Life Cycle Assessment of Different Powertrain Alternatives for a Clean Urban Bus Across Diverse Weather Conditions

Abstract

1. Introduction

2. Materials and Methods

2.1. Goal and Scope

- an ICEV fueled by diesel,

- a series Hybrid Electric Vehicle (HEV), featuring a diesel ICE as APU,

- a series hybrid FCEV,

- a series Hydrogen Hybrid Electric Vehicle (H2HEV) featuring an ICE fueled by hydrogen as APU,

- a BEV.

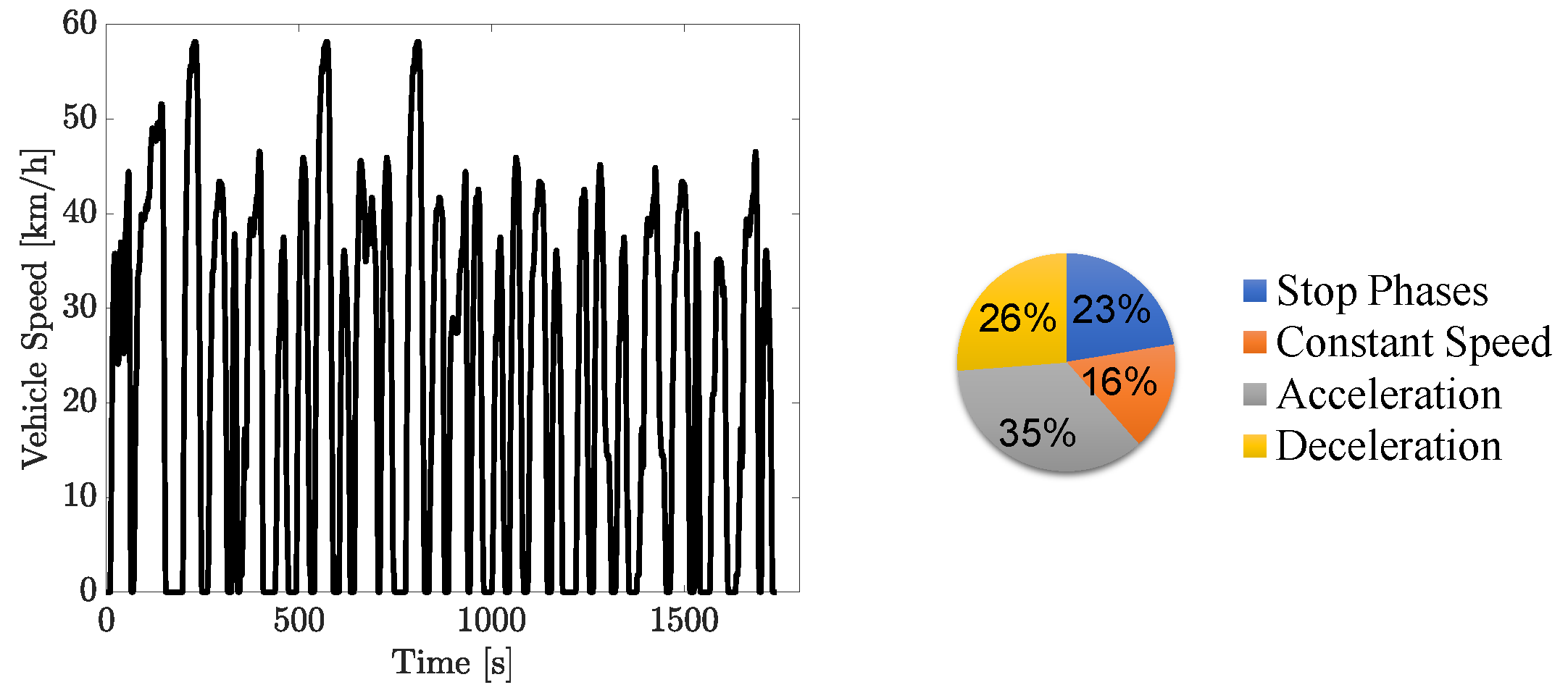

2.2. Case Study: Reference Vehicle and Powertrain Characteristics

2.3. System Boundaries

2.4. Data Acquisitions and Assumptions

2.5. Power Absorption of the Bus Auxiliaries

3. Results

3.1. TtW Analysis

3.2. Powertrains Life Cycle at Different External Temperatures

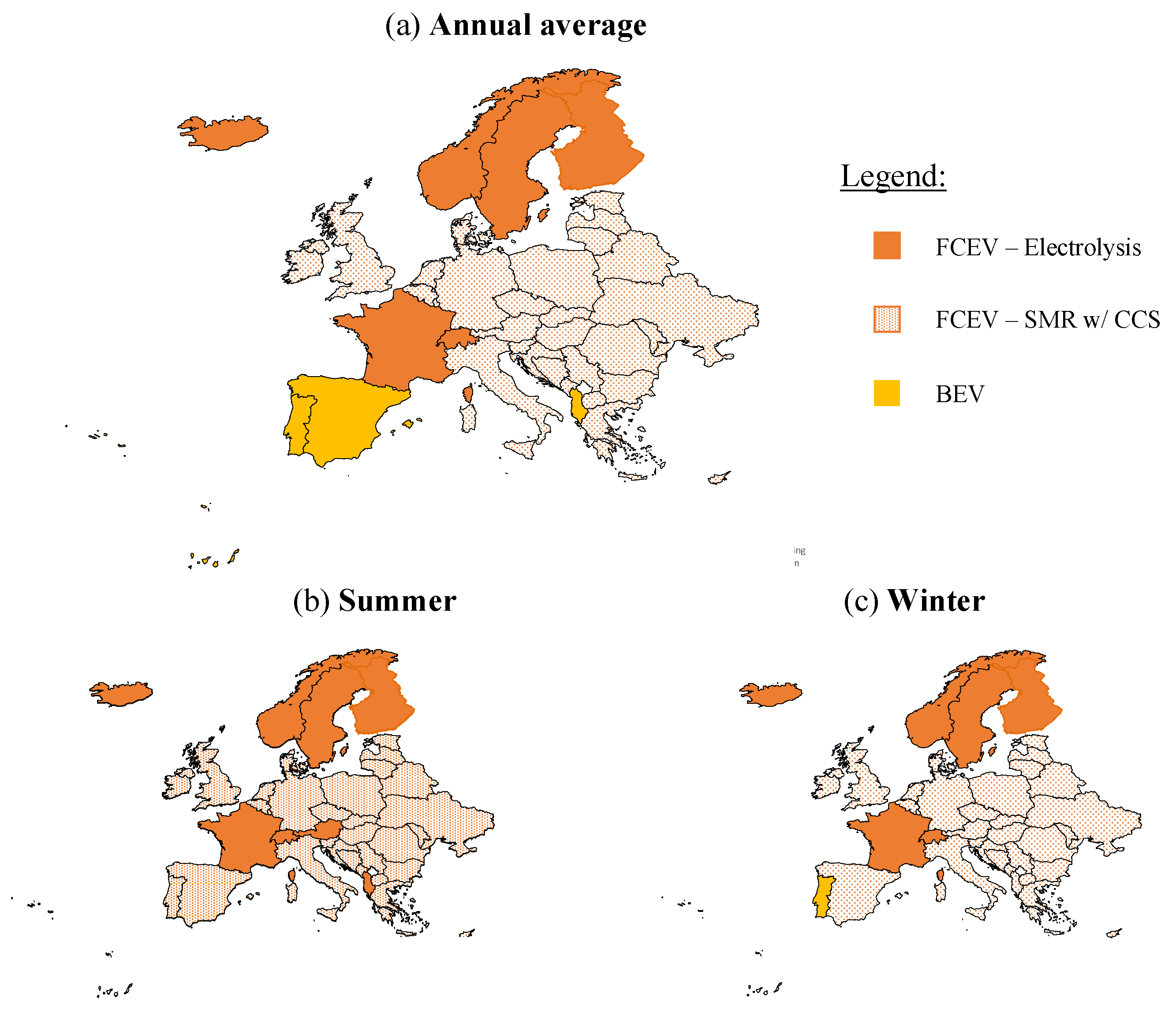

- At extreme cold conditions (Figure 9a), FCEVs exhibit the lowest CF across most of the CI values, regardless of hydrogen production method, owing to their reduced power demand from the auxiliaries and, consequently, lower energy demand in cold conditions (see Figure 8). Finally, for CI values above 500 gCO2/kWh, the HEV shows slightly lower CF than FCEV.

- At intermediate external conditions (Figure 9b,c), the range of CIs where the BEV has the lowest CF begins to expand. However, for low-carbon grids (CI < 90–100 gCO2/kWh), the FCEV remains the most sustainable option, while for grids with high fossil fuel dependence (CI > 400–500 gCO2/kWh), the HEV continues to exhibit the lowest CF.

- At hot conditions (Figure 9d), BEVs outperform other powertrains in CF for grid CI values ranging from approximately 60 gCO2/kWh to 600 gCO2/kWh.

3.3. European Countries’ Analysis of Clean Bus Alternatives

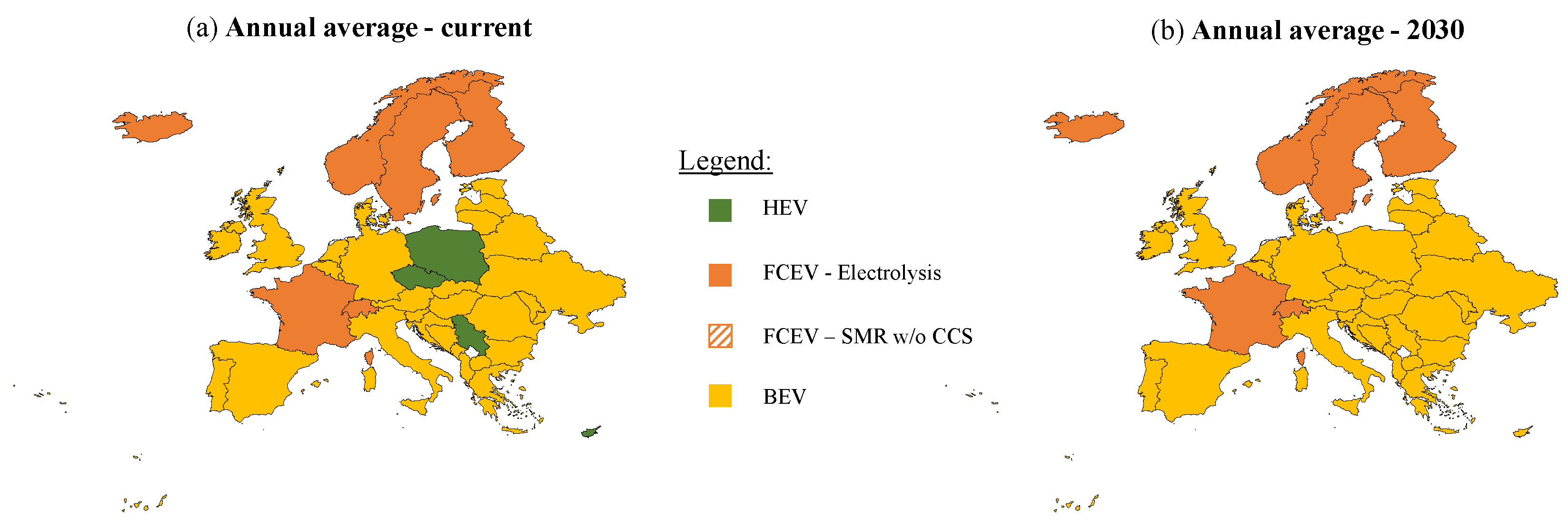

3.4. European Context for Clean Bus Alternatives in the Future Scenario

- This outcome is likely attributable to the use of a uniform emission factor for hydrogen production throughout Europe. When this value is reduced to 6 kgCO2/kgH2 in a projected 2030 scenario, FCEVs powered by green hydrogen become a more favorable option in a greater number of European countries.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| APU | Auxiliary Power Unit |

| BEV | Battery Electric Vehicle |

| BoP | Balance of Plant |

| BTM | Battery Thermal Management |

| CF | Carbon Footprint |

| CI | Carbon Intensity |

| ECMS | Equivalent Consumption Minimization Strategy |

| EoL | End of Life |

| FC | Fuel Cell |

| FCEV | Fuel Cell Electric Vehicle |

| FCTM | Fuel Cell Thermal Management |

| FU | Functional Unit |

| H2HEV | Hydrogen Hybrid Electric Vehicle |

| HDV | Heavy Duty Vehicle |

| HEV | Hybrid Electric Vehicle |

| HV | High Voltage |

| HVAC | Heating, Ventilation, and Air Conditioning |

| ICE | Internal Combustion Engine |

| ICEV | Internal Combustion Engine Vehicle |

| LCA | Life Cycle Assessment |

| LFP | Lithium iron phosphate |

| NMC | Nickel Manganese Cobalt |

| PM | Permanent Magnet |

| SMR | Steam Methane Reforming |

| TtW | Tank-to-Wheel |

| WtT | Well-to-Tank |

| WtW | Well-to-Wheel |

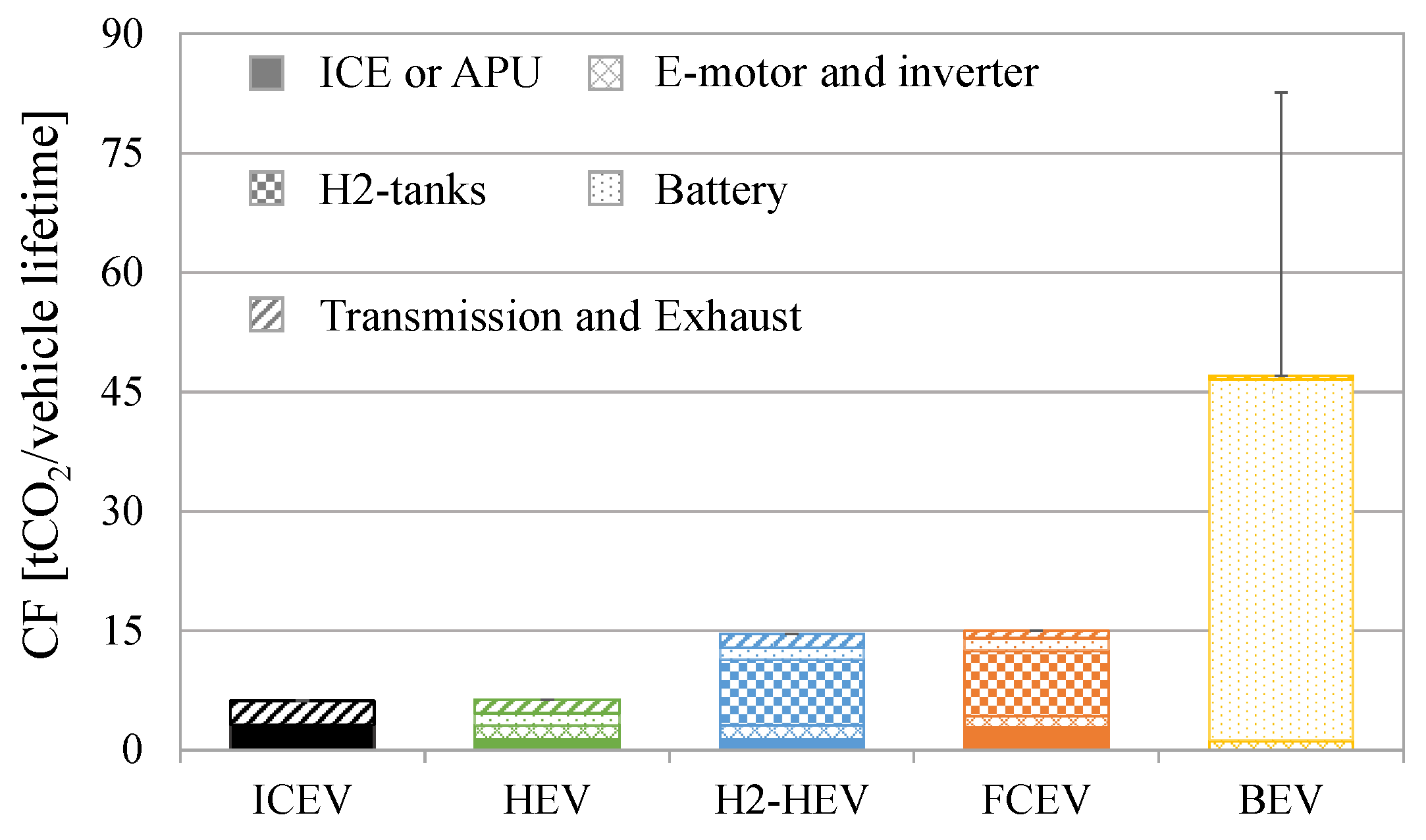

Appendix A. Production, Maintenance, and EoL Data

| Item | ICEV | HEV | H2HEV | FCEV | BEV | |

|---|---|---|---|---|---|---|

| Glider | CF | Not considered | ||||

| ICE | CF [kgCO2/kW] | 13 [52] | - | - | ||

| FC | CF [kgCO2/kW] | - | 28 [53] | - | ||

| E-motor | CF [kgCO2/kW] | - | 3.6 [54] | |||

| Inverter | CF [kgCO2/kW] | - | 2.4 [55] | |||

| H2-tank | CF [kgCO2/kgH2] | - | - | 280 [53] | - | |

| Battery | CF [kgCO2/kWh] | - | 80 [56] | 135 [57] | ||

| Energy Demand [kWh/km] | Battery Size [kWh] | Battery CF [tCO2/Battery] |

|---|---|---|

| <1.3 | 336 | 45.4 |

| 1.3–1.6 | ≈400 | 54.0 |

| 1.6–2.0 | ≈500 | 67.5 |

| >2.4 | ≈600 | 81.0 |

| Time Horizon | Units Sold per Year | CF | |

|---|---|---|---|

| FC [kgCO2/kW] | 2024 | 200 | 28 |

| 2030 | 1000 | 13.7 | |

| H2-tank [kgCO2/kgH2] | 2024 | 200 | 280 |

| 2030 | 1000 | 234 | |

| Battery [kgCO2/kWh] | 2024 | 200 | 135 |

| 2030 | 1000 | 90 |

References

- International Energy Agency. IEA, Emissions by Region, Europe. 2022. Available online: https://www.iea.org/regions/europe/emissions (accessed on 18 August 2025).

- European Environment Agency. Passenger Transport Activity. 2024. Available online: https://www.eea.europa.eu/en/analysis/publications/sustainability-of-europes-mobility-systems/passenger-transport-activity (accessed on 18 August 2025).

- Heid, B.; Martens, C.; Orthofer, A. How Hydrogen Combustion Engines Can Contribute to Zero Emissions. 2021. Available online: https://www.mckinsey.com/industries/automotive-and-assembly/our-insights/how-hydrogen-combustion-engines-can-contribute-to-zero-emissions (accessed on 18 August 2025).

- Ercan, T.; Tatari, O. A hybrid life cycle assessment of public transportation buses with alternative fuel options. Int. J. Life Cycle Assess. 2015, 20, 1213–1231. [Google Scholar] [CrossRef]

- Peters, J.F.; Baumann, M.; Zimmermann, B.; Braun, J.; Weil, M. The environmental impact of Li-Ion batteries and the role of key parameters—A review. Renew. Sustain. Energy Rev. 2017, 67, 491–506. [Google Scholar] [CrossRef]

- Basma, H.; Mansour, C.; Haddad, M.; Nemer, M.; Stabat, P. Comprehensive energy modeling methodology for battery electric buses. Energy 2020, 207, 118241. [Google Scholar] [CrossRef]

- Corazza, M.; Conti, V.; Genovese, A.; Ortenzi, F.; Valentini, M.P. A procedure to estimate air conditioning consumption of urban buses related to climate and main operational characteristics. World Electr. Veh. J. 2021, 12, 29. [Google Scholar] [CrossRef]

- Lajunen, A. Lifecycle costs and charging requirements of electric buses with different charging methods. J. Clean. Prod. 2018, 172, 56–67. [Google Scholar] [CrossRef]

- Qu, Y.; Li, D.; Wang, R. Study on integrated thermal management system of hydrogen fuel cell vehicles based on heat pump air conditioning. J. Clean. Prod. 2024, 434, 139951. [Google Scholar] [CrossRef]

- Broatch, A.; Olmeda, P.; Margot, X.; Aceros, S. Different strategies in an integrated thermal management system of a fuel cell electric bus under real driving cycles in winter. Energy Convers. Manag. 2023, 288, 117137. [Google Scholar] [CrossRef]

- Lee, H.; Lee, D.; Kim, Y. Heating performance of a coolant-source heat pump using waste heat from stack and electric devices in fuel cell electric vehicles under cold conditions. Energy Convers. Manag. 2022, 252, 115092. [Google Scholar] [CrossRef]

- Kivekäs, K.; Lajunen, A.; Vepsäläinen, J.; Tammi, K. City bus powertrain comparison: Driving cycle variation and passenger load sensitivity analysis. Energies 2018, 11, 1755. [Google Scholar] [CrossRef]

- Mehmeti, A.; Angelis-Dimakis, A.; Arampatzis, G.; McPhail, S.J.; Ulgiati, S. Life cycle assessment and water footprint of hydrogen production methods: From conventional to emerging technologies. Environments 2018, 5, 24. [Google Scholar] [CrossRef]

- Staffell, I.; Scamman, D.; Velazquez Abad, A.; Balcombe, P.; Dodds, P.E.; Ekins, P.; Shah, N.; Ward, K.R. The role of hydrogen and fuel cells in the global energy system. Energy Environ. Sci. 2019, 12, 463–491. [Google Scholar] [CrossRef]

- Peiretti Paradisi, B.; Pulvirenti, L.; Vinogradov, A.; Rolando, L.; Piano, A.; Millo, F.; Prussi, M. A techno-economic life cycle assessment of H2 fuelled and electrified urban buses. Appl. Energy 2025. under review. [Google Scholar]

- Muncrief, R.L.; Cruz, M.; Ng, H.; Harold, M. Impact of Auxiliary Loads on Fuel Economy and Emissions in Transit Bus Applications; SAE Technical Papers 2012-01-1028; SAE International: Warrendale, PA, USA, 2012. [Google Scholar] [CrossRef]

- Jiménez-Espadafor, F.J.; Guerrero, D.P.; Trujillo, E.C.; García, M.T.; Wideberg, J. Fully optimized energy management for propulsion, thermal cooling and auxiliaries of a serial hybrid electric vehicle. Appl. Therm. Eng. 2015, 91, 694–705. [Google Scholar] [CrossRef]

- Bartłomiejczyk, M.; Kołacz, R. The reduction of auxiliaries power demand: The challenge for electromobility in public transportation. J. Clean. Prod. 2020, 252, 119776. [Google Scholar] [CrossRef]

- O’Boyle, C.; Blades, L.A.W.; McGrath, T.; Early, J.; Harris, A. Investigating Route Gradient and Thermal Demand on Hydrogen Fuel Cell Electric Bus Energy Consumption; SAE Technical Papers 2024-01-2176; SAE International: Warrendale, PA, USA, 2024. [Google Scholar] [CrossRef]

- Zacharof, N.; Özener, O.; Broekaert, S.; Özkan, M.; Samaras, Z.; Fontaras, G. The impact of bus passenger occupancy, heating ventilation and air conditioning systems on energy consumption and CO2 emissions. Energy 2023, 272, 127155. [Google Scholar] [CrossRef]

- International Energy Agency. Global Hydrogen Review 2024. 2024. Available online: https://www.iea.org/reports/global-hydrogen-review-2024; (accessed on 18 August 2025).

- UITP. An Overview of Clean Buses in Europe Clean Bus Report. January 2024. Available online: https://cms.uitp.org/wp/wp-content/uploads/2022/05/ASSURED-Clean-Bus-report_final2.pdf (accessed on 18 August 2025).

- Pulvirenti, L.; Rolando, L.; Vinogradov, A.; Paradisi, B.P. Comparison of hydrogen-fueled powertrains for urban bus applications—Design, modeling, and energy management. Int. J. Hydrogen Energy 2024, 110, 560–574. [Google Scholar] [CrossRef]

- Millo, F.; Rolando, L.; Fuso, R.; Mallamo, F. Real CO2 emissions benefits and end user’s operating costs of a plug-in Hybrid Electric Vehicle. Appl. Energy 2014, 114, 563–571. [Google Scholar] [CrossRef]

- Arsie, I.; Battistoni, M.; Brancaleoni, P.P.; Cipollone, R.; Corti, E.; Di Battista, D.; Millo, F.; Occhicone, A.; Paradisi, B.P.; Rolando, L.; et al. A New Generation of Hydrogen-Fueled Hybrid Propulsion Systems for the Urban Mobility of the Future. Energies 2024, 17, 34. [Google Scholar] [CrossRef]

- Golisano, R.; Scalabrini, S.; Arpaia, A.; Pesce, F.; Vassallo, A.; Borgia, F.; Cubito, C.; Biasin, V.; Knichel, T.; Millo, F.; et al. Hydrogen Internal Combustion Engine & KERS: An Appealing Value-Proposition for Green Power Pack. In Proceedings of the 42nd International Vienna Motor Symposium, Vienna, Austria, 29–30 April 2021. [Google Scholar]

- Bianchi, D.; Rolando, L.; Serrao, L.; Onori, S.; Rizzoni, G.; Al Khayat, N.; Hsieh, T.M.; Kang, P. Layered control strategies for hybrid electric vehicles based on optimal control. Int. J. Electr. Hybrid Veh. 2011, 3, 191. [Google Scholar] [CrossRef]

- Millo, F.; Piano, A.; Rolando, L.; Accurso, F.; Gullino, F.; Roggio, S.; Bianco, A.; Pesce, F.; Vassallo, A.; Rossi, R. Synergetic Application of Zero-, One-, and Three-Dimensional Computational Fluid Dynamics Approaches for Hydrogen-Fuelled Spark Ignition Engine Simulation. SAE Int. J. Engines 2021, 15, 561–580. [Google Scholar] [CrossRef]

- Millo, F.; Rolando, L.; Piano, A.; Peiretti Paradisi, B.; Vinogradov, A. Hydrogen Powertrains: A Comparison Between Different Solutions for an Urban Bus. In Proceedings of the 22. Internationales Stuttgarter Symposium, Stuttgart, Germany, 15–16 March 2022; pp. 259–271. [Google Scholar] [CrossRef]

- Handwerker, M.; Wellnitz, J.; Marzbani, H. Comparison of Hydrogen Powertrains with the Battery Powered Electric Vehicle and Investigation of Small-Scale Local Hydrogen Production Using Renewable Energy. Hydrogen 2021, 2, 76–100. [Google Scholar] [CrossRef]

- Rivard, E.; Trudeau, M.; Zaghib, K. Hydrogen storage for mobility: A review. Materials 2019, 12, 1973. [Google Scholar] [CrossRef]

- A123 Systems. Nanophosphate® High Power Lithium-Ion Cell. 2023. Available online: https://www.batteryspace.com/prod-specs/6610.pdf (accessed on 18 August 2025).

- Borghetti, F.; Longo, M.; Bonera, M.; Libretti, M.; Somaschini, C.; Martinelli, V.; Medeghini, M.; Mazzoncini, R. Battery Electric Buses or Fuel Cell Electric Buses? A Decarbonization Case Study in the City of Brescia, Italy. Infrastructures 2023, 8, 178. [Google Scholar] [CrossRef]

- ZeEUS. EBus Report #2: An Updated Overview of Electric Buses in Europe. August 2024. Available online: https://zeeus.eu/uploads/publications/documents/zeeus-ebus-report-2.pdf (accessed on 18 August 2025).

- Introduction of Samsung SDI’s 94Ah Cells. January 2024. Available online: https://cdn.shopify.com/s/files/1/0480/6521/6669/files/BMW_Samsung_SDI_94Ah_Datasheet.pdf?v=1605781107. (accessed on 18 August 2025).

- Europe Environment Agency. Greenhouse Gas Emission Intensity of Electricity Generation in Europe. July 2024. Available online: https://www.eea.europa.eu/en/analysis/indicators/greenhouse-gas-emission-intensity-of-1 (accessed on 18 August 2025).

- Scarlat, N.; Prussi, M.; Padella, M. Quantification of the carbon intensity of electricity produced and used in Europe. Appl. Energy 2022, 305, 117901. [Google Scholar] [CrossRef]

- Electricity Maps. Electricity Maps Monthly. 2025. Available online: https://app.electricitymaps.com/map/all/monthly (accessed on 18 August 2025).

- Climate Change Knowledge Portal. Data Catalog. 2025. Available online: https://climateknowledgeportal.worldbank.org/ (accessed on 18 August 2025).

- International Energy Agency. CO2 Emissions Intensity of Electricity Generation in the Announced Pledges Scenario, 2022–2030. 2024. Available online: https://www.iea.org/data-and-statistics/charts/co2-emissions-intensity-of-electricity-generation-in-the-announced-pledges-scenario-2022-2030 (accessed on 18 August 2025).

- Prussi, M.; Yugo, M.; Prada, L.; De Padella, M.; Edwards, R. JEC Well-To-Wheels Report v5:Well-to-Wheels Analysis of Future Automotive Fuels and Powertrains in the European Context; JRC Science for Policy Report; JRC: Brussels, Belgium, 2020. [Google Scholar] [CrossRef]

- OpenLCA Software. August 2024. Available online: https://www.openlca.org/ (accessed on 18 August 2025).

- Sens, M.; Danzer, D.; Essen Cvon Brauer, M.; Wascheck, R.; Seebode, J.; Kratzsch, M. Hydrogen Powertrains in Competition to Fossil Fuel based Internal Combustion Engines and Battery Electric Powertrains. In Proceedings of the 42nd International Vienna Motor Symposium, Vienna, Austria, 29–30 April 2021. [Google Scholar]

- Brèque, F.; Nemer, M. Cabin Thermal Needs: Modeling and Assumption Analysis. In Proceedings of the 12th International Modelica Conference, Prague, Czech Republic, 15–17 May 2017; Linköping University Electronic Press: Linköping, Sweden, 2017; pp. 771–781. [Google Scholar] [CrossRef]

- Basma, H.; Mansour, C.; Haddad, M.; Nemer, M.; Stabat, P. Comprehensive energy assessment of battery electric buses and diesel buses. In Proceedings of the 32nd International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems, Wrocław, Poland, 23–28 June 2019. [Google Scholar]

- Broatch, A.; Olmeda, P.; Bares, P.; Aceros, S. Integral Thermal Management Studies in Winter Conditions with a Global Model of a Battery-Powered Electric Bus. Energies 2023, 16, 168. [Google Scholar] [CrossRef]

- García, A.; Monsalve-Serrano, J.; Lago Sari, R.; Tripathi, S. Pathways to achieve future CO2 emission reduction targets for bus transit networks. Energy 2022, 244, 123177. [Google Scholar] [CrossRef]

- Lozanovski, A.; Whitehouse, N.; Ko, N.; Whitehouse, S. Sustainability assessment of fuel cell buses in public transport. Sustainability 2018, 10, 1480. [Google Scholar] [CrossRef]

- Nordelöf, A.; Romare, M.; Tivander, J. Life cycle assessment of city buses powered by electricity, hydrogenated vegetable oil or diesel. Transp. Res. Part D Transp. Environ. 2019, 75, 211–222. [Google Scholar] [CrossRef]

- Gustafsson, M.; Svensson, N.; Eklund, M.; Dahl Öberg, J.; Vehabovic, A. Well-to-wheel greenhouse gas emissions of heavy-duty transports: Influence of electricity carbon intensity. Transp. Res. Part D Transp. Environ. 2021, 93, 102757. [Google Scholar] [CrossRef]

- Brancaleoni, P.P.; Damiani Ferretti, A.N.; Corti, E.; Ravaglioli, V.; Moro, D. Lifecycle CO2 analysis for urban emission reduction of hydrogen-fuelled and battery electric buses in the European Union current and future energetic scenarios. Int. J. Hydrogen Energy 2025, 123, 335–353. [Google Scholar] [CrossRef]

- Wolff, S.; Seidenfus, M.; Gordon, K.; Álvarez, S.; Kalt, S.; Lienkamp, M. Scalable life-cycle inventory for heavy-duty vehicle production. Sustainability 2020, 12, 5396. [Google Scholar] [CrossRef]

- Miotti, M.; Hofer, J.; Bauer, C. Integrated environmental and economic assessment of current and future fuel cell vehicles. Int. J. Life Cycle Assess. 2017, 22, 94–110. [Google Scholar] [CrossRef]

- Nordelöf, A.; Grunditz, E.; Lundmark, S.; Tillman, A.M.; Alatalo, M.; Thiringer, T. Life cycle assessment of permanent magnet electric traction motors. Transp. Res. Part D Transp. Environ. 2019, 67, 263–274. [Google Scholar] [CrossRef]

- Nordelöf, A. A scalable life cycle inventory of an automotive power electronic inverter unit—Part II: Manufacturing processes. Int. J. Life Cycle Assess. 2019, 24, 694–711. [Google Scholar] [CrossRef]

- Quan, J.; Zhao, S.; Song, D.; Wang, T.; He, W.; Li, G. Comparative life cycle assessment of LFP and NCM batteries including the secondary use and different recycling technologies. Sci. Total Environ. 2022, 819, 153105. [Google Scholar] [CrossRef]

- Accardo, A.; Dotelli, G.; Musa, M.L.; Spessa, E. Life cycle assessment of an NMC battery for application to electric light-duty commercial vehicles and comparison with a sodium-nickel-chloride battery. Appl. Sci. 2021, 11, 1160. [Google Scholar] [CrossRef]

- Candelaresi, D.; Valente, A.; Iribarren, D.; Dufour, J.; Spazzafumo, G. Comparative life cycle assessment of hydrogen-fuelled passenger cars. Int. J. Hydrogen Energy 2021, 46, 35961–35973. [Google Scholar] [CrossRef]

- Houchins, C.; James, B.D. DoE Hydrogen and Fuel Cells Program Review Hydrogen Storage Cost Analysis (ST100). 2019. Available online: https://www.hydrogen.energy.gov/docs/hydrogenprogramlibraries/pdfs/progress18/h2f_james2_2018.pdf?sfvrsn=ae86594d_1 (accessed on 18 August 2025).

- Cooney, G.; Hawkins, T.R.; Marriott, J. Life cycle assessment of diesel and electric public transportation buses. J. Ind. Ecol. 2013, 17, 689–699. [Google Scholar] [CrossRef]

- Cusenza, M.A.; Bobba, S.; Ardente, F.; Cellura, M.; Di Persio, F. Energy and environmental assessment of a traction lithium-ion battery pack for plug-in hybrid electric vehicles. J. Clean. Prod. 2019, 215, 634–649. [Google Scholar] [CrossRef]

- Hydrogen and Fuel Cell Technologies Office, United States Department of Energy. DoE Technical Targets for Polymer Electrolyte Membrane Fuel Cell Component. 2024. Available online: https://www.energy.gov/eere/fuelcells/doe-technical-targets-polymer-electrolyte-membrane-fuel-cell-components (accessed on 18 August 2025).

- Lotrič, A.; Sekavčnik, M.; Kuštrin, I.; Mori, M. Life-cycle assessment of hydrogen technologies with the focus on EU critical raw materials and end-of-life strategies. Int. J. Hydrogen Energy 2021, 46, 10143–10160. [Google Scholar] [CrossRef]

| Length [m] | 12 |

| Curb weight [ton] | 12 |

| Fully loaded weight [ton] | 18 |

| Passenger capacity [-] | 90 |

| Road Load @50 km/h [kW] | 16 |

| Lifespan [km] | 700.000 |

| Configurations | ICEV | HEV | H2HEV | |

|---|---|---|---|---|

| ICE | Fuel [-] | diesel | diesel | hydrogen |

| Displacement [L] | 6.5 | 3.0 | 3.0 | |

| Max. Power [kW] | 250 | 100 | 100 | |

| Configurations | FCEV | |||

| PEM FC | Fuel [-] | hydrogen | ||

| Net Power [kW] | 100 | |||

| Configurations | HEV/H2HEV E-Generator | HEV/H2HEV/FCEV/BEV E-traction | ||

| EMs | Technology [-] | PMSM | PMSM | |

| Max Power [kW] | 90 | 200 | ||

| Max Torque [Nm] | 440 | 1500 | ||

| Configurations | HEV/H2HEV/FCEV | BEV | ||

| HV Battery | Technology [-] | LiFePO4 | NMC | |

| Capacity [kWh] | 20 | 336 | ||

| Configurations | H2HEV/FCEV | |||

| Hydrogen Tank | Technology [-] | Carbon fiber tank | ||

| Capacity [kg] | 28 | |||

| Pressure [bar] | 700 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peiretti Paradisi, B.; Pulvirenti, L.; Prussi, M.; Rolando, L.; Vinogradov, A. Life Cycle Assessment of Different Powertrain Alternatives for a Clean Urban Bus Across Diverse Weather Conditions. Energies 2025, 18, 4522. https://doi.org/10.3390/en18174522

Peiretti Paradisi B, Pulvirenti L, Prussi M, Rolando L, Vinogradov A. Life Cycle Assessment of Different Powertrain Alternatives for a Clean Urban Bus Across Diverse Weather Conditions. Energies. 2025; 18(17):4522. https://doi.org/10.3390/en18174522

Chicago/Turabian StylePeiretti Paradisi, Benedetta, Luca Pulvirenti, Matteo Prussi, Luciano Rolando, and Afanasie Vinogradov. 2025. "Life Cycle Assessment of Different Powertrain Alternatives for a Clean Urban Bus Across Diverse Weather Conditions" Energies 18, no. 17: 4522. https://doi.org/10.3390/en18174522

APA StylePeiretti Paradisi, B., Pulvirenti, L., Prussi, M., Rolando, L., & Vinogradov, A. (2025). Life Cycle Assessment of Different Powertrain Alternatives for a Clean Urban Bus Across Diverse Weather Conditions. Energies, 18(17), 4522. https://doi.org/10.3390/en18174522