1. Introduction

Induction motors (IM) operate smoothly and efficiently in many industrial applications, turning electrical energy into mechanical energy [

1]. These machines are widely used in sectors such as railway, automotive transportation, manufacturing, air conditioning, and power energy, where their reliable and robust operation is essential [

2]. Given their widespread use, ensuring fault-free operation and optimizing the performance of induction motors have become a critical area of research [

3]. To achieve these objectives, IM must be properly controlled and continuously monitored to maintain an optimal performance and prevent the development of electrical and mechanical faults, such as broken rotor bars, rotor misalignment, and bearing failures [

4]. One of the key aspects in achieving effective control and fault-free operation is the accurate information of the instantaneous motor speed, which not only enables the implementation of control strategies to enhance efficiency but also allows for fault detection, thereby minimizing downtime and reducing maintenance costs [

5]. Speed estimation in IM is particularly significant, as physical sensors are replaced by advanced algorithms that infer the rotor speed from electrical signals, specifically from stator voltage and current measurements [

6]. This estimation approach enhances systems reliability by eliminating vulnerable electronic signal paths and reducing instrumentation costs.

Among the approaches developed to estimate motor speed without relying on physical speed sensors, model-based techniques have received considerable attention due to their capacity to exploit the physical principles governing motor behavior [

7]. These sensorless estimation methods utilize mathematical models to infer speed and other internal states from measurable electrical quantities, thus reducing system costs while maintaining the monitoring and control performance [

8]. Within this category, methods include observer-based structures such as the Extended State Observers [

9], Luenberger Observers [

10], and Sliding Mode Observers [

11,

12], which are widely recognized for their ability to enhance convergence speed and estimation accuracy across different induction motor sizes. While these observers show a reliable performance under nominal or steady-state conditions, their sensitivity to external disturbances and time-varying operating regimes often limits their robustness in practical applications. To address these challenges, stochastic estimation techniques have been introduced, incorporating process and measurement noise covariance matrices to improve accuracy under uncertainty. For example, a comparative analysis in [

13] of the Extended Kalman Filter (EKF) and Unscented Kalman Filter highlights the EKF as a suitable compromise between computational efficiency and estimation performance in scenarios with incomplete dynamic information. However, tuning the noise covariance matrices remains a critical challenge, frequently requiring expert knowledge and adjustment [

14]. To enhance adaptability, a hybrid adaptive EKF utilizing a sliding window strategy has been proposed in [

15], which enables the adjustment of covariance matrices and improves the resilience to time-variant conditions. Similarly, combined estimation schemes, such as the integration of a Luenberger Observer with a Model Reference Adaptive System, have been explored to account for speed variations, achieving a reduced computational burden through inertia estimation [

16]. Nevertheless, these methods continue to exhibit sensitivity to transient load variations, which can compromise the quality of estimation during dynamic behavior. Recent advancements have focused on refining model structures and integrating multiple estimation strategies. For instance, a discrete-time Kalman filter approach with automated noise covariance tuning has been implemented in [

17] to support rotor speed estimation with improved robustness. Despite the high accuracy and precision achieved by these developments, the effectiveness of all model-based techniques remains highly dependent on the accuracy of the motor model itself. Moreover, the implementation of such techniques implies a considerable computational cost, as they require monitoring multiple signals and solving several simultaneous differential equations.

As an alternative to model-based approaches, several techniques have been proposed for estimating the speed of induction motors without requiring the computation of a mathematical motor model. Instead, these methods rely on tracking the spectral signature of rotor slot harmonics, which are present in the stator current due to the geometric characteristics of the rotor, as explained in

Section 2.1. This motor model independence significantly enhances the adaptability of RSH-based methods across a wide range of motor types and operating conditions [

18]. For example, in [

19], enhancements to the Chirp-Z Transform have demonstrated an improved frequency resolution for identifying slot harmonic frequencies without increasing the computational complexity typically associated with full-spectrum Fast Fourier Transform (FFT)-based methods. Another FFT-based estimator in [

20] can follow the time evolution of spectral components, enabling speed tracking. Other proposals, such as the adaptive sinusoidal mode decomposition in [

21] and harmonic enhancement via synthesized vibration signals in [

22], address non-stationary behaviors but involve complex processing steps or require supplementary sensors. Additional methods have been proposed, ranging from signal demodulation with Hall effect sensors in [

23] to the zero-crossing detection of high-order RSHs [

24] and from injected carrier signals [

25] to harmonic separation using phase-locked loop (PLL) structures in [

26]. These techniques have the objective of increasing estimation accuracy and tracking performance. Sparse spectral analysis methods have also been proposed to enhance robustness in noisy environments. In [

27], the use of a sparsity-driven algorithm combined with a singular value decomposition has shown promising results in extracting RSH under variable speed conditions. This technique enables RSH tracking under high-level speed changes. Similarly, an approach that integrates digital adaptive filters and PLL architectures within the current and speed control loops has demonstrated low latency in [

7]. Another strategy, ref. [

28], relies on monitoring multiple harmonic components simultaneously using the Short-Time Fourier Transform, providing an estimation during transient operations while avoiding dependence on motor-specific parameters. Time-domain approaches have also emerged, such as the use of histograms of oriented gradients for rotor speed estimation from single-phase stator current measurements [

29], enabling a high response.

Table 1 shows a comparative analysis of these methods from which the following conclusions can be drawn: (i) Most existing methods rely on full-band signal processing, which inherently reduces noise immunity and increases computational requirements; (ii) methods with a high accuracy typically come with increased computational complexity; (iii) dynamic condition suitability often requires either complex processing algorithms or additional sensors; and (iv) the trade-off between computational efficiency and performance under varying conditions remains a significant challenge. In summary, despite the diversity and sophistication of these methods, all rely on a full-band signal, require high-dimensional feature extraction, and are reliable only under steady-state conditions, which complicates practical implementation and reduces noise immunity under industrial constraints.

To overcome these challenges, this study introduces a new subband signal processing method aimed at estimating motor speed under changing operating conditions within the manufacturer’s specified limits. The central idea is to narrow the analysis bandwidth to a specific spectral region where the RSH is located, thereby eliminating the need to process irrelevant frequencies. This approach significantly reduces the length of the signal to be analyzed, thereby minimizing the computational burden and making the technique highly suitable for real-time applications. By avoiding a full-bandwidth analysis, the method also enhances noise resilience, as only the frequency region containing the useful harmonic content is processed. To further improve harmonic detection, the method incorporates a statistical spectral estimator based on an eigenvalue analysis of the autocorrelation matrix of the signal. This estimator enables high-frequency resolution using short-length data and robust identification of the speed-related harmonic, even when the stator current is heavily contaminated by noise. The proposed methodology has been validated through simulations and experimental tests on induction motors working under variable load profiles within the manufacturer’s specified operational limits. The results demonstrate a superior performance in estimation accuracy, computational efficiency, and robustness when compared to techniques that rely on FFT analysis.

The remainder of this paper is organized as follows:

Section 2 reviews the theoretical foundations of the study.

Section 3 details the proposed methodology, including the signal processing stages.

Section 4 presents the numerical results obtained through simulation, providing initial validation of the method.

Section 5 outlines the experimental setup used for real-world testing.

Section 6 presents and discusses the experimental results. Finally,

Section 7 concludes the paper with a summary of key findings and suggestions for future work.

3. Proposed Method

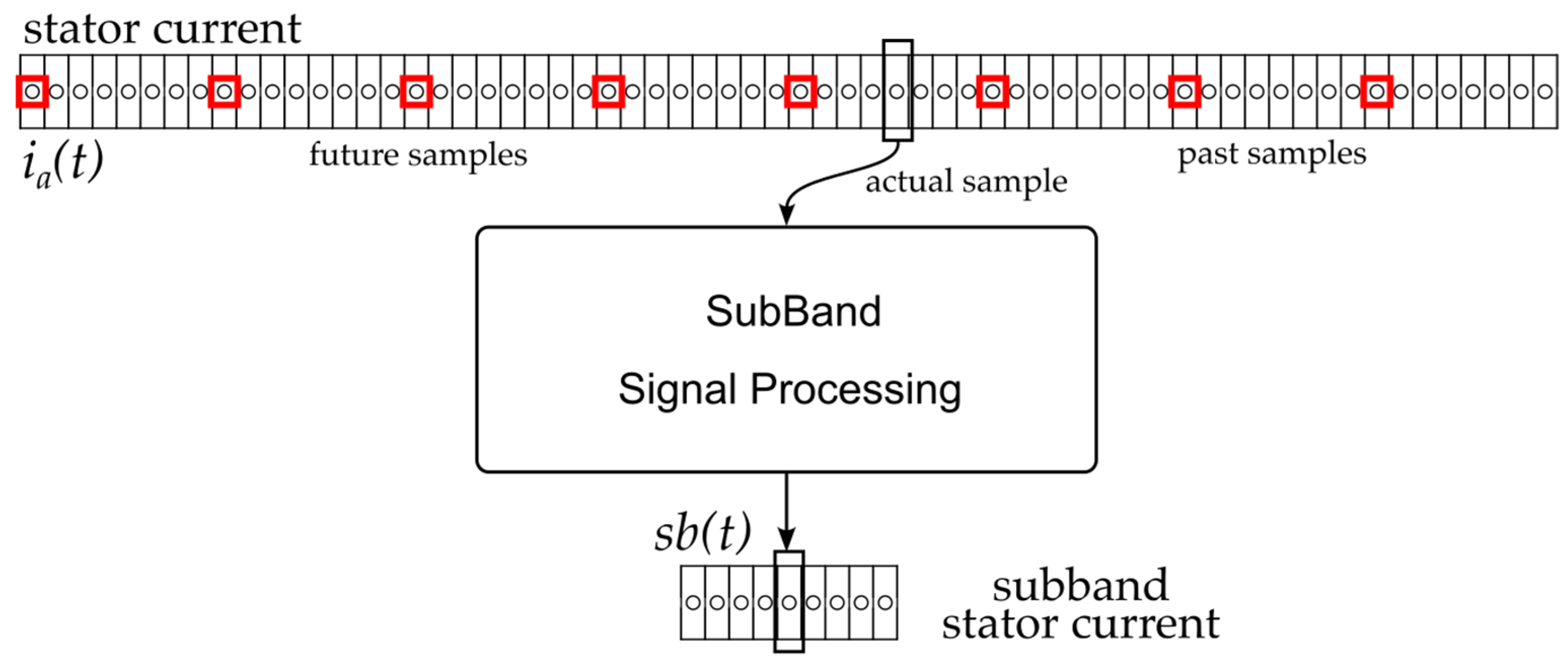

In this section, the proposed method is presented, which employs time-domain signal processing to improve the resolution of speed estimation, addressing the limitations of conventional methods that rely on various sensor measurements and require high computational costs. The input stator current signal

ia(

t) is composed of a sequence of samples, comprising past, present (actual), and future values, as demonstrated in

Figure 3. The output is referred to as

sb(

t), which contains a frequency subband of

ia, in which components are independent for further analysis. At the end, samples of the stator current signal

ia(

t), which contain the RSH, are chosen for the subband signal processing.

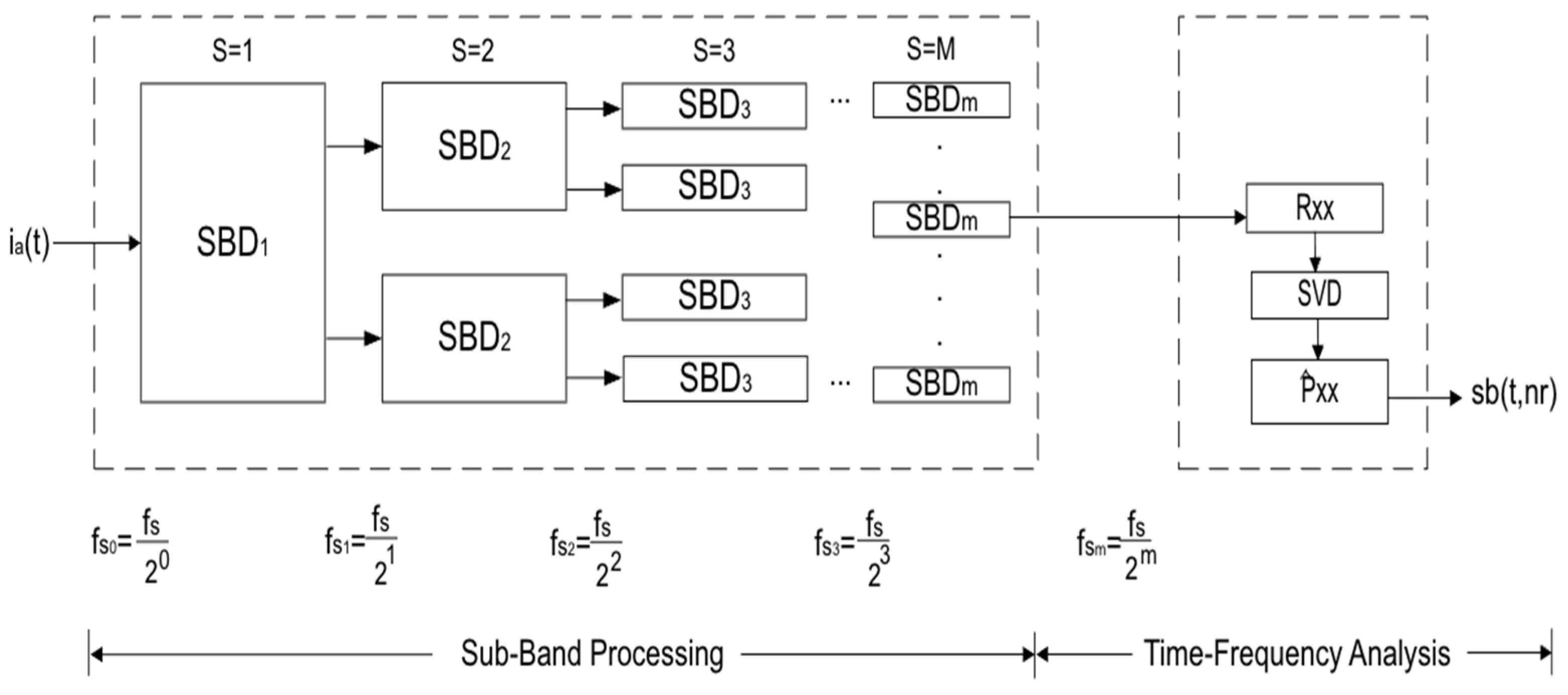

The detailed signal processing method is depicted in

Figure 4. The input to the method is the stator current signal, while the output is a time-resolved map of the rotor speed waveform.

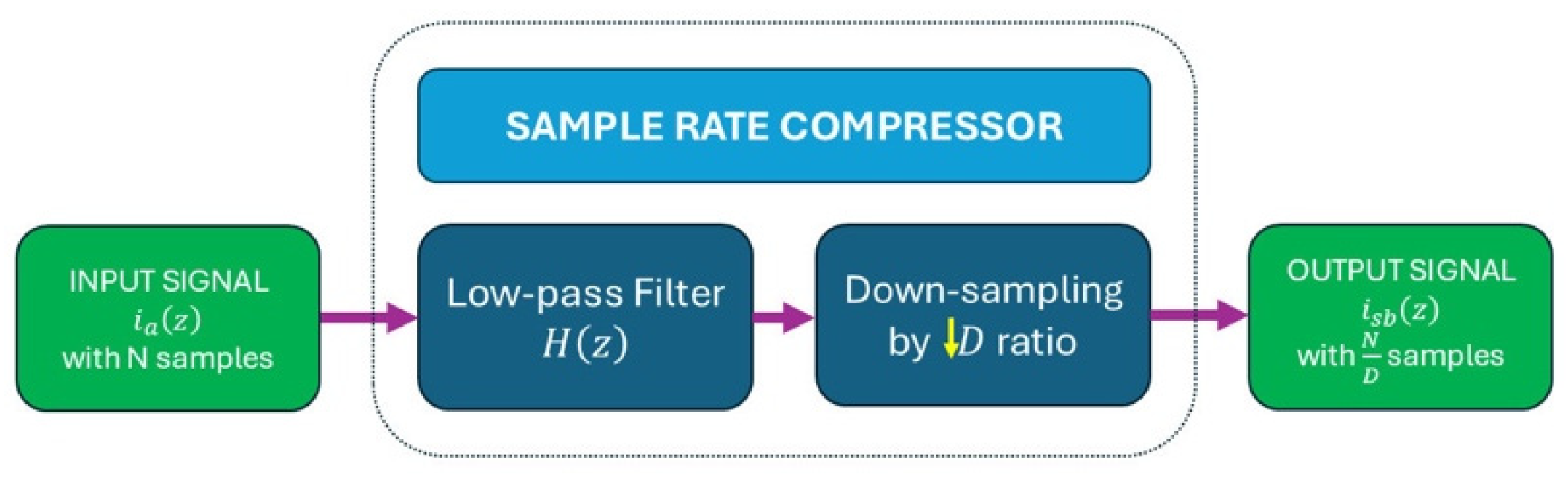

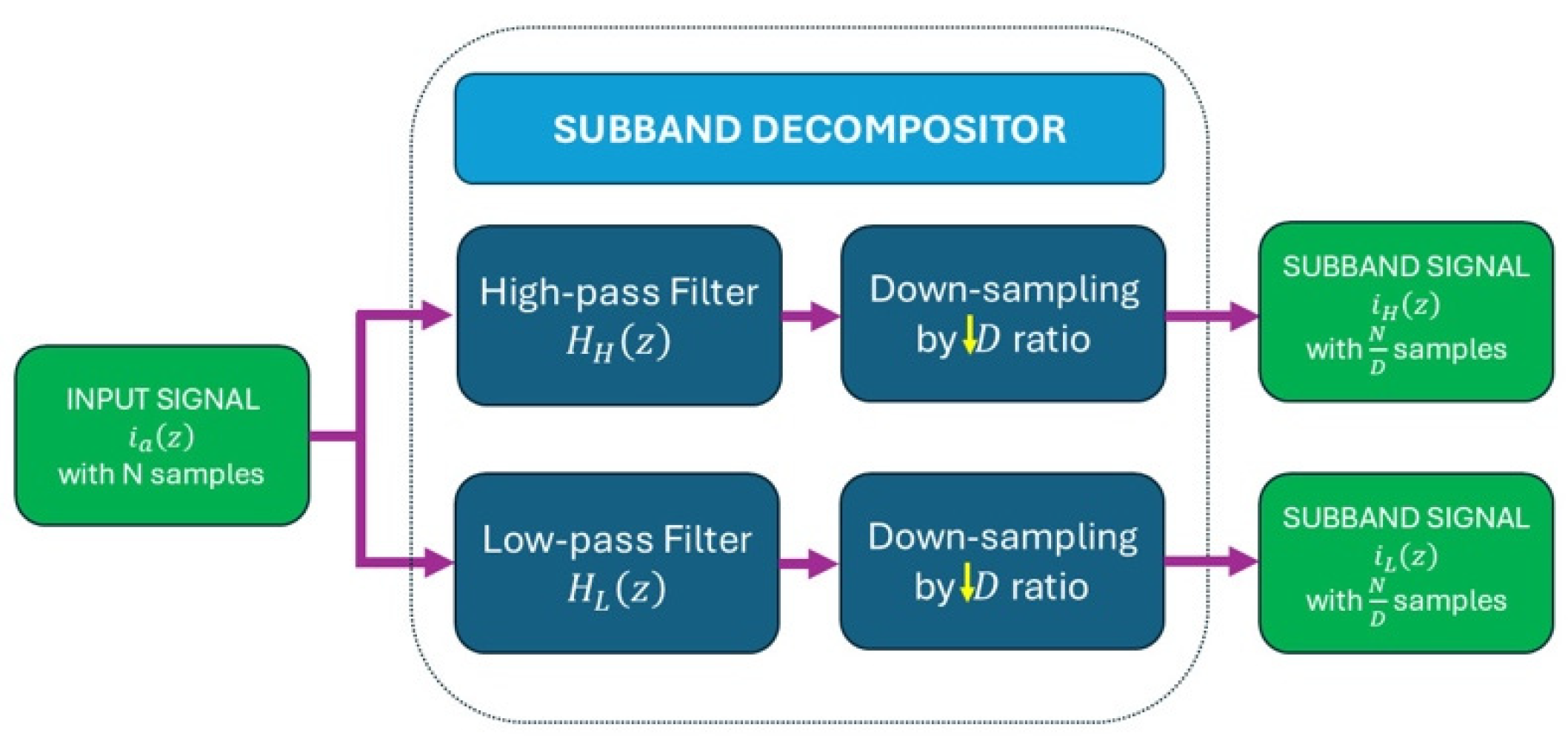

The first stage consists of frequency subband division, where the broadband stator current signal is decomposed into multiple narrowband components. The block diagram in

Figure 4 represents a general multi-stage subband decomposition structure comprising M stages. This configuration divides the original bandwidth [0,

fs/2) into

k uniform subbands, each with an identical frequency bandwidth of [0,

fs/2)/

k Hz. The implementation employs

k/

2 subband decompositions, as detailed in

Section 2.2.2. This multi-stage division enables the selective isolation of spectral regions associated with the rotor speed component, while allowing a reduction in the number of samples to minimize subsequent computation. The selection of the spectral bandwidth for the analysis subband is based on the expected frequency variation in the principal rotor slot harmonic,

fsh, across the nominal operating range of the motor. The upper frequency bound of the subband corresponds to the

fsh frequency when the motor is operating under no-load conditions, which represents the maximum rotational speed. This value is determined using Equation (3), with

s = 0 and the positive harmonic sign. Conversely, the lower limit reflects the

fsh frequency when the motor is operating under the maximum rated load, calculated using Equation (3), using the maximum slip provided by the motor manufacturer. This defines the subband where the motor will operate according to industrial reliability standards, ensuring the motor is sized to prevent overload conditions. The difference between these two frequency limits defines the minimum required spectral bandwidth, denoted as

sbf, that allows for the accurate tracking of motor speed under all nominal conditions. To ensure that the selected subband encompasses the full operating range, the condition

fs/2

k >

sbf must be satisfied. However, to optimize computational efficiency, the value of

fs/2

k is chosen to be as close as possible to

sbf, minimizing the frequency range.

After subband decomposition, the signal containing the relevant rotor-related spectral components is analyzed using the high-resolution time-frequency technique. The STMN transform is applied to achieve precise spectral estimation. This stage begins with the computation of the autocorrelation matrix Rxx for the subband signal over a short-time window. Singular value decomposition is then performed on Rxx to separate the signal subspace from the noise subspace, effectively discarding the eigenvalues corresponding to noise. Once the signal subspace is identified, the spectral content is constructed for each short-time segment, resulting in a spectral representation of the subband signal. This representation is subsequently transformed into a time-speed distribution (t, nr), which provides a detailed depiction of the dynamic rotor speed behavior over time. This methodology enables fast processing, as the analysis is performed in a short time, and due to the subband decomposition, the matrix decomposition required by the spectral estimator is of a reduced order.

5. Experimental Test Bench

The test bench described below and shown in

Figure 7 was assembled for this study. This laboratory setup comprises a three-phase induction motor, a controllable magnetic powder brake, a current clamp, an encoder, anti-aliasing filters, a data acquisition board, and a laptop PC.

Table 2 summarizes the specifications of the tested induction motor.

The motor is loaded with a Lucas-Nülle magnetic powder brake, model SE 2662-5R. The braking power is 1 kW and allows the load torque to be set manually or via a voltage control signal. The following motor signals are captured during the tests: stator current and rotational speed. The stator current is measured with a YHDC current clamp, model SCT013. Its nominal peak current is 5 A, providing a proportional voltage signal in the range of ± 1 V. The D-70054 model from Kübler is the encoder used to record the speed. The encoder is a push–pull type, with an output of 24 V, and offers 1024 PPR. The current signal is passed through an LTC 1564 filter from Linear Technology Corporation (Milpitas, CA, USA). The cutoff frequency was set at 10 kHz. The signals are captured using a National Instruments system (Austin, TX, USA) consisting of the cDAQ-9174 chassis equipped with two modules. One allows the capture of the current (module NI-9215) and the other (module NI-9361) the output of the encoder. This system is connected via a USB port to a laptop PC equipped with Windows 10 OS. Acquisition is performed at a sampling frequency of 20 kHz over a 10 s period. The encoder speed is captured with a specific function provided by Mathworks (Natick, MA, USA). Several trials were performed when the motor, fed from the mains, was running in a stationary state and subjected to load changes that produced variations in its speed.

6. Experimental Results

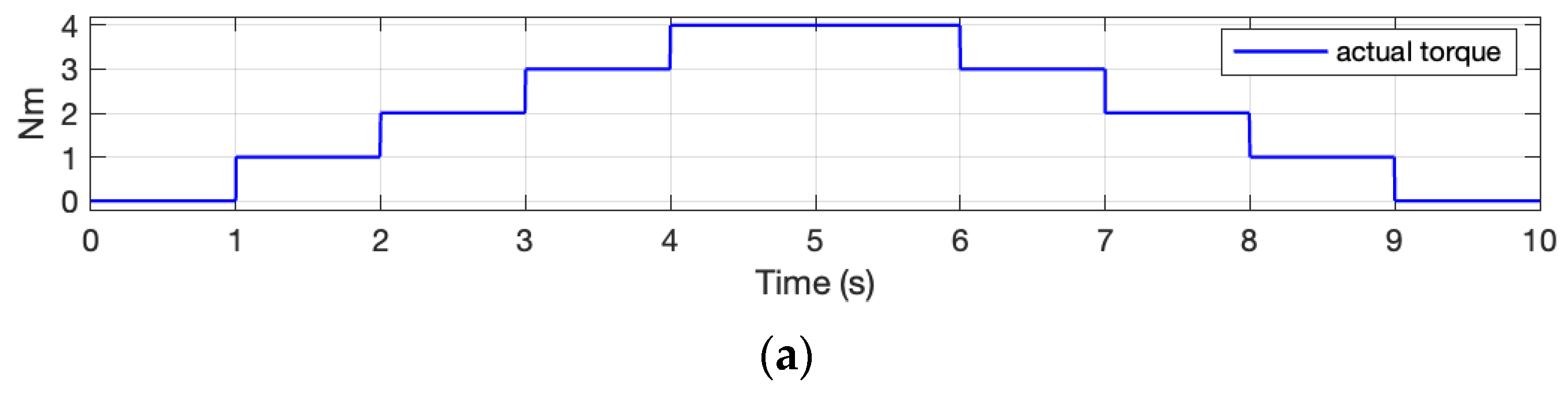

To validate the proposed methodology, experimental tests were conducted under both stationary and non-stationary operating conditions of the induction motor. The testing scenarios are three representative cases: constant load, instantaneous step load changes, and soft torque step variations. These torque disturbances were selected due to their prevalence in mechanical systems driven by induction motors, where speed variations are primarily induced by variations in the load torque. Time-frequency decompositions were performed using the same short-time parameters to ensure consistency across test cases. The stator current analysis employed the minimum norm algorithm (

Section 2.3) with a short-time processing scheme, using 100 samples per window, a 2-sample hop size, and an analysis order of eight. This uniform setup enables a reliable comparative evaluation of the method’s performance across diverse dynamic conditions, reflecting real-world applications. The subband decomposition stage is implemented using nine successive binary divisions (

M = 9) of the original signal bandwidth. Starting with a sampling frequency of 100 kHz, this process yields 512 subbands, each with a bandwidth of 97.65 Hz. This frequency range is sufficient to track the complete spectral evolution of the

fsh across the full nominal speed range of the motor. The use of binary decomposition (

D = 2) not only facilitates isolation but also enables an efficient digital implementation of the down-sampling stages, utilizing the symmetry of the digital structures and minimizing computational processing. The subband selection, while static and motor construction dependent (

z and

p in Equation (3)), can be recalculated for motors with different rotor slots (

z) or pole pair numbers (

p) by adjusting the expected frequency limits via Equation (3).

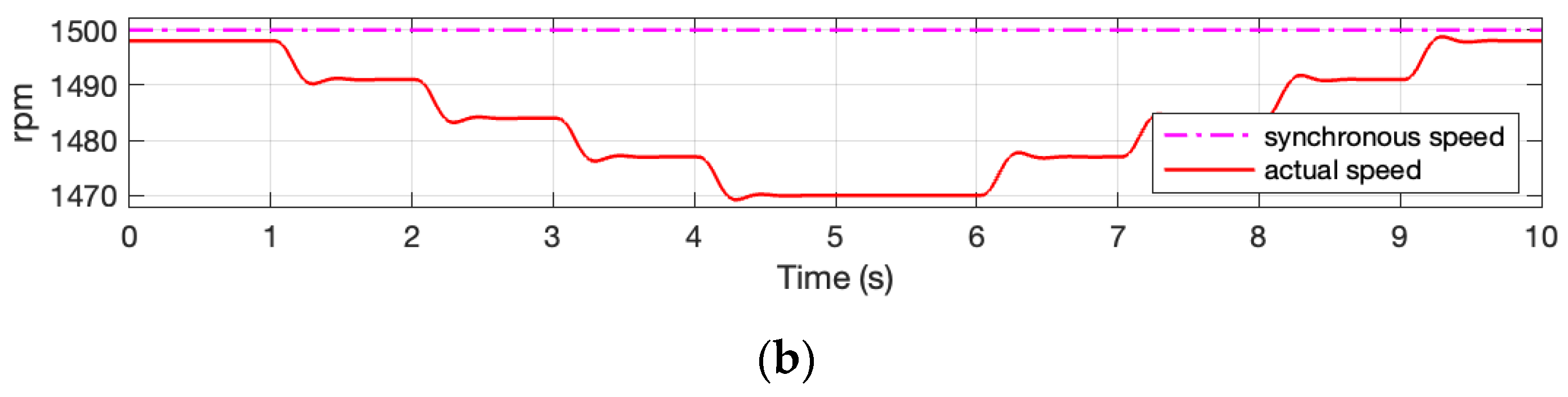

6.1. Motor Speed Estimation Under Constant Load Conditions

Figure 8a,b illustrates the rotor speed estimation obtained using the proposed method when the induction motor operates under constant load conditions.

Figure 8a displays the estimated speed in the case where the motor operates without a mechanical load, consuming a line current of 1.94 A. Under these conditions, the instantaneous speed remains relatively stable over time. The method accurately estimates an average speed of 1491 r.p.m. throughout the duration of the experiment, from 0 to 10 s. Furthermore, the method captures minor speed variations with instantaneous values ranging between 1488 and 1495 r.p.m., thereby highlighting its capability to track small variations under steady-state conditions.

Figure 8b presents the speed estimation results when the motor is subjected to a rated load torque, corresponding to a rated line current of 2.2 A. Under this scenario, the motor experiences a high slip level, and the results correctly reflect a reduction in rotor speed due to the increased load. The average speed decreases to 1394 r.p.m., representing a drop of approximately 100 r.p.m. compared to the no-load condition. Despite this reduction, the instantaneous speed remains consistently stable, with small fluctuations of less than 10 r.p.m. throughout the analyzed time (0 to 10 s). Unlike traditional methods, which typically estimate the average motor speed by identifying a peak in the stator current spectrum, the proposed approach can estimate the instantaneous motor speed.

The absence of a load corresponds to the motor’s maximum speed (

Figure 8a), while full-load conditions define its minimum operating speed (

Figure 8b). This range delineates the nominal operating range of the motor. Introducing a disturbance exceeding this scenario would lead to an overload condition, pushing the machine beyond its rated operational limits as an induction motor. The proposed technique is designed for induction motor operation within the nominal range, as defined by the manufacturer, from no-load to full-load conditions, and is capable of tracking transients that occur within the motor operational band. Additionally, it relies solely on the spectral properties of a single stator line current. These spectral characteristics are not affected by the direction of rotation. Therefore, the functionality is preserved regardless of whether the motor operates in the forward or backward direction.

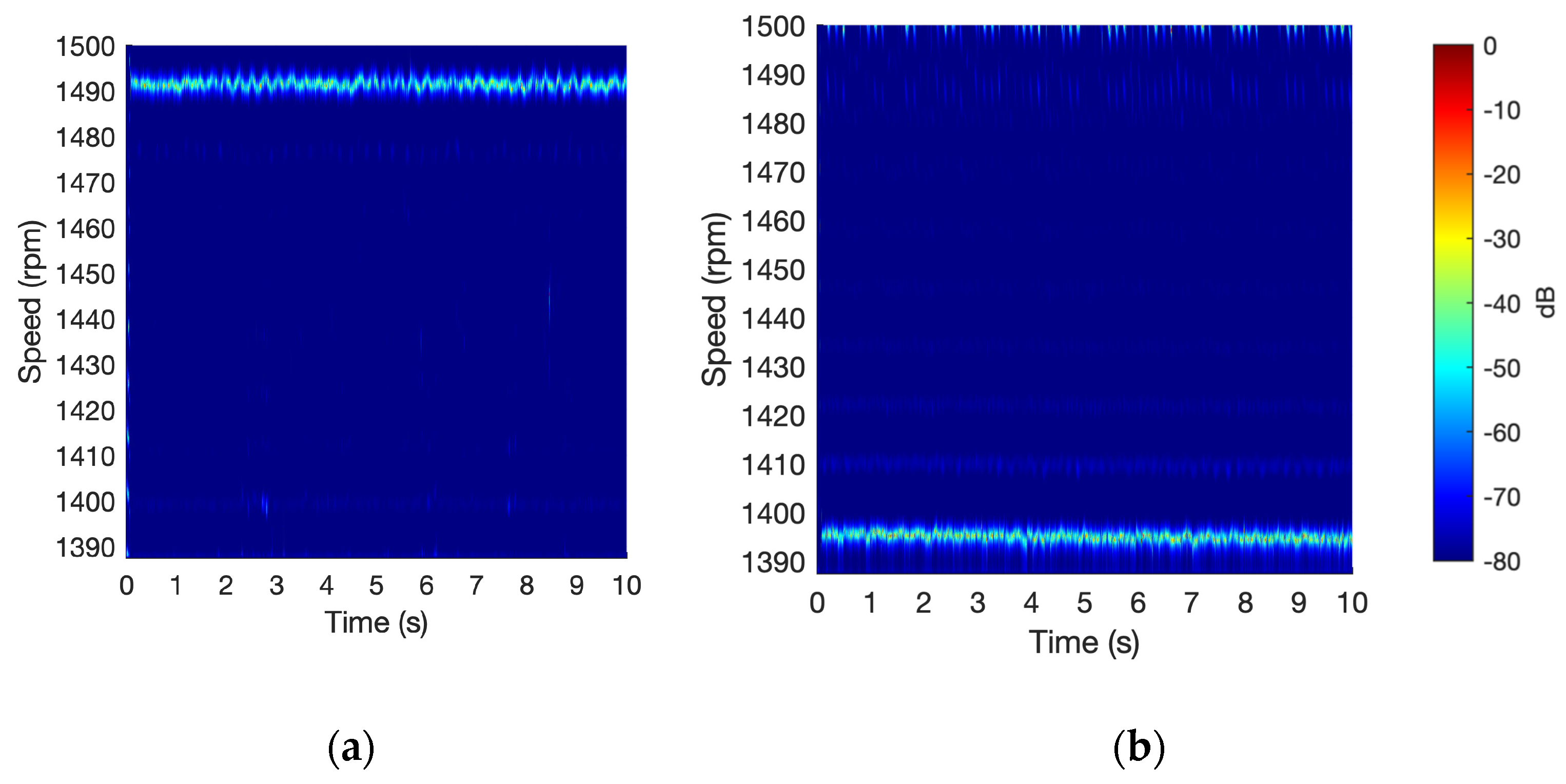

6.2. Induction Motor Under Load Transients

For the purposes of motor control and health condition monitoring, it is critical to evaluate not only the steady-state behavior but also the dynamic performance of instantaneous speed. To this end, experimental tests involving abrupt speed changes were conducted. These changes were induced by sudden variations in the load torque applied through the powder magnetic brake. The corresponding results are depicted in

Figure 9.

Figure 9a illustrates the rotor speed response to a positive torque step. The motor maintains an average constant speed of approximately 1490 r.p.m. from the start of the test until second 4.8. At this point, a rapid speed drop is observed, reaching 1430 r.p.m. by second 5.2. The proposed method enables an accurate estimation of this speed transition, allowing for the evaluation of a decay time of 0.59 s. The speed quickly settles at a mean value of 1440 r.p.m., approximately 1.25 s after the torque change is applied. Conversely,

Figure 9b presents the response to a negative load step, where the torque load is abruptly removed. The proposed methodology estimates a constant speed of 1441 r.p.m. during the first 5.5 s of operation. Following the load removal, a sudden increase in speed is observed. In this case, no overshoot is present in the speed response, and the speed stabilizes within 200 milliseconds, which is faster than in the previous scenario.

As illustrated in

Figure 9, the proposed short-time subband analysis of the stator current successfully captures abrupt changes in the speed.

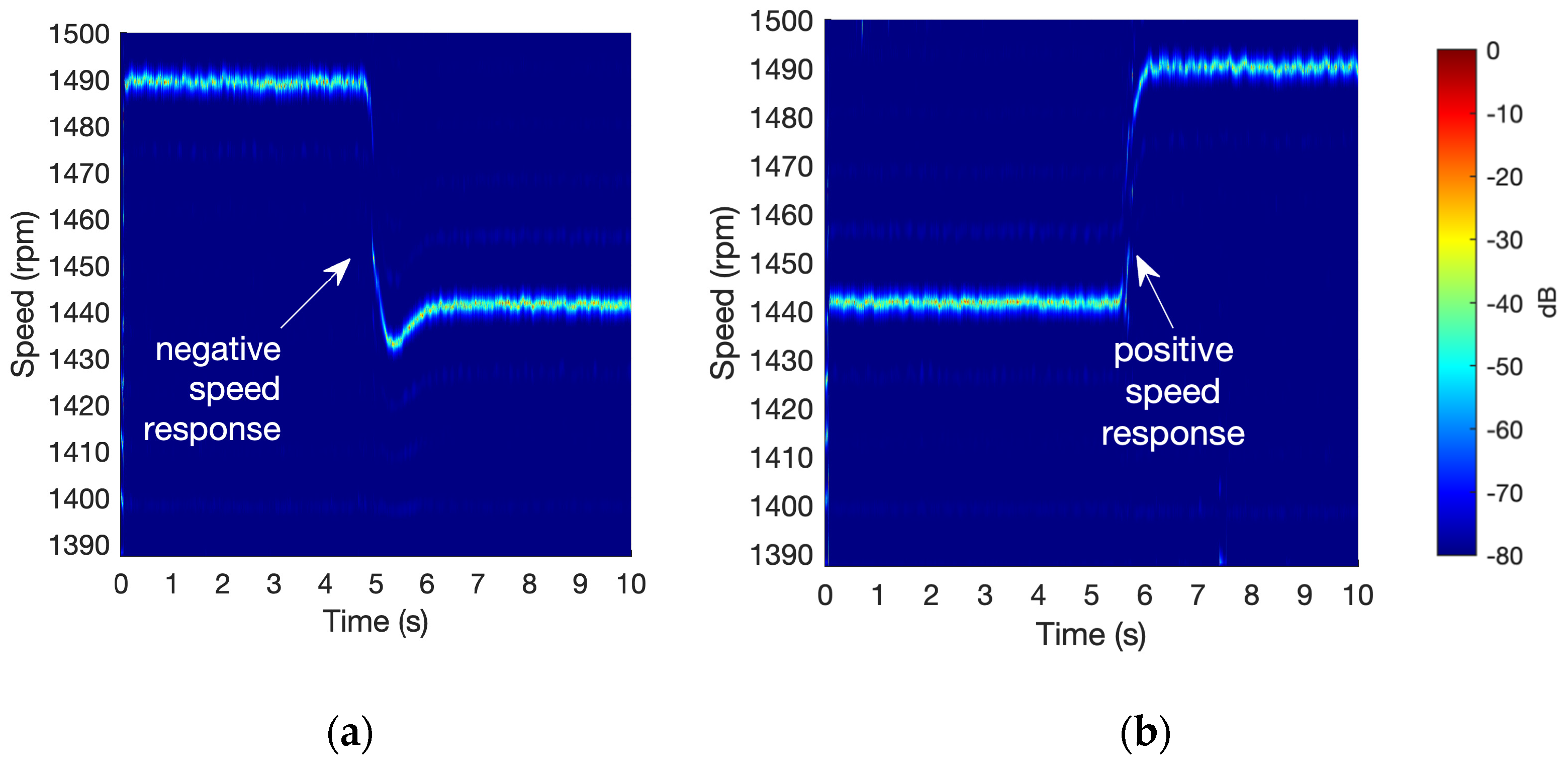

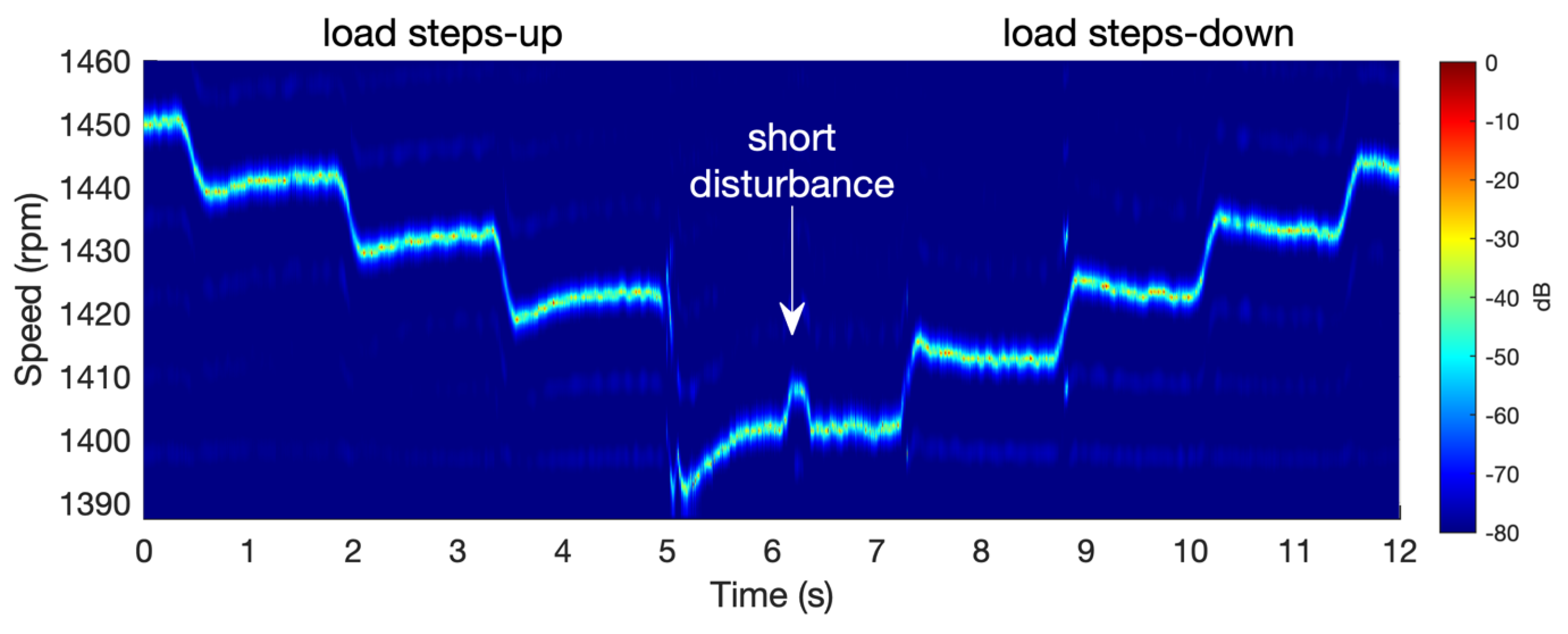

Figure 10 presents the experimental results obtained when the induction motor is subjected to multiple speed and acceleration profiles. In the first part of the experiment, the motor is exposed to load increases that induce a gradual deceleration from 1450 to 1400 rpm. In the second phase, stepwise reductions in load are applied, resulting in a progressive increase in motor speed. The experimental results clearly demonstrate the method’s ability to estimate the actual motor speed, accurately capturing both deceleration and acceleration phases. The observed variations in slope reflect the dynamic response of the motor due to its inherent inertia. Furthermore, at second 6.2, a brief load disturbance is introduced to assess the method’s responsiveness. The method successfully detects this event, capturing the corresponding short-duration variation in motor speed.

Finally, the motor is subjected to multiple smooth torque variations within a single test, each with a different amplitude level. This test aims to evaluate the system’s response across a wide range of speeds.

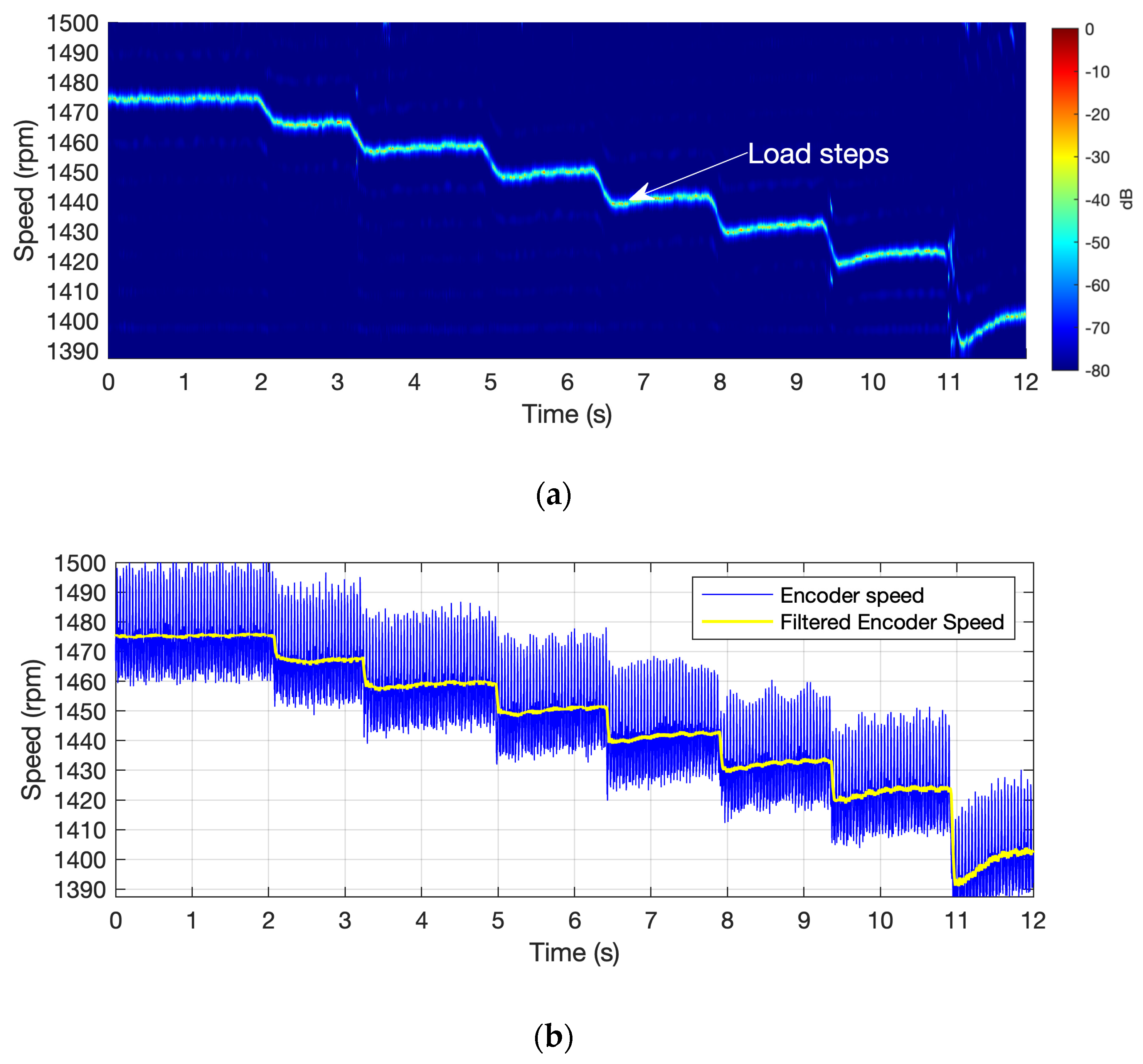

Figure 11a presents the result obtained using the proposed method, while

Figure 11b shows the reference speed signal for comparison. The time-speed analysis, depicted in

Figure 11a, clearly identifies seven smooth speed transitions corresponding to the applied torque changes, starting with a 10 r.p.m. speed reduction (torque increment) at second 2 and concluding with a 30 r.p.m. step down at second 11. In contrast,

Figure 11b (solid blue line) illustrates the speed signal captured by the optical encoder. This signal exhibits significant high-frequency content, resulting from the wide bandwidth sensitivity provided by the optical sensor (1024 pulses per revolution). However, when the encoder signal is processed using a moving average filter (yellow line), it becomes evident that the proposed method (

fsh) closely follows the behavior of the filtered encoder signal. This filtering process is commonly implemented in motor control systems to attenuate noise in feedback signals, thereby highlighting the practical applicability of the proposed approach.

The proposed methodology successfully tracks the rotor speed dynamics under various step changes in both amplitude and duration. The experimental results validate the effectiveness of the method in estimating instantaneous motor speed using only a single-phase current measurement. The tests confirm its reliability under both steady-state and dynamic operating conditions, including scenarios involving rapid and large speed transitions. This method offers the advantage that RSH tracking enables speed estimation without necessitating specific knowledge of motor parameters, such as rotor resistance, leakage inductance, or system inertia.

Table 3 shows a comparison of signal processing using two known techniques and the technique proposed in this paper. The first technique is the Short-Time Fourier Transform (STFT), the standard signal processing technique in the time-frequency domain [

33]. The second technique is the Short-Time Multiple Signal Classification (MUSIC) [

34], a high-resolution spectral estimator. The third technique compared is the one proposed in this work. All three tools have processed the same signal sampled at a frequency of 100 kHz. Two different analysis times, 5 and 10 s, have also been compared. The test was performed on a PC with Windows 11 Pro, an Intel Core i7-12700K processor, and 64 GB of RAM. The scripts were run on a single core in MATLAB version 2024b. The CPU execution time and maximum RAM were compared.

It can be seen that the signal processing time with STMUSIC is much longer than with STFT and the proposed methodology (approximately four orders of magnitude). The execution time of the proposed method is 1.8 times more than that obtained with STFT. However, the memory used is 7.7 times less for the 5 s signal and 3.8 times less for the 10 s signal. The memory usage of STMUSIC, which required an order of 800 to observe the harmonics in the band of interest, is 700 times greater than that of the proposed methodology.

The subband processing captures only the frequency range containing the oscillation of the principal slot harmonic. This frequency bandwidth segmentation enables the frequency estimator (minimum norm) to operate at a reduced order, specifically using the minimum order λm = 2. As a result, the subspace decomposition achieves a maximum performance by enhancing the projection of orthogonal spaces, while also reducing computational costs through a minimum order. Both the predefined frequency band and the parameters for the short-time analysis are static, thus avoiding the use of adaptive algorithms, which are sensitive to estimator instability and require higher computational effort. It is important to emphasize that the subband preprocessing stage introduces a delay of approximately 60 µs in the generation of an instantaneous speed estimation value. This duration has been minimized through the design of the digital processing architecture and is significantly shorter than the typical dynamic response times of mechanical systems driven by induction motors. Although the proposed preprocessing approach is employed in this work to enhance the performance of a statistical estimator, the underlying signal decomposition remains fully compatible with a broad range of spectral analysis techniques and is well-suited for real-time implementation in industrial motor control systems.