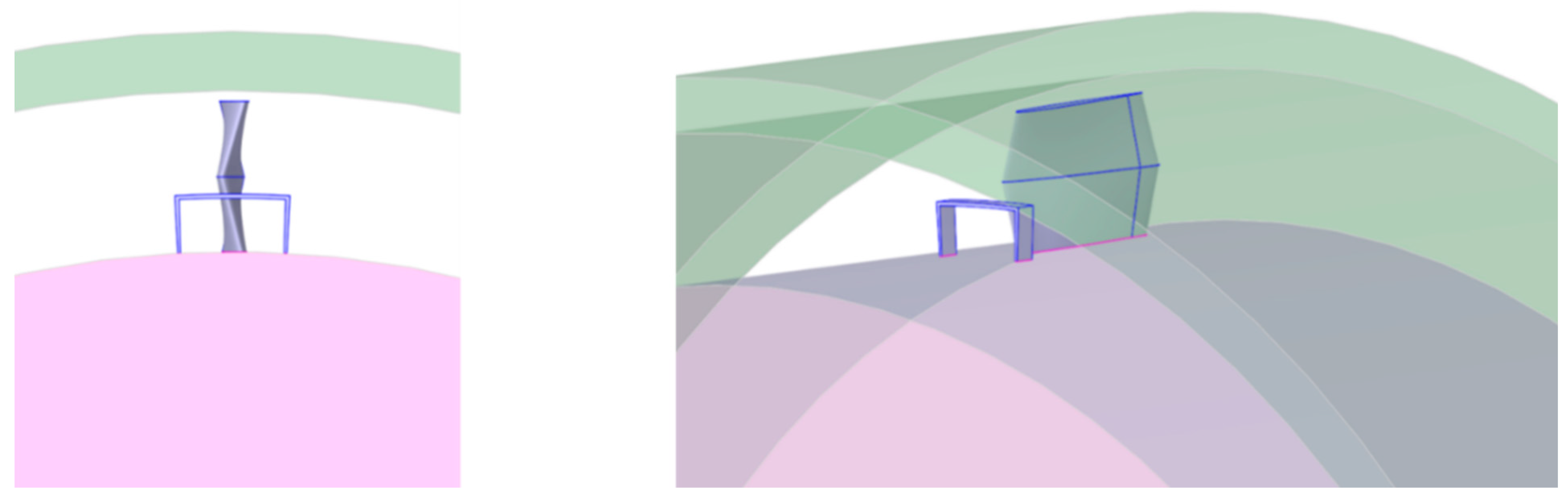

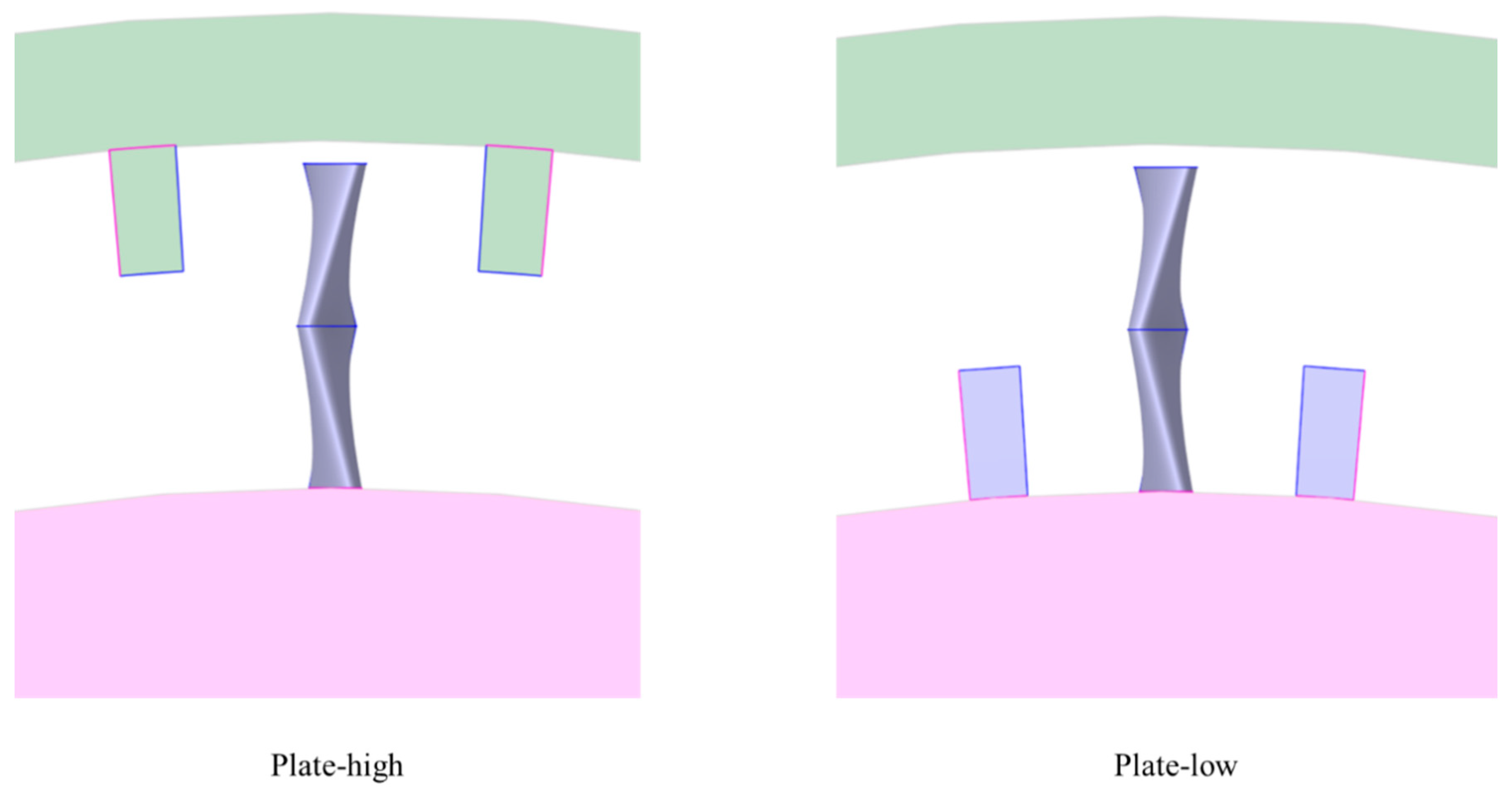

3.2. Effect of Upstream Baffle Design on Flow Field

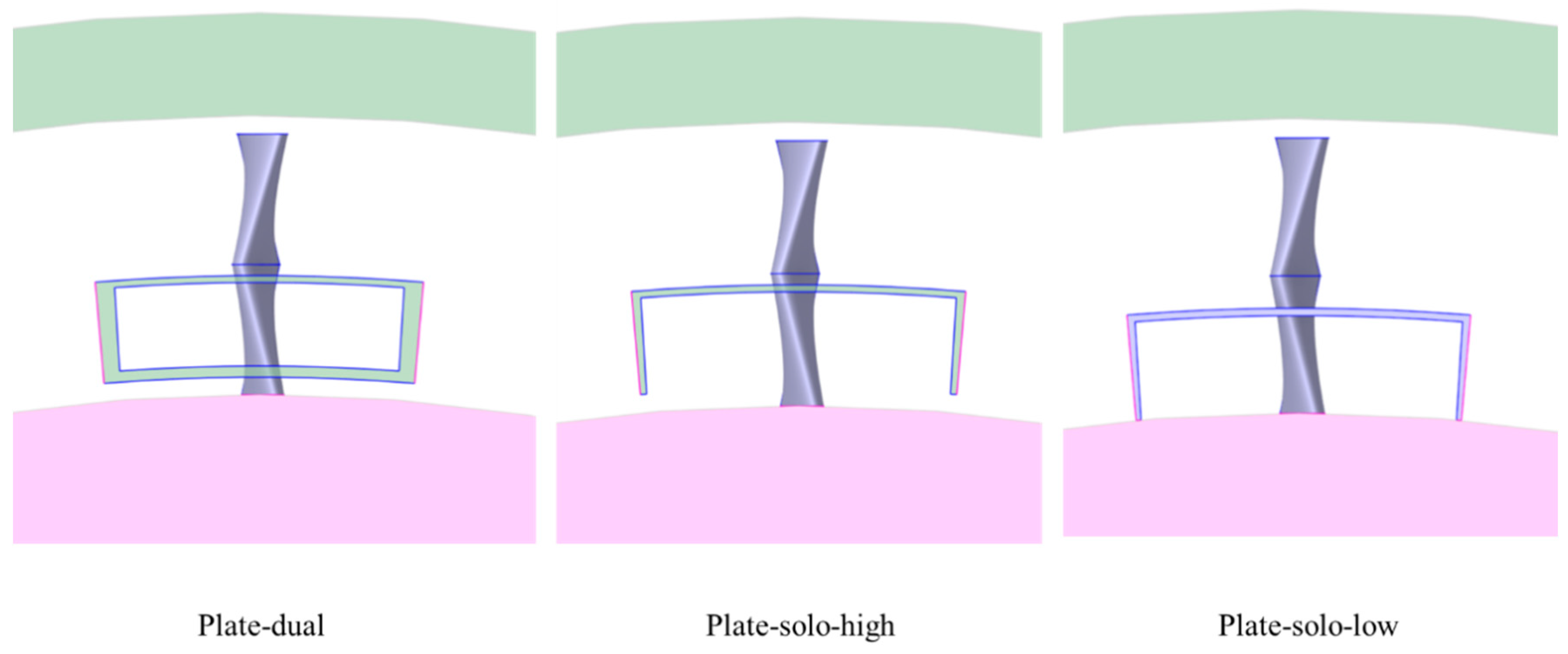

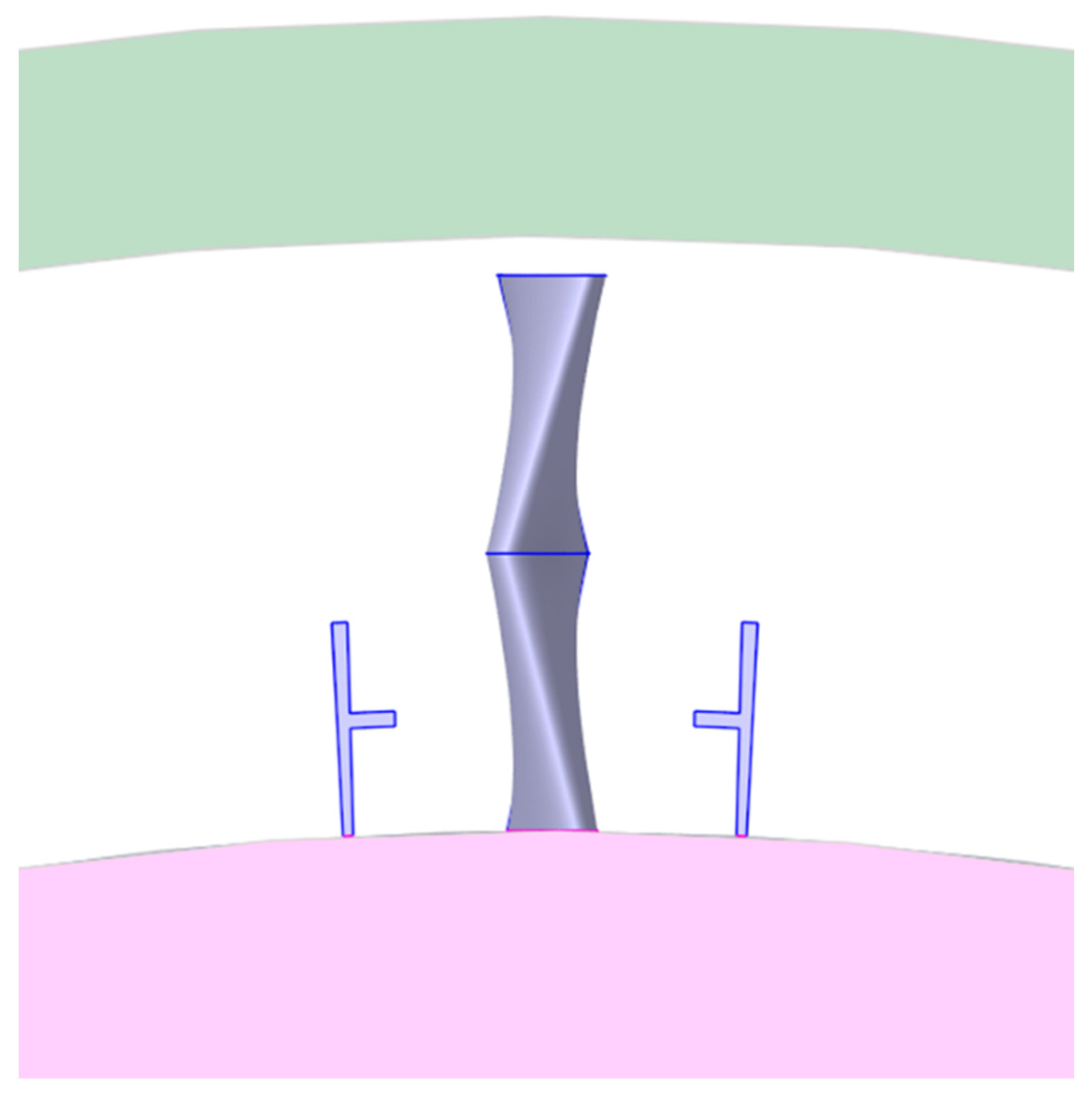

3.2.1. Front-End Baffle Structure

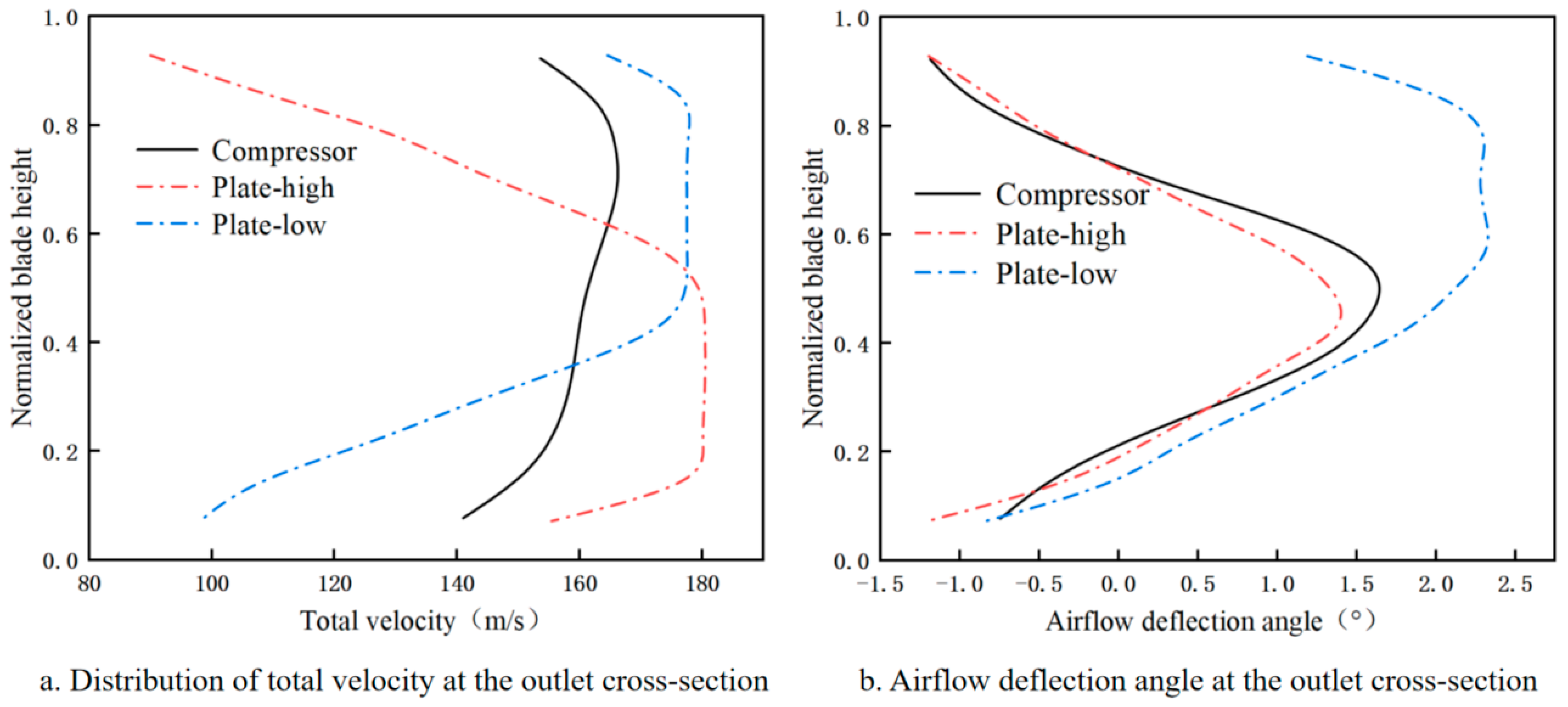

3.2.2. Effect of Front-End Baffle Position on Total Velocity

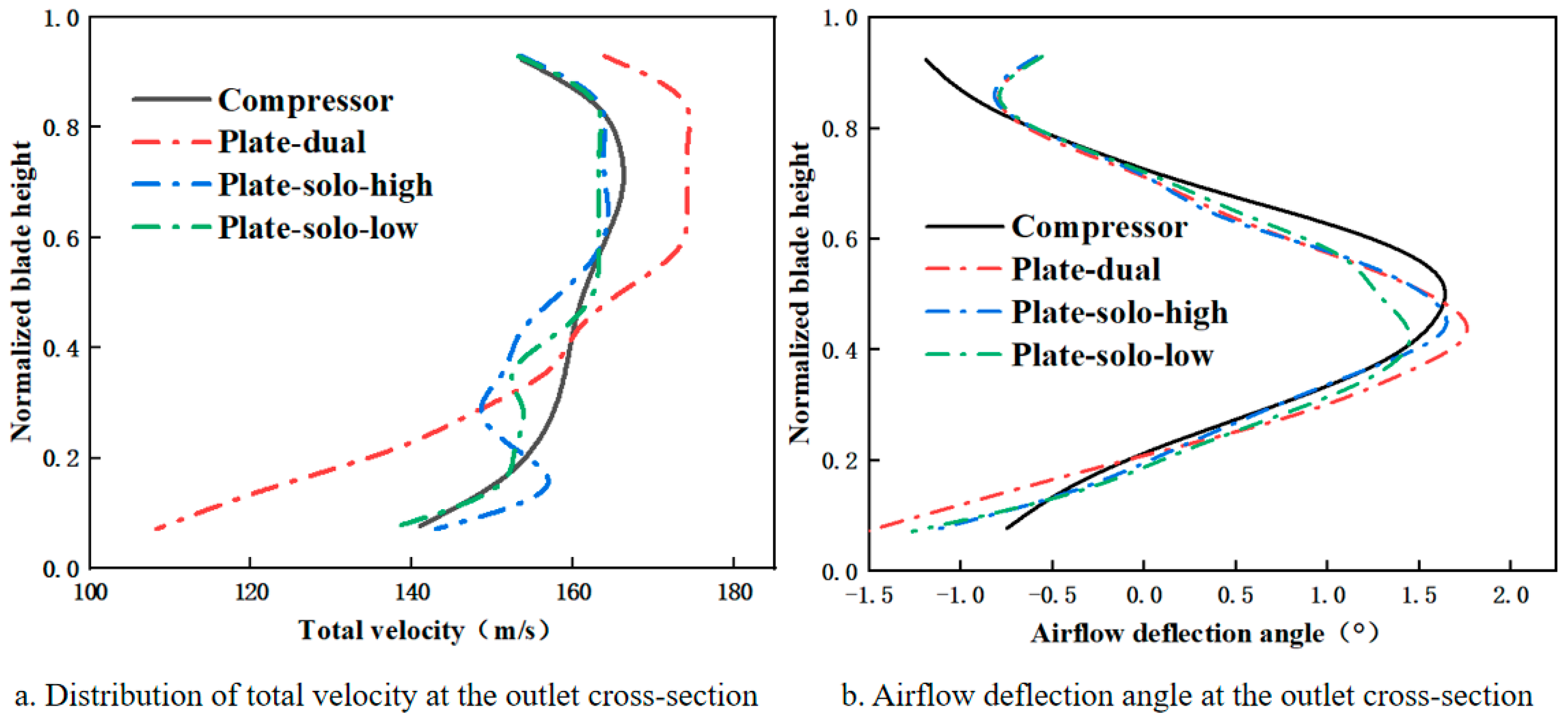

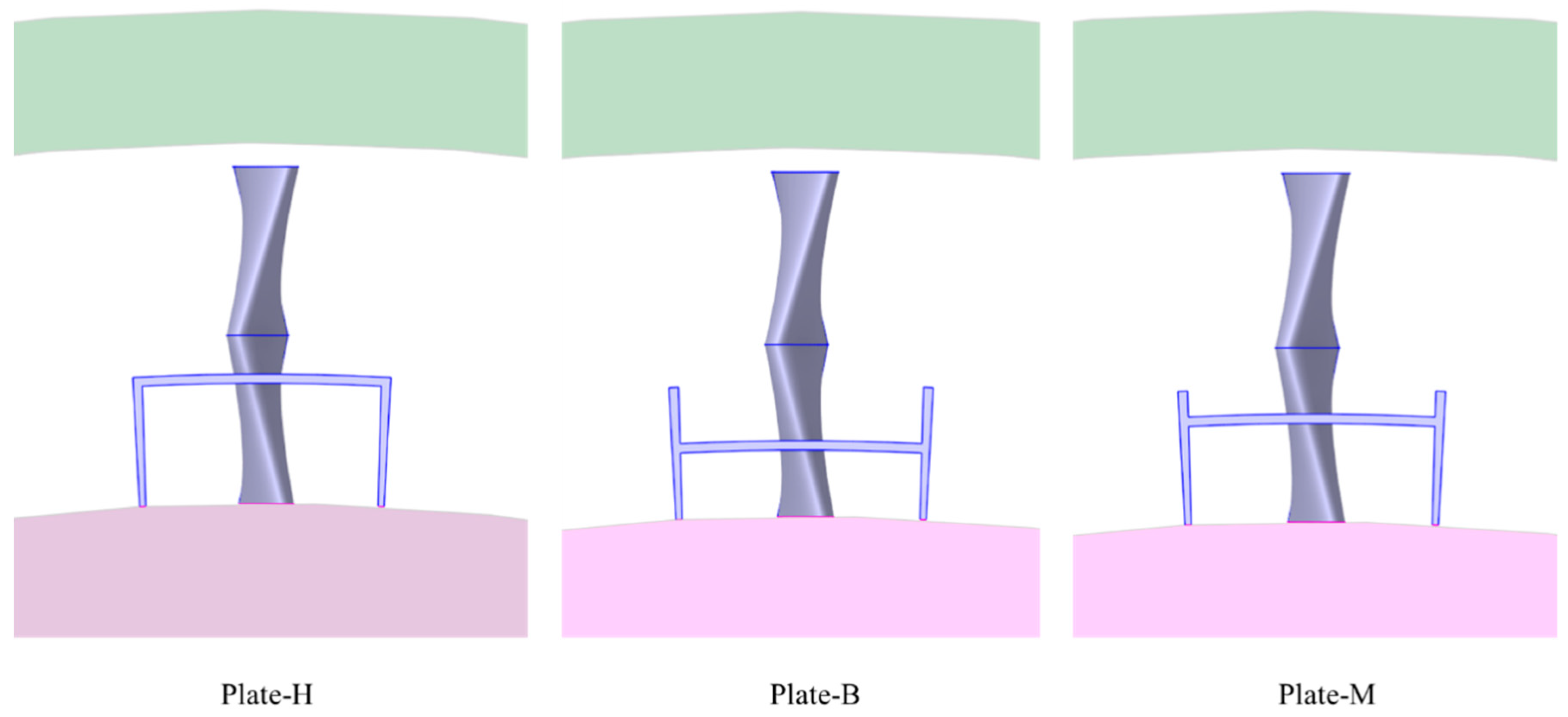

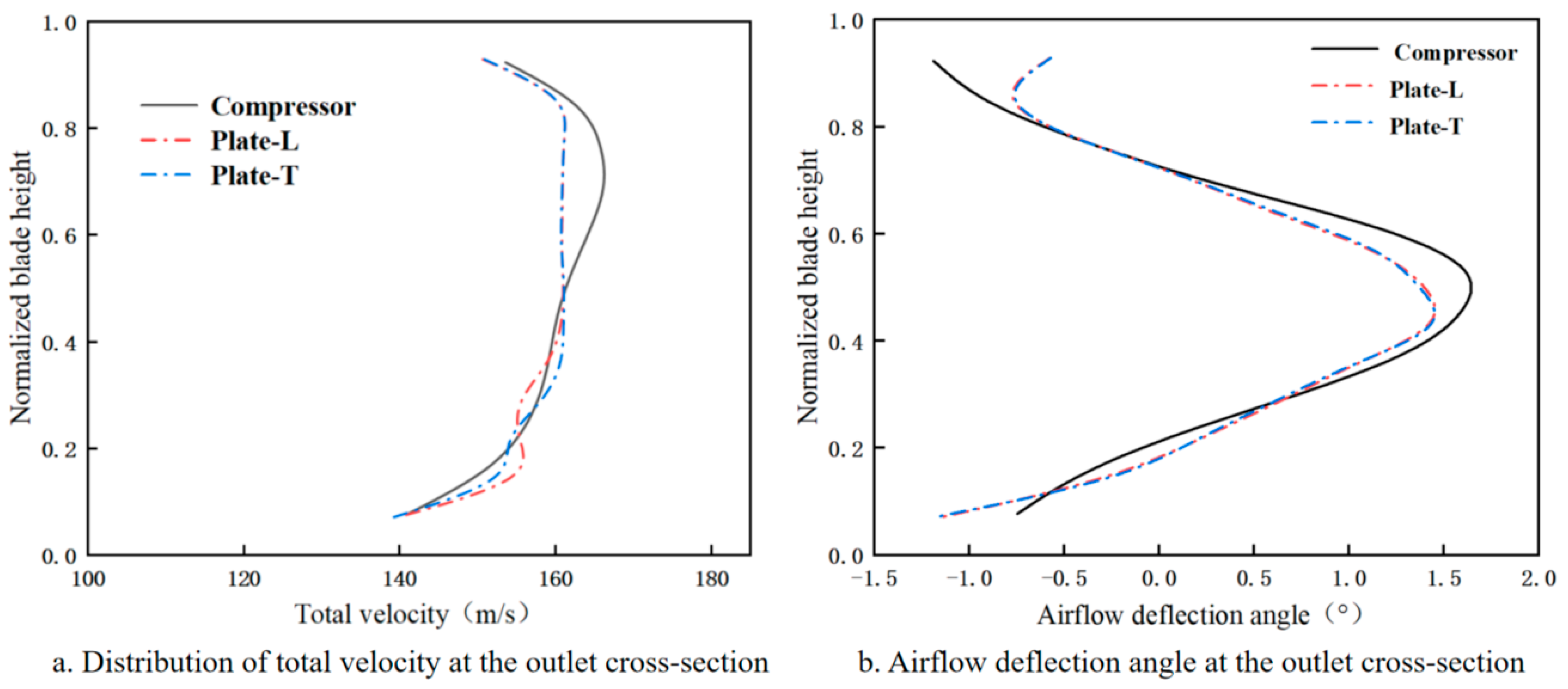

3.2.3. Effect of Upstream Baffle Geometry on Total Velocity

4. Conclusions

- (1)

- When a variable-twist blade configuration with a consistent twist direction at the blade root and tip is adopted, the airflow deflection angle distribution at the outlet cross-section of the simulation device exhibits strong agreement with that of the compressor outlet. For the B4.5M-5.5T6 configuration—with twist angles of 4.5° (bottom), 5.5° (middle), and 6° (top)—the peak airflow deflection angle at the outlet is 1.45°, differing by 0.23° from the compressor outlet value. The corresponding peak position is 0.50, representing a 7.1% deviation from that of the compressor outlet. Both deviations fall within the acceptable error range.

- (2)

- Introducing horizontal and vertical baffles upstream from the blade passage effectively modifies the total velocity distribution at the outlet cross-section of the simulation device by increasing velocity near the blade tip and decreasing it near the blade root. When the Plate-T baffle configuration is applied, the peak total velocity at the outlet is 161.57 m/s, representing a 3% deviation from the compressor outlet. The peak position is 0.72, with a deviation of 8.5%. Both values fall within the acceptable deviation range.

- (3)

- Numerical simulations show that placing baffles at the blade tip or blade root leads to inverse trends in peak velocity positioning within the outlet cross-section. Reducing baffle thickness, decreasing vertical baffle spacing, shortening horizontal baffle length, and lowering horizontal baffle placement along the blade span effectively controls the total velocity distribution near the blade root and tip, thereby reducing deviations from the compressor outlet. Ultimately, the Plate-T configuration limits the errors in peak total velocity magnitude and position to approximately 3.0% and 8.4%, respectively, meeting the design requirements. These results highlight the critical importance of upstream baffle geometry optimization in achieving precise flow field control within the simulation device.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, X.; Zhang, T.; Sheng, H. A novel aeroengine real-time model for active stability control: Compressor instabilities integration. Aerosp. Sci. Technol. 2024, 145, 108844. [Google Scholar] [CrossRef]

- Silva, C.F.; Duran, I.; Nicoud, F.; Moreau, S. Boundary conditions for the computation of thermoacoustic modes in combustion chambers. AIAA J. 2014, 52, 1180–1193. [Google Scholar] [CrossRef]

- Semlitsch, B. Boundary conditions to represent the wave impedance characteristics of axial compressors. Appl. Acoust. 2023, 204, 109236. [Google Scholar] [CrossRef]

- Agarwal, A.; Kalenga, M.K.W.; Ilunga, M. CFD Simulation of Fluid Flow and Combustion Characteristics in Aero-Engine Combustion Chambers with Single and Double Fuel Inlets. Processes 2025, 13, 124. [Google Scholar] [CrossRef]

- Palanti, L.; Pampaloni, D.; Andreini, A.; Facchini, B. Numerical simulation of a swirl stabilized methane-air flame with an automatic meshing CFD solver. Energy Procedia 2018, 148, 376–383. [Google Scholar] [CrossRef]

- Fan, L.; Yang, G.; Zhang, Y.; Gao, L.; Wu, B. A novel tolerance optimization approach for compressor blades: Incorporating the measured out-of-tolerance error data and aerodynamic performance. Aerosp. Sci. Technol. 2025, 158, 109920. [Google Scholar] [CrossRef]

- Zhou, J.-W.; Qin, Z.; Zhai, E.; Liu, Z.; Wang, S.; Liu, Y.; Chu, F. Bend-twist adaptive control for flexible wind turbine blades: Principles and experimental validation. Mech. Syst. Signal Process. 2025, 224, 111981. [Google Scholar] [CrossRef]

- Rahimi, H.; Schepers, J.G.; Shen, W.Z.; García, N.R.; Schneider, M.S.; Micallef, D.; Herráez, I. Evaluation of different methods for determining the angle of attack on wind turbine blades with CFD results under axial inflow conditions. Renew. Energy 2018, 125, 866–876. [Google Scholar] [CrossRef]

- Zhang, K.; Hayostek, S.; Amitay, M.; He, W.; Theofilis, V.; Taira, K. On the formation of three-dimensional separated flows over wings under tip effects. J. Fluid Mech. 2020, 895, A9. [Google Scholar] [CrossRef]

- Silva, L.J.O.; Wolf, W.R. Embedded shear layers in turbulent boundary layers of a NACA0012 airfoil at high angles of attack. Int. J. Heat Fluid Flow 2024, 107, 109353. [Google Scholar] [CrossRef]

- Bashir, M.; Zonzini, N.; Botez, R.M.; Ceruti, A.; Wong, T. Flow Control around the UAS-S45 Pitching Airfoil Using a Dynamically Morphing Leading Edge (DMLE): A Numerical Study. Biomimetics 2023, 8, 51. [Google Scholar] [CrossRef]

- Qi, W.; Yang, J.; Zhang, Z.; Wu, J.; Lan, P.; Xiang, S. Investigation on thermal management of cylindrical lithium-ion batteries based on interwound cooling belt structure. Energy Convers. Manag. 2025, 340, 119962. [Google Scholar] [CrossRef]

- Deng, H.; Luo, L.; Yan, H.; Zhou, X.; Du, W.; Luo, Q. Experimental and numerical study on a three-stage high-load axial compressor with 3D blade design. Energy 2025, 316, 134399. [Google Scholar] [CrossRef]

- Zhang, X.; Ju, Y.; Li, Z.; Liu, F.; Zhang, C. Optimization of Three-Dimensional Blade and Variable Stators for Efficiency and Stability Enhancement of Multistage Axial Flow Compressor at Variable Speeds. J. Turbomach. 2023, 146, 041004. [Google Scholar] [CrossRef]

- Zhang, X.; Ju, Y.; Li, Z.; Liu, F.; Zhang, C. Metamodel-Interpreted Data Mining for Stability and Efficiency Enhancement of Multistage Axial-Flow Compressors. J. Turbomach. 2022, 145, 041001. [Google Scholar] [CrossRef]

- Asgari, M.; Ommi, F.; Saboohi, Z. Aeroelastic modeling and multi-objective optimization of a subsonic compressor rotor blade using a combination of modified NSGA-II, ANN, and TOPSIS. Results Eng. 2025, 26, 104615. [Google Scholar] [CrossRef]

- Xu, J.; Wang, L.; Yuan, J.; Fu, Y.; Wang, Z.; Zhang, B.; Tan, A.C. Mesh-based data-driven approach for optimization of tidal turbine blade shape. Energy 2025, 328, 136699. [Google Scholar] [CrossRef]

- Krishnan, A.; Al-Obaidi, A.S.M.; Hao, L.C. A comprehensive review of innovative wind turbine airfoil and blade designs: Toward enhanced efficiency and sustainability. Sustain. Energy Technol. Assess. 2023, 60, 103511. [Google Scholar] [CrossRef]

- Fan, M.-Y.; Chen, J. Nonlinear dynamics of rotating functionally graded graphene platelets/titanium alloy trapezoid plates under 1:3 internal resonance. Nonlinear Dyn. 2024, 112, 20793–20812. [Google Scholar] [CrossRef]

- Mansouri, Z.; Jefferson-Loveday, R. Heat transfer characteristics of a high-pressure turbine under combined distorted hot-streak and residual swirl: An unsteady computational study. Int. J. Heat Mass Transf. 2022, 195, 123143. [Google Scholar] [CrossRef]

- Fathi, S.; Boroomand, M.; Eshraghi, H. Improving near-stall performance of axial flow compressors using variable rotor tandem stage. A steady analysis. Phys. Fluids 2024, 36, 097101. [Google Scholar] [CrossRef]

- Qi, W.; Lan, P.; Yang, J.; Chen, Y.; Zhang, Y.; Wang, G.; Hong, J. Multi-U-Style micro-channel in liquid cooling plate for thermal management of power batteries. Appl. Therm. Eng. 2024, 256, 123984. [Google Scholar] [CrossRef]

- Liu, C.; Guo, J.; Wang, C.; Liu, P.; Ding, S. An adjustable vane-shaped nozzle-based modulated pre-swirl system for gas turbine aero-engine: Structure parameters and aerodynamic performance analysis. Appl. Therm. Eng. 2024, 257, 124302. [Google Scholar] [CrossRef]

- Asim, T.; Singh, D.; Siddiqui, M.S.; McGlinchey, D. Effect of Stator Blades on the Startup Dynamics of a Vertical Axis Wind Turbine. Energies 2022, 15, 8135. [Google Scholar] [CrossRef]

- Hurtado, J.P.; Villegas, B.; Pérez, S.; Acuña, E. Optimization Study of Guide Vanes for the Intake Fan-Duct Connection Using CFD. Processes 2021, 9, 1555. [Google Scholar] [CrossRef]

- Jiang, D.; Li, H.; Liu, C.; Hu, Y.; Li, Y.; Yan, Y.; Zhang, C. Aerodynamic Characteristics of Typical Operating Conditions and the Impact of Inlet Flow Non-Uniformity in a Multi-Stage Transonic Axial Compressor. Processes 2025, 13, 1428. [Google Scholar] [CrossRef]

- Nakhchi, M.E.; Naung, S.W.; Rahmati, M. Influence of blade vibrations on aerodynamic performance of axial compressor in gas turbine: Direct numerical simulation. Energy 2022, 242, 122988. [Google Scholar] [CrossRef]

- Şöhret, Y.; Ekici, S.; Altuntaş, Ö.; Hepbasli, A.; Karakoç, T.H. Exergy as a useful tool for the performance assessment of aircraft gas turbine engines: A key review. Prog. Aerosp. Sci. 2016, 83, 57–69. [Google Scholar] [CrossRef]

- Liu, X.; Guo, S.; Wang, Y.; Wang, D.; Wang, G.; Li, H. CFD-based unsteady simulation and performance analysis of scroll compressor. Int. J. Refrig. 2025, 170, 150–163. [Google Scholar] [CrossRef]

- Huang, P.; Bu, X.; Lin, G.; Wen, D. Numerical simulations of ice crystal icing within a 1.5-stage compressor in an aero-engine. Case Stud. Therm. Eng. 2025, 69, 106026. [Google Scholar] [CrossRef]

- Kumar, A.; Bharti, R.P. Assessment of RANS-based turbulence models for isothermal confined swirling flow in a realistic can-type gas turbine combustor application. J. Comput. Sci. 2024, 81, 102362. [Google Scholar] [CrossRef]

- Waluyo, R.; Aziz, M. Advanced numerical simulation of hydrogen/air turbulent non-premixed flame on model burner. Therm. Sci. Eng. Prog. 2024, 49, 102467. [Google Scholar] [CrossRef]

- Pope, S.B. Turbulent Flows; Cambridge University Press: Cambridge, UK, 2000. [Google Scholar]

- Nallasamy, M. Turbulence models and their applications to the prediction of internal flows: A review. Comput. Fluids 1987, 15, 151–194. [Google Scholar] [CrossRef]

- Gong, C.; Zhao, S.; Chen, W.; Li, W.; Zhou, Y.; Qiu, M. Numerical study on the combustion process in a gas turbine combustor with different reference velocities. Adv. Aerodyn. 2023, 5, 24. [Google Scholar] [CrossRef]

- Amerini, A.; Paccati, S.; Andreini, A. Computational Optimization of a Loosely-Coupled Strategy for Scale-Resolving CHT CFD Simulation of Gas Turbine Combustors. Energies 2023, 16, 1664. [Google Scholar] [CrossRef]

| Symbol/Variable | Definition | Unit |

|---|---|---|

| ρ | Fluid density | kg/m3 |

| v | Velocity vector | m/s |

| vi | Velocity component in the i-th Cartesian coordinate direction (i = 1, 2, 3) | m/s |

| p | Static pressure | Pa |

| τij | Shear stress component in the i-th direction on a plane normal to the j-th direction | Pa |

| f | External body force vector | N/m3 |

| fi | External body force component in i-th direction | N/m3 |

| Vz | Axial velocity component | m/s |

| Vt | Tangential velocity component | m/s |

| Vr | Radial velocity component | m/s |

| Vm | Meridional velocity magnitude (Vm = sqrt(Vz2 + Vr2)) | m/s |

| Operating Parameters | Values |

|---|---|

| Operating Pressure Po/MPa | 0.51 |

| Inlet Temperature T1/K | 620 |

| Inlet Air Flow Rate (kg/s) | 6.574 |

| Outlet Gauge Pressure Pg2/MPa | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, D.; Li, H.; Li, X.; Li, Y.; Hu, Y.; Liu, C.; Zhang, C.; Yan, Y. Simulation of Combustor Inlet Flow Field via Segmented Blade Twist and Leading-Edge Baffles. Energies 2025, 18, 4535. https://doi.org/10.3390/en18174535

Jiang D, Li H, Li X, Li Y, Hu Y, Liu C, Zhang C, Yan Y. Simulation of Combustor Inlet Flow Field via Segmented Blade Twist and Leading-Edge Baffles. Energies. 2025; 18(17):4535. https://doi.org/10.3390/en18174535

Chicago/Turabian StyleJiang, Dong, Huadong Li, Xiang Li, Yongbo Li, Yang Hu, Chang Liu, Chenghua Zhang, and Yunfei Yan. 2025. "Simulation of Combustor Inlet Flow Field via Segmented Blade Twist and Leading-Edge Baffles" Energies 18, no. 17: 4535. https://doi.org/10.3390/en18174535

APA StyleJiang, D., Li, H., Li, X., Li, Y., Hu, Y., Liu, C., Zhang, C., & Yan, Y. (2025). Simulation of Combustor Inlet Flow Field via Segmented Blade Twist and Leading-Edge Baffles. Energies, 18(17), 4535. https://doi.org/10.3390/en18174535