1. Introduction

The growing demand for transportation and concern about the environmental impact of fossil fuel combustion have led to a surge in EV production. Electric motors (EMs) in these vehicles offer advantages over internal combustion engines, such as higher efficiency and a longer, consistent power range [

1,

2]. To meet the needs of EVs, EMs must have specific characteristics, including high power and torque density, low torque ripple, and a wide power range. Reliability and fault tolerance are also crucial for ensuring passenger safety in EVs [

3,

4,

5].

In recent years, there has been a lot of research focused on developing and designing EMs for EVs to improve their overall performance. Permanent magnet synchronous motors (PMSPMs) are the preferred choice for EV applications [

6,

7,

8]. Among PMSMs, IPMSMs are favored because they offer a wide constant power range, superior high-speed performance, and reluctance torque compared to surface-mounted permanent magnet synchronous motors (SMPMSMs) [

9,

10].

Some studies have presented methods for optimizing the design of IPMSMs to improve torque output, mechanical characteristics, and reliability. The placement of the flux barrier is crucial in optimizing IPMSMs, as presented in a study where optimizing the flux barrier angle within the motor design resulted in improved electrical and mechanical behavior [

11]. The growing importance of IPMSMs in EVs has led to improvements in various rotor designs. While there have been few comprehensive studies on various types of IPMSM rotors, it has been suggested that V-shaped, U-shaped, and double-layer PM rotors provide optimal torque output [

12].

Reference [

13] presents a method for obtaining the optimal design of a V-shaped IPMSM using continuum-sensitivity. This method significantly reduces computation time, especially with numerous design variables. The standard parameters were optimized using the orthogonal experimental method (OEM), while the significant parameters were optimized using a combination of multi-island genetic algorithm (MIGA) and radial basis function neural networks (RBF-NNs) to reduce torque ripple of the IPMSM [

14]. To improve the torque performance of high-speed IPMSM electromagnetics, a Surrogate model is used for optimization [

15].

First, a design of experiment (DOE) is conducted, followed by fitting multiple Surrogate models. The models with the lowest error are selected using error evaluation indexes for optimization. The non-dominated sorting genetic algorithm (NSGA) is then used to obtain the optimal solution [

16,

17]. The NSGA is a popular optimization method that uses the elitist strategy with the crowding distance operator to preserve diversity and the non-dominated sorting operator to select the Pareto dominant solutions. In [

18], the IPMSM is optimized for multiple objectives and multi-load points using a global response surface method (GRSM) to minimize torque ripple and maximize average torque. Hybrid optimization algorithms, such as DOE, Sensitivity Analysis (SA), Response Surface Method (RSM), and PSO, are utilized to determine the rotor design parameters that maximize the output torque of the PMSM across three different load conditions [

11]

Proposal [

19] introduces a multi-objective layered optimization method based on parameter hierarchical design combined with the Taguchi method and RSM. An improved iterative Taguchi method has been proposed in [

20], involving narrowing optimization ranges to find optimal structural parameters efficiently. Its superiority is verified by comparing it with the conventional Taguchi method.

The review of the research performed on multi-objective optimization techniques is listed in

Table 1. In this paper, a novel technique that optimizes two comprehensive approaches of robust combinatorial optimization is used in a U-shaped IPMSM. According to

Table 1, the novelties of this paper are the following:

Most of the combined optimization methods are on V-shaped PMs. Therefore, compound optimization on U-shaped magnets is necessary for new studies;

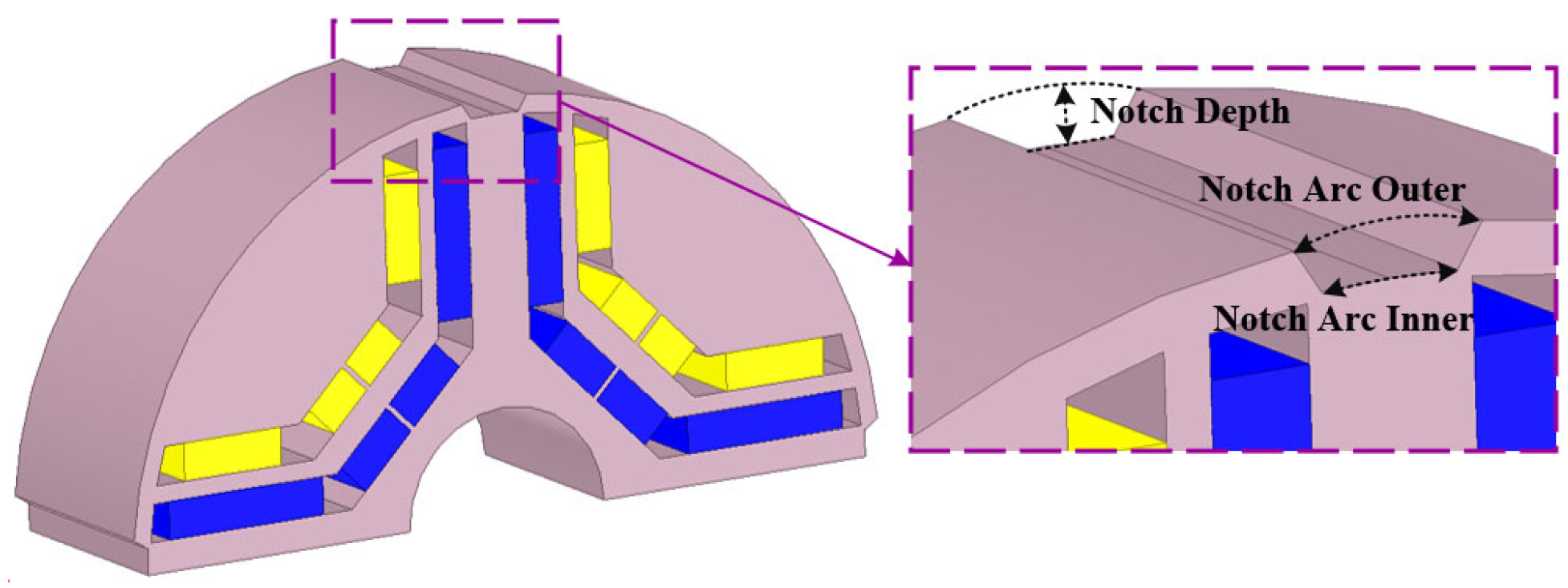

From the Surrogate model with the approval of the NSGA, only one case has been implemented on the V-shaped PM. Also, this method is performed on a ship-shaped notch into the bridge area between double U-shaped layers for the first time in this study;

In this study, we used an optimization approach with a parameter optimization hierarchy, implementing DOE, Optimal Latin Hypercube Sampling Designs (OLHSD), and Pearson Correlation for a ship-shaped notch double U-shaped layers machine. Then, we used the Surrogate model’s SA and Anisotropic Kriging model to finalize the mathematical model of the parameters;

The combined GA and SQP algorithm is used to validate the accuracy of the final model extracted;

The hybrid model optimized with common algorithms such as GA and PSO is compared, and its superiority compared to other methods is determined.

Table 1.

Review of multi-objective optimization techniques.

Table 1.

Review of multi-objective optimization techniques.

| Ref. | Type of Machine | Type of PM | Optimization Techniques | FEM/Experimental |

|---|

| [13] | IPMSM | V-shaped | Continuum-Sensitivity | ✓/✗ |

| [14] | OEM/MIGA/RBF-NN |

| [15] | Surrogate models/NSGA | ✓/✓ |

| [18] | GRSM |

| [11,21] | DOE/SA/RSM/PSO | ✓/✗ |

| [22,23] | Taguchi Method | ✓/✓ |

| [19] | Taguchi method/RSM | ✓/✓ |

| [16] | C-shaped | NSGA |

| [20] | U-shaped | Taguchi method |

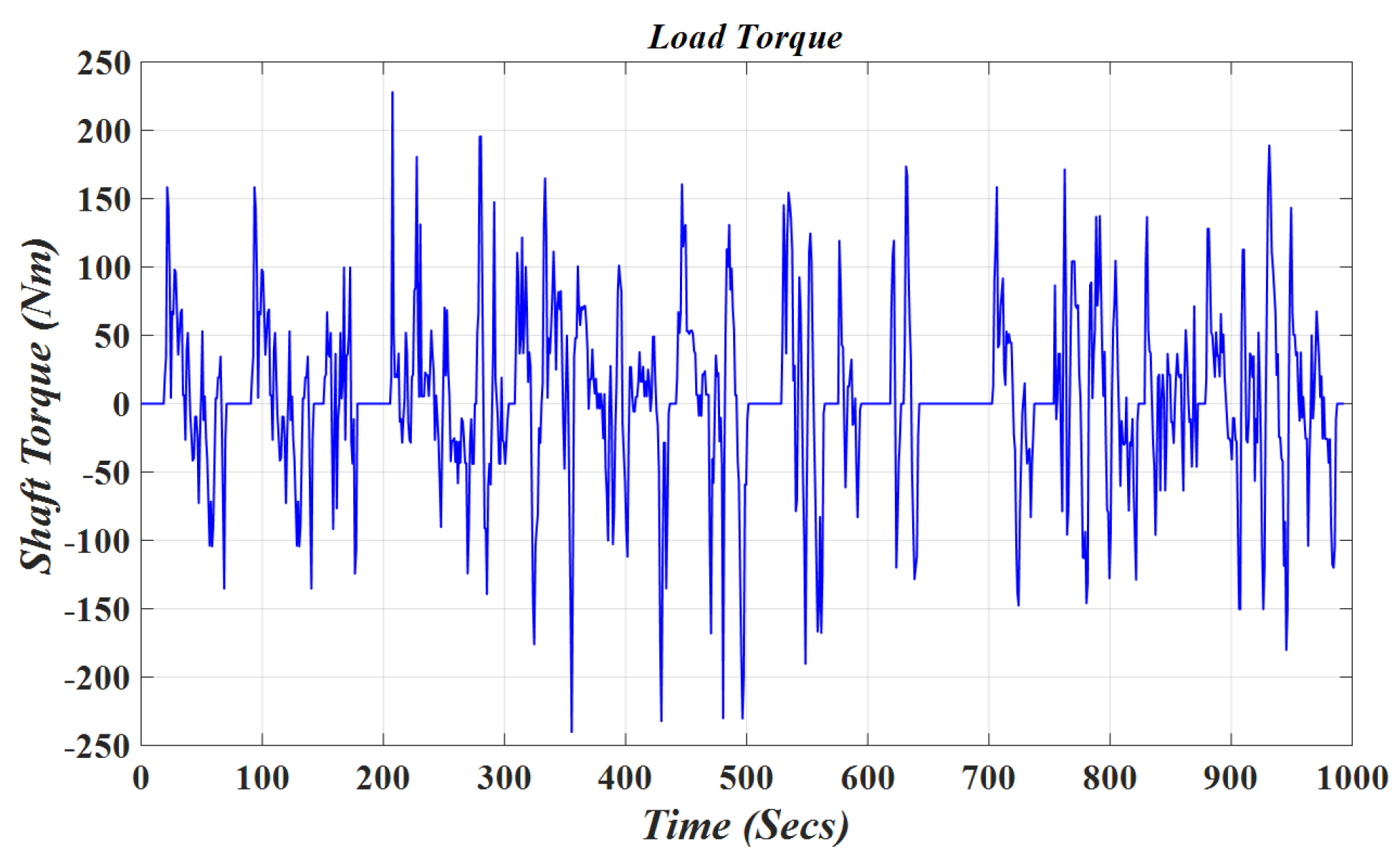

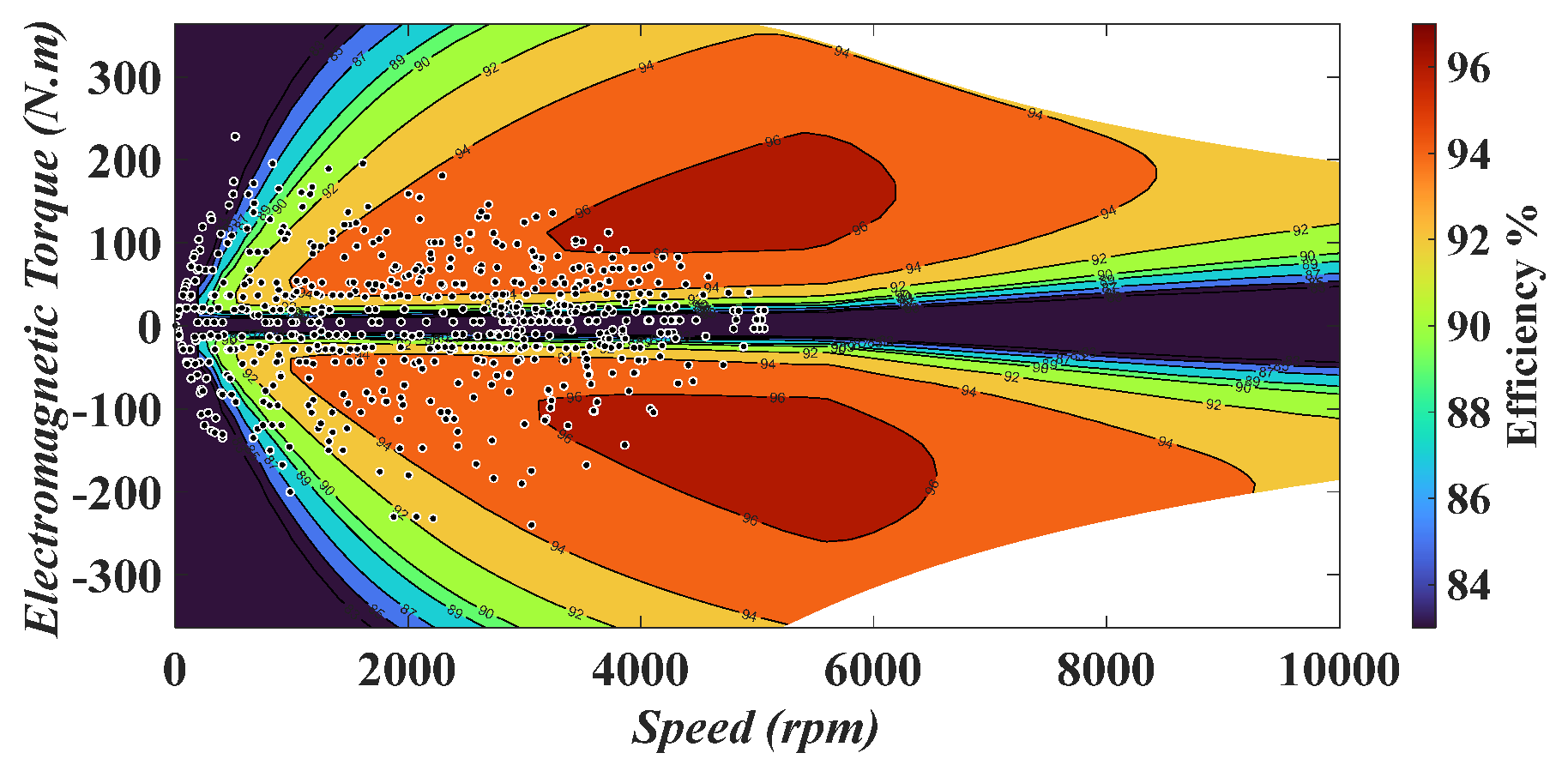

To achieve the desired torque, U-shaped and V-shaped structures were designed and then compared. A notched ship-shaped is subsequently created on the rotor surface of the chosen structure to minimize torque variation. The primary objective of this research is to utilize a new optimization approach that is both precise and resilient in optimizing the selected structure. This methodology is then compared to traditional optimization methods. Furthermore, the electromagnetic performance and mechanical analysis of this optimized structure are examined. Lastly, the EM is evaluated under load under EV standards to ascertain its suitability.

2. Topologies and Features

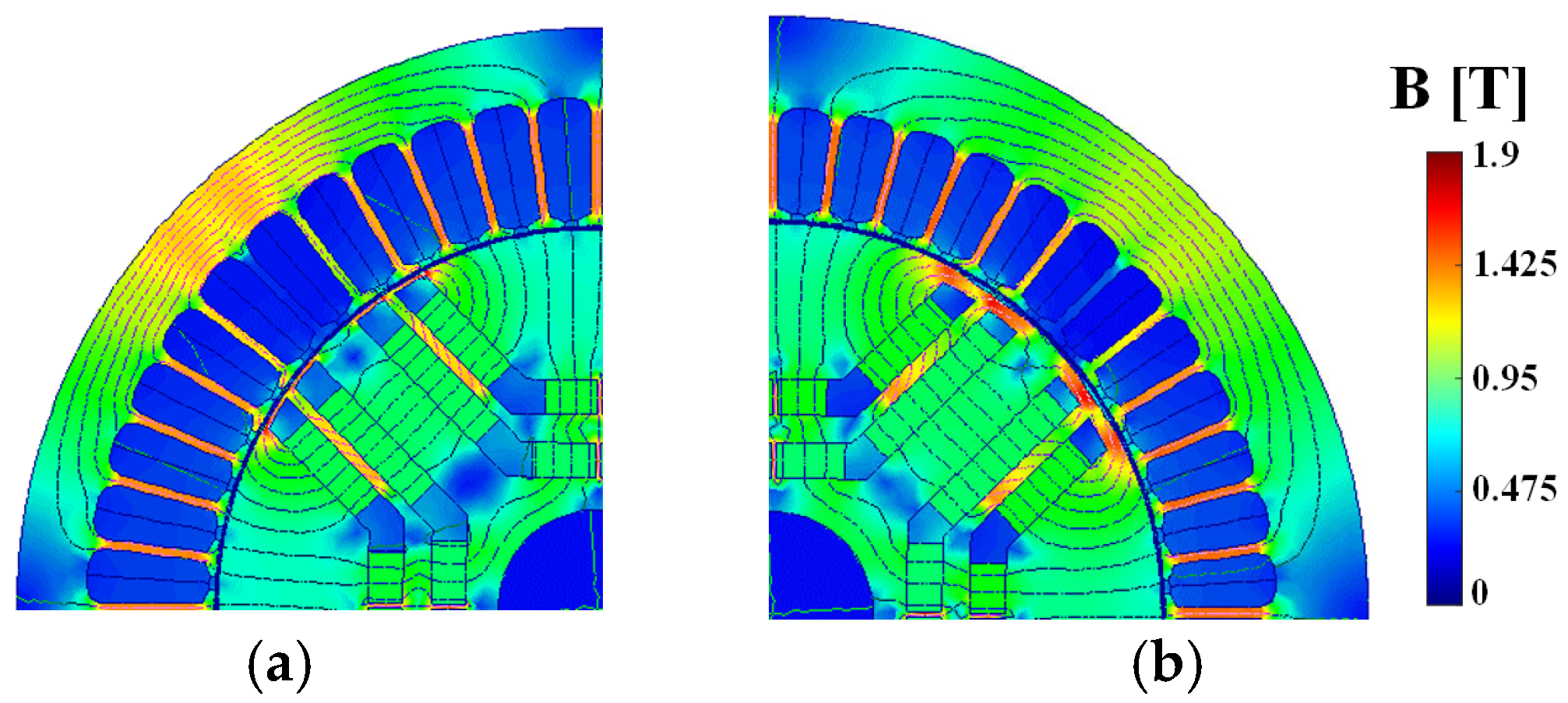

The electromagnetic and mechanical results of the two designs under investigation are presented in

Table 2. It can be inferred that the mechanical properties, such as the safety factor, performed better in the V-shaped design compared to the U-shaped design. Conversely, the electromagnetic characteristics, including the produced torque and efficiency, were better in the U-shaped design compared to the V-shaped design.

The U-shaped design is used to continue the design. IPMSMs are often designed with multiple layers to reduce higher-order spatial flux harmonics [

24], reduce torque ripple [

25,

26], and increase salience [

27]. In [

28], a lot of research is presented on the performance of different layers on the behavior of the IPMSM.

3. Robust Optimization Technique

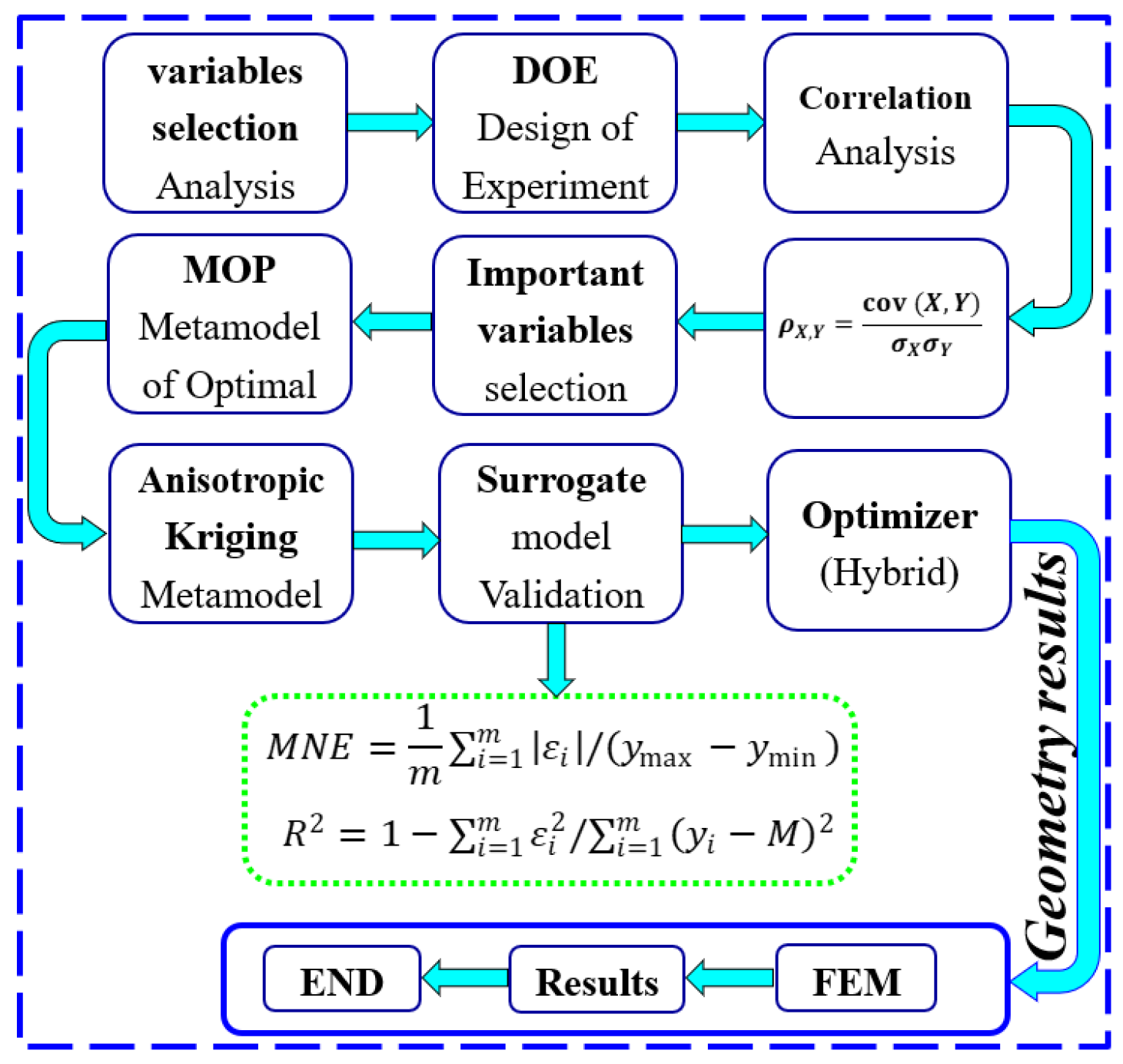

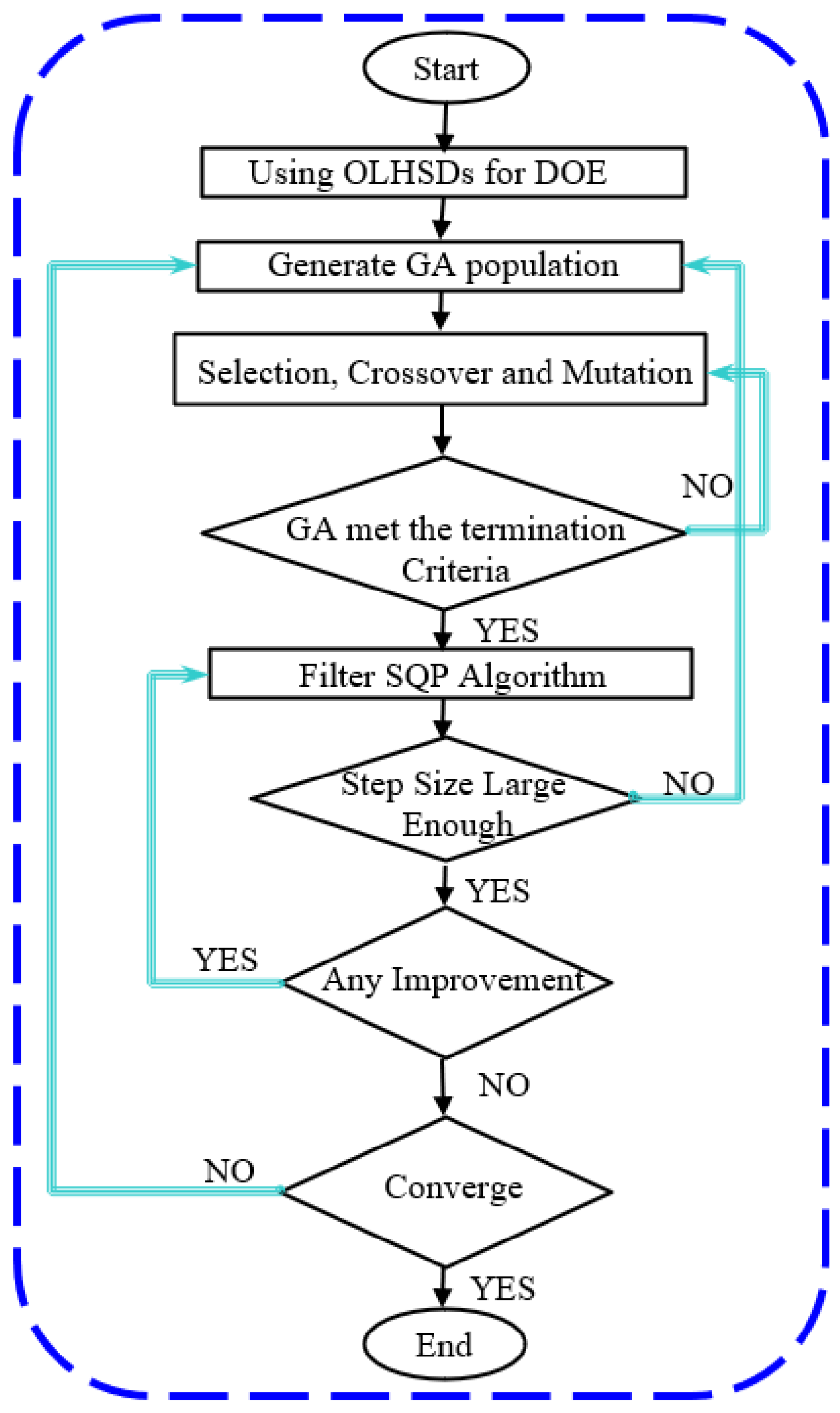

The study utilizes a robust hybrid optimization method, which is illustrated in

Figure 4. The proposed hybrid optimization entails two approaches to identify important variables and select a robust model with minimal error. The provided flowchart will guide you through nine steps for finding and achieving the objectives.

i: The first approach entails identifying important variables:

Step 1: optimizing the selection of the design DOE using the OLHSD;

Step 2: along with Correlation analysis, the Pearson Correlation method is selected among its types, including Spearman Correlation, Pearson and Partial Correlation, and Partial Correlation;

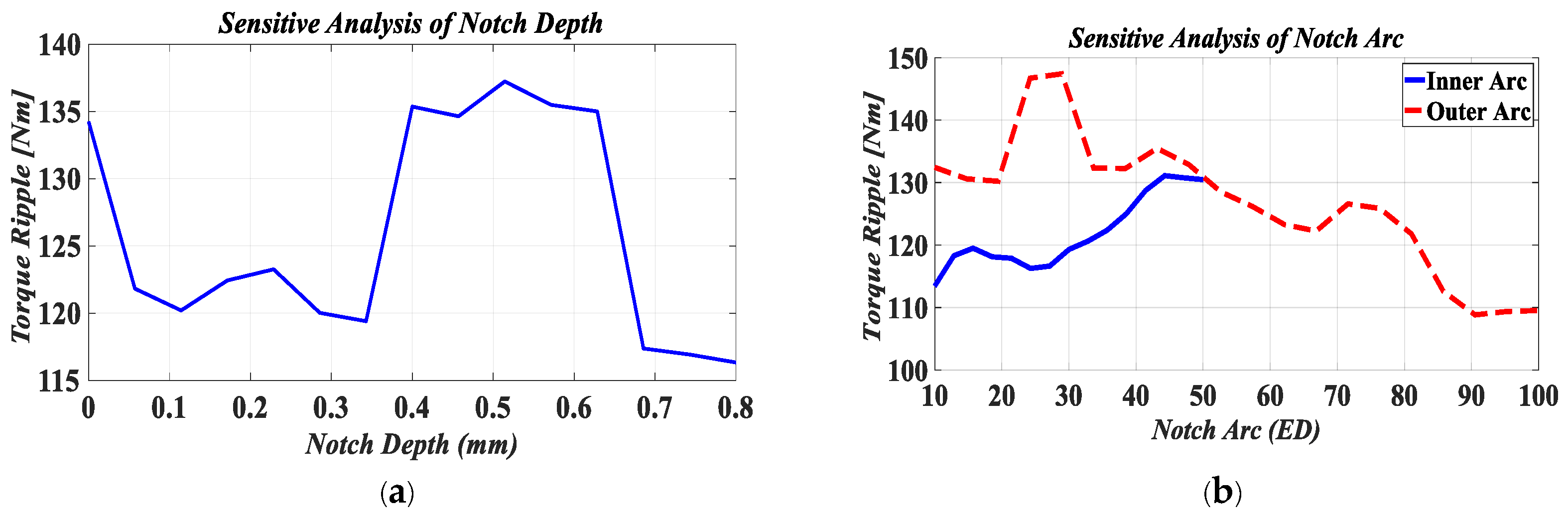

Step 3: the optimization objectives are evaluated through sensitivity analysis. To streamline the optimization process and reduce the number of equations involving two geometric variables, we remove all correlation coefficients that have low values with the objective functions;

Step 4: geometric variables are implemented on the machine with a notch;

Step 5: selecting two methods from the Surrogate model includes the Anisotropic Kriging model, kriging model, response surface, and Artificial neural network;

Step 6: investigating two methods of the Surrogate model: Anisotropic Kriging and Kriging on MEN and R2, then confirming Anisotropic Kriging with FEM.

ii: The second approach aims to select a strong model with minimum error:

Step 7: the final structure is optimized using a combination of GA and SQP algorithms for multi-objective optimization;

Step 8: comparison of the proposed algorithm with GA and PSO algorithms;

Step 9: validation of the proposed algorithm with FEM results.

3.1. DOE and Correlation Analysis

The DOE is created using OLHSD designs to gain maximum design insight with minimal FEA simulation. It can efficiently and optimally cover the design space. In the next step, the optimization is analyzed with correlation analysis. Correlation is a measure of the linear relationship between two variables, with a value between −1 and 1. If the correlation is 1, the two variables are strongly positively correlated, and all values lie on a straight line with a positive slope. If the correlation is 0, the variables are uncorrelated, meaning they are linearly unrelated. If the correlation is −1, the two variables are completely negatively correlated and all values lie on a straight line with a negative slope. The following equation shows the correlation equation between x and y, as follows:

where the

is the number of pairs of values.

,

,

,

, and

are the sum of the products of paired values, Sum of x values, sum of rakes, sum of squared x values, and sum of squared y values, respectively.

The Pearson Correlation analysis method is used in this optimization process. It is implemented as

where

stands for covariance,

represents the standard deviation of X, and

represents the standard deviation of Y. (2) can be expanded as

where

stands for the expected value, and

, and

represent the mean of X and Y, respectively.

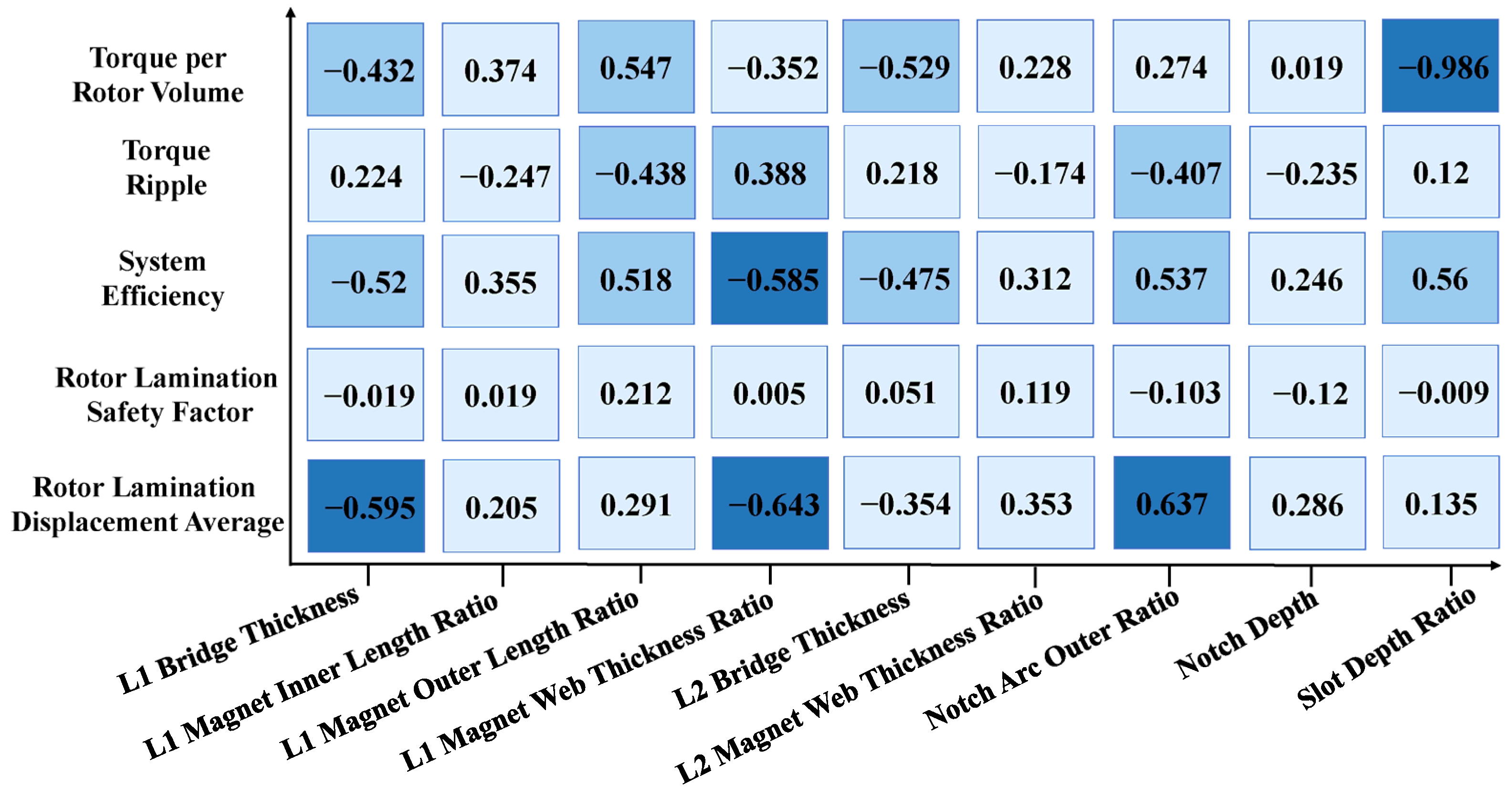

The DOE has been used to examine the correlation between the variables of the optimization objective functions. These functions include torque per rotor volume (), torque ripple (), efficiency (), and rotor lamination safety factor () with a rotor lamination displacement average (). To check the correlation, the influential geometrical variables, which were already checked to some extent through sensitivity analysis, have been used in the U-shaped IPMSM along with the dimensions of the cut ship-shape design.

The correlation results between variables and functions are displayed in

Figure 5. For this study, a correlation coefficient ranging from 0 to 0.4 indicates low correlation, 0.4 to 0.6 suggests a medium correlation, and anything from 0.6 to 1 represents a high correlation. To streamline the optimization process and minimize the number of equations for two geometric variables, any correlation coefficients falling within the low range are disregarded. Additionally, to enhance the model’s reliability and address geometric errors, most variables susceptible to geometric errors are redefined as

3.2. The Surrogate Model

The Surrogate model is a functional relationship between the design variable and the response and guarantees low computational cost, good accuracy, and highly reliable performance. At this stage, Anisotropic Kriging modeling is utilized due to its superior accuracy compared to the RSM and Kriging method and its lower complexity compared to the artificial neural network [

25].

The DOE dataset, consisting of 1152 data points, was split into training and testing sets using an 80–20% ratio. The main modeling method employed in the paper is the Anisotropic Kriging model, along with the simple kriging method to demonstrate the accuracy of Anisotropic Kriging. The results are presented as a Surrogate model. In evaluating the model, two parameters, mean normalized error (MNE) and

, are used. Additionally, the mean relative error (MRE) parameter is also utilized, but the evaluation primarily focuses on MNE and

. The mathematical definitions of these two parameters are defined as

where

represents the number of data to be evaluated,

is the difference between the predicted value and the actual value of the function,

is the value of the ith design function, and

, M, and

are the minimum, average, and maximum values of the output values, respectively. The higher the accuracy of the system, the closer the

value is to one and the MNE value is closer to zero.

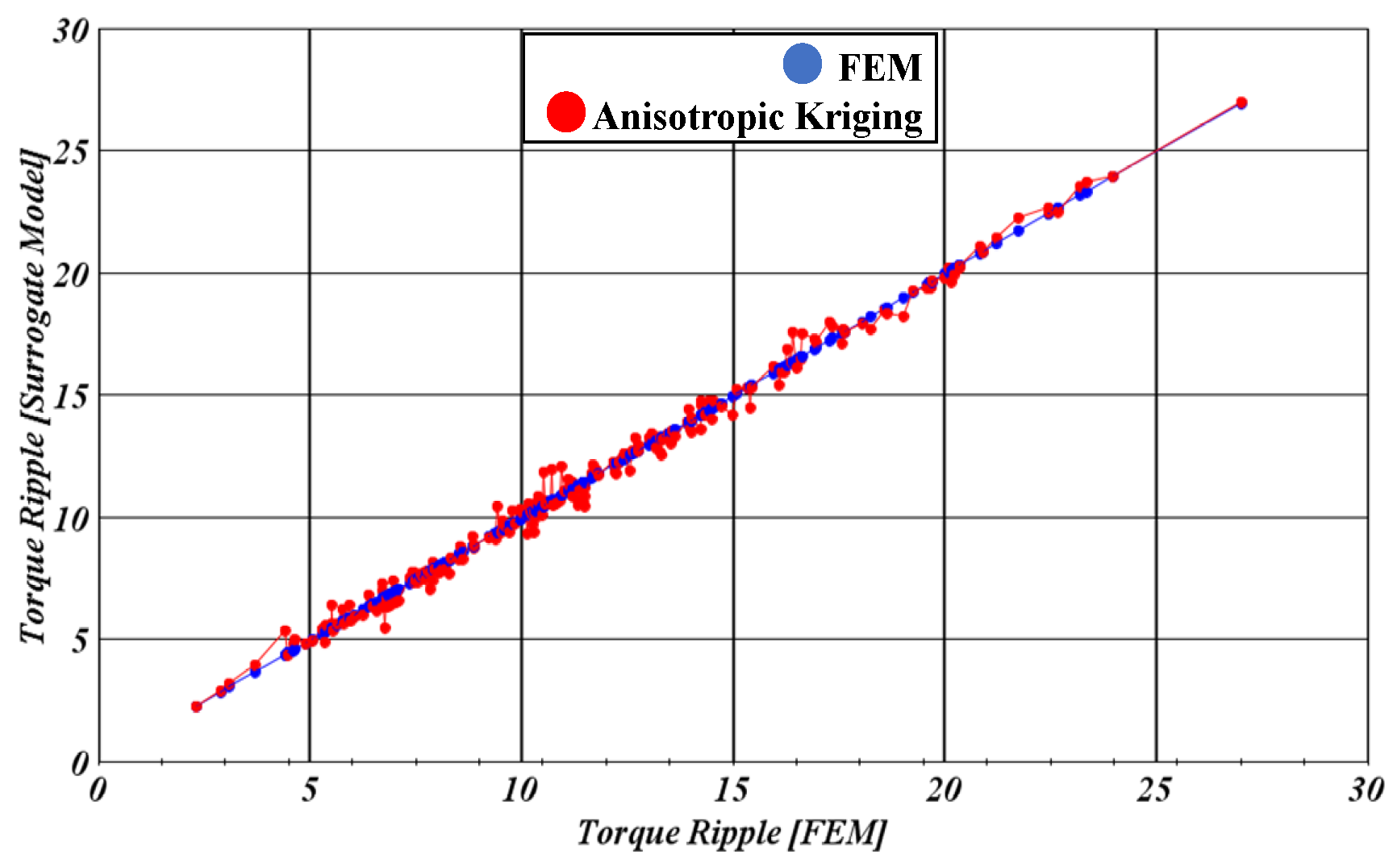

Table 4 compares the performance of Anisotropic Kriging and standard Kriging Surrogate models across five optimization objectives. For torque per rotor volume, Anisotropic Kriging achieves an MNE of 0.000842 with R

2 = 1, while standard Kriging achieves MNE = 0.000773 and R

2 = 1, indicating highly accurate predictions for both models. Torque ripple predictions show slightly higher errors, with Anisotropic Kriging MNE = 0.018 and R

2 = 0.993, compared to Kriging MNE = 0.018 and R

2 = 0.984. Efficiency is predicted almost perfectly by both models (MNE = 0.0022 and 0.0024, R

2 = 1). For the rotor lamination safety factor, Anisotropic Kriging shows lower error (MNE = 0.0224, R

2 = 0.975) than Kriging (MNE = 0.0667, R

2 = 0.862), while for maximum rotor lamination displacement, Anisotropic Kriging achieves MNE = 0.0024 and R

2 = 1 versus Kriging MNE = 0.0067 and R

2 = 0.999. Overall, these results indicate that both models are highly accurate, with Anisotropic Kriging performing slightly better for structural parameters.

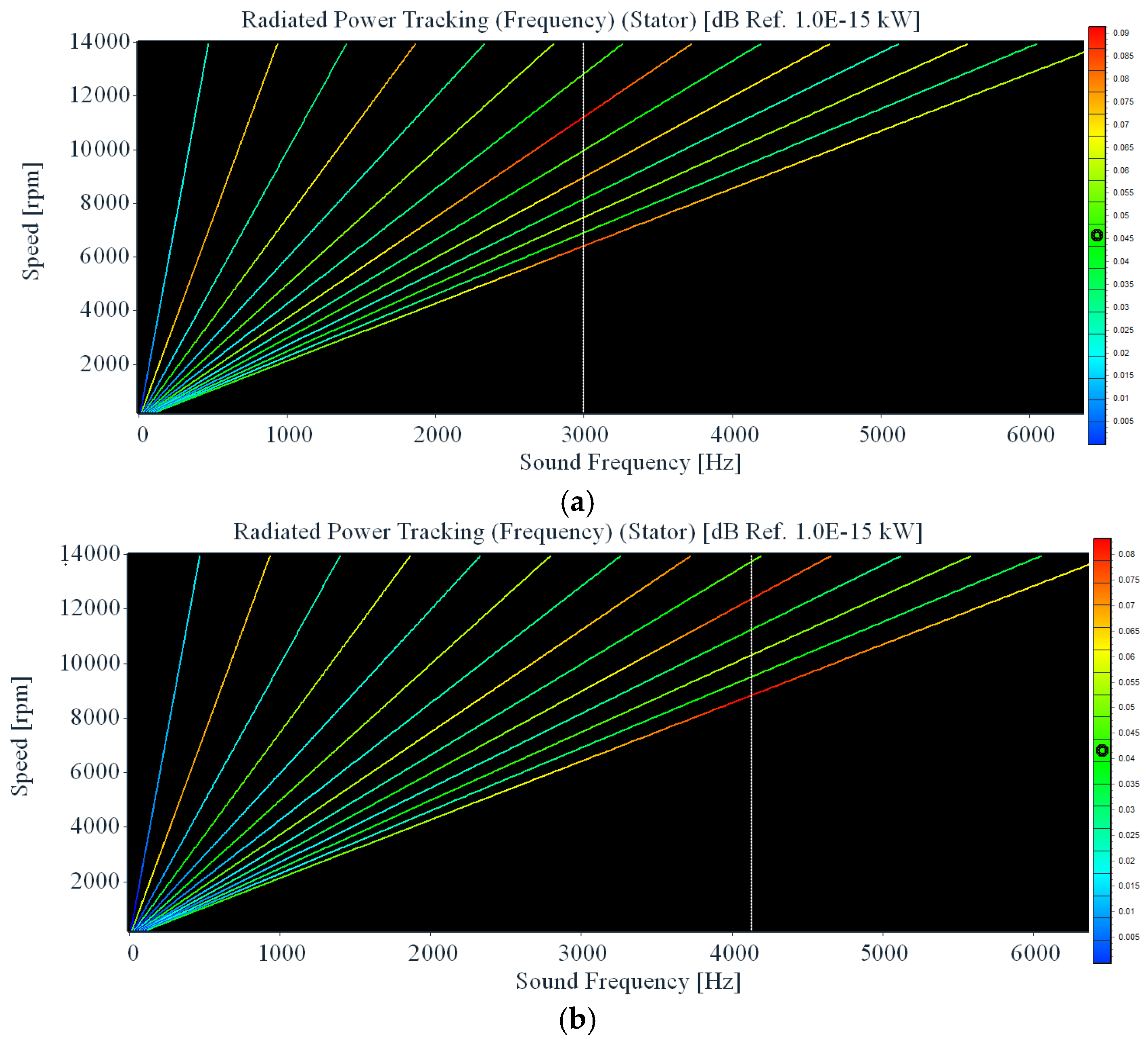

Figure 6 displays the evaluation of the accuracy of the created model for torque ripple and safety factor, which is considered the most important optimization factor.

3.3. Hybrid Algorithms

The optimization problem for EMs is non-linear, which leads to many local optima due to its geometric nature. If we use a deterministic optimization method like SQP, we can quickly obtain a solution if the initial value is sufficiently good. However, deterministic methods are prone to becoming stuck in local optima. On the other hand, stochastic optimization methods like GA converge slowly, especially toward the end of the optimization when the objective function is close to optimal. This slowness is more noticeable in EM analysis due to the challenging multi-physical nature of finding the best points. This process is very important but also quite complex.

This paper discusses the use of a hybrid GA-SQP algorithm to optimize electric motors for electric vehicles. The algorithm begins with a GA to establish an initial point since the SQP method is sensitive to this. The GA runs until a certain objective function value or a specific number of generations is reached. During this time, the objective function becomes closer to the local or global optimum. Then, the SQP method is employed due to its high efficiency. If the step size becomes too small to continue, the algorithm switches back to GA to prevent becoming stuck in local optima. Alternatively, if SQP does not lead to any improvement in target performance, the algorithm switches back to GA. This process may repeat until the optimal solution is found.

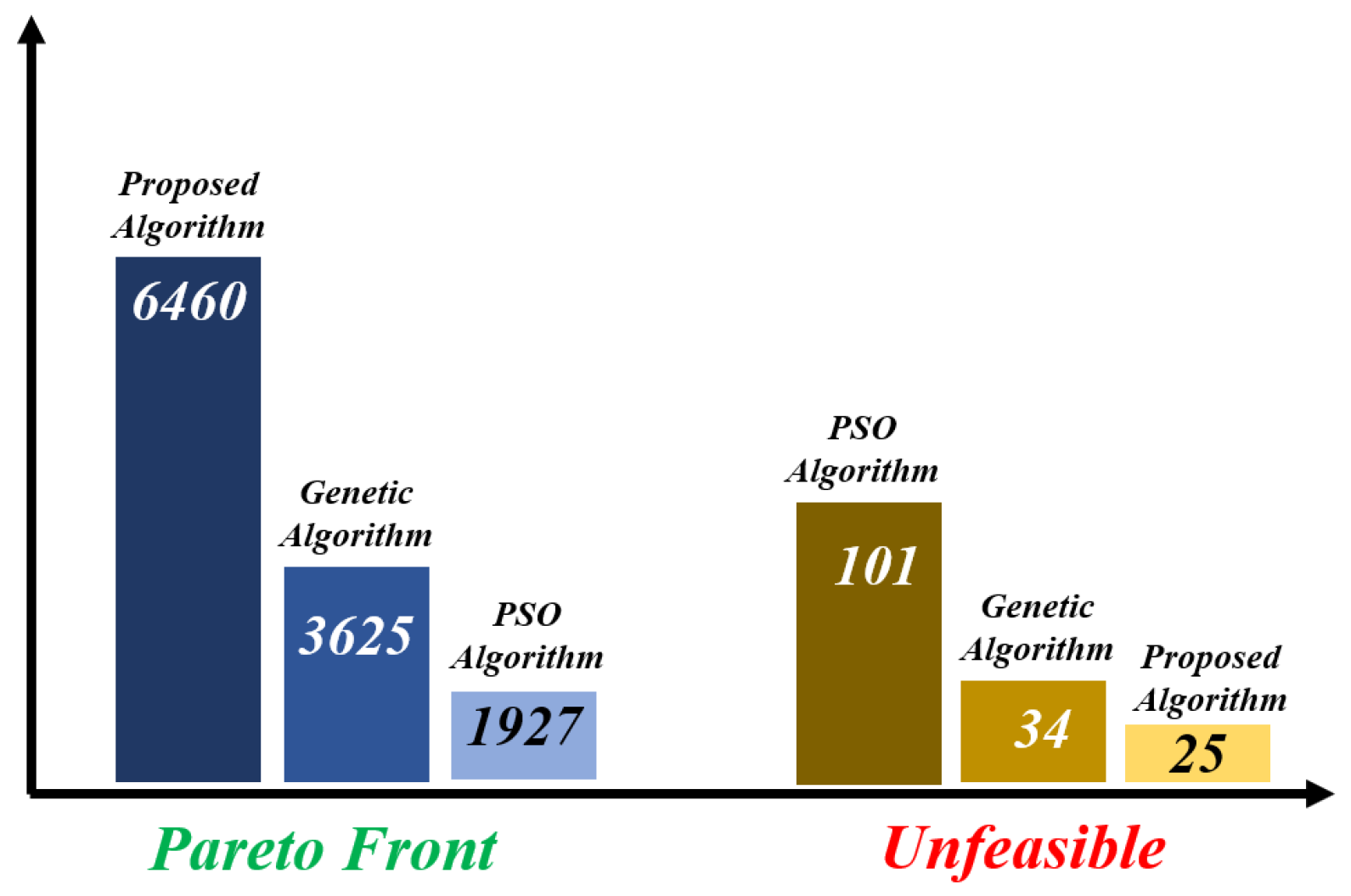

The flowchart of the algorithm used is displayed in

Figure 7. As mentioned earlier, the combination of two genetic algorithms and SQP for geometric optimization of the EM has proven to be very effective due to its ability to handle local points and a variety of functions. To validate this assertion, 10,000 designs were created using the proposed hybrid algorithm and compared with two powerful and popular algorithms. The geometric optimization results for the EM are illustrated in

Figure 8. As is evident from the comparison, the proposed algorithm outperforms the two GAs as well as the PSO algorithm, obtaining more points closer to the optimal point and reducing the search range.

3.4. Validation of the Proposed Algorithm with FEM

In this section, to simplify the optimization process, multi-objective optimization to single-objective optimization is set out. As a result, the objective in this part is to minimize the following objective function.

Here, , , , , and represent the initial values of torque per rotor volume, torque ripple, efficiency, rotor lamination safety factor, and rotor lamination displacement average, respectively. The denominator terms , , , , and correspond to their updated or optimized values during the iterative process.

In the objective function mentioned (6), the maximum weight is assigned to reducing ripple torque. In the subsequent section, the most important mechanical objective function is the safety factor. The proposed method has been used to find the optimal point of the minimum objective function.

The algorithm’s results should be compared with the FEM results to ensure the accuracy of the proposed optimization process. The comparison is presented in

Table 5, showing very close results. This demonstrates the effectiveness of the optimization process and the accurate selection of geometric variable ranges.

6. Conclusions

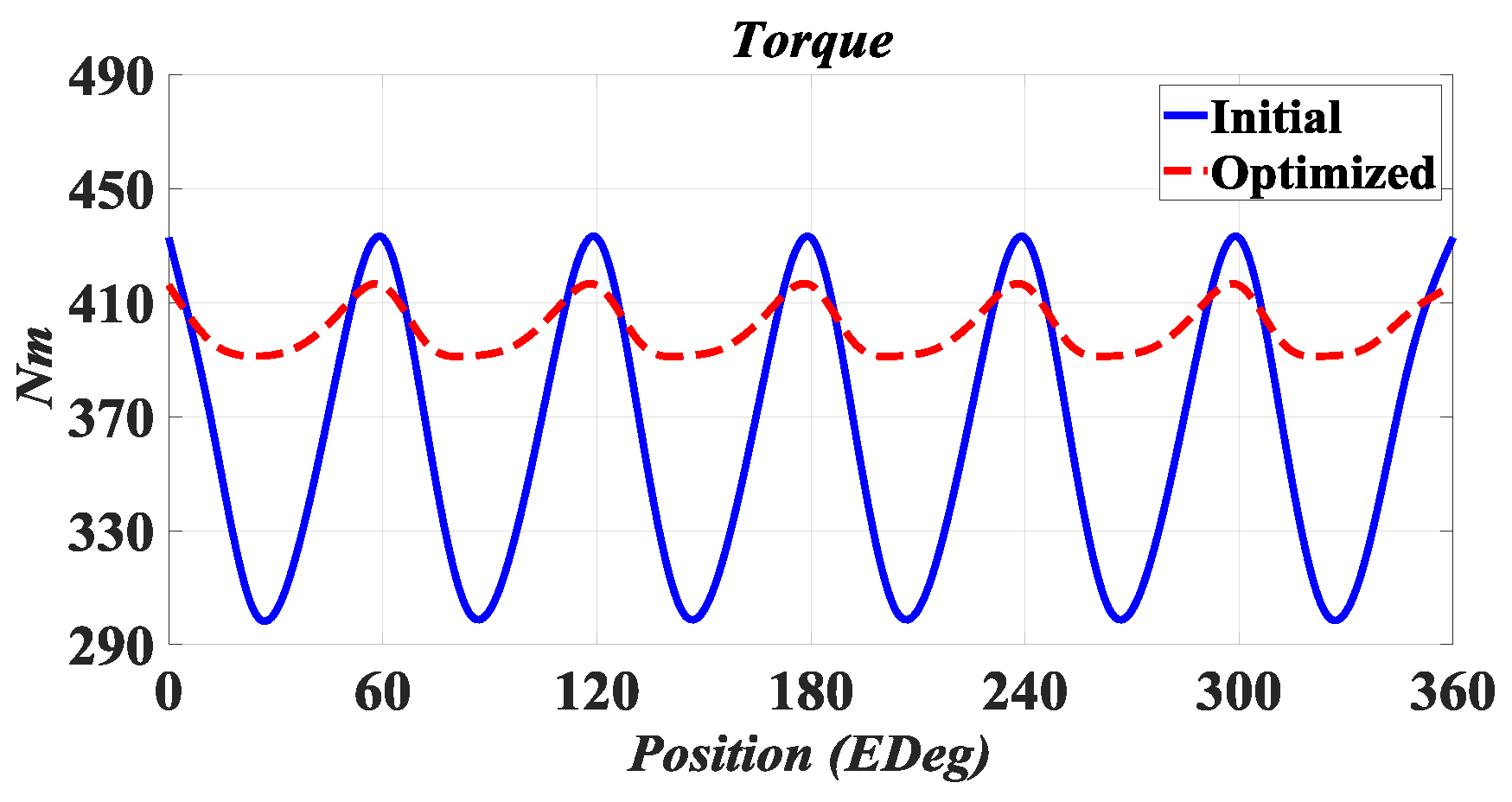

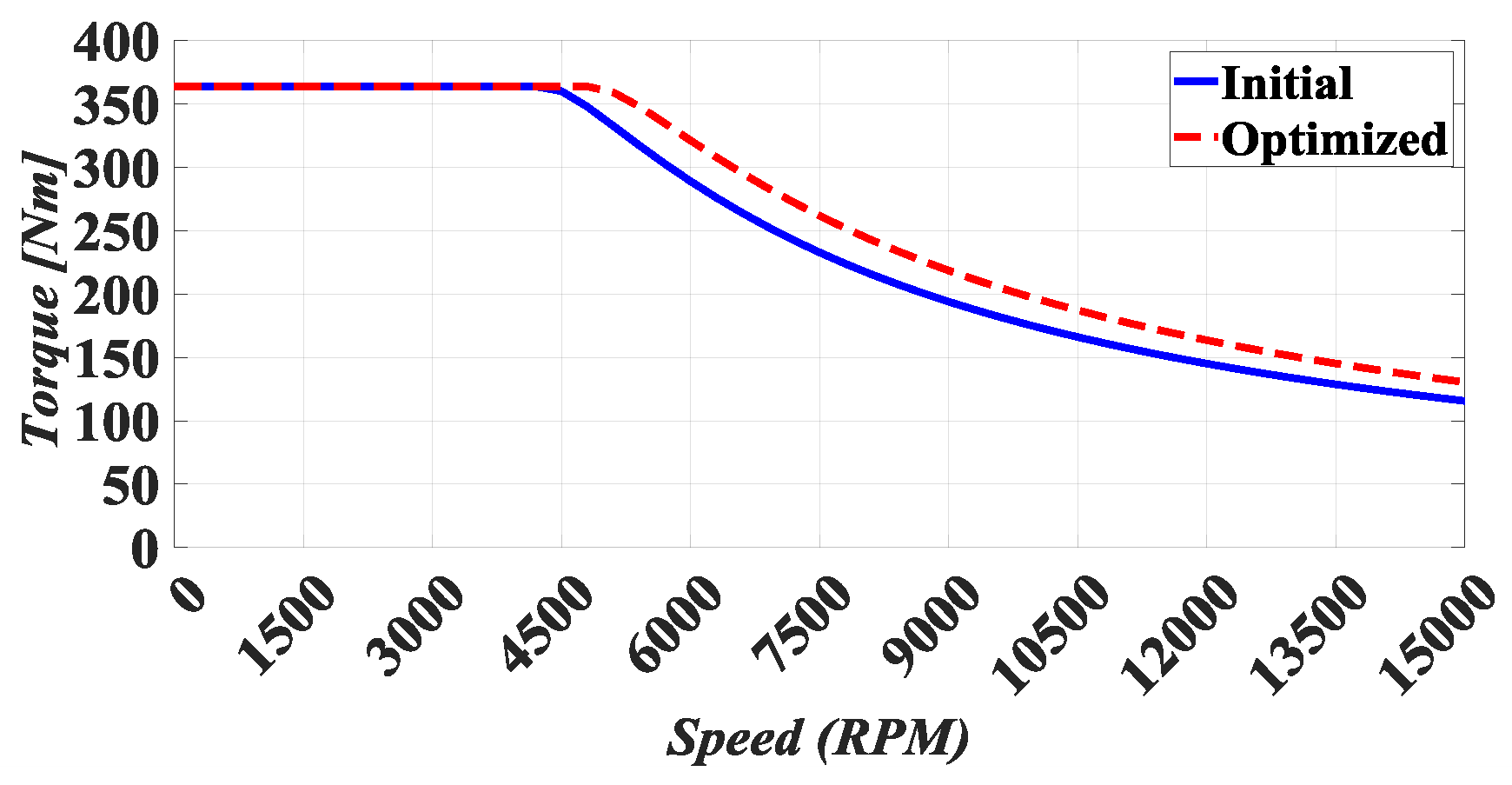

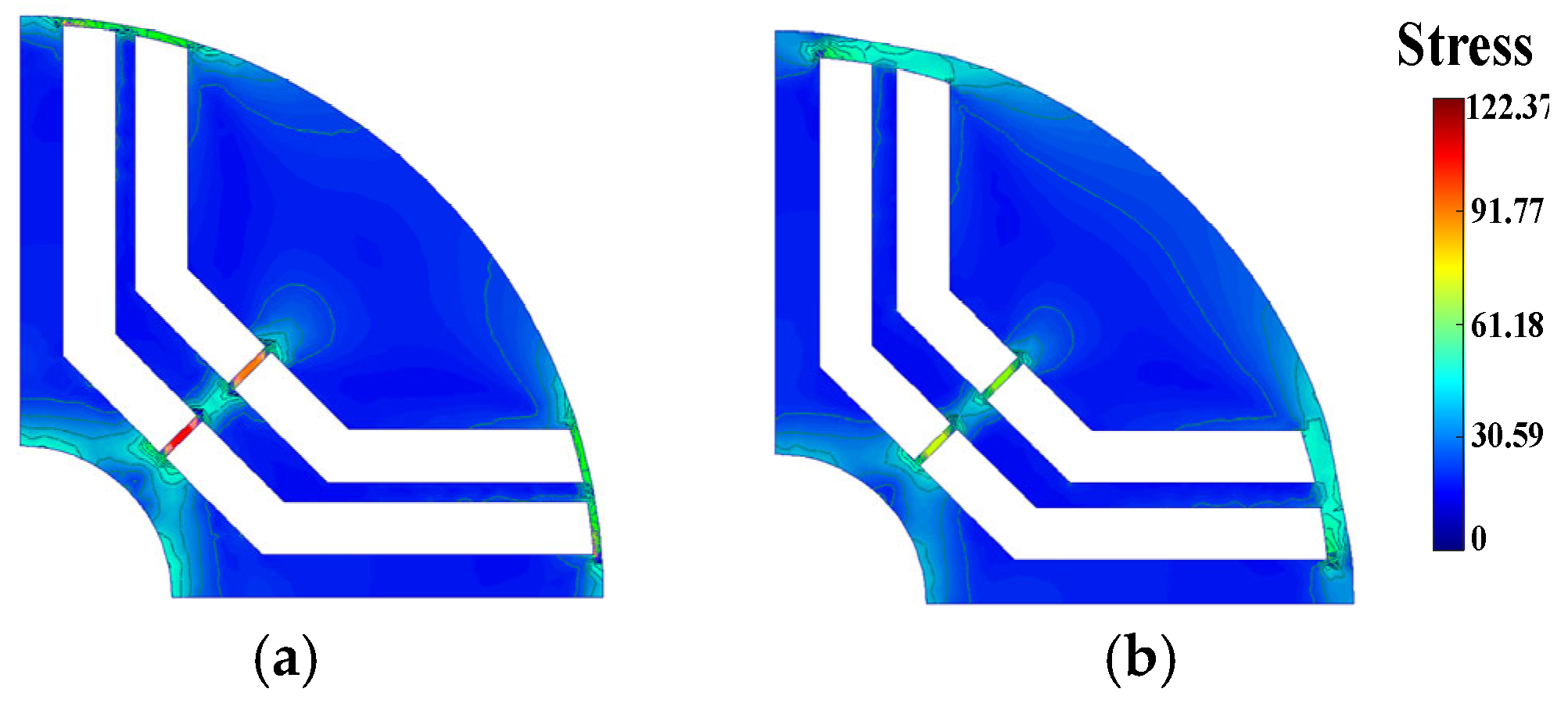

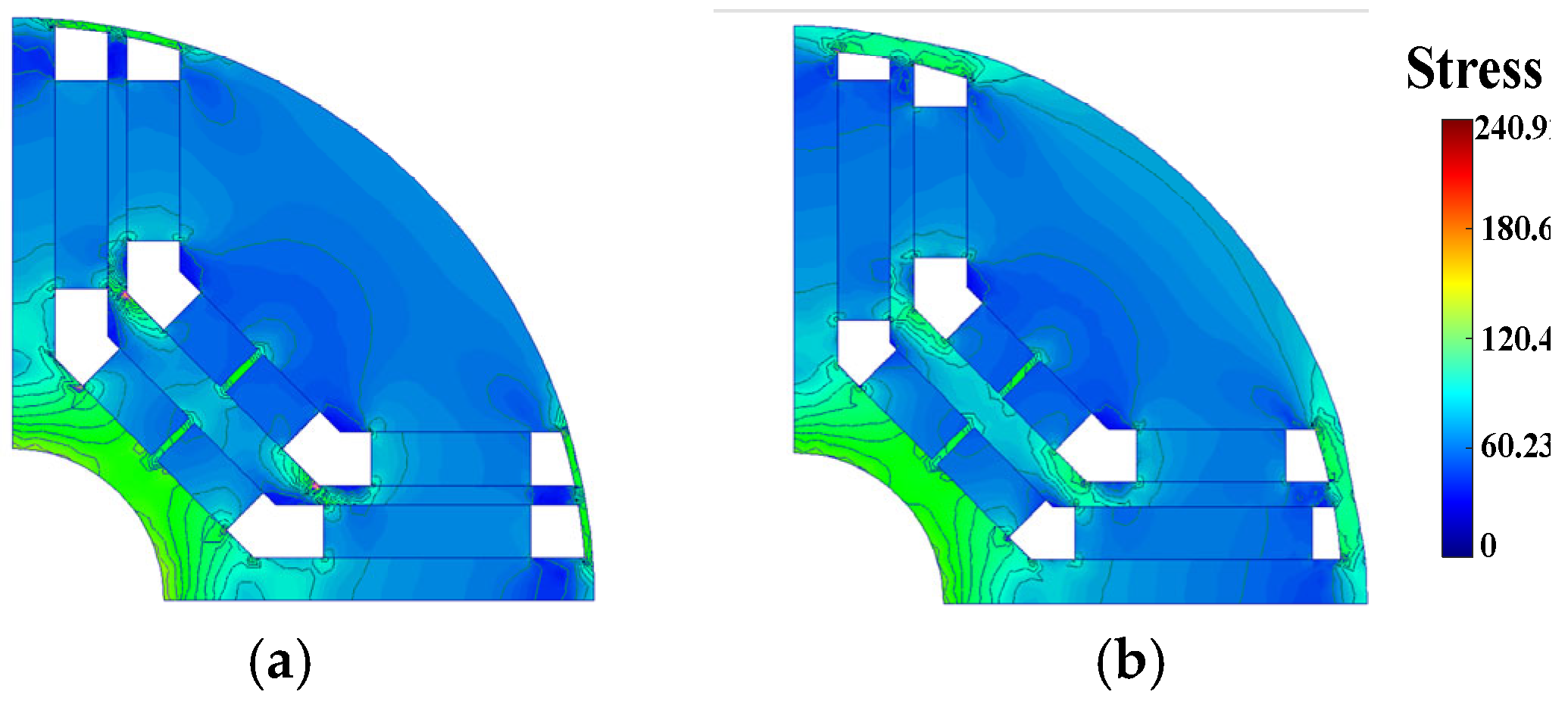

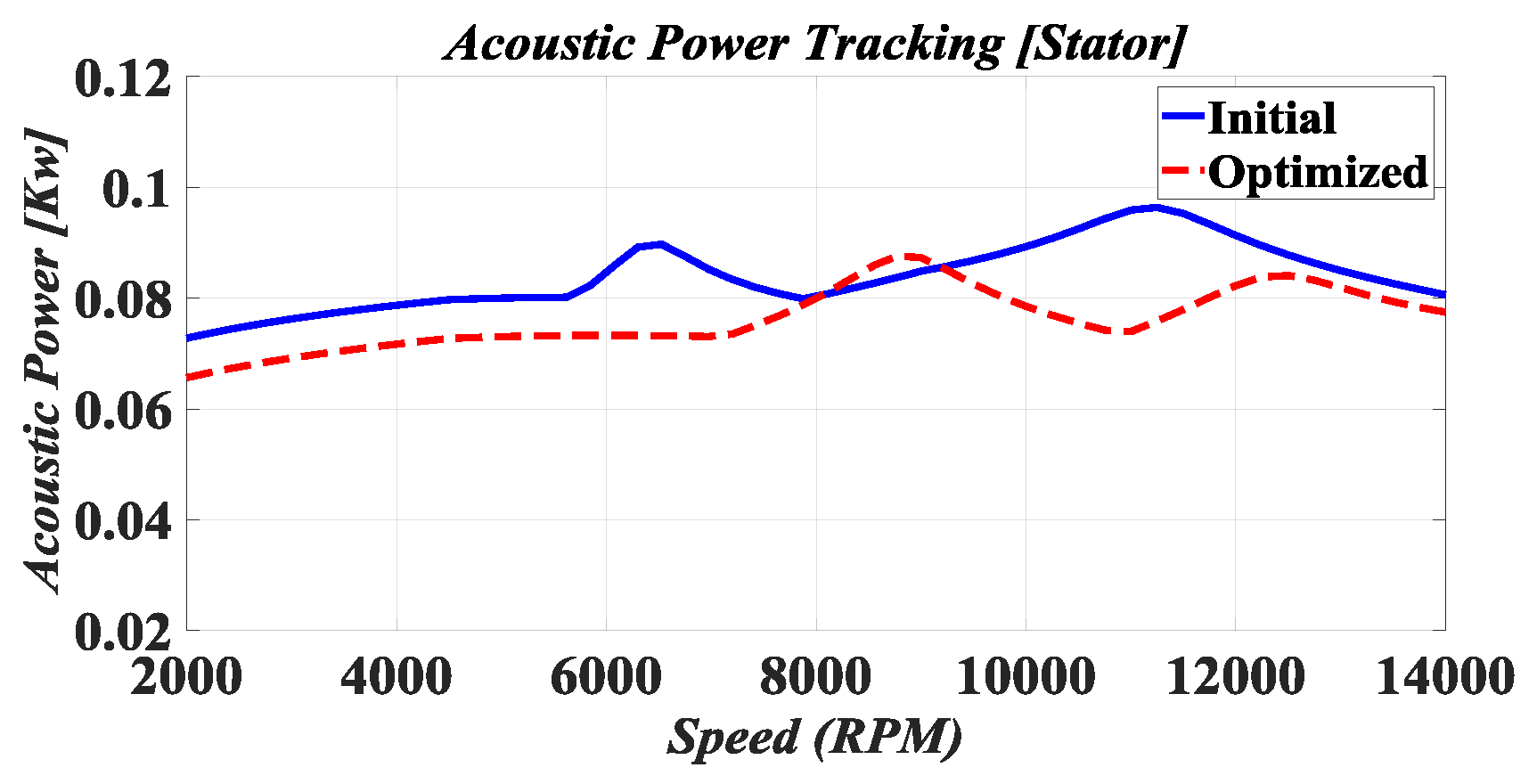

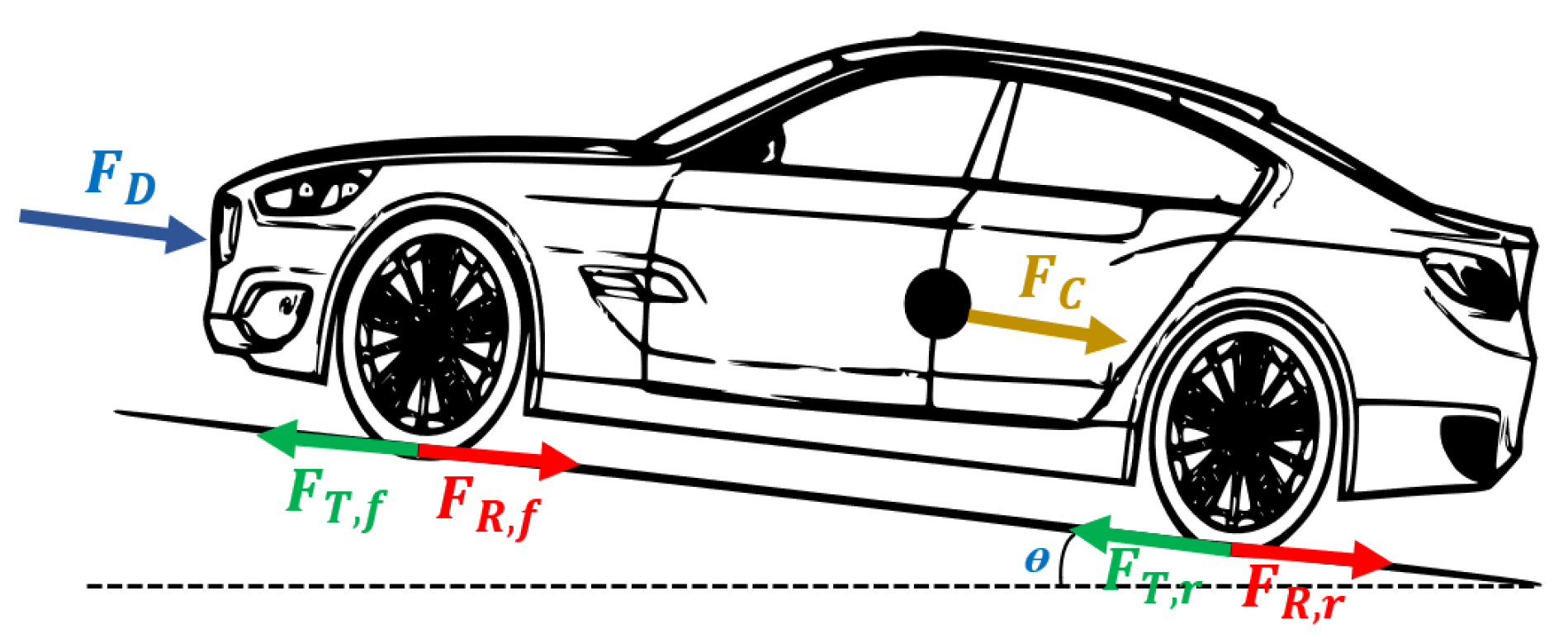

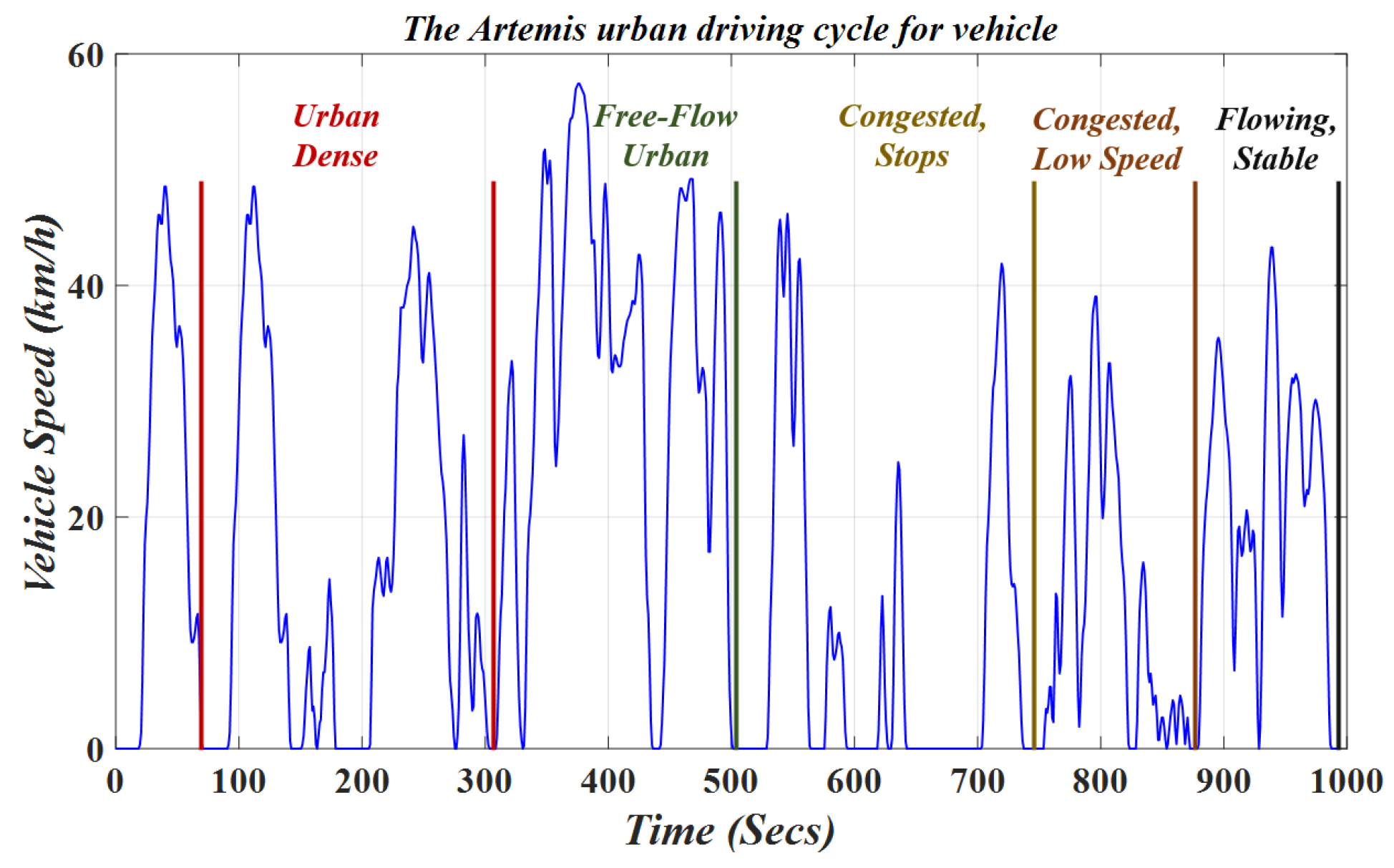

This study compared V-shaped and U-shaped IPMSM designs to identify the optimal configuration for EV applications, focusing on torque ripple, power, and efficiency. A ship-shaped notch was introduced in the bridge area between the double U-shaped layers to further reduce torque ripple. Key design variables were identified, and a robust optimization framework combining Pearson Correlation, Anisotropic Kriging-based Surrogate modeling, MOGA, and SQP was applied for the first time to these machines.

Validation using FEM, GA, and PSO confirmed that the optimized PMSM outperforms alternative designs in EV performance indices. The proposed motor efficiently handles European driving loads, achieves high average efficiency, and exhibits reduced torque ripple, leading to lower vibration and noise. These results demonstrate the potential of the optimized PMSM as a high-performance, low-noise solution for electric vehicles.